Page 1

Qudos 28s

Fan Powered High Efficiency

Modulating Domestic Condensing

Gas System Boiler

User, Installation And Servicing

Instructions

CE/PI No : 87BR36

Qudos 28s - GC No : 41-930-17

Qudos 28sP - GC No : 41-930-18

These instructions must be left either with

the user or next to the site gas meter.

34 West Common Road

Hayes, Bromley, Kent BR2 7BX

Tel. +44 (0)20 8462 0262 Fax. +44 (0)20 8462 4459

email : info@keston.co.uk web : www.keston.co.uk

COMPLIANT WITH BUILDING REGULATION PART L1 & L2

SEDBUK A RATED

WD420/3/2007 The Keston Qudos 28s & Qudos 28sP Boilers

Page 2

CONTENTS

NB : These instructions are an integral part of the appliance. This document must be handed over to

the user on completion of the installation to ensure compliance with the Gas Safety (Installation

& Use) Regulations.

Section Description

0 HANDLING INSTRUCTIONS

0.1 List of contents

0.2 Recommended handling procedure

1 USER INSTRUCTIONS

1.1 Introduction

1.2 Maintenance

1.3 Boiler Setup and Operation

1.4 Safety Information

2 GENERAL INSTRUCTION

2.1 Description

2.2 Boiler Schematic

2.3 Related Documents

2.4 Physical Data

2.5 Optional Accessories

2.6 Performance Data

3 BOILER LOCATION

3.1 Dimensions & Minimum Clearances

3.2 Service Connections

3.3 Position

3.4 Electrical

3.5 Boiler Size Selection

3.6 Gas Supply

3.7 Water Systems

3.8 Flue System

3.9 Air Supply

3.10 Compartment Installation

3.11 Condensate Drainage

4 INSTALLATION OF THE BOILER

4.1 Wall Mounting Bracket

4.2 Mounting The Boiler

4.3 Assembly Practice

4.4 Installing Flue And Air Pipes

4.5 Condensate Drainage

4.6 Water System

4.7 Gas Supply

4.8 Electrical Supply

4.9 Exchanging A Boiler

5 COMMISSIONING OF THE BOILER

5.1 Initial Flushing

5.2 Gas Supply

5.3 Electrical Installation

5.4 LP Gas

5.5 Initial Firing

WD420/3/2007 The Keston Qudos 28s & Qudos 28sP Boilers

Page : i

Page 3

5.6 Hot Flushing

5.7 Combustion Testing

5.8 Checking The Gas Pressure

5.9 Timing The Gas Meter

5.10 Handing Over To The User

6 FAULT FINDING

6.1 Electrical Control Sequence

6.2 Normal Operation

6.3 Fault Modes

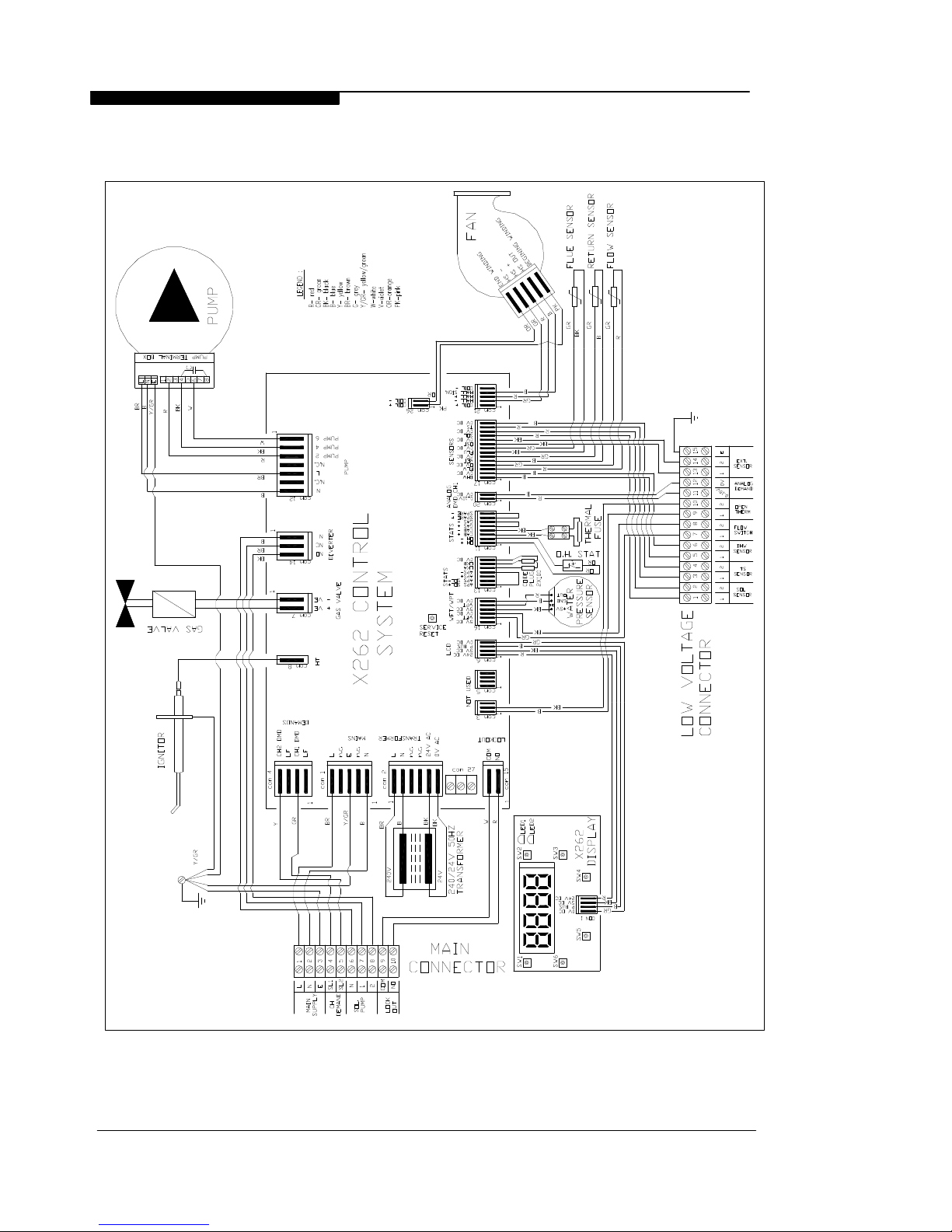

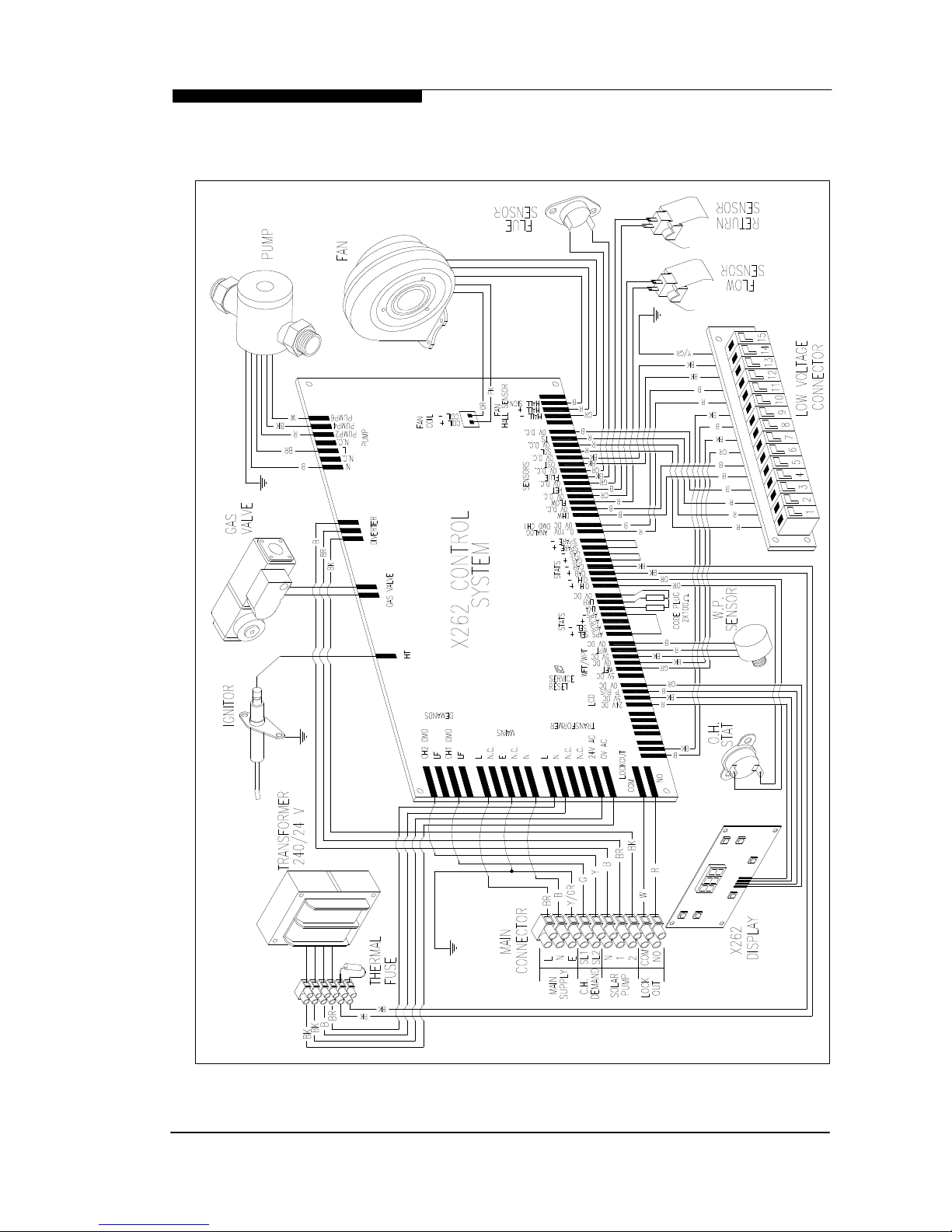

6.4 Functional Flow Wiring Diagram

6.5 Electrical Wiring Diagram

6.6 Illustrated Wiring Diagram

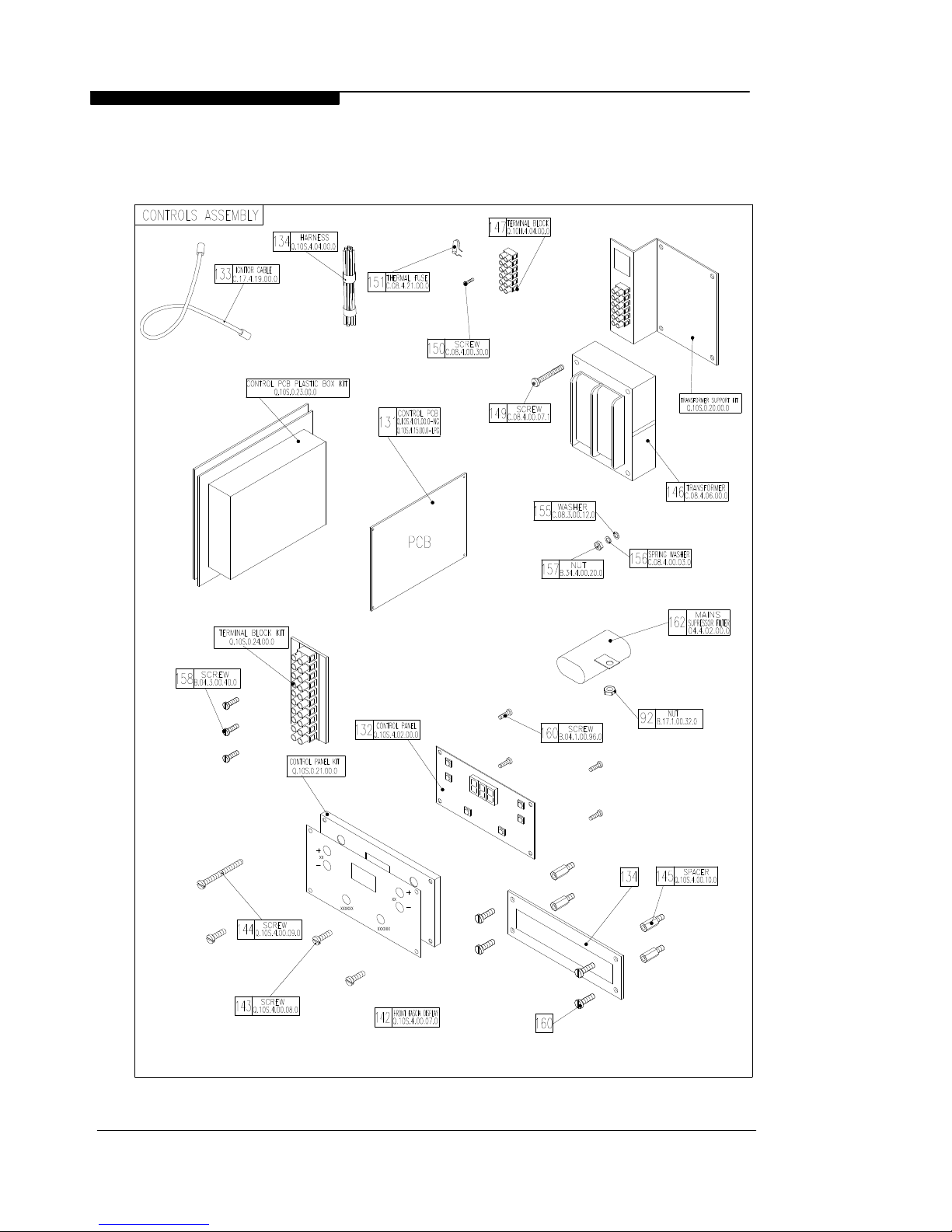

6.7 Exploded Assembly Diagrams

7 SERVICING

7.1 Pre Service Checks

7.2 Recommended Routine Service

8 REPLACEMENT OF PARTS

8.0 General

8.1 Precautions

8.2 Access

8.3 Replacement Procedure

8.4 Electrical Components

8.5 Spark Ignition/Flame Detection Electrode

8.6 Burner

8.7 Heat Exchanger

8.8 Condensate Trap

8.9 Pump

8.10 Expansion Vessel

9 SPARE PARTS LISTINGS

10 GAS BOILER COMMISSIONING CHECKLIST

WD420/3/2007 The Keston Qudos 28s & Qudos 28sP Boilers

Page : ii

Page 4

0. HANDLING INSTRUCTIONS

0.1 LIST OF CONTENTS

The Keston Qudos 28s and Qudos 28sP are supplied almost totally pre-assembled. The units

use standard 50 mm muPVC (BS5255 and/or BSEN1566-1 and BSEN1329) pipe for the flue

and air intake systems. The boiler is packed in a single box without additional flue kit. All

additional components are packed inside the boiler cabinet itself. The following is a list of

components and their location in the boiler cabinet

Equipment List

Item Quantity Location

Wall Bracket Rawl Plugs 6 Inside accessories bag

Wall Bracket Wall Fixing Screws 6 Inside accessories bag

Wall Mounting Bracket 1 Secured to inside right

hand side of boiler case

Wall Mounting Bracket Nuts 1 Inside accessories bag.

