Kenwood X-92-4570-0x Service Manual

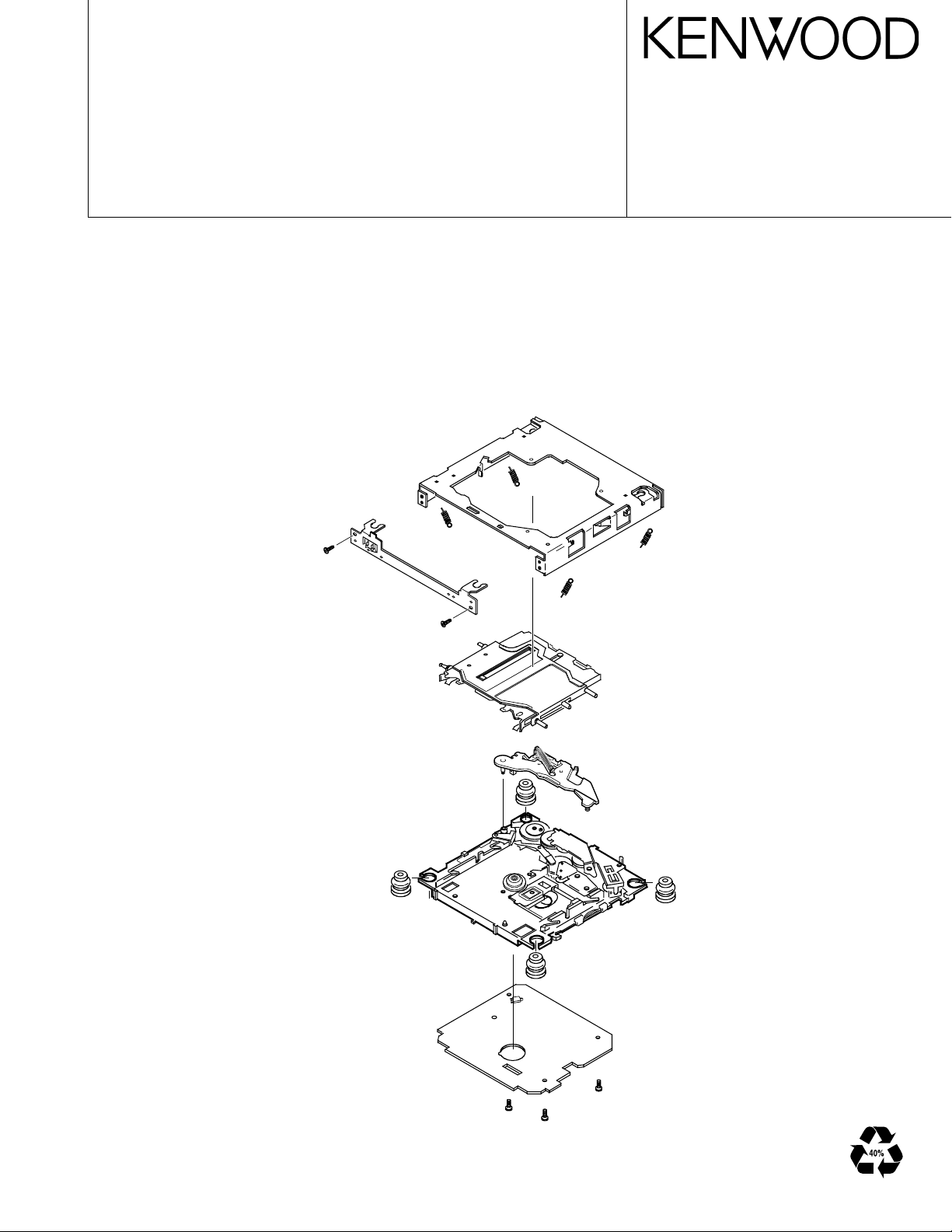

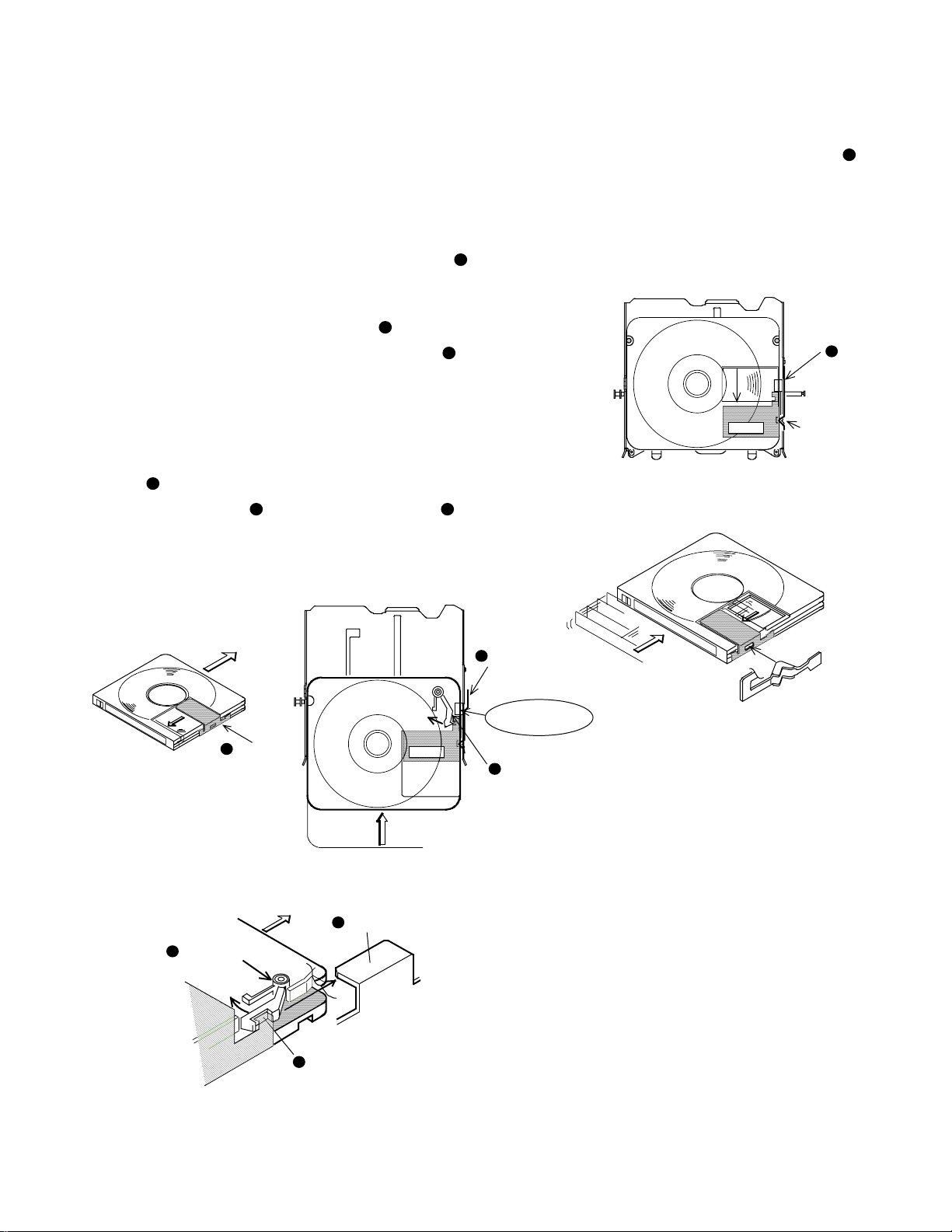

MD MECHANISM ASSY

DESCRIPTION MECHANISM

CONSTRUCTION OF MAJOR PARTS

X92-4110-00 (MDS-3100W)

