Page 1

WD50/2/1997 The Keston 50, 60 & 80 Condensing Boilers

Fan Powered High Efficiency Condensing Gas Boiler

Installation And Servicing Instructions

Keston 50 - GC No 41 930 01

Keston 60 - GC No 41 930 02

Keston 80 - GC No 41 930 03

PI No. : 87AQ306

These instructions must be left either with the user or next to

the household gas meter.

34 West Common Road

Hayes, Bromley, Kent BR2 7BX

Tel. (44)0208 462 0262 Fax. (44)0208 462 4459

0087

Page 2

WD50/2/1997 The Keston 50, 60 & 80 Condensing Boilers

CONTENTS

Section Description

1 GENERAL INSTRUCTION

1.1 Description

1.2 Boiler Schematic

1.3 Related Documents

1.4 Performance Data

1.5 General Data

2 BOILER LOCATION

2.1 Dimensions & Minimum Clearances

2.2 Service Connections

2.3 Position

2.4 Electrical

2.5 Boiler Size Selection

2.6 Gas Supply

2.7 Water Systems

2.8 Flue System

2.9 Air Supply

2.10 Compartment Installation

2.11 Condensate Drainage

2.12 Radiant Floor Heating

2.13 Low Water Volume Boiler vs. Cast Iron Boiler

2.14 Determine Radiation Needed Room-By-Room

3 INSTALLATION OF THE BOILER

3.1 Wall Mounting Bracket

3.2 Mounting The Boiler

3.3 Assembly Practice

3.4 Installing Flue And Air Pipes

3.5 Condensate Drainage

3.6 Water System

3.7 Gas Supply

3.8 Electrical Supply

3.9 Exchanging A Boiler

4 COMMISSIONING OF THE BOILER

4.1 Initial Flushing

4.2 Gas Supply

4.3 Electrical Installation

4.4 LP Gas Conversion

4.5 Initial Firing

4.6 Hot Flushing

4.7 Checking The Gas Pressure

Page : i

Page 3

WD50/2/1997 The Keston 50, 60 & 80 Condensing Boilers

4.8 Timing The Gas Meter

4.9 Handing Over To The User

5 FAULT FINDING

5.1 Electrical Control Sequence

5.2 Fault Finding Flow Chart

5.3 Continuity Checking

5.4 Functional Flow Wiring Diagram

5.5 Electrical Wiring Diagram

5.6 Illustrated Wiring Diagram

5.7 Exploded Assembly Diagrams

6 SERVICING

6.1 Pre Service Checks

6.2 Recommended Routine Service

7 REPLACEMENT OF PARTS

7.1 General

7.2 Precautions

7.3 Access

7.4 Electrical

7.5 Gas Orifice

7.6 Spark Ignition/Flame Detection Electrode

7.7 Burner Head & Burner

7.8 Heat Exchanger

7.9 Air Filter

7.10 Condensate Trap

7.11 Pressure Gauge

7.12 Sight Glass

7.13 HT Ignition Lead

7.14 Air Vent

7.15 Air Orifice

8 SPARE PARTS LISTINGS

Page : ii

Page 4

WD50/2/1997 Chapter 1 : General Instruction The Keston 50, 60 & 80 Condensing Boiler

1. GENERAL INSTRUCTION

1.1 DESCRIPTION

The Keston Condensing Boiler is unique in its concept and design. While the application

for which the boiler was designed is the same as those which other boilers are us ed the

Keston boiler has the added advantage of very high efficiency, and small diameter plastic

flue which can be extended to 10 metres horizontally or vertically.

The Keston uses a high power combustion blower to deliver a pre-mix of gas and air to a

downward firing burner in a high efficiency, single pass heat exchanger.

o

Normally the combustion temperature of the air gas mixture is around 1800

Keston achieves combustion at an am azing 1000

o

C thereby reducing the NOx emissions

down to an incredible less than 5 p.p.m.

The flue system is room sealed and fan powered. The ignition is direct spark and fully

automatic. The boiler housing is not waterproof. The boiler should be installed in a

position where it will always be dry. A small air intake point is incorporated within the

appliance cabinet to ensure that the interior of the cabinet is maintained under a slight

negative pressure. This is a safety feature to ensure no products may leak out of the

cabinet into the installation space.

C but the

s

The boiler is suitable f or connection to open vented or sealed s ystems. T he system mus t

be pumped central heating or pumped central heating with combined indirect domestic hot

water. Gravity circuits must not be used.

The boiler has a primary heat exchanger which, through its combustion chamber and

corrugated coil, transf ers the heat produced in the hot gas es of combus tion process into

the circulating water. Head characteristics of the boiler coil must be taken into

consideration when calculating the pump size.

The Keston boiler is not a high water content boiler and does not contain the metal mass ,

or water volume, of a cast iron or steel boiler. This boiler is of low mass and low water

content and therefore responds fast er when there is a call for heat. Th is f eatur e requir es a

higher water pumping rate thr ough the boiler otherwise localised boiling will occur within

the boiler.

Allow a pressure drop through the boiler of 3.2 ft head and a water flow of 4.2 gallons (19

litres) per minute f or the Keston 50, 4.3 f t head and 5 gallons (23 litres) per m inute for the

Keston 60 and 9 ft head and 6.7 gallons (30.5 litres) per minute for the Keston 80.

The boiler selected m ust be sized relative to the total c alculated heat loss of the building.

The boiler rated output should not be greater than the total required to make up the

calculated heat loss plus the heat required to provide domestic hot water. If there are

special conditions such as excessive domestic hot water usage consult the manufacturer.

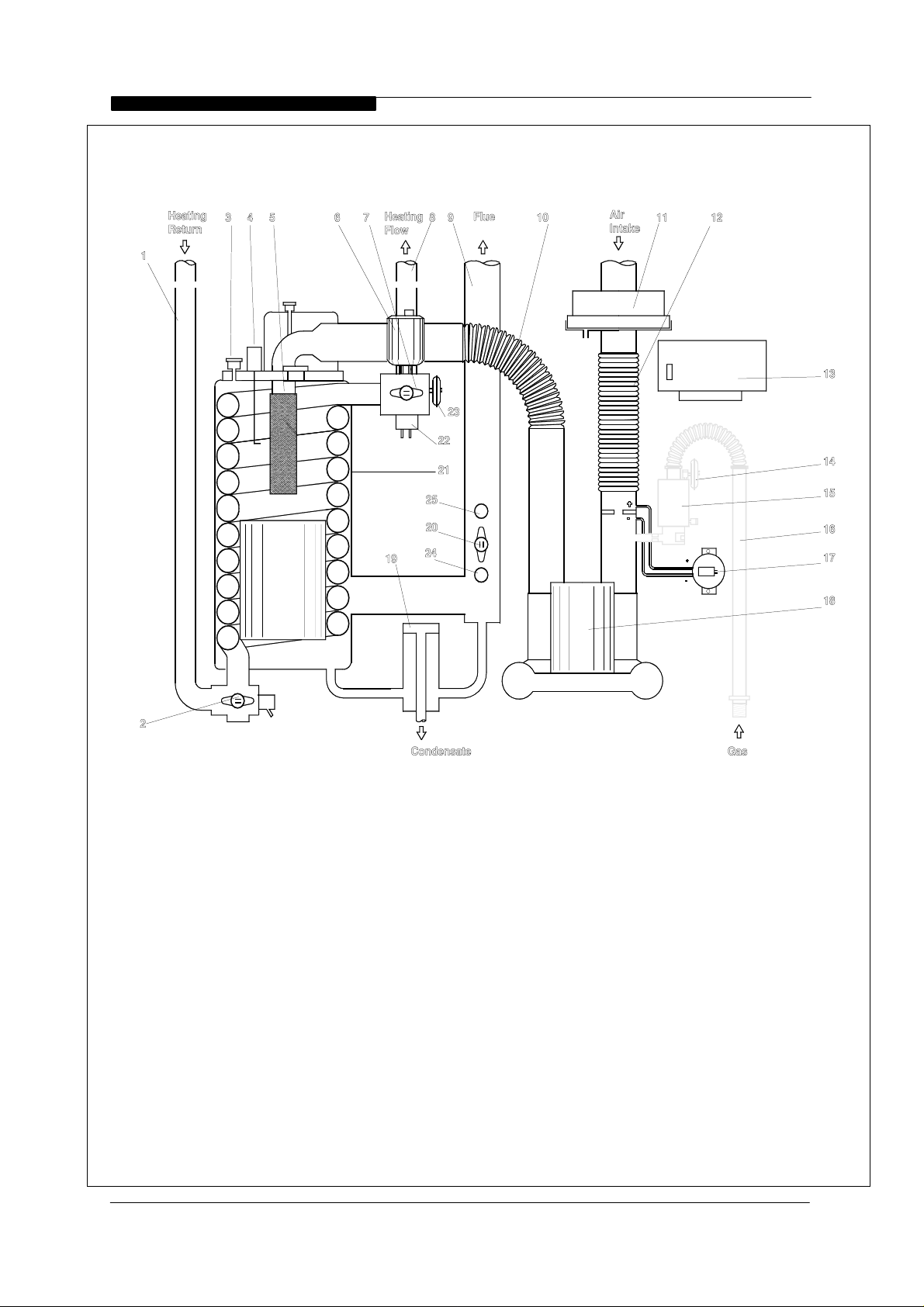

1.2 BOILER SCHEMATIC

Air is drawn into the boiler through a 40mm ( BS5255) m uPVC pipe. T he air f low is proved

by a differential pressure across the air control orifice.

Gas is mixed with com bustion air at the inlet to the fan. The gas flow is regulated by an

orifice located in the housing downstream of the gas valve.

Installation & Servicing Instructions

Page : 1

Page 5

WD50/2/1997 Chapter 1 : General Instruction The Keston 50, 60 & 80 Condensing Boiler

Figure 1.2 Boiler Schematic

s

LEGEND

1 Heating Return

2 Water Return Thermo stat

3 Downstr eam Pr essture Test Nipple

4 Flame Ignition/Sensing Probe

5 Burner

6 Automatic Air Vent

7 High Limit Thermostat

8 Heating Flow

9 Flue Exhaust

10 Air/Gas Flexible Connector

11 Air Filter

12 Air Inlet Flexible Connector

Installation & Servicing Instructions

13 Ignition Control Box

14 Gas Low Pressure Switch

15 Gas Multifunctional Control

16 Gas Inlet Flexible Connector

17 Air Pressure Switch

18 Combustion Blower

19 Condensate Trtap

20 Flue Overheat Thermostat

21 Heat Exchanger

22 Flow Overheat Thermostat

23 Water Low Pressure Switch

24 Combustion Test Point

Page : 2

Page 6

WD50/2/1997 Chapter 1 : General Instruction The Keston 50, 60 & 80 Condensing Boiler

The gas and air are thoroughly mixed in the blower and f ed into the burner located at the

top end of the heat exchanger module. The gas and air mixture is ignited by a direct spark

ignition control system and burns with a blue flame j ust off the surface of the burner. As

the hot products of com bustion pass downwards, they are cooled, exchanging heat with

the circulating water which enters the heat exchanger coil at the bottom of the heat

exchanger.

When the return water temperature is below 54oC, part of the water vapour in the

combustion products will condense ins ide the heat exchanger, thus increasing the boiler

efficiency. This condensate falls to the bottom of the heat exc hanger where it is s eparated

from the flue gases and exits from the boiler through the condensate drain. Any

condensate formed in the flue runs back down the flueway and is drained at the base of

the flue connection to the heat exchanger.

The condensate is very slightly acidic (about the same acidity as vinegar) and should be

piped in a plastic pipe. It is not harmful to the waste disposal system and may be disposed

of as normal waste water.

The flue gases are piped in a 40m m m uPVC pipe to the outside. The temper ature of the

flue gases are usually less than

10oC above the temperature of the retur n water. The flue

pipe should be terminated outside the building from where they cannot re-enter the

building or any other adjacent building or cause a nuisance by pluming.

s

The heating level may be controlled by room thermo stats, hot water cylinder thermostats

and programmer time clocks.

1.3 RELATED DOCUMENTS

The Keston Condensing Boiler must be ins talled in accordance with the current issue of

the Gas Safety ( Installation and Use) Regulations, current IEE W iring Regulations, Safety

document no. 635 - The Electricity At Work Regulations 1989, Building Regulations,

Building Standards (Scotland) Consolidation, and the Bye Laws of the local Water

Undertaking.

In addition, due account must be taken to the following Codes Of Practice:

BS 6891 : Gas Supplies

BS 6798 : Installation Central Heating Boilers

BS 5449 : Installation Pumped Central Heating

BS 5546 : Installation Domestic Hot Water

BS 5440.1 : Flues

BS 5440.2 : Air Supply

BS 5482.1 : Domestic Propane & Butane Burning Installations

BS 7074.1 : Expansion Vessels

BS 7593 : Treatment of Water in Hot Water Central Heating

BS 7671 : Requirements for Electrical Installations. IEE Wiring

Systems

Regulations 16th Edition.

