Page 1

KODAK VERSAMARK

Changing Fluid Containers

DP7122 Printer

Kodak Versamark, Inc.

Page 2

Page 3

KODAK VERSAMARK DP7122 Printer

Changing Fluid Containers

Block 3 Mod 11

Page 4

FCC Compliance Statement

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference, in which case the user will be required to correct the interference at his own expense.

Note: Good quality, shielded (braided shielded) cables must be used for the RS-232-C and Centronics interfaces.

Canadian EMI Compliance Statement

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites applicables aux appareils numériques de la classe A

prescrites dans le Règlement sur le brouillage radioélectrique édicté par le ministère des Communications du Canada.

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital apparatus set out in the Radio Interference Regulations of the Canadian Department of Communications.

EMI-CISPR 22/EN 55 022/CE Marking

Warning: This is a Class A product. In a domestic environment, this product may cause radio interference in which case the user may be

required to take adequate measures.

KODAK VERSAMARK DP7122 Printer

Changing Fluid Containers

Part Number Medium Revision Date Description ECN

0114208-602

0114208-603

0114208-602

0114208-603

0114208-602

0114208-603

Print

PDF

Print

PDF

Print

PDF

002 05/2004 19L cans, 4L cans (US) and 5L cans (Europe) K4315

001 12/2003 1L and 5L bottles, 19L metal cans (released for Block 3) SDP1019

000 09/2003 1L and 5L bottles, 19L metal cans (preliminary) Not released

© Eastman Kodak Company, 2004.All rights reserved.

This document contains proprietary information of Kodak Versamark, Inc. or its licensors and is their exclusive property. It may not be

reproduced without a written agreement from Kodak Versamark, Inc. No patent or other license is granted to this information.

The software described in this document is furnished under a license agreement. The software may not be used or copied except as provided

in the license agreement.

Kodak Versamark, Inc. makes no warranty of any kind with regard to the contents of this document, including, but not limited to, the implied

warranties of merchantability and fitness for a particular purpose. Kodak Versamark shall not be liable for any errors or for compensatory,

incidental or consequential damages in connection with the furnishing, performance, or use of this document or the examples contained herein.

Information concerning products not manufactured by Kodak Versamark, Inc. is provided without warranty or representation of any kind, and

Kodak Versamark, Inc. will not be liable for any damages resulting from the use of such information.

Kodak and Versamark are trademarks of Eastman Kodak Company.

0114208-602

0114208-603 07/2004 Printed in U.S.A.

Page 5

Scope

This guide describes how to connect the fluid supply containers to the

7122 Printer that are required for printer operation. Fluid supply containers are metal cans of the following types:

• 19-liter cans of ink and replenisher

• 4-liter cans of ink (US)

• 5-liter cans of ink (Europe).

Upgrading from bottles to 19-liter cans requires supply can kit 0193756

and grounding kit 0193830.

This guide applies to the following groups of printers:

• Pre-production (serial numbers 7000+)

• Block 1 and Block 2 production (7100+)

• Block 1 upgraded to Block 3 (7150+)

• Block 2 upgraded to Block 3 (7200+)

• Current, Block 3 production (7300+).

All fluids used with the 7122 are hazardous and must be used and

handled in accordance with all applicable regulations. Read “Safety Information” on page 2 before starting any procedure.

For more information about fluid supply containers, contact technical

support.

iii

Page 6

Scope

Text Notations

Safety Notations

Note: Information that needs to be brought to the reader’s attention.

Caution: A situation where a mistake could result in the destruction of data or

This manual uses the following typogra phi ca l conv en tio ns .

This style Refers to

Ready

go

ENTER

[NEXT] Buttons and lights on the printer operato r pa nel .

Save Software command buttons and sections of dialog boxes,

File → Open

ALT+F1

ALT, TAB

xx,yy

jobfile.dat File names.

Text displayed by the software .

Anything you type, exactly as it appears, whether referenced

in text or at a prompt.

Special keys on the keyboard, such as enter, alt, and

spacebar.

such as group boxes, text boxes, and text fields.

A menu and a specific menu command.

Pressing more than one key at the same time.

Pressing more than one key in sequen ce .

Variable in error messages and text.

The following definitions indicate safety precautions to the operator.

system-type damage.

!

WARNING

A potential hazard that could result in serious injury or death.

!

DANGER

An imminent hazard that will result in serious injury or death.

iv

Page 7

Scope

Service and Support

Technical equipment support is available 24 hours a day, 7 days a week.

