MD MECHANISM ASSY

X92-3770-00,0-01

X92-3780-00,0-01

SERVICE MANUAL

C

2000-5 PRINTED IN JAPAN

B51-7623-00 (4) 3360

CONTENTS

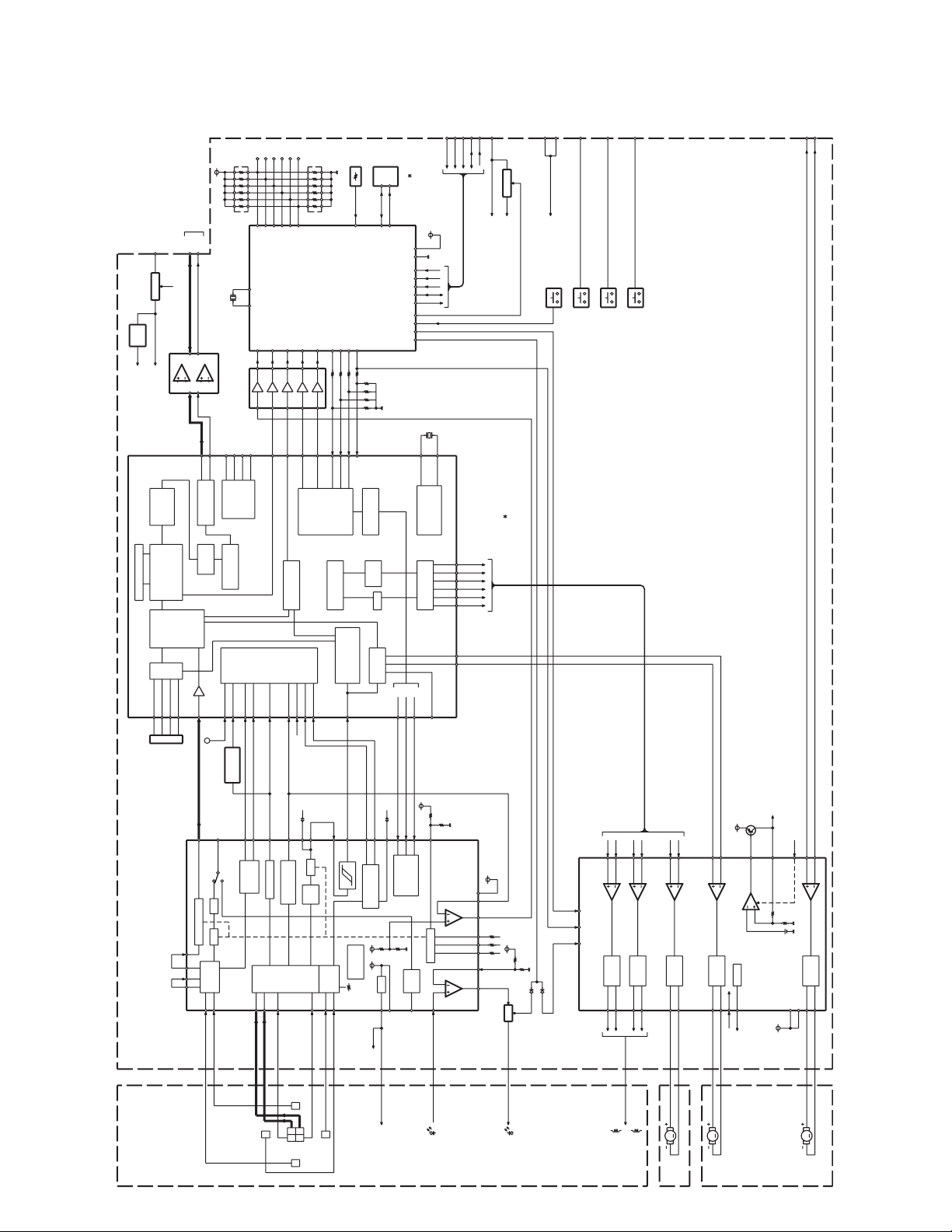

BLOCK DIAGRAM..............................................................2

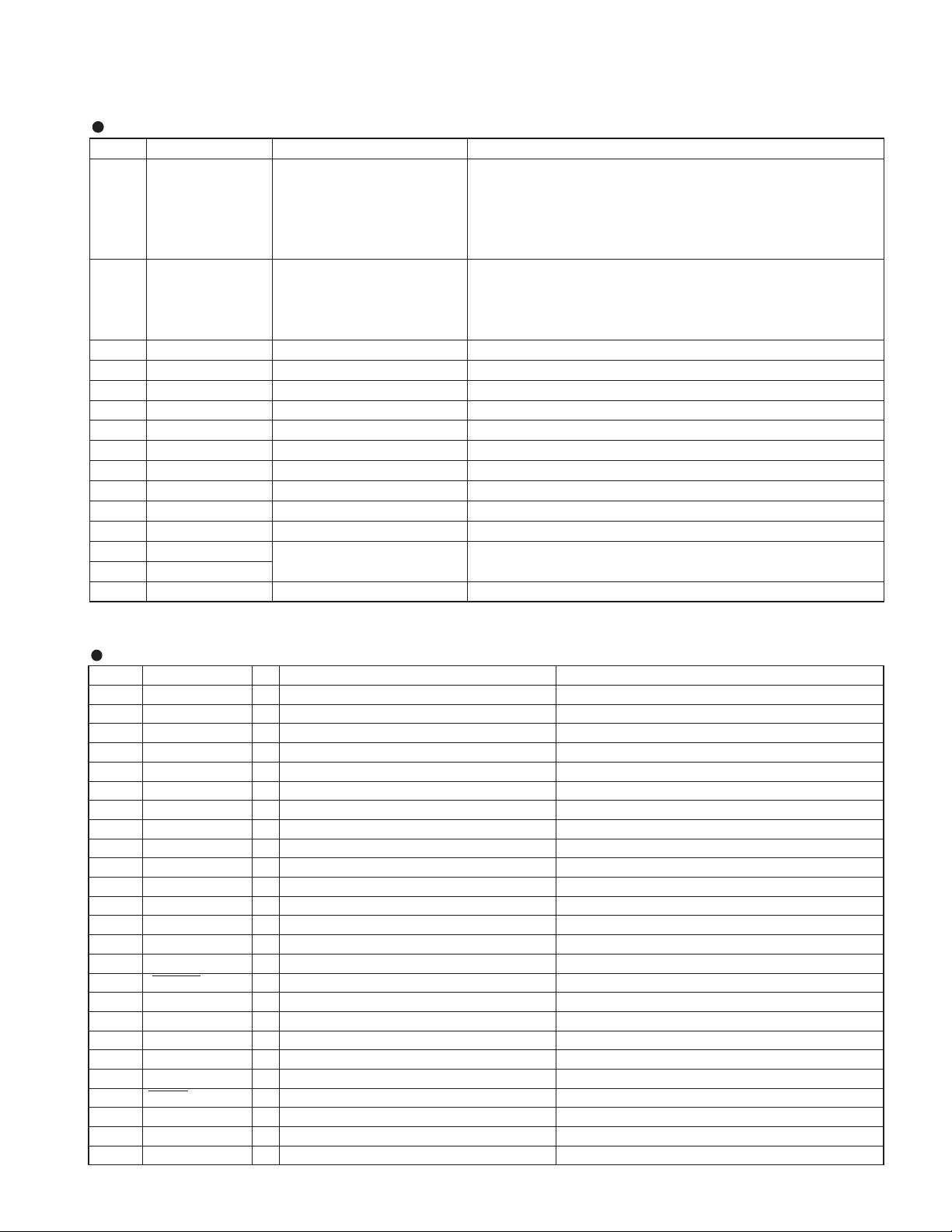

COMPONENT DESCRIPTION........................................... 3

MICROCOMPUTER'S TERMINAL DESCRIPTION........... 3

ADJUSTMENT.................................................................... 5

MECHANISM OPERATION DESCRIPTION .....................7

PC BOARD ....................................................................... 24

EXPLODED VIEW ............................................................26

SCHEMATIC DIAGRAM................................................... 27

PARTS LIST .....................................................................29

1

2

456

789

31514

I

J

A

B

C

D

E

F

11

12

22

23

25