For Timber Framed Buildings, British Gas Publications DM2. Also British Gas

Publications 'Guidance Notes For The Installation Of Domestic G as Condensing

Boilers' and 'Specification For Domestic Wet Central Heating Systems'.

Installation & Servicing Instructions

Page : 3

Page 7

WD50/2/1997 Chapter 1 : General Instruction The Keston 50, 60 & 80 Condensing Boiler

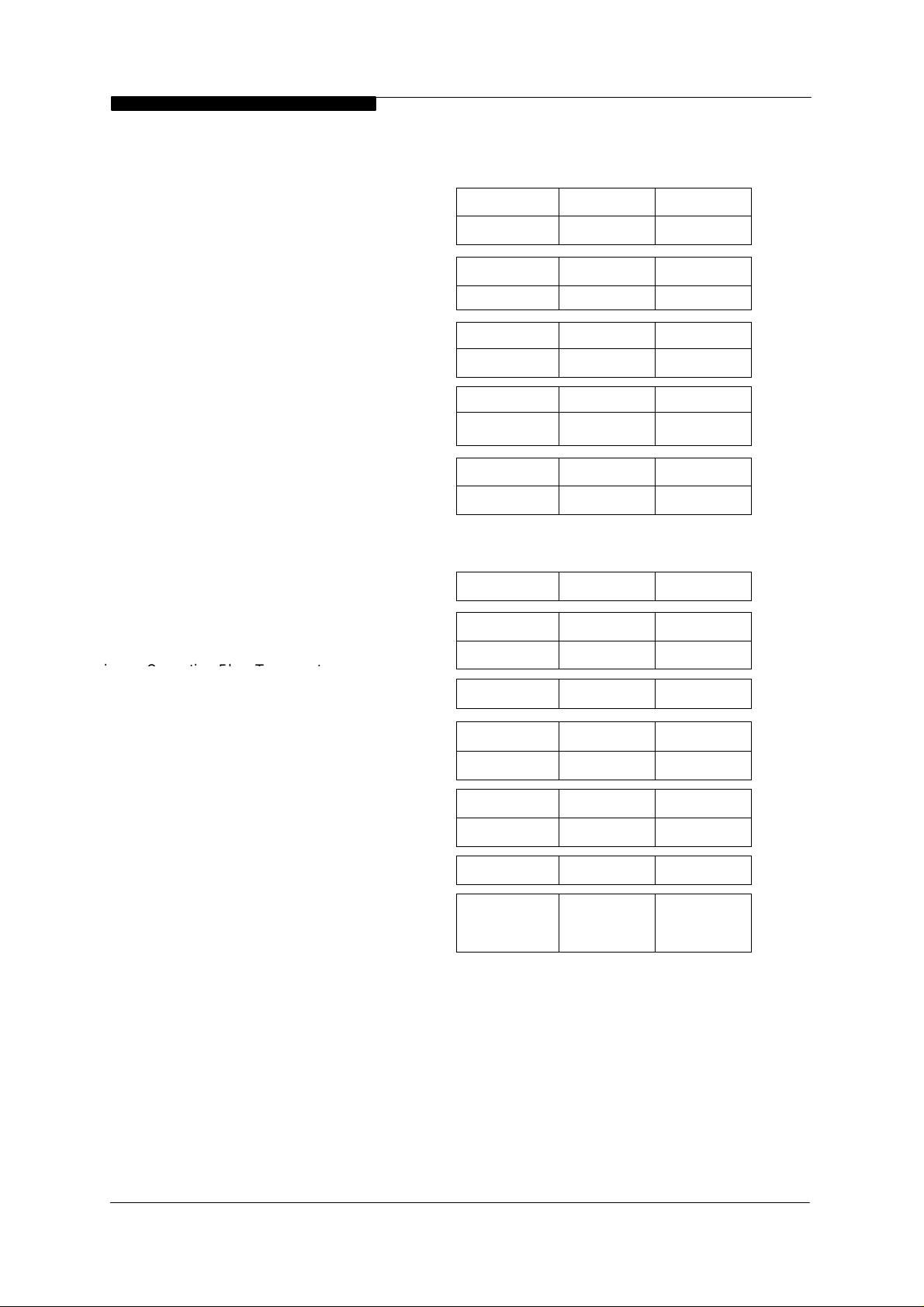

1.4 PERFORMANCE DATA

s

o

C Flow 60oC Return

o

C Flow 40oC Return

(FACTORY PRESET)

(CV of Gas - 38.7 MJ/m3)

(1038 Btu/Ft

3

)

Keston 50 Keston 60 Keston 80

27.119.916.6KWBoiler Input

92,50068,30056,500Btu/h

23.5 17.514.7KWBoiler Output To Water

80,00060,00050,000Btu/h80

2619.215.8KWBoiler Output To Water

88,80065,00054,000Btu/h60

1096mbarBurner Setting Pressure (Hot)

3.943.542.36in w.g.

0.70.510.43L/SGas Consumption After 10 mins

3

/HrRunning

o

CMaximum Operating Flow

89.1165.854.43Ft

80.0080.0080.00

30.5030.5030.50MMaximum Head (Open Systems)

Differential

Ft

o

100.0100.0100.0Ft

2.702.702.70BarMaximum Pressure (Sealed Systems)

2.5MMinimum Head (Open Systems)

2.5

8.08.0

2.5

8.0

20.020.020.0mbarInlet Gas Pressure

8.08.08.0in. w g

3.432.712.38mmGas Orifice Size

CRecommended Temperature

10 to 1510 to 1510 to 15

Installation & Servicing Instructions

Page : 4

Page 8

WD50/2/1997 Chapter 1 : General Instruction The Keston 50, 60 & 80 Condensing Boiler

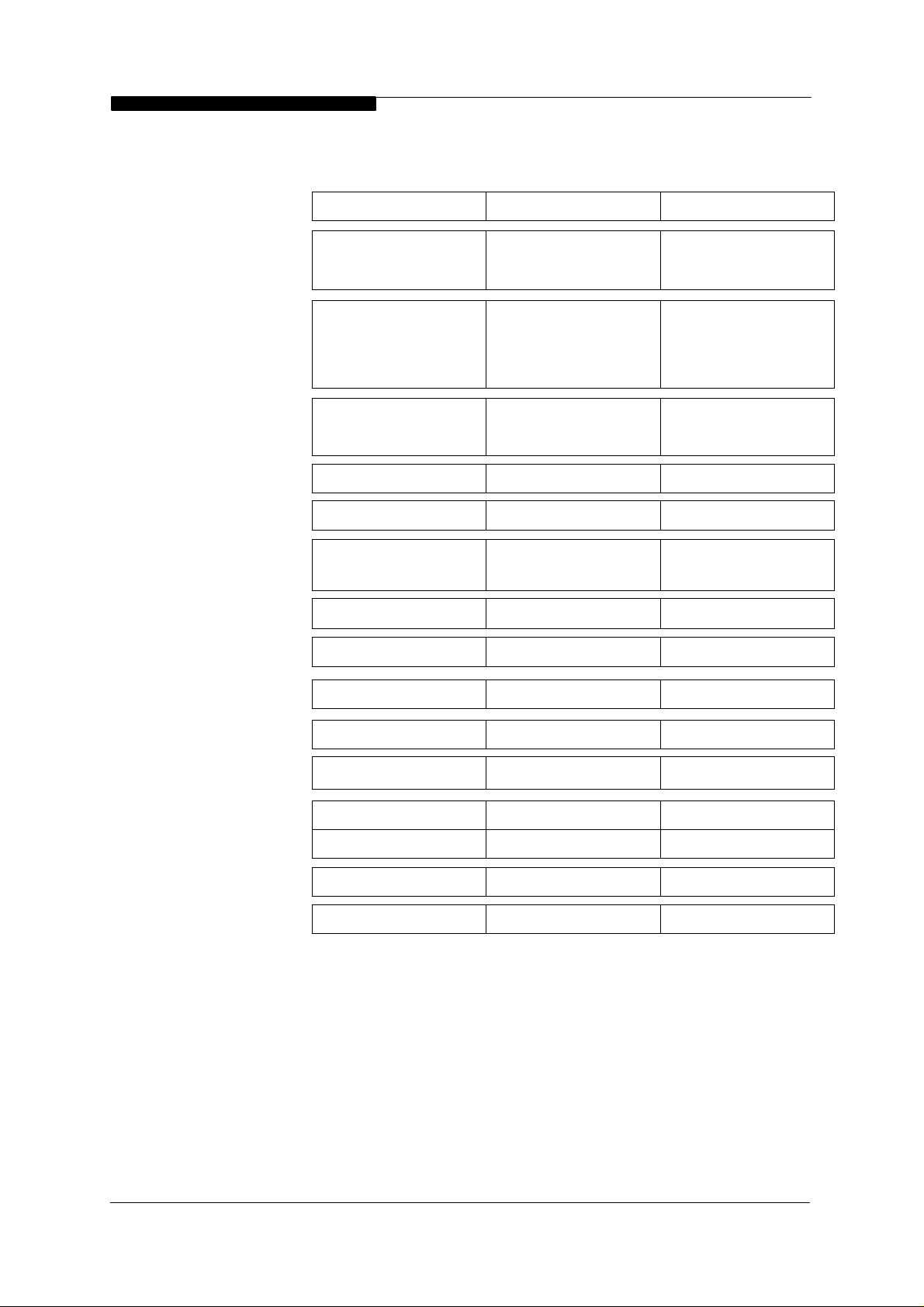

1.5 GENERAL DATA

s

Direct Spark

Gas Supply

Connection

Keston 50 Keston 60 Keston 80

Electronics

RAM

0.5 inch BSPT Male

(15mm to gas cock)

28 mm

CopperFlow Connection

0.5 inch BSPT Male

(15mm to gas cock)

Keston PremixKeston PremixKeston PremixMain Burner

White RogersWhite RogersWhite Rogers Gas Control

36E Series36E Series36E Series

KestonKestonKestonCombustion Fan

Type LPB 102 220/240Type LPB 102 220/240Type LPB 102 220/240

0.18 KW 2900 RPM0.18 KW 2900 RPM0.18 KW 2900 RPM

RAM ElectronicsRAM Electronics

Full Sequence ControlFull Sequence ControlFull Sequence ControlIgnition

Tridelta FS 6717 - 1428Tridelta FS 6717 - 1428Tridelta FS 6717 - 1428Air Pressure Switch

Keston FilterKeston Filter Keston FilterFilter

0.5 inch BSPT Male

(15mm to gas cock)

28 mm Copper28 mm Copper

Return Connection

28 mm

Copper

28 mm Copper28 mm Copper

230V 50Hz230V 50 Hz230V 50 Hz Power Supply

175 W140 W140 WPwr Consumption

5 Amps5 Amps5 AmpsExt. Fuse Rating

52 kg (114 lbs)46 kg (101 lbs)46 kg (101 lbs)Weight - Full

50 kg (110 lbs)44 kg (97 lbs)44 kg (97 lbs)Weight - Empty

Rear panel inside caseRear panel inside caseRear panel inside caseData Badge Posn