Software and applications support is available 8:00 a.m. to 5:00 p.m.

EST/EDT, Monday through Friday.

Call for telephone or on-site technical support; to order parts or supplies;

to request documentation or product information.

Phone Fax

U.S.A., Canada, and

worldwide

Europe +41-21-806-0404 +41-21-806-1920

Asia/Pacific Rim +65-6744-6400 +65-6744-6700

Japan +81-3-3256-2613 +81-3-3256-2616

Updated service

information

Customer support customer@kodakversamark.com

http://www.kodakversamark.com

+1-800-472-4839

+1-937-259-3739

+1-937-259-3808

v

Page 8

Page 9

Contents

Safety and Preparation

Safety Information................................................................................................. 2

Required Tools and Equipment............................................................................ 4

Standard Tools............................................................................................... 4

Special Tools.................................................................................................. 4

Flush Kit ....................... ...... ...... ....... ...... ....... ...... ....... ...... ............................... 4

Printer Preparation................................................................................................ 5

Ink and Replenisher Procedures

Draining Fluids...................................................................................................... 8

Changing Filters.................................................................................................. 11

Connecting Fluid Containers .............................................................................. 12

3.8-liter Can Connection .............................................................................. 13

5-liter Can Connection ................................................................................. 14

19-liter Can Connection ............................................................................... 15

Connecting Waste Tanks.................................................................................... 18

System Waste Tank Connection.................................................................. 19

Catch Pan Waste Tank Connection............................................................. 20

Filling the System ............................................................................................... 21

vii

Page 10

Page 11

Figures and Tables

Figure 1 Safety label locations, 7122 printer and printhead...........................2

Figure 2 Line switch and input power connection, back panel.......................5

Figure 3 Vent fitting, installed on replenisher tank.........................................8

Figure 4 Drain container in position...............................................................9

Figure 5 Drain fitting, replenisher tank.........................................................10

Figure 6 Ink tank draining ............................................................................10

Figure 7 Filter assembly locations, fluid compartment.................................11

Figure 8 Draw tubes and cap assembly, 7122 fluid can supply kit..............12

Figure 9 Small ink can, 3.8-liter (1 gal US)..................................................13

Figure 10 Small ink can, 5-liter European......................................................14

Figure 11 Fluid supply setup, 5-liter and 19-liter cans ...................................14

Figure 12 Grounding 19-liter can...................................................................15

Figure 13 Grounding clamp attachment, 19-liter can.....................................16

Figure 14 Lid removal, 19-liter can ................................................................16

Figure 15 Fill tube insertion, 19-liter can........................................................17

Figure 16 19-liter can connection...................................................................17

Figure 17 3.8-liter and 19-liter can setup.......................................................17

Figure 18 System waste tank connection......................................................19

Figure 19 Catch pan waste tank connection..................................................20

Table 1 Contents, flush kit 0192263............................................................ 4

Table 2 Fluid supply containers, 7122 printer............................................ 12

Table 3 Contents, supply can accessories kit 0193756............................. 15

Table 4 Waste tank kits ............................................................................. 18

ix

Page 12

Page 13

Tables

Table 1 Contents, flush kit 0192263............................................................ 4

Table 2 Fluid supply containers, 7122 printer............................................ 12

Table 3 Contents, supply can accessories kit 0193756............................. 15

Table 4 Waste tank kits ............................................................................. 18

Changing Fluid Containers xi

Page 14

Changing Fluid Containers xii

Page 15

Safety and Preparation

Read through all the following sections before start ing any fluid container

connection procedure:

• Safety information

• Required tools and equipment

• Printer preparation.

1

Page 16

Safety and Preparation

Safety Information

Safety Information

Apply all of the following safety guidelines to all 7122 procedures:

• Follow all instructions in the Material Safety Data Sheets shipped with

the ink and replenisher. The ink and replenisher used in the 7122

printer are regulated materials in the classifications shown below.

Transportation, storage, handling, and disposal must be done in

accordance with all applicable local, State, and Federal regulations.

The labels below identify hazards related to handling ink and

replenisher.

• Verify that the installation location has sufficient airflow and

ventilation. The 7122 printer produces 160 cubic feet per minute of

exhaust, and that exhaust contains 50 parts per million of solvent

(MEK). The recommended ventilation is a 400 cubic feet per minute

intrinsically safe blower fan (non-sparking).

• Note the safety labels on the printer that identify hazards and

describe mandatory safety precautions (see Figure 1). Take

appropriate safety precautions at all times.

