Keston K60, K80, K50 Installation Manual

WD50/2/1997 |

The Keston 50, 60 & 80 Condensing Boilers |

|

|

Fan Powered High Efficiency Condensing Gas Boiler

Installation And Servicing Instructions

Keston 50 - GC No 41 930 01

Keston 60 - GC No 41 930 02

Keston 80 - GC No 41 930 03

PI No. : 87AQ306

These instructions must be left either with the user or next to the household gas meter.

34 West Common Road

Hayes, Bromley, Kent BR2 7BX

Tel. (44)0208 462 0262 Fax. (44)0208 462 4459

0087

WD50/2/1997 The Keston 50, 60 & 80 Condensing Boilers

|

|

CONTENTS |

|

|

|

Section |

|

Description |

1 |

GENERAL INSTRUCTION |

|

1.1 |

|

Description |

1.2 |

|

Boiler Schematic |

1.3 |

|

Related Documents |

1.4 |

|

Performance Data |

1.5 |

|

General Data |

2 |

BOILER LOCATION |

|

2.1 |

|

Dimensions & Minimum Clearances |

2.2 |

|

Service Connections |

2.3 |

|

Position |

2.4 |

|

Electrical |

2.5 |

|

Boiler Size Selection |

2.6 |

|

Gas Supply |

2.7 |

|

Water Systems |

2.8 |

|

Flue System |

2.9 |

|

Air Supply |

2.10 |

|

Compartment Installation |

2.11 |

|

Condensate Drainage |

2.12 |

|

Radiant Floor Heating |

2.13 |

|

Low Water Volume Boiler vs. Cast Iron Boiler |

2.14 |

|

Determine Radiation Needed Room-By-Room |

3 |

INSTALLATION OF THE BOILER |

|

3.1 |

|

Wall Mounting Bracket |

3.2 |

|

Mounting The Boiler |

3.3 |

|

Assembly Practice |

3.4 |

|

Installing Flue And Air Pipes |

3.5 |

|

Condensate Drainage |

3.6 |

|

Water System |

3.7 |

|

Gas Supply |

3.8 |

|

Electrical Supply |

3.9 |

|

Exchanging A Boiler |

4 |

COMMISSIONING OF THE BOILER |

|

4.1 |

|

Initial Flushing |

4.2 |

|

Gas Supply |

4.3 |

|

Electrical Installation |

4.4 |

|

LP Gas Conversion |

4.5 |

|

Initial Firing |

4.6 |

|

Hot Flushing |

4.7 |

|

Checking The Gas Pressure |

Page : i

WD50/2/1997 |

|

The Keston 50, 60 & 80 Condensing Boilers |

|

|

4.8 |

|

Timing The Gas Meter |

|

|

||

4.9 |

|

Handing Over To The User |

|

5 |

FAULT FINDING |

||

5.1 |

|

Electrical Control Sequence |

|

5.2 |

|

Fault Finding Flow Chart |

|

5.3 |

|

Continuity Checking |

|

5.4 |

|

Functional Flow Wiring Diagram |

|

5.5 |

|

Electrical Wiring Diagram |

|

5.6 |

|

Illustrated Wiring Diagram |

|

5.7 |

|

Exploded Assembly Diagrams |

|

6 |

SERVICING |

||

6.1 |

|

Pre Service Checks |

|

6.2 |

|

Recommended Routine Service |

|

7 |

REPLACEMENT OF PARTS |

||

7.1 |

|

General |

|

7.2 |

|

Precautions |

|

7.3 |

|

Access |

|

7.4 |

|

Electrical |

|

7.5 |

|

Gas Orifice |

|

7.6 |

|

Spark Ignition/Flame Detection Electrode |

|

7.7 |

|

Burner Head & Burner |

|

7.8 |

|

Heat Exchanger |

|

7.9 |

|

Air Filter |

|

7.10 |

|

Condensate Trap |

|

7.11 |

|

Pressure Gauge |

|

7.12 |

|

Sight Glass |

|

7.13 |

|

HT Ignition Lead |

|

7.14 |

|

Air Vent |

|

7.15 |

|

Air Orifice |

|

8 |

SPARE PARTS LISTINGS |

||

Page : ii

WD50/2/1997 Chapter 1 : General Instruction |

The Keston 50, 60 & 80 Condensing Boilers |

|

|

|

|

1. GENERAL INSTRUCTION

1.1DESCRIPTION

The Keston Condensing Boiler is unique in its concept and design. While the application for which the boiler was designed is the same as those which other boilers are used the Keston boiler has the added advantage of very high efficiency, and small diameter plastic flue which can be extended to 10 metres horizontally or vertically.

The Keston uses a high power combustion blower to deliver a pre-mix of gas and air to a downward firing burner in a high efficiency, single pass heat exchanger.

Normally the combustion temperature of the air gas mixture is around 1800oC but the

Keston achieves combustion at an amazing 1000oC thereby reducing the NOx emissions down to an incredible less than 5 p.p.m.

The flue system is room sealed and fan powered. The ignition is direct spark and fully automatic. The boiler housing is not waterproof. The boiler should be installed in a position where it will always be dry. A small air intake point is incorporated within the appliance cabinet to ensure that the interior of the cabinet is maintained under a slight negative pressure. This is a safety feature to ensure no products may leak out of the cabinet into the installation space.

The boiler is suitable for connection to open vented or sealed systems. The system must be pumped central heating or pumped central heating with combined indirect domestic hot water. Gravity circuits must not be used.

The boiler has a primary heat exchanger which, through its combustion chamber and corrugated coil, transfers the heat produced in the hot gases of combustion process into the circulating water. Head characteristics of the boiler coil must be taken into consideration when calculating the pump size.

