Page 1

Publication No. SM5766-1

23JUL01

Supersedes SM5766 -1

13MAY97

SERVICE MANUAL

for the

Kodak Ektalite 500 PROJECTOR

PROJECTORS

Service Code: 5766

A091_4000BA

Page 2

WIRE ASSEMBLIES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Removal for the LOWER HOUSING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation for the LOWER HOUSING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Removal for the FAN SHAFT ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation for the FAN SHAFT ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . 10

Removal for the MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Installation for the MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Removal for the WORM PULLEY and MECHANISM BELT . . . . . . . . . . . . . 13

Installation for the WORM PULLEY and MECHANISM BELT . . . . . . . . . . . 14

Removal for the THERMAL FUSE ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . 15

Installation for the THERMAL FUSE ASSEMBLY . . . . . . . . . . . . . . . . . . . . 16

Removal for the LAMP MODULE RECEPTACLE. . . . . . . . . . . . . . . . . . . . . 17

Installation for the LAMP MODULE RECEPTACLE . . . . . . . . . . . . . . . . . . . 18

Removal for the CYCLE SOLENOID ASSEMBLY . . . . . . . . . . . . . . . . . . . . 19

Installation for the CYCLE SOLENOID ASSEMBLY . . . . . . . . . . . . . . . . . . 20

Removal for the MECHANISM ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . 21

Installation for the MECHANISM ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . 22

Removal for the AUTO-FOCUS BRACKET ASSEMBLY - 1500 and

2000 PROJECTORS Only. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Installation for the AUTO-FOCUS BRACKET ASSEMBLY - 1500 and

2000 PROJECTORS Only. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Removal for the CAM STACK ASSEMBLY and CYCLE LEVER ASSEMBLY 24

Installation for the CAM STACK ASSEMBLY and

CYCLE LEVER ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Removal for the Style 2 LAMP SOCKET TERMINAL ASSEMBLY . . . . . . . 30

Page 3

Installation for the LAMP SOCKET TERMINAL ASSEMBLY . . . . . . . . . . . 31

Removal for the LENS MOUNT ASSE MBLY - 1500 and

2000 PROJECTORS Only. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Installation for the LENS M OUNT ASSEMBLY - 1500 and

2000 PROJECTORS Only. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Removal for the LENS MOUNT ASSE MBLY - 500 and

1000 PROJECTORS Only. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Installation for the LENS M OUNT ASSEMBLY - 500 and

1000 PROJECTORS Only. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Removal for the AUTO-FOCUS SWITCH ASSEMBLY -

Models 1500 and 2000 PRO JECTORS Only . . . . . . . . . . . . . . . . . . . . . . . 34

Installation for the AUTO-FOCUS SWITCH ASSEMBLY -

Models 500 and 2000 PROJECTORS Only. . . . . . . . . . . . . . . . . . . . . . . . 35

Removal for the FOCUS SHAFT ASSEMBLY -

1500 and 2000 PROJ ECTORS Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Installation for the FOCUS SHAFT ASSEMBLY - 1500 and

2000 PROJECTORS Only. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Removal for the FOCUS SHAFT ASSEMBLY - 500 and

1000 PROJECTORS Only. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Installation for the FOCUS SHAFT ASSEMBLY - 500 and

1000 PROJECTORS Only. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

CYCLE SOLENOID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

INDEXER LEVER ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

SLIDE LIFT LEVER MANUAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

SLIDE LIFT LEVER POWER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

ZERO POSITION SWITCH - 2000 PROJECTOR Only . . . . . . . . . . . . . . . . . 45

Focus Light Path - 1500 and 2000 PROJECTORS Only . . . . . . . . . . . . . . . 46

NULL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

PHOTOCELL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

CLAMP PAD ASSEMBLY - 15 00 and 2000 PROJECTORS On ly . . . . . . . . 55

DARK SHUTTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

MAIN MOTOR - Voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

12-PIN APPLICATIONS PLUG - Voltages, 2000 PROJECTORS Only . . . . . . . . 71

PHOTOCELL - Voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

6-PIN REMOTE PLUG - Voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Page 4

SMALL COMPONENT BOARD ASSEMBLY - Voltages, 1500 and 2000

PROJECTORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

MAIN COMPONENT BOARD ASSEMBLY - Voltages,

1500 and 2000 PROJECTO RS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Voltage Specificat ions - General Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Power, Illumination, and Cooling Malfunctions. . . . . . . . . . . . . . . . . . . . . . . . . . 80

Slide Transport Malfunctions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Focus Malfunctions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Page 5