X92-4110-01 (MDS-3101W)

X92-4570-00 (MDS-3200W)

X92-4570-01 (MDS-3201W)

MP START : Nov. 2001

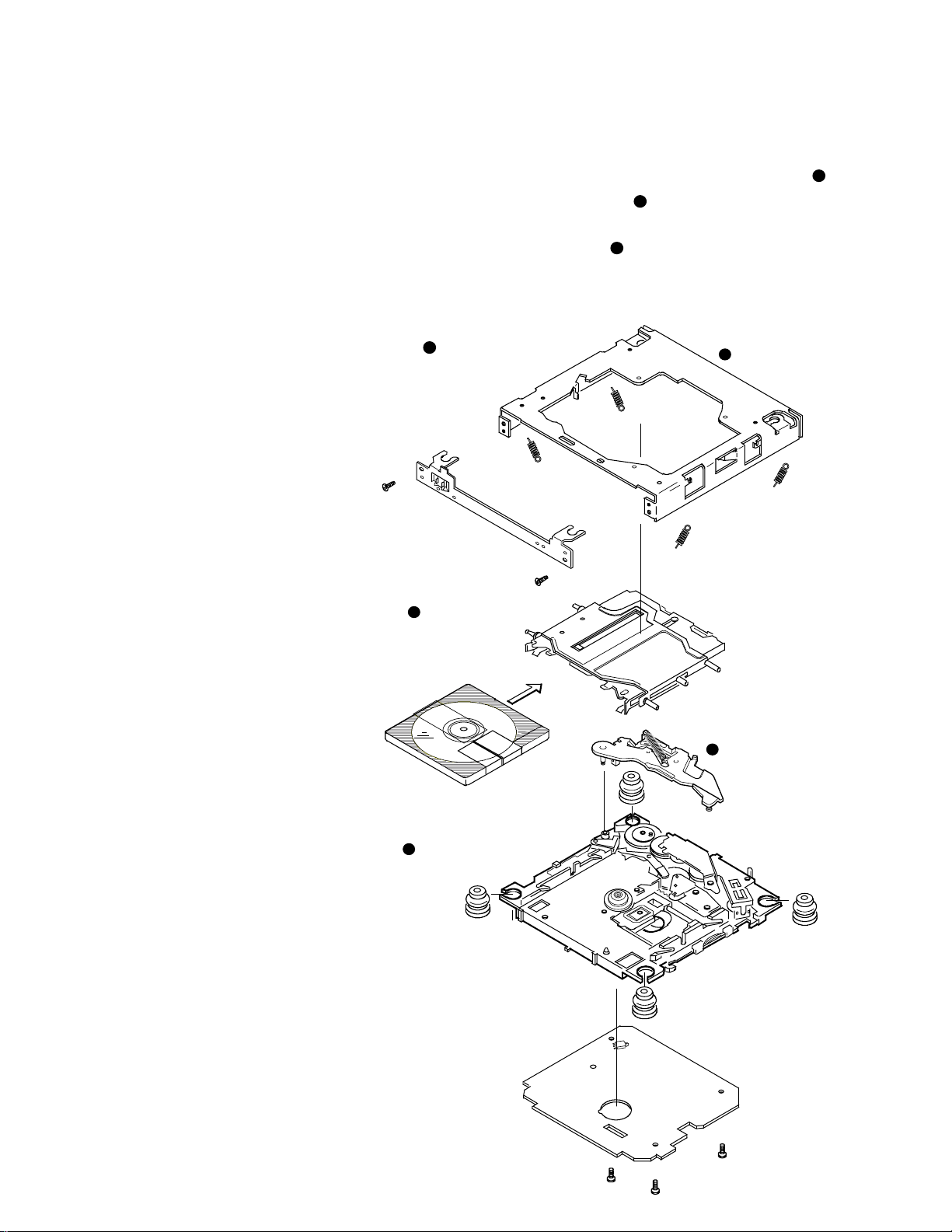

Outer chassis

Front chassis

Upper chassis assy

Mecha. PCB

Travers chassis assy

Loading arm assy

Air damper x4

Suspension spring x4

X92-4110-0x

X92-4570-0x

SERVICE MANUAL

© 2002-3 PRINTED IN JAPAN

B51-7887-00 (N) 517

2

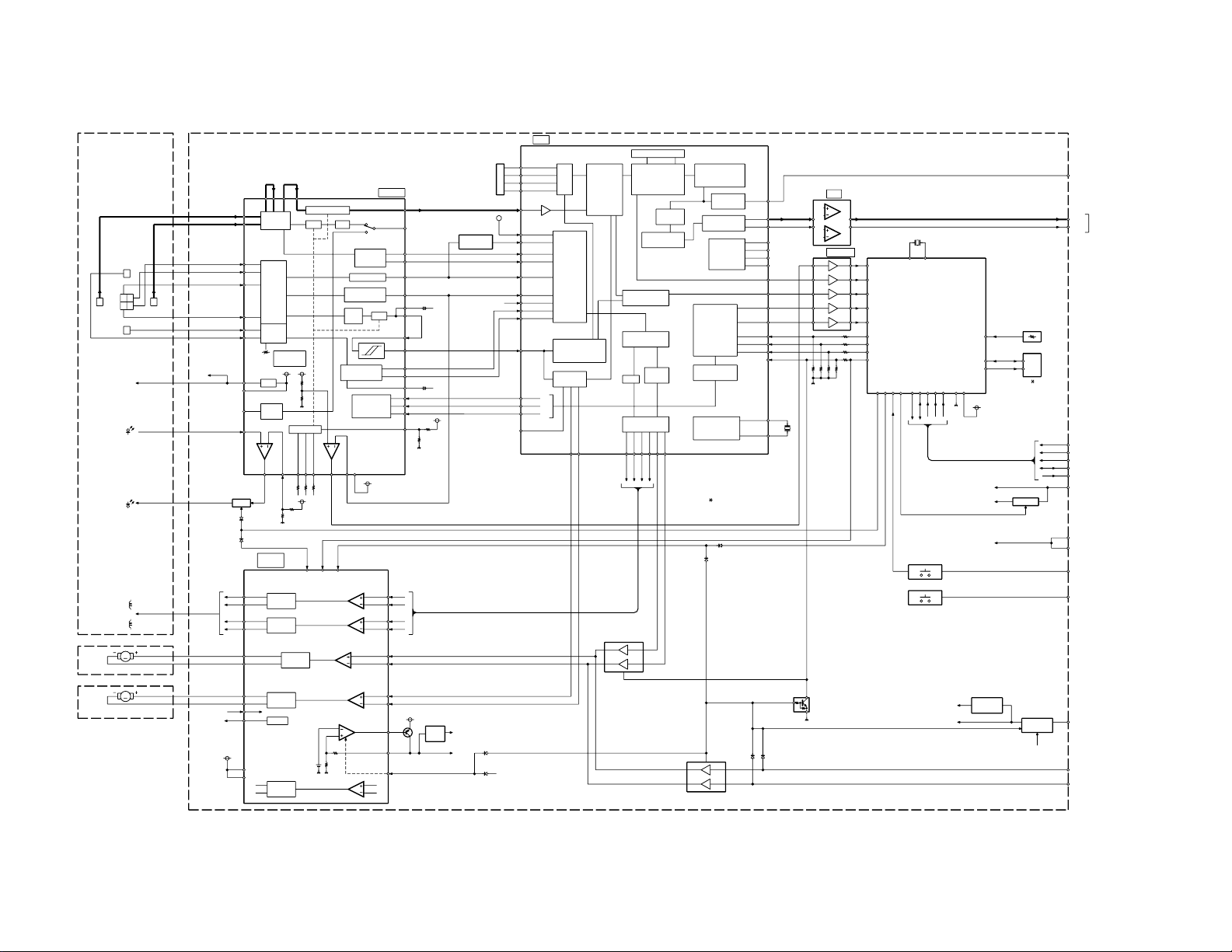

RF AMP

RF AGC & EQ

IC1

BPF P-P

PEAK &

BOTTOM

ABCD AMP

IV AMP

IV AMP

CVB

AMP

TEMP

VICCONV

ERROR AMP

FOCUS

AT

AMP

BPF

TRACKING

ERROR AMP

SERIAL

PARALLEL

DECODER

BALANCE

E-F

FILTER

PLL

DECODER

ACIRC

EFM

MEMORY

RESISTANT

SHOCK

CONTROLLER

DYNAMIC RAM

ATRAC/ATRAC3

DECODER

DIGITAL

FILTER

CONVERTER

D/A

POST FILTER

CONTROL

MONITOR

ANALOG

MUX

ADIP

DEMODULATOR

DECODER

SPINDLE

SERVO

GENERATOR

PWM

APC

DSP

SERVO

CONVERTER

A/D

CLOCK

GENERATOR

AUTO

SEQUENCER

I/F

CPU

PROCESSOR

SUBCODE

IC7

MECHA MI-COM

CH2

DRIVER

CH1

DRIVER

DRIVER

CH4

DRIVER

CH3

VREF

DRIVER

CH5

IC5

LOE/LIM-SW

LOS/EJE-SW

ATRAC/ATRAC3 DECODER

DET.

REFLECT

APC

CB

DA

F

E

JI

DETECTOR

TRACKING

COIL

FOCUS

COIL

M

LOADING/EJECT/SLED MOTOR

SPINDLE MOTOR

M

THERMISTER

IC9

256

SW+5V

EFM/ACIRC DECODER

SHOCK PROOF MEMORY CONTROLLER

