Page 1

Part No. 4B1709User’s Guide

KODAK XLS 8400 PS Printer

Page 2

Page 3

Contents

Introduction v. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About Your Printer v. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Image Sizes vi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Host Interfaces vi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printer Drivers and Export Modules vii. . . . . . . . . . . . . . . . . . . . . . . . .

Fonts viii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About this Guide viii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Radio Frequency Interference ix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Regulatory Information x. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Regulations xi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Getting Started 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking Contents 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing the Shipping Pins 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Finding a Location 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Components of the Printer 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reviewing the Components 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Attaching the Power Cord 1–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Attaching the Interface Cable 1–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning the Thermal Head 1–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printer Media 1–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About Ribbon 1–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About Paper 1–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About Transparency Material 1–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Turning on the Power 1–34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part No. 4B1709 March 1995

i

Page 4

Contents

Understanding the Display Panel 1–35. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Indicator Lights 1–36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LCD Panel 1–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Buttons 1–38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the Printer 1–39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using Setup Menus 1–39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting a Language for the Display Panel 1–40. . . . . . . . . . . . . . . . . .

Selecting Defaults 1–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifying Port Information 1–42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifying the Mode 1–46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Making a Test Print 1–47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printing from Computer Applications 1–48. . . . . . . . . . . . . . . . . . . . . . . . . .

Job Scheduling 1–49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storing Prints and Transparencies 1–50. . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Maintaining the Printer 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Supplies 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ordering Accessories and Supplies 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Alcohol Cleaning Pads 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ribbon 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transparency material 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storing Supplies 3–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ribbon 3–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Paper 3–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transparency material 3–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

Part No. 4B1709 March 1995

Page 5

Contents

4 Correcting Problems 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Understanding Error Messages 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mismatch Conditions 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ribbon Type Mismatch 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiver Type Mismatch 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiver Size Mismatch 4–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 4–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Handling for Humidity-related Paper Problems 4–9. . . . . . . . . . . . . . . . .

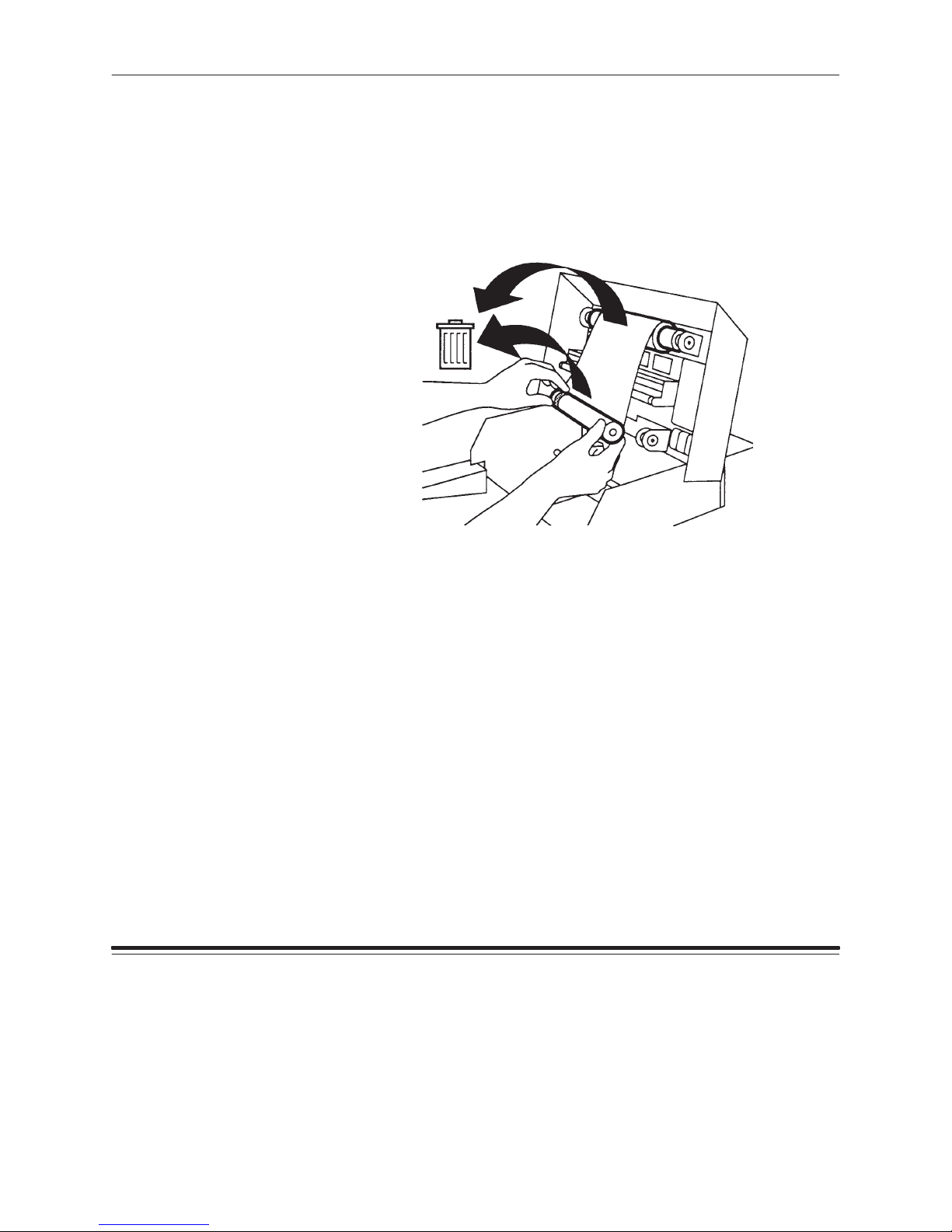

Alternate Head Cleaning Instructions 4–10. . . . . . . . . . . . . . . . . . . . . . . . . .

Clearing the Paper Path 4–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repacking the Printer 4–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Getting Help 4–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A Printer Specifications A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Size A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Weight A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Environment A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Space Requirements A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Requirements A–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix B Customizing Your Printer B–1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Index

Part No. 4B1709 March 1995

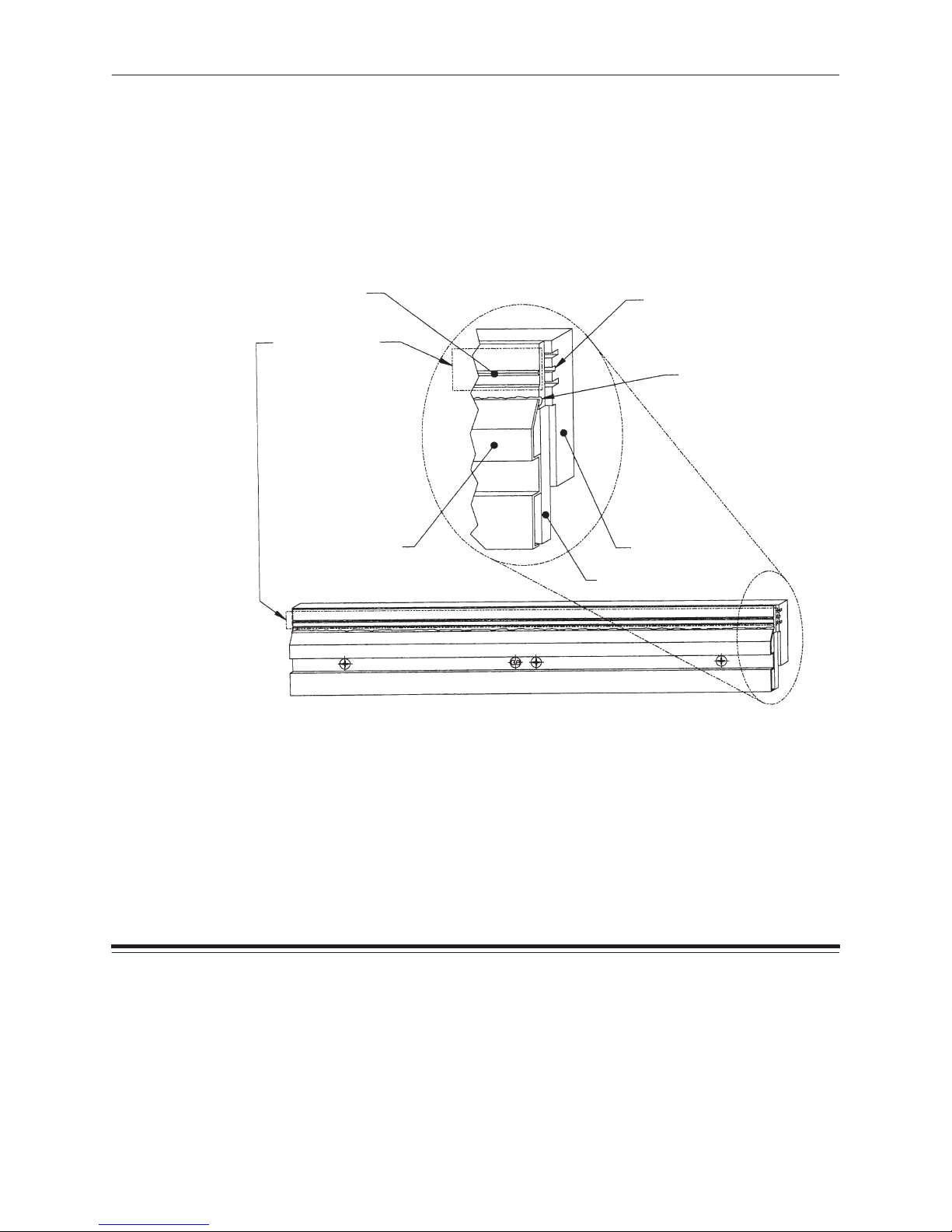

Adding a Hard Disk for Font Storage B–1. . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Hard Drive B–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Downloading Fonts B–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adding More Memory B–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting up for the Installation B–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Opening the Printer B–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Card B–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Closing the Printer B–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iii

Page 6

Page 7

Introduction

About Your Printer

Thank you for purchasing the KODAK XLS 8400 PS Printer. This printer

will be referred to throughout this book as the XLS 8400 PS Printer.

The XLS 8400 PS Printer is a thermal dye diffusion device with superior

printing speed. It contains a 33 MHz MIPS RISC processor, has a

resolution of 300 pixels per inch (PPI), and prints at approximately 75

seconds per three-color page. Printed images are high-contrast and

long lasting.

A number of communication ports are provided on the printer. In addition

to these standard ports, the optional KODAK Network Interface Card

allows your printer to tie into networks using Ethernet cabling.

Printer Drivers and Export Modules were developed for the XLS 8400 PS

Printer based on high-quality Kodak photographic printing methods. The

color-rendering processes that evolved from this comparison are highly

sophisticated. Using the Printer Drivers and Export Modules allow you to

access advanced printing options based on Kodak color-science.

Part No. 4B1709 March 1995

v

Page 8

Introduction

Image Sizes

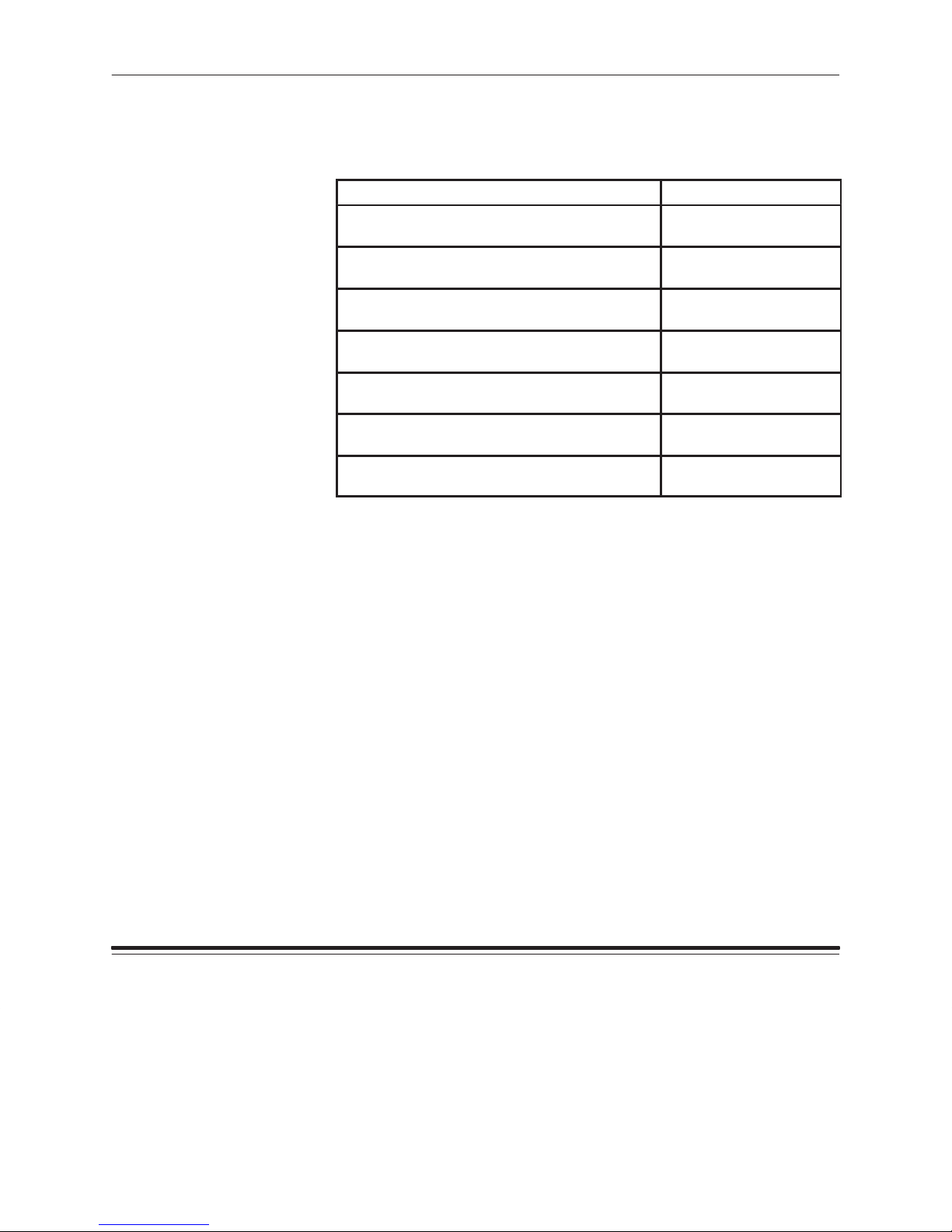

The XLS 8400 PS Printer can print on the following media sizes.