CAPACITOR

LINE

CAPACITOR

POWER INLET BROWN or

BLUE across

POWER INLET

LONG

AF/TIMER

MOTOR 8 FOCUS MOTOR BLUE

all wires and

FUSES

AF/TIMER

MOTOR 12 PHOTOCELL BROWN

all wires and

FUSES

Page 6

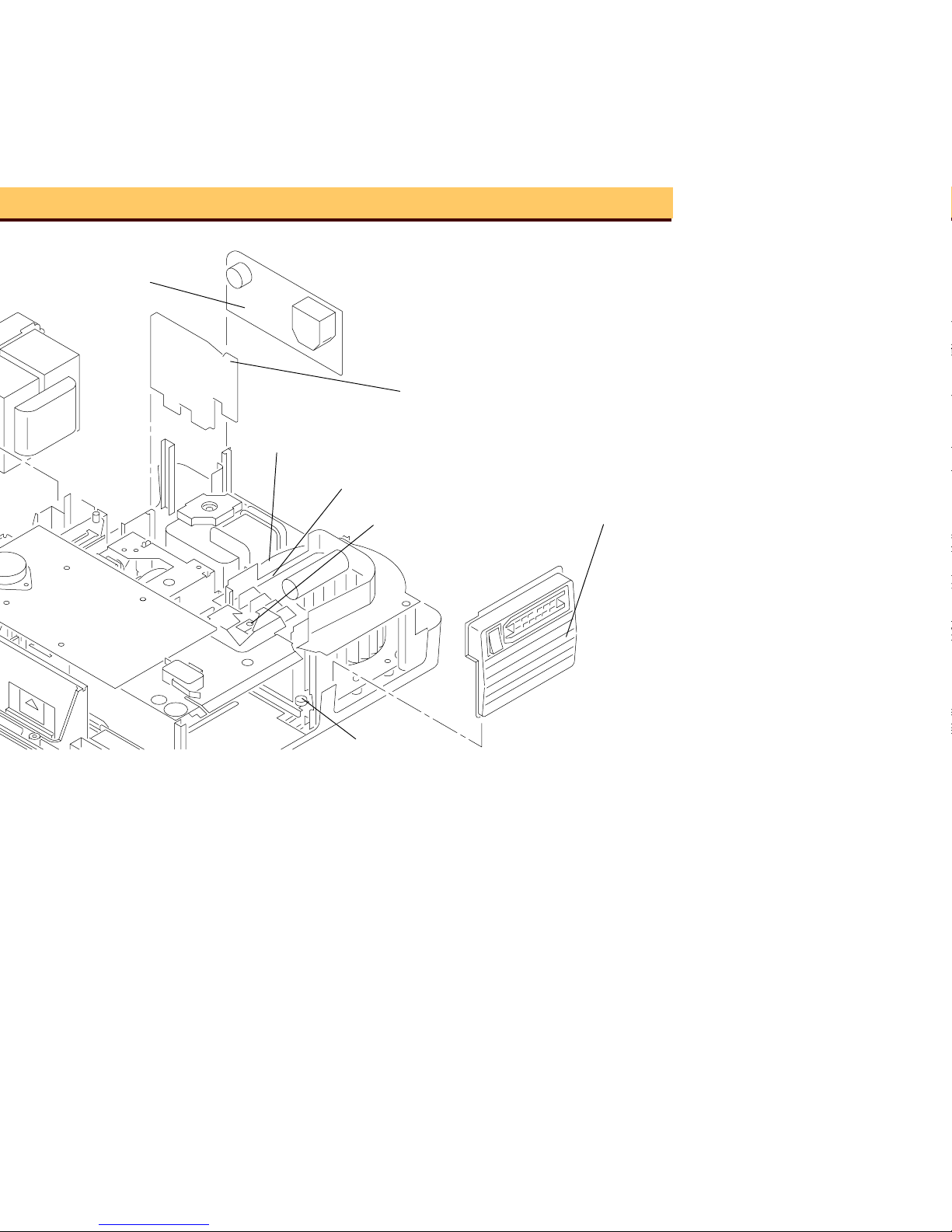

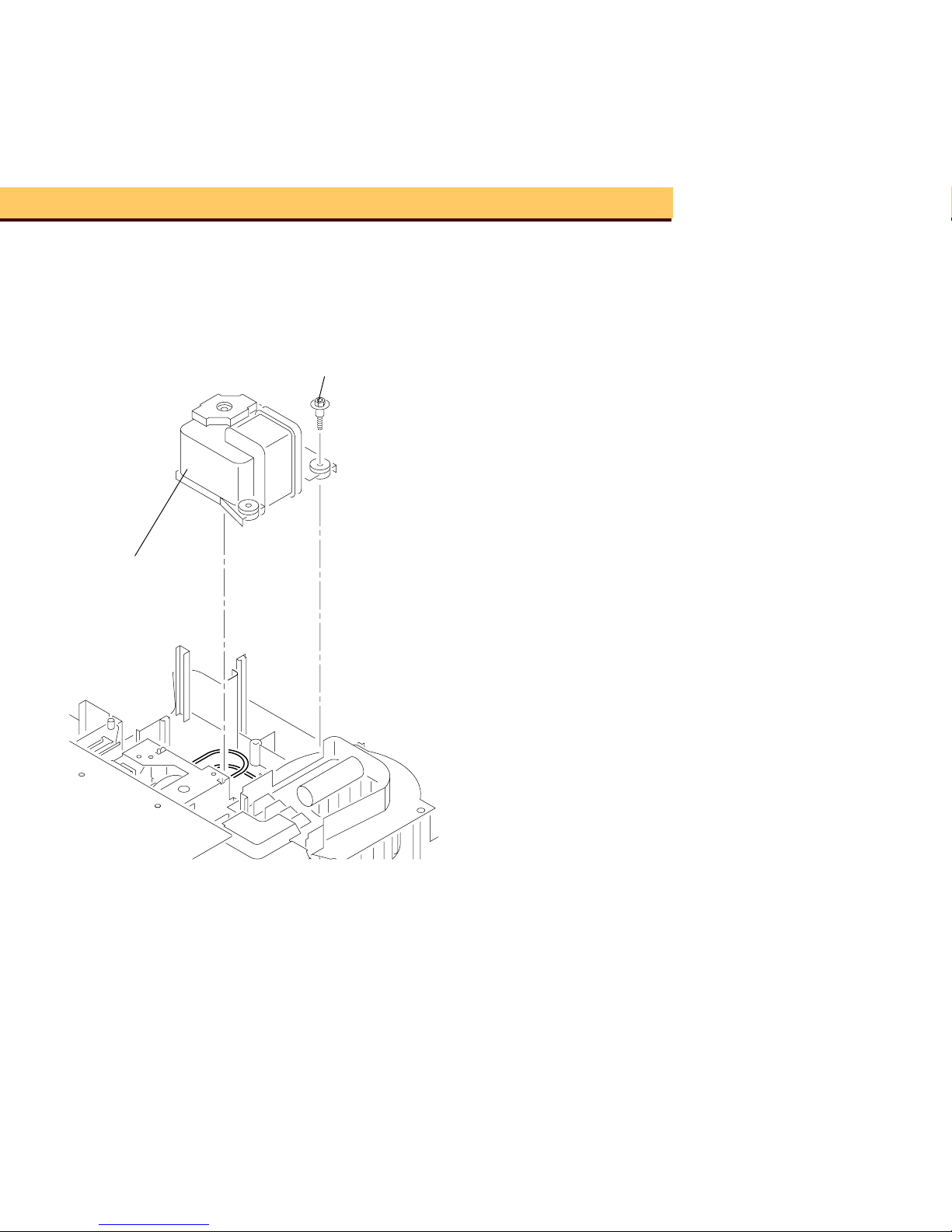

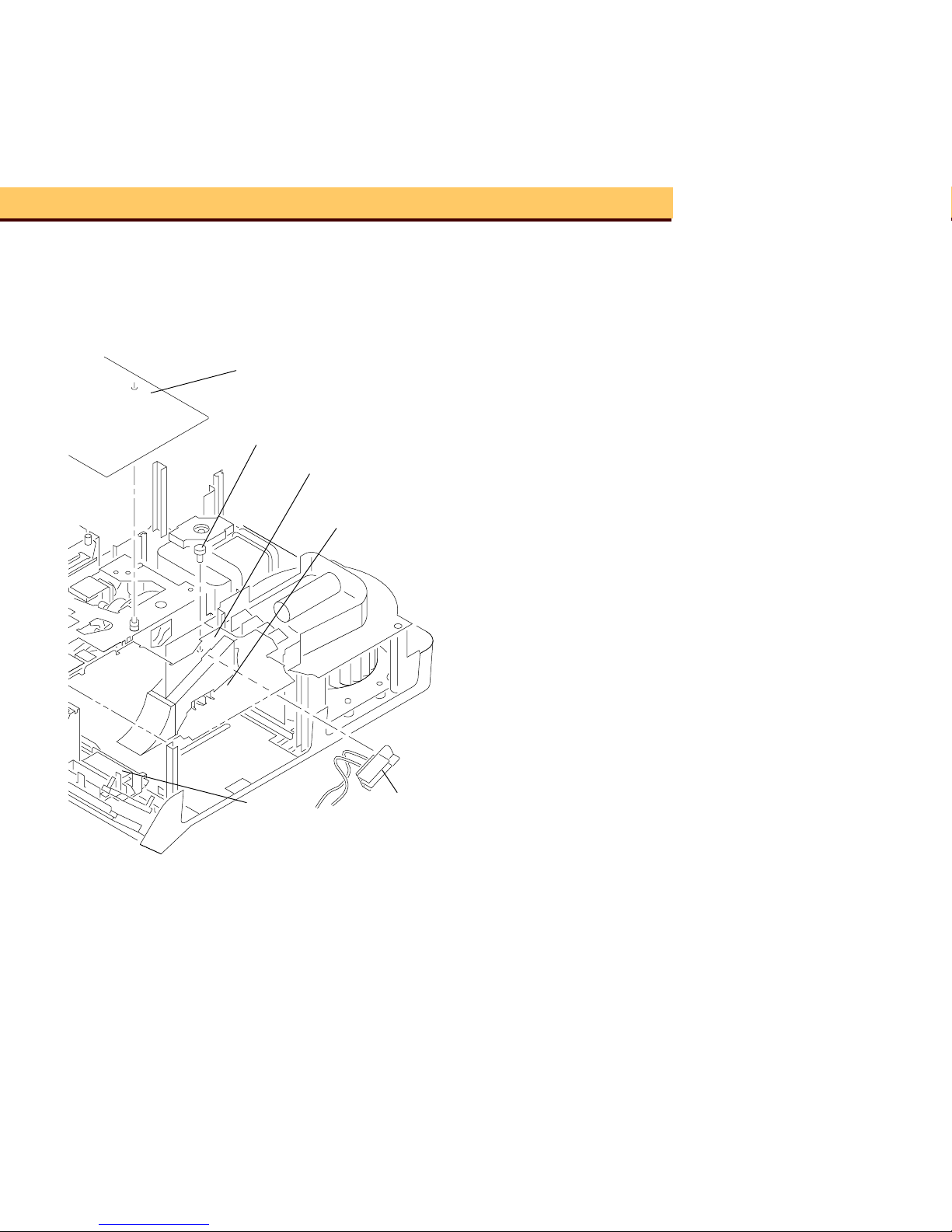

A091_0001HA

LAMP MODULE

A091_0001HCA

HOUSING

LOWER

Page 7

Page 8

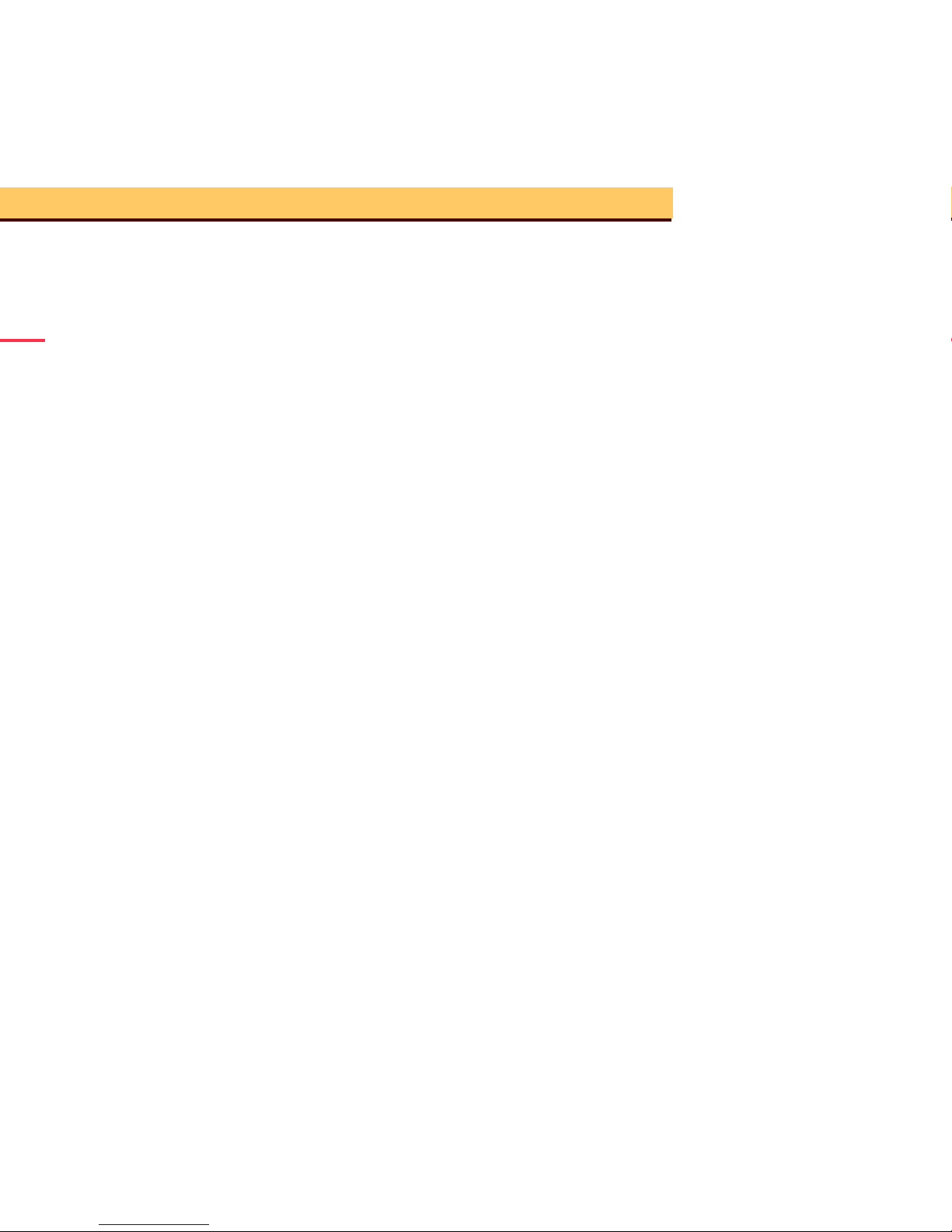

A091_4011HA

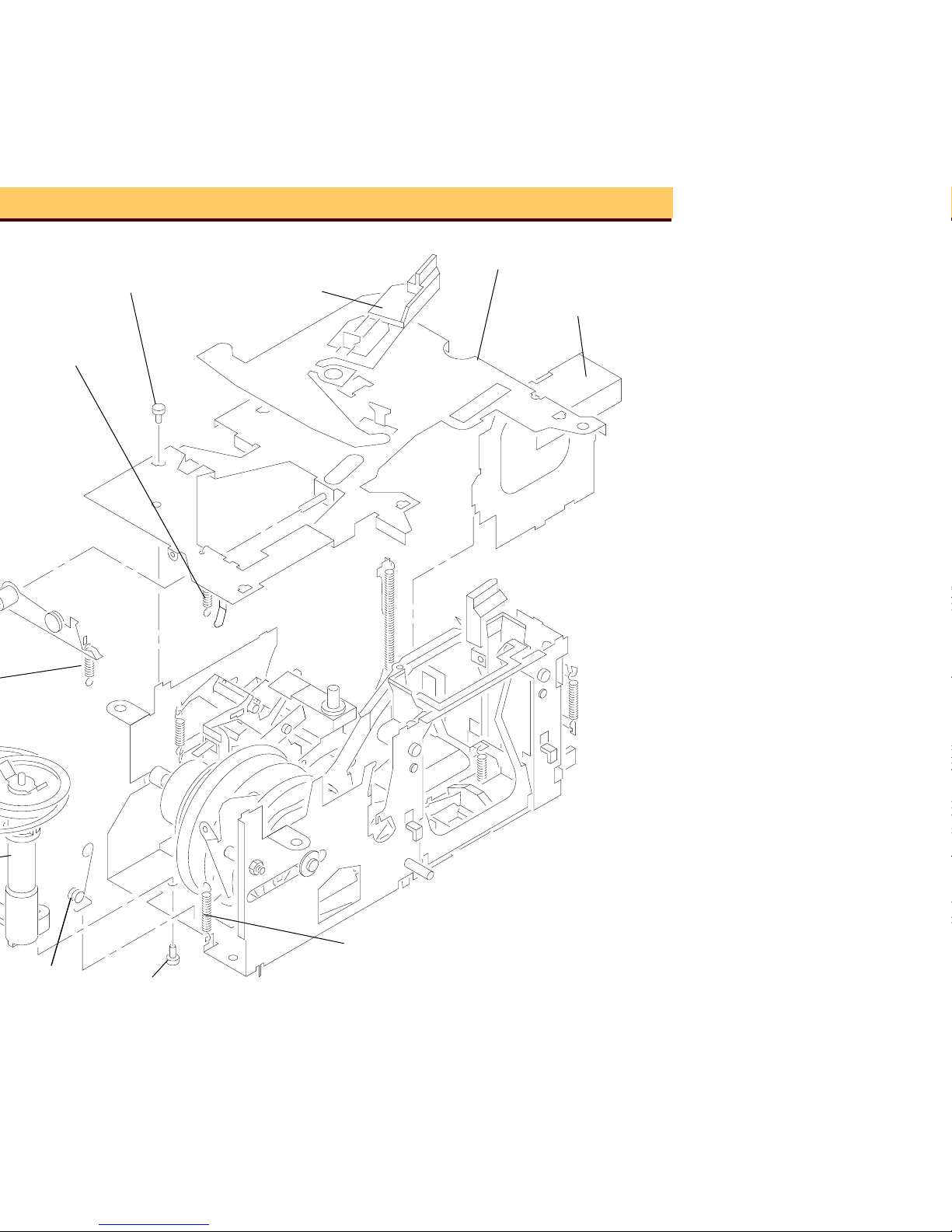

SCREW (not shown)