Wall Mounting Bracket Washers 1+1 Inside accessories bag

Wall Bracket Bolt Insulation 1 Inside accessories bag

50 mm muPVC Air/Flue Terminals 2 Inside accessories bag

Air Inlet Spigot (50 mm) 1 Inside accessories bag

Flue Outlet Spigot (50 mm) 1 Inside accessories bag

Air Inlet Spigot Gasket 1 Inside accessories bag

Air Inlet Spigot + Flue Outlet Spigot M6 Screws 4+2 Inside accessories bag

Cabinet Cable Entry Clamps 2 Inside accessories bag

Gas Isolating Cock 1 Inside accessories bag

Condensate Trap 1 Inside accessories bag

Condensate Trap fixing screws 2 Inside accessories bag

Condensate Trap fixing washers 2 Inside accessories bag

Condensate Trap Gasket 1 Inside accessories bag

50 mm muPVC Pipe 2 Inside boiler case

50 mm muPVC Elbow 2 Inside boiler case

Document List

Item Quantity Location

Registration of Purchase 1 In A4 envelope

Installation Template 1 In document bag

Remove the cabinet shell by removing the two retaining screws in the top of the cabinet and

the two retaining screws in the bottom of the cabinet.

0.2 RECOMMENDED HANDLING PROCEDURE

NB : The following lift operation exceeds the recommended weight for a one-man lift as

specified in the Manual Handling Operations 1992 Regulations.

For the carriage of carton it is recommended at least two people perform any lift. Clear the

carriage route of the carton from point of delivery to point of installation. Take care to avoid trip

hazards, slippery or wet surfaces and when climbing steps and stairs. Always use assistance

if required. If a sack truck is used it is recommended the carton is strapped to the truck.

For the unpacking of the appliance from the carton, it is recommended at least two people

perform any lift. It is recommended to cut the base end of carton and open the carton flaps.

Ensure the protective packing over the boiler tappings at the base of the boiler is kept in place,

then tilt the boiler forwards from its back onto its base and remove carton by sliding up over

the boiler. When lifting this appliance the back should be kept straight at all times. Avoid

WD420/3/2007 The Keston Qudos 28s & Qudos 28sP Boilers

Page : iii

Page 5

twisting at the waist - reposition the feet instead. Avoid upper body bending when holding the

appliance and keep the boiler as close to the body as possible.

Before hanging the appliance on the wall it is best to store the appliance laid on its back with

the casing on. When ready to hang the boiler on the wall remove the casing and place to one

side. At this stage it is assumed that the wall bracket is correctly positioned and secured on

the wall face.

a) Have the wall bracket nut and washers to hand so that they can be accessed whilst

holding the boiler in position on its mounting bracket.

b) The boiler has a dry weight of 43 kg (95 lbs) and will therefore require at least two people

to lift without the use of lifting aids - ensure co-ordinated movements durring lift. Always

use assistance if required.

c) Lift the boiler by gripping at the four corners of the boiler back plate. When lifting this

appliance the back should be kept straight at all times. Avoid twisting at the waist reposition the feet instead. Avoid upper body bending when holding the appliance and

keep the boiler as close to the body as possible.

d) Lift the boiler and locate onto the stud and the two pegs of the wall mounting bracket.

e) Place the wall mounting bracket washers over the bracket stud protruding through the

back plate of the boiler.

f) Secure the boiler onto the wall bracket by fixing the wall mounting bracket nut onto the

wall bracket stud. This must be tightened well.

Safety footwear and gloves are recommended PPE when lifting this appliance - to protect

against sharp edges and ensure good grip.

The Qudos 28s and Qudos 28sP boilers can be fitted in compartments with very small

clearances required around the appliance (refer to Section 3.1). Due consideration should

therefore be given to access within the compartment for lifting and positioning.

WD420/3/2007 The Keston Qudos 28s & Qudos 28sP Boilers

Page : iv

Page 6

1. USER INSTRUCTIONS

1.1 INTRODUCTION

Thank you for choosing this Keston Qudos 28s for your household heating. The boiler is

designed to be very straightforward to operate and has no user serviceable parts inside the

cabinet. The following instructions are to provide you with information on the operation and

maintenance of your Qudos 28s and what to do in the unlikely event of a fault.

These user instructions should be read carefully to ensure safe and economical use of your

Qudos 28s or Qudos 28sP. The Qudos 28s model is for use with natural gas only, the Qudos

28sP model is for use with LPG only.

1.2 MAINTENANCE

Servicing

To ensure continual safe and efficient operation and to maintain product warranties it is a

requirement that the appliance is checked and serviced at least once per year. It is the law

that any servicing must be carried out by a competent person. Removal of the appliance

cabinet by anyone other than a competent person will automatically invalidate the

appliance warranty.

Clearances

If fixtures are to be positioned close to the boiler, the following minimum clearances must be

observed: Top 150mm, Left 5mm, Right 5mm, Base 200mm, Front 10mm. Extended

clearance is required to the front for servicing (300mm).

Cleaning

Normal case cleaning only requires dusting with a dry cloth. To remove more stubborn marks

wipe with a damp cloth and finish with a dry cloth.

1.3 BOILER SETUP & OPERATION

Check that the gas supply from the gas meter is turned on. Switch on the electrical supply to

the boiler. The display will now run through a self check procedure. Set any controls to call for

heat.

To light the boiler

The Qudos 28s features two temperature controls to allow different settings depending on the

source of the demand, ie heating or hot water. Identify the which setting is demanded. Using

the “” on the left of the display, select the setpoint you wish to adjust, generally the one

indicated by a radiator symbol with a “1” to the left. Set the required temperature using the “+”

or “-” buttons associated with the heating zones or hot water temperature. After the selection

of the desired tempreatures press ENTER and then preset “RESET” to return to the normal

display.

If the actual temperature is less than the desired temperature the boiler will fire and, after a

few seconds, a “flame” will appear on the display to show that the boiler is alight.

NB: Where the demand is via 0-10VDC or Opentherm the boiler setpoint is set using the

external controller in use.

Normal Operation

During normal operation the digital display will show the current boiler temperature and will

show relevant operational symbols to confirm what action the boiler is taking. If the the

“radiator”, or “z

zz

z” symbol is shown on the display the boiler is receiving a demand for that

function.

WD420/3/2007 Chapter 1 : User Instructions The Keston Qudos 28s & Qudos 28sP Boilers

Installation & Servicing Instructions Page : 1

Page 7

Fault Modes

In the event that the boiler detects a situation which it considers to be a fault the display will

change to show a flashing fault code starting with an “E” and then a two digit number. The

table below explains these codes and the action you should take.

The cabinet has overheated - consult your Service Engineer before operating the boiler

further - SERVICE RESET REQUIRED

E70

Water pressure too high - check that the system water pressure top-up valve has not

been left open or consult your installer to check the expansion vessel.

E62

The flue temperature is too high. Consult your Service Engineer - SERVICE RESET

REQUIRED

E52

The boiler temperature is rising too fast - ask your Service Engineer to check for

system blockage or pump failure.

E25

The system water pressure is too low. Check the system has water in and, for sealed

systems, top up the system water pressure to restore a pressure of between 1 and 2

bar. (Consult your installer for instruction how to top up water pressure - repeated need

for restoration of water pressure indicates a system leak which should be investigated)

E26 or

E67

Flow overheat - the boiler has exceeded it maximum water temperature. Check that any

by-pass is open and the controls are operating correctly

E12

Flame failure whilst running - the boiler is having difficulty maintaining the flame.

Consult your Service Engineer and check for flue, gas supply or condensate drainage

obstruction

E04

Ignition lockout - the boiler has attempted to light five times and not succeeded - check

the gas supply is on.

E02

Description of faultDisplay

The above is an abbreviated list of possible error codes. If the code is not in the list above

consult a CORGI registered engineer. A full list of codes can be found in Chapter 6 of this

manual. If a code appears and you feel the original cause has been rectified and it has not

been designated as requiring a “Service Reset”, press the “Reset” button to resume boiler

operation. Otherwise, or if the code persists consult a CORGI registered engineer.

Raise up the system pressure until error E67 or E26 disappears from display (the boiler will

enter in standby mode or will start to fire up if a heat demand exists). To check the system

pressure press the “” button repeatedly until the display shows the water pressure, indicated

by the word “bar” to the right of the number. To return to main screen press the RESET

button.

Precautions

Care must be taken at all times to ensure that no blockage or obstruction is present in the

condensate drainage line. In addition, the air intake and flue exhaust terminals must be free

from obstruction at all times.

Care should be taken not to damage the condensate trap protruding from the base of the

boiler. Any sign of leakage of this part should be reported to a CORGI registered engineer

immediately. If the part becomes broken the boiler should be turned off and a CORGI

registered engineer contacted to make a repair.

Any indication of leakage from the boiler cabinet should be investigates by a CORGI engineer.

Frost Protection

The Qudos 28s has an integral frost protection function. However, care should also be taken

that any exposed pipework is adequately insulated to prevent freezing.

WD420/3/2007 Chapter 1 : User Instructions The Keston Qudos 28s & Qudos 28sP Boilers

Installation & Servicing Instructions Page : 2

Page 8

1.4 SAFETY INFORMATION

IF YOU SUSPECT A GAS LEAK TURN OFF THE APPLIANCE IMMEDIATELY, TURN OFF

THE GAS TAP TO THE APPLIANCE (LOCATED UNDERNEATH) AND CONTACT YOUR

GAS SUPPLIER WITHOUT DELAY.

Benchmark Initiative

As part of the industry wide “Benchmark” initiative Qudos 28 boiler manual includes Gas

Boiler Commissioning Checklist (Chapter 10). This form should be completed by your

installer at the end of the installation and commissioning process. The details of the Checklist

will be required in the event of any warranty work being required. There is also Service

Interval Record (Chapter 10) to be completed after each annual service visit.

These forms (Chapter 10) should be kept in a safe place for the life of the boiler.

The boiler should be installed and serviced only by CORGI registered operatives. All CORGI

registered Installers carry a CORGI ID card and have a registration number. Both should be

recorded in your boiler manual (Chapter 10: GAS BOILER COMMISSIONING

CHECKLIST). You can check your installer by calling CORGI direct on 01256 372300.

WD420/3/2007 Chapter 1 : User Instructions The Keston Qudos 28s & Qudos 28sP Boilers

Installation & Servicing Instructions Page : 3

Page 9

2. GENERAL INSTRUCTION

2.1 DESCRIPTION

The KESTON Qudos 28s and Qudos 28sP boilers utilize the latest in condensing

technology to produce a high efficiency boiler with SEDBUK A rated efficiency plus

advance controls to maximize operational efficiency.

The Qudos 28s is unique in concept and design. It comprises a high efficiency stainless

steel heat exchanger coupled with a low emissions burner to deliver ultra high efficiency

condensing mode operation within a compact wall hung cabinet. The unit automatically

adjusts gas and air rate according to demand to give a heating input in the range of 7.8kW

to 29.4kW (GCV). The integral pump assembly, in the Qudos 28s, is automatically speed

controlled to best match water flow rate to heat output & further increase appliance

efficiency.

The Qudos 28s has been developed to embrace the concept of advanced controls to

ensure the ultra high performance burner and heat exchanger system is run to optimum

performance levels whilst provided or exceeding the comfort levels demanded. As a result

the boilers feature a host of additional connections for:

- an optional outside sensor to enable the boilers inbuilt weather compensation

option which delivers enhanced user comfort levels with peak operating efficiency

due to the lower flow temperatures involved.

- an optional “Opentherm” connection point for the Keston Room Control module

which provides further advanced user control for room temperature compensation

and optimum start.

- optional 0-10VDC input where temperature control is provided by external 3rd

party intelligent controls

- optional connection of a DHW thermistor to enable modulated reheat of DHW and

optional legionella prevention function

Further, the Qudos 28s is developed with the concept that the gas boiler in the modern

home is often supplemented by alternative or renewable energy sources. As a result the

Qudos 28s features:

- optional connection of a solar thermal system, pump, panel and DHW sensor, for

direct control of solar thermal system from the boiler. Other additional energy

source systems, such as Ground Source Heat Pump, will be accommodated

soon.

The boilers have the added advantage of very high efficiency, and small diameter muPVC

plastic flue which can be extended up to 20 metres horizontally or vertically. The boilers

also feature an optional remove fascia panel so the boiler can be controlled from within

the house where the boiler is located outside the house or in the loft.

The Keston Qudos 28s uses a variable speed combustion blower to deliver a premix of

gas and air to a downward firing burner in a high efficiency, single pass heat exchanger.

The flue system is room sealed and fan powered. The ignition is direct spark and fully

automatic. The boiler housing is not waterproof and should be installed in a position

where it will always be dry. Combustion air is drawn from the cabinet which is connected

to outside atmosphere via a small diameter plastic intake pipe. The cabinet therefore

remains under negative pressure at all times the boiler is operating.

These boilers are designed for use as part of a sealed water central heating system with

fully pumped circulation. The pump, an 8l expansion vessel and associated safety devices

are all fitted within the Qudos 28s boiler. However, consideration should be given to

additional expansion vessels on larger systems where 8 litres may be inadequate.

WD420/3/2007 Chapter 2 : General Instruction The Keston Qudos 28s & Qudos 28sP Boilers

Installation & Servicing Instructions Page : 4

Page 10

The boiler heat exchanger is made from highly corrosion resistant stainless steel in

corrugated pipe form which provides massive surface area within a compact dimension.

The hot combustion gases from the down firing burner pass around the stainless steel

pipes imparting heat into the system water. On the Qudos 28s integral variable speed

pump within the appliance cabinet ensures the heat exchanger receives correct water flow

when firing. The Qudos 28s is not a high water content boiler and does not contain the

metal mass, or water volume, of a cast iron or steel boiler. This boiler is of low mass and

low water content and therefore responds faster when there is a call for heat. The Qudos

28 features full user diagnostics, integral frost protection function, automatic pump and

fan exercise in periods of inactivity, anti cycle control and dry fire protection.

