Page 1

Magnus VLF With ContinuousLoad

Platesetter

653-00832E-EN Rev A

Internal 732-00027E-EN Rev A

Visual Reference Guide

Original instructions

English

Page 2

1

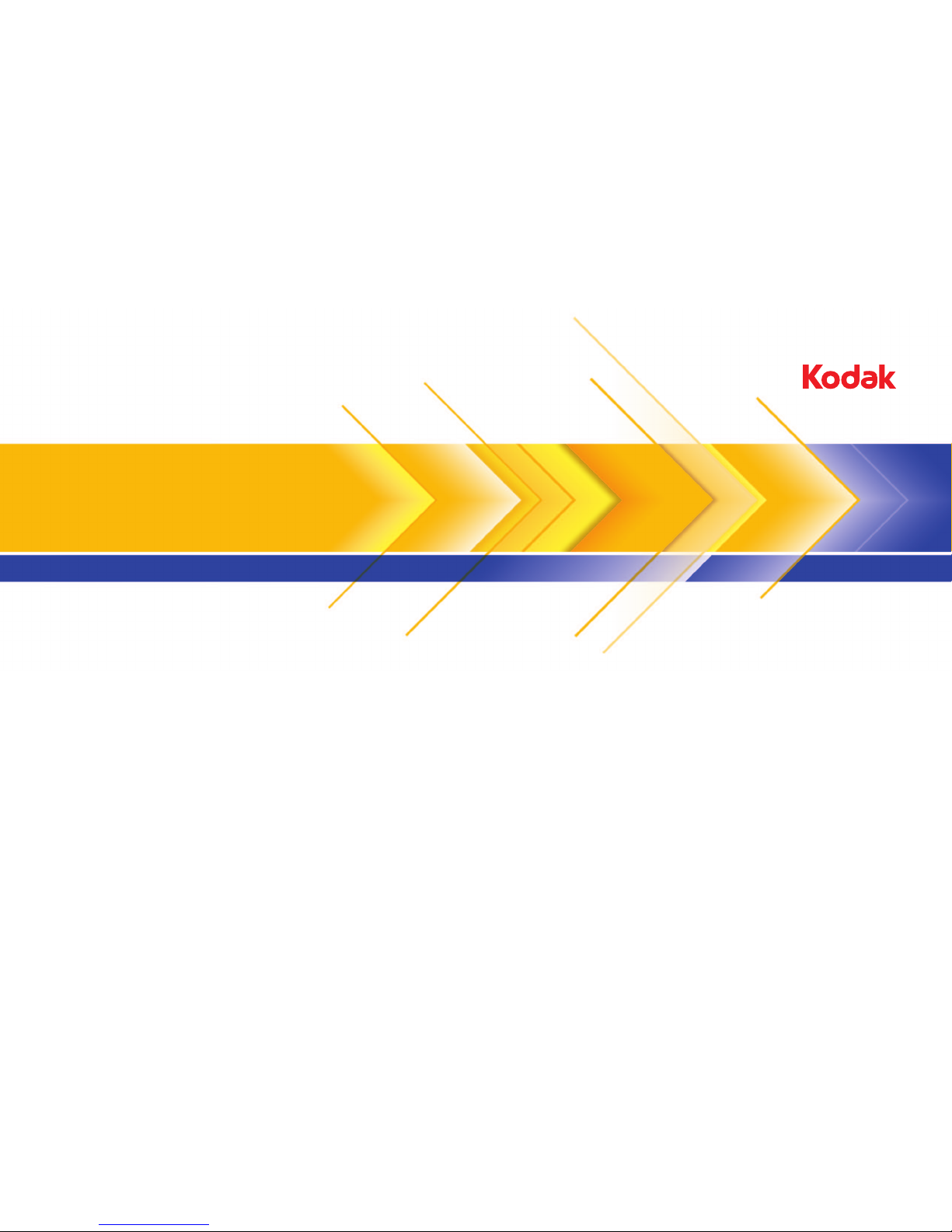

Status light Device ready and start buttons Operator action

O Solid green

The platesetter is ready. Submit a job from the workflow

software when you are ready.

Solid blue

Solid green

Flashing green

Place the plate on the load table. Push the plate in against

the plate stopper and then press a start button or the

Device Ready button.

Solid green Solid green Wait—the platesetter is exposing a plate.

Flashing green Solid green Wait—the platesetter is unloading and ejecting a plate.