Figure 1 Safety label locations, 7122 printer and printhead

Safety labels

2

Page 17

Safety and Preparation

Safety Information

• Note the safety label symbols listed below; these warning symbols

are used on the printer and printhead for general reference, and in

the text to identify hazards related to specific procedures or actions.

Warning: Electrostatic Sensitive Devices

Avoid generating static electricity. Static can ignite ink, replenisher, or vapor.

Strictly follow all grounding instructions.

Warning: Flammable Material

Never expose the printer, printhead, ink, replenisher or vapor to a heat source or

ignition source.

Warning: General Danger

Read all safety information and operator procedures through before performing

any action.

Warning: Irritant

Avoid contact with all fluids, ink and replenisher.

Mandatory Action: Consult Operator’s Manual

Read all safety information and operator procedures through before performing

any action.

Mandatory Action: Wear Eye Protection

Avoid contact with all fluids, ink and replenisher.

Prohibition: No Smoking

Never expose the printer, printhead, ink, replenisher or vapor to a heat source or

ignition source.

3

Page 18

Safety and Preparation

Required Tools and Equipment

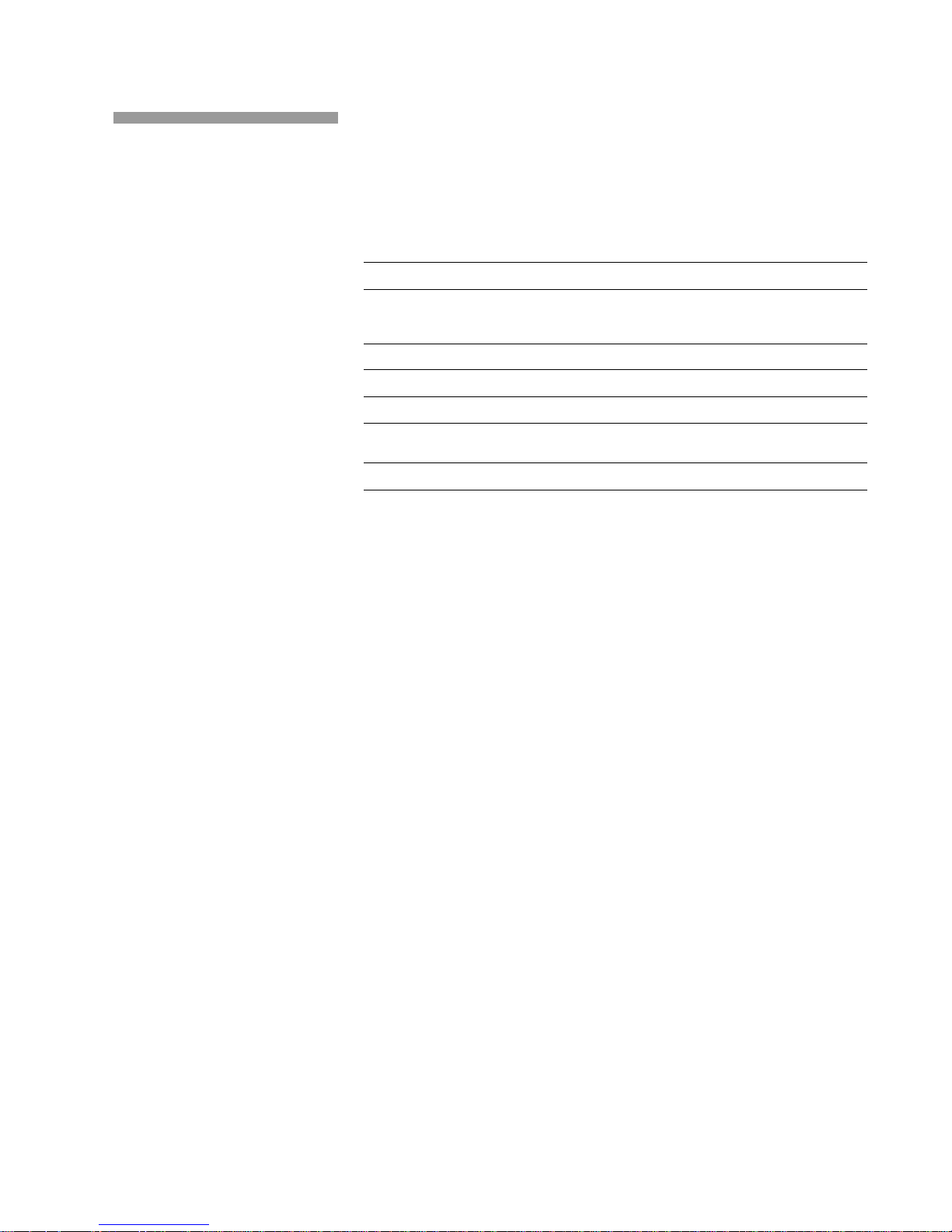

Required Tools and Equipment

The following sections list all items required to perform fluid container

connection procedures.

