Page 1

COMBINATION WALL HUNG

GAS BOILER

MODEL RSM 20/FB

INSTALLATION & SERVICING

INSTRUCTIONS

DATA BADGE UNDER FRONT PANEL ON BURNER COVER

Manufactured by

THERMOMATIC SRL Casalecchio Di Reno Bologna Italy

exclusively for

High Efficiency Domestic & Commercial Boilers

34 West Common Road Hayes Bromley Kent BR2 7BX

Telephone : 020 8462 0262 Fax : 020 8462 4459

e-mail: info@keston.co.uk Web: www.keston.co.uk

Page 2

Page 2

Page 3

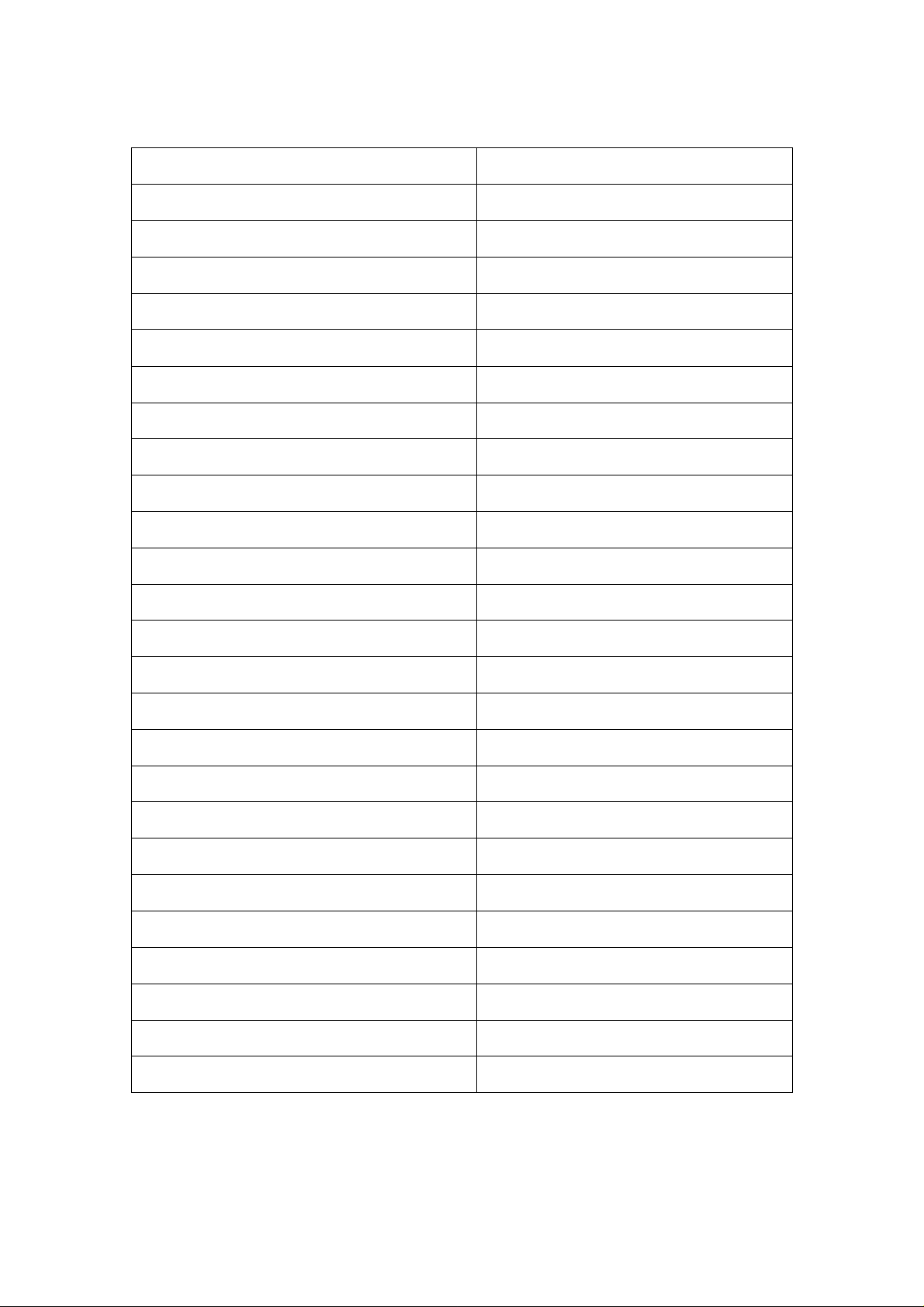

TECHNICAL DATA

Heal input (fixed) 26.2kW (89.400 Btu/h)

Heal output 23kW (78.500 Btu/h)

Burner pressure

Burner

14mbar(5.6in.w.g.)

Inlet 2Ombar

Worgas Thermomatic

3 injector 2.35 - 2.70 - 2.35 n

Gas control valve Honeywell VK 4105G

Control Box Honeywell VK 4105G

Filling loop

Inter Albion with Alhilil

double check valve

Boiler control thermostat Ranco K36 Y21

Bimetallic Priority thermostat Cewal 91931199

Overheat thermostat Ranco LM7 P5 043

Anticondensing Thermostat Imit TR2

Electrical supply 240V-50HZ

Power consumption 180 W

Internal fuse rating 3A

Weight empty 77 kg (169.7 Ib)

Weight full 92 kg (203.O Ib)

CH max pressure 3 bar (44 psi)

CH min working pressure 0.5 bar (7.4 psi)

DHW max pressure 10 bar (146 psi)

DHW min working pressure 0.6 bar (8.7 psi)

CH expansion vessel 8 litres charged to 0.5 bar (7.4 psi)

DHW expansion vessel

0.1 60 litres charged lo 3.5 L

(51.5 psi)

CH max temperature 90°C

Design temperature rise 11°C

DHW flow at 30'c rise 11.0 l/min

DHW flow at 35'c rise 9.21 l/min

Page 3

Page 4

43

Contents Figures

Section Page No. Page

Technical Data Inside Internal Design 1.1 5

Front Cover Control Panel 2.1 6

General Description 1 5 Connections 3.1 6

Operating Sequence 2 6 Alternative top tip system 3.1. A 7

Related Documents 3.1 6 Sealed system filling & make-up 3.1. B 8

Gas Supply 3.2 6 Pump Performance 3.2 9

Water Systems 3.3 7 Typical Heating System 3.3 7

Flue Systems 3.4 9 Domestic Hot Water Supply 3.4 9

Appliance Location 3.5 10 Standard Flue Kit Components 3.5 9

Electrical 3.6 11 Optional Horizontal Extension

Flue

Installation Procedures 4 13 Kit Components 3.6 9

Flue System: Cutting & Siting of Terminal 3.7 7

Assembly 4.7 13 Clearances 38 11

Connecting Services 4.8 18 Functional Flow Wiring Diagram 3.9 10

Filling Loop Assembly 4.9 18 Disassembly of panels 3.10 12

Commissioning 5 18 Wiring Diagram 3.11 38

Procedures for part

replacement

Draining 6.3 20

Replacing Fan 6.5 20 Appliance Mounting 4.1 13

Replacing Air Pressure Switch 6.6 21 Flue Positioning 4.2 13

Replacing DHW Expansion

Vessel

Flue Connection 4.4 14

Replacing Automatic Air Vent 6.8 21 Flue Connection 4.5 14

Replacing CM Expansion

Vessel

Replacing Bimetallic Priority Vertical Flue Terminal Locations 4.7 16

Thermostat 6.10 21 Assembled Extended Vertical

Replacing Solenoid of Gas Kit 4.9

Control Valve 6.11 21

Replacing Multifunctional Filling Loop Assembly 4.11 18

Gas Control Valve 6.12 22 Gas Control Valve 5.1 19

Replacing Circulating Pump 6.13 22 Central Heating Expansion

Replacing thermostatic

T/P Gauge 6.14 22 Thermostat Positions 6.4 22

Replacing Safety Valve 6.15 22 Pressure Relief Valve 6.5 22

Replacing Burner 6.16 23 6.7 23

Replacing Injectors 6.17 23 Top view of Boiler 8.1 32

Replacing Flame Sensing

Ignition Electrodes 6.18 23

Replacing Electronic Control

Box 6.19 23

Replacing Green Operating

Light & Red Lockout Button 6.20 23

Replacing On/Off Summer/

Winter Switches 6.21 23

Replacing Filling Loop 6.22 23

Fault Finding Algorithm 7.1-12 24 – 31

Routine Servicing and

Cleaning 8 32

Short Spare Parts List 34 – 36

Complete Boiler Wiring Schematic 37

Wiring Diagram 38 Manual Addendums 40 -

6 20 Time Clock Wiring 3.12 39

Honeywell T6360B Room Slat

Wiring 3.13 39

6.7 21 Flue Positioning 4.3 14

6.9 21 Vertical Flue Clearances 4.6 16

Flue

Vessel

Spare Parts

4.8 & 17

6.2 21

33, 34

Page 4

Page 5

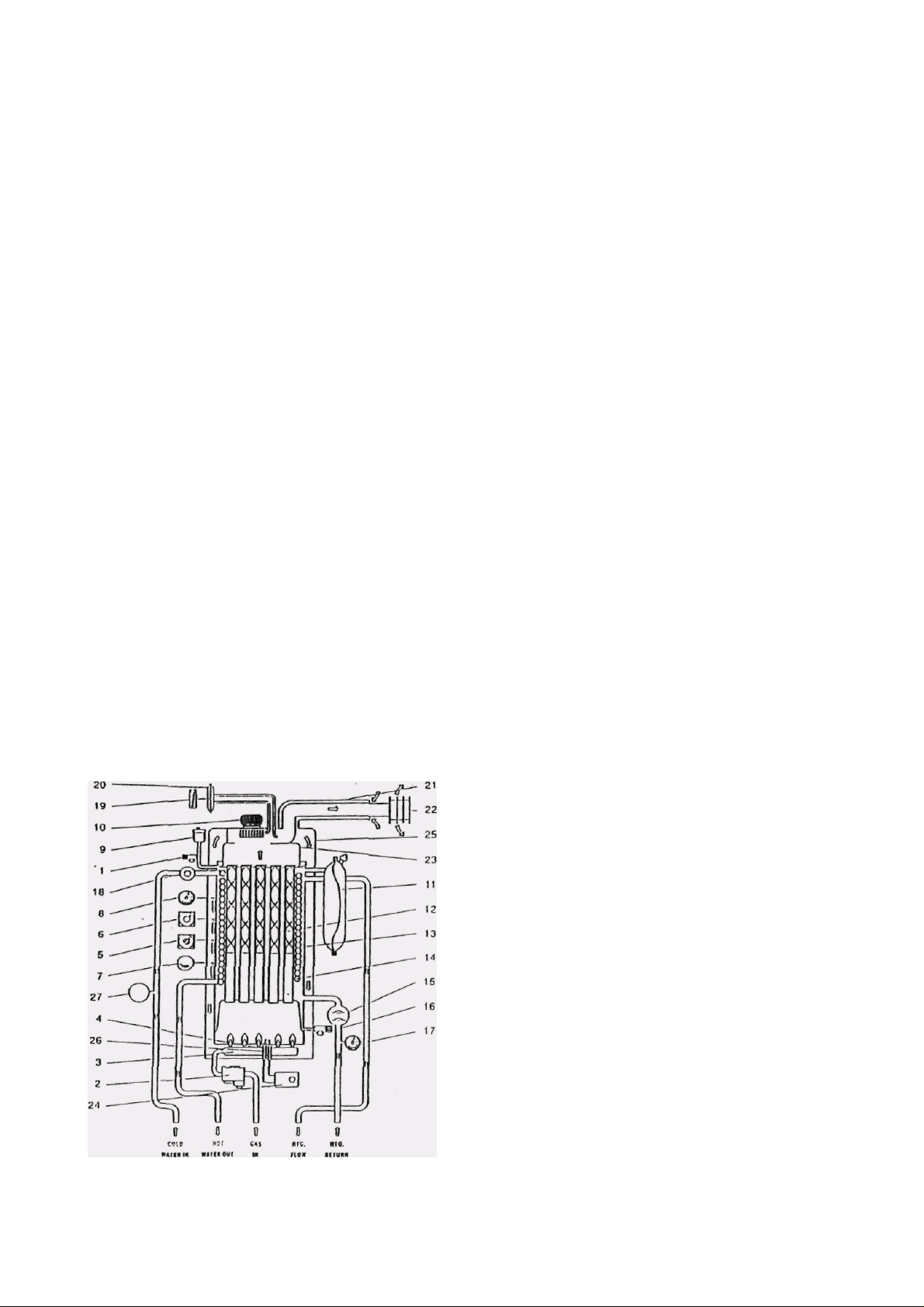

1 GENERAL DESCRIPTION (Fig.1.1)

The Thermomatic RSM 20/FB is a wall mounted

water jacketed vertical tube Combination Boiler fitted

with a copper coil to give an immediate supply of hot

water.

The appliance is room sealed and fitted with a coaxial

duct for fan powered ventilation, designed for exit to

either side or to the rear of the appliance.

The copper coil containing 2 litres of hot water is

indirectly heated, giving an immediate and continuous

hot water supply.

The central heating pump will not operate until

the boiler temperature reaches 60°C. The pump is

controlled by a capillary thermostat called the anticondensing thermostat. In addition, a bimetallic

priority thermostat will stop the pump as soon as

domestic hot water is drawn. This allows the full heat

output to be directed to supplying hot water only.

The appliance jacket extends to burner level, so the

walls of the combustion chamber are water-cooled.

This prevents the intense local heating usually

associated with combination boilers and considerably

prolongs the appliance life.

The domestic hot water, being indirectly healed

through a coil of a larger diameter than normally

used, is not so easily affected by calcium impurities

that build up lime scale. This together with the flexing

of the coil due to temperature changes, means

calcium "build-up" is considerably lessened.

With the Summer/Winter switch set to Winter the

appliance will automatically adjust to the central

heating output, which may be a single radiator, ot

any number within the heat ouput of the appliance.

The Thermomalic does not require a 'by-pass' and all

radiators can be fitted with thermostatic radiator

valves.

Unlike many other combination boilers, the Thermomalic will operate on low water pressures. The

boiler within the casing is cylinder shaped and fitted

with vertical copper flue tubes through which the gas

products pass. These tubes are fitted wiih stainless

steel baffles to increase efficiency and to rapidly

conduct the heat from the gas products to the water

contained within the cylindrical heat exchanger.

