Page 1

EVERYTHING IS POSSIBLE

USER GUIDE

Heat2 45, 45P, 55, 55P

When replacing any part on this appliance, use only spare parts that you can be

assured conform to the safety and performance specification that we require.

Do not use reconditioned or copy parts that have not been clearly authorised by Keston.

For the very latest copy of literature for specification and maintenance practices visit our website

www.keston.co.uk where you can download the relevant information in PDF format.

August 2019

220384 A02

Page 2

CONTENTS

1. Introduction ................................................... 3

Safety .............................................................. 3

Electricity Supply ............................................. 3

Important Notes ............................................... 4

Minimum Clearances ....................................... 4

2. Boiler Operation ............................................ 5

Controls Diagram............................................. 5

To light the boiler ............................................. 6

Operating Status.............................................. 7

Settings............................................................ 8

3. Installer Connections .................................. 20

4. Faults ............................................................ 21

Faults - Hardware (Thermistors, Actuators)... 22

Faults - Temperature Supervisions ................ 23

Faults -

Faults - Internal System................................. 25

5. General Information .................................... 26

To shut down the boiler .................................. 26

To relight the boiler ........................................ 26

Frost Protection ............................................. 26

Boiler Overheat Thermostat .......................... 29

Condensate Drain.......................................... 26

Escape of Gas ............................................... 27

Cleaning ........................................................ 27

6. System Set up information ......................... 28

System (Flame, Fan, Hydraulic, etc.)

. 24

2

Page 3

KESTON HEAT2

45, 55

45, 55P

Natural Gas & Propane

Destination Countries: GB, IE, RO

1. INTRODUCTION

The KESTON HEAT2 is a wall mounted,

room sealed, super efcient condensing

boiler featuring full sequence automatic

spark ignition and fan assisted

combustion.

Due to the very high efciency, condensate

is produced from the ue gases and this

is drained to a suitable disposal point

through the plastic waste pipe at the

bottom of the boiler. A condensate

‘plume’ will also often be visible at the

ue terminal.

SAFETY

Current Gas Safety (Installation & Use)

Regulations or rules in force.

In your own interest, and that of safety, it

is the law that this boiler must be installed

and maintained by a suitably qualied

Gas Safe registered engineer or in IE a

competent person, in accordance with the

above regulations.

The appliance should be serviced at

least once a year by a suitably qualied

Gas Safe registered engineer or in IE a

competent person.

It is essential that the instructions in this

booklet are strictly followed, for safe and

economical operation of the boiler.

ELECTRICITY SUPPLY

The appliance must be earthed.

Supply 230 V - 50 Hz, 4 Amp fuse.

This appliance is intended to be connected

to the supply via a double-pole switch,

having a 3mm contact separation in both

poles, serving only the boiler and system

controls.

3

Page 4

IMPORTANT NOTES

• This appliance must not be operated

without the casing correctly tted and

forming an adequate seal.

• If the boiler is installed in a

compartment then the compartment

MUST NOT be used for storage

purposes.

• Do not store objects around or on the

boiler, and keep access clear at all

times.

• Do not obstruct ventilation ducts,

condensate pipework, grilles or

openings in the boiler room, room

space or compartment that the

appliance is installed in, or the

passage of combustion and ventilation

to the boiler.

• Do not turn off the boiler if it is to be

left unattended in frosty weather.

• If it is known or suspected that a fault

exists on the boiler then it MUST NOT

BE USED until the fault has been

corrected by a suitably qualied Gas

Safe registered engineer or in IE a

competent person.

• Flammable materials must not

be placed in close proximity to

the appliance. Materials giving off

ammable vapours must not be stored

in the same room as the appliance.

This appliance can

•

be used by children 8

years and above. Also

persons with reduced

physical, sensory or

mental capabilities, or

lack of experience and

knowledge, provided

they have been given

supervision or instruction

concerning use of the

appliance in a safe

way and understand

the hazards involved.

Children shall not play

with the appliance.

Cleaning and user

maintenance shall not be

made by children without

supervision.

• Children should be supervised to

ensure that they do not play with the

appliance.

In cases of repeated or continuous shutdown

a suitably qualified Gas Safe registered

engineer or in IE a competent person

should be called to investigate and rectify

the condition causing this and carry out an

operational test after each intervention on the

device. Only the manufacturers original parts

should be used for replacement.

MINIMUM CLEARANCES

Clearances of 450mm above, 300mm below,

25mm at the sides and 450mm at the front

of the boiler casing must be allowed for

servicing.

