Page 1

WD435/0/2006 DRAFT2 Keston Solar Thermal

SOLAR THERMAL

SYSTEMS

User, Installation and Servicing

Instructions

These instructions must be left with the

user

Keston Boilers Ltd

34 West Common Road

Hayes, Bromley, Kent BR2 7BX

Tel. +44 (0)20 8462 0262 Fax. +44 (0)20 8462 4459

email : info@keston.co.uk web : www.keston.co.uk

Page 2

WD435/0/2006 DRAFT2 Keston Solar Thermal

CONTENTS

Section Description

0 LIST OF CONTENTS

1 GENERAL INSTRUCTION

2 INSTALLATION

3 COMMISSIONING

4 HANDING OVER TO THE USER

5 ROUTINE SERVICING

6 FAULT FINDING

7 PARTS LIST

Page : i

Page 3

T

1 Collector

R

1 Pump Cable

Flowmeter

SRV

AAV

TMV

CW

HW

DTC

Manometer

Thermometers

Collector

WD

435

/0/2006

Chapter 1 :

General

Instruction

Keston

Solar

Thermal

1.

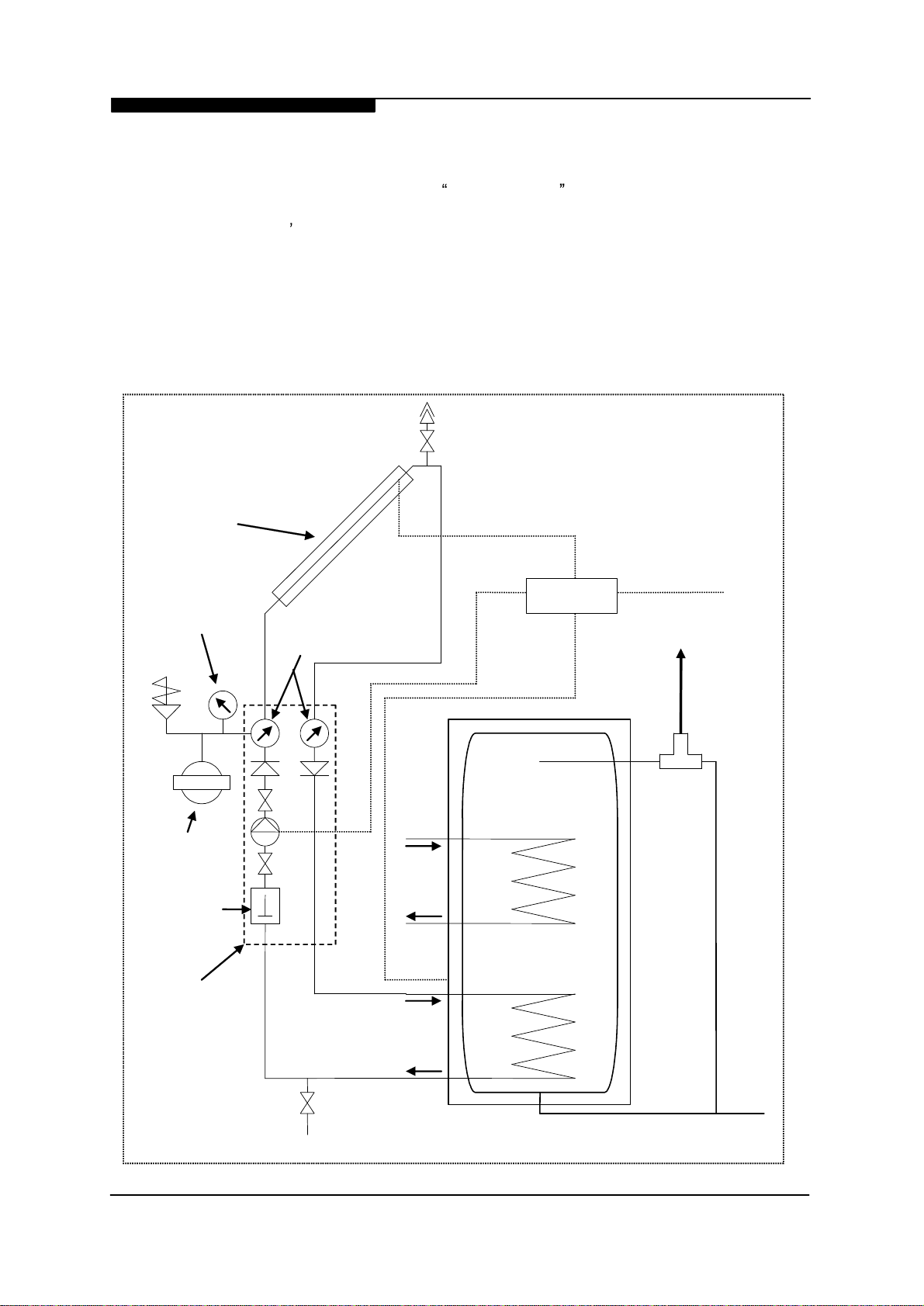

The Keston Solar Thermal System is a state-of-the-art solar system. It features high

performance collectors with highly advanced features. The collector has been awarded the

Solar Keymark, the EUs quality mark for solar collectors. The collectors are mounted on a

fast-to-fit frame and, for the Solar Packs and Solar Duet, a solar pump station is also

supplied to ease the internal component location. The Keston Solar Controller ensures

efficient use of the available solar energy at any given time and features several extra

functions such as modulating pump speed which further improve system efficiency

Keston Solar System

General Instruction and Schematic Layout

Recommended

Solar

Hydraulic and Control Circuit Layout

Sensor Cable

230 V Live

Exp

ansion

Vessel

Pump

Station

T

2 Sensor Cable

Boiler

Coil

Solar

Coil

Installation & Servicing Instructions

Page :

1

Page 4

WD

435

/0/2006

Chapter 1 :