An extended copper coil fitted around the vertical

flue tubes is within the water content. The water

content connects to the central healing system and

indirectly heats the domestic water passing through

the coil.

A SIT Controls multifunctional control with electric

ignition is used and temperatures of both central

heating and hot water ate controlled by capillary

thermostats.

The flue extract fan incorporates a pressure control

switch which activates the gas control. In the case of

a fan failure of any kind the gas control fails to safely.

It is recommended that a scale inhibitor should

be fitted in hard water areas.

FIG.1.1 INTERNAL DESIGN

1 Manual air vent cock

2 Gas control valve

3 Stainless steel burners

4 Ignition electrode

5 Pocket for an anticondensing thermostat phial

6 Pocket For safety thermostat phial

7 Pocket for boiler healing thermostat phial

8 Water temperature gauge

9 Automatic air vent

10 Fan motor

11 Expansion vessel

12 Stainless steel Hue baffles

13 Boiler shell

14 Domestic hoi water copper coil

15 Circulating pump

16 Pressure relic! Safely valve

17 Water pressure gauge

18 Bimetallic priority thermostat

19 Air pressure microswitch

20 Air pressure switch body

21 Concentric flue/air pipe

22 Flue terminal

23 Flue hood

24 Electronic control box

25 Room sealed combustion chamber

26 Flame detection probe

27 Mini expansion vessel (Domestic)

Page 5

Page 6

2 OPERATING SEQUENCE (Fig.2.1}

Red Light Central Heating Switch Temp. Press. Guage

Boiler Control Green Light Fuse On/Off Switch Overheat Switch

2.1 ON-OFF MAIN SWITCH

Allows the appliance to be manually switched on and

off.

2.2 CENTRAL HEATING SWITCH (SUMMERWINTER)

Allows the central heating and domestic hot water

supply to be switched on. or domestic hot water only

to be switched on.

2.3 BOILER CONTROL THERMOSTAT

Controls the temperature of the water fed to the

central healing system. The temperature can be manually adjusted between approximately 50" - 90*C ±

2°C.

2.4 OVERHEAT SWITCH

A boiler overheat switch will operate if the boiler

thermostat exceeds 90*C ± 3%. After determining the

season (of the boiler overheat thermostat operating,

the thermostat can be manually re-set. Note: thermostat control cannot be re-set until boiler temperature

falls below 80"C.

2.5 PRESSURE AND TEMPERATURE GAUGE

A combined boiler pressure and temperature gauge

indicates the pressure and temperature of the water in

the boiler. As a guide the pressure of water in the

boiler, with a pressurised system, can be set at 1 bar

when the water is cold.

2.6 BIMETALLIC PRIORITY THERMOSTAT

A bimetallic priority thermostat is fitted al the connection of the domestic cold water inlet to the boiler.

When a hot lap is opened, the bimetallic priority

thermostat is operated by the flow of cold water into

the boiler.

If the central heating switch (summer/winter switch)

is in the Winter position (i.e. central heating ON) the

bimetallic priority thermostat turns off the central

healing circulating pump.

When the domestic hoi water demand is satisfied the

bimetallic priority thermostat allows the pump to

restart.

When only a small domestic hot water flow is drawn

the bimetallic priority thermostat does not intervene.

2.7 ANTICONDENSING THERMOSTAT

This thermostat prevents the central heating emulating pump from operating until the boiler water

temperature reaches 60"C

3 GENERAL REQUIREMENTS

3.1

RELATED DOCUMENTS

It is the law that gas appliances be fitted by a

competent person. Failure to do so could lead to

prosecution. It is in your own interest, and that of

safety, to ensure compliance with the law.

Installation shall be in accordance with the following

documents:

- Gas Safety (Installation and Use) Regulation 1984

- Building Regulations

- Building Standards (Scotland) Consolidation

- Current IEE Wiring Regulations

- By-Laws of the Local Water Authority

- BS.6798: Boilers of rated input not exceeding 60KW

- BS5449: Forced circulation hot water systems

- BS.5546: Gas hot water supplies

- BS.5440: Part 1: Flues

- BS.5440: Part 2: Ventilation

- BS.6891: Gas supply

-

Where the appliance is installed in a timber framed

building, reference should be made to the British Gas

Publication reference DM2.

3.2 GAS SUPPLY

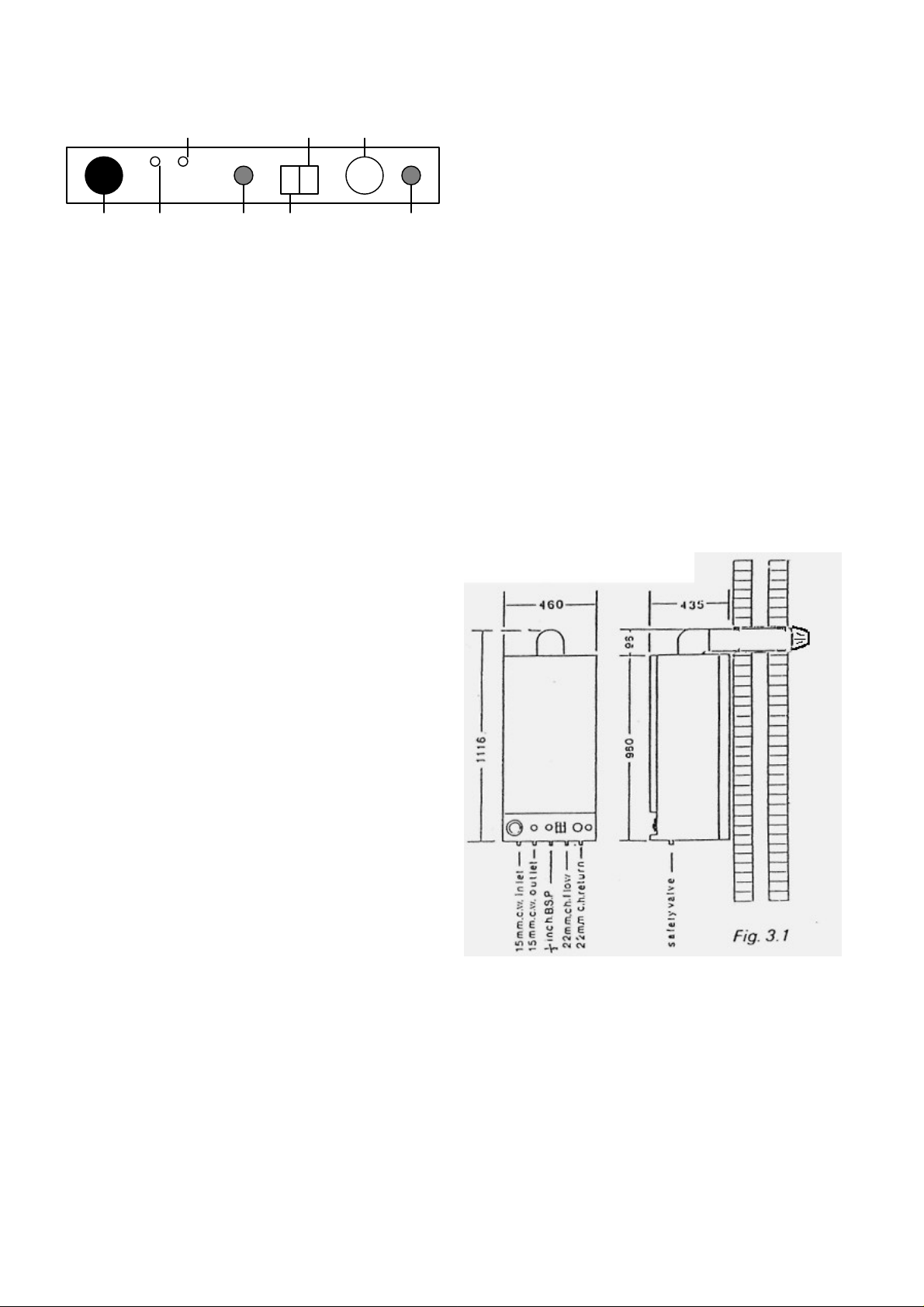

See fig.3.1 for connection

Fig. 3.1

A gas meter can only be connected by local gas

legions or by a local gas region contractor. An existing

meter should be checked, preferably by the gas

region, to ensure the meter is adequate to deal with

the rate of gas supply.

Installation of pipes should be in accordance with

BS.6891.

Pipework from the meter to the appliance must be of

adequate size.

Do not use pipes of a smaller size than the appliance

gas inlet connection.

The complete installation must be tested for soundness and purged as described in the above code

Page 6

Page 7

3.3 WATER SYSTEMS

Fig. 3.3 TYPICAL HEATING SYSTEM

3.3.1 Central heating

See Fig.3. f for connections

WARNING: When radiator(s) are at a higher level than the

boiler. A NON-RETURN VALVE MUST BE FITTED lo the

central healing systems flow pipe.

A. Old systems.

These* are likely to contain sludge and debris which, if passed

into the appliance, may cause irreparable damage to the pump

and other components. It is. therefore, highly recommended

that the old system be thoroughly flushed using such as

Fernox cleaner - use in accordance with the manufacturer's

instructions.

B. New systems

Must always be flushed of debris.

C. Design of system

The primary system must be of the sealed type, the designed

temperature rise should be 1 PC.

The following sealed system components are included on the

appliance:

i. Double check valve, stop valve and filling loop,

ii. 8 lilre central heating expansion vessel,

iii. Circulating pump.

iv. CALEFFI relief (safety) valve.

v. D.H.W, Expansion Vessel

vi. Combined temperature and pressure gauge.

D. Expansion vessel/sizing of system

Guidance is provided in BS.7074. Part 1 and BS.5449. The

maximum permissible capacity of the system, including the

appliance, will depend upon the initial design pressure.

As an example, for an initial design pressure of 1 bar the

maximum permitted capacity, including the appliance, is 70

titles.

For calculation purposes:

Existing vessel capacity - 8 litres

(charged at 0.5 bar)

Capacity of appliance - 15 litres

Safely valve setting - 3 Bar

If the system capacity exceeds the allowed value then

an additional vessel must be provided, connected as

close as possible to the appliance heating return.

E. Pressure relief (safety) valve

The valve outlet must be routed to a suitable point of

drainage where there will be no hazard to occupants

and where freezing will not take place.

F. Filling the system

A double check valve, stop valve and filling loop are

supplied. Before using ensure that the arrangement

complies with the requirements of the Local Water

Authority. Alternatively BS 5449:1990 (fig 3.1A) shows

other methods of filling.

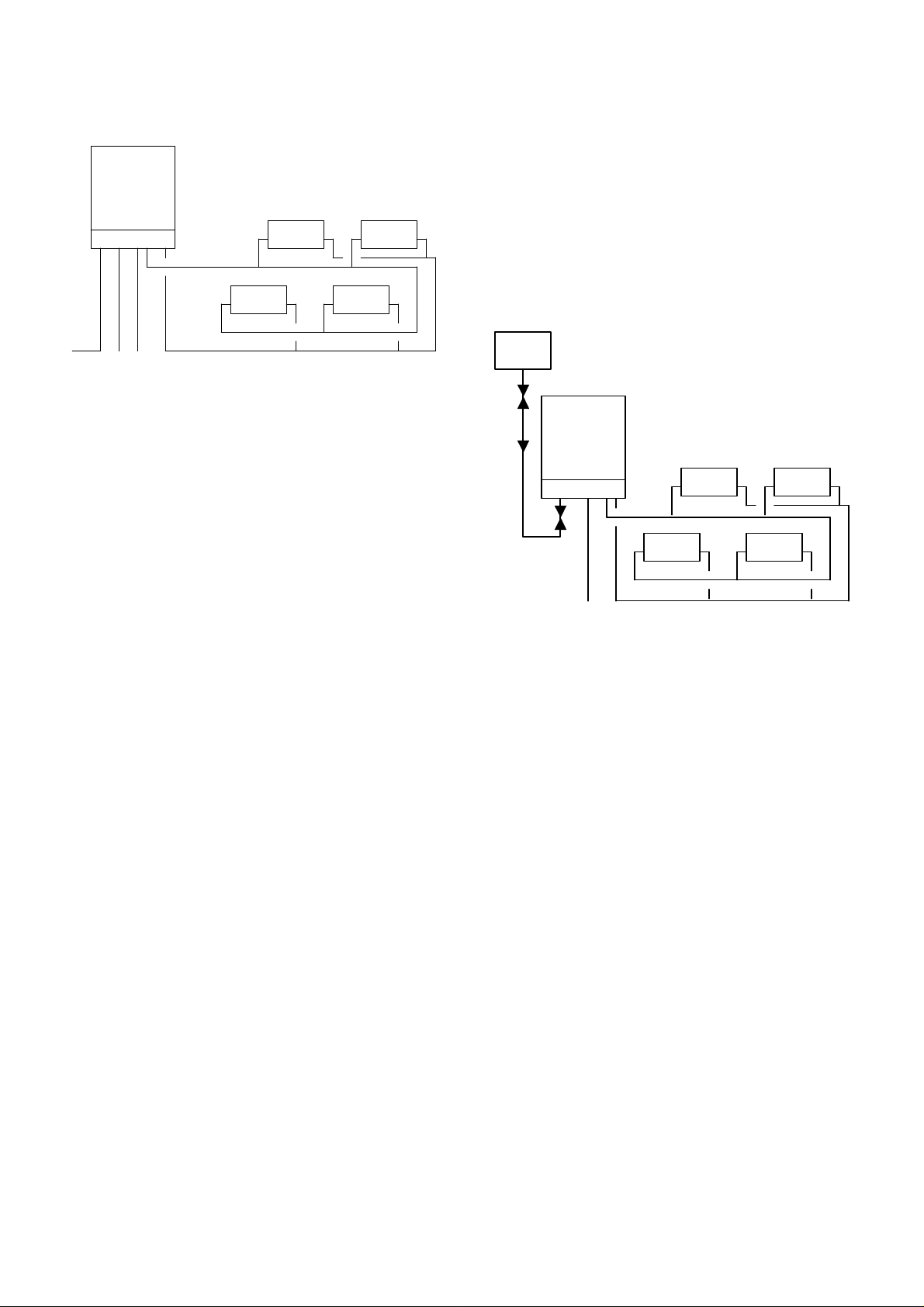

Fig. 3.1.A ALTERNATIVE TOP UP SYSTEM

G. System make up

There must be no direct permanent connection to the

mains water supply, hence the filling loop must be

disconnected at one end alter use.

