Page 1

Publication No. 990602

INSTALLATION INSTRUCTIONS

for the

January 1996

Supersedes 990602

August 1993

Kodak X-Omatic

MODELS 4, 4L, and 4SL

IDENTIFICATION CAMERA

© Eastman Kodak Company

Page 2

PLEASE NOTE The information contained herein is based on the experience and knowledge relating to the

subject matter gained by Eastman Kodak Company prior to publication.

No patent license is granted by this information.

Eastman Kodak Company reserves the right to change this information without notice, and

makes no warranty, express or implied, with respect to this information. Kodak shall not be liable

for any loss or damage, including consequential or special damages, resulting from any use of

this information, even if loss or damage is caused by Kodak’s negligence or other fault.

This equipment includes parts and assemblies sensitive to damage from electrostatic

discharge. Use caution to prevent damage during all service procedures.

Table of Contents

Description Page

Electrostatic Discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Description and Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Space Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Cassettes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Unpacking the ID CAMERA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Setting Up the ID CAMERA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Selecting the Correct Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Selecting the Date Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Selecting the Time Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Setting the Date and Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Clearing the Date and Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Performing the Density Step Test Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Publication History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2 January 1996 – 990602

Page 3

Section 1: Electrostatic Discharge

Overview

Electrostatic discharge (ESD) is a primary source of

• product downtime

• lost productivity

• costly repairs

While you cannot feel a static charge of less than 3,500 volts, as few as 30 volts can damage or destroy

essential components in electronic equipment.

Preventive Measures

• Always look for an ESD warning label before doing any procedure involving static-sensitive

components such as CIRCUIT BOARDS. All static-sensitive components are marked with bright

graphic labels, which frequently include instructions. Follow all label instructions.

• Wear a grounding strap whenhandling static-sensitive components. Alwaysmake certain that the

clip remains attached to a properly grounded, unpainted, clean surface.

• Repair static-sensitive components at an ESD-protected work station or use a portable grounding

mat. For help in setting up an ESD-protected work station, contact your Kodak representative

• When you move static-sensitive components from one area to another, insert and transport the

components in ESD-protective packaging.

Electrostatic Discharge

990602 – January 1996 3

Page 4

INSTALLATION INSTRUCTIONS

Section 2: Description and Specifications

Description

The

Kodak X-Omatic

CAMERA), records patient identification data onto x-ray film in lighttight cassettes.

The camera provides:

• Dual lenses for use with C-1 and C-1N windows for MODELS 4 and 4L

• Excellent image quality with high-quality lenses

• Operation in normal room illumination

• The exact time anddate of the exposurerecorded on the film witha variety of customizeddate and time formats

available

• The serial number of the camera is recorded on the film for all models and lens positions except the C-1N lens

position in the MODEL 4L.

• Choice of both anterior-posterior and posterior-anterior imaging

• MODEL 4 records patient data on the upper corner of the film

• MODELS 4L and 4SL record patient data on the lower corner of the film

When you insert a CASSETTE correctly into the SLOT above the BASE, and a patient ID CARD is in either the PA or A-P SLOT, the camera automatically:

[1] Actuates a mechanical ARM to open a WINDOW in the CASSETTE.

[2] Illuminates the LAMP to record the identification data, time, and date on the film.

[3] Closes the WINDOW in the CASSETTE.

This entire operation takes approximately 2 seconds.

IDENTIFICATION CAMERA, MODELS 4, 4L, and 4SL (hereafter referred to as the ID

Specifications

Space Requirements

• The physical characteristics of the camera are:

Height: 32.5 cm (12.80 in.)

Width: 32.4 cm (12.76 in.)

Depth: 43.5 cm (17.13 in.)

Weight: 12 kg (26.5 lb)

• Install the camera on a flat surface, with a minimum overhead clearance of approximately 75 cm (30 in.).

