Keston Heat 55kw, Heat 45kw Installation Manual

Installation and Servicing Instructions

FAN POWERED HIGH EFFICIENCY

MODULATING CONDENSING

GAS BOILER

CE/PI No. 86-CN-69

Heat 45 - GC No. 41-930-40

Heat 55 - GC No. 41-930-41

Heat 45 & 55

These instructions must be left either with the

user or next to the site gas meter.

Keston Heating

PO Box 103, National Avenue, Kingston Upon Hull, HU5 4JN

Tel. +44 (0) 1482 443005 Fax. +44 (0) 1482 467133

email : info@keston.co.uk web : www.keston.co.uk

COMPLIANT WITH BUILDING REGULATION PART L1 & L2

SEDBUK A RATED

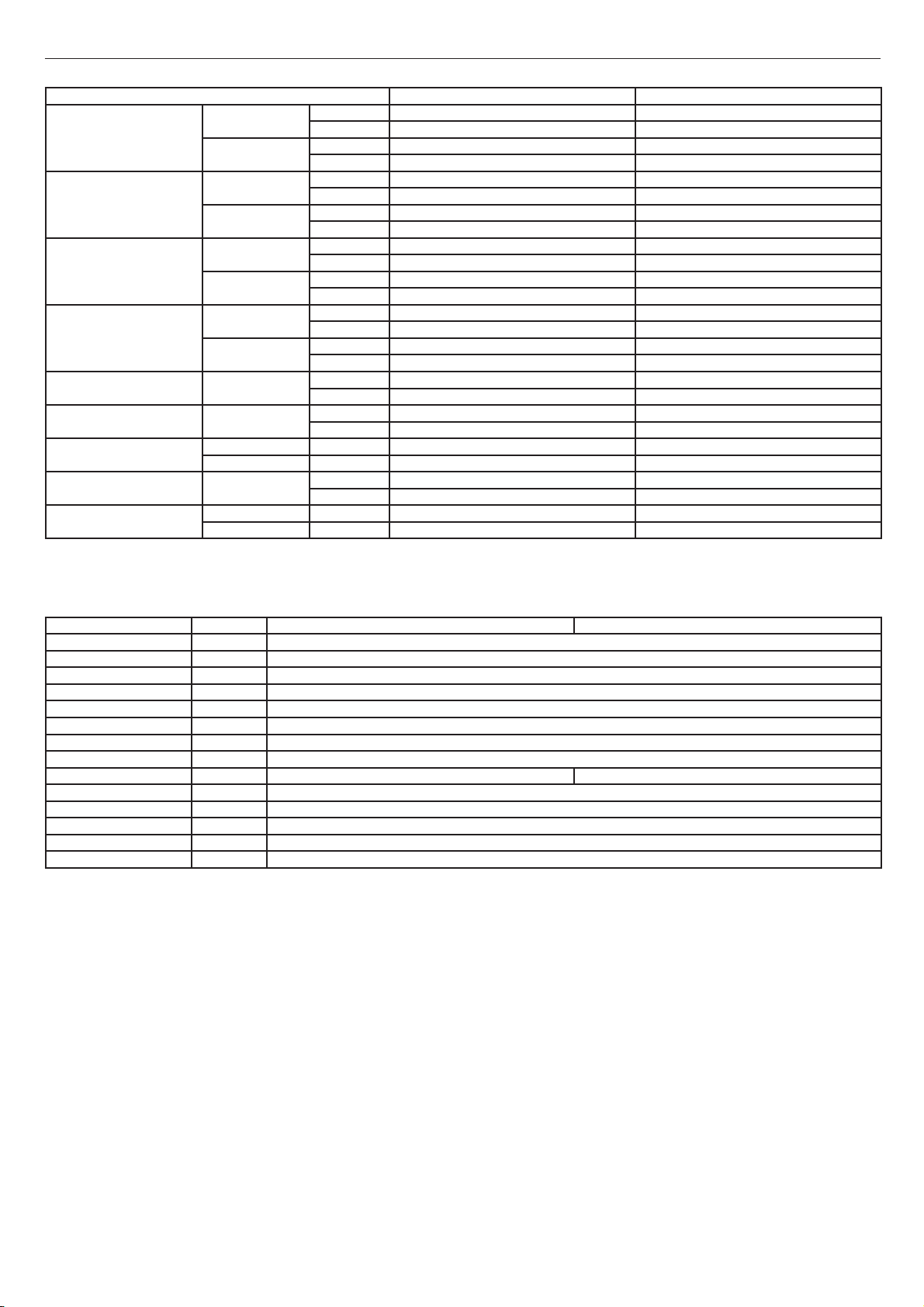

Table 1 Performance Data (Natural Gas)

Keston Heat Model 45 55

Boiler Output

(non-condensing)

Mean 70°C

Boiler Output

(condensing)

Mean 40°C

Boiler Input

Max Rate

Boiler Input

Min Rate

Gas Rate Max Rate

Flue Gas Flow Rate Max Rate

CO

(±0.5%)

2

NO

x

Efciency

Max

Min

Max

Min

Nett

Gross

Nett

Gross

Max Rate % 9.3 9.5

Min Rate % 8.4 8.4

Weighted

Seasonal % 96.0 96.7

*SEDBUK 2009 % 89.2 89.6

GENERAL

kW 42.6 52.1

Btu/hr 145400 177800

kW 12 12

Btu/hr 40900 40900

kW 45 55

Btu/hr 153500 187700

kW 12.7 12.7

Btu/hr 43300 43300

kW 43.2 52.7

Btu/hr 147400 179800

kW 47.9 58.5

Btu/hr 163400 199600

kW 12.2 12.2

Btu/hr 41600 41600

kW 13.5 13.5

Btu/hr 46100 46100

3

m

/hr 4.56 5.57

3

ft

/hr 161.2 196.9

3

m

/hr 66.4 81.0

3

ft

/hr 2343 2861

mg/kWh 38.6 38.3

ppm DAF 21.9 21.7

Table 2 General Data

Keston Heat Model 45 55

Gas Supply 2H – G20 – 20mbar / 3P - G31 - 37mbar

Gas Supply Connection G

Flow Connection G1 1/4

Return Connection G1

Max Pressure (sealed sys)

Maximum Static Head

Electricity Supply 230V - 50Hz

Fuse Rating

Power Consumption

IP Rating IP20

Nominal ue dia - Concent. Twin 50mm

Condensate Drain 25

Water Content

Dry Weight

* The value is used in the UK Government’s Standard Assessment

Procedure (SAP) for energy ratings of dwellings. The test data from which

it has been calculated have been certied by a notied body.

Note.

Natural gas consumption is calculated using a caloric value of

37.8MJ/m

15

a. For l/s divide the gross heat input (kW) by the gross C.V. of the

b. For ft/h

3

o

(1038Btu/ft3) gross or 34 MJ/m3 (910 Btu/ft3) nett at

C and 1013.25 mbar.

gas (MJ/m

3

)

3

divide the gross heat input (Btu/h) by the gross C.V. of

Bar (psi)

m

A

W

L

Kg

202 262

HEALTH & SAFETY DOCUMENT NO. 635

The electricity at work regulations, 1989. The manufacturer’s

notes must NOT be taken, in any way, as overriding statutory

obligations.

IMPORTANT. These appliances are CE certied for safety

and performance. It is, therefore, important that no external

control devices, e.g. ue dampers, economisers etc., are

directly connected to these appliances unless covered by

these Installation and Servicing Instructions or as otherwise

recommended by Keston in writing. If in doubt please enquire.

3

/4

1

4.0 (58)

40.7

4.0

5.0

60.3

/4

the gas (Btu/ft3).

c. For m

3

/h multiply l/s by 3.6.

Any direct connection of a control device not approved by Keston

could invalidate the certication and the normal appliance

warranty. It could also infringe the Gas Safety Regulations and

the above regulations.

2

Keston Heat - Installation & Servicing

GENERAL

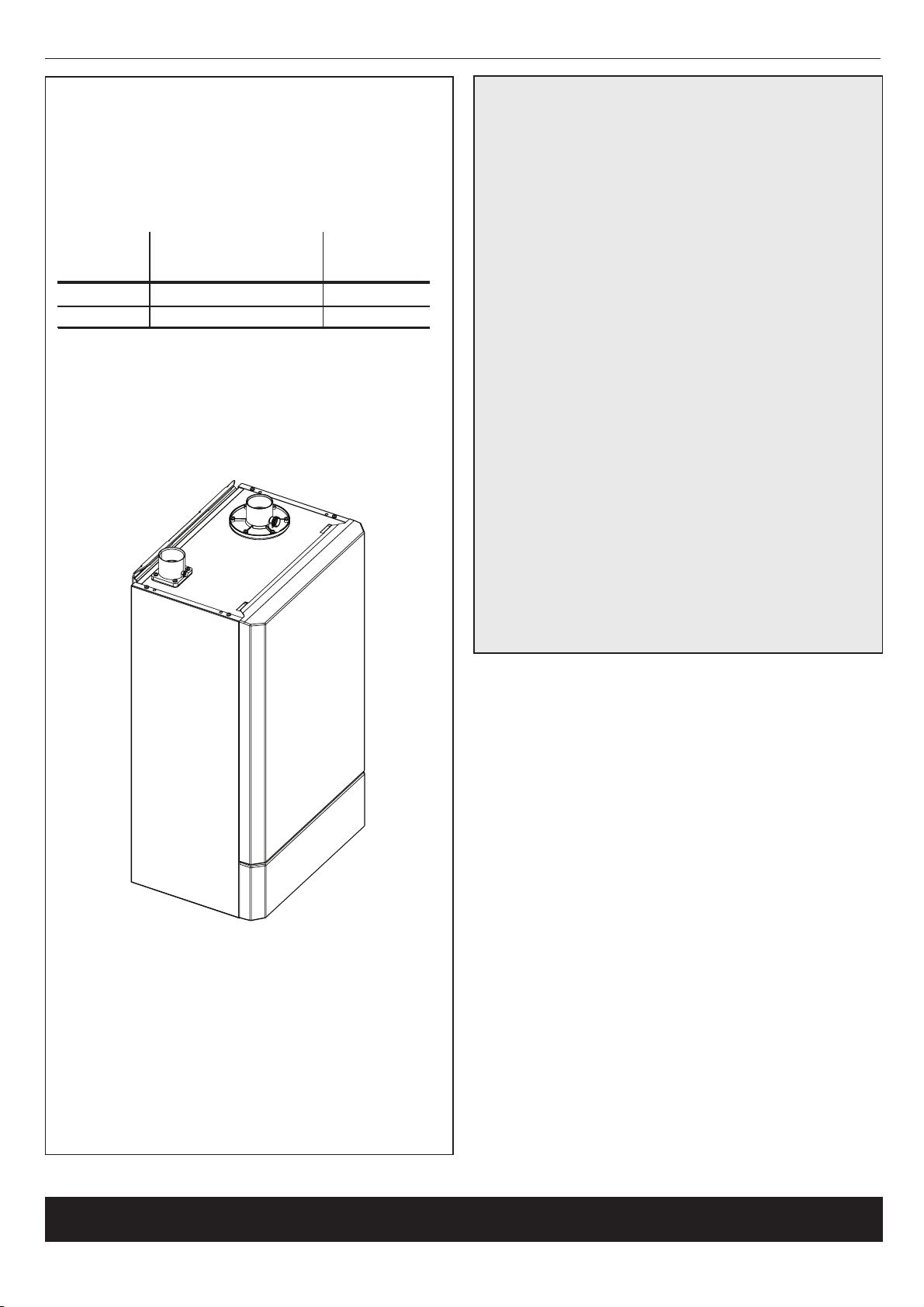

Keston Heat

45 & 55

Natural Gas

Destination Countries: GB, IE, RO

Boiler size G.C. Appliance No. PI No.

(Benchmark No.)

45 41-930-40 86-CN-69

55 41-930-41 86-CN-69

CONTENTS

Boiler Assembly - Exploded view. ...................................9

Boiler Clearances. .............................................................7

Commissioning and Testing. .......................................... 38

Electrical Connections. ...................................................23

Electrical Supply. ...............................................................6

Fault Finding. ...................................................................49

Flue Installation. ................................................................5

Gas Safety Regulations ...................................................4

Gas Supply. ........................................................................5

Introduction. .......................................................................4

Initial Lighting. .................................................................39

Installer Connections. .....................................................24

Installation. ....................................................................9-40

Mounting Boiler. ..............................................................12

Option Kits. ........................................................................4

Performance Data. .............................................................2

Servicing. ....................................................................41-48

Short List of Parts. ..........................................................59

Ventilation. .......................................................................12

Water Circulation. ..............................................................5

Water Connections. .........................................................22

Water System Requirements. ...........................................8

Water Treatment. ...............................................................6

Wiring Diagrams. .............................................................25

Key to symbols

IE = Ireland,

GB = United Kingdom (Countries of destination)

RO = Romania

PMS = Maximum operating pressure of water

C53 = A room sealed boiler which is connected via

its separate ducts to two terminals that may

terminate in zones of different pressure.