If an automatic top up method is required, then this

must be done via either a cistern which has no other

purpose or a top up bottle. Full details are provided in

BS.5449:! 990 (fig 3.1 B) Again, always check local

Water By-laws before installation. See also Fig.3. l.A.

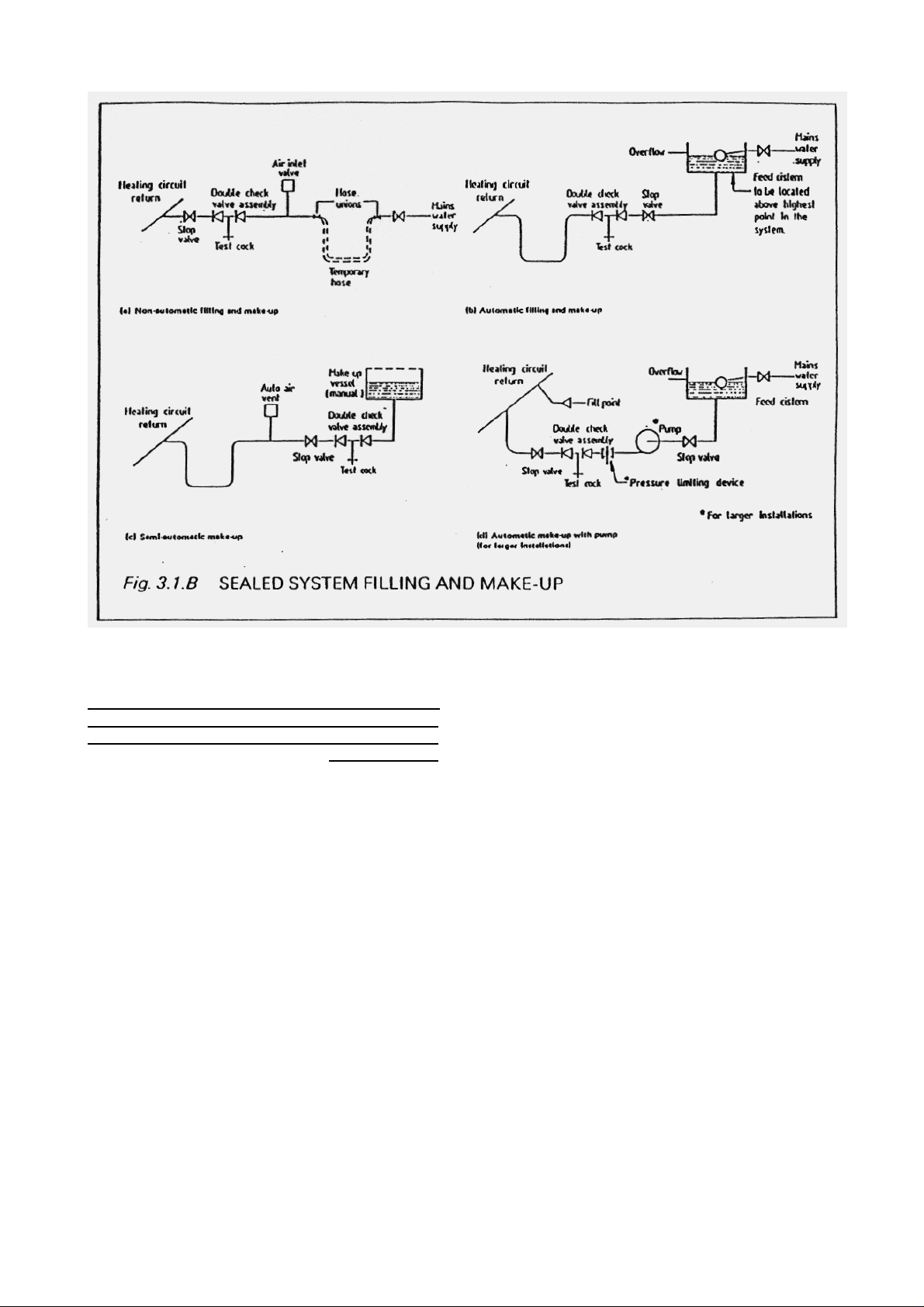

H. Pump performance

Fig.3.2 shows the pump performance characteristics

and values given take due account of the losses

through the appliance.

I. Thermostatic radiator valves

A by-pass is not required and such valves can be fitted

on all radiators if desired.

J. Drain points

Drain taps should be lilted on the lowest point of the

system, the taps complying with BS.2879

K. Vents

Although an automatic air vent & manual air vent is

provided on the appliance, further facility to vent the

system should be provided.

L. All components and fillings used should be

suitable for temperatures of up to 11O°C and pressures

of up to 3 bar.

All syslem components added must be in occoidance

with US 5-149 and BS.G798.

Page 7

Page 8

Position 1

1000

30-

35 016

Position It

170O

45-

60 025 Position III

2450

72.92

038

Speed RPM Watts

Input

Full Load

Current in Amps

Fig. 3-2 PUMP PERFORMANCE

M. Central heating pressure

We recommended that the initial design pressure, i.e. when cold, be 1 bar When fully heated and drawing

a full load, the resultant hot pressure must not exceed 2.7 bar. The safety valve will discharge at 3 bar ± 0.3

bar.

N. System design

A typical sealed system is shown in Fig.3.3.

3.3.2 Domestic hot water circuit

See Fig.3.1 for connections

An extended copper coil is filled which is healed from the primary water. Starting from cold, the appliance

should be fully heated before full capacity hot water supply is obtained

IMPORTANT

To conform to the requirements of the National Water Council, il the main water pressure is at any lime in

excess of 73 psi. (5 bars) {1 69(1) a Pressure Limiting or Pressure Reducing Valve must be fined by the

installer into the mains supply in an inconspicuous approved by Ihe NWC and must not allow more than 73

psi. (5 bars) pressure to the appliance.

Page 8

Page 9

Fig. 3.4 DOMESTIC HOT WATER SUPPLY

3.4 FLUE SYSTEM

3.4.1 The standard balanced flue system can be

directed to the right, left or rear of the appliance.

3.4.2 As supplied, the standard horizontal flue assembly

will cover a distance of up to 910 mm from the centre

line of (he appliance for side flues. for rear flues, a wall

thickness of up to 800mm can be accommodated. Both

dimensions are to the outside wall face.

An optional 1m extension flue system kit (Pan No

R3000050) is available which allows the maximum

lengths to be increased to 1840 mm and 1730 mm

respectively.

An optional 2m extension flue system kit (Pan No

R3000014) is available which allows the maximum

lengths to be increased lo 2840 and 2730 respectively

3.4.4 If a vertical flue is required an optional vertical

flue system kit (Part No R3000030) is available

which replaces the standard 1m horizontal Hue

assembly supplied. The vertical flue assembly will

cover a distance of up to 1m from the top of the

boiler flue hood to the end of the air pipe and comes

complete with a terminal rain hood.

Optional extension flue system kits are available to

allow the maximum vertical lengths lo be increased

lo 1975mm (Part No 3OO0050) or 2975mm (Part No

3000014).

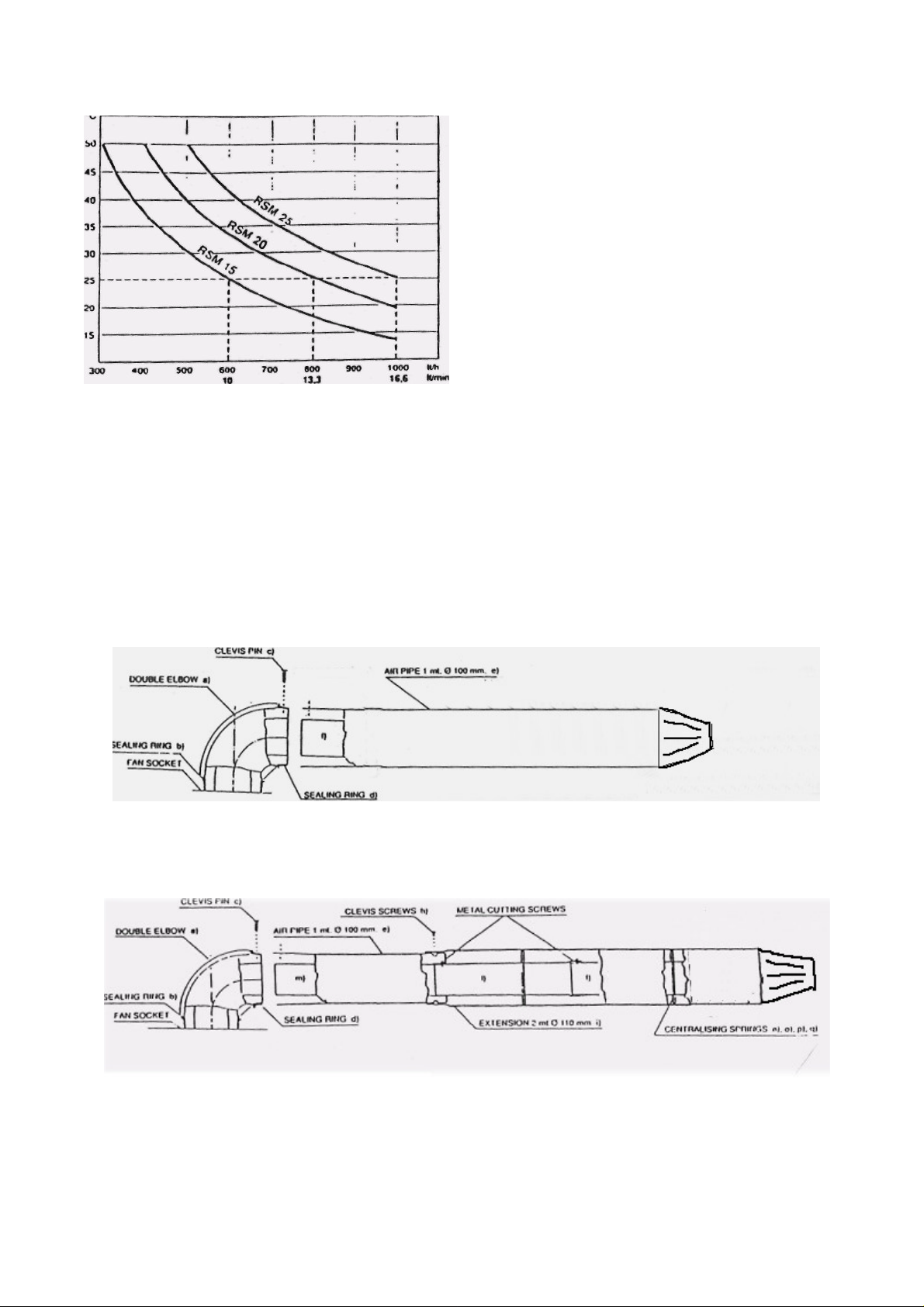

Fig. 3.5 STANDARD HORIZONTAL FLUE SYSTEM KIT COMPONENTS

Fig. 3.6 OPTIONAL HORIZONTAL

EXTENSION FLUE

SYSTEM KIT COMPONENTS

Page 9

Page 10

3.4.5 The flue system must be installed in accordance

with BSS440 Part 1.

3.4.6 Siting of flue terminal

It is essential that products of combustion cannot enter

any building through such as openable windows, doors,

air bricks, etc.

Fig 3.7 gives details of the minimum required spacing of

the 'terminal from building features.

3.4.7 Terminal guard

Where the terminal is fitted within 2m of a walkway. a

balcony or a fiat roof to which people have access, then

a terminal guard, model C.1 must be fitted centrally over

the terminal. This guard is available from KESTON

BOILERS.

3.4.8 Air supply

This appliance is room sealed and. when installed in a

room or space, requires no ventilation. If installed in a

cupboard/compartment, air is required for cooling

purposes, as follows:

Fig. 3.7 SITING OFTHE TERMINAL

Position of Air

Vents

Air from Room

or Internal

Air Direct from

Outside

Space

High level 236 cm²

36-6 ins²

Low level

36.6 ins²

236 cm²

18.3 ins²

1 1 8 cm²

18.3 ins²

1 1 8 cm²

Both air vents must communicate with the same

room or space, or both must be on the same wall to

outside air.

3.5 APPLIANCE LOCATION

3.5.1 This appliance is not suitable for external

installation.

3.5.2 The wall on which the appliance is mounted

must be of suitable load bearing capacity

3.5.3 Installation in a compartment is permitted (full

guidance is provided in BS.6798).

3.5.4 Adequate space must be allowed for installation, subsequent servicing, and safe operation.

Appliance dimensions and the minimum allowable

clearances required are shown in Figs. 3. t and 3.8

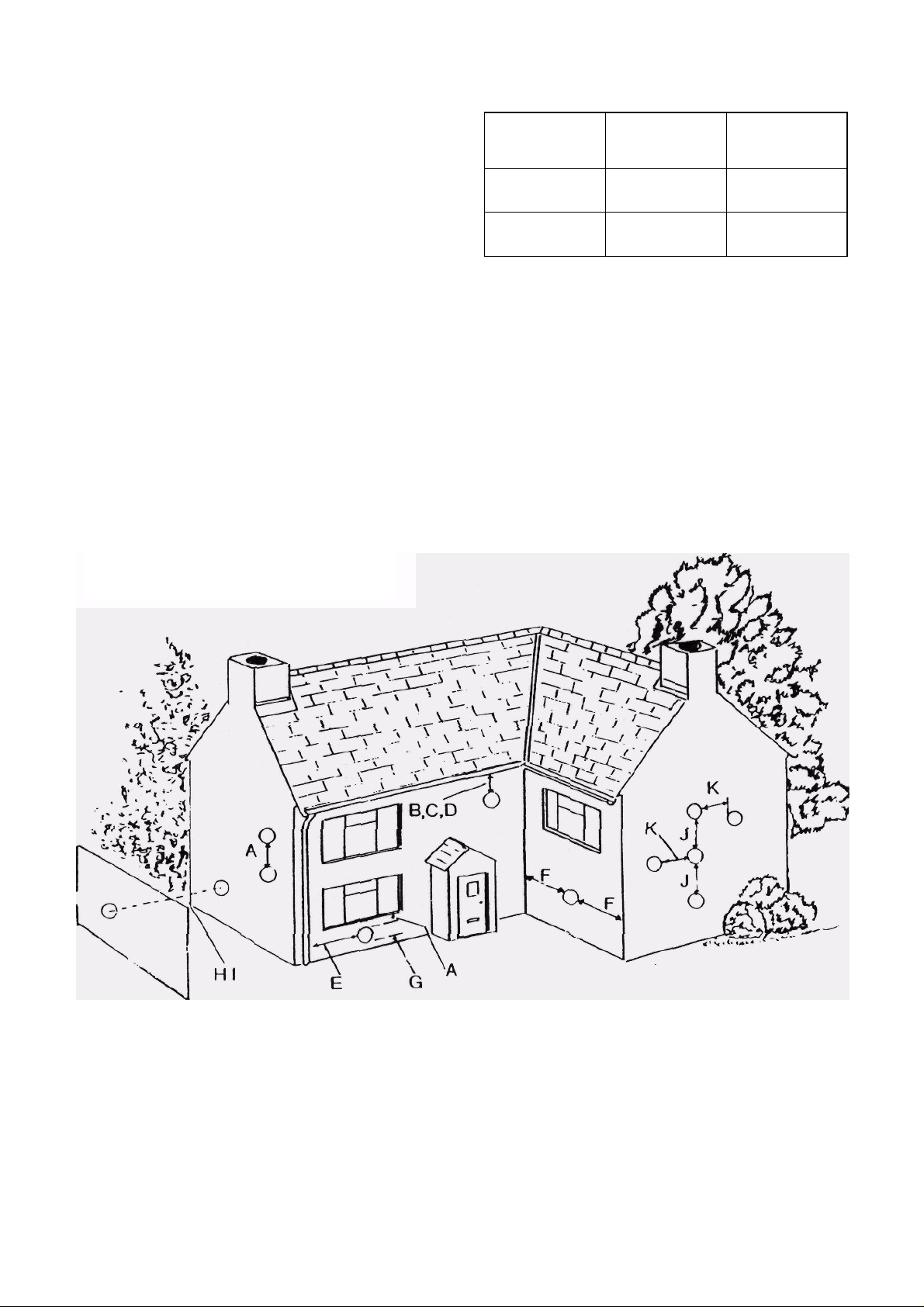

TERMINAL POSITION Minimum distance

Fanned draught.

