Page 1

FRAME & HEADER KIT

INSTRUCTIONS

Keston Heat 45

Keston Heat 55

Keston Heating

PO Box 103, National Avenue, Kingston Upon Hull, HU5 4JN

Tel. +44 (0) 1482 443005 Fax. +44 (0) 1482 467133

email : info@keston.co.uk web : www.keston.co.uk

Page 2

This kit is suitable for the following boilers:

Keston Heat 45 & 55

CONTENTS

1 Introduction and General Description ..........................3

2 General Description of Cascade System .....................4

3 Multiple Boiler System Components ............................5

4 Installation Drawings for Multiple Boiler Systems ......8

5 Wall Mounted Installation Procedure .........................11

6 Frame Kit Installation Procedure ................................13

7 Header Kit Assembly ....................................................14

8 Electrical Connections .................................................17

9 Commissioning and Testing ........................................ 17

2

Keston Heat - Frame & Header Kits

Page 3

1 INTRODUCTION

This technical data contains information for dimensioning & assembly of a cascade system kit for the Keston Heat range of

products.

Header and Frame kits are available in line (from 2 to 6 boilers long).

GENERAL DESCRIPTION OF FRAME & HEADER KITS

A requirement to spread the total required heat output over several boilers can be accommodated by the use of the Keston Heat

multiple boiler frame & header kit options.

An optional sequencer kit can be specied to switch boilers in cascade on or off dependent on total heat demand.