DIGITAL SERVO PROCESSOR

DIGITAL SIGNAL PROCESSOR

1M-WORD 4BIT DYNAMIC RAM

DIGITAL FILTER. D/A CONVERTER

IC2

FOCUS/TRACKING COIL DRIVER

SPINDLE/SLED MOTOR DRIVER

IC4

LOADING/EJECT MOTOR DRIVER

REG.

A3.3V

IC6

A. 8V SW

8BIT

Q8

IC11

IC10

2.5V

REG.

IC3

AUDIO I/F

DIGITAL

Q1,2

5ch BTL

DRIVER

Q4

RF AMP

Q3

DSP

LPF

IC8

Q7

Q5,6,9

1

2

4

5

6

7

8

9

3

15

14

I

J

A

B

C

D

E

F

11

12

22

23

25

41

42

19

APC

APCREF

EQADJ

3TADJ

WBLADJ

FZC

RF

AUX1

AUX2

PEAK

BOTTOM

ABCD

FE

VC

SWDT

SCLK

XLAT

FOCONT

114

113

848577

76

112

111

SPFD

SPRD

FFDR

FRDR

TFDR

TRDR

SFDR

SRDR

25

28

5

15

21

20

MNT0

MNT1

MNT2

MNT3

XINT

SQSY

SENS

SRDT

SCLK

SWDT

XLAT

XRST

44

45

46

62

18

20

19

17

16

FZC

XINT

SQSY

SENS

SRDT

SCLK

SWDT

XLAT

XRST

12

56

231115

1314433659

60

LDON

SDMUTE

LIMIT SW

P-ON

AMUTE

MSDA

MSCL

MSTOP

MRST

TYPE 1

TYPE 2

33

7

8

HOT

ESDA

ESCL

20

19

17

16

30

29

23

22

26

25

24

TRK+

TRK-

FCS+

FCS-

LOAD/SLED+

EJECT/SLED-

SPDL+

SPDLVC

VREF0

VCC2

VCC1

10

11

12

13

7

6

8

9

28

27

3

14

TFDR

TRDR

FFDR

FRDR

LOAD/SFDR

EJECT/SRDR

SPFD

SPRD

REG IN

REG OUT

ENREG

1

11

9

14

13

20

19

15

18

5

6

2

21

7

8

DOUT

L-CH

R-CH

MRST

MSTOP

MSCL (IIC BUS)

