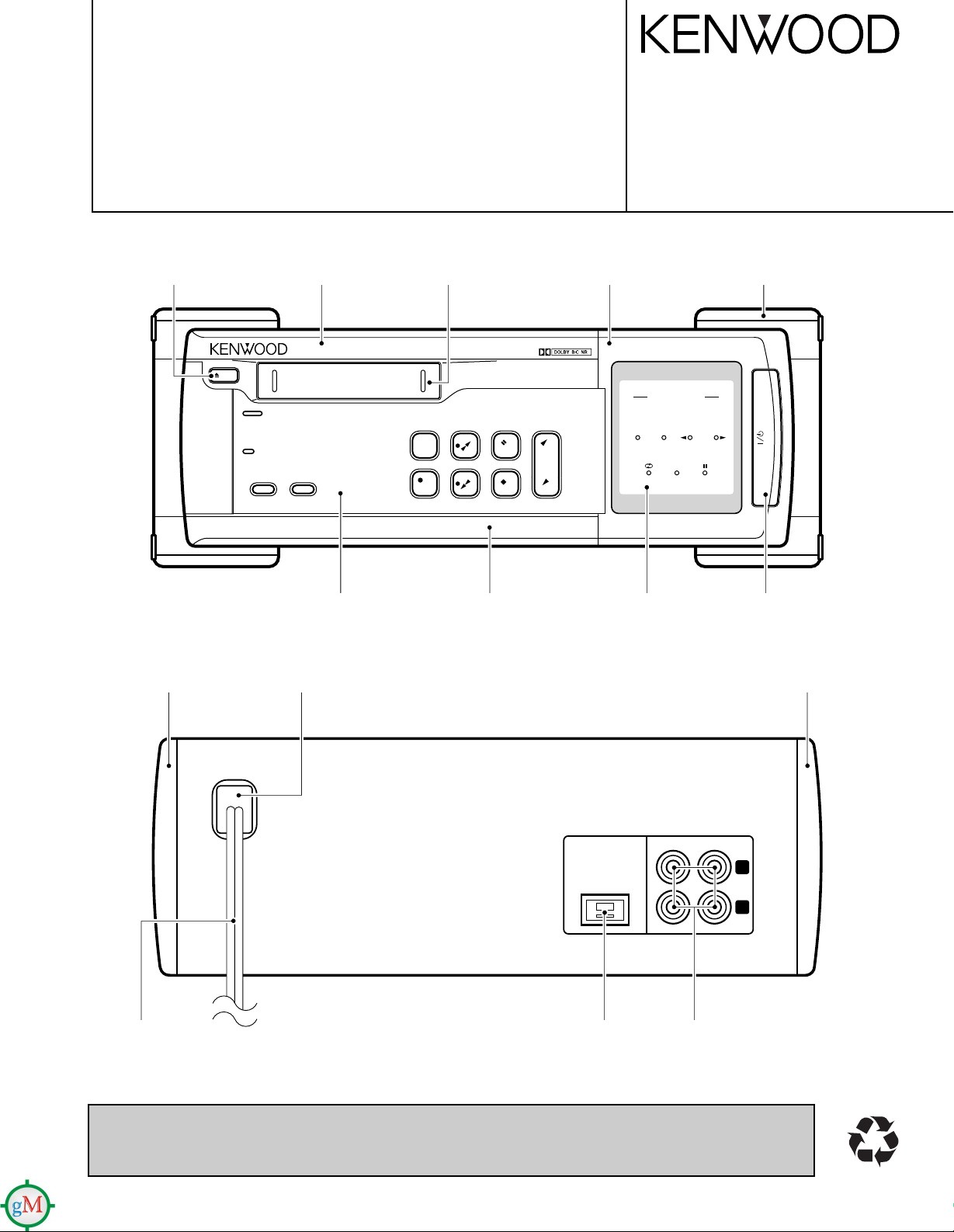

Kenwood XVH-7 Service manual

STEREO AUTO REVERSE CASSETTE DECK

646610607605660

recording

function indicator

Dolby NR

B-type

crls

C-type

direction

eject

standby

on/standby

fwd

rev

rec

/arm

crls

stop

pause

tape loading mechanism

rev.mode Dolby NR

auto reverse cassette deck X-VH7

pause

forwardreverse

rev.mode

609 654

608

SYSTEM

CONNECTOR

L

R

REC IN REC OUT

70%

X-VH7

SERVICE MANUAL

(VH-700)