GRILLE

WIRE TIE

LOWER LIGHT

BLOWER COVER

(not shown)

WIRE TIE (2)

ASSEMBLY

A091_4011HCA

SCREW

BAFFLE TAB

POWER MODULE

Page 9

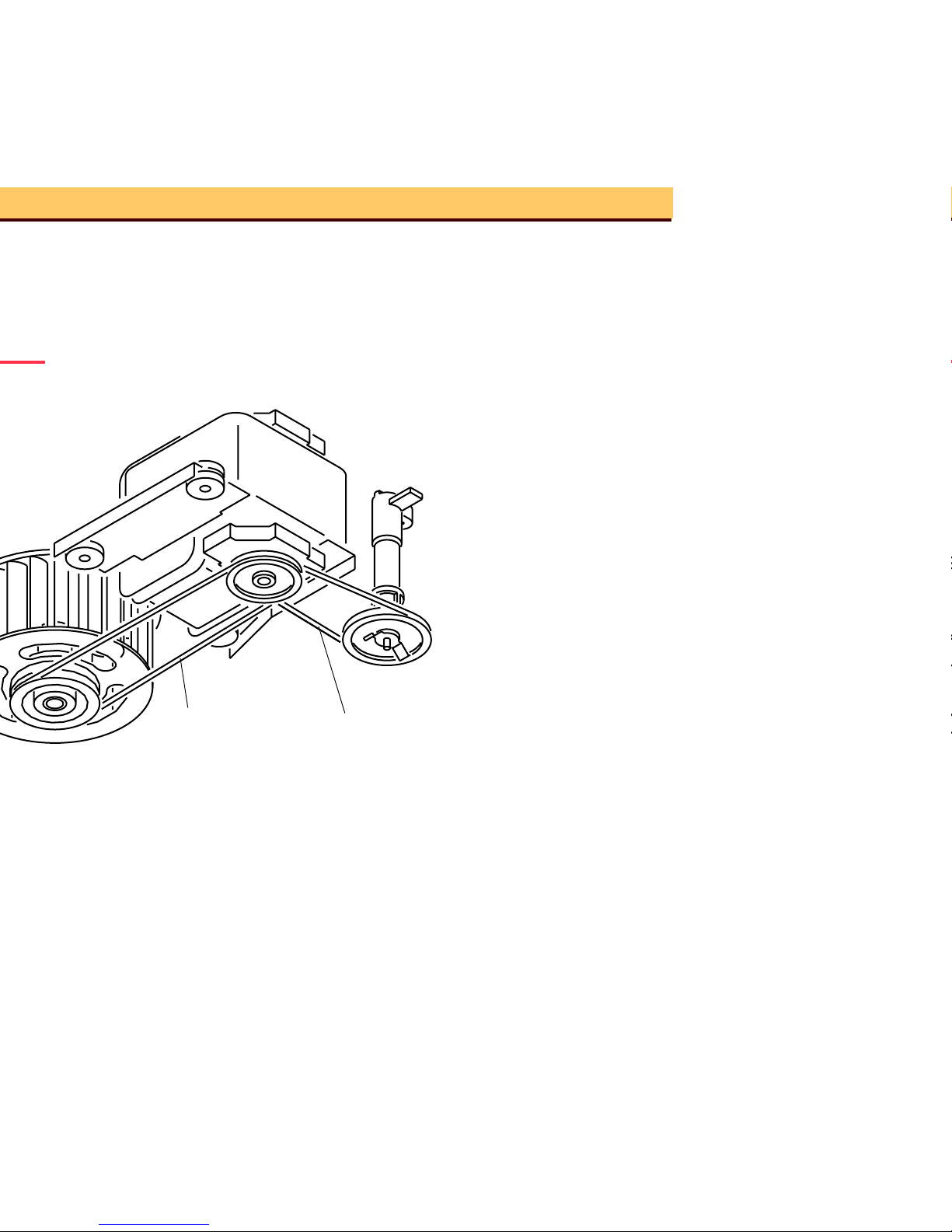

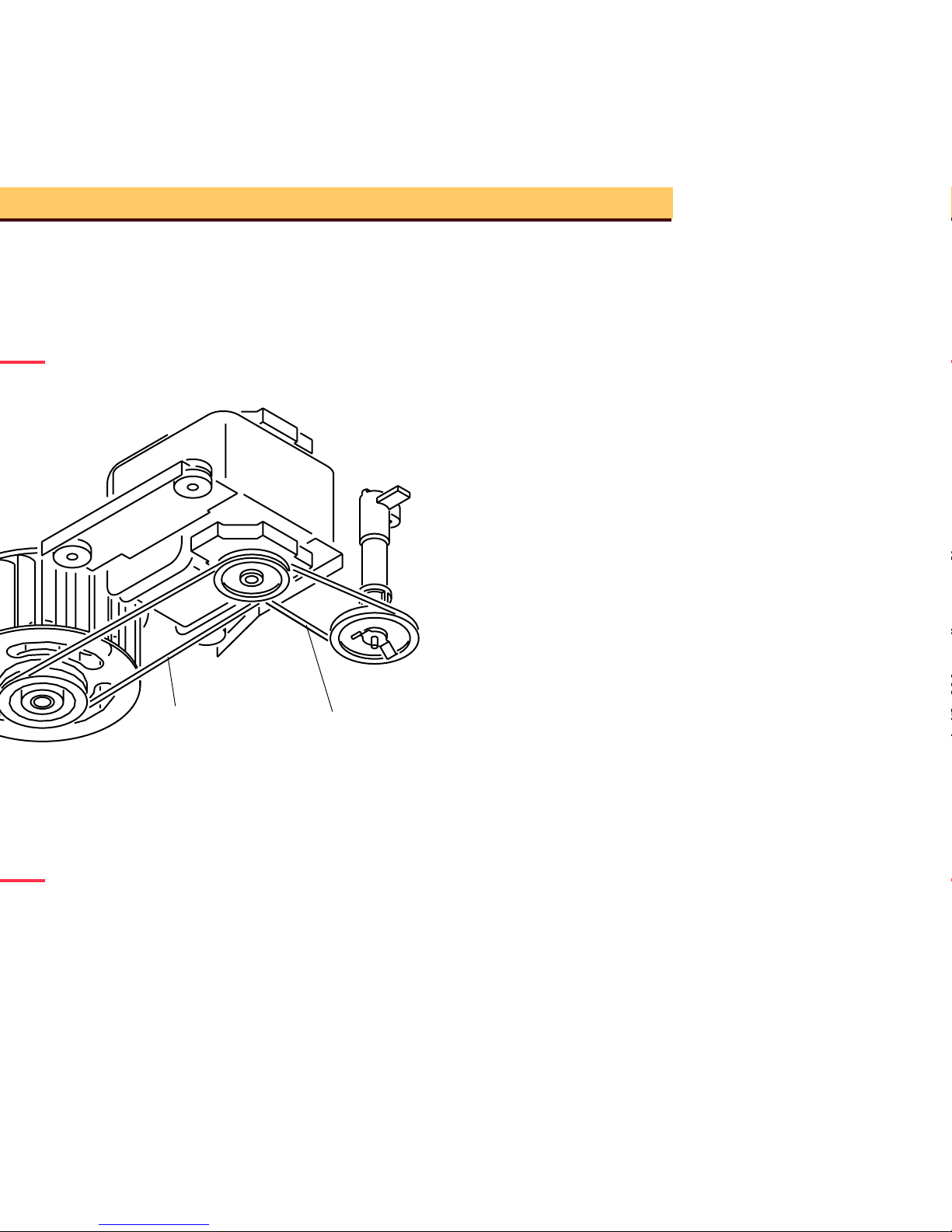

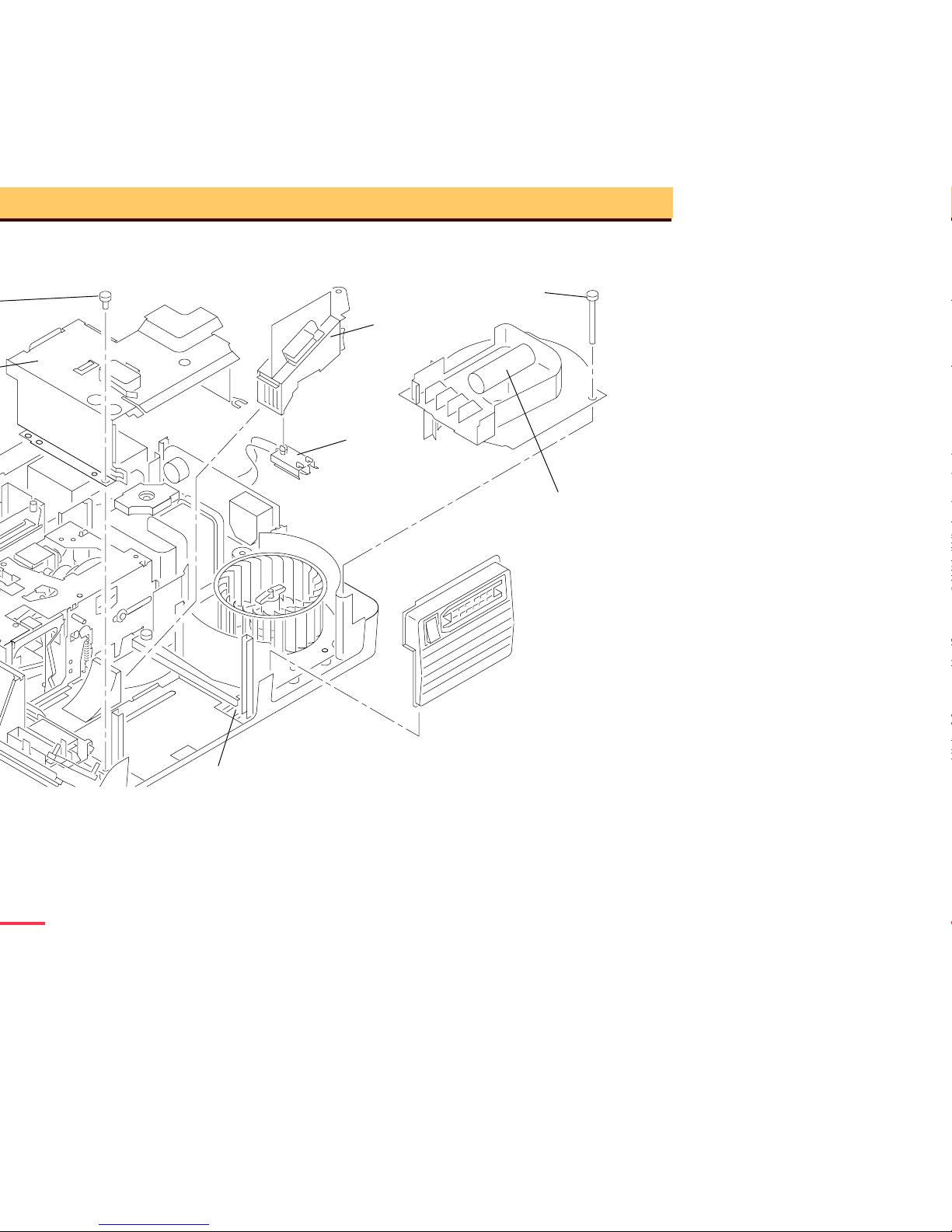

A091_4012HA

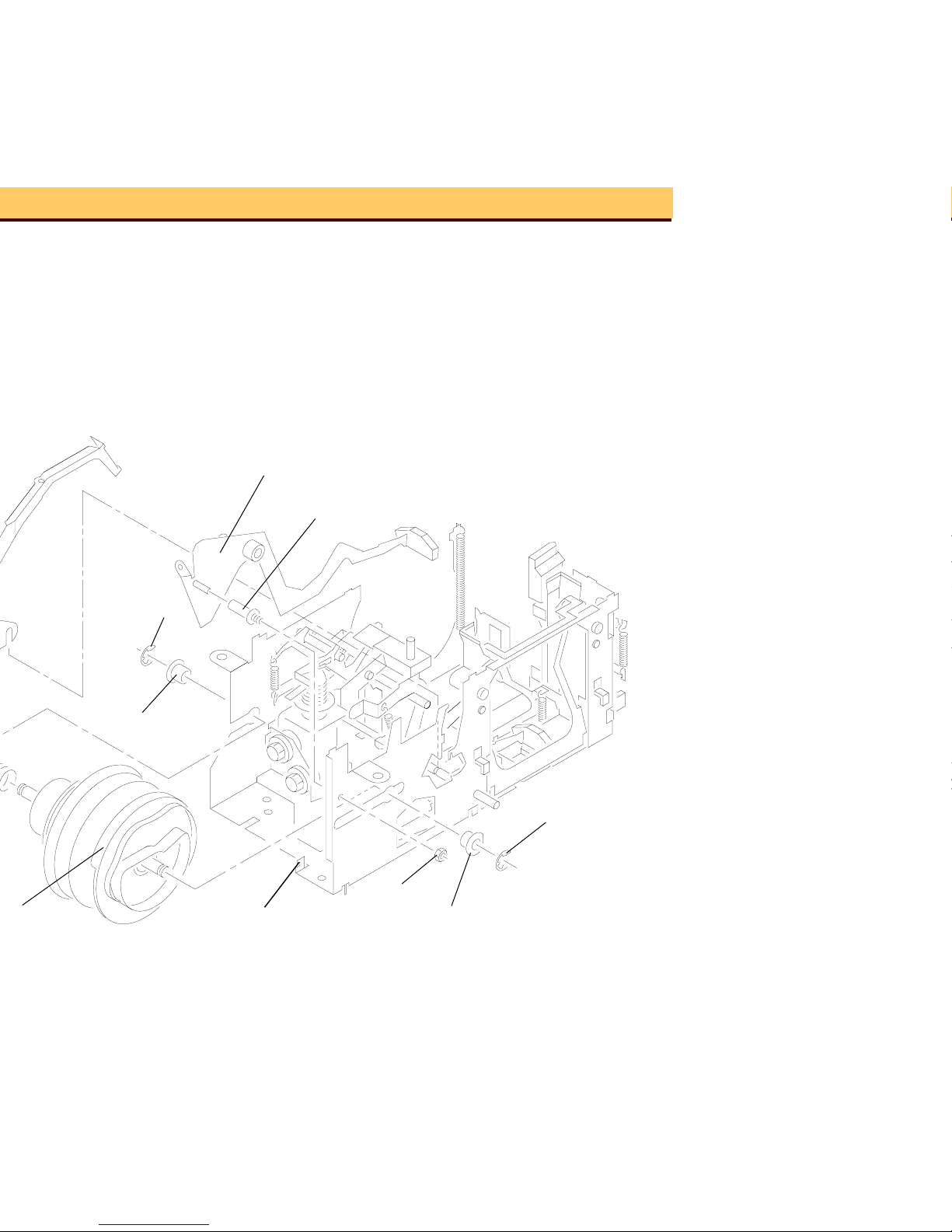

