KEPCO BOP-GL 1KW Quick Start Guide

QUICK START GUIDE

KEPCO An ISO 9001 Company.

BOP

1KW-GL

BOP 1KW-GL POWER SUPPLY

This guide gives a brief introduction to the BOP 1KWGL Power supply, shows simple load connections, and allows you to verify the power supply is working. The guide also shows you how to perform the most commonly used functions.

ACCESSING MANUALS. First determine your Firmware Version (see below), then download the BOP 1KW-GL Operator’s Manual from www.kepcopower.com/support/opmanls.htm#bop-gl

Refer to the BOP 1KW-GL Operator’s Manual for full specifications, installation considerations and operating instructions. The BOP 1KW-GL Operator’s Manual also includes a full description of the digital interfaces and the SCPI command language.

FIRMWARE VERSION. With no load connected and power off, use either the GPIB port or RS 232 port (see page 6) to accept remote commands.

If necessary, refer to “Reset Power-up” on page 8 and Figure 5 to configure the GPIB address (default is 6) or configure the RS 232 baud rate (default is 9600).

Apply power to the unit and send *IDN? query. The unit responds with a character string containing the following fields: <Manufacturer>,<Model VoltageCurrent Calibration Date>,<Serial Number>, <Firmware Version> e.g., KEPCO, BOP1KW 20-50 09/30/ 2001,123456,4.01.

ACCESSING DRIVERS. Drivers are accessed from www.kepcopower.com/drivers/drivers-dl3.htm.

CONTENTS

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 Equipment Supplied . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Preliminary Operational Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Input Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 Load Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 Local Sensing (Factory Default). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 Remote Sensing Select. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 Analog I/O Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 Trigger Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 GPIB Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 RS 232 Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 Power-up Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 Turning The Power Supply On. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 Reset Power-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Normal Power-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Power Supply Basics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 Voltage and Current Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 Setting Voltage or Current Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 Voltage/Current Protect Limits (Limit Channel Software Limits). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 Software Limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 Maximum/Minimum Protection Limits (Software-controlled). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 Determining How the Unit Responds when Output is OFF (Load Type). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 Configure Load Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 Enabling/disabling Output Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Additional Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

KEPCO, INC. |

131-38 SANFORD AVENUE |

FLUSHING, NY. 11355 U.S.A. |

TEL (718) 461-7000 |

FAX (718) 767-1102 |

|

|

http://www.kepcopower.com |

email: hq@kepcopower.com |

|

||

093013 |

228-1699 REV 2 |

1 |

I — DESCRIPTION

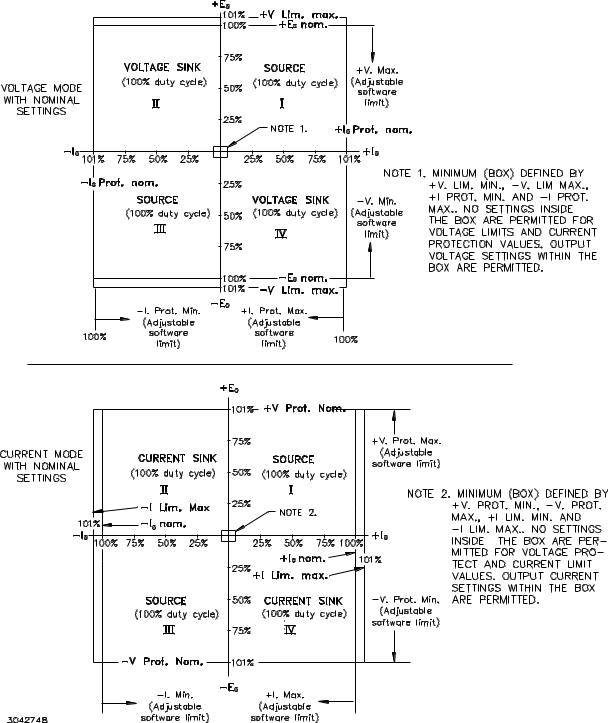

The BOP 1KW-GL Series hereafter referred to as BOP-GL, are true 4-quadrant programmable voltage and current power supplies, meaning they are capable of both sourcing and sinking power (see Figure 1).