General

Instruction

Keston

Solar

Thermal

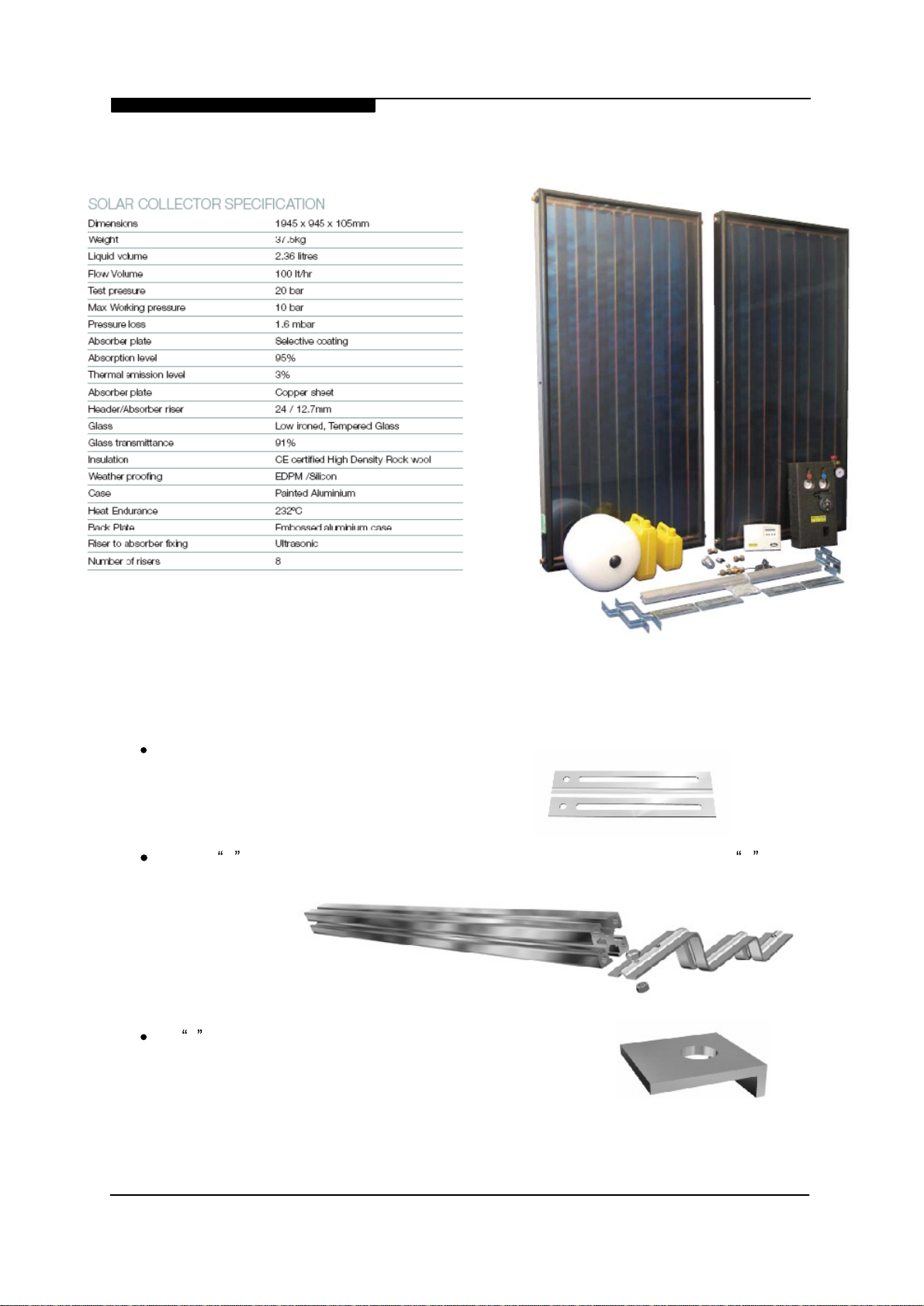

1.1

Performance Requirements

The Keston Solar System uses a similar hydraulic circuit to a standard system boiler.

However, there are several important differences between these two circuits. A solar circuit

has to manage both freezing and steam conditions in the solar collector.

The freezing is managed by using a suitable solar-grade glycol antifreeze within the circuit

mixed to a suitable ratio for the climatic conditions.

The steam conditions can occur during stagnation . The Differential Temperature Controller

(DTC) has an setting for the maximum temperature of stored (secondary) water in the cylinder (st. limit). During the summer months, when the building is unoccupied for several days,

this store limit can be exceeded and the DTC will switch the solar primary pump off. With no

flow through the collector, the collector temperature can exceed 200 °C on sunny days and

steam will be generated in the collector. This steam can travel up to 2 m down both the flow

and return pipes. In this condition, when the pump is eventually switched on again, the

steam will travel down the flow line and typically condense when it reaches the hot water

store. In this way the return line can contain water at up to 3 bar and 140 °C. The system

has to be installed to manage these conditions.

1.2

Keston Solar Pack Contents

In your Solar Pack, Keston has provided you with the following:

Solar-grade glycol antifreeze (which is designed to evaporate and condense)

A solar pump station where all the components are designed to withstand these

temperatures and pressures.

Solar-grade Auto Air Vent (AAV) with manual isolator

DTC with silicon high temperature collector sensor and intermediate temperature

cylinder sensor

A 2 or 3 collector system

Pitched roof mounting kit OR

Flat roof mounting frame

(depending on pack type)

Before starting any work you should check that you have all the above items. A full break

down of each parts list is provided in each relevant section of this manual.

1.3

Parts Not Included in the Solar Pack

You will have to provide all pipework, fittings and insulation. The following specifications are

required for items provided by the installer:

Pipework.

This should be 15 mm copper or flexible stainless on both flow and return.

Plastic pipework is not suitable for the temperature extremes possible in solar

circuits

. Pipe clips must withstand the temperatures mentioned above. It is suggested to

use gutter type external brackets over the insulation.

Fittings.

Brass olive compression fittings must be used within 2 metres of the flow and

return pipework from the collector. Lead free soldered fittings or brass olive compression

fittings can be used on the rest of the solar primary circuit. Unleaded solder is not designed

for solar circuits. Alternatively, high performance crimped fittings or similar performance

Installation & Servicing Instructions

Page :

2

Page 5

WD

435

/0/2006

Chapter 1 :

General

Instruction

Keston

Solar

Thermal

fittings can be used. Any drain valves etc. must be capable of handling the temperatures and

pressures indicated above.

Insulation.

This should be High Temperature Armaflex or similar grade insulation or

above. Class O Armaflex is not UV-resistant or designed for the temperatures realised in the

solar primary circuit. Polyethylene insulation will melt on a solar primary circuit. All external

items such as cable clips to hold the collector sensor must be UV-resistant.

Flexible stainless steel hose is available in pre-insultated form using suitable high

temperature UV-resistant insulation and a suitable two-core cable for the solar collector

sensor. This hose is specifically designed for solar applications. Contact Keston Technical

Support for further detail.

1.4

Collector Sizing and Location

Typically, approximately one square metre of solar collector should be supplied for each

house occupant. Each Keston Solar Collector panel has an external area of 1.85 sq. m.

Therefore, the Keston 2 collector array is ideal for a 3 to 4 person household and the Keston

3 collector array for a 5 to 6 person household. The collector array should be located

anywhere between South-West and South-East at a pitch of 10° to 50°. Anywhere within this

bandwidth will be within 10% of the ideal South facing 30° pitch. For an East-West roof,

either an East-West application can be installed with a collector on each pitch or additional

collector(s) can be fitted on either the East-West roof. For example, a 3 collector array on an

East facing roof would be ideal for 4 to 5 occupants where there is a 20 % loss in performance as compared to the ideal South facing 30° pitch. There should be no significant overshading of buildings, trees or other obstructions. Even obstructions to the north of the

collector can block a significant proportion of the diffuse solar radiation. Significant

overshading can be compensated by over-sizing the solar system.

