Keston Spa 120 litre, Spa 150 litre, Spa 210 litre, Spa 300 litre, SpaTwin 210 Installation Instructions And Performance Specification

...Page 1

KESTON

SPA

UNVENTED

STORAGE

CYLINDERS

SINGLE ANDTWIN

COIL MODELS

lnsta

llation

lnstructions

&

Perfo

rma

nce

Specification

Fully Approved

To

Building

Regulations

G3 and

L

WRAS Approved

to

theWater Regulations

KESTON

BOILERS

LTD

34 WEST

COMMON

ROAD

HAYES,

BROMLEY

KENT BR2

7BX

Tel:(+44)

020 8462

0262

Fax(+44)

02084624459

Email: info@keston.co.uk

Web: www.keston.co.uk

Single

Coil

Models

Spa 120

litre

Spa

150 litre

Spa

210 litre

Spa

300 litre

Twin

Coil

Models

SpaTwin

210

SpaTwin

300

lndirect

Stainless

Steel

Cylinders

with

Ultra-High

Performance

lssue

04-2007

Specialists

in high

Efficiency

Commercial

& Domestic

Heating

Equipment

Page 2

READ

CAREFU

LLY

BEFORE

INSTALLATION

INCORRECT

INSTALLATION

MAY

INVALIDATE

GUARANTEE

CONTENTS

1.

Component

Check List

2.

Handling

and Storage

3. Location

and Cylinder

Mounting

4.

Warnings

5.

Markings

and

Specification

6.

Connection

Layout

and

Recommendations

for

Pipework

and

Discharge

Lines

7.

Flushing

and Commissioning

8.

Electrical

Specification

and

Wiring

g.

SecondaryCirculation

10.

Scale

Advice and

Maintenance

1 1.

Trouble

Shooting

and

Maintenance

12.

Spares

13.

Safety

&

Relevant

British

Standards

14.

Tank

Data Plate

Note

to

lnstaller:

Please leave

lnstallation

manual

with Householder

after installation

PAGE

3

4

4

4

5

6

9

I

10

1',r

't2

13

't4

14

.'.1

.,..:

,,-..-i

,'....j

-.i

Page 3

INTRODUCTION

The Keston

Spa is

a range

of Duplex

stainless

steel

un-vented

water

heaters

with

ultra

high

performance

coils for

indirect

heating.The

use

of stainless

steel for

both

coil

and

iank

ensures

long

lifJ

and

high

strength

ensuring

high

pressure

performance.The

ultra high

efficiency

coils

give

rapid reheat

and high

volume

hot water

delivery.

The

units

are supplied

with manifold

type

pressure

regulating/expansion

relief

valves

preset

to

3bar

and

with

integral

strainer.

However,the

manifold

can be

separated

to tlvo

sections

should

you

wish

to install

the

pressure

regulating

valve at

a remote

location.

An

expansion

vessel

is also

suppliei

for

connection

to

the

cold

supply.

Use

of an

externat

expansion

vessel

allows

the

entire

volume

of ihe

tank

to be

used for

water

storage.

The units

are also

fitted

with a

3kW electric

immersion

heater

as standby

heating

and

adjustable

thermostat

with

overheat

shut down

to control

the

supply

of indirect

heat

to thl

unit.

EI

E

r

#

Operating Data:

Maximum

Water

Supply

Pressure

to

pressure

iegulating

ralve

Operating Pressure

of

unit

Expansion

Vessel

Charge

Pressure

Expansion

Relief

Valve

Setting

Maximum

Primary

Working

Pressure

Opening

Temperature

of T&P

Valve

Opening

Pressure

ofT&P

Valve

Performance

Data:

Model

Spa

Spa

i

Spa

Spa

't20

150

210

300

Re-heat

15C60C(approx)

23mins

25mins

35mins

44mins

lSmins

Re-heat

after 7006

draw-off

l Tmins

l Tmins

22 mins

2g

mins

1l

mins

(approx)

NB: Above

figures

assume

constant

primary

coil flow

of

82C and

sufficient

heat input

to fully

utilise

the coil

output.5paTwin

figures

assume

both

coils used

concurrently

with

sufficient

boiler

power

'1.

ComponentCheck-List

The following

items

accompany

your

Spa Unvented

Storage

Cylinder.