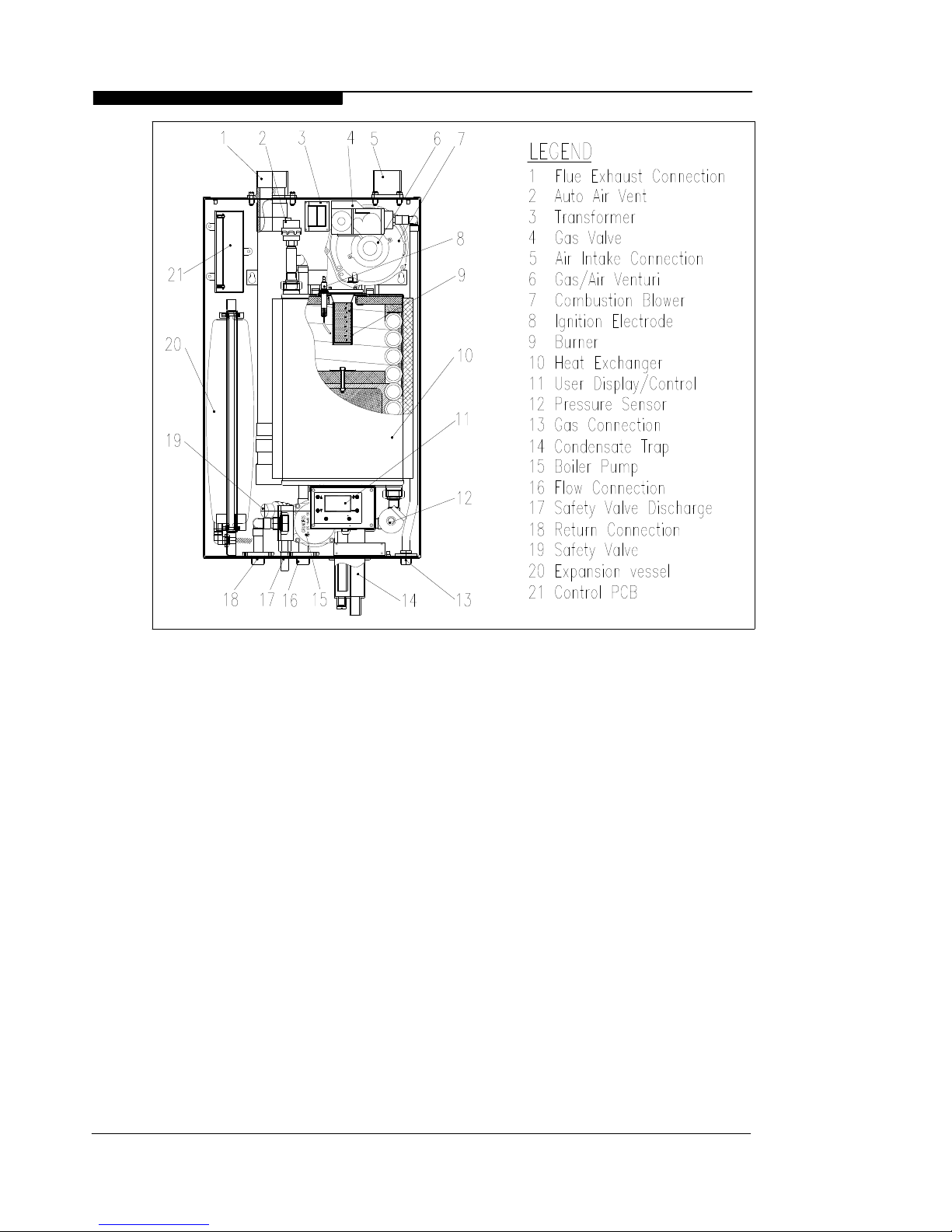

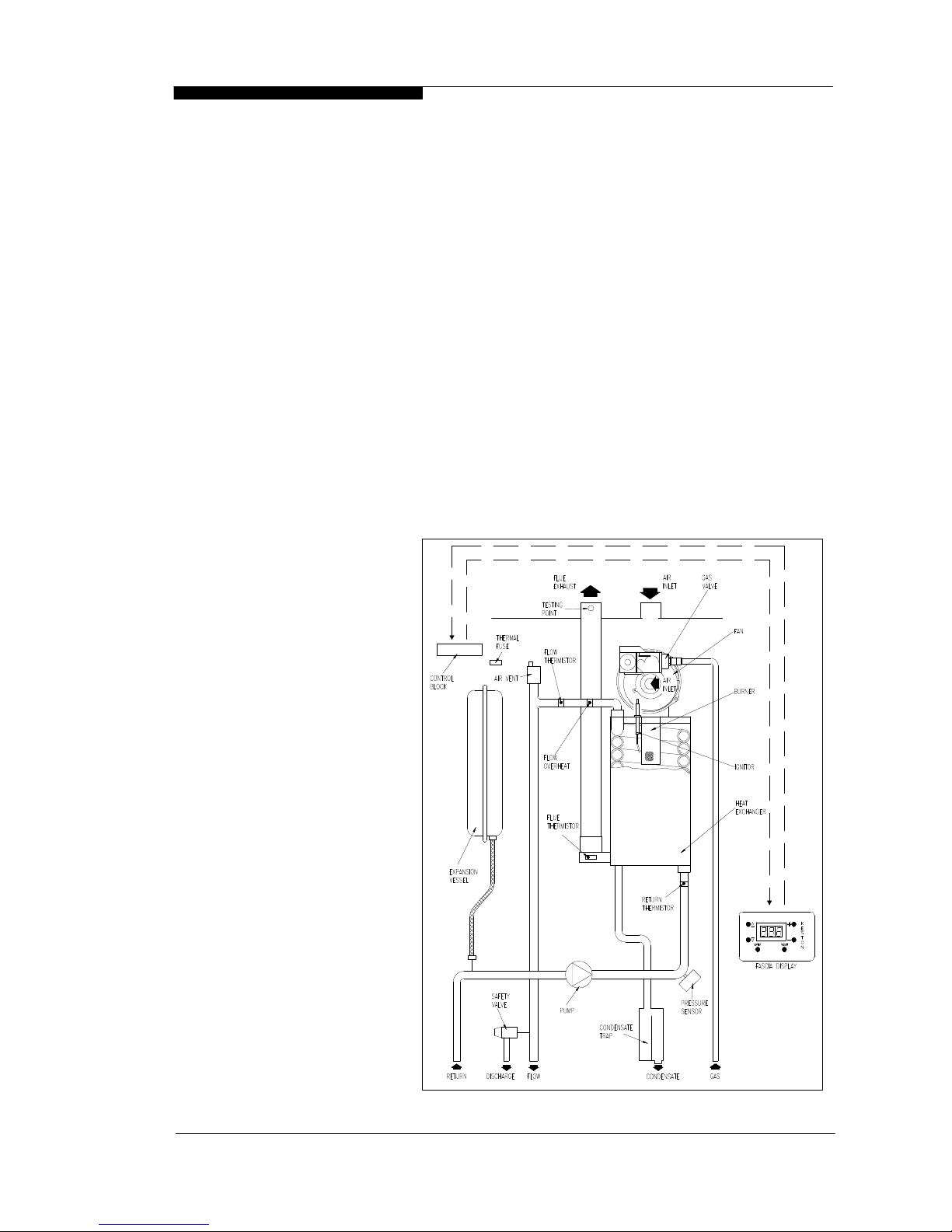

2.2 BOILER SCHEMATIC

Air is drawn into the boiler through a 50 mm muPVC (BS5255 and/or BSEN1566-1 and

BSEN1329) plastic pipe or, alternatively, via a 75mm Keston composite plastic pipe. Gas

is mixed with combustion air at the inlet to the fan. The gas flow is automatically regulated

by the gas valve according to the air flow generated by the fan. The gas and air are

thoroughly mixed in the blower and fed into the burner located at the top end of the heat

exchanger module. The gas and air mixture is ignited by a direct spark ignition control

system and burns with a blue flame just off the surface of the burner. As the hot products

of combustion pass downwards, they are cooled by exchanging heat with the circulating

water which enters the heat exchanger at the bottom of the heat exchanger. The optimum

heat input is detected by monitoring flow and return temperatures and is adjusted by

controlling the speed of the fan. The optimum pump speed is also detected and

automatically selected by the boiler.

When the return water temperature is below 55oC, part of the water vapour in the

combustion products will condense inside the heat exchanger, thus increasing the boiler

efficiency further by releasing the latent heat of condensation. This condensate falls to the

WD420/3/2007 Chapter 2 : General Instruction The Keston Qudos 28s & Qudos 28sP Boilers

Installation & Servicing Instructions Page : 5

ENTER RESET

Page 11

bottom of the heat exchanger where it is separated from the flue gases and exits from the

boiler through the condensate drain. Any condensate formed in the flue runs back down

the flueway and is drained at the base of the flue connection to the heat exchanger or

drain points within the flue.

The condensate is very slightly acidic (about the same acidity as vinegar) and should be

piped in a plastic pipe. It is not harmful to the waste disposal system and may be disposed

of as normal waste water.

The flue gases are piped in a 50 mm muPVC (BS5255 and/or and BSEN1329) plastic or,

alternatively, 75mm Keston composite plastic pipe to outside. The temperature of the flue

gases are usually around 5oC to 10oC above the temperature of the return water. The flue

pipe should be terminated outside the building from where they cannot re-enter the

building or any other adjacent building. It should also be terminated such that flue

products cannot be drawn into the boiler air intake terminal.

The heating level may be controlled by room thermostats, programmer time clocks and

compatible energy management systems. An optional Keston room controller can be

connected which will provide enhanced controls such as room compensation to further

increase efficiency and comfort levels. However, this is only recommended for heating

only applications. Once the controls are set the boiler operates automatically. Further, a

Keston outside sensor can be connected to the boiler which will automatically invoke

weather compensated heating which further boosts user comfort and boiler efficiency.

In the event of the

boiler overheating the

safety devices will

cause a safety

shutdown. A safety

discharge valve and

discharge pipe is fitted

to the boiler.

The Qudos 28s

features an integral

frost protection

function which will

operate the pump,

regardless of the

external controls,

should the boiler

temperature fall below

10oC. In the event the

boiler temperature

falls below 5oC the

boiler will also fire.

This is to avoid

damage to the boiler

through freezing of

boiler water. The

boiler will turn off

when the flow

temperature exceeds

15oC.

The Qudos 28s

features an integral

pump exercise

function which will run

the pump, without

WD420/3/2007 Chapter 2 : General Instruction The Keston Qudos 28s & Qudos 28sP Boilers

Installation & Servicing Instructions Page : 6

Page 12

firing the boiler, for 10 seconds in the event the boiler is on standby for in excess of 24

hours without firing. This is to help prevent seizing of the pump due to long periods of

inactivity.

2.3 RELATED DOCUMENTS

The Keston Qudos 28s and Qudos 28sP Condensing Boilers must be installed in

accordance with the current issue of the Gas Safety (Installation and Use) Regulations

1996, current IEE Wiring Regulations, Building Regulations, Building Standards (Scotland)

Consolidation, and the Bye Laws of the local Water Undertaking. It is the law that ALL

gas appliances are installed by a competent person in accordance with the above

regulations.

In addition, due account must be taken to the following Codes Of Practice:

BS 6891 : Gas Supplies

BS 6798 : Installation Central Heating Boilers

BS 5449 : Installation Pumped Central Heating

BS 5546 : Installation Domestic Hot Water

BS 5440.1 : Flues

BS 5440.2 : Air Supply

BS 5482.1 : Domestic Propane and Butane Burning

Installations

BS 7074.1 : Expansion Vessels

BS 7593 : Treatment of Water in Hot Water Central

Heating Systems

BS 7671 : Requirements for Electrical Installations. IEE

Wiring Regulations 16th Edition.

For Timber Framed Buildings, British Gas Publications DM2. Also British Gas

Publications 'Guidance Notes For The Installation Of Domestic Gas Condensing

Boilers' and 'Specification For Domestic Wet Central Heating Systems'.

In IE, the installation must be carried out by a competent person and installed in

accordance with the current edition of IS813 “Domestic Gas Installations”, the current

Building Regulation and reference should be made to the current ETC1 rules for electrical

installations.

No alterations should be made to the boiler without written permission from Keston Boilers

Ltd. Any unauthorised modification will invalidate the warranty and may affect the safe and

efficient operation of the boiler.

WD420/3/2007 Chapter 2 : General Instruction The Keston Qudos 28s & Qudos 28sP Boilers

Installation & Servicing Instructions Page : 7

Page 13

2.4 PHYSICAL DATA - Qudos 28s & Qudos 28sP

Cabinet Height mm 700

Cabinet Width mm 435

Cabinet Depth mm 280

Top Clearance mm 150

Side Clearance mm 5

Base Clearance mm 200

Front Clearance (for servicing) mm 300

Weight - Full kg / (lbs) 47/(104)

Weight - Empty kg / (lbs) 43/(95)

Flow and Return Connection G3/4

Gas Connection G1/2

Condensate Connection overflow 22mm plastic

Safety Valve Connection discharge 15mm copper

IP Rating IP20 (IPX0)

Flue and Air Intake Material 50mm muPVC (BS5255 and/or BSEN1566-1 and BSEN1329)

Flue Pipe Size (nominal bore) mm / (in) 50 / (2)

Air Intake Pipe Size (nominal bore) mm / (in) 50 / (2)

Max. Air Intake Length m 39

Max. Flue Outlet Length m 20

Max. Total Flue Outlet and Air Intake Length m 40

Flue and Air Intake Material 75mm Keston Composite

Flue Pipe Size (nominal bore) mm / (in) 75 / (3)

Air Intake Pipe Size (nominal bore) mm / (in) 75 / (3)

Max. Air Intake Length m 117

Max. Flue Outlet Length m 60

Max. Total Flue Outlet and Air Intake Length m 120

2.5 OPTIONAL ACCESSORIES

A range of accessories are available from Keston Boilers Ltd to compliment an installation.

Terminal wall sealing collars are available to make good the external all face whilst working from

the inside of the building using 50mm muPVC (BS5255 and/or BSEN1566-1 and BSEN1329)

pipe. Stand-off frames are available to leave a 50mm gap behind the boiler to allow routing of

pipes behind the boiler.

Description Part Number

Flue Terminal Wall Sealing Collar (50mm) C.08.0.00.07.0

Air Terminal Wall Sealing Collar (50mm) C.08.0.00.07.0

50/75mm Flue Adapter C.17.2.00.60.0

Flue Outlet Terminal (75mm) C.17.2.26.00.0

Air Inlet Terminal (75mm) C.17.2.26.00.0

Stand Off Back Plate Q.10S.0.01.00.0

Outside Temperature Sensor C.10C.0.09.00.0

Keston Chronotherm Room Controller C.17.4.21.00.0

Remote Fascia Kit Q.10S.0.03.00.0

DHW Tank Sensor Q.10S.0.04.00.0

Solar Sensors Kit (Panel sensor and 2 x DHW Tank Sensors) Q.10S.0.05.00.0

WD420/3/2007 Chapter 2 : General Instruction The Keston Qudos 28s & Qudos 28sP Boilers

Installation & Servicing Instructions Page : 8

Page 14

2.6 PERFORMANCE DATA - Qudos 28s & Qudos 28sP

Seasonal Efficiency (SEDBUK) = 91.1 (Qudos 28s) & 92.9 (Qudos 28sP)

This value is used in the UK Government's Standard Assessment Procedure (SAP) for

energy rating of dwellings. The test data from which it has been calculated have been

certified by Advantica Technologies Ltd

Keston Boilers Ltd declare that there are no substances harmful to health within the

appliance or used during the production of the appliance.

