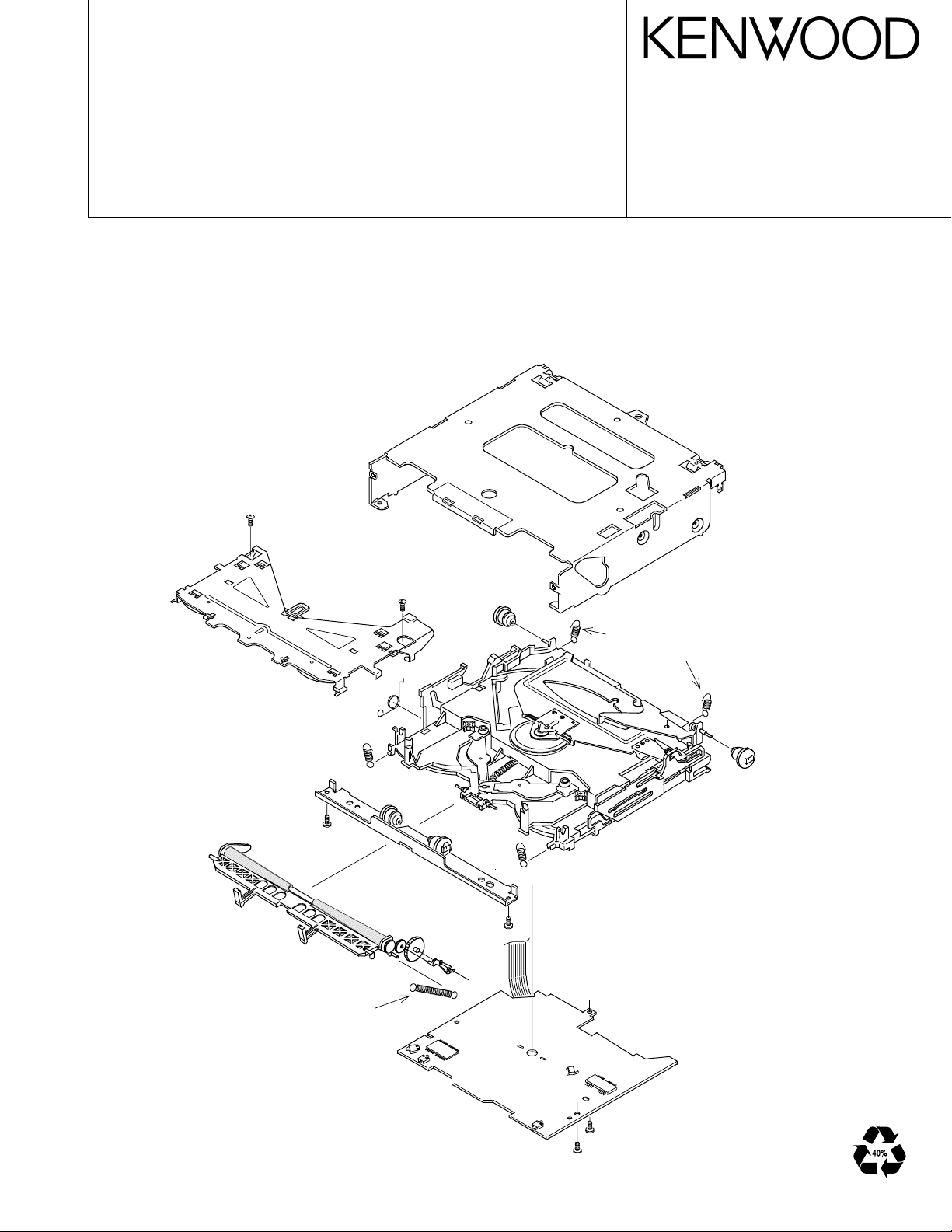

CD MECHANISM ASSY

X92-4470-0x

SERVICE MANUAL

DESCRIPTION MECHANISM

X92-4470-00 (DXM-6500W)

X92-4470-01 (DXM-6501W)

X92-4470-02 (DXM-6502W)

X92-4470-03 (DXM-6503W)

