Page 1

Modular Wall

Mounted

Ultra-High

Efficiency Gas

Condensing

Boilers

for Low Cost

Commercial

and Industrial

Heating

● Small diameter plastic flue systems

can be extended up to 39 metres

vertically or horizontally

● Low cost plastic flue material saving

thousands of pounds on installation

costs

● Boilers from 38 kW to 100 kW output

● Modular systems available to match

any heating output

● Compact size and preassembled

design reduces space requirements

and installation time.

CONDENSING BOILERS

Page 2

Keston BOILERS

The commercial range of Keston wall mounted gas condensing boilers covers outputs from 38 kW

(Keston 130) to 100 kW (Keston 340) with single boiler units. As with all Keston Boilers each has

an extremely high efficiency performance of 98% (GCV).

Despite their powerful outputs each unit is designed for wall mounting though floor standing

installations can be accommodated for the Keston 260 and Keston 340 using an optional floor

standing frame.

Keston Boilers offer complete and cost effective solutions to commercial and industrial heating and

in all installations can offer the highest quality systems. These are very often at much lower costs

than a single commercial boiler of equivalent output.

● Practically any heating output possible with modular system

● Wall mounted with optional floor standing frame

● Compact size from 889H x 500W x 327D

● Up to 99.1% efficient – can save 30% or more on fuel bills

● with virtually no NOx emissions (Class 5 rated)

● Flue system is small diameter plastic pipe with lengths up to

39m (Keston 260 and 340) - vertical or horizontal - can

save thousands of pounds in installation costs

● Purpose designed boiler plant rigs available for easy

installation and drastically reduced site time.

● Simple and quick to install and maintain - all access from

front and top.

● Completely room sealed, can site practically anywhere,

no need for expensive dedicated boiler room with

combustion air ventilation.

● Integral shunt pumps on Keston 260 and 340 models

● Perfect match for Keston Spa hot water storage system -

high efficiency commercial models up to 450 litre

storage.

● No complicated PCB's

● Exceptionally high quality stainless steel single pass heat

exchanger

● LPG options available for Keston 130 and Keston 170

● CE Marked, British Gas Approved and manufactured to

ISO 9001

Power POINTS

COMBUSTION EMISSIONS NOx PPM

The patented

micro-mesh burner

produces a low flame

temperature and super

low NOx combustion

at levels well below

any published

requirement.

120

110

100

90

80

70

60

50

40

30

20

10

CONVENTIONAL

SYSTEMS

PROPOSED

GERMAN

‘BLUE-ANGEL’

LIMIT

KESTON

2

Page 3

Keston Commercial - Higher Output Keston 260 and Keston 340

Following the immediate success of the Keston 130 (38 kW) and the Keston 170 (50 kW) light

commercial models Keston Boilers launched two additional commercial condensing gas boilers to

further extend its range of ultra high efficiency boilers

The Keston 260 (76 kW output) and Keston 340 (100 kW output) are unique in concept and design

and each have an exceptionally high efficiency at 98% (GCV).

Despite their powerful output the boilers are designed to be wall mounted, though floor standing installations can be

accommodated using the optional floor standing frame.

The compact size means these boilers can be sited practically anywhere without the need for a dedicated boiler room.

Each model comprises two boiler modules with individual gas valve, fans, burners and heat exchanger assemblies. Each module

operates completely independently and is automatically sequenced to offer maximum load matching.

Firing sequence is regularly rotated automatically to even usage levels.

Unique FLUE SYSTEM

All Keston boilers have the advantage of a small diameter

plastic flue system and the commercial range is no

exception.

The 50 mm diameter plastic flue used on the Keston 130

and Keston 170 can be extended up to 29 metres away

from the unit. The 100 mm diameter plastic flue on the

Keston 260 and Keston 340 can be extended up to 39

metres. All boilers can accommodate vertical or horizontal

flue routes. The usage of low cost plastic pipe for the flue

can save thousands of pounds on installation costs when

compared to a conventional flue. In refurbishment projects

there is no need for expensive relining of the flue. This

system is also ideal for buildings with difficult flue options and

particularly listed buildings with various restrictions.

Added benefits of

the flue flexibility is

that the boiler can

be sited practically

anywhere in the

most convenient

position and the

flue can be

terminated in a

location where the

"plume" generated

with a condensing

boiler does not

cause a visual

nuisance.