The Keston boiler is not a high water content boiler and does not contain the metal mass, or water volume, of a cast iron or steel boiler. This boiler is of low mass and low water content and therefore responds faster when there is a call for heat. This feature requires a higher water pumping rate through the boiler otherwise localised boiling will occur within the boiler.

Allow a pressure drop through the boiler of 3.2 ft head and a water flow of 4.2 gallons (19 litres) per minute for the Keston 50, 4.3 ft head and 5 gallons (23 litres) per minute for the Keston 60 and 9 ft head and 6.7 gallons (30.5 litres) per minute for the Keston 80.

The boiler selected must be sized relative to the total calculated heat loss of the building. The boiler rated output should not be greater than the total required to make up the calculated heat loss plus the heat required to provide domestic hot water. If there are special conditions such as excessive domestic hot water usage consult the manufacturer.

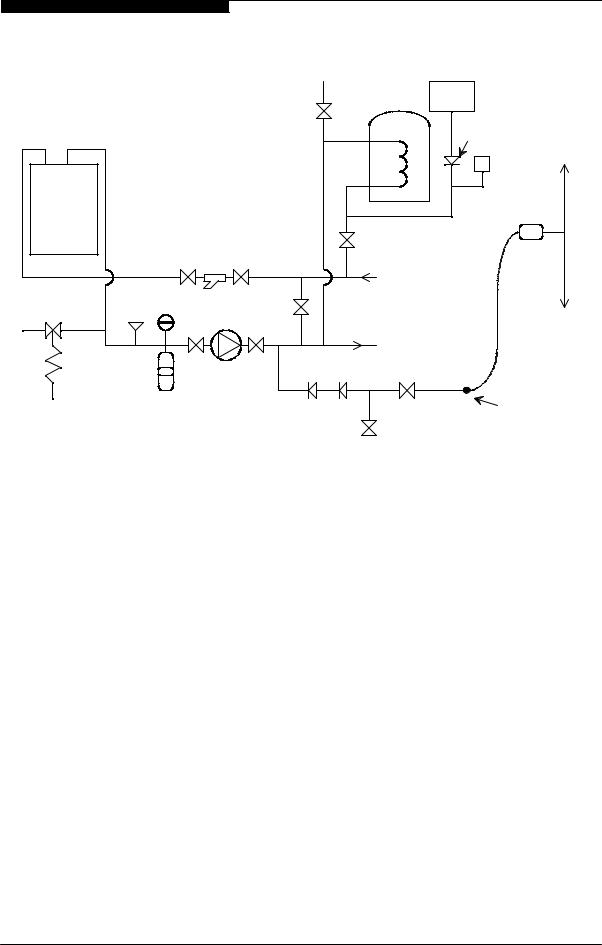

1.2BOILER SCHEMATIC

Air is drawn into the boiler through a 40mm (BS5255) muPVC pipe. The air flow is proved by a differential pressure across the air control orifice.

Gas is mixed with combustion air at the inlet to the fan. The gas flow is regulated by an orifice located in the housing downstream of the gas valve.

Installation & Servicing Instructions

Page : 1

WD50/2/1997 |

Chapter 1 : General Instruction |

The Keston 50, 60 & 80 Condensing Boilers |

||

|

|

Figure 1.2 Boiler Schematic |

||

LEGEND |

|

|

|

|

1 |

Heating Return |

|

13 |

Ignition Control Box |

2 |

Water Return Thermostat |

14 Gas Low Pressure Switch |

||

3 Downstream Pressture Test Nipple |

15 |

Gas Multifunctional Control |

||

4 |

Flame Ignition/Sensing Probe |

16 |

Gas Inlet Flexible Connector |

|

5 |

Burner |

|

17 Air Pressure Switch |

|

6 |

Automatic Air Vent |

18 |

Combustion Blower |

|

7 |

High Limit Thermostat |

19 |

Condensate Trtap |

|

8 |

Heating Flow |

|

20 Flue Overheat Thermostat |

|

9 |

Flue Exhaust |

|

21 |

Heat Exchanger |

10 |

Air/Gas Flexible Connector |

22 |

Flow Overheat Thermostat |

|

11 Air Filter |

|

23 |

Water Low Pressure Switch |

|

12 |

Air Inlet Flexible Connector |

24 |

Combustion Test Point |

|

Installation & Servicing Instructions

Page : 2

WD50/2/1997 Chapter 1 : General Instruction |

The Keston 50, 60 & 80 Condensing Boilers |

|

|

|

|

The gas and air are thoroughly mixed in the blower and fed into the burner located at the top end of the heat exchanger module. The gas and air mixture is ignited by a direct spark ignition control system and burns with a blue flame just off the surface of the burner. As the hot products of combustion pass downwards, they are cooled, exchanging heat with the circulating water which enters the heat exchanger coil at the bottom of the heat exchanger.

When the return water temperature is below 54oC, part of the water vapour in the combustion products will condense inside the heat exchanger, thus increasing the boiler efficiency. This condensate falls to the bottom of the heat exchanger where it is separated from the flue gases and exits from the boiler through the condensate drain. Any condensate formed in the flue runs back down the flueway and is drained at the base of the flue connection to the heat exchanger.

The condensate is very slightly acidic (about the same acidity as vinegar) and should be piped in a plastic pipe. It is not harmful to the waste disposal system and may be disposed of as normal waste water.

The flue gases are piped in a 40mm muPVC pipe to the outside. The temperature of the flue gases are usually less than 10oC above the temperature of the return water. The flue pipe should be terminated outside the building from where they cannot re-enter the

building or any other adjacent building or cause a nuisance by pluming.

The heating level may be controlled by room thermostats, hot water cylinder thermostats and programmer time clocks.

1.3RELATED DOCUMENTS

The Keston Condensing Boiler must be installed in accordance with the current issue of the Gas Safety (Installation and Use) Regulations, current IEE Wiring Regulations, Safety document no. 635 - The Electricity At Work Regulations 1989, Building Regulations, Building Standards (Scotland) Consolidation, and the Bye Laws of the local Water Undertaking.