• To be able to insert the largest CASSETTES, provide these clearances:

1 m (3 ft) between the front edge of the camera and the nearest wall

1 m (3 ft) between the right edge of the camera and the nearest wall

Environmental Requirements

The camera operates in the ambient room conditions normally encountered in an x-ray department:

15 to 30˚C (59 to 86˚F)

15 to 76% relative humidity

4 January 1996 – 990602

Page 5

Description and Specifications

Cassettes

The ID CAMERA will operate with the following CASSETTES:

• All sizes of

• All sizes of

• All sizes of

Kodak X-Omatic

Kodaflex

Kodak Min-R

CASSETTES with C-1 windows

2 CASSETTES with C-1N windows

CASSETTES with C-1 windows

Power Requirements

[1] For theMODELS4,4L,and4SL ID CAMERAS: These cameraswill operate correctly at the followingvoltages

and tolerances. The cameras are internally switchable to obtain each of the following voltage ranges.

[2] Do not connect the camera to a power source that serves other equipment.

[3] Small variations in the voltage can cause variations in the density of the film. If necessary, install a voltage

regulator for a constant AC voltage to the camera.

[4] Use a reliable earth ground.

[5] Use the correct FUSE for your current.

Frequency

Model

4, 4L, and 4SL 50 or 60 1.5 220 TUV 1 A

(Hz)