The Qudos 28s is intended for domestic and commercial EMC environments and on a

governed G20 meter supply.

The Qudos 28sP is intended for domestic and commercial EMC environments and on a

governed G31 supply.

This boiler meets the requirements of SI 3083 The Boiler (Efficiency) Regulations and is therefore

deemed to meet the requirements of Directive 92/42/EEC. The CE mark on the appliance shows

compliance with Directives 90/396/EEC, 73/23/EEC and 89/336/EEC.

IMPORTANT

This product contains ceramic fibre boards, which although not regarded as a risk, contain

ceramic fibre which may cause temporary irritation to eyes, skin and respiratory tract. The

fibres are held in place by inorganic binders. Therefore as long as the boards are not

WD420/3/2007 Chapter 2 : General Instruction The Keston Qudos 28s & Qudos 28sP Boilers

Installation & Servicing Instructions Page : 9

Qudos 28s Qudos 28sP

Nat. Gas (G20) LPG (G31)

Min. Input (Gross CV) kW/(Btu/h) 7.8/(26,600) 7.6/(26,000)

Max. Input (Gross CV) kW/(Btu/h) 29.4/(100,300) 28.8/(98,300)

Max. Output To Water

(80/60oC Flow/Return) kW/(Btu/h) 26.4(90,500) 26.4/(90,500)

(50/30oC Flow/Return) kW/(Btu/h) 28.4/(96,900) 28.4/(96,900)

Min. Output To Water

(80/60oC Flow/Return) kW/(Btu/h) 7.0/(24,900) 7.0/(24,900)

(50/30oC Flow/Return) kW/(Btu/h) 7.8/(26,600) 7.6/(26,000)

Max. Burner Press.-Hot (Factory Preset) mbar/(in w.g) 0/(0) 0/(0)

Max. Gas Cons. After 10 mins (DHW) l/s / (Ft3/hr) 0.76/(96.6) 0.35/(45.0)

Max. Operating Flow Temp.

o

C 82 82

Max. Press. (Sealed System) bar 2.50 2.50

Inlet Gas Pressure mbar/(in w.g) 20.0 / (8.0) 37.0/(14.8)

Recommended Temp Diff.

o

C 8 to 20 8 to 20

Electrical Supply 230V 50Hz 230V 50Hz

Power Consumption (Max) W 150 150

Power Consumption (Standby) W 7 7

Type of Gas G20 Natural Gas G31 LPG

Optimum Flue Gas CO2 Level (at max CH rate, case on) 9.1 10.5

Expected CO/CO2 Ratio (at max CH rate, case on) 0.0007 0.001

Destination Countries GB/IE GB/IE

SEDBUK Efficiency 91.0 93.0

NOx Class 5 5

Safety Valve bar / (lbf/sq in) 3 / (43.5) 3 / (43.5)

Expansion Vessel Capacity litre 8 8

SEDBUK Rating A (91.1%) A (92.9%)

[NB: For larger systems an additional expansion vessel may be required]

Expansion Vessel Charge Pressure bar / (lbf/sq in) 1.0 / (14.5)

Heating System Minimum Pressure bar / (lbf/sq in) 0.6 / ( 8.7)

Page 15

disturbed they will not be released. Since the boards are non-servicable parts there should

be no risk. Under no circumstances should the user interfere with any sealed parts.

To ensure that the release of fibres from these RCF articles is kept to a minimum, during

installation and servicing we recommend that you use a HEPA filtered vacuum to remove

any dust accumulated in and around the appliance before and after working on the appliance. When replacing these articles we recommend that the replaced items are not broken

up, but are sealed within heavy duty polythene bags, and clearly labelled as RCF waste.

RCF waste is classed as a stable, non-reactive hazardous waste and may be disposed at a

landfill licensed to accept such waste. Protective clothing is not required when handling

these articles, but we recommend you follow the normal hygiene rules of not smoking,

eating or drinking in the work area and always wash your hands before eating or drinking.

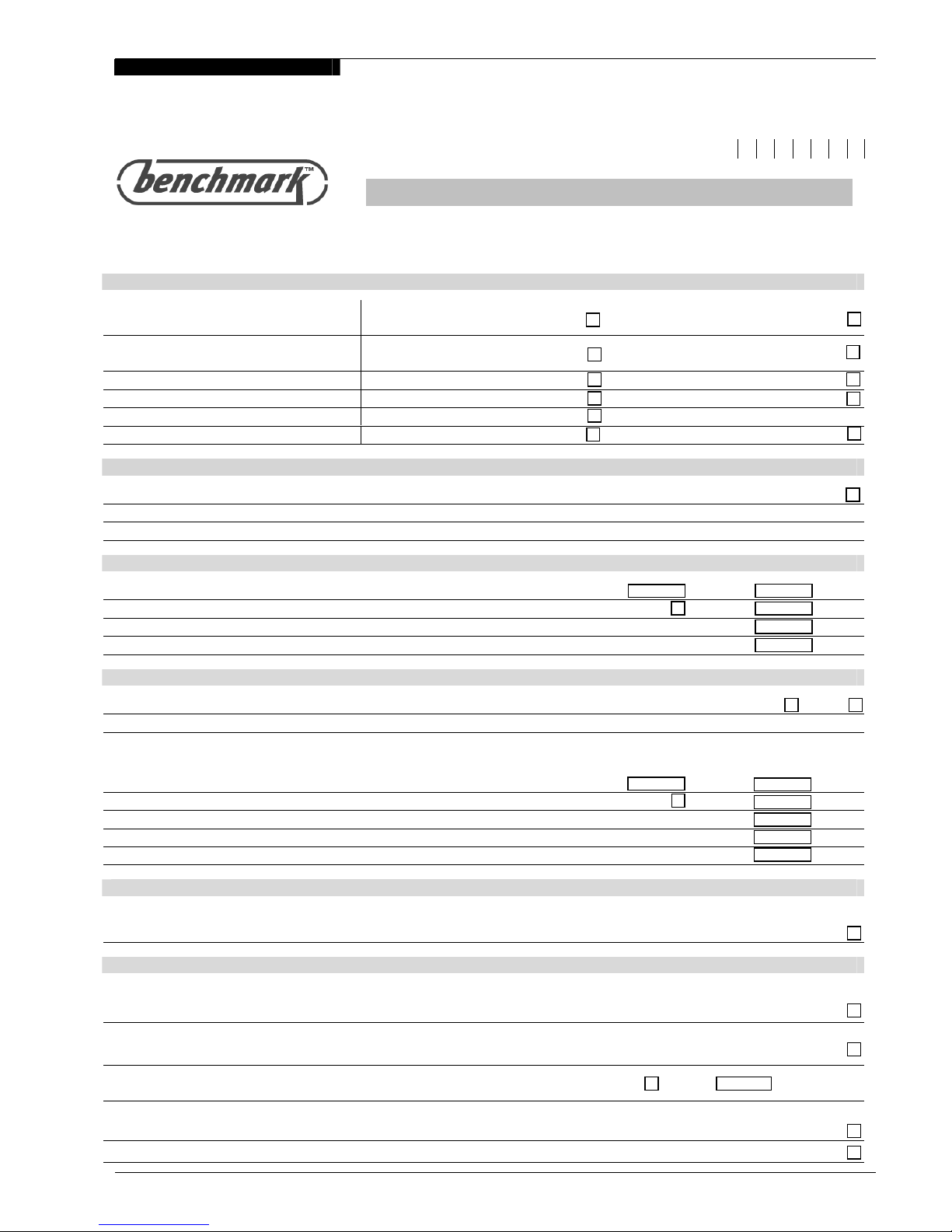

Benchmark Initiative

As part of the industry wide “Benchmark” initiative Qudos 28S boiler manual includes Gas Boiler

Commissioning Checklist (Chapter 10). This form should be completed by your installer at the

end of the installation and commissioning process. The details of the Checklist will be required in

the event of any warranty work being required. There is also Service Interval Record (Chapter

10) to be completed after each annual service visit.

These forms (Chapter 10) should be kept in a safe place for the life of the boiler.

The boiler should be installed and serviced only by CORGI registered operatives. All CORGI registered Installers carry a CORGI ID card and have a registration number. Both should be recorded

in your boiler manual (Chapter 10: GAS BOILER COMMISSIONING CHECKLIST). You can

check your installer by calling CORGI direct on 01256 372300.

WD420/3/2007 Chapter 2 : General Instruction The Keston Qudos 28s & Qudos 28sP Boilers

Installation & Servicing Instructions Page : 10

IN THE EVENT OF A GAS LEAK

Turn off the gas isolation valve to the property immediately. Extinguish

all naked flames or other sources of ignition. Do not operate electrical

switches on or off. Open all doors and windows to ventilate the area.

Page 16

3. BOILER LOCATION

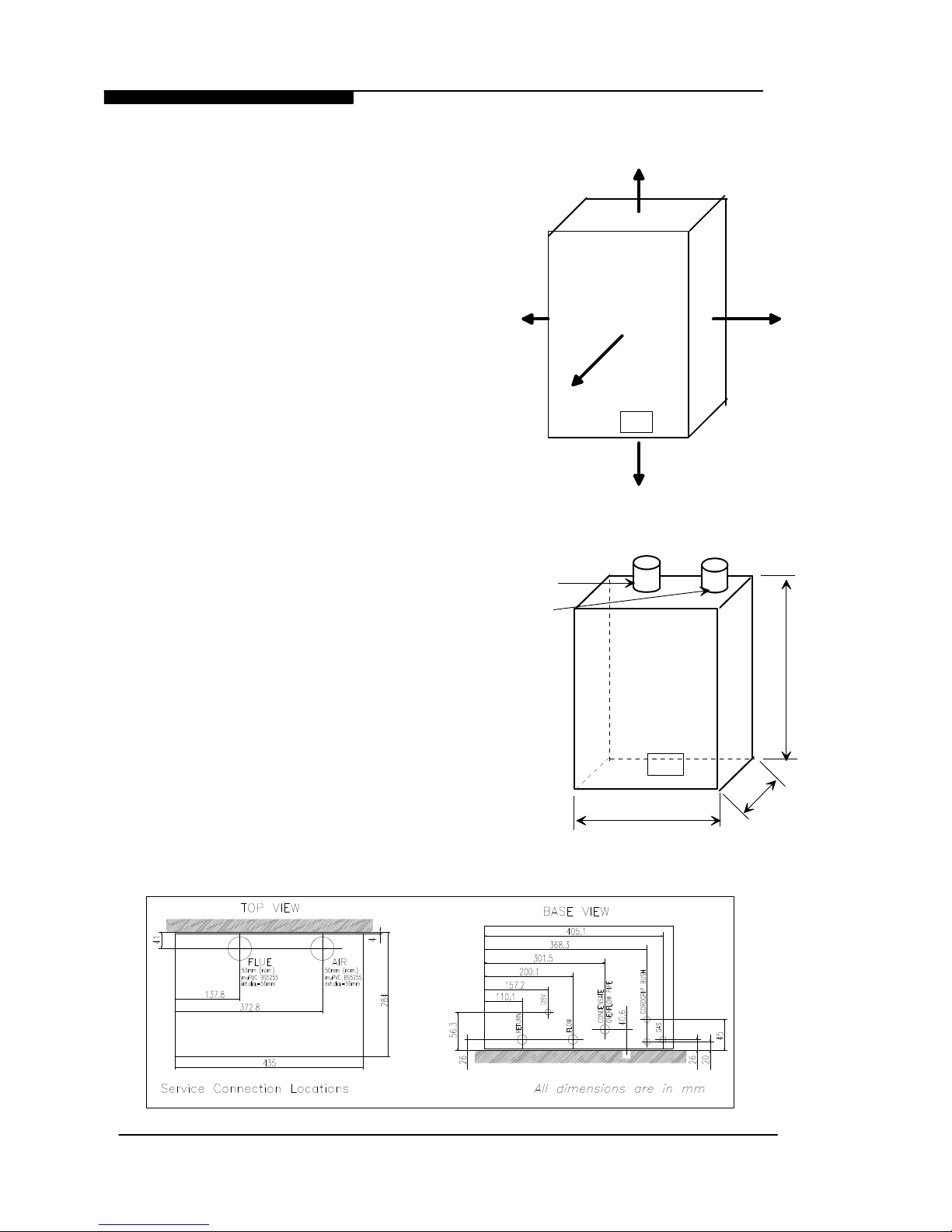

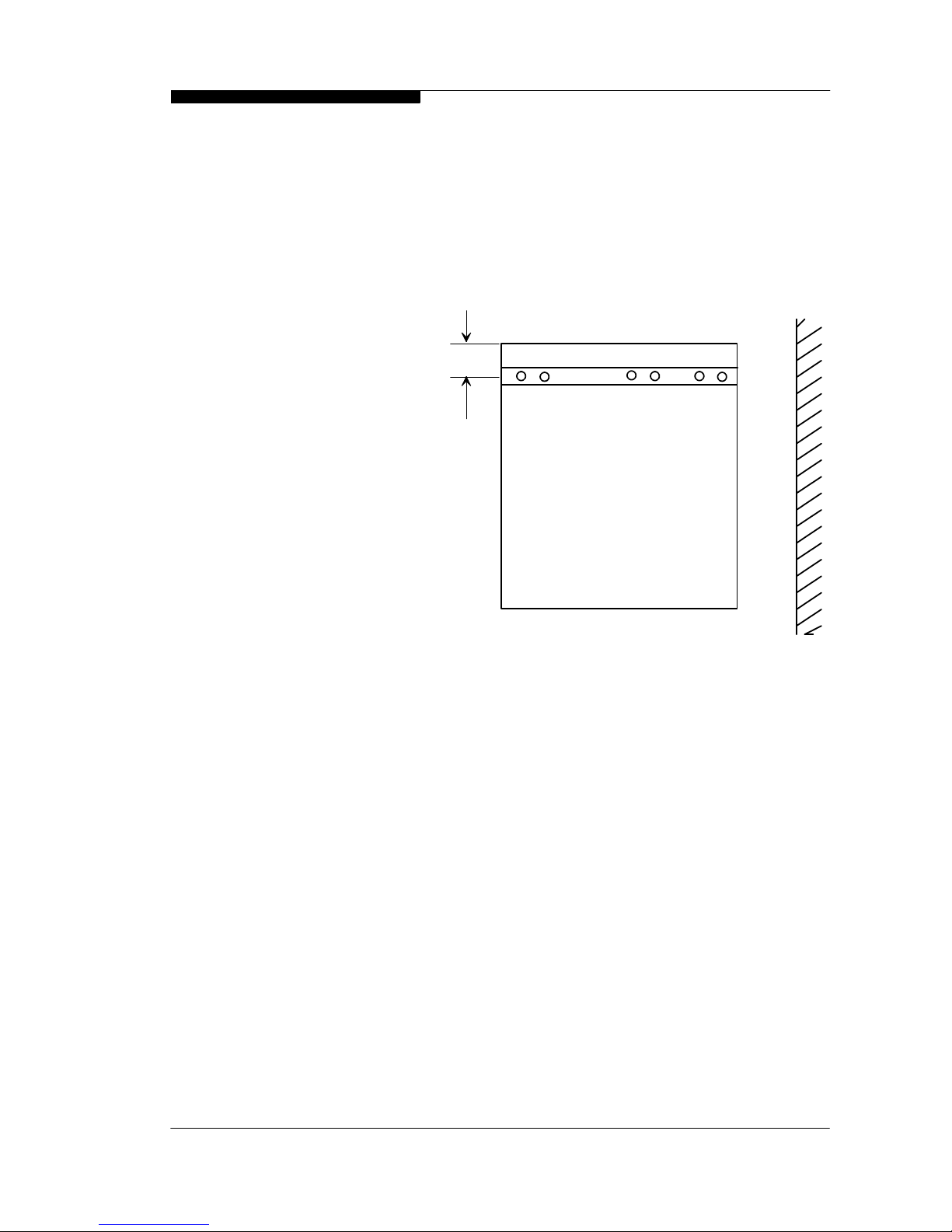

3.1 DIMENSIONS AND MINIMUM

CLEARANCES

The boiler must be installed in minimum

clearances shown to allow subsequent

servicing, and safe operation. However, larger

clearances may be required during installation.

