Keston C55P Installation and Servicing Manual

WD265/0/2002 The Keston C40, C40P, C55 & C55P

Fan Powered High Efficiency

Modulating Domestic Condensing Gas Boiler

Installation And Servicing Instructions

C40, C40P, C55 & C55P Models

CE/PI No : 87BN14

C40 - GC No : 41-930-07

C40P - GC No : 41-930-08

C55 - GC No : 41-930-09

C55P - GC No : 41-930-10

These instructions must be left either with

the user or next to the site gas meter.

34 West Common Road

Hayes, Bromley, Kent BR2 7BX

Tel. +44 (0)20 8462 0262 Fax. +44 (0)20 8462 4459

email : info@keston.co.uk web : www.keston.co.uk

COMPLIANT WITH BUILDING REGULATION PART L1 & L2 2002

SEDBUK A RATED

WD265/0/2002 The Keston C40, C40P, C55 & C55P

CONTENTS

Section Description

0 HANDLING INSTRUCTIONS

0.1 List of contents

0.2 Recommended handling procedure

1 GENERAL INSTRUCTION

1.1 Description

1.2 Boiler Schematic

1.3 Related Documents

1.4 Physical Data

1.5 Performance Data C40 and C40P

1.6 Performance Data C55 and C55P

1.7 Optional Accessories

2 BOILER LOCATION

2.1 Dimensions & Minimum Clearances

2.2 Service Connections

2.3 Position

2.4 Electrical

2.5 Boiler Size Selection

2.6 Gas Supply

2.7 Water Systems

2.8 Flue System

2.9 Air Supply

2.10 Compartment Installation

2.11 Condensate Drainage

3 INSTALLATION OF THE BOILER

3.1 Wall Mounting Bracket

3.2 Mounting The Boiler

3.3 Assembly Practice

3.4 Installing Flue And Air Pipes

3.5 Condensate Drainage

3.6 Water System

3.7 Gas Supply

3.8 Electrical Supply

3.9 Exchanging A Boiler

Page : i

WD265/0/2002 The Keston C40, C40P, C55 & C55P

4 COMMISSIONING OF THE BOILER

4.1 Initial Flushing

4.2 Gas Supply

4.3 Electrical Installation

4.4 LP Gas

4.5 Initial Firing

4.6 Hot Flushing

4.7 Combustion Testing

4.8 Checking The Gas Pressure

4.9 Timing The Gas Meter

4.10 Handing Over To The User

5 FAULT FINDING

5.1 Electrical Control Sequence

5.2 Normal Operation

5.3 Fault Modes

5.4 Functional Flow Wiring Diagram

5.5 Electrical Wiring Diagram

5.6 Illustrated Wiring Diagram

5.7 Exploded Assembly Diagrams

6 SERVICING

6.1 Pre Service Checks

6.2 Recommended Routine Service

7 REPLACEMENT OF PARTS

7.0 General

7.1 Precautions

7.2 Access

7.3 Replacement Procedure

7.4 Electrical Components

7.5 Spark Ignition/Flame Detection Electrode

7.6 Burner

7.7 Heat Exchanger

7.8 Condensate Trap

7.9 Pump

8 SPARE PARTS LISTINGS

9 GAS BOILER COMMISSIONING CHECKLIST

Page : ii

WD265/0/2002 The Keston C40, C40P, C55 & C55P

0. HANDLING INSTRUCTION

0.1 LIST OF CONTENTS

The Keston C40 and C55 are supplied almost totally pre-assembled. Since the units use

standard 50 mm muPVC pipe for the flue and air intake systems the boiler is packed in a

single box without additional flue kit. All additional components are packed inside the boiler

cabinet itself. The following is a list of components and their location in the boiler cabinet

Equipment List

Item Quantity Location

Wall Bracket Rawl Plugs 5 Inside accessories bag

Wall Bracket Wall Fixing Screws 5 Inside accessories bag

Wall Mounting Bracket 1 Secured to inside right hand

side of boiler case

Wall Mounting Bracket Nuts 2 Inside accessories bag.

Wall Mounting Bracket Washers 2 Inside accessories bag

Gas Cock (22 mm cxc) 1 Inside accessories bag

50 mm muPVC Air/Flue Terminals 2 Inside accessories bag

Air Inlet Spigot (50 mm) 1 Inside accessories bag

Air Inlet Spigot Gasket 1 Inside accessories bag

Air Inlet Spigot Screws 4 Inside accessories bag

Flue Spigot Screws 2 Inside accessories bag

Cabinet Cable Entry Clamps 2 Inside accessories bag

User Control Knobs 2 Inside accessories bag

Document List

Item Quantity Location

User Instructions 1 In A4 envelope

Registration of Purchase/Extended Warranty 1 In A4 envelope

Installation Template 1 In document bag

Remove the cabinet shell by removing the four retaining screws in the top of the cabinet and

the three retaining screws in the bottom of the cabinet.

0.2 Recommended Handling Procedure

Before hanging the appliance on the wall it is best to store the appliance laid on its back with

the casing on. When ready to hang the boiler on the wall remove the casing and place to one

side. At this stage it is assumed that the wall bracket is correctly secured on the wall face.

a) Have the wall bracket nuts and washers to hand so that they can be accessed whilst

holding the boiler in position on its mounting bracket.

b) The boiler has a dry weight of 61.5kg (136 lbs) and will therefore require at least two

people to lift without the use of lifting aids.

c) Lift the boiler by gripping at the four corners of the boiler back plate. When lifting this

appliance the back should be kept straight at all times. Avoid twisting at the waist reposition the feet instead. Avoid upper body bending when holding the appliance and

keep the boiler as close to the body as possible.

d) Lift the boiler and locate onto the two studs of the wall mounting bracket.

e) Hold the boiler on the wall bracket by applying pressure onto the front surface of the heat

exchanger.

f) Place the wall mounting bracket washers over the bracket studs protruding through the

back plate of the boiler.

g) Secure the boiler onto the wall bracket by fixing the wall mounting bracket nuts onto the

wall bracket studs. These should be tightened well.

Page : iii

WD265/0/2002 The Keston C40, C40P, C55 & C55P

In the event the appliance must be fitted by one operative the integral circulating pump head

and complete combustion fan/gas valve/venturi assembly can be removed from the appliance

prior to lifting. However, the resulting weight will still be higher than considered acceptable for

a one-man lift.

Safety footwear and gloves are recommended PPE when lifting this appliance.

The C40 and C55 boilers can be fitted in compartments with very small clearances required

around the appliance (refer to Section 1.4). Due consideration should therefore be given to

access within the compartment for lifting and positioning.

Page : iv

WD265/0/2002 Chapter 1 : General Instruction The Keston C40, C40P, C55 & C55P

1. GENERAL INSTRUCTION

1.1 DESCRIPTION

The Keston C40 and C55 are unique in concept and design. They comprise a high

efficiency stainless steel heat exchanger coupled with a low emissions burner to deliver

ultra high efficiency condensing mode operation within a compact wall hung cabinet. The

unit automatically adjusts gas and air rate according to demand to give an output in the

range of 11kW to 40kW (C40 & C40P) and 14kW to 55kW (C55 & C55P). The integral

Grundfos pump is automatically controlled to best match water flow rate to heat output &

further increase appliance efficiency. In addition, they feature an optional connection for

an outside sensor to enable the boilers inbuilt weather compensation option. Separate

inputs are provided for hot water and central heating demand signals to enable different

temperature levels to be set (ideal for underfloor heating systems). While the application

for which the C40 and C55 were designed is the same as those which other boilers are

used, the Keston C40 and C55 have the added advantage of very high efficiency, and

small diameter plastic flue which can be extended up to 45 metres horizontally or

vertically.

The Keston C40 and C55 uses a variable speed combustion blower to deliver a premix of

gas and air to a downward firing burner in a high efficiency, single pass heat exchanger.

The flue system is room sealed and fan powered. The ignition is direct spark and fully

automatic. The boiler housing is not waterproof and should be installed in a position

where it will always be dry. Combustion air is drawn from the cabinet which is connected

to outside atmosphere via a small diameter plastic intake pipe. The cabinet therefore

remains under negative pressure at all times the boiler is operating.

The boiler is suitable for connection to open vented or, preferably, sealed systems.

The boiler heat exchanger is made from highly corrosion resistant stainless steel in

corrugated pipe form which provides massive surface area within a compact dimension.

The hot combustion gases from the down firing burner pass around the stainless steel

pipes imparting heat into the system water. The integral variable speed Grundfos pump

within the appliance cabinet ensures the heat exchanger receives correct water flow when

firing. The C40 and C55 are not high water content boilers and do not contain the metal

mass, or water volume, of a cast iron or steel boiler. This boilers are of low mass and low

water content and therefore responds faster when there is a call for heat. The C40 and

C55 feature full user diagnostics, integral frost protection function, automatic pump and

fan exercise in periods of inactivity, anti cycle control, dry fire protection and connections

for remote lockout and run monitoring (optional accessory).