41

42

19

APC

APCREF

EQADJ

3TADJ

WBLADJ

FZC

RF

AUX1

AUX2

PEAK

BOTTOM

ABCDFEVC

SWDT

SCLK

XLAT

FOCONT

109

108

103

104

101

100

107

106

SPFD

SPRD

FFDR

FRDR

TFDR

TRDR

SFDR

SRDR

1114119

6

13

12

MNT0

MNT1

MNT2

MNT3

XINT

SQSY

SENS

SRDT

SCLK

SWDT

XLAT

XRST

363839

14

57

595823

22

FZC

XINT

SQSY

SENS

SRDT

SCLK

SWDT

XLAT

XRST

28

32

17

27

26

62

64

37

35

61

3

LDON

SDMUTE

LIMIT SW

P-ON

AMUTE

MSDA

MSCL

MSTOP

MRST

TYPE 1

TYPE 2

1510111213

16

472930

MNT 4

MNT 3

MNT 2

MNT 1

MNT 0

4M/16M

HOT

ESDA

ESCL

2019171629

30

23

22

26

252432

33

TRK+

TRK-

FCS+

FCS-

SLED+

SLED-

SPDL+

SPDL-VCVREF0

VCC2

VCC1

LOAD

EJECT

10

11

12

13

6

7

8

9

28

27

3145

TFDR

TRDR

FFDR

FRDR

SFDR

SRDR

SPFD

SPRD

REG IN

REG OUT

ENREG

LOAD

EJECT

11

10

8

131219

18

14

17

4

5

1

20

21

6

7

A8V

L-CH

R-CH

MRST

MSTOP

MSCL (IIC BUS)