MECHANISM BELT

MOTOR

FAN BELT

SCREW

BLOWER

SCREW (3)

ASSEMBLY

FAN PLATE

A091_4012HCA

ASSEMBLY

RETAINER CLIP

FAN

SCREW (2)

Page 10

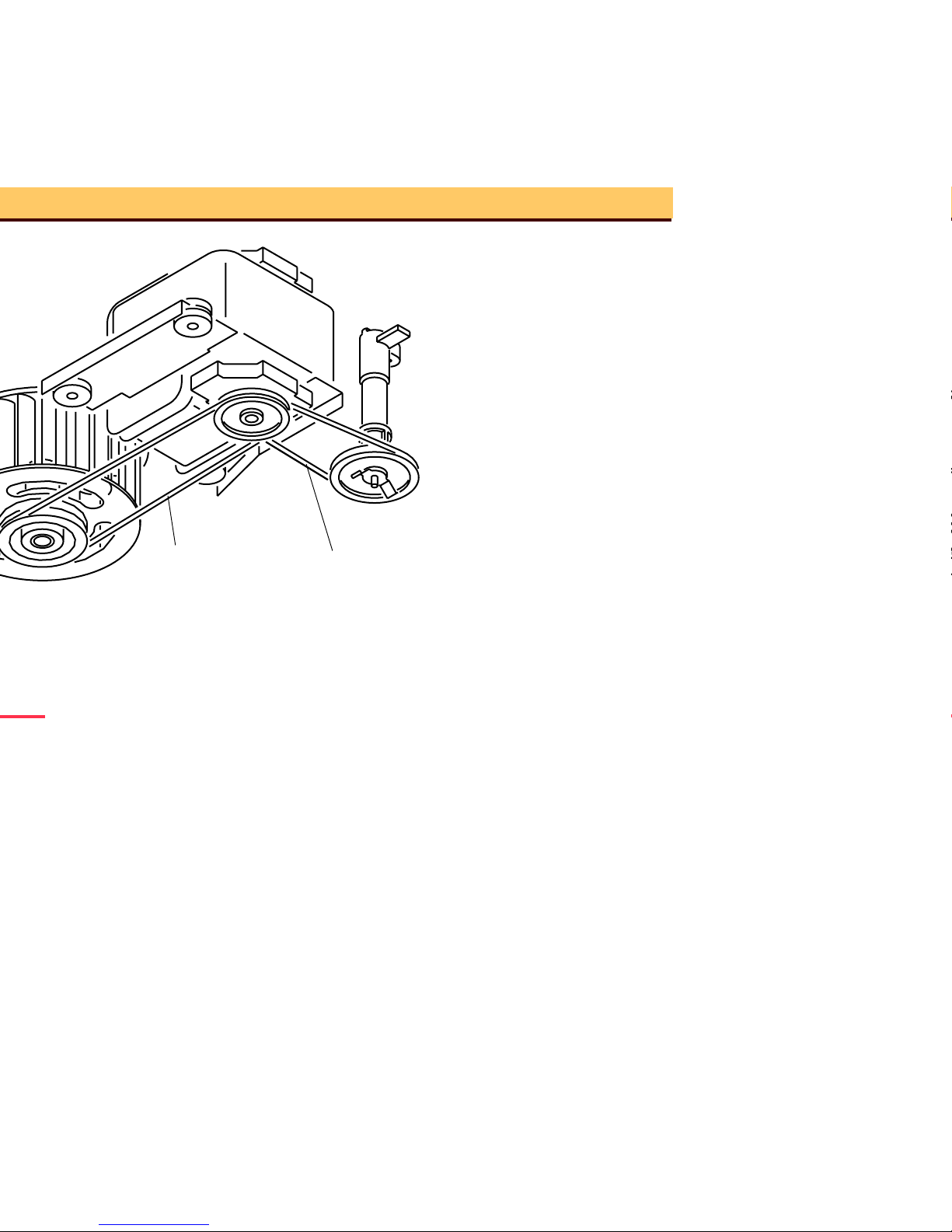

A091_4015BA

A091_4015BCA

MECHANISM BELT

FAN BELT

Page 11

Page 12

A091_4016GA

MOTOR

SCREW (3)