Standar d Tools

To disconnect and connect the various types of ink and replenisher

containers, the following items are required:

•Flashlight

• Two 9/16-inch open-ended wrenches (see note below)

• Two 11/16-inch open-ended wrenches

• Phillips #2 screwdriver

• Teflon tape.

Note: Two of each size of wrench are needed to hold and loosen, or hold and

tighten, the waste tank and manifold fittings.

All these tools are included in the FE tools 5120/5240 kit.

Special Tools

No special tools are required for 19-liter cans in the U.S. European cans

have a lid that requires a non-sparking drum-plug (bung) wrench to open.

Flush Kit

To change the type of ink or replenisher used in the printer, flush kit

0192263 is required. Check the contents of the kit and make sure that you

have all the required items (see Table 1).

Table 1 Contents, flush kit 0192263

Part Number Description Quantity

0101099-202 FITTING-SNAP COUPLING 1/8 FLOW

0101070-090 TUBING-FLEX.250/.375 TYGON (2075) 72A

0190794 INK FILTER ASSEMBLY 2

1. QUANTITY IS INCHES (EQUALS APPR O X IMATELY 1 METER)

INSERT.250D TBG

CLEAR

1

2

40

4

Page 19

Printer Preparation

Safety and Preparation

Printer Preparation

Before starting the flush procedure, complete the following steps:

1. Read the “Safety Information” section.

Mandatory Action: Wear Eye Protection

Avoid contact with all fluids, ink and replenisher. Wearing goggles, gloves, and a

face shield is highly recommended.

2. Read the “Drain and Fill” procedure.

3. Perform a normal shutdown.

4. Power off the printer at the line switch (see Figure 2).

5. Unplug the input power cord from its connector.

Warning: Electrostatic Sensitive Devices

Line switch

Input power connector

Do not disconnect the printer ground wire. If necessary, leave the power cord

plugged in to maintain an earth ground. The printer and waste container must

remain properly grounded at all times.

6. If you move the printer, check that all ground connections are

maintained and that all fluid containers have been properly

disconnected.

Figure 2 Line switch and input power connection, back panel

5

Page 20

Page 21

Ink and Replenisher Procedures

Changing the ink and replenisher in a 7122 printer consists of the

following procedures:

• Draining fluids

• Changing filters

• Connecting fluid containers

• Connecting waste tanks

• Filling the system.

Before starting any procedure, read “Safety Information” through

completely.

7

Page 22

Ink and Replenisher Procedures

Draining Fluids

Draining Fluids

Use the following procedure to drain the ink and replenisher from the

7122 printer:

1. Check that the printer is ready for service (see “Printer Preparation”).

2. Put on gloves and eye protection.

Avoid spilling ink and avoid direct contact with ink.

3. Attach the drain tubing (0101070-090) to one of the quick disconnect

fittings (0101099-202).

4. Open both doors of the fluid cabinet.

5. Plug the second quick-disconnect fitting into the unused quick

disconnect on top of the tank (see Figure 3).

The second quick-disconnect fitting is used as a tank vent. Venting

accelerates the emptying of the tank. If you do not vent it, the tank will

take at least 30 minutes to drain and may not drain completely.

Vent fitting

Note: Which tank is drained first is not significant. Draining the rear (replenisher)

tank first prevents having to reach over any dripped or spilled fluid to

connect the fittings.

Figure 3 Vent fitting, installed on replenisher tank

8

Page 23

Tank connection

Ink and Replenisher Procedures

Draining Fluids

6. Use the external waste tank or any suitable container to receive the

drained ink (see Figure 4).

If another container is used, it must be approved to hold MEK.

7. Put the open end of the drain tube inside the container (see Figure 4).

This ensures that the fluid flow does not spill. Fluid will flow as soon

as the tube is connected to the quick disconnect.

Figure 4 Drain container in position

8. Connect the fitting on the long tube to quick disconnect on the bottom

of the tank (see Figure 5).