1.5

Planning Permission

Planning permission for the Keston Solar System is generally only required if you are in a

conservation area or you are installing a solar system on a listed building. Solar water

heating has permitted development status. Some local councils are objecting to this ruling

and insisting that Solar requires planning permission but this is only the case if your building

is listed or you are in a conservation area. If in doubt, contact your local council planning

office.

1.6

Warranty

As you would expect, the Keston Solar Thermal system is supplied with a comprehensive

warranty cover of 5 years for the solar collector and 1 year for all other components. The

warranties are provided on a parts only basis and are conditional upon provision of the

relevant registration.

Installation & Servicing Instructions

Page :

3

Page 6

WD

435

/0/2006

Chapter 2 :

Installation

Keston

Solar

Thermal

2.1

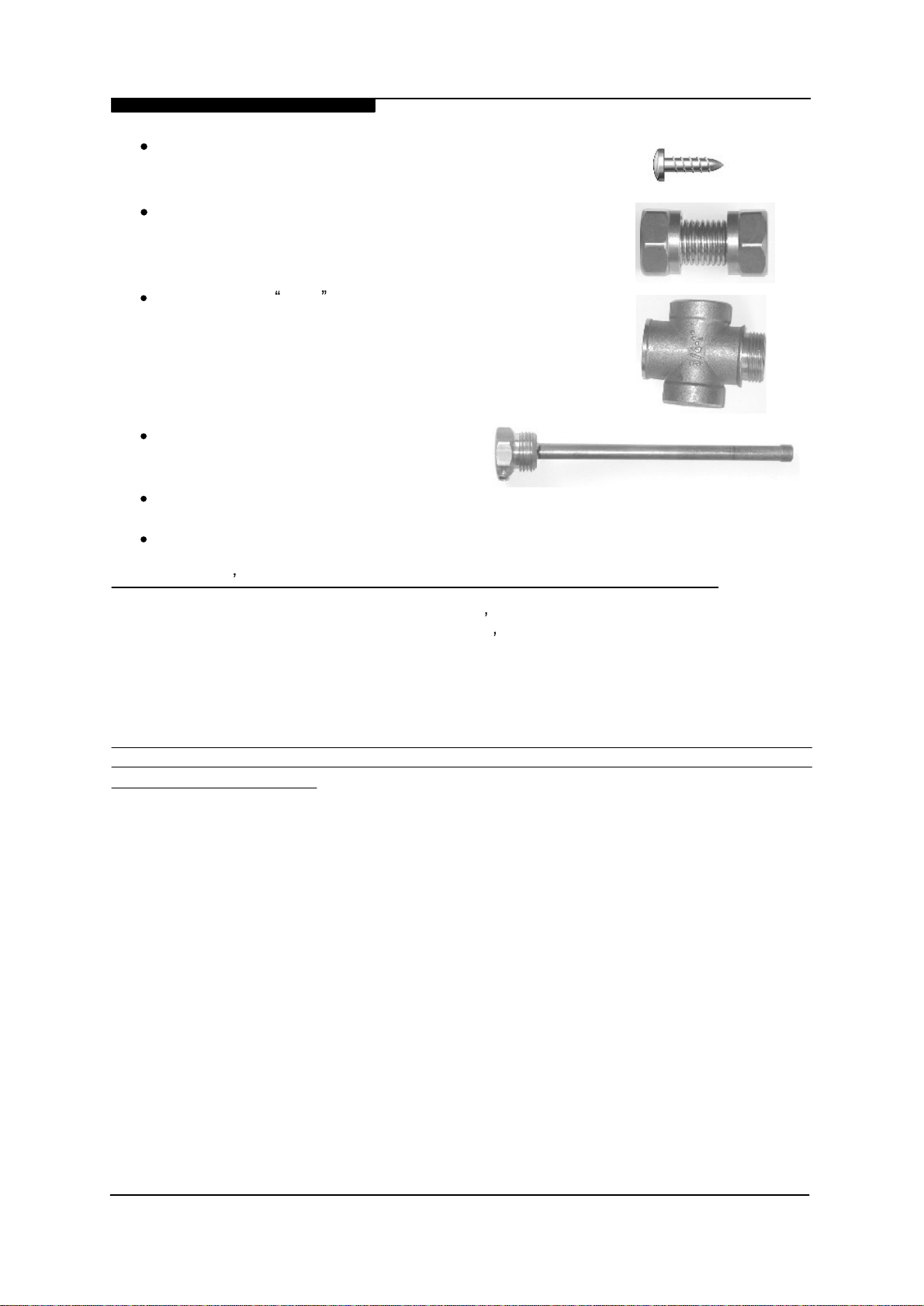

Installation of the Collector and external components

The Keston solar collector is made to an advanced specification. The collector is ultrasonic

welded and made with a vacuum deposited titanium selective surface. For pitched roof

installations, the collector comes with a roof mounting frame which consists of:

4 mounting plates (6 mounting plates for 3

collector systems)

2 roof S -brackets with top mounting bar and fixing nuts and bolts (3 roof S

-brack

ets for 3 collector systems)

4 L

-brackets for each collector

-

Installation & Servicing Instructions

Page :

4

Page 7

WD

435

/0/2006

16 coach screws (24 coach screws for 3 collector systems)

2 Collector Inter-connectors (4 collector inter-connectors for

3 collector systems)

Collector flow cross fitting with integral sensor pocket and

top outlet (used for connection of the solar AA

tion valve, if roof mounted)

Temperature sensor dry pocket

Chapter 2 :

Installation

V and isola

-

Keston

Solar

Thermal

8 nuts, bolts and spring washers

4 aluminium strips (6 aluminium strips for 3 collector systems)

It is the installers responsibility to make sure the roof is water tight and secure.

Solar Thermal System is designed for operation in standard UK geographic applications. For

high wind exposure applications, it is the installer s responsibility to make sure the collectors

are suitably fixed to the roof. It is also the installer s responsibility to maintain the necessary

Health and Safety standards. Keston recommend the use of either scaffolding and/or custom

made solar installation access equipment for the safe lifting and installation of the solar

collectors. If in doubt, please use a competent roofer to install the collectors

The National Federation of Roofing Contractors (NFRC) offers a solar panel roof mounting

service via its network of approved members. The NFRC can be contacted on 020 7436

0387 or via www.nfrc.co.uk

The mounting plate and roof bracket are designed for use with concrete flat or profiled

pantiles. For rosemary clay tiles or slate, the top and bottom mounting bar can be fixed with

the 4 aluminium strips. Slates can be drilled with tile drills and rosemary tiles with a diamond

drill. Any holes in the roof (which ideally should be completely avoided) should be sealed

with an external grade low modulus silicon sealant or proprietary O rings. The aluminium

strips can be bent to the shape of the tile to suit any profile. The aluminium strips must be

coach screwed to either the rafters or noggins firmly located between the rafters. For

rosemary tiles, Keston suggests using two coach screws to fix one end of the aluminium

strip to the rafter and the feeding the strip out between two tiles and screwing the mounting

bar to the exposed end of the strip.