Sheltered Housing Project:

3 Keston 170’s

How It Works

The Keston modules use

a high powered

combustion blower to

deliver a premix of gas

and air to a downward

firing burner in a high

efficiency single pass heat

exchanger. The heat exchanger is made from highly

corrosion resistant stainless steel formed into a tightly wound

coil. Hot combustion gases pass through the coil providing

heat to the water system.

Shunt pumps, integral to the appliance on the Keston 260

and Keston 340, will ensure each module receives the

correct water flow when firing.

The Keston boilers are of low mass and low water content

giving a rapid response when there is a call for heat.

The design of Keston boilers, with its single pass heat

exchanger, avoids the complications associated with other

condensing boilers and as a result does not require

complicated printed circuit boards. The unit is totally room

sealed and requires no ventilation for combustion air to the

room or compartment in which it is installed.

The Keston commercial boilers are exceptionally easy to install

and maintain and pipework header assemblies are available as

an option to assist speedy installation. They are completely

environmentally sound with negligible NOx emissions (Class 5

rated) and can save 30% on the heating bill.

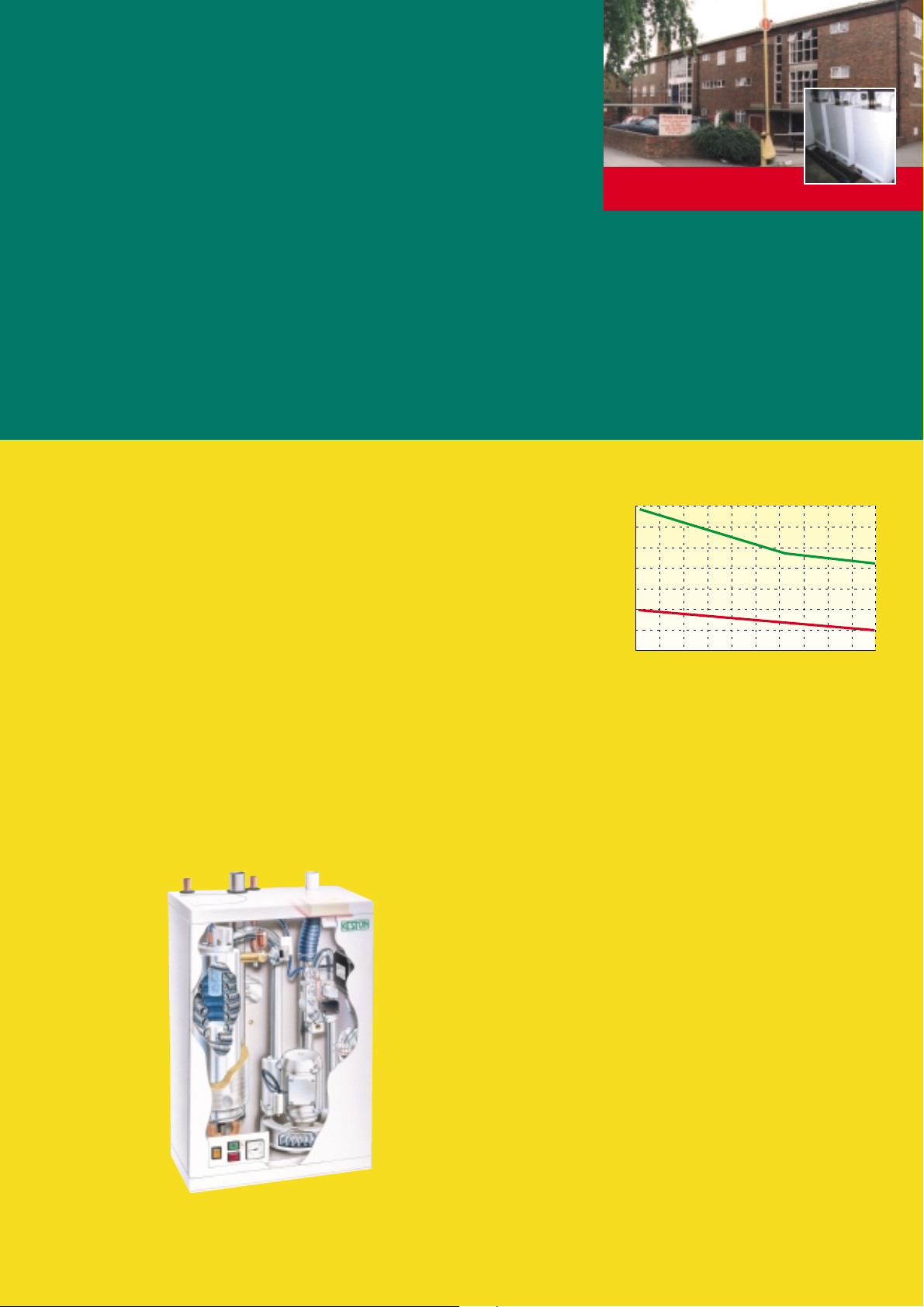

Full Load Efficiency vs. Return Water Temperature

BOILER EFFICIENCIES IN %

WATER RETURNING TO BOILER °C

High efficiency condensing boilers produce more heat, using

the same amount of gas, than any other type of gas boiler.

20

30 40

50

60 70

100

95

90

85

80

75

70

CONDENSING

STAN

DARD

3

Page 4

Practically ANY HEATING OUTPUT

Because of its modular design the Keston lends itself to almost any required heating output by way of multiple unit installations for

larger commercial or industrial applications and the benefits over a single commercial boiler are immense. The Keston modular

system is perfect for decentralisation programmes now happening in many commercial installations such as hospitals and

universities where one large commercial boiler is being replaced. From initial purchase through to installation, running and

maintenance, the Keston saves money, time, valuable space and aggravation.

In many commercial applications the Keston modular system has proved to be far less expensive to buy or install than the

equivalent output single commercial boiler.

Hydraulic SYSTEM DESIGN

● The Keston commercial boilers suitable for use on open,

vented water systems with combined feed and vent. It is

preferable for use on sealed water systems, provided the