Paper/Transparency material size Maximum image size

8.5 x 11.0 / 216 x 279 mm 8.0 x 8.93 /

204 x 228 mm

8.27 x 11.69 / 210 x 297 mm

(A4)

8.5 x 12.0 / 216 x 307 mm 8.0 x 10.0 /

8.27 x 12.0 / 210 x 307 mm 8.0 x 10.0 /

8.5 x 14.0 / 216 x 358 mm 8.0 x 12.0 /

8.27 x 14.0 / 210 x 358 mm 8.0 x 12.0 /

9.5 x 14.0 / 243 x 358 mm* 8.42 x 12.0 /

*Transparency material is not available in the 9.50 x 14.0 size.

8.0 x 9.6 /

204 x 246 mm

204 x 256 mm

204 x 256 mm

204 x 307 mm

204 x 307 mm

214 x 307 mm

Host Interfaces

Centronics(Parallel) and LocalTalk host interfaces are standard with

the printer.

EtherTalk, NovellNetWare, and TCP/IP Ethernet interfaces are provided

through the optional Network Interface Card.

vi

Part No. 4B1709 March 1995

Page 9

Introduction

Printer Drivers and Export Modules

Printing software for popular image-editing and desktop applications is

included with the printer.

The following packages are designed to be used with the

XLS 8400 PS Printer.

D KODAK XLS 8400 PS Printer Driver for MACINTOSH COMPUTERS

D KODAK XLS 8400 PS Printer Driver for MICROSOFT WINDOWS 3.1

D KODAK XLS 8400 PS Printer Export Module

for ADOBE PHOTOSHOP Software and MACINTOSH Computers

D KODAK XLS 8400 PS Printer Export Module

for ADOBE PHOTOSHOP Software and MICROSOFT WINDOWS 3.1

For information about installing and using these packages, refer to their

User’s Guide.

Part No. 4B1709 March 1995

vii

Page 10

Introduction

Fonts

A set of 35 screen fonts is resident on the printer.

Refer to Appendix B,

Customizing your printer,

for more information

about fonts and font storage.

The following fonts are resident on the printer.

D Courier, Courier Oblique, Bold, Bold Oblique

D Helvetica, Helvetica Oblique, Bold, Bold Oblique

D Times Roman, Times Italic, Bold, Bold Italic

D Symbol

D Helvetica Narrow, Narrow Oblique, Narrow Bold, Narrow Bold Oblique

D ITC Avant Garde Gothic Book, Book Oblique, Demi, Demi Oblique

D ITC Bookman Light, Light Italic, Demi, Demi Italic

D ITC Zapf Chancery Medium Italic

D ITC Zapf Dingbats

D New Century Schoolbook Roman, Italic, Bold, Bold Italic

D Palatino Roman, Italic, Bold, Bold Italic

You can also attach an external disk drive to the printer for font storage.

Refer to Appendix B,

Customizing your printer,

for more information

about fonts and font storage.

viii

About this Guide

This manual contains the information necessary for setting up and using

your XLS 8400 PS Printer. It consists of four chapters:

Getting Started; Maintaining the Printer; Supplies;

Problems.

Specifications,

Additional information is provided in the appendices

and

Customizing Your Printer.

and

Correcting

Printer

Part No. 4B1709 March 1995

Page 11

Introduction

Radio Frequency Interference

This equipment generates, uses, and can radiate radio frequency energy.

If it is not installed and used in accordance with the User’s Guide, this

energy may cause interference to radio and television reception.

This equipment has been type tested and found to comply with the following:

This device meets FCC Class B emission limits for verification pursuant

to Part 15 of the Federal Communications Commission Rule of the

United States.

“The class B limits for radio noise emissions from digital apparatus as set

out in the interference-causing equipment standard entitled “Digital

Apparatus”, ICES–003 of the Department of Communications.”

“Cet appareil numérique respecte les limites de bruits radioléctriques

applicables aux appareils numériques de Classe B prescrites dans la

norme sur le matriél brouilleur : “Appareils Numériques”, NMB–003

édicté par le minstre des Communications.”

D 47CFR Part 15 SubPart B (North American – USA) – Class B or

“meets Class B limits for verification”

D ICES–003 (North American – Canada) – Class B

D VCCI–2 (Japan) – Class B

Requirements of the EMC directive 89/336/EEC were met through

compliance with the following:

D EN50081–1 (European – EU) consists of: EN55022 (class B)

D EN50082–1 (European – EU) consists of: IEC 801 – 2/91 (ESD)

IEC 801 – 3/84

(rf immunity)

IEC 801 – 4/88 (EFT)

“Changes or modifications not expressly approved by the party responsible

for compliance could void the user’s authority to operate the equipment.”

Part No. 4B1709 March 1995

ix

Page 12

Introduction

Regulatory Information

The foregoing limits are designed to provide reasonable protection

against harmful interference when operated in a residential installation.

However, there is no guarantee that interference will not occur in a

particular location. If this equipment does cause interference to radio or

television reception (determined by turning the equipment off and on),

you are encouraged to try to correct the interference by one or more of

the following measures:

D Reorient or relocate the receiving antenna

D Relocate the printer with respect to the receiver

D Move the printer away from the receiver

D Plug the printer into a different outlet so that the receiver and printer

are on different branch circuits

If problems persist, consult an experienced radio/television technician for

additional suggestions. You may also find the following booklet, prepared

by the Federal Communications Commission, helpful: “How to Identify

and Resolve Radio–TV Interference Problems.” This booklet can be

purchased by contacting the Superintendent of Documents, U.S.

Government Printing Office, Washington, DC 20402.

x

Part No. 4B1709 March 1995

Page 13

Introduction

Important

This equipment was tested using shielded interface cables. The use of

these cables is required to reduce the possibility of causing interference

to radio and television reception.

Das Gerät ist gemäß Amtsblattberfügung 243/91 funkenstört und wurde

der Deutschen Bundespost gemeldet. Kodak AG, Stuttgart.

DIESES GERÄT WURDE SOWOHL EINZELN ALS IN EINER ANLAGE,

DIE EINEN NORMALEN ANWENDUNGSFALL NACHBILDET, AUF DIE

EINHALTUNG DER FUNKENTSTÖRBESTIMMUNGEN GEPRÜFT. ES

IST JEDOCH MÖGLICH, DASS DIE FUNKENSTÖRBESTIMMUNGEN

UNTER UNGÜNSTIGEN UMST ÄNEN BEI ANDEREN

GERÄTEKOMBINATIONEN NICHT EINGEHAL TEN WERDEN. DER

BETREIBER IST FÜR DIE EINHAL TUNG DER FUNKENTSTÖRUNGS

BESTIMMUNGEN SEINER GESAMTEN ANLAGE VERANTWORTLICH,

IN DER DIESES GERÄ T BETRIEBEN WIRD.

This equipment has been tested and found to comply with the following:

UL 1950

CSA 950

TUV EN60950

Part No. 4B1709 March 1995

Safety Regulations

The following symbol has been placed on areas of the printer where

electrical shock is possible. Take extra precautions in these areas.

xi

Page 14

Page 15

1 Getting Started

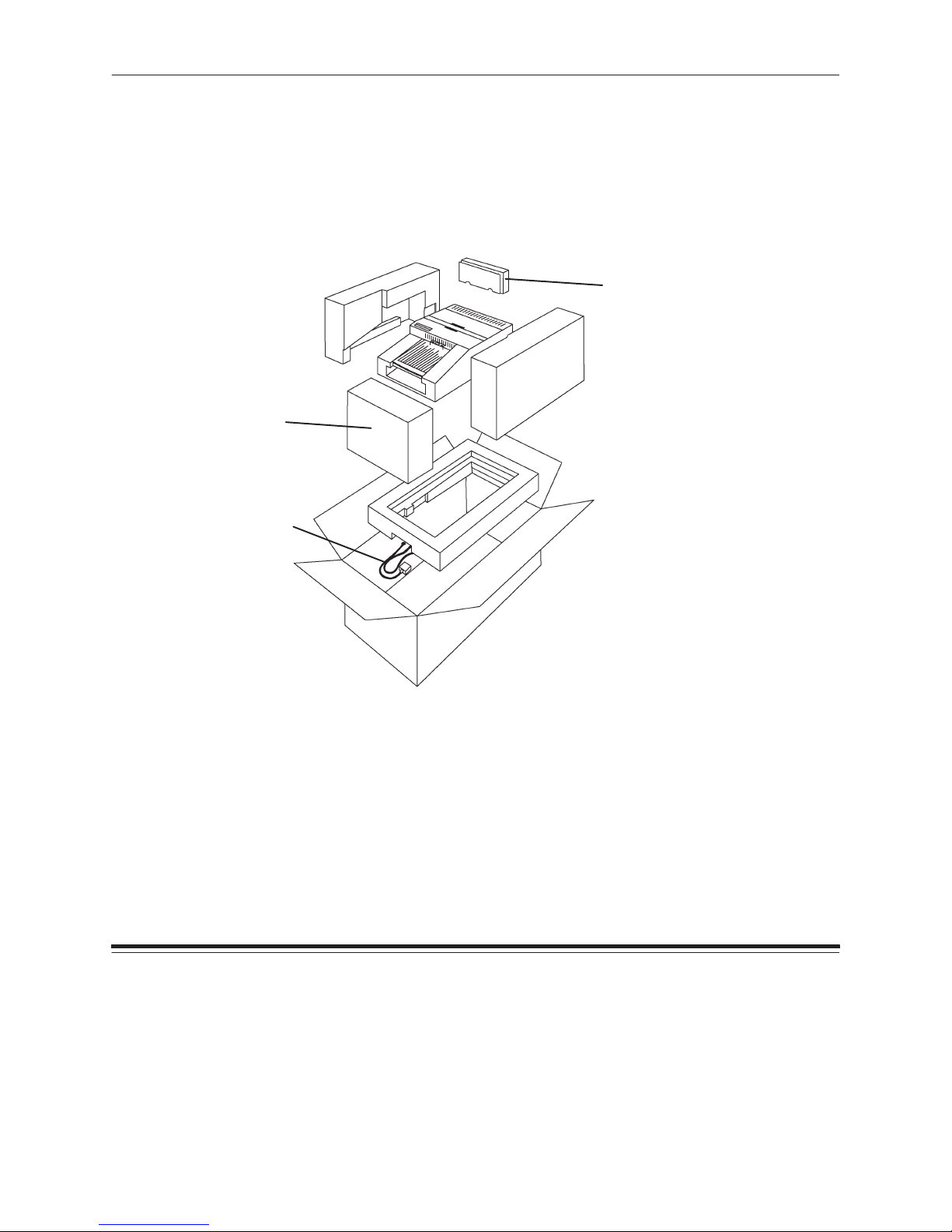

Checking Contents

As you unpack your new printer, make sure the following items

are included:

Paper tray

Power cord

Language kit

Included in this box:

SCSI terminator

Printer users guide (1)

Printer Drivers and Export Modules (3)

Software users guides (2)

Head cleaning pads (4)

Warranty card (1)

Part No. 4B1709 March 1995

Contact your place of purchase if any items are missing from the box.

