New ELECTRIC UNIT (X34-) for 2008 CD RECEIVER

X34-56xx-xx

SERVICE MANUAL

© 2008-1 CREATED IN JA PAN

B53-0608-00 (N) 0

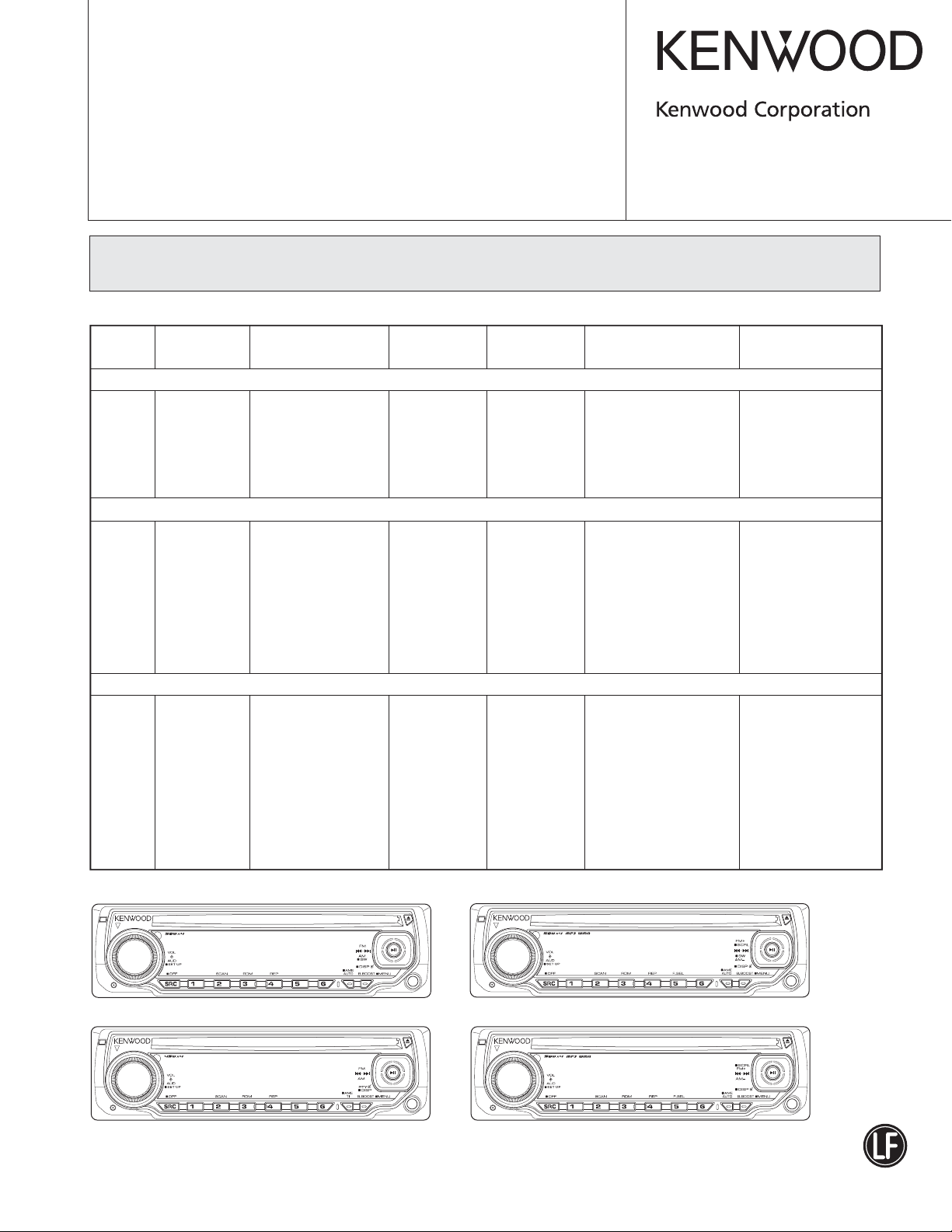

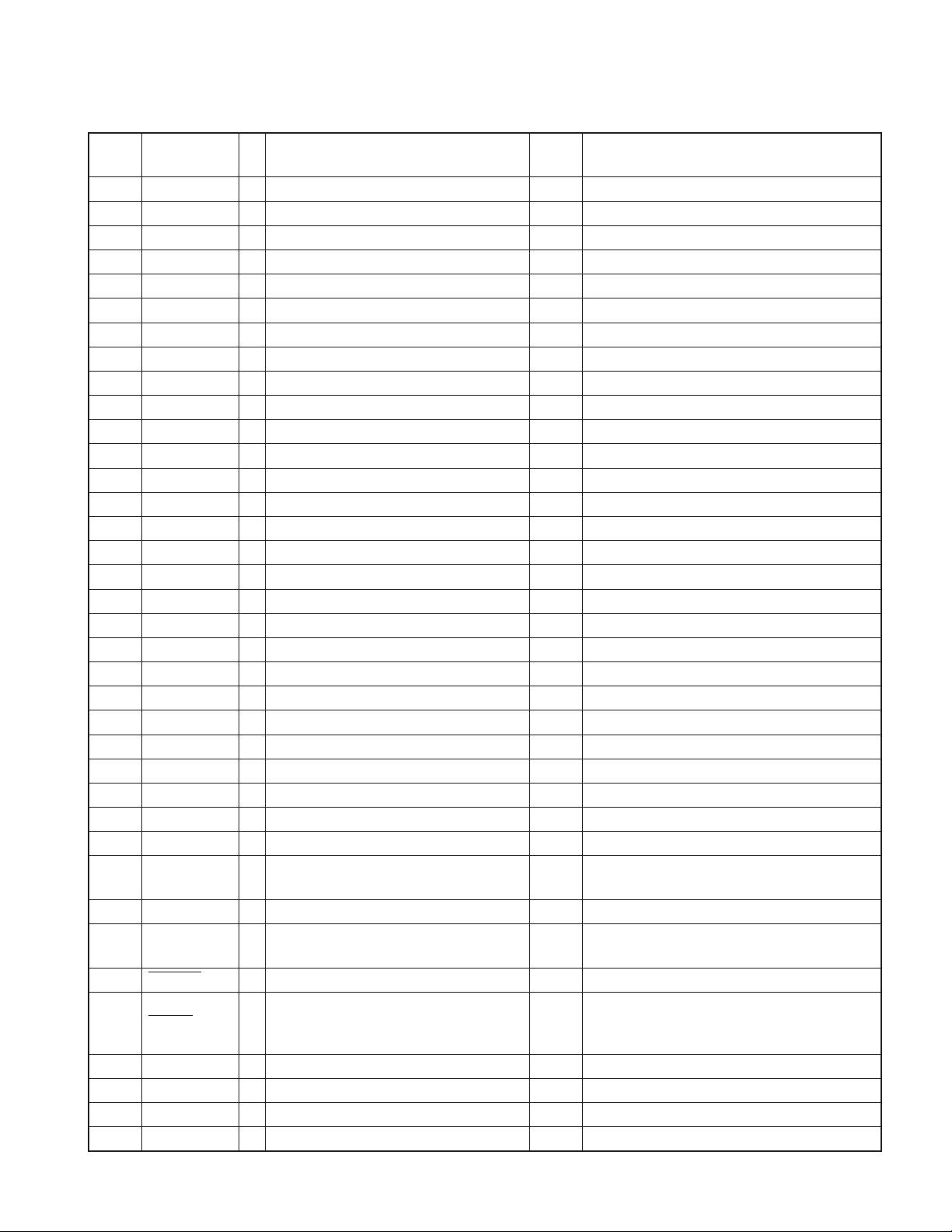

ELECTRIC UNITs for the following 2008 CD receivers which are produced after November of 2007

are changed as follows. This service manual is only for the changed new ELECTRIC UNITs.

DESTI-

NATION

K 7-SEG LCD KDC-138 X34-5640-10 X34-5670-10 71109301 / 71200001 KDC-138/...............

K 7-SEG LCD KDC-138CR X34-5640-11 X34-5670-11 71200001 KDC-138/...............

K 14-SEG VFD KDC-MP208 X34-5640-14 X34-5670-14 71103501 / 71208401 KDC-MP208/..........

K 14-SEG VFD KDC-MP238 X34-5640-12 X34-5670-12 71106402 / 80100001 KDC-MP208/..........

K 14-SEG VFD KDC-MP238CR X34-5640-13 X34-5670-13 71200001 / 80100001 KDC-MP208/..........

M 7-SEG LCD KDC-139 X34-5640-21 X34-5670-21 71110201 KDC-138/...............

M 7-SEG LCD KDC-139S X34-5640-21 X34-5670-21 - KDC-138/...............

M 14-SEG VFD KDC-MP239 X34-5640-23 X34-5670-23 71200001 KDC-MP208/.........

M 14-SEG VFD KDC-MP3039 X34-5640-23 X34-5670-23 - KDC-MP208/.........

M 14-SEG VFD KDC-MP339 X34-5640-23 X34-5670-23 - KDC-MP208/.........

M 14-SEG VFD KDC-MP339S X34-5640-23 X34-5670-23 - KDC-MP208/.........

M 14-SEG VFD KDC-MP439 X34-5640-22 X34-5670-22 V1100701 KDC-MP208/.........

E 14-SEG VFD KDC-241SA X34-5652-70 X34-5682-70 V1101001 KDC-241SA/..........