In addition, due account must be taken to the following Codes Of Practice:

BS 6891 |

: |

Gas Supplies |

BS 6798 |

: |

Installation Central Heating Boilers |

BS 5449 |

: |

Installation Pumped Central Heating |

BS 5546 |

: |

Installation Domestic Hot Water |

BS 5440.1 |

: |

Flues |

BS 5440.2 |

: |

Air Supply |

BS 5482.1 |

: |

Domestic Propane & Butane Burning Installations |

BS 7074.1 |

: |

Expansion Vessels |

BS 7593 |

: |

Treatment of Water in Hot Water Central Heating |

|

|

Systems |

BS 7671 |

: |

Requirements for Electrical Installations. IEE Wiring |

|

|

Regulations 16th Edition. |

For Timber Framed Buildings, British Gas Publications DM2. Also British Gas Publications 'Guidance Notes For The Installation Of Domestic Gas Condensing Boilers' and 'Specification For Domestic Wet Central Heating Systems'.

Installation & Servicing Instructions

Page : 3

WD50/2/1997 |

Chapter 1 : General Instruction |

The Keston 50, 60 & 80 Condensing Boilers |

|

|

|

|

|

1.4PERFORMANCE DATA

Boiler Input |

KW |

Keston 50 |

Keston 60 |

Keston 80 |

16.6 |

19.9 |

27.1 |

||

|

|

|

|

|

|

Btu/h |

56,500 |

68,300 |

92,500 |

|

|

|

|

|

|

|

|

|

|

Boiler Output To Water |

KW |

14.7 |

17.5 |

23.5 |

80oC Flow 60oC Return |

|

|

|

|

Btu/h |

50,000 |

60,000 |

80,000 |

|

|

|

|

|

|

Boiler Output To Water |

KW |

15.8 |

19.2 |

26 |

|

|

|

|

|

60oC Flow 40oC Return |

Btu/h |

54,000 |

65,000 |

88,800 |

|

|

|

|

|

Burner Setting Pressure (Hot) |

mbar |

6 |

9 |

10 |

(FACTORY PRESET) |

|

|

|

|

in w.g. |

2.36 |

3.54 |

3.94 |

|

|

|

|

|

|

|

|

|

|

|

Gas Consumption After 10 mins |

L/S |

0.43 |

0.51 |

0.7 |

Running |

Ft3/Hr |

|

|

|

54.43 |

65.8 |

89.11 |

||

(CV of Gas - 38.7 MJ/m3) |

|

|

|

|

(1038 Btu/Ft3) |

|

|

|

|

|

|

|

|

|

Maximum Operating Flow |

oC |

80.00 |

80.00 |

80.00 |

|

|

|

|

|

Maximum Head (Open Systems) |

M |

30.50 |

30.50 |

30.50 |

|

|

|

|

|

|

Ft |

100.0 |

100.0 |

100.0 |

|

|

|

|

|

|

|

|

|

|

Maximum Pressure (Sealed Systems) |

Bar |

2.70 |

2.70 |

2.70 |

|

|

|

|

|

|

|

|

|

|

Minimum Head (Open Systems) |

M |

2.5 |

2.5 |

2.5 |

|

|

|

|

|

|

Ft |

8.0 |

8.0 |

8.0 |

|

|

|

|

|

|

|

|

|

|

Inlet Gas Pressure |

mbar |

20.0 |

20.0 |

20.0 |

|

|

|

|

|

|

in. w g |

8.0 |

8.0 |

8.0 |

|

|

|

|

|

|

|

|

|

|

Gas Orifice Size |

mm |

2.38 |

2.71 |

3.43 |

|

|

|

|

|

|

|

|

|

|

Recommended Temperature |

oC |

10 to 15 |

10 to 15 |

10 to 15 |

Differential |

|

|

|

|

|

|

|

|

|

Installation & Servicing Instructions

Page : 4

WD50/2/1997 Chapter 1 : General Instruction |

The Keston 50, 60 & 80 Condensing Boilers |

|

|

|

|

1.5GENERAL DATA

|

Keston 50 |

Keston 60 |

Keston 80 |

Main Burner |

Keston Premix |

Keston Premix |

Keston Premix |

|

|

|

|

|

|

|

|

Gas Control |

White Rogers |

White Rogers |

White Rogers |

|

36E Series |

36E Series |

36E Series |

|

|

|

|

|

|

|

|

Combustion Fan |

Keston |

Keston |

Keston |

|

Type LPB 102 220/240 |

Type LPB 102 220/240 |

Type LPB 102 220/240 |

|

0.18 KW 2900 RPM |

0.18 KW 2900 RPM |

0.18 KW 2900 RPM |

Direct Spark |

|

|

|

|

|

|

|

RAM Electronics |

RAM Electronics |

RAM Electronics |

|

Ignition |

Full Sequence Control |

Full Sequence Control |

Full Sequence Control |

|

|

|

|

|

|

|

|

Air Pressure Switch |

Tridelta FS 6717 - 1428 |

Tridelta FS 6717 - 1428 |

Tridelta FS 6717 - 1428 |

|

|

|

|

|

|

|

|

Filter |

Keston Filter |

Keston Filter |

Keston Filter |

Gas Supply |

|

|

|

|

|

|

|

0.5 inch BSPT Male |

0.5 inch BSPT Male |

0.5 inch BSPT Male |

|

Connection |

(15mm to gas cock) |

(15mm to gas cock) |

(15mm to gas cock) |

|

|

|

|

|

|

|

|

Flow Connection |

28 mm Copper |

28 mm Copper |

28 mm Copper |

Return Connection |

|

|

|

|

|