Combined

control and

overheat

thermostat

with

manual

cut-out

switch,

variable

thermostat

(30

-70C)

and

sensor.

90C/7

bar ?Temperature

and

Pressure

(T&P)

relief

valve

Discharge

tundish

2-Port Motorised

Valve

Expansion

vessel,

hose

and

wall mounting

kit

12.0

bar

3.0

bar

3.0 bar

6.0

bar

3.5 bar

90c

7 bar

Spa

Twin

Spa Twin

210

300

22mins

14 mins

Combined

strainer/pressure

reduction valve.3.0

bar,

with

stop

tap, check valve,expansion

relief valve

6

bar.

3kW

/230VAC electric

element

with

safety

cut-out

switch and

variable

thermostat -

1.75" BSP head

Diagnostic

gauge

M

ry

w

@

Page 4

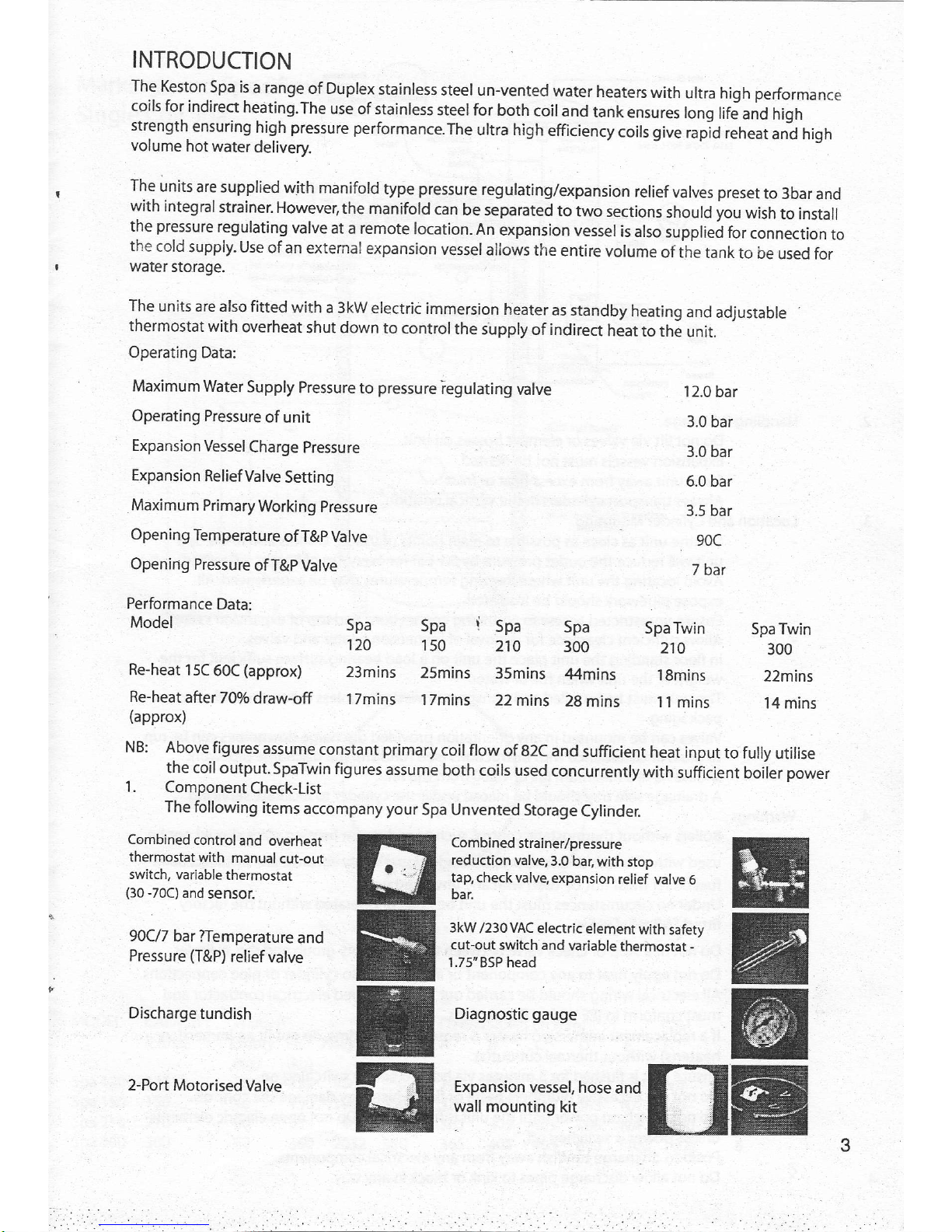

Lpanslon

wlthWall

Eracket

Ssndary ktum Circult

(21o,250&

300 Lilzes

Flexlble

Ho*

Enhanced

Cold Conn*tbn

Handling & Storage

-

Do not lift via valves

or element

bosses

on unit

-

Expansion vessels

must not

pe

dented.