A091_4016GCA

Page 13

A091_4015BA

A091_4015BCA

MECHANISM BELT

FAN BELT

Page 14

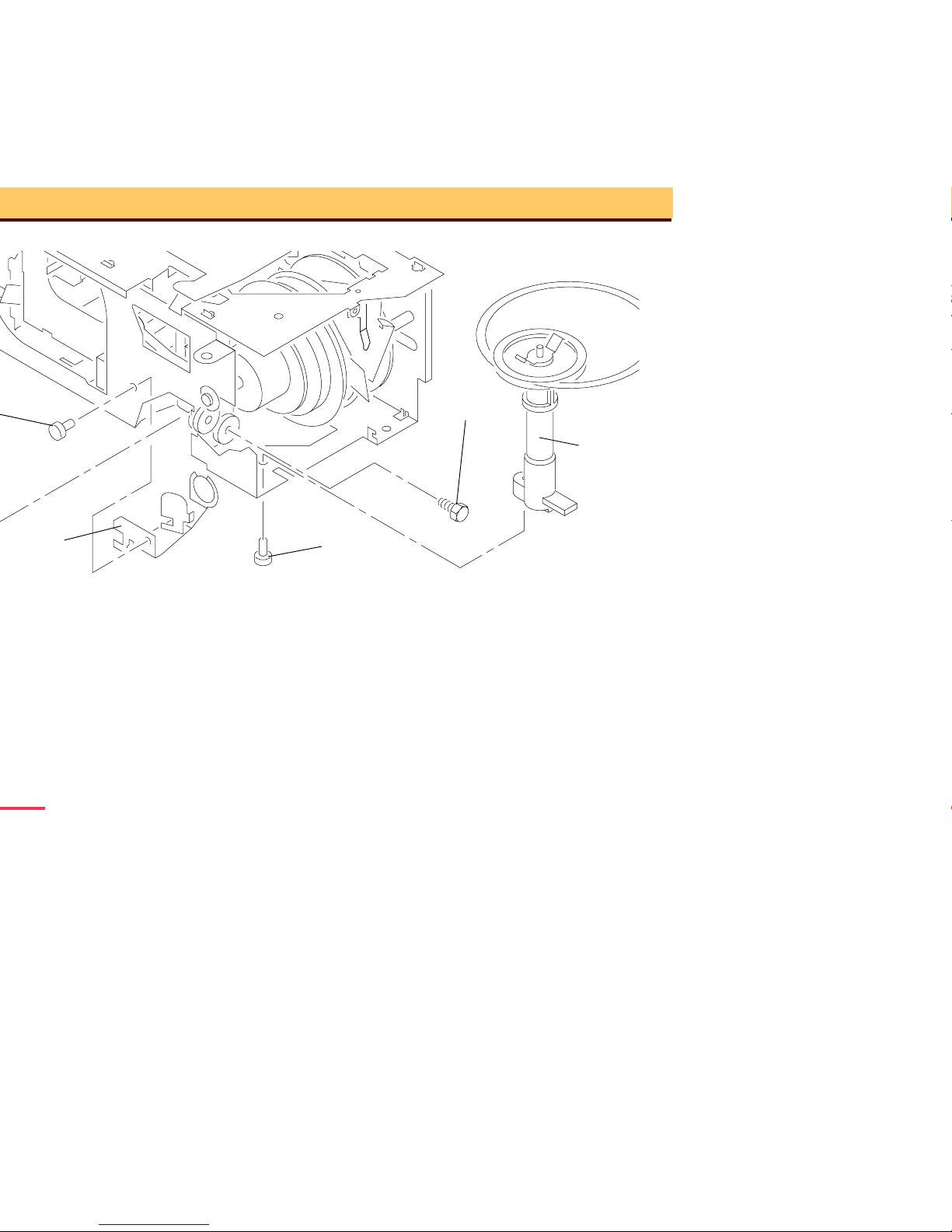

A091_4017GA

WORM PULLEY

BELT

MECHANISM

A091_4017GCA

SCREW

Page 15

A091_4015BA

A091_4015BCA

MECHANISM BELT

FAN BELT

Page 16

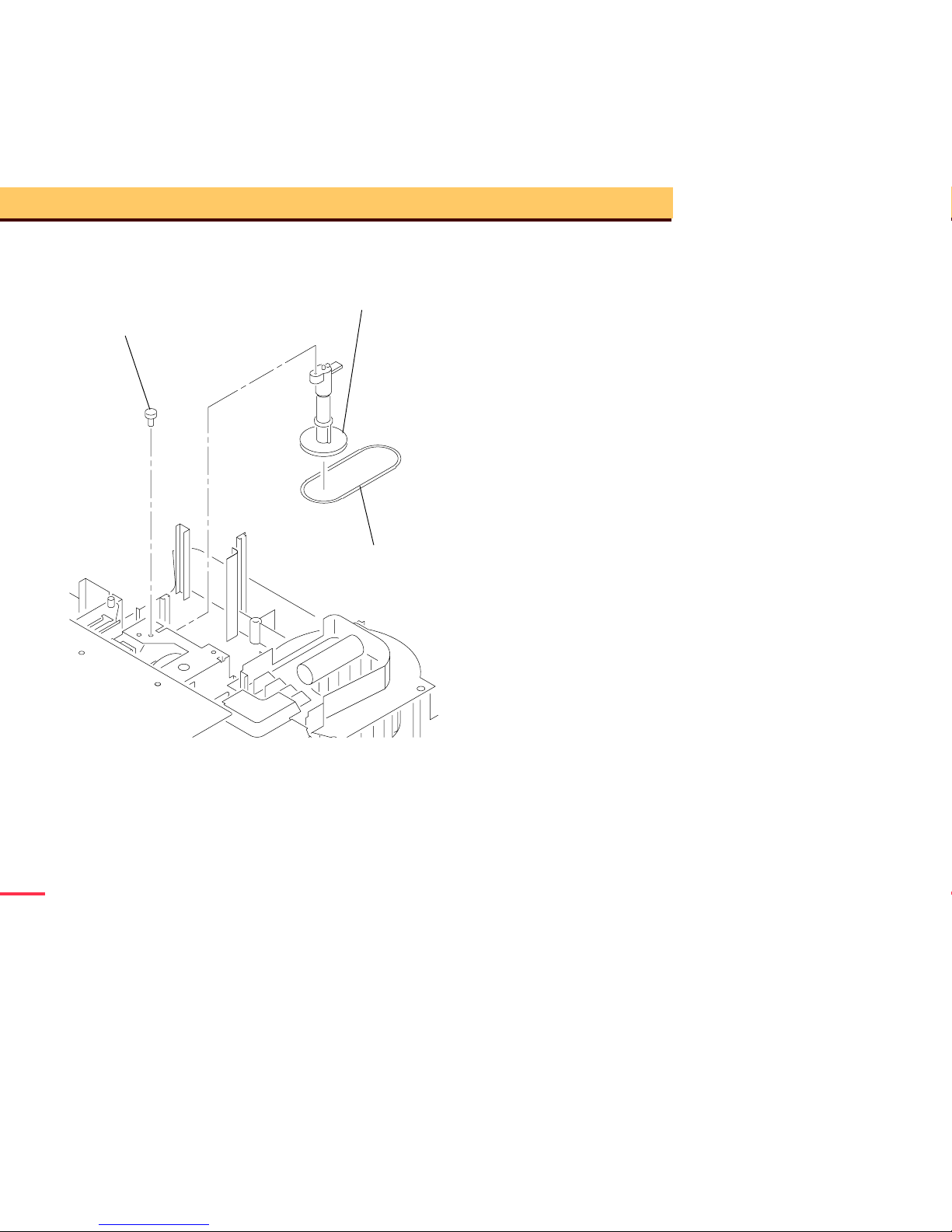

A091_4018GA

(not shown)

SWITCH

INTERLOCK

PRE-HEAT

FUSE

THERMAL

A091_4018GCA

MAIN CIRCUIT BOARD

SWITCH

POWER

DUCT

SCREW

Page 17

Page 18

A091_4013HA

SCREW (not shown)

A091_4013HCA

ASSEMBLY

COVER

BLOWER

SCREW (2)