3.2 SERVICE CONNECTIONS

Gas, water, air and flue pipe, condensation,

and electrical connections are as shown in the

diagram below. Gas : 15mm compression.

Flow/Return 0.75 inch BSP male, Gas 0.5 inch

BSP male, PRV 15mm copper pipe and

Condensate 21.3mm plastic pipe .

An optional stand-off frame (part number

Q.28S.0.01.00.0) is also available which

mounts behind the boiler to leave a 50mm

deep space behind the boiler. This is to

permit pipe routing behind the boiler if

required. See Section 2.5 - Optional

Accessories.

3.3 POSITION

The Qudos 28s and Qudos 28sP are not

suitable for external installation. The boiler

may be installed in any room or internal

space, although particular attention is drawn

to the requirements of the current IEE Wiring

Regulations and, in Scotland, the electrical

provisions of the Building Regulations

applicable in Scotland, with respect to the

installation of the boiler in a room or internal

space containing a bath or shower.

Where a room-sealed appliance is installed

in a room containing a bath or shower, any

electrical switch or appliance control, utilising

mains electricity, should be so situated that it

cannot be touched by a person using the

bath or shower. The Qudos 28S and Qudos 28SP are classified as IP20 (IPX0) and are

therefore suitable for installation in Zone 3 areas, unless subject to hose down.

WD420/3/2007 Chapter 3 - Boiler Location The Keston Qudos 28s & Qudos 28sP Boilers

Installation & Servicing Instructions Page : 11

All dimensions in mm.

150

300 When servicing appliance

200

Figure 3.1.1

Minimum Clearances

55

10 When appliance is operating

All dimensions in mm.

435

2

8

0

Figure 3.1.2

Dimensions

Flue Exhaust

Air Intake

700

mm

Page 17

Compartment installation is permitted - such compartments must be constructed in

accordance with BS 6798.

The wall on which the boiler is mounted must be of suitable load bearing capacity and

must be non-combustible.

The Keston Qudos 28s can be located virtually anywhere desired provided that all

regulations are complied with. Because of the boiler's compact size and venting flexibility,

the installation is not limited to a boiler room setting. Before locating the boiler near a living

space consider whether the sounds generated by the boiler will be objectionable. The

boiler may be located within a cupboard enclosure to reduce noise levels if located within

a living space. LPG boilers must not be installed in a cellar.

3.4 ELECTRICAL

3.4.1 Electrical Connections

The boiler must be connected to a permanent 230V ~ 50Hz supply, fused at 3A.

The boiler can be wired to a single switched live 230VAC signal input.

However, the boiler has TWO thermostats, and will therefore accept up to

TWO switched live 230VAC signal inputs, such as heating and hot water or

radiators and underfloor heating zones. Alternatively, a Keston Room

Controller can be connected directly, via two core low voltage cable, to the

terminals marked “OT”. The Keston Room Controller will then provide fully

room compensated control to ensure the boiler output is matched to the

rooms requirements at optimum boiler efficiency. This is only

recommended for heating only applications. The boiler can also be driven

by an external 0-10VDC input.

Wiring external to the boiler must be in accordance with current I.E.E wiring

regulations and local regulations.

The method of connection to the mains electricity supply must facilitate complete

electrical isolation of the boiler, preferably by the use of a fused, unswitched three

pin plug and a shuttered socket-outlet, both complying with the requirements of

WD420/3/2007 Chapter 3 - Boiler Location The Keston Qudos 28s & Qudos 28sP Boilers

Installation & Servicing Instructions Page : 12

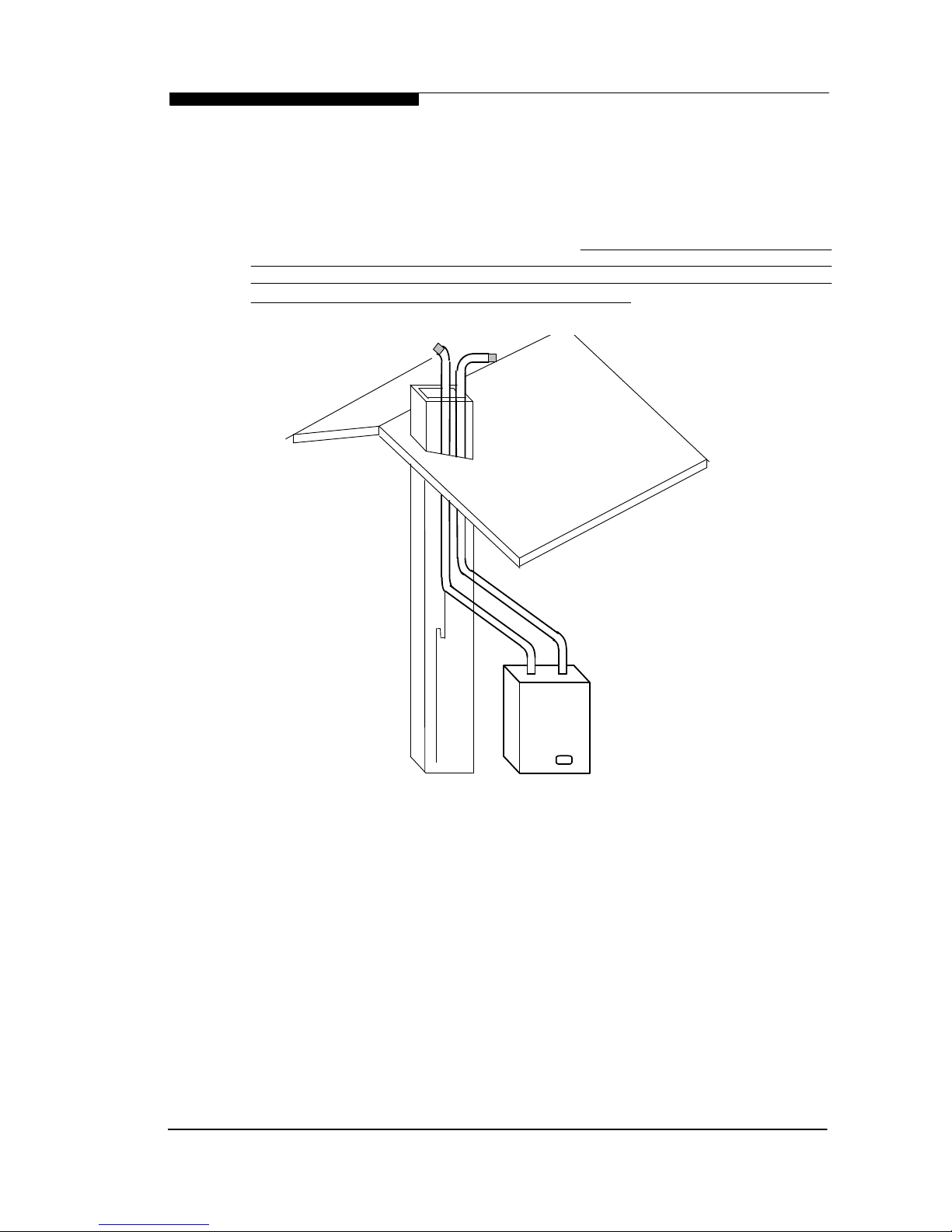

Chimneys not used for

venting any other

appliance may be used.

Figure 3.3

Secure air & flue pipes at

chimney outlet.

[NB: Refer to

Section 3.8.3]

Page 18

BS 1363. There must be only one common method of isolation for the boiler and

its control system.

The appliance must be connected to the 3A supply via a fused double-pole switch

having at least 3 mm (1/8 inch) contact separation in both poles, serving only the

boiler and the system controls.

The connection point to the mains supply should be readily accessible and

adjacent to the boiler, except for rooms containing a bath or a shower. Refer to

section 3.3 Position.

3.4.2 External Wiring & Controls

1. The boiler is designed so that all control wiring is external to the boiler.

2. Heating control signal inputs must be 230VAC "switched live" type unless

using a Keston Room Controller (see below) or 0-10VDC input.

3.4.2.1 Enhanced Control Options

The Qudos 28s can be wired into a conventional heating installation using only

permanent and switched live connections.

However, the Qudos 28s features a wide range of OPTIONAL control features

normally associated with commercial boilers installations at additional cost. These

are provided as standard in the Qudos 28s and require low costs sensors to be

added to activate them. The features provided are detailed below. Refer to

Chapter 4.8 for further wiring detail.

Room Compensation (Opentherm)

A Keston Room Controller may be used to provide room compensated

control to ensure the boiler output is matched to the rooms requirements

at optimum boiler efficiency. This is only recommended for heating only

applications

Weather Compensation (Ext Sensor)

A Keston outside temperature sensor may be connected as an option.

The boiler will automatically detect this connection and will operate on a

"weather compensation" basis when receiving a heating demand signal

from the SL terminal or from a Keston Room Controller. Screened cable

(80% density) must be used to connect the outside temperature sensor.

Solar Control

Where a solar thermal system is in use, with a twin coil cylinder such as

the Kesotn SpaTwin, the Qudos 28s will control operation of the solar

pump in conjunction with the boiler. The boiler requires connection to the

solar tank sensor, solar panel sensor and solar pump

Modulating DHW Reheat

The Qudos 28s can provide direct modulation to maximise the re-heat

performance of the DHW cylinder. A DHW cylinder sensor can be

connected directly to the Qudos 28. A DHW demand input can also be

provided to control DHW reheat activity, perhaps in conjunction with Solar

Thermal. With this facility connected an automatic anti-legionnella facility

can also be provided.

Analog Demand (0-10VDC)

Where external control panels are used, in boiler room applications, a

0-10VDC input can be connected to the boiler, in place of the SL1

switched live demand. The 0-10VDC signal will drive the first setpoint at

1VDC = 10C setpoint (NB: <0.5VDC is off, >8.0 VDC is 80C)

External Lockout Signal

Where remote monitoring and/or alarms are installed the boiler offers a

volt-free lockout signal output. The boiler will provide a closed circuit

across the two output points when the boiler is in lockout.

WD420/3/2007 Chapter 3 - Boiler Location The Keston Qudos 28s & Qudos 28sP Boilers

Installation & Servicing Instructions Page : 13

Page 19

Remote Fascia Panel

For installations where the boiler is located outside of the living area, such as the loft or an

out-house, a remote fascia control can be fitted within the living area. This will allow full

functionality normally access via the boiler fascia panel.

3.5 BOILER SIZE SELECTION

The Qudos 28s will automatically adjust heat output and pump speed to match the system

requirements at any given time. Efficiency and combustion levels are maintained at

optimum levels throughout the possible output range. The Qudos 28s is therefore suitable

for all systems with a total heat load within the maximum range of the boiler.

3.6 GAS SUPPLY

A gas meter should be connected to the service pipe by the local gas region or their

contractor. An existing meter should be checked preferably by the gas region to ensure

that the meter is adequate to deal with the rate of gas supply required. Installation pipes

should be fitted in accordance with BS 6891.

Minimum/Maximum Gas Pressure:

Natural gas pressure before the gas valve must be maintained at between 18 mbar (7.2 in

WG) and 22 mbar (8.8 in) while the boiler is running.

LPG pressure must be maintained between 31.5 mbar (12.4 in w.g) and 37.6 mbar (14.8

in w.g) while the boiler is running.

Gas pressures above or below these levels will lead to problems associated with the gas

valve's internal pressure regulator.

Supply pipes to the boiler must not be sized less than the boiler inlet connection

(15 mm). Due consideration must be given to the supply pressure to other gas

appliances in the premises. Reduction in dynamic gas supply pressure will result in

intermittent ignition failures. Ensure gas supply pipe work is adequately sized for

the length of run from the meter to the boiler at a supply rate of 28.4kW (i.e. a natural

gas supply should be considered to be a minimum of 22mm diameter, reducing to 15mm

at the boiler. If gas runs greater than 12m, including the allowance for bends, are involved

the pipe size should be increased further).

3.7 WATER SYSTEMS

All piping must be installed in accordance with all applicable local and Water Supply

Bylaws for forced hot water heating systems.

Consideration must be given to pipe capabilities and pressure drop through the piping

when selecting pipe sizes. The primary pipe connections to the boiler must be sized

according to the system load, not dictated by the boiler connection sizes.

Water treatment must be carried out to BS 7593 : Treatment of Water in Hot Water

Central Heating Systems.

In IE the requirements given in the current edition of IS813 and the current Building

Regulations must be followed.

a The Keston Qudos 28s is designed for installation on sealed water systems only.

With fully pumped water circulation. The pump, an 8l expansion vessel and

associated safety devices are fitted within the boiler.

b Any system must be thoroughly flushed clean of grease, dirt and debris, prior to

connection with the boiler. A trap may be installed in the flow line to collect any

solder, or other debris, from the installation.

c All water systems must be constructed to comply with requirements of the Local

Water Authority.

d Always use a system complying with the requirements of BS 5449 and BS 6798.

e System design must ensure an open circuit is always available to ensure

circulation when the pump overrun function is operating after boiler shutdown.

f Isolation valves must be fitted on the flow and the return to enable isolation when

maintaining the boiler.

WD420/3/2007 Chapter 3 - Boiler Location The Keston Qudos 28s & Qudos 28sP Boilers

Installation & Servicing Instructions Page : 14

Page 20

g Copper tubing to BS 2871 Part 1 or barrier plastic pipe suitable to 110 oC, such as

Unipipe, is recommended.

h Jointing should be either with capillary, threaded or compression fittings. Pipes

should have a gradient to ensure air is passed easily to vent points and water

flows readily to drain points.

i Draining taps must be located in accessible positions which permit the draining of

the boiler. Draining taps should be at least 22 mm in nominal size and be in

accordance with BS 2879.