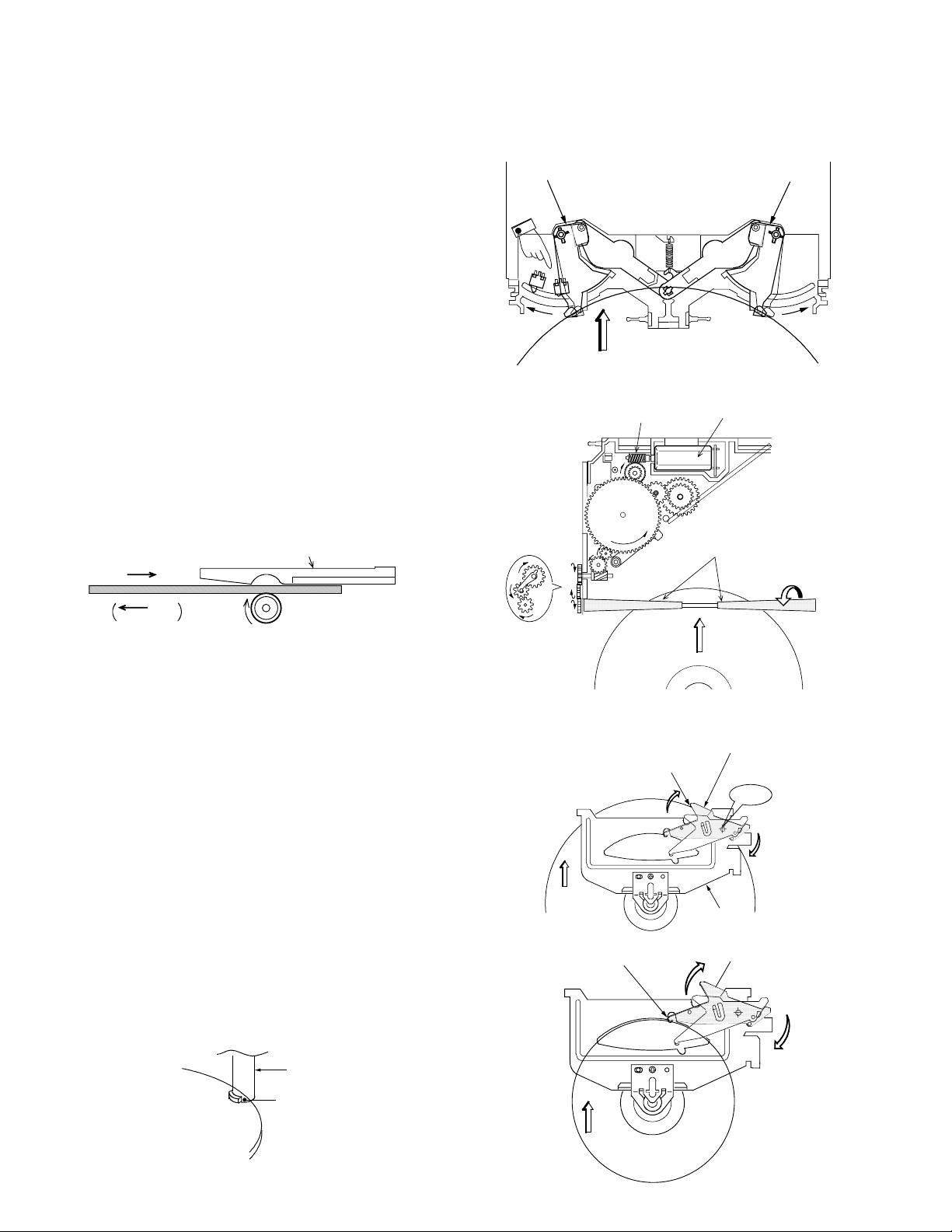

CONSTRUCTION OF MAJOR PARTS

© 2002-1 PRINTED IN JAPAN

B51-7899-00 (N) 3412

outer-chassis

disc guide assy

damper bracket

roller lever assy

dumper (X4)

floating spring (X4)

