Page 1

Prefabricated Plant Rigs

Installation & Control

Instructions

34 West Common Road

Hayes, Bromley, Kent BR2 7BX

Tel. +44 (0)20 8462 0262 Fax. +44 (0)20 8462 4459

Email : info@keston.co.uk web : www.keston.co.uk

Page 2

WD309/0/2003 The Keston Prefabricated Plant Rigs

1.0 INTRODUCTION

The Keston Pre-Fabricated Plant Rigs are designed as complete heating plant

packages for rapid site installation and commissioning. The units are supplied

to site pre-piped and pre-wired on a floor standing frame (a wall hung option is

available for the two boiler rigs). The rigs are supplied complete with a Keston

Rig Controller module.

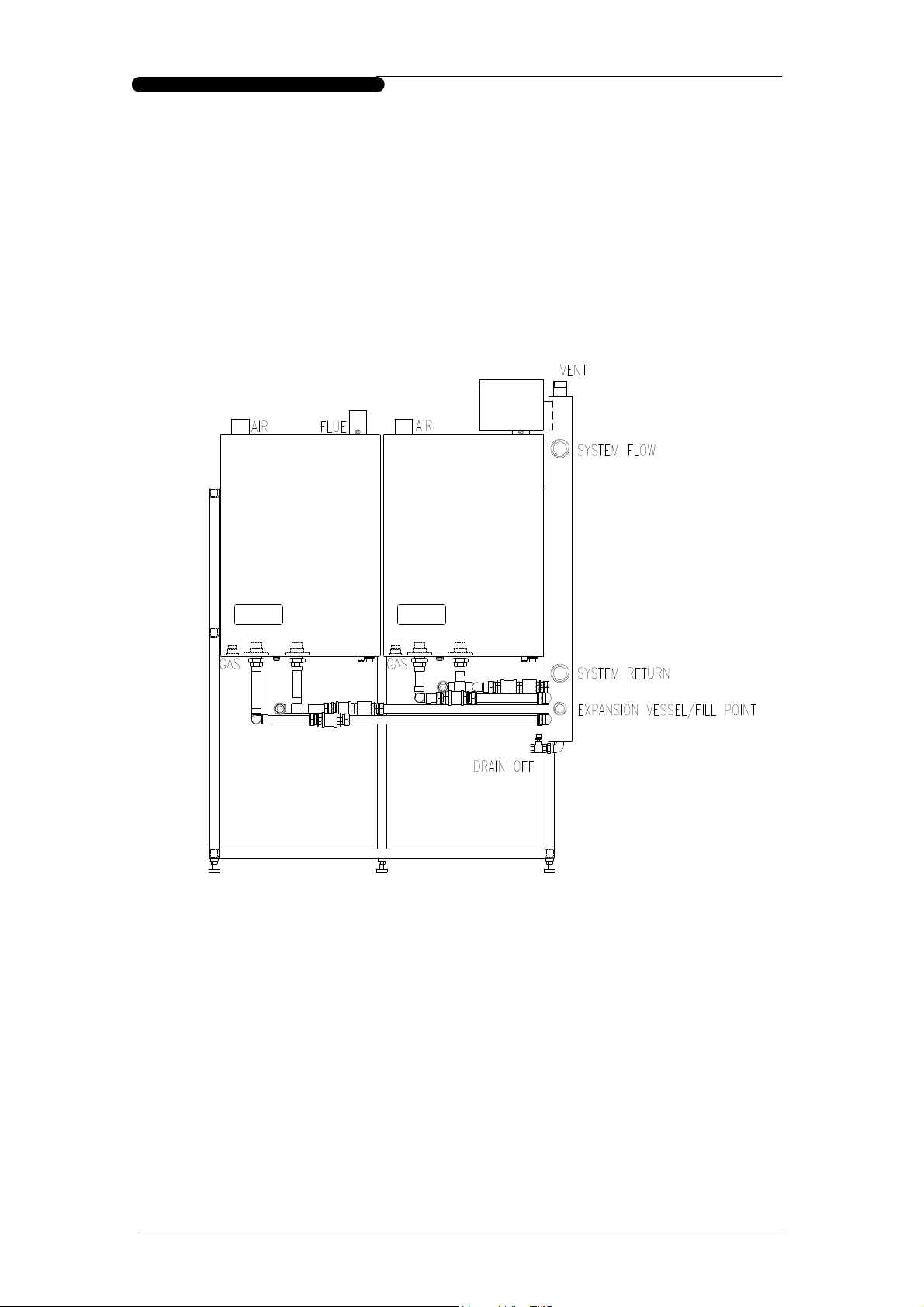

2.0 PIPE CONNECTIONS

Although most pipework is already complete within the rig. The final

connections for gas, condensate, flue exhaust and air supply will need to be

made to each boiler. The connections should be made following all

requirements laid out in the boilers Installation & Servicing Instructions.