50 or 60 3 100 UL/CSA 3 A

50 or 60 3 120 UL/CSA 3 A

50 or 60 1.5 230 TUV 1 A

50 or 60 1.5 240 TUV 1 A

Maximum

Current (A) V AC 10% Fuse

990602 – January 1996 5

Page 6

INSTALLATION INSTRUCTIONS

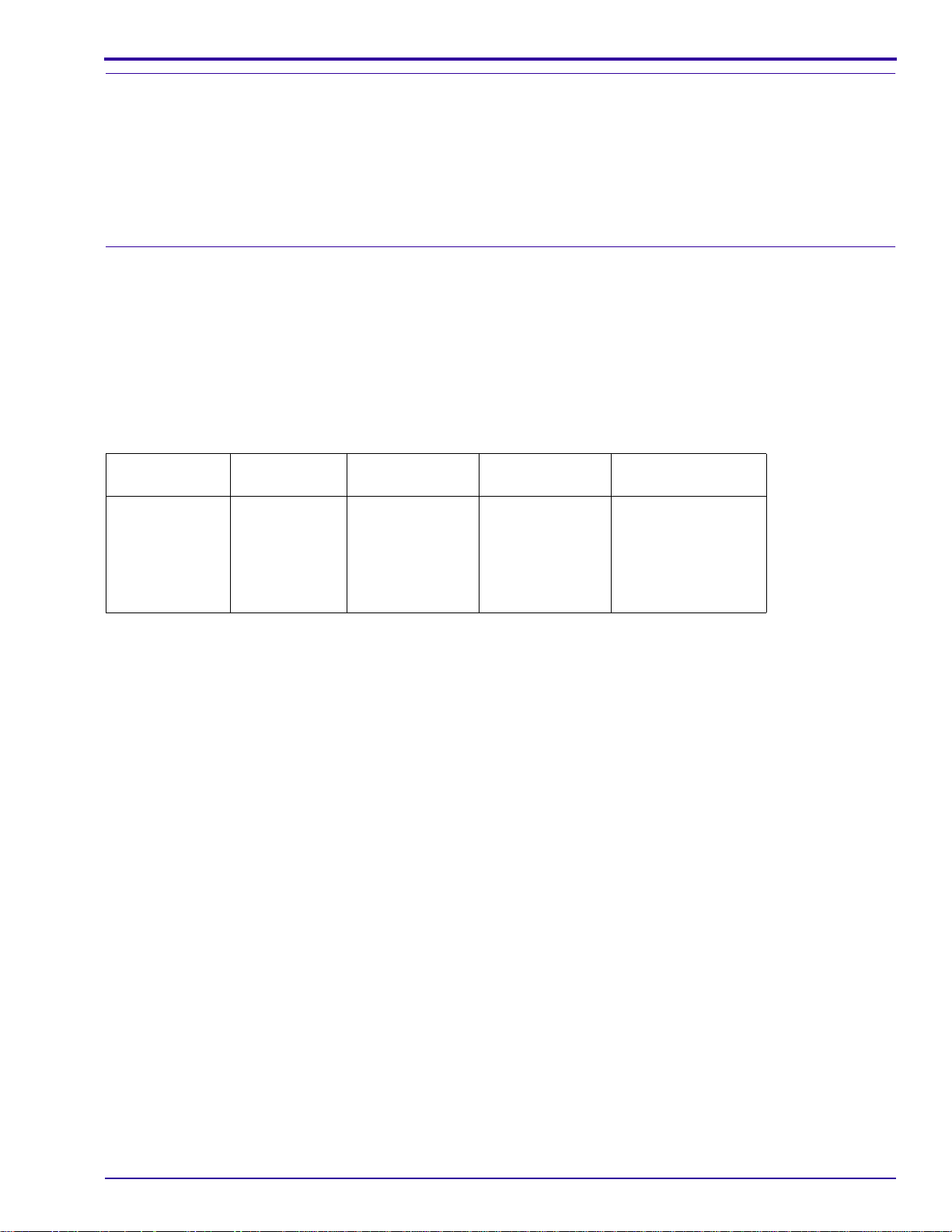

Section 3: Unpacking the ID CAMERA

SUPPORT (4)

SUPPORT

(4)

RETAINING

CUSHION

ACCESSORY

BOX

CAMERA

BOX

Caution

Do not turn the shipping carton upside down.

Important

Be careful opening the shipping carton and removing

the packing material. Keep the carton and all packing

materialfor the customer, incase the ID CAMERA must

be returned for service.

[1] Remove the sealing tape from the shipping

carton.

[2] Removethe4 SUPPORTSfrom the topcornersof

the CAMERA BOX.

[3] Open the CAMERA BOX.

[4] Remove the RETAINING CUSHION and the

ACCESSORY BOX.