Keston Heat - Frame & Header Kits

3

Page 4

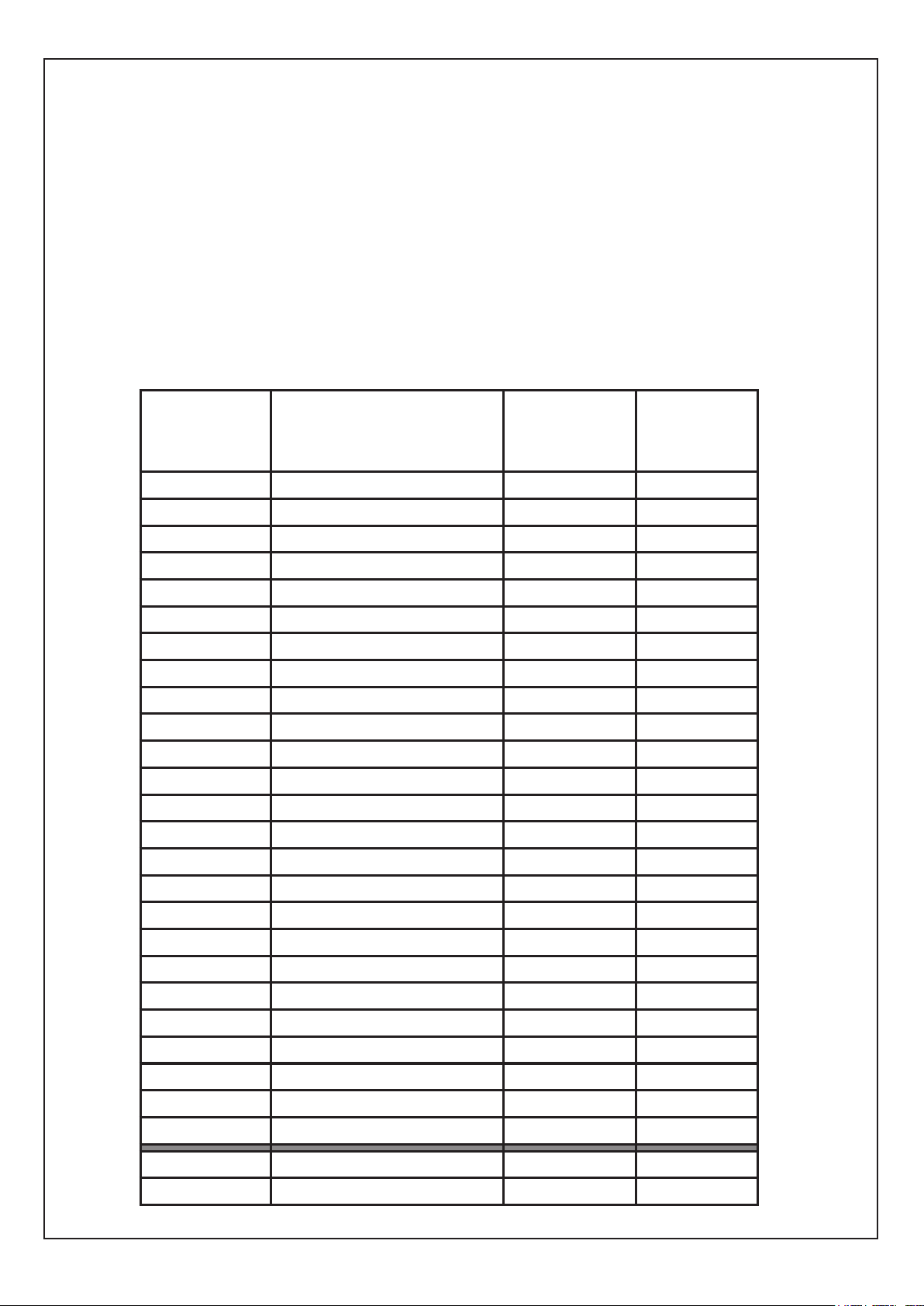

2 GENERAL DESCRIPTION OF CASCADE SYSTEMS

2.1 FRAME AND HEADER KIT DESIGN OPTIONS

The Keston Heat boilers are suitable for use in a multiple boiler conguration. The multiple boiler system is available as a wall

or frame mounted side by side conguration with the use of the relevant frame / header kits. This gives opportunity to choose

the optimum footprint size or wall space for a given output. The table below states options available and gives the minimum

number of appliances required, the appropriate oor space & the kit product number (N.B. The kits do not include the boilers).

Side by side kits do not include the support frame as the boilers can be wall mounted but a frame kit is available if wall space

etc. does not facilitate boiler/header wall mounting.

Flue conguration for the appliance is C53 and C13 only (see appliance manual).

FRAME AND HEADER KIT SYSTEM DESIGN OPTIONS

Total Output

Required Kw

Side By Side Option –

Number Of Boilers/Output

Required

Side by Side

Footprint Size

W x D (mm)

90 2 x 45 1500x560 355014

100 1 x 45 - 1 x 55 1500x560 355014

110 2 x 55 1500x560 355014

135 3 x 45 2055x560 355015

145 1 x 55 - 2 x 45 2055x560 355015

155 2 x 55 - 1 x 45 2055x560 355015

165 3 x 55 2055x560 355015

180 4 x 45 2600x560 355016

190 1 x 55 - 3 x 45 2600x560 355016

200 2 x 55 - 2 x 45 2600x560 355016

210 3 x 55 - 1 x 45 2600x560 355016

220 4 x 55 2600x560 355016

225 5 x 45 3150x560 355017

235 1 x 55 - 4 x 45 3150x560 355017

Header Kit

Product No.

Side By Side

245 2 x 55 - 3 x 45 3150x560 355017

255 3 x 55 - 2 x 45 3150x560 355017

265 4 x 55 - 1 x 45 3150x560 355017

275 5 x 55 3150x560 355017

280 1 x 55 - 5 x 45 3700x560 355018

290 2 x 55 - 4 x 45 3700x560 355018

300 3 x 55 - 3 x 45 3700x560 355018

310 4 x 55 - 2 x 45 3700x560 355018

320 5 x 55 - 1 x 45 3700x560 355018

330 6 x 55 3700x560 355018

In line frame kit 355013

Header Low Loss DN80 Kit 355019

4

Keston Heat - Frame & Header Kits

Page 5

2.2 MULTIPLE BOILER INSTALLATIONS

For installing 2 to 6 boilers, the product range includes water and gas headers capable of assembly using threaded socket,compression

and ange connections.