1–1

Page 16

Getting Started

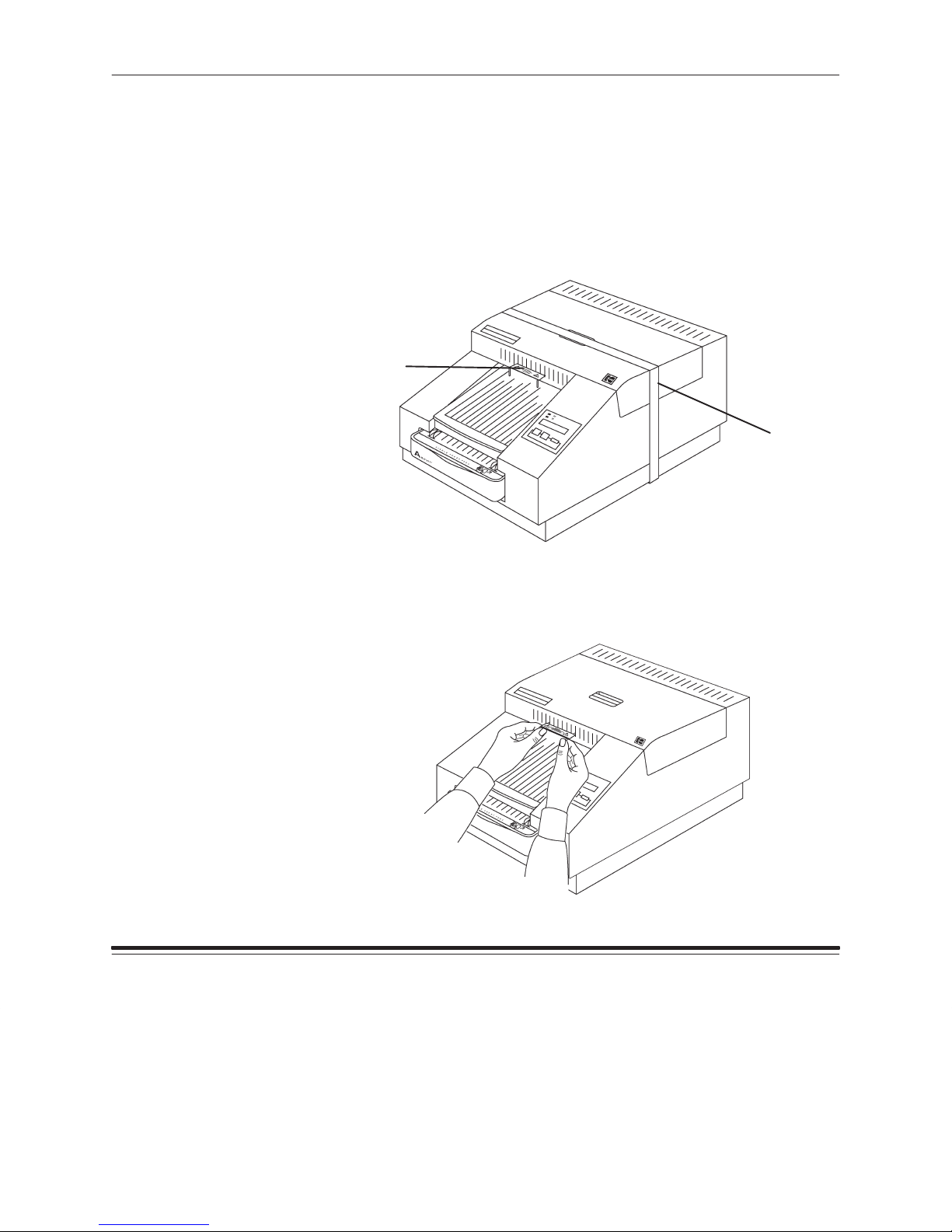

Removing the Shipping Pins

Shipping pins are used to ensure safe shipment of your XLS 8400 PS

Printer. Save the printer’s packaging and these pins in case you need to

ship your printer in the future.

CAUTION:Do not use the printer until you remove the shipping pins.

1. Remove the printer from the plastic bag.

shipping

pins

shipping

tape

1–2

2. Remove the tape from the printer cover.

3. Carefully pull out the shipping pins.

Part No. 4B1709 March 1995

Page 17

Getting Started

Finding a Location

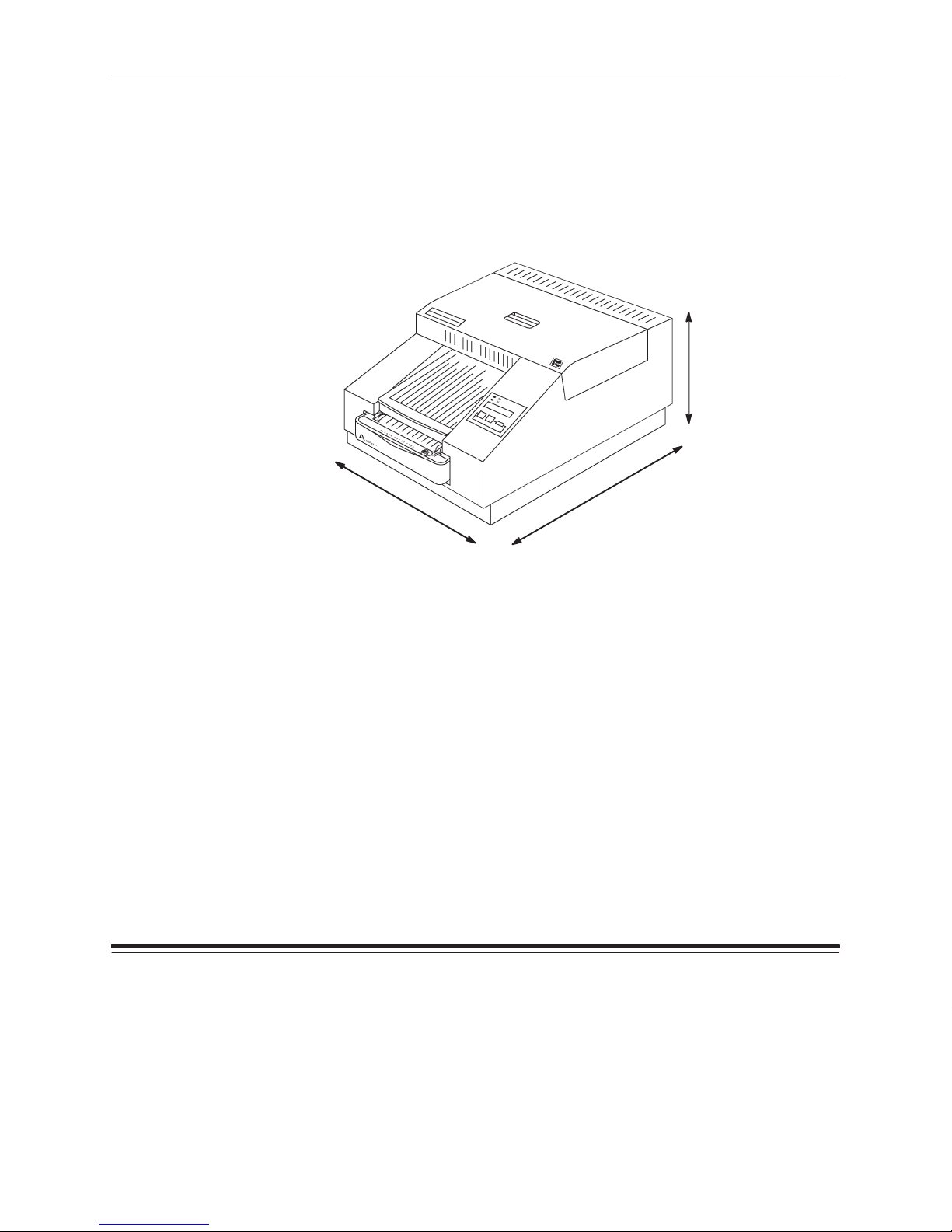

As you determine the best location for the XLS 8400 PS Printer, be

aware that certain connections and operations require access behind

and on the side of the printer. You should place the printer so that air

flow is not blocked. The following diagram illustrates the necessary

space requirements.

17

24

(plan for 37

to allow room for

removing tray)

1

/2

12

(plan for 20

to allow room for

opening cover)

1

/4

Airborne dirt particles can cause image quality problems. Avoid placing

the printer in areas where ventilation ducts, open doors, or frequent

passers-by might expose the printer and media to high levels of debris.

NOTE:Allow two (2) inches (about 5 cm) on all sides of the printer for

easy access.

Refer to Appendix A,

Printer Specifications,

for more information about

site requirements.

Part No. 4B1709 March 1995

1–3

Page 18

Getting Started

Components of the Printer

The following sections provide instructions for setting up your XLS 8400

PS Printer.

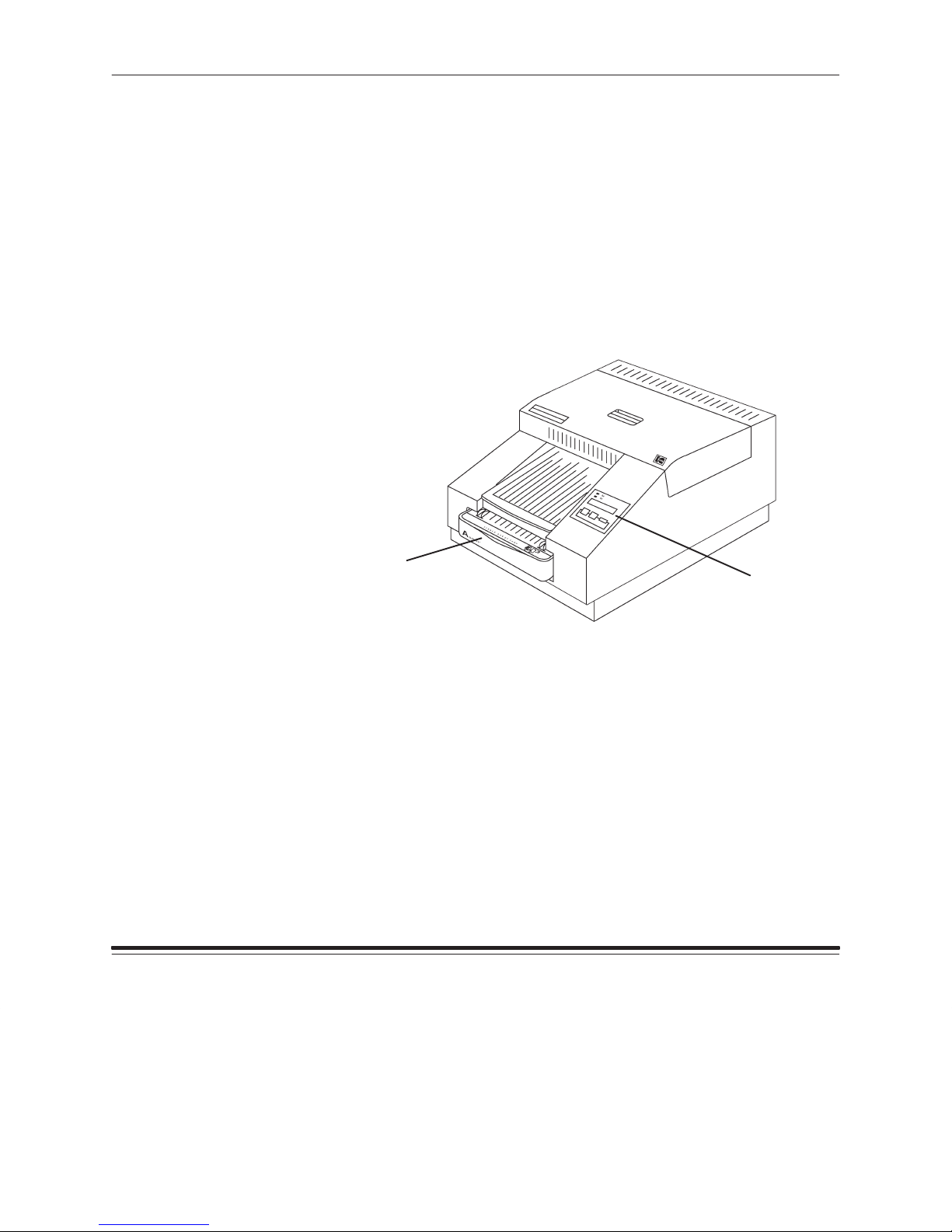

Reviewing the Components

Familiarize yourself with the printer components in the illustrations and

descriptions that follow.

Printer Front View

The components of the printer are shown below.

1–4

paper tray

display panel

Paper tray—the paper tray can hold up to 100 sheets of paper or

transparency material. One of three standard paper trays was provided

with your printer, based on your order. Optional trays are also available.

Refer to Chapter 3,

Supplies

for more information about paper trays.

Part No. 4B1709 March 1995

Page 19

Getting Started

Display panel—the display panel indicates printer status and is

described in detail later in this chapter. You can select the language that

you would like to read on the display panel by using the setup menu.

The following languages are available: English, French, German, Italian,

and Spanish.