|

|

28 mm Copper |

28 mm Copper |

28 mm Copper |

|

|

|

|

|

|

|

|

|

Power Supply |

230V 50 Hz |

230V 50 Hz |

230V 50Hz |

|

|

|

|

|

|

|

|

Pwr Consumption |

140 W |

140 W |

175 W |

|

|

|

|

|

|

|

|

Ext. Fuse Rating |

5 Amps |

5 Amps |

5 Amps |

|

|

|

|

|

|

|

|

Weight - Full |

46 kg (101 lbs) |

46 kg (101 lbs) |

52 kg (114 lbs) |

|

|

|

|

Weight - Empty |

44 kg (97 lbs) |

44 kg (97 lbs) |

50 kg (110 lbs) |

|

|

|

|

|

|

|

|

Data Badge Posn |

Rear panel inside case |

Rear panel inside case |

Rear panel inside case |

|

|

|

|

|

|

|

|

Water Content |

2.35 litres |

2.35 litres |

3.30 litres |

|

|

|

|

Installation & Servicing Instructions

Page : 5

WD50/2/1997 |

Chapter 2 - Boiler Connections |

The Keston 50, 60 & 80 Condensing Boilers |

|

|

|

|

|

|

|

|

|

2. BOILER LOCATION

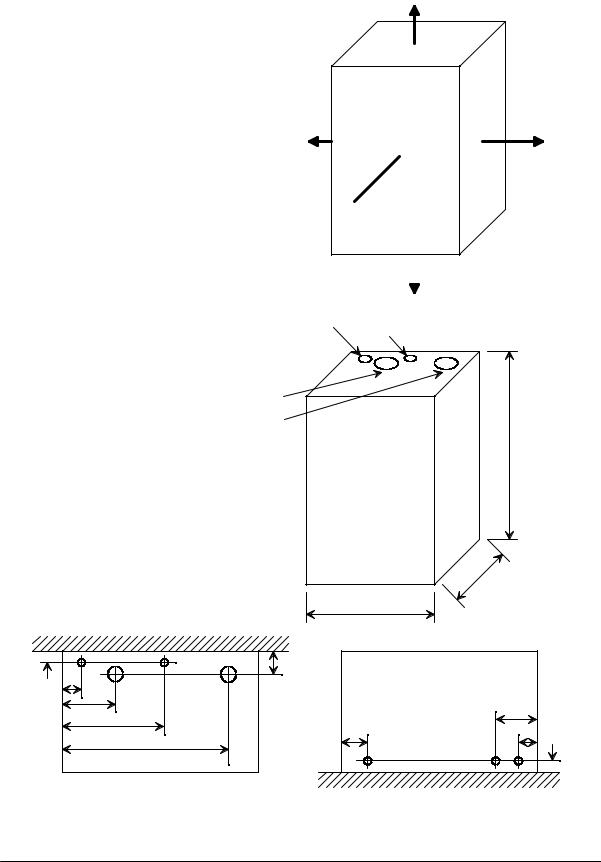

2.1DIMENSIONS AND MINIMUM CLEARANCES

The boiler must be installed in minimum clearances shown to allow subsequent servicing, and safe operation.

2.2SERVICE CONNECTIONS

Gas, water, air and flue pipe, condensation, and electrical connections are as shown. Gas : 0.5 inch BSP male. Flow/Return : 28 mm copper.

All dimensions in mm.

254

1 |

1 |

305

305

2.3POSITION

The Keston is not suitable for external installation. The boiler may be installed in any room or internal space, although particular attention is drawn to the requirements of the current IEE Wiring Regulations and, in Scotland, the electrical provisions of the Building Regulations applicable in Scotland, with respect to the installation of the boiler in a room or internal space containing a bath or shower.

Where a room-sealed appliance is installed in a

|

|

|

Figure 2.1.1 |

|

|

127 |

Minimum Clearances |

Return |

Flow |

All dimensions in mm. |

|

|

|||

Flue

Air Intake

(Keston 50 & 60) |

890 (Keston 80) |

712 |

|

Figure 2.1.2 |

|

|

0 |

|

|

|

|

|

|

0 |

|

Dimensions |

500 |

3 |

|

|

|

||

|

|

|

|

All dimensions are in mm.

27 |

60 |

|

|

|

|

47 |

|

|

181 |

|

68 |

237 |

97 |

30 |

|

405 |

37 |

|

|

|

Top View |

|

Base View |

Service Connection Locations

Installation & Servicing Instructions

Page : 6

WD50/2/1997 |

Chapter 2 - Boiler Connections |

The Keston 50, 60 & 80 Condensing Boilers |

|

|

|

|

|

|

|

|

|

room containing a bath or shower, any electrical switch or appliance control, utilising mains electricity, should be so situated that it cannot be touched by a person using the bath or shower.

Compartment installation is permitted - such compartments must be constructed in accordance with BS 6798.

The wall on which the boiler is mounted must be of suitable load bearing capacity and must be non-combustible.

Important : It is not recommended to install the boiler on a studded wall or similar - it is possible that the vibration from the fan would be amplified and transmitted to other parts of the house.

[NB: Refer to Section 2.8.3]

Chimneys not used for venting any other appliance may be used. Secure air & flue pipes at chimney outlet.

Figure 2.3

Condensate drain

The Keston can be located virtually anywhere desired provided that all regulations are met. Because of the boiler's compact size and venting flexibility, the installation is not limited to a boiler room setting. Before locating the boiler near a living space consider whether the sounds generated by the boiler will be objectionable. Sound levels from the boiler are no greater than from any other type of high-efficiency boiler but even minimal levels may be objectionable if located near a bedroom or in a living area.

2.4ELECTRICAL

2.4.1Electrical Connections

The boiler must be connected to a 230V ~ 50Hz supply, fused at 5A. All external controls and wiring must be suitable for mains voltage. Wiring external tothe boiler must be in accordance with current I.E.E wiring regulations and local regulations.