E 14-SEG VFD KDC-241SG X34-5652-70 X34-5682-70 W0100001 KDC-241SA/..........

E 14-SEG VFD KDC-W241AY/GY X34-5652-71 X34-5682-71 V1110501 KDC-W241AY/......

E 14-SEG VFD KDC-W3041A/G X34-5652-72 X34-5682-74 V1101601 KDC-W241AY/......

E 14-SEG VFD KDC-W3041AY/GY X34-5652-73 X34-5682-75 V1102501 KDC-W241AY/......

E 14-SEG VFD KDC-W312A/G X34-5652-72 X34-5682-74 V1101601 KDC-W241AY/......

E 14-SEG VFD KDC-W312AY/GY X34-5652-73 X34-5682-75 V1102501 KDC-W241AY/......

E 14-SEG VFD KDC-W312SAY X34-5652-73 X34-5682-75 V1102501 KDC-W241AY/......

DISPLAY

TYPE

MODEL OLD X34- NEW X34-

SERIAL No.

FROM

ORIGINAL

SERVICE MANUAL

KDC-138

KDC-241

This product uses Lead Free solder.

This product complies with the

KDC-MP208

KDC-W241

RoHS directive for the European market.

X34-56xx-xx

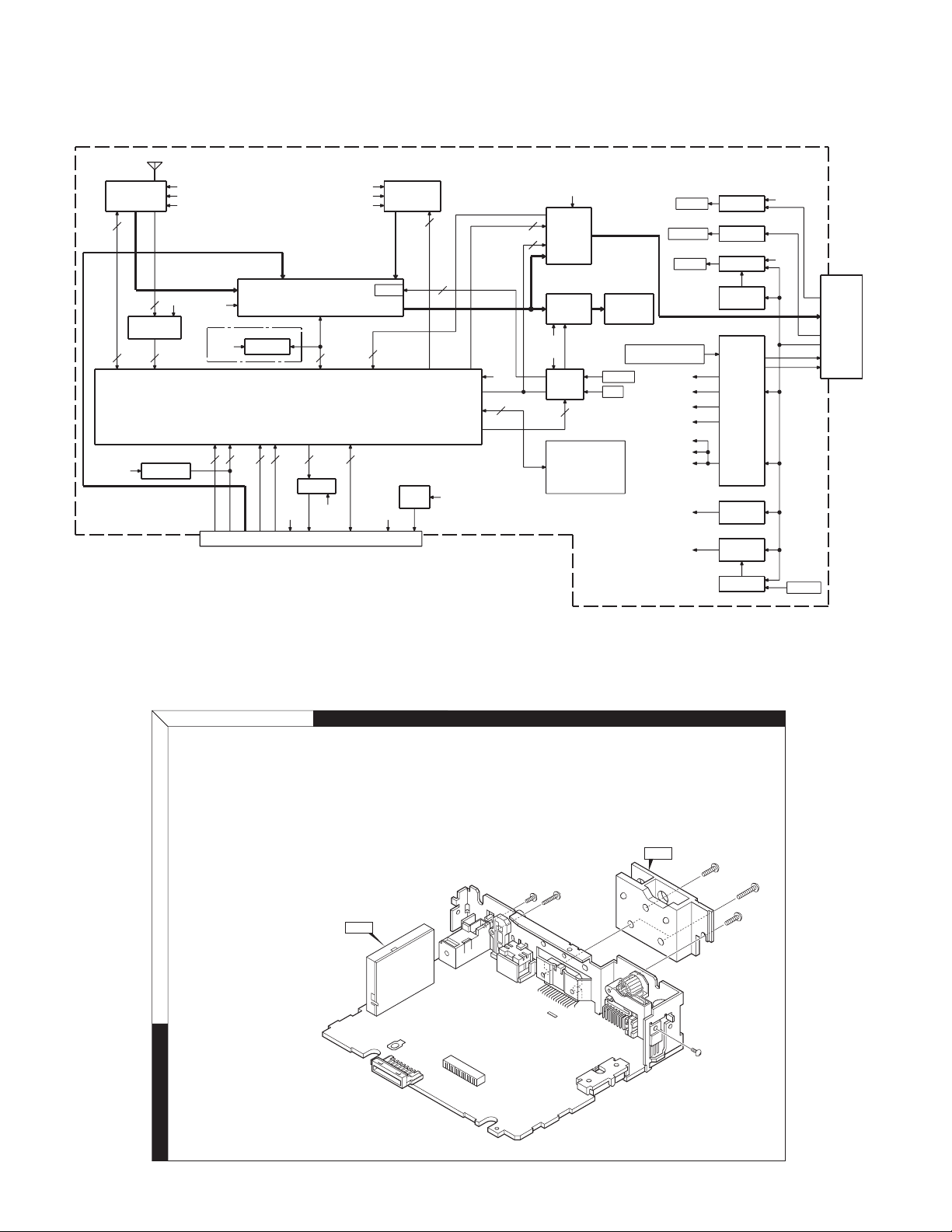

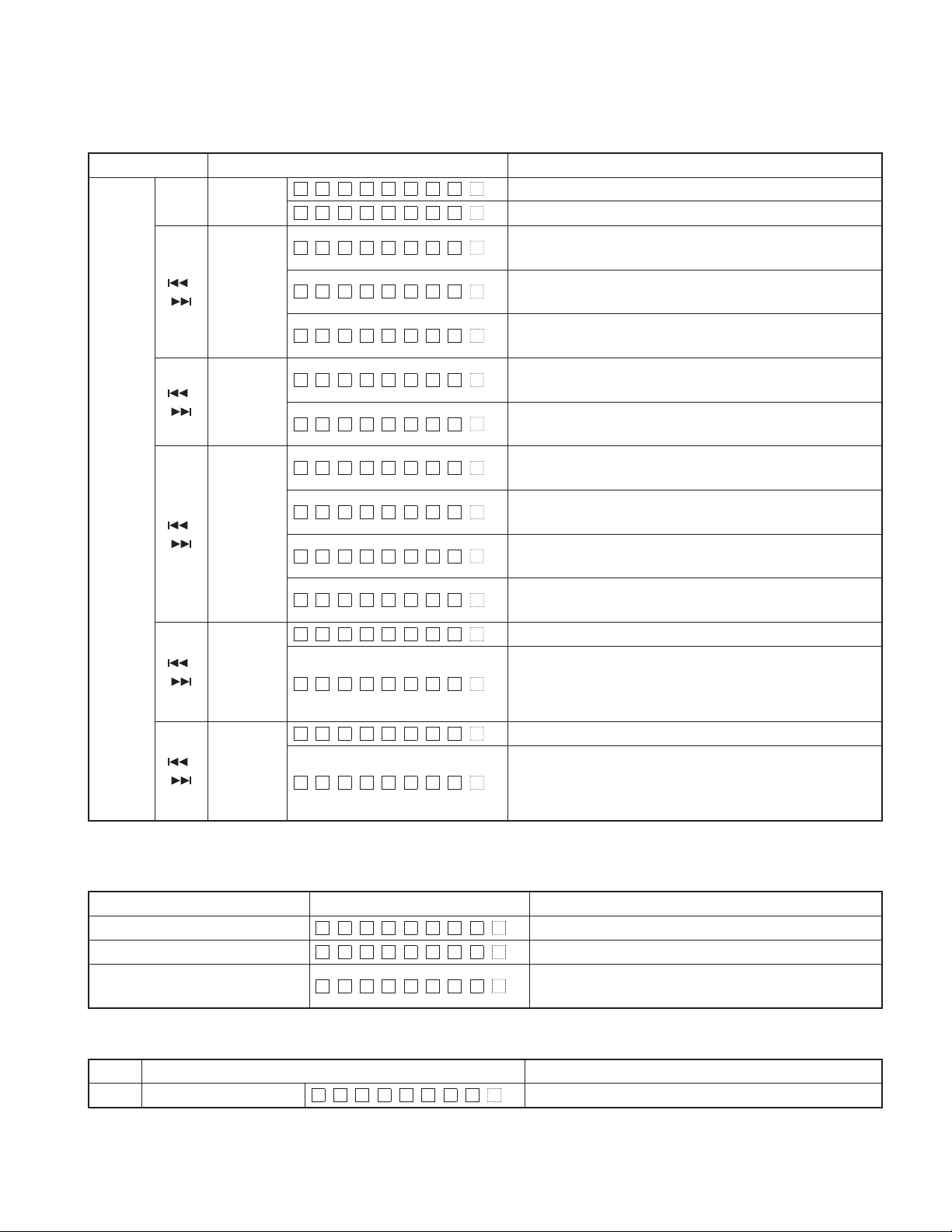

ELECTRIC UNIT (X34- )

J2

1

IC7

RDS

DECODER

3

IC8

RESET IC

ANT.