Part No. 4B1709 March 1995

1–5

Page 20

Getting Started

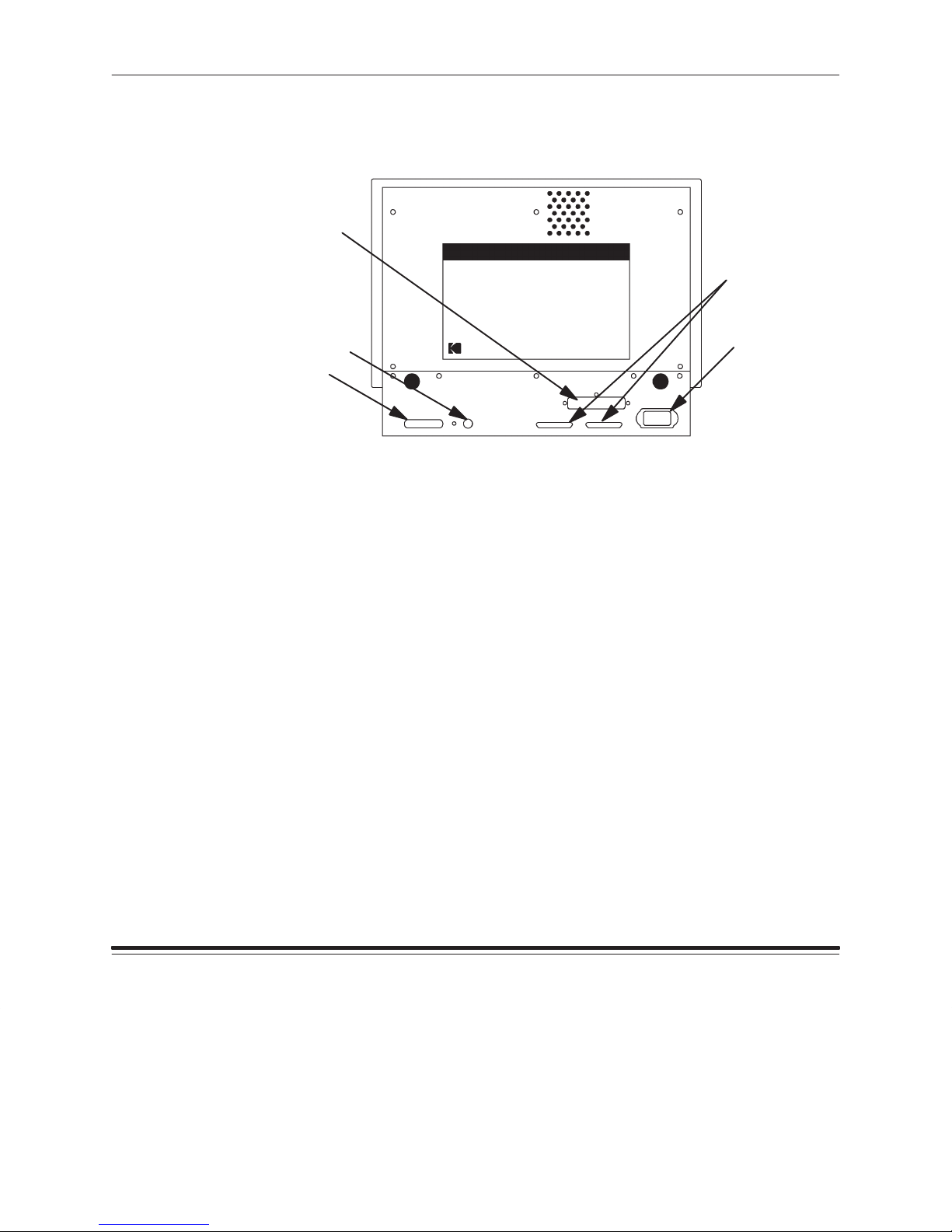

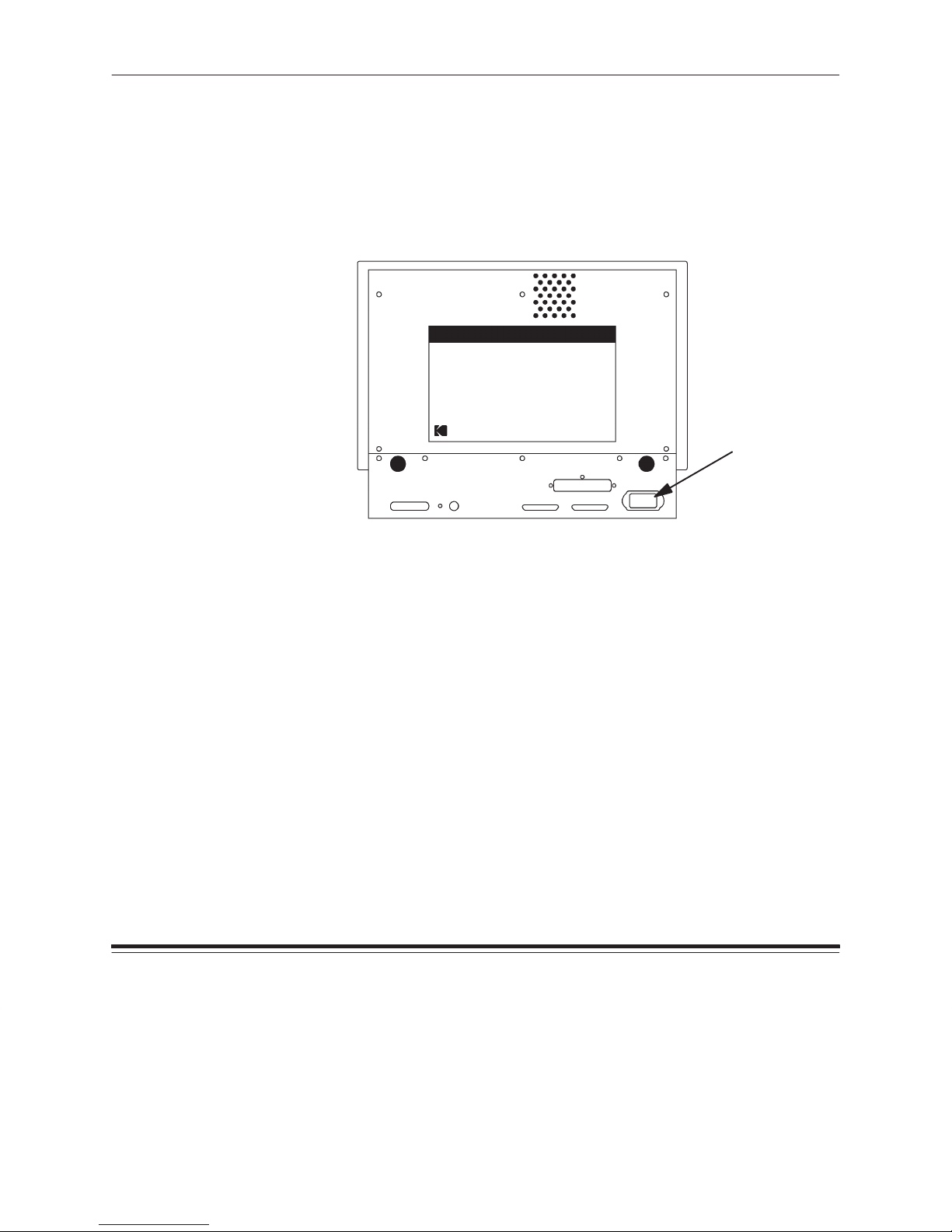

Printer Back View

The back of the printer is shown below.

slot for optional

Network

Interface Card

SCSI ports

LocalT alk port

Parallel port

Power cord inlet—one of four standard power cords is included with

your printer. The standard types are for North America/Japan, UK,

Europe Continental, and Australia. If you will be using the printer outside

of these areas, you may need to purchase a power cord.

Ports—a variety of ports is provided on the back of your printer. Ethernet

ports will be in place if the optional Network Interface Card is installed.

Parallel (Centronics) port

LocalTalk port

SCSI ports—these ports are active for external SCSI font disk drive

connections. A 50-pin submini SCSI terminator is included in the

printer package.

Ethernet 10BaseT and 10Base2 ports—these ports appear only when

the Network interface card is installed.

For more information about connecting the printer, refer to the “Attaching

the Interface Cable” section of this chapter.

power cord inlet

1–6

Part No. 4B1709 March 1995

Page 21

Getting Started

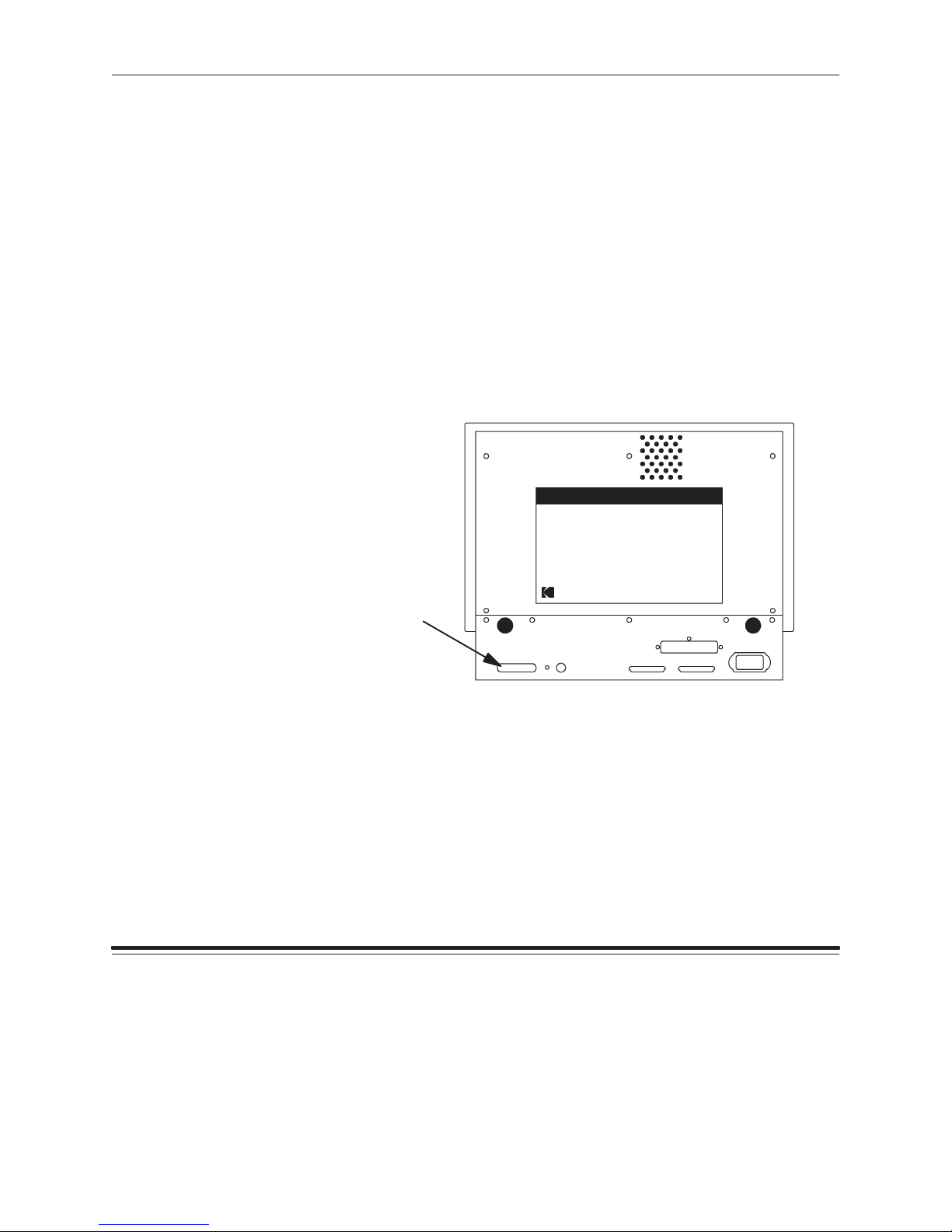

Printer Side View

The side of the printer is shown below.

Power switch—turn the power switch to “I” to turn the printer power on,

or to “O” to turn the power off.

power switch

K number label

K number label—a label next to the power switch displays the printer’s

K number. Provide this number to the technical support group when

contacting Kodak for service.

Part No. 4B1709 March 1995

1–7

Page 22

Getting Started

Printer Inside View

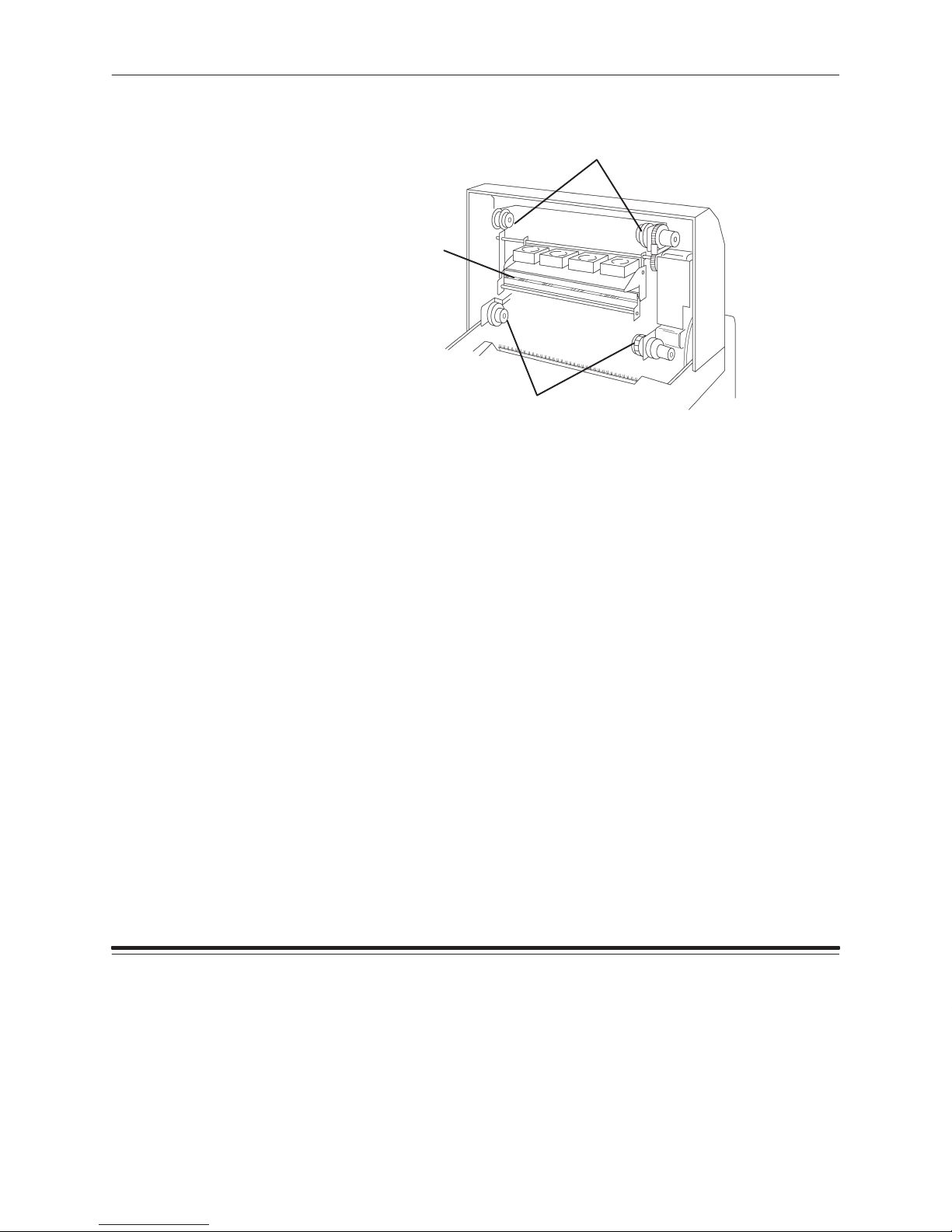

takeup spool holders

thermal

head

supply spool holders

Thermal head—the thermal head heats the ribbon to transfer the color

dyes to paper or transparency material.