traverse chassis assy

roller spring

Mecha PCB

X92-4470-0x

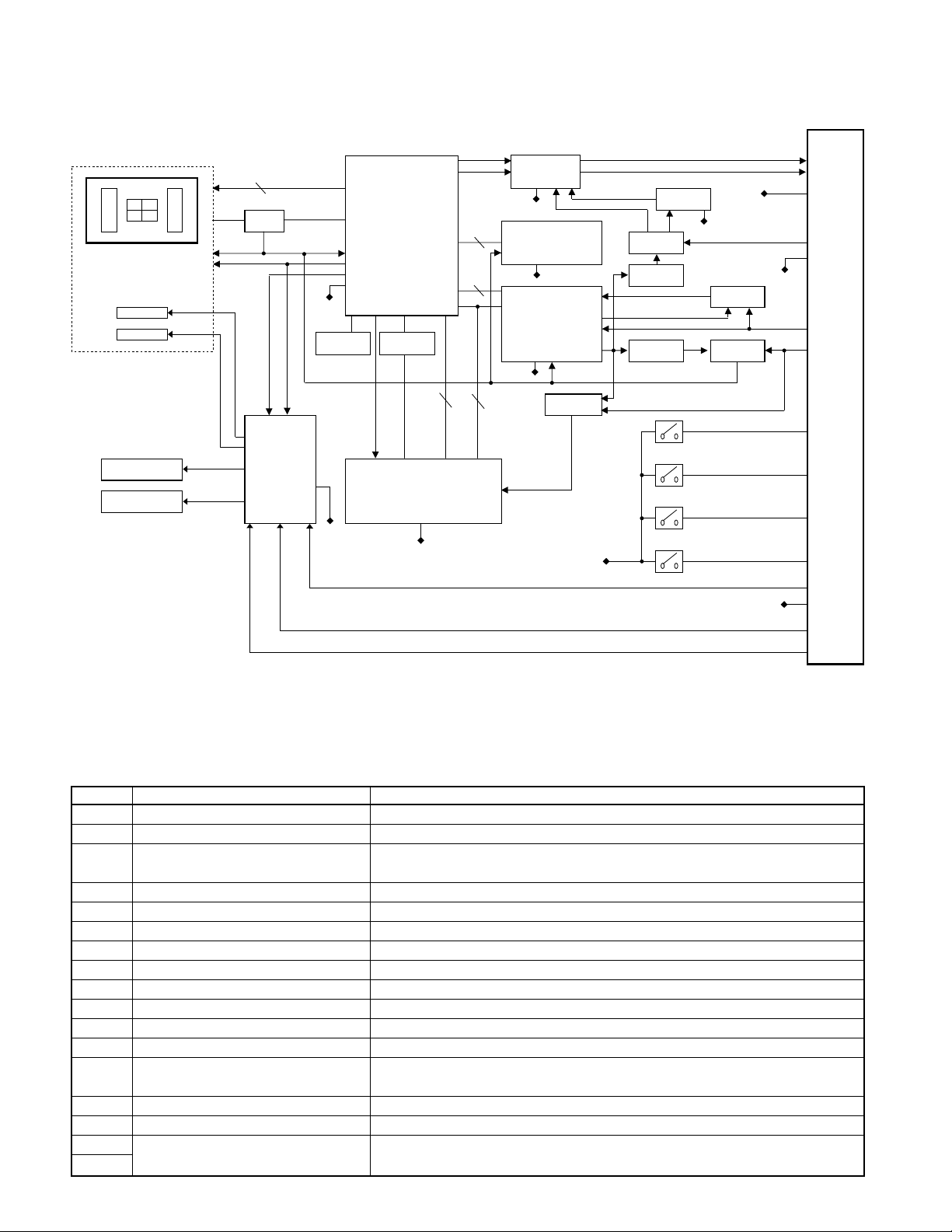

BLOCK DIAGRAM

Pick-Up

B

A

E

C

D

Tr Coil

Fo Coil

Spindle Motor

Loading & Sled

Motor

A.GND

SW

0-01 Only

Mother Board

R-ch

L-ch

A.GND

A.+8V

D.GND

Bu.+5V

D4.7VD3.3VReg

Loe/Lim SW

8Eje SW

12Eje SW

S7.5V

S.GND

IC10

7

F

Q2

APC

IC4

Motor Driver

D.GND

X2

Clock

16.93MHz

16.93MHz

S.GND

1Chip IC

Servo Processor

RF Amp

MP3 Decorder

Vref

IC8

+

+

X3

Clock

24.57MHz

WMA Decorder

D.GND

9

IC12

LPF

A.GND

IC11

30

9

16

DRAM

D.GND

IC5 Q1 D.GND

/PON

µ-Com

D.GND

IC3

2.5V Reg

D.GND Los SW

IC6

A3.3 Reg

Q4

8V SW

Q5

SW

SW5V

Q3 IC2

SWPON

S3

S4

S2

S1

COMPONENTS DESCRIPTION

●CD PLAYER UNIT (X32-5220-0x)