AM+B

A8V

SW5

SW5

A8V

ROM CORRECTION (NOT USED)

12

J3

CN

IC2

IC10

E2PROMSW5

SYSTEM u-COM

A1

TUNER

FRONT-END

3

3

IC1

BU5

SW5

E-VOL

2

111

Q301

PAN5V

BLOCK DIAGRAM

DME1

BU

CD

A8V

1

MUTE

ILLUMI+B

MECHA

R11-15

1/2W

Rx5

16

1

FL+B

SERVO+B

5

BU5

BU5

9

BU

IC6

POWER

2

IC

1

Q701,702

PRE-OUT

MUTE

BU5

BU5

Q705

MUTE

1

DC-CN etc

PHONE

ACC DET / BU DET

P.ON FL

PS1-1 / PS1-2 / PS1-3

PS2-1 / PS2-2

J5

PRE-OUT

FRONT/

REAR/SW

PS1 1 / PS1 2 / PS1 3

PS2 1 / PS2 2

BU DET

RST

ACC DET

BU DET

FL+B

AM+B

SW5

A8V

SW5

BU5

SERVO+B

ILLUMI+B

PHONE

D5

R103

PHONE

Q101

ACC-DET

Q103

BU-DET

Q102

SURGEDET

IC4

POWER

SUPPLY

IC

Q2

CD

SERVO

Q8,9

ILLUMI

+B

Q7,10

SW14V

BU5

BU5

P.ON FL

J1

DC-CN

PHONE

SP-OUT

ACC

B.U.

P-ANT

P-CON

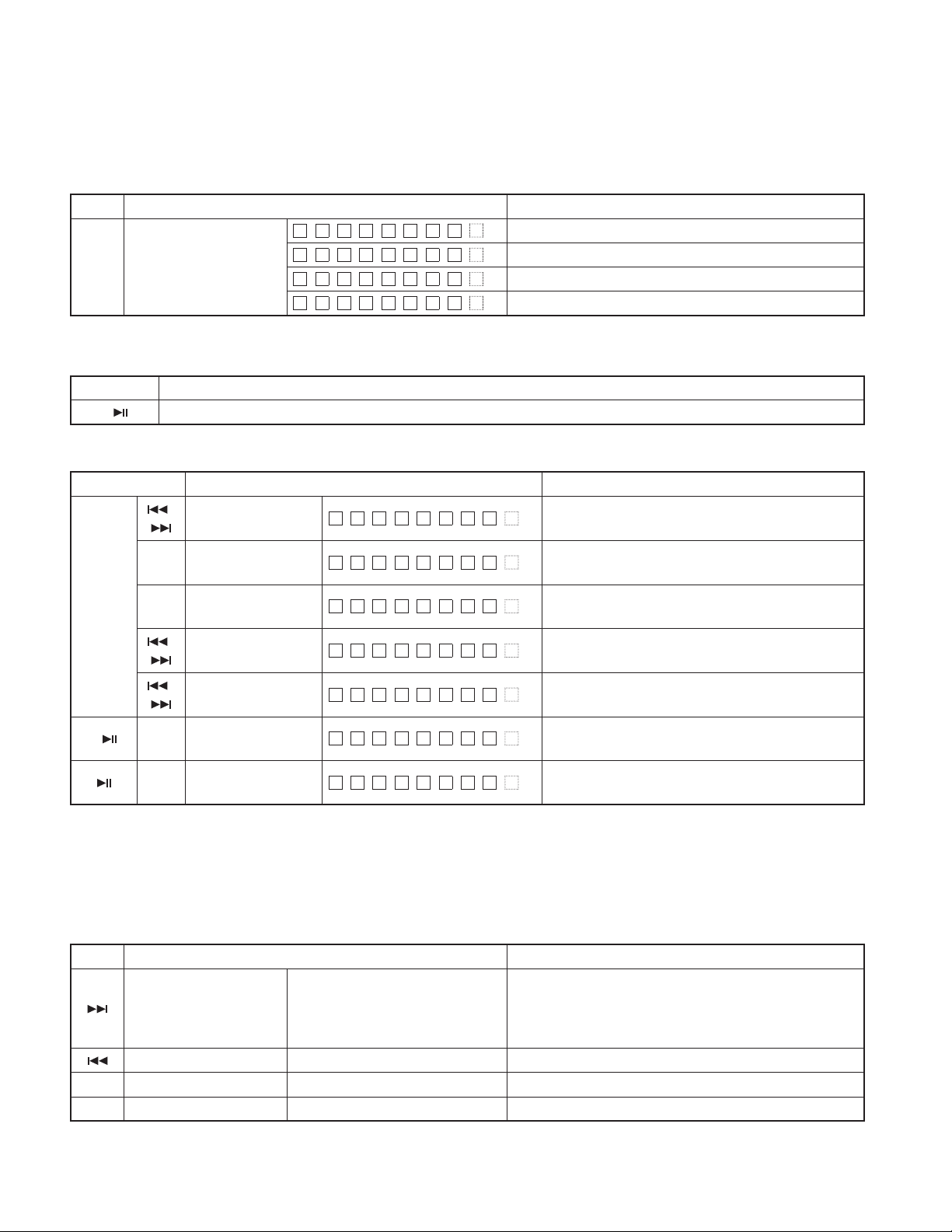

EXPLODED VIEW (UNIT)

C

: N80-3010-48

F

: N83-3005-48

G

: N83-3016-48

H

: N86-2606-48

J

L

2

: N89-3010-48

(X34)

A1

(X34-)

3

D

(X34)

786

G

F

L

x2

H

L

J

2

Parts with the exploded numbers larger than 700 are not supplied.

X34-56xx-xx

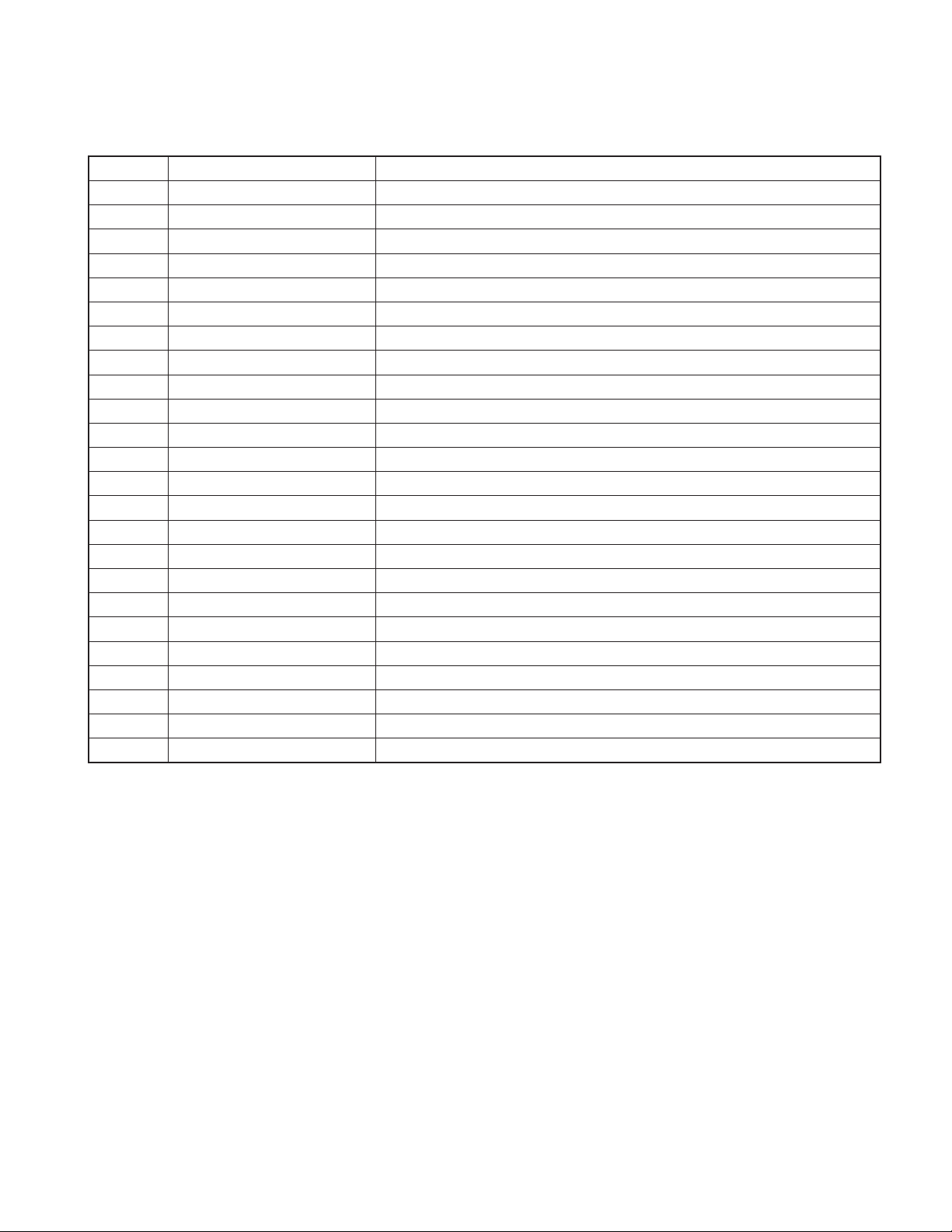

COMPONENTS DESCRIPTION

ELECTRIC UNIT (X34-56xx-xx)

●

Ref. No. Application / Function Operation / Condition / Compatibility

IC1 System μ-COM Controls FM/AM tuner, the changer, CD mechanism, panel, volume and tone.

IC2 E-VOL Controls the source, volume and tone.

IC4 Power Supply IC Outputs 5Vx2, 8.1Vx2, 10.2V, P-CON and P-ANT.

IC6 Power IC Amplifi es the front L/R and the rear L/R to 50W maximum.

IC7 RDS IC RDS decoder.

IC8 Reset IC Lo when detection voltage goes below 3.6V.

Q2 Servo+B AVR When Q3’s base goes Hi, Servo+B AVR outputs 7.5V.