Knob (EJECT)

(K29-7554-04)

Dressing panel

(A21-3764-02)

Dressing panel

(A21-3765-03)

Panel

(A29-1052-14)

Dressing panel

(A21-3758-02)

Panel

(A60-1648-01)

Front glass

(B10-3488-03)

© 1999-5/B51-5532-00 (K/K) 3632

Insulator assy

(J02-1444-04)

Knob (POWER) *

(K29-)

Side plate

(A50-1326-02)

AC cord *

(E30-)

Refer to X-E9 and X-SA7 service manuals (B51-4926-00/B51-5214-00),

ACcord bushing

(J42-0083-05)

Side plate

(A50-1327-02)

Rectangular receptacle

(E08-0311-05)

* Refer to parts list on page 13.

Phono jack

(E63-0136-15)

if you require in detail.

X-VH7

REMOVE EARTH METAL

3

4

1

FRONT

X28 (A/4)

x2

2

DECK MECHA

ASSEMBLY EARTH METAL

6

5

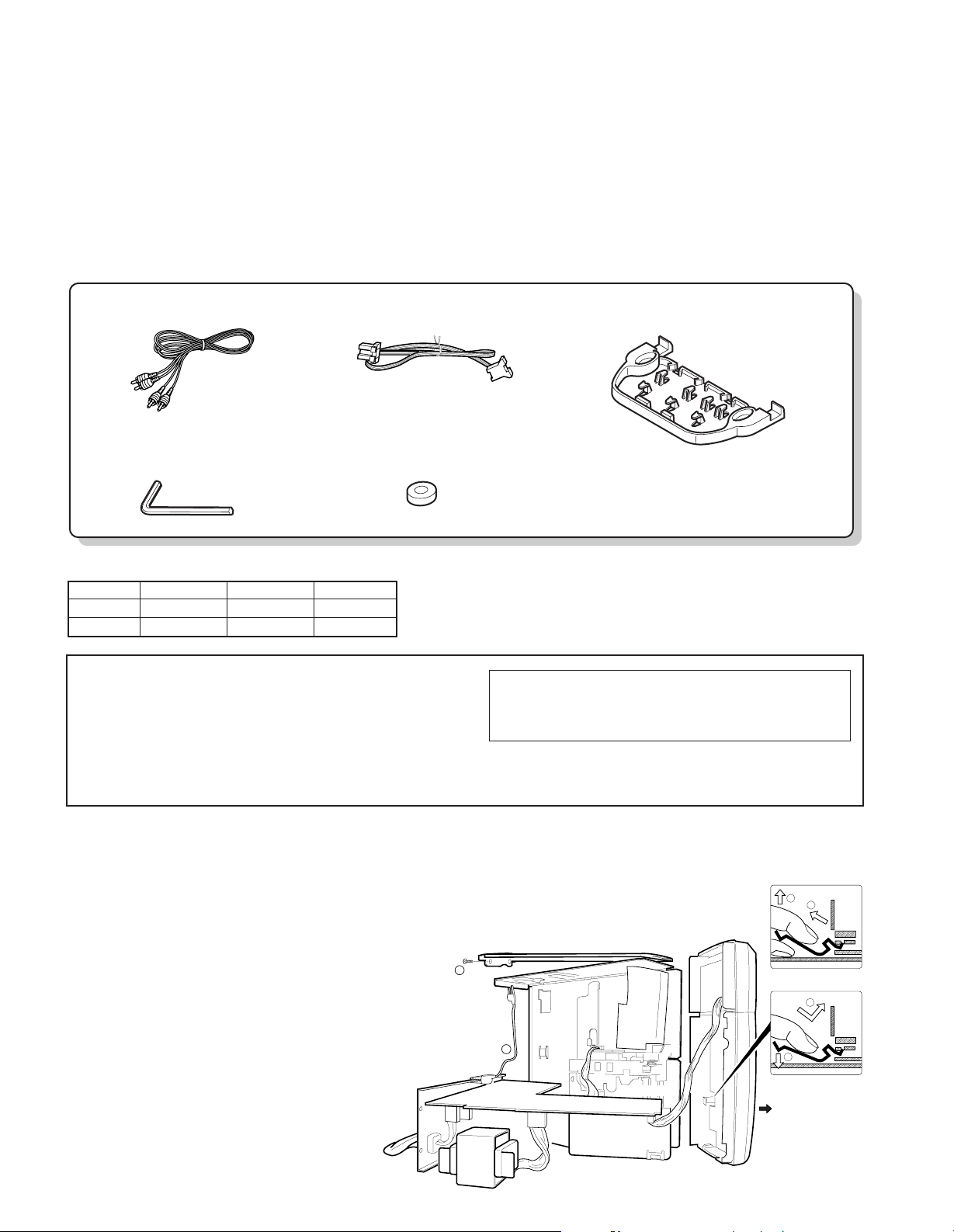

CONTENTS / ACCESSORIES

Contents

CONTENTS / ACCESSORIES .................................. 2

DISASSEMBLY FOR REPAIR....................................2

CIRCUIT DESCRIPTION............................................3

ADJUSTMENT............................................................6

PC BOARD ................................................................ 7

Accessories

SCHEMATIC DIAGRAM............................................ 9

EXPLODED VIEW ....................................................12

PARTS LIST..............................................................13

SPECIFICATIONS ......................................Back cover

Audio cord (2)

(E30-0615-05)

Front feet replacement tool (1)

(Allen wrench)

(W01-0084-05)

System control cord (1)

(E30-2628-05)

Replancement front feet (2)

(J02-0130-05)

System configurations

SYSTEM RECEIVER CASSETTE SPEAKER

VH-600 RD-VH7 - LS-VH7

VH-700 RD-VH7 X-VH7 LS-VH7

Operation to reset

The microcomputer may fall into malfunction (impossibility to operate, erroneous display, etc.) when the

power cord is unplugged while power is ON or due to

an external factor. In this case, execute the following