RECEPTACLE

MODULE

LAMP

DUCT

PRE-HEAT

Page 19

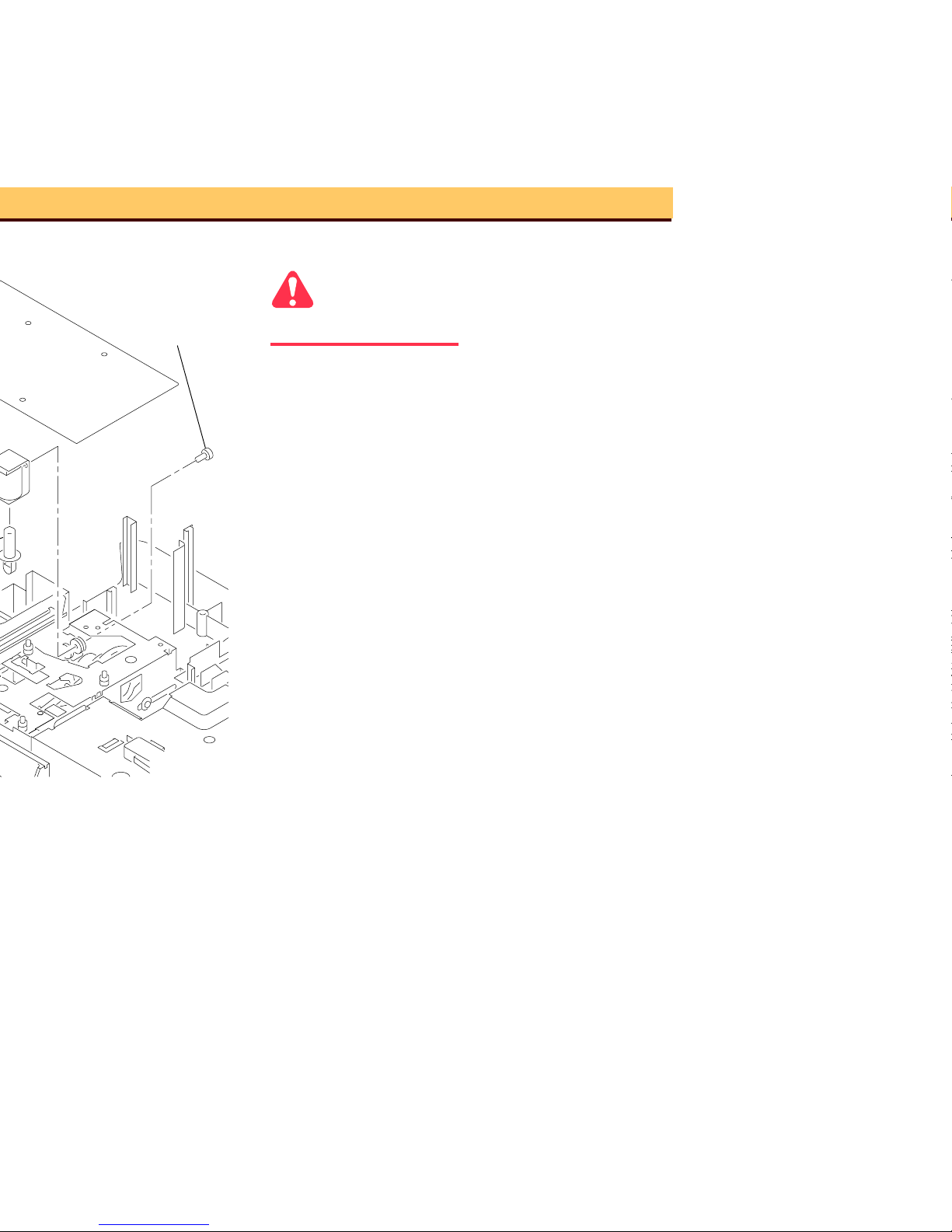

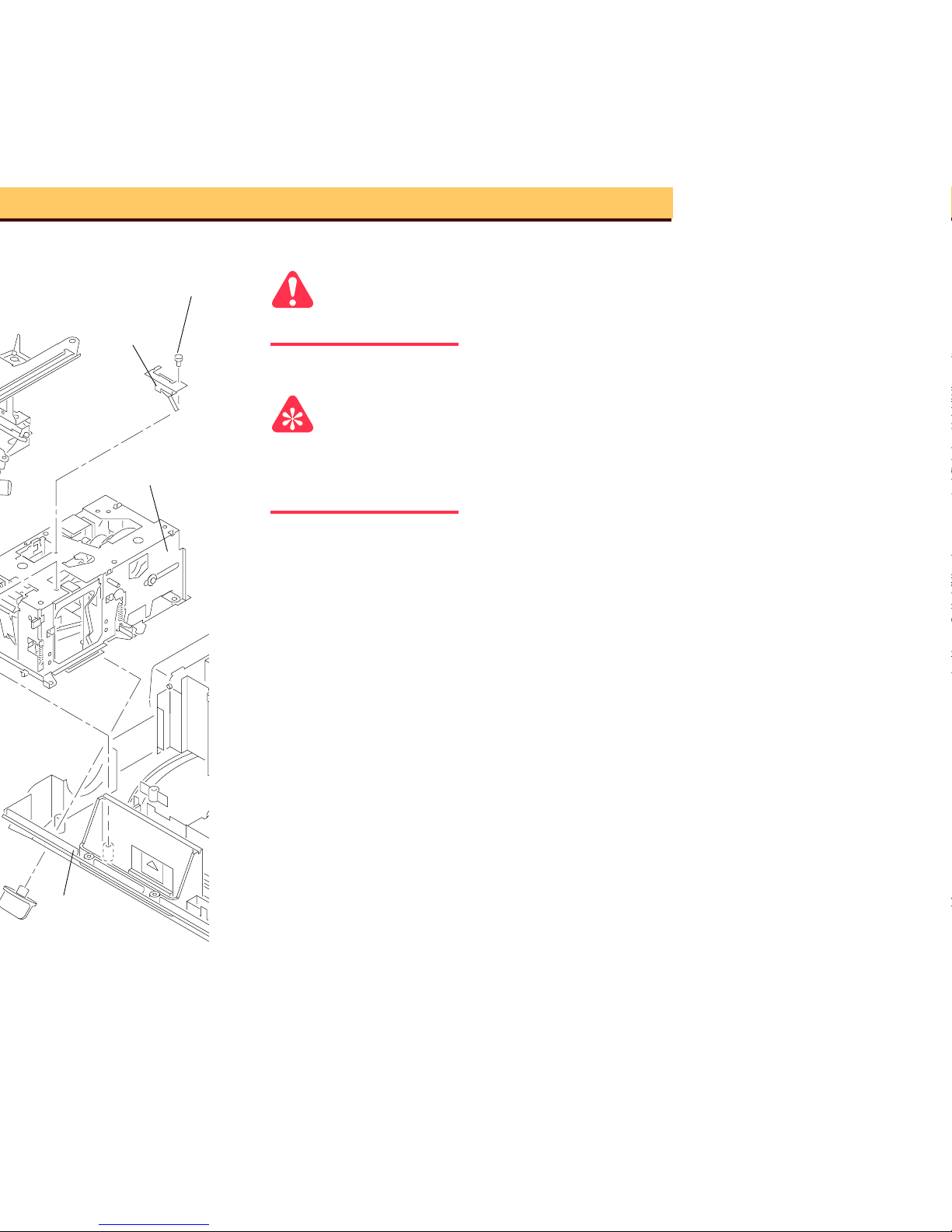

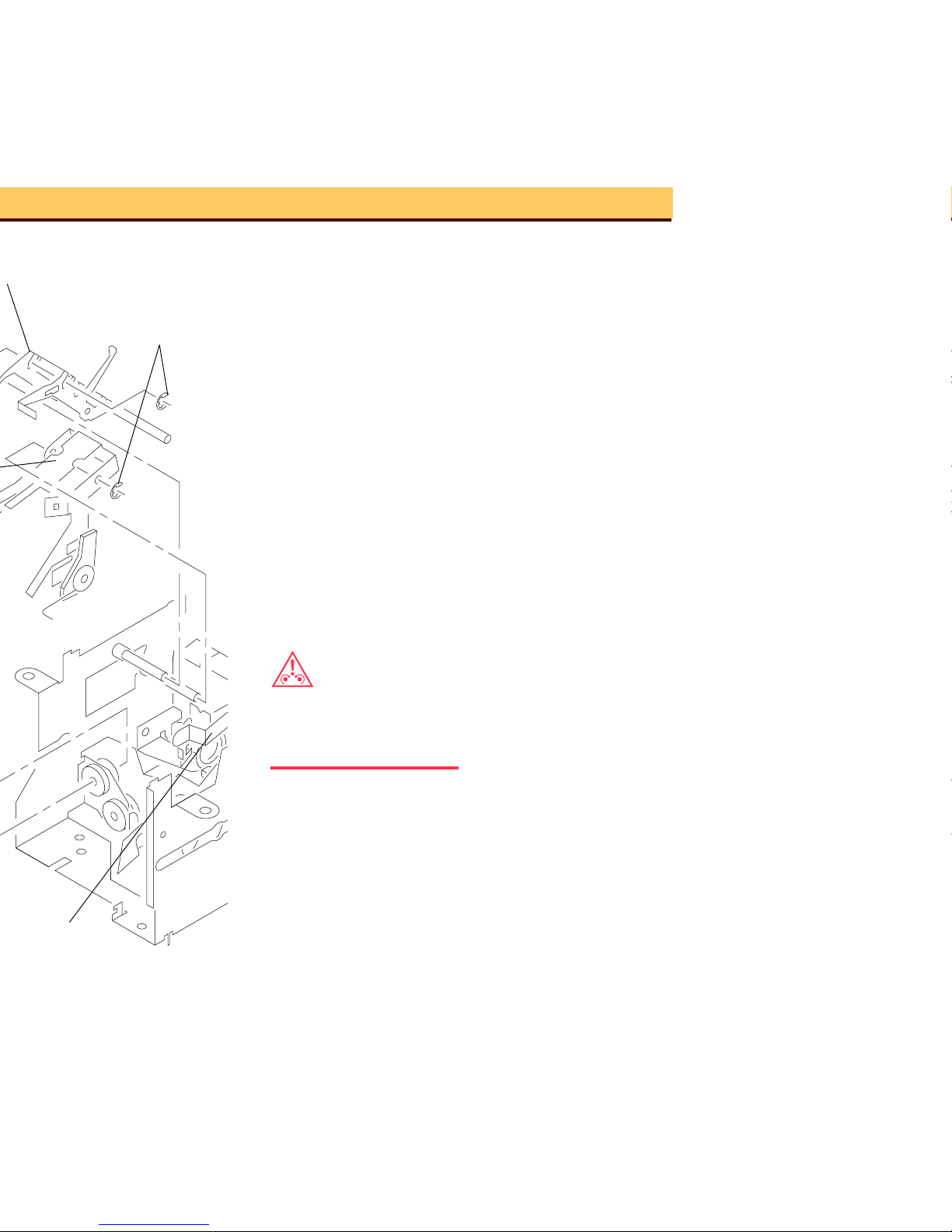

Warning

Dangerous Voltage

1 Disconnect the main power.

2 Do the removals for the LOWER

HOUSING ASSEMBLY and the

MOTOR.

3 Disconnect the 3 CONNECTORS on

the MAIN BOARD. It is not necessary to

disconnect the CONNECTORS next to

the LOWER LIGHT BAFFLE

ASSEMBLY.

4 Lift the MA IN BOARD up.

5 Cut and remove the necessary WIRE

TIES.

6 Disconnect t he 2 violet wires from the

CYCLE SOLENOID on the SMALL

BOARD.

7 Pull the SMALL BOARD up.

8 Remove the Torx SCREW from the

WORM PULLEY SHAFT.

9 Move the TAB on the WORM PULLEY

ASSEMBLY out of the MECHANISM

ASSEMBLY.

10 Lift and remove the WORM PULLEY

ASSEMBLY.

A091_4014GA

A091_4014GCA

SCREW (2)

Page 20

Page 21

Warning

Dangerous Voltage

1 Disconnect the main power.

Important

The Models Style 2 1500 and 2000 have a

DARK SHUTTER SWITCH and AUTO

FOCUS SHUTTER DEFEAT SWITCH.

2 Do the removal for the LOWER

HOUSING ASSEMBLY.

3 Disconnect the 3 CONNECTORS on

the MAIN BOARD. It is not necessary to

disconnect the CONNECTORS next to

the LOWER LIGHT BAFFLE

ASSEMBLY.

4 Lift the MA IN BOARD up.

5 Cut and remove the necessary WIRE

TIES.

6 Disconnect t he 2 violet wires from the

CYCLE SOLENOID on the SMALL

BOARD.

7 Pull the SMALL BOARD up.

SWITCH

DARK

SHUTTER

ASSEMBLY

MECHANISM

(not shown)

DEFEAT SWITCH

AUTO FOCUS

SCREW (3)

SCREW

Page 22

Page 23

Page 24

A091_4023BA

ASSEMBLY

BRACKET

FOCUS

AUTO

SCREW (2)

SCREW

A091_4023BCA

PULLEY

WORM

Page 25

Page 26

A091_0011DA

TOP LIGHT

BAFFLE

TOP PLATE

A091_0011DCA

SELECT LEVER SPRING

INDEXER

ASSEMBLY

LEVER

SCREW (7)

LIFT LEVER

SPRING

SCREW

Page 27

A091_0010HA

A091_0010HCA

TAB

LIFT

LEVER

BEARING

NUT

E-RING

E-RING

BEARING

LIFT LEVER SHAFT

Page 28

19 Remove the 2 SCREWS from the

CYCLE SOLENOID.

20 Remove the CYCLE SOLENOID.

21 Slide the PLUNGER a nd PLUNGER

SPRING off the CYCLE LEVER.

22 Remove the HALF CYCLE SPRING

between the CYCLE LEVER

ASSEMBLY and the HALF CYCLE

LEVER.

23 Disconnect the INDEX LEVER SPRING

from the MECHANISM ASSEMBLY.

24 Push the INDEX LEVER back.

25 Remove the 2 E-RINGS:

• 1 on the CYCLE LEVER ASSEMBLY

• 1 on the HALF CYCLE LEVER

Caution

Keep both the CYCLE LEVER ASSEMBLY

and the HALF CYCLE LEVER together and

observe the orientation of both LEVERS.

26 Slide both the CYCLE LEVER and

HALF CYCLE LEVER off the SHAFT.

A091_0009CA

and SPRING

INDEX LEVER

(not shown)

A091_0009CCA

E-RING (2)

Page 29

Page 30

Warning

Dangerous Voltage

1 Disconnect the main power.

Important

The EXTRA BRIGHT LAMP MODULE does

not have a HEAT ABSORBING GLASS and

has a LABEL on the LAMP DOOR.

2 Remove the LAMP MODULE.

3 Remove the PROJECTION LAMP from

the LAMP MODULE.

4 Remove the SCREW from the LAMP

DOOR PLATE ASSEMBLY.

A091_0018CA

LAMP DOOR

LAMP

LAMP

HEAT ABSORBING

PLATE ASSEMBLY

PROJECTOR

EJECTOR

ASSEMBLY

TERMINAL

LAMP SOCKET

GLASS

A091_0018CCA

LENS

CONDENSER

Page 31

Page 32

Warning

Dangerous Voltage

1 Disconnect the main power.

2 Do the removal for the LOWER

HOUSING ASSEMBLY.