AIR VENT POINTS

j These must be fitted at all high points where air will naturally collect and must be

sited to allow complete draining of the system.

Table 3.7 Additional Expansion Vessel Selection

13.6

125 litres

10.9

100 litres

8.2

75 litres

5.4

50 litres

2.7

25 litres

Vessel

Volume

Total Water Content of system in

excess of 125 litres

1.0 bar

Vessel charge & initial system

pressure.

3.0 bar

Safety Valve Setting

k. The boiler is supplied with an integral expansion vessel of 8l capacity. This is

suitable for systems of up to 125 litres system volume. Table 3.7 Expansion

Vessel Selection provides guidance for the correct additional expansion vessel

size to use for systems with a water content larger than 125 litres. Any additional

vessel must be fitted on the boiler primary return.

l A filling point must be fitted, in accordance with local water authority

requirements.

WD420/3/2007 Chapter 3 - Boiler Location The Keston Qudos 28s & Qudos 28sP Boilers

Installation & Servicing Instructions Page : 15

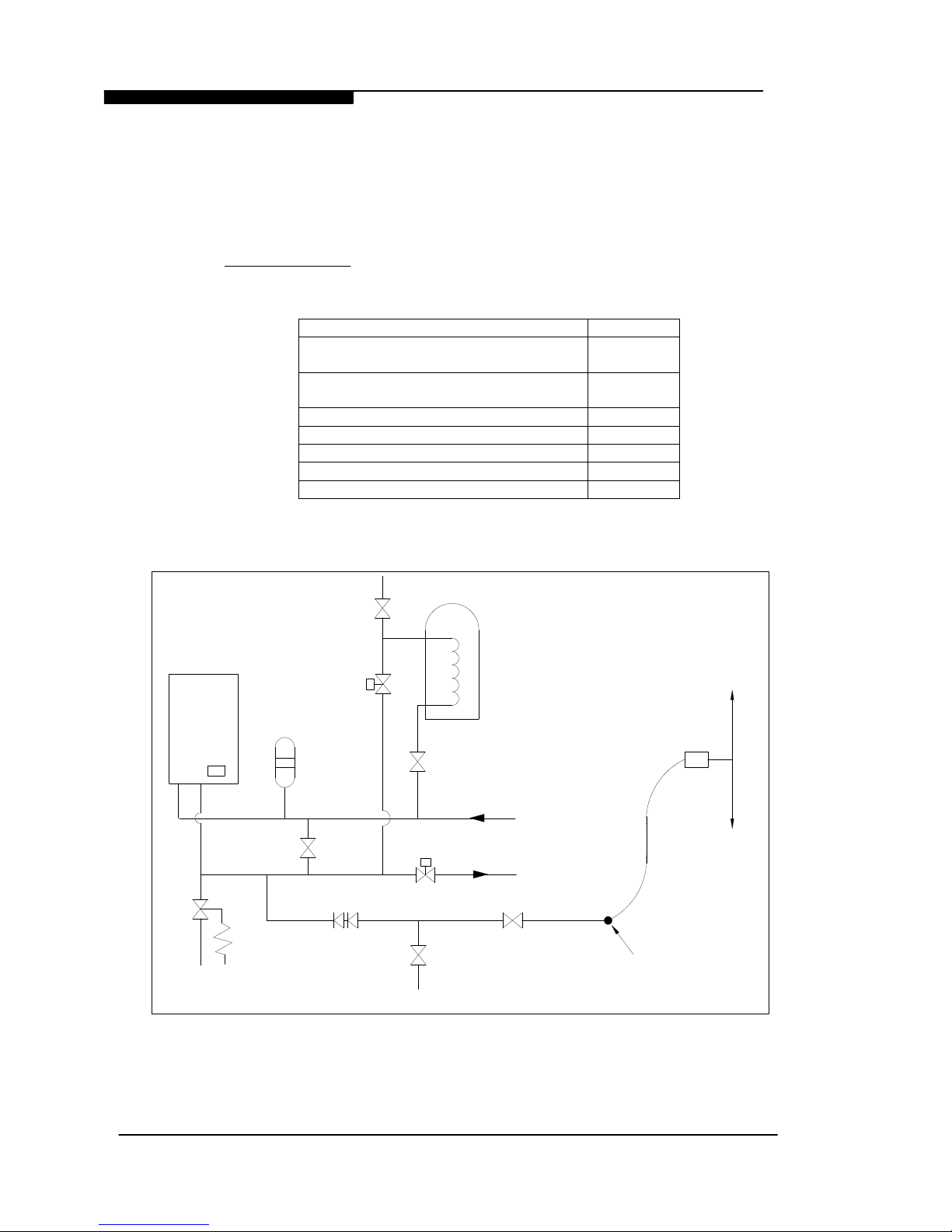

Stop Tap

BS 1010:2

Cock

Test

bib tap

Hose Union

after filling)

(disconnected

Hosepipe

Connector

Hose

Dbl Check Valve

L/S

Air Vent

RETURN

Vessel

Expansion

(if required)

HEATING CIRCUIT

Qudos 28s

KESTON

By-pass

Cock

Drain

Figure 3.7 : Sealed Systems Diagram

FLOW

Additional

Page 21

m The installation must be designed to work with flow temperatures of up to 110 oC.

All components of the system must be suitable for a working pressure of 3 bar

and a temperature of 110 oC. Care should be taken in making all connections that

the risk of leakage is minimised.

n The pipe from the safety discharge valve must not discharge above an entrance,

window or any type of public access area. The boiler safety discharge valve pipe

must be extended using not less than 15mm pipe to discharge, in a visible

position, outside the building, facing downwards, preferably over a drain. The

pipe must have a continuous fall and be routed to a position so that any discharge

of water, possibly boiling, or steam cannot create any danger to persons, damage

to property or external electrical components or wiring. To ease future servicing it

is advisable to use a compression type fitting to extend the safety discharge valve

pipe.

3.7.1 Boiler By-pass Piping

Boiler water flows are critical to the operation of the boiler. If flow cannot be maintained

through the system piping to meet the minimums required by the boiler, insufficient water

flows through the boiler will cause the boiler to "kettle" or even produce steam which can

damage the heat exchanger and will invalidate the heat exchanger warranty. In addition,

an open circuit is required after boiler shutdown to permit circulation during the boilers 2

minute pump overrun sequence.

It is advisable to incorporate a boiler by-pass in the system, especially if thermostatic

radiator valves are used. The flow/return differential should be 10oC to 20oC. To comply

with the Building Regulations Part L1 the bypass must of the automatic type.

3.7.2 Air Elimination

In the initial charge of water to the boiler system and in all subsequent additions of water

to the system some air will be dissolved in the water. As the water is heated the air is

driven out of the solution and will collect in high spots in the system. These air bubbles

can interfere with pumping and heat transfer and must be eliminated.

Installation of air bleed valves at the high spot(s) in the system will allow for air elimination

when filling the system and will allow re-venting in a day or so after all air has been driven

out of solution.

3.7.3 System Pump

Selection (if required)

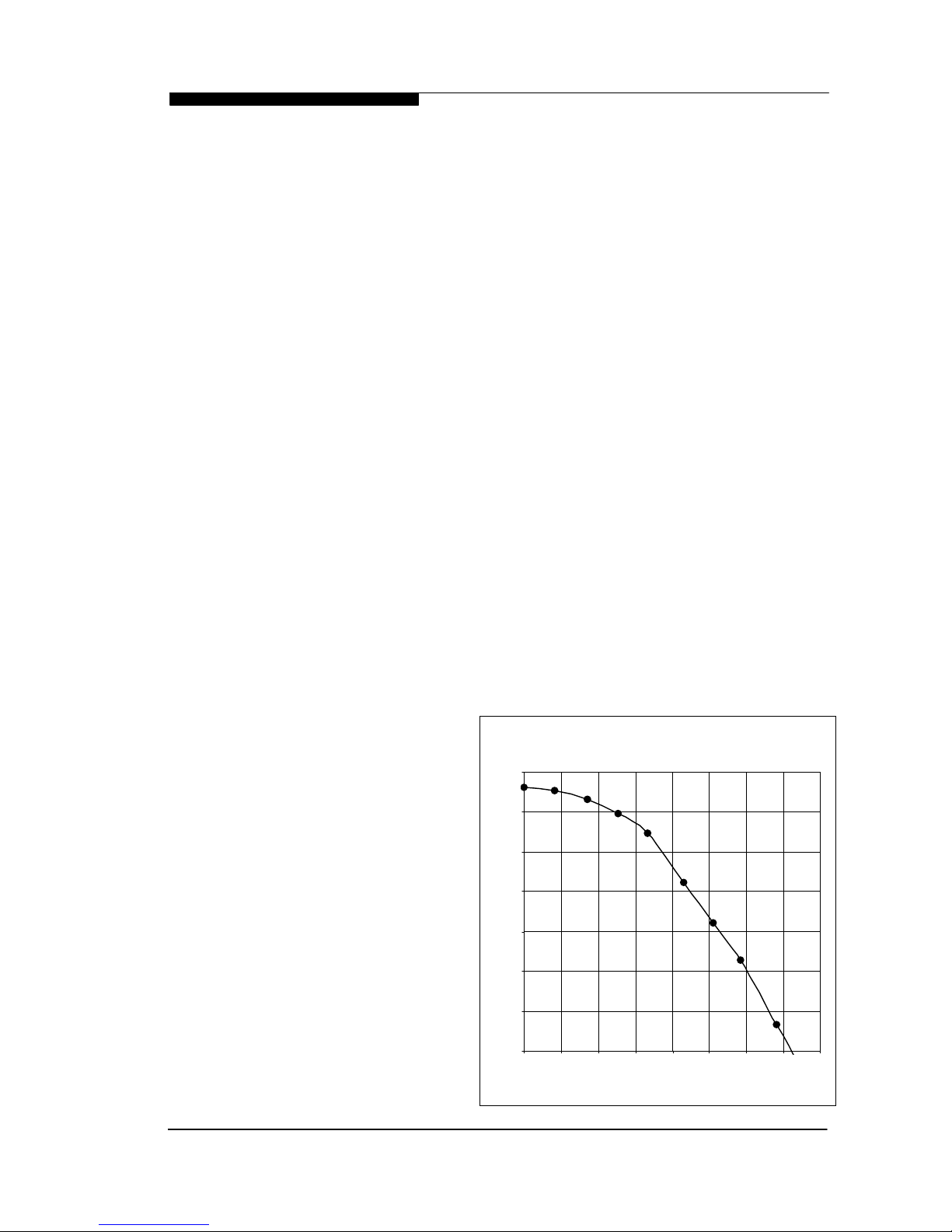

The Qudos 28s features an

integral circulating pump which

has sufficient excess head to

drive most domestic systems.

The available head is shown in

the graph below. If the system

index circuit resistance is in

excess of the available head

from the integral pump an

additional system pump will be

required.

The schematic below illustrates

a recommended approach to

using an additional system

pump. The additional system

pump should be sized to

overcome the index circuit

resistance only as the boilers

integral pump will overcome

boiler resistance.

WD420/3/2007 Chapter 3 - Boiler Location The Keston Qudos 28s & Qudos 28sP Boilers

Installation & Servicing Instructions Page : 16

Q28s Available pump head

0

1

2

3

4

5

6

7

0 5 10 15 20 25 30 35 40

Flow Rate (lpm)

Pump Head (m)

Page 22

If an additional pump is required the selected pump must comply with BS 1394. Provision

must be made in the system design for control of the additional pump. A connection point

is availble within the boiler to signal operation of the additional pump. However, this will

need to drive the additional pump via a suitable relay.

3.7.4 Hot Water System (if applicable)

The hot water storage vessel must be of the indirect type (certain direct cylinders can be

used provided they are suitably adapted by fitting an immersion calorifier). DIRECT

CYLINDERS MUST NOT BE USED. Further guidance is provided in BS 1394. It is

advisable to fit a locksheild valve on the cylinder return to enable balancing of the flow rate

through the cylinder.

The Keston Spa range of stainless steel unvented cylinders are an ideal option for

use with the Keston range. The Keston Spa range combine exceptional recovery

times with durable, long life stainless steel construction and all associated

controls. Contact Keston Boilers Ltd for information

The Qudos 28s also has advance control options built in which enable modulated reheat

of DHW and anti-legionella function. Refer to Chapter 4 for more detail.

3.7.5 Filling The System

The system should be filled using a G24 approved filling loop. The system pressure

should be set to between 1.0 and 2.0 bar. To display the system water pressure press the

“” button repeatedly until the water pressure is displayed (indicated by the word “bar” to

the right of the pressure reading). Fill the system and monitor the pressure dispalyed.

When the pressure is set, press the “RESET” button until the normal display is resumed.

3.8 FLUE SYSTEM

NB: When installing a replacement boiler a

new flue system must be used. Do not

re-use the existing boiler flue installation.

3.8.1 Design

Individual air supply and flue outlet pipes are used.

The material used for flue outlet &/or air inlet must be

muPVC to BS 5255 and/or BSEN1566-1 and

BSEN1329 of an internal diameter of 51 mm. (i.e.

nominal 50 mm diameter muPVC solvent weld waste

pipe)

Alternatively, where flue or air intake lengths of up to

60m are require, Keston Composite 75mm flue and

WD420/3/2007 Chapter 3 - Boiler Location The Keston Qudos 28s & Qudos 28sP Boilers

Installation & Servicing Instructions Page : 17

By-pass

Open 28mm

Permanently

FLOW

RETURN

Cock

Drain

Vessel

Expansion

KESTON

HEATING CIRCUIT

Q28s

(if required)

(if required)

Pump

Additional System

Flue Outlet/Air Inlet Terminals

Figure 3.8.1 : Terminals

Page 23

air pipe can be used (contact your Keston stockist for details). Keston Composite 75mm

pipe MUST be painted where exposed to UV light.

Both 50mm flue outlet terminal and 50mm air inlet terminal are supplied and are illustrated

in Figure 3.8.1. Both terminals are identical. If 75mm terminals are required these can be

obtained from your Keston Boilers stockist. Request part numbers C.17.2.26.00.0

(terminals) and C.17.2.00.60.0 (50 to 75 adapters).

3.8.2 Maximum Lengths

The maximum lengths of both air inlet pipe and flue outlet pipe, when no bends are used,

are as detailed below.

However, each bend used has an equivalent length that must be deducted from the

maximum straight length stated above. Knuckle bends must not be used.

A 92.5o sweep elbow is equivalent to 1.0m straight length. A 45o bend is equivalent to

0.5m straight length.