Ref.No. Application/Function Operation/Condition/Compatibility

IC2 D3.3V AVR Power supply for the pickup, IC5, IC8-10 and IC11

IC3 D2.5V AVR Power supply for IC8

IC4 4CH BTL driver

IC5 Mecha. control MI-COM.

IC6 A3.3V AVR Power supply for DAC, LPF operational reference voltage

IC7 Level shifting (3.3V→5V) Buffer and logic level conversion from IC10 to IC5

IC8 WMA decoder

IC9 Clock buffer for WMA

IC10 RF amplifier+CD DSP+MP3 decoder

IC11 4M bit DRAM For data buffer

IC12 Low pass filter 2nd low pass filter for audio signals

IC13 Schmitt trigger for WMA

Q1 SW5V SW

Q2 APC LD power control

Q3 D3.3V SW When PON (10pin) goes Hi, Q3 is turned on, and IC2 is working.

Q4

Q5 and IC12.

A.8V SW

Focusing coil, tracking coil, spindle motor and sled motor driv er, disc loading and

eject operation.

When PON (11pin) goes Lo, Q1 is turned on, and SW5V is supplied to IC7 and

AVREF (73PIN).

When PON (10pin) goes Hi, Q4 and Q5 are turned on, and A.8V is supplied to IC6

Lo/Ej

Motor

2

X92-4470-0x

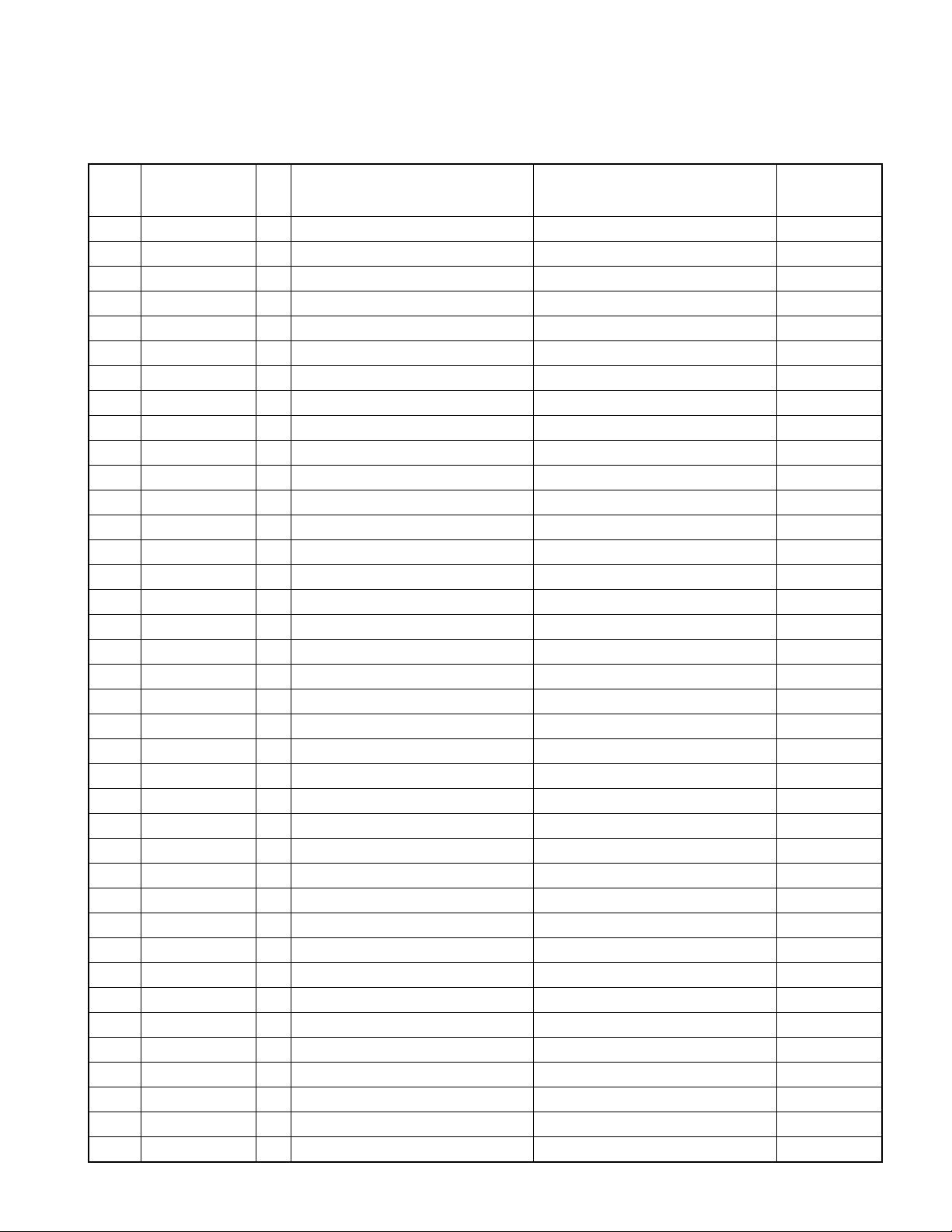

MICROCOMPUTER’S TERMINAL DESCRIPTION

MECHANISM MICROCOMPUTER (IC5 : X32)