The Keston

.

Installation & Servicing Instructions

Page :

5

Page 8

WD

435

/0/2006

Profile of Aluminium

Strip

Chapter 2 :

Installation

Suggested side profile

shape of aluminium

strip for a rosemary tile

roof

Keston

Solar

Thermal

Mounting

Bar

Location of

coach screws

Another method for Rosemary tiles is to use the roof S -brackets as provided and then

weathering the roof S -brackets into the roof with code 4 lead.

For slates, the tiles will need to be

drilled. The internal rafters can be

located by feeding an aluminium strip

out from the loft between the felt

sarking layers and then abutting the

aluminium strip against the roofing

rafter. The external exposed end of the

aluminium will indicate the location of

the internal rafter. Alternatively, use

noggins between the rafters to firmly

locate the aluminium strips.

Installation & Servicing Instructions

Sugges

ted

side profile

aluminium strip

Location of

Coach Screws

Profile of

Aluminium Strip

shape of

for a slate roof

Location of

Coach Screws

Mounting Bar

Felt Sarking

Slate Roof

Wooden Battens

Page :

6

Page 9

WD

435

/0/2006

Chapter 2 :

Installation

Keston

Solar

Thermal

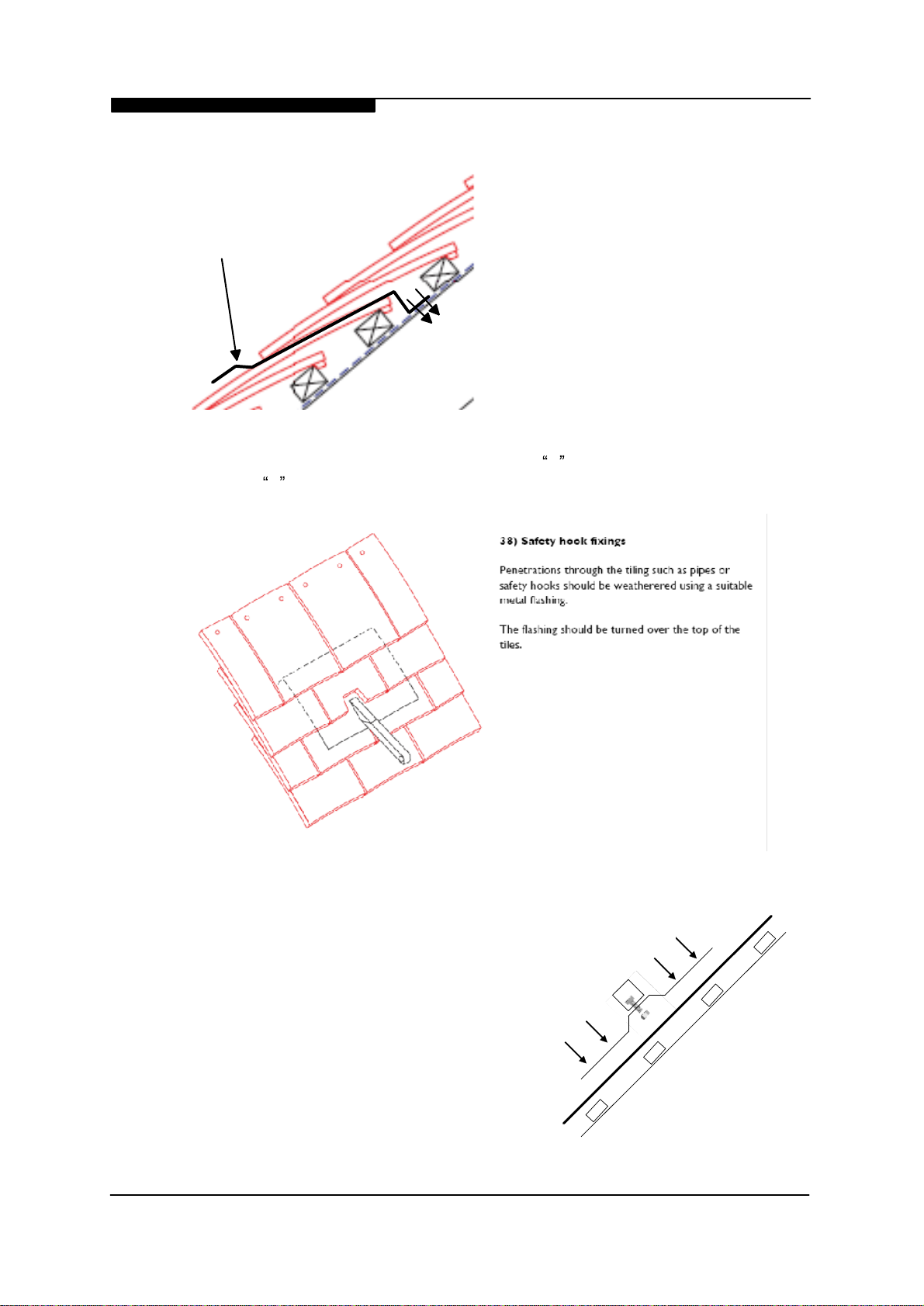

For flat or mildly profiled concrete pantiles, the roof hooks should be mounted as follows:

If the pantile is profiled, there might be a need to locate the roof hook to the joist using the

mounting plate as a connector. Here is an example:

This example is based on a roof

with a timber sarking. If no

timber sarking is available, the

nuts, bolts and spring washers

as provided can be used to bolt

the roof hook to the mounting

plate. Another alternative is to

place a noggin between the

rafters to strengthen the mounting structure and screw the roof

hook to the noggin.

Once the 4 roof S -brackets (or

6 roof S -brackets for 3 collectors) are firmly located and in

position, the tiles which were

Rafters

Max 185cm

Installation & Servicing Instructions

Page :

7

Page 10

WD

435

/0/2006

Chapter 2 :

Installation

Keston

Solar

Thermal

removed to locate the hooks can be replaced. The top and bottom mounting bars can then

be bolted to the roof hooks.

The first collector slides into the bottom

bracket and is located on either side by

the L-brackets:

Bottom Fixing of the Collector:

Top Fixing of the Collector

Three dimensional diagram of final location of top of the collector:

:

Installation & Servicing Instructions

Page :

8

Page 11

WD

penetration

penetration

AAV

Connectors

Connector

Connector

435

/0/2006

Chapter 2 :

The second collector is then

joined to the first collector using

the supplied Collector

Connectors:

The flow and return pipework can

be passed through the roof either

with a proprietary roof penetration tile or a Code 4 lead custom

made roof penetration tiles.