4

Page 5

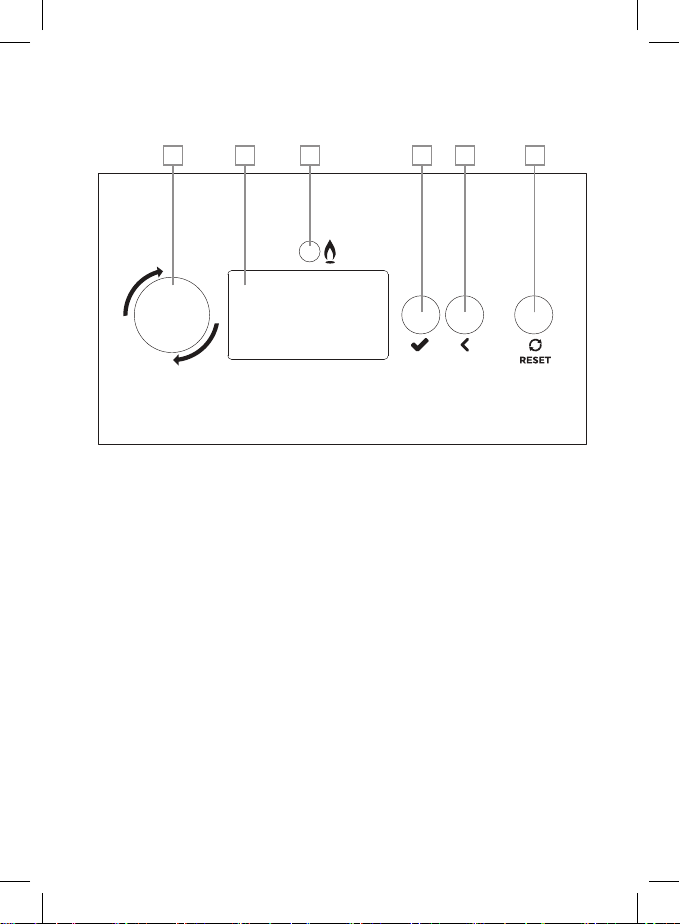

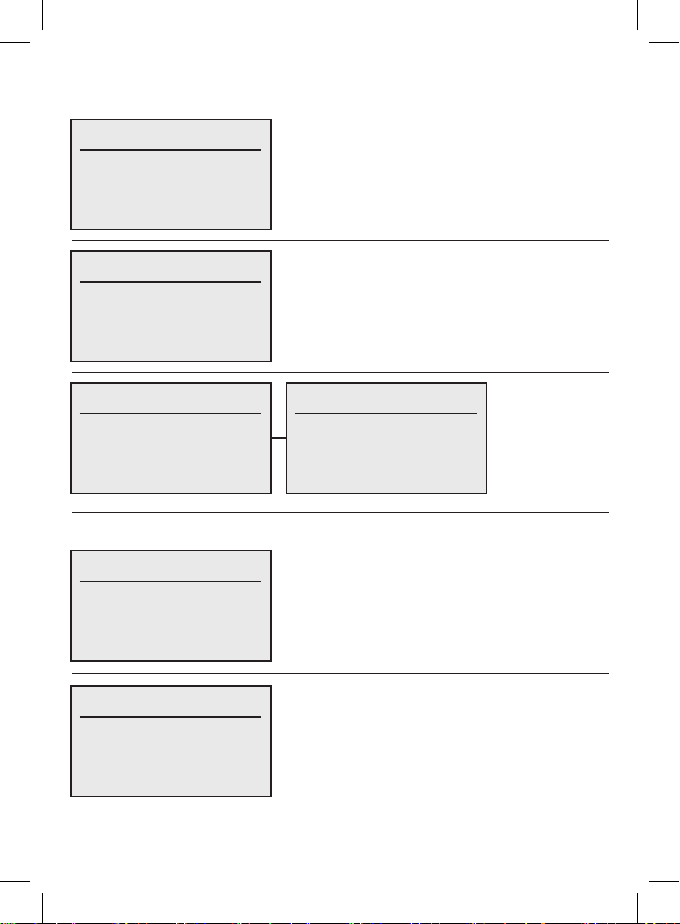

2. BOILER OPERATION

CONTROL DIAGRAM

A B C D E F

BACK

OK

A. ROTARY KNOB

• Enter a menu, if in the normal

operation screen, and highlight the

rst menu item.

Scroll up (anti-clockwise) or down

•

(clockwise) in a menu

• Change the value in parameter

setting.

• If an error is showing in the title

bar, scroll to the associated error

screen(s), and return.

