Page 1

July 2016

UIN 215348 A01

Combi C30 & C35

When replacing any part on this appliance, use only spare parts that you can be

assured conform to the safety and performance specication that we require.

Do not use reconditioned or copy parts that have not been clearly authorised by Keston.

For the very latest copy of literature for specication and maintenance practices visit our website

www.keston.co.uk where you can download the relevant information in PDF format.

FAN POWERED HIGH EFFICIENCY

MODULATING DOMESTIC CONDENSING

GAS COMBINATION BOILER

Installation and Servicing Instructions

Page 2

2

Installation and Servicing

MODEL

SYMBOL UNITS 30 35

Condensing Boiler n/a n/a yes yes

Low Temperature Boiler n/a n/a no no

B1 Boiler n/a n/a no no

Cogeneration Space Heater n/a n/a no no

Equipped with a Supplementary Heater n/a n/a no no

Combination Heater n/a n/a yes yes

Nominal Heat Output for Space Heating

Full Load P

4 kW 24.2 24.2

Part Load P

1 kW 7.9 7.9

Auxiliary Electricity Consumption

Full Load el

max kW 0.032 0.042

Part Load el

min kW 0.013 0.013

Standby P

SB kW 0.005 0.005

Seasonal Space Heating Energy Efciency

Full Load

ƞ

4

% 90 90

Part Load

ƞ

1

% 98.6 98.6

Standby Loss P

stby kW 0.05 0.05

Ignition P

ign kW 0 0

Emissions NO

x mg/kWh 27.8 33.1

Annual Energy Consumption Q

HE GJ 74.1 74.1

Sound Power Level, Indoors L

WA dB 46 44

Domestic Hot Water

Q

elec kWh 0.075 0.074

ƞ

WH

% 78 78.4

Q

fuel kWh 7.7 7.7

AEC kWh 16.3 16

AFC GJ 5.8 5.7

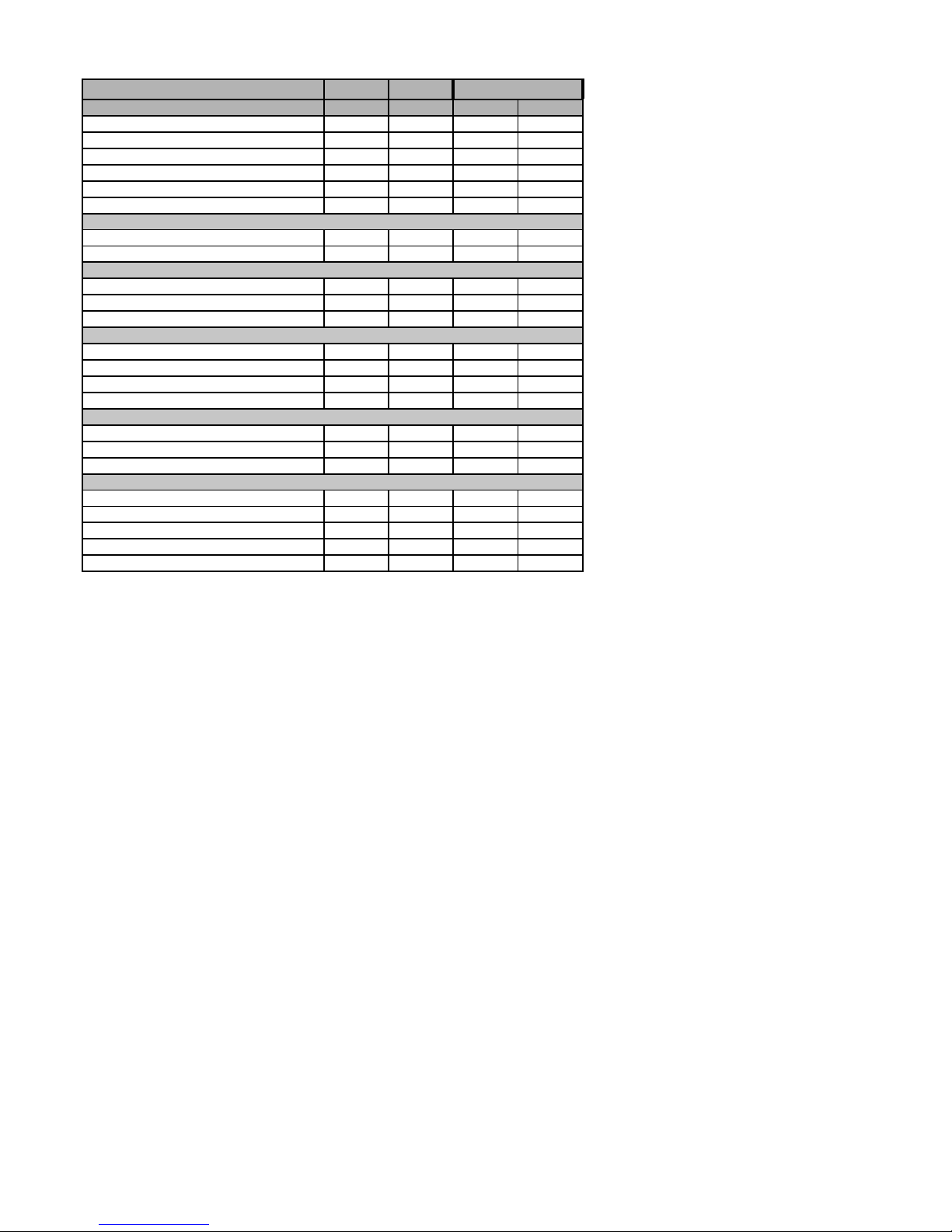

ERP DATA

Page 3

3

Installation and Servicing

KESTON COMBINATION BOILER

Ideal Boilers

ERP DATA

SYMBOL UNITS MODEL

30 35

Condensing boiler Yes

Seasonal Space heating efciency class A

Rated heat output kW 24

Seasonal space heating energy efciency

ƞs

% 94

Annual energy consumption Q

HE GJ 74.1

Sound power level, indoors L

WA dB 46 44

Water heating energy efciency class A

Seasonal Space Heating Energy Efciency of the Boiler *%

Temperature control (from che of temperature control) %

Class I Class II Class III Class IV Class V Class VI Class VII Class VIII

1% 2% 1.5% 2% 3% 4% 3.5% 5%

PRODUCT FICHE

The energy efciency of the package of products provided for in this document may not correspond to its actual energy efciency once installed in a

building, as the efciency is inuenced by further factors such as heat loss in the products in relation to the building size and its characteristics

Collector Size

(in m2)

Tank Volume

(in m3)

Collector

Efciency

(in %)

Tank rating

A* = 0.95

A = 0.91

B = 0.86

C = 0.83

D-G = 0.81

Solar Contribution (from che of solar device)

Seasonal Space Heating Energy Efciency of Package

TOTAL: A+B+C=

Seasonal Space Heating Energy Efciency Class of Package

= (‘III ’x + ‘IV ’ x ) x 0.9 x ( / 100 x =

%

%

GG F E D C B A A+ A++

A+++

< 30% ≥ 30% ≥ 34% ≥ 36% ≥ 75% ≥ 82% ≥ 90% ≥ 98% ≥ 125% ≥ 150%

A

B

C

Page 4

4

Installation and Servicing

Page 5

5

Installation and Servicing

Relevant Installation changes implemented in this book from Mod Level ..............................A01 (July 2016)

DOCUMENT AMENDMENTS

Keston reserve the right to vary specication without notice

FOR ANY TECHNICAL QUERIES PLEASE RING THE KESTON

INSTALLER/TECHNICAL HELPLINE : 01482 443005

NOTE. BOILER RESTART PROCEDURE -

Press the RESTART button. The boiler will repeat the ignition sequence if a heat demand is present.

NOTES FOR THE INSTALLER

Page 6

6

Installation and Servicing

Page 7

7

Installation and Servicing

CONTENTS

1 GENERAL .................................................................... 8

1.1 Introduction ................................................................10

1.2 Operation ...................................................................10

1.3 Safe Handling ............................................................. 10

1.4 Optional Extra Kits .....................................................10

1.5 Safety ......................................................................... 11

1.6 Safe Handling Of Substances .................................... 11

1.7 Location Of Boiler ...................................................... 11

1.8 Gas Supply ................................................................. 12

1.9 Water Circulation System ........................................... 12

1.10 Boiler Control Interlocks .............................................12

1.11 Electrical Supply ......................................................... 12

1.12 Condensate Drain .................................................... 12

1.13 Boiler Dimensions, Services & Clearances ................ 13

1.14 System Requirements - Central Heating .................... 14

1.15 System Balancing ......................................................15

1.16 Water Treatment......................................................... 15

2 INSTALLATION .........................................................16

2.1 Boiler Assembly - Exploded View ...............................16

2.2 Unpacking .................................................................. 17

2.3 Flue System ............................................................... 18

2.4 Flue Installation Example Keston Combi C30 ............ 20

2.5 Flue Installation Example Keston Combi C35 ............ 20

2.6 Flue Termination Position ........................................... 21

2.7 Installing The Boiler .................................................... 22

2.8 Wall Mounting Template ............................................. 22

2.9 Preparing The Wall .....................................................22

2.10 Fitting The Wall Mounting Plate ................................. 23

2.11 Mounting The Boiler ................................................... 23

2.12 Assembly Practice ...................................................... 24

2.13 Fitting The Flue Sleeve .............................................. 25

2.14 Condensate ................................................................ 26

2.15 Connections & Filling .................................................28

2.16 Electrical Connections ................................................ 30

2.17 Installer Wiring ...........................................................30

2.18 External Wiring ........................................................... 31

2.19 Replacing Pre-Fitted Mains Cable .............................31

2.20 Ch Operation .............................................................. 32

2.21 The Weather Compensation Kit ................................. 33

2.22 Wiring Diagram ..........................................................34

2.23 Commissioning And Testing ....................................... 35

2.24 Initial Lighting ............................................................. 36

2.25 The Display ................................................................ 37

2.26 General Checks .........................................................41

2.27 Restart Procedure ...................................................... 42

2.28 Handing Over ............................................................. 42

3 SERVICING ............................................................... 43

3.1 Servicing Schedule ...................................................43

3.2 Boiler Front Panel Removal / Replacement ............... 44

3.3 Fan And Venturi Assembly Removal And Cleaning ....44

3.4 Burner Removal And Cleaning ................................... 45

3.5 Cleaning The Condensate Trap/Siphon ..................... 45

3.6 Cleaning The Heat Exchanger ................................... 46

3.7 Reassembly ...............................................................46

3.8 Replacement Of Components .................................... 47

3.9 Fan Replacement ....................................................... 47

3.10 Burner Injector Replacement .....................................48

3.11 Burner Replacement .................................................. 48

3.12 Return Thermistor Replacement ................................ 49

3.13 Ignition Electrode Replacement ................................. 49

3.14 Flame Detection Electrode Replacement ................... 50

3.15 Spark Generator Replacement ..................................50

3.16 Gas Control Valve Replacement ................................ 50

3.17 Diverter Valve Actuator Replacement ........................ 51

3.18 Condensate Trap/Siphon Replacement ..................... 51

3.19 PCB Replacement ...................................................... 52

3.20 Draining The Boiler ....................................................53

3.21 DHW Flow Turbine Sensor Replacement .................. 53

3.22 Pressure Gauge Replacement ................................... 53

3.23 Safety Relief Valve Replacement ............................... 54

3.24 Pump Automatic Air Vent Replacement .....................54

3.25

DHW Filter & Flow Regulator Cleaning/Replacement .....

54

3.26 Diverter Valve Body Assembly Replacement ............. 55

3.27 DHW Plate Heat Exch. Replacement ......................... 55

3.28 Pump Head Replacement .......................................... 55

3.29 CH Water Pressure Switch Replacement .................. 56

3.30 Flow Thermistor Replacement ................................... 56

3.31 Heat Engine Replacement ......................................... 57

3.32 Expansion Vessel Recharging & Replacement .......... 58

4 FAULT FINDING ........................................................ 59

4.1 Fault Finding Chart Main Menu .................................. 59

4.2 Overheat Lockout ....................................................... 61

4.3 Ignition Lockout .......................................................... 61

4.4 Flame On Before Gas Valve On .................................62

4.5 Low Water Pressure ................................................... 62

4.6 Flame Loss ................................................................. 62

4.7 Fan Fault .................................................................... 63

4.8 Flow Thermistor Fault ................................................63

4.9 Return Thermistor Fault ............................................. 63

4.10 Outside Sensor Fault .................................................64

4.11 No CH Operation But DHW Works OK ...................... 65

4.12 No HW But CH On ..................................................... 66

4.13 No Display .................................................................. 66

5 SPARE PARTS .......................................................... 67

6 BENCHMARK & COMMISSIONING ......................... 68

Page 8

8

Installation and Servicing

SECTION 1 - GENERAL

Table 1 - General Data

*Required for maximum ow rate. Boiler operates down to 2 l/min DHW delivery

** In areas of low water pressure the DHW restrictor can be removed

30 35

Gas supply 2H - G20 - 20mbar

Gas Supply Connection 15mm copper compression

Injector Size mm 4.65 4.9

Inlet Connection DHW 15mm copper compression

Outlet Connection DHW 15mm copper compression

Flow Connection CH 22mm copper compression

Return Connection CH 22mm copper compression

Flue Terminal Diameter mm (in) 50 (nominal)

Average Flue Temp-Mass Flow Rate (DHW) 68

o

C - 13g/s 73ºC - 15g/s

Maximum Working Pressure (Sealed Systems) bar (lb/in

2

) 2.5 (36.3)

Maximum Domestic Hot Water Inlet Pressure

bar (lb/in2) (kPa)

10.0 (145) (1000)

Minimum Domestic Hot Water Inlet Pressure*

bar (lb/in2) (kPa)

1.3 (18.9) (130) 1.3 (18.9)** (130)

Minimum DHW Inlet Pressure to operate at 0.6

bar system pressure

bar 0.5

Electrical Supply 230 V ~ 50 Hz.

