Keston SPA Installation Manual

KESTON

SPA

UNVENTED

SINGLE ANDTWIN

lnsta

Perfo

llation

rma

STORAGE

COIL MODELS

lnstructions

&

nce

Specification

CYLINDERS

Single

Twin

Stainless

Cylinders

Coil

Models

Spa 120

Spa

Spa

Spa

Coil

SpaTwin

SpaTwin

litre

150 litre

210 litre

300 litre

Models

210

300

lndirect

Steel

with

Ultra-High

Performance

Fully Approved

WRAS Approved

KESTON

34 WEST

HAYES,

KENT BR2

BOILERS

COMMON

BROMLEY

7BX

To

Building

to

theWater Regulations

LTD

ROAD

Regulations

Tel:(+44)

Fax(+44)

Email: info@keston.co.uk

Web: www.keston.co.uk

G3 and

020 8462

02084624459

0262

L

Efficiency

& Domestic

lssue

Specialists

Commercial

Equipment

04-2007

in high

Heating

READ

CAREFU

LLY

BEFORE

INSTALLATION

INCORRECT

CONTENTS

1.

Component

2.

Handling

3. Location

4.

Warnings

5.

Markings

6.

Connection

Pipework

7.

Flushing

8.

Electrical

INSTALLATION

Check List

and Storage

and Cylinder

and

Specification

Layout

and

Discharge

and Commissioning

Specification

Mounting

and

Recommendations

Lines

and

MAY

Wiring

INVALIDATE

for

GUARANTEE

PAGE

3

4

4

4

5

6

9

I

.'.1

.,..:

,,-..-i

,'....j

-.i

g.

SecondaryCirculation

10.

Scale

Advice and

1 1.

12.

13.

14.

Note

Trouble

Spares

Safety

Tank

lnstaller:

to

Shooting

Relevant

&

Data Plate

Please leave

Maintenance

and

Maintenance

British

lnstallation

Standards

manual

with Householder

10

1',r

't2

13

't4

14

after installation

INTRODUCTION

The Keston

coils for

strength

volume

The

with

the

the

water

indirect

ensuring

hot water

units

integral

pressure

cold

supply.

storage.

Spa is

a range

heating.The

high

delivery.

are supplied

strainer.

regulating

Use

of Duplex

use

pressure

with manifold

However,the

valve at

of an

externat

stainless

of stainless

performance.The

manifold

a remote

expansion

type

steel

steel for

pressure

can be

location.

vessel

un-vented

ultra high

regulating/expansion

separated

An

allows

both

coil

efficiency

expansion

the

water

and

to tlvo

vessel

entire

heaters

iank

ensures

coils

relief

sections

is also

volume

with

give

valves

should

suppliei

of ihe

ultra

high

long

lifJ

and

rapid reheat

preset

you

wish

for

connection

tank

to be

performance

high

and high

to

3bar

and

to install

used for

to

The units

thermostat

Operating Data:

Operating Pressure

Expansion

Maximum

Opening

Opening

Performance

Maximum

Expansion

are also

with

Water

Vessel

Relief

Primary

Temperature

Pressure

Data:

Model

Re-heat

15C60C(approx)

Re-heat

after 7006

(approx)

