Page 1

CURRENT INFORMATION SUMMARY May 2005 • CIS-254

Using the KODAK Negative Film Processing

Cartridges FC1 and FC2

The KODAK Negative Film Processing Cartridges FC1

and FC2 and KODAK Rinse Tablets are designed for use

in FUJI FP363SC and FP563SC Film Processors using

process cycle CN-16S. The FC1 and FC2 cartridges are

drop-in cartridges that provide convenience and ease of

use. The FC1 cartridge will process 200 rolls of 135-24

film; the FC2 cartridge will process 1000 rolls of 135-24

film.

The cartridges and tablets are part of Kodak’s systems

approach that enables users of other manufacturers’

minilabs to provide customers with high-quality film

processing in Kodak chemicals.

KODAK Negative Film Processing

Cartridge FC1 and Shipping Corrugate

KODAK Negative Film Processing

Cartridge FC2 and Shipping Corrugate

©Eastman Kodak Company, 2005

Page 2

OBTAINING THE CHEMICALS

Preparing Fresh Working Tank Solutions

Catalog numbers are as follows:

Product

KODAK Negative Film

Processing Cartridge

FC1

KODAK Negative Film

Processing Cartridge

FC2

KODAK Rinse Tablets* 4 191 3110

KODAK Negative Film

FC Tank Developer

KODAK Negative Film

FC Tank Bleach

KODAK Negative Film

FC Tank Fixer

KODAK Negative Film

FC Tank Rinse

*Used in water reservoir on processor

Min/Mult

Order Qty

2 801 7519

2 867 2701

1 833 9723

1 107 2024

1 813 4421

3 872 4791

CAT Number

SAFE HANDLING OF PHOTOGRAPHIC

CHEMICALS

Handle all chemicals carefully. When you mix solutions,

wear goggles or a face shield, a protective rubber apron,

and protective gloves made with neoprene or nitrile

rubber. Clean protective clothing after use to remove any

chemical residue that can cause contamination. For more

information about potential health hazards and safe

handling of specific Kodak chemicals, see the label and

the Material Safety Data Sheet (MSDS) for the chemical.

Consult the MSDS for regional contact information.

MSDS copies are available at the Kodak website at

www.kodak.com/go/photochemicals.

CONVERTING TO THE KODAK

NEGATIVE FILM PROCESSING

CARTRIDGES

Use the following Kodak chemicals to prepare fresh

working tank solutions:

Developer Tank (N1)

Use KODAK Negative Film FC Tank Developer

CAT No. 833 9723. Each kit makes 5.2 litres. Two kits

are required for the FP363SC processor. Three kits are

required for the FP563SC processor. Follow the directions

in the following table:

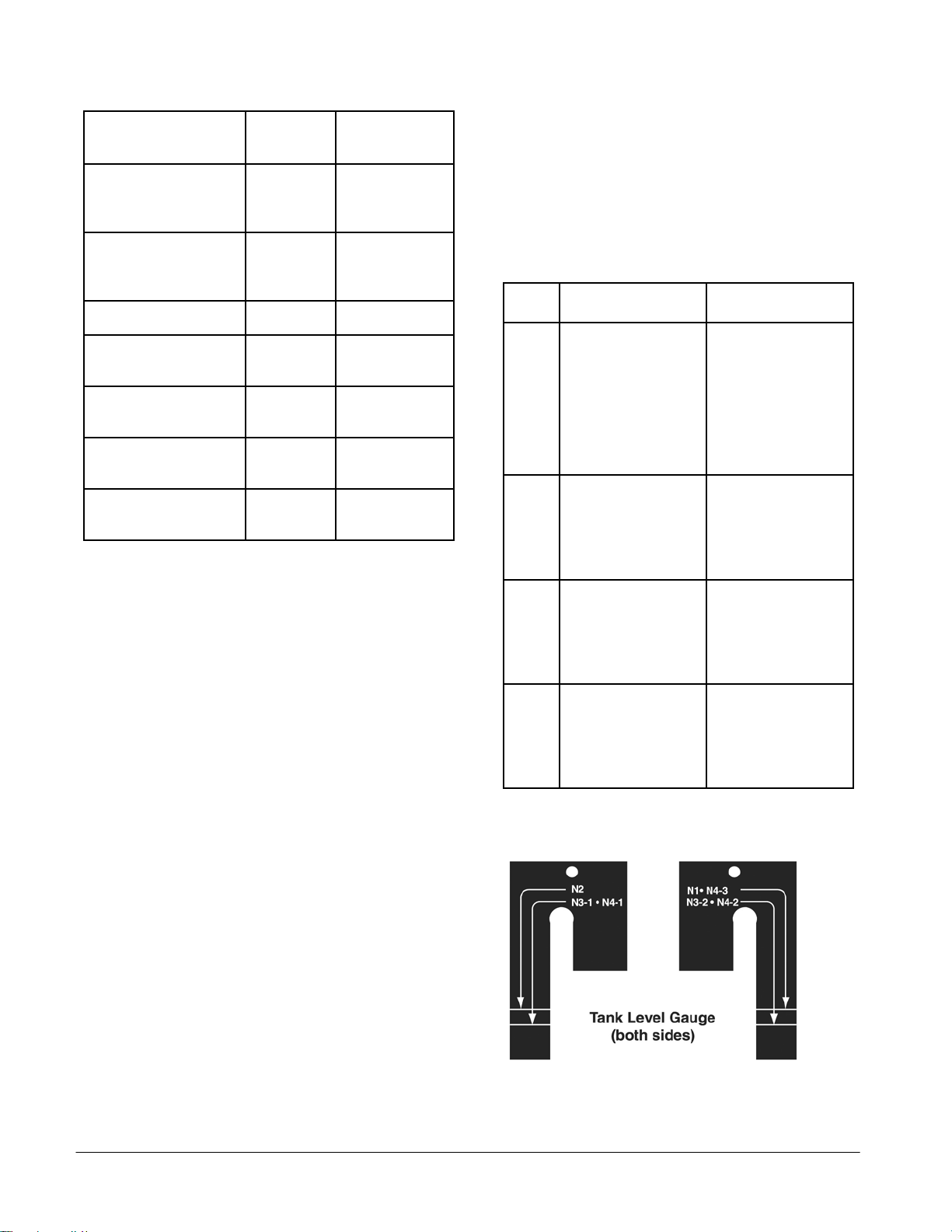

Step

1

2

3

4

FP363SC

Processor

Mix 2 bottles of

developer Part A

with 2 litres of water

in mixing bottle. Add

solution to processor

developer (N1) tank.

Mix 2 bottles of

developer Part B

with 2 litres of water

in mixing bottle. Add

solution to processor

developer (N1) tank.

Mix 2 bottles of

developer Part C

with 2 litres of water

in mixing bottle. Add

processor developer

(N1) tank.

Position tank level

gauge on processor

developer (N1) rack.

Add water to N1

level mark (about

2.3 litres).

FP563SC

Processor

Add 4 litres of water

to processor

developer (N1) tank.

Then mix 3 bottles of

developer Part A

with 2 litres of water

in mixing bottle. Add

solution to processor

developer (N1) tank.

Mix 3 bottles of

developer Part B

with 2 litres of water

in mixing bottle. Add

processor developer

(N1) tank.

Mix 3 bottles of

developer Part C

with 2 litres of water

in mixing bottle. Add

processor developer

(N1) tank.

Position tank level

gauge on processor

developer (N1) rack.

Add water to N1

level mark (about

2.4 litres).

No processor adjustments are required to use KODAK

Negative Film Processing Cartridges FC1 and FC2. These

cartridges are designed to mix and replenish on top of

existing solution. Use the same processor settings that you

use with your current chemical cartridge. Standard

conditions are shown in Figure 1 on page 3.

2 Using the KODAK Negative Film Processing Cartridges FC1 and FC2 • CIS-254

Page 3

Bleach Tank (N2)

Use KODAK Negative Film FC Tank Bleach,

CAT No. 107 2024. Each kit makes 3.6 litres of tank

bleach solution. One kit is required to prepare the bleach

tank in either the FP363SC processor or the FP563SC

processor. Add the contents of 1 bottle to the empty

bleach (N2) tank. Position the tank level gauge on the

bleach (N2) tank rack, and add water to the N2 level mark

on the gauge. For faster warm-up, use water close to

operating temperature (31 to 41˚C [88 to 106˚F]).