CAUTION:Never rub or wipe anything across the thermal head

except when cleaning it. Refer to the section entitled

“Cleaning the thermal head,” in this chapter for more

information.

1–8

Ribbon spool holders—the ribbon contains dye that creates printed

images. These holders hold the ribbon supply and take-up spools in place.

Part No. 4B1709 March 1995

Page 23

Getting Started

Attaching the Power Cord

Follow these instructions to attach the power cord:

1. Make sure that the printer is turned off.

2. Plug the appropriate end of the power cord into the inlet on the back

of the printer.

Power cord inlet

Part No. 4B1709 March 1995

3. Plug the other end into an AC outlet.

NOTE:The printer will automatically accept input voltages from 90 to

250V and frequencies from 47 to 60 Hz.

1–9

Page 24

Getting Started

Attaching the Interface Cable

The sections below describe how to attach various cable types. You are

responsible for providing the necessary cable.

NOTE:Ethernet cabling can be used if the optional Network Interface

Card is installed on your printer. Refer to the documentation for

the Network Interface Card for more information.

Centronics Cable (Parallel Connection)

Follow these steps to attach a Centronics cable:

1. Make sure that the host computer is turned on.

2. Make sure that the printer is turned off.

3. Connect the Centronics cable to the printer’s parallel port.

1–10

Parallel port

4. Connect the other end of the Centronics cable to your computer.

5. Turn the printer on.

Part No. 4B1709 March 1995

Page 25

Getting Started

LocalTalk Cable

When connecting the printer directly to a computer using LocalTalk cable,

you will need two LocalTalk connectors and a LocalTalk cable to run

between them.

Follow these steps to connect the computer directly to the printer using

LocalTalk cable:

1. Make sure that the host computer is turned on.

2. Make sure that the printer is turned off.

3. Attach one of the LocalTalk connectors to the computer’s

LocalTalk port.

4. Attach the other LocalTalk connector to the printer’s LocalTalk port.

Part No. 4B1709 March 1995

LocalT alk port

5. Attach a LocalTalk cable between the two connectors.

6. Turn the printer on.

NOTE:The printer will not initialize if the host computer is not running.

1–11

Page 26

Getting Started

Cleaning the Thermal Head

It is important to clean the printhead when you are installing the printer,

and periodically afterward to remove dust and debris. Dirt can usually be

removed easily by following the head cleaning instructions below.

Clean the printhead each time you replace the ribbon to avoid lines or

streaks in your prints. You may need to clean it more often if your site is

particularly dusty. A cleaning pad is provided with each ribbon spool.

NOTE:If a cleaning pad is not available, use the alternate cleaning

method described in Chapter 4. You can order extra cleaning

pads by contacting Kodak Parts Services at 1–800–431–7278.

The part number for 160 of these pads is TL3127.

1. Turn the printer off.

2. Open the printer cover.

1–12

3. Remove the ribbon spools carefully if a ribbon is loaded in the printer.

NOTE:When handling thermal ribbon, hold it by the ends of the white plastic

spools. Wearing lint-free gloves is recommended. Fingerprints on the

ribbon web may severely reduce image quality.

Part No. 4B1709 March 1995

Page 27

Getting Started

4. Stand the ribbon spools on end or set the ribbon on a clean surface so

that dust and dirt are not picked up.

5. Open the cleaning pad.

6. Rub the cleaning pad back and forth along the entire length of

the printhead’s heater line which is shown in area A of the

following diagram.

(A) Heater Line

(Bead)

Clean this area

only, along entire

length of Heater

Line. Do not clean

or wipe below this

area, as damage to

the Thermal Head

could result.

(C) Circuit Cover

Center (filled) slot

aligns with Heater Line

when viewed from front.

Sealant Protecting

Circuit Row

DO NOT VIOLATE

(B) Backing Plate

Circuit Board

Thermal Print Head

Part No. 4B1709 March 1995

The heater line (A) aligns with the center (filled) slot on the backing

plate (B). Be careful not to rub the sealant which protrudes from

beneath the circuit cover (C) as damage to the printhead could occur.

1–13

Page 28

Getting Started

7. Repeat the back and forth motion several times to insure that the

head is completely clean.

The cleaning pad may become discolored.

8. Wait for the printhead to dry thoroughly before reloading the ribbon.

9. Reload the ribbon spool by following the loading instructions

beginning on page 1–16.

10. Close the printer cover.

11. Turn on the printer.

12. Press the print button on the display panel to make a test print.

You may want the first print after cleaning to be on paper rather than

on transparency material.

If the printhead was cleaned because of poor image quality and the

quality has not returned to normal, use the alternate cleaning method

described in Chapter 4.

1–14

Part No. 4B1709 March 1995

Page 29

Getting Started

Printer Media

This section describes ribbon, paper, and transparency material, and lists

handling instructions for them.

CAUTION:Use only the materials listed in Chapter 3,

Supplies,

with

the XLS 8400 PS Printer. Using other materials may

cause printer problems.

About Ribbon

The ribbon provides dyes for printing images.

Color ribbon contains three dye patches: one yellow patch; one magenta

patch; and one cyan patch. Each color ribbon contains enough dye to

generate 100 prints.

Refer to Chapter 3,

ordering ribbon.

Handling

When handling ribbon spools, follow these guidelines:

D Hold the ribbon spools by the ends to avoid fingerprints. Lint free

gloves are recommended. Fingerprints on the ribbon web will cause a

severe reduction in image quality.

D Don’t remove the tape from the new spool until the spool is mounted in

the printer and the ribbon is ready to attach to the take-up spool.

D Store ribbon according to the instructions listed in Chapter 3,

Supplies,

for more information about storing and

Supplies.

Part No. 4B1709 March 1995

1–15

Page 30

Getting Started

Loading

The ribbon fits easily in the printer. There is only one way to place the

spools correctly. Follow these steps to insert the ribbon:

NOTE:Wear lint free gloves during this procedure for best results.

1. Remove the old ribbon spools from the printer and dispose of them.

1–16

NOTE:Images remain on the ribbon after printing. If you are working with

confidential documents, you may want to secure and dispose of

the ribbon accordingly.

2. Clean the thermal head as described in the previous section.

3. Remove the new ribbon spools from the box.

The supply spool is longer than the take-up spool. For new ribbons,

the supply spool will be loaded with ribbon and the take-up spool will

be empty.

4. Push the left side of the take-up spool into the left side of the top spool

holder (the holders are spring-loaded).

5. Match the notches in the take-up spool with the notches on the right

spool holder.

6. Insert the right side of the take-up spool into the holder on the right.

Part No. 4B1709 March 1995

Page 31

Getting Started

7. Hold the supply spool so that the adhesive strip on the ribbon is facing

you and the barcode is on the left.

adhesive strip

barcode

8. Make sure that the spool notches are on the right.

This is particularly important when you are reloading a partially used

spool of ribbon.

9. Push the left side of the supply spool into the left side of the bottom

spool holder (the holders are spring-loaded).

Part No. 4B1709 March 1995

1–17

Page 32

Getting Started

10. Match the notches in the supply spool with the notches on the right

spool holder.

11. Insert the right side of the supply spool into the holder on the right.

12. Remove the tape from the adhesive strip.

1–18

13. Fold any excess ribbon behind the adhesive strip.

14. Pull the ribbon up carefully and stick the adhesive onto the take-up spool.

Part No. 4B1709 March 1995

Page 33

Getting Started

NOTE:Keep the ribbon as straight as possible.

15. Smooth the ribbon over the adhesive strip with your fingers.

16. Wind the take-up spool several times.

The first full set of dye patches is not used for printing.

Part No. 4B1709 March 1995

17. Close the printer cover.

1–19

Page 34

Getting Started

About Paper

Thermal paper is available in a variety of sizes. Refer to Chapter 3,

Supplies,

recommendations, and catalog numbers.

The paper looks and feels like photographic paper, but it is not light

sensitive. The back of this paper is printed with a logo to make it easy to

tell which side to put facedown in the tray.

Handling

When handling paper, follow these guidelines:

D Hold paper by the edges to avoid fingerprints which reduce

print quality.

D Handle the package of paper with the cardboard stiffener sheets

in place.

Loading

The paper tray adjusts to the size of the paper you want to load. Be sure not

to force paper that is too long or too wide into the tray. Follow the

instructions below to adjust the tray to the proper size and to load the paper.

for more information about image sizes, storage

1–20

NOTE:Although other Kodak paper trays may fit your printer, you should

only use trays designed for the XLS 8400 PS Printer. Using other

trays may cause paper jams, especially when printing images that

do not take up the maximum image area of the receiver that is

loaded in the tray.

Contact your printer dealer if you need a tray in a size other than

the one supplied with the printer. (Refer to Chapter 3,

Supplies,

for catalog numbers.)

Part No. 4B1709 March 1995

Page 35

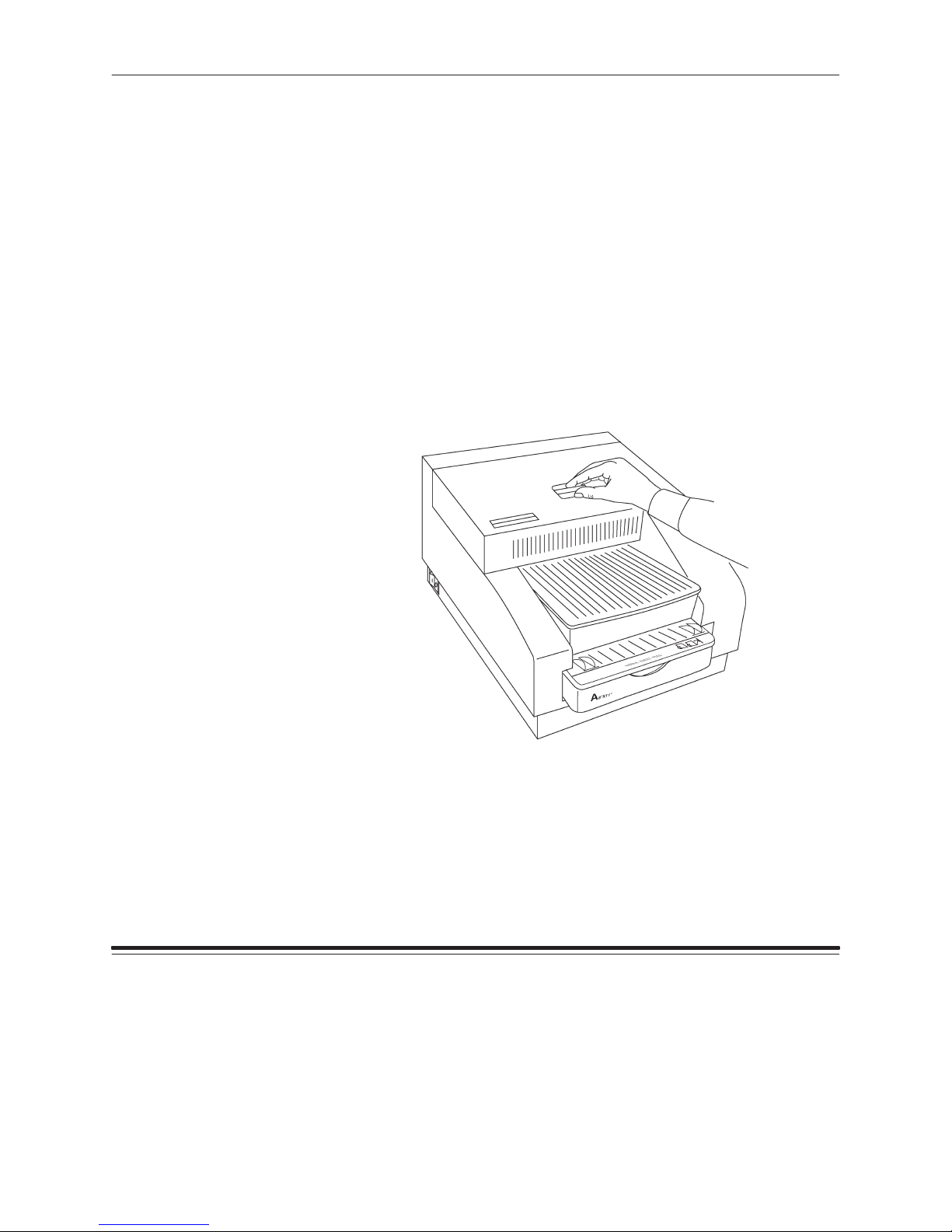

1. Remove the paper tray from the printer.

2. Push in the latches and take off the paper tray lid.

Getting Started

Part No. 4B1709 March 1995

latch

latch

1–21

Page 36

Getting Started

3. Adjust the paper tray size (if you are changing the size of the paper

that you are loading) by performing the following steps.