C13 = A room sealed boiler which is connected via

its ducts to a horizontally installed terminals

that terminate within a common pressure

zone

I2H = An appliance designed for use on 2nd Family

gases.

NOTE TO THE INSTALLER:

LEAVE THESE INSTRUCTIONS ADJACENT TO THE GAS METER.

Keston Heat - Installation & Servicing

3

GENERAL

INTRODUCTION

The Keston Heat boilers are fully automatically controlled, wall

mounted, fanned, super efcient condensing appliances.

The Keston Heat condensing boilers can be installed either on

the wall or into a prefabricated oor mounted frame.

Through a sophisticated control system combined with premix

burner arrangement the boilers are capable of high seasonal

efciencies of >96% and low emissions.

These boilers are certied to meet the requirements of the EC

Gas Appliance Directive, Boiler Efciency Directive, EMC and

Low Voltage Directive.

Note. These boilers cannot be used on systems that include

gravity circulation.

The boiler are suitable for connection to fully pumped, open

vented or sealed water systems. Adequate arrangements for

completely draining the system by provision of drain cocks MUST

be provided in the installation pipework.

Boiler is suppled with internal pump

OPTIONAL EXTRA KITS

• Air Terminal Finishing Kit

• Programmable Room Thermostat Kit

• Modulating Sequencer Kit

• Tank Sensor Kit

• Safety Interlock Kit

• Flue Sleeve Kit

• Room Sensor Kit

• Frame and Header Kit

Detailed recommendations are contained in the following Codes

of Practice:

BS. 6891

BS. 5440

Part 1 Specication for installation of ues.

Part 2 Specication for installation and maintenance of

BS. 6798

BS. 6880 Low temperature hot water heating systems of

Part 1 Fundamental and design considerations.

Part 2 Selection of equipment.

Part 3 Installation, commissioning and maintenance.

BSEN.12828:2003

BSEN.12831:2003

BSEN.13831 Specication for: Expansion vessels using an

BSEN.14336:2004

Where reference is made throughout these instructions I.S.813:2002

“Domestic Gas Installations” reference should also be made to

I.S.820:2000 “Non-Domestic Gas Installations” as applicable.

Installation of low pressure gas pipework of up to

28mm (R1) in domestic premises (2nd family gas).

Inst. and maintenance of ues and ventilation for

gas appliances of rated input not exceeding 70kW

net (1st, 2nd and 3rd family gases).

ventilation for gas appliances.

Installation and maintenance of gas red hot water

boilers of rated input not exceeding 70kW net.

output greater than 45kW.

Heating Systems in buildings: Design for water

based systems.

Heating Systems in buildings: Method for

calculation of the design heat load.

internal diaphragm, for sealed hot water heating

systems.

Heating Systems in buildings: Installation and

commissioning of water based heating systems.

SAFETY

Current Gas Safety (Installation and Use) Regulations

or rules in force

The appliance is suitable only for installation in GB and IE and

should be installed in accordance with the rules in force.

In GB, the installation must be carried out by a Gas Safe

Registered Engineer or in IE by a competent person. It must be

carried out in accordance with the relevant requirements of the:

• Gas Safety (Installation and Use) Regulations

• The appropriate Building Regulations either The Building

Regulations, The Building Regulations (Scotland), Building

Regulations (Northern Ireland).

• The Water Fittings Regulations or Water byelaws in Scotland.

• The Current I.E.T. Wiring Regulations.

Where no specic instructions are given, reference should be

made to the relevant British Standard Code of Practice.

In IE, the installation must be carried out by a Competent Person

and installed in accordance with the current edition of I.S.813

“Domestic Gas Installations” or I.S. 820 “Non-Domestic Gas

Installations” as appropriate, the current Building Regulations and

reference should be made to the current ETCI rules for electrical

installation.

The Keston Heat boilers have been tested and certied to;

EN 483, EN 677, BSEN 60335-2-102, BSEN 55014-1 and BSEN

55014-2 for use with Natural Gas.

SAFE HANDLING

This boiler may require 2 or more operatives to move it to its

installation site, remove it from its packaging base and during

movement into its installation location. Manoeuvring the boiler may

include the use of a sack truck and involve lifting, pushing and pulling.

Caution should be exercised during these operations.

Operatives should be knowledgeable in handling techniques when

performing these tasks and the following precautions should be considered:

• Grip the boiler at the base.

• Be physically capable.

• Use personal protective equipment as appropriate, e.g.

gloves, safety footwear.

During all manoeuvres and handling actions, every attempt should

be made to ensure the following unless unavoidable and/or the

weight is light.

• Keep back straight.

• Avoid twisting at the waist.

• Avoid upper body/top heavy bending.

• Always grip with the palm of the hand.

• Use designated hand holds.

• Keep load as close to the body as possible.

• Always use assistance if required.

4

Keston Heat - Installation & Servicing

GENERAL

25 30 35 40 45 50 55 60 65 70

0

1

2

3

4

5

6

7

8

Available System Capacity

20 deg C differential

15 deg C differential

11 deg C differential

Keston Evomax 45 - Hydraulic System Capacity

Water Flow Rate [L/m]

Pressure [m WG]

SAFE HANDLING OF SUBSTANCES

No asbestos, mercury or CFCs are included in any part of the

boiler or its manufacture.

LOCATION OF BOILER

The boiler must be installed on a at and vertical wall, capable of

adequately supporting the weight of the boiler and any ancillary

equipment.

The boiler must not be tted outside.

GAS SUPPLY

The local gas supplier should be consulted, at the installation

planning stage, in order to establish the availability of an adequate

supply of gas. An existing service pipe must NOT be used without

prior consultation with the local gas supplier.

A gas meter can only be connected by the local gas supplier or by

a Gas Safe Registered Engineer or in IE by a competent person.

An existing meter should be checked, preferably by the gas

supplier, to ensure that the meter is adequate to deal with the

rate of gas supply required. A minimum working gas pressure of

17.5mbar MUST be available at the boiler inlet for Natural gas

Do not use pipes of smaller size than the boiler inlet gas

connection.

The complete installation MUST be tested for gas soundness and

purged in accordance with the appropriate standards listed on

page 4.

FLUE INSTALLATION

Individual air supply and ue outlet pipes are used. The material

used for the ue outlet and the air intake systems, must be

muPVC to BS 5255. In addition the ue outlet and air intake

pipework must be marked BSEN 1566-1 and the ttings must be

marked BSEN 1329. Marley muPVC Solvent Weld Waste System

(50mm) and Polypipe System 2000 muPVC Solvent Weld Waste

System (50mm) are recommended. DO NOT USE ABS PIPE OR

FITTINGS.

IMPORTANT

It is the responsibility of the installer to ensure, in practice, that

products of combustion discharging from the terminal cannot

re-enter the building or any other adjacent building through

ventilators, windows, doors, other sources of natural air inltration,

or forced ventilation / air conditioning.

If this should occur the appliance MUST be turned OFF, labelled

as ‘unsafe’ and corrective action taken.

Where the lowest part of the terminal is tted less than 2m (80”)

above a balcony, above ground or above a at roof to which

people have access then the terminal MUST be protected by a

purpose designed guard. The minimum spacing between the

balcony and the terminal should be 75mm, in order to allow a

terminal guard to be tted.

Terminal guards are available from boiler suppliers

Ensure that the guard is tted centrally.

The air inlet/products outlet duct and the terminal of the

boiler MUST NOT be closer than 25mm (1”) to combustible

material. Detailed recommendations on the protection of

combustible material are given in BS. 5440-1: 2008. In IE refer to

I.S.813:2002.

The ue must be installed in accordance with Building

Regulations and the recommendations of BS. 5440-1:2008 for

inputs up to 70kW nett.

WATER CIRCULATION SYSTEM

The boiler must NOT be used for direct hot water supply. The hot

water storage cylinder MUST be of the indirect type.

Single feed, indirect cylinders are not recommended and MUST

NOT be used on sealed systems.

The appliances are NOT suitable for gravity central heating nor

are they suitable for the provision of gravity domestic hot water.

The hot water cylinder and ancillary pipework, not forming part of

the useful heating surface, should be lagged to prevent heat loss

and any possible freezing - particularly where pipes run through

roof spaces and ventilated underoor spaces.

The boiler must be vented.

Draining taps MUST be located in accessible positions, which

permit the draining of the whole system - including the boiler

and hot water storage vessel. They should be at least 1/2” BSP

nominal size and be in accordance with BS. 2879.

The central heating system should be in accordance with the

relevant standards listed on page 4.