Fixer Tanks (N3-1 & N3-2)

Use KODAK Negative Film FC Tank Fixer,

CAT No. 813 4421. Each kit makes 3.6 litres of tank fixer

solution. One kit is required to prepare each fixer tank in

either the FP363SC processor or the FP563SC processor

(two tanks per machine). Add the contents of 1 bottle to

each empty tank (N3-1 and/or N3-2). Position the tank

level gauge on the fix tank rack (N3-1 or N3-2), and add

water to the N3-1 or N3-2 level mark on the gauge. For

faster warm up, use water close to operating temperature

(31 to 41˚C [88 to 106˚F]).

Figure 1

Stabilizer/Final Rinse Tanks (N4-1, N4-2, N4-3)

Use KODAK Negative Film FC Tank Rinse,

CAT No. 872 4791. The kit contains three bottles of

concentrate. Each bottle will make 1.9 litres of rinse tank

solution. One bottle is required to make a rinse tank

solution in each rinse tank of the FP363SC processor or

the FP563SC processor (three tanks per machine). Add

the contents of one bottle to each empty tank (N4-1, N4-2,

N4-3). Position the tank level gauge on the rinse tank

rack, and add water to the N4-1, N4-2 or N4-3 level mark

on the gauge (depending on which tank is being mixed.).

For faster warm up, use water close to operating

temperature (31 to 41˚C [88 to 106˚F]).

Water Reservoir

Use KODAK Rinse Tablets, CAT No. 191 3110. Add

tablet(s) into the loading port on top of the reservoir

before adding water. Use one tablet for every 4 litres of

water.

CN-16S

Replenishment

Rate

mL/135-24 roll

(mL/M)

Time

min:sec

Temperature

C ( F)

Process Cycle with

KODAK Negative Film

Cartridge Chemistry

FC1 Cartridge

Negative Film

Developer

Replenisher

N1-RA

15 (13.5)

N1 N2 N3-1 N3-2 N4-1 N4-2

3:05 0:50

+

_

38.0 0.2

+

_

(100.4

0.4)

1

The N4-2 Rinse is pumped into the N3-2 Fixer Tank to dilute the Fixer

Replenisher to specification.

Negative Film

Bleach

Replenisher

N2-R

to

0:70

Negative Film

Fixer

Replenisher

N3-R

0:50

to

0:70

0:50 0:30

to

0:70

35 - 41 (95 - 106)

1

Negative Film

Developer

Replenisher

1

FC2 Cartridge

N1-RB

RinseDeveloper FixerBleach Fixer Rinse

0:20

Negative Film

Rinse

Replenisher

N4-R

30 (27)7.5 (6.75)5 (4.5)

Rinse

N4-3

0:20

Dry

Using the KODAK Negative Film Processing Cartridges FC1 and FC2 • CIS-254 3

Page 4

USING KODAK CONTROL STRIPS,

PROCESS C-41, TO MONITOR THE

PROCESS

Use KODAK Control Strips, Process C-41, to monitor

process performance

Each time you process a control strip, position it in

the same location in the processor. Process a control strip

at these times:

• At the beginning of the day or shift, before processing

customer work

• At the end of the day or shift

Plotting Control-Strip Densities

Create a control chart by using the KODAK Process

Record Form Y-55 or similar graph paper. Your chart

should have the same format as the Process CN-16S

“Visual Process Control Guide” shown on page 8.

Tolerances and Limits for KODAK Control Strips,

Process C-41

Color-

Balance

Spread

Limit

Aim-Value

Adjust-

ment

Tolerance

Measure-

ment

D-min ±0.03 +0.03 +0.05 —

LD ±0.04 ±0.06 ±0.08 —

HD-LD ±0.03 ±0.07 ±0.09 0.09

Action

Limits

Control

Limits

C-41

9141

KODAK Control Strip,

Process C-41

CAT No. 180 3709

Yellow

D-max

HD

LD

D-min

Cutoff

Notch

D-maxb-Yb

±0.07 +0.10 +0.12 —

1. Before you begin to use a box of control strips,

remove the reference strip from the box, and store it at

room temperature.