processing

Pin Name I/O Purpose Processing operation description description in

STBY

1~5 NC O Not use Low fixation Low

6 VDD - 5V potential

7 GND - GND potential

8,9 NC O Not use Low fixation Low

10 PON O Power ON/OFF control H : ON L : OFF Low

11 /PON O Power ON/OFF control H : OFF L : ON High

12 LOE/LIM_SW I Down limit SW detection L : inside circumference detection Hi-Z

13 8EjE_SW I Not use Low fixation Hi-Z

14 LOS_SW I Not use Low fixation Hi-Z

15 12EjE_SW I Not use Low fixation Hi-Z

16,17 NC O Not use Low fixation Low

18 IC/Vpp - Writing voltage (FLUSH) 19 MUTE_L O Lch audio mute control L : mute ON H : mute OFF Low

20 MUTE_R O Rch audio mute control L : mute ON H : mute OFF Low

21~25 NC O Not use Low fixation Low

26 EFLG I WMA error detection H : error L : not error Out-Low

27 WAIT I Weight control signal detection Out-Low

28 FOK I Focus condition detection H : Focus OK L : Focus NG Out-Low

29,30 NC O Not use Low fixation Low

31 RESET I Reset detection H : normal L : reset Hi-Z

32 XT1 I Not use Hi-Z

33 XT2 - Not use 34 REGC 35 X2 36 X1 I Hi-Z

37 Vss - GND potential

38 VDD - 5V potential

39 NC O NC Output stop Low

40 WRL O Multiplexer WRITE signal _LBEN : 61002 (not use) _WRL : 63760 Out-Low

41 NC O Not use Low fixation Low

42 R/W O Multiplexer _R/W signal _R/W : 61002 _WRH : 63760 (not use) Out-Low

43 DSTB,RD O Multiplexer DSTB or RD signal _DSTB : 61002 _RD : 63760 Out-Low

44 ASTB O Multiplexer ASTB signal Out-Low

45,46 NC O Not use Low fixation Low

47~54 AD0~7 I/O Multiplexer address/data Out-Low

55 BVdd - Power supply for bus inter face

56 BVss - GND for bus inter face

57~64 AD8~15 I/O Multiplexer data/address Out-Low

3

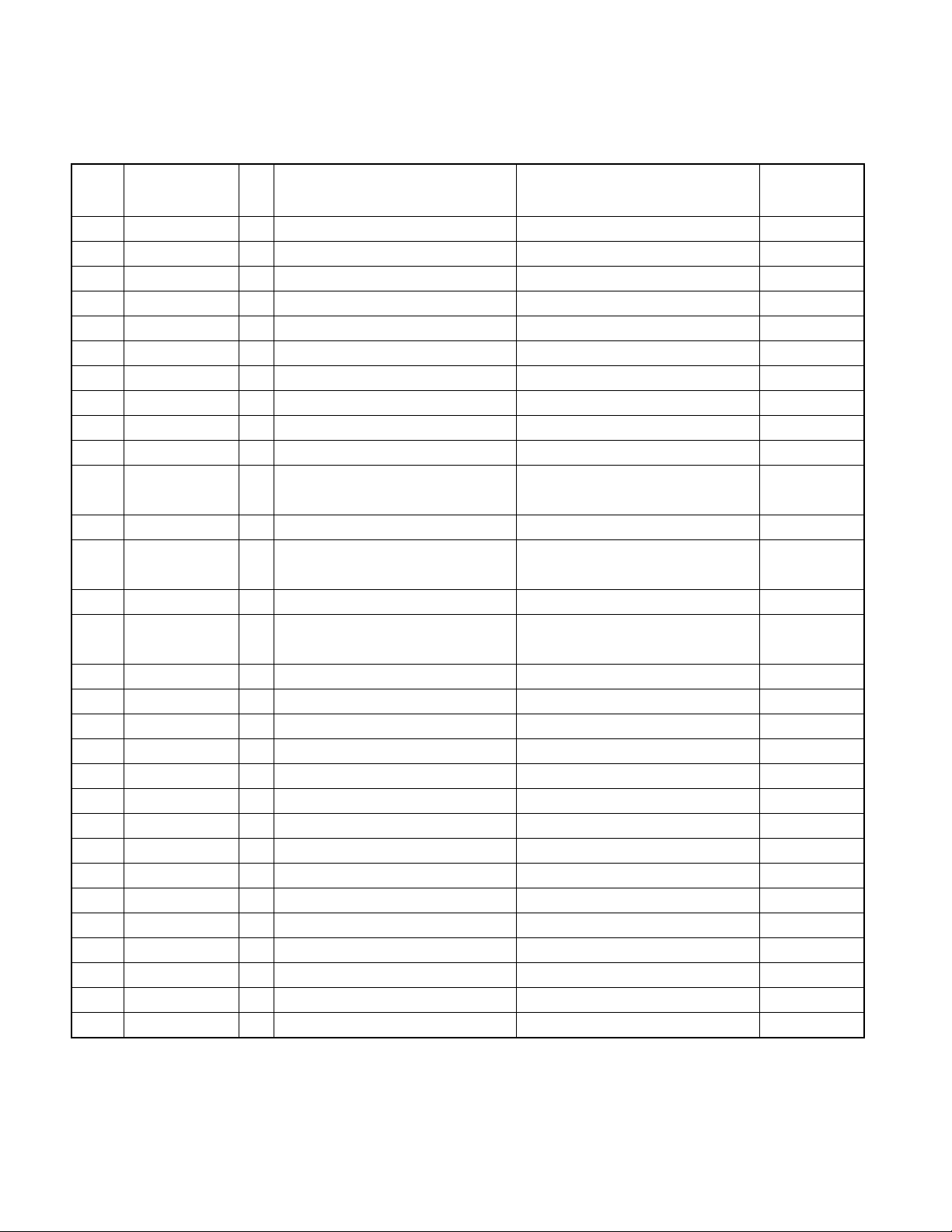

X92-4470-0x

MICROCOMPUTER’S TERMINAL DESCRIPTION

Pin Name I/O Purpose Processing operation description description in

65 /HCSB O Chip selection control H : OFF L : ON Low

66 /CS O Chip selection control H : OFF L : ON Low

67 DSP RESET O DSP reset control H : normal L : reset Low

68 REQ I data transmit request input Hi-Z

69 DBBWRDY0 I DBB00 register writing permit input Hi-Z

70 DBBRRDY0 I DBB00 register reading permit input Hi-Z

71 Avdd 72 Avss 73 Avref I A/D port standard voltage input

74~77 NC I Not use Low fixation Hi-Z

78 HOT I temperature shift detection

79 M-CONT I Not use Low fixation Hi-Z

80 WMA I WMA correspondence switching

