Page 1

ASSEMBLY INSTRUCTIONS

DALLAS FENCE

ITEM : 000001 VER : 0 USA

IMPORTANT: You must read these instructions carefully before you start to assemble this fence. Please carry out the steps in the order set out in these instructions.Keep these instructions

in a safe place for future reference.

GENERAL INFORMATION: The Keter Fence is easy to install. We incorporate methods and procedures used by professional installers to guide you through to the successful

completion of your fence.

GENERAL ADVICE: This is a 2 person assembly job.If it is a property line fence, you will want to confirm your property lines

before ordering your fence.The component parts should be checked and laid out in an orderly way, close at hand.Keep all small parts

(screws, etc.) in a bowl so that they do not get lost.

Please keep the tracking number which appears on the box, and refer to this number when calling the service office for questions or complaints.

CARE & MAINTENANCE :When your fence needs a clean, use a mild detergent solution and rinse with cold clean water.

DO NOT use acetone, abrasive cleaners or other special detergents to clean the fence.

For general support and replacement parts, please contact :

U.S: Call Toll Free:1-(888)-374-4262 , fax 317-575-4502, 11495 North Pennsylvania ST., Suite 110 Carmel, Indiana, 46032, U.S.A

Canada: Tel: 514-7486-721 , Fax: 514-7487-793 , E-mail: jessicaz@accenthome.com

United Kindom: Keter (UK) Ltd. Unit 4, Woodgate Business Park, Clapgate Lane, Birmingham, B32 3DB, United Kindom. Tel: 0121-5060008, Fax: 0121-4220808

The Netherlands: Keter Benelux, Ericssonstraat 17, Postbus 224, 5120 AE Rijen, The Netherlands. Tel: 31-1612-28301, Fax: 31-1612-28322