2. Use a precision densitometer to measure the densities

in the center of the Yellow, HD, LD, and D-min

patches on the reference strip. Do not move the strip as

you make the density readings or you may affect the

precision and repeatability of the measurement. Use

transmission mode Status M.

3. To obtain the aim densities, apply the correction

factors to the densities read in Step 2. The correction

factors are found on a sheet packaged with the

control strips. Make sure you use the correction

factors for Process CN-16S. To obtain the HD-LD

aim value, subtract the adjusted LD value form the

adjusted HD value. To obtain the D-max

-Yb aim

b

value, subtract the adjusted blue density of the yellow

step from the adjusted blue density of the D-max

step. Use the Process CN-16S Reference Aims

Worksheet on page 9 to help calculate the aim

densities.

Note: If you are using an older code of control strip

that does not list correction factors for Process

CN-16S, apply the Process Factors listed in the

following table to the density readings after applying

the regular correction factors for Process C-41.

4 Using the KODAK Negative Film Processing Cartridges FC1 and FC2 • CIS-254

Page 5

Additional Process CN-16S

Adjustment Factors for Use with

Process C-41 Control Strips

Step R G B

Yellow 0.00 0.00 0.00

D-max 0.00 0.00 +0.07

HD +0.04 0.00 +0.07

LD 0.00 0.00 0.00

D-min 0.00 0.00 0.00

4. Process a control strip and measure the Yellow,

D-maxb-Y

HD, LD, and D-min patches.

b,

5. Calculate the variations from aim by subtracting the

aim densities from your control-strip densities. Plot

the variations on your control chart. Plot variations

that are higher than the corresponding aim values

(+ values) above the aim line. Plot variations that are

lower than the aim values (– values) below the aim

line.

If any of the variations from aim plots beyond the

action or control limits, process another control strip. If

the second control strip confirms the results of the first

strip, determine the cause of the problem. Using the

“Visual Process Control Guide” on page 8 provides a

good starting place. If the problem is not readily

correctable, contact Kodak Service and Support at

(866) 352-4367.

USING THE “VISUAL PROCESS

CONTROL GUIDE” AND KODAK

CONTROL STRIPS TO TROUBLESHOOT

PROCESS CN-16S

If your Process CN-16S control chart indicates an out-ofcontrol plot position, use the “Visual Process Control

Guide” as follows to troubleshoot the process and apply

corrective action.

First check for operational errors:

• Make sure the control-strip code matches the

reference-strip code.

• Calibrate the densitometer.

• Re-check the control-strip aims and verify the

correction factors.

• Verify the problem by processing a second control

strip.

• Determine if any recent processor maintenance could

have caused a problem.

• Verify that tank and replenisher solutions were mixed

correctly.

• Use an accurate thermometer to verify that the

developer temperature and other solution temperatures

are correct.

Match your plots to the “Visual Process Control

Guide” to identify the problem:

• Match your control plots to the examples given on the

“Visual Process Control Guide.” Compare only one

plot parameter at a time (D-max

, HD-LD, LD,

b-Yb

D-min). Note that the pattern of the red, green, and

blue plot deviations can be an indicator of different

problems.

• Write down the problems indicated by each parameter

for the plots that are out of control. Consider that you

may have more than one problem occurring at the

same time.

• Consider each potential cause of the out-of-control

condition, and verify the operational conditions of the

processor.

When you have determined the most likely cause(s)

of the out-of-control condition, take corrective action to

eliminate the cause, and use the prescriptions to eliminate

the symptom of the problem.

Corrective Action and Prescriptions

D-maxb – Yb:

This parameter monitors the performance of the bleach

solution for retained silver. A bleach solution that is

underreplenished or diluted will not efficiently bleach the

film, leaving retained silver in higher-density areas. If the

D-max

with the following test:

1. Immerse the processed control strip in the bleach tank,

and soak it for 7 minutes.

2. Remove the strip, rinse it thoroughly with water for

3 minutes, and dry it.

3. Re-read the strip, re-plot D-max

new plot to the earlier plot. If the new plot shows a

difference of -0.05 density unit or more (lower), it

confirms a bleaching problem. If there is no change or

less than a 0.05 change, the bleach is not a problem.