procedure to reset the microcomputer and return it to

normal condition.

¶ Please note that resetting the microcomputer clears the contents

stored in it returns it to condition when it left the factory.

Spacer for stacked installation (1)

(J19-5996-02)

Unplug the power cord from the AC outlet and, while

holding the "00eject" key depressed, plug the power

cord again.

¶ If a tape is loaded in the deck, it will be ejected now.

DISASSEMBLY FOR REPAIR

ELECTRIC CHECK

1) Remove insulator a'ssy, then remove some

screw of L,R side board(

top and the bottom boards, then remove the

power transformer and the rear panel assembling PCB.

2) Connect GND between PCB and the deck

mechanism with a alligator clip lead weir (2).

REMOVE EARTH METAL

Support the earth metal by your finger to

keep the shape, then pull up (3) and remove

(4) the earth metal .

ASSEMBLE EARTH METAL

Insert the tip of the earth metal (5), then support the earth metal by your finger, push

down it (6).

2

1). Next remove the

CIRCUIT DESCRIPTION

1. Deck Microprocessor : CXP 84124-150 (X28 : IC1)

1-1 Features

1) Single loading cassette deck.

2) Equipped with DPSS. UP search, DOWN search, 1 tune

repeat, RWD play, dash and play, REREC standby.

1-2 Microprocessor periphery block diagram

X-VH7

3) Dolby NR B/C

4) One touch edit.(only remocon)

5) CRLS

6) One touch operation

LED

3

4

KEY

MATRIX

3

CXP84124-150

u–COM (IC1)

21

10 7

DECK MECHA

(ADR-2176ST)

3

2

2

IC2

SYSTEM IC

HA12167FB

SLOT

MECHANISM

REC /PB CIRCUIT

SERIAL COMMUNICATION LINE

SIGNAL LINE/ CONTROL LINE

1-3 KEY matrix, LED matrix

1-3-1 KEY matrix

KS0(6) KS1(7) KS2(9) KS3(8)

KR0(15) POWER

KR1(16)

KR2(14)

1-3-2 LED matrix

LED0(19) EJECT STANDBY DOLBY B RECORDING

LED1(20) PAUSE CRLS REV. MODE DOLBY C

LED2(18) - - - - - - - - REVERSE FORWARD - - - - - - - -

210 ¶

38

KS0(6) KS1(7) KS2(9) KS3(8)