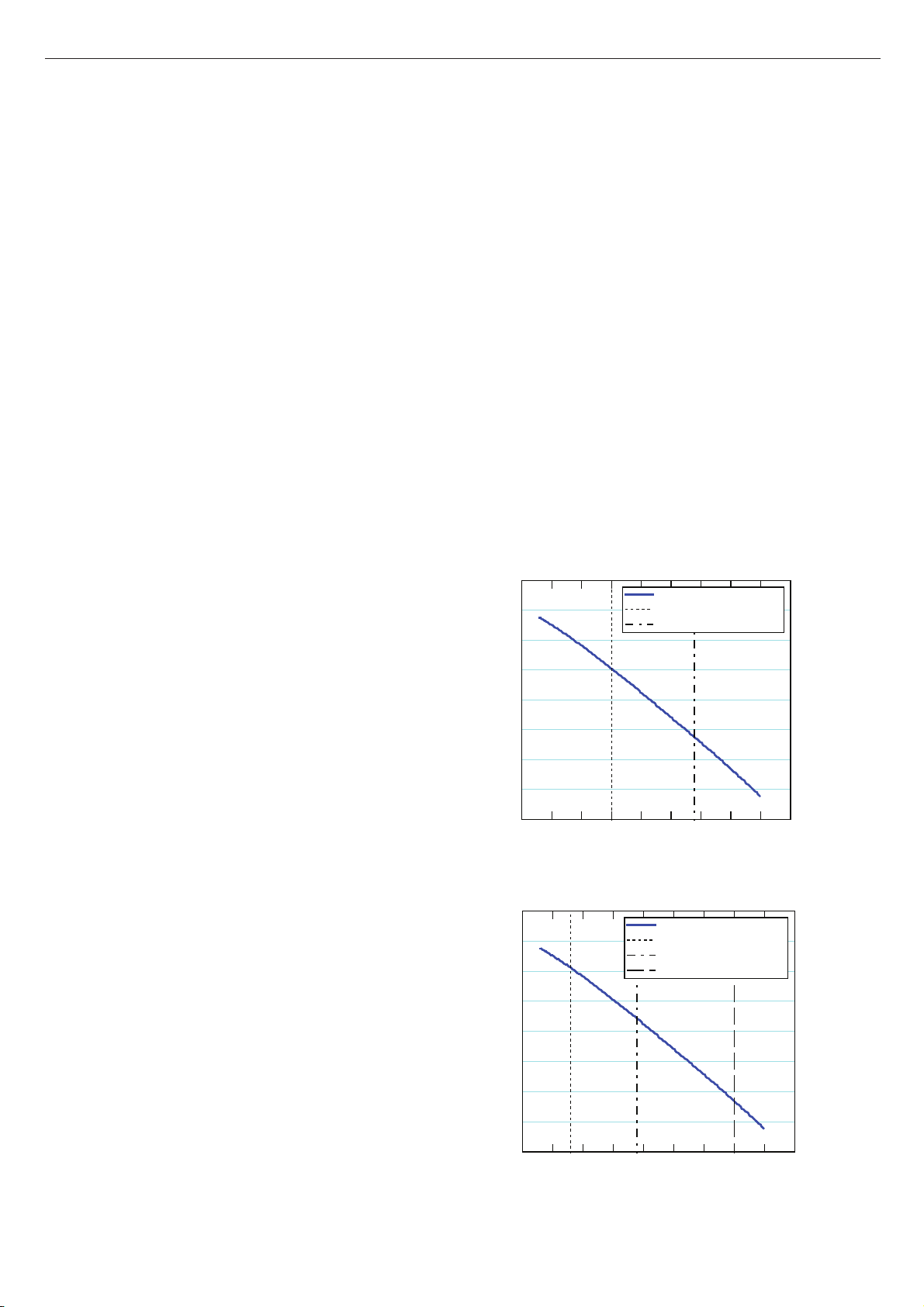

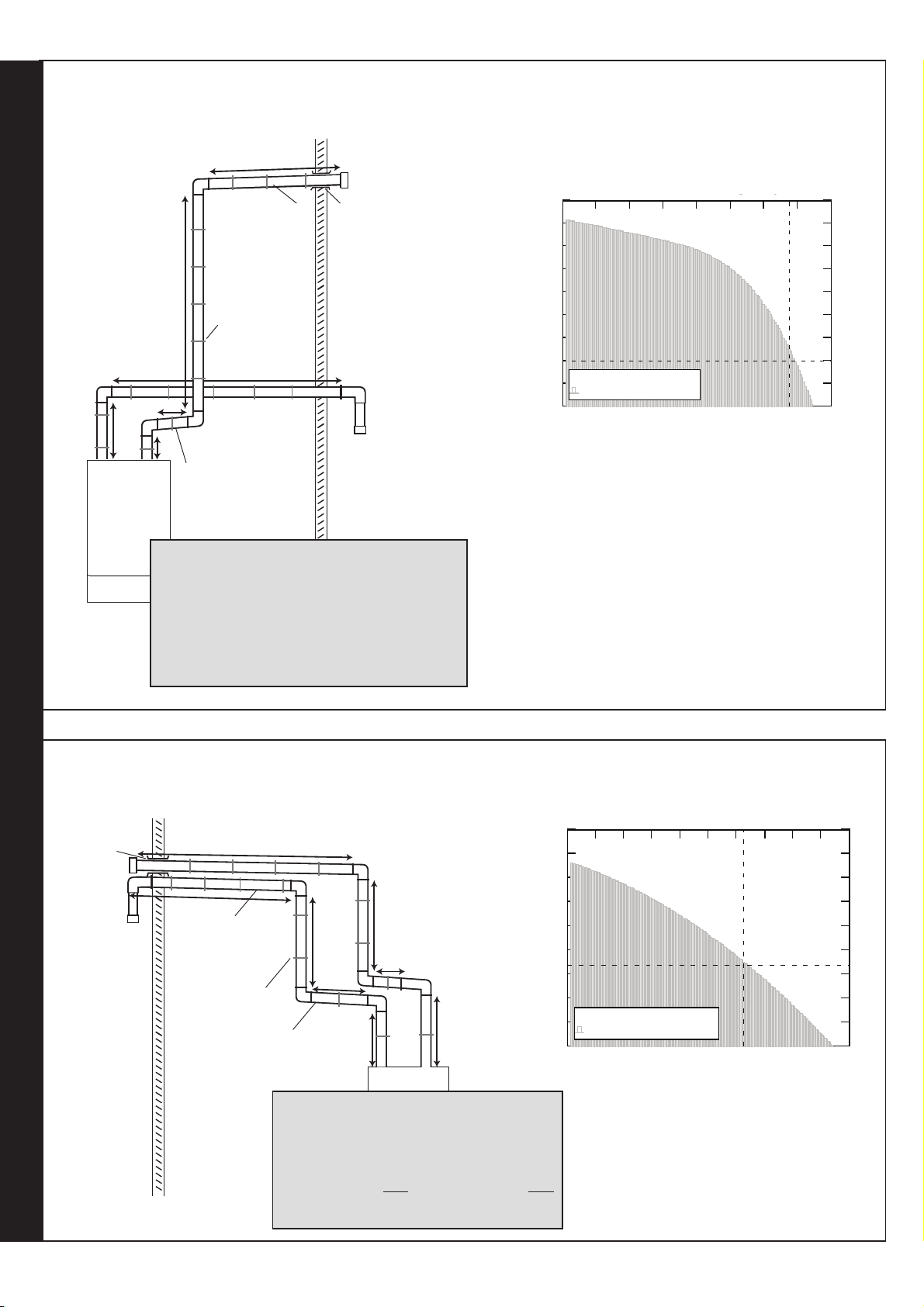

The Keston boilers feature an integral circulating pump which

has sufcient excess head to drive most domestic systems. The

available head is indicated in the chart below. If the system

resistance, at the desired ow rate, is in excess of the available

head from the integral pump an additional system pump will be

required.

Keston Heat 55 - Hydraulic System Capacity

Keston Evomax 55 - Hydraulic System Capacity

8

7

6

5

4

3

Pressure [m WG]

2

1

0

25 30 35 40 45 50 55 60 65 70

Water Flow Rate [L/m]

Keston Heat 45 - Hydraulic System Capacity

Available System Capacity

20 deg C differential

15 deg C differential

Keston Heat - Installation & Servicing

continued . . . . . .

5

GENERAL

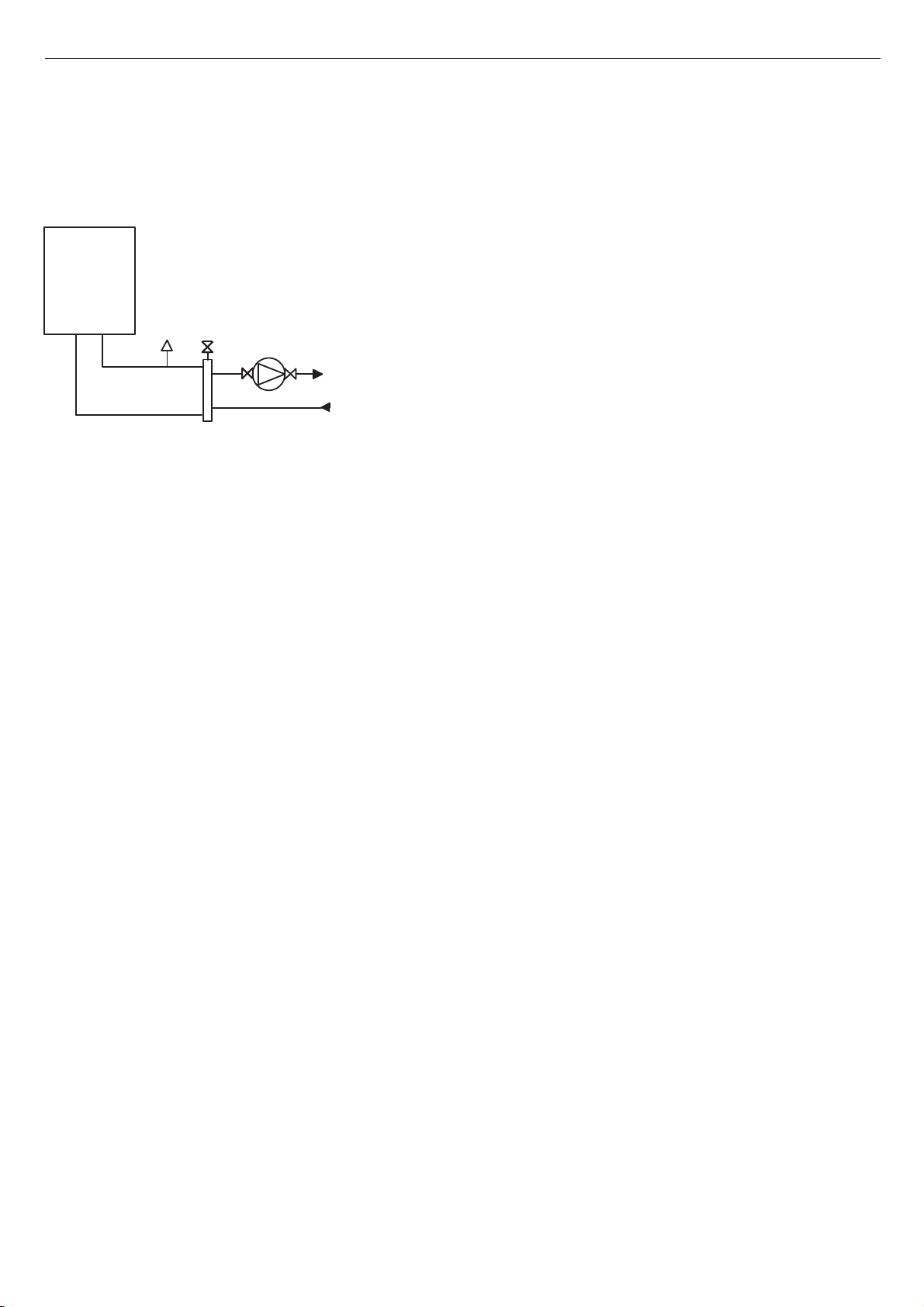

The schematic below illustrates a recommended approach to

using an additional system pump. The additional system pump

should be sized to overcome the index circuit resistance only as

the boilers integral pump will overcome boiler resistance.

If an additional pump is required the selected pump must comply

with BS 1394.

Boiler

Safety

Valve

42mm

Header

Installation of air bleed valves at the high spot(s) in the system will

allow for air elimination when lling the system and will allow re-

venting in a day or so after all air has been driven out of solution.

Note.

• With the boiler ring at minimum rate, the temperature

differential should not be greater than 35

generating higher temperature differentials will lead to lock out

of the boiler.

In installations where all radiators have been provided with

thermostatic radiator valves, it is essential that water circulation

through the boiler is guaranteed. This can be best achieved

by means of a differential pressure valve, which is installed in a

bypass between the ow and return pipes. The bypass should

be tted at least 6m from the boiler, and should use a minimum

size of 28mm pipe. The bypass should be capable of allowing

a minimum ow rate to achieve a temperature differential of no

greater than 35

o

C at minimum rate.

AAV

Additional

System

Pump

Primary Flow

Primary Return

o

C. Lower ow rates

WATER TREATMENT

These boilers incorporate an ALUMINIUM heat exchanger.

IMPORTANT. The application of any other treatment to this

product may render the guarantee of Keston INVALID.

Keston recommend Water Treatment in accordance with

Guidance Notes on Water Treatment in Central Heating Systems.

Keston recommend the use of Fernox Copal or MB1 or GE

Betz Sentinel X100 inhibitors and associated water treatment

products, which must be used in accordance with the

manufacturers’ instructions.

For further information contact:

Fernox Cookson Electronics,

Forsyth Road, Sheerwater, Woking, Surrey, GU21 5RZ

Tel: +44 (0) 870 601 500

or

Sentinel Performance Solutions, The Heath Business and

Technical Park, Runcorn, Cheshire, WA7 4QX

Tel: 0800 389 4670

www.sentinel-solutions.net

Notes.

1. It is most important that the correct concentration of the

water treatment products is maintained in accordance with

the manufacturers’ instructions.

2. If the boiler is installed in an existing system any unsuitable

additives MUST be removed by thorough cleansing.

BS7593:1992 details the steps necessary to clean a

domestic heating system.

3. In hard water areas, treatment to prevent limescale may be

necessary - however the use of articially softened water is

NOT permitted.

4. Under no circumstances should the boiler be red before

the system has been thoroughly ushed.

ELECTRICAL SUPPLY

Wiring external to the appliance MUST be in accordance with

the current I.E.T. (BS7671) Wiring Regulations and any local

regulations which apply. For Ireland reference should be

made to the current ETCI rules for electrical installations

The point of connection to the mains should be readily

accessible and adjacent to the boiler.

CONDENSATE DRAIN

Refer to Frames 24, 25 & 60

A condensate drain is provided on the boiler. This drain must

be connected to a drainage point on site. All pipework and

ttings in the condensate drainage system MUST be made of

plastic - no other materials may be used.

IMPORTANT.

Installation must be in accordance with BS 6798.

The drain outlet on the boiler is sized for standard 21.5mm

(3/4”) overow pipe. It is a universal tting to allow use of

different brands of pipework.

Note that all external runs must be insulated.