50mm 75mm

Maximum Air Inlet Length : 39.0m 117.0m

Maximum Flue Outlet Length: 20.0m 60m

Maximum Total Flue and Air Intake Length : 40.0m 120.0m

Example (assuming 50mm muPVC flue and air pipework)

Air inlet uses two one 92.5o sweep elbows. Hence, maximum length permissible

(i.e. a+b in figure 3.8.2) = 39.0m - 1.0m - 1.0m = 37.0m

Flue outlet uses one 92.5o sweep elbow.

Hence, maximum length permissible (i.e.

c+d in figure 3.8.2 = 20.0m - 1.0 m = 19.0m

3.8.3 Slope

‘Horizontal' flue outlet pipework MUST

slope at least 2 degrees (32 mm per metre

run) downwards towards the boiler.

Pipework can be vertical. Only swept

elbows can be used.

Air inlet pipework can be truly horizontal or

vertical, or sloping in a downward direction

towards the boiler but in this case rain, etc.,

must be prevented from entering the pipe.

There must be no troughs in any of the

pipework, whether it be air inlet or flue

outlet.

Due the low temperature of the flue gases

further condensate will form within the flue

system. Drain points, with suitable traps,

must therefore be incorporated within the flue

system at the base of vertical flue sections in

excess of 6m, for 50mm muPVC pipe flue

systems. These additional condensate drains

must be run to discharge as detailed in

section 3.11. Such drain points can be

formed using standard muPVC fittings. Refer

to the example in Figure 3.8.3.

WD420/3/2007 Chapter 3 - Boiler Location The Keston Qudos 28s & Qudos 28sP Boilers

Installation & Servicing Instructions Page : 18

Figure 3.8.2 : Flue & Air Maximum Length Example

FLUE

c

d

AIR

a

b

KESTON Qudos 28s

6 in min.

Figure 2.8.3 :

Flue Condensate Drain

Point Example

Tee Fitting

To Boiler

To Terminal

Page 24

3.8.4 Terminations

Air inlet terminals must be facing horizontally or downwards to prevent entry of rain into

the terminal and positioned to ensure only fresh air is drawn into the boiler. The air

terminal must be located outside of the building.

Flue and air terminals must be positioned so that flue products are not drawn into the air

inlet. Site specific wind conditions should be considered to achieve this.

Drawing of combustion air directly from a ventilated boiler room invalidates the heat

exchanger warranty.

The flue outlet terminal is designed to face outwards but can, if desired, be adapted to

face in any direction BUT must not be directed in the region of the air inlet. The flue

terminal and air inlet terminal can be located on different, but not opposing wall faces.

The two terminals are subject to the requirements of BS 5440 Pt 1 for clearances from

features of the building although some can be decreased to the values indicated.

The Keston Qudos 28s and Qudos 28sP, as with any condensing boiler, will

generate a condensate “plume” from the flue terminal in all weather conditions.

Consideration must therefore be given to the effect of this “plume” when selecting

a location for the flue terminal. It is the responsibility of the installer to ensure the

selected terminal location does not cause nuisance.

300300L Horizontally from terminal on same wall.

1,5001,500K Vertically from terminal on same wall.

1001,200J From opening in a car port.(not recommended)

1,2001,200I From terminal facing a terminal.

100600H From surface or boundary facing a terminal. *

100200G Above ground or balcony or roof.

50200F From internal or external corner or to a

boundary alongside the terminal. *

5075E From vertical drain or soil pipes.

50200D Below balconies or car port roof (lowest point).

50200C Below eaves.

7575B Below gutters, soil pipes, drain pipes.

50300A Below, above or beside openable window, air

brick, etc.

Air

Inlet

Flue

Terminal

Dimensions (mm)

*The dimensions given in the table above may need to be increased to avoid wall staining

and nuisance depending on site conditions.

It is advisable for horizontal flue terminals to place a 45o elbow at the end of the flue to

direct the condensate plume up and away from the property. If the air intake is within

500mm of the flue outlet the air must not terminate at a level above that of the flue

If either the air inlet or flue outlet terminate at a height of less than 2.1m above ground

level, the terminal must be protected by a suitable guard. The K4 terminal guard (with

plastic coating), manufactured by Tower Flue Components Ltd is suitable for this purpose

3.8.5 Clearances From Wall

Flue outlet and air inlet terminations must be at least 40 mm from the wall face.

3.8.6 Distance Between Flue Outlet & Air Inlet

There is no maximum - the terminations must not be on opposite sides of the

dwelling but can be in areas of unequal pressure..

A minimum clearance of at least 200 mm must be left between the terminations.

WD420/3/2007 Chapter 3 - Boiler Location The Keston Qudos 28s & Qudos 28sP Boilers

Installation & Servicing Instructions Page : 19

Page 25

3.8.7 General Installations

All parts of the system must be constructed in accordance with BS 5440 Part 1,

except where specifically mentioned in these instructions.

All pipe work must be adequately supported.

All joints other than approved push-on or plastic compression connectors must be

made and sealed with solvent cement suitable for muPVC pipes and conforming

to BS 6209: 1982.

External wall faces and any internal faces of cavity walls must be made good.

Rubber collars are available for flue and air terminals to finish the external wall

face around the terminals (Part No C.08.0.00.07.0)

3.9 AIR SUPPLY

The KESTON Qudos 28s and Qudos 28sP are room sealed appliances and therefore do

not require purpose provided ventilation to the boiler room for combustion air.

3.10 COMPARTMENT INSTALLATION

Due to the low casing temperatures generated by the boiler, no compartment ventilation is

required. However, the cupboard or compartment must not be used for storage.

3.11 CONDENSATE DRAINAGE

Being a condensing boiler, the Qudos 28S and Qudos 28SP are fitted with a condensate

trap at the base of the heat exchanger and flue assembly, with facility to connect to a

drain point underneath the appliance.

The condensate trap is packed loose with the appliance and MUST be fitted

BEFORE firing the appliance.

Use only plastic piping and do not reduce below 15 mm internal diameter within the

dwelling. Condensate should preferably be drained into the sanitary waste system or,

alternatively, the rainwater system of the property in most cases. Ensure in all cases that

the disposal of the condensate is in accordance with any local regulations in force.

Termination of the pipe must be either at a branch or stack internal to the house, or

externally at an open gully. Alternatively, discharge into a purpose made condensate

soakaway can be considered. Existing or purpose built drains must use suitable corrosion

resistant material as condensate is mildly acidic.

The connection to the condensate drain of the boiler, and the condensate drain pipework

itself, should be properly sealed to ensure there is no possibility of leakage into the

dwelling.

A minimum slope downwards towards the drain of 1 in 20 is essential. Freezing of the

termination and pipework must be prevented. Any drainage pipes outside the property

must be at least 32 mm inside diameter.

WD420/3/2007 Chapter 3 - Boiler Location The Keston Qudos 28s & Qudos 28sP Boilers

Installation & Servicing Instructions Page : 20

Page 26

4. INSTALLATION OF THE BOILER

Read Chapter 3 - Boiler Location and decide upon the position of the boiler.

Installation of the boiler is straightforward but consideration must be given to access to allow flue

and air pipes to be pushed through walls and ceilings. The order in which the components are

installed will depend upon particular site conditions, but in general it will be easiest and most

accurate to install the boiler and then build up the flue outlet and air inlet pipes to the terminal - this

is the sequence described.

4.1 WALL MOUNTING

BRACKET

a Place the bracket on the wall

horizontally with the

pre-drilled holes at the

bottom and position as

dictated by the template

supplied within the boiler

packaging.

b Drill through the centre hole

of the bracket, plug the hole

and fix in position.

c Using a spirit level make

sure the bracket is

completely level and mark

the position of the other

screw holes.

d Remove the bracket and drill

the holes in the positions

marked. Plug these holes.

e Screw the bracket to the wall

using screws of an

appropriate size for the wall

type (No. 12 x 2 inch wood

screws normally suffice).

4.2 MOUNTING THE BOILER (after system cleaning and testing)

a Lift and locate the boiler onto the stud and the two locating pegs protruding from

the wall bracket. (lift the boiler via the back frame only)

b Lower the boiler for hanging on the two pegs.

c Fix the boiler on the bracket stud using the nut and the washers supplied.

d Make the gas, flow, return, condensate and PRV connections to the system.

Check all joints for tightness

DO NOT FIRE THE BOILER UNTIL THE CONDENSATE TRAP IS SECURED IN

POSITION.

4.3 ASSEMBLY PRACTICE

Remove all plastic debris and burrs when installing air intake piping. Plastic filings caused

by cutting muPVC pipe must not be allowed to be drawn into the combustion air blower.

Prevent dust entering the air intake when cutting on building sites. Blower failure which is

determined to be caused by plastic filings or other debris will not be covered by guarantee.

4.4 INSTALLING FLUE AND AIR PIPES

IMPORTANT - When installing the boiler on an existing system a new flue and air

intake system MUST also be installed. You must NOT re-use existing flue or air

pipework components.

NB: When installing the boiler, consider:

Flue Spigot Assembly

The flue spigot (50mm muPVC) is inside the accessory bag.

WD420/3/2007 Chapter 4 : Installation The Keston Qudos 28s & Qudos 28sP Boilers

Installation & Servicing Instructions Page : 21

All dimensions in mm.

Figure 4.1 Wall Mounting Fixing Locations

156

Page 27

Put the flue spigot assembled with the test plug on the cabinet frame and secure

it by fastening the two M6 screws. Couple the spigot to the internal flue pipe using

the flexible couple and fastening clips. Ensure the clips are properly secured and

no leakage can occur.

Remember the flue pipe must slope downwards back towards the boiler and this

is best achieved using 92.5o bends.

a Using the template supplied within the boiler packaging mark the

positions of the two holes for the flue and air pipes on the wall(s) or

ceiling.

b Drill the two holes in the wall/ceiling, preferably using a core drill.

c Measure, cut and check the air and flue pipes to pass to the exit from the

wall(s) or ceiling.

Always thoroughly deburr all pipes and, most important, remove shavings from

within the pipe.

d Mount the boiler on the wall bracket and fix the air spigot (packed loose

with the boiler and with appropriate gasket) to the boiler air inlet

connection tightly to ensure there is no leakage. Assemble, using

adhesive, the pipework from the boiler connections to the exit from the

first wall/ceiling (remount the boiler if removed). When pushing pipe

through walls, ensure grit and dust is not allowed to enter the pipe.

Ensure pipes are fully engaged into sockets and solvent welded with no

leaks.

e Using the same methods drill any further holes (always covering existing

pipework), cut and assemble the pipework.

f From outside, complete the two terminations - See Section 3.8 Flue

System and make good all holes. (wall sealing collars are available to

make good hole areas on the wall face (part number C.08.0.00.07.0)

g Support any pipes whose route could be displaced either of its own

accord or by accident. Any horizontal run over 1m or vertical runs of any

length must always be supported. Brackets should be placed at intervals

of approximately 1m.

h Check all connections for security and re-seal any joints using solvent

cement where soundness may be in doubt.

Note: It is equally important to seal the air inlet with solvent cement as the flue outlet

pipe joints.

4.5 CONDENSATE DRAINAGE

NB: When installing the boiler, consider:

Condensate Trap Assembly

The condensate trap is fitted loose inside the cabinet.

i) Fit the condensate trap through the hole in the base of the boiler frame.

ii) Remove the cap fitted to the condensate drain spigot at the base of the

heat exchanger.

iii) Securely connect the condensate trap inlet to the heat exchanger drain

spigot. Be carefully to the correct position of sealing O-ring.

Iv) Secure the trap to the boiler frame using the fixing bolts supplied.

Connect the condensate drainage system to the boiler. It is advisable to use a detachable

fitting at connection to the boiler to enable easy removal for servicing.

Fill the condensate trap by pouring water into the boiler flue until water is seen to flow

freely from the condensate drainage system. Make the final connection of flue pipe to the

boiler.

Details are provided in Chapter 3 - Section 3.11 Condensate Drainage

Connection : 22 mm plastic pipe.

WD420/3/2007 Chapter 4 : Installation The Keston Qudos 28s & Qudos 28sP Boilers

Installation & Servicing Instructions Page : 22

Page 28

4.6 WATER SYSTEM

Connect the flow and return HEATING CIRCUIT system pipework to the boiler. Details of

system requirements are given in Chapter 3 - Section 3.7 Water Systems.

Connections : 0.75 inch BSPM

For optimum performance after installation, this boiler and its associated central heating

system must be flushed in accordance with the guidelines given in BS7592:1992,

"Treatment of water in domestic hot water central heating systems".

This must involve the use of a proprietary cleaner, such as Fernox Superfloc, or

BetzDearborn's Sentinel X300 or X400. Full instructions are supplied with the products,

but for immediate information, please contact Fernox on 01799 550811 or BetzDearborn

on 0151 420 9563.

For long term protection against corrosion and scale, after flushing, it is recommended

that an inhibitor such a Fernox MB1 or BetzDearborn's Sentinel X100 is dosed in

accordance with the guidelines given in BS7593:1992.

4.7 GAS SUPPLY

Connect the gas supply to the appliance. Details of gas supply requirements are given in

Chapter 3 - Section 3.6 Gas Supply. Supply of adequate gas pressure (with the boiler

running) is critical to ensure reliable operation of the boiler.

Connections : 0.5 inch BSPM

4.8 ELECTRICAL SUPPLY

The entry point(s) for the electrical supply cable(s) is in the base of the appliance (see

Section 3.2 Service Connections fig. 3.1.2) via a cordgrip bush. Feed the cable through

the bush and route inside the cabinet to the connection strip located to the front bottom

right area of the cabinet.

1. The electrical supply must be as specified in Chapter 3 - Section 3.4 Electrical

Supply.

WARNING : THIS APPLIANCE MUST BE EARTHED.

2. All external controls and wiring must be suitable for mains voltage. Supply wiring

should be in PVC insulated cable not less than 0.75mm2 (8.0mm dia) to BS 6500

Table 16 (material code H05VV-F).

3. The permanent live supply connection may be via a 3 amp fused double pole

switch, serving only the boiler. (Refer to Chapter 3 - Section 3.4 Electrical Supply).

Any 230VAC system controls for the boiler must also be supplied via this isolator.

4. Basic Wiring Installation

Securely tighten the terminal screws and route the cable(s) through the

re-openable cable clips. Ensure all cables are secured and that the cord grip bush

is tightened to securely grip the main cable at entry to the cabinet. Remove the

factory fitted link wire between the room thermostat terminals on the boiler.

The supply cable(s) must be connected to the main terminals as follows:-

Main Supply L - Brown wire (Live) 3A permanent supply

Main Supply N - Blue wire (Neutral) for 3A permanent

Main Supply E - Yellow/Green Wire (Earth)

CH Demand SL1 - 230V Switched Live - i.e. Room Thermostat

Ensure connection is made such that if the cable slips in its anchorage the current

carrying conductors become taut before the earthing conductor.

5 Advanced Features Wiring

The Qudos 28s features comprehensive and advance functionality as standard.