A. Directly below an openable window or other

opening. e.g. an air brick 300 mm

B. Below gutters, soil pipes or drain pipes 75 mm

C. Below eaves 200 mm

D. Below balcony 200 mm

E. From vertical drain pipes and soil pipes 75 mm

F. From internal or external corners 300 mm

TERMINAL POSITION Minimum distance

Fanned draught.

G. Above ground or balcony level 300 mm

H. From a surface facing a terminal 600 mm

I. From a terminal facing a terminal 1200 mm

J. Vertically from a terminal on the

same wall 1500 mm

K. Horizontally from a terminal on the

same wall 300 mm

Page 10

Page 11

A flexible three-core PVC insulated cable must be

used between the isolator and terminal block with a

minimum cable size of 0.75 mm1 (24 x 0.2 mm)

BS.6500 Table 16

Ensure all cables are secure.

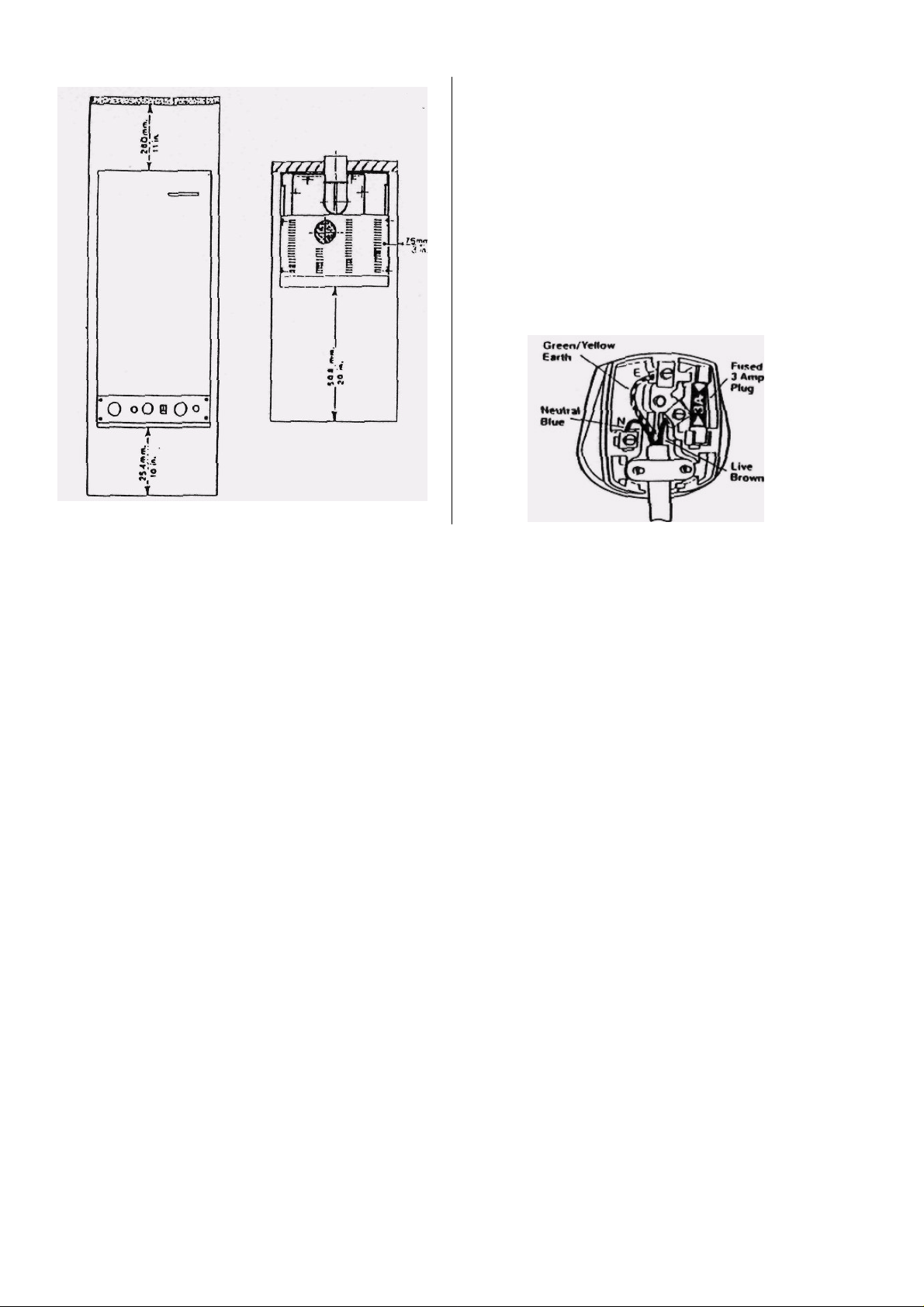

3.6.3 ELECTRICITY SUPPLY

WARNING: THIS APPLIANCE MUST BE EARTHED.

Connection shall be made to a 240 Volts 50 Hz supply. K a mains plug connection is used it must be

of a three-pin type and fused to 3 Amps.

To connect a plug

Fig. 3.8 MINIMUM CLEARANCES

3.5.6 The position must allow for correct termination of the

flue system (see Section 3.4).

3.5.6 The combination boiler may be installed in any room

or internal space, although particular attention is drawn to

the requirements of the current I.E.E. Wiring Regulations,

and in Scotland, the electrical provisions of the Building

Regulations applicable in Scotland, with respect to the

installation of the combination boiler in a room or internal

space containing a bath or shower.

Where a room-sealed appliance is installed in a room

containing a bath or shower, any electrical switch or

appliance control utilising mains electricity should be so

situated that it cannot be touched by a person using the

bath or shower.

3.6 ELECTRICAL

3.6.1 Electrical connections and installation must

conform to current IEE Regulations and. in Scotland, the

electrical provisions of the Building Regulations.

The appliance must be earthed.

Wiring external to the appliance MUST be carried out by a

competent person in accordance with the current IEE

Regulations and Local Regulations which apply. The

Thermornatic Combination Boiler is supplied for

connection to a 240V-50Hz single phase. The appliance is

fused at 3A

3.6.2 The method of connection to the electricity supply

MUST provide means of completely isolating the electricity

supply to the boiler and its ancillary control, preferably by

using a 3A fused three-pin plug and unswitched shuttered

socket outlet both complying with the requirements of 8S.1

363. or alternately a 3A fused double-pole switch having n

3 mm contact separation on both poles.

As the colour of the wires in the mains lead of (he

appliance may not correspond with the coloured

markings identifying the terminals in your plug, proceed

as follows:—

The wire which is coloured green-and-yellow must be

connected to the terminal in the plug which is marked

with the letter E or by the earth symbol or coloured

green or green-and-yellow.

The wire which is coloured blue must be connected to

the terminal which is marked with the tetler:N or

coloured black.

The wire which is coloured brown must be connected to

the terminal which is marked with the letter L or

coloured red.

ELECTRICAL CONNECTIONS

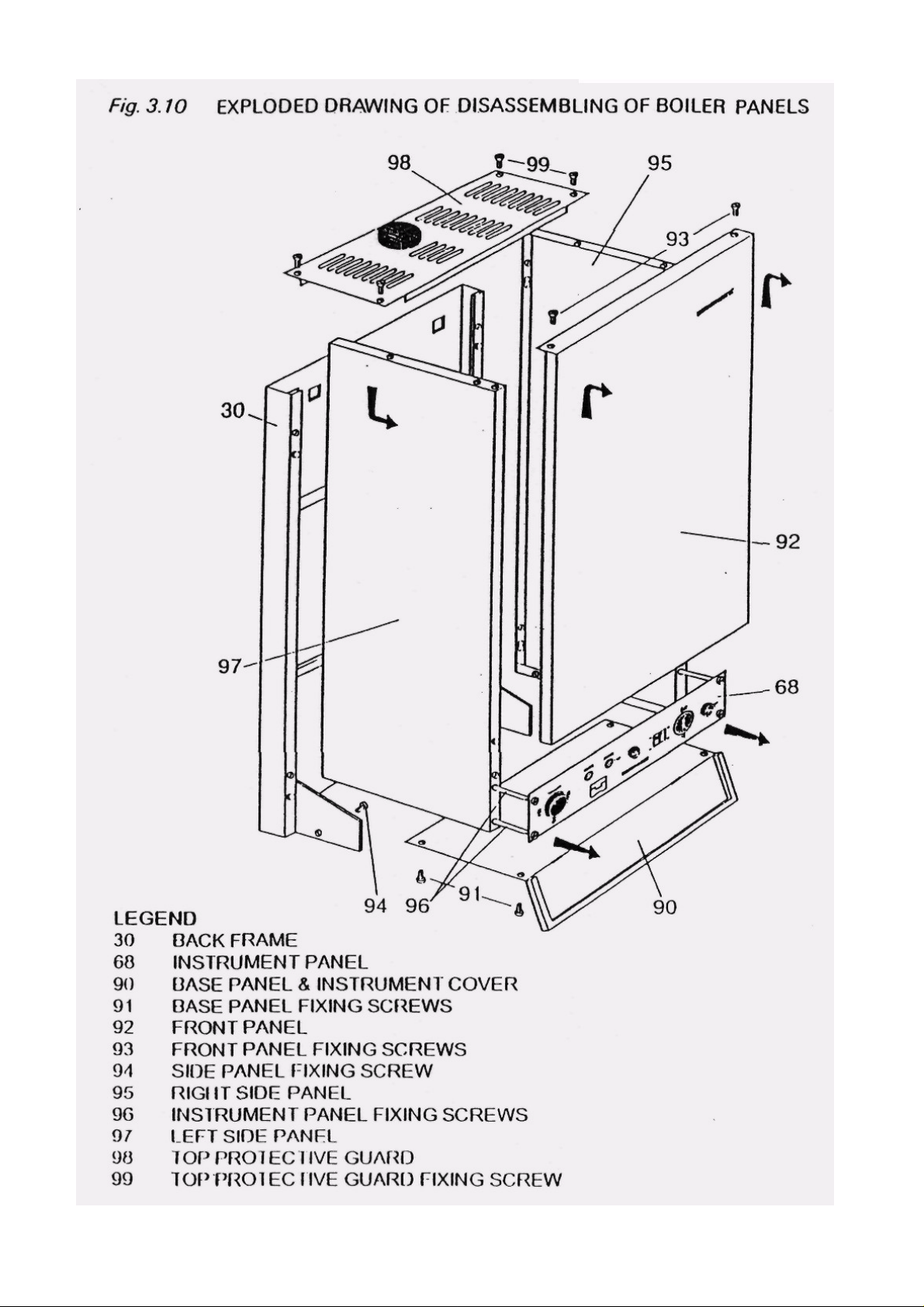

3.6.4 To gain access to the terminal block remove me

four screws fixing (he base panel with the attached front

door and remove the panel (see Fig. 3.10, item 9'1

3.6.5Thread the main supply cable through the cable

restraining clamp, leave enough cable for removal of

control panel to replace any boiler controls.

3.6.6 Ensure earth wire is longer than current carrying

conductors so that if cables are strained or slip in their

anchorage, the current carrying conductors become taut

before the earth wire.

Page 11

Page 12

Page 12

Page 13

4. INSTALLATION PROCEDURES

4.1 Unpack the appliance, check the contents:

Combination

i

boiler

Wall plugs

ii

Fixing brackets

iii

Connection

iv

plate with ball

valves

T-bar template

v

Flue assembly with

vi

elbow

Wall liner with flexible

vii

washer

Filling loop with double

vii

check valve

i

4.2 Select the appliance position, taking due account

of Section 3.

4.3 PREPARATION FOR MOUNTING THE

APPLIANCE

The Thermomatic Combination Boiler is supplied with

a connection plate with ball valves and a T-bar

template that allow the installer to make all water and

f Insert the plastic plugs and screw in the fixing brackets

to within 2 of 3 mm ol the wall face.

4.3 Hang the T-bar template on the fixing brackets

and check that it is perfectly horizontal and seated on

the fixing brackets.

4.4.1 Hang the connection plate carrying the valves on

the T-bar template hung on the wall in 4.4 and fix

together using the screws.

Drill four holes in the wall for fixing the connection plate

to the wall, using the existing holes on the connection

plate as a template.

Fix the connection plate to the wall using lour screws in

the holes drilled.

4.4.2 Once the T-bar template and connection plate

have been fixed securely lo the wall make all the gas

and water connections.

4.4.3 Remove the T-bar template and hang the

appliance on the fixing brackets via the two square cut

outs on the top of the appliance.

4.5 Remove the base panel. 4 screws (see fig. 3.10

item 91 Exploded drawing of disassembling the boiler

panels).