Flashing yellow Solid green

An error has occurred and the job is suspended. Follow

the instructions on the Messages tab in the Kodak® Print

Console software.

Operational lights and what they mean

Status light

Device Ready button

Start buttons

Page 3

2

Emergency stop button

Emergency stop button

Power switch

Emergency stop locations

Emergency stop button

Press the emergency stop button to stop

mechanical movement and laser operation.

Activate an emergency stop device to stop mechanical movement and laser operation.

Power/emergency stop switch

The power switch disconnects power to the platesetter so

that you can safely perform maintenance procedures or

retrieve stuck media. When you are instructed to turn o

power to the platesetter, turn the switch counterclockwise to

the OFF position and secure it with a padlock.

To turn on the power,

turn the switch

clockwise to the ON

position.

Insert a padlock here.

OFF ON

The switch can be used as an emergency

stop mechanism when you cannot reach an

emergency stop button.

To reset the platesetter, turn the

emergency stop button clockwise until

it pops up and then select the Reset

operation in Print Console.

The emergency stop button stops laser operation

and mechanical movement, but the power remains

connected. If any internal or external emergency

stop button is pushed, you must reset the

platesetter before it can resume regular operations.

Page 4

3

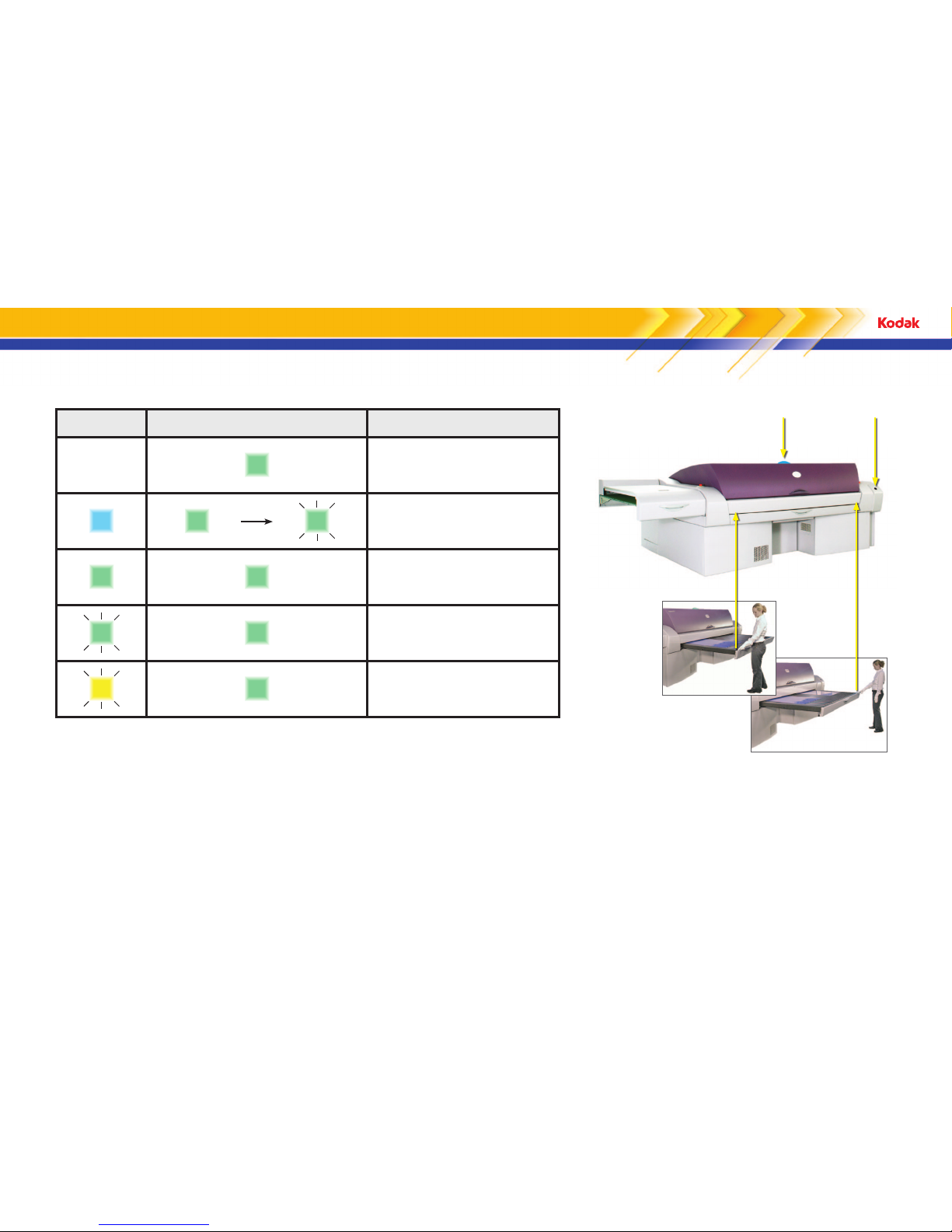

Using Print Console

Status mode—perform daily tasks

Tools mode—configure Print Console

Modes control what you see on-screen.

Operation buttons and menu items allow you to quickly perform everyday tasks. Only

buttons and menu items that are relevant to your platesetter appear on-screen.

For information about all screen elements, see the Print Console Help.

Important messages appear here.

The status light and text are visible from a distance.

Queue tab—displays the status

of plates as they move through

each stage in the platesetter

Messages tab—displays

error messages and tells how

to correct errors that have

suspended operations

Miniview mode—monitor plates

and workflow at the same time

Print Console Help

Device Configuration—view platesetter-specific information

Media Tool—define media sizes Preferences Tool—set preferences (for example, language)