MSDA

AMUTE

BU5V

S5V

S5V

LOE-SW

LOS-SW

DET-SW

LOAD

EJECT

36

30

293134

35

37

33

38

47

46

48

40

10

28

26

32

171820

27

16

42

41

MORF RFO

AUX 1

FOCONT

XSTBY

ADFG

22.58MHz

118

117

116

19754213

7374757670819077787980

93

97

96

95

94

82

89

88

1

13

1159

10

8

12

2

6

8.38MHz

4

MUTE 1

MUTE 2

1

2

MUTE 3

36

CH1,2

CH3

CH4

31

57

SW+5V

DAVDD

AUDIO +B

JITTER

RECORD IN

VC

TE

SE

VC

VC

VC

VC

PD

LD

STBY

TO CH5 OP

S+B

SW+5V

S5V

+3.3V

BU+5V

6

5

BU+5V

1.2V rms

1KHz 0dB

SW+5V

TO SERVO DRIVER

BU+5V

ILCC

LDON

RF AMP

RF AGC & EQ

RF AMP

CXA2523AR

BPF P-P

PEAK &

BOTTOM

ABCD AMP

IV AMP

IV AMP

CVB

AMP

TEMP

VICCONV

ERROR AMP

FOCUSATAMP

BPF

TRACKING

ERROR AMP

SERIAL

PARALLEL

DECODER

BALANCE

E-F

FILTER

PLL

DECODER

ACIRC

EFM

MEMORY

RESISTANT

SHOCK

CONTROLLER

DYNAMIC RAM

ATRAC

DECODER

DIGITAL

FILTER

CONVERTER

D/A

POST FILTER

CONTROL

MONITOR

ANALOG

MUX

ADIP

DEMODULATOR

DECODER

SPINDLE

SERVO

GENERATOR

PWM

APC

DSP

SERVO

CONVERTER

A/D

CLOCK

GENERATOR

AUTO

SEQUENCER

I/F

CPU

PROCESSOR

SUBCODE

TC74HCT7007AF

MECHA u-COM

UPD78015FYGC

CH2

DRIVER

CH1

DRIVER

DRIVER

CH4

DRIVER

CH3

VREF

DRIVER

CH5

NJM4565MD

LPF

SW+8V

A3.3V

REG.

LIMIT SW

LOE-SW

LOS-SW

DET-SW

ATRAC DECODER

DET.

REFLECT

APC

CB

DA

F

E

JI

DETECTOR

TRACKING

COIL

FOCUS

COIL

M

SLED MOTOR

SPINDLE MOTOR

M

LOADING/EJECT MOTOR

M

THERMISTER

EEPROM

S-24C01B

128 8BIT

SW+5V

EFM/ACIRC DECODER

SHOCK PROOF MEMORY CONTROLLER

DIGITAL SERVO PROCESSOR

DIGITAL SIGNAL PROCESSOR

1M-WORD 4BIT DYNAMIC RAM

DIGITAL FILTER. D/A CONVERTER

CDX2659R

FOCUS/TRACKING COIL DRIVER

SPINDLE/SLED MOTOR DRIVER

LA6552

LOADING/EJECT MOTOR DRIVER

IC1

Q1

IC4

Q3

IC2

IC11

IC9

IC5

IC8

Q10

IC12

Q13

Q7

MOTOR ASS'Y

KMS-242B

OPTICAL PICKUP BLOCK

MOTOR BLOCK

X33 UNIT

X92-3770-00,0-01/X92-3780-00,0-01

BLOCK DIAGRAM

2

X92-3770-00,0-01/X92-3780-00,0-01

COMPONENT DESCRIPTION

MD PLAYER UNIT (X33-3040-00/0-01)

Ref. No. Component Name Application/Function Operation/Condition/Compatibility

IC1

IC2

IC4

IC5

IC8

IC9

IC11

IC12

Q1

Q2

Q3

Q7

Q10

Q12

Q13

CXA2523AR

CXD2659R

LA6552

NJM4565MD

LP2982-3.3

TC74HCT7007AF

78015FYGC-R08

S-24C01B

2SA1362(Y)

DTA114EUA

2SC4116(Y)

MCH6101

2SA1576A

DTC143EUA

2SA1576A

RF matrix amp.

Digital signal processor

5ch BTL driver

LPF

3.3V AVR

CMOS buffer

MD mechanism MI-COM.

E2PROM

APC

LD SW

Disc reflection detection

3.3V AVR

A 8VSW

P ON 5V SW

RF amplifier (pit and groove switching, AGC, EQ), gain switching

I-V amplifier.

Amplification of the light intensity signal output, peak hold output,

bottom hold output, FE output, TE output, SE output, ADIP binary

output, VREF output and APC PD

EFM decording, EFM digital PLL, ACIRC decording, auto link processing, ADIP decording.

Digital servos (focusing, tracking, sled, spindle CLV).

ATRAC decording, 1bit D/A, analog post-filtering, memory control.

Drives actuators and motors, +3.3V REGULATOR

Third active filter

D/A audio +B

Level shifting from 3.3V to 5.0V

Servo control, memory control, system control and interfacing

Servo coefficients and servo adjustment data backup memory

Laser power control.