The rigs are provided complete with a balance header which is prepiped to

each boiler. A pair of system tappings, flow and return, are provided on the

header plus connection points for fill point, expansion vessel, air vent and

drain off. The diagram below shows the relative position of these connection

points and their intended purpose.

3.0 CONTROL MODULE

The Keston Rig Controller is a comprehensive controller offering a wide range of

facilities to the end user. However, it is recognised that customers control

requirements vary widely and that some functions are not always required. The rigs

are supplied preset for option 1) Basic Sequence Control. To enable modes 2), 3) or

4) additional sensors may be required. In addition, commissioning set-up will be

required by Keston Boilers Ltd, or its approved agents.

Installation & Control Instructions

Page 2 of 10

Page 3

WD309/0/2003 The Keston Prefabricated Plant Rigs

3.1 AVAILABLE FUNCTIONS

To enable simple application the functionality is divided into four distinct groups as

detailed below:

3.1.1 Entry Level (Factory Default)

This is the mode in which all rig controllers are set by the factory, and therefore no

further components or action are necessary to realise these facilities.

Boiler Sequencing

In this mode the controller sequences the operation of the boilers to ensure the

required flow temperature is maintained with the minimum boiler operation. The

required flow temperature is set by the user.

Boiler Load Averaging

The switching order of the boilers is changed once per week, based on the hours

each boiler has run, to ensure even usage of each boiler over time.

Frost Protection

The Controller also provides frost protection, which will fire the boiler(s) in the

event the main flow temperature falls below 5OC. The boiler will remain on until

the flow temperature is raised above 15OC.

System Pump Overrun & Seizure Protection

The controller also provides a 230VAC output for connection to a system pump.

The pump is run when the rig is enabled and will also provide a 2 minute overrun

on shutdown. The controller will also operate the system pump at least once daily

to prevent seizure.

Fault Signal

A volt free pair of contacts are provided which move the closed circuit in the event

of a fault being identified

Control Signal

The Controller will fire the boiler(s) when enabled via a volt free contact pair.

3.1.2 Compensated Heating & Time Control

This mode provides all the features detailed in “Basic Sequence Control” plus the

additional features detailed below. However, to access this mode an outside

temperature sensor (part no C.17.4.17.00.0) is required. These are available from

Keston Boilers Ltd via your preferred stockist.

Weather Compensated Heating Control

The boiler flow temperature is adjusted automatically according to the outside

temperature. This provides even building temperatures and maximises boiler

efficiency.

Comprehensive Heating Time Control

The controller features an integral time programmer for heating periods permitting

a different heating pattern for each day of the week with up to two heating periods

per day. Holiday dates can also be programmed. The user may then specify three

temperature levels – day, night and holiday. The room temperature is estimated

based on outside temperature, boiler flow temperature and the building

construction.

DHW Override

In the event a volt free signal is received from the hot water system the weather

compensated heating control is suspended and the unit runs at the specified flow

temperature until the volt free signal is removed.

Outside Temperature Frost Protection

The outside temperature is constantly monitored such that, in the event the

outside temperature falls below 3OC the boiler is fired to maintain a boiler flow

temperature of 20OC. Once the outside temperature rises to 4OC or above this

action is stopped. This feature is design to ensure protection of system pipes

against freezing. However, it can be disabled if required.

Installation & Control Instructions

Page 3 of 10

Page 4

WD309/0/2003 The Keston Prefabricated Plant Rigs

3.1.3 Full Room Temperature Modulation

This mode provides all the features detailed in “Basic Sequence Control” and

“Compensated Heating & Time Control” plus the additional features detailed below.

However, to access this mode a room temperature sensor (part no C.17.4.31.00.0) is

required. This is available from Keston Boilers Ltd via your preferred stockist.

Accurate Room Temperature Control

The controller constantly monitors the room temperature to ensure that the

requested room temperature is maintained without deviation. The boilers are

directly controlled in terms of output and temperature to ensure this is achieved.

Optimum Start Control

During non-heating times the room temperature, and outside temperature, are

constantly monitored to identify the latest time at which the boilers can be fired to

riase the room temperature to the required temperature at the required time.

Room Frost Protection

The room temperature is constantly monitored such that, in the event the room

temperature drops to 3OC or less the boiler is fired at the minimum boiler flow

temperature until the room reaches 5OC.