Warning: Irritant

Avoid prolonged contact with the ink and replenisher. Clean up any spilled fluid.

9. Monitor the fluid as it drains (see Figure 6).

10. Move the vent fitting to the replenisher (cleaner) tank.

9

Page 24

Ink and Replenisher Procedures

Draining Fluids

Drain fitting

Figure 5 Drain fitting, replenisher tank

Drain connection

11. Move the drain tube to the other tank.

12. Monitor the draining of the second tank (see Figure 6).

Figure 6 Ink tank draining

Caution: Remove the vent fitting when finished. If left on, it will prevent the tanks

10

13. Continue with the “Changing Filters” procedure.

from holding vacuum and slow or prevent filling.

Page 25

Changing Filters

Ink and Replenisher Procedures

Changing Filters

Use the following procedure to change the ink and replenisher (cleaner)

filter assemblies:

1. Unpack the two replacement ink filters (0190794) in kit.

Use either assembly as the replenisher (cleaner) filter assembly; the

two assemblies are identical.

2. Power up the printer with the fluid system bypassed.

3. Enter diagnostics and put the printer in Normal Up State 1.

This state pulls vacuum and prevents bleeding.

4. Put on gloves and eye protection.

Avoid spilling ink and avoid direct contact with ink.

5. Locate the ink and cleaner filter assemblies in the fluid compartment

on either side of the R-cell assembly (see Figure 7).

Either filter assembly can be replaced first.

Note: Fluid lines are omitted from Figure 7 for clarity.

Figure 7 Filter assembly locations, fluid compartment

Cleaner filter

R-cell

Ink filter

11

Page 26

Ink and Replenisher Procedures

Connecting Fluid Containers

6. Disconnect the two top SWAGLOK fittings on the ink filter housing.

Open the top fittings first to prevent siphoning from the R-Cell and

fluid manifold.

7. Disconnect the top SWAGLOK fitting.

8. Remove the filter housing.

9. Repeat these steps for the cleaner filter.

Disconnecting the bottom fitting will siphon through the fluid left in the

lines to the cleaner tank and the ‘T’ fitting going to the cleaner supply.

10. Install the replacement filter assemblies.

1 1. Continue with either of the following procedures, which is appropriate:

• “Connecting Fluid Containers” if new fluid containers must be

connected.

• “Filling the System” is the proper fluid containers are connected.

Connecting Fluid Containers

Use one of the following procedures to identify and install the proper ink

and replenisher supply container for the 7122 printer:

• 3.8-liter can connection

• 5-liter can connection

• 19-liter can connection.

Caution: Do not use 1.5-liter and 5-liter plastic ink bottles with the 7122 printer.

Table 2 lists and describes the approved ink and replenisher packages

that can be ordered for the 7122 printer.

Table 2 Fluid supply containers, 7122 printer

Part Number Description

6077101-74 KODAK VERSAMARK 7101 SOLVENT BLACK INK-19 LITER CAN

6077102-74 KODAK VERSAMARK 7102 SOLVENT REPLENISHER-19 LITER CAN

Two different lengths of draw tubes are provided for use with large or

small cans (see Figure 3). The same cap assembly is used with both

tubes.

Figure 8 Draw tubes and cap assembly, 7122 fluid can supply kit

12

Page 27

Cap and tubing assembly

Ground clamp

3.8-liter can

Ink and Replenisher Procedures

Connecting Fluid Containers

3.8-liter Can Connection

The 3.8-liter (1 gallon) ink can (019xxxx) uses the same cap and tubing

assembly as the 19-liter can. This ink container is provided for use in the

U.S. only (see Figure 9).

Figure 9 Small ink can, 3.8-liter (1 gal US)

Use the following procedure to connect a 3.8-liter can to the 7122 printer:

1. Put the printer in Standby if it is powered up.

2. Wearing gloves and eye protection is recommended.

Avoid spilling ink and avoid direct contact with ink.

3. Check that the fill tube is connected to the printer back panel fitting

(C1 for ink).

4. Unscrew the cap from the empty can. Remove the empty can and

dispose of it in accordance with all local, state, and Federal

regulations regarding hazardous substances.

5. Remove the cap from the new can and replace it with the cap

connected to the printer.

If you are installing this container for the first time, connect the short

draw tube to the cap assembly and connect the supply tube (C1) to

the cap.

6. Place the securely capped can near the printer (see Figure 17) or in

the 2-container tray.