Installation & Servicing Instructions

Page : 7

WD50/2/1997 |

Chapter 2 - Boiler Connections |

The Keston 50, 60 & 80 Condensing Boilers |

|

|

|

|

|

|

|

|

|

The method of connection to the mains electricity supply must facilitate complete electrical isolation of the boiler complying with the requirements of BS 1363.

The appliance must be connected to the supply via a fused double-pole switch, having at least 3mm (1/8 inch) contact separation in both poles, serving only the boiler and the system controls.

The connection point to the mains supply should be readily accessible and adjacent to the boiler, except for rooms containing a bath or a shower. Refer to section 2.3 Position.

2.4.2External Wiring & Controls

1.The boiler is deisgned so that all control wiring is external to the boiler. Hence, any programmers or room thermostats etc must act by switching the 230V supply to the boiler.

2.System designs which allow the boiler to fire when there is no pumped circulation must NOT be used.

3.A programmer may be used with zone valves to give independent control of central heating and hot water.

2.5BOILER SIZE SELECTION

The size of the boiler to be used is determined by the total calculated heat loss of the building. Match the calculated heat loss with the boilers rated output. If a boiler is installed with an output rating greatly exceeding the total capacity of the distribution system the efficiency of the boiler will be reduced. If the boiler is to be used to heat domestic hot water no additional capacity is normally needed for the average residential installation since there is usually some excess capacity in the boiler as water heating is an intermittent load.

2.6GAS SUPPLY

A gas meter should be connected to the service pipe by the local gas supplier or their contractor. An existing meter should be checked preferably by the gas region to ensure that the meter is adequate to deal with the rate of gas supply required. Installation pipes should be fitted in accordance with BS 6891.

Minimum/Maximum Natural Gas Pressure:

Natural gas pressure before the gas valve must be maintained at 20 mbar (8 in w.g) while the boiler is running.

Gas pressures above or below this level will lead to problems associated with the gas valve's internal pressure regulator.

Minimum/Maximum L P Gas Pressure:

LPG pressure must be maintained between 31.5 mbar (12.4 in w.g) and 37.6 mbar (14.8 in w.g) while the boiler is running.

Gas pressures above or below these levels will lead to problems associated with the gas valve's internal pressure regulator.

Supply pipes to the boiler must not be sized less than the boiler inlet connection (15 mm) Due consideration must be given to the supply pressure to other gas appliances in the premises.

Installation & Servicing Instructions

Page : 8

WD50/2/1997 |

Chapter 2 - Boiler Connections |

The Keston 50, 60 & 80 Condensing Boilers |

|

|

|

|

|

|

|

|

|

A gas cock is supplied loose with the boiler. This cock should be fitted in the gas line to the boiler as close to the boiler as possible so that it is easily identified as the cock to isolate the boiler.

2.7WATER SYSTEMS

All piping must be installed in accordance with all applicable local and Water Supply Bylaws for forced hot water heating systems.

Consideration must be given to pipe capabilities and pressure drop through the piping. Water treatment must be carried out to BS 7593 : Treament of Water in Hot Water Central Heating Systems.

Pump isolating valves must be positioned as close to the pump as possible.

aThe Keston is suitable for use on open, vented water systems with combined feed and vent.

bIt is preferable for use on sealed water systems, provided the appropriate components required (see Section 2.7.2 Sealed Systems) are included in the system.

cAny system must be thoroughly flushed clean of grease, dirt and debris, prior to connection with the boiler. A trap may be installed in the flow line to collect any solder, or other debris, from the installation.

dAll water systems must be constructed to comply with requirements of the Local Water Authority.

eOnly fully pumped systems can be used - gravity systems are strictly not suitable.

fAlways use a system complying with the requirements of BS 5449 and BS 6798.

gThe system must be so arranged that there shall always be a minimum flow of 4.2 gpm (19 litres/min) [Keston 50], 5 gpm (23 litres/min) [Keston 60] or 6.7 gpm (30.5 litres/min) [Keston 80] when the boiler is firing. This can be via a specially installed by-pass arrangement.

hCopper tubing to BS 2871 Part 1 is recommended.

iJointing should be either with capillary or compression fittings. Pipes should have a gradient to ensure air is passed easily to vent points and water flows readily to drain points.

jDraining taps must be located in accessible positions which permit the draining of the boiler and hot water storage vessel. Draining taps should be at least 15

mm in nominal size and be in accordance with BS 2879.

AIR VENT POINTS

k These must be fitted at all high points where air may collect.