3.30 litres2.35 litres2.35 litresWater Content

Installation & Servicing Instructions

Page : 5

Page 9

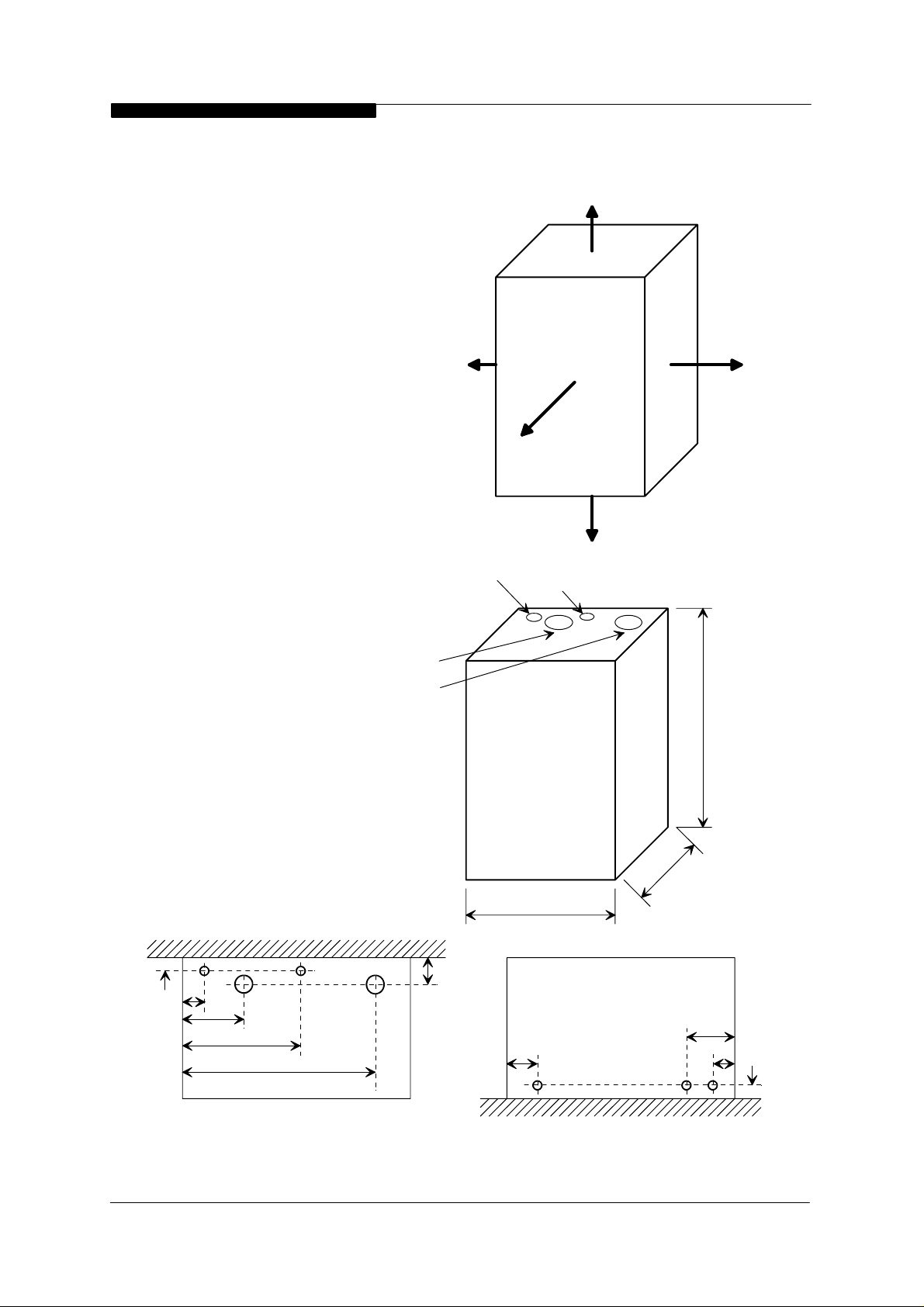

WD50/2/1997 Chapter 2 - Boiler Connections The Keston 50, 60 & 80 Condensing Boilers

2. BOILER LOCATION

All dimensions in mm.

2.1 DIMENSIONS AND MINIMUM

CLEARANCES

The boiler must be installed in

minimum clearances shown to allow

subsequent servicing, and safe

operation.

254

2.2 SERVICE CONNECTIONS

Gas, water, air and flue pipe,

condensation, and electrical

connections are as shown. Gas : 0.5

inch BSP male. Flow/Return : 28 mm

copper.

2.3 POSITION

The Keston is not

suitable for external

installation. The boiler

may be installed in any

room or internal space,

although particular

attention is drawn to the

requirements of the

current IEE Wiring

Regulations and, in

Scotland, the electrical

provisions of the Building

Regulations applicable in

Scotland, with respect to

the installation of the

boiler in a room or

internal space containing

a bath or shower.

Air Intake

Flue

1

305

Figur e 2.1.1

Return

127

Flow

Minimum Clearances

All dimensions in mm.

1

890 (Keston 80)

712 (Keston 50 & 60)

Where a room-sealed

appliance is installed in a

27

47

181

237

405

Top View

Installation & Servicing Instructions

Figure 2.1.2

Dimensions

60

Service Connection Locations

Page : 6

500

97

All dimensions are in mm.

Base View

0

0

3

68

30

37

Page 10

WD50/2/1997 Chapter 2 - Boiler Connections The Keston 50, 60 & 80 Condensing Boilers

room containing a bath or shower, any electrical switch or appliance control, utilising

mains electricity, should be so situated that it cannot be touched by a person using the

bath or shower.

Compartment installation is permitted - such compartments must be constructed in

accordance with BS 6798.

The wall on which the boiler is mounted must be of suitable load bearing capacity and

must be non-combustible.

Important : It is not recommended to install the boiler on a studded wall or similar - it is

possible that the vibration from the fan would be amplified and transmitted to other parts

of the house.

[NB: Refer to

Section 2.8.3]

The Keston can be located virtually anywhere desired provided that all regulations are

met. Because of the boiler's compact size and venting flexibility, the installation is not

limited to a boiler room setting. Before locating the boiler near a living space consider

whether the sounds generated by the boiler will be objectionable. Sound levels from the

boiler are no greater than from any other type of high-efficiency boiler but even minimal

levels may be objectionable if located near a bedroom or in a living area.

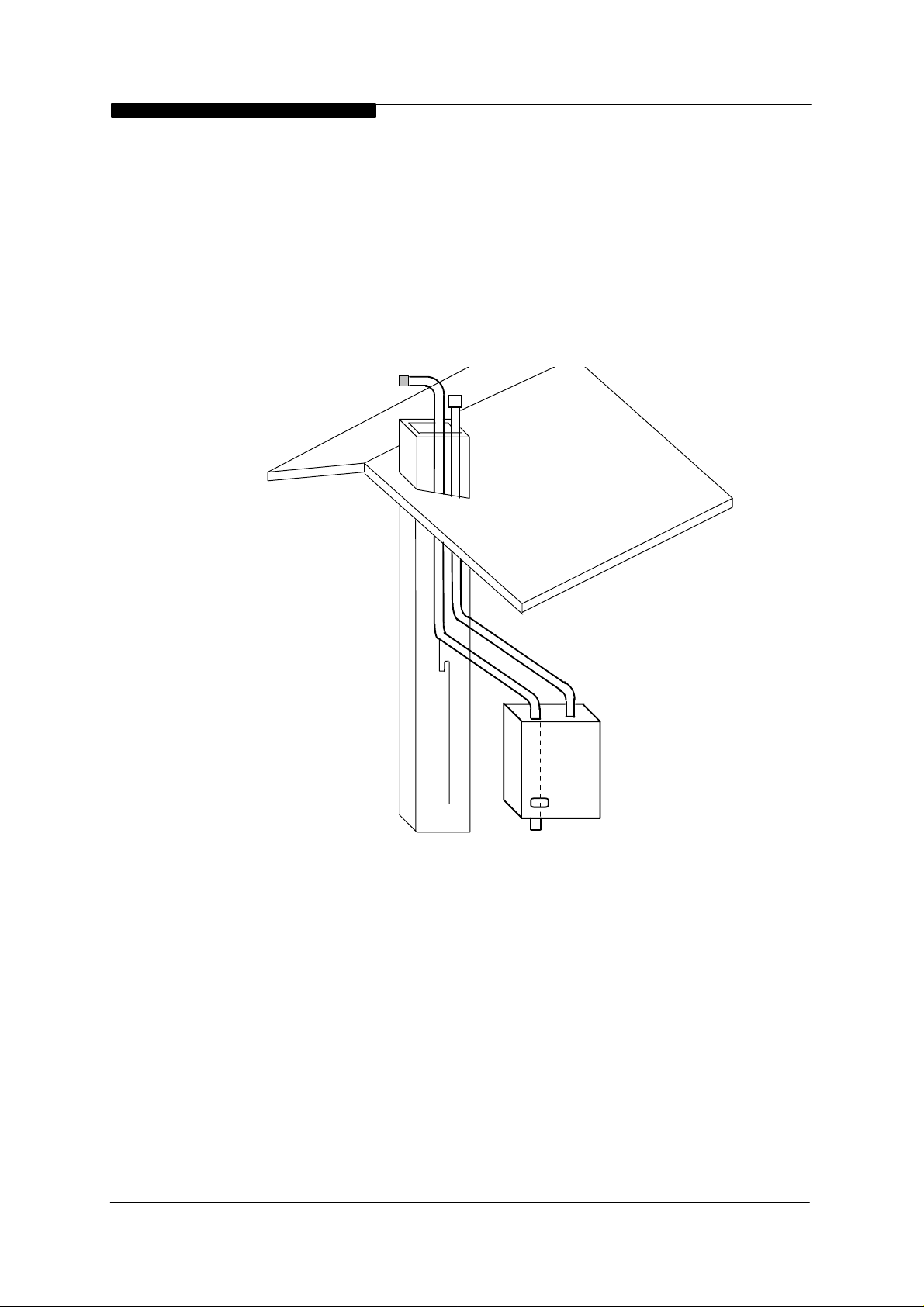

2.4 ELECTRICAL

2.4.1 Electrical Connections

Chimneys not used for

venting any other

appliance may be used.

Secure air & flue pipes at

chimney outlet.

Figure 2.3

The boiler must be connected to a 230V ~ 50Hz supply, fused at 5A. All

external controls and wiring must be suitable for mains voltage. Wiring

external tothe boiler must be in accordance with current I.E.E wiring regulations

and local regulations.

Installation & Servicing Instructions

Page : 7

Page 11

WD50/2/1997 Chapter 2 - Boiler Connections The Keston 50, 60 & 80 Condensing Boilers

The method of connection to the mains electricity supply must facilitate

complete electrical isolation of the boiler complying with the requirements of BS

1363.

The appliance must be connected to the supply via a fused double-pole switch,

having at least 3mm (1/8 inch) contact separation in both poles, serving only the

boiler and the system controls.

The connection point to the mains supply should be readily accessible and

adjacent to the boiler, except for rooms containing a bath or a shower. Refer to

section 2.3 Position.

2.4.2 External Wiring & Controls

1. The boiler is deisgned so that all control wiring is external to the boiler.

Hence, any programmers or room thermostats etc must act by switching

the 230V supply to the boiler.

2. System designs which allow the boiler to fire when there is no pumped

circulation must NOT be used.

3. A programmer may be used with zone valves to give independent

control of central heating and hot water.

2.5 BOILER SIZE SELECTION

The size of the boiler to be used is determined by the total calculated heat loss of the

building. Match the calculated heat loss with the boilers rated output. If a boiler is

installed with an output rating greatly exceeding the total capacity of the distribution

system the efficiency of the boiler will be reduced. If the boiler is to be used to heat

domestic hot water no additional capacity is normally needed for the average residential

installation since there is usually some excess capacity in the boiler as water heating is

an intermittent load.

2.6 GAS SUPPLY

A gas meter should be connected to the service pipe by the local gas supplier or their

contractor. An existing meter should be checked preferably by the gas region to ensure

that the meter is adequate to deal with the rate of gas supply required. Installation pipes

should be fitted in accordance with BS 6891.

Minimum/Maximum Natural Gas Pressure:

Natural gas pressure before the gas valve must be maintained at 20 mbar (8 in w.g)

while the boiler is running.

Gas pressures above or below this level will lead to problems associated with the gas

valve's internal pressure regulator.

Minimum/Maximum L P Gas Pressure:

LPG pressure must be maintained between 31.5 mbar (12.4 in w.g) and 37.6 mbar (14.8

in w.g) while the boiler is running

Gas pressures above or below these levels will lead to problems associated with the gas

valve's internal pressure regulator.

.

Supply pipes to the boiler must not be sized less than the boiler inlet connection (15 mm)

Due consideration must be given to the supply pressure to other gas appliances in the

premises.

Installation & Servicing Instructions

Page : 8

Page 12

WD50/2/1997 Chapter 2 - Boiler Connections The Keston 50, 60 & 80 Condensing Boilers

A gas cock is supplied loose with the boiler. This cock should be fitted in the gas line to

the boiler as close to the boiler as possible so that it is easily identified as the cock to

isolate the boiler.

2.7 WATER SYSTEMS

All piping must be installed in accordance with all applicable local and Water Supply

Bylaws for forced hot water heating systems.

Consideration must be given to pipe capabilities and pressure drop through the piping.

Water treatment must be carried out to BS 7593 : Treament of Water in Hot Water

Central Heating Systems.

Pump isolating valves must be positioned as close to the pump as possible.

a The Keston is suitable for use on open, vented water systems with combined feed

and vent.

b It is preferable for use on sealed water systems, provided the appropriate

components required (see Section 2.7.2 Sealed Systems) are included in the

system.

c Any system must

connection with the boiler. A trap may be installed in the flow line to collect any

solder, or other debris, from the installation.

d All water systems must be constructed to comply with requirements of the Local

Water Authority.

e Only fully pumped systems can be used - gravity systems are strictly

suitable.

f Always use a system complying with the requirements of BS 5449 and BS 6798.

g The system must be so arranged that there shall always be a minimum flow of 4.2

gpm (19 litres/min) [Keston 50], 5 gpm (23 litres/min) [Keston 60] or 6.7 gpm

(30.5 litres/min) [Keston 80] when the boiler is firing. This can be via a specially

installed by-pass arrangement.

h Copper tubing to BS 2871 Part 1 is recommended.

i Jointing should be either with capillary or compression fittings. Pipes should have

a gradient to ensure air is passed easily to vent points and water flows readily to

drain points.

j Draining taps must be located in accessible positions which permit the draining of

the boiler and hot water storage vessel. Draining taps should be at least 15

mm in nominal size and be in accordance with BS 2879.