7. Connect the ground wire clamp to the can rim.

13

Page 28

Ink and Replenisher Procedures

Connecting Fluid Containers

5-liter Can Connection

The 5-liter ink can (019xxxx) uses the same cap and tubing assembly as

the 3.8-liter can. This ink container is provided for use in Europe only. Use

the following procedure to connect a 5-liter can to the 7122 printer:

1. Put the printer in Standby if it is powered up.

2. Wearing gloves and eye protection is recommended.

Avoid spilling ink and avoid direct contact with ink.

3. Disconnect the supply tube from the old can and remove the cap.

4. Put the cap and tubing assembly on the new can (see Figure 10).

If you are installing this container for the first time, connect the short

draw tube to the cap assembly.

Figure 10 Small ink can, 5-liter European

Cap and tubing assembly

Ground clamp

5-liter can

5. Place the can near the printer and connect the supply line (C1) to the

cap on the new can (see Figure 11).

6. Connect the ground wire clamp to the can rim.

Figure 11 Fluid supply setup, 5-liter and 19-liter cans

14

Page 29

Ink and Replenisher Procedures

Connecting Fluid Containers

19-liter Can Connection

To use metal cans used as fluid supply containers for the 7122 printer

requires the SUPPLY CAN ACCESSORIES kit (0193756). This kit is

shipped with every system and is available separately to upgrade

systems originally shipped with other containers.

Table 3 lists the contents of these kits. If you do not have the proper

hardware to connect cans to the 7122, contact technical support.

Table 3 Contents, supply can accessories kit 0193756

KIT-FLUID SUPPLY TUBE 0192279

Part Number Description Qty

0192277 30" TUBE ASSY 2

0192278 20" TUBE ASSY 1

0193870 SUPPL Y CAN DRA W TUBE 2

7122 FLUID CAN GROUNDING KIT 0193830

0101247-385 CLAMP ASSY -GROUND PLIER-TYPE CLAMP W/55#

SPRING AND.125D FLEX ORANGE VINYL-COAT

INSULA T ED 5FT LG CABLE W/.250 RING

TERMINAL

0101000-333 NUT-KEPS #10-32 Zn 2

0101006-510 WASHER-LOCK INT/EXT T #10 x .60 Zn 2

0192260 GROUND LUG ASSY PROCEDURE (DWG) 1

2

Use the following procedure to connect any ink or replenisher provided in

a 19-liter can (see Table 2):

1. Put the printer in Standby if it is powered up.

2. Wearing gloves and eye protection is recommended.

Avoid spilling ink and avoid direct contact with ink.

3. Connect the ring end of the clamp assembly ground cable to a stud

on the back of the printer and secure it with a nut and washer (see

Figure 12).

Figure 12 Grounding 19-liter can

15

Page 30

Ink and Replenisher Procedures

Connecting Fluid Containers

4. Attach the clamp of the ground wire to the rim of the can (see Figure

13).

Figure 13 Grounding clamp attachment, 19-liter can

5. Connect the SWAGLOK fitting on the fill tube to the appropriate

connection on the printer back panel (C1 for ink, or C2 for

replenisher).

6. Remove the can lid (see Figure 14). Retain the lid and replace it on

the empty can prior to disposal.

Warning: Store and dispose of empty cans properly

Comply with all local, state, and Federal regulations governing the storage and

disposal of metals cans containing residual hazardous liquid.

Figure 14 Lid removal, 19-liter can

16

Page 31

Ink and Replenisher Procedures

Connecting Fluid Containers

7. Insert the free end of the fill tube into the can (see Figure 15).

Figure 15 Fill tube insertion, 19-liter can

8. Connect the fill tube to the cap assembly quick disconnect (see

Figure 16).

Figure 16 19-liter can connection

9. Complete the fluid supply setup by connecting a replenisher supply

(19-liter can) and the external waste tank (see Figure 17).

Figure 17 3.8-liter and 19-liter can setup

17

Page 32

Ink and Replenisher Procedures

Connecting Waste Tanks

Connecting Waste Tanks

The 7122 printer requires the following two external waste tank

connections:

• System waste tank

• Catch pan waste tank.

Each tank is part of a kit shipped with the printer (see T able 4). The same

T ANK-2 GALLON ASME UM CODE CONSTRUCTION MAAX WORKING

PRESSURE=190psi@100 DEG F 1-11 1/2NPT FLOAT SWITCH PORT

(0101270-022) is used in both kits.