Power Consumption W 101 114

Fuse Rating External : 3A Internal : T4A HRC L250 V

Water content CH litre (gal) 1.2 (0.26)

DHW litre (gal) 0.5 (0.11)

Packaged Weight kg 34.40 34.50

Maximum Installation Weight kg 31.40 31.50

Boiler Casing Size Height mm 700

Width mm 395

Depth mm 278

Note. Gas consumption is calculated using a

caloric value of 38.7 MJ/m3 (1038 Btu/ft3) gross

or 34.9 MJ/m

3

(935 Btu/ft3) nett

To obtain the gas consumption at a different

caloric value:

a. For l/s - divide the gross heat input (kW) by

the gross C.V. of the gas (MJ/m

3

)

b. For Btu/h - multiply the gross heat input (kW)

by 26.8

c. For ft

3

/h - divide the gross heat input (Btu/h)

by the gross C.V. of the gas (Btu/ft3)

d. For m

3

/h - multiply l/s by 3.6

Key to symbols

GB = United Kingdom IE = Ireland (Countries of destination)

PMS = Maximum operating pressure of water

C13 C33 C53

= A room sealed appliance designed for connection via ducts to a

horizontal or vertical terminal, which admits fresh air to the burner

and discharges the products of combustion to the outside through

orices which, in this case, are concentric. The fan is up stream of

the combustion chamber.

I

2H

= An appliance designed for use on 2nd Family gas, Group H only.

* The value is used in the UK Government’s Standard Assessment Procedure (SAP) for energy rating of dwellings. The test data from

which it has been calculated have been certied by a notied body.

Table 2 - Performance Data - Central Heating Table 3 - Performance Data - Domestic Hot Water

Boiler Input : Max. Min. 30 Min. 35

Boiler Input ‘Q’ Nett CV kW 24.3 6.1 7.1

Gross CV kW 27.0 6.7 7.9

Gas Consumption m

3

/h 2.512 0.623 0.734

(ft

3

/h) (89) (22) (25.9)

Boiler Output :

Non Condensing 70

o

C Mean Water temp. kW 24.2 6.1 7.1

Condensing 40

o

C Mean Water temp. kW 25.6 6.4 7.5

Seasonal efciency* SEDBUK 2005

SEDBUK 2009

91.1%

89.6%

91.1%

89.6%

NOx Classication CLASS 5

Maximum DHW Input : 30 35

Nett CV kW 30.4 35.4

Gross CV kW 33.7 39.3

Gas Consumption m

3

/h 3.135 3.658

(ft

3

/h) (111 ) (129)

Maximum kW 30.3 35.3

DHW Flow Rate l/min 12.4 14.5

at 35°C temp. rise. (gpm) (2.8) (3.2)

DHW Specic Rate l/min 14.5 16.9

(gpm) (3.2) (3.7)

Page 9

9

Installation and Servicing

SECTION 1 - GENERAL

Boiler Page

Make and model ......................................................... 9

Appliance serial no. on data badge .......... Front Cover

SEDBUK No. % .......................................................... 8

Controls

Time and temperature control to heating .................31

Time and temperature control to hot water .............31

Heating zone valves ................................................ n/a

TRV’s........................................................................ 12

Auto bypass ............................................................. 12

Boiler interlock .......................................................... 12

For .................................................................... all boilers

Flushing to BS.7593 ................................................. 14

Inhibitor ....................................................................15

Central heating mode

Heat input ...................................................to be calculated

For assistance see Technical Helpline on the back page

Page

Burner operating pressure ...................................... n/a

Central heating ow temp. ...........measure and record

Central heating return temp. ........measure and record

For combination boilers only

Scale reducer ........................................................... 15

Hot water mode

Heat input ............................................to be calculated

Max. operating burner pressure .............................. n/a

Max. operating water pressure ........ measure & record

Cold water inlet temp ...................... measure & record

Hot water outlet temp. ..................... measure & record

Water ow rate at max. setting ........ measure & record

For condensing boilers only

Condensate drain ..................................................... 26

For all boilers: complete, sign & hand over to customer

For GB, to comply with Building Regulations Part L1 (Part 6 in Scotland) the boiler should be tted in accordance with the

manufacturer’s instructions. Self-certication that the boiler has been installed to comply with Building Regulations can be

demonstrated by completing and signing the Benchmark Commissioning Checklist.

Before installing this boiler, read the Code of Practice sheet at the rear of this book.

BENCHMARK COMMISSIONING CHECKLIST DETAILS

NOTE TO THE INSTALLER:

COMPLETE

THE BENCHMARK COMMISSIONING

CHECKLIST AND LEAVE THESE

INSTRUCTIONS WITH APPLIANCE

Boiler size G.C. Appliance No. PI No.

(Benchmark No.)

30 47-930-07 86CR18

35 47-930-08 86CR18

Natural Gas only

Destination Country: GB, IE

KESTON COMBI C30 & C35

Page 10

10

Installation and Servicing

SECTION 1 - GENERAL

1.1 INTRODUCTION

The Keston Combi boiler is a wall mounted, full sequence,

automatic spark ignition, low water content, fanned ue, high

efciency, condensing, combination gas boiler.

Note. Due to the high efciency of the boiler a plume of water

vapour will form at the terminal during operation.

Central heating (CH) output is fully modulating with a range of:

30 6.1 to 24.2kW

35 7.1 to 24.2kW

Instantaneous domestic hot water (DHW) output is also fully

modulating with a maximum of :

30 30.3kW

35 35.3kW

The boiler is supplied fully assembled with DHW plate heat

exchanger, diverter valve, circulating pump, pressure gauge,

safety valve and CH expansion vessel.

Variable CH and DHW temperature controls are tted on the user

control and the boiler features a DHW preheat facility.

The boiler includes as standard:

- Automatic bypass

- Boiler frost protection

- Daily pump and diverter valve exercise.

- Weather Compensation Kit

The boiler casing is of white painted mild steel with a white

polymer front panel.

The boiler temperature controls are visible located in the control

panel on the front of the boiler.

The heat exchanger is manufactured from cast aluminium.

The boiler is suitable for connection to fully pumped, sealed

heating systems ONLY. Adequate arrangements for completely

draining the system by provision of drain cocks MUST be

provided in the installation pipework.

Pipework from the boiler is routed downwards.

Data Plate

The boiler model and serial number can be located on the bottom

of the boiler casing, shown in Frame 1 - Water & Gas Connection

Diagram.

1.2 OPERATION

With no demand for CH, the boiler res only when DHW is drawn

off, or periodically for a few seconds without any DHW draw-off, in

order to maintain the DHW calorier in a heated condition. This

only occurs if pre-heat knob is in the ‘ON’ period.

When there is a demand for CH, the heating system is supplied at

the selected temperature of between 30

o

C and 80oC, until DHW

is drawn off. The full output from the boiler is then directed via

the diverter valve to the plate heat exchanger to supply a nominal

DHW draw-off of:

30 12.4 l/min at 35

o

C temperature rise.

35 14.5 l/min at 35

o

C temperature rise.

When using the outside sensor provided please refer to page 33.

The DHW draw off rate specied above is the nominal that the

boiler ow regulator will give. Due to system variations and

seasonal temperature uctuations DHW ow rates/temperature

rise will vary, requiring adjustment at the draw off tap.

At low DHW draw-off rates the maximum temperature may

exceed 65ºC.

The boiler features a comprehensive diagnostic system which

gives detailed information on the boiler status when operating,

and performance of key components to aid commissioning and

fault nding.

1.3 SAFE HANDLING

This boiler may require 2 or more operatives to move it to its

installation site, remove it from its packaging base and during

movement into its installation location. Manoeuvring the boiler

may include the use of a sack truck and involve lifting, pushing

and pulling.

Caution should be exercised during these operations.

Operatives should be knowledgeable in handling techniques

when performing these tasks and the following precautions should

be considered:

• Grip the boiler at the base.

• Be physically capable.

• Use personal protective equipment as appropriate, e.g.

gloves, safety footwear.

During all manoeuvres and handling actions, every attempt

should be made to ensure the following unless unavoidable and/

or the weight is light.

• Keep back straight.

• Avoid twisting at the waist.

• Avoid upper body/top heavy bending.

• Always grip with the palm of the hand.

• Use designated hand holds.

• Keep load as close to the body as possible.

• Always use assistance if required.

1.4 OPTIONAL EXTRA KITS

Please visit www.keston.co.uk to access the Flue and

Accessories Guide for this boiler.

Page 11

11

Installation and Servicing

SECTION 1 - GENERAL

1.5 SAFETY

Current Gas Safety (installation and use) regulations or rules

in force:

The appliance is suitable only for installation in GB and IE and

should be installed in accordance with the rules in force.

In GB, the installation must be carried out by a Gas Safe

Registered Engineer. It must be carried out in accordance with

the relevant requirements of the:

• Gas Safety (Installation and Use) Regulations

• The appropriate Building Regulations either The Building

Regulations, The Building Regulations (Scotland), Building

Regulations (Northern Ireland).

• The Water Fittings Regulations or Water byelaws in Scotland.

• The Current I.E.E. Wiring Regulations.

Where no specic instructions are given, reference should be

made to the relevant British Standard Code of Practice.

In IE, the installation must be carried out by a Registered Gas

Installer (RGII) and installed in accordance with the current edition

of I.S.813 “Domestic Gas Installations”, the current Building

Regulations and reference should be made to the current ETCI

rules for electrical installation.

Detailed recommendations are contained in the following British

Standard Codes of Practice:

BS. 5440:1 Flues (for gas appliances of rated input not

exceeding 70 kW).

BS. 5440:2 Ventilation (for gas appliances of rated input not

exceeding 70 kW).

BSEN. 12828:2003 Heating Systems in buildings: Design for

water based heating systems.

BSEN 12831:2003 Heating Systems in buildings: Method for

calculation of the design heat load.

BSEN 14336:2004 Heating Systems in buildings: Installation

and commissioning of water based heating

systems.

BS. 5546 Installation of gas hot water supplies for domestic

purposes (2nd Family Gases)

BS. 6798 Installation of gas red hot water boilers of rated

input not exceeding 70 kW.

BS. 6891 Low pressure installation pipes.

Health & Safety Document No. 635.

The Electricity at Work Regulations, 1989.

The manufacturer’s notes must NOT be taken, in any way, as

overriding statutory obligations.

IMPORTANT. These appliances are CE certicated for safety

and performance. It is, therefore, important that no external

control devices, e.g. ue dampers, economisers etc., are

directly connected to these appliances unless covered by

these Installation and Servicing Instructions or as otherwise

recommended by Keston in writing. If in doubt please enquire.

Any direct connection of a control device not approved by Keston

could invalidate the certication and the normal appliance

warranty. It could also infringe the Gas Safety Regulations and

the above regulations.

1.6 SAFE HANDLING OF SUBSTANCES

No asbestos, mercury or CFCs are included in any part of the

boiler or its manufacture.

1.7 LOCATION OF BOILER

The boiler must be installed on a at and vertical internal wall,

capable of adequately supporting the weight of the boiler and any

ancillary equipment.

The boiler may be tted on a combustible wall and insulation

between the wall and the boiler is not necessary, unless required

by the local authority.

For electrical safety reasons there must be no access available

from the back of the boiler.

The boiler must not be tted outside.

Timber Framed Buildings

If the boiler is to be tted in a timber framed building it should

be tted in accordance with the Institute of Gas Engineering

document IGE/UP/7:2006 Edition 2.

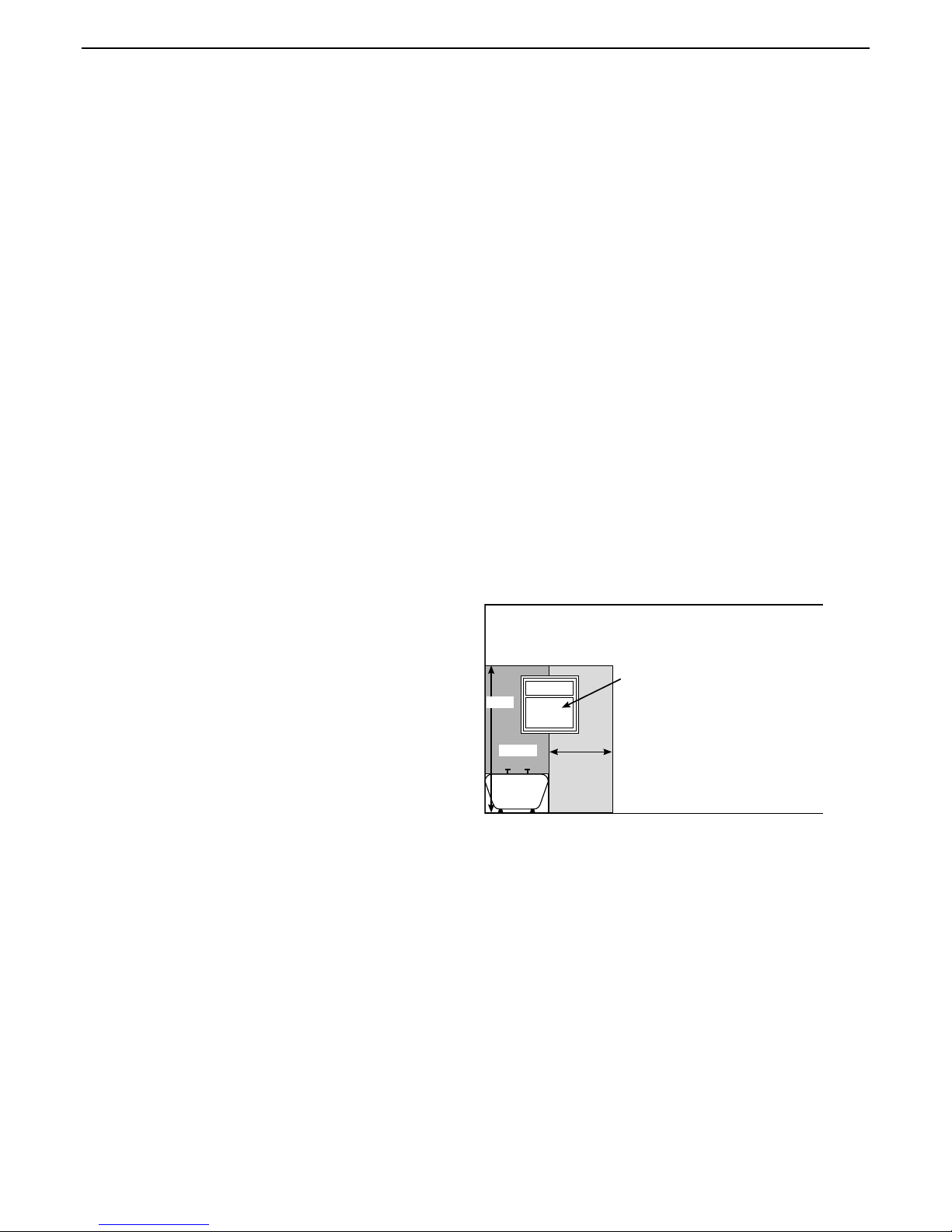

Bathroom Installations

This appliance is rated IP20.