Messages History—review recent messages

Registration Tool—define registration settings

Page 5

4

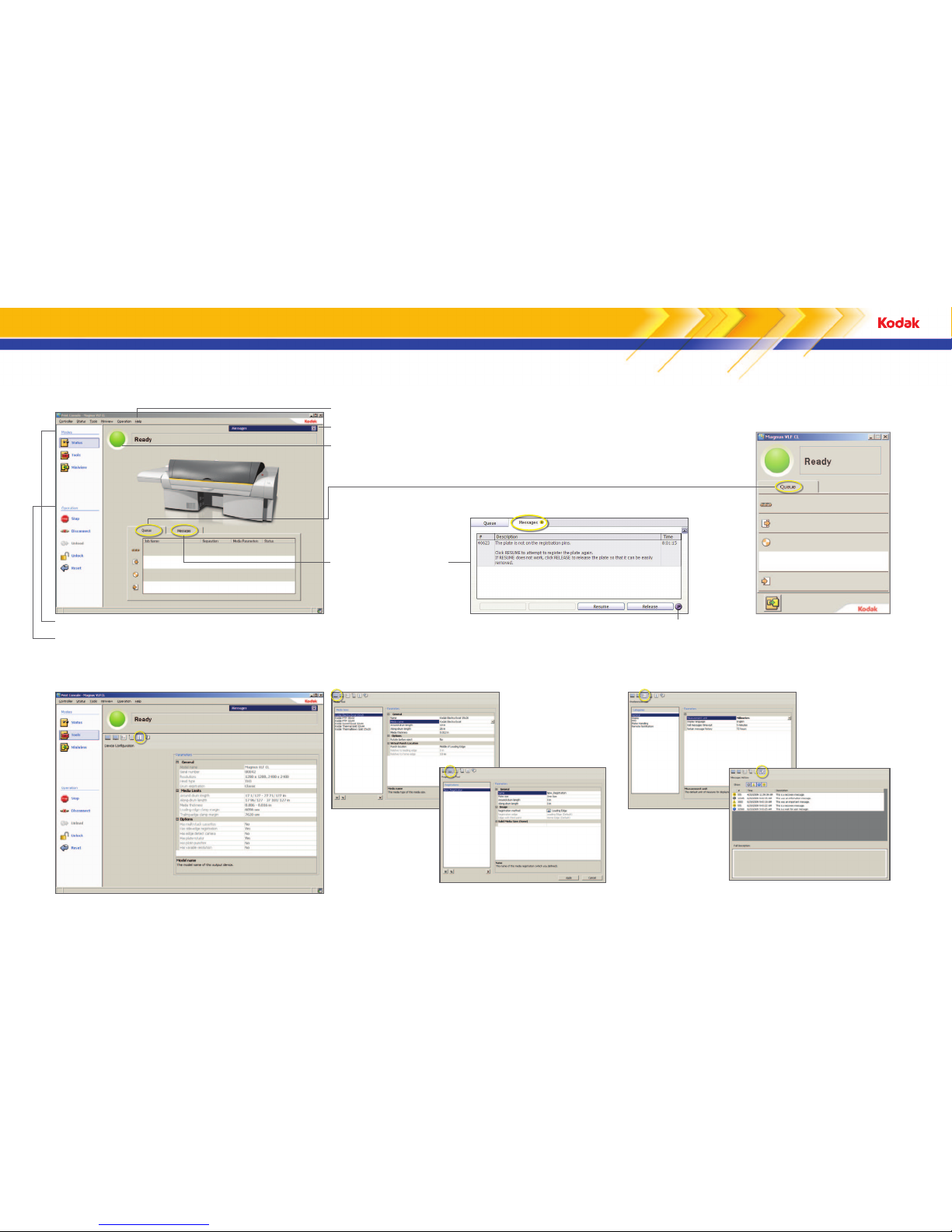

Double plates

Right side

Ensure that the platesetter has a

Ready status.

2 3

Ensure that the correct plate size is available

for loading.

Single plate

Double plates

4

Pull out the bypass load table.

5

Place the plate or plates on the load table.

6

Remove the slip sheet.

7

Align the plate or plates with the media

alignment labels.

Plate

Media alignment labels

8

Register the plate or plates. Position the

leading edge against the end stop.

9

Press a start button.

Double plates

Double plates

Single plate

Single plate

Left side

Loading and imaging a plate

Kodak Prinergy® Connect™ workflow

CAUTION: Wear protective gloves when handling plates to protect your hands from the sharp edges

and corners of the plates. Failure to wear protective gloves may result in minor or moderate injury.

In the workflow software, submit the file.

Kodak Brisque® workflow

Note: You must have a Prinergy Evo TIFF output

template and hot folder already set up.

Single plate

The exposed plate or plates exit the

platesetter through the bridge.

1

On the Print Console Queue tab, follow

the progress of the plate or plates

through the platesetter.

10

Kodak Prinergy Evo™ workflow

Accurate alignment ensures accurate

punching. Ensure that the plate is no farther

than 3 mm (0.12 in.) from the alignment

label.

Page 6

5

Operation

Turn on the platesetter

1

These operations are required for some of the

maintenance procedures below.

Turn o the platesetter

2

Reset the platesetter

3

Maintenance procedure Work to be done How often

Date work

completed

Exterior surfaces Clean

Weekly

Edge detection strip

1

4

Clean

Six months or

as needed

Plate roller

1

5

Clean

Rear fan filters

1

6

Replace

328-00036

Punch chip collection box

1, 3

Empty