D Look through the opening on the side of the tray so that you can

see the sensor label.

sensor label

(through opening)

This label indicates the current paper size setting. The part of the label

that you see changes as you move the media-length sensor slider.

media-length

sensor slider

1–22

Part No. 4B1709 March 1995

Page 37

Getting Started

D Move the media-length sensor slider on the inside of the paper tray

so that the media size you want displays through the opening on

the side of the tray.

The options on the sensor labels for the three trays are shown

below.

Part No. 4B1709 March 1995

Letter Adjustable Tray

A4 Adjustable Tray

9.5 x 14 in Tray

NOTE:You do not have to move the slider if you are using the

9.5I x 14I tray.

Moving the slider sets the sensor so that the printer can detect

the size of the paper that is loaded.

1–23

Page 38

Getting Started

D Lift and move the media-length stop to the appropriate position for

the paper you are loading.

A label on the bottom of the tray shows the available settings.

1–24

label

NOTE:You cannot change the media length stop on the 9.5 I x 14I tray.

4. Remove and discard any blue stiffener sheets that remain in the

paper tray.

5. Remove the paper from the package.

NOTE:Handle the paper stack by the edges to avoid fingerprints on the

top page.

6. Remove the blue stiffener sheet from the logo-printed side of the

paper stack.

Leave the other blue stiffener sheet on the bottom of the stack.

7. Place the paper in the tray with the logo side facing up.

Part No. 4B1709 March 1995

Page 39

Getting Started

Make sure that the front corners of the paper stack are under the

triangular metal tabs.

8. Put the paper tray lid back on.

Part No. 4B1709 March 1995

9. Make sure that the latches on the two sides of the paper tray latch into

place in the paper tray lid.

1–25

Page 40

Getting Started

10. Insert the paper tray in the printer until it locks into position.

11. Verify that the correct paper size is listed on the display panel.

1–26

Part No. 4B1709 March 1995

Page 41

Getting Started

About Transparency Material

Transparency material is available in a variety of sizes. Refer to Chapter

3,

Supplies,

recommendations, and transparency material catalog numbers.

Handling

When handling transparency material, follow these guidelines:

D Hold transparency material by the edges to avoid fingerprints,which

reduce print quality.

D Handle the package of transparencies with the cardboard stiffener

sheets in place.

Loading

You can adjust the paper tray to the size of the transparency material you

want to load. The printer uses a sensor on the tray to determine the

correct paper size.

Be sure not to force transparency material that is too long or too wide

into the tray.

for more information about image sizes, storage

Part No. 4B1709 March 1995

NOTE:Although other Kodak paper trays may fit your printer, you should

only use trays designed for the XLS 8400 PS Printer. Using other

trays may cause paper jams, especially when printing images that

do not take up the maximum image area of the receiver that is

loaded in the tray.

Contact your printer dealer if you need a tray in a size other than

the one supplied with the printer. (Refer to Chapter 3,

Supplies,

for catalog numbers.)

1–27

Page 42

Getting Started

Follow the instructions below to adjust the tray to the proper size and to

load transparency material.

1. Remove the paper tray from the printer.

2. Push in the latches and take off the paper tray lid.

1–28

latch

latch

Part No. 4B1709 March 1995

Page 43

Getting Started

3. Adjust the paper tray size (if you are changing the size of the

transparency material that you are loading) by performing the

following steps.

D Look through the opening on the side of the tray so that you can

see the sensor label.

sensor label

(through the

opening)

This label indicates the current paper size setting. The part of the label

that is shown changes as you move the media-length sensor slider.

media-length

sensor slider

Part No. 4B1709 March 1995

1–29

Page 44

Getting Started

D Move the media-length sensor slider on the inside of the paper tray

so that the media size you want displays through the opening on

the side of the tray.

The options on the sensor labels for the three trays are shown

below.

1–30

Letter Adjustable Tray

A4 Adjustable Tray

9.5 x 14 in Tray

NOTE:You do not have to move the slider if you are using the

9.5I x 14I tray.

Moving the slider sets the sensor so that the printer can detect

the size of the transparency material that is loaded.

Part No. 4B1709 March 1995

Page 45

Getting Started

D Lift and move the media-length stop to the appropriate position for

the transparency size you are loading.

A label on the bottom of the tray shows the available settings.

Part No. 4B1709 March 1995

label

NOTE:You cannot change the media length stop on the 9.5 I x 14I tray.

4. Remove and discard any blue stiffener sheets that remain in the

paper tray.

5. Remove the transparencies from the package, keeping the blue

stiffener sheets in place.

1–31

Page 46

Getting Started

6. Place the stack of transparencies in the tray with the orientation notch

on the lower right-hand side and with a blue stiffener sheet on the

bottom of the stack.

Make sure that the front corners of the transparency stack are under

the triangular metal tabs.

7. Remove the blue stiffener sheet from the top of the stack.

1–32

8. Put the paper tray lid back on.

Part No. 4B1709 March 1995

Page 47

Getting Started

9. Make sure that the latches on the sides of the paper tray latch into

place in the paper tray lid.

10. Insert the paper tray in the printer until it locks into position.

11. Verify that the correct paper size is listed on the display panel.

Part No. 4B1709 March 1995

1–33

Page 48

Getting Started

Turning on the Power

Press the “|” side of the power switch to turn on the printer. The switch is

located on the lower left side of the printer.

It may take up to one minute for the printer to initialize. During this time,

the power light will illuminate and two messages will display alternately

on the display panel:

INITIALIZING*

INITIALIZING**

PLEASE WAIT

1–34

When the printer is ready a set of three messages will flash on the

display panel:

READY

media type

ribbon type

media type

in the paper tray. For example, “210X307 mm TRANS”.

ribbon type

printer. For example, “XTRALIFE COLOR”.

If the printer fails to initialize, the following message will appear on the

control panel:

If this message appears, turn the printer off and back on again.

NOTE:If the connection type is parallel, make sure that the host

If the message appears again, the printer requires service.

will be replaced by the size and type of media that is loaded

will be replaced by the type of ribbon that is loaded in the

INIT ERROR

computer is up and running before turning the printer on again.

Part No. 4B1709 March 1995

Page 49

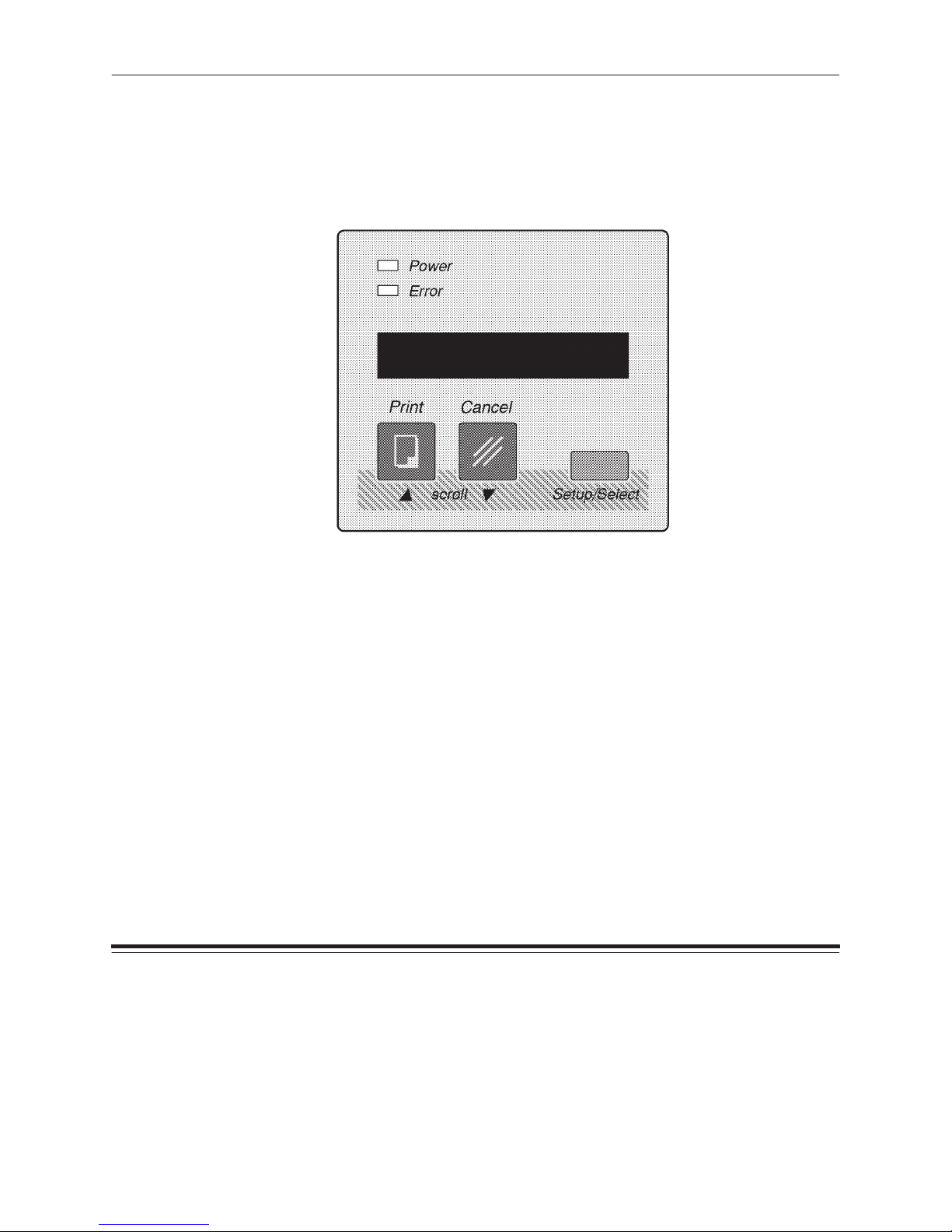

Understanding the Display Panel

Familiarize yourself with the display panel shown below.

Getting Started

Part No. 4B1709 March 1995

A description of each item is on the following pages.

1–35

Page 50

Getting Started

Indicator Lights

The indicator lights on the display panel illuminate according to the status

of the printer. There are two indicator lights:

Power

The Power light indicates that the printer is turned on.

Error

The Error light indicates that there is an error condition. When this light is

lit, a message will be displayed. There are two types of error conditions:

user-correctable errors; and errors requiring service.

User-correctable error—when the error light is lit but is not flashing, you

can correct the problem yourself. The light will stay on until you have

responded to all messages displayed in the LCD panel.

Service call error—when the error light flashes, a system error message

will be displayed on the LCD panel. Turn the printer off and then on

again. If the error continues, service is required.

1–36

Part No. 4B1709 March 1995

Page 51

Getting Started

LCD Panel

The LCD (Liquid Crystal Display) panel displays one 16-character line at

a time. Messages longer than 16 characters are broken into 16-character

sections and are alternated in the display.

The LCD panel displays messages on the current status of the printer.

Job-related messages refer to the status of the job closest to completion.

Media-related messages indicate the type of media and ribbon that are

loaded in the printer. Messages also appear when the paper tray is

empty, when the printer’s cover is open, and when errors occur.

Messages

The printer’s display panel provides information about the status of the

printer. The information that appears depends on the current state of

the printer.

The following status information is displayed when the printer is idle.

Media—the size of the paper or transparency material that is loaded in

the paper tray.

Ribbon—the type of ribbon that is loaded.

Part No. 4B1709 March 1995

Status information is returned to the computers which send files to the

printer. Refer to Chapter 4,

Correcting problems,

and to the printing

software documentation for more information.

1–37

Page 52

Getting Started

Buttons

The buttons on the display panel allow you to set the printing features of

the printer, cancel print jobs, override mismatches, and generate test

prints. Following are descriptions of each button.

Cancel (B)

The Cancel (B) button allows you to abort the job that is closest to

completion. For example, you may have a job printing and a job processing.

If you press the Cancel (B) button, the job being printed is aborted

immediately. No additional pages in that job are printed, and the page that is

currently being printed is ejected. If you press the Cancel (B) button again,

the next job will be cancelled if one exists.

The Cancel (B) button also scrolls down through the Setup menu when

using the Setup button. For more information, refer to the section entitled

“Configuring the Printer” in this chapter.

Setup/Select

The Setup/Select button allows you to enter the Setup mode to control

printer parameters. See the section entitled “Configuring the Printer” in

this chapter for more details.

1–38

Print (Y)

The Print (Y) button:

D Generates a test print when the printer is not processing other jobs

and READY appears in the LCD panel.