NB: Above

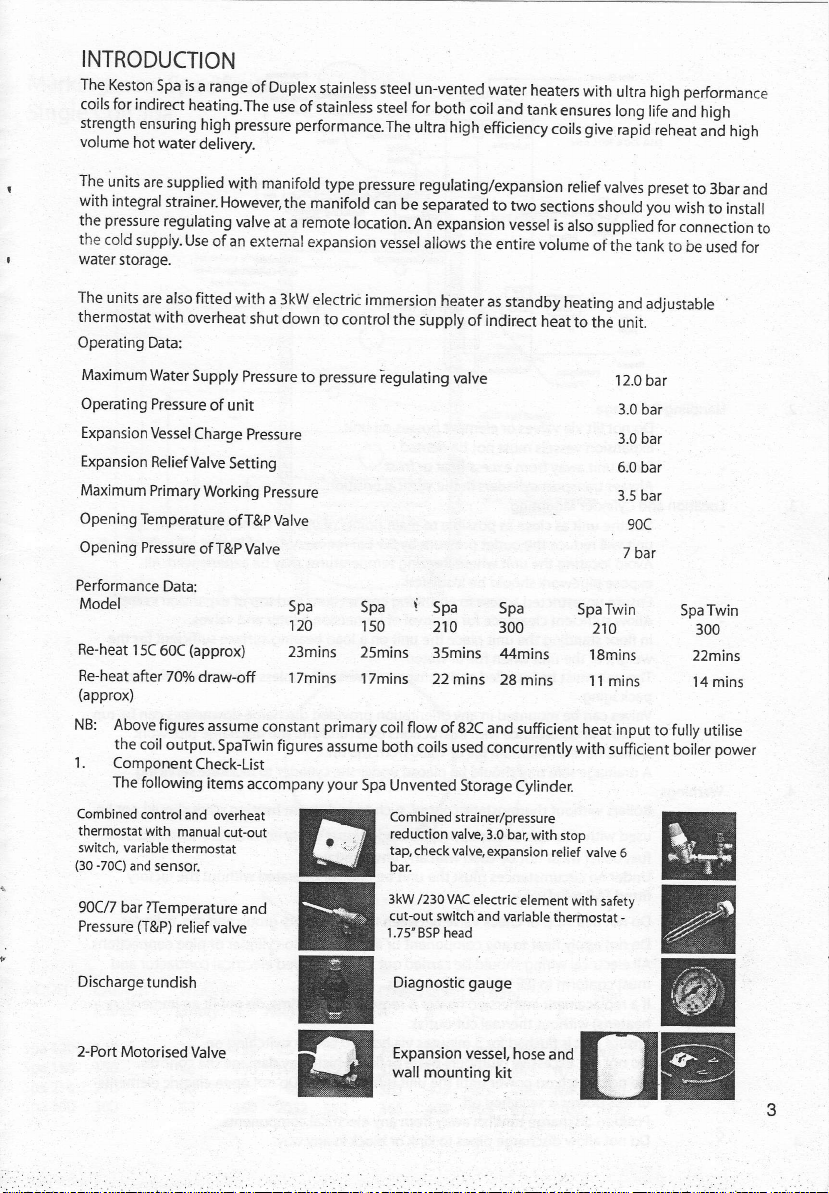

'1.

Combined

thermostat

switch,

(30

-70C)

90C/7

Pressure

Discharge

figures

the coil

output.5paTwin

ComponentCheck-List

The following

control and

with

manual

variable

thermostat

and

sensor.

bar ?Temperature

(T&P)

relief

tundish

fitted

with a

overheat

Supply

Pressure

of

unit

Charge

Pressure

Valve

Setting

Working

of T&P

ofT&P

Valve

draw-off

assume

items

accompany

overheat

cut-out

and

valve

3kW electric

shut down

to

Pressure

Valve

Spa

't20

23mins

l Tmins

constant

figures

EI

E

to control

pressure

Spa

150

25mins

l Tmins

primary

assume

your

Spa Unvented

immersion

iegulating

the

supply

i

Spa

heater

of indirect

ralve

210

35mins

22 mins

coil flow

both

of

82C and

coils used

Storage

Combined

reduction valve.3.0

tap, check valve,expansion

bar.

3kW

cut-out

1.75" BSP head

Diagnostic

strainer/pressure

/230VAC electric

switch and

gauge

as standby

heat

Spa

300

44mins

2g

mins

sufficient

concurrently

Cylinder.

bar,

with

relief valve

element

variable

thermostat -

heating

to thl

Spa

lSmins

1l

heat input

with

stop

with

and

unit.