6

Keston Heat - Installation & Servicing

GENERAL

299

206210-10155

1

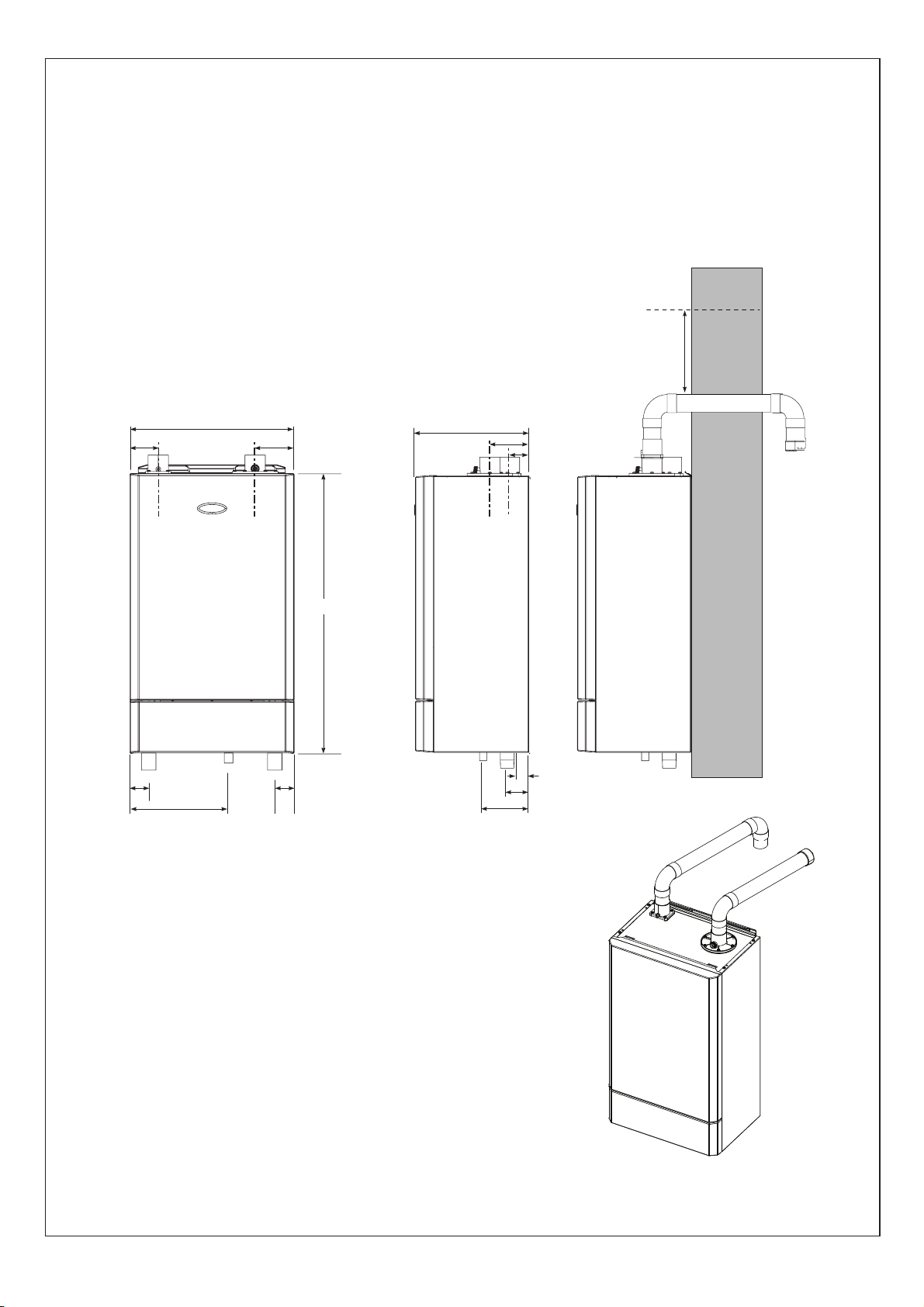

BOILER CLEARANCES AND CONNECTIONS

The following minimum clearances must be maintained for operation

and servicing.

Front of boiler - 450mm

Sides of boiler - 25mm

Above boiler - 350mm

Below boiler - 300mm

Clearance between multiple boiler installations - 25mm

500

86

Air

Flue Centre Line

Flow Return

59 59

Flue

Gas

118

Flue Centre Line

850

360

131

Flue Centre Line

Gas Pipe

155

Minimum Top Clearance

70

Flue Centre Line

Condensate Drain

Flow/Return

68

81

30mm

Front clearance

The minimum front clearance when built in to a cupboard is 5mm

from the cupboard door but 450mm overall clearance is still

required, with the cupboard door open, to allow for servicing.

Keston Heat - Installation & Servicing

7

GENERAL

Feed/expansion

cistern

500mm

minimum

3000mm

minimum

System

flow to

pump

Inverted cold

feed entry

Cold

Feed

Water

level

(cold)

Open vent

System

return

Connections

to boiler

ima5351

3000

minimum

CV CV

Resillient

seat control

valves

Supply

pipe

DT

CV = Control Valve

DT = Drain Ta p

Air

gap

Tundish

Strainer

Type BA backflow

prevention device

(RP2 valve assembly)

primary flow

and return

ima7349

2

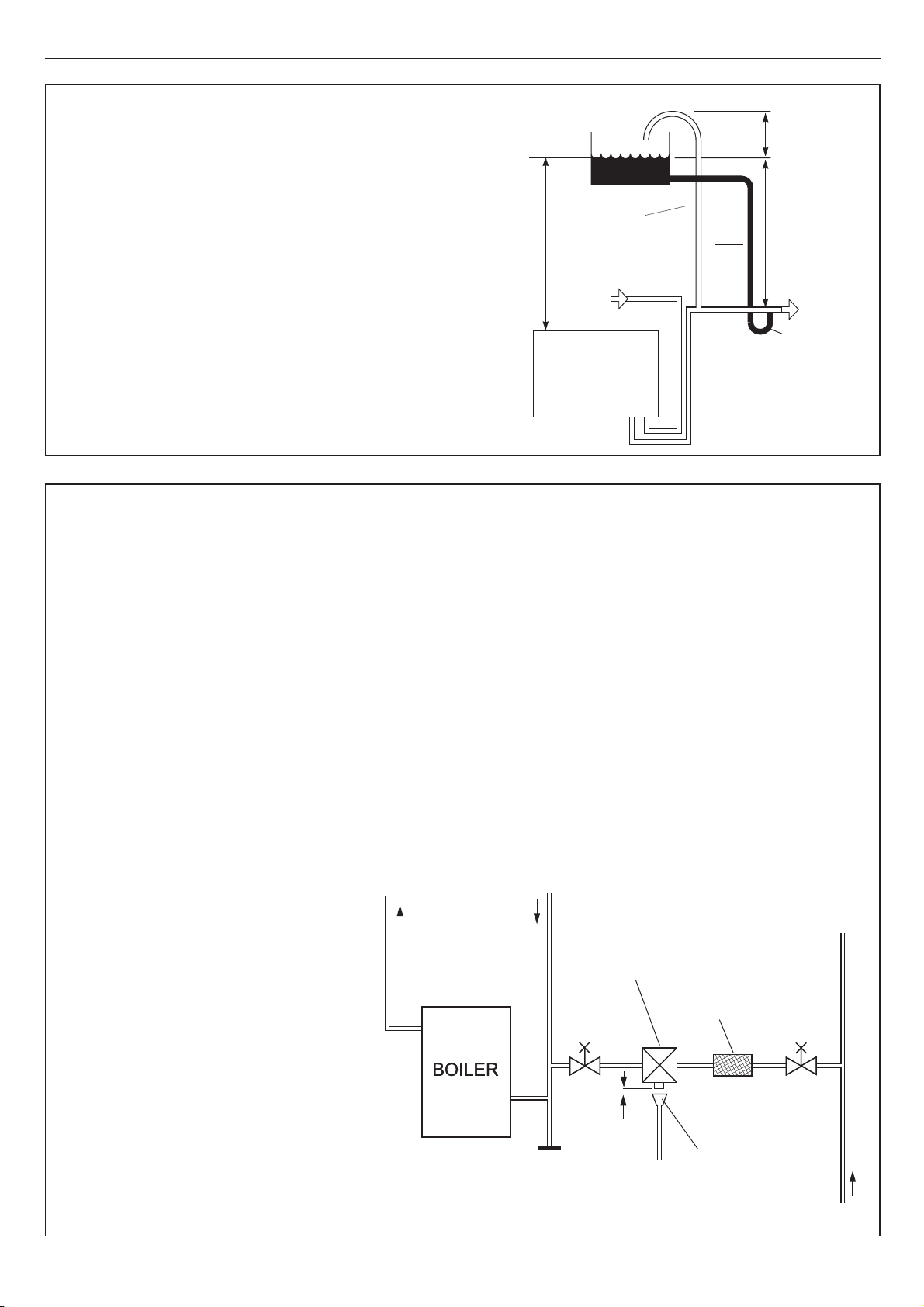

OPEN VENTED SYSTEM REQUIREMENTS

Detail reference should be made to the appropriate standards listed on

page 4.

The information and guidance given below is not intended to override

any requirements of the above publications or the requirements of the

local authority, gas or water undertakings.

The vertical distance between any additional pump and feed/expansion

cistern MUST comply with the pump manufacturer’s minimum

requirements, to avoid cavitation. Should these conditions not apply

either lower the pump position or raise the cistern above the minimum

requirement specied by Keston. The isolation valves should be tted

as close to the pump as possible.

The boiler is tted with an automatic air vent, located in the left top

side of the interior. This air vent must never be shut off, as this could

result in dry ring of the boiler and subsequent damage to the heat

exchanger.

3

SEALED SYSTEM REQUIREMENTS

Note. The method of lling, relling, topping up or ushing

sealed primary hot water circuit from the mains for a nondomestic property is shown below.

1. General

a. Detail reference should be made to the appropriate

b.

c. All components of the system, including the heat

d. The boiler is tted with an automatic air vent, located in

2. Safety Valve (supplied with boiler)

A spring loaded safety valve complying with

the relevant requirements of BS. 6759 Pt. 1

must be tted in the ow pipe as close to the

boiler as possible and with no intervening

valve or restriction. The valve should have

the following features:

a. A non-adjustable preset lift pressure not

The supplied Pressure Relief Valve is for

8

standards listed on page 4. The information and guidance

given below is not intended to override any requirements

of these publications or the requirements of the local

authority, gas or water undertakings.

The installation should be capable of working with ow

temperatures of up to 90oC and a temperature differential of

up to 20oC.

exchanger of the indirect cylinder, must be suitable for a

working pressure of 4 bar (60 lbf/in2) and temperature of

110oC. Care should be taken in making all connections so

that the risk of leakage is minimised.

the left top side of the interior. This air vent must never be

shut off, as this could result in dry ring of

the boiler and subsequent damage to the

heat exchanger.

exceeding 4 bar (60 lbf/in

boiler protection only in the event that the

ow and return isolators have been turned

off. If converting to a sealed system a

separately sized PRV suitably sized will

need to be tted in addition on the heating

circuit.

2

).

b. A manual testing device.

c. Provision for connection of a discharge pipe. The

valve or discharge pipe should be positioned so that

the discharge of water or steam is visible, but will not

cause hazard to user or plant.

3. Pressure Gauge

A pressure gauge covering at least the range 0-4bar

must be tted to the system. The gauge should be

easily seen from the lling point and should preferably

be connected at the same point as the expansion

vessel.

4. Expansion Vessel

Expansion vessels used must comply with BS. EN

13831. Connection to the system must not incorporate

an isolating valve.