4.6Remove the front panel. 2 screws (see fig 3.10 item

93). lift and disengage. Remove the plugs from the cold

water inlet and domestic hot water outlet

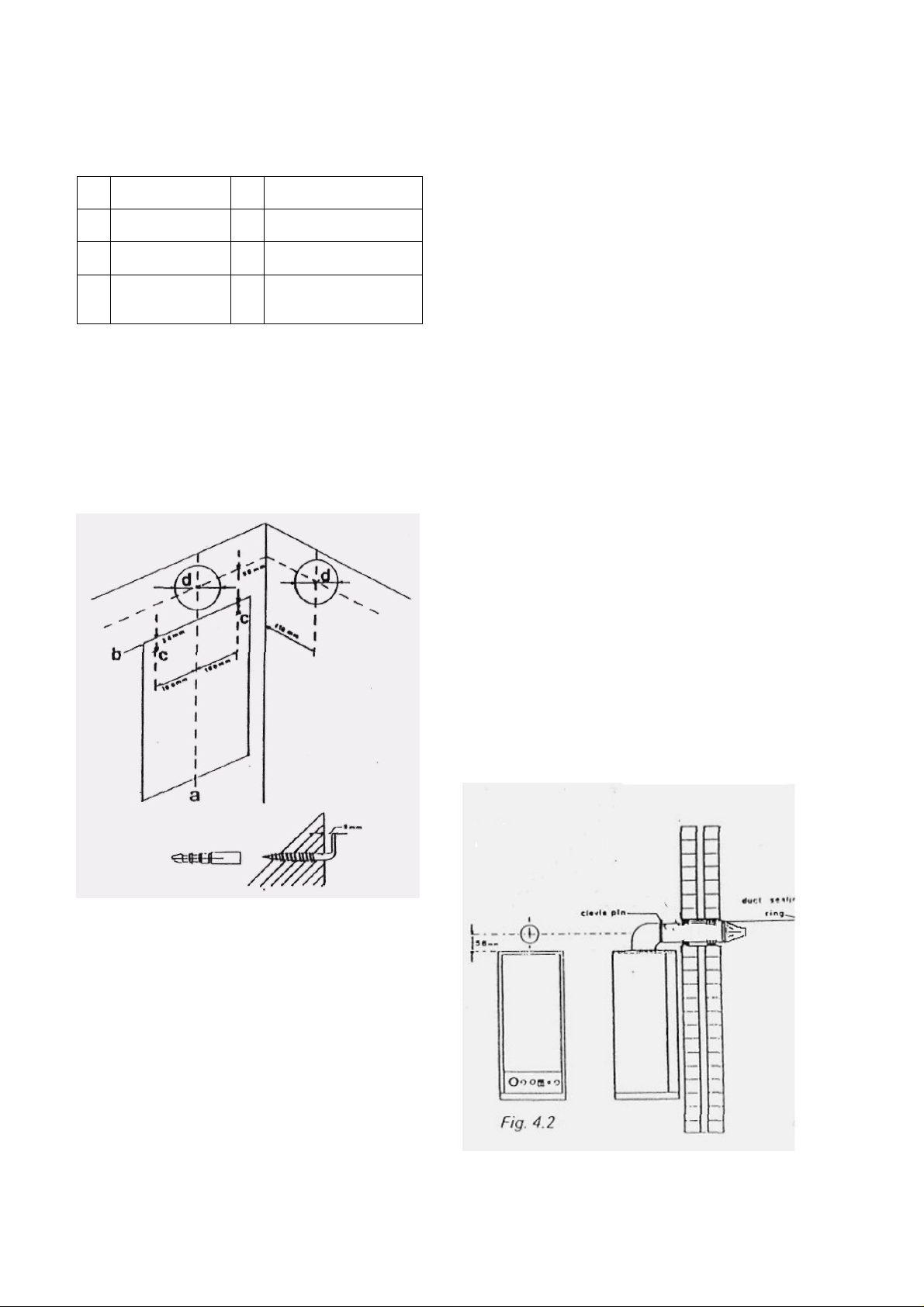

4.7 FLUE SYSTEM: CUTTING AND ASSEMBLY

4.7.1 Standard Flue Systems

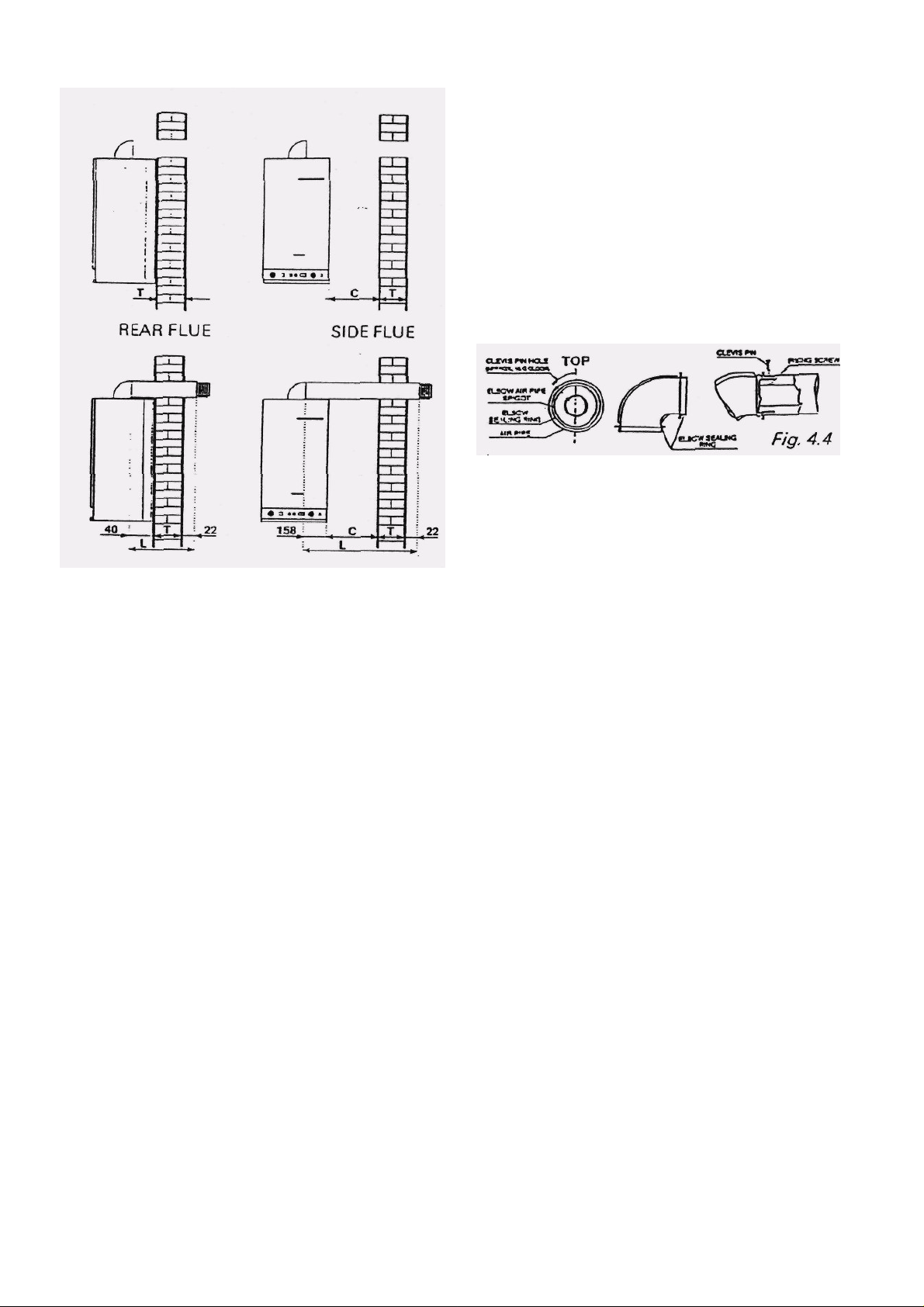

When fully assembled, the standard flue system will be

shown, side or rear flue (fig. 4.2).

gas connections and test the system before hanging

the boiler. Hence, the boiler itself need only be hung

at the final stage of the works.

a Mark a vertical line for the centre of the appliance

b Mark a horizontal line for the top of the appliance.

c Lay the top edge of the T-bar template onto the

horizontal line and mark two holes on the wall for the

fixing brackets.

d Mark the flue hole centre, either on the rear wall.

ceiling or extended to the required side wall as shown.

e For standard flue systems, drill the flue hole 130mm

diameter, preferably using a core drill.

For extended Flue systems, drill the Flue hole 145

mm diameter

IMPORTANT: The plastic liner must always be used

and the air pipe fixed at the appliance elbow ONLY.

Page 13

Page 14

Fig. 4.3

a Measure the wall thickness T (fig. 43).

b Maximum available lengths of plastic liner:

Rear flue Maximum wall thickness (standard liner):

580 mm (T)

Maximum wall thickness (optional extension

liner) 828 mm (T).

Side flue Maximum distance from appliance side to

outer wail face: 680 mm (T+ C)

(with maximum wall thickness T as for rear

flues)

When measuring and cutting, always separate the inner

(flue) pipe wiih terminal from the outer (air) pipe.

c Cut the air pipe fig. 3.5 — cut from the plain end.

Rear Flue To overall length (L) oFT + 62 mm.

Side Flue To overall length (L) ofT + C+ 180mm

When cutting the air pipe, take care not to ovalise it and

remove the internal sharp edges produced when cutting

the pipe.

Drill again a hole (4 mm diameter) at a distance of 7mm

from the pipe end F) Fig 3 5 to [he hole center

d Cut the flue pipe — cut from the plain end.

Any Flue Cut off exactly the same amount as removed

from the air pipe.

Drill again a hole (3mm diameter) at a distance of 16

mm from the end of pipe to the centre of hole

e Cut the plastic- liner (S)

f Insert the flue pipe/terminal F) into the elbow A) and

secure with the specific screw.

g Insert the terminal into the plain, i.e. unchannelled

end of the air pipe E).

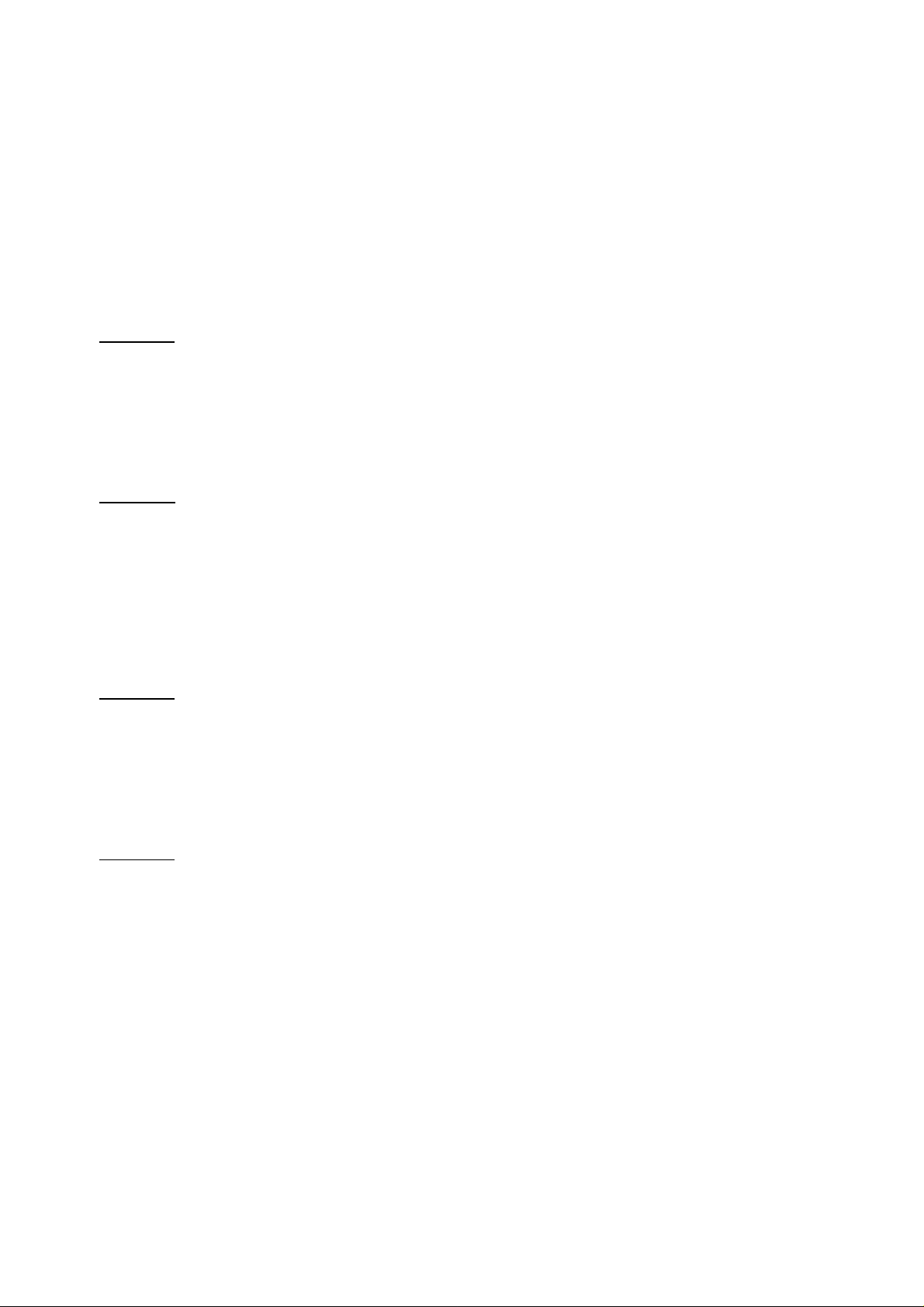

h IMPORTANT

Before inserting the air pipe into the elbow. LUBRICATE THE ELBOW SEAL WITH OIL. then insert the air

pipe completely into the elbow.

If the elbow seal is not lubricated, it is not possible to

insert the air pipe into the elbow.

Take care to let the holes correspond, then insert the

clevis pin (fig 4.4).

i Pass the flue/air pipe assembly through the plastic

liner S).

j Fully insert the elbow A) into the fan socket, ensuring

that the elbow seal is correctly located.

k Check that the terminal protrudes the correct amount

from the wall face (fig. 4.3.).