MSDA

AMUTE

BU5V

S5V

S5V

LOE/LIM-SW

LOS/EJE-SW

LOAD

EJECT

36

30

29

31

34

35

37

33

38

474648

40

10

28

26

32

17

18

20

27

16

41

40

MORF RFO

AUX 1

FOCONT

XSTBY

ADFG

22.579MHz

6

7

8

35

16

14

13

10

9

11

104

105

106

107

102

84

93

80

81

82

83

67

73

72

71

70

85

92

91

5

11

13

3

1122

10

6

4

8.388MHz

MUTE 1

MUTE 2

1

2

MUTE 3

36

CH1,2

CH3

CH4

21

67

JITTER

RECORD IN

VC

TE

SE

VC

VC

VC

VC

PD

LD

STBY

TO CH5 OP

S+B

SW+5V

S5V

+3.3V

6

5

BU+5V

1.2Vrms

1kHz 0dB

SW+5V

TO SERVO DRIVER

BU+5V

ILCC

LDON

AUDIO +B

DAVDD

SW+5V

A8V

12

34

+2.5V

MOTOR ASSY

DPU1

OPTICAL PICKUP BLOCK

MOTOR BLOCK

MD UNIT

BUFFER

X92-4110-0x/4570-0x

BLOCK DIAGRAM

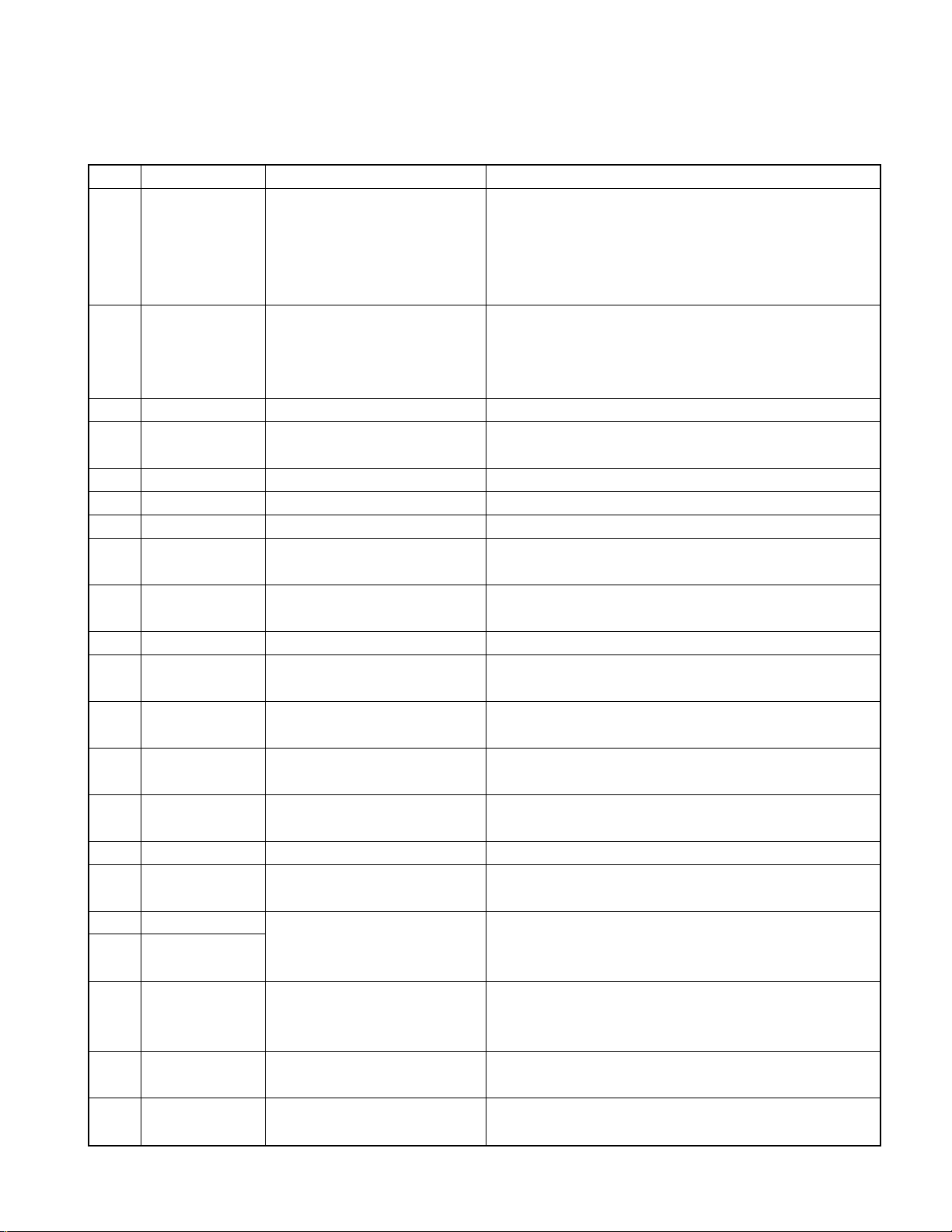

X92-4110-0x/4570-0x

COMPONENT DESCRIPTION

●MD UNIT(X33-3160/3180-00)

Ref.No.

IC10 TC7WH126FU 3-State buffer

IC11 TC7WH126FU 3-State buffer

Component name Application/Function Operation/Condition/Compatibility

RF amplifier(pits and groove selector type, AGC, EQ), Gain selector

type I-V amplifier, Amplification of the light intensity signal output,

IC1 CXA2523AR RF amplifier for MD Peak hold output, Bottom hold output, FE output, TE output, SE

output, ADIP binary output, VREF output, APC PD amplifier and

FZC formation comparator.

EFM decoding, EFM digital PLL, ACIRC decoding, auto link

IC2 CXD2667R Digital signal processor for MD

IC3 S-817A25ANB +2.5V AVR Power supply for IC2 internal logic circuits.

IC4 LA6572 5 Ch BTL driver

IC5 NJM4580M1 Low pass filter 2nd low pass filter for audio signals.

IC6 LP2982-3.3 A.3.3V AVR Power supply for DAC and LPF operational reference voltage.

IC7 TC74HCT7007AF Buffer Buffer and logic level conversion from IC1,2 to IC8.

780076YGK-R11

IC8

(X33-3160-00)

780076YGK-R14

IC8

(X33-3180-00) Adapted to MD Group.

IC9 W05-0906-00 EEPROM Servo coefficients and servo adjustment data backup memory

2SA1362(Y) or

Q1

2SB1295

DTA114EUA or

Q2

KRA302 or UN5111 turned off.

Q3 2SC4116(Y) Disc refrection detect SW On when focusing point is passed during upward search.

Q4 MCH6101 D.3.3V AVR driver

Q5 DTA143XUA

DTC143EUA or A.8V SW

Q6

KRC401

KTA2014(Y,GR) or

Q7 2SA1576A or SW5V SW

DTC143EUA or

Q8

KRC401 IC10's outputs is Hi-Z operation.

DTC143EUA or

Q9

KRC401 A.+8V is supplying to A.3.3V AVR and low pass filter circuit.

Mecha.MI-COM. Servo control, memory control, system control and interfacing.