AIR VENT POINTS

k These must be fitted at all high points where air may collect.

be thoroughly flushed clean of grease, dirt and debris, prior to

not

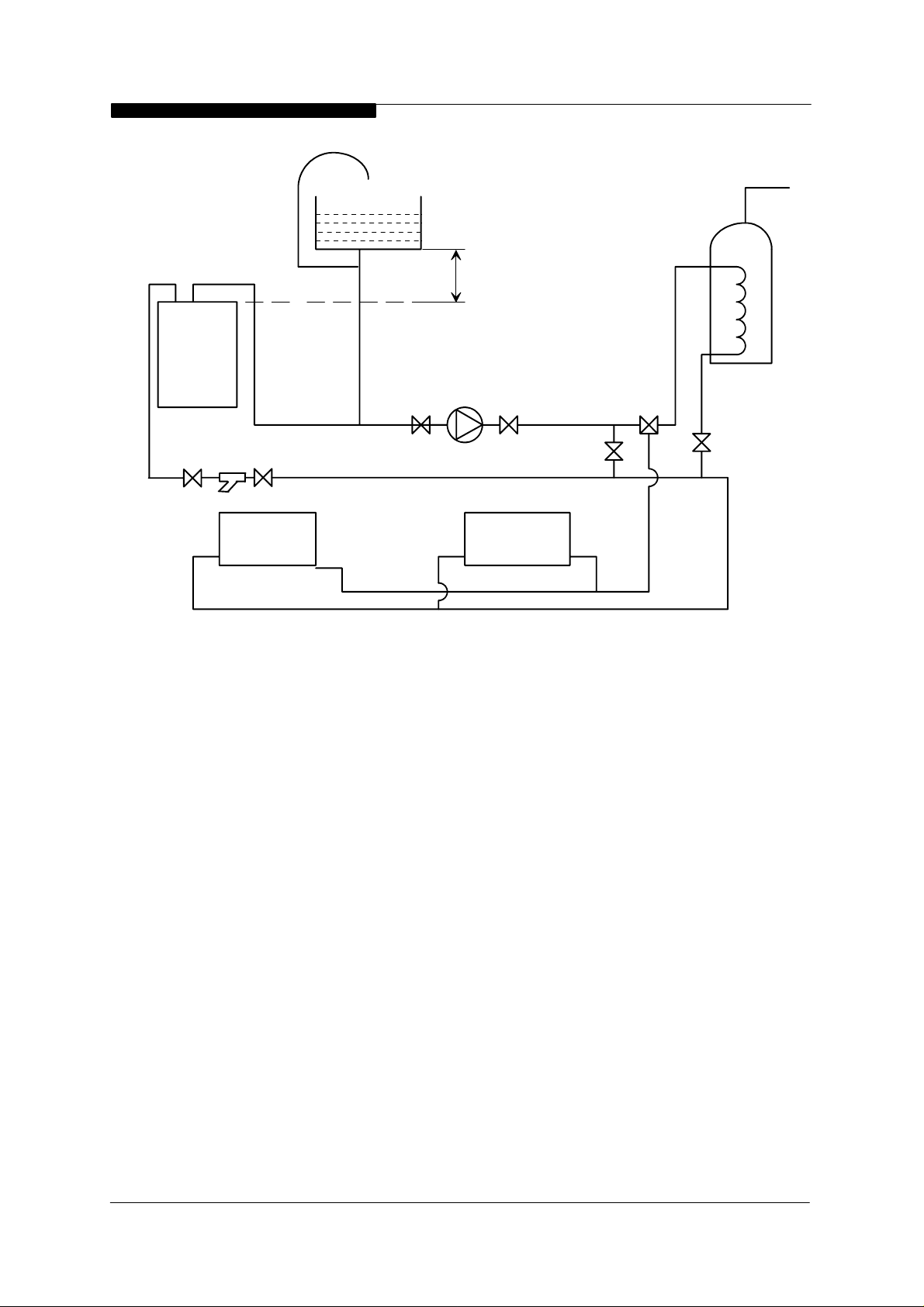

2.7.1 Open Vented Systems

A typical system is shown in Figure 2.7.1 which includes a combined feed and

vent. Note there must be no valve between the boiler flow and the open vent.

Note that the minimum static head required is 8 ft at the boiler flow pipe. If the

cold feed/vent is not brought to the flow pipe as shown, then the pressure loss

across the heat exchanger may have to be taken into account when estimating

the static pressure.

Although suitable for open vented systems with combined feed and vent

arrangements, the Keston is a low water content boiler. As such, any air

entrainement within the system water will produce boiler "kettling". It is

therefore recommended, if in any doubt, to consider the use of sealed

systems where possible.

Installation & Servicing Instructions

Page : 9

Page 13

WD50/2/1997 Chapter 2 - Boiler Connections The Keston 50, 60 & 80 Condensing Boilers

Boiler

Expansion

Pipe

22mm pipe

(minimum)

Keston

Strainer

Rad. 2 Rad. 1

Expansion

Tank

Pump

Minimum

8ft Height

By-pass

Bal.

Valve

3 Way

Valve

Cylinder

L/S

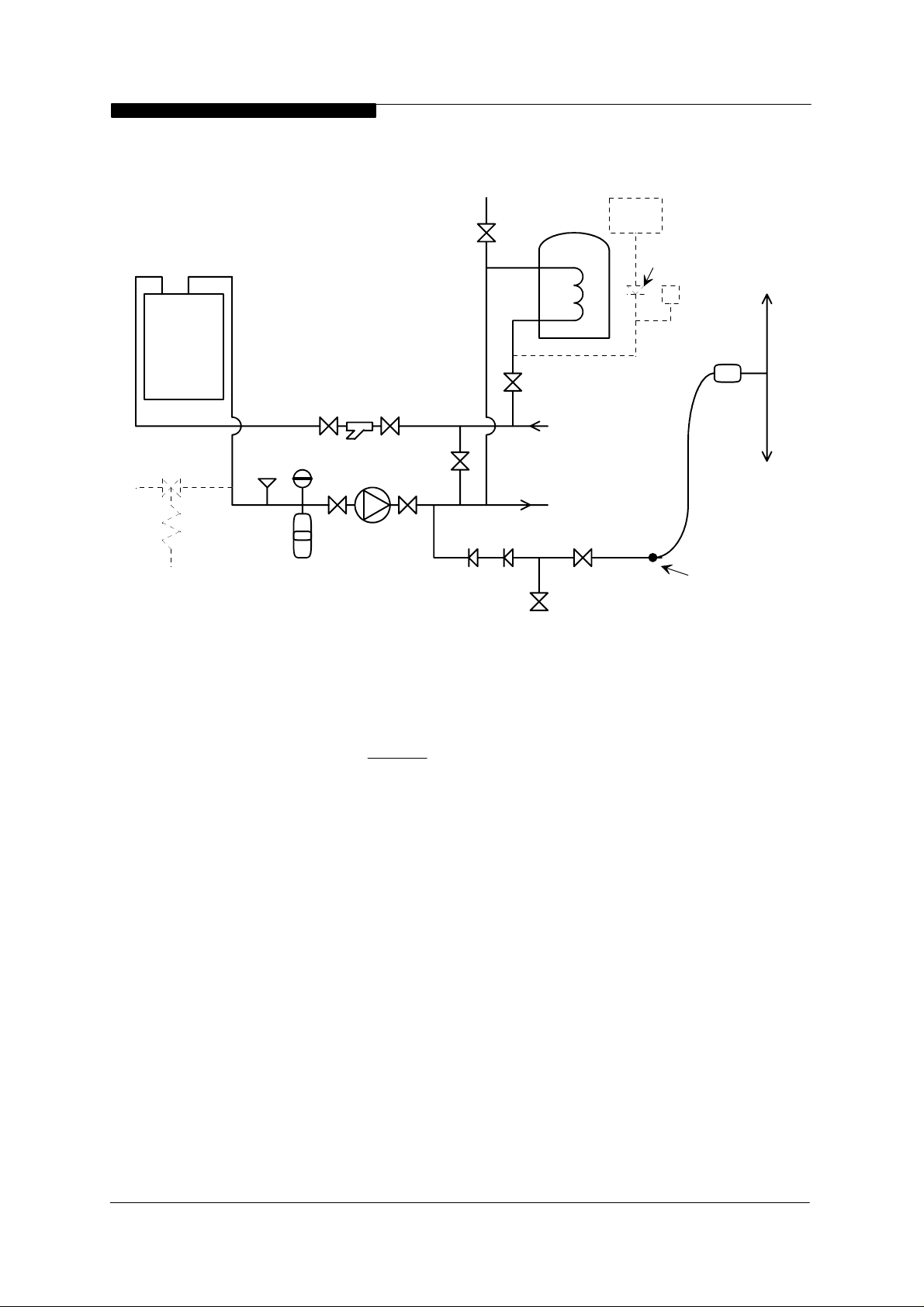

2.7.2 Sealed Systems

Sealed systems must be designed in accordance with BS 5449 and BS 7074 Pt1.

A typical sealed system is shown in Figure 2.7.2. It must include :

(i) A safety valve fitted on the flow, adjacent to the boiler. It must be non

adjustable and preset to 3 bar. A drain pipe must be attached, at least as

big as the valve connection, and routed to drain in any area not

hazardous nor where it may be subject to freezing.

(ii) An expansion vessel complying with BS 4814 and sized in accordance

with the requirements of BS 5449 and BS 7074 Pt 1. The vessel must be

positioned on the inlet to the pump.

(iii) A filling point, in accordance with local water authority requirements.

(iv) A method of system make-up (automatic or manual), in accordance with

local water authority requirements.

(v) There must be no permanent connection of mains water to the boiler

system.

(vi) The installation must be designed to work with flow temperatures of up to

110

o

C.

All components of the system including the heat exchanger of the indirect

cylinder must be suitable for a working pressure of 3 bar and a temperature of

o

C. Care should be taken in making all connections that the risk of leakage is

110

minimised.

Figure2.7.1 : Open Vented System Diagram

Installation & Servicing Instructions

Page : 10

Page 14

WD50/2/1997 Chapter 2 - Boiler Connections The Keston 50, 60 & 80 Condensing Boilers

Make -up vessel.

Max. capacity of

Air Vent

3 lt. (5pt)

Boiler

Keston

Drain

Cock

Safety

Relief

Valve

Pressure

Gauge

Expansion

Vessel

Strainer

By-pass

Bal.

Valve

Pump

Doubl e Check

Valve

Test Cock

Figure 2.7.2 : Sealed System Diagram

L/S

RETURN

HEATING CIRCUIT

FLOW

BS 1010:2

Stop T ap

Non-Return

Valve

Auto Air

Vent

Hose

Union

bib tap

Hosepipe

(disconnected

after filling)

Hose

Connector

2.7.3 Hot Water System (if applicable)

The hot water storage vessel must be of the indirect type (certain direct cylinders

can be used provided

they are suitably adapted by fitting an immersion

calorifier). DIRECT CYLINDERS MUST NOT BE USED. Further guidance is

provided in BS 1394. It is advisable to fit a lockshield valve on the cylinder return

to enable balancing of flow rate through the cylinder.

2.7.4 Boiler By-pass Piping

Boiler water flows are critical to the operation of the boiler. If flow cannot be

maintained through the system piping to meet the minimums required by the

boiler (see paragraph 2.7 (g)). Insufficient water flows through the boiler will cause

the boiler to "kettle" or even produce steam which can damage the heat

exchanger and will invalidate the heat exchanger warranty.

It is normally advisable to incorporate a boiler by-pass in the system, especially if

thermostatic radiator valves are used. The by-pass should be fitted with a

lockshield valve to permit balancing of the by-pass flow rate. The flow/return

differential should be 10

o

C to 15oC. The lockshield valve can be adjusted to

maintain this condition with the radiators fully heated.

Installation & Servicing Instructions

Page : 11

Page 15

WD50/2/1997 Chapter 2 - Boiler Connections The Keston 50, 60 & 80 Condensing Boilers

2.7.5 Air Elimination

In the initial charge of water to the boiler system and in all subsequent additions

of water to the system some air will be dissolved in the water. As the water is

heated the air is driven out of the solution and will collect in high spots in the

system. These air bubbles can interfere with pumping and heat transfer and

must be eliminated.