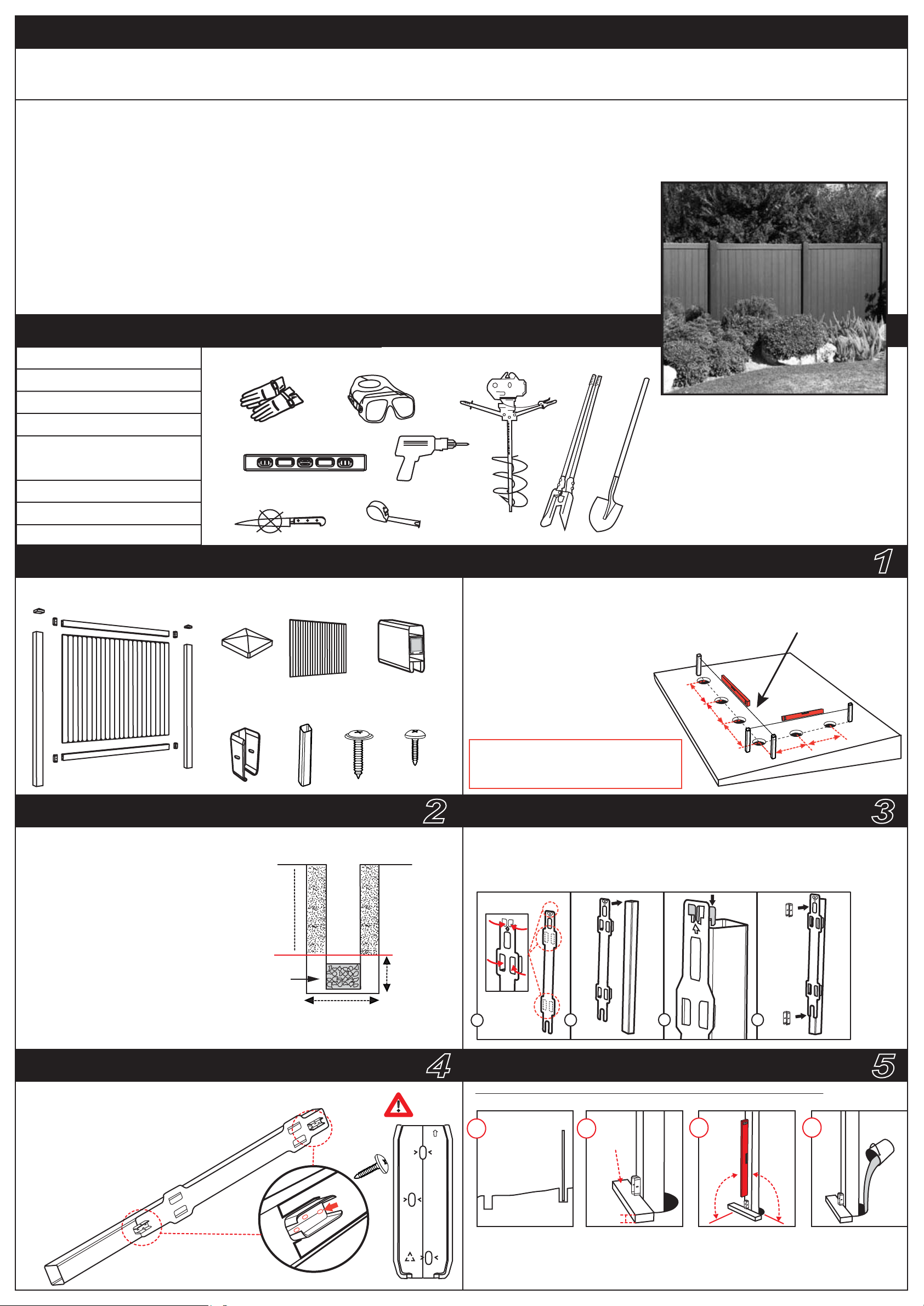

TOOLS & MATERIALS

string line

post hole digger / power auger

A-13-00 544993

mallet

work shoes

4 timber stakes

2”x 2”x24” (5cm x 5cm x 60cm)

concrete / dry mix

PARTS & DIMENSION

POST

CAP x2

BRACKET

x4

fcb

u

PANEL

x1

POST

x 2

SC35B x8

(1.4”)

RAILS

x 2

SC15 x12

(0.6”)

PROJECT PLANNING

1. Stake out fence from beginning to end.

.2. Estimate the ground level.

3. Start at the highest side of the fence line !

4. Dig hole under post line. make sure the

distance between holes centers is 6’ (183cm).

For fence sections that are less than the standard

6’ (183 cm) center-to-center, simply cut to size the

rails and the fence panels, using a power saw

(use metal fit blade).

.

183cm

6’

183cm

6’

183cm

6’

www.keter.co.il

String fence line to show

horizontal accuracy

6’

183cm

6’

183cm

1

GENERAL ADVICE ON POST HOLES POSITIONING GUIDE

Using post hole digger or power auger

or simple shovel dig the hole 12” (30cm)

in diameter. Main and gate posts should

be 6” (15cm) deeper for extra strength.

Backfill each hole with 6” of gravel to drain

water away.

(24”) 65cm hole depth

Gravel to reduce

frost HEAVE

Hole diameter (12”) 30cm

BRACKETS ASSEMBLY FIXING FIRST POST

1.

Attach two rail bracketsTS to One side of the posts

using the positioning guide.

2.Do not assemble brackets on both sides

of the post !

3.Locate all bracket screws on center

of elongated holes on bracket for

expansion and contraction.

The lip of the bracket

should be on the

bottom.

POST

TOP

X3

up

2

(6”) 15cm

below frost line

4

Top of

bracket

fcb

up

1. Use the positioning guide to place the brackets .

A. fold the positioning guide wings.

B. Attach the positioning guide to the post as shown.

C. Place the bracket within the positioning guide holes.

A

Place first post in the hole, checking that it satisfies ALL the following conditions:

START AT THE HIGHEST

GROUND POINT

A

GROUND

A. Position the first post at the highest ground point of the fence line !

B. Place 2’’ (5cm) timber, under the bracket to maintain the gap between the fence and the ground.

C. Check for VERTICAL in two directions.

D. Fill the hole with concrete leaving a slope for water drainage.

E. Allow concrete to set for 10-15 minutes

B

HEIGHT

B

TIMBER

2”