3.1.4 Communication Options

For installations where additional control and monitoring is required the Keston Rig

Controller offers a wealth of communication options as follows:

Multiple Rig Control

Up to 150 boiler rigs, each with four boilers, may be connected and controlled

from a single controller which is designated as the “Master” controller

Fax Modem

A modem may be connected to the controller. The controller may then be

configured to send a status report by fax once per week. In addition, the

controller may be configured to send a fault report by fax should an fault occur on

a boiler or a sensor.

Remove PC Link

A windows software package is available to enable remote monitoring and control

of rig controllers via modem link or direct connection via RS232 cable.

Hours Run Data

The unit can be interrogated to identify the hours of operation of each boiler, at

high and low fire rates, and the system pump.

Datalogging

The integral data logging can be interrogated to provide details, at 5 minute

intervals, of boiler operations, pump operation and sensor readings over a period

of up to 7 days.

3.1.5 Other Configuration Options

The controller is configured at the factory for what is considered to be the most

popular configuration options. However, Keston Boilers Ltd, as part of the optional

commissioning process can reconfigure to suit specific customer requirements.

Specific options include:

Variations to system pump overrun timings.

Specification of up to 8 holiday periods during which the system will be

maintained at a lower temperature.

Changing the volt free input to provide timer override or forced holiday mode.

3.1.6 Keston Chronotherm Room Controller

For user control of room temperature levels and operating times a Keston

Chronotherm room controller (part no C.17.4.21.00.0) may be connected to the

Keston Rig Controller. Using the same user interface as a standard programmable

room thermostat, this controller will allow override and re-programming of switching

times and heating levels by the building occupant form within the heated area.

Contact Keston Technical Department for further details of this option.