On at base"L" while laser is OFF.

On when focusing point is passed during upward search.

Servo +B

Analog 8V power supply.

On at base"L"

MICROCOMPUTER'S TERMINAL DESCRIPTION

Microprocessor : 78015FYGC-R08 (X33 : IC11)

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

Pin Name

TEST0

JTIME

TYPE2

TEST3

TESTE

M REM

NC

NC

VSS

IVRTBAL PASS

AGC PASS

C1 COUNT

NC

SENS

AUDIO INV

4M/16M

LIMSW

NC

NC

NC

DEEM

XRST

XLAT

VSS

NC

I/O

I

Test mode input 0

I

Groove area jump time selection input

I

Destination selector 2

I

Test mode input 3

I

E2PROM external input test mode

O

Test mode memory remainder output

O

OPEN

O

OPEN

I

No auto align mode input

I

No auto align mode input

I

C1 error count mode input

I

GND

I

Internal status input from DSP LSI

I

DAC output polarity reversal input

I

DRAM size selection input

I

Pickup innermost limit detection

O

OPEN

O

OPEN

O

OPEN

O

De-emphasis output to external DAC

O

Reset output to DSP LSI and servo driver IC

O

Latch output to DSP LSI

O

OPEN

Description Processing Operation

"H" turns normal test mode ON.

"L": 200ms, "H": 300ms

"L": 2655R, 2652AR, "H": 2655BR, 2654R

"H" turns special test mode ON.

"H" turns external input mode ON.

75% or more remains at "H"

IVR-TBAL auto align bus at "H"

AGC auto align bus at "H"

Error count mode at "H"(When it's in text mode)

Reverse polarity at "H".

"H" turns 16M bit operation (fixed on RESET)

"L" when innermost limit is detected.

During 2652AR : ON at "H", during 2654R : ON at "L"

Active : "L"