Installation of air bleed valves at the high spot(s) in the system will allow for air

elimination when filling the system and will allow re-venting in a day or so after all

air has been driven out of solution.

Installation of an automatic air vent will ensure that any air, even minute

amounts, which subsequently enters the system will be automatically removed.

2.7.6 Strainers

Debris in the heating system

can cause noise if it enters the

heat exchanger. Fitting of a

Y-strainer ahead of the

circulating pump will trap any

debris left in the system and

will protect the pump from

damage.

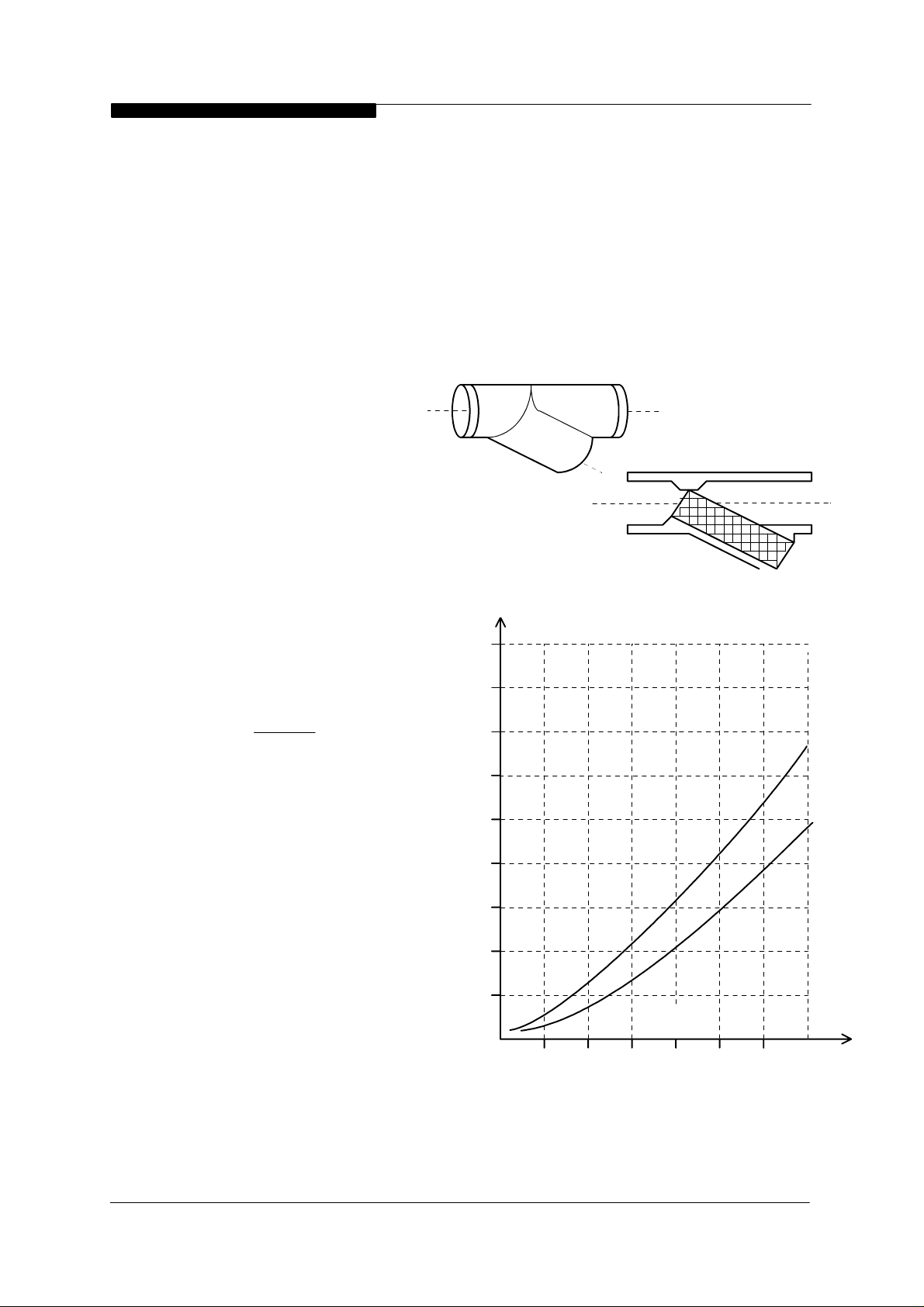

2.7.7 Pump Selection

The Keston boilers have low

water content heat exchangers

with a high resistance to flow,

when compared with cast iron

heat exchanger boilers. As a

result selection of the correct

pump is essential

avoid localised boiling within

the heat exchanger. The

selected pump must be

capable of maintaining the

required flow rate for the boiler

against the pressure losses

contributed by the boiler and

the rest of the system.

Refer to the pressure loss/flow

rate Table 2.7.7 to determine

the pressure loss from the

boilers. Add this to the

pressure loss caused by the

rest of the system and select a

pump capable of meeting the

flow rate required at the total

pressure loss generated by the

boiler and the rest of the

system. The selected pump

must comply with BS 1394.

in order to

Y-Strainer will

collect an y loose

debris in the piping.

4.5

4.0

3.5

3.0

2.5

2.0

Pressure Loss - m

1.5

1.0

0.5

Figure 2.7.7 : Pressure Loss Graph

10 15 20 25 30

5

Water Flow - L/min

Figure 2.7.6 Strainers

Keston 80

Keston 50

Keston 60

35

Installation & Servicing Instructions

Page : 12

Page 16

WD50/2/1997 Chapter 2 - Boiler Connections The Keston 50, 60 & 80 Condensing Boilers

It is important to note that the minimum flow rate must be maintained whenever the

boiler is firing. Systems using zone valves must be specifically designed to only fire the

boiler when the pump is running and the minimum flow rate can be achieved.

The Wilo Salmson Gold Star pump, or the Grundfoss 15/60 pump is normally suitable for

use with the Keston condensing boiler range. However, in all cases due consideration

must be given to the resistance to flow offered by the rest of the system when making a

final pump selection. This is particularly important when using small bore underfloor

heating pipework.

Keston 80Keston 60Keston 50Boiler Model

Min Flow Rate

Required

Pressure Loss

Through

Boiler

4.2 GPM

19.1 litres/min

3.2 ft

0.97m

9.7 kPa

5.0 GPM

22.7 litres/min

4.3 ft

1.3m

13 kPa

6.7 GPM

30.5 litres/min

9.0 ft

2.75m

27.5 kPa

Table 2.7.7 Pump Selection

2.8 FLUE SYSTEM

2.8.1 Design

Individual air supply and flue outlet pipes are used. The material used for flue

outlet &/or air inlet must be muPVC to BS 5255 and of an internal diameter of 38

mm.

Both flue outlet terminal and air inlet terminal are supplied and are illustrated in

Figure 2.8.1.

2.8.2 Maximum Lengths

The maximum lengths of both air inlet pipe and flue outlet pipe, when no bends

are used, are as detailed below.

Maximum Air Inlet Length : 10.0 m

Maximum Flue Outlet Length : 10.0 m

However, each bend used has an equivalent length that must be deducted from

the maximum straight length stated above.

A 92.5

Example:

o

sweep elbow is equivalent to 1.0m straight length.

Air inlet uses two 92.5o sweep elbows. Hence, maximum length permissible (ie

a+b in figure 2.8.2) = 10.0m - 1.0m - 1.0m = 8.0m

Flue outlet uses one 92.5

c+d in figure 7 = 10.0m - 1.0 m = 9.0m

Installation & Servicing Instructions

Page : 13

o

sweep elbow. Hence, maximum length permissible (ie

Page 17

WD50/2/1997 Chapter 2 - Boiler Connections The Keston 50, 60 & 80 Condensing Boilers

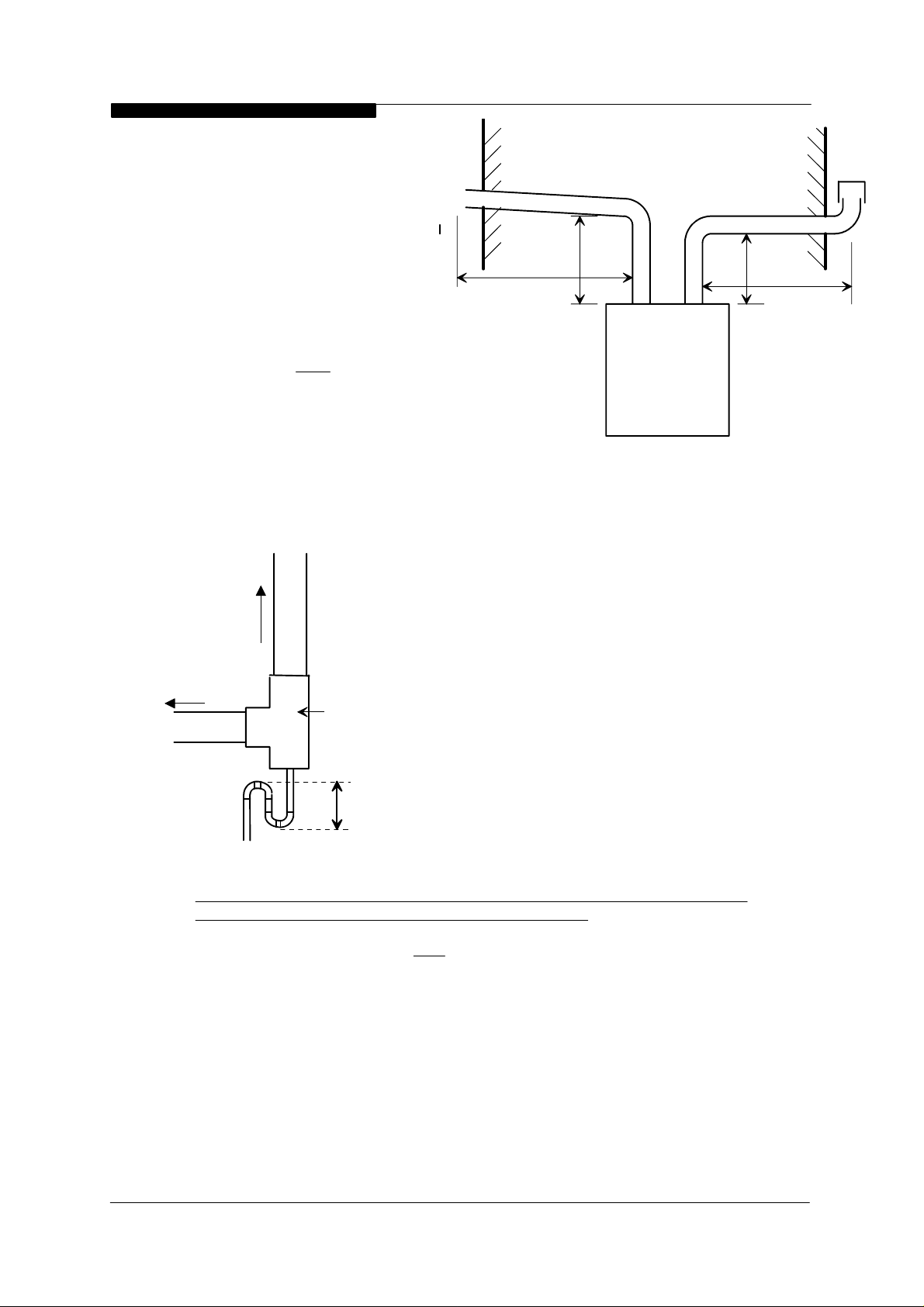

2.8.3 Slope

'Horizontal' flue outlet pipework

MUST slope at least 2.5

FLUE

degrees (45 mm per metre

run) downwards towards the

boiler. Pipework can be

vertical. Only swept elbows can

be used.

c

d

Air inlet pipework can be truly

horizontal or vertical, or

sloping in a downward direction

towards the boiler but in this

case rain, etc, must

be

prevented from entering the

pipe. There must be no

troughs in any of the

pipework, whether it be air

inlet or flue outlet. If a 45

Figure 2.8.2 : Flue & Air Maximum Length Example

Keston

mm per meter slope is not

possible, contact Keston Boilers Technical Department for further guidance.

Due the low temperature of

the flue gases further condensate

will form within the flue system. Drain

Figure 2.8.3 :

Flue Condensate Drain

Point Example

points, with suitable traps, must

therefore be incorporated within the

flue system at the base of vertical

flue sections in excess of 2m. These

additional condensate drains must

To Termina l

be run to discharge as detailed in

section 2.11. Such drain points can

To Boiler

40mm Tee Fitting

be formed using standard muPVC

fittings. Refer to the example in

Figure 2.8.3.