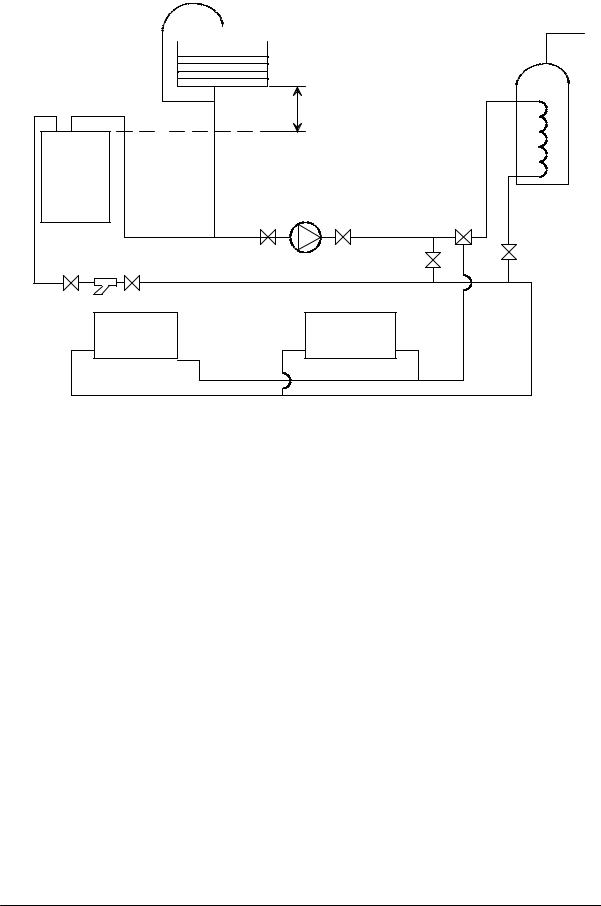

2.7.1Open Vented Systems

A typical system is shown in Figure 2.7.1 which includes a combined feed and vent. Note there must be no valve between the boiler flow and the open vent. Note that the minimum static head required is 8 ft at the boiler flow pipe. If the cold feed/vent is not brought to the flow pipe as shown, then the pressure loss across the heat exchanger may have to be taken into account when estimating the static pressure.

Although suitable for open vented systems with combined feed and vent arrangements, the Keston is a low water content boiler. As such, any air entrainement within the system water will produce boiler "kettling". It is therefore recommended, if in any doubt, to consider the use of sealed systems where possible.

Installation & Servicing Instructions

Page : 9

WD50/2/1997 |

Chapter 2 - Boiler Connections |

The Keston 50, 60 & 80 Condensing Boilers |

|

|

|

|

|

|

|

|

|

Expansion |

Expansion |

|

|

Tank |

|

|

|

Pipe |

|

|

|

|

|

|

|

|

Minimum |

|

|

|

8ft Height |

|

|

Boiler |

22mm pipe |

|

|

|

(minimum) |

|

|

Keston |

|

3 Way |

Cylinder |

Pump |

Valve |

|

|

|

|

||

|

|

By-pass |

L/S |

Strainer |

|

Bal. |

|

|

|

||

|

Valve |

|

|

|

|

|

|

Rad. 2 |

Rad. 1 |

|

|

Figure2.7.1 : Open Vented System Diagram

2.7.2Sealed Systems

Sealed systems must be designed in accordance with BS 5449 and BS 7074 Pt1. A typical sealed system is shown in Figure 2.7.2. It must include :

(i)A safety valve fitted on the flow, adjacent to the boiler. It must be non adjustable and preset to 3 bar. A drain pipe must be attached, at least as big as the valve connection, and routed to drain in any area not hazardous nor where it may be subject to freezing.

(ii)An expansion vessel complying with BS 4814 and sized in accordance with the requirements of BS 5449 and BS 7074 Pt 1. The vessel must be positioned on the inlet to the pump.

(iii)A filling point, in accordance with local water authority requirements.

(iv)A method of system make-up (automatic or manual), in accordance with local water authority requirements.

(v)There must be no permanent connection of mains water to the boiler system.

(vi)The installation must be designed to work with flow temperatures of up to 110 oC.

All components of the system including the heat exchanger of the indirect cylinder must be suitable for a working pressure of 3 bar and a temperature of 110 oC. Care should be taken in making all connections that the risk of leakage is minimised.

Installation & Servicing Instructions

Page : 10

WD50/2/1997 |

Chapter 2 - Boiler Connections |

The Keston 50, 60 & 80 Condensing Boilers |

|||||

|

|

|

|

|

Make -up vessel. |

|

|

|

|

|

|

|

Max. capacity of |

|

|

|

|

|

Air Vent |

|

3 lt. (5pt) |

|

|

|

|

|

|

|

Non-Return |

Hose |

|

|

|

|

|

|

Union |

||

|

|

|

|

|

Valve |

|

|

|

|

|

|

|

|

bib tap |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Auto Air |

|

Boiler |

|

|

|

|

|

Vent |

|

|

|

|

|

|

|

|

|

Keston |

|

|

|

L/S |

|

|

|

|

|

Strainer |

|

RETURN |

|

|

|

|

|

|

|

|

|

|

|

|

Safety |

Pressure |

By-pass |

|

|

|

|

|

Relief |

Gauge |

HEATING CIRCUIT |

|

Hosepipe |

|

|

|

Valve |

|

Bal. |

|

|

||

|

|

|

Valve |

|

|

(disconnected |

|

|

|

|

|

|

|

||

Drain |

|

|

|

FLOW |

|

after filling) |

|

|

Pump |

|

|

|

|

|

|

Cock |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Expansion |

Double Check |

BS 1010:2 |

Hose |

|

||

|

Vessel |

|

|||||

|

Valve |

Connector |

|

||||

Stop Tap

Test Cock

Figure 2.7.2 : Sealed System Diagram

2.7.3Hot Water System (if applicable)

The hot water storage vessel must be of the indirect type (certain direct cylinders can be used provided they are suitably adapted by fitting an immersion calorifier). DIRECT CYLINDERS MUST NOT BE USED. Further guidance is provided in BS 1394. It is advisable to fit a lockshield valve on the cylinder return to enable balancing of flow rate through the cylinder.

2.7.4Boiler By-pass Piping

Boiler water flows are critical to the operation of the boiler. If flow cannot be maintained through the system piping to meet the minimums required by the boiler (see paragraph 2.7 (g)). Insufficient water flows through the boiler will cause the boiler to "kettle" or even produce steam which can damage the heat exchanger and will invalidate the heat exchanger warranty.

It is normally advisable to incorporate a boiler by-pass in the system, especially if thermostatic radiator valves are used. The by-pass should be fitted with a lockshield valve to permit balancing of the by-pass flow rate. The flow/return differential should be 10oC to 15oC. The lockshield valve can be adjusted to maintain this condition with the radiators fully heated.