7

REV. MODE CRLS

DOLBY

{( )u-COM IC PORT}

¡

3

X-VH7

CIRCUIT DESCRIPTION

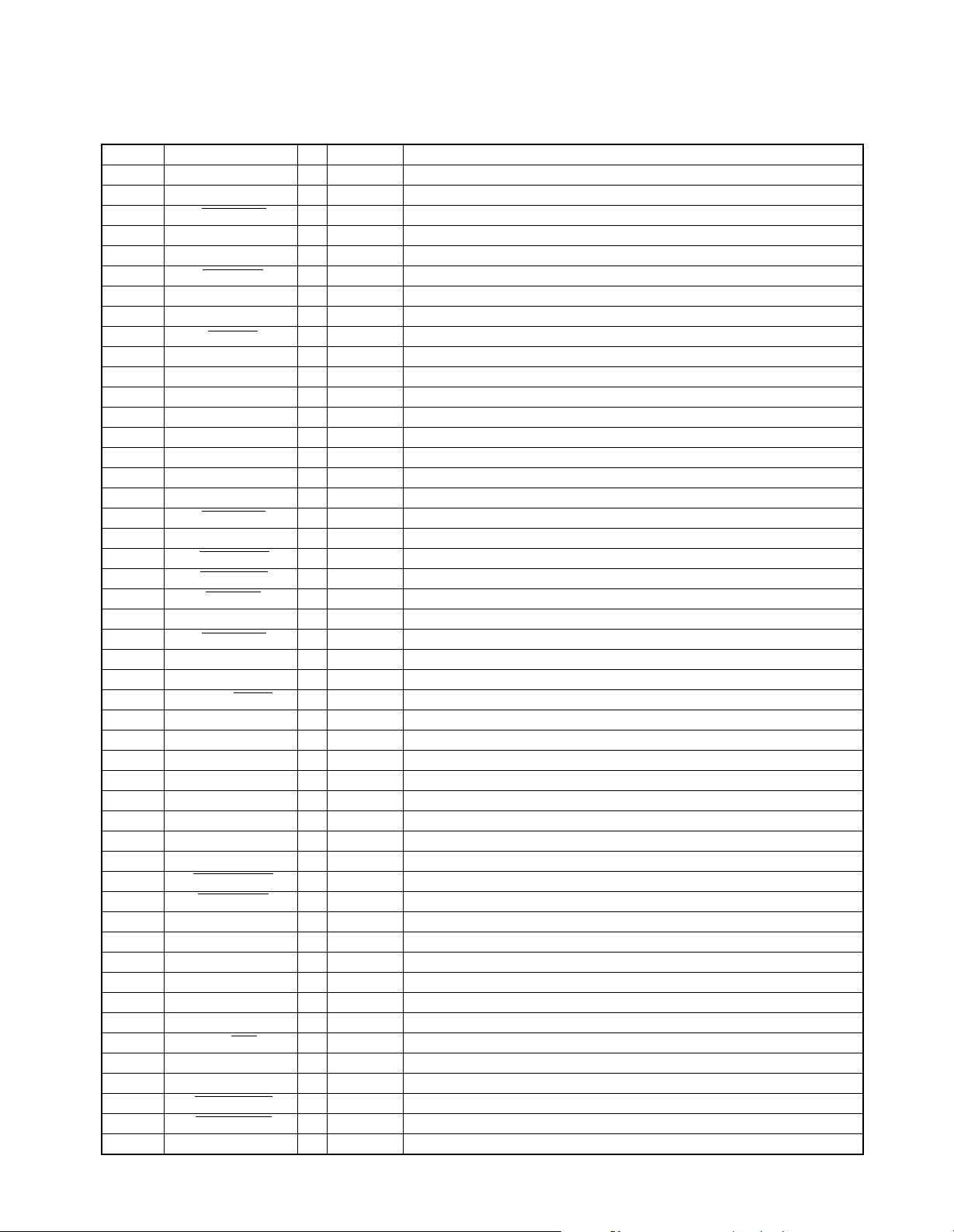

1-4 Pin description

Pin Name I/O Connect Description

1 S.BUSY I/O OPEN Serial communication BUSY signal H: BUSY L: READY

2~5 — I OPEN No used

6~9 KS0,1,3,2 O PU KEY SCAN 0,1,3,2

14~16 KR2,0,1 I PD KEY RETURN 2,0,1

17 — I OPEN No used

18~20 LED2,0,1 O OPEN LED drive output2,0,1 L: ON

21 BACKLIGHT_ON O PD BACK LIGHT LED drive output H: ON

22~29 — O OPEN No used

30 RESET I PU u-com RESET signal detect L: RESET

31 EXTAL I OPEN MAIN CLOCK(10MHz)

32 XTAL — OPEN

33 VSS(GND) — GND GND

34 TX — OPEN No used

35 TEX(GND) I GND GND

36 AVSS(GND) — GND A/D converter GND

37 AVREF I +5V A/D converter reference voltage

38 SOL O PD MECHA solenoid control H: ON

39 R_INH_F I PU FWD REC permission detect signal input L: REC

40 PHOTO SW I PU REAL drive pulse input

41 HALF_SW I PU Cassette half detect signal input L: CASSETTE EXIST