The BOP-GL models have been optimized for exceptionally low current ripple and noise and improved stability (drift and temperature), making them ideal for driving inductive loads such as large magnets or motors. These bipolar power supplies pass smoothly through zero without switching to provide true ± voltage and ± current. These BOP-GL power supplies use switch mode technology for low dissipation. A bi-directional, isolating, a-c input power factor correcting (PFC) circuit recuperates

energy sinked from an active load and sends it back into the line to maintain low dissipation.

These BOP power supplies can be controlled remotely by an analog ±10V input for the main channel (voltage or current), and by a +1 to +10V input for the limit channels. They can also be controlled through one of the standard digital interfaces (GPIB or RS 232) to set voltage and current and the four protection limits (+voltage, –voltage, +current and – current.) Output voltage and current can be remotely monitored via the analog monitor signals present at the rear panel Analog I/O Port connector, or by using SCPI commands via either the RS 232 or GPIB ports.

.

TABLE 1. BOP-GL 1000 WATT MODEL PARAMETERS

|

d-c Output Range |

Closed Loop Gain |

||

Model |

|

|

|

|

EO Max |

IO Max |

Voltage |

Current |

|

|

Channel |

Channel |

||

1000 WATT MODELS |

|

|

|

|

|

|

|

|

|

BOP 10-100GL |

±10V d-c |

±100A d-c |

1.0 |

10.0 |

|

|

|

|

|

BOP 20-50GL |

±20V d-c |

±50A d-c |

2.0 |

5.0 |

|

|

|

|

|

BOP 36-28GL |

±36V d-c |

±28A d-c |

3.6 |

2.8 |

|

|

|

|

|

BOP 50-20GL |

±50V d-c |

±20A d-c |

5.0 |

2.0 |

|

|

|

|

|

NOTE: When connecting active loads, the steady-state voltage of the active load must not exceed the maximum voltage rating of the BOP. Otherwise the overvoltage protection will shut down the power supply.

II — UNPACKING

This instrument has been thoroughly inspected and tested prior to packing and is ready for operation. After careful unpacking, inspect for shipping damage before attempting to operate. Perform the “Preliminary Operational Check” on page 5. If any indication

of damage is found, file an immediate claim with the responsible transport service.

III — EQUIPMENT SUPPLIED

See Table 2.

TABLE 2. EQUIPMENT SUPPLIED

ITEM |

FUNCTION |

PART NUMBER |

|

|

|

Source Power Entry mating connector |

Mates with source power entry connector |

142-0381 (Kepco) (IEC 320) |

|

|

|

PAR/SER CONTROL - IN |

Mates with PAR/SER CONTROL - IN port to allow |

142-0488 (Kepco) |

mating connector |

access to pins required for calibration |

|

|

|

|

Mating Connector, Trigger |

Mates with Trigger port. |

142-0527 (Kepco) |

|

|

SP2501 (CUI Stack) |

|

|

|

Mating Connector, Analog I/O Port |

Mates with connector for Analog I/O port A2A5J6 |

|

(15-pin DSUB Connector) |

Dsub 15 pin hood |

108-0374 |

|

|

(Tyco-Amp 207470-1) |

|

Dsub 15 pin male |

142-0449 |

|

|

(Amphenol 17S-DA15P) |

|

|

|

KEPCO, INC. |

131-38 SANFORD AVENUE |

FLUSHING, NY. 11355 U.S.A. |

TEL (718) 461-7000 |

FAX (718) 767-1102 |

|

|

http://www.kepcopower.com |

email: hq@kepcopower.com |

|

||

2 |

228-1699 REV 2 |

093013 |

FIGURE 1. BOP-GL OUTPUT CHARACTERISTICS

KEPCO, INC. |

131-38 SANFORD AVENUE |

FLUSHING, NY. 11355 U.S.A. |

TEL (718) 461-7000 |

FAX (718) 767-1102 |

|

|

http://www.kepcopower.com |

email: hq@kepcopower.com |

|

||

093013 |

228-1699 REV 2 |

3 |

IV — ACCESSORIES See Table 3.