B. LCD DISPLAY SCREEN

• Menu and status display.

C. BURNER LED

• Will be on if the burner is lit.

D. SELECT BUTTON

• Enter a menu, if in the normal

operation screen, and highlight the

rst menu item.

• Enter the highlighted menu (sub

menu or parameter), if in a menu or

sub menu.

• If in a parameter setting, select a

parameter which will then ash for

adjustment, once adjusted using the

rotary knob press again to store and

move on.

E. BACK BUTTON

• In a menu, return to the previous

menu layer.

• In parameter setting, exit the

parameter without storing the value.

• In a guided assistant, go back to the

previous screen.

F. RESET BUTTON

• Reset the associated boiler module

error, if a resettable (lockout) error is

active.

• Return to the normal operation

screen.

5

Page 6

TO LIGHT THE BOILER

A. Stand alone boiler, or a master

boiler in a cascade, or a master

boiler with an extension module:

Set the operating mode in the plant

menu operating mode to: Automatic

Ensure that there is a demand

present on the boiler from the

external controls, depending upon the

conguration.

If there are no local heating or DHW

circuits, set the plant / operating mode

to: Day

If there are local heating circuits,

set one of them - heating circuits /

HC1 Boiler 1.1 or HC2 Boiler 1.2 /

Operating mode to: Day

If there is a local DHW circuit set the

DHW / Operating mode / DHW1 Boiler

1 to: Day

If there is an extension module

congured with Heating circuits or

DHW circuits set the Operating mode

to: Day

e.g. Heating circuits / Operating mode

/ HCx EMy.z

DHW / Operating mode / DHWx

EMy.z

Key: x is the Heating or DHW circuit

number, y is the Extension Module

designation and z its local Heating or

DHW circuit designation.

B. Slave Boiler in a Cascade:

Refer to the Installation manual.

The boiler will commence the ignition sequence, supplying heat to the system. Ensure that

the controls are then set to the operating mode required.

Note. Not all menus and options will be available depending upon the access level selected.

6

Page 7

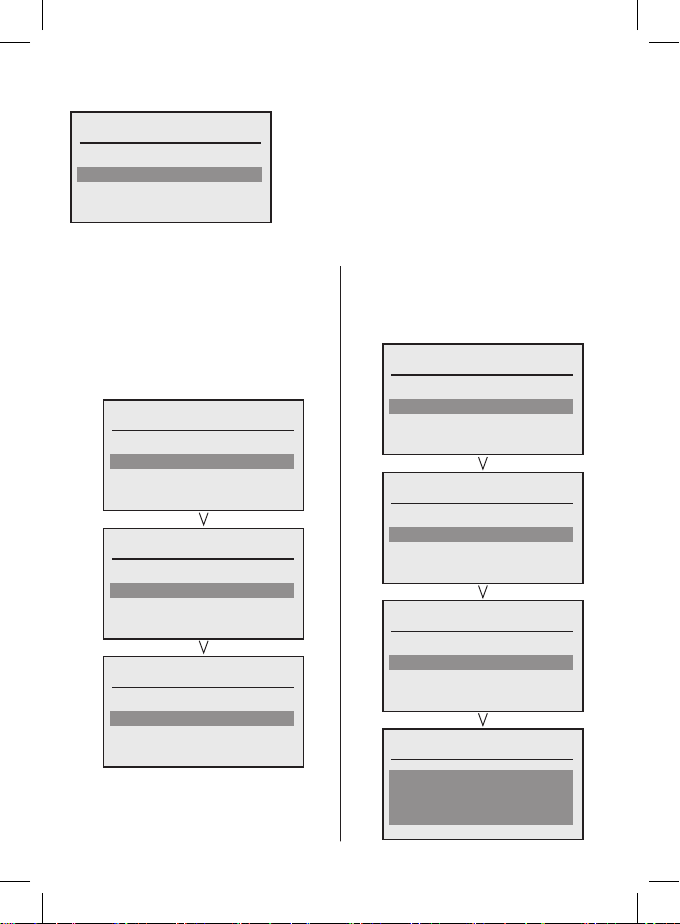

OPERATING STATUS

The status screens are dependent upon the boiler conguration, they are shown below:

KESTON HEAT 2 55kW

Operation: Htg. with temp.

Master non cascade

Flow Set point: 40.2ºC

Flow temp: 40.2ºC

KESTON HEAT 2 55kW

Operation: Htg. with capacity

Capacity Set point: 40%

Master / Non cascade / Slave

Capacity: 0%

Flow temp: 40.2ºC

KESTON HEAT 2 55kW

Operation: Htg. with temp.