D Begins printing after mismatch errors are listed. For more

information, refer to the section “Mismatch Conditions” in

Chapter 4,

Correcting Problems.

The Print (Y) button also scrolls up through the Setup menu when using

the Setup button. For more information, refer to the section entitled

“Configuring the Printer” in this chapter.

Part No. 4B1709 March 1995

Page 53

Getting Started

Configuring the Printer

A number of printer configuration parameters must be established by

using the Setup/Select button on the display panel. The Setup program

includes a list of menus and submenus that you can access and

manipulate by using the Setup/Select, Print (Y), and Cancel (B) buttons.

Using Setup Menus

Entering Setup Mode

Press the Setup/Select button while the printer is in the READY state to

enter the Setup mode. The first option you will see is SETUP:EXIT.

Selecting Options

You can scroll up through the list of setup features by pressing the

Print (Y) button or you can scroll down through the list by pressing the

Cancel (B) button. The scrolling feature takes you through the options in

a loop; it is not necessary to scroll up to get to SETUP:EXIT.

When you find the desired option in the submenu, press the Setup/Select

button to select that option.

Part No. 4B1709 March 1995

An asterisk (*) to the right of an option on the display panel indicates that

the option is currently selected on your printer. In the descriptions that

follow, options marked with asterisks (*) are factory settings.

Exiting Setup Mode

Select the SETUP:EXIT option to leave Setup mode.

1–39

Page 54

Getting Started

Selecting a Language for the Display Panel

Press the Setup/Select button when SETUP:LANGUAGE appears in the

display panel. You can choose from the following languages:

LANG:ENGLISH*

LANG:ESPANOL

LANG:FRANCAIS

LANG:DEUTSCH

LANG:ITALIANO

LANG:EXIT

Use the Print (Y) and Cancel (B) buttons to scroll through the list.

Press the Setup/Select button to make your choice. The change takes

place immediately .

Select LANG:EXIT once you have made your selection.

Selecting Defaults

Press the Setup/Select button when SETUP:DEFAULTS appears in the

display panel to change the printer’s default settings.

Restoring Factory Settings

Use the DEFAULTS:FACTORY menu to return all option settings to those

that were in place when the printer was installed.

FACTORY:RESET

FACTORY:EXIT

Select FACTORY :RESET to restore all operating parameters to the

factory settings. The printer will reboot immediately so that the new

options will be in place.

NOTE:Resetting the printer to factory defaults may cause network

printing problems if the optional Network Interface Card is

installed in the printer.

Select FACTORY :EXIT when you are finished.

1–40

Part No. 4B1709 March 1995

Page 55

Getting Started

Selecting a Default Media Type

Use the DEFAULTS:MEDIA menu to choose the media type that will act

as the default when a job is sent to the printer without a media-type

specification. The new option will be in effect when you exit Setup mode.

MEDIA:PAPER*

MEDIA:TRANS

MEDIA:EXIT

Select MEDIA:PAPER if you want paper to be the default media type.

Select MEDIA:TRANS if you want transparency material to be the default

media type.

Select MEDIA:EXIT once you have made your selection and select

DEFAULTS:EXIT when you are finished.

Part No. 4B1709 March 1995

1–41

Page 56

Getting Started

Specifying Port Information

Use the SETUP:PORTS menu to change the default port information.

Press the Setup/Select button to get into the SETUP:PORTS submenu.

The options you select must match your host computer settings.

NOTE:The submenus that appear for this menu depend on whether the

Network Interface Card is installed in the printer.

Setting up a Parallel Connection

Use the PORTS:PARALLEL menu to establish information about

connecting the printer through a parallel port. The new option will be in

place once you exit Setup mode.

PARA:MODE—This menu specifies whether the parallel port should

accept data in normal PostScript mode or in Adobe binary mode. Normal

PostScript mode can only support printable characters; it does not accept

characters in the high ASCII range (128–255). Adobe binary mode

supports the high ASCII range. Full 8-bit data may be sent.

The following settings are available.

MODE:NORMAL*

MODE:BINARY

MODE:EXIT

1–42

Select MODE:EXIT once you have made your selection and select

PARA:EXIT when you are finished.

Part No. 4B1709 March 1995

Page 57

Getting Started

Setting up an EtherTalk Connection

Use the PORTS:ETHERTALK menu to establish information about

connecting the printer through an EtherTalk connection. The new option

will be in place once you exit Setup mode. The only options available in

this submenu are E–TALK:VERSION and E–TALK:EXIT.

This menu option will appear only if the Network Interface Card is

installed in the printer.

E–TALK:VERSION—This menu specifies whether version 1 or 2 of

AppleTalk will be used on the EtherTalk connection. The following

settings are available.

VER:2*

VER:1

VER:EXIT

Select VER:EXIT once you have made your selection and select

E–TALK:EXIT when you are finished.

Setting up an IPX (Novell NetWare) Connection

Use the PORTS:IPX menu to establish the framing type the printer should

expect. The new option will be in place once you exit Setup mode.

Part No. 4B1709 March 1995

This menu option will appear only if the Network Interface Card is

installed in the printer.

The following settings are available.

IPX:802.3

IPX:802.2

IPX:SNAP

IPX:ETHERNET 2

IPX:AUTOSELECT*

IPX:EXIT

Select IPX:EXIT when you are finished.

1–43

Page 58

Getting Started

Setting up a TCP/IP Connection

Use the PORTS:TCP/IP menu to establish the internet address of the

printer within a TCP/IP network. The address will be in place once you

exit Setup mode.

This menu option will appear only if the Network Interface Card is

installed in the printer.

The following settings are available.

TCP/IP:ADDRESS

TCP/IP:EXIT

Select TCP/IP:ADDRESS to access a screen which allows you to enter

digits for the address. The address is represented as four groups of 3

digits each, separated by periods. (For example, nnn.nnn.nnn.nnn). The

cursor will be positioned in the left-most digit place. Press the up arrow

button to increment the number in that position by one. Press the down

arrow button to move the cursor to the next digit to the right. Press Select

to accept the address and exit the screen.

Select TCP/IP:EXIT when you are finished.

1–44

Part No. 4B1709 March 1995

Page 59

Getting Started

Setting up a SCSI Connection to an External Disk

Use the PORTS:SCSI menu to establish information about connecting

the printer to an external disk through a SCSI port. The new options will

be in place once you exit Setup mode.

SCSI:INITIATOR—This menu allows you to access the

INITIATOR:ENABLE and INITIATOR:ID menus.

INITIATOR:ENABLE—This menu allows you to determine whether or

not the printer should act as the SCSI bus initiator. The only time that

this option should be enabled is when an external disk drive for font

storage is connected to the printer.

The following settings are available.

ENABLE:YES

ENABLE:NO*

ENABLE:EXIT

INITIATOR:ID—This menu allows you to specify the ID for the printer

that will act as the SCSI bus initiator.

The following addresses are available.

Part No. 4B1709 March 1995

INITIATOR ID:0

INITIATOR ID:1

INITIATOR ID:2

INITIATOR ID:3

INITIATOR ID:4

INITIATOR ID:6*

INITIATOR ID:7

INITIATOR ID::EXIT

Select TARGET ID:EXIT once you have made your selection, and

SCSI:EXIT when you are done.

1–45

Page 60

Getting Started

Specifying the Mode

Use the SETUP:MODE menu to specify whether the printer should run in

normal PostScript mode or in calibration mode. The printer should run in

PostScript mode when you are sending printing jobs, and in calibration

mode when you are sending color calibration files.

The following settings are available.

MODE:POSTSCRIPT*

MODE:CALIBRATE

MODE:EXIT

Select MODE:EXIT when you are done. The printer will reboot when you

exit Setup mode and run in the mode you selected.

1–46

Part No. 4B1709 March 1995

Page 61

Getting Started

Making a Test Print

The XLS 8400 PS Printer can print a test page without needing a file sent

from a computer. The test image helps you to verify proper setup and

printer operation, and to confirm print quality.

You should make a test print after installing the printer to check

print quality.

To make a test print, follow these steps:

1. Make sure that READY appears on the display panel.

2. Press the Print button on the display panel.

It takes less than four (4) minutes for a test image to process

and print.

While image data is processing, the following message will appear on

the display panel:

PROCESSING:

TEST PRINT

Once the image data is processed, the following message will be

displayed:

Part No. 4B1709 March 1995

PRINTING

As printing takes place, the printer moves the paper through the imaging

path multiple times. During this process, the paper will partially exit the

printer. Do not pull on the print during any of the passes. Wait until the

print exits completely before touching it.

NOTE:When you run a test print, the printer expects that the loaded

media will match the media type specified as the default through

the display panel’s DEFAULTS:MEDIA option. For example, if the

DEFAULTS:MEDIA option is set to PAPER, the printer will expect

that paper is loaded when the Print button is pressed. If

transparency material is loaded in this situation, a mismatch

message will appear on the display panel. If you choose to make

the test print with the incorrect media type loaded, the print will

not have proper color reproduction for that media type.

1–47

Page 62

Getting Started

Printing from Computer Applications

Printing is initiated through your application software using the Printer

Drivers and/or Export Modules that were provided with your printer. Refer

to the printing and application software user‘s guides for instructions.

The time it takes for an image to print depends on the application you are

running and on the type of image being printed. Some images take much

longer to print than others. A file made up of lines generally takes less

time to print than a file which is defined in bits, such as a scanned image.

While image data is processing, the following message will appear on the

display panel:

PROCESSING

Once the image data is processed, the following message will be

displayed:

PRINTING

If you press the Cancel button while the printer is processing or printing a

job, the following message will be displayed:

CANCELLING JOB

1–48

As printing takes place, the printer moves the paper through the imaging

path multiple times. During this process, the paper will partially exit the

printer. Do not pull on the print during any of the passes. Wait until the

print exits completely before touching it.

Part No. 4B1709 March 1995

Page 63

Getting Started

Job Scheduling

The number of jobs that can be queued to the printer at one time

depends on the available memory in the printer. If large image files are

sent, fewer jobs can be processed. Installing optional memory in the

printer increases the number of jobs that can be processed concurrently

and is described in Appendix B.

The other factor that impacts job scheduling is the network configuration

in which the printer is installed. When the printer is connected through

more than one port, the printer polls the ports in a round robin manner.

This means that once a job is received by the printer, it stops polling the

ports until the job has finished printing. When the job is complete, the

printer then looks to the next port in the list. The position of the ports in

the list therefore impacts the order in which jobs are processed. Timing of

when jobs are sent is not the sole determinant of when jobs will be

processed and printed.

Part No. 4B1709 March 1995

1–49

Page 64

Getting Started

Storing Prints and Transparencies

The image stability of thermal prints depends on factors such as

temperature; relative humidity; and exposure to light, biological, or

chemical contaminates. Thermal prints and transparencies should be

stored in a cool, dry environment that is free of chemical contamination.

D The lower the temperature the better. Avoid temperatures higher than

72_F (25_C) for extended periods.

D A relative humidity between 30% and 50% is ideal.

D Avoid exposure to high-intensity light sources, particularly florescent

light and sunlight which are rich in ultraviolet radiation.

D Avoid exposure to vinyl items (those made of polyvinyl chloride [PVC])

or any plastic which contains plasticizer. These items usually have a

distinctive “plastic” odor. If you use transparency sleeves, make sure

that they are not PVC-based.

D Handle prints as little as possible. When handling prints, make sure

your hands are clean and free of food, oil, and grease. Wear clean

gloves when possible, and hold prints by the edges.

1–50

Your thermal images will last for a long time if you handle and store them

as described above.

Part No. 4B1709 March 1995

Page 65

2 Maintaining the Printer

A clean and dust-free environment is recommended when using the

XLS 8400 PS Printer.

D Keep the printer clean and the surrounding area vacuumed and

litter-free.

D Do not expose the printer to tobacco smoke or liquid spills.

D Do not place objects on top of the printer.

The major enemies of good printer performance and high-quality output are

dust and dirt. Perform the following preventive maintenance periodically to

help assure good printing results.

D Clean the thermal head each time you load a new ribbon or if you

notice image quality problems.

Refer to the thermal head cleaning procedure detailed in Chapter 1,

Getting Started.

D Clean the roller bar.

D Clean the paper tray area, paper exit area, and printer cabinet with a

damp, lint-free cloth. This eliminates dust buildup and prevents dirt

from getting in the printer.

Part No. 4B1709 March 1995

CAUTION:Always turn the printer off and unplug it before cleaning.

Never use abrasives or harsh chemicals to clean any part

of the printer. Do not use thermal head cleaning pads to

clean the printer cabinet.

D Clean the area around and under the printer to keep dust out of the

cooling fan on the bottom. Do not put paper under the printer because

it can block the fan.

2–1

Page 66

Page 67

3 Supplies

This chapter describes how to order and store supplies.

Ordering Accessories and Supplies

The following products are available for use with your

XLS 8400 PS Printer.

Alcohol Cleaning Pads

Alcohol cleaning pads can be ordered by contacting Kodak Parts

Services at 1–800–431–7278.

CESD Part

Cleaning Pads

Alcohol cleaning pads (box of 160) TL3127

Accessories

The table below lists printer accessories and their catalog numbers.

These items can be purchased through your printer dealer or distributor.