Latch at falling edge

3

X92-3770-00,0-01/X92-3780-00,0-01

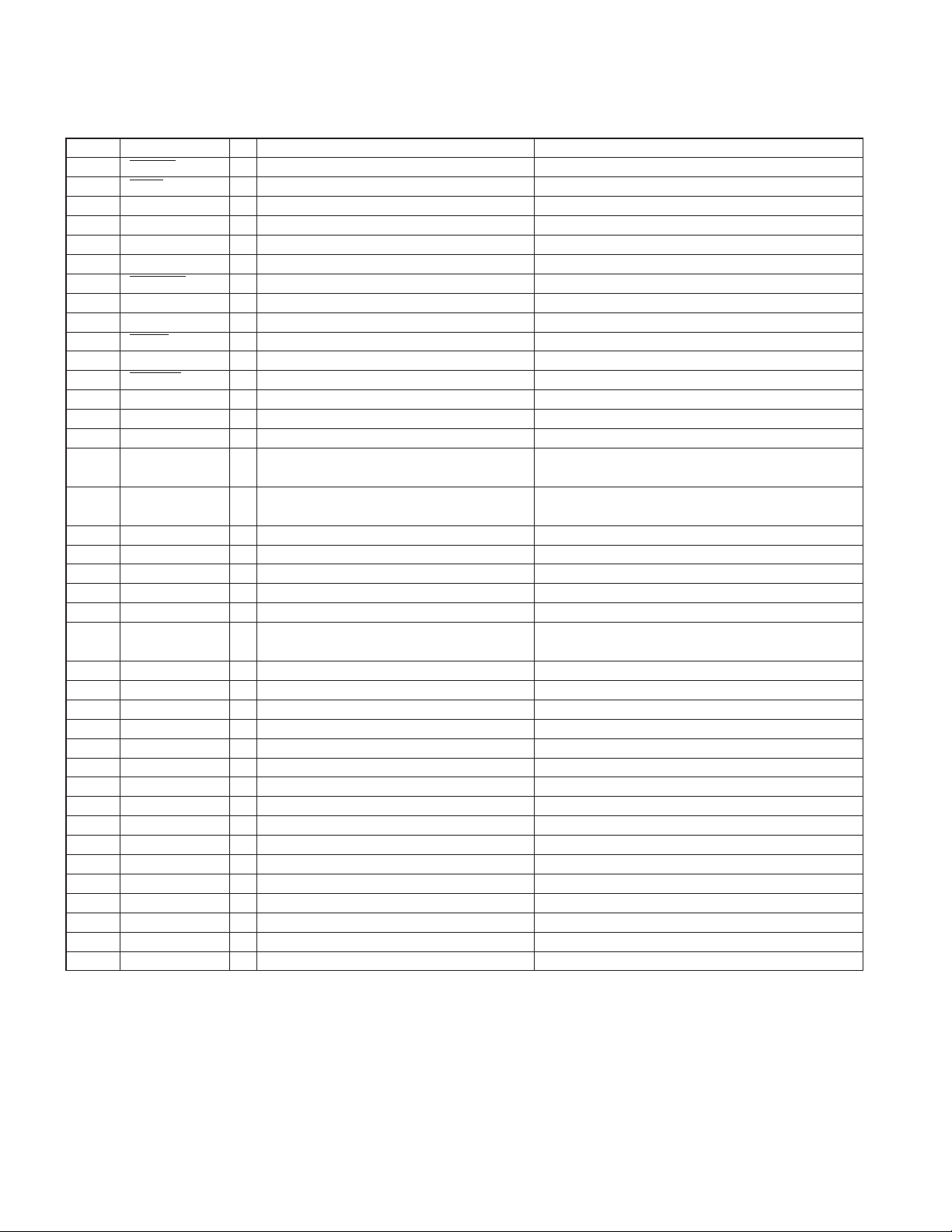

MICROCOMPUTER'S TERMINAL DESCRIPTION

Pin No. Description Processing OperationI/OPin Name

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

AMUTE

P-ON

LDON

ESDA

ESCL

NC

SDMUTE

NC

NC

MRST

FZC

M-STOP

XINT

SQSY

VDD

X2

X1

IC

XT2

NC

AVSS

HOT

AUX1/NC

NC

NC

NC

NC

NC

AVCON

AVDD

AVREF

SRDT

SWDT

SCLK

LADJ1

TYPE1

MSDA

NC

MSCL

Audio mute output

O

Unit internal system power control output

O

Laser APC control output

O

E2PROM serial data line

I/O

E2PROM serial clock line

I/O

OPEN

O

Sled driver mute output

O

OPEN

O

OPEN

O

Reset input from system µ-COM.

I

FZC interrupt request input

I

Standby control input from system µ-COM.

I

Interrupt request from DSP LSI

I

Sub-code Q sync or ADIP sync input

I

Connect crystal oscillator as main system

clock.

Connect crystal oscillator as main system

clock.

(not used : BU5V connection)

I

Temperature detection input

I

AUX1 input durring 2654R mode/

I/O

others not used

OPEN

O

OPEN

O

OPEN

O

OPEN

O

OPEN

O

AVREF terminal control output

O

Connected to AVCON terminal

Serial data input from DSP LSI

I

Serial data output to DSP LSI

O

Shift clock output to DSP LSI

O

Manual adjustment mode input

I

Destination selector 1

I

Serial data line with system µ-COM.

I/O

OPEN

O

Serial clock line with system µ-COM.

I/O

Active : "L"

Active : "L"

Active : "H"

(I2C-BUS)

(I2C-BUS)

Active : "L"

Active : "L"

"H"for interrupt request generation

Active : "L"

"L"for interrupt status generation

Vth On : 3.87V, Vth Off : 3.74V, Vth Low : 0.43V

Jitter input during FBAL alignment

"H"with AVREF reference voltage

"H"for manual adjustment mode

"L": 2655R, 2655BR, "H": 2652AR, 2654R

(I2C-BUS)

(I2C-BUS)

4

X92-3770-00,0-01/X92-3780-00,0-01

ADJUSTMENT

Service Test Mode (Manual Adjustment Mode) of the MDS-2200

The focusing bias (balance) adjustment of the MDS-2200 has been subjected to automatic adjustment at the factory and the

obtained bias value has been written in the E2PROM, and the set performs adjustment by reading the E2PROM data.

Consequently, after the pickup has been replaced in servicing, it is required to adjust the focusing bias again. This can be done

automatically if the dedicated commander for the MDS-2200 and a jitter meter are available, but the set also incorporates a

service test mode (manual adjustment mode) for use in case these instruments are not available.

• Adjustment procedure (Be sure to begin setup while the power of the set is off.)

1. Pull up pin 60 (LADJ1 (check land 1)) of lC11 in the X33-unit to BU5V (check land BU5).

2. Lead wires from check land ARF and check land SAG (servo GND) in the X33-unit so that they an be monitored with an

oscilloscope.

3. Turn the set on and perform the reset power-ON operation.

∗ The adjustment includes three modes ; the Iow-reflection pit and groove modes for recordable discs and the high-reflection

pit mode for premastered discs.

4. Load a disc to enter the adjustment mode.

<With a recordable disc>

5. The low-reflection pit play mode starts when TNo.1 is displayed.

The time code display shows “50”.

6. While monitoring ARF with an oscilloscope, vary the focusing bias using the Track UP and DOWN keys.

7. The optimum values can be obtained by varying the bias in the UP and DOWN directions, locating the upper and lower values

at which the ARF waveform is disturbed or the 3T waveform level drop, and calculating the center value of the two values.

For example, when the value located in the UP direction is 58 and that located in the DOWN direction is 46, the optimum value

is their center value, i. e. 52.

8. When the optimum value is obtained, set the focusing bias to that value and press the ManuaI UP or DOWN key to enter the

value.

(With normal sets, press and hold the Track UP or DOWN key.)

9. After the low-reflection pit adjustment in step 8, the pickup automatically moves to the groove area.

10. The groove play mode starts when TNo.2 is displayed.

11. Perform the same operations as steps 6, 7 and 8.

12. The disc stops after the groove area adjustment .

Eject the disc and complete adjustment.