Voltage: 5.6V

Flow Set point: 40.2ºC

Flow temp: 40.2ºC

KESTON HEAT 2 55kW

Operation: Htg. with capacity

Voltage: 5.6V

Capacity Set point: 40%

Capacity: 0%

Master non cascade,

0-10V control

The heating circuits and DHW circuits also have status screens associated with them. e.g.

KESTON HEAT 2 55kW

Status: OpenTherm

Operation: Day

Room set point: 20.0ºC

Menu item: Heating circuit / Status / Summary /

HC1 Boiler 1.1

Flow set point: 60.0ºC

KESTON HEAT 2 55kW

Status:

Operation: Night

Tank temperature: 45.0ºC

Menu item: DHW / Status / Summary / HC1

Boiler 1.1

Flow set point: 30.0ºC

7

Page 8

SETTINGS

1. Heating Circuits

Menu

Plant

Heating circuits

DHW

Each heating circuit that is congured has the following settings:

a. Operating mode selection:

Every heating circuit can be

individually set to one of the

following modes;

Standby / Time clock single day

/ Time clock multiple day / Day /

Night.....e.g.:

Heating circuits

Status

Operating mode

Room temperature

Flow temperature

b. Room temperature

A temperature can be set for each

heating circuit for the following periods:

Day / Night / Holiday.....e.g.:

Heating circuits

Operating mode

Room temperature

Flow temperature

Settings

Room temperature

Heating circuits

HC1 Boiler 1.1

HC2 Boiler 1.2

HC1 Boiler 1.1

Operating mode

Standby

HC1 Boiler 1.1

HC2 Boiler 1.2

HC1 Boiler 1.1

Room temperature. day

Room temperature. night

Room temperature. holiday

Room temperature, day

20.0

8

Page 9

c. Flow temperature

A maximum ow temperature can be

set for each heating circuit for the

following periods

Day / Night / Holiday.....e.g.:

Heating circuits

Room temperature

Flow temperature

Settings

Time clock

Flow temperature

HC1 Boiler 1.1

HC2 Boiler 1.2

HC1 Boiler 1.1

Flow temperature. day

Flow temperature. night

Flow temperature. holiday

Flow temperature, day

70.0

d. Settings

Each heating circuit has a number

of settings that can be congured.

Most settings are only accessible

at Installer access levels.

Day / Night / Holiday.....e.g.:

Heating circuits

Flow temperature

Settings

Time clock

Holiday program

Settings

HC1 Boiler 1.1

i. Preheat - Preheat can be enabled

for a heating circuit and a

maximum time can be set.

HC1 Boiler 1.1

Preheat

Heating limit

Room temp. switch diff.

Preheat

Preheat switch

Maximum preheat time

CONTINUED OVERLEAF

9

Page 10

i. Preheat - Preheat can be enabled

for a heating circuit and a

maximum time can be set.

HC1 Boiler 1.1

Preheat

Heating limit

Room temp. switch diff.

ii. Heating Limit- Heating limit can be

enabled for a heating circuit with a

limit temperature set.

HC1 Boiler 1.1

Preheat

Heating limit

Room temp. switch diff.

Pump

Preheat

Preheat switch

Maximum preheat time

Preheat switch

On/Off

Preheat switch

On/Off

Preheat

Preheat switch

Maximum preheat time

Maximum preheat time

120 minutes

Heating limit

Heating limit switch

Heating limit temperature

Heating limit switch

On/Off

Heating limit switch

On/Off

Heating limit

Heating limit switch

Heating limit temperature

10

Page 11

Heating limit temperature

On/Off

Heating limit temperature

On/Off

iv. Pump - The heating circuit pump

overrun time can be set here.

If the heating circuit pump is

controlled by 0-10V then additional

speed parameters can be set..

HC1 Boiler 1.1

Room temp. switch diff.

Pump

Frost protection

Pump

iii. Room Temperature Switching

Differential - When a room sensor

is congured for a heating circuit,

the switching differential may be

set.

HC1 Boiler 1.1

Heating limit

Room temp. switch diff.

Pump

Frost protection

Room temp. switch diff.

1ºC

Overrun time

Overrun speed

Maximum speed

Overrun time

10 secs

Pump

Overrun time

Overrun speed

Maximum speed

Overrun speed

70%

CONTINUED OVERLEAF

11

Page 12

Pump

Overrun speed

Maximum speed

Maximum speed

v. Frost Protection - The heating

circuit frost protection can be set

to be triggered on a number of

temperature sources if congured.