C D

VERTICAL

C

builder's

level.

o

90

3

5

ADD CONCRETE

D

o

90

Page 2

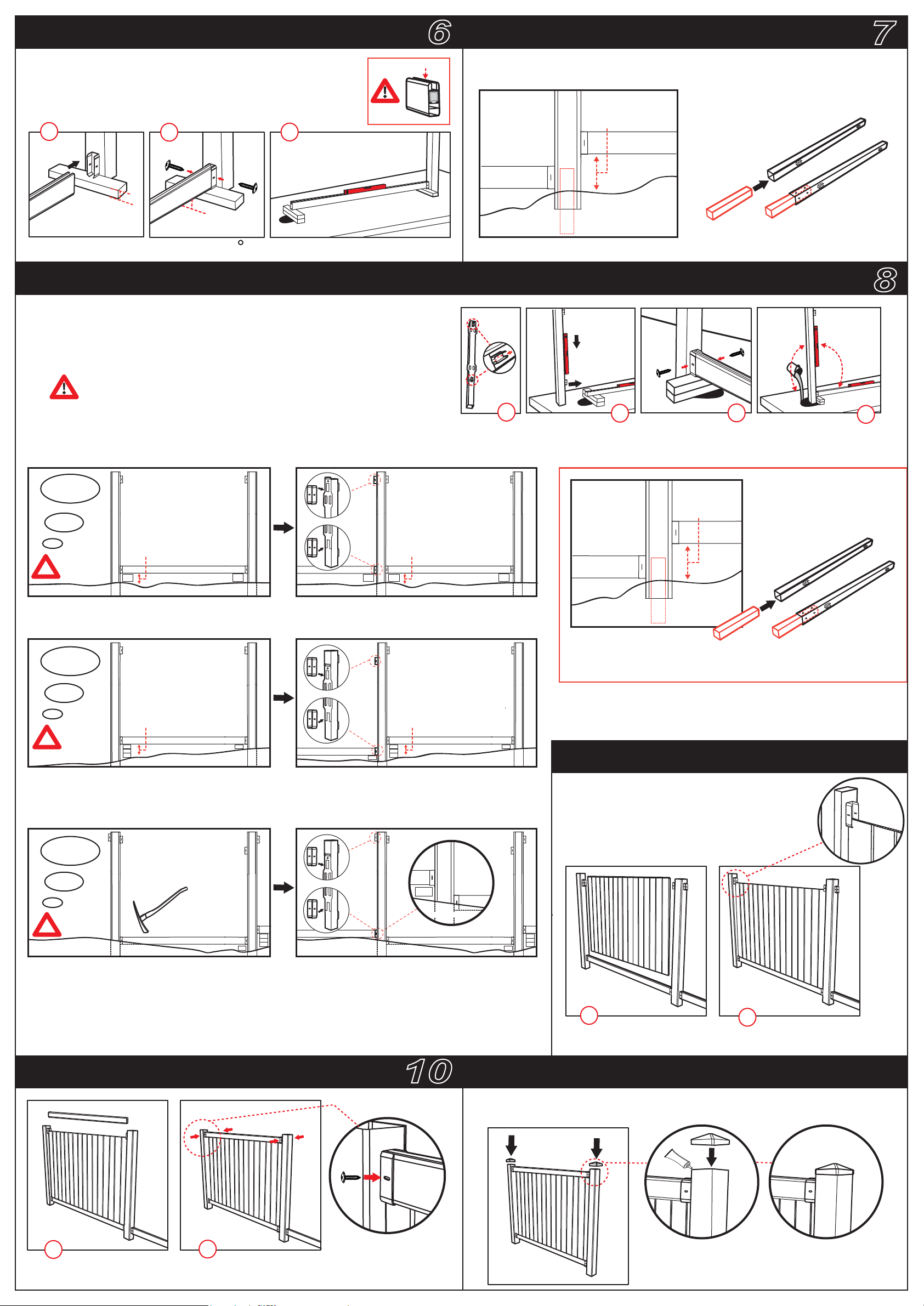

FIXING FIRST RAIL

6

EXTENDING THE POST

7

1. Place the lower rail in position.

2. Fix the rail to the post with 2 screws (SC35B), through the

bracket holes.