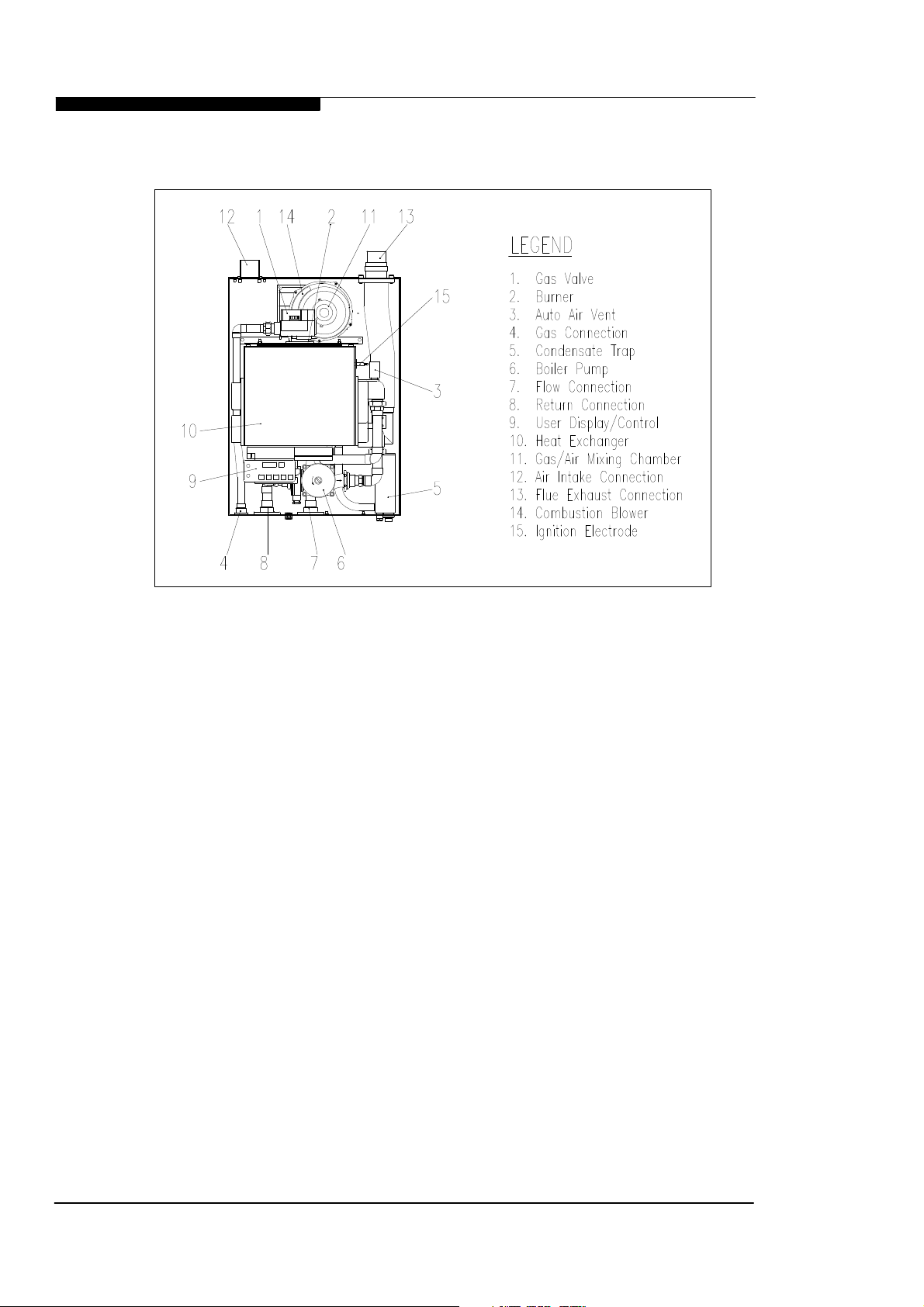

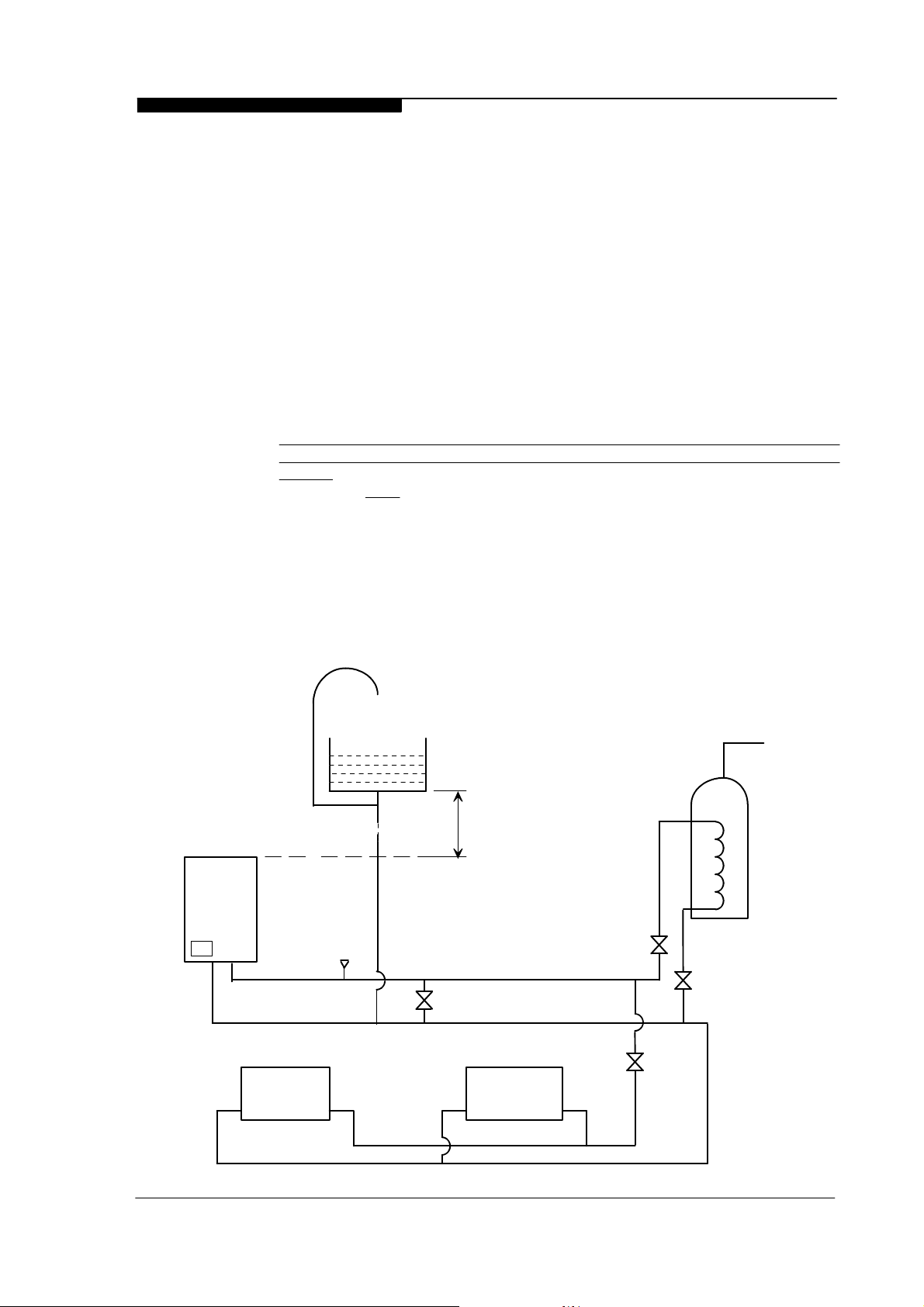

1.2 BOILER SCHEMATIC

Air is drawn into the boiler through a 50 mm muPVC (BS5255 and/or BSEN1566-1 and

BSEN1329) plastic pipe or, alternatively, via a 75mm composite plastic pipe. Gas is mixed

with combustion air at the inlet to the fan. The gas flow is automatically regulated by the

gas valve according to the air flow generated by the fan. The gas and air are thoroughly

mixed in the blower and fed into the burner located at the top end of the heat exchanger

module. The gas and air mixture is ignited by a direct spark ignition control system and

burns with a blue flame just off the surface of the burner. As the hot products of

combustion pass downwards, they are cooled by exchanging heat with the circulating

water which enters the heat exchanger at the bottom of the heat exchanger. The optimum

heat input is detected by monitoring flow and return temperatures and is adjusted by

controlling the speed of the fan. The optimum pump speed is also detected and

automatically selected by the boiler.

When the return water temperature is below 55oC, part of the water vapour in the

combustion products will condense inside the heat exchanger, thus increasing the boiler

efficiency further by releasing the latent heat of condensation. This condensate falls to the

bottom of the heat exchanger where it is separated from the flue gases and exits from the

boiler through the condensate drain. Any condensate formed in the flue runs back down

Installation & Servicing Instructions Page : 1

WD265/0/2002 Chapter 1 : General Instruction The Keston C40, C40P, C55 and C55P

the flueway and is drained at the base of the flue connection to the heat exchanger or

drain points within the flue.

Fig. 1.2 - Boiler Layout

The condensate is very slightly acidic (about the same acidity as vinegar) and should be

piped in a plastic pipe. It is not harmful to the waste disposal system and may be disposed

of as normal waste water.

The flue gases are piped in a 50 mm muPVC (BS5255 and/or BSEN1566-1 and

BSEN1329) plastic or, alternatively, 75mm composite plastic pipe to the outside. The

temperature of the flue gases are usually around 5oC to 10oC above the temperature of

the return water. The flue pipe should be terminated outside the building from where they

cannot re-enter the building or any other adjacent building.

The heating level may be controlled by room thermostats, hot water calorifier thermostats,

programmer time clocks and energy management systems. A Keston room controller can

be connected which will provide enhance controls such as room compensation and

optimum start to further increase efficiency and comfort levels.

The C40 and C55 feature an integral frost protection function which will operate the pump,

regardless of the external controls, should the boiler temperature fall below 7oC. In the

event the boiler temperature falls below 3oC the boiler will also fire. This is to avoid

damage to the boiler through freezing of boiler water. The boiler will turn off when the flow

temperature exceeds 10oC.