4.7.2 HORIZONTAL EXTENSION FLUE SYSTEM

a Measure wall thickness T (rig. 4.3)

Page 14

Page 15

Maximum distance from appliance side to outer wall

face:.273Qmm (T+ C), or (torn inner wall lace to outer

wall face: 2840 mm.

When measuring and cutting, always separate the flue

pipe with terminal from the air pipe.

b Join air pipe extension to standard pipe, cut the air

pipe extension (I) 110 mm diameter (fig. 3.6).

Cut from plain end to overall length of T + C + 1 80mm.

When culling the air pipe, take care not to ovalize it and

remove the internal sharp edges produced when cutting

the pipe.

c Cut the flue pipe (I) (fig.3.6) —cut from the plain

end:

Any flue: cut off exactly the same amount as removed

from the air pipe.

Drill again a hole (3 mm diameter) at the same distance

from the pipe end as it was before.

d Position the centralising springs n) o) p) q) (fig.3.6) at

about half of each flue pipe extension (I) and (f).

e Insert flue pipe (m) into (I) and secure with the

specific metal cutting screw; then insert flue pipe with

terminal (f) into (I) and secure with the specific screw.

f Insert the air pipe extension onto the standard air pipe

(e). and make sine that (he hole on the air pipe

extension corresponds to the groove on the standard

air pipe

g Insert the extended flue pipe into the extended air

pipe, from the side of bigger diameter (0110 mm).

h Insert the Hue pipe into Ilie elbow and secure it with

the specific screw

m Slip the ducting sealing ring over the air pipe and

position it near the terminal, at about 50 mm from the

air pipe end.

Then see section 4.7.1 k, I. rn. n. o.

4.7.3 VERTICAL FLUE SYSTEM

a Unpack the 1m vertical flue kit (kit VF/1). The

contents should be:

1 off 3060218 Fan socket sealing washer (1)

1 off R3560630 Conical adaptor Ø118/Ø80 with

test point (2)(3)

1 off R3560632 Concentric roof terminal Ø118

length 120cm(4)

1 off Roofing tile(5)

b Preparations:

- Drill a hole Ø130mm on the roof, in axis to the

fan socket. If this is not possible, consider the

above mentioned losses for every bend.

- In relation to the overall length, arrange for the

proper anchorages along the wall where the

flue kit is going to be positioned.

c Installation:

1. Fit the sealing washer (1) onto the fan socket.

2. Fit the conical adaptor (2)(3)m to the fan

socket.

3. In case of extensions, check that in the

sockets of the flue pipe extensions Ø180mm

(7) there are the Ors (6) and that these are

correctly positioned. Measure the overall

length to be realized and, if necessary, shorten

always from the plain end of the pipe

extensions.

4. In case of extension, connect the air intake

extensions Ø118 (8) one to the other, after

having shortened the extensions, if necessary,

of the same size and always from the plain

end of the air intake extension.

5. Insert the so-assembled flue pipe extension

into the air pipe extension, then fit the whole

assembly into the adaptor(2)(3) already on the

boiler.

6. Properly position the roof finishing tile (5) and

insert the terminal (4) into the hole on the roof,

so that the tile remains at the roof outside.

7. Make the sliding air intake pipe of the terminal

to slide upwards, so to leave the flue pipe

uncovered, and insert the flue pipe into the

flue pipe extension already fitted on the boiler.

Then make the sliding air intake terminal pipe

to slide downwards and fit it into the air intake

extension already on the boiler.

8. Anchor the so assembled flue kit to the wall by

means of proper anchorages.

9. Finish the internal wall face around the hole in

the ceiling.

IMPORTANT:

For vertical concentric flue kits shorter than 1

meter and up to 1 meter of length, from paragraph

B) read directly paragraph F).

Page 15

Page 16

If the flue length required falls between 1m and 1975 mm.

reduce the 910 mm length of 110 mm air pipe by the

required amount and remove the same amount from the

plain end of the inner flue pipe.

If the flue length required falls between 1975mm and

2975mm. reduce the 191O mm length of 110mm air pipe

by the required amount and remove the same amount from

the plain end of the inner flue pipe.

NB: The minimum height of a vertical flue is 1 metre.

f Measure a distance of 113 mm from the face of the wall to

the centre of the flue position and drill a hole of 130 mm

diameter through the ceiling or roof above the boiler to

receive the 100 mm diameter pipe or a hole of 145 mm

diameter to receive the 110 mm diameter pipe.

N6: If the ceiling is of a combustible material use a Ceiling

Fire Stop Plate in accordance with the manu- facturers

instruction.

g Wall mount the boiler in accordance with the paras 4.3 to

4.6. leaving a minimum distance of 450 mm above the

boiler.

h Fit the flue and air pipe extension pieces to the flue and

air connections on the top of the Boiler i If the extended

vertical flue kit is not being used continue the procedure

from step q of these Installation Steps.

For extended vertical flues only, (for tm vertical flues skip

steps j to p):

j Fix the wall bracket in the correct position to support the

flue assembly when in place. (See Fig 4.6)

k Separate the flue pipe with the terminal from the 1 metre

length of 1OO mm diameter air pipe.

I Fit the spring clips at equal intervals onto the metre length

flue pipes from the Extended Vertical Flue Kit. m Fit the110

mm x 100 mm reducing adaptor to the plain end of the

metre length of 100 mm diameter air pipe so that the air

pipe contacts the stop pins in the reducing adaptor Use the

reducing adaptor as a template to pre-drill 2 mm diameter

holes and secure using the screws provided.

n Fully engage the 110 mm air pipe to the 110 mm x 100

mm reducing adapter. Again use the reducing adaptor as a

template to pre-drill 2 mm diameter holes and secure using

the screws provided to Fit the flue pipe with terminal to the

remaining Section(s) of flue pipe to form a complete length

of flue pipe. Use the pre-drilled holes as a template to drill

2 mm diameter holes and secure all connection with the

screws provided

p Push the assembled flue pipe through the assem-bled air

pipe so that the terminal is just clear of the air pipe as

shown in Figs 4 8 & 4 9 For 1m and extended vertical flues.

q Slacken off the screws on the detachable flue pipe sleeve

and slide over the end of the flue pipe extension piece

attached to the outer (See fig 4 8)

r Lousely assemble the 110 mm long by 60 mm diameter

distance piece into the open end of the detachable flue

pipe sleeve (See Fig 3)

Page 16

Page 17

Page 17

Page 18

Fig. 4.10 RAIN HOOD ASSEMBLY

s Working from either the roof or floor level, which-ever

is the most convenient, pass the complete flue/air

assembly through the pre-drilled hole(s) in the

ceiling(s). Ensure that the inner flue pipe abuts the

distance piece (See Fig. 4.8).

t Securely fix the flue assembly in position using the

wall bracket fitted in Step 4.3. The outer pipe (air pipe)

must be securely bracketed or strapped if in the roof

space (Roof strapping is not supplied).

4.8 Connect the gas and water services (Fig 3.1)

i Gas: 15mm compression,

ii CH flow and return: 22mm compression

iii DHW in and out: 15mm compression,

iv Safety valve. 1 5mm compression.

4.9 Assemble the filling loop system.

(Refer to Fig 4 11 Filling Loop Assembly)

Loosely connect the flow end of the double check

valve (D) to the matching connection of the 'S'

shaped pipe (E)

Loosely connect the wingnut end of the flexible pipe

(C) to the free end of the double check valve (D)

Having rolled the flexible hose (C) about one turn

the connection point on the heating return ball valve

(F) including one of the fibre washers supplied (B)

Connect the free end of the filling loop assembly to the

filling cock (A) including the other fibre washer supplied

(B). Ensure that the assemble filling loop does not

interfere with the operation of the gas cock (G).

Tighten all connections.

4.70 Connect the electrical supply:

i Thread the main input cable through the cable damp.

ii Connect the cables to terminal block as shown in the

functional flow wiring diagram.

4.11 In preparation for Commissioning, close all

appliance service cocks and isolate the electrical supply.

Fig. 4.11 FILLING LOOP ASSEMBLY

5. COMMISSIONING

5.1- GAS INSTALLATION

Inspect the entire gas installation, including the meter,

purge and test for soundness in accordance with

BS6891.

(Open doors and windows when purging. Extinguish

naked flames and do not smoke.)

5.2 ELECTRICAL INSTALLATION

Preliminary electrical system checks to ensure electrical

safety must be carried out by a competent person (earth

continuity, polarity, short circuit, resistance to earth), if a

fault has occurred on the appliance the fault finding

procedure (Section 7) should be followed as specified.

5.3. WATER INSTALLATIONS

Ensure that the systems, old or new. have been

thoroughly flushed and cleaned without the appliance in

circuit

5.3.1 Connect the appliance to the connection plate

already fixed to the wall and assemble the Tighten all

connections & open all valves

Page 18

Page 19

5.3.2 Fill the central heating circuit (loosen the cap on

the automatic air vent, item 47 Fig. 6.1) &open the

manual air vent below.

5.3.3 Continue to fill until water comes out of the

manual air vent. Dose the manual air vent.

5.3.4 Repeat the process with the manual air vent until

the appliance has been thoroughly vented. If

necessary restore the pressure to about 1.2 bar.

5.3.5 Test the complete system for water soundness

5.3.6 Drain the system to rectify any leaks and refill to

the initial system design pressure venting all radiators.

DO NOT LOOSEN THE VALVE CAP ON THE EXPANSION VESSEL. Set the red pointer on the pressure gauge to the initial system design pressure.

5.3.7 Once filling is complete, ensure the water

supply valve is off, then DISCONNECT THE FILLING

LOOP AT THE OUTLET FROM THAT VALVE.

Permanent connection of the loop is not permitted.

5.3.8 Open all hot taps and allow water in flow until no

air is present. Close the laps.

5.3.9 Check the water supply connections for soundness. Rectify leaks where necessary.

5.4 Fully open the remotest hot tap. and check that

the flow rate is at least 8.8 litres/min.

5.4.1 With all services checked. all valves open,

continue to commission the appliance.

5.4.2 Isolate the electrical supply.

5.4.3 Remove the boiler front panel (Section 6-2.1).

5.4.4 Light the burner {fig 1.1)

i Connect the electrical supply.

ii Select MAX on boiler control thermostat.

iri Select WINTER on the SUMMER/WINTER switch.

iv Turn on the electrical supply and set any external

controls to call for heat

v Select ON on the ON/OFF switch.

The boiler will now go through its ignition sequence

and the green light will illuminate when the burner has

lit.

If the burner fails to light, the appliance will go to

lockout (red light illuminated) In this case the cause is

probably air in the gas supply line. Wait 10 seconds.

Then press the fed button to restart the sequence.

Once lit the appliance will heal the content of the

appliance then commence supplying central heating.

5.4.6. After 10 minutes check that the burner pressure reading is as given in Section 2. If it is not adjust

the pressure as follows (fig.5 J):

Gas Inlet

1

Solenoid inlet and

2

protection

Inlet gas pressure test

3

point

Outlet gas pressure

4

test point

PROCEOURE TO ADJUST THE GAS PRESSURE

TO THE BURNER

Connect a suitable pressure gauge to the burner

pressure test point (fig 51 item G) The pressure

should read 14 mbar.

Remove the black dust cap covering the inlet gas

pressure lest point (fig 5.1 item 8).

Rotate the regulating screw (fig 5.1 item 3) underneath the cap: clockwise will decrease the pressure,

anti-clockwise will increase the pressure.

5.4.7 Open a hot tap fully, the burner will light; green

operating light ON.

5.4.8 Select SUMMER on the SUMMER/WINTER

switch Operating light ON.

5.4.9 Recheck the burner pressure.

5.4.10 Close the hot tap select OFF on the ON/OFF

switch, the burner will extinguish

5.4.11 Remove the' pressure gauge, retighten the

screw.

5.4.12Relight and check for gas soundness of the

appliance components.

5.4.13Reassemble

i Refil the base panel.

ii Relit the (rout panel

5.4.14 Relight the appliance and leave it running

checking that all air is vented, that all radiators

function and that all system controls react to various

demands.

5.5 HAND OVER THE INSTALLATION TO THE

USER

Gas outlet

5

Gas pressure regulatory

6

screw with cap

Control box with first

7

step (ignition flame)

regulatory roller.

Page 19

Page 20

5.5.1 Hand the Users Instructions to the user and

explain how to operate the appliance and any additional controls.

5.5.2 Advise of the precautions necessary to prevent

damage to the appliance and system by frost

5.5.3 Advise that, for continued safe and efficient

operation of the appliance it is recommences that it be

serviced at less; annually.

5.5.4Either hand these instructions to the user or leave

them at the gas meter.

6. REPLACEMENT OF PARTS

6.1 GENERAL

6.1.1 Part numbers — see exploded diagram, fig. 6.1

6.1.2 Isolate the electricity supply and turn off the gas

supply at the service cock (item 31).

6.1.3 Always check for gas and water soundness of

joints broken during Servicing.

6.2 ACCESS

Certain items need to be removed for access:

6.Z1 Front panel

Remove two screws (fig. 3.10. B). lift and disengage.

6.2.2 Top panel

Remove four screws (fig. 3. JO. 8). and remove.

6.2.3Base panel with attached front door.

Remove four screws and remove panel (fig.3. JO. B)

6.2.4Side panels

After having removed the front, top and base panels.

remove the two screws securing the instrument panel

to the respective side panel. Remove the respective

side panel fixing screw Pull down to disengage (fig.3.

10. item 94).

6.2.5 Withdrawal of instrument panel

Open the front door.

Unscrew four screws until firs: section of thread is free.

Withdraw panel forwards (fig. 3.10. A).

6.3 DRAINING WATER CIRCUITRY OF

APPLIANCE

6.3.1 Isolate the circuit via the cocks (item 41 and 33

[2 off]).

6.3.2 Drain the central heating circuit via the safety

valve (item 27).

6.3.3 Drain the domestic hot water circuit via a hot tap.

6.3.4 Whenever the central heating circuit of the

appliance is drained, the pressure in the sealed

system must be restored upon completion of work.

6.3.5 If the DHW isolation cock is closed, it must later

be readjusted to give a flow of 10 litres/minute at any

tap.

6.4 REPLACEMENT

6.4.1 Replacement is always in reverse order to

dismantling unless otherwise stated.

6.4.2 Electrical connections must be remade in

accordance with the wiring diagram. Fig 3.11

6.5 FAN, ITEM 7

6.5.1 Refer to sections 6.1, 6.2.1, 6.2.2 and 6.4 above.

Page 20

Page 21

6.5.2 Disconnect leads at the in line connectors and

remove the earth wire From the top of the appliance.