Keston Heat - Installation & Servicing

4

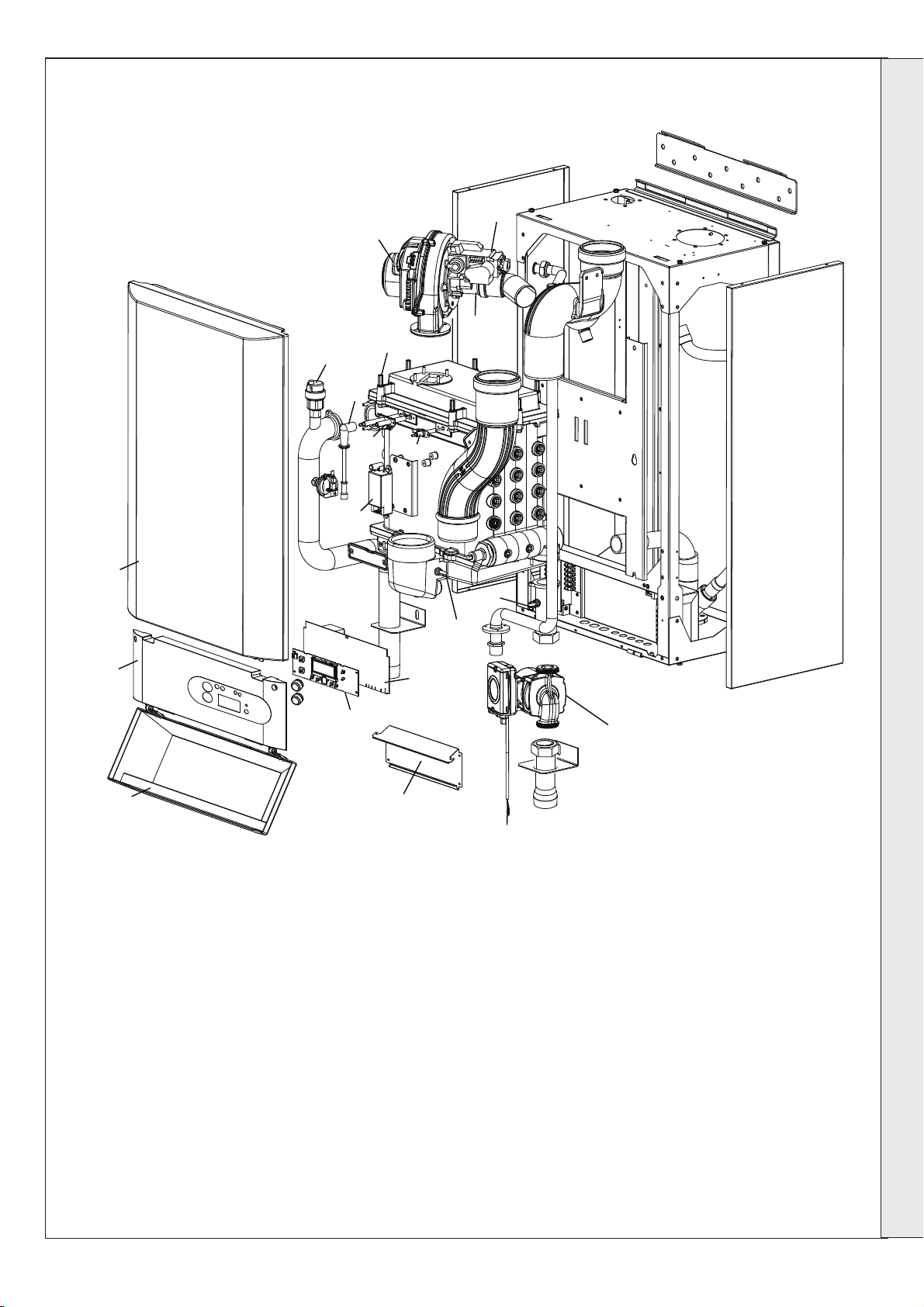

BOILER ASSEMBLY - Exploded View

230

INSTALLATION

231

501

308

105

302

304

309

306

208

305

310

508

232

301

INSTALLATION

510

502

KEY

105 Auto Air Vent

208 Burner Fixings Kit

230 Fan

231 Gas Valve Kit

232 Venturi Kit

301 Dry Fire Thermistor Kit

302 Lead Ignition Kit

509

304 Ignitor Unit

305 Electrode Detection Kit

306 Ignition Electrode Kit

308 Fascia Plastic

309 HMI Board

310 Primary PCB

Jacket Assembly Keston Heat

501

Kit

502 Door Assembly Keston Heat Kit

508 Flue Stat

509 Bulk Head Acccess plate

510 Pump

Keston Heat - Installation & Servicing

9

5

PACKAGING REMOVAL

iNSTALLATiON

• The boiler should be laying on its back with the straps

removed.

• Carefully read the installation instructions before proceeding.

• Remove the accessory Box.

• Remove the outer packing sleeve.

• Remove the protective cardboard wall mounting template

from the front of the boiler.

• Remove the packing piece from the top of the boiler.

• Check the contents against the list in Frame 6 ‘Unpacking’.

Note: some items are contained within the top packing

piece.

• The boiler may now be stood on its base, with the

cardboard bottom packing piece still in place to protect the

connections. Due care should be taken when standing up

the boilers, with respect to their weights, see Table 2 on

page 2.

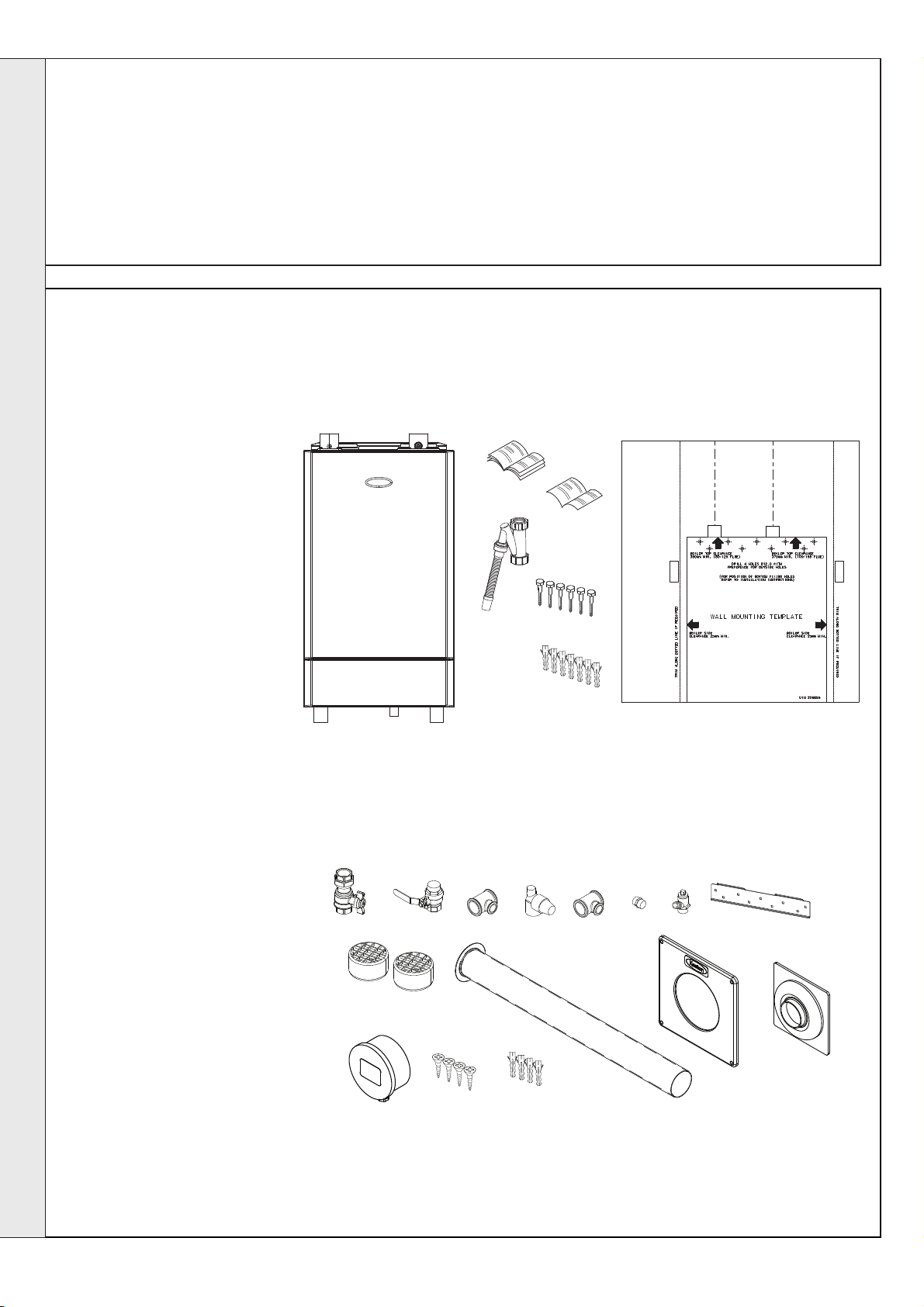

6

UNPACKING

INSTALLATION

The boiler is supplied fully assembled in one pack. When unpacking the boiler check the contents against the list shown.

Do not dispose of the packaging until all contents are accounted for, as some parts are held within the cardboard packing

pieces.

Pack Contents

A Fully assembled boiler

A

B

D

C

B Installation & Servicing/User

Instructions

E

C Log Book

D Wall mounting template

E Condensate Trap

F

F M10 x 70 Hex Head Coach

Screws - 6 off

G M10 Wall Plug - 6 off

G

Accessory Box

A Gas cock

B Ball Valve - 2 off

C M1 Tee

D Pressure Relief Valve

E M1 Tee

F Drain Nipple

G Drain Nipple

H Wall Mounting Plate

J Terminals - 2 off

K Flue Sleeve

L Wall Plate & Screws

M Wall Seal

N Weather Compensation

P Screws - 4 off

Q Wall Plugs - 4 off

10

A

N

B

J

C

P

D

E

F

K

Q

G

L

H

M

Keston Heat - Installation & Servicing

7

X

Y

120 245 365 490

Vertical Offset From X mm

Distance from flue centre line (Y) to outside wall surface.

For lengths greater than 8m, increase offset (X) by 60mm

for every additional 1m.

Does not apply to air intake.

8m

6m

4m

2m

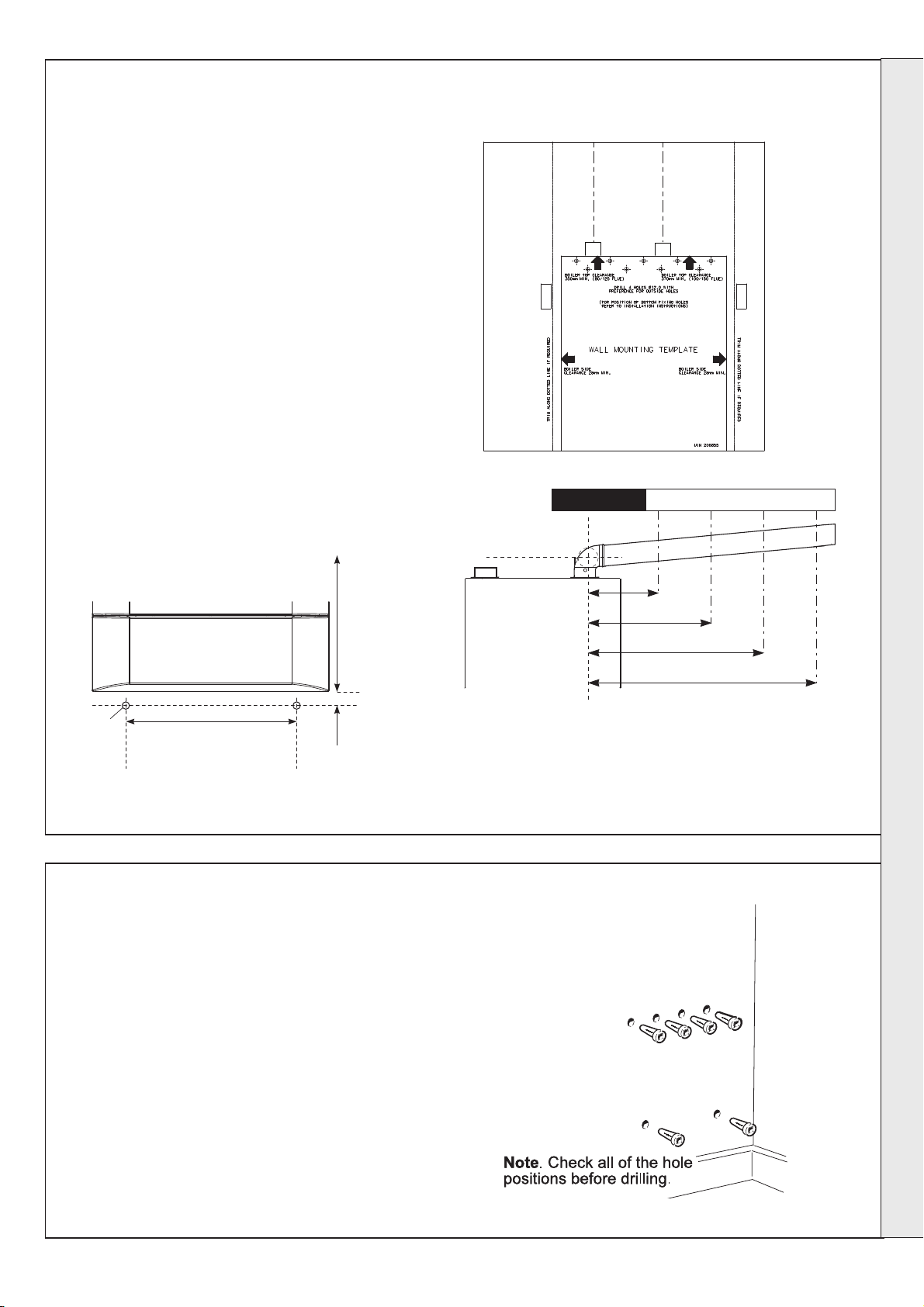

WALL MOUNTING TEMPLATE

Note. The template shows the positions for the

top xing holes. Care must be taken to ensure

the correct holes are drilled.