The boiler may be installed in any room or internal space,

although particular attention is drawn to the requirements of

the current IEE (BS.7671) Wiring Regulations and the electrical

provisions of the building regulations applicable in Scotland,

with respect to the installation of the boiler in a room or internal

space containing a bath or shower. For IE reference should be

made to the current ETCI rules for electrical installations and I.S.

813:2002.

If the appliance is to be installed in a room containing a bath or

shower then, providing water jets are not going to be used for

cleaning purposes (as in communal baths/showers), the appliance

must be installed beyond Zone 2, as detailed in BS.7671.

0.6m

Zone 0

Recessed

window

Zone 2

Ceiling

3G8913a

2.25m

Zone 1

Compartment Installations

A compartment used to enclose the boiler should be designed

and constructed specially for this purpose.

An existing cupboard or compartment may be used, provided that

it is modied for the purpose.

In both cases, details of essential features of cupboard /

compartment design, including airing cupboard installation, are to

conform to the following:

• BS 6798 (No cupboard ventilation is required - see ‘Air Supply’

for details).

• The position selected for installation MUST allow adequate

space for servicing in front of the boiler.

• For the minimum clearances required for safety and

subsequent service, see the wall mounting template and

Section 1.13. In addition, sufcient space may be required to

allow lifting access to the wall mounting plate.

• The boiler must be installed on a re resistant surface.

Page 12

12

Installation and Servicing

SECTION 1 - GENERAL

1.8 GAS SUPPLY

The local gas supplier should be consulted, at the installation

planning stage, in order to establish the availability of an adequate

supply of gas. An existing service pipe must NOT be used without

prior consultation with the local gas supplier.

The boiler MUST be installed on a gas supply with a governed

meter only.

A gas meter can only be connected by the local gas supplier or

by a Gas Safe Registered Engineer. In IE by a Registered Gas

Installer (RGII).

An existing meter should be checked, preferably by the gas

supplier, to ensure that the meter is adequate to deal with the rate

of gas supply required.

It is the responsibility of the Gas Installer to size the gas

installation pipework in accordance with BS6891:2005. Whilst the

principle of the 1:1 gas valve ensures the Keston Combi range

is able to deliver its full output at inlet pressures as low as 14mb,

other gas appliances in the property may not be as tolerant.

When operating pressures are found to be below the minimum

meter outlet of 19mb these should be checked to ensure this is

adequate for correct and safe operation.

Allowing for the acceptable pressure loss of 1mb across the

installation pipework, it can be assumed that a minimum permitted

operating pressure of 18mb will be delivered to the inlet of

the appliance. (Reference BS 6400-1 Clause 6.2 Pressure

Absorption).

The external gas cock could further reduce the operating pressure

when measured at its test point. The pressure drop is relative to

the heat input to the boiler (kW), refer to graph below.

0

0.5

1

1.5

2

2.5

3

0 10 20 30 40 50

Pressure drop (mbar )

Heat Input to Boiler (kW)

Gas Cock Pressure Drop

IMPORTANT.

Installation pipes must be tted in accordance with BS.6891. In IE

refer to IS.813:2002.

The complete installation MUST be tested for gas tightness and

purged as described in the above code.

1.9 WATER CIRCULATION SYSTEM

IMPORTANT.

A minimum length of 1 metre of copper pipe MUST be tted

to both ow and return connections from the boiler before

connection to any plastic piping.

The central heating system should be in accordance with BS.6798

and, in addition, for smallbore and microbore systems, BS.5449.

WATER TREATMENT - see Section 1.16

1.10 BOILER CONTROL INTERLOCKS

Central heating systems controls should be installed to ensure

the boiler is switched off when there is no demand for heating, in

compliance with Building Regulations.

Heating systems utilising full thermostatic radiator valve control

of temperature in individual rooms should also be tted with a

room thermostat controlling the temperature in a space served by

radiators not tted with such a valve.

When thermostatic radiator valves are used, the space heating

temperature control over a living / dining area or hallway having

a heating requirement of at least 10% of the minimum boiler heat

output should be achieved using a room thermostat, whilst other

rooms are individually controlled by thermostatic radiator valves.

However, if the system employs thermostatic radiator valves on all

radiators, or two port valves, then a bypass circuit must be tted

with an automatic bypass valve to ensure a ow of water should

all valves be in the closed position.

1.11 ELECTRICAL SUPPLY

WARNING.

This appliance must be earthed.

Wiring external to the appliance MUST be in accordance with

the current I.E.E. (BS.7671) Wiring Regulations and any local

regulations which apply. For IE reference should be made to the

current ETCI rules for electrical installations.

The mains supply to the boiler and system wiring centre shall

be through one common fused double pole isolator and for

new heating systems, and where practical replacement boiler

installations, the isolator shall be situated adjacent to the

appliance.

1.12 CONDENSATE DRAIN

Refer to Section 2.14

A condensate drain is provided on the boiler. This drain must be

connected to a drainage point on site. All pipework and ttings in

the condensate drainage system MUST be made of plastic - no

other materials may be used.

IMPORTANT.

Any external runs must be in accordance with BS 6798.

The drain outlet on the boiler is sized for standard 21.5mm (3/4”)

overow pipe. It is a universal tting to allow use of different

brands of pipework.

Page 13

13

Installation and Servicing

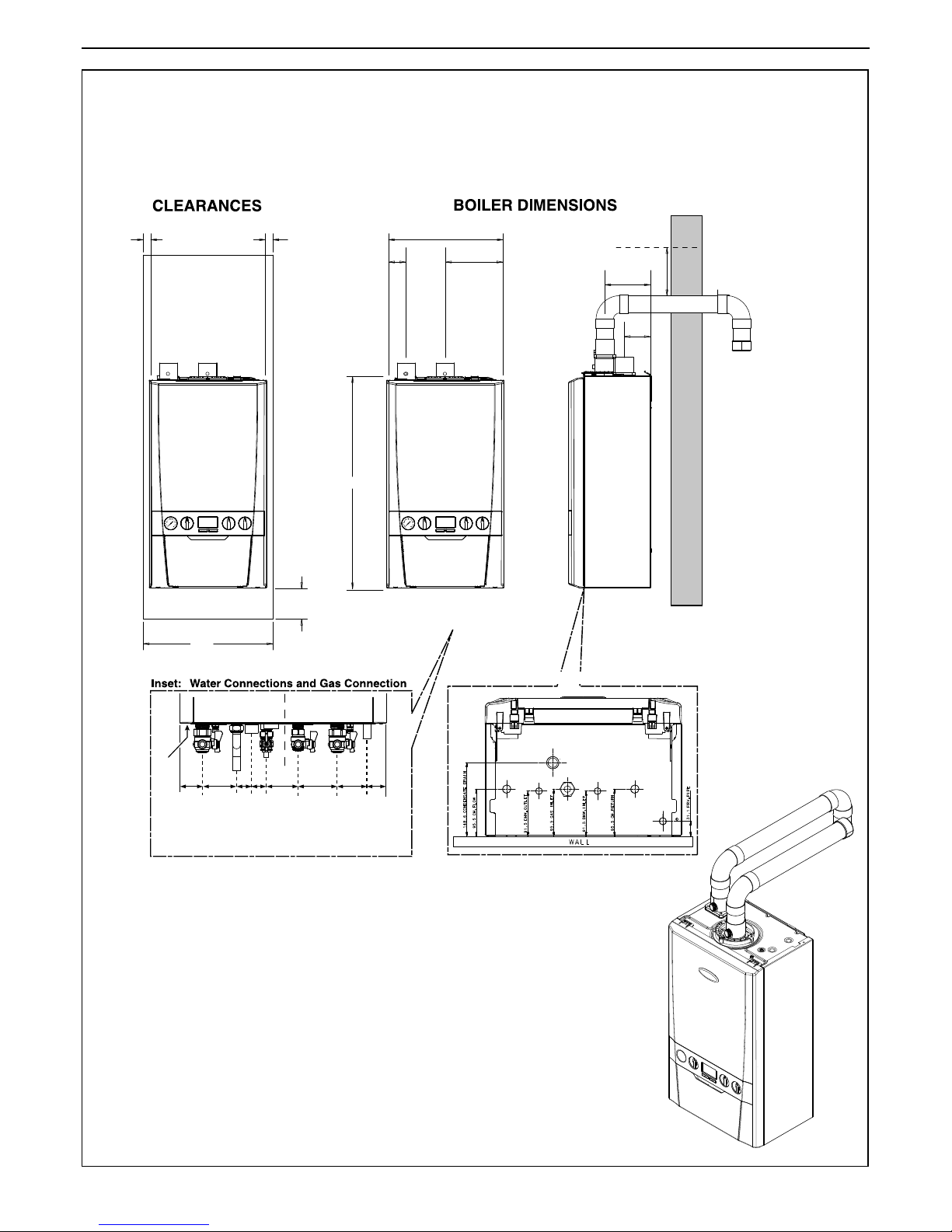

SECTION 1 - GENERAL

395

198

89

155

62

30mm

Minimum Top Clearance

100

Air Flue

400

700

2.5

2.5

from case

*

CH FLOW

DATA PLATE

DHW OUTLET

COND. DRAIN

GAS INLET

Centre line

of boiler

DHW INLET

CH RETURN

PRV

43.5 65

28.5 28.5

60.6 75 37.556.4

Underside View - Dimensions to Wall

1.13 BOILER DIMENSIONS, SERVICES & CLEARANCES

The boiler connections are made on the boiler connection tails.

Refer to Section 2.15.

The following minimum clearances must be maintained for

operation and servicing.

Additional space will be required for installation, depending

upon site conditions.

Front clearance

The minimum front clearance when built in to a cupboard is 5mm from

the cupboard door but 450mm overall clearance is still required, with the

cupboard door open, to allow for servicing.

* Bottom clearance

Bottom clearance after installation can be reduced to 5mm.

This must be obtained with an easily removable panel to provide the

100mm clearance required for servicing.