Q3 Control SW for Servo+B ON when the base goes Hi.

Q7 VFD+B SW ON when the base goes Hi.

Q8 VFD+B AVR When Q9’s base goes Hi, Servo+B AVR outputs 10.5V.

Q9 Control SW for VFD+B ON when the base goes Hi.

Q10 VFD+B SW ON when Q7’s base goes Hi.

Q11 14V SW ON when the base goes Hi.

Q12 14V SW ON when the base goes Lo.

Q13 Control SW for IC4 ON when the base goes Hi.

Q14 Control SW for IC4 ON when the base goes Lo.

Q101 ACC DET ON when the base goes Hi during ACC is applied.

Q102 Serge DET When the base goes Hi, surge voltage is detected.

Q103 BU DET ON when the base goes Hi during BU is applied.

Q104,105 Mute Control ON when the base goes Hi.

Q301 Panel 5V SW ON when the base goes Lo.

Q701~704 Pre-out Mute SW When a base of the 4 transistors goes Hi, pre-out is muted.

Q705 Mute Driver for Pre-out ON when the base goes Lo.

Q801

Electric Discharge Circuit for C805 (SVR)

ON when the base goes Lo.

3

X34-56xx-xx

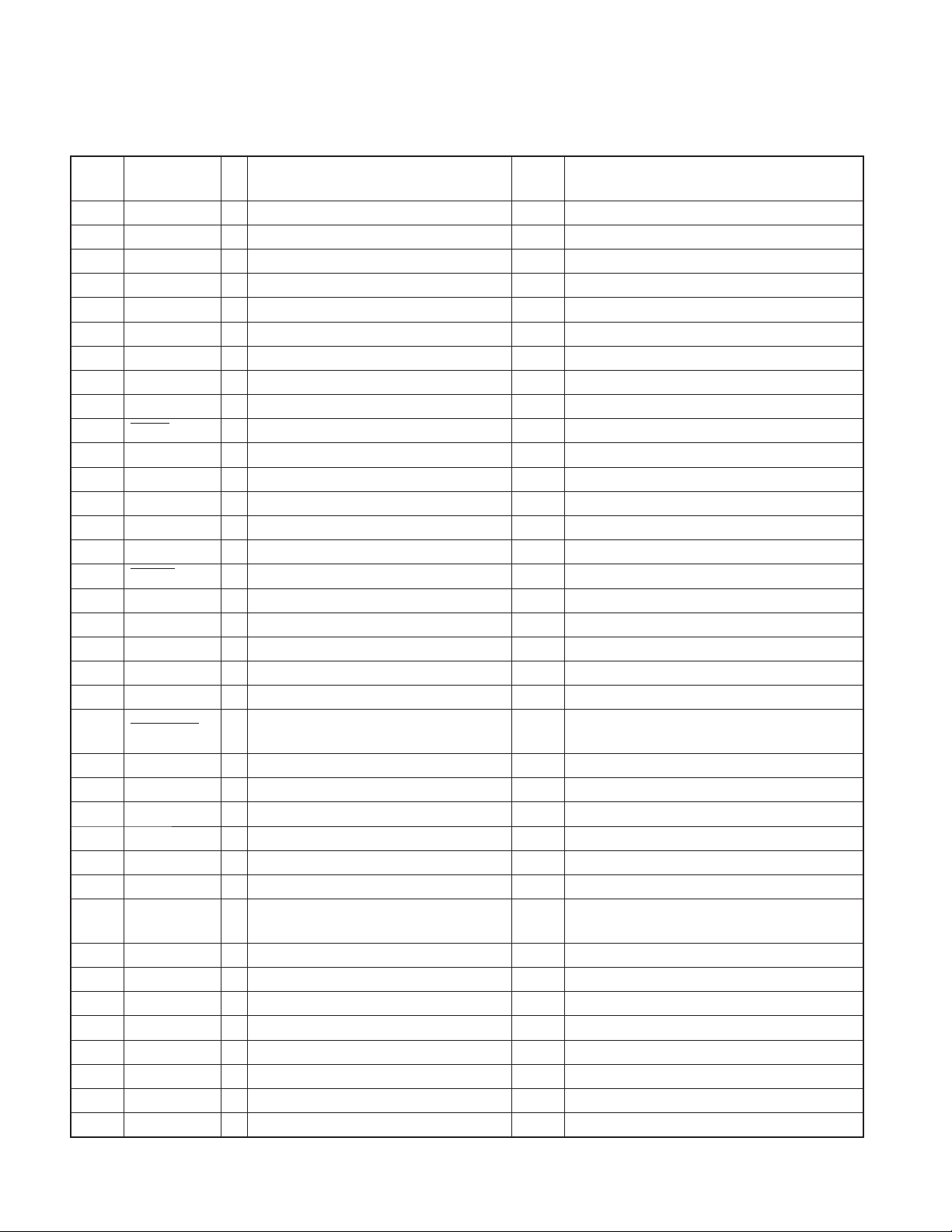

MICROCOMPUTER’S TERMINAL DESCRIPTION

SYSTEM μ-COM: IC1 on X34- (ELECTRIC UNIT)

●

Pin No. Pin Name I/O Application

1 LX DATA M I/O Data to slave unit Pull-down (GND)

2 LX CLK I/O LX-BUS clock 125k~65kHz

3~5 NC - Not used Output L fi xed

6 REMO I Remote control signal input Detects pulse width

7 NC - Not used Output L fi xed

8 BYTE - Memory extended bus width setting Connects to VSS

9 CNVSS - Connects to VSS

10 XCIN - 32.768kHz

11 XCOUT - 32.768kHz

12 RESET

13 XOUT - 10.0MHz

14 VSS -

15 XIN - 10.0MHz

16 VCC1 -

17 NMI I Connects to VCC

18 CN DET

19,20 NC - Not used Output L fi xed

21 ROMCOR DET I E2PROM writing request H: Writing

22,23 NC - Not used Output L fi xed

24 PON FL O Key illumination power supply control ON: H, OFF: L

25 NC - Not used Output L fi xed

26 PON PANEL

27,28 NC - Not used Output L fi xed

29 AUD SCL I/O E-VOL clock output

30 AUD SDA I/O E-VOL data input/output

31 VFD SYS DATA O VFD data output

32 VFD PAN DATA I VFD data input

33 VFD CLK O VFD clock output 125kHz

34 VFD BLK O VFD data blanking output

35 CD SI O CD mechanism serial output

36 CD SO I CD mechanism serial input

37 BUCK O Serial clock output 1MHz

38 CD LOS SW I CD loading detection

39 PIO0 I

40 CD SRAMSTB O 1M-bit SRAM standby H: SRAM standby

41 EPM I Flash EPM input Connects to VSS

42

CD LOE LIM SW

- L: Reset

I Panel communication detection H: Panel detached, L: Panel attached

I/O Panel 5V control

Communication request from mechanism DSP

I CD detection (Chucking SW) H: Loading completed, L: No disc

Truth Value

Table

ON: L, Momentary power down/Panel detached:

Hi-Z, 11 minutes after ACC OFF: Hi-Z

H: Reset cancelled, L: Reset, Momentary power down

/Panel detached: L, 11 minutes after ACC OFF: L

H: Data request

Processing Operation Description

4

X34-56xx-xx

MICROCOMPUTER’S TERMINAL DESCRIPTION

Pin No. Pin Name I/O Application

43 PON CD O CD mechanism power supply control H: Power ON

44 CD LOEJ I/O CD motor control

45 CD MOTOR I/O CD motor control

46 VFD CE O VFD control request

47

48 CD CCE O CD mechanism chip enable

49 NC - Not used

50 CD MRST O CD mechanism μ-com reset H: Normal, L: Reset

51~53 NC - Not used Output L fi xed

54 CD MUTE I CD mute request L: Mute request

55 CD DISC12 SW I 12cm disc detection Pull-up (B.U.)

56 ROTARY CCW I VOL key input Detects pulse width

57 ROTARY CW I VOL key input Detects pulse width

58~61 NC - Not used Output L fi xed

62 VCC2 -

63 NC - Not used Output L fi xed

64 VSS -

65 NC - Not used

66 TUN IFC OUT I Front-end IFC-OUT input H: Station found, L: No station

67 NC - Not used

68 MUTE I/O Mute L: Mute OFF, Hi-Z: Mute ON

69 NC - Not used

70 LX RST O Forced reset to slave unit H: Reset, L: Normal

71 LX CON O Start-up request to slave unit H: Slave unit ON, L: Slave unit OFF

72 LX MUTE I Mute request from slave unit H: Mute ON, L: Mute OFF

73 LX REQ M O Communication request to slave unit

74 NC - Not used

75 LX REQ S I Communication request from slave unit Pull-down (GND)

76 PWIC SVR O SVR discharging circuit

77 PWIC STBY O Power IC standby control Power ON: H, Power OFF: L

78 PWIC MUTE O Power IC mute

79 ACC DET

80 BU DET

81~83 NC O Not used Output L fi xed

84 TUN SMETER I S-meter input

85 TYPE1 I Destination switching

86 TYPE2 I Destination switching

CD DRIVEMUTE

O Motor driver mute output

I ACC power supply detection ACC found: L, No ACC: H

I Detection of momentary power down

Truth Value

Table

q

q

Processing Operation Description

Refer to the truth value table

Refer to the truth value table

During 500ms after power OFF and momentary

power down: H, Since then: L

STANDBY source/Momentary power down: L,

TEL mute: L

BU found: L, No BU/Momentary power down: H

(Operates after less than 4ms after momentary

power down is detected)

5

X34-56xx-xx

MICROCOMPUTER’S TERMINAL DESCRIPTION

Pin No. Pin Name I/O Application

87 PWIC DC DET I DC offset detection

88 LINE MUTE I Line mute detection TEL mute: Below 1V, NAVI mue: Over 2.5V

89 NC - Not used

90 PS2 2 O Power supply IC control

91 PS2 1 O Power supply IC control

92 PS1 1 O Power supply IC control

93 PS1 2 O Power supply IC control

94 PS1 3 O Power supply IC control

95 NC - Not used Output L fi xed

96 AVSS -

97 REF CON O VREF control Connects to VREF

98 VREF -

99 AVCC -

100 LX DATA S I Data from slave unit Pull-down (GND)

Truth Value

Table

r

r

r

r

r

Processing Operation Description

If DC offset is found 20 times in 100ms with condition

of over 1.0V, it will be judged as DC offset detected.