2.3 HYDRAULIC ISOLATION: MIXING HEADER (HEADER KITS INCLUDE A LOW LOSS MIXING HEADER)

A low loss header allows ow separation within a hydronic system.

This essentially creates linked stand alone ow circuits with their own ow rates and pressure drops. Allowing for the modern high

resistant high efciency boilers to operate under their optimum conditions, while the main heating circuit operates to its own controlled

optimum requirements.

2.4 OUTPUT CONTROL

An optional sequencer kit is available to maximise the efciency of a multiple boiler installation. Instructions for installation and use are

contained in the sequencer kit. The sequencer kit facilitates control of up to ve boilers in cascade.

2.5 GAS SUPPLY

The 45-55kW boilers are suitable for use with natural gas. Connect the boilers to the gas mains in accordance with the applicable

regulations The gas header connection is a 2” female thread with test points at each end. It is the test point nearest the inlet of the

group of appliances that becomes the appliance inlet pressure point. Refer to the boiler Installation & Servicing Instructions for general

GAS SUPPLY details.

2.6 ASSEMBLY

The frames and headers must stand on a at and level oor of suitable load bearing capacity.

2.7 SAFE HANDLING

This boiler may require 2 or more operatives to move it to its installation site, remove it from its packaging base and during movement into its

installation location. Manoeuvring the boiler may include the use of a sack truck and involve lifting, pushing and pulling.

Caution should be exercised during these operations.

Operatives should be knowledgeable in handling techniques when performing these tasks and the following precautions should be considered:

• Grip the boiler at the base.

• Be physically capable.

• Use personal protective equipment as appropriate, e.g. gloves, safety footwear.

During all manoeuvres and handling actions, every attempt should be made to ensure the following unless unavoidable and/or the

weight is light.

• Keep back straight.

• Avoid twisting at the waist.

• Avoid upper body/top heavy bending.

• Always grip with the palm of the hand.

• Use designated hand holds.

• Keep load as close to the body as possible.

• Always use assistance if required.

3 MULTIPLE BOILER SYSTEM COMPONENTS

3.1 GENERAL

The multiple boiler systems consist of the following components:

• Frame kit. (Optional only with In-line kits)

• Boiler gas header.

• Boiler ow and return headers supported on mounting skid

• Low loss mixing header

• Hardware packs (includes essential connection and valve components)

3.2 MAIN WATER HEADERS

The main water headers consist of: insulated water ow, insulated water return headers custom sized for all boilers. It is possible to

extend the system to a maximum of 6 boilers in a linear conguration.Each header kit provides water ow and return headers sized

either DN80 or DN100 dependent on total maximum combined heating output required.

Keston Heat - Frame & Header Kits

5

Page 6

3.3 GAS HEADER

7

The Gas header consists of a custom manufactured 2” manifold. This is located in a cradle incorporated within the header mounting skid.

3.4 MIXING HEADER

The mixing headers are insulated and are supplied with an auto air vent and drain point as standard.