appropriate components required are included in the

system.

● The Keston commercial boilers do not incorporate a

system safety valve or system expansion vessel. Correctly

sized and rated safety valve(s) and expansion vessel(s)

must be provided by the installer.

● The hot water storage vessel, if applicable, must be of

the indirect type, direct cylinders must not be used. The

Keston Spa unvented calorifier range is ideally suited to

the Keston commercial boiler.

● Multiple Keston commercial

boilers can be installed to meet

any required heating output. The

implementation of a balance

header is recommended to

ensure adequate water

circulation is maintained through

the boiler by the boiler shunt

pumps (integral on Keston 260

and Keston 340), irrespective of

system conditions. Suitable

balance header assemblies are

available from Keston Boilers as

an optional extra.

● The Keston 260 and Keston 340 boilers are supplied

complete with integral boiler shunt pumps. However,

these pumps are sized purely to provide adequate flow

rate through the boiler at the pressure drop caused by

the boiler itself. No allowance has been provided in the

shunt pump size for system resistance. A system pump(s)

should therefore be selected sized to provide the

required system flow rate at the pressure drop created

by the system index circuit.

4

(integral on Keston 260

and Keston 340 models)

Safety Valve

Boiler

IV

Shunt Pump

AV

IV

Low loss

header

IV

DOC

Pump

IV IV

IV

Strainer

Expansion

Vessel

System flow(s)

IV

System return(s)

Fill Point

Page 5

School Project:

3 Keston 170’s on a rig

The Keston Condensing Boiler uses premix combustion technology which requires

adequate gas supply pressure and flow at all times during operation. Care should

therefore be taken to ensure that the supply, meter and distribution pipework is correctly sized for the gas flows required.

Details of gas consumption are provided on the back page of this brochure.

Flue SYSTEM DESIGN

The Keston commercial condensing boiler range use high

powered combustion blowers that enable flueing over

exceptional distances using small diameter plastic flue pipe

and fittings.

The exceptionally high efficiency of the units ensure very low

flue temperatures which permits the use of such low cost

plastic pipe for the flue duct. A second plastic pipe carries

combustion air from outside the building enabling the boiler

to be installed in a room without ventilation for combustion

air purposes. Boiler room combustion air ventilation is

therefore not required for a Keston commercial installation.