Refer to the truth value table

Refer to the truth value table

Refer to the truth value table

Refer to the truth value table

Refer to the truth value table

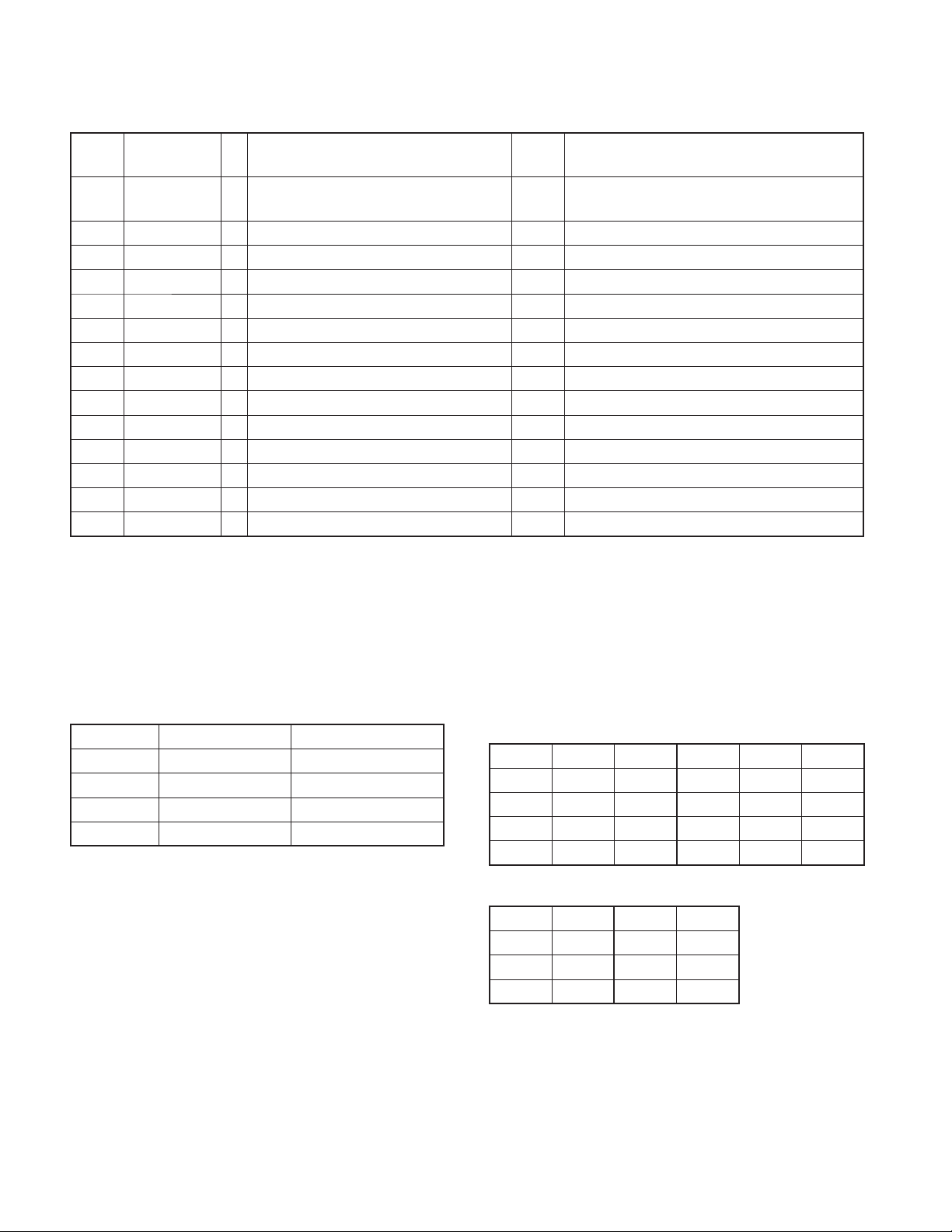

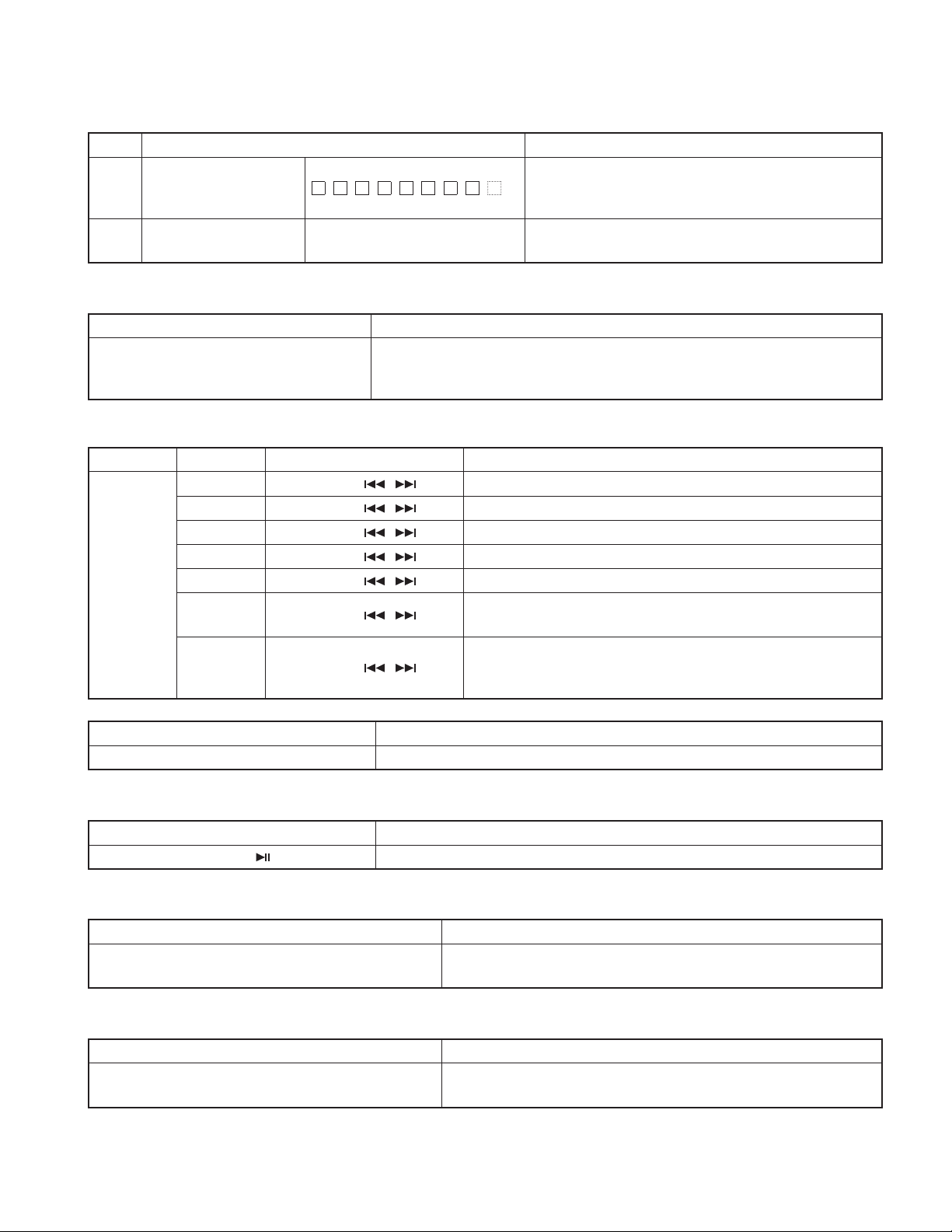

• Truth value table

CD motor control

q

CD motor CD loading/eject

Stop L L

Load H L

Eject H H

Brake H Hi-z

Power supply IC (IC4) control

r

SEL1 (Pin 10)

PS1-2 PS1-3 PS2-1 ILLUMI P-CON P-ANT

L L L OFF OFF OFF

L L H ON OFF OFF

H L H ON ON OFF

H H H ON ON ON

SEL2 (Pin 11)