H139_0072CCA

H139_0072CC

6 January 1996 – 990602

Page 7

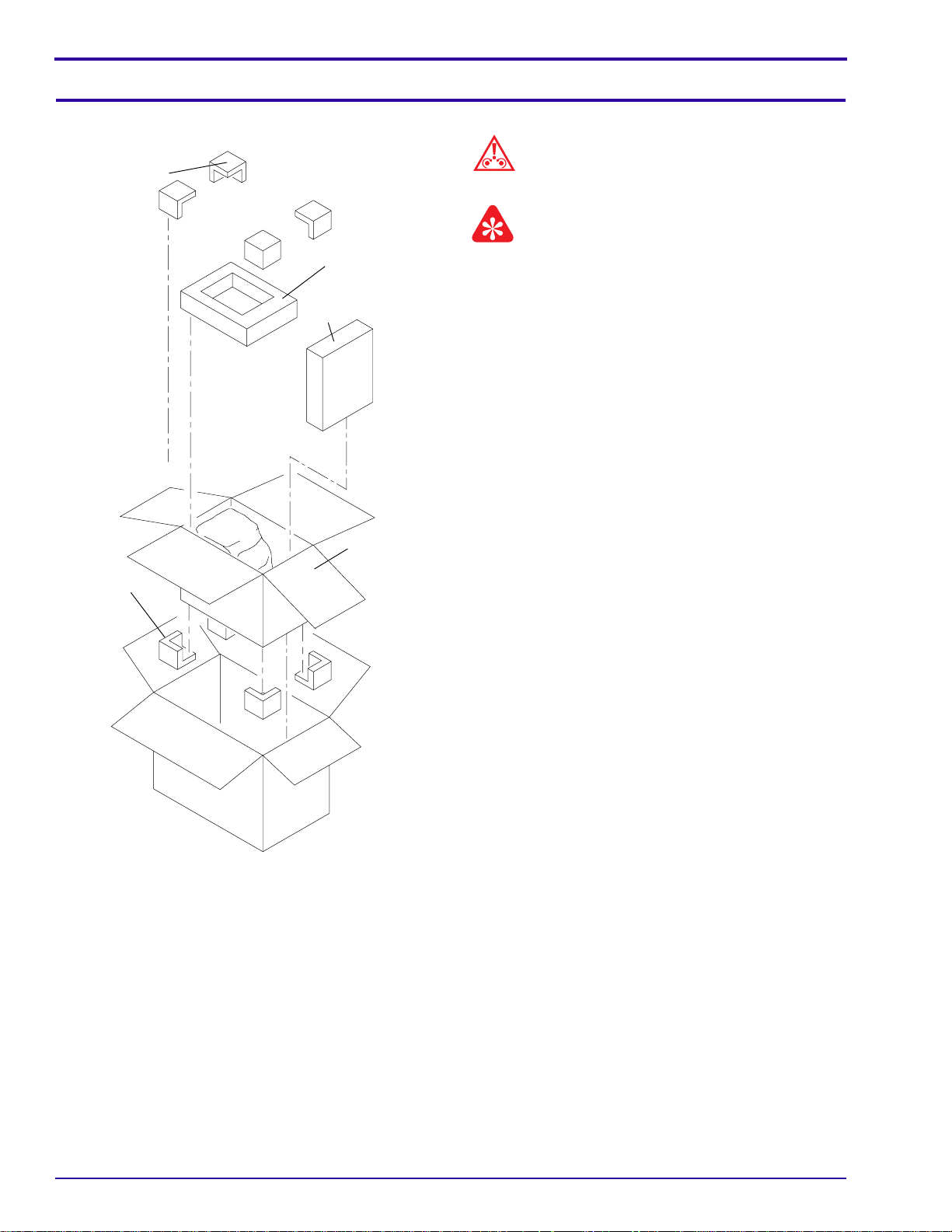

BAG

H139_0014ACA

H139_0014AC

Unpacking the ID CAMERA

[5] Take the aluminum shielding BAG containing the

ID CAMERA out of the CAMERA BOX.

(a) Cut the BAG carefully and remove the ID

CAMERA.

(b) Remove the dessicant container from the

back of the ID CAMERA.

[6] Remove the PROTECTIVE SHEET from the ID

CAMERA.

PROTECTIVE SHEET

H139_0073ACA

H139_0073AC

CASSETTE

SLOT

H139_0001ACB

H139_0001AC

Check the Contents of the ACCESSORY BOX

Caution

When moving the ID CAMERA, do not put your hands

into the CASSETTE SLOT. Hold the ID CAMERA from

underneath. If excessive force is applied to the

CASSETTE SLOT, it might break.

990602 – January 1996 7

Page 8

INSTALLATION INSTRUCTIONS

Check that the ACCESSORY BOX contains the following:

• 2 spare MAIN EXPOSURE LAMPS 10 W, 4.6 V

• 1 spare UL CSA FUSE 3 A

• 1 spare TUV FUSE 1 A

• 2 spare CLOCK LAMPS

• 2 POWER CORDS: one for 100 or 120 V AC operation and one for 220, 230, or 240 V AC operation

• Warranty card

• “Cassette Window Description” and “Error Code Label” Part No. 1C0069

• “Character Label” for Serial No. identification when replacing the A-P or P-A CIRCUIT BOARDS

• Publication No. 2B6405, containing the Operator Manual, Installation Instructions, and the Service Guide

Important

Remember to keep the shipping carton and all packing material for the customer, in case it is necessary to

return the ID CAMERA for service.