-

Store unit away

from excess

heat or

frost

-

Always

transport

cylinders

in the

vertical

position

Location and Cylinder

Mounting

-

Site the

unit as close

as

possible

to

main

points

of usage.

Outlets above

the Spa

unit will reduce

the outlet

pressure

by 0.1 bar

for every

1m of height

difference.

-

Avoid

locating the unit

where

freezing temperatures

may be experienced.All

expose

pipework

should

be

insulated.

-

Ensure unrestricted

access to

plumbing

connections

and top

of expansion

vessel

-

Allow

sufficient

clearance

for

removal of

immersion

heater and

valves.

-

ln floor standing

the unit

place

the

unit on

a

load

bearing

surface

sufficient

for the

weight

of

the unit

when

full of

water.

-

The unit must be

installed and

transported

vertically unless

otherwise

indicated

on

packaging

-

Valves

can be

mounted

in any

orientation

provided

discharge

downpipes can

be run

to drain in accordance

with instructions

(seeTundish).The

discharge

pipework

should have a minimum

fall of

1:200 from the

unit.

-

A drainage safe

tray should

be

placed

under

the cylinder

to

facilitate servicing

Warnings

-

Boilers without thermostatic

control,such

as and steam

heating

plant

should

not be

used

with this unit unless

appropriate

additional

safety

controls

are installed.

Solid

fuel boiler must

not be used

with any

unvented

unit.

-

Under no circumstances

must.the

unit be

filled or operated

without

the

factory

fitted T&P relief valve.

I

-

Do not fit a stop or check

valve between

the inlet safety

group

and the cylinder

-

Do not

apply

heat

to any component

or any welding

to cylinder

or

pipe

connections.

-

All electrical

wiring should

be carried

out by

a registered

electrical

contractor

and

must conform to

IEE Wiring

Regulations.

-

lf a

replacement immersion

heater

is required at

any time,

do not

fit

an

immersion

heate(s)

without thermal

cut-out(s).

-

Ensure unit is

flushed for 3

minutes

via

hot tap before

switching

on.

-

Do not use

excessive

plumbers

paste

or

flux, which

may damage

the controls'

-

Do

not

swit{h on

power

until

the

unit is full of

water.

Do

not open electric

elements

unless

power

is switched

off.

-

Position discharge

tundish

away

from any electrical

components.

-

Do not allow

discharge

pipes

to

kink or block

in any

way.

goller

Boller

Return

Non

Return

Bonze

Pump

lmmttlon

[hter

Page 5

2b

Hot DE

r

t\

o'"

':-o

r)

\-/

*To--....

ulo

,i*o*""--"**==ot.,

):ur:;Jr

r..*.i'

i-*____l

\-**-- ,

1..--................................_.*_

i

i

-_--

")

il/#

Markings

and

Specification

Single

Coil

Spa

l/2'F PTRY

Bo$

Sond

..__

llrwdon

H6ter

.

(rct.lw.yr

fitt€d,

sbbte)

t/2T

Sbt

80s

'

zmm

Cold fed whh

dtp

plpo

to

d.i€toa ln bottom

ofcyllnder

DIMENSIONS

(in

mm)

IMM

ABCDEF

MODEL

CAPACTY

WEIGHT

(Litres)

Empty

Full

Height Dia

(ks)

(ks)

Spa 120

120

35

,

:

155

Spa 150 150

40

.

190

Spa 210

2lO

50

260

Spa

300 3oo

60

360

906 550

1093

550

1469

5s0

2032 550

290

330

365

365

(kw)

3

'3

3

6

330

370

405

405

390

34s N/F

N/F

465

385 N/F

N/F

46s

465

N/F

11s0

465

660 1100 1600

Page 6

Double

CoilSpaTwin

l/2'F PTFw E6t

l/2'F Sbt 86s

,/

*

i

s*nd"ty

t"ru.