PS1-1 PS2-2

L L OFF OFF

H L ON OFF

H H ON ON

AUDIO/SW5

AM

6

X34-56xx-xx

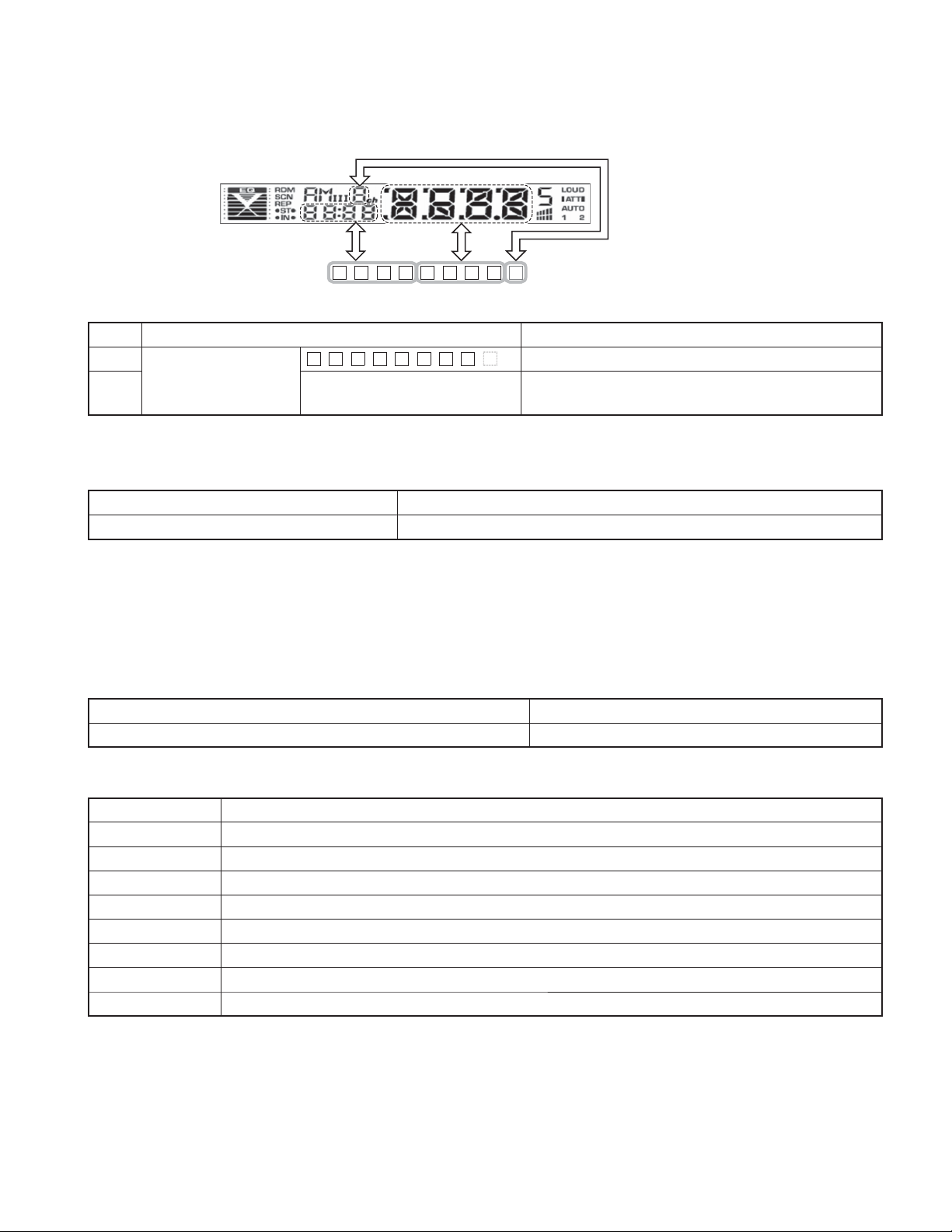

TEST MODE (7-SEG LCD)

Example

■

Key Description of display Description

5

Disc EJECT times display

5

■

A symbol “■” in the key column indicates that the key should be pressed and held for 1 second or longer.

How to enter the test mode

■

Procedure Note

Press and hold the [1] key and [3] key and reset.

EJCXXXXX

Disc EJECT times display. MAX 65535 (times)

While disc EJECT times is displayed, press and hold for

2 seconds or longer to clear disc EJECT times.

All lamps blink when it is detected that the sub-clock resonator is disconnected.

When having started up in the test mode, change the LINE MUTE inhibition time from 10 seconds to 1 second.

When operating in the test mode, even if a DC offset error occurs, detection information is not written in the E2PROM.

Forced disc ejection is prohibited in the test mode.

How to clear the test mode

■

Procedure Note

Reset, momentary power down, ACC OFF, Power OFF, Panel detached. Clearing the test mode

Test mode default condition

■

Description Default values

Source STANDBY

Display Display lights are all turned on.

Volume -10dB (“30” is displayed.)

Bass Boost OFF

CRSC OFF regardless of having/not having the switching function.

AUX ON (Only model equipped with AUX)

System Q NATURAL (FLAT)

Preout Rear

7

X34-56xx-xx

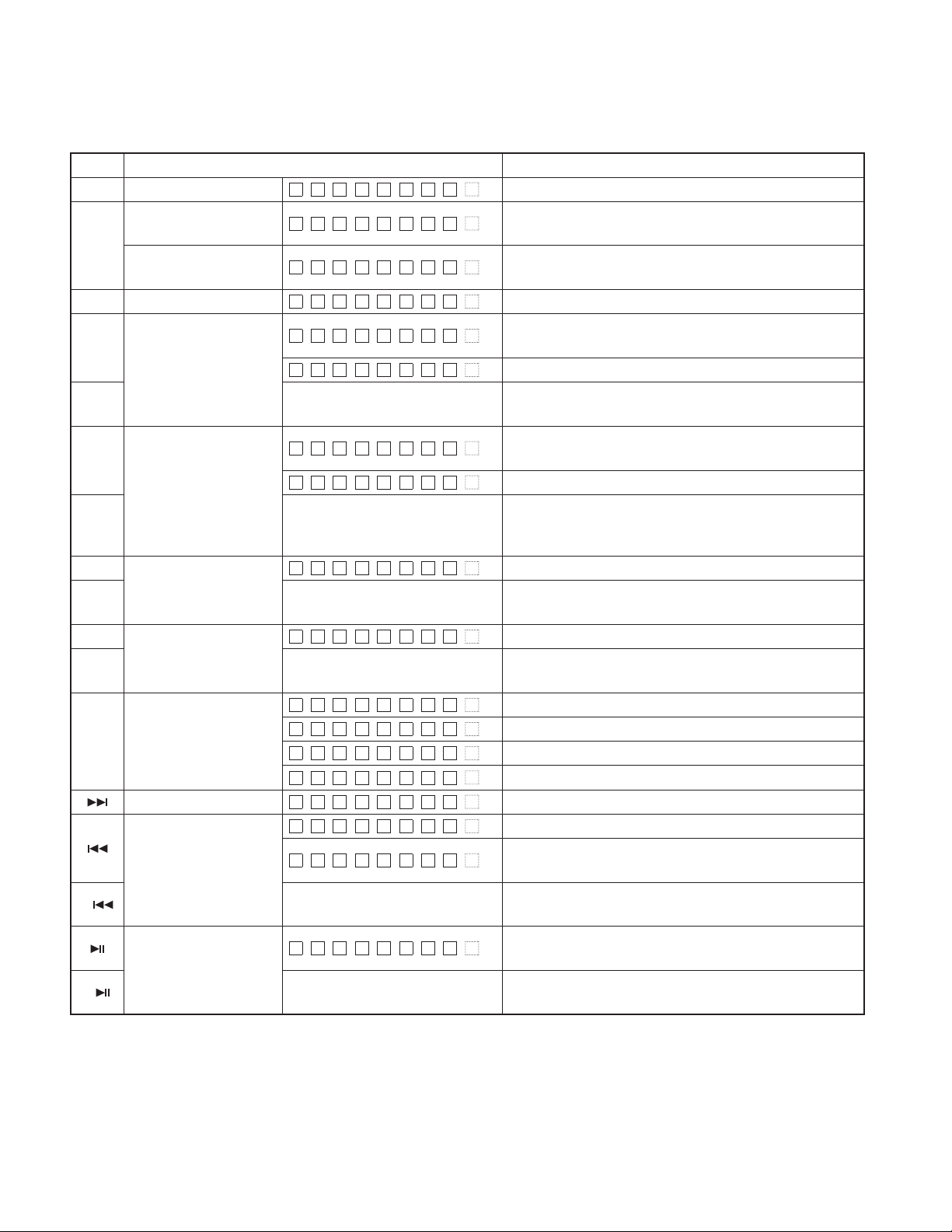

Special displays when all lights are on in STANDBY source

■

Key Description of display Description

Common

■

All lights ON. All lights ON.

Destination terminal

condition indication

1

Development ID

condition indication

2 Serial No. display

3

Power ON time display

3

■

4

Disc operation time dis-

play

4

■

5

Disc EJECT times display

5

■

6

Panel open/close

times display

6

■

ROM correction version

FM

display

Audio data initialization

Forced Power OFF

information display

CD information display

mode ON/OFF

■

TEST MODE (7-SEG LCD)

TP11

8:00701K

00000000

Pon 0HXX

PonXXXXX

PLy 0HXX

PLy XXXXX

EJCXXXXX

PC XXXXX

0123

ER

––––

oooo

InIT

POFF –––

POF F Pn L

“TYPE” indicates system μ-com (IC1) destination, and shows

real-time condition of the destination terminal.

Development ID – Version (system μ-com: IC1)

Serial No. is displayed (8 digits)

00~50 is displayed for “XX”. When less than 1 hour,

displayed by displayed by increments of 10 minutes.