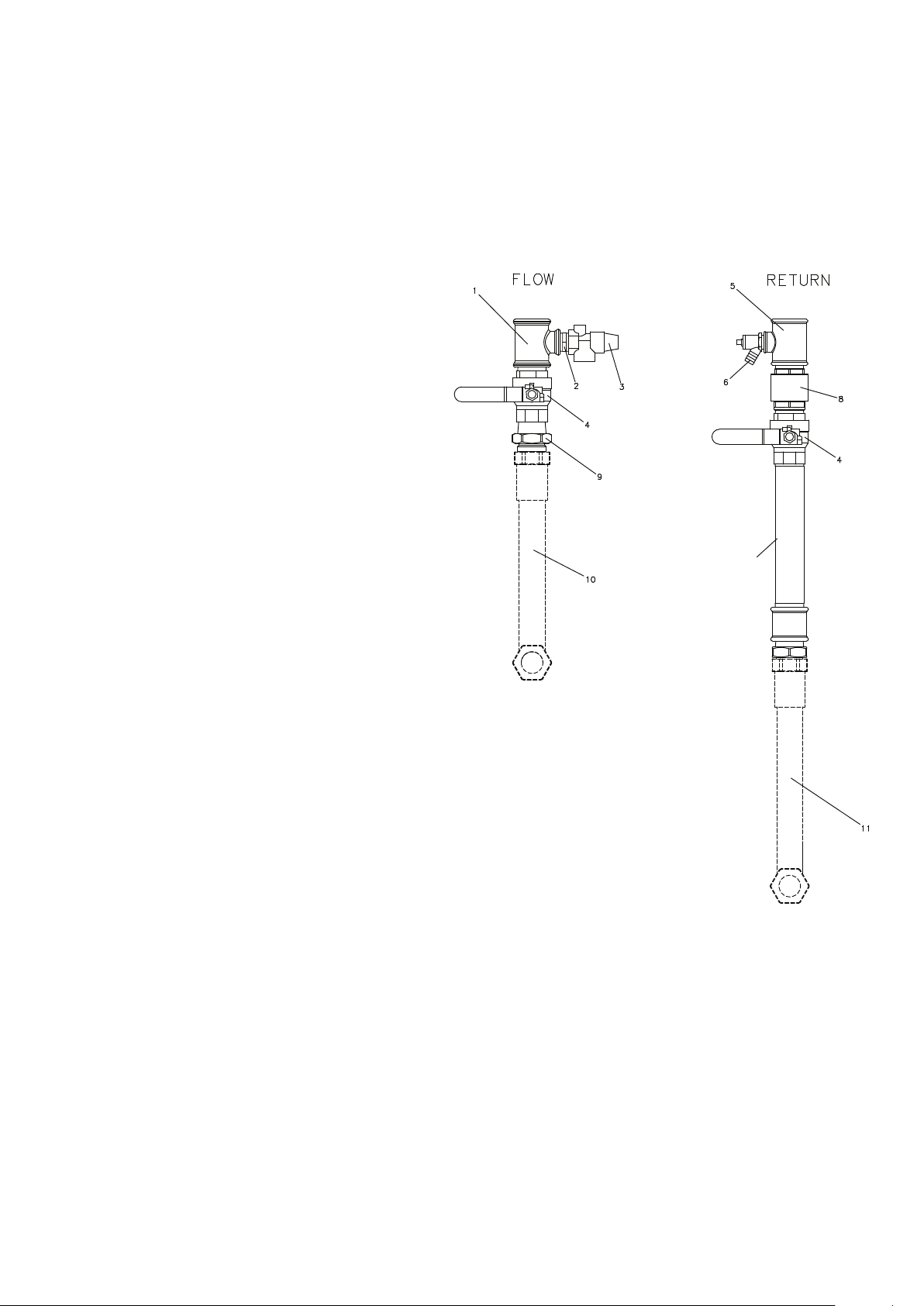

3.5 BOILER CONNECTION KITS

Legend

1. 11/4" x 3/4" x 11/4" Te e

2. Close Taper Nipple

3. Safety Relief Valve 6 bar

4. Isolation Valve

5. 11/4" x 1/2" x 11/4" Te e

6. Drain O Cock

7. Connection Pipe Assembly

8. Non Return Valve

9. 11/4" Taper Male to 11/4" Parallel Hex Adapter

10. Boiler Flow Flexible Connection from Header

11. Boiler Return Flexible Connection from Header

Items 1,2,3,4,5 & 6 are supplied with the boiler. (AL-208973

Isolation Valve Kit)

Items 7, 8 & 9 are supplied with the Header Kit

Items 10 & 11 are pre-assembled to the water header.

Assemble ttings together as shown using appropriate sealing

material. Do not t the safety relief valve (item 3) at this stage.

When assemblies are complete t to boiler ow and return stubs

with suitable sealing material. The safety valve (item 3) can now

be tted using suitable sealing material.