Ventilation tiles can sometimes

be adapted for this purpose.

Alternatively a silicon dektite

can be used or Keston also

supply as an optional extra a

lead pipe flashing tile which can

be adapted to suit most roof tiles.

Any exposed elements of the

roof penetration must be

carefully sealed with exterior

grade low modulus silicone.

Installation

Keston

Solar

Thermal

Roof penetration using a lead pipe flashing tile

Flow roof

Flow

Collector

Collector

Collector

The collectors should be

hydraulically piped as follows:

Return roof

Return

The AAV must be installed internally at a level above that of the panels (i.e. within the pitch

of the roof) to allow access for manual venting from within the roof space. The final part of

the roof installation is the insertion of the silicon PT1000 Collector Sensor into its mounting

pocket in the Flow Connector and feeding of the cable through or under the flow roof

penetration and through the felt or timber sarking so that the sensor cable is visible in the loft

space.

Installation & Servicing Instructions

Page :

9

Page 12

WD

435

2.

/0/2006

2

Installation of the Pump Station and other internal

Chapter 2 :

Installation

Keston

Solar

Thermal

components

The Keston Solar System features a flow and return line solar pump station and a solar

grade expansion vessel. This expansion vessel is 24 litres because it needs to absorb the

expansion of the steam in the collector during stagnation . All the components in the pump

station are solar grade.

The pump station has 28 mm flow and return fittings.

The pump is on the return line. The pump station contains a flowmeter, 2 check valves (to

stop the heat thermosyphoning out of the cylinder during the night), a pump, a flow and

return line thermometer, a manometer, two drain/fill valves, an SRV and a connection point

for the expansion vessel.

Mount the pump station on a suitable wall and connect:

top of the return line to the bottom of the collectors

top of the flow line to the top of the collectors

bottom of the return line to the bottom connection on the solar coil of the cylinder

bottom of the flow line to the top connection of the solar coil of the cylinder

a suitable drain valve in the return line

the manually isolated AAV in the flow line either internally or externally as close as

possible to the collectors

This can be seen in the Hydraulic and Control Circuit Layout in chapter 1. Externally terminate the Safety Relief Valve (SRV) where the exhaust can not scald anyone. If necessary,

this SRV can be removed and blanked off from the pump station and fitted in the return line

loft space to assist the external termination of the exhaust. The pipework from this valve to

the external location must be in copper, stainless or other suitable pipe and it is the

installer s responsibility to take into account the steam or extremely hot water that might

exhaust from this SRV.

These need to be reduced to 15 mm.

The expansion vessel should be fitted vertically at the end of at least 1m of 22 mm pipework.

This pipe length is to provide a water buffer to protect the vessel from extreme

temperatures generated during stagnation conditions. If 1m of pipe cannot be

accommodated a small buffer vessel may be considered. The expansion vessel must be

mounted with the water side of the diaphragm above the air side.

2.

3

Electrical installation and Solar Unvented Cylinders

The Keston Solar System is supplied with a Differential Temperature Controller (DTC) and 2

silicone high temperature PT1000 temperature sensors. The Keston DTC has several

functions which improve performance and efficiency and also record historical data which is

useful for diagnostic analysis of the system performance. All electrical installation must take

into account part P of the wiring regs and pipes, pump, cylinder etc. must be bonded in

accordance to BS 7671.

Installation & Servicing Instructions

Page :

10

Page 13

WD

435

/0/2006

Chapter 2 :

Installation

Keston

Solar

Thermal

Power for the DTC can be taken from either the 10 way central wiring centre if used (the

solar controller is part of the heating control circuit and so this is the ideal location) or alternatively from a 230 V 3A fused spur.

The DTC is designed

for use with solar

thermal water heating

systems only

The Keston DTC is permanently on and functions by measuring the temperature in the

collector (T1) and the temperature in the solar section of a twin coil cylinder (T2). When the

difference between collector and cylinder temperatures (T1 T2) reaches 8 degrees (adjustable), the DTC switches the solar pump (R1) on. When the difference between collector and

cylinder temperatures (T1 T2), reaches 4 degrees (adjustable), the DTC switches the solar

pump (R1) off again.

The Keston DTC also has modulating speed control of the pump, storage temperature limita

tion and full monitoring of the hours of operation and maximum and minimum temperatures

at T1 and T2. It is strongly recommended that the collector temperature limit, solid fuel/flue

tank regulation and antifreeze functions are left switched off.

Installation

Choose a suitable location where the building occupants can easily access the control

buttons and display of the DTC and fix screw 1 to the wall. Hang the controller onto this

screw and use the DTC as a template to position screws 2 and 3.

Electrical Socket connections on the DTC

Electrical Connections. To avoid potential interference, the low voltage cables connecting

sensors T1 and T2 to the DTC should be run at least 10 cm distant from any power cables.

-

Sensor T1 should be located in the flow panel connector and terminated in the loft.

Installation & Servicing Instructions

Page :

11

Page 14

WD

435

/0/2006

Chapter 2 :

Installation

Keston

Solar

Thermal

Both sensors T1 and T2 have no polarity. If the cable length between the DTC and T1 is less

than 75m connect T1 to the DTC with 0.75 mm2 dia two core cable. If the cable length

between T1 and the DTC is between 75 and 150 metres, use 1.5 mm2 dia two core cable.

The cable length between T1 and the DTC must be no more than 150m.

Position the ends of the T1

cable in sockets 7 and 8 on the

DTC. Connect sensor T2 in

sockets 9 and 10 and the

sensor end in the solar section

sensor pocket location in the

twin coil cylinder. This should

be either close above or in the

middle of the solar coil. If

sensor T2 needs extending,

please follow the same cable

diameters requirements as for

T1.

Connect the 230 V 3A fused

live to socket 4, the associated neutral to socket 3 and earth to socket 1 or 2. Using appropriate heat resistant flex, wire the solar pump in the pump station to socket 6 for live, socket

5 for neutral and either sockets 1 or 2 for earth. Replace the electrical connection cover.

The above diagram shows the four control buttons and LCD display on the DTC. The DTC

has 2 main menu options,

When in

READINGS

READINGS

and

ADJUSTMENTS

.

, after pressing the OK button, you can scroll up and down through

the readings using the up and down scroll buttons. At any time whilst scrolling through the

readings, you can return to the main menu by pressing the Menu button. The available

readings are:

stor. Tank:

Collector:

col.