1. Tape template into the selected position.

2. Ensure squareness by hanging a plumbline.

3. Mark on to the wall:

a. The top 4 wall mounting plate screw

positions.

b. The 2 boiler lower xing positions using

diagram below

c. The position of the ue duct. Mark

the centre of the hole as well as the

circumference.

4. Remove the template from the wall.

INSTALLATION

Note: Horizontal ue runs must be inclined

at 3.5o to the horizontal to allow condensate

to drain back to the boiler.

INSTALLATION

BOILER LOWER FIXING POSITIONS

Ø12mm

8

PREPARING THE WALL

IMPORTANT. Ensure that, during the cutting

operation, masonry falling outside of the building

does not cause damage or personal injury.

1. Drill 4 boiler top xing holes with a 12mm

1

(

/2”) masonry drill and insert the plastic plugs

provided, for the wall mounting plate.

2. Drill the 2 boiler lower xing holes with a 12mm

1

/2”) masonry drill, insert the plastic plugs

(

provided .

3. Fix the wall bracket, supplied in accessory

box, into place with 4 M10x70 hex head coach

screws provided.

332mm

850mm to top of boiler18mm

Keston Heat - Installation & Servicing

11

9

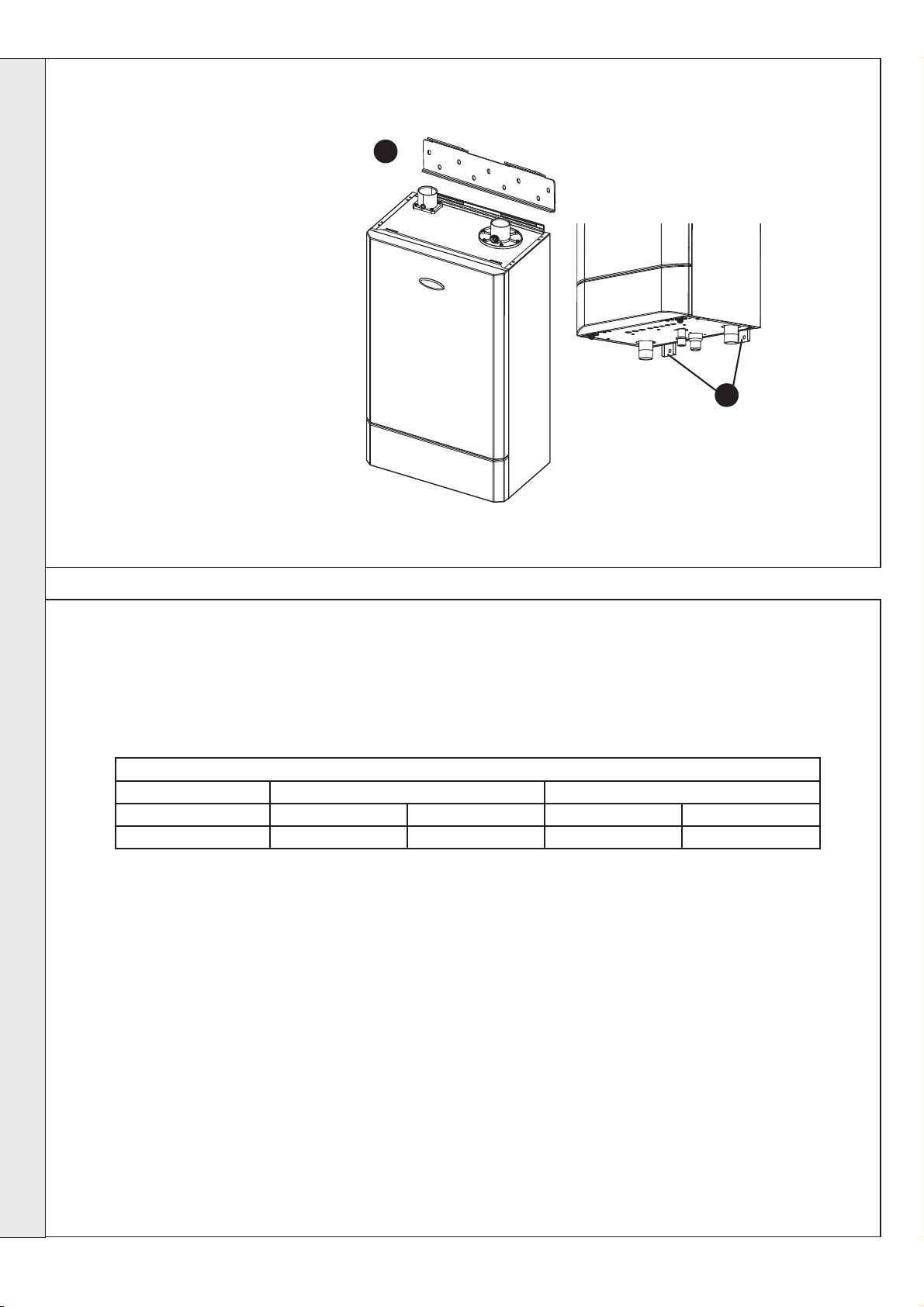

1

2

MOUNTING THE BOILER

• Due care should be taken

when lifting the boilers, with

respect to their weights, see

Table 2 on Page 2. Also refer

to Safe Handling on Page 4.

1. Lift the boiler onto the wall

mounting plate as shown.

Note: It is not necessary to

hold the boiler at an angle

to engage the wall mounting

plate.

2. Using the remaining coach

INSTALLATION

screws, secure the bottom of

the boiler to the wall through

the attached brackets.

iNSTALLATiON

10

VENTILATION

Keston ventilation requirements when installed in a compartment up to 70kW (BS5440)

To a room or internal space To outside Air

Model 45 55 45 55

Min Free Area (cm

2

) 432 527 216 263

Keston Heat 45/55 (multiple boiler applications)

Detail reference should be made to BS. 6644 for inputs

between 70kW and 1.8MW (net). In IE refer to the current

edition of I.S.820. The following notes are for general

guidance only:

If ventilation is to be provided by means of permanent

high and low vents communicating direct with outside air,

then reference can be made to the sizes below. For other

ventilation options refer to BS. 6644. In IE refer to the

current edition of I.S.820.

12

Keston Heat - Installation & Servicing

INSTALLATION

11

FLUE SYSTEM

Note. When installing a replacement boiler a new ue system

must be used. Do not re-use the existing boiler ue installation.

Design

Individual air supply and ue outlet pipes are used as standard.

The material used for ue outlet &/or air inlet must be

muPVC (PVC-C) to BS 5255 and/or BSEN 1566-1 and BSEN

1329 of an internal diameter of 51mm. (i.e. nominal 50mm

diameter muPVC solvent weld waste pipe).

Marley muPVC (PVC-C) Solvent Weld Waste System

(50mm) and Polypipe System 2000 muPVC (PVC-C) solvent

weld waste (50mm) are the only systems approved for this

application.

The following pipes and ttings are approved:

Polypipe System 2000 muPVC solvent Weld Waste System

(50mm)

Poly Pipe Code

MU 301 4m length muPVC wastepipe 5/225

MU 313 50mm x 45 deg muPVC obtuse bend

MU 314 50mm x 92.5 deg muPVC swept bend

MU 310 50mm muPVC straigh coupling

MU 316 50mm x 92.5 deg muPVC swept pipe

Marley muPVC solvent Weld Waste System (50mm)

Marley Code

KP 304 50mm x 4m double spigot pipe

KP32 50mm x 45 deg bend

KSC3 50mm straight coupling

KB3 50mm x 88.5 deg bend

KT3 50mm swept tee

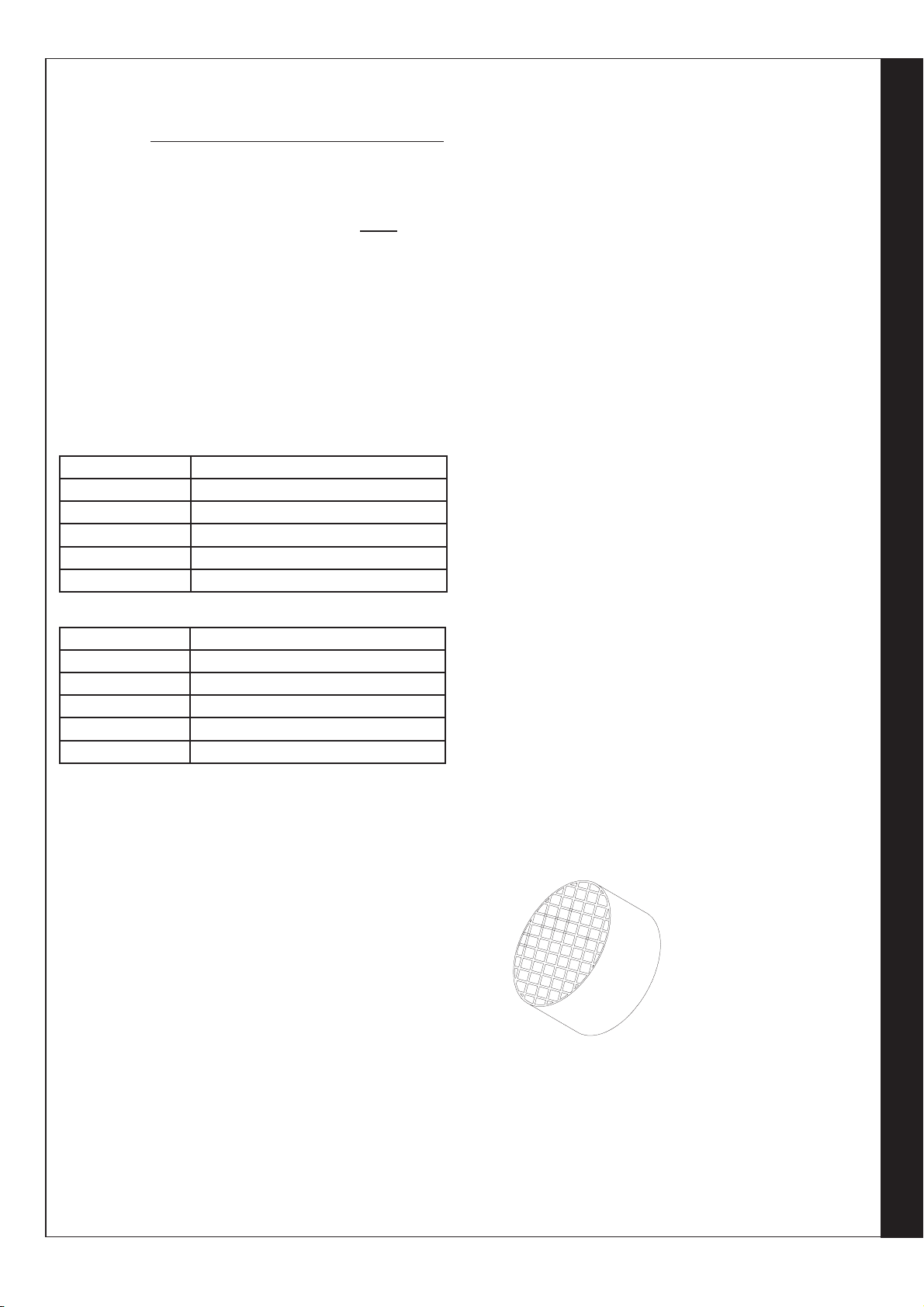

Both the 50mm ue

outlet terminal and

the 50mm air inlet

terminal are supplied

with the ue pack and

are illustrated in Fig. 1

and must be used in

ALL installations. (Both

terminals are identical).