Installation & Control Instructions

Page 4 of 10

Page 5

WD309/0/2003 The Keston Prefabricated Plant Rigs

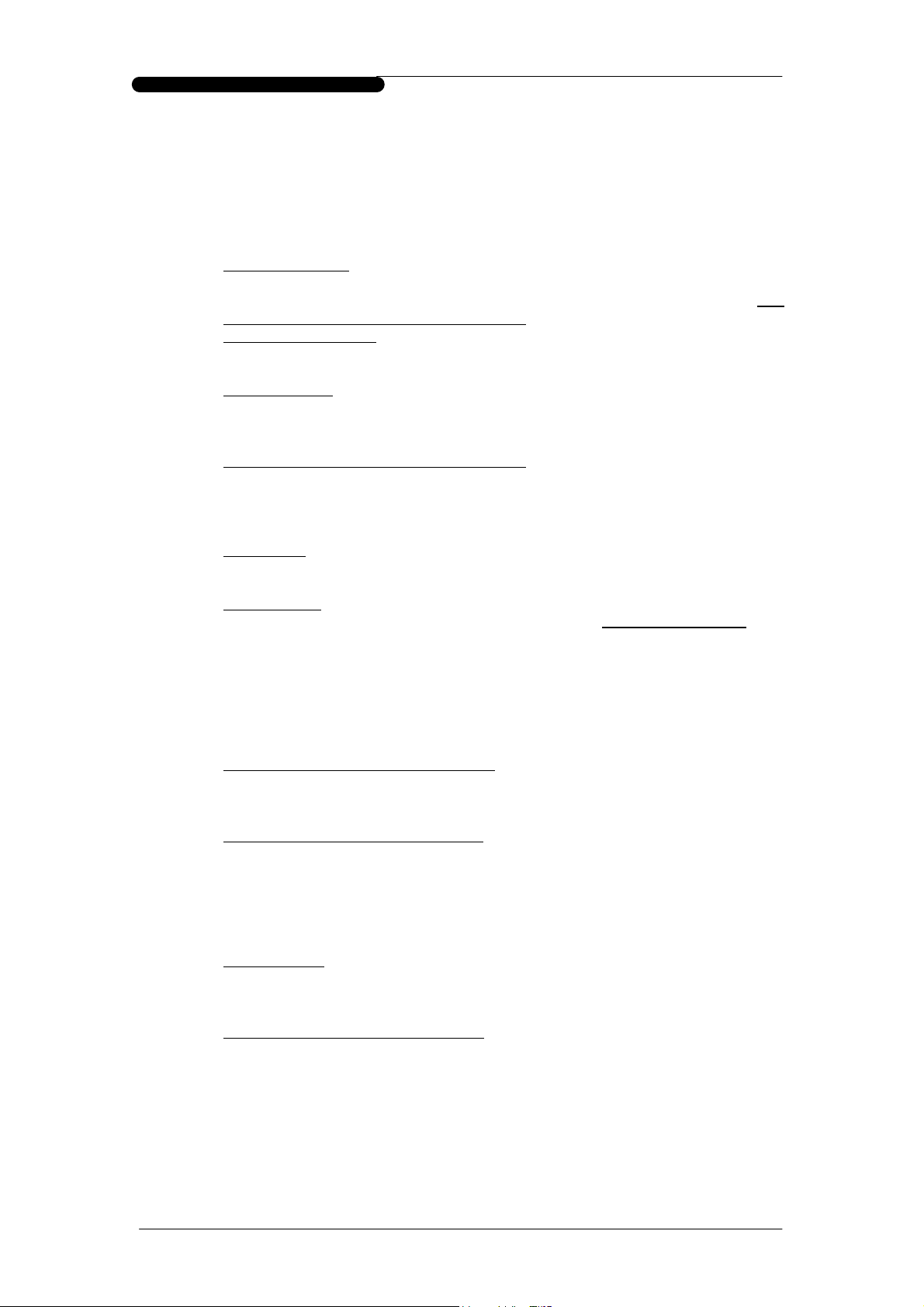

4.0 ELECTRICAL CONNECTIONS

This section details the actions required to implement to control level required:

4.1 Basic Sequence Control (Factory Default)

Electrical Connection

a) A 230VAC 5A supply is required and should be wired to the switched spur

unit mounted near the rig controller on frame. This power supply will serve

the controller, the boilers and the system pump.

b) The electrical cover at the base of the Rig Contoller should be removed to

expose the wiring connection points.

c) The following user connections should be made (refer to the diagram above)

a. The external controls should generate a volt free signal (closed on

demand) which should be connected to pins 6 and common on the rig

connection strip

b. The system pump may be connected to the vacant live (L) and (N)

connections on the rig connection strip. This will also provide a pump

overrun facility and anti-seizure operation of the system pump in periods

of inactivity

c. Rig connection strip terminals 1 and 2 will provide volt free alarm signal

(closed on alarm) for remote alarm indication

NB: The resistor factory fitted between terminals 4 and common should be left in

place.

Installation & Control Instructions

Page 5 of 10

Page 6

WD309/0/2003 The Keston Prefabricated Plant Rigs

4.2 Compensated Heating & Time Control

Electrical Connection

a) A 230VAC 5A supply is required and should be wired to the switched spur

unit mounted near the rig controller on the frame. This power supply will

serve the controller, the boilers and the system pump.

b) The electrical cover at the base of the Rig Controller should be removed to

expose the wiring connection points.

c) The resistor factory fitted between connection strip terminals 4 and common

should be removed and discarded.

d) The following user connections should be made (refer to the diagram above)

a. The system pump may be connected to the vacant live (L) and (N)

connections on the rig connection strip. This will also provide a pump

overrun facility and anti-seizure operation of the system pump in periods

of inactivity.

b. Rig connection strip terminals 1 and 2 will provide volt free alarm signal

(closed on alarm) for remote alarm indication.

c. The external temperature sensor (which must be mounted outside the

building on a north facing wall, not in direct sunlight) must be connected

to terminals 4 and common. Screened cable must be used. The cable

screen must be connected to the earth terminal.

d. A heating override signal (ie from a hot water calorifier) may be

connected as a volt free signal to terminals 6 and common. This signal

will cause the rig to provide a constant 80OC flow regardless of heating

and outside temperature demand. The 80OC flow setting can be adjusted

to a lower temperature if required.

Installation & Control Instructions

Page 6 of 10

Page 7

WD309/0/2003 The Keston Prefabricated Plant Rigs

4.3 Full Room Temperature Modulation

Electrical Connection

a) A 230VAC 5A supply is required and should be wired to the switched spur unit

mounted near the rig controller on the frame. This power supply will serve the

controller, the boilers and the system pump.

b) The electrical cover at the base of the Rig Controller should be removed to

expose the wiring connection points.

c) The resistor factory fitted between connection strip terminals 4 and common

should be removed and discarded.

d) The following user connections should be made (refer to the diagram above)

a. The system pump may be connected to the vacant live (L) and (N)

connections on the rig connection strip. This will also provide a pump

overrun facility and anti-seizure operation of the system pump in periods

of inactivity.

b. Rig connection strip terminals 1 and 2 will provide volt free alarm signal

(closed on alarm) for remote alarm indication.

c. The external temperature sensor (which must be mounted outside the

building on a north facing wall, not in direct sunlight) must be connected

to terminals 4 and common. Screened cable must be used. The cable

screen must be connected to the earth terminal.

d. The room temperature sensor (which must be mounted in a common

area without thermostatic radiator valves fitted) must be connected to

terminals 5 and common. Screened cable must be used. The cable

screen must be connected to the earth terminal.

e. A heating override signal (ie from a hot water calorifier) may be

connected as a volt free signal to terminals 6 and common. This signal

will cause the rig to provide a constant 80OC flow regardless of heating

and outside temperature demand. The 80OC flow setting can be adjusted

to a lower temperature if required.

f. The controller will require a change to its configuration settings to

recognise the additional room sensor – See section 5.4.