00001~10922 is displayed for “XXXXX”. MAX 10922 (hours)

When Power ON time is displayed, press and hold for

2 seconds or longer to clear Power ON time.

00~50 is displayed for “XX”. When less than 1 hour,

displayed by increments of 10 minutes.

00001~10922 is displayed for “XXXXX”. MAX 10922 (hours)

While the disc operation time is displayed, press and hold for

2 seconds or longer to clear the disc operation time.

(Cleared only for displayed media.)

Disc EJECT times display. MAX 65535 (times)

While disc EJECT times is displayed, press and hold for

2 seconds or longer to clear disc EJECT times.

PANEL open/close times display. MAX 65535 (times)

Press the key for more than 2 seconds while the PANEL open/

close count is displayed and PANEL open/close count is cleared.

The number is the ROM correction version number.

When E2PROM is not installed.

When not written in yet.

When data not matched. (due to the difference in versions)

AUDIO setting value is re-set to the test mode default value.

No forced power OFF

Forced power OFF by communication error between system

μ-com and panel.

While the forced power OFF data is displayed, press and

hold for 2 seconds to clear the data.

For the display contents, refer to “CD information display

mode” in the next section.

While in CD information display mode, press and hold for

2 seconds or longer to clear all CD information.

8

• CD information display mode

Key Description of display Description

I2C communication

status

CD mecha-

/

nism error

log display

CD Load

/

error

information

display

FM

(forward

rotation)

AM

(reverse

rotation)

CD Ejection

/

error

information

display

CD time code

error count

/

data display

(Missing

counts)

CD time code

error count

/

data display

(count not

updated)

TEST MODE (7-SEG LCD)

ICOK

ICER

1:X X M – E R

2:X X M – E R

3:X X M – E R

1:X X L D E R

2:X X L D E R

1:XXEJER

2:XXEJER

3:XXEJER

4:XXEJER

LOSE

:X X C D D A

STAY

:X X C D D A

I2C communication OK

I2C communication NG

Mechanism error log 1 (Latest)

XX: Error number. “– –” is displayed in case there is no error.

Mechanism error log 2 (Latest)

XX: Error number. “– –” is displayed in case there is no error.

Mechanism error log 3 (Latest)

XX: Error number. “– –” is displayed in case there is no error.

Load error switch 1

XX: Number of errors. “– –” is displayed in case there is no error.

Load error switch 2

XX: Number of errors. “– –” is displayed in case there is no error.

Ejection error switch 1

XX: Number of errors. “– –” is displayed in case there is no error.

Ejection error switch 2

XX: Number of errors. “– –” is displayed in case there is no error.

Ejection error switch 3

XX: Number of errors. “– –” is displayed in case there is no error.

Ejection error switch 4

XX: Number of errors. “– –” is displayed in case there is no error.

CD time code error count data (Missing counts) mode display.

Number of CD-DA count errors

XX: Number of errors. “– –” is displayed in case there is no error.

CD time code error count data (count not updated) mode display.

Number of CD-DA count errors

XX: Number of errors. “– –” is displayed in case there is no error.

X34-56xx-xx

Test mode specifi cations in TUNER source

■

Error is found in front-end (A1), etc. if indications below is displayed while in tuner source.

Status Display Description

Front-end (A1) E2PROM data error

Front-end (A1) communication error

Destination mismatch

E2ER

ICER

TPER

Front-end (A1) E2PROM is still the default (unspecifi ed) value.

Communication with front-end (A1) is not possible.

When destination is mismatch between front-end (A1)

E2PROM and the product.

• TUNER preset operation

Key Description of display Description

4 Preset function

9 8.3

Change to 98.3MHz with the preset key [4].

9

X34-56xx-xx

TEST MODE (7-SEG LCD)

• K3I forced switching

Every time when [6] key is pressed in tuner FM source, switched in the following order: AUTO → Forced WIDE → Forced MIDDLE → Forced

NARROW → AUTO. Default status is AUTO, and displayed as shown below.

Key Description of display Description

A98.1

6 K3I Forced switching

398.1

298.1

198.1

• FST adjustment mode

Perform FST soft-mute adjustment.

Key Note

■

Operations in the FST adjustment mode are as follows:

Key Description of display Description

Enter the FST adjustment mode. (Press for 1 second or longer.)

/

Soft-mute adjustment

SD– F

AUTO (1)

Forced WIDE (2)

Forced MIDDLE (3)

Forced NARROW (4)

0 ↔ 7

Seek Stop Level

FM

(UP)

AM

(DOWN)

■

Switch Local Seek ON or OFF by briefl y pressing [AUTO]/[TI] key when the Local Seek ON/OFF switching is allowed in the band.

After completing the FST adjustment, if you wish to clear the test mode, you can do this using the reset button.

Test mode specifi cations in CD source

■

adjustment (Auto)

Seek Stop Level

adjustment (Auto)

/ Seek Stop Level

adjustment (Manual)

/ Seek Stop Level

adjustment (Manual)

Adjustment value

memory

Mode clear

ATn

ATL

MN n

MN L

WR T

A98.3

0.00 (V) ↔ 5.00 (V). Normal (Local OFF)

0.00 (V) ↔ 5.00 (V). Normal (Local ON)

0.00 (V) ↔ 5.00 (V). Normal (Local OFF)

0.00 (V) ↔ 5.00 (V). Normal (Local ON)

Displays the data that has been written in the E2PROM

when pressing the key for 2 seconds or longer.

Clear the FST adjustment mode. (Returns to normal

display and the test mode is retained.)

• Procedure in CD-DA media (KTD-02A)

Key Description of display Description

Every time pressed, jumps to the track shown below.

Track up procedure

Track down procedure Goes down by 1 track from the currently played track.

1 Jump procedure

2 Jump procedure Jump to No. 14 (Blurring surface disc TCD-731RA Tr14)

No.9 → No.15 → No.10 → No.11 → No.12 → No.13 → No.22

No.14 → No.9 (recursive) But in case the disc has 8 tracks

or less, playback starts with track No.1.

Jump to No. 28 (Scratch 0.7mm for MUSIC line vibration testing)

→

10

X34-56xx-xx

TEST MODE (7-SEG LCD)

Key Description of display Description

Information display

3

Mechanism model name

Mechanism version

6 Jump procedure

Audio-related test mode

■

Procedure Note

Press the [AUD] key (main unit)

Press the [AUD] and [∗] keys (Remote control)

About audio adjustment items (include both Audio Function Mode and Audio Setup Mode)

Procedure Item Procedure Description

Fader [VOL] knob and [ / ] key Adjust to 3 steps of R15 ↔ 0 ↔ F15. (Default value: 0)

Balance [VOL] knob and [

For item

forwarding

procedure,

press [AUD]

key and

[FM] key

Bass Level [VOL] knob and [

Middle Level [VOL] knob and [

Treble Level [VOL] knob and [

LPF Sub

woofer

Volume Offset [VOL] knob and [

6C000000

Enter audio adjustment mode (the initial item should be Fader, and then, Balance →

Bass Level → Middle Level → Treble Level → SW Level → System Q → V-Offset →

LPF Sub Woofer.

/ ] key Adjust to 3 steps of L15 ↔ 0 ↔ R15. (Default value: 0)

/ ] key Adjust to 3 steps of -8 ↔ 0 ↔ +8. (Default value 0)

/ ] key Adjust to 3 steps of -8 ↔ 0 ↔ +8. (Default value 0)

/ ] key Adjust to 3 steps of -8 ↔ 0 ↔ +8. (Default value 0)

[VOL] knob and [ / ] key

/ ] key

Adjust to 2 steps of 80Hz ↔ Through. (Default value: Through)

(Only in models with Sub Woofer output)

Adjust to 2 steps of -8 ↔ 0. (Default value 0) (Other than model with internal AUX)

Adjust to 3 steps of -8 ↔ 0 ↔ +8. (Default value 0)

(Only models with internal AUX)

Display of Mechanism model name and Mechanism version.

(When key is pressed while the display in the left is being

shown, returns to normal display.)

Jump to No. 15. Set the volume value to “25”.

(For 20Hz 0dB DC protection false-operation FCT checking)

Procedure Note

Press the [B.BOOST] key for 1 second or longer Switch Bass Boost (Note: Front key functions as MENU.)

[ATT] key operation

■

Procedure Note

In the TUNER source, press [

MENU-related test mode

■

Press the [B.BOOST] key (main unit)

Press the [DNPP/SBF] and [DIRECT] keys (Remote control)

Backup current measurement

■

While ACC OFF (Back Up ON), Reset

] key ATT OFF/ON

Procedure Note

Continuous forwarding by remote control is prohibited

Procedure Note

MUTE terminal is OFF after 2 seconds, not after 15 seconds.

(During this time, the CD mechanism does not function.)

11

X34-56xx-xx

TEST MODE (7-SEG LCD)

PREOUT switching (KDC-138/139/139S only)

■

Procedure Note

In the STANDBY source, press and hold [AUTO] key for

1 second or longer

LCD (ED1) short check

■

Procedure Note

In the STANDBY source, press [ATT] key

Clearing CD mechanism information / Service information / DC offset error information (Clearing E2PROM data)

■

Status Display Description

While pressing and holding [2] key

and [5] key, reset-start.

This mode is cancelled by resetting. (The last screen will not be retained.)

Data to be cleared is shown below.