AIR

b

a

6 in min.

2.8.4 Terminations

It is not advisable to terminate air

intake or flue within a car port area.

Air inlet terminals must be facing upwards and positioned to ensure only fresh air

is drawn into the boiler directly from outside the property.

The flue outlet terminal is designed to face outwards but can, if desired, be

adapted to face in any direction BUT

must not be directed in the region of the air

inlet.

The two terminals are subject to the requirements of BS 5440 Pt 1 for clearances

from features of the building although some can be decreased to the values

indicated. If either the air inlet or the flue outlet terminate at a height of less than

2m (6ft) above ground level the termination must be protected by a suitable

guard. The K4 terminal guard, manufactured by Tower Flue Components Ltd, is

suitable for this purpose and can be obtained from Keston Boilers.

The Keston Condensing Boiler, as with any condensing boiler, will generate a

condensate "plume" from the flue terminal in all weather conditions.

Consideration must therefore be given to the effect of this "plume" when

selecting a location for the flue terminal.

Installation & Servicing Instructions

Page : 14

Page 18

WD50/2/1997 Chapter 2 - Boiler Connections The Keston 50, 60 & 80 Condensing Boilers

g

O43

36

70

65

Flue Outlet Terminal

Fi

ure 2.8.1 : Terminals

It is advisable for horizontal flue terminals to place a 45o elbow at the end of the

flue to direct the condensate plume up and away from the property.

Dimensions (mm)

170

O67

O43

Air Intake Terminal

Flue

Terminal

Air

Inlet

50300A Below openable window, air brick, etc.

7575B Below gutters, soil pipes, drain pipes.

50300C Below eaves.

50200D Below balconies.

5075E From vertical drain or soil pipes.

50600F From internal or external corner.

100300G Above ground or balcony or roof.

100600H From surface facing a terminal

1.21.2I From terminal facing a terminal.

1001.2J From opening in a car port.

1.51.5K Vertically from terminal on same wall.

300300L Horizontally from terminal on same wall.

Table 2.8.4 Minimum Flue Terminations & Air Inlet Dimensions

2.8.5 Clearances From Wall

Flue outlet and air inlet termination must be at least 60 mm and 95 mm

respectively from the wall face.

2.8.6 Distance Between Flue Outlet & Air Inlet

There is no maximum - the terminations can be on opposite sides of the dwelling

if desired.

Installation & Servicing Instructions

Page : 15

Page 19

WD50/2/1997 Chapter 2 - Boiler Connections The Keston 50, 60 & 80 Condensing Boilers

A minimum clearance of at least 350 mm must be left between the terminations.

2.8.7 General Installations

All parts of the system must be constructed in accordance with BS 5440 Part 1,

except where specifically mentioned in these instructions.

All pipework must be adequately supported.

All joints other than push-on or plastic compression connectors must be made

and sealed

with solvent cement suitable for muPVC pipes and conforming to BS

6209: 1982.

External wall faces and any internal faces of cavity walls must be made good.

2.9 AIR SUPPLY

The Keston is a room sealed appliance and therefore does not require purpose provided

ventilation for combustion air.

2.10 COMPARTMENT INSTALLATION

Where the appliance is installed in a cupboard or compartment, no air vents are

required. The boiler will run sufficiently cool without ventilation.

2.11 CONDENSATE DRAINAGE

Being a condensing boiler, the Keston is fitted with a condensate trap at the base of the

heat exchanger and flue assembly, with facility to connect to a drain point underneath the

appliance.

Use only plastic piping and do not reduce below 22mm internal diameter within the

dwelling. Condensate should preferably be drained into the house sanitary waste system

or, alternatively, the rainwater system. Termination of the pipe must be either at a branch

or stack internal to the house, or externally at an open gully. Alternatively, discharge into

a purpose made condensate soakaway can be considered. Existing or purpose built

drains must use suitable corrosion resistant material as condensate is mildly acidic.

A minimum slope downwards towards the drain of 2.5

Freezing of the termination and pipework must be prevented. Any drainage pipes outside

the house must be at least 32 mm inside diameter.

Further guidance is given in the British Gas Publication 'Guidance Notes for the

Installation of Domestic Gas Condensing Boilers'.

2.12 RADIANT FLOOR HEATING

This type of heat distribution creates an exceptionally evenly heated environment and

since it is hidden beneath the finished flooring does not interfere with furniture

placement. The homeowner has complete freedom to decorate without having to

contend with any heating equipment visible in the homes interior. The low operating

temperatures of this type of system lead to very good operating efficiencies. In fact,

under floor heating can produce in excess of 95% operating efficiency from a Keston

condensing boiler. Water temperatures in radiant floor heating systems must be kept

relatively low, generally under 48

to the touch. If radiant heating is only one application for a multi-zone system which also

requires higher delivery water temperatures for other zones (i.e. water heating, skirting

heaters etc.) then the radiant floor zone temperature will need to be controlled separately

from the boiler.

o

(45mm fall in 1m) is essential.

o

C, so that surfaces do not become uncomfortably warm

If radiant floor heating is the only application of the boiler, the boilers temperature limits

can be lowered accordingly by introducing an external thermostat control mounted on the

return pipework into the boiler. This thermostat can then be used to interrupt power

Installation & Servicing Instructions

Page : 16

Page 20

WD50/2/1997 Chapter 2 - Boiler Connections The Keston 50, 60 & 80 Condensing Boilers

supply to the boiler when the required temperature is reached. Mixing valves are also

available which will mix return water from the system with boiler output water to dilute the

temperature of water transmitted to the distribution system. Mixing valves may create

problems with low flow and high temperatures through the boiler unless care is taken to

design a system which will provide proper flows and will fully load the boiler. Keeping the

boiler's temperature high will prevent the boiler from operating at peak efficiencies.

Systems which maintain boiler temperatures in this way should be avoided.

If only a portion of the boiler's available output is to be used for radiant floor heating a

thermal storage tank will improve the boiler's operation and give adequate control of

temperature for the distribution system. By heating water to be distributed to the radiant

floor zone to the proper temperature in an indirect-fired water heater, full load conditions

will be available to the boiler because the heat exchanger in the tank can be sized to

match the boiler's output. The tank's thermostat can be set at the optimum operating

temperature needed by the distribution system and short-cycling of the boiler will be

prevented. In such insulations it is advisable to calibrate the thermal store's operating

thermostat to become the controlling thermostat of the boiler, ie the thermal store

operating thermostat is always activated to shut off the boiler before the boilers own

thermostat is activated. An insulated thermal storage tank without the heat exchanger may

also be used.

2.13 LOW WATER VOLUME BOILER VS. CAST IRON BOILER

Because of their high water content and mass of metal, cast iron and steel boilers are less

responsive but somewhat more forgiving of design errors. Short-cycling of the

burner on the temperature limit control is less pronounced, though no less detrimental to

operation, because the boiler itself will absorb and radiate a significant amount of heat.

Low water volume boilers respond more quickly to a call for heat, can be made more

compact and lightweight, but must have adequate heat delivery systems to avoid

short-cycling of the burner on the temperature limit control. The heat delivery system's

output must be equal to or greater than the boiler's output to fully load the boiler or

short-cycling will occur.

Likewise, pumping rates of water through low water volume boilers must be maintained so

that water is moved through the boiler fast enough so as not to reach boiling

temperatures. The slower the water moves through the boiler the more heat it will absorb

and the higher the temperatures will rise. Consequently, the pump selected must be

adequate to maintain that critical flow of water.

2.14 DETERMINE RADIATION NEEDED ROOM-BY-ROOM

A radiator or convector's ability to deliver heat is related to the water temperature and the

rate of delivery to the unit. Most systems in the past have been rated at about 80

Higher efficiencies can be gained from a condensing boiler if ratings published at lower

temperatures are used. However, this is not imperative. With normal 80

condensing boiler will still deliver significantly higher efficencies than a non-condensing

boiler. Lower water temperatures in the system tend to increase the efficiency of the

boiler and will help assure that the boiler is subjected to a sufficient load to avoid

short-cycling.

o

C.

o

C ratings used a

The Keston boilers are capable of temperatures of up to 80

temperature of the return water, the lower the efficiency of the system. This is true of all

boilers, though all non-condensing boiler must be kept at higher temperatures to avoid

condensation in the boiler which destroys such boilers quickly. Materials used in the

Keston are made to withstand the condensates corrosive nature.

Installation & Servicing Instructions

Page : 17

o

C but the higher the

Page 21

WD50/2/1997 Chapter 3 : Installation The Keston 50, 60 & 80 Condensing Boilers

3. INSTALLATION OF THE BOILER

Read Chapter 2 - Boiler Location and decide upon the position of the boiler.

Installation of the boiler is straightf orward but consideration m ust be given to access to allow f lue

and air pipes to be pushed through walls and ceilings. The order in which the components are

installed will depend upon particular site conditions, but in general it will be easiest and most

accurate to install the boiler and then build up the flue outlet and air inlet pipes to the terminal this is the sequence described.

3.1 WALL MOUNTING BRACKET

a Place the bracket on the wall

horizontally with the pre-drilled

holes at the bottom.

b Drill through the centre hole of

the bracket, plug the hole and

fix in position.

c Using a spirit level make sure

the bracket is completely level

and mark the position of the

other screw holes.

d Remove the bracket and drill the

holes in the positions marked.

Plug these holes.

e Screw the bracket to the wall

using screws of an appropriate

size for the wall type (No. 12 x 2

inch wood screws normally

suffice).

f Mark the bottom fixing hole and

drill for a No 8 x 1 inch wood

screw. Insert plug.

All dimensions in mm.

110

285

250

Figure 3.1 Wall Mounting Fixing Locations

3.2 MOUNTING THE BOILER

a Lift and locate the upper rear lip on the boiler to the boiler wall bracket.

b Move the boiler sideways to centralise the boiler on the bracket.

c Screw in the lower fixing screw.

3.3 ASSEMBLY PRACTICE

Remove all plastic debris and burrs when installing air intake piping. Plastic filings

caused by cutting muPVC pipe must not be allowed to be drawn into the filter or

combustion air blower. Prevent dust entering the air intake when cutting on building sites.

Blower failure which is determined to be caused by plastic filings or other debris will not

be covered by guarantee.

Installation & Servicing Instructions

Page : 18

Page 22

WD50/2/1997 Chapter 3 : Installation The Keston 50, 60 & 80 Condensing Boilers

Combustion air filters are fitted to the Keston condensing boilers as standard. This

filter must be examined at least once every year, and more often in particularly

dusty and dirty areas.

The combustion air filter will prevent plugging of the burner caused by dirt being trapped

in the burner's outer mesh. The filter element supplied with the boiler is obtainable from

Keston Boilers or its distributors.

3.4 INSTALLING FLUE AND AIR PIPES

Remember the flue pipe must

achieved using 92.5

o

bends.

slope downwards back towards the boiler and this is best

a From the two connections on the boiler, mark the positions of the two holes for

the flue and air pipes on the wall(s) or ceiling. To allow access to drill the holes it

may be necessary to temporarily remove the boiler. If the boiler stays put then it

is imperative that the front panel and top access plate are replaced and the two

plastic pipes capped off whilst drilling. Under no circumstances must debris from

the wall or cut pipes be allowed to enter the appliance or the plastic pipework.

b Drill the two holes in the wall/ceiling, preferably using a core drill.

3.4.1 Diameter of holes.

i) Allowance must be made for

socketed lengths if these are

to be passed through the

holes :

du = unsocketted

T

d

D

diameter

= 43 mm

ds = socketed

diameter

= 50 mm

L

u

T

ii) For 'horizontal' runs of flue

pipe the holes must either be

oversized or cut at a 5

(the latter may be difficult on

long holes).

3.4.2 Oversizing

For every 1m length of run, L, the minimum diameter of the horizontal hole, D,

must be du + 10 mm or ds + 10 mm respectively, assuming the pipe touches the

wall at points T otherwise D will have to be increased by clearance from T. See

Section 3.4.3 - Examples.

3.4.3 Examples

a. Wall Depth L = 750 mm

Unsocketted pipe du = 43 mm

Diameter hole D = 43+{(

Installation & Servicing Instructions

Page : 19

o

slope

Flue Pipe

750

= 43+7.5

= 50.5 mm

/

1000

d

)X10}

s

Page 23

WD50/2/1997 Chapter 3 : Installation The Keston 50, 60 & 80 Condensing Boilers

b. Wall depth L = 2.3 m

Socketed Pipe ds = 50 mm

Diameter Hole D = 50+{2.3x10}

= 50+23

= 73 mm

c. Measure, cut and check the air and flue pipes to pass to the exit from the

wall(s) or ceiling.