I {rct

,tmys Rn"a1

',

i!

,

j*

22sm Cold H wlth

dlp

Flpe

b defldo. ln botum

ofcylhds

MODEL

CAPACIIY

WEIGHT

(Litres)

Empty Full Heighr

Dia

.(kst

(ks)

SpaTwin2l0

210

55 265 1469

550

SpaTwin3@

300 60 365 2032 550

DMENSIONS

(in

mm)

IMM

ABCDEFGH(kW)

36s

420

779 834 lrso t268 46s 830 3

365 420

979

1034 1600 1832 465

1030 3

Page 7

3.

14.

5.

6.

6.

Connection

Layout

& Recommendations

The

performance

of any unvented mains

fed

cylinder is

always limited

by the

supply of mains

water

to

the unit.

A high

static mains

pressure

is not

a

guarantee

of adequate

supply. The

static mains

supply

pressure

should

be measured

as well as

the size

of tfue supply

pipe.

Unvented mains fed

cylinders

should

not be

used where

the water

supplies have

inadequate

pressurg

flow rate or where

the supply

may

be

intermittent.

1 .

For

cylinder

sizes up

to 300 litres

a suggested

supply

pressure

of 1 bar or more is

desirable.

2.

For

cylinders

of

200

litres

or below with water

pressure

below 1.5 bar use 22mm

supply and

distribution pipework

Use 22mm

pipe

distribution up

to the first

branch connection

For

300 litres

and over use 28mm

or larger

pipework

lf

long

pipe

runs

are required

extra

expansion

vessel

capacity may be

necessary.

All hot

pipework

should be insulated.

Use

the balanced cold

take-off

connectiori

of the

pressure

reduction valve to ensure

satisfactory

shower

performance.

However,

it

should be noted

that

this witl reduce

the total

available

regulated

flow available

from

the tank

Do

not vent

the

primary

circuit from

the

boiler to the water heater

system.

Better

performance

will

be obtained

by

using 22mm

pipe,

limiting the number

of elbows and

fittings

and using swept

bends.

Follow

connection layout

on

page

3.

Connect valves with

flow in

arrow direction

marked

on

valve

bodies.

10.

For

indirect

cylinders

the control

thermostat

and overheat

thermostat must be wired to

the

Motorized

valve

supplied, or

some other

suitable

device to shut off the flow

to the coil that

is

approved

by a member of EOTA

or by

a body with NACCB

accreditation.

1 1 .

The

high

efficiency coil of

the Spa

tank offer a higher

resistance

to boiler water flow than

other

lower

efficiency traditional

cylinders.

Consideration

should

therefore be

given

to

additional

pump

capacity

or a

coil flow/return

bypass arrangement.

Such a by-pass may then

be adjusted

to

balance

cylinder

and boilpr

flow accordingly.

Refer to the

cylinder coil

pressure

drop

curves

below for

pump

selection.

'

12.

For

twin

coil models the boiler

should

be connected

to

the upper coil.The

lower

coil should

be

used for the additional

heat

source,

such as s6lar

thermal or heat

pump.

Coil

Pressure

Drop Curves

f

8t

l!/

.s f.

"/*

t

#/

7

"4/"j

Y

r,//

,/z

./

{

,/. tr

/'/

1-1

47

F

4

F-5

s.E

7.

8.

{.5

4.

3.5

3.t

2.1

1.S

1.5

:<

o

o

o

o

f

c,

c.5

a:

Water

FlowThrough

Coil

-

Usec

f.i 0.8

0"9

Page 8

How

to

drain the

System

1. Switchofftheelectrical

powertotheimmersionheate(s)andshutdowntheboiler.Closethestop

cock valve.

2.

Open a hot

water

tap on

order

to reduce

pressure

in

the cylinder.

Leave

the hot water

tap

open.

3.

Connect a hose

to the draining

tap ensuring

it reaches

a level

below

the

unit

(this

will

ensuie a

siphon

is established

to drain the

maximum

amount

of water)

CAUTTON

WATER

DRATNED

OFF

MAy BE

VERY HOTI

Discharge

Pipework

and Tundish

-

Tundish

must

be

visible

-

Dischargepipemustbetofixedgratingandnotlocatedtocausepossibledischargeinjurytopersons.