HC1 Boiler 1.1

Pump

Frost protection

100%

Frost Protection

Flow temperature

Outside temperature

Room temperature

Frost Protection

Temperature

Hysteresis

Temperature

5ºC

Hysteresis

15ºC

12

Page 13

Frost protection

Flow temperature

Outside temperature

Room temperature

Temperature

6ºC

Outside temperature

Temperature

Hysteresis

Temperature

0ºC

Hysteresis

5ºC

Frost protection

Outside temperature

Room temperature

Room temperature

Temperature

Hysteresis

Hysteresis

2ºC

13

Page 14

e. Time clock

Each heating circuit can be

programmed to a specic time clock

with three periods per day, single

days individually Monday through to

Sunday, or multiple days Monday to

Friday or Saturday and Sunday

Single / Multiple.....e.g.:

Heating circuits

Settings

Time clock

Holiday programme

f. Holiday programme

Each heating circuit can have up

to 8 holiday periods which are

programmed between start and end

dates.....e.g.:

Heating circuits

Time clock

Holiday programme

Holiday programme

Time clock

HC1 Boiler 1.1

HC2 Boiler 1.2

Time clock

Single day

Multiple days

Single day

Monday

Period1: 06:00-22:00

Period2: 00:00-00:00

Period3: 00:00-00:00

HC1 Boiler 1.1

HC2 Boiler 1.2

Holidays

Period 1

Start: 01/01/2014

End: 01/01/2014

14

Page 15

2. DHW Circuits

Menu

Heating circuits

DHW

The DHW circuit when congured has the following settings:

a. Operating mode selection:

The DHW circuit can be set to any

of the following:

DHW

Status

Operating mode

Tank temperature

Settings

Operating mode

DHW1 Boiler 1

DHW1 Boiler 1

Standby

b. Tank temperature

A temperature can be set for each

DHW circuit for the following periods:

Day / Night / Holiday.....e.g.:

DHW

Operating mode

Tank temperature

Flow temperature

Tank temperature

DHW1 Boiler 1

DHW1 Boiler 1

Tank temp day

Tank temp night

Tank temp holiday

Tank temp day

65ºC

15

Page 16

d. Settings

Each DHW circuit has a number

of settings that can be congured.

Most settings are only accessible

at Installer access levels.

Day / Night / Holiday.....e.g.:

On/Off

One time boost

DHW

Tank temperature

Settings

Time clock

Holiday program

Settings

DHW1 Boiler 1

i. One time boost - One time boost

can be enabled and hot water

tank will be charged to set a

temperature at any required time.

DHW1 Boiler 1

One time boost

Primar pump

Legionalla

One time boost

On/Off

Temperature

On/Off

One time boost

One time boost

On/Off

Temperature

Temperture

60ºC

16

Page 17

ii. Primary pump - This is where the

pump control parameters for the

Hot Water Tank primary charge

pump may be set..

DHW1 Boiler 1

One time boost

Primary pump

Legionalla

Frost Protection

Primary pump

Overrun speed

Minimum speed

Maximum speed

Minimum speed

Primary pump

Overrun time

Overrun speed

Minimum speed

Overrun time

10secs

Primary pump

Overrun time

Overrun speed

Minimum speed

Maximum speed

Overrun speed

50%

10%

Primary pump

Minimum speed

Maximum speed

Maximum pseed

100%

17

Page 18

iii. Legionella - The legionella

functionality can be set to either a

xed weekday or a time interval.

The temperature can also be set.

DHW1 Boiler 1

Primary pump

Legionella

Frost prtoection

None /Weekday /Interval

LegionellaPrimary pump

Operation mode

Temperture

Interval

Legionella

Operation mode

Temperture

Interval

Temperature

65ºC

Interval

7day(s)

iv. Frost Protection - The minimum

flow temperature for a frost

protection demand can be set.