Always thoroughly deburr all pipes and, most important, remove shavings from

within the pipe.

d. Assemble, using adhesive, the pipework from the boiler connections to

the exit from the first wall/ceiling (remount the boiler if removed). When

pushing pipe through walls, ensure grit and dust is not allowed to enter

the pipe.

Ensure pipes are fully engaged into

sockets.

Connect the condensate drainage

system and fill the condensate trap by

pouring water down the boiler flue

spigot ( See Section 3.5 Condensate

Drainage).

Make the final connection of flue

and air pipe to the boiler using push

on, or plastic compression

couplings. Ensure that the connectors

are set vertically otherwise leakage of

condensate may occur which will corrode the casing. Do not use

adhesive on the 'push on' end of the connecting couplings.

Adhesive

Fully Engaged

FA

e. Using the same methods drill any further holes (always covering existing

pipework), cut and assemble the pipework.

f. From outside, complete the two terminations - See Section 2.8 Flue

System and make good all holes.

g. Support any pipes whose route could be displaced either of its own

accord or by accident. Any horizontal run over 1m or vertical runs of any

length must always be supported.

h. Check all connections for security and re-seal any joints using sovent

cement where soundness may be in doubt.

Note: It is equally important to seal the air inlet with solvent cement as

the flue outlet pipe joints.

3.5 CONDENSATE DRAINAGE

Connect the condensate drainage system to the boiler. It is advisable to use a

detachable fitting at connection to the boiler to enable easy removal for servicing.

Fill the condensate trap by pouring water into the boiler flue spigot until water is seen to

flow freely from the condensate drainage system. Make the final connection of flue pipe to

the boiler.

Details are provided in Chapter 2 - Section 2.11 Condensate Drainage

Connection : 22 mm plastic pipe.

Installation & Servicing Instructions

Page : 20

Page 24

WD50/2/1997 Chapter 3 : Installation The Keston 50, 60 & 80 Condensing Boilers

3.6 WATER SYSTEM

Connect the flow and return pipework to the boiler. Ensure a detachable coupling is used

at connection to the boiler (ie compression fitting) to enable heat exchanger removal if

required. Details of system requirements are given in Chapter 2 - Section 2.7 Water

Systems.

Connections : 28mm copper

3.7 GAS SUPPLY

Connect the gas supply to the appliance. Details of gas supply requirements are given in

Chapter 2 - Section 2.6 Gas Supply.

Connections : 0.5 inch BSP male. (15mm connection to gas cock).

3.8 ELECTRICAL SUPPLY

The entry point for the electrical supply cable is in the base of the appliance (see Section

2.2 Service Connections fig. 2.1.2) via a cordgrip bush. Feed the cable through this bush

and route inside the cabinet to the connection strip located to the front bottom right of the

cabinet.

1. The electrical supply must be as specified in Chapter 2 - Section 2.4 Electrical

Supply.

WARNING : THIS APPLIANCE MUST BE EARTHED.

2. All external controls and wiring must be suitable for mains voltage. Wiring should

be in 3 core PVC insulated cable not less than 24/0.2 mm (0.75mm) to BS 6500

Table 16.

3. The supply connection must be via a 5 amp fused double pole switch, serving

only the boiler and system controls. (Refer to Chapter 2 - Section 2.4 Electrical

Supply).

4. Securely tighten the terminal screws and route the cable through the re-openable

cable clips. Ensure all cables are secured and that the cord grip bush is tightened

to securely grip the main cable at entry to the cabinet.

The mains cable must be connected to the terminals as follows:-

N - Blue wire (Neutral)

L - Brown wire (Live)

- Yellow/Green Wire (Earth)

Ensure connection is made such that if the cable slips in its anchorage the current

carrying conductors become taut before the earthing conductor.

3.9 EXCHANGING A BOILER

Before removing an existing boiler add Fernox Supafloc , or equivalent cleaning agent,

in accordance with the manufacturers instructions. Open all radiator valves and fire the

boiler. When the system is fully heated, shut off the gas supply and drain down the central

heating system.

Installation & Servicing Instructions

Page : 21

Page 25

WD50/2/1997 Chapter 3 : Installation The Keston 50, 60 & 80 Condensing Boilers

Important

The Keston condensing boiler contains components which could be damaged or

blocked by grease, dirt or solder etc. It is essential that sludge or scale is removed

from an existing system.

Connect the new boiler as instructed in this manual and fit in accordance with Sections

3.1 to 3.8

For sealed systems, fill to a pressure of about 2.7 bar. Check the complete system for

water soundness. If leaks need to be rectified using flux or solder the system must be

flushed cold again before proceeding.

Reduce the pressure to the Initial System Design Pressure for sealed systems, if

applicable. Vent the system.

Gas Supply

The complete gas installation up to the boiler service cock must be checked for

soundness. BS 6891.

Electrical Installation

Carry out preliminary electrical safety checks, i.e. Earth continuity, Polarity, Resistance

to Earth, Short Circuit using a suitable test meter.

Initial Firing

Checking The Gas Pressure At The Burner Pressure Test Nipple

The gas burner pressure must be checked at the burner pressure test nipple (Figure 5.7.3

item 54). Full details of this procedure

are given in Section 4.7 Checking The

Gas Pressure.

The gas pressure setting is factory

adjusted to within the required range

and should not normally need

re-adjustment. If the reading is incorrect

then check such factors as soundness of

the air and flue pipe joints, pressure

sensible joints and the gas inlet pressure

(20 mbar required). If all joints are sound

and the gas inlet pressure is satisfactory

set the gas pressure to the required

pressure.

Burner pressure

Adjustment

Burner pressure

test nipple.

GAS VALVE

Installation & Servicing Instructions

Page : 22

Page 26

WD50/0/1996 Chapter 4 : Commissioning The Keston 50, 60 & 80 Condensing Boilers

4. COMMISSIONING OF THE BOILER

Important:

This condensing boiler c ontains components which could be dam aged or block ed by grease, dirt,

solder etc., from the water system. The following commissioning procedures must be followed

precisely.

4.1 INITIAL FLUSHING

All waterways within the Keston are either copper or high alloy stainless steel. As a result

standard water treatment chemicals for conventional central heating boilers are suitable.

In any event reference must be made to BS 7593 : Treatment Of Water In Hot Water

Central Heating Systems.

a. Disconnect the boiler from the system at the flow and return connections and

temporarily

b. Flush the entire system until clean water is discharged, free from dirt, flux, solder

etc. The use of a flushing chemical is recommended, e.g. Fernox Supafloc.

Sludge and scale must be removed from an existing system.

c. Connect the system to the boiler and fill in accordance with Section 2.7 - Water

Systems. At this stage, for sealed systems, fill to a pressure of about 2.7 bar.

link the flow and return pipes on the system.

d. Check the complete system for water soundness. If leaks need to be rectified

using flux and solder, the system must be flushed cold again before proceeding.

e. Reduce the pressure to the Initial System Design Pressure for sealed systems, if

applicable. Vent the system

4.2 GAS SUPPLY

The complete gas installation up to the boiler service cock must be checked for

soundness. BS 6891.

4.3 ELECTRICAL INSTALLATION

Carry out preliminary electrical safety checks, i.e. Earth continuity, Polarity, Resistance to

Earth, Short Circuit using a suitable test meter.

4.4 LP GAS CONVERSION

All Keston condensing boilers are built and shipped as natural gas fired units. Field

conversion kits are available to convert Keston condensing boilers to use LPG. Suitable

instructions are supplied with the LPG field conversion kits.

4.5 INITIAL FIRING

Important

Checking the gas pressure to the pre-mix burner requires a special procedure, outlined

below, which must be carried out.

a. Purge the gas supply in accordance with BS 6891.

b. Turn the gas service cock OFF.

c. Loosen the screw in the burner pressure test point (Figure 5.7.3 item 106A) on

the gas valve and attach a suitable gauge.

Installation & Servicing Instructions

Page : 23

Page 27

WD50/0/1996 Chapter 4 : Commissioning The Keston 50, 60 & 80 Condensing Boilers

d. Turn on the electrical supply, setting any external controls to call for heat.

e. ON/OFF switch - select 'ON'. The amber 'run' light will illuminate on the ON/OFF

switch, the red 'lockout' light will illuminate, the blower and pump will start and,

after about 15 seconds, a spark will attempt to light gas at the burner. With the

gas service cock off, the boiler will go to lockout - red light illuminated, but the

blower and pump will continue to run. At intervals of approximately 1 minute the

boiler will make two further attempts to fire. After the final attempt the blower will

run for a further 20 seconds before shutting down.

f. Vent the water system.

Important:

Keston heat exchanger consists of a single coil which can trap an air pocket.

The

Great care must be taken to ensure that water flow has been established through

the heat exchanger and thus ensuring no air pockets remain in the heat

exchanger and pipe work. Firing the boiler while an air pocket exists in the heat

exchanger could damage it.

g. Note the reading on the pressure gauge caused by the suction of the blower. This

should be approximately minus 12 mbar for the Keston 80, minus 26 mbar for the

Keston 60 and minus 32mbar for the Keston 50. If it is not, check the system as

follows:

If the negative pressure exceeds the required figure, then it suggests

that there is a possible restriction in the air inlet pipework.

If the negative pressure is less than required figure, then it suggests

that there is a possible restriction in the flue outlet pipework. Note the

exact reading.

h. Turn the gas service cock to ON.

i. Turn off the electricity supply, wait 10 seconds and turn back on. The boiler will

again go through its ignition sequence but this time the main burner will light,

provided all air has been purged from the gas supply to the boiler. When the

burner is lit and the boiler is operating normally the the green (run) lamp, the

upper lamp adjacent to the flame symbol, will also be illuminated indicating

successful ignition.(If it does not, air is indicated - turn off and repeat the

procedure).

If this does not occur, the green (run) lamp, the upper lamp adjacent to the flame

symbol, will be extinguished and, at approximately 1 minute intervals, the

electronic ignition system will make two further attempts to light the burner.

If the ignition is successful and the boiler is operating normally, the green (run)

lamp, the upper lamp adjacent to the flame symbol, and the red (lockout) lamp will

be illuminated simultaneously.

If, after three automatic attempts, the boiler still fails to ignite, the green (run)

lamp, the upper lamp adjacent to the flame symbol, will be extinguished and the

red (lockout) lamp will remain illuminated.

If, after five manual attempts (to allow for purging of any air in the gas line), the

boiler still fails to ignite (indicated by the red (lockout) lamp) refer to Section 5.2 Fault Finding Flow Chart.

j. Check for gas soundness between the gas service cock and connection to the

burner manifold.

Installation & Servicing Instructions

Page : 24

Page 28

WD50/0/1996 Chapter 4 : Commissioning The Keston 50, 60 & 80 Condensing Boilers

Fig 4.7

GAS VALVE

4.6 HOT FLUSHING

a. Allow the system to heat up,

checking for water soundness.

b. Follow instructions provided with

the cleaning agent, ie Fernox

Supafloc. Turn off the boiler and

flush the water system while still

hot. Thoroughly flush the system

with clear water.

c. Refill the system using a quality water treatment such as Fernox MB1 or Fernox

Super Concentrate. If aluminium radiators are used then Fernox Copal should be

used. For sealed systems, fill to the required Initial Design Pressure.

4.7 CHECKING THE GAS PRESSURE

With the boiler running measure the burner pressure at the burner pressure test nipple.

The gas setting is factory adjusted to within the required range and should not normally

need re-adjustment unless the unit has also been converted to LPG as part of the

installation. If the reading is incorrect then check such factors as soundness of the air and

flue pipe joints and the gas inlet pressure (20 mbar required). If all joints are sound and

the gas inlet pressure is satisfactory remove the brass dust cap covering the burner

pressure adjustment screw on the gas valve (See fig. 4.7). Set the gas pressure to the

required value as stated in table 1.4 by turning the exposed burner pressure adjustment

screw (clockwise will increase burner pressure, anti-clockwise will decrease burner

pressure). Replace the brass dust cap to cover the burner pressure adjustment screw.

4.8 TIMING THE GAS METER - NATURAL GAS

Burner pressure

Adjustment

Burner pressure

test nipple.

NB:

Table 4.8 Meter Timings

After the boiler has been started, and with no other appliances using gas, time the gas

meter to be certain that the unit is running at the proper gas input. Determine the cubic

feet of gas passing through the meter and determine the input in Btu per hour. Input must

be within plus or minus 5% of the rated input.

Time, in seconds, the time taken to pass 2 cubic feet of gas through the meter (ie one

revolution of a 2 cu ft dial) or 0.1 cubic metres if the meter is of the new metric digital type.