If the printer and its associated fluid containers are moved, the waste

tanks must be properly reconnected before resuming operation.

Table 4 Waste tank kits

Part Number Description

0193854 SERVICE CATCH PAN KIT (see Figure 19)

0193835 WASTE TANK KIT

Exercise caution when moving the printer. Before moving the printer,

disconnect and move all fluid containers. After positioning the printer, lock

its casters, then reconnect and properly ground all fluid containers before

powering up the printer.

Warning: Elect rostatic Sensitive Devices

Avoid generating static electricity. Static can ignite ink, replenisher, or vapor.

Strictly follow all grounding instructions.

Warning: General Danger

Read all safety information and operator procedures through before performing

any action.

Warning: Irritant

Avoid contact with all fluids, ink and replenisher.

18

Page 33

Ink and Replenisher Procedures

Connecting Waste Tanks

System Waste Ta nk Connection

The system waste tank must be connected to the printer at all times

during operation. The waste tank must be grounded at all times. Connect

the waste line (C3) to Port 1 on the waste tank, and the waste reclaim

line (C4) to Port 2 (see Figure 18). For detailed instructions on connecting

the system waste tank, see the printer

Mod 11

Upgrade Instructions

(01 14222).

Warning: General Danger

Never disconnect the waste tank line or the waste tank ground. Do not move the

printer without first moving all fluid containers. Store and dispose of all waste in

accordance with all local, state, and Federal regulations. Read all procedures

through before performing any action.

Figure 18 System waste tank connection

Installation Guide

(0113974) or the

Waste tank

19

Page 34

Ink and Replenisher Procedures

Connecting Waste Tanks

Catch Pan Waste Tank Connection

The metal service catch pan shipped with the printer has its own waste

tank to collect fluid during printhead swabbing procedures. Connect the

waste tank to the catch pan as shown in Figure 19. For instructions on

using the service catch pan, see the printer

603). For printhead procedures, see the

Instructions

(0114195-603).

Warning: General Danger

Never use any plastic or in su lat ing mate rial to collect ink from the 7122 printh ead .

Never apply charge voltage with the catch pan installed or touch the printhead or

catch pan except as required to perform the procedures described in the

Operator’s Guide

Figure 19 Catch pan waste tank connection

. Read all procedures through before performing any action.

Operator’s Guide

(0114130-

Printhead Replacement

20

Page 35

Filling the System

Ink and Replenisher Procedures

Filling the System

Use the following procedure to fill the internal ink and replenisher tanks of

the 7122 printer:

1. Connect the good ink and replenisher supply containers.

Note: Leave the cabinet open to check for leaks.

2. Power up the printer with the fluid system bypassed.

3. Go to Circulate Table state 3 to fill the tanks.

4. When the tanks are full, go to Circulate Table State 6 for 15 minutes.

This is a diagnostic circulate state.

5. Go to Printhead Down.

6. Change State Table type back to Normal.

7. Bring the system through a Normal Up and Printhead Shutdown

cycle.

8. Power off the printer.

9. Repeat step 3 through step 6 of the “Filling the System” procedure

and then skip to step 10.

10. If you are going to resume production, bring the printer through a

Normal Up to Ready.

Note: Normal Up = bypassed fluid system. Use the Standby button to bring the

printer to Ready.

21

Page 36

Page 37

Page 38

0114208-602

0114208-603

©Kodak Versamark, Inc .

Page 39

G:/framestyles6/covers versamark/images/ ..book2.tif @ 300 dpi.......... 1 - 1

G:/framestyles6/covers versamark/images/ ..pie.tif @ 300 dpi.......... 1 - 1

G:/framestyles6/covers versamark/images/ ..financial.tif @ 300 dpi.......... 1 - 1

G:/framestyles6/covers versamark/images/ ..account.tif @ 300 dpi.......... 1 - 1

G:/framestyles6/covers versamark/images/ ..23seconds.tif @ 275 dpi.......... 1 - 1

../../graphics.fdr/............................................028 7122 safety.gif @ 150 dpi.......... 1 - 2

../../graphics.fdr/............................................029 7122 safety.gif @ 150 dpi.......... 1 - 2

../../graphics.fdr/............................................119 7122 sg.eps 1 - 2

G:/techcomm/safety labels/...........................avoid static touch.gif @ 75 dpi............ 1 - 3

G:/techcomm/safety labels/...........................flammable material.gif @ 75 dpi............ 1 - 3

G:/techcomm/safety labels/...........................general danger.gif @ 75 dpi............ 1 - 3