The C40 and C55 feature an integral pump exercise function which will run the pump,

without firing the boiler, for 10 seconds in the event the boiler is on standby for in excess

of 24 hours without firing. This is to help prevent seizing of the pump due to long periods

of inactivity.

1.3 RELATED DOCUMENTS

The Keston C40 and C55 Condensing Boiler must be installed in accordance with the

current issue of the Gas Safety (Installation and Use) Regulations 1996, current IEE

Wiring Regulations, Building Regulations, Building Standards (Scotland) Consolidation,

and the Bye Laws of the local Water Undertaking.

Installation & Servicing Instructions Page : 2

WD265/0/2002 Chapter 1 : General Instruction The Keston C40, C40P, C55 & C55P

In addition, due account must be taken to the following Codes Of Practice:

BS 6891 : Gas Supplies

BS 6798 : Installation Central Heating Boilers

BS 5449 : Installation Pumped Central Heating

BS 5546 : Installation Domestic Hot Water

BS 5440.1 : Flues

BS 5440.2 : Air Supply

BS 5482.1 : Domestic Propane and Butane Burning Installations

BS 7074.1 : Expansion Vessels

BS 7593 : Treatment of Water in Hot Water Central Heating

Systems

BS 7671 : Requirements for Electrical Installations. IEE Wiring

Regulations 16th Edition.

For Timber Framed Buildings, British Gas Publications DM2. Also British Gas

Publications 'Guidance Notes For The Installation Of Domestic Gas Condensing

Boilers' and 'Specification For Domestic Wet Central Heating Systems'.

Cabinet Height mm 720

Cabinet Width mm 520

Cabinet Depth mm 320

Top Clearance mm 150

Side Clearance mm 25

Base Clearance mm 150

Front Clearance (for servicing) mm 305

Weight - Full kg / (lbs) 70.5/(157.8)

Weight - Empty kg / (lbs) 61.5/(135.8)

Flow and Return Connection Rp 1" F

Gas Connection Rp 0.75" F

Condensate Connection mm 22mm plastic overflow

IP Rating IP20 (IPX0)

Flue and Air Intake Material 50mm muPVC (BS5255 and/or BSEN1566-1 and BSEN1329)

Flue Pipe Size (nominal bore) mm / (in) 50 / (2)

Air Intake Pipe Size (nominal bore) mm / (in) 50 / (2)

Max. Air Intake Length m 29

Max. Flue Outlet Length m 15

Max. Total Flue Outlet and Air Intake Length m 30

Flue and Air Intake Material 75mm Keston Composite

Flue Pipe Size (nominal bore) mm / (in) 75 / (3)

Air Intake Pipe Size (nominal bore) mm / (in) 75 / (3)

Max. Air Intake Length m 87

Max. Flue Outlet Length m 45

Max. Total Flue Outlet and Air Intake Length m 90

1.4 PHYSICAL DATA - C40 and C55

Keston Boilers Ltd declare that there are no substances harmful to health within the

appliance or used during the production of the appliance.

The C40 and C55 are intended for domestic and commercial EMC environments and on a

governed G20 meter supply.

The C40P and C55P is intended for domestic and commercial EMC environments and on a

governed G31 supply.

Installation & Servicing Instructions Page : 3

WD265/0/2002 Chapter 1 : General Instruction The Keston C40, C40P, C55 and C55P

1.5 PERFORMANCE DATA - C40 & C40P

C40 C40P

Nat. Gas (G20) LPG (G31)

Min. Input (Gross CV) kW/(Btu/h) 12.9/(43,900) 12.6/(43,000)

Max. Input (Gross CV) kW/(Btu/h) 45.6/(155,600) 43.2/(147,400)

Max. Output To Water

(80/60oC Flow/Return) kW/(Btu/h) 40.3/(137,600) 39.1/(133,300)

(50/30oC Flow/Return) kW/(Btu/h) 44.9/(153,400) 43.2/(147,400)

Min. Output To Water

(80/60oC Flow/Return) kW/(Btu/h) 11.3/(38,500) 11.4/(38,800)

(50/30oC Flow/Return) kW/(Btu/h) 12.6(43,000) 12.6(43,000)

Max. Burner Press.-Hot (Factory Preset) mbar/(in w.g) 0 0

Gas Consumption After 10 mins l/s / (Ft3/hr) 1.21/(153.4) 0.451/(57.4)

Max. Operating Flow Temp.

o

C 82.00 82.00

Max. Head (Open Systems) m / (ft) 30.50 / (100) 30.50 / (100)

Max. Press. (Sealed System) bar 2.70 2.70

Min. Head (Open Systems) m 3.0 3.0

Inlet Gas Pressure mbar/(in w.g) 20.0 / (8.0) 37.0/(14.8)

Recommended Temp Diff.

o

C 8 to 20 8 to 20

Electrical Supply 230V 50Hz 230V 50Hz

Power Consumption (Max) W 260 260

Power Consumption (Standby) W 8 8

Type of Gas G20 Natural Gas G31 LPG

Optimum Flue Gas CO2 Level % 8.3 9.9

Expected CO/CO2 Ratio (at max rate) 0.001 0.0013

Destination Countries GB/IE GB/IE

SEDBUK Efficiency 90.4% 92.5%

1.6 PERFORMANCE DATA - C55 & C55P

C55 C55P

Nat. Gas (G20) LPG (G31)

Min. Input (Gross CV) kW/(Btu/h) 14.3/(48,800) 14.8/(50,500)

Max. Input (Gross CV) kW/(Btu/h) 56.5/(192,800) 53.4/(182,300)

Max. Output To Water

(80/60oC Flow/Return) kW/(Btu/h) 49.7/(169,700) 48.0/(163,900)

(50/30oC Flow/Return) kW/(Btu/h) 55.2/(188,500) 53.4/(182,300)

Min. Output To Water

(80/60oC Flow/Return) kW/(Btu/h) 12.5/(42,900) 12.9/(44,100)

(50/30oC Flow/Return) kW/(Btu/h) 14.3/(48,800) 14.8/(50,500)

Max. Burner Press.-Hot (Factory Preset) mbar/(in w.g) 0 0

Gas Consumption After 10 mins l/s / (Ft3/hr) 1.50/(190.1) 0.54/(68.3)

Max. Operating Flow Temp.

o

C 82.00 82.00

Max. Head (Open Systems) m / (ft) 30.50 / (100) 30.50 / (100)

Max. Press. (Sealed System) bar 2.70 2.70

Min. Head (Open Systems) m 3.0 3.0

Inlet Gas Pressure mbar/(in w.g) 20.0 / (8.0) 37.0/(14.8)

Recommended Temp Diff.

o

C 8 to 20 8 to 20

Electrical Supply 230V 50Hz 230V 50Hz

Power Consumption (Max) W 260 260

Power Consumption (Standby) W 8 8

Type of Gas G20 Natural Gas G31 LPG

Optimum Flue Gas CO2 Level % 8.8 10.2

Expected CO/CO2 Ratio (at max rate) 0.001 0.0013

Destination Countries GB/IE GB/IE

SEDBUK Efficiency 90.2% 92.2%

Installation & Servicing Instructions Page : 4

WD265/0/2002 Chapter 1 : General Instruction The Keston C40, C40P, C55 & C55P

Seasonal Efficiency (SEDBUK) = 90.4% (C40), 92.5% (C40P), 90.2% (C55) & 92.2 (C55P)

This value is used in the UK Government's Standard Assessment Procedure (SAP) for

energy rating of dwellings. The test data from which it has been calculated have been

certified by Advantica Technologies Ltd

IMPORTANT

This product contains ceramic fibre boards, which although not regarded as a risk, contain

ceramic fibre which may cause temporary irritation to eyes, skin and respiratory tract. The

fibres are held in place by inorganic binders. Therefore as long as the boards are not

disturbed they will not be released. Since the boards are non-servicable parts there should

be no risk.

To ensure that the release of fibres from these RCF articles is kept to a minimum, during

installation and servicing we recommend that you use a HEPA filtered vacuum to remove

any dust accumulated in and around the appliance before and after working on the appliance. When replacing these articles we recommend that the replaced items are not broken

up, but are sealed within heavy duty polythene bags, and clearly labelled as RCF waste.

RCF waste is classed as a stable, non-reactive hazardous waste and may be disposed at a

landfill licensed to accept such waste. Protective clothing is not required when handling

these articles, but we recommend you follow the normal hygiene rules of not smoking,

eating or drinking in the work area and always wash your hands

before eating or drinking.

BENCHMARK INITIATIVE

As part of the industry wide “Benchmark” initiative C40 & C55 boilers manual includes Gas Boiler

Commissioning Checklist (Chapter 9). This form should be completed by your installer at the

end of the installation and commissioning process. The details of the Checklist will be required in

the event of any warranty work being required. There is also Service Interval Record (Chapter 9)

to be completed after each annual service visit.

These forms (Chapter 9) should be kept in a safe place for the life of the boiler.

CORGI INFORMATION

The boiler should be installed and serviced only by CORGI registered operatives. All CORGI

registered Installers carry a CORGI ID card and have a registration number. Both should be

recorded in your boiler manual (Chapter 9: GAS BOILER COMMISSIONING CHECKLIST).

You can check your installer by calling CORGI direct on 01256 372300.

1.7 OPTIONAL ACCESSORIES

A range of accessories are available from Keston Boilers Ltd to compliment an installation.