42 PLAY SW I PU MECHA HEAD position detect L: ON

43 TYPE II I PU TYPE Ö†detect signal input L: TYPE II

44,45 LEVEL L/R I PD Lch/Rch level input

46 R_INH_R I PU RVS. REC permission detect signal input L: REC

47 CPM O PD Capstan motor control H: ON

48 CLOCK O OPEN System IC CLOCK output

49 REC/PLAY O OPEN REC/PLAY changeover H: REC L: PLAY

50 ERASE O PD ERASE HEAD control output H: ON

51 DATA O OPEN System IC DATA output

52 STB O OPEN System IC STROBE signal output

53~59 — O OPEN No used

60 BIAS NOR O PD BIAS CONTROL H: NORMAL TAPE

61~63 — I OPEN No used

64 SLOT OPEN O OPEN SLOT OPEN motor control H: ON

65 SLOT CLOSE O OPEN SLOT CLOSE motor control H: ON

66 CLOSE SW O PU SLOT CLOSE detect SW input L: ON

67 OPEN SW O PU SLOT OPEN detect SW input L: ON

68 — O OPEN No used

69 CE O PU AC OFF detect signal input L: AC OFF

70 DOLBY_RESET O OPEN DOLBY IC RESET control L: RESET

71 — O OPEN No used

72 VDD(+5V) — +5V power supply

73 — — +5V No used(Connect to VDD(+5V))