∗ Since the low-reflection pits are present only in the TOC area, their total play time is about 40 seconds. When the pit area

is over, the retry operation starts and the adjustment is invalid in this period.

<With a premastered disc>

13. When the high-reflection play mode starts, perform operations in steps 5, 6, 7 and 8.

14. The disc stops after the adjustment. Eject the disc and complete adjustment.

∗ The coarse adjustment of the EF balance is also performed during this test mode.

However, it is an automatic adjustment and does not require external poeration.

5

X92-3770-00,0-01/X92-3780-00,0-01

ADJUSTMENT

• Display in service test mode (Display on the set)

Start of pit adjustment mode [01-_ : _ ]

Pit adjustment enabled [01-_ : 50]

Pit adjustment in progress (∗∗ =Adjustment data) [01-_ : ∗∗]

Pit adjustment result entered (Start of groove adjustment mode) [02-_ : _ ]

Groove adjustment enabled [02-_ : 50]

Groove adjustment in progress (∗∗ =Adjustment data) [02-_ : ∗∗]

Groove adjustment result entered (Normal completion) [02-_ : _ ]

• Error display (∗∗=Error status)[∗∗_ : _ ]

∗∗ = 03 : Error during low-reflection pit EF balance adjustment

∗∗ = 04 : Error during low-reflection pit focusing bias adjustment

∗∗ = 05 : Error during low-reflection pit data write in E2PROM

∗∗ = 19 : Error during groove EF balance adjustment

∗∗ = 20 : Error during groove focusing bias adjustment

∗∗ = 21 : Error during groove data write in E2PROM

∗∗ = 35 : Error during high-reflection pit EF balance adjustment

∗∗ = 36 : Error during high-reflection pit focusing bias adjustment

∗∗ = 37 : Error during high-reflection pit data write in E2PROM

• Adjustment parameters

Adjustment condition : Setting the LADJ 1 pin to Hi then reset-starting the set.

Adjustment keys : Track UP/DOWN keys.

Entry key : Pressing the Manual UP/DOWN key (or pressing and holding the adjustment key with some sets).

∗∗ Notes ∗∗

1. Always be sure to enter the results obtained with each medium.

If the medium is ejected without entering the results and the adjustments of another medium is started, the E2PROM data will

be destroyed.

2. Varying the focusing bias value extremely in the UP or DOWN direction degrades the focusing performance.

Although this degradation can usually be recovered by retrying, there is also a potential of error occurrence or keys becoming

invalid.

In such a case, restart adjustment by reset-starting the set.

(This also applies to the case in which data has been entered using an extreme value.)

3. Note on “E-99”

“E-99” which usually indicates a mechanism error is also displayed when E2PROM data is destroyed.

If a wire is attached or removed while the set’s power is on (BU UP), the E2PROM data could be destroyed ; be sure to attach

or remove wire while the power is on (BU UP).

This also applies to the attaching and removal of the card cable (flexible cable) to or from the mechanism.

(Unlike the MDS-1000, normal operation cannot be resumed by turning the T0 pin Hi.)

4. Note on E2PROM

The E2PROM stores a variety of initial data for the MD DSP, and some of the initial data is rewritten at the time of adjustment.

As a result, note that an error occurs if the E2PROM in use does not store the initial data.