81 NC I Not use Hi-Z

82 ASEL I Audio output polarity switching

83 DASC I Shock proof specification switching H : shock proof ON L : shock proof OFF Hi-Z

84 TEST2 I Test terminal 2 Hi-Z

85 TEST3 I Test terminal 3 Hi-Z

86 NC O Not use Low fixation Low

87 MSTOP I Standby return interrupt H : stop cancel L : stop Hi-Z (Low input)

88 INTSV I Interrupt from servo IC H : interrupt Hi-Z

89 FOGUP I Focus gain up interrupt H : Fo gain up L : normal Hi-Z

90 ZMUTE_R I 0bit mute detection H : mute ON L : mute OFF Hi-Z

91 ZMUTE_L I 0bit mute detection H : mute ON L : mute OFF Hi-Z

92 NC O Not use Low fixation Low

93 D-MUTE O Mute driver H : OFF L : ON Low

94 SYS_SDA I/O system microcomputer 12C data Hi-Z

95 NC O Not use Low fixation Low

96 SYS_SCL I/O system microcomputer 12C clock Hi-Z

97~100 NC O Not use Low fixation Low

Detection voltage 4V cancel

voltage 3.9V

H : DXM-6500 (correspond to WMA)

L : DXM-6400 (Don't correspond to WMA)

H : turning-over output

L : non- turning-over output

processing

STBY

Hi-Z

Hi-Z

Hi-Z

4

OPERATION DESCRIPTION

Center

of rotation

X92-4470-0x

[1] Disc Loading

(1) Turning the loading switch ON

1)When a disc is inserted, the disc arms open to the left and

right and the claw below disc arm (L) sets the loading switch

ON.

2)The above starts the motor rotation.

(2) Loading the disc

1) When the motor starts rotation, the worm gear also starts

to turn as shown in the figure.

2) The rotation force is transmitted to the gear train.

3)When the force is transmitted to the final gear, the rollers

rotate to pull in the disc.

Disc guide

Disc IN

Disc

Switch ON!

Disc arm(L) Disc arm(R)

Disc

Worm gear

Motor

Rubber rollers

Disc OUT

The disc is pulled in or out when the rollers are pushed against

the disc guide.

Roller

[2] Operation of Slider (R)

(1) Activating the trigger arm

1) When the disc is pulled in by the rollers, the disc edge pushes

the trigger arm and rotates it.

2)When the disc is an 8cm disc, it is pulled upwards by the

tapering on the disc guide. The trigger arm is rotated when

the disc pushes the claw (section A) located before the trigger arm.

When the 8cm disc reaches the loading end position, the roller

areas supporting the disc decreases. To prevent the disc from

dropping in this case, the claw is provided with a projection f or

supporting the disc.

Claw (A)