See the “Visual Process Control Guide” for other

possible causes.

bleach tank solution with fresh solution made from the

KODAK Negative Film FC Tank Bleach, as described on

page 3. Also check the output of the bleach replenisher

pump and calibrate. Be sure that the bleach replenishment

rate is set correctly.

indicates a retained-silver problem, confirm it

b-Yb

, and compare the

b-Yb

If the test confirms a bleaching problem, replace the

Using the KODAK Negative Film Processing Cartridges FC1 and FC2 • CIS-254 5

Page 6

HD-LD (Contrast):

This parameter monitors developer activity. Contrast is

the primary indicator of developer agitation, oxidation,

concentration, or contamination. If the developer tank

solution is under-agitated, too dilute, or oxidized, the

plots will be low. If the developer tank solution is overconcentrated or contaminated, the plots will be high. If

the process is very out of control, i.e., by more than 0.15

density unit over or under aim, replace all of the

developer tank solution. If the developer is contaminated,

make sure you rinse the tank out thoroughly, and then

replace all of the developer tank solution. If the plots are

less than 0.15 density unit over or under aim, you can risk

a prescription.

Prescriptions:

• For high HD-LD plots:

Overconcentration: Dilute the developer with warm

water in an amount equal to 5 percent of the volume in

the developer tank. Repeat as necessary until the

process is in control.

• For low HD-LD plots:

Under concentrated (Diluted): Replace developer tank

with a tank mix of KODAK Negative Film FC Tank

Developer, use mixing instructions on page 2.

Under agitation: Call a service representative to fix the

agitation pump on the processor.

Oxidation: Check for air bubbles in the developer

tank, and call a service technician if bubbles are

visible. If oxidation is caused by low utilization, see

the corrective action in KODAK Publication No.

CIS-246, Operating Minilabs at Low Levels of

Utilization. This publication is available on the Kodak

website at www.kodak.com/go/photochemicals.

LD (speed):

This parameter monitors developer activity. Speed is the

primary indicator of problems with developer time,

temperature, and especially replenishment rate. For

development time that is too long, temperature that is too

high, or overreplenishment, the LD plots will be high. For

time that is too short, temperature that is too low, or

underreplenishment, the LD plots will be low. Check the

developer time and temperature, and adjust them to

specification. The developer time should be 3:05 ± 0:05;

the temperature should be 38 ± 0.2˚C.

If the plots are very out of control, i.e., by more than

0.12 density unit over or under aim, dump and replace all

of the developer tank solution. If the plots are less than

0.12 density over or under aim, you can risk a

prescription.

Prescriptions:

• For high LD plots:

Overreplenishment: Replace a portion of the developer

tank solution (5.2 litres) with one KODAK Negative

Film FC Tank Developer Kit. Check the replenishment

rate setting. Check the output of the developer

replenisher pump and calibrate. Lower the developer

replenishment rate by 10 percent or more if necessary.

• For low LD plots:

Underreplenishment: Replace a portion of the developer

tank (5.2 litres) with one KODAK Negative Film FC

Tank Developer Kit. Check the replenishment rate

setting, and check the pump output of the developer

replenisher pump and calibrate. Increase the developer

replenishment rate by 10 percent or more if necessary.

6 Using the KODAK Negative Film Processing Cartridges FC1 and FC2 • CIS-254

Page 7

D-min (Clear Area of Film):

This parameter may monitor developer, bleach, or fixer

problems. If a developer problem is indicated, see the

HD-LD or LD parameter for confirmation and corrective

action. If a bleach or fixer problem is indicated, see the

corrective action below:

Bleach (Stain):

Developer carryover into the bleach can form a staining

by-product that can elevate D-min, especially the green

D-min. This occurs when the bleach is underreplenished

or under-aerated.

Prescriptions:

• Replace the bleach tank solution with KODAK

Negative Film FC Tank Bleach. Refer to the directions

on page 3.

• Check the bleach aeration to make sure it is working

properly.

• Check the output of the bleach replenishment pump

and calibrate.

• Check the replenishment rate for bleach, and adjust to

the correct rate.

Fixer (Retained Silver Halide):

Retained silver halide is caused by an exhausted fixer

solution due to underreplenishment, dilution, or oxidation.