TABLE 3. ACCESSORIES

ITEM |

FUNCTION |

PART NUMBER |

|

|

|

|

|

|

Mating Connector, Trigger |

Mates with Trigger port. |

142-0527 (Kepco) |

|

|

SP2501 (CUI Stack) |

|

|

|

IEEE 1118 (BITBUS) |

Allows connection to IEEE 1118 (BITBUS) port. |

142-0485 (Kepco) |

Mating connector |

|

KMDLA-5P (Kycon Inc.) |

|

|

|

IEEE 488 Cable, (1 meter long) |

Connects BOP-GL power supply to GPIB bus. |

SNC 488-1 |

|

|

|

IEEE 488 Cable, (2 meter long) |

Connects BOP-GL power supply to GPIB bus. |

SNC 488-2 |

|

|

|

IEEE 488 Cable, (4 meter |

Connects BOP-GL power supply to GPIB bus. |

SNC 488-4 |

longs) |

|

|

|

|

|

Line Cord (250V, 20A) |

Provides connection to a-c mains via Nema 6-20P connector. |

118-1087 |

|

|

|

Line Cord (250V, 20A) |

Provides connection to a-c mains via Nema L6-20P locking type con- |

118-1088 |

|

nector. |

|

|

|

|

|

|

|

RS 232 Cable Kit |

Contains RJ11 to RJ45 Patch cord, RJ 45 Patch cord, two RS 232 |

|

|

adapters, one with male pins to connect to DTE equipment and one |

KIT 219-0436 |

|

with female pins to connect to a PC (personal computer), two RS 232 |

|

|

Loop Back test Connectors (one 6-pin and one 8-pin) to test RS 232 |

|

|

communication and aid in isolating RS 232 communication problems. |

|

|

|

|

RS 232 Adapter (Male pins) |

Allows RS 232 port to be connected to DTE equipment. (Supplied in |

142-0487 |

|

KIT 219-0436.) |

(L-COM RA098M) |

|

|

|

RS 232 Adapter (Female pins) |

Allows RS 232 port to be connected to a PC (personal computer). (Sup- |

142-0506 |

|

plied in KIT 219-0436.) |

(L-COM RA098F) |

|

|

|

15-pin DSUB Connector |

Mating connector for Analog input connector A2A5J6 |

|

|

Dsub 15 pin hood |

108-0374 |

|

|

(Tyco-Amp 207470-1) |

|

Dsub 15 pin male |

142-0449 |

|

|

(Amphenol 17S-DA15P) |

|

|

|

IDC 6-pin connector |

Mating connector for RS-232 PORT, connector A1J5 and PROTEC- |

142-0536 |

|

TION EXT. PORT, connector A2A5J7 |

(Amphenol 5-555176-3) |

|

|

|

IDC 8-pin plug |

Mating connector for PAR/SER PROTECT PORT (IN and OUT) con- |

142-0535 |

|

nectors. |

(Amphenol 5-555176-3) |

|

|

|

Slides |

Allows easy withdrawal of unit from rack (Model CS 04 includes slides, |

CS 04 |

|

brackets, all mounting hardware and installation instructions.) |

|

|

|

|

|

|

|

Heat Sink |

Provides adequate cooling for calibration sense resistors. |

136-0451 |

|

|

|

V — SAFETY See Table 4

|

|

|

TABLE 4. SAFETY SYMBOLS |

|

|

|

|

|

SYMBOL |

MEANING |

|

|

|

|

|

|

|

|

CAUTION: RISK OF ELECTRIC SHOCK. |

|

|

|

|

|

|

|

|

! |

|

CAUTION: REFER TO REFERENCED PROCEDURE. |

|

|

|

||

|

|

|

|

|

WARNING |

INDICATES THE POSSIBILITY OF BODILY INJURY OR DEATH. |

|

|

|

|

|

|

CAUTION |

INDICATES THE POSSIBILITY OF EQUIPMENT DAMAGE. |

|

|

|

|

|

KEPCO, INC. |

131-38 SANFORD AVENUE |

FLUSHING, NY. 11355 U.S.A. |

TEL (718) 461-7000 |

FAX (718) 767-1102 |

|

|

http://www.kepcopower.com |

email: hq@kepcopower.com |

|

||

4 |

228-1699 REV 2 |

093013 |

A simple operational check after unpacking and |

! |

CAUTION: |

|

|

before equipment installation is advisable to ascer- |

DO NOT repeatedly toggle |

the |

||

tain whether the power supply has suffered damage |

|

|||

|

POWER circuit breaker/switch |

as |

||

resulting from shipping. |

|

|||

|

this may damage the unit. |

|

||

1. With POWER switch set to off position, connect |

|

|

||

4. Connect the power supply to source power. With |

||||

the power supply to source power (see “Input |

||||

no load connected, set POWER switch to the ON |

||||

Connections” below). |

||||

position. |

|

|||

2. Verify that the power-up switches at the top cover |

|

|||

5. Each time the unit is turned on an internal self- |

||||

are set to the factory default positions shown in |