Page 14

14

Installation and Servicing

SECTION 1 - GENERAL

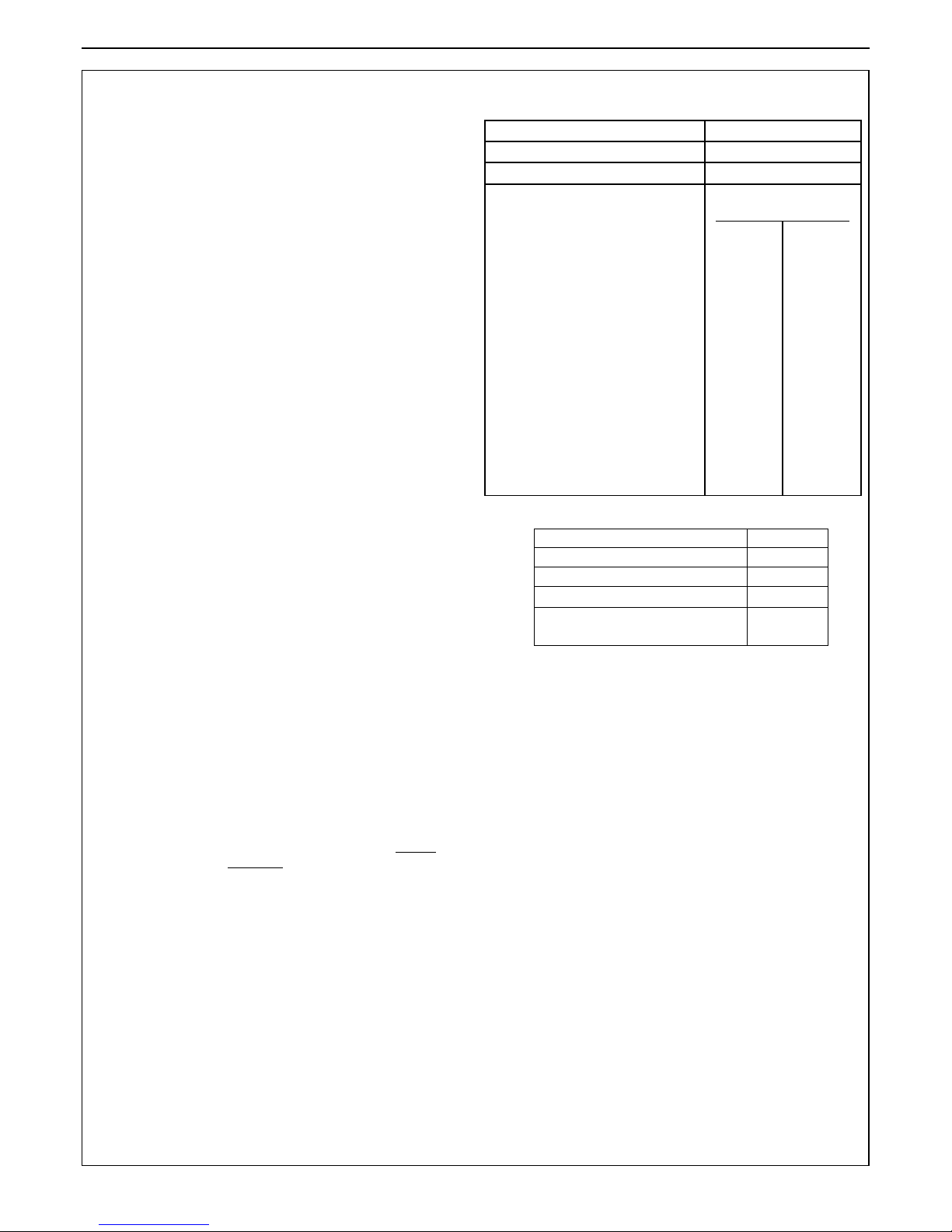

Safety valve setting bar 3.0

Vessel charge pressure bar 0.5 to 0.75

System pre-charge pressure bar None 1.0

System volume

(litres)

Expansion vessel

volume (litres)

25 1.6 1.8

50 3.1 3.7

75 4.7 5.5

100 6.3 7.4

125 7.8 9.2

150 9.4 11.0

175 10.9 12.9

190 11.9 14.0

200 12.5 14.7

250 15.6 18.4

300 18.8 22.1

For other system volumes

multiply by the factor access 0.063 0.074

Water Flow Rate and Pressure Loss

Max CH Output kW 24.2

Water ow rate l/min 17.3

(gal/min) (3.8)

Temperature Differential

o

C 20

Head available for m.w.g. 3.4

system (ft.w.g.) (11.1)

1.14 SYSTEM REQUIREMENTS - Central Heating

Notes

a. The method of lling, relling, topping up or ushing sealed

primary hot water circuits from the mains via a temporary hose

connection is only allowed if acceptable to the local water

authority.

b. Antifreeze uid, corrosion and scale inhibitor uids suitable for

use with boilers having aluminium heat exchangers may be used

in the central heating system.

General

1. The installation must comply with all relevant national and local

regulations.

2. The installation should be designed to work with flow

temperatures of up to 84

o

C.

3. All components of the system must be suitable for a working

pressure of 3 bar and a maximum design temperature of 110

o

C. Extra care should be taken in making all connections so

that the risk of leakage is minimised.

The following components are incorporated within the appliance:

a. Circulating pump.

b.

Safety valve, with a non-adjustable preset lift pressure of 3 bar.

c. Pressure gauge, covering a range of 0 to 4 bar.

d. An 8-litre expansion vessel, with an initial charge pressure

of 0.75 bar.

4. ‘Make-up’ Water. Provision must be made for replacing water

loss from the system, either :

a. From a manually lled ‘make-up’ vessel with a readily visible

water level. The vessel should be mounted at least 150mm

above the highest point of the system and be connected

through a non-return valve to the system, tted at least

150mm below the ‘make-up’ vessel on the return side of

the radiators. or

b. Where access to a ‘make-up’ vessel would be difcult, by

pre-pressurisation of the system.

The maximum cold water capacity of the system should

not exceed 143 litres, if not pressurized. However, if

the system is to be pressurized, the efciency of the

expansion vessel will be reduced and a larger vessel

(or smaller system volume) may be necessary. If the

capacity of the vessel is not considered sufcient for this,

or for any other reason, an additional vessel MUST be

installed on the RETURN to the boiler.

Guidance on vessel sizing is given in Table opposite.

5. Filling

The system may be lled by the following method:

Where the mains pressure is excessive a pressure reducing

valve must be used to facilitate lling.

a. Thoroughly ush out the whole system with cold water.

b. Fill and vent the system until the pressure gauge

registers 1bar and examine for leaks. Refer to Section

2.15 for lling detail.

c. Check the operation of the safety valve by raising the

water pressure until the valve lifts. This should occur

within 0.3bar of the preset lift pressure.

d. Release water from the system until the

minimum system design pressure is reached;

1.0 bar if the system is to be pre-pressurised.

DOMESTIC HOT WATER

1. The domestic hot water service must be in accordance with

BS 5546 and BS 6700.

2. Refer to Table 1 for minimum and maximum working

pressures. In areas of low mains water pressures the

domestic hot water regulator may be removed from

the DHW ow turbine cartridge. Refer to Section 3.25.

The boiler will require the ow rate to be set to obtain a

temperature rise of 35

o

C at the tap furthest from the boiler.

3. The boiler is suitable for connection to most types of

washing machine and dishwasher appliances.

4. When connecting to suitable showers, ensure that:

a. The cold inlet to the boiler is tted with an approved

anti-vacuum or syphon non-return valve.

b.

Hot and cold water supplies to the shower are of equal

pressure.

5. Hard Water Areas

Where the water hardness exceeds 200mg/litre, it is

recommended that a proprietary scale reducing device is

tted into the boiler cold supply within the requirements of

the local water company.

IMPORTANT

Provision MUST be made to accommodate the expansion of

DHW contained within the appliance, if a non-return valve is tted

to the DHW inlet, or a water meter with a non-return valve is

installed.

Cold water rising main and pipework in exposed areas need to

be suitably lagged to prevent freezing.

Page 15

15

Installation and Servicing

SECTION 1 - GENERAL

1.15 SYSTEM BALANCING

The boiler does not normally need a bypass but at least some

radiators on the heating circuit, of load of at least 10% of the

minimum boiler output, must be provided with twin lockshield

valves so that this minimum heating load is always available.

See note regarding thermostatic radiator valves on page 12.

Note. Systems incorporating zone valves which could

completely cut off the ow through the system must also

include a bypass.

BALANCING

1. Set the programmer to ON.

Close the manual or thermostatic valves on all radiators,

leaving the twin lockshield valves (on the radiators referred

to above) in the OPEN position.

Turn up the room thermostat and adjust the lockshield

valve to give an uninterrupted ow through the radiator.

These valves should now be left as set.

2. Open all manual or thermostatic radiator valves and adjust

the lockshield valves on the remaining radiators, to give

around 20

o

C temperature drop at each radiator.

3. Adjust the room thermostat and programmer to NORMAL

settings.

1.16 WATER TREATMENT

CENTRAL HEATING

The Keston Combi range boiler has an ALUMINIUM alloy heat

exchanger.

IMPORTANT.

The application of any other treatment to this product may

render the guarantee of Keston Invalid.

Keston recommend Water Treatment in accordance with the

Benchmark Guidance Notes on Water Treatment in Central

Heating Systems.

If water treatment is used Keston recommend only the use of

SCALEMASTER GOLD 100, FERNOX, MBI, ADEY MC1, SENTINEL

X100 or CALMAG CM100 inhibitors and associated water

treatment products, which must be used in accordance with the

manufacturers’ instructions.

Notes.

1. It is most important that the correct concentration of the

water treatment products is maintained in accordance with

the manufacturers’ instructions.

2. If the boiler is installed in an existing system any unsuitable

additives MUST be removed by thorough cleansing. BS

7593:2006 details the steps necessary to clean a domestic

heating system.

3. In hard water areas, treatment to prevent lime scale may be

necessary - however the use of articially softened water is

NOT permitted.

4. Under no circumstances should the boiler be red before

the system has been thoroughly ushed.

DOMESTIC HOT WATER

In hard water areas where mains water can exceed 200ppm

Total Hardness (as dened by BS 7593:2006 Table 2) a scale

reducing device should be tted into the boiler cold supply

within the requirements of the local water company. The use of

articially softened water, however, is not permitted.

Keston recommend the use of Fernox Quantomat, Sentinel

Combiguard or Calmag CalPhos I scale reducing devices

together with scalemaster in-line scale inhibitor branded Ideal,

which must be used in accordance with the manufacturers’

instructions.

For further information contact:

Fernox Cookson Electronics

Forsyth Road, Sheerwater, Woking, Surrey GU21 5RZ

+44 (0) 870 601 500

Sentinel Performance Solutions

The Heath Business & Technical Park, Runcorn, Cheshire WA7

4QX

Tel: 0800 389 4670

www.sentinel-solutions.net

Scalemaster Water Treatment Products

Emerald Way, Stone, Staffordshire ST15 0SR

Tel: +44 (0) 1785 811636

Calmag Ltd.

Unit 3-6, Crown Works, Bradford Road, Sandbeds, Keighley,

West Yorkshire BD20 5LN

Tel: +44 (0) 1535 210 320

Adey Professional Heating Solutions

Gloucester Road, Cheltenham GL51 8NR

Tel: +44 (0) 1242 546700

Page 16

16

Installation and Servicing

SECTION 2 - INSTALLATION

504

227

224

503

505

215

309

306

308

204

211

214

206

205

223

110

114

113

121

118

131

127

124

120

119

117

104

106

203

106

107

105

112

228

229

304

116

115

219

401

218

307

506

217

111

108

326

135

325

302

324

313

507

231

320

INSTALLATION

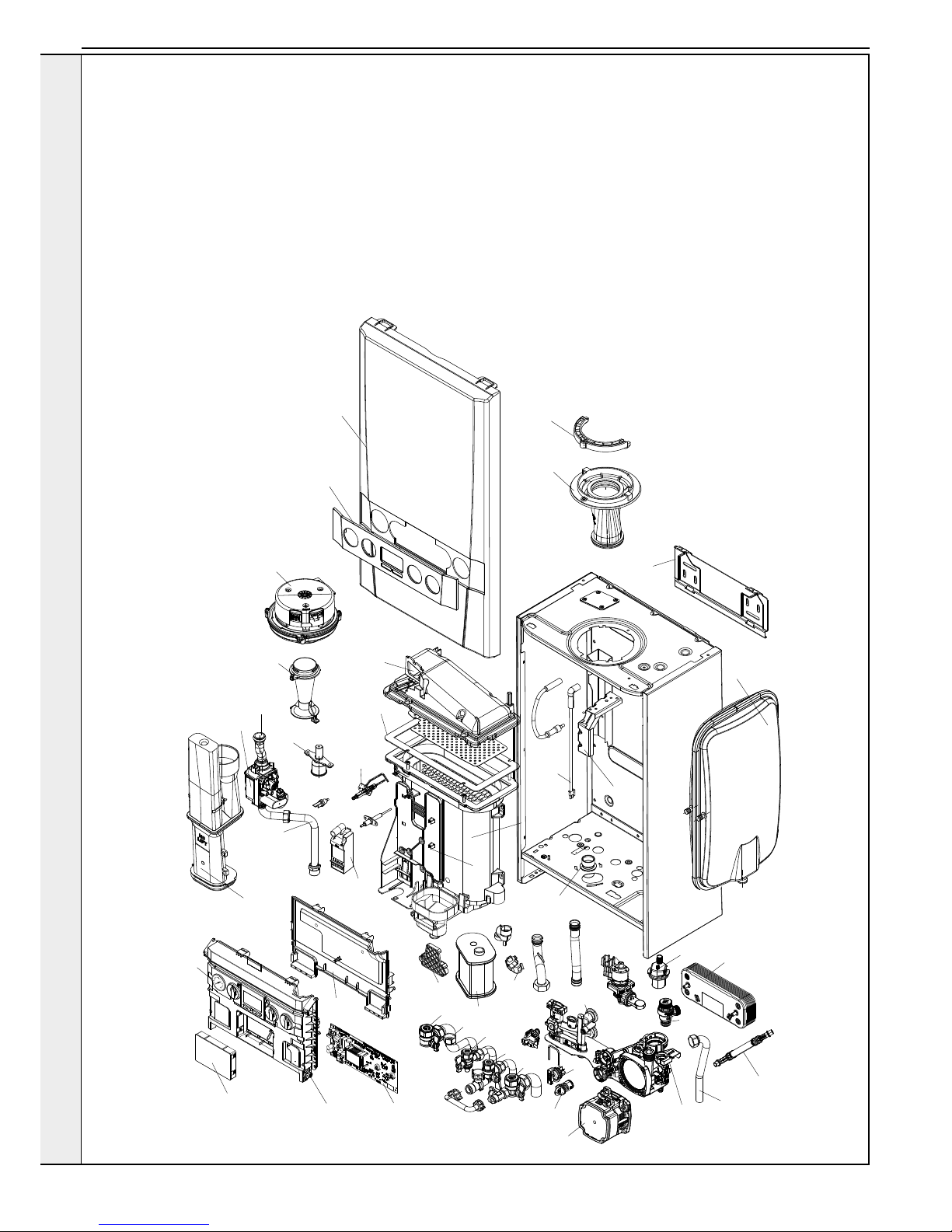

2.1 BOILER ASSEMBLY - EXPLODED VIEW

104 CH Return Valve

105 CH Flow Valve

106 DHW Inlet & Outlet

107 Filling Loop Pipe

108 Pump Head

110 Auto Air Vent

111 Divertor Valve Motor

112

Divertor Valve Body & Paddle

113 Pressure Relief Valve

114 Pipe - PRV Outlet

115 Pipe - Flow

116 Pipe - Return

117 Pipe - Expansion Vessel

118 Expansion Vessel

119 Return Group Manifold

120 Flow Group Manifold

121 Plate Heat Exchanger

124 Flow Regulator

127 Flow Sensor/Turbine

131 Water Pressure Switch

135 Pressure Gauge

203 Gas Cock

204 Pipe - Gas Inlet

205 Gas Valve

206 Pipe - Gas Injector

211 Injector Assy

214 Venturi

215 Fan

217 Burner

218 Gasket - Burner

219 Sump Clean Out Cover

223 Flue Manifold

224 Flue Manifold Top

227 Clamp Retaining Flue Turret

228 Hose Condensate Internal

229 Siphon Trap

231

Condensate Outlet Connection

302 PCB

304

Control Thermistor (Return)