G:/techcomm/safety labels/...........................irritant.gif @ 75 dpi............ 1 - 3

G:/techcomm/safety labels/...........................consult manual 2.gif @ 75 dpi............ 1 - 3

G:/techcomm/safety labels/...........................eye protection.gif @ 75 dpi............ 1 - 3

G:/techcomm/safety labels/...........................no smoking.gif @ 75 dpi............ 1 - 3

G:/techcomm/safety labels/...........................eye protection.gif @ 75 dpi............ 1 - 5

G:/techcomm/safety labels/...........................avoid static touch.gif @ 75 dpi............ 1 - 5

../../graphics.fdr/............................................114 7122 sg.jpg @ 150 dpi.......... 1 - 5

G:/techcomm/safety labels/...........................eye protection.gif @ 75 dpi............ 2 - 8

../../graphics.fdr/............................................160 7122 sg.jpg @ 150 dpi.......... 2 - 8

../../graphics.fdr/............................................159 7122 sg.jpg @ 150 dpi.......... 2 - 9

G:/techcomm/safety labels/...........................irritant.gif @ 75 dpi............ 2 - 9

../../graphics.fdr/............................................158 7122 sg.jpg @ 150 dpi........ 2 - 10

../../graphics.fdr/............................................161 7122 sg.jpg @ 150 dpi........ 2 - 10

G:/techcomm/safety labels/...........................eye protection.gif @ 75 dpi.......... 2 - 11

../../graphics.fdr/............................................065 7122 ip.jpg @ 300 dpi........ 2 - 11

../../graphics.fdr/............................................386 7122 draw tubes.jpg @ 150 dpi........ 2 - 12

../../graphics.fdr/............................................397 7122 small can and draw tube.jpg @ 150 dpi........ 2 - 13

G:/techcomm/safety labels/...........................eye protection.gif @ 75 dpi.......... 2 - 13

G:/techcomm/safety labels/...........................eye protection.gif @ 75 dpi.......... 2 - 14

../../graphics.fdr/............................................402 7122 tan can no red ink.jpg @ 150 dpi........ 2 - 14

../../graphics.fdr/............................................403 7122 tan and large black can setup.jpg @ 150 dpi........ 2 - 14

G:/techcomm/safety labels/...........................eye protection.gif @ 75 dpi.......... 2 - 15

../../graphics.fdr/............................................255 7122 sg.jpg @ 150 dpi........ 2 - 15

../../graphics.fdr/............................................256 7122 sg.jpg @ 150 dpi........ 2 - 16

G:/techcomm/safety labels/...........................general danger.gif @ 75 dpi.......... 2 - 16

../../graphics.fdr/............................................257 7122 sg.jpg @ 150 dpi........ 2 - 16

../../graphics.fdr/............................................387 7122 large can draw tube.jpg @ 150 dpi........ 2 - 17

../../graphics.fdr/............................................392 7122 large can setup.jpg @ 150 dpi........ 2 - 17

../../graphics.fdr/............................................403 7122 little and large black can setup.jpg @ 150 dpi........ 2 - 17

G:/techcomm/safety labels/...........................avoid static touch.gif @ 75 dpi.......... 2 - 18

G:/techcomm/safety labels/...........................general danger.gif @ 75 dpi.......... 2 - 18

G:/techcomm/safety labels/...........................irritant.gif @ 75 dpi.......... 2 - 18

G:/techcomm/safety labels/...........................general danger.gif @ 75 dpi.......... 2 - 19

../../graphics.fdr/............................................410 7122 cfc.jpg @ 150 dpi........ 2 - 19

G:/techcomm/safety labels/...........................general danger.gif @ 75 dpi.......... 2 - 20

../../graphics.fdr/............................................260 7122 sg.tif @ 150 dpi........ 2 - 20

G:/framestyles6/covers versamark/images/ ..bill4.tif @ 300 dpi.......... 1 - 2

G:/framestyles6/covers versamark/images/ ..survey.tif @ 300 dpi.......... 1 - 2

G:/framestyles6/covers versamark/images/ ..drawing.tif @ 234 dpi.......... 1 - 2

G:/framestyles6/covers versamark/images/ ..visa.tif @ 300 dpi.......... 1 - 2

G:/framestyles6/covers versamark/images/ ..23seconds.tif @ 275 dpi.......... 1 - 2

Operator’s Guide 1 - 1

Page 40

1 - 2 Print Station 90

Loading...

Loading...