Mecha.MI-COM.

APC(Auto Power Control) LD power control

LD SW

2SB1218A

IC10 OUTPUT Hi-Z SW

A.8V SW

processing, ADIP decoding, Digital servos(focusing, tracking, sled,

spindle CLV), ATRAC/ATRAC3 decoding, 1 bit D/A converter,

Analogue post filter and 4M(1Mx4) DRAM built in.

Focusing coil, tracking coil, spindle motor and sled motor driver, disc

loading and eject operation.

Servo control, memory control, system control and interfacing.

When 1, 7 pin goes Hi, Sled servo operation is selected.

When 1, 7 pin goes Lo, IC10's outputs is Hi-Z operation.

When 1, 7 pin goes Hi, Loading/Eject operation is selected.

When 1, 7 pin goes Lo, IC11's outputs is Hi-Z operation.

When Laser OFF mode is selected, Q2's base goes Lo, and Q1 is

When Loading/Eject operation or MD source is selected, Q4's output

is supplying D.3.3V to IC1-3, IC10 and IC11.

When SW5V SW is turned on, Q5 and Q6 are turned on, and A.+8V

is supplying to A.3.3V AVR and low pass filter circuit.

When MD source is selected, P-ON output goes Lo, and BU5V is

supplying to microprocessor peripheral circuits and A.8V SW.

When Loading/Eject operation is selected, Q8's base goes Hi, and

When Loading/Eject operation is selected, Q9's base goes Hi, and

3

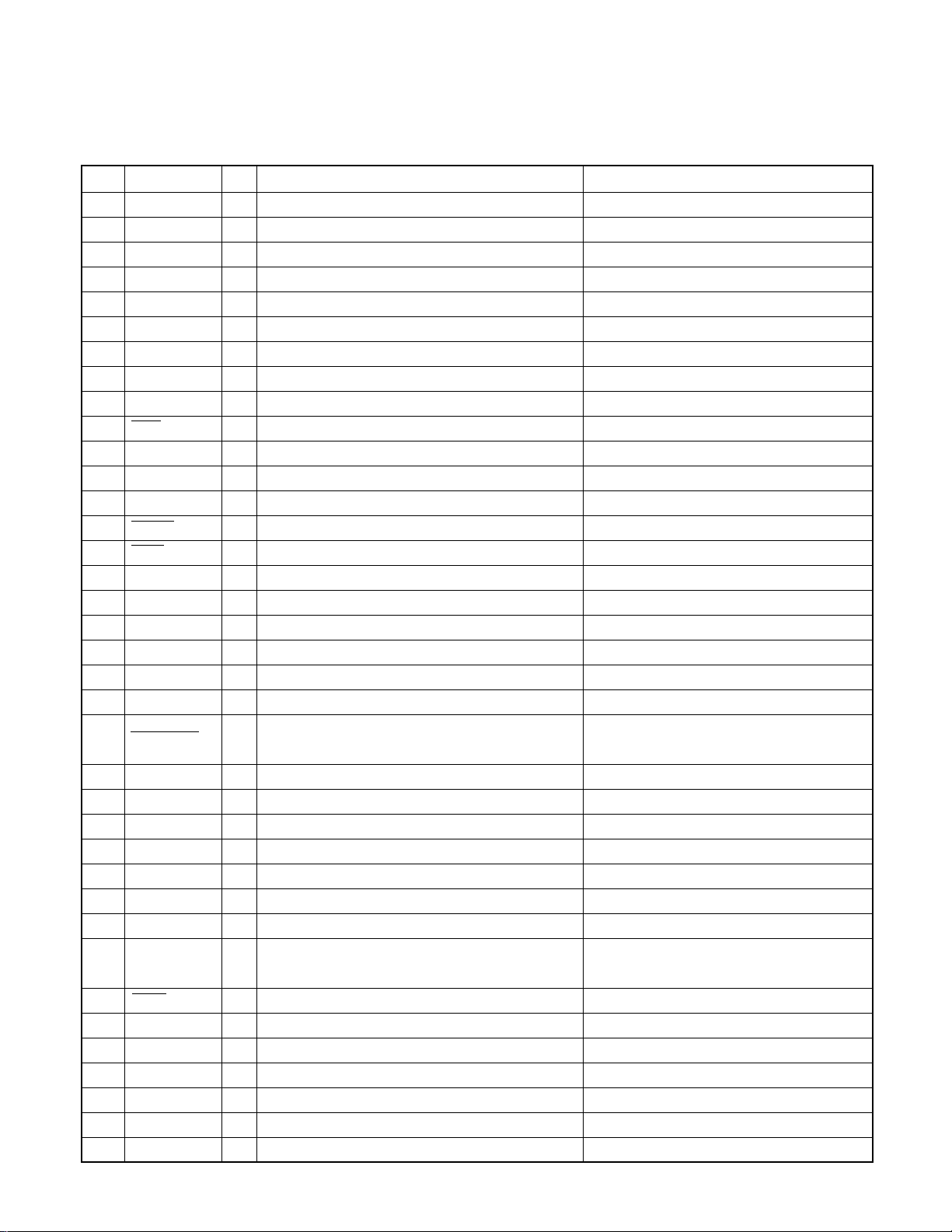

X92-4110-0x/4570-0x

MICROCOMPUTER’S TERMINAL DESCRIPTION

●IC8 (MD UNIT: X33-3160/3180-00)

Pin No.

5,6 NC O Not used (N.C.)

10 VDD0 - Positive power supply connection terminal Connected to BU5V lines.

11 P-ON O Unit internal power supply control output Lo: Power on

12 LDON O Laser APC control output Hi: LD on

13 MSDA I/O

14 MSCL I/O

15 AMUTE O Audio muting output Lo: Audio signal muting

16 XRST O DSP LSI & servo driver reset output Lo: Reset

17 XLAT O Latch output to DSP LSI Latch at fall down edge pulse

18 SRDT I Serial data input from DSP LSI

19 SWDT O Serial data output to DSP LSI

20 SCLK O Shift clock output to DSP LSI

21 FLRxD O Data line for flush ROM writing Not used (N.C.)

22 FLTxD O Clock line for flush ROM writing Not used (N.C.)

23 LOE/LIMSW I

24 VDD1 - Positive power supply connection terminal Connected to BU5V lines.

25 AVSS - Ground connection terminal Connected to GND lines.

26 MECHA SEL I Mechanism destination selection input Not used (Connected to GND line)

27-31 NC I Not used (Connected to GND line)