Accessory

KODAK Network Interface Card (NIC)

for KODAK XLS 8600 PS Printer

KODAK Letter Adjustable Tray 101 8969

KODAK A4 Adjustable Tray 851 1420

KODAK 9.5 x 14 Adjustable Tray

Number

Catalog

Number

897 1244

882 0060

Part No. 4B1709 March 1995

Ribbon

The table below lists ribbon types and their catalog numbers. These

items can be purchased through your printer dealer or distributor.

Catalog

Ribbon Type

KODAK EKTATHERM XLS Color Ribbon 887 3945

KODAK EKTATHERM XLS Oversize Color Ribbon 871 5963

NOTE:Each ribbon can print 100 images.

Number

3–1

Page 68

Supplies

Paper

The table below lists paper sizes and their catalog numbers. The

maximum image size that can print on the page is also illustrated. These

items can be purchased through your printer dealer or distributor.

NOTE:Paper is shipped in packages of 100 sheets.

Catalog

Paper Type

KODAK EKTATHERM XLS Print Paper

8.5 x 11

216 x 281mm

(for use with the KODAK Letter Adjustable Tray)

Image area:

8.0 x 8.93

204 x 228mm

Number

861 4364

3–2

KODAK EKTATHERM XLS Print Paper

210 x 297mm (A4)

8.27 x 11.69

(for use with the KODAK A4 Adjustable Tray)

Image area:

8.0 x 9.6

204 x 246mm

881 6514

Part No. 4B1709 March 1995

Page 69

Paper Type

KODAK EKTATHERM XLS Print Paper

8.5 x 12

216 x 307mm

(for use with the KODAK Letter Adjustable Tray)

Image area:

8.0 x 10

204 x 256mm

Supplies

Catalog

Number

868 4623

KODAK EKTATHERM XLS Print Paper

210 x 307mm

8.27 x 12

(for use with the KODAK A4 Adjustable Tray)

Image area:

8.0 x 10

204 x 256mm

KODAK EKTATHERM XLS Print Paper

8.5 x 14

216 x 358mm

(for use with the KODAK Letter Adjustable Tray)

Image area:

8.0 x 12

204 x 307mm

875 1596

856 5699

Part No. 4B1709 March 1995

3–3

Page 70

Supplies

Paper Type

KODAK EKTATHERM XLS Print Paper

210 x 358mm

8.27 x 14I

(for use with the KODAK A4 Adjustable Tray)

Image area:

8.0 x 12I

204 x 307mm

Catalog

Number

807 5640

KODAK EKTATHERM XLS Print Paper

9.5 x 14I

243 X 358mm

(for use with the KODAK 9.5 x 14I Adjustable Tray)

Image area:

8.42 x 12I

214 x 307mm

867 7759

3–4

Part No. 4B1709 March 1995

Page 71

Supplies

Transparency material

The table below lists transparency sizes and their catalog numbers. The

maximum image size that can print on the page is also illustrated. These

items can be purchased through your printer dealer or distributor.

NOTE:Transparency material is shipped in packages of 100 sheets.

Catalog

Transparency Type

KODAK EKTATHERM XLS Transparency Material

8.5 x 11

216 x 281mm

(for use with the KODAK Letter Adjustable Tray)

Image area:

8.0 x 8.93

204 x 228mm

Number

852 6618

Part No. 4B1709 March 1995

KODAK EKTATHERM XLS Transparency Material

210 x 297mm (A4)

8.27 x 11.69

(for use with the KODAK A4 Adjustable Tray)

Image area:

8.0 x 9.6

204 x 246mm

850 3005

3–5

Page 72

Supplies

Transparency Type

KODAK EKTATHERM XLS Transparency Material

8.5 x 12

216 x 307mm

(for use with the KODAK Letter Adjustable Tray)

Image area:

8.0 x 10

204 x 256mm

Catalog

Number

853 4059

KODAK EKTATHERM XLS Transparency Material

210mm x 307mm

8.27 x 11.69

(for use with the KODAK A4 Adjustable Tray)

Image area:

8.0 x 10

204 x 256mm

871 7001

3–6

Part No. 4B1709 March 1995

Page 73

Transparency Type

KODAK EKTATHERM XLS Transparency Material

8.5 x 14

216 x 358mm

(for use with the KODAK Letter Adjustable Tray)

Image area:

8.0 x 12

204 x 307mm

Supplies

Catalog

Number

852 9679

KODAK EKTATHERM XLS Transparency Material

210mm x 358mm

8.27 x 14

(for use with the KODAK A4 Adjustable Tray)

Image area:

8.0 x 12

204 x 307mm

861 0651

Part No. 4B1709 March 1995

3–7

Page 74

Supplies

Storing Supplies

Always keep your work area and material storage area as clean

as possible.

Ribbon

For highest image quality, follow these ribbon storage instructions:

D Store unopened ribbon at temperatures below 77_F (25_C).

Avoid exposure to temperatures higher than 100_F (38_C).

D Wrap partially used ribbons in their original wrappers to protect them

from dust and dirt when they are not loaded in the printer. Dust and dirt

specs on the ribbon show up as much larger spots on prints. When

handling the ribbons, hold the spools only by the ends. Lint free gloves

are recommended.

D Do not expose the ribbon to direct sunlight, extreme heat, dust,

or liquids.

D Leave the printer cover closed except when you need to access the

inside of the printer.

Refer to the storage instructions on the package for more information.

3–8

Part No. 4B1709 March 1995

Page 75

Supplies

Paper

For highest image quality, follow these paper storage instructions:

D Store opened paper at temperatures below 77_F (25_C). Avoid

exposure to temperatures higher than 100_F (38_C).

D Relative humidity level for storing and using paper should be between

40% and 60%. Relative humidity lower than 20% or higher than 76%

should be avoided even for short periods of time. Print paper can

tolerate a relative humidity between 20% and 40% and between 60%

and 76% for up to a few hours without curling.

High relative humidity tends to cause paper to curl toward its image

side. Low relative humidity tends to cause paper to curl away from its

image side. Low relative humidity also tends to increase static

attraction of dust and dirt.

D Keep the bottom stiffener board in place when handling stacks of

paper to avoid fingerprints on the printing surface.

D Avoid storing loose stacks of paper out of their wrapper.

D Do not use wet or damaged stock.

Part No. 4B1709 March 1995

D Keep the lid on the paper tray and the paper tray inserted in the printer

to protect media from exposure to light, dust, and dirt.

If you experience humidity-related paper problems, refer to Chapter 4,

Correcting problems,

for additional storage recommendations.

3–9

Page 76

Supplies

Transparency material

For highest image quality, follow these transparency storage instructions:

D Store opened transparency material at temperatures below 77_F

(25_C). Avoid exposure to temperatures higher than 100_F (38_C).

D Keep the bottom stiffener board in place when handling stacks of

paper to avoid fingerprints on the printing surface.

D Avoid storing loose stacks of transparencies out of their wrapper.

D Do not use wet or damaged stock.

D Keep the lid on the paper tray and the paper tray inserted in the printer

to protect media from exposure to light, dust, and dirt.

3–10

Part No. 4B1709 March 1995

Page 77

4 Correcting Problems

Understanding Error Messages

Error messages are displayed on the printer display panel. High priority

events or states are displayed before lower priority ones. It is possible for

more than one error to occur at the same time; however, the panel can

display only one error message at a time. You must resolve the problems

in the order that they appear on the panel. For example, a CLOSE

COVER message may appear. After you close the printer cover, a paper

mismatch message may appear. After you fix the paper mismatch

problem, and if there are no other errors, READY will be displayed.

Following is an alphabetical list of the most common error messages that

appear on the printer’s LCD display.

CHANGE RIBBON

The printer is unable to advance the ribbon because the supply spool is

empty or the ribbon’s barcode cannot be read. Open the cover and

change the ribbon, or check to see if the barcode is legible. Refer to

Chapter 1,

CHECK TRA Y

The printer senses a paper jam in the tray area, the tray is not seated

properly, or the tray is empty. Remove the tray, clear the area or add

paper, and reinsert the tray.

Getting Started,

for ribbon loading instructions.

Part No. 4B1709 March 1995

CLEAR P APER PATH

The printer finds paper in the paper path and cannot clear it. Open the

printer cover, clear the path, and close the cover. Refer to the “Clearing

the Paper Path” section in this chapter for instructions.

4–1

Page 78

Correcting Problems

CLEAR RIBBON JAM

The printer senses that ribbon is jammed. Open the printer cover, clear

the jam, and close the cover.

CLOSE COVER

The printer cover is open. Close it to make the printer ready.

INIT ERROR

The printer failed to initialize. Restart the printer. If the message is still

displayed, service is required.

INSERT TRAY

The printer senses that the paper tray is not in place. Insert the paper

tray to make the printer ready.

LOAD P APER

(

Paper Size)

The printer senses that the tray is empty or the wrong paper is loaded.

The message specifies the requested paper size.

LOAD RIBBON

(

Ribbon Type)

4–2

The printer checks the ribbon’s barcode and detects that the ribbon type

that is loaded does not match the requested ribbon type. Open the cover

and load the correct ribbon. The message specifies the requested ribbon

type.

LOAD TRANS

(

T ransparency Size)

The printer senses that the tray is empty or the wrong transparency

material is loaded. The message specifies the requested transparency

size.

SERVICE REQ

XXX

The printer detects an error. The message includes a 4-digit error code.

Restart the printer. If the message is still displayed, service is required.

Part No. 4B1709 March 1995

Page 79

Correcting Problems

Mismatch Conditions

Printer mismatches can be due to discrepancies in requested ribbon

type, media (receiver) type, or receiver size.

Ribbon Type Mismatch

If you send a print job from a computer and request a ribbon size that is

not currently loaded in the printer, you will be notified of a mismatch. (For

example, if a large image-size is requested, but the oversize ribbon is not

loaded). For these situations, you must change the ribbon or press

Cancel to cancel the job.

Receiver Type Mismatch

If you send a print job from a computer and request a media type that is

not currently loaded in the printer (for example, if paper is requested, but

transparency material is loaded), you will be notified of a mismatch. In

this situation, you can load the correct media type, press the Print button

to override the error without changing media, or cancel the job.

NOTE:Printing without loading the correct media type may result in poor

color reproduction.

Part No. 4B1709 March 1995

4–3

Page 80

Correcting Problems

Receiver Size Mismatch

If you send a print job from a computer and request a media size that is

not currently loaded in the tray, you will be notified of a mismatch. There

are two size-mismatch situations:

D If the image size will fit on the loaded media, you can either load the

correct media size, or press the Print button and the job will print on

the loaded media.

D If the image size is larger than the loaded media, you must either

change the media or press Cancel to cancel the job.

4–4

Part No. 4B1709 March 1995

Page 81

Correcting Problems

Troubleshooting

Before requesting service, you may be able to identify or correct

problems yourself. Make a test print and then use the following chart to

find quick solutions to some general printer problems. If you can’t resolve

the situation, refer to the “Getting Additional Help” section at the end of

this chapter.

Symptom

Possible solution(s)

Printer does not power up. D Make sure the power switch is

in the “I” position.

D Make sure all cables and cords

are plugged in properly.

Printer does not initialize. D Parallel connection only:

The host computer must be

running before the printer is

turned on.

1. Turn off the printer.

2. Make sure the host computer

is up and running.

3. Turn on the printer.

D Other connection types:

1. Turn off the printer and the

host computer.

2. Disconnect the interface

cable from the printer.

3. Turn both machines back

on again.

4. Reconnect the interface cable

to the printer.

Printing takes significantly more

time than usual.

D Image file size may be larger

than usual and may therefore

take longer to process.

Part No. 4B1709 March 1995

D Reduce the room temperature

or turn the printer off for ten

minutes to let it cool.

4–5

Page 82

Correcting Problems

Symptom Possible solution(s)

Printer does not print when job is

sent from the host.

Streaks, lines, or spots appear

on prints.

D Wait to see if the job is still

processing.

D Try printing a file that has

printed previously.

D Verify all export module or

printer driver settings.

D Check communications settings

for compatibility between printer

and host.

D Follow instructions for “Printer

does not initialize.”

D Disconnect the communications

cable from the back of the

printer and try a test print.

If this does not work, service

is required.

D Check to see that the paper or

transparency material in the tray

is clean and free of streaks.

4–6

D Check to see that the ribbon

is clean.

D Clean the thermal head per the

instructions in

Getting Started.

If streaks persist, use the

alternate procedure described

in this chapter.

Part No. 4B1709 March 1995

Page 83

Correcting Problems

Symptom Possible solution(s)

Multicolored spots appear

on prints.

D Clean the printer and the area

around it.

D Move printer away from

ventilation ducts or open doors.

Printer initializes, but does not

enter the READY state.

D Disconnect and reconnect the

interface cable to the printer.

D Restart the printer. If the

problem persists, service

is required.

Edges of transparency material

curl on dense prints.

D Put prints in transparency

sleeves.

D Try using the Printer Driver or

Export Module’s

Mirror

which will change the way that

the ink is applied to the page.

Paper will not feed. D Look at the paper and

remove any sheets from the

stack that have irregularities.

option

Part No. 4B1709 March 1995

D Reduce the size of the stack of

media in the paper tray.

D Make sure that the blue stiffener

sheet is at the bottom of the

paper tray.

4–7

Page 84

Correcting Problems

Symptom Possible solution(s)

No printer response when

buttons are pressed.

You may have pressed invalid

buttons.

1. Make sure the printer cover is

closed.