Compressed air supply

(particulate filter only)1

8

Replace

328-00001

Power box intake air filter1

9

Replace

55-1292A

Heat exchanger intake air

filter

1, 2

10

Replace

55-1293A

As needed

Debris removal filter1

Replace

MDRC: 252-11119A

UDRC: 57-8792D

As needed

1

This procedure is included in this visual reference guide.

2

This procedure applies only to models with the heat exchanger option.

3

This procedure applies only to models with the punch option.

For more information, see the Print Console User Guide.

Operator maintenance schedule

4

5

1

2

7

8

10

9

3

6

7

11

11

Page 7

6

Turn o the compressed air.

0 psi

Replacing the air supply particulate filter

1

3 4

Unscrew the bowl. Pull the tab down and turn

the bowl 45° to the left.

6

Clean the inside of the bowl with

warm water and mild soap.

7

Replace the O-ring, if necessary.

8

Reattach the bowl. Push the bowl up

and turn it to the right until it clicks.

9

Turn on the compressed air.

100–125 psi

5

Install the new filter.

Particulate filter

Bowl

Tab

CAUTION: To prevent possible serious injury

from flying parts or loud noise caused by

the release of high-pressure air during filter

replacement, confirm that the compressed air

supply is turned o before installing the new

air supply particulate filter.

Particulate filter

Open the rear hood:

a

In Print Console, unlock

the panels.

b

Turn the handle counterclockwise and lift the hood.

2

Use a slotted screwdriver

to loosen the two screws

that secure the rear panel

to the platesetter.

Close the rear panel, tighten the

screws, and close the rear hood.

10

In Print Console, lock the panels.

11

Page 8

7

Cleaning inside the platesetter

Cleaning the edge detection strip

Rotate the drum to expose the edge detection strip.

Dampen a cloth with water, and slide

it along the edge detection strip.

3 4

Cleaning the plate roller

Locate the blue plate roller.