This is indicated by a high D-min, especially the red

D-min. To confirm retained silver halide, run this test:

1. Immerse the processed control strip in the fixer tank

and soak it for 7 minutes.

2. Remove the strip, rinse it thoroughly with water for

3 minutes, and dry it.

3. Re-read the strip and re-plot D-min. Compare the red

D-min to the earlier plot. If the new plot shows a

difference of at least 0.05 (lower), it confirms a fixer

problem. Replace both fixer tanks with KODAK

Negative Film FC Tank Fixer. Use directions on

page 3. Also, check the output of the fixer replenisher

pump and calibrate. Set the fixer replenishment rate to

the correct value.

If there is no change or less than a 0.05 change, the

fixer is not a problem. See the “Visual Process Control

Guide” for other possible causes.

MANAGING EMPTY CARTRIDGES

In most regions, it should be possible to participate in a

local community recycling program. Check with program

authorities to determine if these packaging materials are

eligible for local recycling. If they are accepted,

disassemble the package and place the bottles and

corrugated material in your recycling bin. Follow all

material preparation instructions from the recycler. See

KODAK Publication No. CIS-148, Recycling KODAK

Photochemical Containers, for more information on

preparing the empty bottles for recycling. CIS-148 and

other publications on waste management are available on

the Kodak website at www.kodak.com/go/KES. If local

recycling is not an option, dispose of the empty bottles

and the package with your normal solid waste.

SILVER RECOVERY

Publications on silver management that include

recommendations and descriptions of silver-recovery

options are available in the Silver Management section of

the Kodak Environmental Services Publications Center at

www.kodak.com/go/KES.