6.5.3 Remove three screws from the fan mountings,

remove fan,

6.5.4 Tighten mounting screws evenly.

6.6 AIR PRESSURE SWITCH, ITEM 16

6.6.1 Refer to Sections 6.1. 6.2.1 and 6.4 above.

6.6.2 Disconnect plastic lubes from switch.

6.6.3 Disconnect three wires from switch.

6.6.4 Remove two screws from supporting bracket

and remove switch.

6.6.5 Plastic tubes are identified red to red.

6.7 DOMESTIC HOT WATER EXPANSION

VESSEL ITEM 46

6.7.1 Refer to Sections 6.1. 6.2.1. 6.2.2. 6.2.4 (left

hand side panel) 6.3 (drain DHW circuit) and 6.4.

6.7.2 Unscrew the vessel.

6.8 AUTOMATIC AIR VENT. ITEM 47

6.8.1 Refer to Sections 6.1. 6.2.1. 6.2.2. 6.4. (drain-

ing not necessary.

6.8.2 Unscrew vent from hexagon nut.

6.9 CENTRAL HEATING EXPANSION VESSEL.

ITEM 49.

6.9.1 Refer to Sections 6.1. 6.2.1. 6.3 (central heat-

ing) and 6.4.

6.9.2 Release union on the top of the vessel.

6.9.3 Remove vessel.

6 10 BIMETALLIC PRIORITY THERMOSTAT ITEM

43.

6.10.1 Refer to Sections 6.1, 6.2.1, 6.2.2, 6.2.4 (left

hand side panel) and 6.4

6.10.2 Disconnect the leads to the thermostat.

6.10.3 Unscrew the two screws & remove the

thermostat.

Fig. 6-2

Page 21

Page 22

6.12 CIRCULATING PUMP ITEM 24

NOTE: The base section of the pump should never

require replacement. Instructions detail replacement of

the pumphead.

6.13.1 Refer (o Section 6.1. 6.2.1. 6.3 (drain CH circuit)

and 6.4.

6.13.2 Remove electrical cover from pump — one screw.

6.13.3 Disconnect two wires and remove the earth

connection — one screw.

6.13.4 Undo two alien screws and remove pump-head.

6.13.5 When replacing, speed adjuster is at top. Set to

the speed setting previously used.

6.14 THERMOSTATS AND TEMPERATURE /

PRESSURE GUAGE

6.14.1 Refer to sections 6.1, 6.2.1, 6.2.4 (right hand side

panel), 6.2.5 (except Anticondensing Thermostat) and 6.4

Fig 6.4 POSITION OF THERMOSTATS AND

THERMOSTAT PHIALS

Thermometer/pressure gauge only — drain CH circuit

— Section 6.3.

6.14.2 Identify the phial of the thermostat or thermometer to be replaced (fig. 6.4).

6.14.3 Remove the spring clip from the respective

phial boss.

6.14.4 Trace the capillary to the control body.

6.14.5 Safety (overheat) thermostat, item 65

i) Unscrew the reset button cover.

II) Disconnect two leads.

iii) Unscrew locknut and remove thermostat.

6.14.6 Anticondensing thermostat, item 62

i) Disconnect two leads and remove thermostat.

ii) Remove the two screws attaching the anticondensing thermostat to the fixing bracket.

6.14.7 Boiler thermostat, item 61

i) Remove control knob.

ii) Remove two fixing screws.

iii) Disconnect two electrical leads.

6.14.8 Pressure temperature gauge, item 67

I)Unscrew the pressure sensor (Union, item 29).

ii) Depress two plastic clips and push gauge out.

forwards

Fig 6.5 PRESSURE RELIEF VALVE

6.15.1 Refer to Sections 6.1. 6.2.1 (right). 6.2 4. 6 3

(Drain CH circuit) and 6.4

6.15.2 Disconnect the water pressure gauges probe

(placed on the top of the valve).

6.1 5.3 Disconnect the valve from the union on the

respective pipe coming out of the boiler Remove the

valve

WARNING- It is essential to fit a suitable discharge

pipe (1 5mm diameter) 10 the pressure relief valve

Page 22

Page 23

Fig. 6.7 BURNER

6.16.1 Refer to Sections 6.1, 6.2.1, and 6.4.

6.16.2 Disconnect the union of the gas feed pipe to

the burner pipe (item 54) and take the spring away.

Remove the union at the left side of the gas valve

pipe (item 51).

6.16.3 Gently press off the sealing plate (item 55)

from the burner cover.

6.16.4 Remove four screws, lift the cover a little and

move it lo the left until it is disengaged.

6.16.5 Disconnect the electrode leads.

6.16.6 Remove the two screws A (fig 6.7) and

withdraw the burner.

6.16.7 Transfer the injectors (6.17) and electrodes

(6.18) to the new burner. Ensure that the larger

injector is sited in the center burner bar.

6.16.8 When reassembling, ensure that the two

seals, one under the burner cover and the other on

the sealing plate, are in good condition. Respective

positions of the electrode leads are not important —

the electrodes are interchangeable.

6:17 INJECTORS. ITEM 78.

6.17.1 Remove the burner sections 6.16.1 to 6.16.7

above.

6.17.2 Unscrew the injectors

6.17.3 Refer to 6.16.8 when reassembling. Ensure

the larger injector is fitted in the center burner bar.

6.18 FLAME SENSING AND IGNITION

ELECTRODES, ITME 59

It is recommended that these are replaced as a pair.

16.18.1 Gain access to the burner – 6.16.1 to 6.19.9

6.18.2 Remove the fixing screws of each electrode &

withdraw the electrodes.

6.18.3 Refer to 16.16.8 when reassembling.

6.19 ELECTRONIC CONTROL BOX. ITEM 66.

6.19.1 Disconnect leads.

6.19.2 Remove the 2 control box fixing screws and

remove the box. Replace if required.

6.20 GREEN OPERATING LIGHT, ITEM 71 & RED

LOCKOUT BUTTON.

6.20.1 Refer to Sections 6.1. 6.2.1. 6.2.5 and 6.4.

6.20.2 Disconnect the electrical leads.

6.203 Press in catches & push lamp forward to

remove it

6.21 ON/OFF — SUMMER/WINTER SWITCHES

ITEM 69.

6.21.1 Refer to Sections 6.1. 6.2.5 and 6.4.

6.21.2 Disconnect four leads,

6.21.3 Press in catches and push switch forwards.

6.22 FILLING LOOP, ITEM 39.

6.22.1 Refer to sections 6.1. 6.2 3. 6.3 (Drain CH

circuit of appliance).

6.22.2 Disconnect the filling loop at both ends.

Page 23

Page 24

SECTION 7 Fault finding algorithm Thermomatic combination boiler model RSM 20/FB

Carry out initial fault finding checks i.e. check gas, water, electrical system check i.e. earth continuity, resistance

to, short circuit, polarity.

Repeat checks after any servicing / fault finding.

Fig. 7.1. CONDITION 1.

Does the fan motor

start?

Replace the fan

assembly

Is the red light on the

No Yes No

No

instrument panel on (shut

down signal)?

No

Is there voltage to the

boiler (240V)

No

Is there Voltage to the fan

motor?

Yes

Is the motor stuck?

Yes

Release the motor or

replace it.

No

No

Press slightly the red button

(restart). Red light off?

Check the main supply 3 A.

fuse for continuity.

Is the safety thermostat (ST)

open?

Yes Yes

Faulty control box.

Replace it.

Has the reload

button tripped

No

Faulty safety

Thermostat (ST)

Replace it.

Unscrew the black cap of safety

Thermostat and push the button to

restore the contact

Does the programming clock

(PC)(if fitted) call for heat?

Yes

Is the main switch (MS) on?

Yes

Is the boiler htg. regulatory thermostat (HT)

calling for heat?

Yes

Does the differential pressure switch

(DPS) give conent (closed circuit

between between terminal C and

NC)?

Yes

Are the wiring connections

of the DPS controls correct?

Yes

Adjust the time of consent

No

No

No

No

No

for boiler operation

Switch on. If faulty,

replace MS.

Replace HT

Replace DPS

Reset the electrical connections

according to the wiring diagram

Is the control box faulty?

Replace control

No

box.

Page 24

Page 25

Fig. 7.2. CONDITION 2.

The fan motor

starts, does the

burner light up?

Are the connection pipes

to the pressure switch

No

squashed, inverted or

Yes

Is there an obstruction at

See condition 3

the outlet of the flue gas

pipe or the air intake pipe?

Does the differential

pressure switch (DPS)

give consent of air

pressure and close the

Is control box faulty? Replace control box.

Fig. 7.3. CONDITION 3.

disconnected?

No

No

circuit C - No?

Yes

Yes

Yes

No

Yes

Restore the proper

connection according to the

identification clour

Clear the pipes.

Does the fan make few turns

No

Faulty DPS., replace it.

Is there current

(240V) at the fan

Yes

Check the electrical

supply or the 3A fuse.

motor?

No

The fan motor starts and the

red light on the instrument

panel comes on. Does the

burner light up?

Yes

Check the electrical

connections referring

to wiring diagram:

Earth

Live

Neutral

Check that the ignition probe (IP) cable is not disconnected.

Position properly IP with respect to the burner, avoiding any

contact with the metal parts. Is IP operating regularly?

Yes

Wrong electrical connections?

Yes

No

Does the gas

reach the valve?

No Yes Yes

No

Does the valve let

the gas pass

through?

No

Is there voltage

(240V) at the gas

valve?

No

Faulty control box

No

Is there a spark

from ignition

electrode?

No

Replace IP

Is the main gas

cock open?

No

Open it.

Check that there is the proper gas pressure at

valve outlet (tap 6 - gas valve drawing fig 6.1) If

necessary remove the closing cover and adjust

Yes

Yes

Yes

the gas pressure acting on screw 3.

Faulty gas valve. Replace it.

Check the gas valve connections and. if necessary

Verify if the connection cable is disconnected.

Check the electrode position comparing to the

No

Does the control box give the

replace control box.

burner (it must not touch the burner). If

necessary replace the electrode.

ignition spark?

No

Check that the proper

gas procedure reach tap

2 on gas valve (see gas

valve drawing fig 5.1)

Check control box connections. If

necessary replace control box.

Replace control box

Page 25

Page 26

Fig. 7.4. CONDITION 4.

The boiler is properly on. Is

the green operating light on?

Fig. 7.5. CONDITION 5.

When the water temperature

of the boiler exceeds 60ºC

does the circulation pump

start (check without drawing

water).

Yes Yes

See condition 6

Is the green lamp burnt

No Yes

Check the electrical

connections.

Does the room

No No

thermostat (RT) call

for heat?

Is there 240V at the

circulation pump?

Yes Yes

No No

out?

No

Replace it.

Set the room thermostat at a higher

temperature so that it can give consent.

Is the summer / winter

switch (SWS) set on

winter?

Set SWS on

winter

Faulty circulation pump,

replace it.

Set at 60ºC.

Is the circulation

No

1.Swicth off electrical supply.

2. Remove vent plug

3. Apply screwqdriver to slot on shaft

end and rotate each way pushing in

and out until shaft turns freely.

4. Replace vent plug and switch on

electrical supply.

Yes

pump stuck?

Yes

Is the AT set too

high?

Yes

Check control box connections. If

necessary replace control box.

No

Check the summer / winter

switch connections and if

necessary replace SWS.

Does the

Anticondensing

thermostat call for heat?

Yes

Check the mounting of and connections to the

BPT. If necessary replace BPT.

No

Is the biometalic priority thermostat

(BPT) contact closed?

Page 26

Page 27

Fig. 7.6. CONDITION 6.

The circulation pump starts,

do the radiators get hot?

Yes

See condition 7

Is there air in the radiators

or in the htg. system?

Yes

Let the air escape from the

various vents of the htg.

system.

No

Is the non-return valve

blocked?

Yes

Unblock or replace it.

No

Are the htgballafix valves

open?

Yes

Is the boiler full of water?

No

Open the cap of the vent valve

and let the air escape. Can the

boiler and the system get

filled?

No

Is there no water or too low

pressure in the water

supply?

No

I the domestic

water regulatory

ball valve closed?

No

Yes

Yes

Yes

No

Open them

Fill the boiler and the system

up to 1 bar of pressure.

Restore the water

supply.

Open it.

Set the pump on high speed, acting on the

proper button.

No

Is the pump speed sufficient?

Yes

Is the pump head insufficient?

Yes

Set the head variator of the pump at

maximum.

Is the flexible filling pipe

No

Is the AT set too high?

squashed?

No

Yes

Yes

Set it in order or replace

it.

Check the filling loop

valves.

Page 27

Page 28

Fig. 7.7. CONDITION 7.

Is the heating from radiators

sufficient?

A complete maintenance

is necessary.

Yes

Dirty Heat exchanger?

No

Do the thermostats opertate? Do the

thermometer show a wrong temperature? (

the above may happen when the thermostat

probes are removed for servicing and

wrongly fitted into the respective

sheathings.)

Yes

Yes

Is the boiler htg regulatory

thermostat (HT) at maximum?

Is the boiler undersized?

Is gas pressure right?

Thermostat and thermometer

bulbs wrongly fitted into the

respective sheathings on the

Yes

boiler. Insert the bulbs into the

sheathing according to the

Yes

No

drawing.

Yes

No

Set HT at

No

maximum.

Check the heat

requirement.

FWith the burner alight, check that

the gas pressure at valve outlet (tap

6) is right. Adjust gas pressure

acting on screw 3 after having

removed the closing cap. (see Fig

5.2)

No

Insufficient water content of the boiler

or of the htg system.

No

Does the safety thermostat (ST) cut

out below 90ºC?

No

Faulty boiler htg regulatory

thermostat (HT)?

No

The boiler is working. Does the boiler

stop at the temperature set by HT?

No

Yes

Yes

Yes

Restore 1 bar of pressure in

the boiler and in the heating

system (at cold)

Faulty ST replace it.

Replace HT

Faulty thermometer

Yes

Replace the thermometer

/ water gauge.

Page 28

Page 29

Fig. 7.8. CONDITION 8.

Is the dom. water coming out

of the taps hot enough?

Yes

When small flows of dom.

water are drawn (3.5

lt/min) is water too hot?

Yes

Id the boiler htg. regulatory

thermostat (HT) set on max?

Yes

Set HT to position min.

No

Is the rate of hot water flow too

high?

No

Wrong setting of the boiler htg.

regulatory thermostat (HT)?