Dampen a lint-free cloth with water,

and slide the cloth over the plate roller.

3

4

Edge detection strips

Note: Do not clean the plate roller with

detergent or alcohol.

5

Close the rear hood:

a

In Print Console, lock the panels.

b

Pull down the rear hood.

1

Ensure that the platesetter

is in an idle state.

2

Open the rear hood:

a

In Print Console, unlock the panels.

b

Turn the handle counterclockwise and lift the hood.

The interior of the platesetter is

exposed for cleaning.

5

Close the rear hood:

a

In Print Console, lock the panels.

b

Pull down the rear hood.

Page 9

8

Replacing the power box intake air filter

Replacing the heat exchanger intake air filter

1

Power box filter panel

Open the power box filter panel:

2

Remove the panel.

3

Remove the old intake air filter

from the panel.

4

Install the new intake air filter.

a

Loosen the thumb screws.

b

Close the power box filter panel:

a

Replace the panel.

b

Tighten the thumb screws.

Debris removal panel

1

Open the debris removal panel:

a

Pull the debris removal panel

toward you.

b

Lift and remove the panel.

2

Remove the old intake air filter.

3

Install the new intake air filter.

Power box intake air filter

Heat exchanger intake air filter

4

Close the debris removal panel:

a

Replace the debris removal

panel.

b

Push the panel back into

place.

Page 10

9

Replacing the rear fan filters

1

Open the hood:

a

In Print Console, unlock the panels.

b

Push the black button and lift the rear hood.

5

4

2

Rear fan filter

3

Remove the old rear fan filters and insert new

filters.

Use the air flow arrow as a guideline for correct

installation. The arrow should point toward the

fan so that the side with the wire mesh faces the

interior of the platesetter.

The Magnus VLF platesetter has two fans at the rear of the platesetter. Replace the filters for these fans every six months.

Use a slotted screwdriver

to loosen the two screws

that secure the rear panel

to the platesetter.

Close the rear panel, tighten the

screws, and close the rear hood.

In Print Console, lock the panels.

Page 11

10

Raising the punch assembly

1

Open the rear hood:

a

In Print Console, unlock the panels.

b

Push the black button and lift the rear hood.

Punch assembly

2

Standing in front of the punch assembly, pull

it toward you.

3

Remove the lifting handle from its storage location.

Lifting handle

4

Push in the blue lock-out knob.

Blue lock-out knob

Crankshaft

5

Attach the lifting handle to the crankshaft

and slowly turn the lifting handle clockwise.

Lift the punch assembly until it reaches your desired

level or is in the fully up position.

The blue light turns on when the

punch table starts to lift.

The punch assembly in the fully up

position.

You may need to raise the punch assembly to perform a recovery procedure. Raising the punch

assembly provides access to the unload table, the load table, and the top of the drum.

Page 12

11

Lowering the punch assembly from the raised position

1

Attach the lifting handle to the crankshaft and slowly turn the lifting handle counterclockwise.

Continue lowering the punch assembly until the blue light turns o.

2

Return the lifting handle to its storage location.

Lifting handle

3

Push the punch assembly forward until you

hear a click. You will feel some resistance.

5

In Print Console, lock the panels.

4

Close the rear hood.

Note: If you do not push the punch

assembly fully forward, you will not be

able to close the rear hood.

Emptying the punch chip collection box

1

Pull out the chip collection box.

2

Empty the chip collection box.

3

Reinsert the chip collection box.

The blue light turns o when

the punch assembly is in its

original position.

Page 13

12

Replacing the debris removal filter

3

4

1

1110

9876

5

12

Shut down the

platesetter by turning

the power switch to

the OFF position.

Pull the debris panel toward

you. The panel unlatches.

Lift the panel up and away

from the platesetter and put

it in an out-of-the-way place.

Vacuum any dust

deposits from around

the tube in the center of

the inner lid. Ensure that

no debris falls into the

filter compartment.

Release the canister lid on the debris

removel unit by pulling the pins on

either side.

Slide the debris removal unit out of

the platesetter and remove the old

filter by grasping the handle and

pulling up.

Place the used filter in

a bag for disposal. A

bag is provided with the

replacement filter.

Remove the filter spacer

from the bottom of the filter

compartment and put it aside.

Reinstall the filter spacer in the

bottom of the filter compartment.