Terminal wall sealing collars are available to make good the external all face whilst working from

the inside of the building using 50mm muPVC (BS5255 and/or BSEN1566-1 and BSEN1329) pipe

or 75mm (actual dimensions are int.dia. = 68mm, ext.dia. = 78mm) Keston Composite pipe.

Stand-off frames are available to leave a 50mm gap behind the boiler to allow routing of pipes

behind the boiler.

Description Part Number

Flue Terminal Wall Sealing Collar (50mm) C.08.0.00.07.0

Air Terminal Wall Sealing Collar (50mm) C.08.0.00.07.0

50/75mm Flue Adapter C.17.2.00.60.0

Flue Outlet Terminal (75mm) C.17.2.26.00.0

Air Inlet Terminal (75mm) C.17.2.26.00.0

Stand Off Back Plate C.17.0.02.00.0

Outside Temperature Sensor C.17.4.17.00.0

Keston Chronotherm Room Controller C.17.4.21.00.0

Installation & Servicing Instructions Page : 5

WD265/0/2002 Chapter 2 - Boiler Location The Keston C40, C40P, C55 & C55P

All dimensions in mm.

mm

2. BOILER LOCATION

All dimensions in mm.

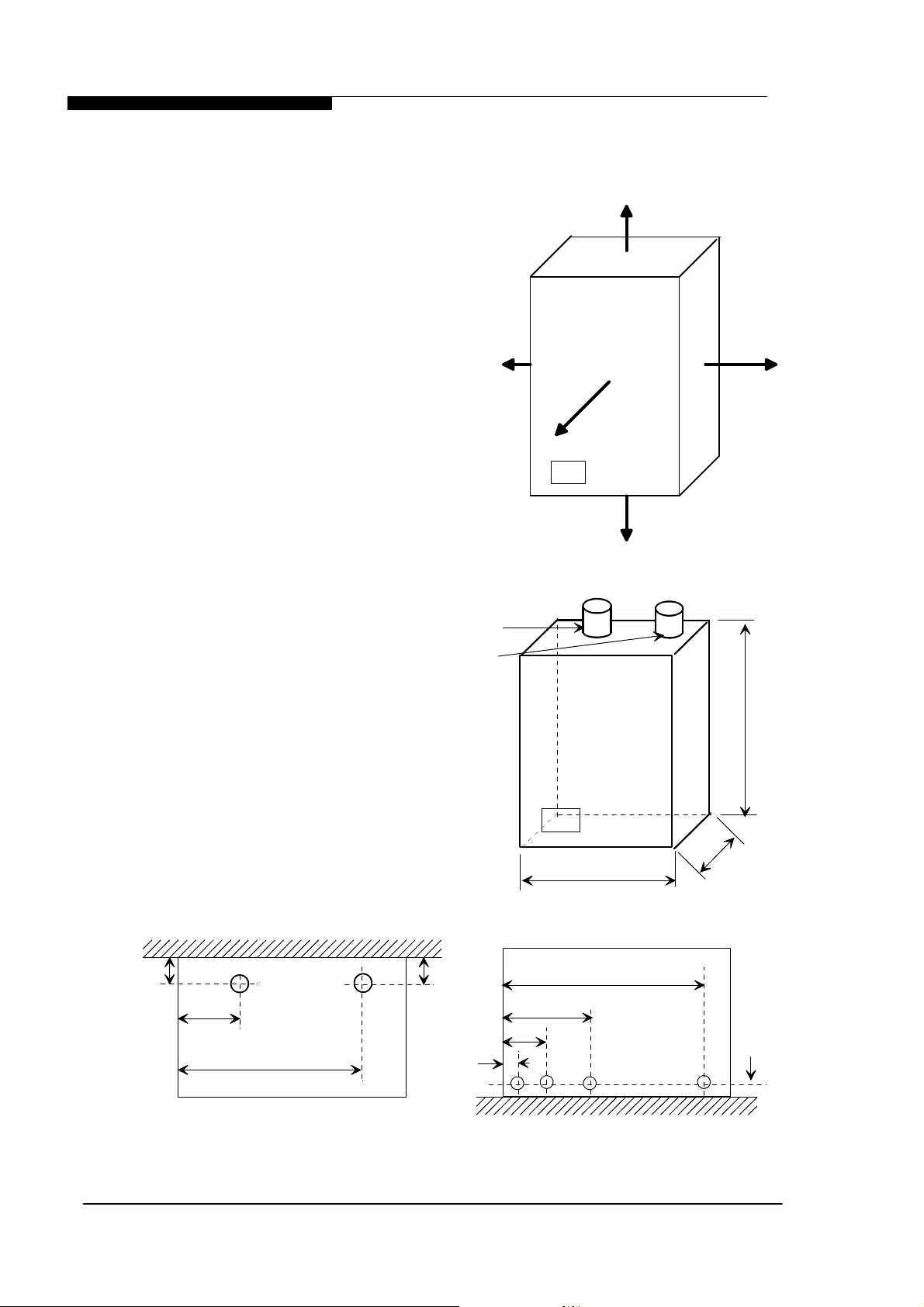

2.1 DIMENSIONS AND MINIMUM

CLEARANCES

The boiler must be installed in minimum

clearances shown to allow subsequent

servicing, and safe operation. However,

larger clearances may be required during

installation.

150

2.2 SERVICE CONNECTIONS

Gas, water, air and flue pipe, condensation,

and electrical connections are as shown.

Gas : 0.75 inch BSP female. Flow/Return 1

inch BSP female.

An optional stand-off frame is also available

which mounts behind the boiler to leave a

50mm deep space behind the boiler. This is

to permit pipe routing behind the boiler if

required. See Section 1.5 - Optional

Accessories.

2.3 POSITION

The C40 and C55 are not suitable for

external installation. The boiler may be

installed in any room or internal space,

although particular attention is drawn

to the requirements of the current IEE

Wiring Regulations and, in Scotland,

the electrical provisions of the Building

Regulations applicable in Scotland,

with respect to the installation of the

boiler in a room or internal space

containing a bath or shower.

Where a room-sealed appliance is

installed in a room containing a bath or

shower, any electrical switch or

appliance control, utilising mains

electricity, should be so situated that it

cannot be touched by a person using

25

Figure 2.1.2

Dimensions

Air Intake

Flue

25

305 (W h en servicing appliance )

10 (W h en appliance is operating )

Figure 2.1.1

150

520

Minimum Clearances

720

0

2

3

Service Connection Locations All dimensions are in mm.

Installation & Servicing Instructions Page : 6

42

65

Top View

Air

447

Flue

51

38

117

Gas

249

Return

Base View

485

Flow

36

Condense

WD265/0/2002 Chapter 2 - Boiler Location The Keston C40, C40P, C55 & C55P

the bath or shower. The C40 and C55 are classified as IP20 (IPX0) and are therefore

suitable for installation in Zone 3 areas, unless subject to hose down.

Compartment installation is permitted - such compartments must be constructed in

accordance with BS 6798.

The wall on which the boiler is mounted must be of suitable load bearing capacity and

must be non-combustible.

The Keston C40 and C55 can be located virtually anywhere desired provided that all

regulations are complied with. Because of the boiler's compact size and venting flexibility,

[NB: Refer to

Section 2.8.3]

the installation is not limited to a boiler room setting. Before locating the boiler near a living

space consider whether the sounds generated by the boiler will be objectionable. The

boiler may be located within a cupboard enclosure to reduce noise levels if located within

a living space. LPG boilers must not be installed in a cellar.

2.4 ELECTRICAL

2.4.1 Electrical Connections

The boiler must be connected to a permanent 230V ~ 50Hz supply, fused at 3A.

The boiler has two thermostats and will therefore accept up to two switched

live signal inputs at 230V, such as heating and hot water demand. For

single signal systems switched live 1 may be used on its own. In the event

the boiler receives a signal from both inputs at the same time the setting of

thermostat 2, usually used for hot water demand, will take priority. Wiring

external to the boiler must be in accordance with current I.E.E wiring regulations

and local regulations.

The method of connection to the mains electricity supply must facilitate complete

electrical isolation of the boiler, preferably by the use of a fused, unswitched three

pin plug and a shuttered socket-outlet, both complying with the requirements of

BS 1363. There must be only one common method of isolation for the boiler and

its control system.