74 70/120 O PD PLAY equalizer control output H: 70µs L: 120µs

75,76 — O OPEN No used

77 AVR_OFF O PD Circuit AVR ON/OFF control H: AVR ON

78 LINE MUTE O PD LINE MUTE control output L: MUTE ON

79 REC MUTE O PD REC MUTE control output L: MUTE ON

80 S.DATA I/O OPEN Serial communication DATA signal

4

CIRCUIT DESCRIPTION

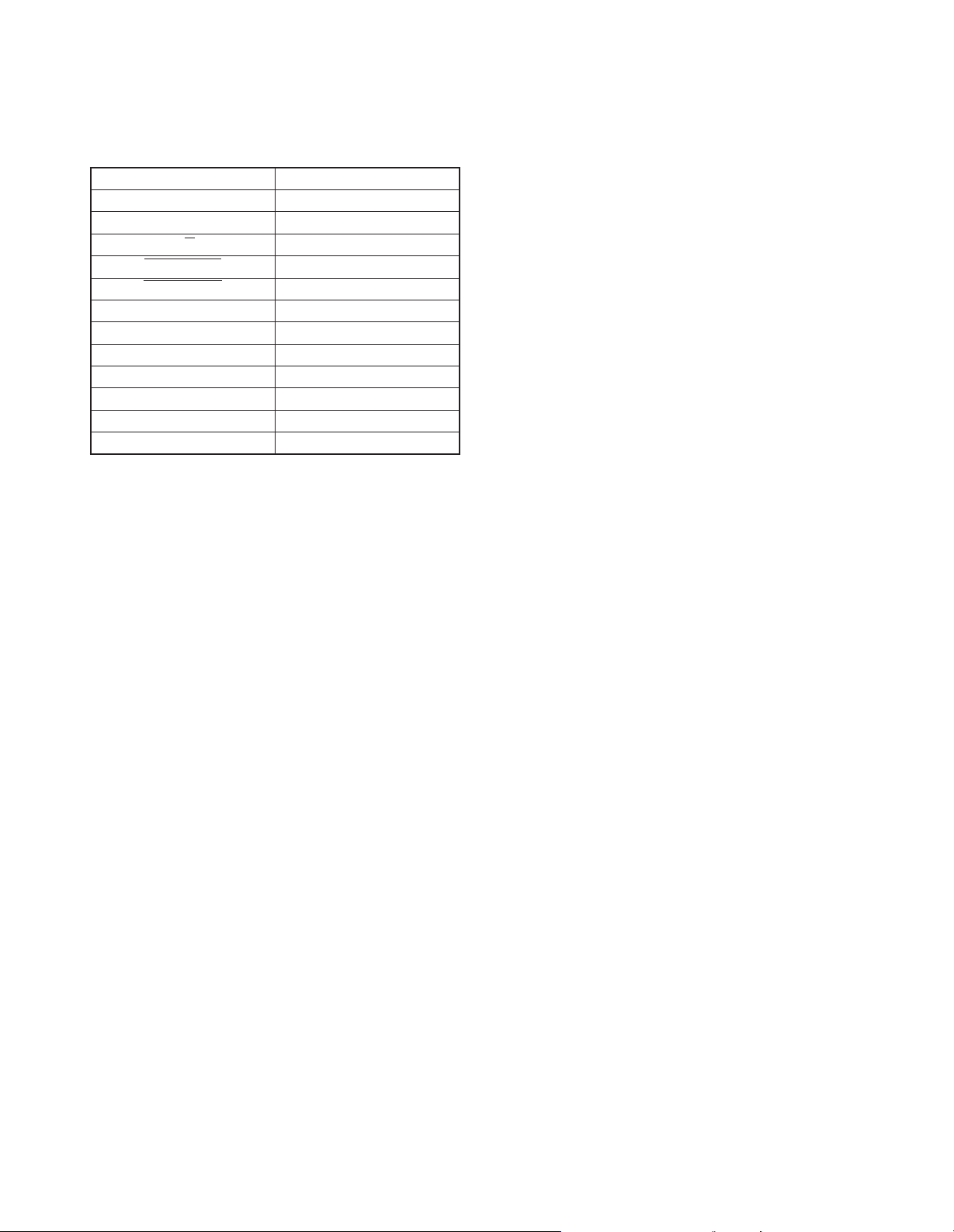

2. DEFAULT STATES

2-1 Main unit default states

ITEM STATE

POWER OFF

DOLBY OFF

R/P PLAY

REC MUTE ON

LINE MUTE ON

BIAS OFF

ERASE OFF

REC LEVEL(E. VOL) -15dB

SOL OFF

CPM

DIRECTION FORWARD

REVERSE MODE ENDLESS MODE

3. TEST MODE

ON(500ms) î OFF

X-VH7

3-5 Set inspection test mode

3-5-1 REC/PB inspection

Press the REC key: 1REC(4sec.)î 2REVERSE(4sec.)

î 3Start PLAY automatically.

But press the REC key with recording again, the recording time be extended for 4 sec per one press.

3-5-2 Test mode initializing condition

Press the STOP key,then be stopped the mechanism

movement.

(But no change of the system IC/IC2 setting up)

And LEDs display normal with the leaf SW.

3-5-3 REC level changeover

Press the CRLS key, changeover REC level.

• LEVEL display: -15dB(LED CRLS blinking)íî0dB(LED

REV.MODE blinking)

3-1 Setting method

While pressing the FWD key, plug the power cord to the

AC wall outlet.(Setting up: MUTE ON)

Set up REC level : -15dB

All LED lighting, then be cancelled to press a key and

insert a tape.

Insert a tape or press the STOP key, then LEDs display

the leaf SW movement of the mechanism.

(ON:LED lighting, OFF:No LED lighting)

DOLBY-B: Mistake REC FWD

DOLBY-C: Mistake REC REV

REV-MODE: PACK DETECT SW

CRLS: CrO2 DETECT SW

3-2 Initializing method

While pressing the EJECT key, plug the power cord to

the AC wall outlet.

Jump out a tape compulsion, then LED STANDBY be

blinked and lighted .

3-3 Cancel test mode

1) AC power OFF: initialize and cancel the test mode.

2) Press the PAUSE key ,then be stopped the mechanism and be cancelled the test mode on POWER ON.

(No jump out a tape compulsion)

3-4 TEST MODE specifications

1) The keys are activated normal except the test mode

indicating key .

2) No mute control by the mode changeover. But mute on

by POWER ON/OFF.

5

Loading...

Loading...