Using the KODAK Negative Film Processing Cartridges FC1 and FC2 • CIS-254 7

Page 8

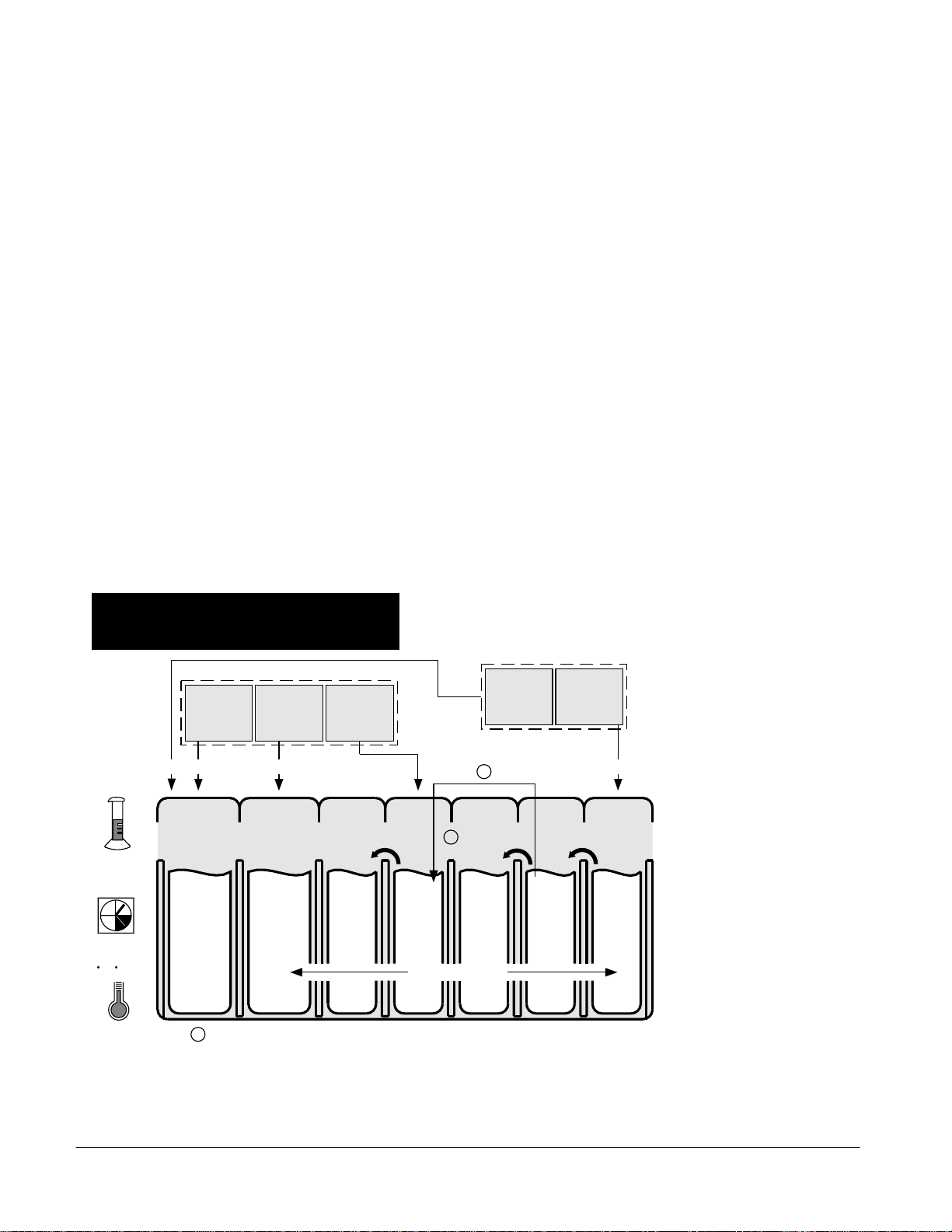

Figure 2

Process

CN-16S Visual Process Control Guide

.25

D-maxB - Y

B

(+ 0.10 & 0.12)

Bleach

Activity

- retained silver

HD-LD

(+/- 0.07 & 0.09)

Developer

Activity

- concentration

- contamination

- oxidation

- agitation

.20

.15

.10

.05

+

-

.05

.10

.15

.20

.25

.25

.20

.15

.10

.05

+

-

.05

.10

.15

.20

.25

Retained Silver

+ Bleach is dilute or

underreplenished

0

+

Over concentrated, if

0

trend

- Underconcentrated,

if trend

- Oxidized, if trend

- Agitation, if rapid

loss

Relative Height of

R

B

G

arrows is an indicator of

control-strip performance

leading to the cause

indicated in text box

+ Contamination, if sudden

+ Possibly frozen reference

LD

(+/- 0.06 & 0.08)

Developer

Activity

- time/temp

- replenishment

D-min

(+ 0.03 & 0.05)

Developer

- overconcentration

- overreplenishment

Bleach

- stain

.15

.10

.05

+

-

.05

.10

.15

.05

+

-

.05

0

0

DATES

+ Developer

temperature too high

or dev time too long

- Developer

temperature too low

or time too short

+ Weak Fixer,

Developer

contamination

or light fog

+Developer

Replenishment too

high (trend)

- Developer

Replenishment too

low (trend)

+ Developer

overreplenished

or over concentrated

Leuco Cyan Dye

Bleach very

dilute or Fixer

underreplenished

(trend)

+ Bleach stain from

too much Developer

carry-over, no

aeration or

underreplenishment

Fixer Activity

- retained silver halide

F002_1271EC

8 Using the KODAK Negative Film Processing Cartridges FC1 and FC2 • CIS-254

PROCESS:

MACHINE:

EASTMAN KODAK COMPANY, Rochester, NY 14650

Page 9

Process CN-16S

Reference Aims Worksheet

Date: Code:

D-maxb Density Readings

Control Strip Correction Factor

Corrected D-max

Yellowb Density Reading

Red Green Blue

Control Strip Correction Factor

Corrected Yellowb

AIM

b-Yb

D-max

HD Density Readings

Control Strip Correction Factors

Corrected HD

LD Density Readings

Control Strip Correction Factors

AIM

LD

AIM

HD-LD

D-min Density Readings

Control Strip Correction Factors

AIM

D-min

Using the KODAK Negative Film Processing Cartridges FC1 and FC2 • CIS-254 9

Page 10

Note: The contents of this publication are subject to change. To be sure you have the

most up-to-date publication, check www.kodak.com/go/photochemicals; select

Technical Information to find Current Information Summaries.

EASTMAN KODAK COMPANY • ROCHESTER, NY 14650

Using KODAK Negative Film Processing

Cartridges FC1 and FC2

KODAK Publication No. CIS-254 Kodak is a trademark.

Digital & Film Imaging Systems

Minor Revision 5-05

Loading...

Loading...