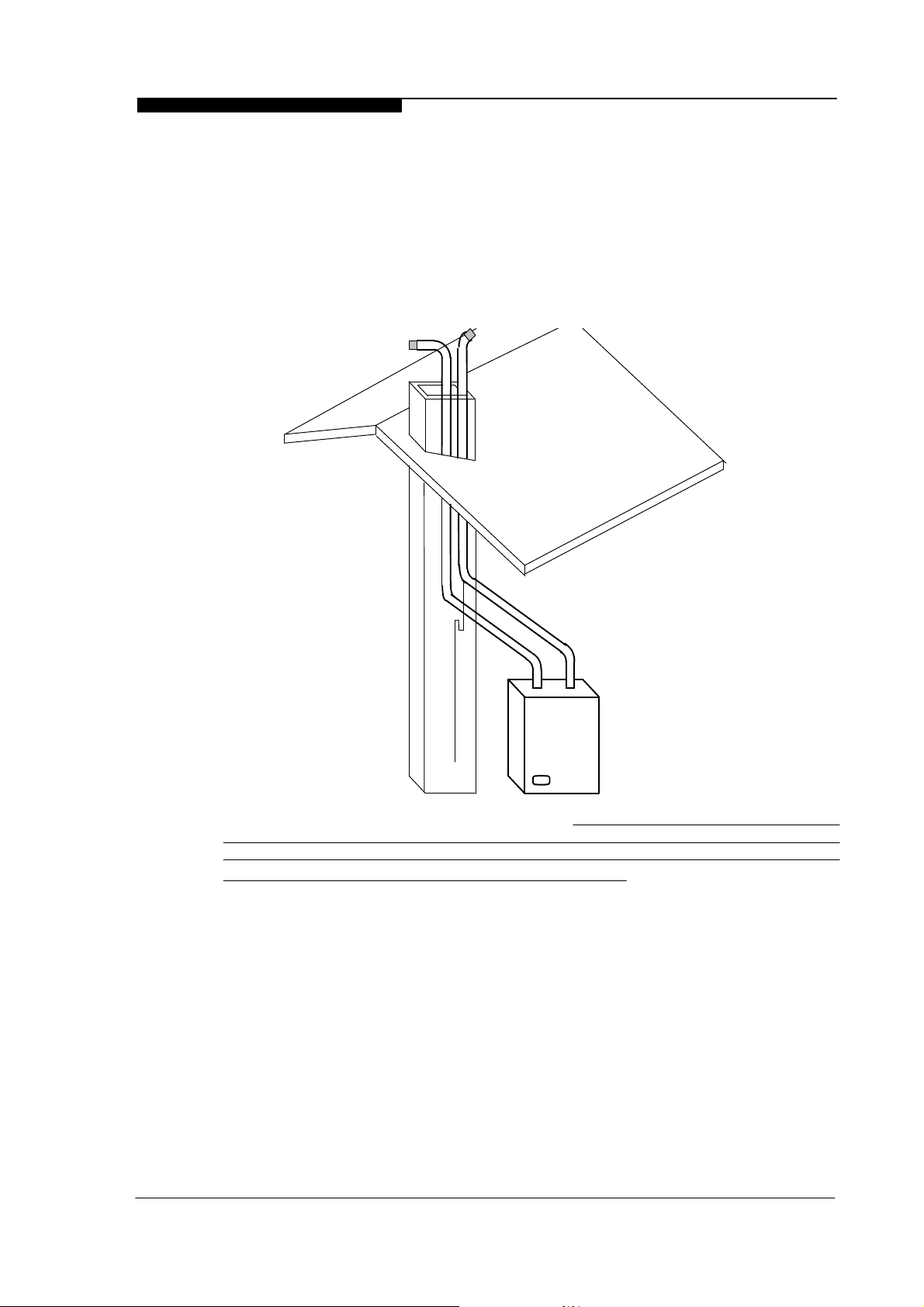

Chimneys not used for

venting any other

appliance may be used.

Secure air & flue pipes at

chimney outlet.

Figure 2.3

Installation & Servicing Instructions Page : 7

WD265/0/2002 Chapter 2 - Boiler Location The Keston C40, C40P, C55 & C55P

The appliance must be connected to the 3A supply via a fused double-pole switch

having at least 3 mm (1/8 inch) contact separation in both poles, serving only the

boiler and the system controls.

The connection point to the mains supply should be readily accessible and

adjacent to the boiler, except for rooms containing a bath or a shower. Refer to

section 2.3 Position.

2.4.2 External Wiring & Controls

1. The boiler is designed so that all control wiring is external to the boiler.

2. A programmer may be used with zone valves to give independent control

of central heating and hot water.

3. A Keston Chronotherm controller may be used to provide room

compensation and optimum stop/start control on heating only systems

4. Control signal inputs must the 230VAC "switched live" type.

5. A Keston outside temperature sensor may be connected as an option.

The boiler will automatically detect this connection and will operate on a

"weather compensation" basis when receiving a signal on switched live 1.

Screened cable (80% density) must be used to connect the outside

temperature sensor.

Brown

V4043H1106

Zone Valve

Heating

V4043H1056

Zone Valve

DHW

2.4.4 Wiring Expample - Honeywell S-Plan for DHW and (Optional) Weather Compensated Heating Control

Blue

Grey

Orange

Green/Yellow

White

Brown

Blue

Grey

Orange

Green/Yellow

5

2

1

9

3

N/U

8

2

1

10

3

Cyl. Thermostat

L641A1039

2.5 BOILER SIZE SELECTION

The C40 and C55 will automatically adjust heat output and pump speed to match the

system requirements at any given time. Efficiency and combustion levels are maintained

at optimum levels throughout the possible output range. The C40 and C55 are therefore

suitable for all systems with a total heat load within the maximum range of the boiler.

2.6 GAS SUPPLY

A gas meter should be connected to the service pipe by the local gas region or their

contractor. An existing meter should be checked preferably by the gas region to ensure

that the meter is adequate to deal with the rate of gas supply required. Installation pipes

should be fitted in accordance with BS 6891.

Minimum/Maximum Gas Pressure:

Natural gas pressure before the gas valve must be maintained at between 18 mbar (7.2 in

WG) and 22 mbar (8.8 in) while the boiler is running.

LPG pressure must be maintained between 31.5 mbar (12.4 in w.g) and 37.6 mbar (14.8

in w.g) while the boiler is running.

Gas pressures above or below these levels will lead to problems associated with the gas

valve's internal pressure regulator.

Supply pipes to the boiler must not be sized less than the boiler inlet connection

(22 mm). Due consideration must be given to the supply pressure to other gas

appliances in the premises. Reduction in dynamic gas supply pressure will result in

intermittent ignition failures. Ensure gas supply pipe work is adequately sized for

Mains Supply

Fused @ 3A

230V

Programmer

ST6300A

L

N

E

SL1

SL2

EX1

EX2

Keston Spa

Cylinder Stat

Keston Spa

Overheat Stat

1

3

2

Live

Neutral

Earth

L

N

1

3

4

C

1

2

1

2

3

1

2

6

4

6

8

Room Thermostat

T6360B1028

KESTON

C55 / C40

OR

C

1

2

C

1

2

4

5

2

1

2

3

9

10

To Keston

Ext. Sensor

[Optional]

6

8

Installation & Servicing Instructions Page : 8

WD265/0/2002 Chapter 2 - Boiler Location The Keston C40, C40P, C55 & C55P

the length of run from the meter to the boiler at a supply rate of 46kW for the C40

and 57kW for the C55 model.

A gas cock is supplied loose with the boiler. This cock should be fitted in the gas line to

the boiler as close to the boiler as possible so that it is easily identified as the cock to

isolate the boiler.

2.7 WATER SYSTEMS

All piping must be installed in accordance with all applicable local and Water Supply

Bylaws for forced hot water heating systems.

Consideration must be given to pipe capabilities and pressure drop through the piping

when selecting pipe sizes. The primary pipe connections to the boiler must be sized

according to the system load, not dictated by the boiler connection sizes.

Water treatment must be carried out to BS 7593 : Treatment of Water in Hot Water

Central Heating Systems.

a The C40 and C55 are suitable for use on open, vented water systems with

combined feed and vent fitted to the boiler return.

b It is preferable for use on sealed water systems, provided the appropriate

components required (see Section 2.7.2 Sealed Systems) are included in the

system.

c Any system must be thoroughly flushed clean of grease, dirt and debris, prior to

connection with the boiler. A trap may be installed in the flow line to collect any

solder, or other debris, from the installation.

d All water systems must be constructed to comply with requirements of the Local

Water Authority.

e Always use a system complying with the requirements of BS 5449 and BS 6798.

f System design must ensure an open circuit is always available to ensure

circulation when the pump overrun function is operating after boiler shutdown.

C40

or

C55

Expansion

Pipe

28mm

Safety

Valve

(See note 2.7.1)

FLOW

RETURN

Rad. 2 Rad. 1

Minimum

Expansion

Tank

Minimum

9ft Height

By-pass

Figure2.7.1 : Open Vented System Diagram

Valve

Valve

Cylinder

L/S

Valve

Installation & Servicing Instructions Page : 9

WD265/0/2002 Chapter 2 - Boiler Location The Keston C40, C40P, C55 & C55P

g Copper tubing to BS 2871 Part 1 or barrier plastic pipe suitable to 110 oC, such as

Unipipe, is recommended.

h Jointing should be either with capillary, threaded or compression fittings. Pipes

should have a gradient to ensure air is passed easily to vent points and water

flows readily to drain points.

i Draining taps must be located in accessible positions which permit the draining of

the boiler and hot water storage vessel. Draining taps should be at least 22 mm in

nominal size and be in accordance with BS 2879.

AIR VENT POINTS

j These must be fitted at all high points where air will naturally collect and must be

sited to allow complete draining of the system.

k. Where thermal stores are to be used the thermal store supplier should be

consulted as to the compatibility of the thermal store with a Keston C40 and C55.

Thermal store units where the boiler directly heats an open vented thermal store

are not suitable for use with the C40 or C55.