8 January 1996 – 990602

Page 9

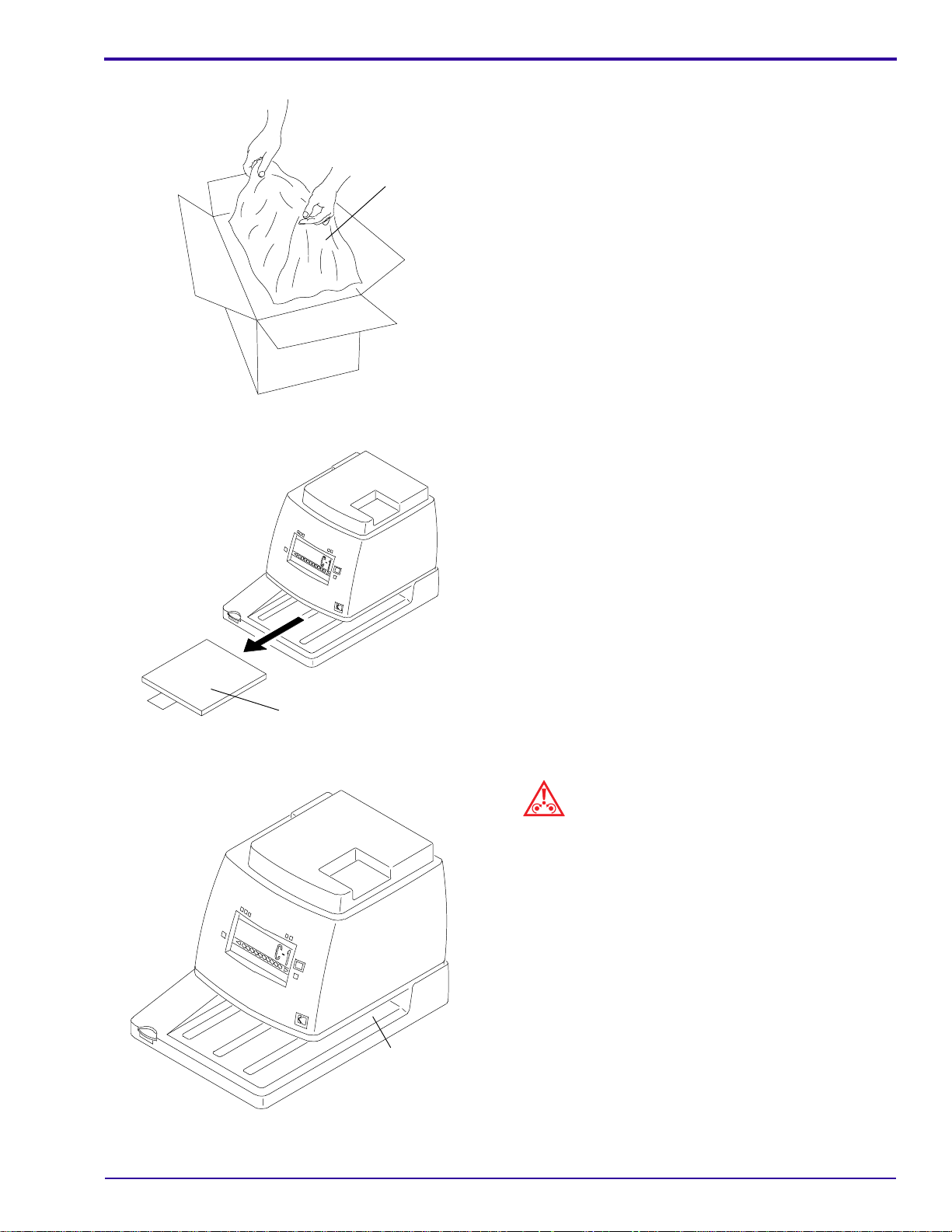

Section 4: Setting Up the ID CAMERA

H139_0066AC

SCREW (6)

COVER PLATE

POWER SWITCH

H139_0066ACA

Selecting the Correct Voltage

Warning

Dangerous Voltage.

Removing the POWER SWITCH COVER PLATE

Setting Up the ID CAMERA

[1] Check that the ID CAMERA is de-energized and that the POWER CORD is disconnected.