Design

For combustion air supply and flue exhaust individual air supply

and flue outlet pipes are used. The material used for flue outlet

&/or air inlet must be 50mm muPVC (BS5255) waste pipe for

the Keston 130 and Keston 170. Keston Composite pipe of an

internal diameter not less than 100mm is required for the

Keston 260 and Keston 340 models. Suitable pipe and fittings

can be obtained via Keston Boilers Ltd appointed distributors.

Both flue outlet terminal and air inlet terminal are supplied

with each boiler.

Minimum & Maximum Lengths

The flue outlet and air inlet pipes must have lengths of at

least 1m each.

The maximum lengths of both air inlet pipe and flue outlet

pipe, when no bends are used, are as detailed.

However, each bend used has an equivalent length that

must be deducted from the maximum straight length stated

above. Knuckle bends must not be used.

A 92.5° sweep elbow is equivalent to 1.0m straight length.

Example

Air inlet uses one 92.5 sweep elbow. Hence, for a Keston 130 or 170 maximum

length permissible = 15.0m - 1.0m = 14.0m.

For a Keston 260 or 340 maximum length permissible = 20.0m - 1.0m = 19.0m.

Flue outlet uses one 92.5 sweep elbow. Hence, for a Keston 130 or 170

maximum length permissible = 30.0m - 1.0 m - total air inlet length = 29.0m total air inlet length.

For a Keston 260 or 340 maximum length permissible = 40.0m - 1.0m - total air

inlet length = 39.0m - total air inlet length.

5

Keston 130 & 170 Keston 260 & 340

Maximum Air Inlet Length 15.0m 20.0m

Maximum Flue Outlet Length 29.0m 39.0m

Maximum Combined Air Inlet 30.0m 40.0m

and Flue Outlet Length

Electrical CONNECTION

Electrical supply and control of the Keston condensing boiler is dependent on model as follows:

● Keston 130 and 170 10A permanent live, 2A switched live on/off control.

Shunt pump overrun control.

● Keston 260 and 340 13A permanent live, volt free link on/off control.

Gas SUPPLY

Flue

Boiler

Air

Page 6

Slope

'Horizontal' flue outlet pipework MUST slope at least 2.5

degrees (45 mm per metre run) downwards towards the

boiler. Pipework can be vertical. Only swept elbows can be

used. For installations requiring reduced slope contact

Keston Boilers Technical Support.

Air inlet pipework can be truly horizontal or vertical, or

sloping in a downward direction towards the boiler but in

this case rain, etc, must be prevented from entering the

pipe. There must be no troughs in any of the pipework,

whether it be air inlet or flue outlet.

Due to the low temperature of the flue

gases further condensate will form within

the flue system. Drain points, with

suitable traps, must therefore be

incorporated within the flue

system at the base of vertical flue sections

in excess of 4m (2m for the Keston 130

and Keston 170). These additional

condensate drains must be run to discharge as detailed in

section "Condensate Drainage". Such drain points can be

formed using standard Keston Composite flue fittings.

Terminations

Air inlet terminals must be positioned to ensure only fresh

air is drawn into the boiler. The air terminal must be located

outside of the building.

Drawing of combustion air directly from a ventilated boiler

room will invalidate the heat exchanger warranty.

The flue outlet terminal is designed to face outwards but

can, if desired, be adapted to face in any direction BUT must

not be directed in the region of the air inlet. Where the air

and flue terminals are located in close proximity the flue

terminal should be located above the level of the air inlet

terminal.

The two terminals are subject to the requirements of BS

5440 Pt 1 for clearances from features of the building

although some can be decreased to the values indicated.

If either the air inlet or the flue outlet terminate at a height

of less than 2m (6ft) above ground level the termination

must be protected by a suitable guard. Suitable terminal

guards can be obtained from Tower Flue Components Ltd

or its distributors.

The Keston Condensing Boiler, as with any condensing

boiler, will generate a condensate "plume" from the flue

terminal in all weather conditions. Consideration must

therefore be given to the effect of this "plume" when

selecting a location for the flue terminal.

It is advisable for horizontal flue terminals to place a 45°

elbow at the end of the flue to direct the condensate plume

up and away from the property.

Flue outlet and air inlet terminations must be at least 60 mm

and 95 mm respectively from the wall face.

There is no maximum distance between flue terminal and

air inlet terminal - the terminations can be on opposite sides

of the dwelling if desired.

A minimum clearance of at least 500 mm must be left

between the terminations.