Max:

col. Min:

st. tank max:

st. tank min:

d-R1 hrs:

x-R1 hrs:

Installation & Servicing Instructions

°C

°C

°C

°C

°C

°C

T2 - temperature in solar section of cylinder

T1 - collector temperature

Maximum collector temperature recorded

Minimum collector temperature recorded

Maximum cylinder temperature recorded

Minimum cylinder temperature recorded

hours Hours

hours

Total hours of solar pump operation since installation of DTC

of solar pump operation since last reset

Page :

12

Page 15

WD

435

/0/2006

All the maximum, minimum and hours readings (except for total pump hours) can be reset by

holding the OK button down for 2 seconds when this reading is visible in the display. These

maximum, minimum and hours readings can be used for diagnostic analysis of the performance of the solar system.

Chapter 2 :

Installation

Keston

Solar

Thermal

Whilst in the main menu, you can scroll between READINGS

using the scroll buttons. Whilst in ADJUSTMENTS , you can enter the submenus

PARAMETERS , FUNCTIONS

Menu at the same time. You can scroll through these 3 submenus using the up and down

scroll buttons.

Whilst in any of the 3 submenus, you can enter the settings by pressing the OK button.

Then, whilst below the submenus, the scroll buttons move you between the various settings.

PARAMETERS

st. Limit:

ON-TDiff:

OFF-TDiff:

The

st. limit: 60 °C

or conditioned water area when the temperature can be reset up to 80 °C. Consideration of

point of use scalding should be considered when altering the store limit temperature.

use of Thermostatic Mixing Valves (TMV) is important for raised store temperatures.

ON-TDiff: 8 K

long pipe run when the two values can be increased in proportion to the temperature drop on

the flow line between the collector and store.

contains the following three settings (with the recommended values):

60 °C

M

8 deg

4 deg

should be left at 60 °C unless the solar system is installed in a soft water

should be left on 8 and

and

MAN. OPERATION by pressing the buttons OK +

aximum store temperature at sensor T2

T1-T2 to bring pump on - default setting 8 deg

T1-T2 to turn pump off

OFF-TDiff: 4 K

- default setting 4 deg

should be left on 4 unless there is a

and ADJUSTMENTS

The

FUNCTIONS

Tmin a. Fuel:

col. Limit:

Antifreeze:

speed contr:

T1: KTY

MAN. OPERATION

pump P1:

preset config.

To change any of the settings whilst in the submenus, the OK button should be held down

for 2 seconds.

All the functions should be left as factory preset. The speed control function will be further

discussed in the commissioning section. The manual control of the pump is useful during

commissioning of the solar system.

Installation & Servicing Instructions

contains the following settings (with the recommended values):

OFF

OFF

OFF

ON (modulating pump speed control. See commissioning)

OFF

contains the following settings (with the recommended values):

OFF

(ON makes the DTC a solid fuel controller)

(collector cooling function not required by Keston solar)

(runs system without antifreeze. For hot climates)

(using system with alternative sensor types

(manual control of the solar pump)

(returns controller to factory preset conditions)

)

Page :

13

Page 16

WD

435

/0/2006

Chapter 2 :

Installation

Resistance values of the temperature sensors

Technical data

Keston

Solar

Thermal

Installation & Servicing Instructions

Page :

14

Page 17

WD

DHW Output

435

/0/2006

Chapter 2 :

Installation

Keston

Solar

Thermal

Unvented cylinders and the Keston Solar System

The second level of control on an unvented G3 cylinder requires that there should be an

isolating valve within one metre on the flow line of the boiler coil to cylinder connection. This

isolating valve is wired to a manual reset thermostat. This boiler system solution is not feasible for a solar system as, due to the raised temperatures and pressures, even solar grade

valves installed on the flow line can fail.

Therefore, ideally the power to the 10 way central heating control box is wired through a

single manual reset thermostat located in the top of the unvented cylinder. This will cut

power to both the boiler and solar circuits.

Proposed Manual Reset and Cylinder Thermostat Electrical Wiring Diagram

L from Fuse board

N from Fuse board

N to 10 way box

L to 10 way box

From Timeclock

N

from

10 way box

E

L from

10 way box

To Boiler

Manual Reset Stat

Cylinder Stat

Dual

Aquastat

Boiler Coil

Motorised Valve

Brown

Blue

Green/Yellow

Grey

Orange

Brown

230 V supply to DTC

(from 10 way box)

E

N from 10 way box

L from 10 way box

Socket 1 or 2

Socket 3

Socket 4

Alternatively, two manual reset thermostats can be employed on the heating system. One

thermostat, located to respond to the boiler coil, is wired conventionally as per manufacturer s instructions to the boiler heating controls and the solar manual reset thermostat,

Installation & Servicing Instructions

Page :

15

Page 18

WD

435

/0/2006

Chapter 2 :

Installation

Keston

Solar

Thermal

located to respond to the solar coil, is wired to isolate power to either the DTC or the solar

pump.

Please also note that if the panel is located below the cylinder, there is potential for the heat

to thermosyphon from the collector to the cylinder and in this case, the only solution is to fit a

solar grade isolating valve within one metre of the solar return line to cylinder connection

and this valve must close as soon as the manual reset thermostat is opened.

Part L Building Regulations

The installer has a requirement under Part L to confirm installation or install a cylinder

thermostat and zone valve to control the boiler section of the cylinder hot water temperature

and to provide a boiler interlock. The cylinder insulation must also be brought up to Part L

standards.

Installation & Servicing Instructions

Page :

16

Page 19

WD

435

/0/2006

3

.

Commissioning of the Solar System

An important safety consideration on filling the solar system is to prevent the fluid boiling on

entry into the collector. If there is any chance that the collector will exceed 100 °C during the

commissioning procedure, the collector must be covered.

By turning both of the thermometers on the pump station an eighth of a turn clockwise, the

check valves are disconnected from the solar primary circuit and fluid can flow in either

direction. By turning both the thermometers a quarter turn clockwise, the check valves are

fully closed.

Chapter 3 :

Commissioning

Keston

Solar

Thermal

1)

2)

3)

4)

5)

6)

7)

8)

9)

10)

11)

12)

13)

14)

Open the circuit by disconnecting both check valves (thermometers an

clockwise).

Fill the solar primary circuit and flush the circuit of all the installation debris.

Mix the Keston supplied antifreeze with water at a ratio of 1 part antifreeze to 3 parts

water (25% concentration). In climates where 20 °C can be realised, increase this

concentration ratio to 40%. We suggest that due to the low volume in the solar primary

circuit, that the solar system is filled from a dosing station as supplied by the water treatment

specialists. Keston strongly recommend that a filling loop is not fitted on the solar primary

circuit as this can lead to dilution of the antifreeze.

Check the expansion vessel has a pre-commissioning pressure of 1 bar.

Connect the dosing vessel to the lower filling valve, make sure that the check valves

are in the open position and that the manual isolator on the

Fill the circuit from the dosing vessel and pressurise the circuit to 1.5 bar.

Manually switch the

Purge the remaining air from the circuit and isolate the

Activate the check valves by turning the thermometers an eighth of a turn anticlockwise.