I2C communication status display

CD mechanism error log display

CD mechanism information

Service Information

DC offset error information

Displays CD loading error data

Displays CD EJECT error data

Displays CD time code count error data (missing count)

Displays CD time code count error data (count not updated)

Power ON time display

CD operation time display

CD EJECT times display

PANEL open/close times display

Forced Power OFF information display

DC offset error 1 display (Provides information on whether there is an improper connection or another error)

DC offset error 2 display (Provides information on the number of capacitor leaks)

CD O

CD –

Switches PREOUT

All lights are off → Turns on odd and even terminals alternatively every

125ms (terminals that have a maximum number of grids) → Turns on only

the odd terminals → Turn on only the even terminals

At normal termination

At abnormal termination

→

Clearing DC offset error detection data (E2PROM data clearing)

■

Procedure Note

While pressing and holding [3] key and [6] key, reset-start. Entering DC offset error display mode.

Procedure Display Description

When DC offset error is detected (when either one of capacitors is

leaking, or an improper connection or another error is detected)

When DC offset error is not detected (when none of capacitors leak,

no improper connection or other error is detected)

When improper connection or other DC offset errors are detected.

When improper connection or other DC offset errors are not detected.

Press and hold the [3] and

[6] keys, and reset-start

1

dC ER

dC OK

dC1 ER

dC1 OK

12

X34-56xx-xx

TEST MODE (7-SEG LCD)

Procedure Display Description

1

■

2

2

■

This mode is cancelled by resetting. (The last screen will not be retained.)

FM/AM channel space switching (except model for European market)

■

While Power OFF, press and hold [1] key and [5] key, and press

[SRC] key to Power ON

ROM data transfer

■

When replacing front-end (A1), this function is used to transfer E2PROM data (ROM correction, security and other data) to front-end (A1) to

E2PROM of to mother unit (X34-), used for saving data, and, after completing replacement of front-end (A1), to recover data from the E2PROM

of the mother unit (X34-), and for saving data to the new front-end (A1). Refer to “ROM data transfer processes” on the next page for details on

front-end (A1) replacement procedures and on the data to be transferred.

Procedure Display Description

While pressing and holding [1]

key and [3] keys, reset-start

Press [B.BOOST] key (MENU)

Press [

(In the above ROM READ

status), ■[

2 seconds or longer

(In the above ROM WRT

status), ■[

2 seconds or longer

(In every status of ROM data

[B.BOOST] transfer processing)

] key or [ ] key

] key for

] key for

dC1 OK

dC2 4

dC2 0

Procedure Note

:

READ

READ

WR T

R–

R–OK

R–02

R–ER

W–

W–OK

W– 0 1

W– 0 2

W– ER

:

When detecting improper connection or other DC offset errors, clears

detection data. (Clear E2PROM)

When detecting capacitor leak, provides information on the number

of capacitor leaks. (0~4)

When detecting capacitor leak, clears the number of capacitor leaks.

(Clear E2PROM)

FM200kHz/AM10kHz ↔ FM50kHz/AM9kHz (Except KDC-138CR)

FM50kHz/AM10kHz ↔ FM200kHz/AM10kHz (KDC-138CR)

All lights ON.

MENU mode

Front-end (A1) → Mother unit (X34-). Data transfer processing.

Mother unit (X34-) → Front-end (A1). Data transfer processing.

Front-end (A1) → Mother unit (X34-). ROM data is being transferred.

Front-end (A1) → Mother unit (X34-).

ROM correction transfer, security and other data is OK.

Front-end (A1) → Mother unit (X34-).

Transfer of security and other data is OK.

Front-end (A1) → Mother unit (X34-). ROM data transfer is NG.

Mother unit (X34-) → Front -end (A1). ROM data is being transferred.

Mother unit (X34-) → Front-end (A1).

ROM correction, security and other data transfer is OK.

Mother unit (X34-) → Front-end (A1).

ROM correction data transfer is OK.

Mother unit (X34-) → Front-end (A1).

Transfer of security and other data is OK.

Mother unit (X34-) → Front-end (A1). ROM data transfer is NG

Clear from ROM correction data transfer processing

13

X34-56xx-xx

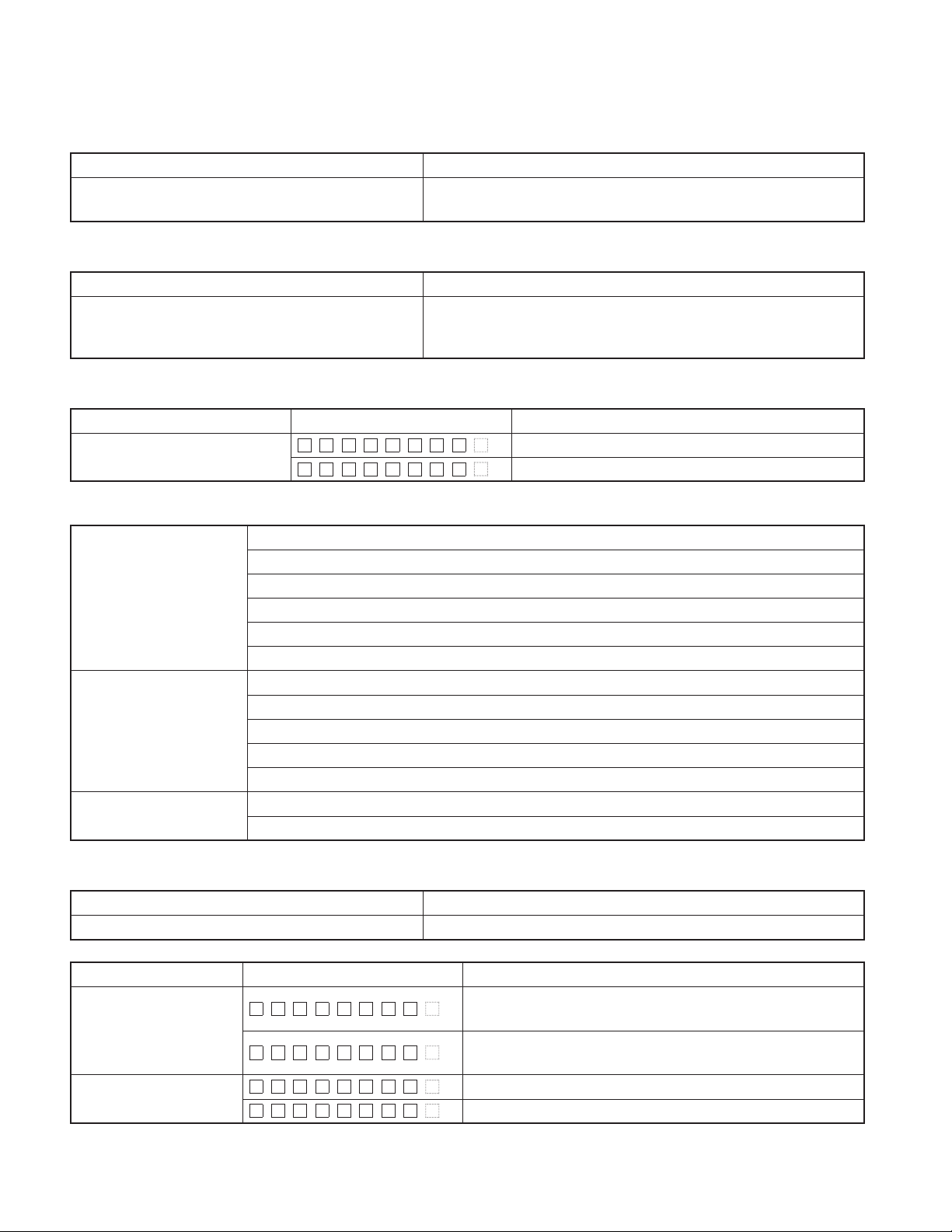

TEST MODE (14-SEG VFD)

Example

■

::.

Key Description of display Description

5

Disc EJECT times display

5

■

A symbol “■” in the key column indicates that the key should be pressed and held for 1 second or longer.

How to enter the test mode

■

Procedure Note

Press and hold the [1] key and [3] key and reset.

EJCXXXXX

While “– – – –” is displayed, power can be turned ON for only 30 minutes.

(KDC-MP238/MP439 only)

Disc EJECT times display. MAX 65535 (times)

While disc EJECT times is displayed, press and hold for 2

seconds or longer to clear disc EJECT times.

All lamps blink when it is detected that the sub-clock resonator is disconnected.

Do not display “CODE_OFF”, “CODE_ON” or “CODE_NG” when Power is ON.

When having started up in the test mode, change the LINE MUTE inhibition time from 10 seconds to 1 second.

When operating in the test mode, even if a DC offset error occurs, detection information is not written in the E2PROM.

When operating in the test mode, CD mechanism error log information clear mode, and DC offset error detection information clear mode, do

not perform DEMO mode operations.

Also, do not display DEMO ON/OFF option items in the MENU in STANDBY source in the above modes.

Forced disc ejection is prohibited in the test mode.

How to clear the test mode

■

Procedure Note

Reset, momentary power down, ACC OFF, Power OFF, Panel detached. Clearing the test mode

Test mode default condition

■

Description Default values

Source STANDBY

Display Display lights are all turned on.

Volume -10dB (“30” is displayed.)

Bass Boost OFF

CRSC OFF regardless of having/not having the switching function.

AUX ON

System Q NATURAL (FLAT)

Preout Rear

14

Loading...

Loading...