||||

test is performed. If the unit passes, it initializes |

||||

Figure 5. This establishes GPIB address 6, stand- |

||||

with the power-up settings established in step 2 |

||||

alone operation, Voltage mode, Analog Input |

||||

and the front panel POWER/FAULT/LIMIT light is |

||||

enabled and internal ±current limits enabled and |

||||

green (power good), the DIGITAL CONTROL light |

||||

set to maximum. |

||||

is not lit (analog input enabled) and the VOLT- |

||||

NOTE: The unit is shipped with load type set to |

||||

AGE/CURRENT light is green (voltage mode), |

||||

Active (for inductive loads). To change the |

||||

MASTER/SLAVE light is green (standalone or |

||||

load type refer to the “Reset Power-up” on |

master configuration) and the OUTPUT ON light |

|||

page 8. The logic for Remote on/off input |

is lit (output enabled). If the front panel POWER/ |

|||

at pin 2 of the Trigger port is set to high (1) |

FAULT/LIMIT light is red, the unit has failed self- |

|||

or open circuit for output on, low (0) or |

test; contact Kepco for further instructions. If the |

|||

short circuit for output off. |

unit beeps, or the MASTER/SLAVE or VOLTAGE/ |

|||

3. Connect a twisted wire pair (either #24 or #22 |

CURRENT light blinks, refer to the BOP-GL Oper- |

|||

ator Manual for troubleshooting. |

|

|||

AWG) to the mating connector for the Analog I/O |

|

|

|

|

|

6. Connect a digital voltmeter (DVM) with resolution |

|

VI — PRELIMINARY OPERATIONAL CHECK |

||

port pins 11 and 10. Connect +10V d-c ±0.1mV to |

and accuracy of 0.01% or better to the OUT S and |

|

pin 11, referenced to pin 10, then install the mat- |

||

COM S terminals at the rear panel terminal block. |

||

ing connector on the Analog I/O port at the rear |

||

7. Verify DVM voltage reading matches the nominal |

||

panel. |

||

voltage of the unit within 0.01% of rated maximum |

||

|

||

|

voltage. |

|

VII — INSTALLATION

Install units either on a bench or in a 19 inch-wide rack. For rack mounting: first remove four feet; rack must provide support at the rear. Optional slides may be used. Leave the front and rear panels clear of obstructions to ensure adequate cooling.

INPUT CONNECTIONS. Source power is connected to the power supply via three-wire input power using the source power mating connector supplied (see Table 3). This power supply operates from single phase a-c mains power (or between two phases of 3-phase a-c mains power), 230V, 50/60Hz nominal (range: 176 - 264V, 47-63Hz) without any need for range selection. The user must provide a properly sized and rated mains lead (line cord) and service with a current rating compatible with the required input current. Line cords available as accessories are listed in Table 3. Plug the source power connector into the source power inlet connector at the rear panel.

LOAD CONNECTIONS.

! CAUTION:

Before connecting a load, verify that power up switch settings (see “Power-up Settings” on page 8) are compatible with your load.

Power connections require wires that are properly rated for the nominal output current of the unit. Connect the load to the OUTPUT and COMMON power terminals on the rear panel (see Figure 3). OUT S and COM S terminal of the Monitor and Sensing Terminal block are for connection of remote sensing leads (after removing the factory-installed local sensing links). NOTE: Output Sense lines must be connected for proper operation, either locally, or at the load (remote). Also use OUT S and COM S to monitor voltage at the load using external equipment such as a DVM, oscilloscope, etc. Use OUT

KEPCO, INC. |

131-38 SANFORD AVENUE |

FLUSHING, NY. 11355 U.S.A. |

TEL (718) 461-7000 |

FAX (718) 767-1102 |

|

|

http://www.kepcopower.com |

email: hq@kepcopower.com |

|

||

093013 |

228-1699 REV 2 |

5 |

Loading...

Loading...