Whilst the

that the

litres/min for 2 collectors and 6.3 & 9.45 litres/min for 3 collectors.

viewed as the bottom line on the

Ideally, the pump is set on speed 1 and the

position.

After purging the air, manually switch the

hydrometer, recheck the concentration of the fluid in the circuit. Adjust to correct

ratio.

Reset the

the

flowrate

by improving the heat recovery from the solar collectors and reducing pumping electrical

losses. Alternatively, if the

litre/min/m2 collector.

The

Leave it on this setting unless soft water is available in the property. If soft water is

available, the thermostatic cylinder limit can be reset up to 80 °C.

Always, even at 60 °C, thermostatic mixing of the water should be considered. Water

can scald from 47 °C. Any

points-of-use should set the temperature above 55 °C and below 60 °C.

DTC

flowrate

DTC

to suit the differential temperature. PSC is employed to improve system efficiency

DTC

thermostatic cylinder limit temperature (

DTC

to on and check pump is running.

is on manual, set the pump on setting 1 and adjust the

is between 1 and 1.5

flowmeter.

to Auto. The Pump Speed Control (PSC) function will automatically adjust

PRC

function is switched off, make sure the

TMVs

litres/minute/m2 collector i.e. between 4.2 & 6.3

If necessary, increase the pump speed settings.

flowmeter

DTC

fitted close to the cylinder with long pipe runs to the

adjustment screw is in the vertical

to off and using a

st.

AAV

is open.

AAV.

The

refractometer

flowrate

limit) has a default of 60 °C.

eigth

flowmeter

flowrate

is set to 1

turn

so

can be

or a

Installation & Servicing Instructions

Page :

17

Page 20

WD

435

/0/2006

Chapter 3 :

Commissioning

Keston

Solar

Thermal

Commissioning Certificate

It is highly recommended that a form of commissioning certificate is left with the

householder for safekeeping. The certificate should contact the following information:

Expansion vessel pre-charge pressure

Solar primary circuit pressure

delta T

delta

st.

TMV

T

Limit

fitted

on

off

If yes, point-of-use temperature

PSC control

If no,

flowrate

set to:

Antifreeze concentration

Antifreeze supplier

bar

bar

K

K

°C

Yes/No

°C

Yes/No

litres/min

%

Keston / Other

Installation & Servicing Instructions

Page :

18

Page 21

WD

435

/0/2006

Chapter 4 :

Handing Over To The User

Keston

Solar

Thermal

4.

Handing over to the user

There is no day-to-day control required of the Keston Solar System. The system is

completely self-sufficient and requires no maintenance on the part of the building occupants.

However, most customers like to be informed about the solar system and how to maximise

the performance of the solar system so that they use as little fossil fuel for hot water heating

as possible.

Therefore, the customer should be shown:

On the

DTC,

the READINGS menu and how to scroll through the readings.

Some explanation of maximum and minimum readings and hours of operation is

recommended.

So that the user can check system operation during solar radiation, the functioning

of the

If an

flowmeter

unvented

and the on symbol on the LCD display of the

DTC

cylinder is fitted (such as the Keston Spa), the manual reset

thermostat and action to take if this thermostat needs to be reset i.e. a solar

competent heating engineer should be called out to check the source of the fault.

The exhaust point of the

SRV

and what action to take if steam or water is seen

coming from the end of this pipe i.e. a solar competent heating engineer should be

called out to check the source of the fault

How to manage the boiler cylinder thermostat and

timeclock

so as to maximise the

solar gain. Please see below.

The installation manual and commissioning certificate, both of which should be left

on-site

Maximising the output from the Keston Solar System

If the solar system has been connected to a twin-coil cylinder, both the boiler heating circuit

and solar heating circuit can heat this cylinder. The lower section of the cylinder is available

for the solar circuit. The upper section of the cylinder is available to the boiler circuit.

The solar heating circuit operates most effectively when it has the largest volume of water to

heat. Therefore, especially during the summer months, Keston strongly recommends that

the boiler control circuit is left off during the solar day (when the sun is likely to heat the

cylinder) so as to provide the solar circuit with as much work as possible. This will minimise

the fossil fuel heating bill. The cylinder is well insulated and so will retain its heat for a long

time unless the water is run off at the points-of-use.

The building occupant s lifestyle will determine the optimum settings for the boiler controls.

The aim is to leave a reasonable volume of water in the boiler section of the cylinder at a

temperature which is warm enough to still provide an adequate temperature at the points-ofuse and cool enough to obtain as much of the available solar energy as possible. Many

occupants find that they can often run on solar only during the summer months. However,

the occupants should be warned about the

legionella

risk of running on a solar only setting

i.e. the boiler section of the cylinder should reach at least 55 °C everyday and preferably 60

°C everyday.

Installation & Servicing Instructions

Page :

19

Page 22

WD

435

/0/2006

Chapter 4 :

Handing Over To The User

Keston

Solar

Thermal

If the customer s find that they have enough water available for washing etc. during the

morning and early afternoon period, one ideal setting is to switch the boiler section of the

cylinder on everyday for an hour between 8 and 9

pm.

This setting will make sure the cylinder passes through the 55 to 60 °C once a day and also provide the solar circuit with the

maximum workload during the solar day.

Ultimately the customer should find their own optimum boiler timings for

their needs. The less the boiler is fired for

DHW,

the better.

DHW

according to

Installation & Servicing Instructions

Page :

20

Page 23

WD

435

/0/200

6

Chapter 5 :

Servicing

Keston

Solar

Thermal

5.

Routine Servicing

MAINTENANCE SCHEDULE TO BS 5918: 1989 -

Code of practice for SOLAR HEATING SYSTEMS FOR DOMESTIC HOT WATER

British Standards Institution (Indirect)

While a properly designed and installed solar heating system should be expected to give a

service life comparable to that of other types of heating systems, some maintenance may be

necessary to maintain the efficiency of the installation.

During a maintenance inspection the following items should be checked:

1. That unions and glands are free from weeps

2.

3.

4.

5.

6.

7.

That the glazing seals are

weathertight

and sound

That the collector circuit is free from air

That all air eliminators, non-return valves, solenoid valves and motorised valves are

operating correctly

That the correct volumes and system pressure are maintained (at rest and in

operation)

That the electrical controls are operating correctly to the manufacturer's instructions

That circulating pump is operating without undue noise or vibration

8.

9.

10.

That all insulation is firmly attached

That all covers are in place

That no condensation or damp spots are apparent, particularly around the pipes and

fixings in the roof

11.

12.

13.

14.

15.

16.

17.

18.

That the roof fixings are firm and the roof covering is free from cracks

That the weathering is properly protecting the structure

That the collector glazing is clean

That the glazing is free from cracks

That there is no evidence of serious corrosion

That any

paintwork

is sound

That all sensing devices are firmly and properly in place

That the life of the heat transfer fluid has not expired

Keston recommend that the above maintenance procedure is followed annually, preferably

when the boiler and/or cylinder is also serviced.