Frost protection

DHW minimum ow

DHW minimum ow

8ºC

Temperture

Interval

Legionella

18

Page 19

d. Time clock

Each DHW circuit can be

programmed to a specic time clock

with three periods per day, single

days individually Monday through to

Sunday, or multiple days Monday to

Friday or Saturday and Sunday

Single / Multiple.....e.g.:

DHW circuits

Settings

Time clock

Holiday programme

e. Holiday programme

Each DHW circuit can have up

to 8 holiday periods which are

programmed between start and end

dates.....e.g.:

DHW circuits

Time clock

Holiday programme

Holiday programme

Time clock

HC1 Boiler 1.1

HC2 Boiler 1.2

Time clock

Single day

Multiple days

Single day

Monday

Period1: 06:00-22:00

Period2: 00:00-00:00

Period3: 00:00-00:00

HC1 Boiler 1.1

HC2 Boiler 1.2

Holidays

Period 1

Start: 01/01/2014

End: 01/01/2014

19

Page 20

3. INSTALLER CONNECTIONS

Mains Voltage/230V 50Hz

I1 I2 I3 I4

1 2 3 1 2 3 4 1 2 1 2

L N PE SL1 L SL2 L ~ ~

Mains Supply

Demand inputs

230V 50Hz

Interlock

Volts Free Contacts

I5 I6

1 2 3 4 5 6 1 2 3 4

C

NO PE C

MFR1 MFR2 MFR3

CNO PE NO

NO

C

MFR4

L

230V 50Hz

Auxiliary

KEY

l1 Mains Supply Connector, 230V

50Hz. Live, Neutral, PE.

l2 Demand inputs, Multifunctional,

230V 50Hz. Typical setting:

SL1, Heating Circuit 1

SL2, Heating Circuit 2/DHW

l3 Optional Interlock input, 230V

50Hz

N

l4 Auxiliary Mains Supply Output,

230V 50Hz. Live, Neutral.

Internal Pump Power Connection.

KEY

I5 Multifunction Volts Free Relay

Outputs, 24V DC to 230V 50Hz.

Typical setting:

MFR1 Heating Circuit 1 Pump

MFR2 DHW Circuit Pump

Internal Pump PE Connection.

I6 MFR3 Burner On Indication

MFR4 Boiler Fault Indication

PELV

I7 I8 I9 I10

1 2 1 2 3 1 2 3 4 5 6 1 2 3 4 5 6 7 8

PELV

Interlock 0-10VPump control OpenTherm Header

KEY

PELV Only

I7 Optional Interlock input.

I8 N/A

I9 Boiler Control:

0-10V Capacity or Temperature.

OpenTherm Interface 1. Boiler, Heating Circuit 1 and/or

DHW Circuit Control.

OpenTherm Interface 2. Heating Circuit 2 Control.

I10 Optional Sensors:

Header Sensor for Cascade Control.

DHW Tank Temperature or Heating Circuit 2 Room

Temperature.

Heating Circuit 1 Room Temperature.

Outside Temperature Sensor for Heating Curve.

S1 GND S2 GND S3 GND S4 GNDOT1+ OT1- OT2+ OT2-PWM GND 10V 10V GNDI0 I1

DHW Tank /

Room 2 Room 1

Outside

Temp.

*Note: The items grayed out are not standard and are connections provided by the relevant option kits.

20

Page 21

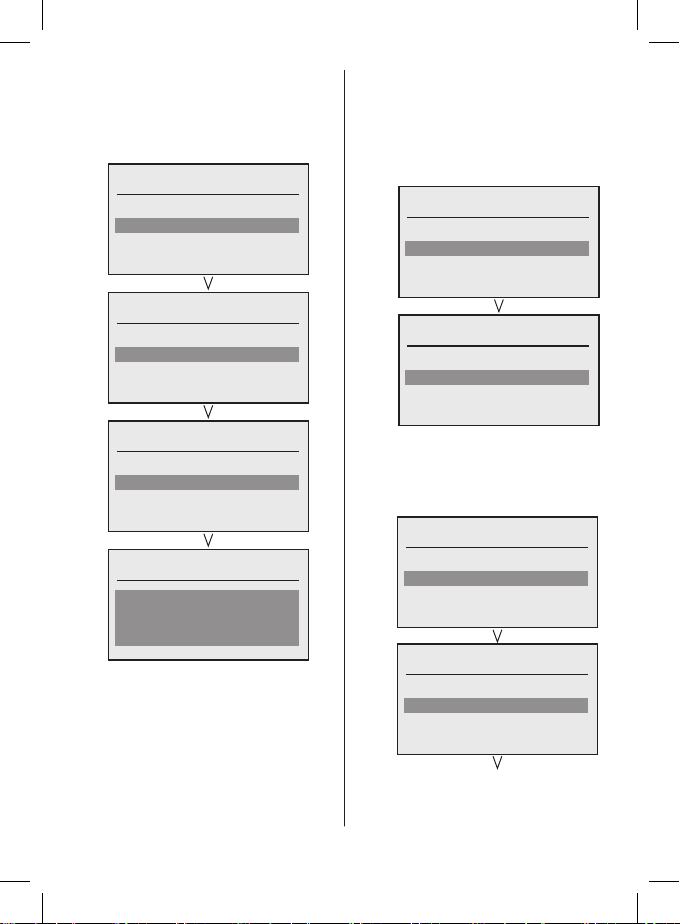

4. FAULTS

When a fault occurs the title bar of the status

display will alternate between:

KESTON HEAT 2 55kW

Operation: Htg. with temp.