[2] Turn the ID CAMERA on its side.

[3] Remove the 6 SCREWS from the POWER SWITCH COVER PLATE, and remove the POWER SWITCH

COVER PLATE.

[4] Use a 3.0 mm ALLEN WRENCH to remove the 3 SCREWS from the bottom of the ID CAMERA.

[5] Turn the ID CAMERA upright.

Caution

Do not stretch the RIBBON CABLE attached to the COVER and CPU BOARD.

990602 – January 1996 9

Page 10

INSTALLATION INSTRUCTIONS

Removing the COVER

COVER

RIBBON

CABLE

CPU BOARD

H139_0042CCA

H139_0042CA

[6] Remove the COVER carefully, and disconnect the RIBBON CABLE from the CPU BOARD. Turn the COVER

upside down and place the COVER next to the ID CAMERA.

10 January 1996 – 990602

Page 11

Setting Up the ID CAMERA

Installing a new FUSE

Selecting the Correct Voltage

VOLTAGE SELECTOR

FUSE CAP

FUSE

VOLTAGE

SELECTOR

H139_0034ACA

H139_0034AC

[7] Usea FLATHEADSCREWDRIVER toremovethe

FUSE CAP holding the FUSE.

[8] Measure the source voltage.

[9] Use a flat WIDEBLADE SCREWDRIVER, or

COIN, to turn the VOLTAGE SELECTOR to the

correct voltage.

[10] Insert the correct FUSE, install the new FUSE

CAP, and press and turn clockwise.

H139_0019ACA

H139_0019AC

Selecting the Date Format

SWITCHES 1 and 2 of DP SW1 control the date format.

Note

If you are installing and setting up the ID CAMERA for

the first time, you can keep the COVER off andbegin at

Step7 on Page 14for the procedure forsetting the Date

Format and with Step 7 on Page 17 for the procedure

for setting the Time Format.

[11] Connectthe RIBBONCABLE to theCPU BOARD,

and place the COVER on the ID CAMERA.

[12] Turn the ID CAMERA on its side.

[13] Install the 3 SCREWS, and the 6 SCREWS and

POWER SWITCH COVER PLATE removed

earlier.

[14] Turn the ID CAMERA upright.

990602 – January 1996 11

Page 12

INSTALLATION INSTRUCTIONS

H

Warning

Dangerous Voltage.

Removing the POWER SWITCH COVER PLATE

POWER SWITC

COVER PLATE

SCREW (6)

H139_0066ACA

H139_0066AC

[1] Check that the ID CAMERA is de-energized and that the POWER CORD is disconnected.

[2] Turn the ID CAMERA on its side.

[3] Remove the 6 SCREWS from the POWER SWITCH COVER PLATE, and remove the POWER SWITCH

COVER PLATE.

[4] Use a 3.0 mm ALLEN WRENCH to remove the 3 SCREWS from the bottom of the ID CAMERA.

[5] Turn the ID CAMERA upright.

Caution

Do not stretch the RIBBON CABLE attached to the COVER and CPU BOARD.

12 January 1996 – 990602

Page 13

Removing the COVER

H139_0042CA

H139_0042CCA

CPU BOARD

CABLE

RIBBON

COVER

Setting Up the ID CAMERA

[6] Remove the COVER carefully, and disconnect the RIBBON CABLE from the CPU BOARD. Turn the COVER

upside down and place the COVER next to the ID CAMERA.

990602 – January 1996 13

Page 14

INSTALLATION INSTRUCTIONS

Locating the DATE DIP SWITCHES

DATE DIP SWITCHES

1

2

3

4

5

6

7

OFF

DP SW1

8

CPU

BOARD

[7] To select themonth-day-year format, to set 02-28-

93, for example:

(a) DIP SWITCH 1 to ON and

(b) DIP SWITCH 2 to OFF

[8] To select the day-month-year format, to set 28-

02-93, for example:

(a) DIP SWITCH 1 to OFF and

(b) DIP SWITCH 2 to ON

[9] To select theyear-month-day format, to set 93-02-

28, for example:

(a) DIP SWITCH 1 to ON and

(b) DIP SWITCH 2 to ON

[10] Connectthe RIBBONCABLE to theCPU BOARD,

and place the COVER on the ID CAMERA.