3 Disconnect the 3 CONNECTORS on

the MAIN BOARD. It is not necessary to

disconnect the CONNECTOR next to

the LOWER LIGHT BAFFLE

ASSEMBLY.

4 Lift the MA IN BOARD up.

5 Remove the FOCUS KNOB.

6 Remove the shor t, gray wire connected

to the AUTO-FOCUS DEFEAT

SWITCH.

Important

It is necessary to push the AUTO-FOCUS

BRACKET backward and forward to allow

access to the SCREWS on the LENS

MOUNT ASSEMBLY.

7 Remove the 3 SCREWS from the LENS

MOUNT ASSEMBLY.

8 Lift and remove the LENS MOUNT

ASSEMBLY.

LENS

MOUNT

ASSEMBLY

SCREW (3)

Page 33

Warning

Dangerous Voltage

1 Disconnect the main power.

2 Do the removal for the LOWER

HOUSING ASSEMBLY.

3 Disconnect the 3 CONNECTORS on

the MAIN BOARD. It is not necessary to

disconnect the CONNECTOR next to

the LOWER LIGHT BAFFLE

ASSEMBLY.

4 Lift the MA IN BOARD up.

5 Remove the FOCUS KNOB.

6 Remove the 3 SCREWS from the LENS

MOUNT ASSEMBLY.

7 Lift and remove the LENS MOUNT

ASSEMBLY.

ASSEMBLY

MOUNT

LENS

Page 34

Warning

Dangerous Voltage

1 Disconnect the main power.

Important

There is no AUTO-FOCUS SWITCH

ASSEMBLY on the Models 500 and 1000.

2 Do the removal for the LOWER

HOUSING ASSEMBLY.

3 Disconnect the 3 CONNECTORS on

the MAIN BOARD. It is not necessary to

disconnect the CONNECTOR next to

the LOWER LIGHT BAFFLE

ASSEMBLY.

4 Lift the MA IN BOARD up.

5 Remove the FOCUS KNOB.

6 Remove the short, gray wire from the

AUTO-FOCUS DEFEAT SWITCH.

A091_4028GA

wires

and black

grey, red,

A091_4028GCA

Page 35

Page 36

Page 37

A091_4029HA

ASSEMBLY

AUTO-FOCUS

SWITCH

SPRING

CLAMP LEVER

LENS SUPPORT BRACKET

SCREW

A091_4029HCA

SOLENOID

PLUNGER

RACK

FOCUS SHAFT

SCREW

SPRING

SCREW

Page 38

Page 39

A091_0020HA

SCREW

BRACKET

LENS SUPPORT

SCREW

A091_0020HCA

FOCUS SHAFT

SPRING

Page 40

Page 41

A091_0007HA

CYCLE

BAR

A091_0007HCA

ASSEMBLY

MECHANISM

Page 42

position 1 position 2

A091_0008HA

MECHANISM

ASSEMBLY

TOP PLATE

Bend

here.

A091_0008HCA

Page 43

A091_0016BA

SELECT

A091_0016BCA

(not shown)

LEVER

SLIDE LIFT

LEVER

Page 44

A091_0016BA

SELECT

A091_0016BCA

(not shown)

LEVER

SLIDE LIFT

LEVER

Page 45

Important

It is necessary use make a 5/16 in.

WRENCH to do this adjustment.

1 Energize the projector.

2 Connect the DIGITAL VOLT METER

(DVM) between PINS B5 and B6 of the

12 PIN APPLICATIONS PLUG.

3 With no TRAY installed, the DVM

should measure •.

4 Install a TRAY.

5 To move the TRAY out of the zero

position, press the “FORWARD” or

“REVERSE” BUTTONS; the DVM

should measure 0 W.

6

5

4

3

a

b

A091_4021AA

A091_4021ACA

Page 46

6 If the measur ements are not with in

specification, adjust the ZERO

POSITION SWITCH ECCENTRIC to

specification.

A091_0017GA

NUT

A091_0017GCA

SWITCH

ZERO POSITION

Page 47

Page 48

A091_4026HA

A091_4026HCA

Page 49

Page 50

TL-3002

TARGET SLIDE

AUTO-FOCUS

light path

NULL position

PAD

CLAMP LEVER

TAB

T-BAR

TL-3003

Page 51

Warning

Dangerous Voltage

1 Disconnect the main power.

2 Do the removal for the LOWER

HOUSING ASSEMBLY.

Important

It is necessary to use a FAN COVER TOOL.

3 Install the FAN COVER TOOL over the

FAN area and the LAMP MODULE.

4 Energize the projector.

5 Set the projector to the LO-LAMP

position.

6 Install and hold the AUTO FOCUS

TA RGET SLIDE TL-3002 until it is fully

seated in the GATE MECHANISM.

7 Look through the PROJECTION LENS

hole and observe the focus light path

on the AUTO-FOCUS TARGET SLIDE

TL-3002. Check that the light path is

correct. If not, do the adjustment for the

FOCUS LIGHT PATH.

A091_4032GA

CIRCUIT BOARD

PHOTOCELL

PHOTOCELL

HOUSING

A091_4032GCA

PHOTOCELL

MASK

FILTER (2)

wratten

Page 52

11 Install the FAN CAP 232729 in the

PHOTOCELL HOUSING.

A091_4033GA

A091_4033GCA

FAN CAP

Page 53

light path

PAD

CLAMP LEVER

TAB

NULL position

Page 54

A091_4030BA

T-BAR TL-3003

light image

FAN CAP

CLAMP PAD

ASSEMBLY

A091_4030BCA

hole

Page 55

Warning

Dangerous Voltage

1 Disconnect the main power.

2 Do the removal for the LOWER

HOUSING ASSEMBLY.

Important

It is necessary to use a FAN COVER TOOL.

3 Install the FAN COVER TOOL over the

FAN area and the LAMP MODULE.

4 Connect the REMOTE CONTROL

ASSEMBLY to the REMOTE

RECEPTACLE.

A091_4041GA

A091_4041GCA

Page 56

Page 57

A091_0013GA

SHUTTER

DARK

PAD

PRESSURE

A091_0013GCA

Page 58

Page 59

A091_4037GA

Page 60

A091_0021GA

Page 61

A091_0023HA

Page 62

A091_0022DA

Page 63

DIGITAL MULTIMETER

Page 64

11.5 cm

(4.5 in.)

A091_0024GA

TOOL

A091_0024GCA

COVER

FAN

Cut here.

Page 65

100, 115, 130, 220, 240 V, 50/60 HZ

TRAY

• Width: 238 mm (12.93 in.)

• Length: 295 mm (11.6 in.)

• The EXTRA BRIGHT MODULE

has a 30% increa se in lumen

output.

• EXR 82 V, 300 W, 35 hours

average life

• EXW 82 V, 300 W, 15 hours

average lamp life

• FHS 82 V, 300 W, 70 hours

average life

• EXY 82 V, 300 W, 200 hours

average life

Page 66

• Lowest corner t o center ratio is

55% minimum

• Te st met ho d

• Ektagraphic

• 102 mm, F/2.8 LENS aperture (24

x 36 mm), compatible with

European specification DIN 19027

low

• 49 × C (120 × F), 15% humidity in

high

• 21 - 27 × C (70 - 80 × F), 20 -

60% humidity op timum

BTUs of heat per hou r

specifications (TS 172)

specifications (TS 218)

Page 67

detachable

• Heat sensitive interrupt fuses

• 117 C ° LAMP THERMAL FUSE

• 169 C ° MOTOR THERMAL

FUSE

• 150 C ° TRANSFORMER

• SAFETY INTERLOCK SWITCH,

deenergizes projector when the

LAMP MODULE is removed.

maximum leakage current is 2.5 mA.

• Operates between th e following

times:

– Fast = 3 ± 1 second

– Slow = 22 ± 6 seconds

assembly.

Page 68

the auto-focus system will adjust

for the difference in the slide

position from slide to slide. This

focus adjustment will occur within

1 second after the slide is

inserted into the GATE.

• The focus adjustment variation

should not change from the focus

and reverse specifications by

more than 3 times the focus and

reverse specifications.

hours or 2,000,000 cycles. The

projector has a MTBF (mean time

between failures) of 7500 op eration

hours.

service person is r ecommended

every 1500 hours of operation, or

after 1 year.

Eastman Kodak Company to operate

correctly for one year from the date

of purchase.

Used for internal and external LAMP

control. The LAMP POWER SWITCH

must be set on either the LO/HI

position in th e “INT” position.

Page 69

• PIN 1 - Connected to PIN 3 =

Reverse

• PIN 2 - Connected to PIN 3 -

Forward

• PIN 3 - 25.5 V AC when used

with PIN 6

• PIN 4 - FOCUS MOTOR

• PIN 5 - FOCUS MOTOR

• PIN 6 - Used with PIN 3 for 25.5

V AC

• A1 - 25.5 V ac when c onnected to

B4

• A2 - No connection

• A3 - 25.5 V AC with a 2.7 K W

impedance load when used with

A4 (DISSOLVE CONTROL)

• A4 - Used with A3

• A5 - 24 V dc when co nnected to

B4

• A6 - SHUTTER SWITCH

• B1 - SHUTTER SWITCH

• B2 - When connected to B4 for

Reverse SLIDE TRAY

• B3 - When connected to B4 for

Forward SLIDE TRAY

• B5 - ZERO POSITION SWITCH

• B6 - ZERO POSITION SWITCH

Page 70

PIN Color

12

11

10

9

8

7

A091_0006BA

brown

white

black

84.2 V

1.6

117 V AC

6.1

LAMP VOLTAGE is

74 V AC

between brown

and white for

LONG LIFE MODELS

A091_0006BCA

Page 71

PIN Voltage

6

5

4

3

2

1

a

b

A091_4021AA

12-PIN APPLICATION PLUG

A091_4021ACA

Page 72

SWITCH

SWITCH

SWITCH

Page 73

PINS Voltage

1

2

3

A091_4036AA

A091_4036ACA

PHOTOCELL

Page 74

CABLE

CONNECTOR

1

2

3

4

5

6

GRAY

BLACK

FOCUS

1

2

3

46

5

S3

RED

YELLOW

25.5 VOLTS AC

LED

R1

2.7 K

GREEN

FWD

S2

A091_0001BA_

Page 75

A091_4034DC

J2

J1

SLIDE PROJECTOR BOARD

Q4

++

Q3

CR6

R15

R14

R13

R10

R11

R12

C2

C3

C4

R17

CR1

R5

R6

R4

Q1

CR3

C5

CR4

R7

F1

CR5

RYGNRWW

YBOVVARKWBW

Page 76

(-)

33.0 V dc

CR4 Red (+) 18.7 V dc

CR4 Black (-)18.7 V dc

Page 77

CR5

CR8

CR9

CR10

CR1

R 9

R 8

R 10

R 2

CR11

CR3

CR4

Q 4

R 4

CR7

CR6

R 7

U 2

R23

R27

R25

R11

R29

U 1

Q 9

C1

CR20

R26

CR17

CR16

R22

R13

Q 7

Q 8

Q 6

R21

R20

R18

R17

R19

Q 5

V101

C 3

VR1

R14

R15

R6

Q 2

CR2

Q 1

R16

C2

CR15

CR14

CR13

CR12

R12

R5

A091_4039DA

Q11

R28

F101

Page 78

MOTOR

INTERNAL setting

is a short•circuit at Q11,

the LAMP will stay on in

the EXT setting)

Page 79

FOCUS TRANSISTOR

(EBC - EMITTER, BASE, COLLECTOR)

(projector ON)

(reverse focus)

(projector ON)

(reverse focus)

(projector ON)

(forward focus)

(projector ON)

(forward focus)

BUTTON.