Installation & Servicing Instructions

Page : 11

WD50/2/1997 |

Chapter 2 - Boiler Connections |

The Keston 50, 60 & 80 Condensing Boilers |

|

|

|

|

|

|

|

|

|

2.7.5Air Elimination

In the initial charge of water to the boiler system and in all subsequent additions of water to the system some air will be dissolved in the water. As the water is heated the air is driven out of the solution and will collect in high spots in the system. These air bubbles can interfere with pumping and heat transfer and must be eliminated.

Installation of air bleed valves at the high spot(s) in the system will allow for air elimination when filling the system and will allow re-venting in a day or so after all air has been driven out of solution.

Installation of an automatic air vent will ensure that any air, even minute amounts, which subsequently enters the system will be automatically removed.

2.7.6Strainers

Debris in the heating system can cause noise if it enters the heat exchanger. Fitting of a Y-strainer ahead of the circulating pump will trap any debris left in the system and will protect the pump from damage.

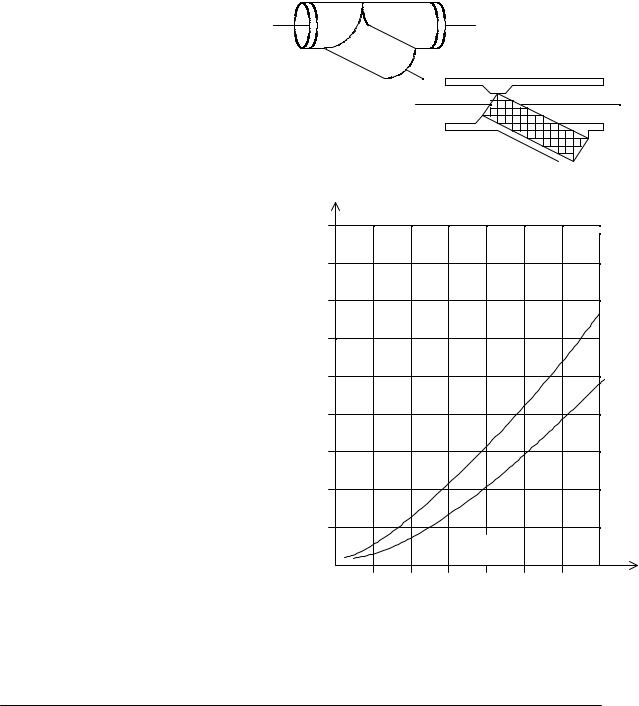

2.7.7Pump Selection

The Keston boilers have low water content heat exchangers with a high resistance to flow, when compared with cast iron heat exchanger boilers. As a result selection of the correct pump is essential in order to avoid localised boiling within the heat exchanger. The selected pump must be capable of maintaining the required flow rate for the boiler against the pressure losses contributed by the boiler and the rest of the system.

Refer to the pressure loss/flow rate Table 2.7.7 to determine the pressure loss from the boilers. Add this to the pressure loss caused by the rest of the system and select a pump capable of meeting the flow rate required at the total pressure loss generated by the boiler and the rest of the system. The selected pump must comply with BS 1394.

Y-Strainer will collect any loose debris in the piping.

4.5

4.0

3.5

3.0

- m |

2.5 |

|

Loss |

||

|

||

Pressure |

2.0 |

|

|

1.5

1.0

0.5

Figure 2.7.6 Strainers

Keston 80

Keston 50

Keston 60

5 |

10 |

15 |

20 |

25 |

30 |

35 |

Water Flow - L/min

Figure 2.7.7 : Pressure Loss Graph

Installation & Servicing Instructions

Page : 12

WD50/2/1997 |

Chapter 2 - Boiler Connections |

The Keston 50, 60 & 80 Condensing Boilers |

|

|

|

|

|

|

|

|

|

It is important to note that the minimum flow rate must be maintained whenever the boiler is firing. Systems using zone valves must be specifically designed to only fire the boiler when the pump is running and the minimum flow rate can be achieved.

The Wilo Salmson Gold Star pump, or the Grundfoss 15/60 pump is normally suitable for use with the Keston condensing boiler range. However, in all cases due consideration must be given to the resistance to flow offered by the rest of the system when making a final pump selection. This is particularly important when using small bore underfloor

heating pipework.

Boiler Model |

Keston 50 |

Keston 60 |

Keston 80 |

Min Flow Rate |

4.2 GPM |

5.0 GPM |

6.7 GPM |

Required |

19.1 litres/min |

22.7 litres/min |

30.5 litres/min |

Pressure Loss |

3.2 ft |

4.3 ft |

9.0 ft |

Through |

0.97m |

1.3m |

2.75m |

Boiler |

9.7 kPa |

13 kPa |

27.5 kPa |

Table 2.7.7 Pump Selection

2.8FLUE SYSTEM

2.8.1Design

Individual air supply and flue outlet pipes are used. The material used for flue outlet &/or air inlet must be muPVC to BS 5255 and of an internal diameter of 38 mm.