Ensure all isolation valves, pressure relief valves and drain valves

are tted to allow unrestricted operation.

3.6 FREE-STANDING FRAMES

If boilers in cascade are positioned in-line the installer has the option to either wall mount the boilers or mount boilers on optional frame

kits available. If mounting in-line product on frames, optional frame kit UIN 355013 must be specied in the correct quantity, one frame

kit for each boiler installed in cascade.

3.7 INSTALLATION AREA AND DIMENSIONS

Care must be taken to ensure adequate access for boiler / cascade system installation and servicing.

A minimum of 450mm must be provided from the front of the installed boilers in cascade to facilitate boiler servicing.

Consideration to connecting heating ow and return pipework, gas supply and condensate drainage must be given. Routing of the

condensate drain must be made to allow a minimum fall of 1 in 20 away from the installed boilers in cascade, throughout its length.

Adequate room above the boilers must be provided to install and service the boiler ue system. Further information with respect to ue

and condensate drain connection is provided in the installation and servicing instructions provided within the boilers packaging carton.

6

Keston Heat - Frame & Header Kits

Page 7

IMPORTANT POINTS

Before commencing installation:

If Wall mounting;

• Ensure wall is capable of supporting the weight of boilers to be mounted

• Mark drill points of header using oor mounting template

• Mark height on to the wall from the oor to the top of the boiler

• Ensure oor is at and level and is of suitable load bearing capacity

If Frame mounting;

• The frames must stand on a at and level oor of suitable load bearing

capacity.

• If using a frame kit (UIN 355013) the header must be bolted to the frame before

the hoses are connected to the boiler.

These Installations refer to perpendicular wall and oor. If walls are not

perpendicular, it is recommended that a frame kit be used (UIN 355013). The

correct number of frames should be ordered (1 per boiler).

Allowances must be made for installation where skirting boards or other features

are in place that may affect the nominal installation conditions.

Keston Heat - Frame & Header Kits

7

Page 8

4 INSTALLATION DRAWINGS FOR MULTIPLE BOILER SYSTEMS

4.1 GENERAL

The multiple boiler systems are available in two formats:

• 2 to 6 boilers in a linear conguration, mounted on a wall.

• 2 to 6 boilers in a linear conguration, mounted on free-standing frames.

The boiler side of the cascade systems is sized to give a water ow and return differential 20ºC.

4.2 SIDE BY SIDE FRAME KIT CONFIGURATION

4.2.1 INSTALLATION DRAWING WITH 2 - 45 or 55 BOILERS (SIDE BY SIDE)

Side by side wall or

frame mounting dimensions

8

Keston Heat - Frame & Header Kits

Page 9

4.2.2 INSTALLATION DRAWING WITH 3 - 45 or 55 BOILERS (SIDE BY SIDE)

Side by side wall or

frame mounting dimensions

Keston Heat - Frame & Header Kits

9

Page 10

4.2.3 INSTALLATION DRAWING WITH 4 - 45 or 55 BOILERS (SIDE BY SIDE)

Side by side wall or

frame mounting dimensions

10

Keston Heat - Frame & Header Kits

Page 11

4.2.4 INSTALLATION DRAWING WITH 5 - 45 or 55 BOILERS (SIDE BY SIDE)

Side by side wall or

frame mounting dimensions

Keston Heat - Frame & Header Kits

11

Page 12

4.2.5 INSTALLATION DRAWING WITH 6 - 45 or 55 BOILERS (SIDE BY SIDE)

Side by side wall or

frame mounting dimensions

12

Keston Heat - Frame & Header Kits

Page 13

5 WALL MOUNTED INSTALLATION PROCEDURE

5.1 WALL MOUNTED SIDE BY SIDE OPTION

Ensure wall is capable of supporting the weight of boilers

to be mounted. Note. boiler weights can found in the

boiler Installation Instructions.