Compartment Installation

The casing temperatures of the Keston commercial boilers

are very low. Due to this fact, no compartment ventilation is

required for cooling purposes.

Condensate Drainage

Being a condensing boiler, the Keston is fitted with a

condensate trap at the base of the heat exchanger and flue

assembly, with facility to connect to a drain point underneath

the appliance.

Use only plastic piping and do not reduce below 22mm

internal diameter within the dwelling. Condensate should

preferably be drained into the sanitary waste system or,

alternatively, the rainwater system of the property.

Termination of the pipe must be either at a branch or stack

internal to the building, or externally at an open gully.

Alternatively, discharge into a purpose made condensate

soakaway can be considered. Existing or purpose built drains

must use suitable corrosion resistant material as condensate

is mildly acidic.

A minimum slope downwards towards the drain of 1 in 20

is essential. Freezing of the termination and pipework must

be prevented. Any drainage pipes outside the property must

be at least 32 mm inside diameter.

To Terminal

To Boiler

Te e

Fitting

6 in

min

6

Minimum Flue Terminations and Flue Air

Air Inlet Dimensions (mm) Terminal Inlet

A Below or beside openable window, air brick etc. 500 50

B Below gutters, soil pipes, drain pipes 75 75

C Below eaves 300 50

D Below balconies or car port roof 200 50

E From vertical drain or soil pipes 75 50

F From internal or external corner 600 50

G Above ground or balcony or roof 300 100

H From surface facing a terminal 600 100

I From terminal facing a terminal 1200 1200

J From opening in a car port 1200 100

K Vertically from terminal on same wall 1500 1500

L Horizontally from terminal on same wall 300 300

Page 7

The modular design of the Keston Commercial range lends

itself ideally to multiple boiler installations. As a result almost

any heating output requirement can be accommodated using

multiple Keston units.

Using this multiple boiler approach the system can be

controlled to ensure optimum matching of boiler output to

load at any given time. In addition, individual units can be

taken off-line for servicing with minimal impact on system

performance.

CLEARANCES

The boilers are designed for ease of servicing and installation.

On the Keston 260 and Keston 340 all servicing is carried

out through the front of the unit. On the Keston 130 and

Keston 170 additional access is required to the top of the

cabinet for removal of the burner.

Details of installation clearances are provided in the table on

the back page of this brochure.

Multiple

BOILER INSTALLATIONS

Preassembled Boiler Plant Rigs

In circumstances where site time and/or space may be at a premium

Keston Boilers can provide a pre-assembled solution to any plant

room needs.

The Keston Rigs are delivered to site pre-assembled and incorporate

up to three units within a floor standing frame. The units are prepiped to a single balance header.

The Keston Rigs include :

● Safety Valves

● Up to three Keston ● Isolating Valves

commercial units as

● Test Points

specified by the customer

● Drain Points

● Individual shunt pumps ● Single Balance Header

for each unit sized according to output

The incorporated equipment is pre-piped and pre-wired ready for

immediate connection within the plant room.

The balance header includes tappings for air vent, fill point/expansion

vessel, drain off and system flow and return. The number and size of

system tappings is as per the customers own specification.

Floor Standing Boiler Frame

Where plant room wall space is at a premium a floor standing frame is

available for the Keston 260 and Keston 340.

Balance Headers

A range of standard headers is available from Keston Boilers Ltd for

single and multiple installations. In addition bespoke headers can be

produced in order to meet customers specific requirements.

Hospital Project:

6 Keston 170’s

OPTIONS

Common Balance Headers

Boiler water flows are critical to the operation of the boilers.

If flow cannot be maintained through the system pipework

to meet the minimums required by the boiler the boiler will

"kettle" or even produce steam. The implementation of a

balance header, as shown in the schematics, is

recommended to ensure adequate water circulation is

maintained through the boiler by the boiler shunt pumps,

irrespective of system conditions.

The size of the balance header is dependant on the number

of boilers serving the header

A guide to sizing is given here:

When assembling a balance

header the following design

considerations must be observed:

a) Each boiler must have its own

flow and return connection to the balance header pipe.

Common flow and return connections with other boilers

can cause reverse circulation effects to occur.

b) The minimum distance between the system flow and

return connections is 600mm

c) A drain off point should be fitted to the base of the

header, along with cleaning access, for sludge removal.