Whilst these advances funtions are not mandatory, they will provide enhanced

boiler operation performance and efficiency. Detailed below are suggested wiring

methods to activate various functions.

WD420/3/2007 Chapter 4 : Installation The Keston Qudos 28s & Qudos 28sP Boilers

Installation & Servicing Instructions Page : 23

Page 29

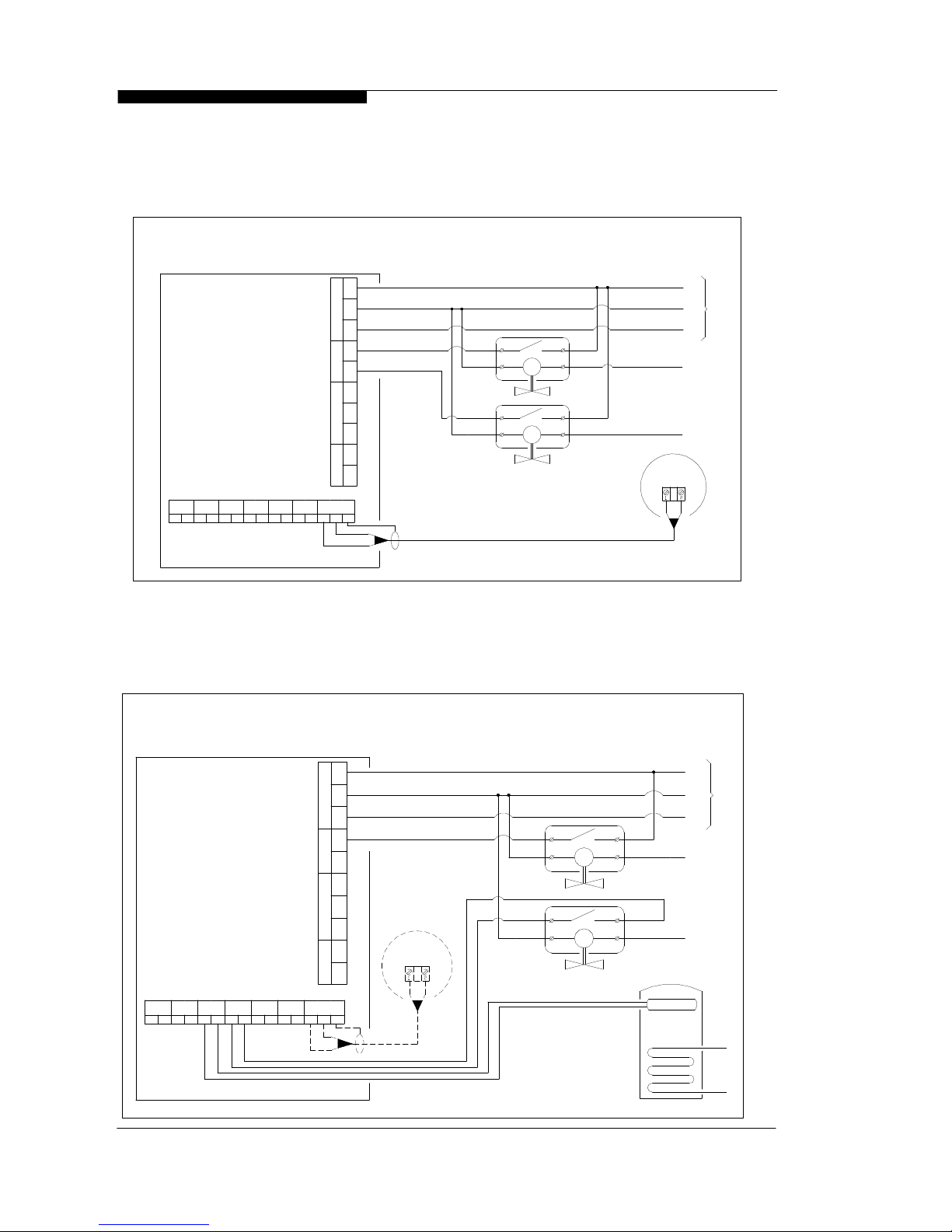

5.1 Twin Thermostat Operation with Weather Compensation

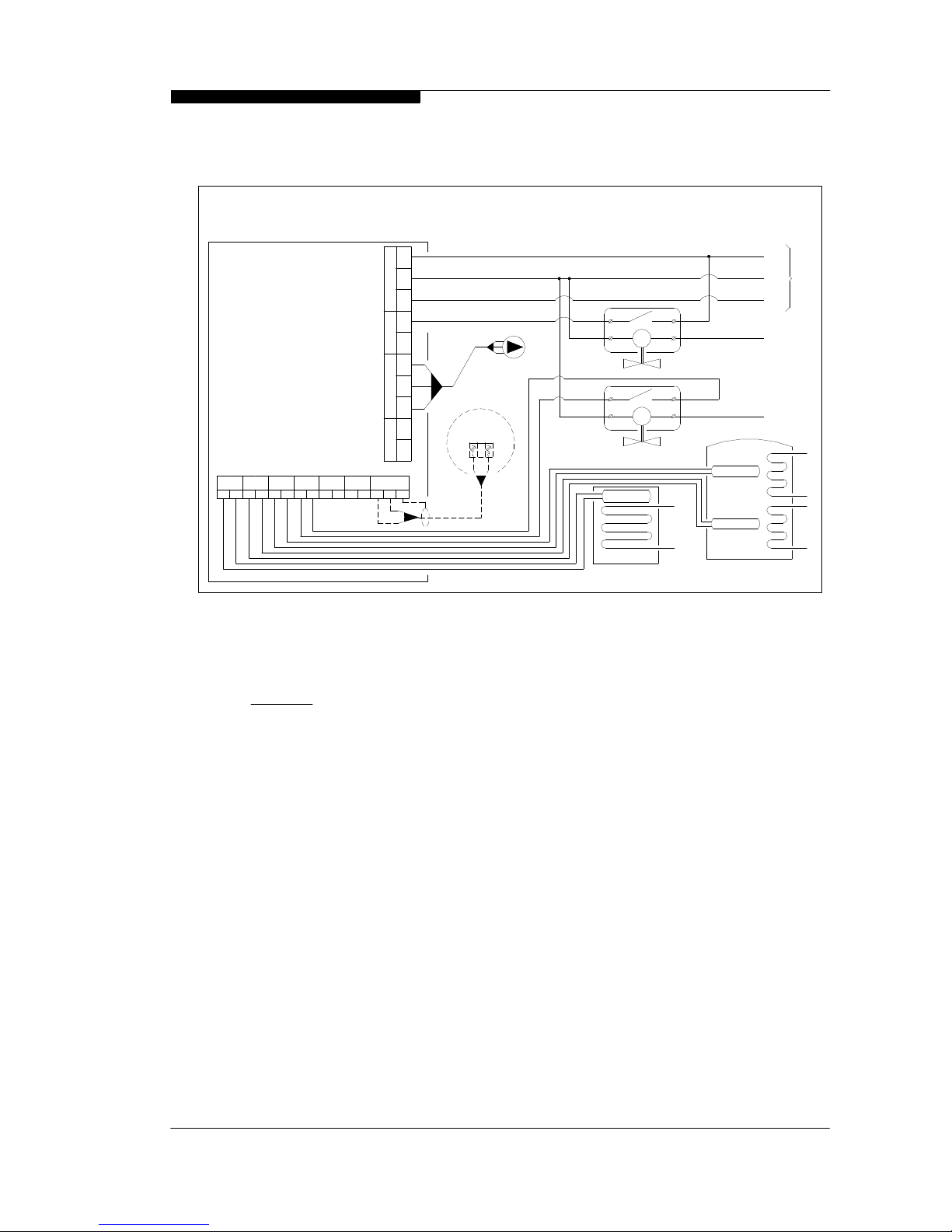

5.2 Modulation of DHW generation

WD420/3/2007 Chapter 4 : Installation The Keston Qudos 28s & Qudos 28sP Boilers

Installation & Servicing Instructions Page : 24

SEPARATE CH & DHW DEMAND WITH ( OPTIONAL ) WEATHER COMPENSATION

CONTROLS

FROM DHW

CONTROLS

FROM CH

( OPTIONAL )

EXTERNAL SENSOR

GREYORANGE

BROWNBLUE

M

VALVE

DHW ZONE

VALVE

CH ZONE

BROWN

GREY

BLUE

ORANGE

M

( 3A FUSE )

230V MAIN SUPPLY

E

N

L

BOILER

MAIN CONNECTOR

LOW VOLTAGE CONNECTOR

Q28S

E

THERMSWITCH

C 2 1

CH1

1

0

-

1

0

V

0v

2

SENSOR

1

2

SENSOR

2

SENSOR

1

1

2

NO

OPEN

SOL.

DHW

TS

FLOW

ANALOG

DEMAND

EXTERNAL

SENSOR

MAIN SUPPLYSOLAR PUMP CH DEMAND

1 N N

SL1SL2

E L

LOCKOUT

COMNO

2

C.10C.0.09.00.0

EXTERNAL SENSOR

( OPTIONAL )

TANK

( OPTIONAL )

DHW SENSOR

SEPARATE CH & DHW DEMAND WITH ( OPTIONAL ) DHW SENSOR CONTROL

CONTROLS

FROM DHW

CONTROLS

FROM CH

GREYORANGE

BROWNBLUE

M

VALVE

DHW ZONE

VALVE

CH ZONE

BROWN

GREY

BLUE

ORANGE

M

( 3A FUSE )

230V MAIN SUPPLY

E

N

L

BOILER

MAIN CONNECTOR

LOW VOLTAGE CONNECTOR

Q28S

E

THERMSWITCH

C 2 1

CH1

1

0

-

1

0

V

0v

2

SENSOR

1

2

SENSOR

2

SENSOR

1

1

2

NO

OPEN

SOL.

DHW

TS

FLOW

ANALOG

DEMAND

EXTERNAL

SENSOR

MAIN SUPPLYSOLAR PUMP CH DEMAND

1 N N

SL1SL2

E L

LOCKOUT

COMNO

2

C.10C.0.09.00.0

Page 30

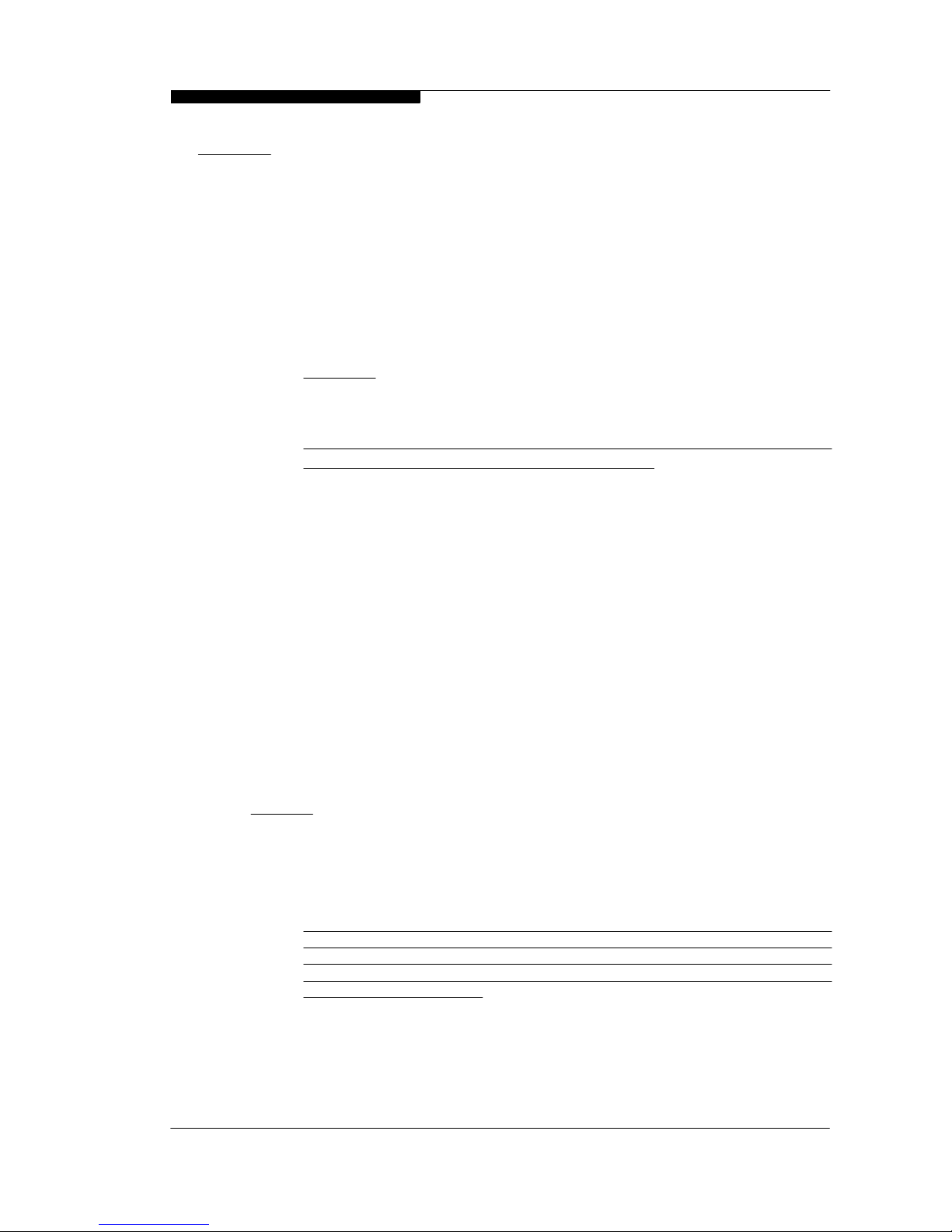

5.3 Solar Control

4.9 EXCHANGING A BOILER

Before removing an existing boiler add Fernox Supafloc, or equivalent cleaning agent, in

accordance with the manufacturers instructions. Open all radiator valves and fire the

boiler. When the system is fully heated, shut off the gas supply and drain down the central

heating system.

Important

The Qudos 28s and Qudos 28sP condensing boilers contain components which could be

damaged or blocked by grease, dirt or solder etc. It is essential that sludge or scale is

removed from an existing system before fitting the boiler.

The guarantee provided with the Keston Qudos 28s and Qudos 28sP does not cover

damage caused by system debris or sludge.

Connect the new boiler as instructed in this manual and fit in accordance with Sections

4.1 to 4.8

Fill to a pressure of about 2.5 bar. Check the complete system for water soundness. If

leaks need to be rectified using flux or solder the system must be flushed cold again

before proceeding.

Reduce the pressure to the Initial System Design Pressure. Vent the system.

Gas Supply

The complete gas installation up to the boiler gas control valve must be checked for

soundness. BS 6891.

Electrical Installation

Carry out preliminary electrical safety checks, i.e. Earth continuity, Polarity, Resistance to

Earth, Short Circuit and earth loop impedance using a suitable test meter.