3. level the rail horizontely use a timber to support.

1

2”

(5cm)

2

2” (5cm)

3

This side up

The post must be at least 12” In ground if you have a slope that is over 12” you

must extend the post with timber as showen.

(30cm-50cm)

GROUND

Make sure the rail is leveled horizontly &90 to the second post

FIXING NEXT POST (Take into account level, downward and upward slopes)

1. Attach two brackets to the post using the positioning guide.

2. place the post in the hole

3. Fix the post to the rail with 2 screws (SC35B) , through the bracket holes.

4. Add Concrete use dry or mix concrete. Allow concrete to set for 10-15 minutes.

up

12”-20”

(use 4”/4”/24”,10cm/10cm/65cm timber 8 screw)

8

90

o

90

o

Verify that rail is leveled and post is vertical on both direction !

1

Position the brackets on the empty side (In continuation direction) of the post considering the 3 following

options: folow

option 1

Level

2nd post

2”-6” (5cm-15cm)

?

GROUND

2” -6” (5cm-15cm) place the positioning guide from top of the post & fix the brakets 3 screw (sc15) for each.

2nd post

2”-6” (5cm-15cm)

GROUND

option 2

Downward slope

2nd post

6”-12” (5cm-15cm)

2nd post

6”-12” (5cm-15cm)

2

12”-20”

(30cm-50cm)

If the distance is more then 12” you must extend the post

3

4

?

GROUND

6” (15cm) And up, place the lower bracket 2” (5cm) from ground use positioning guide for the second

bracket.

GROUND

option 3

Upward slope

3th post

?

GROUND

In the case of upward slope, connect the brackets 2” (5cm) up and/or position the new post

lower while digging a trench for the rail .

Make sure (using the positioning guide) that upper bracket on the left side is not out of the post top.

2nd post

GROUND

3th post

GROUND

INSTALLING FENCE SECTION

2nd post

1

1. Assemble the first panel into

the bottom rail.

2

2. Make sure the panel goes into

the brackets.

9

INSTALLING FENCE SECTION

1

Assemble the upper rail on

top of the panel.

2

Use two screws to fix the rail

to the bracket

10

X2

SCREW FROM

BOTH SIDES

ATTACH POST CAPS.

1.Press caps down on post top.

2. you can secure the caps with super glue

11

PP GLUE

Page 3

INSTRUCCIONES DE ENSAMBLADO

DALLAS 6x6

IMPORTANTE: debe leer estas instrucciones con atención antes de intentar armar esta cerca.

Siga estos pasos en el orden que se indica en las instrucciones, las cuales deberá guardar en un lugar seguro, para su futura referencia.

INFORMACIÓN GENERAL: la cerca KETER es fácil de instalar. Incorporamos métodos y procedimientos

empleados por instaladores profesionales para guiarlo mientras completa correctamente el armado de su cerca.

CONSEJOS GENERALES: esta tarea de armado requiere la intervención de 2 personas.

Si se trata de una cerca para delimitar una propiedad, le conviene confirmar cuáles son los límites de la misma antes de pedir su cerca.

Las partes componentes deben ser verificadas y tendidas en forma ordenada y debe tenerlas a mano.

Mantenga todas las partes pequeñas (tornillos etc.) en un recipiente, para no perderlos.

Conserve el número de guía [tracking number] que aparece en la caja y remítase a este número cuando llame a la oficina de servicio para hacer preguntas o reclamos.

CUIDADOS Y MANTENIMIENTO: cuando tenga que limpiar su cerca, utilice una solución detergente suave y enjuáguela con agua limpia y fría.

NO use acetona, limpiadores abrasivos u otros detergentes especiales para limpiar la puerta.