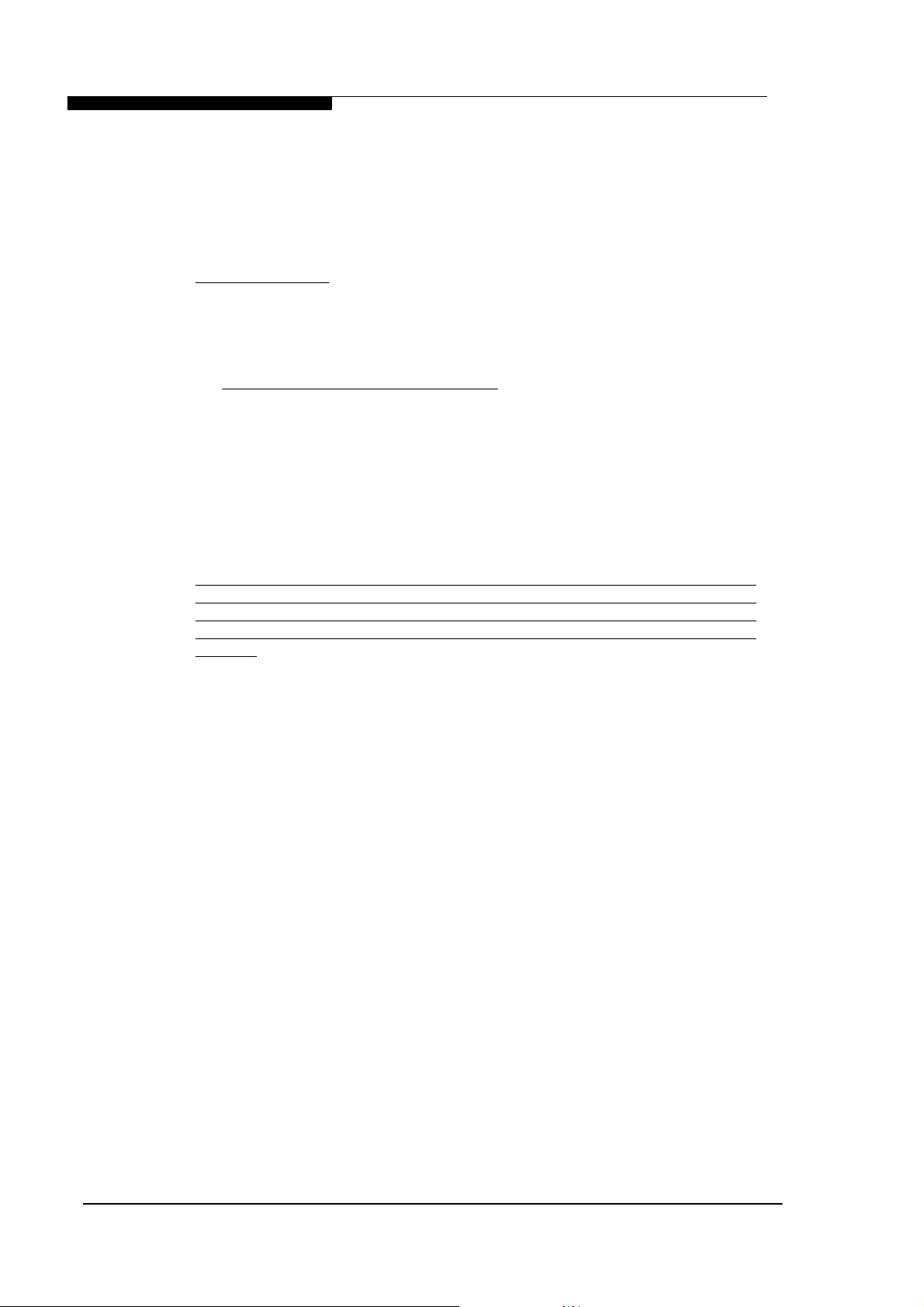

2.7.1 Open Vented Systems

A typical system is shown in Figure 2.7.1 which includes a combined feed and

vent. Note that the combined feed and vent must be fitted to the primary

RETURN. A safety valve is specified for the primary flow to ensure discharge path

at all times in the event the feed/vent connection is isolated from the boiler flow

[see 2.7.2(i)]. However, in the event the system is configured with no isolation

valve on the primary flow and wired such the boiler cannot fire when all zone

valves are closed, then the safety valve may be omitted. Note that the minimum

static head required is 9 ft at the top of the boiler.

Although suitable for open vented systems with combined feed and vent

arrangements, the C40 and C55 are low water content boilers. As such, any air

entrainment within the system water will produce boiler “kettling”. It is therefore

recommended, if in any doubt, to consider the use of sealed systems where

possible.

2.7.2 Sealed Systems

Sealed systems must be designed in accordance with BS 5449 and BS 7074 Pt1.

A typical sealed system is shown in Figure 2.7.2. It must include :

(i) A safety valve fitted on the flow, adjacent to the boiler. It must be non

adjustable and preset to 3 bar. A drain pipe must be attached, at least as

big as the valve connection, and routed to drain in any area not

hazardous nor where it may be subject to freezing.

(ii) An expansion vessel complying with BS 4814 and sized in accordance

with the requirements of BS 5449 and BS 7074 Pt 1. The vessel must

be positioned on the primary return to the boiler. Table 2.7.2

Expansion Vessel Selection provides guidance for the correct expansion

vessel size to use.

(iii) A filling point, in accordance with local water authority requirements.

(iv) A method of system make-up (automatic or manual), in accordance with

local water authority requirements.

(v) There must be no permanent connection of mains water to the boiler

system.

(vi) The installation must be designed to work with flow temperatures of up to

110 oC.

All components of the system including the heat exchanger of the indirect cylinder

must be suitable for a working pressure of 3 bar and a temperature of 110 oC.

Care should be taken in making all connections that the risk of leakage is

minimised.

Installation & Servicing Instructions Page : 10

WD265/0/2002 Chapter 2 - Boiler Location The Keston C40, C40P, C55 & C55P

Air Vent

Hose

Union

bib tap

C40

or

C55

Drain

Cock

Expansion

Vessel

By-pass

Bal.

Valve

Safety

Valve

L/S

RETURN

HEATING CIRCUIT

FLOW

Double Check

Valve

Hosepipe

( disconnected

after filling )

Test Cock

Figure 2.7.2 : Sealed System Diagram

Safety Valve Setting

Vessel charge & initial system

pressure.

25 litres

50 litres

75 litres

100 litres

125 litres

150 litres

175 litres

200 litres

225 litres

250 litres

275 litres

300 litres

Multiplying factor for other system

volumes

BS 1010:2

Stop Tap

3.0 bar

Hose

Connector

1.5 bar1.0 bar0.5 bar

VolumeVessel ExpansionTotal Water Content of system

3.92.72.1

7.85.44.2

11.78.26.3

15.610.98.3

19.513.610.4

23.416.312.5

27.319.114.6

31.221.816.7

35.124.518.7

39.027.220.8

42.930.022.9

46.832.725.0

0.1560.1090.0833

Table 2.7.2 Expansion Vessel Selection

2.7.3 Hot Water System (if applicable)

The hot water storage vessel must be of the indirect type (certain direct cylinders

can be used provided they are suitably adapted by fitting an immersion calorifier).

DIRECT CYLINDERS MUST NOT BE USED. Further guidance is provided in BS

1394. It is advisable to fit a locksheild valve on the cylinder return to enable

balancing of the flow rate through the cylinder.

The Keston Spa range of stainless steel unvented cylinders are an ideal

option for use with the Keston range. The Keston Spa range combine

Installation & Servicing Instructions Page : 11

WD265/0/2002 Chapter 2 - Boiler Location The Keston C40, C40P, C55 & C55P

Primary Return

exceptional recovery times with durable, long life stainless steel

construction and all associated controls. Contact Keston Boilers Ltd for

information

2.7.4 Boiler By-pass Piping

Boiler water flows are critical to the operation of the boiler. If flow cannot be

maintained through the system piping to meet the minimums required by the

boiler, insufficient water flows through the boiler will cause the boiler to "kettle" or

even produce steam which can damage the heat exchanger and will invalidate the

heat exchanger warranty. In addition, an open circuit is required after boiler

shutdown to permit circulation during the boilers 2 minute pump overrun

sequence.

It is normally advisable to incorporate a boiler by-pass in the system, especially if

thermostatic radiator valves are used. The flow/return differential should be 10oC

to 20oC. To comply with the new Building Regulations Part L1 the bypass

must of the automatic type.