306 Electrode Ignition

307 Electrode Detection

308 Ignitor Unit

309 Thermistor Flow

313 Ignition Lead

320 Detection Lead

324 Control Box Lid

325 Control Box Front

326 Programmer Insert

401 Heat Engine

503 Wall Mounting Bracket

504 Front Panel

505 Fascia

506 Bracket - Gas Valve

507 Bracket - Expansion Vessel

Page 17

17

Installation and Servicing

SECTION 2 - INSTALLATION

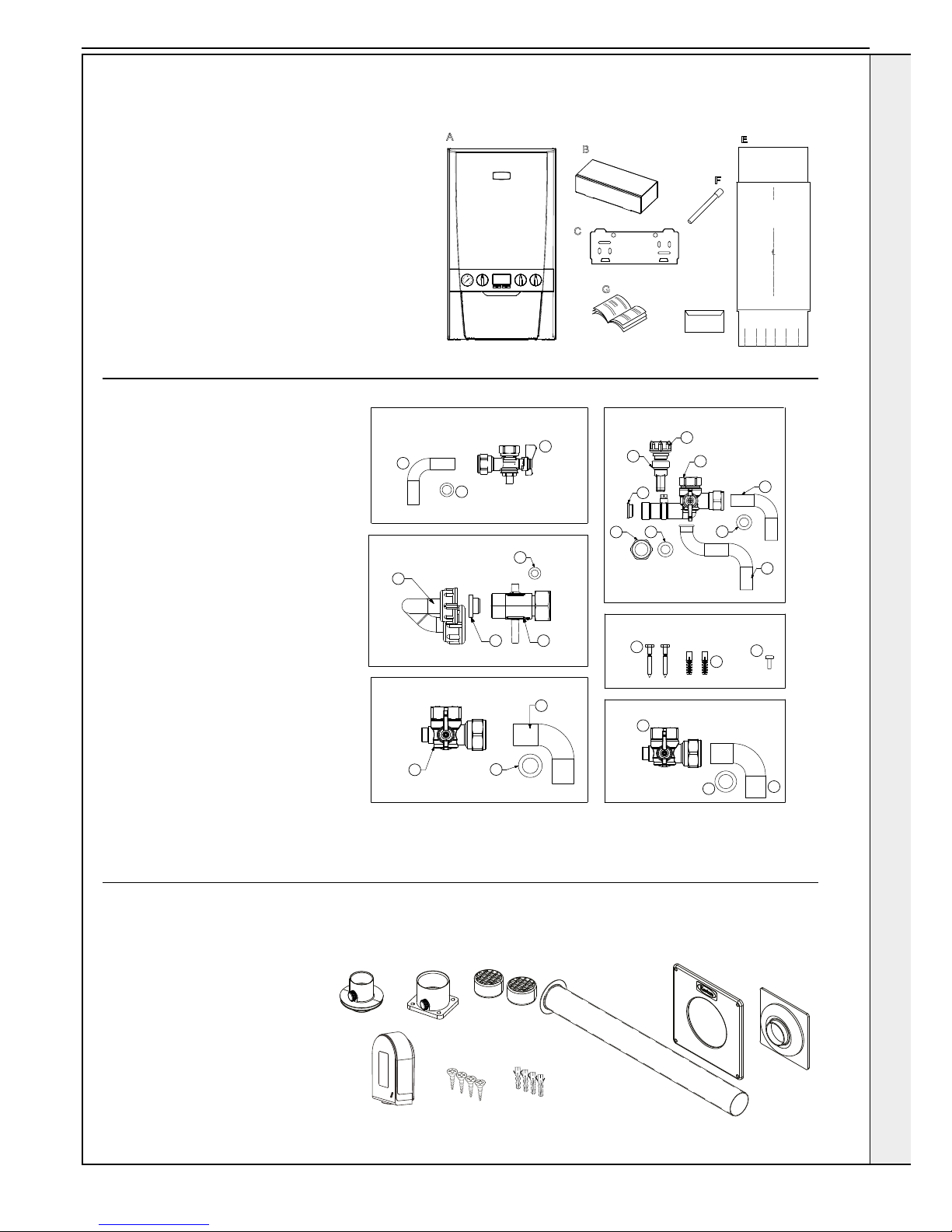

C

A

G

F

B

E

H

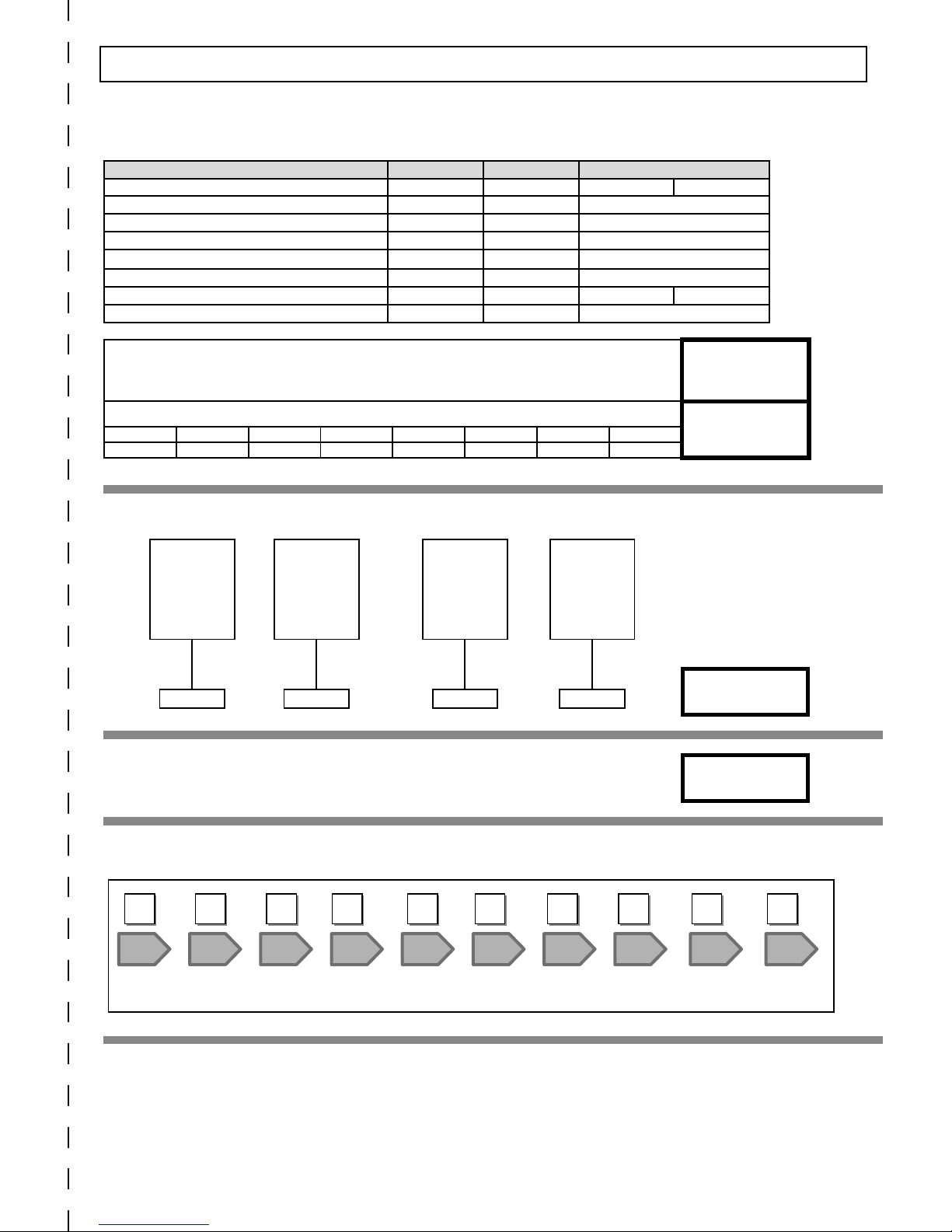

Boiler Guarantee

HARDWARE PACK CONTENTS

Gas Valve Pack DHW Pack

Accessory Pack

Flow Valve Pack

Return Valve Pack

Filling Loop

Gas Valve Pack

1. Pipe - Gas Inlet

2. Washer - Gas (blue)

3. Gas Cock

Filling Loop Pack

1. 3/8" Top Hat Washer

2. Valve Filling Loop

3. Pipe Filling Loop

4. Washer

Return Valve Pack

1. Pipe CH Return

2. Washer

3. Valve Return

DHW Pack

1. 1/2" Top Hat Washer (x2)

2. Cap Female

3. Plug Male and Clip

4. Nut G1/2 16 Brass (Flat)

5. Washer 18.5 x 11 x 11.8 (x2)

6. Pipe DHW Outlet

7. Pipe DHW Inlet

8. Valve DHW Inlet

Accessory Pack

1. Screw (x2)

2. Wallplug (x2)

3. Turret Clamp Screw (spare)

Flow Valve Pack

1. Pipe CH Flow

2. Washer CH

3. Valve Flow

1

1

1

3

2

2

2

3

3

1

2

3

2

8

3

3

1 2

1

7

5

6

4

5

4

B

A

G

H

J

F

E

D

C

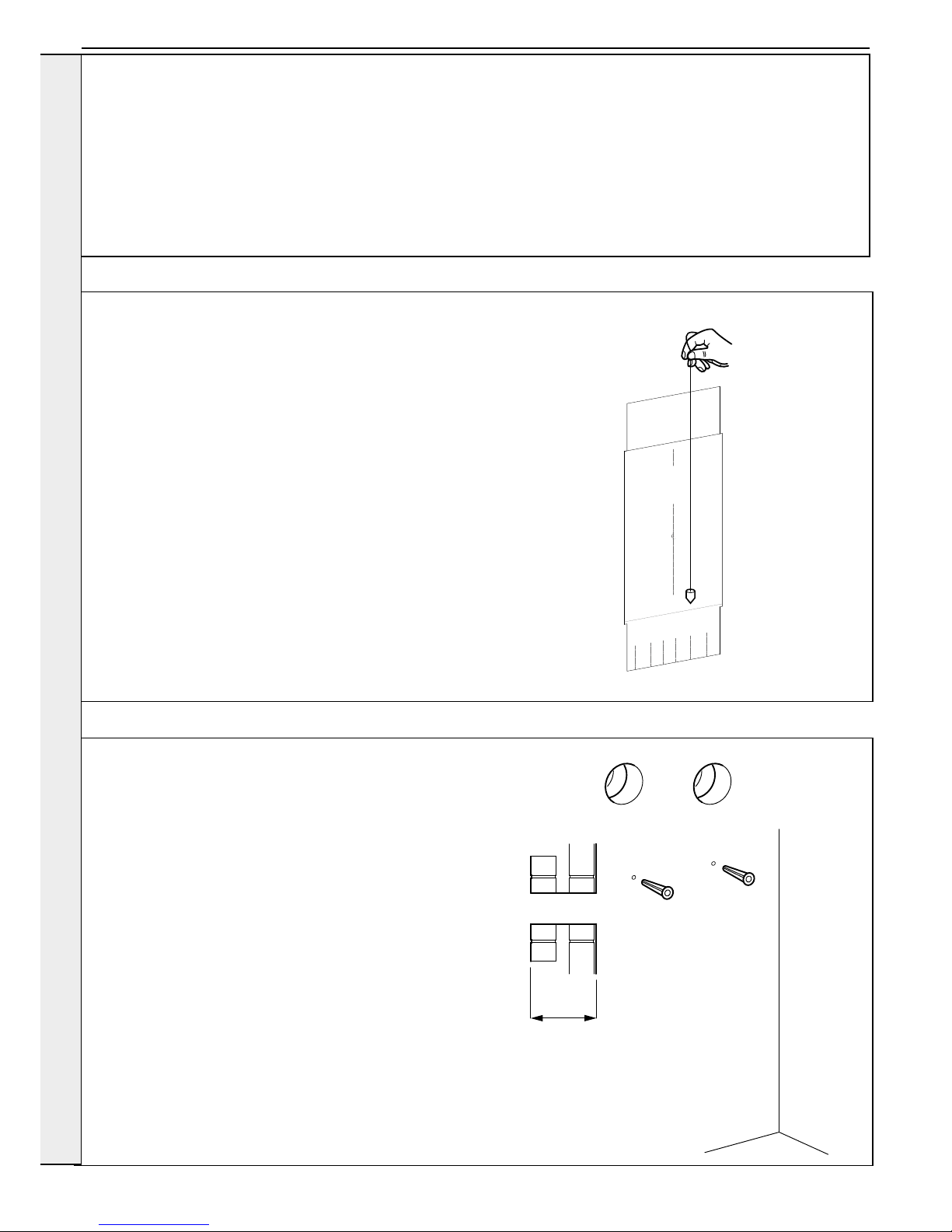

2.2 UNPACKING

Unpack and check the contents.