6

X92-3770-00,0-01/X92-3780-00,0-01

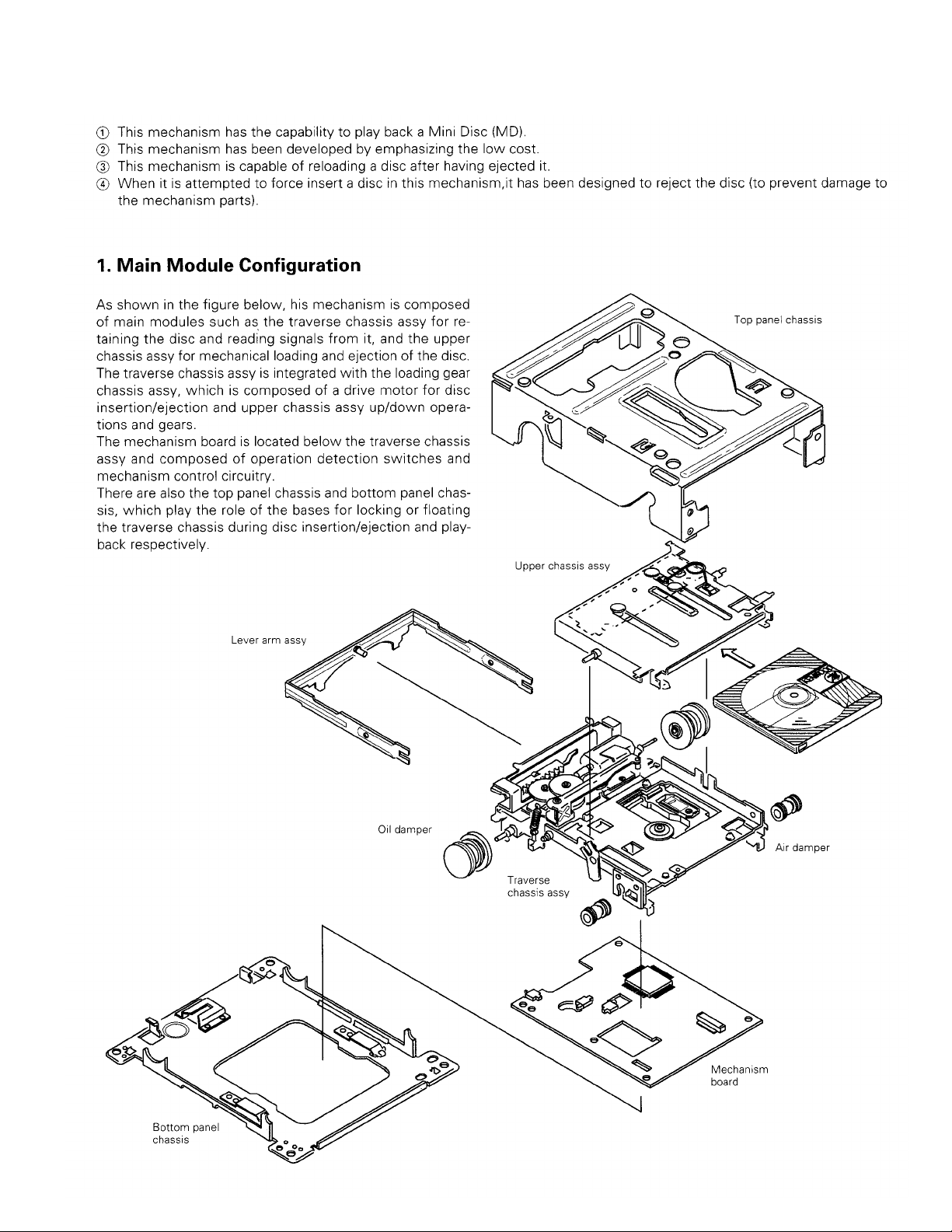

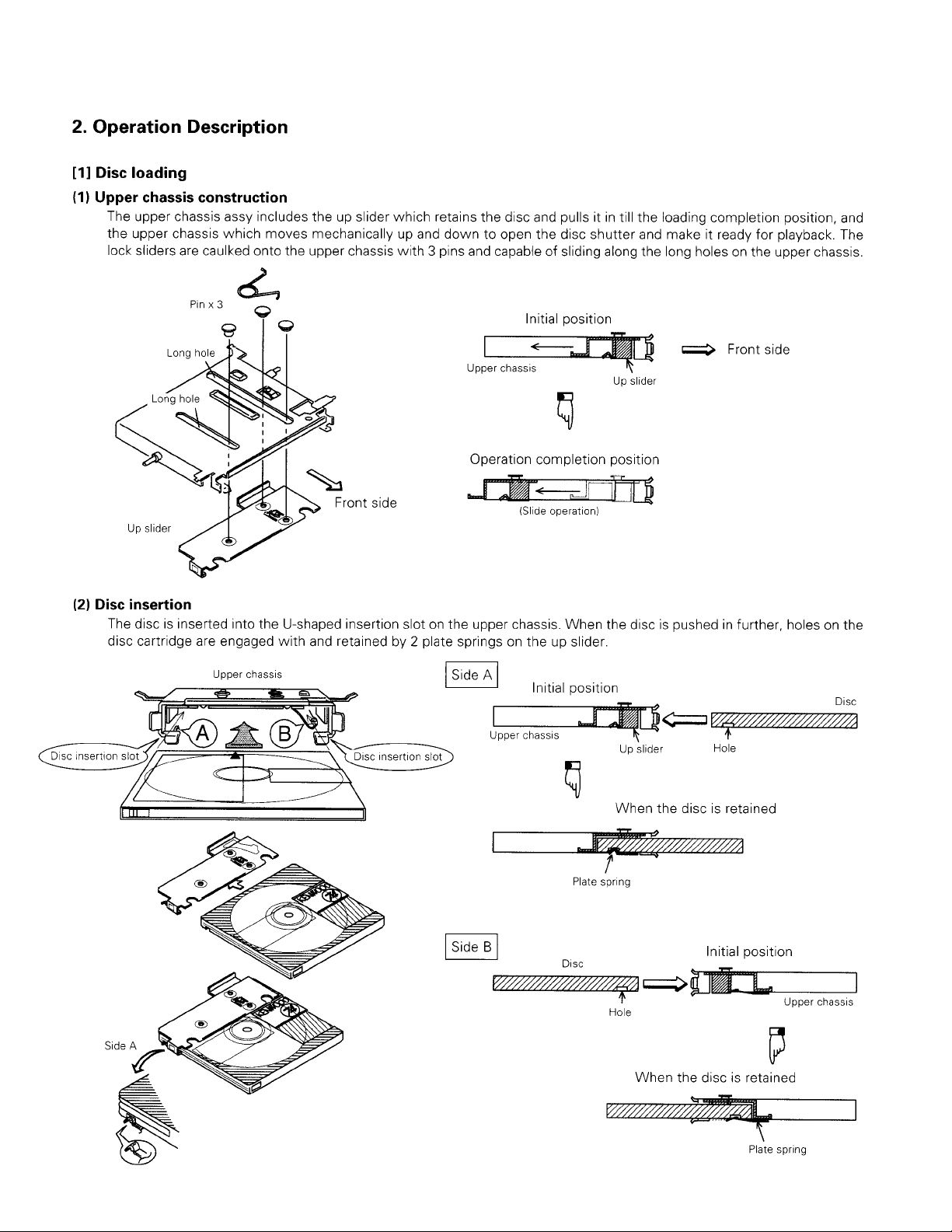

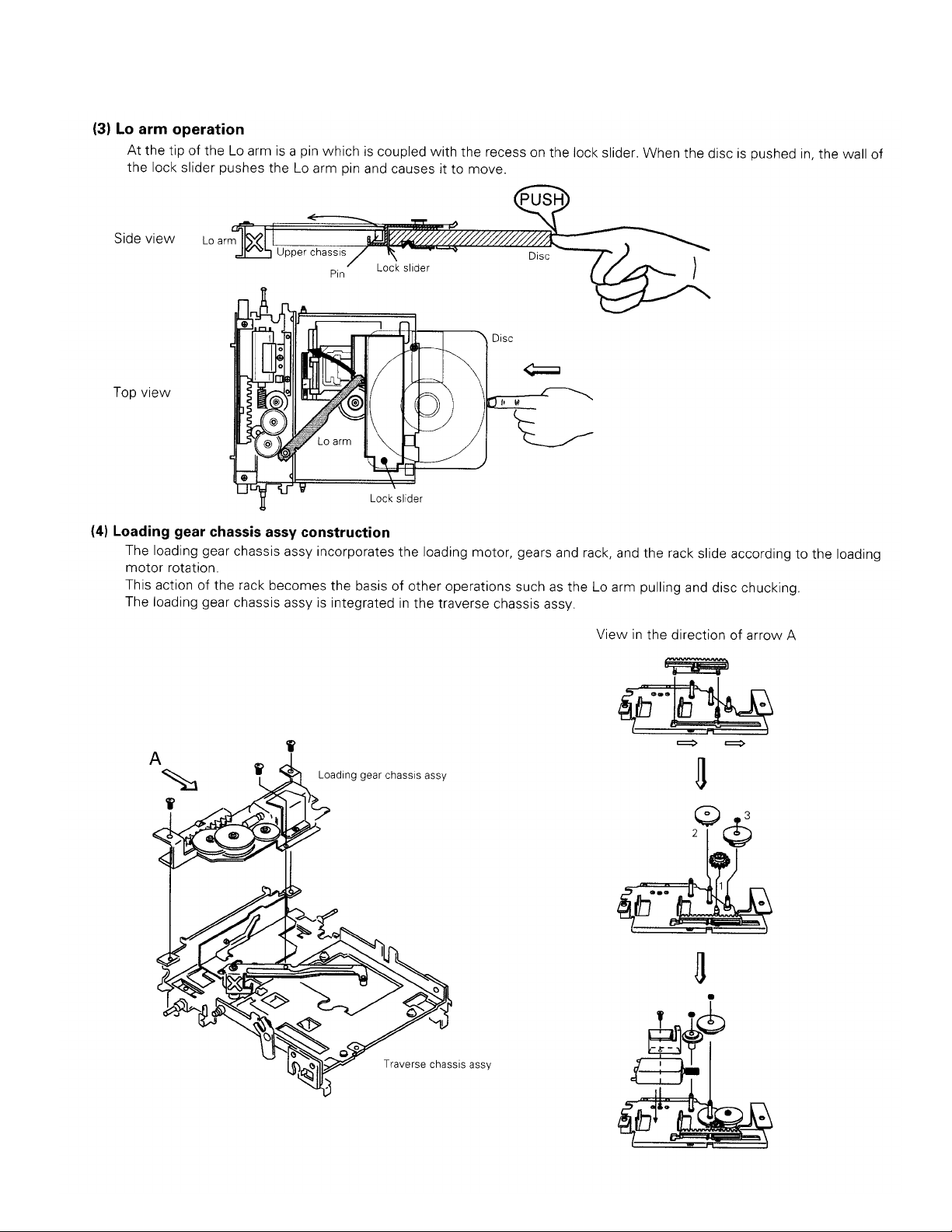

MECHANISM OPERATION DESCRIPTION

7

X92-3770-00,0-01/X92-3780-00,0-01

MECHANISM OPERATION DESCRIPTION

8

X92-3770-00,0-01/X92-3780-00,0-01

MECHANISM OPERATION DESCRIPTION

9

Loading...

Loading...