[11] Turn the ID CAMERA on its side.

[12] Install the 3 SCREWS, and the 6 SCREWS and

POWER SWITCH COVER PLATE removed

earlier.

[13] Turn the ID CAMERA upright.

[14] Energize the ID CAMERA while holding the

DENSITY DECREASE BUTTON. This will reset

the microprocessor.

SW2

H139_0033CCA

H139_0033CC

Selecting the Time Format

SWITCHES 1 and 2 of SW2 control the time format.

Warning

Dangerous Voltage.

14 January 1996 – 990602

Page 15

Removing the POWER SWITCH COVER PLATE

H139_0066AC

SCREW (6)

COVER PLATE

POWER SWITCH

H139_0066ACA

Setting Up the ID CAMERA

[1] Check that the ID CAMERA is de-energized and that the POWER CORD is disconnected.

[2] Turn the ID CAMERA on its side.

[3] Remove the 6 SCREWS from the POWER SWITCH COVER PLATE, and remove the POWER SWITCH

COVER PLATE.

[4] Use a 3.0 mm ALLEN WRENCH to remove the 3 SCREWS from the bottom of the ID CAMERA.

[5] Turn the ID CAMERA upright.

Caution

Do not stretch the RIBBON CABLE attached to the COVER and CPU BOARD.

990602 – January 1996 15

Page 16

INSTALLATION INSTRUCTIONS

Removing the COVER

COVER

RIBBON

CABLE

CPU BOARD

H139_0042CCA

H139_0042CA

[6] Remove the COVER carefully, and disconnect the RIBBON CABLE from the CPU BOARD. Turn the COVER

upside down and place the COVER next to the ID CAMERA.

16 January 1996 – 990602

Page 17

Setting Up the ID CAMERA

Locating the Time Date DIP SWITCHES

DP SW1

CPU

BOARD

[7] To select the 12-hour time format, set:

(a) DIP SWITCH 1 to OFF and

(b) DIP SWITCH 2 to OFF

[8] To select the 24-hour time format, set:

(a) DIP SWITCH 1 to ON and

(b) DIP SWITCH 2 to OFF

[9] Connectthe RIBBONCABLE to theCPU BOARD,

and place the COVER on the ID CAMERA.

[10] Turn the ID CAMERA on its side.

[11] Install the 3 SCREWS, and the 6 SCREWS and

POWER SWITCH COVER PLATE removed

earlier.

[12] Turn the ID CAMERA upright.

[13] Energize the ID CAMERA while holding the

DENSITY DECREASE BUTTON. This will reset

the microprocessor.

SW2

TIME DIP SWITCHES

O

F

F

1

2

H139_0032CCA

H139_0032CC

Setting the Date and Time

[1] Check that the ID CAMERA is connected to a power source with a reliable earth ground. Energize the ID

CAMERA.

990602 – January 1996 17

Page 18

INSTALLATION INSTRUCTIONS

DATE BUTTONS

DATE DISPLAY

DENSITY

DECREASE

BUTTON

PM

TIME BUTTONS

TIME DISPLAY

WINDOW

BUTTON

2

1

4

3

8

765

10

9

LCD PANEL

[2] Set the date and time:

(a) Press the DENSITY INCREASE andDENSITY DECREASE BUTTONS at the same time. The values in

the DATE and TIME DISPLAYS will flash.

(b) Press the DATE BUTTONSto select the date you want. The DATE BUTTONSare programmed to the date

format selected earlier.