39 Ω, 18.7 V dc

Page 80

85-86 V ac without a

LAMP MODULE

installed

position.

3.0 Ω, 10.6 V ac drop

across

POWER FUSE, THERMAL

FUSE ASSEMBLY, and MOTOR

FUSE.

2. Check VARISTOR V101 on the

MAIN BOARD for damage.

VARISTOR V101 is damaged if

the voltage is not in the correct

position, for example, if the

voltage is set at 130 V when it

is necessary to operate at 240

V.

3. Check that the pr imary voltage

on the MAIN MOTOR is correct.

4. Check that the voltage on

POWER SWITCH is correct.

1. Check that the FAN BELT is not

broken.

2. Check and remove obstructions

in the FAN area.

Page 81

1. Check and remove obstructions

in the FAN area.

2. Check that the te nsion is c orrect

on the FAN BELT.

3. Check that the FAN BELT is

clean.

4. Check the condit ion of the

BEARING in the FAN

ASSEMBLY.

Page 82

1. Check the LAMP ASSEMBLY for

damage.

2. Check the LAMP RECEPTACLE

ASSEMBLY for damage.

3. Manually actuat e the

INTERLOCK SWITCH, then

check that the voltage is correct

across the LAMP RECEPTACLE

ASSEMBLY. If you do not

manually actuate the

INTERLOCK SWITCH, there will

be no voltage across the LAMP

RECEPTACLE ASSEMBLY.

4. Check that the voltage is corre ct

across the TRIAC on the MAIN

BOARD.

5. Check the LAMP TERMI NAL

ASSEMBLY in the LAMP

MODULE ASSEMBLY for

damage.

6. Check the “EXT/INT” SWITCH;

it should be in the “INT”

position.

• For 2000 PROJECTORS

Only: All THERMAL FUSES

and the LAMP MODULE

operate correctly.

Page 83

DROPPING RESISTOR is 3 W.

2. Check that the wire connections

on the POWER SWITCH are

correct.

3. Check the POWER SWITCH for

correct operation.

1. Check the DARK SHUTTER for

correct operation. See the

adjustment for the DARK

SHUTTER.

2. Check the LIGHT BAFFLE in

the MECHANISM for damage; it

should not cause a jam in the

SHUTTER.

Page 84

1. Check that the secondary voltage

on the MAIN MOTOR is correct.

2. Check that the voltage across the

CYCLE SOLENOID is correct.

3. Check that th e W across th e

CYCLE SOLENOID COIL are

correct.

1. Check that the CYCLE LEVER

and RATCHET PLATE are clean.

Clean and lubricate the parts as

necessary. Use SUPER LUBE TL-

4276.

2. Install a new CAM STACK

ASSEMBLY; the malfunction is

within the CAM.

1. Do the adjustment for the CYCLE

SOLENOID.

2. Check that the DIRECTION

LEVER SPRING is on the

DIRECTION LEVER.

3. Check the DIRECTION LEVER

for binds. Excessive lubrication

and dirt can cause binds.

Page 85

1. Check for a broken MECHANISM

DRIVE BELT.

2. Check the CYCLE LEVER and

RATCHET LEVER on the CAM

SHAFT ASSEMBLY for the

following:

• correct alignm ent of the

CYCLE LEVER

• damage to parts

• lubrication of the CYCLE

LEVER (use SU PER LUBE

TL-4276)

3. Check the CYCLE SOLENOID for

correct operation. See the Voltage

chart.

Page 86

correct alignment. See the

adjustment for the CYCLE

LEVER.

2. Check for damage to par ts.

3. Check for a shor t•circuit in the

wires:

• Use a tool to hold the CYCLE

LEVER down on the

RATCHET LEVER. If there is

a short•circuit causing the

malfunction, the SOLENOID

will be energized. If there is a

bind, the CAM will not rotate.

4. Check that the CAM SHAFT

ASSEMBLY RATCHET SPRING is

installed correctly.

The CYCLE LEVER and t he

RATCHET PLATE are d irty. Clean

and apply lubricant SUPER LUBE

TL-4276 to the CYCLE LEVER and

RATCHET PLATE. If this does not

correct the malfunction, install a new

CAM SHAFT ASSEMBLY.

Page 87

1. Check the SLIDE TRAY LATCH

for correct alignment.

2. Operate the pr ojector in the

forward direction.

• Check that the INDEXER

LEVER ASSEMBLY is in the

correct alignment with the

holes at positions A and B.

• Do the adjustment for the

INDEXER LEVER ASSEMBLY.

• Check the condition of the

LOCATOR LEVER, it should

not be bent.

• Check the height of the SLIDE

LIFT LEVER; the lower corner

of the LIFT LEVER LAMP is

parallel with the TOP

HOUSING. If the height is not

correct, do the adjustment for

the MANUAL and POWER

SLIDE LIFT LEVER

ECCENTRICS.

1. Do the adjustment for the CYCLE

SOLENOID.

2. Check for a bind in the

DIRECTION LEVER ASSEMBLY.

3. Check that the DIRECTION

LEVER LINK is in the correct

position.

Page 88

1. Press and release the SELECT

BUTTON.

• Check that the LOCATOR

LEVER moves correctly and is

not bent.

2. Press and hold the SELECT

BUTTON down.

• Check the SLIDE LIFT LEVER

RAMP for damage.

3. Check the height of the SLIDE

LIFT LEVER; the lower corner of

the LIFT LEVER LAMP is parallel

with the TOP HOUSING. If the

height is not correct, do the

adjustment for the MANUAL and

POWER SLIDE LIFT LEVER

ECCENTRICS.

1. Check the VARIABLE RESISTOR

for correct operation and inst all a

new part if necessary.

2. Move the TIMER BUTTON

forward and backward; use a

DVM to check for changes in W.

3. Energize the projector and move

the TIMER to “S”.

• Check the voltages on CR3,

Q3, and Q4, see the voltage

table.

Page 89

1. Energize the projector and

release the DARK SHUTTER to

allow projection.

2. Check for continuity between

PINS A6 and B1 on the 12-PIN

DISSOLVE PLUG.

3. Press the “FORWARD” or

“REVERSE” BUTTONS to close

the DARK SHUTTER.

4. In the closed position, the DVM

should measur e 0 W.

5. If this procedure does not correct

the malfunction, install a new

DARK SHUTTER SWITCH.

Page 90

1. De-energize the projector.

2. Check for continuity between PIN

B5 and B6 on the 12-PIN

DISSOLVE PLUG.

3. Install a SLIDE TRAY.

4. Rotate the SLIDE TRAY to

engage the ZERO POSITION

SWITCH, the DVM should

measure 0 W.

5. If the W measurement is not

correct, see the adjustment for the

ZERO POSITION SWITCH. Install

a new ZERO POSITION SWITCH

if necessary.

1. Remove R3 and install a new 68K

W 1/4 W RESISTOR (part

220040).

2. If there is still a malfunction,

install a new PHOTOCELL.

Page 91

SPRING for the correct tension.

2. Check the LENS SUPPORT

SPRING for correct tension.

3. Check the LENS DRIVE GEAR on

the FOCUS SHAFT ASSEMBLY

for damage and install a new part

if necessary.

1. Check the REMOTE CORD for

damage; use a REMOTE CORD

that has no damage.

2. Actuate and hold the REMOTE

CONTROL.

3. Check that the voltage across the

FOCUS MOTOR is correct.

4. Check that the secondary voltage

on the MAIN MOTOR is correct.

This condition will occur only when

the MAIN MOTOR is operating at the

same time you connect the REMOTE

CONTROL. It will not occur if the

MAIN MOTOR is not operating. This

is a normal condition; there is no

procedure to cor rect this condition.

Page 92

1. Check that the REMOTE CORD

operates correctly; use a

REMOTE CORD you know is

good.

2. Actuate and hold the REMOTE

CONTROL.

3. Check that the voltage across the

FOCUS MOTOR is correct.

4. Check the AUTO FOCUS

SWITCH ASSEMBLY for correct

operation.

5. Check the secondary voltages on

the MAIN MOTOR.

Page 93

1. Check that the AUTO-FOCUS

DEFEAT SWITCH is in the “ON”

position.

2. Check that the MAIN

PROJECTION LAMP operates

correctly.

3. Insert the TARGET SLIDE TL-

3002 in the GATE MECHANISM.

• Check that the TA RGET is

correctly aligned. If not, see

the Adjustment section.

4. Check that the voltages across the

PHOTOCELL are correct. The

voltage from 1 to 2 is 14.5 V ac.

The voltage from 2 to 3 is 14.5 V

ac. The voltage from 1 to 3 is 29

V ac.

5. Make a short• between 1 and 2;

the FOCUS MOTOR should rotate.

6. Make a short•circuit between 2

and 3; the FOCUS MOTOR

should rotate in the reverse

direction.

7. If the FOCUS MOTOR operates

correctly, install a new

PHOTOCELL. If the FOCUS

MOTOR does not op erate

correctly, measure the voltages on

the BOARD.

Page 94

1. Check that the alignment of the

FOCUS LIGHT PATH and NULL is

correct.

2. Check the resolution of the

FOCUS LIGHT PATH. Clean the

AUTO FOCUS MIRROR and

BRACKET ASSEMBLY.

3. Install a new PROJECTION LAMP

if necessary.

4. Install a new PHOTOCELL.

5. Check the components on the

BOARD for damage.

Page 95

1. Install the TARGET SLIDE TL-

3002 in the GATE MECHANISM.

2. Check that the alignment of the

TA RGET and NULL is correct. If

not, see the Adjustments section.

3. Check for a light leak:

• Install a different LAMP

MODULE ASSEMBLY. If the

FOCUS MOTOR stops

operating continually, install a

new LAMP MODULE

ASSEMBLY.

4. Check that the voltages across the

PHOTOCELL are correct. The

voltage from 1 to 2 is 14.5 V ac.

The voltage from 2 to 3 is 14.5 V

ac. The voltage from 1 to 3 is 29

V ac.

5. Check that the PHOTOCELL

HOUSING has 2 FILTERS.

6. Install a new PHOTOCELL.

7. Check the components on the

BOARD for damage.

Check that the wires of the AUTO

FOCUS MOTOR are in the correct

position; the blue wire goes to the

mark on the AUTO FOCUS MOTOR.

Do the adjustment for the CLAMP

LEVER ASSEMBLY.

Page 96

Kodak and Ektalite are trademark s.

Loading...

Loading...