1. Cut the sides off the cardboard wall mounting

template/s (found in the boiler packaging) to create

the 50mm side clearance required.

2. Mark the height on to the wall from the oor to the top

of the boiler 1919mm.

2

1

4. Drill the required holes in the wall to t the wall mounting

plate plugs. (See boiler Installation Instructions for details)

4

5. Screw the wall mounting plate(s) to the wall.

5

3. Tape the template/s to the wall ensuring the 50mm

side clearance per boiler requirement is adhered to.

3

Keston Heat - Frame & Header Kits

Floor Mounting: Align centre line of template

to centre line of boiler and drill holes for

headers.

continued . . . . .

13

Page 14

5.1 WALL MOUNTED SIDE BY SIDE OPTION CONT'D............

PLAN VIEWSIDE VIEW

Careful consideration MUST be given to the installation tolerances. If these are not

adhered to, hoses may become kinked or connections may not t.

Bolt header to oor using template provided (front xings only). Connect up hoses (see

page 15)

14

Keston Heat - Frame & Header Kits

Page 15

6 FRAME KIT INSTALLATION PROCEDURE

6.1 SIDE BY SIDE FRAME KIT MOUNTING PROCEDURE

1. Place the frame kit sections in the required position and bolt them together at the top and bottom with the bolts, nuts and

washers provided.

1

2

2. If additional stability is required

remove the plastic foot covers and

drill the oor. Then bolt the frame

to the oor using suitable bots and

xings (bolts not supplied).

Keston Heat - Frame & Header Kits

15

Page 16

6.2 BOILER MOUNTING

1. As appropriate mount the boilers onto either the wall plates or the side

by side frame kit.

1

2. Ensure the two boiler bottom xing brackets

are screwed to the frame or wall.

2

7 HEADER KIT ASSEMBLY

7.1 FITTING MIXING HEADER AND BLANKING FLANGES

1. Fit the mixing header and blanking anges in the chosen positions, with the bolts, washers and seals supplied.

Note. Mixing header can be located either LHS or RHS of the headers.

Mixing Header Blanking Flange

16

Keston Heat - Frame & Header Kits

Page 17

7.2 FITTING HEADER KIT ASSEMBLY

1. Slide the header kit assembly between the frame legs but

do not screw the header kit to the frame at this stage.

1

2. Screw the header legs to the frame feet with the bolts,

nuts & washers provided. Tighten nuts after the exible

hoses have been tted to the boiler.

2

3. Fit the two exible header connections to the boiler

ow and return connections ensuring the sealing

washers are tted.

Keston Heat - Frame & Header Kits

17

Page 18

7.3 FITTING GAS CONNECTION

1. Fit the gas isolation valve assembly supplied with the boiler to the boiler gas connection ensuring the sealing washer is tted.

1

2. Fit the copper gas pipe provided in the header kit to the isolating valve and the header gas connection using

22mm compression ttings provided.

2

7.4

PRESSURE RELIEF VALVE CONNECTION

1. Ensure each boiler pressure relief connection is piped to a

safe discharge point.

2

7.5 CONDENSATE TRAP FITTING

1. Fit the condensate trap to the boiler and pipe to drain

following the recommendations contained in the boiler

Installation instructions.

1

18

1

Keston Heat - Frame & Header Kits

Page 19

8 ELECTRICAL CONNECTIONS

Refer to the Installer Wiring Connection section in the boiler Installation Instructions for wiring details.

9 COMMISSIONING AND TESTING

Electrical and gas safety checks must be carried out on completion of installation as with individual boiler commissioning.

Keston Heat - Frame & Header Kits

19

Page 20

Keston Heating, PO Box 103, National Avenue, Kingston Upon Hull, HU5 4JN

Tel. +44 (0) 1482 443005 Fax. +44 (0) 1482 467133. www.keston.co.uk

Keston pursues a policy of continuing improvement

in the design and performance of its products.

The right is therefore reserved to vary specication without notice.

June 2013 UIN 209785 A01

Loading...

Loading...