Flow Set point: 40.2ºC

Flow temp: 40.2ºC

Operation: Htg. with temp.

Flow Set point: 40.2ºC

Flow temp: 40.2ºC

Using the scroll knob the detail of the fault

can be displayed. e.g.:

Fault 39

Blocking Interlock

Function activated

(controlled shutdown)

The fault once rectied can now be reset by

pressing the reset button whilst in this display.

If there are multiple faults then a list of faults

will be shown. e.g.:

Faults

Fault 39

Fault 01

Fault 23

Each fault may be highlighted and selected

to show the detail as above

Fault

21

Page 22

BOILER FAULTS

ERROR TYPE

(Warning,

Blocking,

Lockout)

HARDWARE (THERMISTORS, ACTUATORS)

B Flow thermistor open circuit (blocking) 1

B Flow thermistor short circuit (blocking) 2

B Return thermistor open circuit (blocking) 3

B / W Return thermistor short circuit (blocking) 4

B / W Flue thermistor open circuit (blocking) 5

B Flue thermistor short circuit (blocking) 6

W DHW thermistor open circuit 7

W DHW thermistor short circuit 8

W Outside thermistor defect (open / short) 9

B Water pressure sensor defect 10

L Flow thermistor open circuit (lockout after 24h) 11

L Flow thermistor short circuit (lockout after 24h) 12

L Return thermistor open circuit (lockout after 24h) 13

L Return thermistor short circuit (lockout after 24h) 14

L Flue thermistor open circuit (lockout after 24h) 15

L Flue thermistor short circuit (lockout after 24h) 16

L Heat thermistor open circuit (lockout after 24h) 17

L Heat thermistor short circuit (lockout after 24h) 18

DESCRIPTION

ERROR CODE

(OpenTherm)

22

Page 23

ERROR TYPE

(Warning,

Blocking,

Lockout)

TEMPERATURE SUPERVISIONS

B Blocking due to ow overheat 30

B Blocking due to return overheat 31

B Blocking due to ue overheat 32

B Flow & return reversed 33

B Thermistor pipe t supervision active (blocking) 34

L Thermistor pipe t supervision (lockout) 35

B Flow gradient supervision 36

B Flue gradient supervision (reserved) 37

B Blocking delta temp ow/return 38

L Lockout ow overheat 39

L Lockout return overheat 40

L

Lockout ue overheat (ue thermistor)

Lockout thermal fuse (thermal fuse)

DESCRIPTION

ERROR CODE

(OpenTherm)

41

23

Page 24

ERROR TYPE

(Warning,

Blocking,

Lockout)

SYSTEM (FLAME, FAN, HYDRAULIC, ETC.)

B Blocking due to no CH water ow 50

B Low water pressure 51

W No ame signal at start (restart) 52

W

L

W Flameloss during stabilisation => restart attempts 55

L

L False ame (with heat demand) 57

L No ame after restarts 58

B/L Fan speed, stand still check 59

L

B/L Error fan speed during pre-purge (5* restarts => lockout ) 61

W

W Warning due to mains overvoltage 63

B Blocking due to mains undervoltage 64

W

L Too many remote resets 66

B No water ow indication 67

B PWM pump blocking error (feedback 90%) 68

B PWM pump electrical error (feedback 85%) 69

B HX water ow fault (feedback < min ow rate) 70

B PWM pump dry run error (feedback 80%) 71

B Warning code from pump (feedback 75%) 72

Flameloss during operation => endless restarts

(Parameter “endless restarts” activated)

Flameloss during operation,

=> Lockout after restarts attempts are used

(Parameter “endless restarts” deactivated)

Flameloss during stabilisation

=> Lockout after restarts attempt are used

Fan speed not achieved, e.g. Pre-purge-test, post-purgetest etc.