PACK 1 CONTENTS

A Boiler

B Hardware Pack Box

C Wall Mounting Plate

D These Installation Instructions

E Wall Mounting Template

(located on internal protective packaging)

F Safety Valve Drain Pipe

G Boiler Guarantee / Registration pack

FLUE PACK CONTENTS

A Flue Adaptor

B Air Spigot

C Terminals - 2 off

D Flue Sleeve

E Wall Plate

F Wall Seal

G Outside Sensor

H Screws - 4 off

J Wall Plugs - 4 off

INSTALLATION

Page 18

18

FLUE OUTLET

18

Installation and Servicing

SECTION 2 - INSTALLATION

continued............

2.3 FLUE SYSTEM

IMPORTANT

When installing a replacement boiler a new ue system is recommended. However re-using the existing

boiler ue installation is acceptable if the installer checks and conrms:

• The ue pipe is the approved Marley/Polypipe/Terrain 50mm muPVC solvent weld ue system

• The ue installation is upgraded to the most recent ue standards taking particular care to comply with

ues in voids

• A risk assessment is conducted to conrm the effectiveness of the ue

• The existing ue will last the lifetime of the new appliance

DESIGN

Individual air supply and ue outlet pipes are used as standard.

The material approved for this application which MUST be used are:

- Marley muPVC Solvent Weld System (50mm)

- Polypipe System 2000 muPVC solvent weld (50mm)

- Polypipe Terrain 200 muPVC Solvent Weld System (50mm)

to BS5255 and/or BSEN1566-11 and BSEN1329, are the only systems approved for this application.

The following pipe and ttings are approved.

Polypipe System 2000 muPVC solvent Weld System (50mm)

Polypipe Code

MU 301 4m length muPVC wastepipe 5/225

MU 313 50mm x 45 deg muPVC obtuse bend

MU 314 50mm x 92.5 deg muPVC swept bend

MU 310 50mm muPVC straight coupling

MU 316 50mm x 92.5 deg muPVC swept tee

Marley muPVC Solvent Weld System (50mm)

Marley Code

KP 304 50mm x 4m double spigot pipe

KP32 50mm x 45 deg bend

KSC3 50mm straight coupling

KB3 50mm x 88.5 deg bend

KT3 50mm swept tee

Polypipe Terraine Solvent Weld System (50mm)

Polypipe Code

200.2.40 4m length muPVC wastepipe

201.2.135 50mm x 135 deg muPVC bend

200.2.91 50mm x 91

1

/4 deg muPVC swept bend

210.2 50mm muPVC straight coupling

204.2.135 50mm muPVC swept tee

Consideration MUST be given to expansion and contraction of the ue. Refer to Assembly Practice (Section 2.12) in this

installation and Servicing Instructions for further guidance.

Page 19

19

FLUE OUTLET

19

Installation and Servicing

SECTION 2 - INSTALLATION

TERMINAL POSITIONS

Flue

Pipe

Elbow

Minimum Separation

140mm

Acceptable

range of air

pipe siting

Terminal

Air Pipe

150mm

FLUE SYSTEM........ CONT’D

TERMINATION OF THE FLUE AND AIR

The ue and air pipes may terminate independently through any

external walls within the same dwelling except on opposing walls,

within the maximum lengths shown in graph below. (Alternatively

a vertical ue pipe termination is acceptable.)

The air pipe must have an elbow and 150mm length of pipe

directed downwards with a termination grill tted.

The air pipe can be situated at the side or beneath the ue pipe to

a minimum dimension of 140mm (see diagram below). It must not

be sited above the ue pipe.

The ue and air pipes must extend by at least 40mm from the wall

surface.

Condensing boiler emit a visible plume of water vapour from the

ue terminal, this is normal. It is the responsibility of the installer

to judiciously select a terminal location that does not cause a

nuisance.

If either the ue or air terminal is below a height of 2m from

ground level a terminal guard must be tted.

Note. Any veritcal termination MUST have the terminals tted

and the air intake comply with the dimensions above.

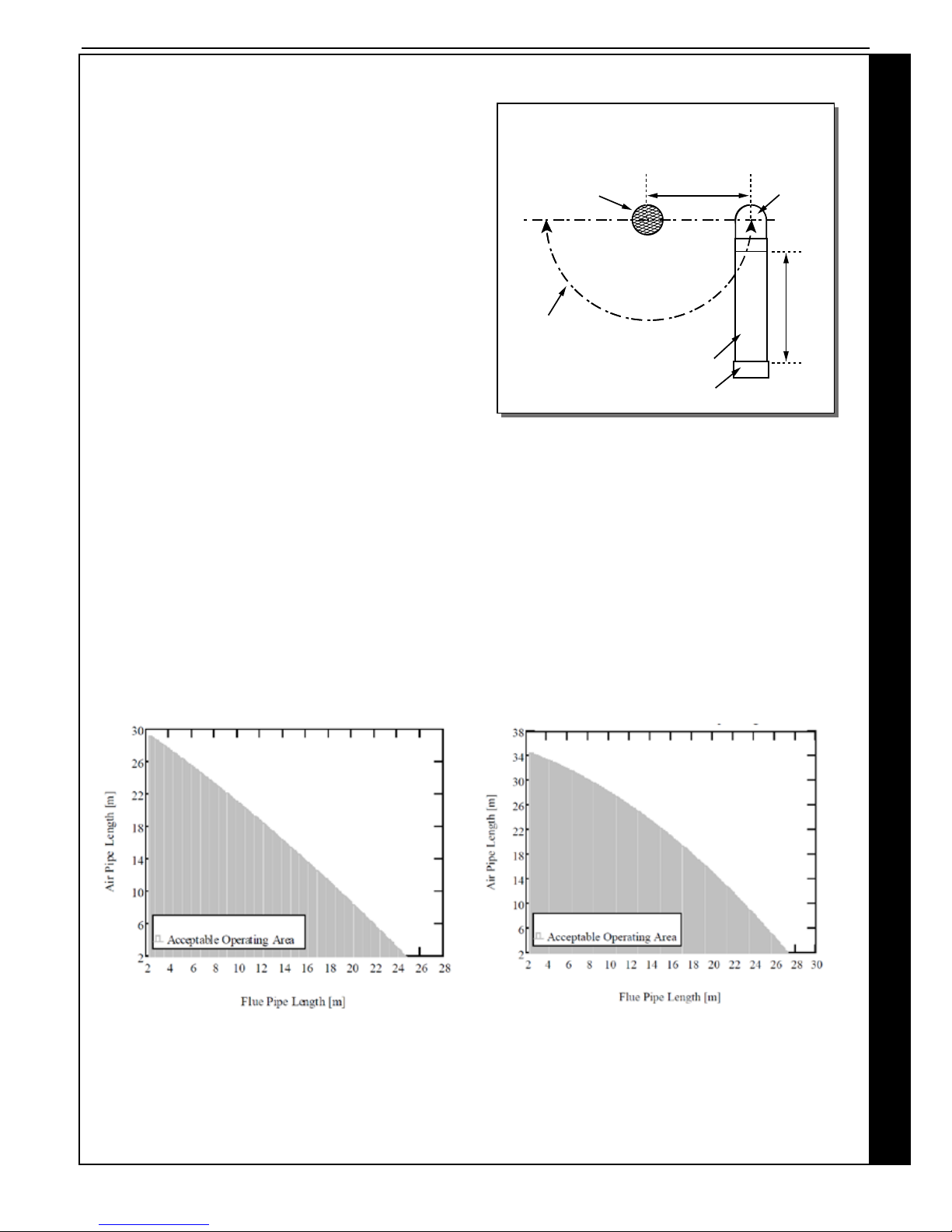

MAXIMUM LENGTHS

Due to the resistance presented by extended ue length a slight reduction in maximum boiler output will occur where combined

ue and air lengths in excess of 18.0m and 16.0m (50mm muPVC) are used. In such cases the boiler output will be reduced by

0.6% and 0.8% per additional metre.

The maximum lengths of both air inlet pipe and ue outlet pipe, when no bends are used, are as detailed in graphs below.

However, each bend used has an equivalent length that must be deducted from the maximum straight length stated in graphs

below. Knuckle bends must not be tted.

A 92.5º swept elbow is equivalent to 1.0m straight length. A 45º bend is equivalent to 0.5m straight length.

It is possible to have variable ue and air lengths as described within the shaded area of graphs below.

SLOPE

‘Horizontal’ ue outlet pipework MUST slope at least 1.5 degrees (26mm per metre run) downwards towards the boiler.

Pipework can be vertical. Only swept elbows can be used.

Air inlet pipework can be truly horizontal or vertical, or sloping in a downward direction towards the boiler but in each case rain,

etc., must be prevented from entering the pipe. There must be no troughs in any of the pipework, whether it be air inlet or

ue outlet.

Keston Combi C35 - Flue & Air Pipe Length Keston Combi C30 - Flue & Air Pipe Length

Page 20

20

FLUE OUTLET

20

Installation and Servicing

SECTION 2 - INSTALLATION

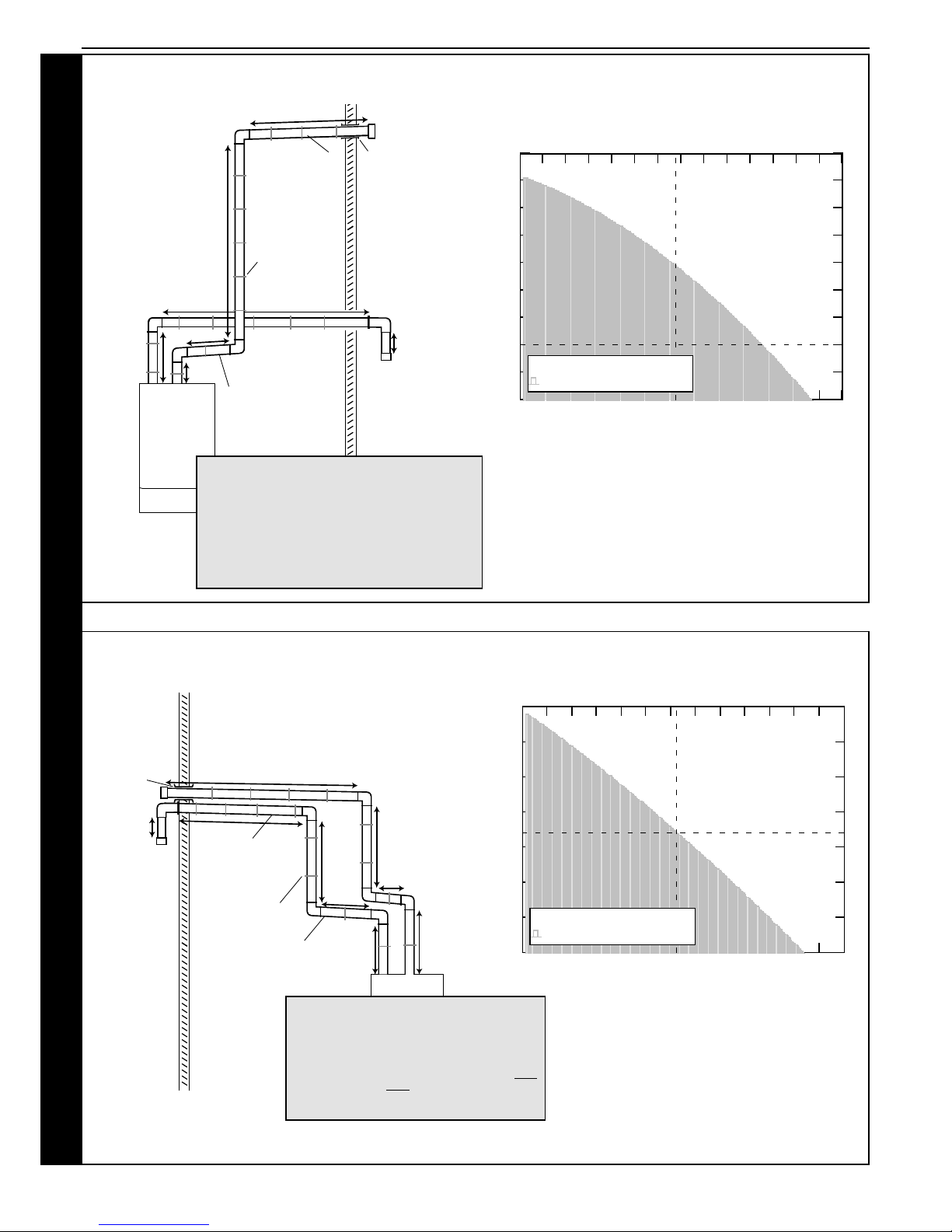

6m

2m

Bracket at

each 1 metre

1m

4m

1.5m

6m

1.5º back

to boiler

1.5º back

to boiler

Air

Elbows 2 x 1m = 2m

Straights 6+2+0.15 = 8.15m

Total = 10.15m

Overall Flue / Air = 25.65m

Flue

Elbows 3 x 1m = 3m

Straights 4+6+1.5+1 = 12.5m

Total = 15.5m

Calculations

0.15m

Sleeve

2m

2.5m

1.5m

2m

4m

4m

0.15m

3.5m

3.5m

1.5º back

to boiler

Air

Sleeve

1.5º back

to boiler

Bracket every

1 metre

Flue

3 x 90º elbows 3

Straight lengths 2.5

1.5

3.5

4

14.5

Overall Flue / Air = 30.15m

Air

4 x 90º elbows 4

Straight lengths 2

2

3.5

4

0.15

15.65

Calculations

2 4 6 8

10

12

14

16

18

20

22

24

26

28

2

6

10

14

18

22

26

30

Accep t able Op erating Area

Keston Combi 35 - Flue & Air Pipe Length

Flue Pip e Length [m]