Wipe the inside of the inner lid, the

deck, and the interior surfaces of

the filter compartment with a clean

rag dampened with water and mild

detergent. Remove all residue by wiping

thoroughly with a clean, damp rag.

15

14

13

WARNING: Do not let water or other liquids run freely into the

platesetter. This can result in serious injury from electrical shock as

well as damage to your platesetter.

Press down on the cannister lid

until you hear a click.

Lower the new filter into the filter

compartment with the gasket

facing up. Ensure that the filter is

fully seated on the spacer.

Slide the debris removal

unit back into the

platesetter.

Align the locating holes

on the bottom of the

panel with the locating

pins on the platesetter.

Push the upper corners of

the panel until you hear

both latches click.

On the Print Console Messages tab,

follow the instructions for clearing the

message.

Wash your hands.

Print Console indicates when the debris removal filter is full and needs to be replaced. When the full filter message appears, you will not be able to continue imaging until the filter is replaced.

Click Eject to eject any plates that are

in the platesetter.

2

Clean the debris removal compartment:

b

a

Reinstall the filter:

b

a

Gasket

Filter spacer

Filter

Replace the panel:

a

b

Lower the bottom of the

panel onto the pins.

Always have a spare filter on hand.

Page 14

13

Removing a plate flyo

CAUTION: Wear protective

gloves when handling

plates to protect your

hands from the sharp edges

and corners of the plates.

Failure to wear protective

gloves may result in minor

or moderate injury.

8

Reposition the trailing-edge clamps:

a

b

Using the clamp removal tool, lift the trailingedge clamps and reposition them. Twist and

pull to remove the clamp removal tool.

Align the trailing-edge clamps so

that their edges press against the

parking pins.

Parking pins

Edge of trailing-edge clamp

9

Replace the rear panel and close

the rear hood.

10

In Print Console, lock the panels.

11

In Print Console, click Media

Removed.

3

Pull the cooling fans away

from the drum.

Cooling fans

4

Rotate the drum to expose the

trailing-edge clamps.

5

Using the clamp removal tool, slide the

trailing-edge clamps o the plate.

6

Fold over the corners of

the plate.

7

Press the leading-edge clamps

to free the plate.

The clamp

removal tool

is stored in

the rear of the

platesetter.

An error message about the

flyo appears.

1

Open the hood:

a

In Print Console, unlock the

panels.

b

Push the black button and lift the rear hood.

2

Use a slotted screwdriver

to loosen the two screws

that secure the rear panel

to the platesetter.

Page 15

14

Plate registration

Punch table

Correct

Plate positioned on the punch table

using Kodak registration. (An X

represents the platesetter registration

pins, and the square shapes represent

the punch registration pins.)

The image is correctly aligned (parallel)

with the punched holes or bend.

The image and punched holes are

aligned without side shift.

Plate

Kodak side registration point

Incorrect

Plate positioned on the punch table

using non-Kodak registration. (An X

represents the platesetter registration

pins, and the square shapes represent

the punch registration pins.)

The image is incorrectly aligned (rotated)

with the punched holes or bend.

Platesetter registration point

The image and punched holes are not

aligned and are shifted sideways.

Non-Kodak side registration point

Registration method

Use the Print Console Registration tool

to create, modify, and delete sets of

registration parameters (registrations).

Registrations ensure that plates imaged

on your platesetter are configured to

match the registration requirements of

the press as closely as possible.

Use the parameters in the Image

category to specify which registration

method to use. The registration

methods that are available for selection

depend on the options that are enabled

on your platesetter.

For more information, see the Print

Console Help.

Side Edge registration method

Third registration point

(fixed)

Registration edge on the

platesetter drum

Registration edge on

the press cylinder

Registration edge on the platesetter drum

Registration edge on the press cylinder

Third registration point

(fixed)

Leading Edge registration method

Leading Edge (third point configurable) registration method

Third registration point—configure

Distance to third point.

Registration edge on the platesetter drum

Registration edge on the press cylinder

Third registration point—

configure (a) Spacing

between points and Center

the points. If Center the

points is No, configure (b)

Distance to first point.

Registration edge on

the platesetter drum

Registration edge on

the press cylinder

Configurable Side Edge registration method

Page 16

Eastman Kodak Company

343 State Street

Rochester, NY 14650 U.S.A.

© Kodak, 2010. All rights reserved.

TM: Kodak

To learn more about solutions from Kodak, visit

graphics.kodak.com

Subject to technical change without notice.

Loading...

Loading...