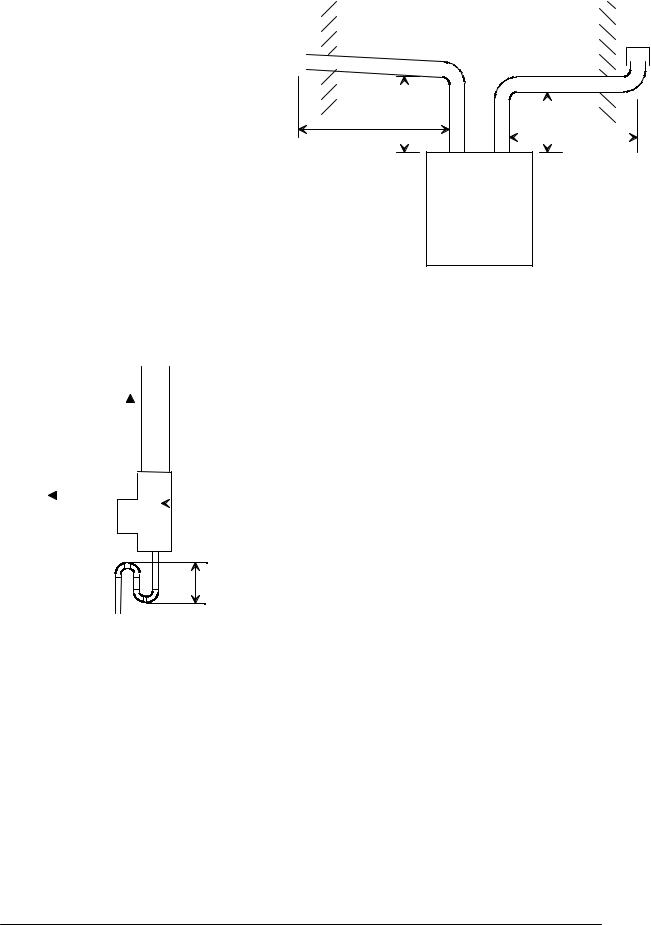

Both flue outlet terminal and air inlet terminal are supplied and are illustrated in Figure 2.8.1.

2.8.2Maximum Lengths

The maximum lengths of both air inlet pipe and flue outlet pipe, when no bends are used, are as detailed below.

Maximum Air Inlet Length |

: |

10.0 m |

Maximum Flue Outlet Length |

: |

10.0 m |

However, each bend used has an equivalent length that must be deducted from the maximum straight length stated above.

A 92.5o sweep elbow is equivalent to 1.0m straight length.

Example:

Air inlet uses two 92.5o sweep elbows. Hence, maximum length permissible (ie a+b in figure 2.8.2) = 10.0m - 1.0m - 1.0m = 8.0m

Flue outlet uses one 92.5o sweep elbow. Hence, maximum length permissible (ie c+d in figure 7 = 10.0m - 1.0 m = 9.0m

Installation & Servicing Instructions

Page : 13

WD50/2/1997 |

Chapter 2 - Boiler Connections |

The Keston 50, 60 & 80 Condensing Boilers |

|

|

|

|

|

|

|

|

|

|

|

|

2.8.3 Slope |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|||

'Horizontal' flue outlet pipework |

|

|

FLUE |

|

|

|

|||||

MUST slope at least 2.5 |

|

|

|

|

|

||||||

|

|

|

|

AIR |

|

|

|

||||

degrees (45 mm per metre |

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|||

run) downwards towards the |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|||

boiler. Pipework can be |

|

|

|

d |

|

|

|

|

|||

vertical. Only swept elbows can |

|

|

c |

|

b |

|

|||||

|

|

|

|

|

|

||||||

be used. |

|

|

|

|

|

a |

|||||

|

|

|

|

|

|

||||||

Air inlet pipework can be truly |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|||

horizontal or vertical, or |

|

|

|

|

|

|

|

|

|

||

sloping in a downward direction |

|

|

|

|

|

|

|

|

|

||

towards the boiler but in this |

|

|

|

|

|

|

|

|

|

||

case rain, etc, must be |

|

|

|

|

|

|

|

|

|

||

prevented from entering the |

|

|

|

|

|

|

|

|

|

||

pipe. There must be no |

|

|

|

|

|

|

|

|

|

||

troughs in any of the |

|

|

|

Keston |

|

|

|

||||

pipework, whether it be air |

|

|

|

|

|

|

|||||

Figure 2.8.2 : Flue & Air Maximum Length Example |

|

|

|

||||||||

inlet or flue outlet. If a 45 |

|

|

|

||||||||

mm per meter slope is not |

|

|

|

|

|

|

|

|

|

||

possible, contact Keston Boilers Technical Department for further guidance. |

|

|

|

||||||||

|

|

|

|

|

Due the low temperature of |

|

|

|

|||

|

|

|

|

|

the flue gases further condensate |

|

|

|

|||

|

|

|

|

|

will form within the flue system. Drain |

|

|

|

|||

|

Figure 2.8.3 : |

|

|

points, with suitable traps, must |

|

|

|

||||

|

Flue Condensate Drain |

therefore be incorporated within the |

|

|

|

||||||

Terminal |

Point Example |

|

|

flue system at the base of vertical |

|

|

|

||||

|

|

|

|

flue sections in excess of 2m. These |

|

|

|

||||

|

|

|

additional condensate drains must |

|

|

|

|||||

To |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

be run to discharge as detailed in |

|

|

|

|

|

|

section 2.11. Such drain points can |

|

To Boiler |

|

|

be formed using standard muPVC |

||

|

|

|

fittings. Refer to the example in |

|||

|

|

|

|

|

40mm Tee Fitting |

|

|

|

|

|

|

||

|

|

|

|

|

Figure 2.8.3. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2.8.4 Terminations

It is not advisable to terminate air intake or flue within a car port area.

Air inlet terminals must be facing upwards and positioned to ensure only fresh air is drawn into the boiler directly from outside the property.

The flue outlet terminal is designed to face outwards but can, if desired, be adapted to face in any direction BUT must not be directed in the region of the air inlet.

The two terminals are subject to the requirements of BS 5440 Pt 1 for clearances from features of the building although some can be decreased to the values indicated. If either the air inlet or the flue outlet terminate at a height of less than 2m (6ft) above ground level the termination must be protected by a suitable guard. The K4 terminal guard, manufactured by Tower Flue Components Ltd, is suitable for this purpose and can be obtained from Keston Boilers.

The Keston Condensing Boiler, as with any condensing boiler, will generate a condensate "plume" from the flue terminal in all weather conditions.

Consideration must therefore be given to the effect of this "plume" when selecting a location for the flue terminal.

Installation & Servicing Instructions

Page : 14

Loading...

Loading...