Air Pipe Length [m]

15.65

14.5

2 4 6 8 10

12

14

16

18

20

22

24

26

28

30

2

6

10

14

18

22

26

30

34

38

Accep t able Op erating Area

Keston Combi 30 - Flue & Air Pipe Length

Flue Pip e Length [m]

Air Pipe Length [m]

10.15

15.5

2.4 FLUE INSTALLATION EXAMPLE KESTON COMBI C30

2.5 FLUE INSTALLATION EXAMPLE KESTON COMBI C35

Page 21

21

FLUE OUTLET

21

Installation and Servicing

SECTION 2 - INSTALLATION

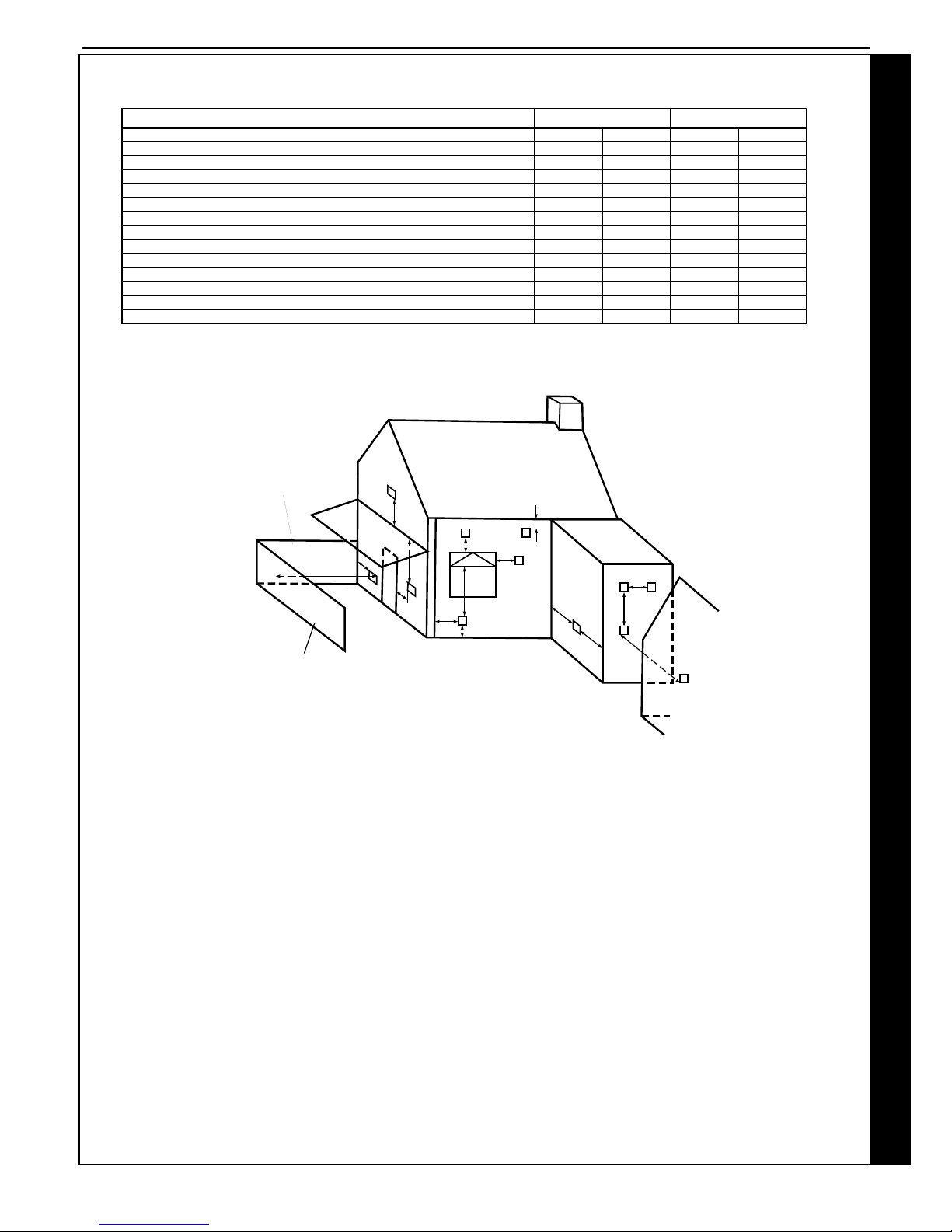

Twin Flue Positions

Below an opening (1)

Above an opening (1)

Horizontally to an opening (1)

Below gutters, soil pipes or drain pipes

Below eves

Below balcony or car port roof

From a vertical drain pipe or soil pipe

From an internal or external corner or to a boundary alongside the terminal

Above ground, roof or balcony level

From a surface or a boundary facing the terminal

From a terminal facing the terminal

From an opening in the car port into the building

Vertically from a terminal on the same wall

Horizontally from a terminal on the same wall

300 mm

300 mm

300 mm

75 mm

200 mm

200 mm

150 mm

300 mm

300 mm

600 mm

1200 mm

1200 mm

1500 mm

300 mm

50 mm

50 mm

50 mm

75 mm

50 mm

50 mm

50 mm

50 mm

100 mm

100 mm

1200 mm

100 mm

1500 mm

300 mm

2"

2"

2"

3"

2"

2"

2"

2"

4"

4"

48"

4"

60"

12"

12"

12"

12"

3"

8"

8"

6"

12"

12"

24"

48"

48"

60"

12"

A.

B.

C.

D.

E.

F.

G.

H.

I.

J.

K.

L.

M.

N.

Flue Minimum Spacing Air Minimum Spacing

(1) An opening here means an openable element, such as a openable window, or a fixed opening such as an air vent. However, in addition, the outlet should not

be nearer than 150mm (fanned draught) to an opening into the building fabric formed for the purpose of accommodating

a built in element, such as a window frame.

The dimensions given in the table above may need to be increased to avoid wall staining and nuisance depending on site conditions.

boundary

boundary

J

H

L

F

I

G

I

A

B

C

D, E

H

H

K

M

N

2.6 FLUE TERMINATION POSITION

GENERAL INSTALLATIONS

All parts of the system must be constructed in accordance with BS 5440 Part 1, except where specically mentioned in these

instructions.

All pipe work must be adequately supported.

All joints other than approved push-on or plastic compression connectors must be made and sealed with solvent cement suitable

for muPVC pipes and conforming to BS 6209: 1982.

Consideration must be given to Corgi/Gas Safe bulletin TB200/TB008 regarding ues in voids.

The boiler casing must always be correctly tted to the boiler when leaving the appliance operational.

External wall faces and any internal faces of cavity walls must be good.

AIR SUPPLY

The Keston Combi is a room-sealed appliance and therefore does not require purpose provided ventilation to the boiler room for

combustion air.

COMPARTMENT INSTALLATION

Due to the low casing temperatures generated by the boiler, no compartment ventilation is required. However, the cupboard or

compartment must not be used for storage.

Note. When running ue pipes vertically they MUST be a

minimum of 140mm apart and termination MUST comply

with Section 2.3 and 2.6.

Page 22

22

Installation and Servicing

SECTION 2 - INSTALLATION

3G10030

X

Section

through wall

Note. Check all of the hole

positions before drilling.

Rear flue only

60mm diameter

holes

2.7 INSTALLING THE BOILER

Installation of the boiler is straightforward but consideration must be given to access to allow ue and air pipes to be pushed

through walls and ceilings. The order in which the components are installed will depend upon particular site conditions, but in

general it will be easiest and most accurate to install the boiler and then build up the ue outlet and air inlet pipes to the terminal this is the sequence described.

2.8 WALL MOUNTING TEMPLATE

The wall mounting template is located on the internal protective packaging.

Note.

The template shows the positions of the xing holes and the position of the air and

ue connections. Care MUST be taken to ensure the correct holes are drilled.

1. Tape template into the selected position. Ensure squareness by hanging a

plumbline as shown.

2. Mark onto the wall the following:

a The wall mounting plate screw positions (choose one from each group).

b The position of the air and ue when exiting straight out of the wall where the

boiler is mounted.

Note. Mark the centre of the hole as well as the circumference.

3. Remove the template from the wall.

2.9 PREPARING THE WALL

IMPORTANT.

Ensure that, during the cutting operation, masonry falling outside of the

building does not cause damage or personal injury.

1. Cut the ue and air holes (preferably with 60mm core bore tool)

ensuring the holes are square to the wall.

2. Drill 2 holes with a 7.5mm / 8mm masonry drill and insert the plastic

plugs, provided, for the wall mounting plate.

3. Locate 2 No.14 x 50mm screws in the wall mounting plate (one at

each side, in any of the 3 holes provided at each side) and screw

home.

INSTALLATION

Page 23

23

Installation and Servicing

SECTION 2 - INSTALLATION

esp9496

Example of fixing

INSTALLATION

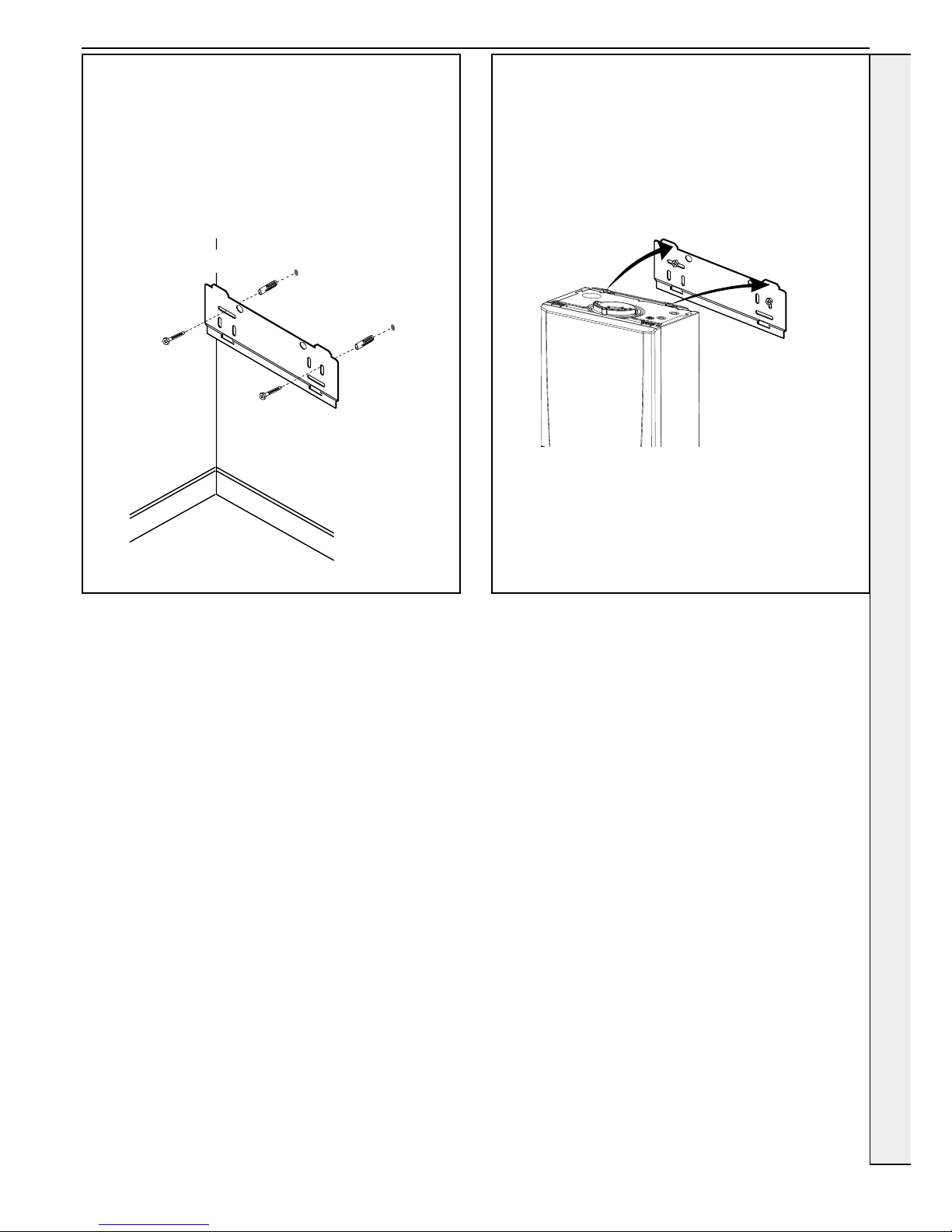

2.10 FITTING THE WALL MOUNTING

PLATE

Screw the wall mounting plate to the wall using 2 wall plugs

(previously tted) with the 2 screws provided.

Choose one of the 2 sets of slots in left and right bank.

Ensuring that at least one of the screws is tted into a top

slot.

2.11 MOUNTING THE BOILER

1. Ensure the plastic plugs are removed from both the CH

and DHW connections before mounting the boiler.

2. Lift the boiler onto the wall mounting plate (refer to the

Introduction section for safe handling advice), locating it

over the two tabs.

Page 24

24

FLUE OUTLET

24

Installation and Servicing

SECTION 2 - INSTALLATION

2.12 ASSEMBLY PRACTICE

Remove all plastic debris and burrs when installing air intake piping. Plastic llings caused by cutting muPVC pipe must not be

allowed to be drawn into the combustion air blower. Prevent dust entering the air intake when cutting on building sites. Blower failure

which is determined to be caused by plastic lings or other debris will not be covered by guarantee.