Projection

Side view

Position pushed by the disc

Disc IN

Trigger arm

Clamper chassis

A

Trigger arm

Disc

8cm Disc

5

X92-4470-0x

Locked

Locked

Center

of rotation

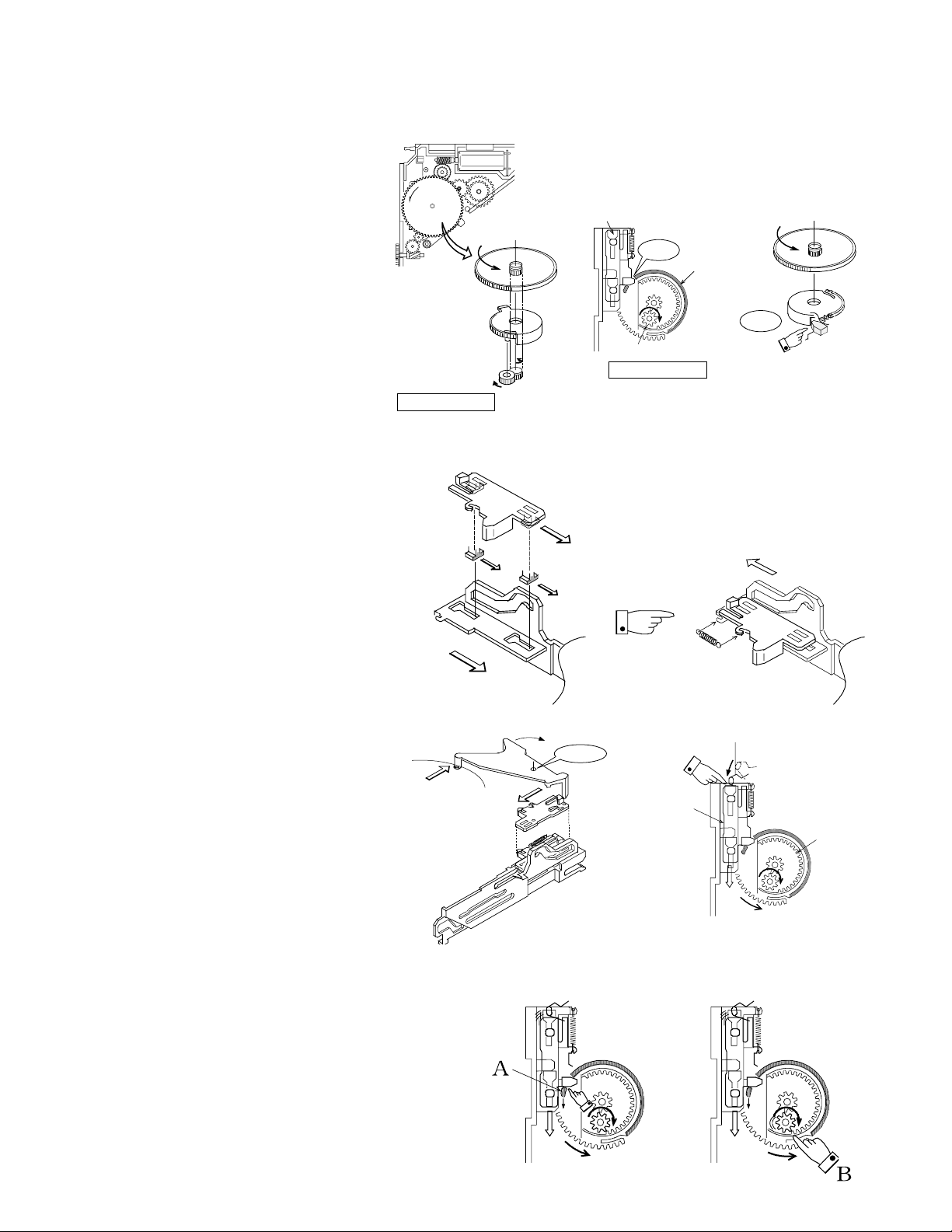

(2)Basic construction (Initial position

of the planetary gear mechanism)

1)Even after the disc has been inserted, the

motor rotated and the gear train also rotated,

slider (R) does not start operation yet.This

is because the planetary gear mechanism

is used and the carrier gear is locked by the

slider mechanism. In this period, the planetary gear is in the loose condition.

2) When the sun gear is rotating and the carrier gear is locked, the planetary gear is running idle.

OPERATION DESCRIPTION

Slider (R)

Sun gear

Carrier

gear

Planetary gear

Planetary gear

Loose condition

Loose condition

Carrier gear's rib

(3) Basic construction (Construction of

the trigger slider and slider (R))

The trigger slider is assembled with slider (R)

and pushed in the direction of the arrow by

the force of a spring.

(4) Operation of slider (R)

1) Activating the trigger slider

When the trigger arm is rotated by the pressure of the disc, the trigger arm pushes the

trigger slider.

Slider (R)

Tigger arm

Disc

Trigger slider

Trigger slider

Trigger slider

Spring

Trigger arm

Gear teeth

on the traverse

chassis

Carrier gear

2) Rotating (engaging) the planetary gear

When the trigger slider is moved, it pushes down the wall

(section A) of the carrier gear. (Initial rotation of the carrier

gear)

This causes the planetary gear, which is attached on a pin

of the carrier gear, to move according to the rotation of the

carrier gear. When the planetary gear is meshed with a gear

tooth (section B) of the traverse chassis , the planetary gear

starts rotation.

The rotation of the planetary gears causes the carrier gear

to rotate.

6

Loading...

Loading...