32 AUX1 I Not used (Connected to GND line)

33 HOT I Temperature detection input Vth On: 3.87V, Vth Off: 3.74V

34 AVREF I AD converter reference voltage input terminal

35 AVCON O AVREF control output

36 MRST I Reset input from the system microprocessor Lo: Reset

37 XT2 - Sub clock resonator connection terminal 2 Not used (N.C.)

38 XT1 I Sub clock resonator connection terminal 1 Not used (Connected to BU5V line)

39 VPP I Flush ROM writing terminal Not used (Pull down to GND line)

40 X2 - Main clock resonator connection terminal 2

41 X1 I Main clock resonator connection terminal 1

42 VSS1 - Ground connection terminal Connected to GND lines.

Pin Name I/O Description Processing Operation

1 DEEM O De-emphasis output (Lo: De-emphasis) Not used (N.C.)

2 CSN O External DAC latch line Not used (N.C.)

3 CCLK O External DAC clock line Not used (N.C.)

4 CDTI O External DAC data line Not used (N.C.)

7 ESDA I/O EEPROM serial data line

8 ESCL I/O EEPROM serial clock line

9 VSS0 - Ground connection terminal Connected to GND lines.

Serial data line with the system microprocessor (I2C BUS)

Serial clock line with the system microprocessor (I2C BUS)

Pickup most inner position detect & loading end detect Hi: Loading end

input Hi→Lo: Pickup most inner position detected

Hi: AVREF reference voltage

Lo: AVREF current cut-off (Standby)

4

X92-4110-0x/4570-0x

MICROCOMPUTER’S TERMINAL DESCRIPTION

Pin No.

43 MSTOP I Standby control input from the system microprocessor

44 FZC I FZC interrupt request input

45 XINT I Interrupt request input form DSP LSI Lo: Interrupt status occurrence

46 SQSY I Sub-code Q sink or ADIP sink input

47 FG I FG pulse input (3 hole pulse equivalent) Not used (Connected to GND line)

48 NC O Not used (N.C.)

49 LDEJ IN I

50 LADJ1 I Manual adjustment mode input Hi: Manual adjustment (Focussing Bias

51 TEST3 I Special test mode terminal 3 Not used (Pull down to GND line)

52

53 AGC PASS I Mode switching terminal without automatic adjustment Not used (Pull down to GND line)

54 SE MNT I SE display mode switching input Not used (Pull down to GND line)

55 4M/16M I DRAM size switching input Not used (Connected to GND line)

56 SDMUTE O Sled driver muting control output Hi: Muting on

57 AUDIO INV I DAC output polarity selection input Lo: Polarity non-inverted, Hi: Polar ity inverted

58 M REM O Test mode memory remains output Not used (N.C.)

59 TYPE1 I Destination selection input 1 Not used (Connected to GND line)

60 TYPE2 I Destination selection input 2 Not used (Connected to BU5V line)

61 C1 COUNT I C1 error count display mode switching input Not used (Pull down to GND line)

62 SENS I Internal status input from DSP LSI

63 TEST0 I Test mode terminal 0 Not used (Pull down to GND line)

64 TESTE I Test mode terminal of EEPROM external input Not used (Pull down to GND line)

Pin Name I/O Description Processing Operation

Lo: Standby mode

Lo→Hi: Operation mode (Standby mode released)

Lo→Hi: Media detection (effective only at the time

of the disc detection)

LOAD/EJECT output monitor input form the system When Hi is detected, mechanism microprocessor

microprocessor moves to the play/stop mode.

Lo: Normal operation

adjustment)

IVRTBAL PASS

I Mode switching terminal without automatic adjustment Not used (Pull down to GND line)

5

X92-4110-0x/4570-0x

DESCRIPTION OF MECHANISM OPERATION

1) This mechanism permits the re-loading of a cartridge after

it has been ejected.

2) A cartridge cannot be inserted during power-off due to builtin automatic push-out cartridge (This is for preventing the

breakage of the mechanism).

1. Configuration of main components

This mechanism consists of main components as shown

in the figure below.

The main purpose of the traverse chassis assembly (

1

is to hold a cartridge and read its signals form it.

The main purpose of upper chassis assembly (

loading arm assembly (

out a cartridge.

The outer case (

assembly and limiting the positions of the mechanism compo-

nents.

In addition, there is a mechanism PCB.

)