Tvoical

Discharoe

Pioe Arranoement

Table

1:

Sizing of copper

discharge

pipe

D2 for

common

temperature

relief

valve outlet

sizes.

Valve

Min

size

Min

size

of Maximum

resistance

allowed

Resistance

created

outlet

ofdischarge

dischargepipe

asalengthofstraightpipe

byeachelbowor

Size

pipe

Dl

D2

from

tundish

(i.e,

no

elbows

or bends)

bend

G1/2

l5mm

22mm

28mm

35mm

G3/4

22mm

28mm

35mm

42mm.

Gl

28mm

35mm

42mm

54mm

up

to 9m

upto 18m

up to 27m

up to

9m

up

to 18m

up

to

27m

up

to 9m

upto 18m

up to 27m

0.8m

-i

1.0m

1.4m

1.0m

1.4m

1.7m

1.4m

1.7m

2.3m

Worked

example:

The

example

below

is for

a G1l2

temperature

relief

valve

with

a discharge pipe

(D2)

having

4 no.elbows

and

length

of 7m from

the tundish

to

the

point

ofdischarge.

From

Table 1

: Maximum

resistance

allowed

for a

straight length

of

22mm

copper discharge

pipe (D2)

from

a Gll2

temperature

relief

valve

is

9.0m. Subtract

the resistance

fo r

4 no.22mtm

elbows

at 0.8m each

=

3.2m

Therefore

the maximum

permitted

length

elbows

equates

to 5.8m is

less

than

the actual length

of 7m

therefore

calculate

the next

largest

size. Maximum

resistance

allowed

for

a

straight length

of zgmm

pipe

(D2)

from

a G112

temperature

relief valve

equates

to l8m.Subtract

the resistanie

for 4 no.2gmm

elbows

at 1.0m

each

=

4m.

Therefore

the

maximum

permitted

length

equates

to l4m.

As

the actual

length

is 7m,

a 28mm

(D2)

copper

pipe

will

be

satisfactory.

The

tundish

should

be

vertical,

located

in

the same

space

as the

Spa

tank and

fitted

as close

as

possible

and

within

500mm

of the

temperature

relief

valre.

The

discharge

pipe

D2 from

the tundish

should

terminate

in

a safe

place

where

there is no

risk

to

persons

in

the vicinity

of

the discharge,

be of metal

and:

a)

be at

least

one

pipe

size larger

than

the nominal

outlet

size

of the

safety device

unless its

total

equivalent

hydraulic

resistance

exceeds

that

of a straight

pipe

9m long i.e.

discharge

pipes

between

9m and

1 8m

equivalent

resistance

length

should

be

at least

two sizes larger

than

the

nominal

outlet

size

of the safety

device,

between 18m

and

27m

at least

3 sizes larger,

and

so

on' Bends

must

be

taken into

account in

calculating

the flow

resistance.

Refer

to the worked

example.

An

alternative

approach for

sizing discharge

pipes

would

be

to

follow

856700:

1987

Specification

for design,

installation,

testing and

maintenance

of services

supplying water

for

I

domestic

use within

buildings

and

their curtilages,

Appendix

E,

section E2

and table 2l .

Page 9

c)

d)

i)

ii)

i ii)

iv)

b) have

a

vertical

section of

pipe

at least 300mm

long,

below

the tundish

before any elbows or

bends in the

pipework

be installed with

a continuous fall.

have discharges visible

at both the tundish and the final

point

of discharge but

where

this

is

not

possible

or is

practically

difficult there should be clear visibility

at one or other

of these

locations. Examples

of acceptable discharge arrangements

are;

ideally below a fixed

grating

and above the water seal in a trapped

gully.

Downward discharges

at

low

level; i.e. up to 1OOmm above external

surfaces

such as car

parks,

hard standings,

grassed

area etc.

are acceptable

providing

that

where

children

may

play

or otherwise come into

contact

with

discharges a wire cage or similar

guard

is

positioned

to

prevent

contact, whilst maintaining visibility.