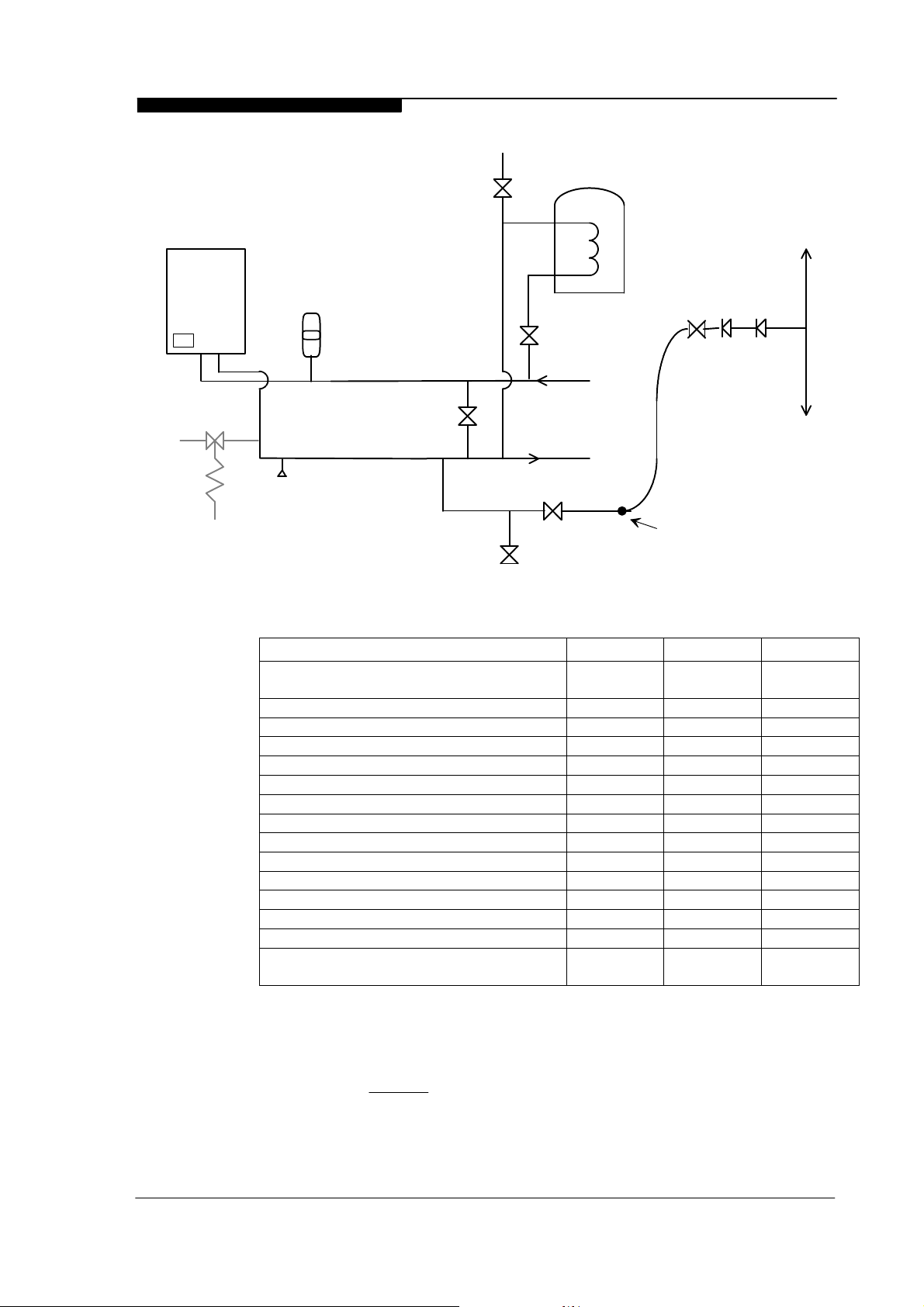

2.7.5 Balance Headers - Multiple Boiler Installations

Where multiple boilers are installed on a common distribution system

maintenance of balanced flow through each boiler is extremely important. The

implementation of a balance header, as detailed below, is recommended to

ensure adequate and balanced water circulation is maintained by each boilers

integral shunt pump, irrespective of system conditions.

The size of the balance header is dependant on the number of boilers serving the

header. A guide to sizing is given below:

Total Boiler Output (Max) Header Diameter

Up to 110kW 3”

Up to 220kW 4”

Up to 330kW 4.5”

Up to 440kW 5”

When assembling the balance header the following design considerations must

be observed:

A) Each boiler must have its own flow and return connections to the balance

header pipe. Common flow and return connections with the other boilers

will cause reverse circulation effects to occur.

B) The minimum distance between the system flow and return connections

is 600mm.

C) A drain off point should be fitted to the base of the header, along with

cleaning access, for sludge removal.

D) The top of the header should be vented.

2.7.6 Air Elimination

In the initial charge of

water to the boiler

system and in all

subsequent additions of

water to the system

some air will be

dissolved in the water.

As the water is heated

the air is driven out of

the solution and will

collect in high spots in

the system. These air

Expansion

Vessel

C40/C55

Safety

Valve

42mm

Header

AAV

Additional system

pump.

Primary flow

Installation & Servicing Instructions Page : 12

WD265/0/2002 Chapter 2 - Boiler Location The Keston C40, C40P, C55 & C55P

Static Pressure - m WC

Figure 2.8.1 : Terminals

bubbles can interfere with pumping and heat transfer and must be

eliminated.

Installation of air bleed valves at the high spot(s) in the system will allow for air

elimination when filling the system and will allow re-venting in a day or so after all

air has been driven out of solution.

2.7.7 System Pump Selection (if required)

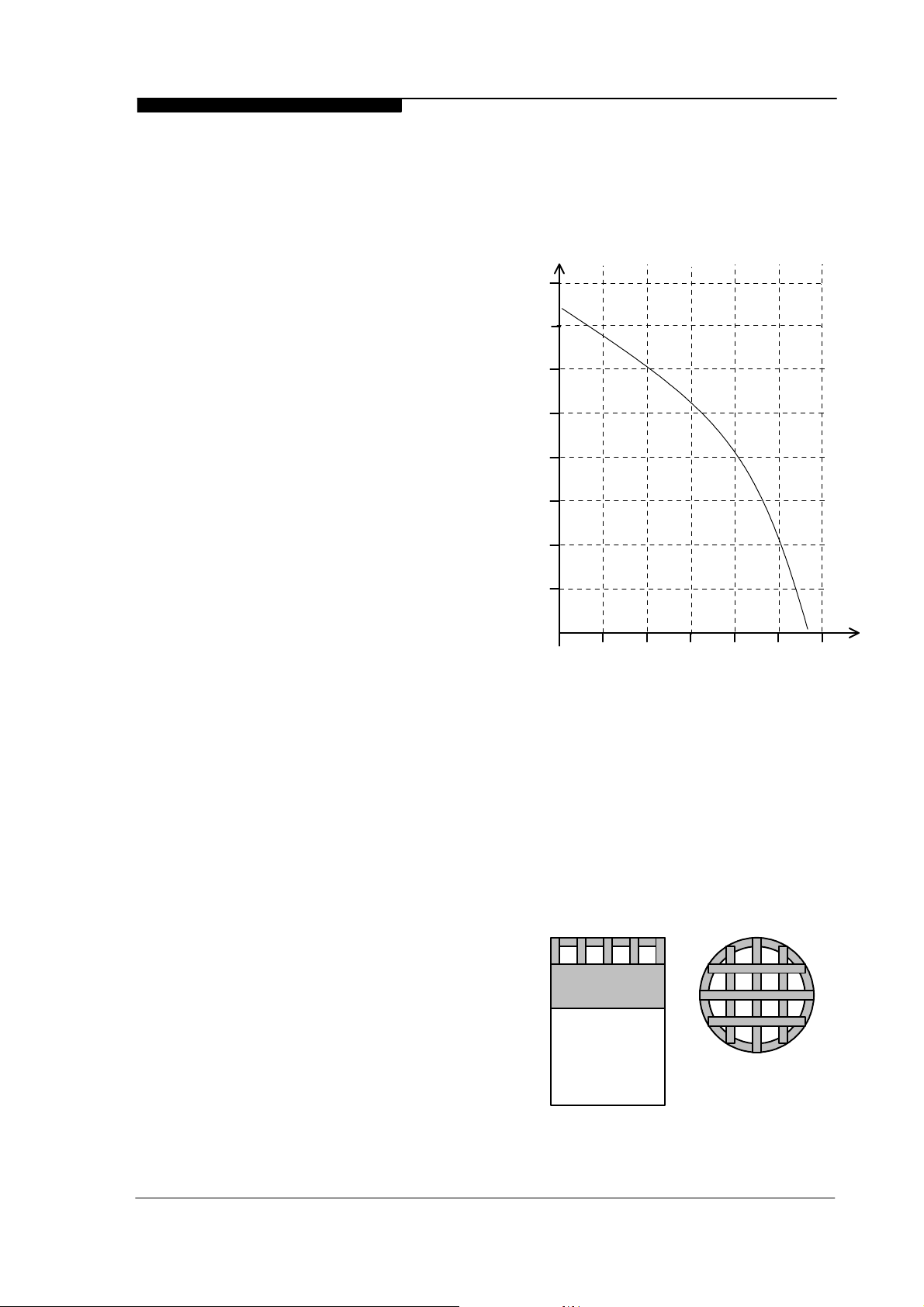

The C40 and C55 feature an

integral circulating pump

8.0

which has sufficient excess

head to drive most domestic

systems. The available head

7.0

is indicated in the chart

below. If the system index

6.0

circuit resistance, at the

desired flow rate, is in excess

of the available head from the

5.0

integral pump an additional

system pump will be required.

4.0

The schematic above

illustrates a recommended

approach to using an

additional system pump. The

additional system pump

should be sized to overcome

the index circuit resistance

only as the boilers integral

pump will overcome boiler

resistance.

If an additional pump is

required the selected pump

must comply with BS 1394.