) is to mechanically pull in and push

3

) is for supporting the traverse chassis

4

4

Outer case

2

) and

2

Upper chassis assembly

Cartridge

Traverse chassis assembly

1

Mechanism PCB

Turntable

Loading arm assembly

3

Optical pickup

Air damper x 4

6

X92-4110-0x/4570-0x

6

DESCRIPTION OF MECHANISM OPERATION

2. Operational explanation

[1] Loading of cartridge

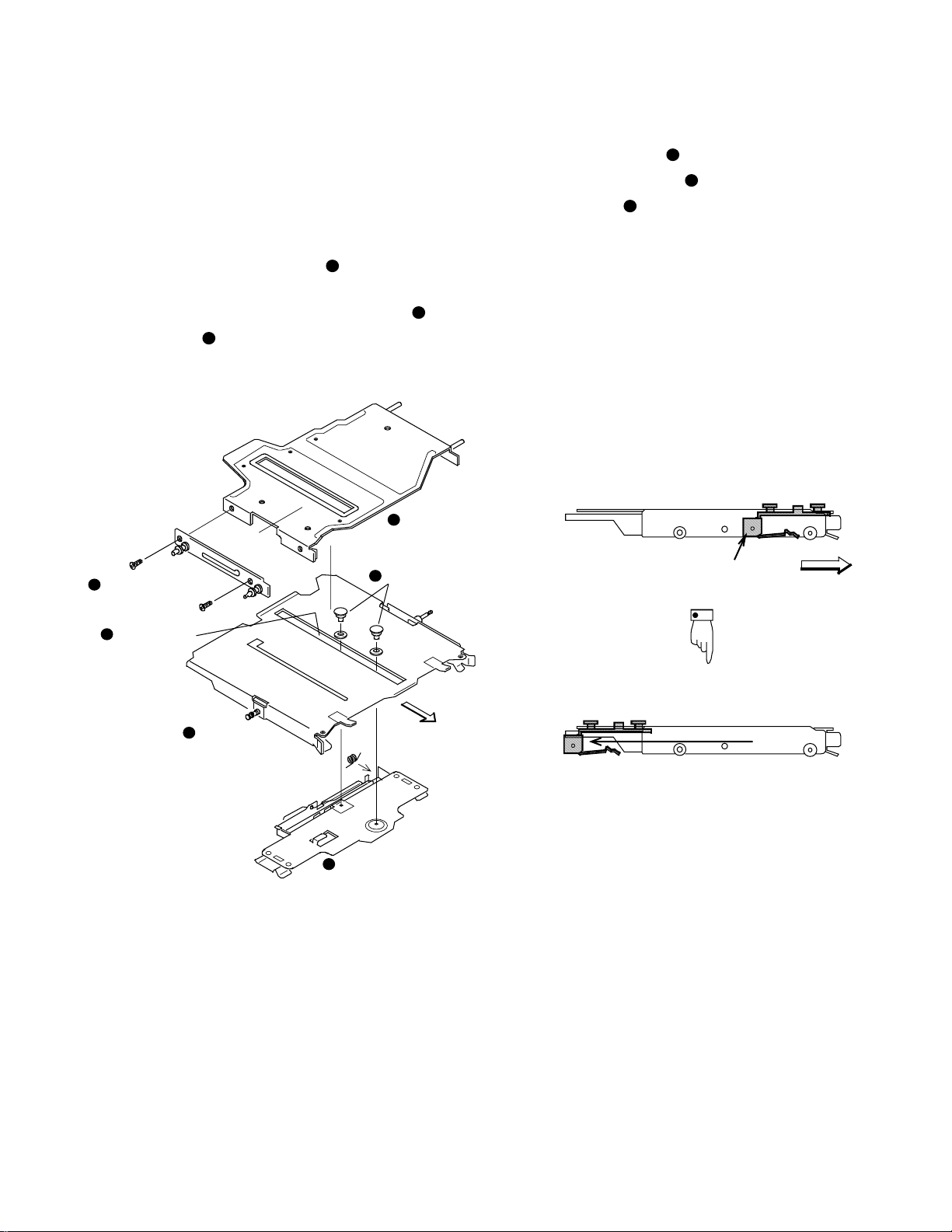

(1) Construction of upper chassis

The upper chassis assembly consists of the carrier f or holding a cartridge and pulling in it up to the position when loading

is to be completed, the carrier base (

moves up and down to playback after opening the shutter of

the cartridge, and the assembly of the UD PLATE (

the UD PLATE L (

rier base.

3

UD PLATE L

) respectively for pushing down the car-

3

) that mechanically

1

2

UD PLATE

2

4

Caulking pins

) and

The carrier assembly (

rier base with caulking pins (

elliptical opening (

) of the carrier base.

5

[Left side view]

Initial position

) is caulking-secured to the car-

) and operates along the long

4

Carrier assembly

Front side

5

Long elliptical

opening

Carrier base

1

6

Carrier assembly

Operation completed position

Front side

(Sliding operation)