Discharges

at

high

level; e.g. into a metal hopper and metal down

pipe

with the

end

of the

discharge clearly visible

(tundish

visible or not) or onto a roof

capable of

withstanding high

temperature discharges of water 3m from

any

plastics guttering

system that

would collect

such discharges

(tundish

visible)

Where

a single

pipe

serves a number of discharges. such as in

block of

flats, the number

served should be limited

to

not more

than 6 systems so that and installation discharging

can

be

traced

reasonable

easily.The single common discharge

pipe

should be at

least

on

pipe

size

larger

than the largest individual discharge

pipe

D2 to be

connected

lf unvented

hot water

storage systems are installed where discharges from safety

devices may

not

be

apparent i.e.

in

dwellings occupied by blind,

infirm

or disabled

people,consideration

should be

given

to

the installation

of an electronically operated device to warn when discharge takes

place.

Urch.rg.dFOl)frm

tsF.turc rclld d€ to

tudl+

thry&UG.g

hFatur.ElrdnlE

11

._-.1_

!

m-.*;1

Tundtsh

r"

-i",

i

tl,

::E.

c

,

:.:

:

,i,

i

I

'mF

tw'Reri'rv'r*

'+'[

-

'fi:*

-_.1_

*"--i1'1-r:

'

-';"f

r''

Frrdc.tins

BFndon

,,1

;.

"\.r*-

Dirh.rg.plr(o2)fr6

I

rudbh;ih(du;@6hr

-

i ,

."._i.

-

_

ididv.r*

';}

.::l'..

",

.-

.

.

,:

rodcur, .1

,

.

"

r

i

:

rundhhrnem.

--.

:c ..

t

i

-

j

(mFlffit,s

dieih.t

, '. .roi-.

I;

Hr."**il"J--'

H;

tundi$lftPdbY@

'.1

l-

P'*ao*to*"n

l.mrature

{d

'\

{ I

i^

neuv.u

-l-

r'\.ir - I

lhm

"

@ndon l\

r,

;r i

hu

t_--

__

t

rdrdvr€

l\.i::Tr:.:r';,

j.

?:.o€:

l;rt"i-r i r

I .

:tl

AhddtiEmahdat

*...1.,

rs..

.^

: I

rmdrfi

ffin :

,l

i.

..

ardEriEmdhd

or

-

, r :. -

' i:"-

lmiNtim .r hlgh r.d

Mutr b

brgs h..

jnl.!

pits

-iY-.':

\'i,j"

\T

l'.\i

[ ! I

tdofdrkh.rg.dFdiametsdpiFhurt

''-l

bkototrmll

Note: The discharge will consist of scalding water and steam. Asphalt, roofing felt

and nonmetallic rainwater

goods

may

be damaged by such discharges.

7.

Flushing and Commissioning

-

Ensure

all

pipe

connections are tight, including immersion heate(s).

-

Check the

immersion

heater setting is not above 60C and that

the

live and neutral connec-

tions

are correct.

-

Open a hot tap

farthest from

the unit. Open the mains stop cock to fill the unit.

-

Flush

for three minutes.

-

Close off taps and check

pipework

for leaks.

-

Switch on electricity

to

the immersion heate(s) or switch on the boiler.

Refer

to boiler

manu

facturer

s instructions or commissioning.

-

Bring

the unit to approx 65C. Check that

water does not discharge via theTundish

pipework

during heating.

Page 10

Cut out

lmmersion

HeaterWring

Connect Live

to

thermostat

Heat resisting

cable

from Double Pole

isolating

switch

Connect

Earth

Connect

Neutral

-

Hand

guarantee

card to

user.

8.

Electrical

Specification

& Wiring

(lmmersion

Heater)

-

Element

terminals are marked

N(Neutral)

and L(Live)

-

Ensure

earth connection

of 3 wire

supply

is connected

to

earth.

-

Recommended

supply for

3kW element is

2.5mm

cable

to

85614l

-

A 16 Amp

timer is recommended

for

3kW

elements

-The

unit is not fitted with

a fuse.

-

All heating

elements

operate

on a 230 VAC

50Hz

mains

supply. Do

not fit immersion

heate(s)

without

thermal

cutout(s).

FUSE

RATING:

The fuse

rating

for two

3kW

immersion

heaters

wired

separately

from

the main fuseboard

should

be l5

Amps.

Electrical

Wiring

Drawing

Cylinder

Thermostat

From Timeclock

Motorised

Valve

DHW Output

N

E

L

To Boiler

Electrical

Specification

and Wiring

(Thermostat

Control)

-

The

cylinder control

thermostat

is mounted

at

the

top of the unit

in a housing with

cable

entry

point.

-

The

unit houses

two thermostats,

a control

thermostat

and

an overheat

thermostat.