Fig.1

Keston Heat - Installation & Servicing

FLUE OUTLET

13

iNSTALLATiON

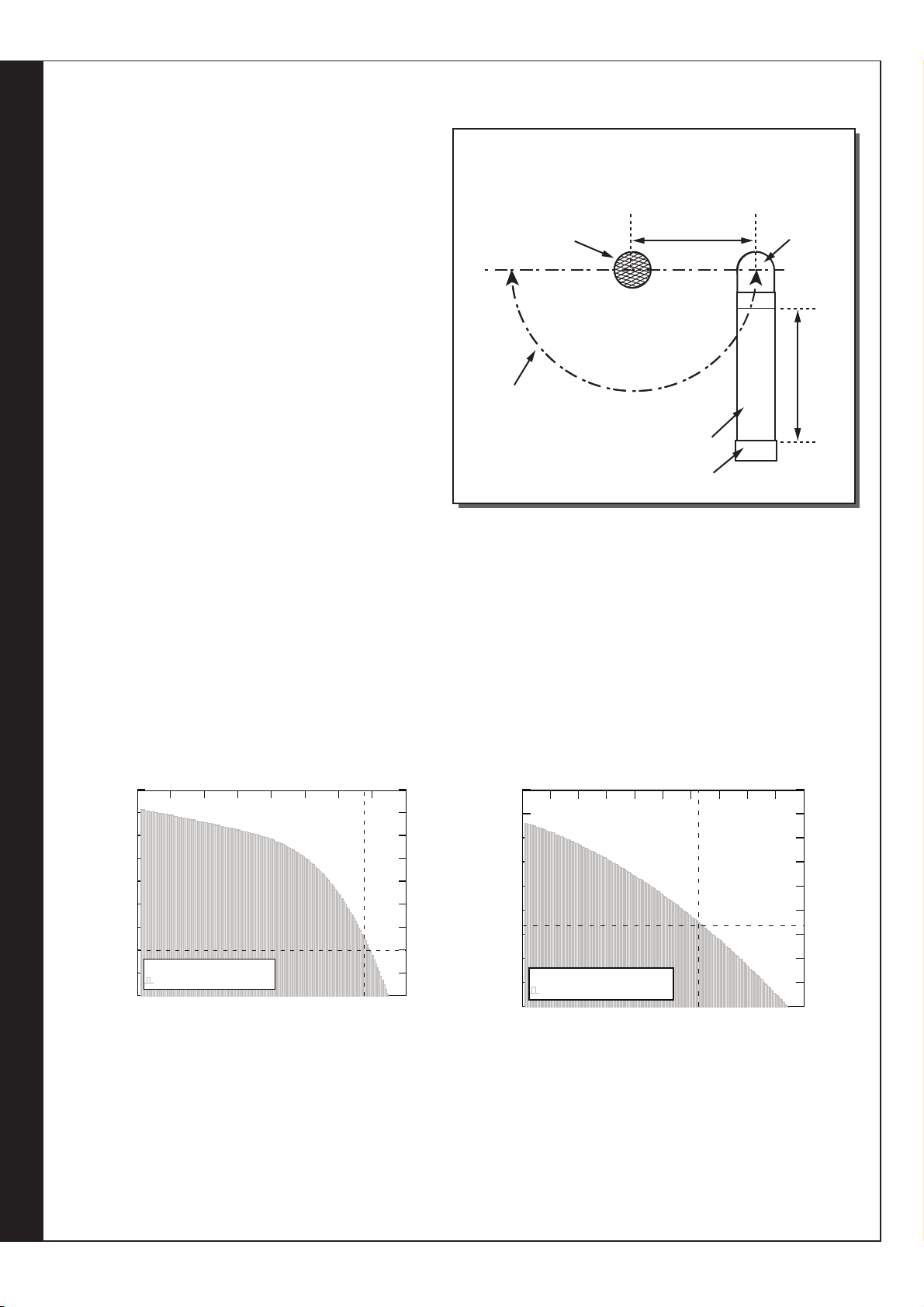

2 4 6 8 10 12 14 16 18

2

6

10

14

18

22

26

30

34

38

Accep table op erating area

Keston Evomax 55 - Flue & Air Pipe Length

Flue P ip e Length [m]

Air Pipe Length [m]

10

15.5

2 4 6 8 10 12 14 16 18 20 22

2

6

10

14

18

22

26

30

34

38

Acceptable Operating Area

Keston Evomax 45 - Flue & Air Pipe Length

Flue Pipe Length [m]

Air Pipe Length [m]

15.5

14.5

TERMINAL POSITIONS

Flue

Pipe

Elbow

Minimum Separation

140mm

Acceptable

range of air

pipe siting

Terminal

Air Pipe

150mm

12

FLUE SYSTEM.... CONT’D

TERMINATION OF THE FLUE AND AIR

The ue and air pipes may terminate independently through

any external walls within the same dwelling except on

opposing walls, within the maximum lengths shown in Fig 3

& 4.

The air pipe must have an elbow and 150mm length of pipe

directed downwards with a termination grill tted.

The air pipe can be situated at the side or beneath the

ue pipe to a minimum dimension of 140mm (see diagram

below). It must not be sited above the ue pipe.

The ue and air pipes must extend by at least 40mm from

the wall surface.

Condensing boiler emit a visible plume of water vapour from

the ue terminal, this is normal. It is the responsibility of the

installer to judiciously select a terminal location that does not

cause a nuisance.

If either the ue or air terminal is below a height of 2m from

ground level a terminal guard must be tted.

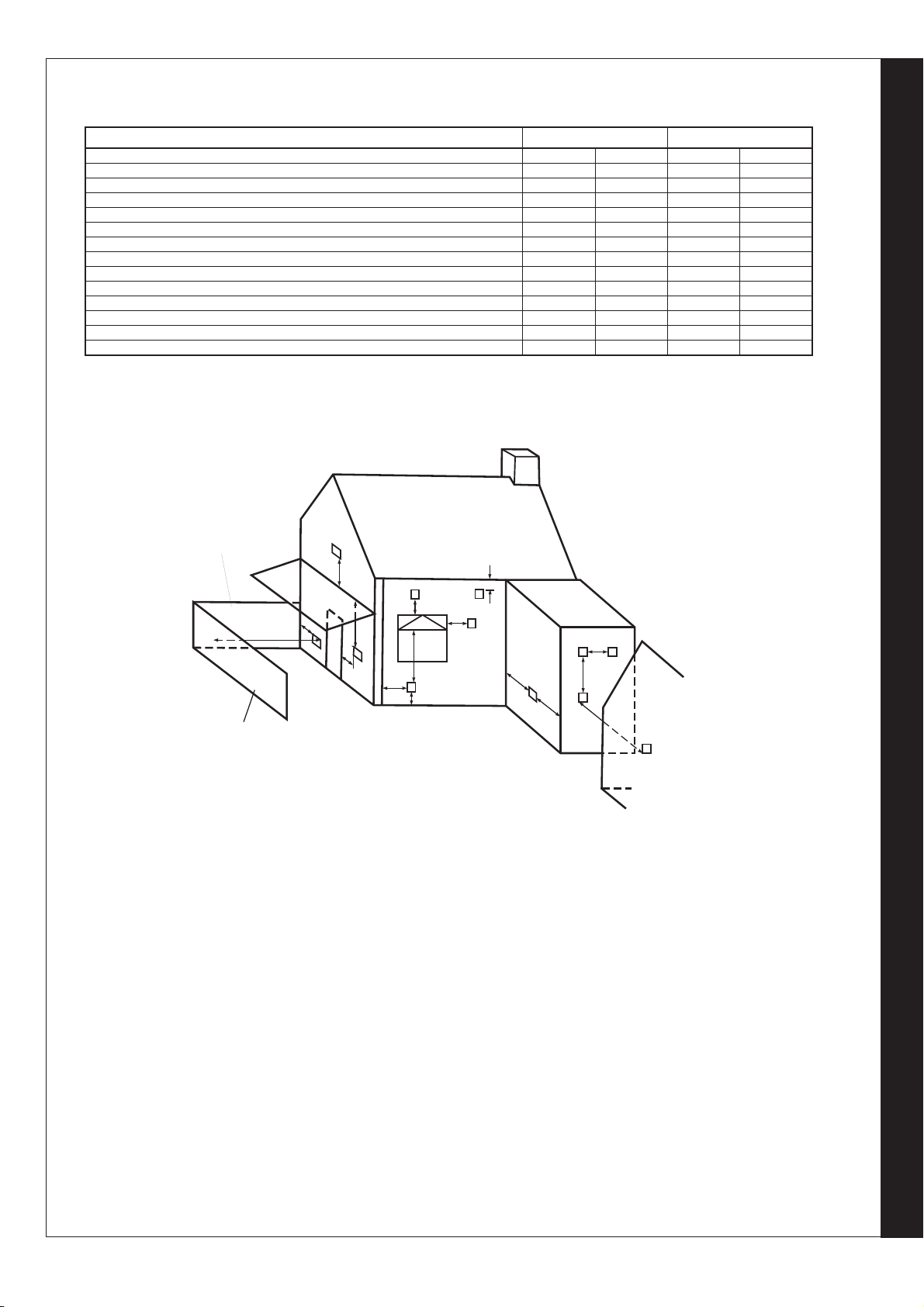

MAXIMUM LENGTHS

Due to the resistance presented by extended ue length a slight reduction in maximum boiler output will occur where

combined ue and air lengths in excess of 16.0m (50mm muPVC) are used. In such cases the boiler output will be reduced by

0.8% per additional metre.

The maximum lengths of both air inlet pipe and ue outlet pipe, when no bends are used, are as detailed in gs 3 & 4.

However, each bend used has an equivalent length that must be deducted from the maximum straight length stated in gs 3 &

4. Knuckle bends must not be tted.

A 92.5º swept elbow is equivalent to 1.0m straight length. A 45º bend is equivalent to 0.5m straight length.

It is possible to have variable ue and air lengths as described within the shaded area of Figs 3 & 4.

FLUE OUTLET

14

SLOPE

‘Horizontal’ ue outlet pipework MUST slope at least 3.5 degrees (60mm per metre run) downwards towards the boiler.

Pipework can be vertical. Only swept elbows can be used.

Air inlet pipework can be truly horizontal or vertical, or sloping in a downward direction towards the boiler but in each case rain,

etc., must be prevented from entering the pipe. There must be no troughs in any of the pipework, whether it be air inlet

or ue outlet.

Fig. 3

Fig. 4

Keston Heat 45 - Flue & Air Pipe LengthKeston Heat 55 - Flue & Air Pipe Length

Keston Heat - Installation & Servicing

13

a built in element, such as a window frame.

The dimensions given in the table above may need to be increased to avoid wall staining and nuisance depending on site conditions.

FLUE TERMINATION POSITION

INSTALLATION

Twin Flue Positions

A.

Below an opening (1)

B.

Above an opening (1)

C.

Horizontally to an opening (1)

D.

Below gutters, soil pipes or drain pipes

E.

Below eves

F.

Below balcony or car port roof

G.

From a vertical drain pipe or soil pipe

H.

From an internal or external corner or to a boundary alongside the terminal

I.

Above ground, roof or balcony level

J.

From a surface or a boundary facing the terminal

K.

From a terminal facing the terminal

L.

From an opening in the car port into the building

M.

Vertically from a terminal on the same wall

N.

Horizontally from a terminal on the same wall

(1) An opening here means an openable element, such as a openable window, or a fixed opening such as an air vent. However, in addition, the outlet should not

be nearer than 150mm (fanned draught) to an opening into the building fabric formed for the purpose of accommodating

boundary

I

Flue Minimum Spacing Air Minimum Spacing

D, E

300 mm

300 mm

300 mm

75 mm

200 mm

200 mm

150 mm

300 mm

300 mm

600 mm

1200 mm

1200 mm

1500 mm

300 mm

12"

12"

12"

3"

8"

8"

6"

12"

12"

24"

48"

48"

60"

12"

50 mm

50 mm

50 mm

75 mm

50 mm

50 mm

50 mm

50 mm

100 mm

100 mm

1200 mm

100 mm

1500 mm

300 mm

2"

2"

2"

3"

2"

2"

2"

2"

4"

4"

48"

4"

60"

12"

B

J

boundary

H

F

L

G

C

A

H

H

I

N

M

K

GENERAL INSTALLATIONS

All parts of the system must be constructed in accordance with BS 5440 Part 1, except where specically mentioned in these

instructions.

All pipe work must be adequately supported.

Marley muPVC (PVC-C) Solvent Weld Waste System (50mm) and Polypipe System 2000 muPVC (PVC-C) solvent weld waste

(50mm) are the only systems approved for this application.

Consideration must be given to Gas Safe Register bulletin TB008 regarding ues in voids and inspection hatches.

The boiler casing must always be correctly tted to the boiler when leaving the appliance operational.

External wall faces and any internal faces of cavity walls must be good.

Rubber collars are available for ue and air terminals to nish the external wall face around the terminals (Part No C.08.00.07.0).

AIR SUPPLY

The Keston Heat is a room-sealed appliance and therefore does not require purpose provided ventilation to the boiler room for

combustion air.