7

X92-4110-0x/4570-0x

DESCRIPTION OF MECHANISM OPERATION

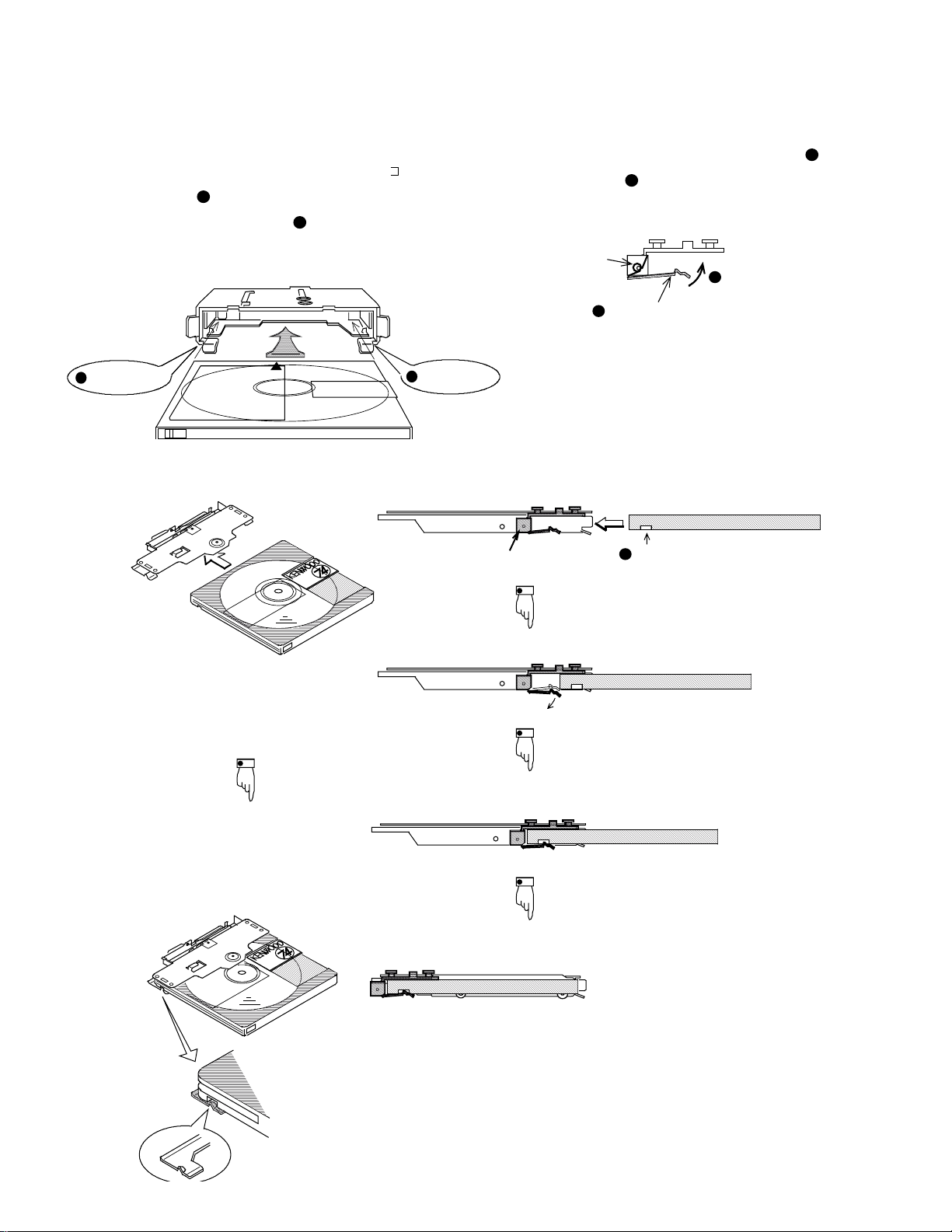

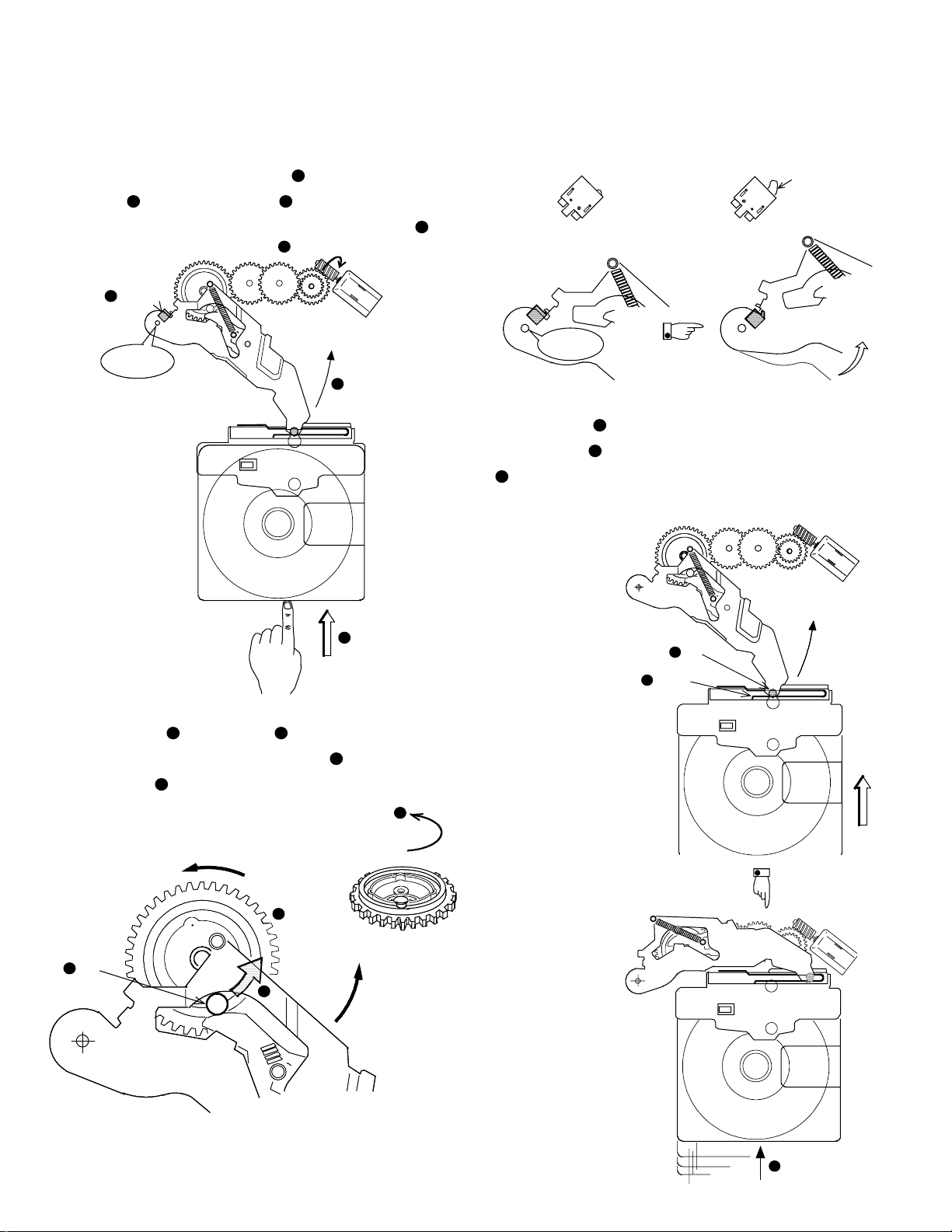

(2) Insertion of cartridge

When a cartridge is made to be passed into the “ ”-char-

acter-shaped inlet (

pushed, the hole of the cartridge (

protrusion for holding the cartridge in the carrier assembly to

hold the cartridge.

1

Inlet of cartridge

) of the carrier base and is moreover

1

) is engaged with the

2

Carrier base

1

Inlet of cartridge

[Flow up to insertion of cartridge]

The sub-chassis under the carrier assembly (

been forced upward (

Spring

3

Initial position

Carrier assembly

) by the force of the spring.

4

4

Pushing force

Sub-chassis (bottom side)

Hole

2

Disc

3

) have

Side A

The bottom portion of a cartridge pushes and opens the sub-chassis.

Condition in which a cartridge is held

Cartridge loading completed position

8

X92-4110-0x/4570-0x

Plate spring

Shutter lock portion

Cartridge

Shutter opens

Fixture

7

Shutter

DESCRIPTION OF MECHANISM OPERATION

(3) Opening/closing construction of disc shutter

A MD (mini-disc) is entirely covered by a plastic case in

order to protect the disc. The disc is not usually touched directly but the disc is exposed to receiv e the laser beam during

recording and playback.

For this reason, a cartridge is provided with a shutter(

1

and when the shutter is opened to record and playback, a part

of the disc can be exposed.

The shutter is locked by the shutter lock (

This shutter is opened or closed by the plate spring (

).

2

3

) at

the right side within the carrier base.

1) When a cartridge is loaded while being held by the carrier assembly, the car tridge slides into the carrier base .

(See “(2) Insertion of cartridge.”) The claw of the shutter

) then slips when the bending-shaped member of

(

6

the carrier base (

) pushes the shutter lock (2) of

4

the cartridge.

Carrier base assembly

2) Next, the plate spring within the carrier base (

7

) is in-

serted into the window of the shutter and the shutter is

held by it, and the shutter is then opened when only the

cartr idge moves. (The bending-shaped member stops

against the shutter, thereby functioning as a stopper and

),

thereafter the shutter is opened.)

Cartridge

Direction of insertion

Disc

2

Shutter lock

1

Shutter

6

Shutter

Cartridge

4

Bending-shaped member

Claw of shutter

Shutter

3

Plate spring

Bending-shaped

member

2

Shutter lock

9

X92-4110-0x/4570-0x

Before a cartrigde is inserted

(Position in which the switch is off)

After a cartridge is inserted

(Position in which the switch is on)

Actuator

Center of

rotation

DESCRIPTION OF MECHANISM OPERATION

(4) Rotation of loading motor

When a cartr idge is inserted (

pushed (

), so that the switch (3) within the mechanism

2

PCB is turned on, and the loading motor starts to rotate (

3

Switch

Center of

rotation

Loading arm

), the loading arm is

1

Loading motor

4

2

).

4

(6) Loading a car tridge

Since the pin (

with the spring (

(

) when the carrier slides along with the rotational opera-

11

) at the end of the loading arm is coupled

9

) within the carrier, a cartridge is pulled in

10

tion of the loading arm.

(5) Operation of loading arm

The cam gear (

ing arm. This pin pulls up the loading arm (

gear rotates (

7

[Start of pulling in]

Pin

6

Cartridge

1

) has the pin (6) engaged with the load-

5

) when the cam

8

).

7

Cam gear

5

8

[Start of pulling in]

[Completion of pulling in]

10

9

Spring

Pin

Carrier

10

Loading arm

11

Loading...

Loading...