Operation of

either thermostat

must

cease

the supply

of heat

to the cylinder.

-

Remove

the thermostat

housing

cover. Wire

the

two thermostats

inside in

series

to the

hot

water

control valve as

shown

below. Electrical

5pecification

and Wiring

(Thermostat

Control)

for additional

heat source refer

to the suppliers

manual.

However,

the manual reset

limit ther

mostat

should be

used to isolate

any further

supply

of

heat to the

Spa.

9. Secondary

Circulation

-

A

pump

is required

together with

a non-return

valve.

-

The

pump

should be fitted with isolating

valves

on either

side and

sited

to minimise

air

accumulation

away from the high

point

of

the circuit.

An

air bleed valve may

be

located

at

1O

the

high

point.

Page 11

-

The return pipe

shourd

be

fitted

to

the

secondary

return/drain

off

tapping

near

the

base

of

the

cylinder.

-

A drain

off

cock

(not

suppried)

shourd

be fitted

iniine

in

the

secondary

return

near

the

connection

to the

cylinder

to,faciritate

dninage.of

the

cyrinder

for

main,"nun..

priiir"r.

-

A

non-return

valve

(not

supplied)

must

be fittea

to

prevent

backflow.

-

calculate

the flow

rate

and

pump

size

by determining

the

totar

heat

ross

in

flow

and return

in wafts.

-

consid,eration

should

be

given

to

the fitting

of

an

additional

vessel

where

excessively

large

secondary

loop

circuits

are

used.

Required

flow

rate

3.Water

is cold

-

Crossflow

from

cold

supply

-

Boiler

not

switched

on

(indirect)

-

Air locked primary

flow

-

Thermostat

settings

incorect

-

Cut

out

switch

need

reset

=

Totalwatts

litres/second

4186x

t000xT

whereT

=

temperature

difference

between

flow

and

return

(normally

the

desirable

drop

is

5C

and

the

hot water

temperature

should

be

60C).

'10.

Scale

Advice

and

Maintenance

-

ln

areas

of

hard

water

high

storage

temperatures

(above

50C) will

result

in scale

deposition

-

lt

is

advisable

to

set-the

thermostat

to

the required

level

and

fit a water

softener

or

scale

inhibitor

(capabre

of the

required

circuit

flowrate)

in

the cord

suppry

rine.

Maintenance

-

The

valve

easing

gear

on the

pressure

and

temperature

relief

valve

must

be

operated

at

least

once

every

6 months.

-

The

charge pressure

of

the

expansion

vessel

should

be

checked

annually

with

a

pressure

gauge

at

the

top

(and

whh

a hot

tap

open

and

the

cold

supply

turned

o?f).

Recharge

with

clean

dry

air

to 3.5

bar.

-

clean

the

pressure

reducing

valve

filter

every 2

years

or

of flow

from

water

heater

begins

to

deteriorate.

l l.Trouble

Shooting

&

Fault

Guide

i

WARNINGS

lf

hot

water

discharges

at tundish

do not

turn off

supply

main,

switch

off

power

to

electric

elements

and

shut

down

heating

boiler

(indirect

modeis)

The

cause

of

this could

be a failure

of

the

safety

controls

and

you

should

immediately

contact

your

installer

or our

service

operator.

SYMPTOM5

POSSIBLE

CAUSES

1. No

or low

flow

-

poor

mains pressure

-

Restricted

pipework

-

Mains

stopcock

-

Sticking

jumper

in

stop

-

Blocked

filter

2. Discharging

cold -

Loss of

expansion

vessel

-

Defective pressure

-

Blocked

or

defective

ACTION

-

Check

that

all arrows

on

valves

are in

water

flow

direction.

-

Use

larger

diameter

pipework

-

Operate

stopcock

or replace

-

Replace

stop

cock

-

Clean

filter

-

Check

and

recharge

vessel

reliefvahe

(with

hot

tap open)

-

Replace

pressure

valve

reducing

valve

-

Operate

expansion

valve

expansion

reliefvalw

mechanism

to

clear

or replace

-

Check

mixer

taps and

fit

check

through

mixer

top

or other

\lalve

on hot

outlet

from

heater

fittlngs.

-

CARRY

OUT

PROCEDURE

BELOW

Warnings

(Electric

Modelt

Always

isolate

the

electrical

supply

before

opening

heating

elements.