Para solicitar soporte en general y partes de reemplazo, comuníquese con el centro de atención al cliente de Accent Home Products:

EE. UU.: 1-888-374-4262

Canadá: 1-800-661-6721

Reino Unido:

Cordel

Taladro perforador / taladro de

tierra mecánico

0121-5060008

South America: Tel. +541145820777 / Fax +541154820188

Otros países europeos: 31-1612-28301

www.keter.com

HERRAMIENTAS Y MATERIALES

562625 A-1342 ES

Maza

Calzado de seguridad

4 maderos

2”x 2”x 24” (5 cm x 5 cm x 60 cm)

Cemento/mezcla seca

PARTES Y DIMENSIÓN

KIT DEL PANEL

PANEL

(x1)

BARANDAS

E INFERIOR/

SUPERIOR

(x2)

POSTE

(x1)

MÉNSULA

(x4)

fcb

u

KIT DEL POSTE

s35 (x8)

20 mm

TAPA DEL

POSTE (x1)

s18b (x12)

15mm

PLANTILLA

(x1)

PLANIFICACIÓN DEL PROYECTO

1. Delimite la cerca del principio al fin.

2. Calcule el nivel del suelo.

3. Comience por el lateral más elevado de la

línea de la cerca.

4. Cave un pozo debajo de la línea del poste.

Asegúrese de que la distancia entre

los centros de los agujeros

sea de 6’ (1,82 m).

Para aquellas secciones de la cerca que

sean más pequeñas que lo convencional,

es decir, menores a 6’ (182 cm) de centro

a centro, simplemente corte las barandas

y la cerca al tamaño adecuado, con una

sierra eléctrica (utilice una hoja metálica).

(1,82 m)

6’

(1,82 m)

6’

(1,82 m)

6’

1

Cordel / línea de la cerca

para demostrar la

precisión horizontal

6’ (1,82 m)

6’ (1,82 m)

RECOMENDACIONES GENERALES SOBRE

LOS POZOS PARA LOS POSTES

Con un taladro perforador, un taladro de tierra mecánico o una pala, cave un pozo de

12” (30 cm) de diámetro y 30” (75 cm) de

profundidad. Agregue 6” (15 cm) de grava

para el drenaje del pozo. Inserte el poste en el

centro del mismo. Nivele el poste y comprímalo

con firmeza dentro del pozo. Llene lo que resta

del pozo con cemento, de acuerdo con las

instrucciones de fábrica.

Profundidad del

pozo 24” (60 cm)

Grava para reducir los

DAÑOS por heladas

Diámetro del pozo

12” (30 cm)

MONTAJE DE LAS MÉNSULAS FIJACIÓN DEL PRIMER POSTE

1. Coloque las dos ménsulas de las barandas (fcb) en un lado de los postes.

2. No coloque las ménsulas en ambos lados del poste.

3. Coloque la guía de posicionamiento a 68” (172 cm)

de la parte superior del poste y luego coloque la ménsula.

4. Sitúe todos los tornillos s18b de las ménsulas

en el centro de los orificios alargados

de la ménsula, para la expansión y contracción.

El reborde de la ménsula debe estar

en la base.

68" (172 cm)

POST

TOP

X3

up

2

6” (15 cm)

debajo de la

línea de la

helada

4

Parte superior

de la ménsula

fcb

up

GUÍA DE POSICIONAMIENTO

A. Doble las aletas de la guía de posicionamiento (plantilla).

B. La guía de posicionamiento debe colocarse a 68” (172 cm) de la parte

superior del poste.

C. Coloque la guía de posicionamiento en el poste, tal como se muestra.

D. Coloque la ménsula dentro del agujero de la guía de posicionamiento.

A

Coloque el primer poste en el pozo, constatando que satisfaga TODAS las condiciones

mencionadas a continuación:

Punto más alto del suelo

A

SUELO

B

B

MADERO

2”

(5 cm)

ALTURA

C D

VERTICAL

C

Nivel

o

90

o

90

AGREGAR CEMENTO

D

3

5

A. Ubique el primer poste en el punto más alto del suelo de la línea de la cerca.

B. Coloque los maderos de 5 cm debajo de la ménsula; mantenga la separación entre la cerca y el suelo.

C. Revise la VERTICALIDAD en ambas direcciones.

D. Utilice cemento o mezcla seca y DÉJELO SECAR durante 10 minutos.

Page 4

FIJACIÓN DE LA PRIMERA BARANDA

6

EXTENSIÓN DEL POSTE

7

1. Coloque la baranda inferior en su posición.

2. Fije la baranda al poste con 2 tornillos s35, a través de los orificios de

la ménsula.