Error min/max supervision fan speed during operation

(restart)

Opentherm plus error (communication faulty; no connection

anymore , etc)

DESCRIPTION

ERROR CODE

(OpenTherm)

53

54

56

60

62

65

24

Page 25

ERROR TYPE

(Warning,

Blocking,

Lockout)

INTERNAL SYSTEM

L Request for re-update 94

B Blocking due to programming mode 95

L Lockout parameter mismatch 96

L Lockout parameter set 97

B/L Internal blocking error 98

L System lockout (internal lockout error) 99

DESCRIPTION

ERROR CODE

(OpenTherm)

25

Page 26

5. GENERAL INFORMATION

TO SHUT DOWN THE BOILER

Note. The inbuilt frost protection for the boiler

will not function if there is no mains supply

to the boiler.

1. For short periods

Set the external controls to OFF. Wait 4

minutes and then isolate the mains supply

to the boiler.

2. For longer periods

Set the external controls to OFF. Switch

the electricity supply to OFF. For longer

periods the entire system should be drained,

including the domestic hot water supply.

TO RELIGHT THE BOILER

Refill the system if it has been drained,

taking care to ensure no air is in the boiler

or system.

Repeat the procedure detailed in ‘To light

the boiler’.

FROST PROTECTION

The KESTON HEAT2 boiler has built into its

control system the facility to protect the boiler

only against freezing.

Note. This may not protect remote parts of

the system, in which case a separate frost

thermostat should be tted.

BOILER OVERHEAT THERMOSTAT

Boiler overheating is detected by electrical

sensors connected to the boiler control

module. If the boiler overheats it will shut

down and the display will show Overheat

Lockout. Press the reset button and the

boiler will relight. If the fault recurs turn off

the boiler and consult a suitably qualied

Gas Safe registered engineer or in IE a

competent person.

CONDENSATE DRAIN

This appliance is fitted with a siphonic

condensate trap system that reduces the risk

of the appliance condensate from freezing.

However should the condensate pipe to

this appliance freeze, please follow these

instructions:

a. If you do not feel competent to carry out

the defrosting instructions below please call

your local Gas Safe Registered installer for

assistance.

If you do feel competent to carry out the

b.

following instructions please do so with care

when handling hot utensils. Do not attempt to

thaw pipework above ground level.

If this appliance develops a blockage in its

condensate pipe, its condensate will build

up to a point where it will make a gurgling

noise prior to locking out displaying “Ignition

Lockout” on the display. If the appliance is

reset it will make a gurgling noise prior to it

locking out displaying “Ignition Lockout” on

the display.

To unblock a frozen condensate pipe;

1. Follow the routing of the plastic pipe from

its exit point on the appliance, through its

route to its termination point.

Locate the frozen blockage. It is likely that

the pipe is frozen at the most exposed point

external to the building or where there is

some obstruction to ow. This could be at

the open end of the pipe, at a bend or elbow,

or where there is a dip in the pipe in which

condensate can collect. The location of the

blockage should be identied as closely as

possible before taking further action.

2. Apply a hot water bottle, microwaveable

heat pack or a warm damp cloth to the frozen

blockage area. Several applications may

have to be made before it fully defrosts.

Warm water can also be poured onto the

pipe from a watering can or similar. DO NOT

use boiling water .

3. Caution when using warm water as

this may freeze and cause other localised

hazards.

26

Page 27

4. Once the blockage is removed and

the condensate can ow freely, reset the

appliance. (Refer to “To Light the boiler”)

5. If the appliance fails to ignite, call your

Gas Safe Registered engineer.

Preventative solutions:

During cold weather, set the boiler stat to

maximum. (Must return to original setting

once cold spell is over).

Place the heating on continuous and turn

the room stat down to 15ºC overnight or

when unoccupied. (Return to normal after

cold spell).

ESCAPE OF GAS

Should a gas leak or fault be suspected

contact your local gas supplier without

delay.

Do NOT search for gas leaks with a

naked ame.

CLEANING

For normal cleaning simply dust with a

dry cloth.

To remove stubborn marks and stains use

a damp cloth and mild detergent.

DO NOT use abrasive cleaning materials.

27

Page 28

SYSTEM SET UP INFORMATION

INSTALLER TO RECORD THE FOLLOWING INFORMATION

Master / Slave:

Boiler Number:

Hydraulic Circuit No:

Plant Conguration:

Local Heating Circuit

Conguration:

Local DHW Circuit

Confgiuration:

Keston Heating pursues a policy of continuing improvement in the design and performance of its products.

The right is therefore reserved to vary specification without notice.

Keston Heating,

PO Box 103, National Avenue, Kingston Upon Hull, HU5 4JN

Tel 01482 443005 Fax 01482 467133 Email info@keston.co.uk

Keston Helpline: 01482 443005

www.keston.co.uk

EVERYTHING IS POSSIBLE

Loading...

Loading...