Keston Heat - Installation & Servicing

FLUE OUTLET

15

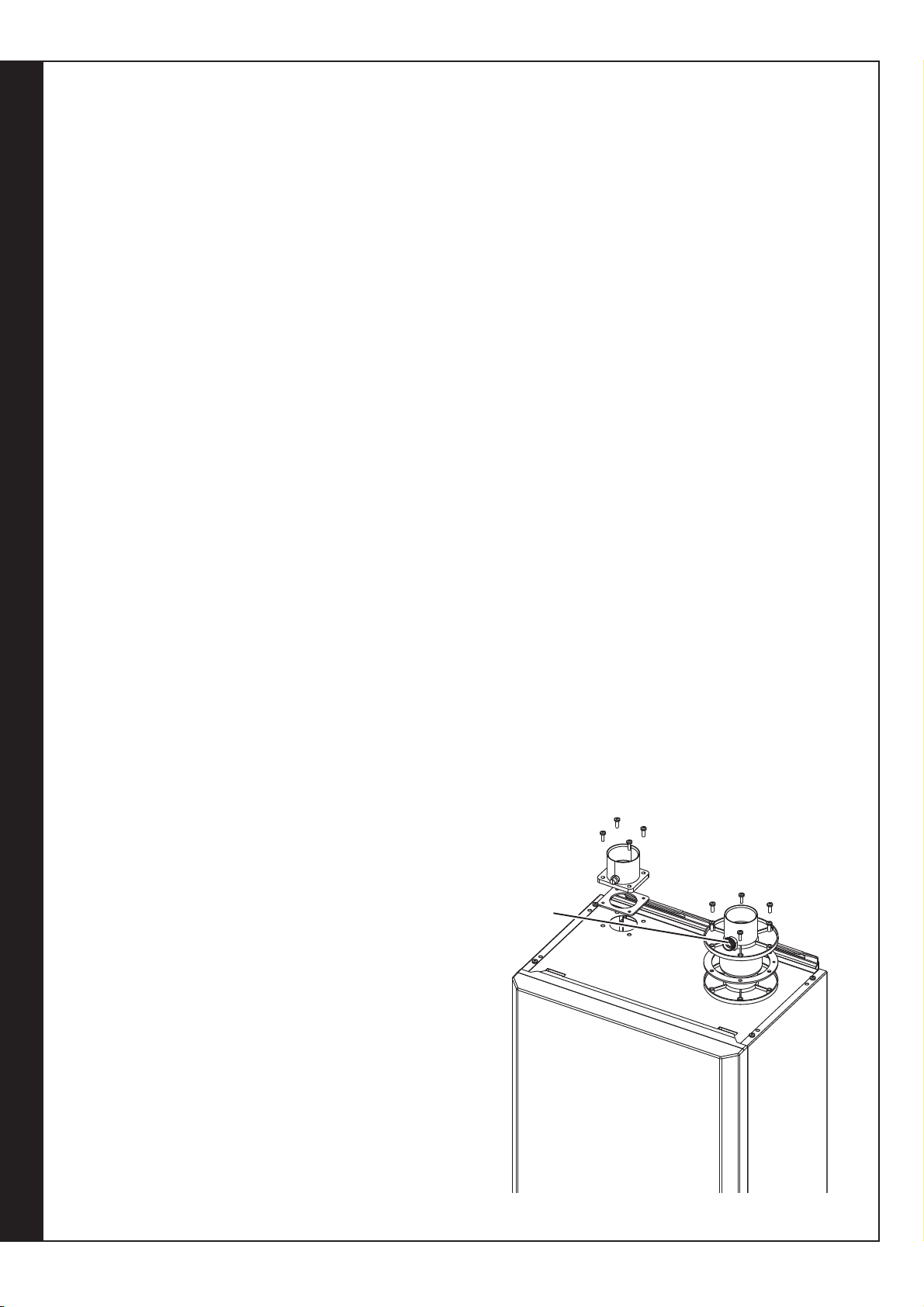

14 ASSEMBLY PRACTICE

iNSTALLATiON

Remove all plastic debris and burrs when installing air intake

piping. Plastic lings caused by cutting muPVC pipe must not

be allowed to be drawn into the combustion air blower. Prevent

dust entering the air intake when cutting on building sites. Blower

failure which is determined to be caused by plastic lings or other

debris will not be covered by guarantee.

INSTALLING FLUE AND AIR PIPES

Important - When installing the boiler on an existing system a

new ue and air intake system MUST also be installed. You

MUST NOT re-use existing ue or air pipework components.

• Remove the ue adaptor and air spigot from the ue pack

supplied with the boiler.

• Remove boiler front panel - Frame 55

• Remove air intake blanking plate by unscrewing 4 x M5

screws and put to one side, leaving sponge gasket in place.

• Fix air spigot to boiler using the 4 M5 screws, see diag.

below. Ensure sponge gasket is in place and not damaged.

• Insert the ue adaptor into the ue manifold on the top of the

boiler and secure using the 6 M5 screws provided

• Measure, cut and check the air and ue pipes to pass to the

exit from the wall(s) or ceiling.

• Using the same methods drill any further holes (always

covering existing pipework), cut and assemble the

pipework.

• From outside, complete the two terminations - See

Frame 11 Flue System and make good all holes. (Wall

sealing collars are available to make good hole areas on

the wall face (part number C.08.0.00.07.0).

• Support any pipes whose route could be displaced

either of its own accord or by accident. Any

horizontal run over 1m or vertical runs of any length

must always be supported. Brackets should be

placed at intervals of approximately 1m. Brackets

should be loose enough on the pipe to allow

thermal expansion and contraction movement.

• Flue pipework through walls MUST be sleeved to

allow thermal expansion and contraction movement.

• Check all connections for security and re-seal any joints

using solvent cement where soundness may be in

doubt.

• Check Sample plug for free movement and seating.

Note. It is equally important to seal the air inlet with solvent

cement as the ue outlet pipe joints.

• Always thoroughly deburr all pipes and most important,

remove shavings from within the pipe.

• Assemble, using solvent weld cement, the pipework from

the boiler connections to the exit from the rst wall/ceiling,

(remount the boiler if removed). Care must be taken when

applying solvent weld to ensure it does not come into contact

with the sample plug. When pushing pipe through walls,

ensure grit and dust is not allowed to enter the pipe.

Ensure pipes are fully engaged into sockets and solvent

welded with no leaks.

Flue

Sampling

Point

FLUE OUTLET

16

Keston Heat - Installation & Servicing

INSTALLATION

15

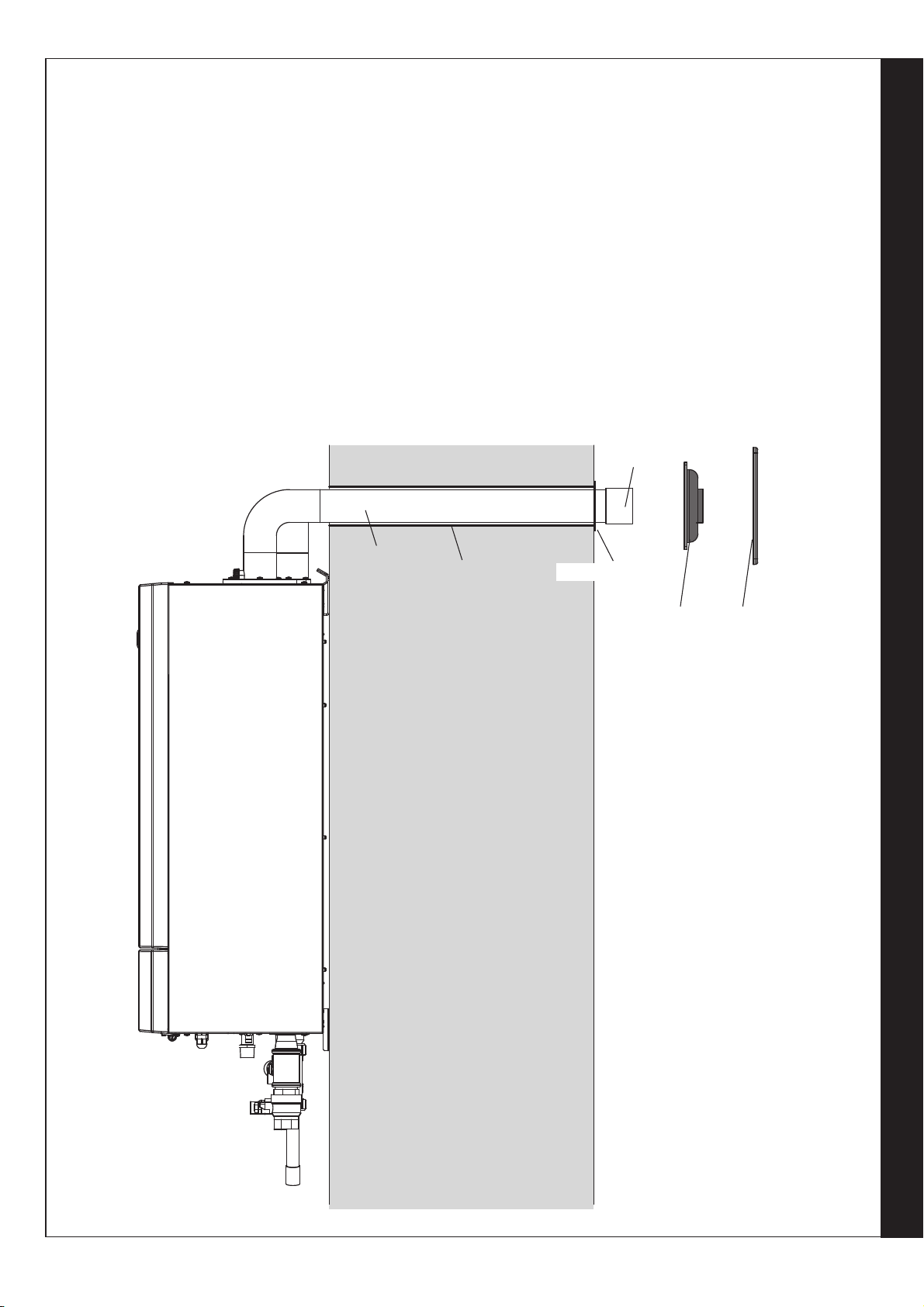

FITTING THE FLUE SLEEVING

1. Cut hole in wall (preferably with 60mm core bore tool).

2. Measure wall Thickness

3. Cut sleeve length to match wall thickness & remove burrs.

4. Grout sleeve into wall with ange on external face.

5. Slide ue pipe into sleeve, checking it is free to slide.

6. Slide Flexible wall seal over ue pipe and push centre ring up to sleeve ange when cold.

7. Locate wall plate over exible wall seal and clamp in place using the raw plug pack.

8. Afx ue terminal

9. During boiler test check that the ue end is free to expand and contract with exible wall seal.

Flue

Terminal

Flue Pipe

Flue Sleeve

Flue Sleeve Flange

Flexible

Wall

Seal

Wall

Plate

Keston Heat - Installation & Servicing

FLUE OUTLET

17

iNSTALLATiON

6m

2m

Bracket at

each 1 metre

1m

4m

1.5m

6m

3.5º back

to boiler

Sleeve

3.5º back

to boiler

Air

Elbows 2 x 1m = 2m

Straights 6+2 = 8m

Total = 10m

Overall Flue / Air = 25.5m

Flue

Elbows 3 x 1m = 3m

Straights 4+6+1.5+1 = 12.5m

Total = 15.5m

Calculations

2 4 6 8 10 12 14 16 18

2

6

10

14

18

22

26

30

34

38

Accep table op erating area

Keston Evomax 55 - Flue & Air Pipe Length

Flue P ip e Length [m]

Air Pipe Length [m]

10

15.5

2 4 6 8 10 12 14 16 18 20 22

2

6

10

14

18

22

26

30

34

38

Acceptable Operating Area

Keston Evomax 45 - Flue & Air Pipe Length

Flue Pipe Length [m]

Air Pipe Length [m]

15.5

14.5

16

FLUE INSTALLATION EXAMPLE KESTON HEAT 55

Fig. 3

Keston Heat 55 - Flue & Air Pipe Length

17

FLUE INSTALLATION EXAMPLE KESTON HEAT 45

Sleeve

Air

FLUE OUTLET

18

4m

4m

3.5º back

to boiler

3.5m

2m

Bracket every

1 metre

3.5º back

to boiler

Air

4 x 90º elbows 4

Straight lengths 2

2

3.5

4

15.5

3.5m

1.5m

2m

Calculations

Overall Flue / Air = 30m

2.5m

Flue

3 x 90º elbows 3

Straight lengths 2.5

1.5

3.5

4

14.5

Fig. 4

Keston Heat 45 - Flue & Air Pipe Length

Keston Heat - Installation & Servicing

Loading...

Loading...