INSTALLING FLUE AND AIR PIPES

Important - When installing a replacement boiler a new ue

system is recommended. However re-using the existing boiler

ue installation is acceptable if the installer checks and conrms:

• Remove the ue adaptor and air spigot from the ue pack

supplied with the boiler.

• Remove boiler front panel - Section 3.2.

• Remove air intake blanking plate by unscrewing 4 x M5

screws and put to one side, leaving sponge gasket in

place.

• Fix air spigot to boiler using the 4 M5 screws, see diag.

below. Ensure sponge gasket is in place and not damaged.

• Ensure the condense trap/siphon is lled with water.

• Insert the ue adaptor into the ue manifold on the top of the

boiler and secure using the clamp provided in the packaging

box, see diagram below.

• Measure, cut and check the air and ue pipes to pass to the

exit from the wall(s) or ceiling.

• Always thoroughly deburr all pipes and most important,

remove shavings from within the pipe.

• Assemble, using solvent weld cement, the pipework from

the boiler connections to the exit from the rst wall/ceiling,

(remount the boiler if removed). When pushing pipe through

walls, ensure grit and dust is not allowed to enter the pipe.

Ensure pipes are fully engaged into sockets and solvent

welded with no leaks.

• Using the same methods drill any further holes (always

covering existing pipework), cut and assemble the pipework.

• From outside, complete the two terminations - See Section

2.3 Flue System and make good all holes. (Wall sealing

collars are available to make good hole areas on the wall

face (part number C.08.0.00.07.0).

• Support any pipes whose route could be displaced

either of its own accord or by accident. Any horizontal

run over 1m or vertical runs of any length must always

be supported. Brackets should be placed at intervals

of approximately 1m. Brackets should be loose enough

on the pipe to allow thermal expansion and contraction

movement.

• Flue pipework through walls MUST be sleeved to allow

thermal expansion and contraction movement.

• Check all connections for security and re-seal any joints

using solvent cement where soundness may be in doubt.

Note. It is equally important to seal the air inlet with solvent

cement as the ue outlet pipe joints.

Page 25

25

FLUE OUTLET

25

Installation and Servicing

SECTION 2 - INSTALLATION

Flue Sleeve

Flue Pipe

Flue

Terminal

Flexible

Wall

Seal

Wall

Plate

Flue Sleeve Flange

2.13 FITTING THE FLUE SLEEVE

1. Cut hole in wall.

2. Measure wall Thickness

3. Cut sleeve length to match wall thickness & remove burrs.

4. Grout sleeve into wall with ange on external face.

5. Slide ue pipe into sleeve, checking it is free to slide.

6. Slide Flexible wall seal over ue pipe and push centre ring

up to sleeve ange when cold.

7. Locate wall plate over exible wall seal and clamp in place

using the raw plug pack.

8. Afx ue terminal

9. During boiler test check that the ue end is free to expand

and contract with exible wall seal.

Page 26

26

Installation and Servicing

SECTION 2 - INSTALLATION

Boiler

with 75mm

sealed

condensate

trap

Min Ø 19mm

Internal pipe

Minimum

connection

height up to 3

storeys

Soil & vent stack

≥ 450

75

Boilers without 75mm sealed

condensate trap must be fitted with

a 75mm trap and visible air break

Sink/basin/

bath or

shower

Boiler

with 75mm

sealed

condensate

trap

Min Ø 19mm

Internal pipe

Internal soil & vent stack

Boilers without 75mm sealed

condensate trap must be fitted with

a 75mm trap and visible air break

75

≥ 100

≥ 100

Figure 1 - Connection of Condensate Drainage Pipe to

Internal Soil & Vent Stack

Figure 2 - Connection of a Condensate Drainage Pipe

Downstream of a Sink, Basin, Bath or Shower Water Trap to

Internal Soil Vent Stack

continued . . . . .

INSTALLATION

2.14 CONDENSATE

137

47

149

Condensate

Drain

This appliance is tted with a siphonic 75mm condensate trap

system that requires lling before operating the appliance for the

rst time or after maintenance.

All condensate pipework should conform to the following:

a. Where a new or replacement boiler is being installed, access to

an internal ‘gravity discharge’ termination should be one of the

main factors considered in determining boiler location.

b. Plastic with push t or solvent connections.

c. Internal plastic pipe work a minimum of 19mm ID (typically

22mm OD)

d. External plastic pipe must be a minimum of 30mm ID (typically

32 OD) before it passes through the sleeved wall.

e. All horizontal pipe runs, must fall a minimum of 45mm per metre

away from the Boiler.

f. External & unheated pipe work should be kept to a minimum

and insulated with Class “O” waterproof pipe insulation.

g. All installations must be carried out in accordance to the

relevant connection methods as shown in the “Condensate

installation diagrams” & BS6798:2009

h. Pipe work must be installed so that it does not allow spillage

into the dwelling in the event of a blockage (through freezing)

i. All internal burrs should be removed from the pipe work and any

ttings.

In order to minimise the risk of freezing during prolonged very cold

spells, one of the following methods of terminating condensate

drainage pipe should be adopted.

Internal Drain Connections

Wherever possible, the condensate drainage pipe should be routed

to drain by gravity to a suitable internal foul water discharge point

such as an internal soil and vent stack or kitchen or bathroom

waste pipe etc. See Figs 1 and 2.

Condensate Pump

Where gravity discharge to an internal termination is not physically

possible or where very long internal pipe runs would be required

to reach a suitable discharge point, a condensate pump of a

specication recommended by the boiler or pump manufacturer

should be used terminating into a suitable internal foul water

discharge point such as an internal soil and vent stack or internal

kitchen or bathroom waste pipe etc. (g 3).

External Drain Connections

The use of an externally run condensate drainage pipe should

only be considered after exhausting all internal termination options

as described previously. An external system must terminate at a

suitable foul water discharge point or purpose designed soak away.

If an external system is chosen then the following measures must

be adopted:

The external pipe run should be kept to a minimum using the most

direct and “most vertical” route possible to the discharge point, with

no horizontal sections in which condensate might collect.

- For connections to an external soil/vent stack see Fig 4.

Insulation measures as described should be used.

- When a rainwater downpipe is used, an air break must be

installed between the condensate drainage pipe and the

downpipe to avoid reverse ow of rainwater into the boiler

should the downpipe become ooded or frozen, see Fig 5.

- Where the condensate drain pipe terminates over an open

foul drain or gully, the pipe should terminate below the grating

level, but above water level, to minimise “wind chill” at the open

end. The use of a drain cover (as used to prevent blockage by

leaves) may offer further prevention from wind chill. See Fig 6.

- Where the condensate drain pipe terminates in a purpose

designed soak away (see BS 6798) any above ground

condensate drain pipe sections should be run and insulated as

described above. See Fig 7

Unheated Internal Areas

Internal condensate drain pipes run in unheated areas, e.g. lofts

basements and garages, should be treated as external pipe.

Ensure the customer is aware of the effects created by a frozen

condensate and is shown where this information can be found in

the user manual.

Page 27

27

Installation and Servicing

SECTION 2 - INSTALLATION

Visible air break

Condensate pump

(Install in accordance with manufacturers instructions)

Min Ø 19mm

Internal pipe

Boiler

with 75mm

sealed

condensate

trap

75

Min Ø 19mm

Internal pipe

Min Ø 30mm

Internal pipe

Air gap

External air

break

combined foul/

rain water drain

Terminated

and cut at 45º

43mm 90º male/

female bend

Water/

weather proof

insulation

68mm Ø PVCU

Strap on fitting

Boiler

with 75mm

sealed

condensate

trap

Boiler

with 75mm

sealed

condensate

trap

Min Ø 19mm

Internal pipe

Min Ø 30mm

Internal pipe

Water/Weather

proof insulation

Max 3m external

pipework

Limestone

chippings

≥ 500

≥ 300

≥ 25

75

Boilers without 75mm sealed

condensate trap must be fitted with

a 75mm trap and visible air break

2 rows of three Ø12mm holes

25mm centres, 50mm from

the bottom of the tube, facing

away from the house

Minimum

connection

height up to 3

storeys

Soil & vent stack

≥ 450

Boiler

with 75mm

sealed

condensate

trap

Min Ø 19mm

Internal pipe

Min Ø 30mm

Internal pipe

Water/weather

proof insulation

75

Boilers without 75mm sealed

condensate trap must be fitted with

a 75mm trap and visible air break

Visible air break

at plug hole

Min Ø 19mm

Internal pipe

Sink, basin, bath or

shower with integral

overflow and 75mm trap

Minimum 30mm

internal pipe

Water/

weather proof

insulation

≥ 25 Below grate

45º pipe

termination

Boiler

with 75mm

sealed

condensate

trap

75

≥ 100

Figure 3 - Connection of a Condensate Pump Typical

Method (see manufacturers detailed instructions)

Figure 4 - Connection of condensate Drainage Pipe to

External Soil & Vent Stack

Figure 5 - Connection of a Condensate Drainage Pipe to an

External Rainwater Downpipe (only combined foul/rainwater

drain)

Figure 7 - Connection of a Condensate Drainage Pipe to an

External Purpose Made Soak Away.

Figure 6 - Connection of Condensate Drainage Pipe

Upstream of a Sink, Basin, Bath or Shower Waste Trap to

External Drain, Gulley or Ranwater Hopper

INSTALLATION

CONDENSATE............ CONT’D

Page 28

28

Installation and Servicing

SECTION 2 - INSTALLATION

INSTALLATION

3G9705

Safety Valve

Drain Connection

15mm elbow

or fittings

(not supplied)

Safety Valve

Drain Pipe

Note. The domestic hot water ow rate is

automatically regulated to a maximum:

30 = 12.4 l/m (2.8 gpm)

35 = 14.5 l/m (3.2 gpm)

Filling

Loop

CH Flow

DHW

Outlet

Gas

Supply

DHW

Inlet

CH

Return

2.15 CONNECTIONS & FILLING

NOTES.

Ensure all boss blanking plugs are removed before connecting hardware. Each

valve must be tted to the correct boss as shown in the picture.

Ensure each union is tted with bre seals provided.

Do not subject any of the isolating valves to heat as the seals may be damaged.

WATER CONNECTIONS CH

1. Connect the CH ow service valve (black handle) and

copper tail provided in the hardware pack to the threaded

boss connection provided at the lower rear of the boiler.

2. Connect the CH rtn. valve (black handle) and copper tail.

WATER CONNECTIONS DHW

1. Fit the DHW inlet service valve (blue handle) and copper

tail to the threaded boss connection ensuring the seal

provided is correctly located.

2. Fit the DHW outlet pipe tail to DHW outlet connection,

ensuring the seal provided is correctly located.

3. Fit the lling loop provided between the DHW inlet valve

and the CH return valve.

GAS CONNECTION

IMPORTANT. The gas service cock is sealed with a non-

metallic blue bre washer, which must not be overheated when

making capillary connections. Refer to Section 1.16 for details

of the position of the gas connection.

For additional gas supply info refer to “Gas Supply” on page 10.

SAFETY VALVE DRAIN

The safety valve connection, located at the bottom right-hand

side of the boiler, comprises a 15mm diameter stub pipe.

The Installer to provide a compression joint on the end of the

stub pipe. This assists with pipe removal when servicing.

The discharge pipe should be positioned so that the discharge

of water or steam cannot create a hazard to the occupants of

the premises or damage the electrical components and wiring.

A purpose made safety valve drain pipe is provided with the

boiler to allow safe discharge through a wall to the outside

of the building. This is particularly relevant to ‘high rise’

installations but can be used for all installations.

Page 29

29

Installation and Servicing

SECTION 2 - INSTALLATION

A

A

B

C

B

C

Filling Loop

(Blue)

Filling Loop

(Blue)

CH Return

(Black)

CH Return

(Black)

DHW Inlet

(Blue)

DHW Inlet

(Blue)

Cap

Cap

Plug

Plug

Filling

Loop

Filling

Loop

Filling Positions shown

Top Up Positions shown

INSTALLATION

FILLING

IMPORTANT - when lling:

When lling there may be a slight water leak from the air vent therefore electrical connections should be protected.

Filling

1. Ensure lling loop is connected and all washers in place.

2. Ensure dust cap on auto air vent is slackened off refer to

Section 3.24.

3. Check the following isolation handles on water connections

are in the horizontal lling position (blue handle on DHW inlet

A

and black handle on CH return C).

Note. The CH ow isolation valve handle MUST be in the vertical

position to enable lling.

4. Slowly turn the lling loop handle (blue B) to the horizontal

open position until the pressure gauge reads between 1 to

1.5 bar.

5. Once the pressure gauge dial reads between 1 to1.5 bar

turn the lling loop handle (blue

B

) back to the closed

(vertical) position.

6. Turn the CH Return handle (black

C

) and the DHW Inlet

handle (blue

A

) to the open (vertical) position.

7. Disconnect the lling loop from the DHW Inlet valve and t

the grey cap to the open end.

8. Fit the Plug to the free end of the lling loop.

Note open all DHW taps to ensure water is owing freely-once

satised close all taps.

Top Up

1. Ensure lling loop is connected and all washers in place.

2. Ensure dust cap on auto air vent is slackened off refer to

Section 3.24.

3. Turn the DHW Inlet handle (blue

A

) to the horizontal

position.

4. Slowly turn the lling loop handle (blue

B

) to the

horizontal open position until the pressure gauge reads

between 1 to 1.5 bar

5. Once the pressure gauge dial reads between 1-1.5 bar turn

the handle (blue

B

) on the lling loop back to the closed

(vertical) position.

6. Turn the DHW Inlet handle (blue

A

) to the open (vertical)

position.

7. Disconnect the lling loop from the DHW Inlet valve and t

the grey cap to the open end.