The top of the header should be vented.

7

Total Boiler Header

Output Diameter

up to 100kW 3"

up to 200kW 4"

up to 300kW 4.5"

up to 400kW 5"

Shunt Pumps

(integral on Keston 260

and Keston 340 models)

Boiler

Safety Valve

Boiler

AV

IV

IV

IV

IV

IV IV

IV IV

Low loss

header

IV

IV

DOC

Pump

Pump

Strainer

Strainer

IV

IV

Fill Point

Expansion

Vessel

System flow(s)

System return(s)

Page 8

34 West Common Road, Hayes

Bromley, Kent, BR2 7BX, UK

Telephone: 020 8462 0262 Fax: 020 8462 4459

Email: info@keston.co.uk Web: www.keston.co.uk

Agent

In accordance with our policy of constant improvement we reserve the right to alter the design and specification without prior notice.

All illustrations included in this brochure are for general guidance only. As such these illustrations are not intended as final design drawings.

10/99

Performance Data

Keston 130 Keston 170 Keston 260 Keston 340

Max Input (GCV) kW/(Btu/h) 42.3/(144,330) 55.0/(187,660) 84.6/(288,650) 110.0/(375,300)

Max Output to water (80/60 Flow/Return) kW(Btu/h) 38.1/(130,000) 49.8/(170,000) 76.1/(259,650) 99.0/(337,800)

Max Output to water (60/40 Flow/Return) kW(Btu/h) 40.0/(136,500) 52.4/(178,800) 79.5/(271,250) 104.0/(354,800)

Max Output to water (50/30 Flow/Return) kW/(Btu/h) 41.4/(141,500) 54.5/(186,000) 82.9/(282,850) 107.8/(367,800)

Burner Setting Pressure - Hot (factory preset) mbar/(in wg) 7.5/(3) 10.0/(4) 9.8/(3.9) 13.0/(5.2)

Gas Consumption after 10 mins l/s / (ft3/hr) 1.09/(139) 1.42/(181) 2.19/(278) 2.84/(362)

Required Inlet Gas Pressure (Dynamic) mbar/(in wg) 20.0/(8.0) 20.0/(8.0) 20.0/(8.0) 20.0/(8.0)

Recommended Temperature Differential °C 10 to 15 10 to 15 10 to 15 10 to 15

Required Water Flow Rate l/s 0.83 1.00 1.60 2.00

Integral Shunt Pumps No No Yes Yes

Max Operating Flow Temperature °C 80.0 80.0 80.0 80.0

Max Head (Open Systems) m 30.5 30.5 30.5 30.5

Max Press. (Sealed Systems) Bar 2.70 2.70 2.70 2.70

Min Head (Open Systems) m 3.0 3.0 3.0 3.0

Electrical Supply 230V 50Hz 230V 50Hz 230V 50Hz 230V 50Hz

Power Consumption (Max) W 600 600 1200 1200

Cabinet Height mm 890 890 1260 1260

Cabinet Width mm 500 500 1080 1080

Cabinet Depth (Max) mm 327 327 350 350

Top Clearance mm 254 254 127 127

Side Clearance mm 1 1 1 1

Base Clearance mm 127 127 127 127

Front Clearance mm 305 305 305 305

Weight – Full kg/(lbs) 68/(150) 68/(150) 165/(363) 165/(363)

Weight – Empty kg/(lbs) 61/(134) 61/(134) 150/(330) 150/(330)

Flow and Return Connections 35mm copper 35mm copper Rp 2"F Rp 2"F

Gas Connection

3

/4BSPT Male

3

/4BSPT Male Rp 1.25"F Rp 1.25"F

Flue Pipe Size (Nominal Bore) mm/(in) 50/(2) 50/(2) 100/(4) 100/(4)

Air Intake Pipe Size (Nominal Bore) mm/(in) 50/(2) 50/(2) 100/(4) 100/(4)

Max Air Intake Length m 15 15 20 20

Max Combined Flue & Air Intake Length m 30 30 40 40

Flue and Air Intake Material muPVC BS5255 Pipe Only Keston Composite Pipe Only

LPG Option available Yes Yes No No

Optimum Flue Gas CO

2

Level (G20) % 8.4 8.4 8.4 8.4

Loading...

Loading...