Confirm

that

power

supply

is reaching

the elemenls.

lfthermal

cut-out

switches

have

operated press

in

the

red button.

rf this

fairs

to

heat

the

cylinder

the

element

has

failed

and

should

be replaced.

Fit

new element

and

reset

thermal

cut-out.

wth

power

to

the

element

and the

cut-out

reset,

check

the vottage

on thermar

cut-out

outpui.

lf this

is incorrect

replace

cut-out

switch.

-

1

1

Page 12

1 2.

Spares

ITEM DESCRIPTION

1/2

inch

Temperature

and

Pressure

ReliefValve

3/4inch

pressure

reduction

valvg

expansion

relief

manifold

1

2 litre

Expansion

Vessel

(1

20,

1 50 litre

sizes)

1

8 litre Expansion

Vessel

(210

litre

size)

24 litre

Expansion

Vessel

(300

litre

size)

'

lmmersion

Heater

Control Thermostat

ovdrheat

Thermostat

Motorized

Valve

22mm

Tundish

Diagnostic

Gauge

Expansion

Vessel

Hose

MODEL

K51.120.04.00.1

K5r.12s.06.00.0

2

K5t.200.01.00.1

KSt.300.03.00.0

K51.400.01.00.1

KSt.125.02.00.1

KS1.12s.03.02.0

K51.125.03.01.0

KSt.125.07.00.2

Kst.l

25.10.00.0

SPECIFICATION

1/2

inch

male inlet,

15mm

comp.

outlet,90C,7

bar

2mm

comp inlet,22mm

comp

outlet,3

bar supply,6

bar relief.

3/4 inch

male inlet.3

bar

3/4 inch

male

inlet.3

bar

3/4

inch

male inlet.3

bar

3kW.

2.25 inch

male.80C

cut-out

1.75inch

boss

Adjustable

30 to 70C

80C

Cut-Out

Manual

Reset

22mm

2-port

VElve

15mm/22mm

Compression

13.

Safety

& Relevant

British

Standards

lnstallation

of this

tank as an

unvented

hot water

system

falls

within

the scope

of the

Building

Regulations

I

995

(Part

G).These

require

that

installation

of

an

unvented

sysiem

shall

be noti

fied

to

the local

authority

Building

control

Department;also

that

the work

mrst be

carried

out

by

a competent

person

as

defined in

the

Approved

Document

G3.

The

Electricity

ar Work

Regulations

1989.

The

manufacturers

notes

must

Nor

be

taken, in

any way,

as overriding

statutory

obligations.

Tank

Data Plate

Single

Coil

Spa

Twin

Coil Soa

ti[S

I $f

$l'.1

I r\iThr

t

il$ t.\t-UtLjt

tEl{

t{ErTfil

?-r'-?'rr

iF

;.

r',\'

:tu-q.:-id

,lil*,

FlEk::

?r$ td:

:3

r.:L

ii:

I

j.'

)ri:

rj

i. .!K _:- : !t

!

q6"

hntst{i{ria(rj.

FJ:tgt:.t

1 ! !!i,.ir-.t

Ar:,

';-;t--

13.

[]"""]--]+

r*-ry

l-r.

ri lx

ttn

'J

L'

'i

ll r'

rbri rlfJrt.

ri

tts

.rrfl*

.l

f,

l.

'e#

eFr*r

f rrr{h.ri.tr

i. it! i.ldrl.rsFr

*.9e1:tl--

relr

!:a!f

Lt:ar lrh!

s I{ t*!r

F!,

.;11.(S.irl

rttlr^r\rEr

ii-]l';}Ja

h

Twin

Coil

Spa

KE$T*{l

Fpi.

uHvEt{'rEn

f.At.oRtFtER

SEffilfi

k3

Nttd !

Aurtas:tu$

qqH*kX3't{iR

;{13 H:

i?,;. th:* r{i

f }

MNru6$u

pl*nlEq:-

.turq

lr.rrs*

,rrFrffi€(.sFw

l{rE:*.!.h

rifffis!dh!

jrt4o.slrekr.(hrE

I'dins,r,{.ri*Ld

-

l.r&JInF-*

ffidrdL&

$r*F

r

l,!rrJidard-Ird.*s

.h.bJstrl'*-.r

l---

-!r'ry1"-----l

Loading...

Loading...