• For example, if your date format is month/day/year, the left DATE BUTTON controls the month, the

middle DATE BUTTON controls the day, and the right DATE BUTTON controls the year.

• If your date format is day/month/year, the left DATE BUTTON controls the day, the middle DATE

BUTTON controls the month, and the right DATE BUTTON controls the year.

• If your date format is year/month/day, the left DATE BUTTON controls the year, the middle DATE

BUTTON controls the month and the right DATE BUTTON controls the day.

(c) Continue to press the appropriate DATE BUTTONS until the correct date is displayed on the LCD.

(d) Press the TIME BUTTONS to select the time. The TIME BUTTONS are programmed to the time format

selected earlier, either a 12- or 24-hour clock.

• In both the 12- and 24-hour time formats, the leftTIME BUTTON controls the hour, and theright TIME

BUTTON controls the minutes.

(e) Continue to press the TIME BUTTONS until the correct time is displayed on the LCD PANEL.

(f) PRESS the DENSITY INCREASE BUTTON only, approximately 2 - 3 seconds,until the DATE and TIME

DISPLAYS stop flashing.

DENSITY

INCREASE

BUTTON

H139_0003BCA

H139_0003BC

Note

• The DENSITY BUTTONS are deactuated while the DATE and TIME DISPLAYS are flashing.

• The time or date cannot be changed if a PATIENT ID CARD is in either the P-A or A-P CARD SLOT.

18 January 1996 – 990602

Page 19

Clearing the Date and Time

DATE BUTTONS

DATE DISPLAY

DENSITY

DECREASE

BUTTON

Setting Up the ID CAMERA

PM

TIME BUTTONS

TIME DISPLAY

WINDOW

BUTTON

2

1

4

3

8

765

10

9

DENSITY

INCREASE

BUTTON

LCD PANEL

H139_0003BCA

To clear the date and time, or set the date and time to “0”, de-energize the CAMERA, press the DENSITY

DECREASE BUTTON and then press the POWER BUTTON. This clears, or resets, the microprocessor.

H139_0003BC

990602 – January 1996 19

Page 20

INSTALLATION INSTRUCTIONS

Section 5: Performing the Density Step Test Procedure

Density Step Test Procedure

The purpose of the Density Step Test Procedure is to choose the preferred density exposure for the customer. It is

important that the customer be involved in this procedure.

This is a good opportunity for you to instruct the customer in the operation of the ID CAMERA. As you perform the

StepTest, allow the customer to help prepare CASSETTES and ID CARDS, and to make a few of the test exposures.

Afterward, give the Operator Manual to the customer and answer any questions.

[1] Prepare 10 ID CARDS bynumbering each from 1 to 10. Prepare 10 CASSETTES by loading with unexposed

film. Use the smallest CASSETTE available.

[2] Exposeeach CASSETTE to an increasing density,making sure to changethe ID CARD foreach exposure. Use

the ID CARD marked “1” for DENSITY SETTING 1, and use the ID CARD marked “2” for DENSITY SETTING

2, and so on. Make the exposures with the CASSETTES used most often.

[3] Process the film. Choose the best exposure. Check the density with a densitometer if one is available. The

background density from a bright white card should be 1.2. Record the preferred exposure for the customer.

Note

If you cannot get satisfactory results, see the Service Manual section “Adjusting Potentiometers” for instructions on

adjusting the LAMP POTENTIOMETERS.

20 January 1996 – 990602

Page 21

Section 6: Publication History

Print Date Pub. No. ECO No. Affected Pages File Name Notes

August 1993 990602 All Pages 3294ii_a.doc First printing.

January

1996

990602 2504-435 All Pages ii3294_1_435.doc Added 4SL information.

Publication History

990602 – January 1996 21

Page 22

Kodak, Kodaflex, Min-R

and

X-Omatic

are trademarks.

ii3294_1.fm

Printed In USA

Health Imaging

EASTMAN KODAK COMPANY ● ROCHESTER, N.Y. 14650

Loading...

Loading...