12.0

3.0

3.0 bar

6.0

3.5 bar

7 bar

Twin

210

mins

sufficient

6

safety

adjustable

bar

bar

bar

90c

to fully

Spa Twin

300

22mins

14 mins

utilise

power

boiler

M

ry

w

2-Port Motorised

Valve

r

#

Expansion

wall mounting

vessel,

kit

hose

@

and

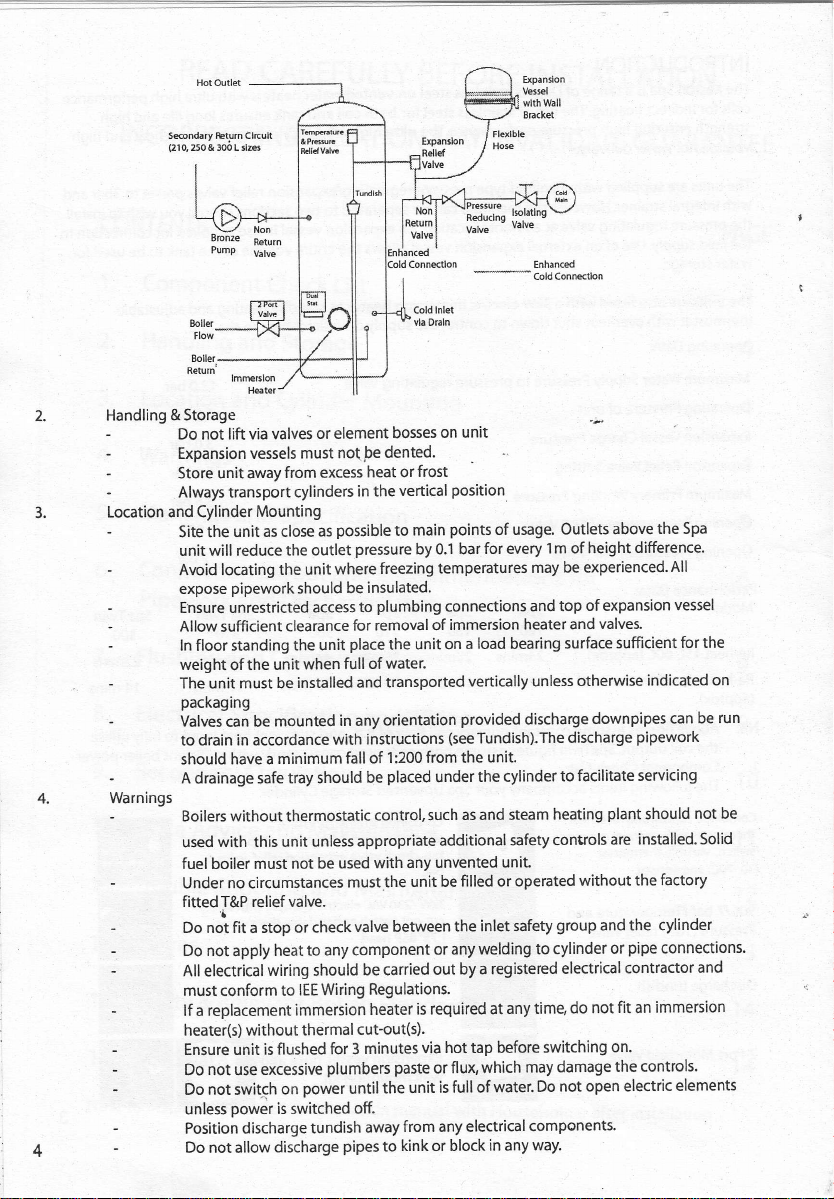

Ssndary ktum Circult

(21o,250&

300 Lilzes

Bonze

Pump

goller

Boller

Return

Handling & Storage

-

-

-

-

Location and Cylinder

-

Do not lift via valves

Expansion vessels

Store unit away

Always

transport

Site the

unit will reduce

-

-

-

-

locating the unit

Avoid

expose

Ensure unrestricted

Allow

sufficient

ln floor standing

weight

-

The unit must be

packaging

-

Valves

can be

to drain in accordance

should have a minimum

-

Warnings

-

A drainage safe

Boilers without thermostatic

with this unit unless

used

fuel boiler must

-

-

-

-

-

Under no circumstances

fitted T&P relief valve.

I

Do not fit a stop or check

Do not

All electrical

must conform to

replacement immersion

lf a

heate(s)

-

-

-

-

-

Ensure unit is

Do not use

not

Do

unless

Position discharge

Do not allow

Non

Return

lmmttlon

[hter

must not

from excess

cylinders

Mounting

unit as close

the outlet

pipework

should

clearance

the unit

of

installed and

when

the unit

mounted

tray should

not be used

to any component

heat

apply

wiring should

IEE Wiring

without thermal

flushed for 3

excessive

swit{h on

power

power

is switched

discharge

or element

pe

dented.

heat or

in the

possible

as

pressure

freezing temperatures

where

insulated.

be

for

place

full of

plumbing

removal of

water.

access to

transported

orientation

in any

with instructions

fall of

be

control,such

appropriate

with any

must.the

valve between

be carried

Regulations.

heater

cut-out(s).

minutes

plumbers

the

until

off.

away

tundish

pipes

to

on unit

bosses

frost

position

vertical

points

main

to

by 0.1 bar

connections

immersion

a

unit on

the

vertically unless

provided

(seeTundish).The

1:200 from the

placed

under

as and steam

additional

unvented

filled or operated

unit be

the inlet safety

or any welding

out by

is required at

hot tap before

via

paste

flux, which

or

unit is full of

from any electrical

kink or block

Lpanslon

wlthWall

Eracket

Flexlble

Ho*

Enhanced

Cold Conn*tbn

of usage.

for every

load

Outlets above

1m of height

may be experienced.All

and top

heater and

bearing

discharge

unit.

the cylinder

to

heating

controls

safety

unit.

group

to cylinder

a registered

electrical

any time,

switching

may damage

not open electric

Do

water.

components.

way.

in any

difference.

of expansion

valves.

sufficient

surface

otherwise

indicated

downpipes can

discharge

pipework

facilitate servicing

plant

should

are installed.

the

without

and the cylinder

pipe

or

contractor

fit

do not

an

on.

the controls'

the Spa

vessel

for the

on

be run

not be

Solid

factory

connections.

and

immersion

elements

Loading...

Loading...