Installation & Control Instructions

Page 7 of 10

Page 8

WD309/0/2003 The Keston Prefabricated Plant Rigs

4.4 Communication Options

The communication options features can be implemented by Keston Boilers Ltd in

conjunction with options 1, 2 or 3. For implementation a telephone line port will be

required in close proximity to the rig. This is for installation of a communications

modem which is supplied and fitted by Keston Boilers Ltd as part of the

implementation procedure.

5.0 CHANGING THE SETTINGS

The default mode of the controller does not permit changes to any of the settings,

including date and time. This is to prevent inadvertent changes by the user. To

permit changes to time and temperature settings the access level must be set to level

2 as follows:

a) Press the “ESC” button repeatedly until the first line of the display shows

“Function 001-x” (where “x” is a letter).

b) Press the up arrow repeatedly until the top line of the display shows

“Function 001-A”.

c) Press the “↵” button once then press the “↓” button repeatedly until the

display shows “Access Level”.

d) Press the “↵” key twice so that the current access level number starts

flashing.

e) Enter the key sequence ↑ ↓ ESC ↵. The access level number will now

change to 2.

f) Press “ESC” repeatedly until the display returns to “Function 001-A”.

The controller is now set to allow changes to time and temperature settings.

5.1 Changing the date and time (all options)

a) Set the Access Level 2 (detailed in section 5.0).

b) Press the “↓” button repeatedly until the top line of the display shows

“Function 001-A”.

c) Press the “↵” button once.

d) Press the “↓” button until the display shows the date and time.

e) Press the “↵” button and the day will start to flash. Adjust the date setting

using the “↑” and “↓” buttons. Press “↵” to store the new setting.

f) Repeat the procedure for the month, year, time, etc.

Installation & Control Instructions

Page 8 of 10

Page 9

WD309/0/2003 The Keston Prefabricated Plant Rigs

5.2 Adjusting the flow temperature when firing due to an external demand signal (all

options)

This temperature is factory set to 80OC. Contact Keston Boilers Ltd for changes to

this setting.

5.3 Modifying the heating on times (options 2, 3 and 4 only)

a) Set the Access Level 2 (detailed in section 5.0).

b) Press the “ESC” button repeatedly until the top line of the display shows

“Function 001-x” where “x” is a letter.

c) Press the “↑” button until the display shows “Function 001-B Plant Control”.

d) Press the “↵” once and then press the “↑” repeatedly until the display shows

“Time Clock”. Press “↵” once.

e) Select the day of the week you wish to change using the “↑” and “↓” buttons.

f) Press the “↵” one so that the first on time flashes. Set the on time to the

desired time using the “↑” and “↓” buttons. Press “↵” to store the new setting.

g) Repeat the operation for the first off time and the second on and off times.

h) Go to step e) for other day settings.

Installation & Control Instructions

Page 9 of 10

Page 10

WD309/0/2003 The Keston Prefabricated Plant Rigs

5.4 Modifying the required room temperature levels (options 2, 3 and 4 only)

a) Set the Access Level 2 (detailed in section 5.0).

b) Press the “ESC” button repeatedly until the top line of the display shows

“Function 001-x” where “x” is a letter.

c) Press the “↑” button until the display shows “Function 001-B Plant Control”.

d) Press the “↵” once and then press the “↑” repeatedly until the display shows

“Settings”. Press “↵” once.

e) Use the “↑” and “↓” buttons to select the temperature setting you wish to

change.

f) Press the “↵” button so that the temperature value flashes. Use the “↑” and

“↓” buttons to set the temperature to the required value. Press “↵” to store

the new setting.

5.5 Configuring the room sensor (option 3 and 4 only)

Contact Keston Boilers Ltd for details.

The rig controller has a comprehensive array of settings and configuration amendments. If

you have a specific requirement, such a heating boost switches, please contact Keston

Technical Support for details.

Installation & Control Instructions

Page 10 of 10

Loading...

Loading...