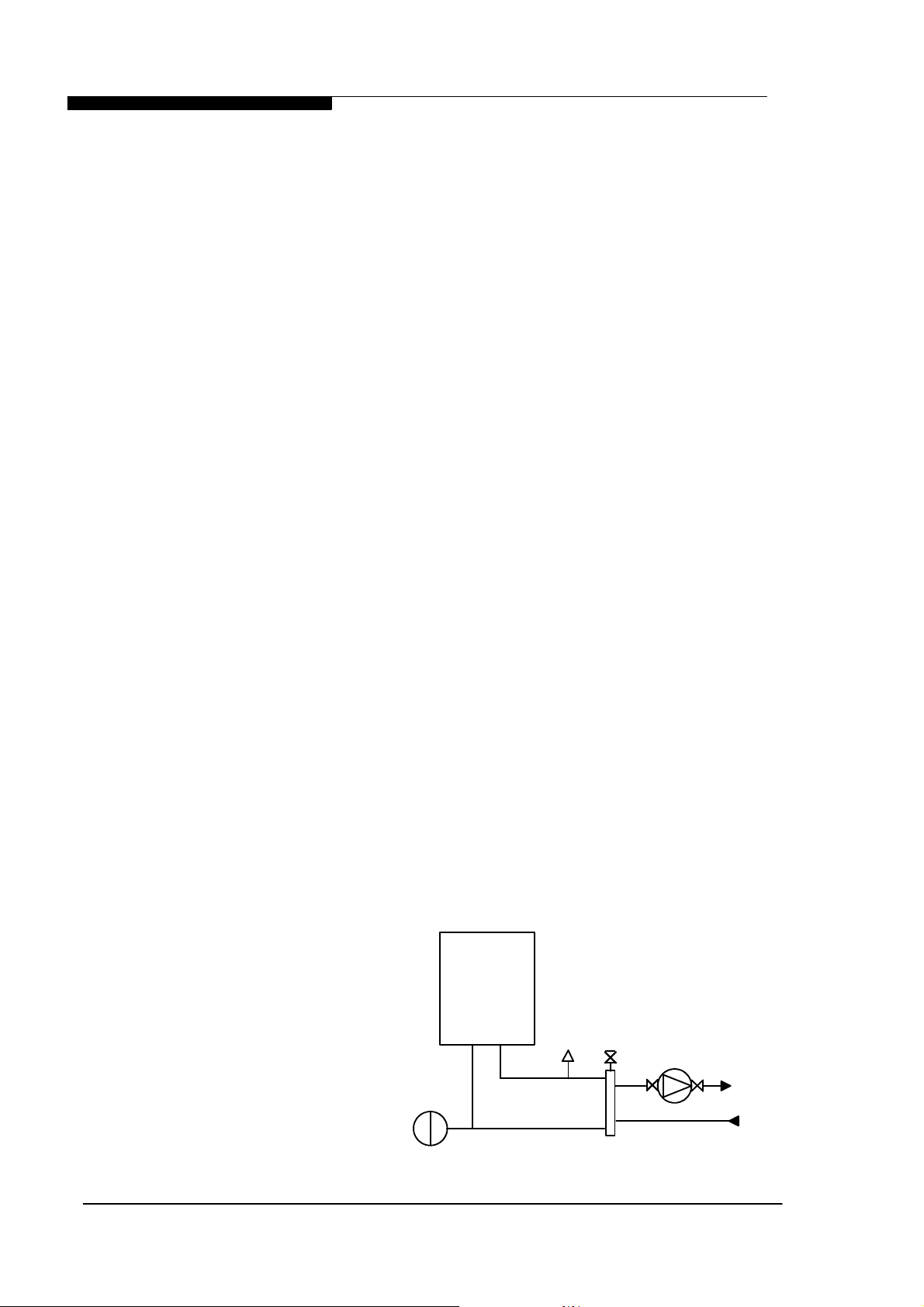

2.8 FLUE SYSTEM

2.8.1 Design

Individual air supply and flue outlet pipes are used. The material used for flue

outlet &/or air inlet must be muPVC to BS5255 and/or BSEN1566-1 and

BSEN1329 of an internal diameter of 51 mm. (i.e. nominal 50 mm diameter

muPVC solvent weld waste pipe)

Alternatively, where flue or air intake

lengths of up to 45m are require,

Glynwed Friatec DN70 pipe may be

used.

Both 50mm flue outlet terminal and

50mm air inlet terminal are supplied

and are illustrated in Figure 2.8.1.

Both terminals are identical. The

flue and air terminals must be fitted

to the appropriate duct using solvent

weld adhesive. If 75mm terminals

are required these can be obtained

from your Keston Boilers stockist.

Request part numbers

C.17.2.26.00.0 (terminals) and

C.17.2.00.60.0 (50 to 75 adapters).

3.0

2.0

1.0

20 30 40 50 60

10

Water Flow - L/min

Fig 2.7.7 Available Pump Head Graph

Flue Outlet/Air Inlet Terminals

Installation & Servicing Instructions Page : 13

WD265/0/2002 Chapter 2 - Boiler Location The Keston C40, C40P, C55 & C55P

2.8.2 Maximum Lengths

The maximum lengths of both air inlet pipe and flue outlet pipe, when no bends

are used, are as detailed below.

50mm 75mm

Maximum Air Inlet Length : 29.0 m 89.0 m

Maximum Flue Outlet Length : 15.0 m 45.0 m

Maximum Total Flue and Air Intake Length : 30.0 m 90.0 m

However, each bend used has an equivalent length that must be deducted from

the maximum straight length stated above. Knuckle bends must not be used.

A 92.5o sweep elbow is equivalent to 1.0m straight length.

Example (assuming 50mm muPVC flue and air pipework):

Air inlet uses two one 92.5o sweep elbows. Hence, maximum length permissible

(i.e. a+b in figure 2.8.2) = 29.0m - 1.0m - 1.0m = 27.0m

Flue outlet uses one 92.5o sweep elbow. Hence, maximum length permissible (i.e.

c+d in figure 2.8.2) = 15.0m - 1.0 m = 14.0m

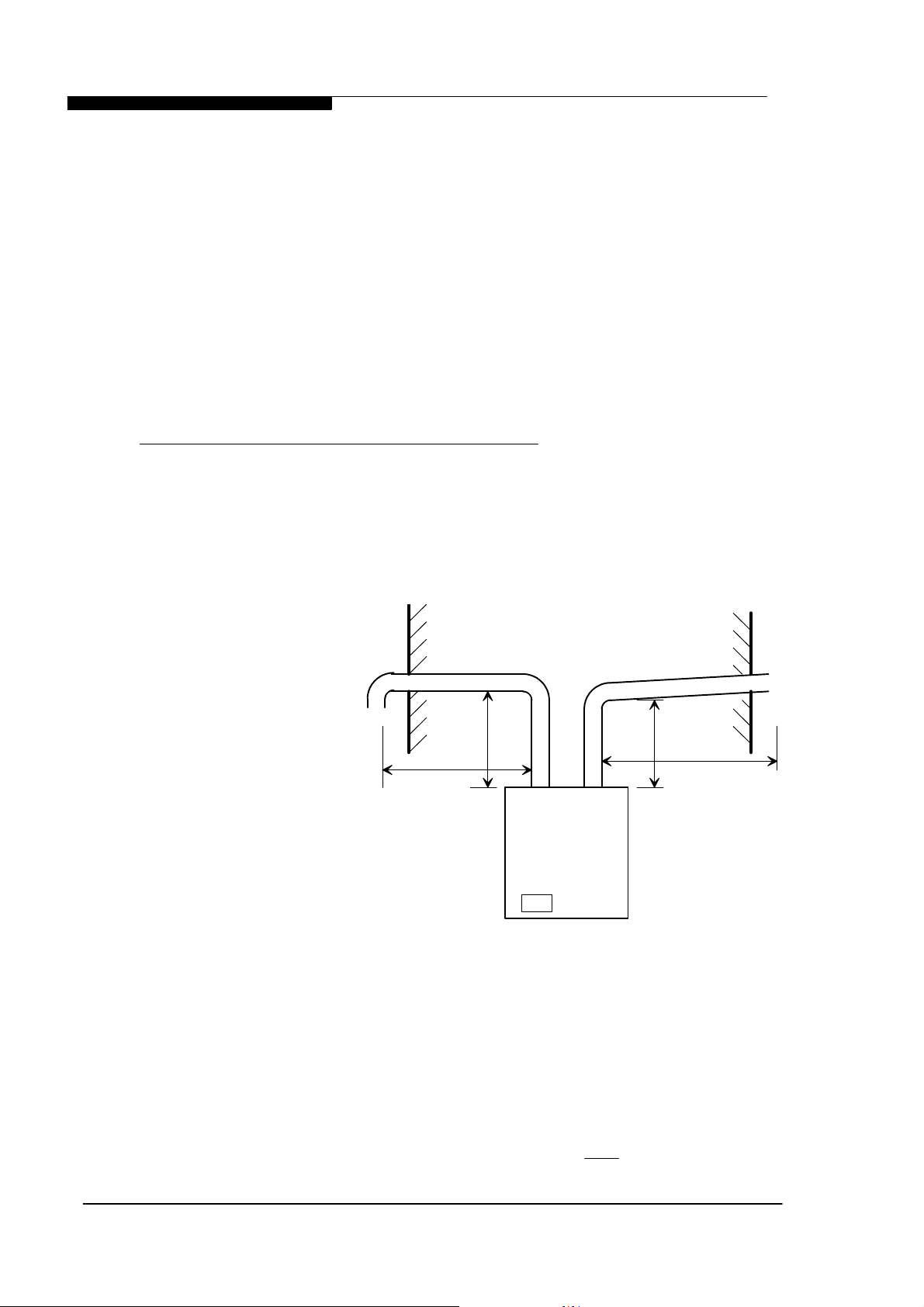

2.8.3 Boiler Output vs Flue Length

Due to the

resistance

presented by

extended flue

length a slight

reduction in

maximum boiler

output will occur

where flue

lengths in

excess of 8m

(50mm

muPVC), or

24m (Friaphon

DN70) are

used. In such

cases the boiler

output will be

reduced by 1%

Figure 2.8.2 : Flue & Air Maximum Length Example

per additional

1m (50mm muPVC) and 1% per additional 3m (Friaphon DN70)

2.8.4 Slope

AIR

b

a

C40 or C55

FLUE

d

c

'Horizontal' flue outlet pipework MUST slope at least 3.5 degrees (61 mm per

metre run) downwards towards the boiler where 50mm muPVC pipe is used. In

the event 75mm Friatec pipe wise used a slope of 2 degrees (32mm per metre

run) can be used. Pipework can be vertical. Only swept elbows can be used.

Air inlet pipework can be truly horizontal or vertical, or sloping in a downward

direction towards the boiler but in this case rain, etc., must

be prevented from

Installation & Servicing Instructions Page : 14

Loading...

Loading...