Refer to table 4.8 to determine the input to the boiler and the time required for 2 ft

Installation & Servicing Instructions

Btu/h Input RequiredModel

1011 btu/h per ft

Page : 25

Seconds For 2 ft

Of Natural Gas

3

Seconds For 0.1 m

Of Natural Gas

3

236.2133.854,400Keston 50

203.9115.563,018Keston 60

152.3686.384,300Keston 80

3

3

(or

Page 29

WD50/0/1996 Chapter 4 : Commissioning The Keston 50, 60 & 80 Condensing Boilers

0.1m3) of natural gas. Adjust the gas valve screw clockwise to increase the input (speed

up the meter) or anticlockwise to decrease the input(slow down the meter) accordingly.

4.9 HANDING OVER TO THE USER

It is important to fully explain the following :

a. Procedure to light and turn off the boiler, including isolation of the electrical supply

if necessary.

b. The function of the lockout feature must be explained :

If the red light only is illuminated for more than four minutes, this means that the

boiler has failed to light. Turn off the electrical supply and wait 20 seconds. Turn

ON again and wait.

i) If lockout recurs immediately then the gas supply should be checked as

ON, otherwise consult a Service Engineer.

ii) If it is not possible to relight, the boiler must be isolated and a Service

Engineer called in to rectify the fault.

c. Advise that a reduction in the water pressure reading on the gauge for sealed

systems indicates a leak which should be rectified before further use.

d. Advise that the appliance should be serviced by a competent person at least once

a year.

e. Advise on frost precautions.

f. Hand over User Instructions.

Installation & Servicing Instructions

Page : 26

Page 30

WD50/2/1997 Chapter 5 : Fault Finding The Keston 50, 60 & 80 Condensing Boilers

5. FAULT FINDING

5.1 ELECTRICAL CONTROL SEQUENCE

When the external controls are calling for heat, power will be fed to the boiler connection

strip at terminals L (Live) and N (Neutral). If the ON/OFF switch is also in the ON position

the boiler ON lamp (amber) will be illuminated. Provided all temperature thermostats and

pressure switches are closed, power will be fed to pin 2 on the control box, initiating the

following sequence.

(1) The boiler lockout lamp (red) will be illuminated

(2) The fan will start.

(3) When the fan reaches running speed, the Air Pressure switch, normally open, will

close which will start the ignition sequence.

(4) After a pre-purge period of about 15 seconds, the gas valve will open to allow gas

to mix with the air at the suction side of the fan and the ignition spark will occur at

the main burner.

(5) When the burner ignites, the flame is detected by the control box through the

combined flame sensor/ignitor and the ignition spark is stopped. Both the lockout

lamp (red) and the boiler run lamp (green), the upper lamp adjacent to the flame

symbol, will be illuminated. The boiler is now in its normal run condition.

(6) The burner will continue to operate until the gas valve interrupts the gas supply.

The gas valve will be closed by the control box if power is interrupted to the boiler

by any external control or the boiler thermostat. If an interruption to the gas supply

causes loss of the flame the control box with pause for approximately 10 seconds

and then attempt to re-ignite the unit. If this attempt fails, ie due to lack of gas

supply, the boiler will make two further attempts to ignite at intervals of

approximately 1 minute and will then go into a lockout state (red lamp illuminated

only). Once gas supply has been resumed the boiler can be reset by turning the

boiler off and then on again via the on/off switch on the boiler control panel.

(7) The boiler can also be shut down by any of the flow limit, flow overheat and the

flue overheat thermostats, gas low pressure switch and by the low water pressure

switch.

In such an event the green (run) lamp, the upper lamp adjacent to the flame

symbol, will be extinguished and only the red (lockout) lamp will be illuminated.

Any failure of the boiler to sequence in the above manner should be investigated using the

following trouble shooting flow diagram.

Before attempting any electrical fault finding, always carry out preliminary electrical system

checks. On completion of any service/fault finding task which has required the breaking

and remaking of electrical connections, the checks, earth continuity, polarity, short circuit,

resistance to earth must be repeated.

Installation & Servicing Instructions

Page : 27

Page 31

WD50/2/1997 Chapter 5 : Fault Finding The Keston 50, 60 & 80 Condensing Boilers

5.2 FAULT FINDING FLOW CHART

STA RT

yes

yes

Is amber switch light on?

no

Is ther e 23 0V be twe en

terminals L & N?

yes

Is the boiler switched on?

yes

Faulty Switch Neon

-Replace.

Is the fan running?

no

Is the boiler thermostat closed?

yes

Is ther e 23 0V be twe en c ontr ol

box pi ns 10 & 2?

Apply Power To Boiler.

no

no

no

no

Check External Controls.

Switch On Boiler.

Boiler return is too hot. Allow

to cool. OR faulty thermostat -

Check continuity (see section

Replce.

5.3)

Is the air pressure switch stuck

in the NO position?

Is there 230V between pins 6 &

Is there con tin uit y bet we en pi n

6 & Neutral through motor

Is motor overload tripped?

Is ther e wi ri ng co nti nu ity

& in-line connector

Continued on sheet 2

yes

no

neutral?

yes

resistance?

no

no

to motor?

yes

no

yes

yes

no

Faulty pipe connections to Air

Press. Switch. OR Faulty Air

Press. Switch - Replace.

Control box faulty.

Motor/Fan faulty - Replace.

Wait for motor to cool.

Identify & correct break.

Installation & Servicing Instructions

Page : 28

Page 32

WD50/2/1997 Chapter 5 : Fault Finding The Keston 50, 60 & 80 Condensing Boilers

Continued from sheet 1

Does ignition sequence start?

yes

no

Is lockout light on?

yes

Has the Air Press. Switch

changed over?

no

Are tubes and connections to

the Air Press. Switch sound?

yes

no

yes

no

Switch off & if problem persists

replace control box.

Blocked air filter - replace

OR

Faulty control box - replace

Correct tube connection

yes

Is the air press. across the Air

Press. Switch more than 4 in

water?

no

Is the air filter dirty or the air

inlet, exhaust or condensate

pipe blocked?

no

Is the Burner blocked

no

Fan faulty - change

Is the gas flow rate to the boiler correct

for the gas type in use (ie LPG or Nat.

Gas)?

no

Is gas supply pressure at gas

valve correct?

yes

Is gas burner pressure per

specification (Section 4.7)?

yes

yes

yes

no

yes

Faulty pressure switc h -

replace

Replace air filter

OR

clear blockage

Clear blockage

Check gas supply or turn on

gas cock.

Replace gas orifice.

no

Is gas valve openeing?

Continued on sheet 3

Installation & Servicing Instructions

yes

Page : 29

Faulty gas valve - replace.

From sheet 3

Page 33

WD50/2/1997 Chapter 5 : Fault Finding The Keston 50, 60 & 80 Condensing Boilers

Continued from She et 2

Is there 230V at valve

Is there 230V at Gas Low

Press. Switch

Faulty Control Box - Replace.

Is there a spark present?

yes

Is the HT voltage present at

top of ignito electrode?

Is the s par k ga p 4 m m?

no

no

no

yes

yes

yes

no

no

Continued on sheet 2

Fault y Ga s Va lve - Re plac e.

Faulty Gas Low Pressure

Switc h - Rep lac e

Faulty Conrtrol Box - Replace.

Replace/Adjust Spark Plug.

Electrode Faulty - Replace.

Does the burner ignite?

yes

Recheck gas output pressure.

Check HT lead is securely

fixed. Clean or replace burner.

Does flame stop after 5 - 10

seconds?

Is boiler earthed correctly?

Are live and neutral supply

lines crossed at terminals L &

N?

yes

no

yes

yes

no

no

yes

Earth Boiler.

Correct Wiring.

Faulty Control Box - Replace.

Installation & Servicing Instructions

Page : 30

Page 34

WD50/2/1997 Chapter 5 : Fault Finding The Keston 50, 60 & 80 Condensing Boilers

5.3 CONTINUITY CHECKING

To check continuity connect one probe to a neutral

and use the other probe to check for 230V.

STAR T

Is there 230 V a t ter mina l L?

yes

Is there 23 0V at the ON /OF F

sw itch ( bo th t erm in als )?

yes

Is there 230V at the bo iler

thermostat (both term inals)?

yes

Is there 230 V a t the flow

overheat thermostat (bo th

term inals) ?

yes

Is there 230V at the th ermal

fuse link (both terminals)?

yes

no

no

no

no

no

Check external c ontrols.

Faulty switch - Re place.

Boiler is up to tem perature.

Allow to cool OR pum p not

running OR fa ulty thermostat -

Thermosta t tripped - reset OR

faulty thermostat - Replace.

High cabinet temperature -

chec k all join ts fo r pro du cts

leakage - Repl ace therma l fuse

Replace

Is there 230V at the flow high

limit th er mo st at (bo th

term inals) ?

Is there 230V at the w ater

press. switch (both terminals)?

Is there 230 V at the flue

protection thermostat (both

Is there 230V at the gas low

press. switch (both terminals)?

term inals) ?

Installation & Servicing Instructions

yes

yes

yes

no

no

no

no

Page : 31

High water temperature OR

faulty thermostat - Replace.

Check w ater level header

tank/system pressure OR faulty

switch - Re plac e

Thermosta t tripped - reset OR

faulty thermostat - Replace.

Ch ec k g as su p ply t o b o iler O R

faulty switch - Replace.

Page 35

WD50/2/1997 Chapter 5 : Fault Finding The Keston 50, 60 & 80 Condensing Boilers

5.4 FUNCTIONAL FLOW WIRING DIAGRAM

L

230V 50Hz

Fuse 5A

Lockout (Red)

Indicator

EMC Filter

ON/OFF Switch

Boiler

Thermostat

Flow Overheat

Thermostat

Thermal Fuse

Link

Gas Low

Pressure

Switch

Run(Green)

Indicator

Gas

Valve

Flow High Limit

Thermostat

Low Water

Pressure Switch

Flue Overheat

Thermostat

5

2

RAM-2EMC22

IGNITION CONT ROL

HT

8

ON/O FF Switc h

1

4

610

Blower

EMC Filter

Air

Pressure

Switch

N

Installation & Servicing Instructions

Page : 32

Page 36

WD50/2/1997 Chapter 5 : Fault Finding The Keston 50, 60 & 80 Condensing Boilers

5.5 ELECTRICAL WIRING DIAGRAM

LEGEND

FLUE OVERHEAT

THERMOSTAT

WATER PRESSURE

SWITCH

FLOW HIGH LIMIT

THERMOSTAT

THERMAL FUSE

FLOW OVERHEAT

THERMOSTAT

BOILER

THERMOSTAT

HV

13 121110

55BR

54G

53W

56R

52BK

59PK

51/OR

RAM-2EMC22

IGNITION CONTRO L

9 8 7 6 5 4 3 2 1

92/OR

93R

95G

6BR

A.P.S.

BLOWER

12B

90 R

RED

LAMP

Y/G

FILTER

7W

6W

BR

B

B

BR

B -BLUE

BK -BLACK

OR -ORA NGE

R -RED

PK -PINK

W -WHITE

G -GREEN

BR -BROWN

V -VIOLET

Y/G-YELLOW-GREEN

GAS

SWITCH

93 OR

M

GAS

VALVE

12

11W

11

10/BK

10

9G

9

8

7

W

6

5BR

5

4B

4

3

N

2

L

1

91/OR

P

APS-AIR PRESSURE

SWITCH

L -INCOMING

LIVE

N -INCOMING

NEUTRAL

-INCOMING EARTH

GREEN

LAMP

12V

ON/OFF

SWITCH

Installation & Servicing Instructions

5R

Page : 33

Page 37

WD50/2/1997 Chapter 5 : Fault Finding The Keston 50, 60 & 80 Condensing Boilers

5.6 ILLUSTRATED WIRING DIAGRAM

ILLUSTRATED WIRING DIAGRAM

Boiler Stat

5R

51OR

Low Water Pressure Switch

Ignition Electrode

Flue Overheat Stat

Overheat Stat

59PK

52BK

Flow Hi gh

Lim it Stat

54G

91OR

Thermal Fuse

d

56R

53W

Gas Low

Pressure Switch

Gas Valve

93OR

11W

92OR

RAM

Control

1

2

3

4

5

6

7

8

9

10

10BK

55BR

Air Pressure Switch

95G

93R

12

11

10

9

8

7W

7

6

5

N

L

E

4

3

2

1

W

5BR

4B

5R

ON/OFF

SWITCH

12V

6W

9G

FILTER

Installation & Servicing Instructions

Lockout

Lamp

Run

Lamp

90R

BR

B

Y-G

90OR

c

Blower

Page : 34

Page 38

WD50/2/1997 Chapter 5 : Fault Finding The Keston 50, 60 & 80 Condensing Boilers

5.7 Exploded Assembly Diagrams

5.7.1 Boiler Controls Assembly

BOILER CONTROLS

ASSEMBLY

K50 - 05.4.00.00.0

K60 - 06.4.00.00.0

K80 - 08.4.00.00.0

108