3. Nivele la baranda horizontalmente, utilizando un madero como ayuda.

1

2”

(5 cm)

Asegúrese de que la baranda esté nivelada horizontalmente a 90º respecto del segundo poste.

2

2”

(5 cm)

3

Este lado hacia arriba

El poste debe colocarse al menos a 12“ (30 cm) en el suelo. Si usted tiene una pendiente

mayor de 12“ (30 cm) debe extender el poste con el madero tal como se muestra.

Utilice un madero de 4”/4”/24” (11/11/60 cm)

Fije con el tornillo 8.

12”-20“ (

30-50 cm)

SUELO

FIJACIÓN DEL SEGUNDO POSTE (tenga en cuenta el nivel y la pendiente ascendente y descendente)

1. Coloque las dos ménsulas en el poste, usando la guía de posicionamiento.

2. Ubique el poste en el pozo.

3. Fíjelo a la baranda, con 2 tornillos (s35), a través de los agujeros de la ménsula.

4. Agregue cemento o mezcla seca. Espere unos 10-15 minutos hasta que el

cemento se endurezca.

Verifique que la baranda esté nivelada y que el poste

esté vertical en ambas direcciones.

up

1

2

3

90

o

90

8

o

4

NIVEL, PENDIENTE DESCENDENTE Y PENDIENTE ASCENDENTE

Ubique las ménsulas del lado vacío (en la dirección de continuación) del poste, considerando las siguientes 3 opciones:

Opción 1

2.º poste

2”-6” (5 cm-15 cm)

?

Si es de 5-15 cm coloque la guía de posicionamiento a 10 cm del suelo y fije las ménsulas

con 3 tornillos (s18b) para cada una.

Opción 2

2.º poste

2”-6” (5 cm-15 cm)

?

Nivel

SUELO

Pendiente

descendente

1.º poste

1.º poste

2.º poste

2”-6” (5 cm-15 cm)

SUELO

2.º poste

2”-6” (5 cm-15 cm)

1.º poste

1.º poste

Opción 3

Pendiente

ascendente

3.º poste

?

SUELO SUELO

En caso de una pendiente ascendente, conecte las ménsulas a 2” (5 cm) arriba y/o

ubique el nuevo poste más abajo, mientras cava una zanja para la baranda.

Asegúrese (usando la guía de posicionamiento) de que la ménsula superior del lado

izquierdo no quede fuera de la partes superior del poste.

2.º poste

3.º poste

SUELO

9

2.º poste

SUELO

Si la distancia es mayor que 6” (15 cm) coloque la ménsula inferior a 2” (5 cm) del suelo

y utilice 3 tornillos (s18b). Fije la segunda ménsula usando la guía de posicionamiento. Utilice 3 tornillos (s18b).

SUELO

INSTALACIÓN DE LA SECCIÓN DE LA CERCA

1

Ensamble el panel

en la baranda inferior.

2

Asegúrese de que el panel

entre en las ménsulas.

3

Coloque la baranda superior

sobre el panel.

4

Utilizando los tornillos (s35),

fije las baranda superior a las ménsulas.

COLOCACIÓN DE LAS TAPAS DE LOS POSTES

10

(x2)

ATORNILLE DESDE

AMBOS LADOS

11

1. Presione las tapas hacia abajo,

sobre la parte superior del poste.

2. Puede fijar las tapas con silicio.

silcion

Para las secciones de la cerca con una

medida inferior a la estándar,

que es de 6’ (182 cm) de centro a centro,

simple - mente corte las barandas al tamaño

y los paneles de la cerca,

con una sierra eléctrica.

Loading...

Loading...