The antifreeze has a service life of 5 years and so this fluid must be changed at each 5 year

interval.

Before decommissioning/draining the solar circuit, make sure there is no chance for collector

temperature to exceed 100 °C, that all check and isolating valves are open and that the

antifreeze mixture is captured in storage vessels for safe disposal at a recognised safe

disposal centre.

Installation & Servicing Instructions

Page :

21

Page 24

WD

435

/0/2006

Chapter 6 :

Fault Finding

Keston

Solar

Thermal

6.

6.1

Fault Finding

No flow solar primary circuit

POSSIBLE CAUSES

System in stagnation

Airlock in circuit

Manometer on low

pressure

Faulty check valve

Steam escaped from

Fluid exhaust from

SRV

Faulty or blocked pump

Frost damage to collector

Blocked circuit

PT1000

Faulty

6.2

sensors loose

DTC

Low performance of solar system

POSSIBLE CAUSES

faulty

DTC/system

settings

AAV

ACTION

Check

st. limit

at

max

Purge air

Refill and manually operate

DTC

Check open and if necessary, replace

Manual isolate

Check expansion vessel,

AAV

and refill. Check expansion

SRV

& refill

vessel

Free, clean and if necessary, replace

Replace collector and

recommission

circuit

Check for degraded old antifreeze blockage or limescale

blockage

Relocate sensors

See below

ACTION

Check delta Ton and delta

Speed Control. Also check functions ON/OFF and

T

settings,

off

flowrate

and

Pump

DTC

Auto

on

F

aulty

PT1000

sensors

Faulty pump

R

estriction in circuit

I

nadequate air removal

L

oss insulation

Boiler primary circuit

providing too much heat

6.3

Water too hot at points-of-use

POSSIBLE CAUSES

Incorrectly set

Incorrectly set

F

aulty boiler primary circuit

6.4

Faulty

DTC

TMV

DTC

POSSIBLE CAUSES

No LCD display

LCD says Short circuit

LCD says

Interruption T1/T2

Check sensor location and check electrical resistance to

temperature (see table in ch 4)

Check pump is rotating. Check valves open and pump

speed correctly set

Check circuit components and for old antifreeze/limes

restriction in pipes

Purge air

R

eattach insulation

R

eset central heating

timeclock

to give solar system more

cylinder water to heat

ACTION

Check

Check output temperature from

st. limit

on

DTC

TMV

Check out boiler primary circuit for faults

ACTION

No power supply, check fuse and 230 V

T1/T2

Check relevant sensor for short circuit

Check relevant sensor for circuit break

cale

Installation & Servicing Instructions

Page :

22

Page 25

WD

435

/0/200

6

Chapter 7 :

Parts List

Keston

Solar

Thermal

7.

Parts List

Keston Boilers Solar Kits contain the following items:

Description

Solar Collector Panel

CLS1808

Onto roof mounting set

Flat Roof Stand

Collector Inter-connectors

Flow connector fitting

Panel Sensor Pocket

Part Number

SP18101000

SP18102000

SP18103000

SP18104000

SP18100040

SP18305000

SP18105010Automatic Air Vent

Isolating Valve

Solar Pump Station

Solar Controller

(DTC)

Expansion Vessel - 18

Expansion Vessel - 25

Vessel Fixing Bracket

Vessel Connecting Hose

litre

litre

SP18106000

SP18202000

SP18301000

SP18402000

SP18407000

SP18407000

SP18408010

Glycol Antifreeze

The above kits are also available with Keston

SpaTwin

200 (200 litre) is packaged with a 2 panel kit, a

SpaTwin

packaged with a 3 panel kit.

Kit

PA2

8

litre

double coil

Kit

PA3

10

litre

SpaTwin

Kit

FA2

Kit

3232

--32

32-2121

1111

1111

1111

1111

1111

1111

-1-1

1-11111

1111

8

litre

unvented

10

cylinders. A

300 (300 litre) is

FA3

litre

Keston supplied optional extras for roof penetration:

Keston can also supply kits for in-roof mounting of the panels. Contact Keston for more

detail.

Installation & Servicing Instructions

Page :

23

Page 26

KESTON SOLAR

THERMAL SYSTEMS

INSTALLATION KEY POINTS

AND

COMMISSIONING CHECKLIST

Installation Manual has been carefully read and followed.

The roof mounting of the collectors is secure from both wind damage and rain

penetration.

The fully-filled solar circuit has been installed to manage both freezing and stagnation conditions.

Has the

and commissioning?

Have both check valves (under temperature gauges) been left in the correct

position?

Does the

and has the flow rate been appropriately set with either PSC or 1

collector?

The solar-grade expansion vessel must also be on the return pipework

be mounted vertically at the end of a 1m length of 22 mm

collector.

installed with a pre-commissioning pressure of 1.0 bar?

Drain/fill valves have been selected to deal with temperatures and pressures

realised

Brass olive compression fittings have been used within 2

lead-free solder fittings on the rest of the solar primary circuit and all the

copper or stainless steel (or superior specification to the above).

High-temperature

solar primary circuit.

All external insulation, cable, cable clips

Thermostatic Mixing Valve

provided.

Diferrential

legionella

The differential controller has been correctly wired. That is an electrical supply of

230 V fused at 3A and the solar pump has been wired in heat resistant flex. Cables

between the sensors and the differential controller are in 0.75

75 m and 1.5

For

tial controller must be wired via a mechanical reset thermostat.

On an

solar-grade 2 way valve must be located in the return

store.

The pipes, pump and cylinder are bonded to BS 7671.

To confirm with Part L, the installation of a cylinder thermostat and zone valve to

control the boiler section of the cylinder hot water temperature and a boiler interlock

has been confirmed or provided. The cylinder has been suitably insulated.

A Commissioning Certificate is completed and the Certificate and solar system has

been fully handed over to the customer.

AAV

been fully isolated after setting the pressure to 1.5 bar, purging of air

SRV

terminate to a safe location, have the pump valves been left open

Expansion vessel is supplied.

in that part of the circuit.

armaflex

Control

protection implemented

unvented

unvented

cylinders, for the second level of control, either the pump or differen

(DTC)

mm2 for up to 150 m length and located away from 230V interference.

cylinder, if the collectors are vertically below the hot water store, a

or similar insulation has been used throughout the

(TMV)

settings are as directed in the manual and suitable

litre/min/m

pipework

Has the expansion vessel been correctly

metres

etc

are UV-resistant.

or similar protection for the building occupants is

pipework

for each m2 of

of the collector and

mm2 cable for up to

within 1 m of the

2

and should

pipework

is

-

WD436/0/2006

Page :1

Loading...

Loading...