No

Does the boiler temperature

stop under 70ºC (without

drawing dom. water)?

No

Is there a temperature loss in the

pipeline connecting to the taps?

No

Insufficient gas delivery?

Yes

Yes

Yes

Yes

Yes

To obtain the desired water

temperature adjust the water flow

acting on the cold water inlet cock

(see no 41 exploded drawing)

Set the HT temperature at

maximum.

Replace HT

Insulate the pipeline.

Set the proper pressure to the gas

valve (see gas valvedrwg.) If faulty

replace the gas valve.

Fig. 7.9. CONDITION 9.

Is the dom. water flow insufficient?

No

Is the domestic coil partly

scaled?

Inadequate pressure in the

Yes Yes

water supply?

No

Is the dom. water regulatory

ball valve too closed or dirty?

No

Are the pipeline or the flow

obstructed?

Yes

Yes

Yes

Clean it.

Restore the water supply.

Open more or clean it.

Clean them.

No

Is the domestic coil obstructed?

Yes

Make an antiscaling washing.

Page 29

Page 30

Fig. 7.10. CONDITION 10.

On summer mode, do the

radiators get hot?

Yes

Is the circulation pump

working?

No

Is the non return valve dirty or

faulty?

Yes Yes

Fig. 7.11. CONDITION 11.

Gas products smell?

Is the summer / winter switch (SWS)

on "winter mode"

No

Is SWS faulty?

Yes

Yes Yes

Clean or replace it.

Are the fire tibes of the heat

exchanger and the baffles dirty?

No

Yes

Switch it to "summer

mode"

Replace it.

A complete cleaning is

necessary.

Wrong fitting of the flue pipe or

of the air intake pipe?

No

Wrong installation of the flue

pipe unit?

No

Obstruction of the flue pipe

terminal?

Yes

Yes

Yes

Remove the flue pipe unit,

clean it and fit it properly to the

boiler.

Remove it. Fit properly and air tight

to the boiler according to the

installation manual.

Remove the obstruction and

leave the terminal clean.

Page 30

Page 31

Fig. 7.12. CONDITION 12.

Water Leakage from the

boiler?

Dirty or faulty valve. Let

water pass through the

valve, turning the red knob,

so to clean it. If necessary,

replace safety valve.

Does water escape from the safety

valve as pressure exceeds 3 bars?

Yes

Does water escape during the

heating cycle?

Does water escape from the

Yes

safety valve below 3 bar?

(pressure relief valve)

Does water escape from the

air vent valve?

No

No

No

No

Filling cock dirty , faulty

Yes Yes

Yes Yes

Yes

or does not stand the

pressure?

Too high boiler

pressure?

Is the expansion vessel

discharged?

Does the vessel hold the

pressure?

Faulty air vent valve, replace it.

Clean up or replace the

filling cock.

Decrease the boiler

pressure to 1 bar.

Fill up the vessel to 1 bar

Yes

No

of pressure.

Leaking valve or faulty

membrane. Replace the

vessel.

Is the filling flexible pipe

leaking?

No

Is the water gauge leaking?

No

Is some washer in the hydraulic

system leaking?

Yes

Yes

Yes

Faulty flexible pipe, replace it.

Faulty water gauge, replace it.

Untight or faulty washer.

Tighten or replace it.

Page 31

Page 32

8. ROUTINE SERVICING INSTRUC-TIONS

To ensure continued safe and efficient operation of

the appliance, it is recommended that servicing and

cleaning of the boiler be carried out at regular

intervals by a competent person.

The frequency of cleaning depends mainly on usage,

but generally once a year should be sufficient. Run

the appliance and detect any faults or servicing which

may be required, noting that the heat exchanger and

burner will be cleaned anyway.

WARNING

Before starting any servicing or replacement of components, always isolate electricity supply to appliance

and turn off the gas supply at the service cock.

8.1 ACCESS

Remove the front, top and base panels (see Section

6.2).

8.2 BURNER/ELECTROOES/INJECTORS

8.2.1Remove the main burner (Section 6171 to

6.17.7).

8.2.2 Clean the burner blades with a soft brush.

8.2.3 Check the condition of-the two electrodes.

8.2.4 If required, remove the injectors and blow or

wash through to clear any deposits.

8.2.5 Do not replace the burner at this time.

8.3 HEAT EXCHANGER CLEANING

(HORIZONTAL FLUE SYSTEMS)

8.3.1 Disconnect the pressure tubes from the inner

top panel (a. fig. 8.!)

8.3.2 Disconnect leads a (the in line connectors (b).

8.3.3 Lift and disconnect the elbow from the fan

socket, then pull the flue assembly out of the plastic

liner.

8.3.4 Remove 8 screws (c) and lift away the fan and

inner top panel complete

8.3.5I n turn, remove the baffle from each heat

exchanger tube and clean the tubes with a suitable

brush

8.4 .6 Rotate the fan checking it runs freely

8.3.7 Replace the baffles, the inner top panel/fan and

the flue elbow Connect the leads (polarity immaterial)

and the pressure tubes (red to red)

8 3.8 Clean any debris from the burner chamber and

order

8.4.1 HEAT EXCHANGER CLEANING (VERTICAL

FLUE SYSTEMS)

8.4.1 Disconnect leads at the in line connectors (b

fig 8 1)

Fig. 8.1 TOP VIEW OF THE BOILER

(Without top protective guard)

8.4.2 Remove the three retaining screws down each

side of the Air Pipe Detachable Sleeve and remove

the sleeve.

8.4.3 Slacken off the screws on the Flue Pipe Detachable Sleeve and slide the sleeve up the flue pipe

and remove the 110 mm length flue pipe distance

8.4.4 Disconnect the pressure tubes from (he inner

top panel (See fig 8.1).

8.4.5 Remove 8 screws {c) and lift away the fan and

inner top panel complete.

8.4.6 In turn, remove the baffle from each heat

exchanger tube and clean the tubes with a suitable

brush.

8.4.7 Replace the baffles and rotate the fan checking

it runs freely

8.4.8 Replace the inner top panel/fan.

8.4.9 Replace the flue Pipe Distance Piece and pull

the flue pipe detachable sleeve back down the flue

pipe until the sleeve covers the top 30 mm of the flue

pipe immediately below the distance piece. Place the

two piece of the air pipe detachable sleeve over the

gap in the air pipe, replace the screws and tighten.

8.4.10 Connect the leads (polarity immaterial) and

the pressure tubes {red to red).

8.4.11 Clean any debris from the burner chamber

and reassemble the remaining components in

reverse order.

8.5 Clean or replace any other components

considered necessary (Instructions for removal are

given in Section 6).

8.6 Relight and check for gas and water soundness

of appliance components.

8.7 Reassemble the appliance casing

Page 32

Page 33

Page 33

Page 34

SHORT SPARE PARTS LIST THERMOMATIC COMBINATION GAS BOILER

MODEL RSM 20/FB

Key

No

Code

62 3020114

Part

Denomination

Aniticondensin

g Thermostat.

Key

No

67 3130201

Code Part Denomination

Overheat

65 3120112

Safety

Thermostat

27 3330342

Temperature &

Pressure Guage

Pressure Relief

Safety Valve

61 3023115

69 303201

Boiler Heating

Regulatory

Thermostat.

On / Off

Summer /

Winter Switch

100 3063287 Inspection Glass

7 R.3000013 Fan Motor

24 3033101 Circulating Pump

Page 34

Page 35

SHORT SPARE PARTS LIST THERMOMATIC COMBINATION GAS BOILER

MODEL RSM 20/FB

Key

No

8 3063218 Sealing Ring.

Code

Part

Denomination

Key

No

43 3424110

Code Part Denomination

47 3330343

70 3520131

Automatic Air

Vent Valve

Operating Light

Neon Bulb.

59 3450113

71 3020157 Lamp Holder

49 3030315

C.H. Expansion

Vessel

Bimetallic Priority

Thermostat

Electrode

(Interchangeable)

53 3544410 Gas Control Valve

16 3063325 Air Flow Switch

66 3523110 Control Box

46 3033315

Domestic Water mini

Expansion Vessel.

Page 35

Page 36

SHORTSPART PARTS LISTTHERMOMATIC COMBI GAS BOILER MODEL

RSM20/FB

Key No CODE PART DENOMINATION

7 R3000013 FAN MOTOR (240Volls)

B 3063218 SEALING RINGS

16 3063325 PRESSURE SWITCH

23 3030341 WASHER FOR WATER CIRCULATOR

24 3033101 WATER CIRCULATOR

27 3330342 SAFETY VALVE TYPE 31 41

31 3033322 GAS COCK TYPE 45

38 3033320 DOUBLE CHECK VALVE'ALBIFIL

40 3033317 FILLING BALL VALVE'ALBIFIL

43 3424110 BIMETALLIC PRIORITY THERMOSTAT

46 3033315 INOX MINI VESSEL

47 3330343 AUTOMATIC AIR VENT

49 3030315 CH. EXPANSION VESSEL 8 LITRES

53 3544410 GAS VALVE

59 3450113 ELECTRODE

61 3023115 HEATING THERMOSTAT

62 3020114 ANTICONDENSING THERMOSTAT

65 3120112 OVERHEAT SAFETY THERMOSTAT

66 3523110 CONTROL SOX

67 3130201 THERMOMETER/WATER GAUGE

69 3033201 DOUBLE SWITCH (Main and Summer/Winter)

78 R3590M20 INJECTORS FOR NATURAL GAS (NG)

R3590G20 INJECTORS FOR LIQUID PROPANE GAS (LPG)

R3000014 OPTIONAL 2M EXTENSION FLUE SYSTEM Kl f

100 3063287 INSPECTION GLASS

Page 36

Page 37

Complete boiler wiring schematic.

Page 37

Page 38

New Thermomatic wiring diagram as from S/No. 00054

When wiring the boiler in conjunction with a time

switch, remove the link plug from the 5 wire block,

(left hand side at the bottom).

Page 38

Page 39

Examples of standard wiring connections to most popular models.

Page 39

Page 40

Page 40

Page 41

Addendum to existing manual.

REGULATION OF THE GAS PRESSURE TO THE NOZZLES

The Thermomatic boilers are delivered already prepared for the required gas, with the gas supply pressures

showed by the specific label slicked inside the front door panel, and also by the scheme of technical data in the

installation instructions (see page 1).

l)First of all check that the available gas and the supply pressure correspond to those for which the boiler has

been prepared.

Should it be necessary to do some adjustment (for example if the supply pressure is another than the

mentioned one (see the specific label), precede as follows:

2)Connect a suitable pressure gauge to the burner pressure test point on the gas control valve (n° 6 in the gas

control valve drawing).

3)Remove the screw cap that covers the gas pressure regulatory screw (6). With the help of an octagonal

screwdriver, turn the regulatory screw (6) until the same burner pressure as shown by the scheme of technical

data (page 1) is achieved:

-turn to the right to decrease the gas pressure;

-turn to the left to increase the gas pressure.

Page 41 (A1)

Page 42

HORIZONTAL CONCENTRIC FLUE EXTENSION FOR RSM20/FB

Identification nr R3501693

In addition to the standard Horizontal Concentric Flue Kit id.n° R3501613 supplied with the boiler, on request

an Extension Kit 1 mt. long (id.n° R3501693) is available.

Important: maximum linear length 3 mt. after the flue elbow;

for every 45° flue elbow consider 0.5mt less;

for every 90° flue elbow consider 1 .Omt less.

The Extension Kit for RSM20/FB id.n° R3501693 consists of:

- Imt. air intake pipe 0100mm. (see n°8 in the enclosed drawing).

- Imt. flue gas ejection pipe 060mm. (7) with centralising spring (9).

- Sealing washer 0100mm. (6) with fixing clamp (10).

On Request:

-R3566490 90° elbow 0100mm/60mm without test points;

-R3566445 45° elbow 0100mm/60nim without test points.

PREPARATION

1 )Remove the elbow (4) after having loosened the respective fixing clamp (10), then remove the standard

concentric flue kit Imt. long.

2)Fit the ORs (3) and sealing washers (2) to the flue elbow (4), and then fit the elbow onto the fancsocket (1)

on the top of the boiler.

3)Drill a hole 110mm of diameter through an outer wall, in line with the flue bend (4) (see also the dimensions

in the Boiler Installation Instructions).

INSTALLATION

l)Properly position the centralising springs (9); insert the flue pipe extensions 060mm (7) one into the other

and then into the standard flue pipe (5).

Shorten, if necessary, always from the plain end of the pipe.

2)Position the sealing washer for pipe junction 0100mm (10) on one end of each air pipe extension

0100mm (8).

3)Fit the air pipe extensions (8) one to the other; properly position the sealing washer (6) on each pipe

junction and tighten it by means of the specific clamp (10).

In case of shortening, cut the air intake pipe of the same length as the flue pipe.

4)Fit the extended flue pipe into the extended air pipe.

5)Fil the wall finishing washer (11) onto the end of the assembled concentric duct.

6)Insert the extended duct into the hole through the wall; make the air pipe slide a little, then fit the flue pipe

into the concentric flue elbow (4).

7)Approach the extended air duct to the flue elbow; properly position the sealing washer (6) and then fix the air

duct to the elbow by means of the fixing clamp (10).

8)Properly finish the internal wall face by means of the wall finishing washer (11).

Page 42 (A2)

Page 43

Horizontal Concentric Flue Extension for RSM20/FB - Legend:

1. Fan socket

2. 3060218 Flue elbow sealing washer

3. 3566291 O-Rings (2 pcs.)

4. 3566290 90° Flue elbow 0100/60 with test points

5. 3566294 Imt Flue ejection pipe 060 (included in the standard flue kit)

6. 3566292 Sealing washer for air pipe junction

7. 1 mt Flue pipe extension 060

8. Imt Air pipe extension 0100

9. 3566296 Centralising spring

10.3566293 Sealing washer fixing clamp for pipe junction

11.3566297 Finishing washer for internal wall face

12.3566295 Imt Air pipe 0100 (included in the standard flue kit)

13.3566299 Anti-wind terminal

14. 3566298 Finishing washer for external wall face

On Request:

R3566490 90° Concentric elbow 0100/60 without test points

R3566445 45° Concentric elbow 0100/90 without test points

Page 43 (A3)

Page 44

PRESSURE RELIEF VALVE:

-Remove the front and the right panels. Then empty the boiler.

-Unscrew and remove the pressure relief valve.

HONEYWELL GAS CONTROL VALVE:

-Close the gas cock in the boiler.

-Remove the front panel.