Kenmore 385.15358 User Manual

SERVICE MANUAL

SEWING MACHINE MODEL

385. 15358

SEPTEMBER, 2006

CONTENTS

LOCATE AND IDENTIFY THE PARTS.......................................................................... 1

WIND THE BOBBIN........................................................................................................ 2

PREPARE YOUR TOP THREAD................................................................................... 3

WHAT TO DO WHEN.................................................................................................. 4-6

SERVICE ACCESS

FACE COVER............................................................................................... 7

BELT COVER................................................................................................ 7

BASE PLATE................................................................................................. 8

FRONT COVER............................................................................................ 9

REAR COVER............................................................................................. 10

MECHANICAL ADJUSTMENT

NEEDLE THREAD TENSION..................................................................... 11

BOBBIN TENSION...................................................................................... 12

PRESSER BAR HEIGHT AND ALIGNMENT

NEEDLE SWING......................................................................................... 14

NEEDLE DROP........................................................................................... 15

CLEARANCE BETWEEN NEEDLE AND HOOK (N0.1)

CLEARANCE BETWEEN NEEDLE AND HOOK (N0.2)

FEED DOG HEIGHT................................................................................... 18

NEEDLE BAR HEIGHT............................................................................... 19

NEEDLE TIMING TO SHUTTLE ................................................................ 20

BUTTONHOLE FEED BALANCE............................................................... 21

DISTORTED PATTERN.............................................................................. 22

BARTACK FEED OF BUTTONHOLE......................................................... 23

DISENGAGEMENT OF CAM FOLLOWER

BUTTUNHOLE FUNCTION

MOTOR BELT TENSION ........................................................................... 26

TO REPLACE NEEDLE THREADER PLATE ............................................ 27

........................................................................

.............................................

............................

............................

................................................

13

16

17

24

25

WIRING ........................................................................................................................ 28

OILING ......................................................................................................................... 29

SPECIAL TOOLS REQUIRED...................................................................................... 30

VI .0

SEWING MACHINE DIV. 20 MODEL 384. 15358

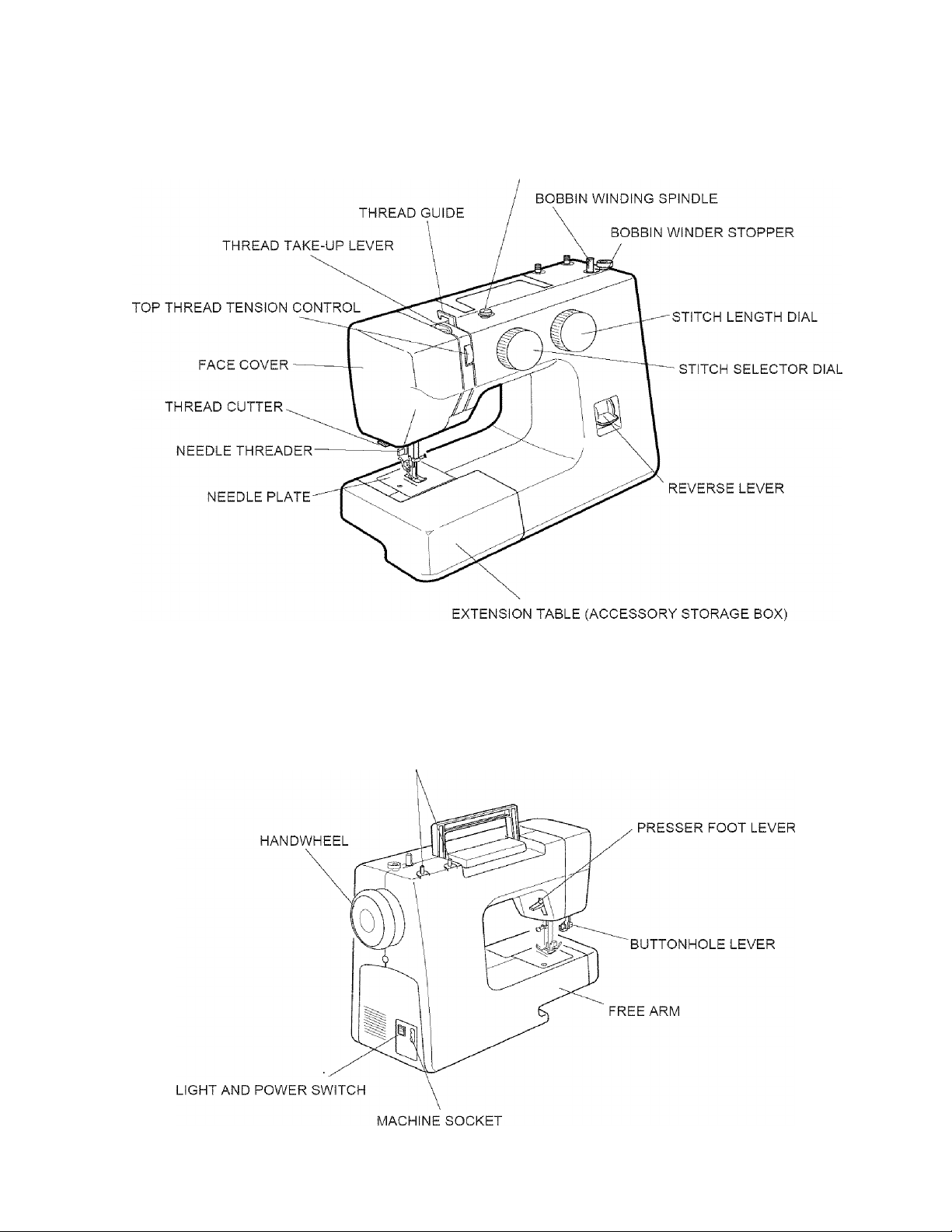

LOCATE AND IDENTIFY THE PARTS

BOBBIN WINDING TENSION DISC

SPOOL PINS

SEWING machíne DIV. 20 MODEL 384. 15358

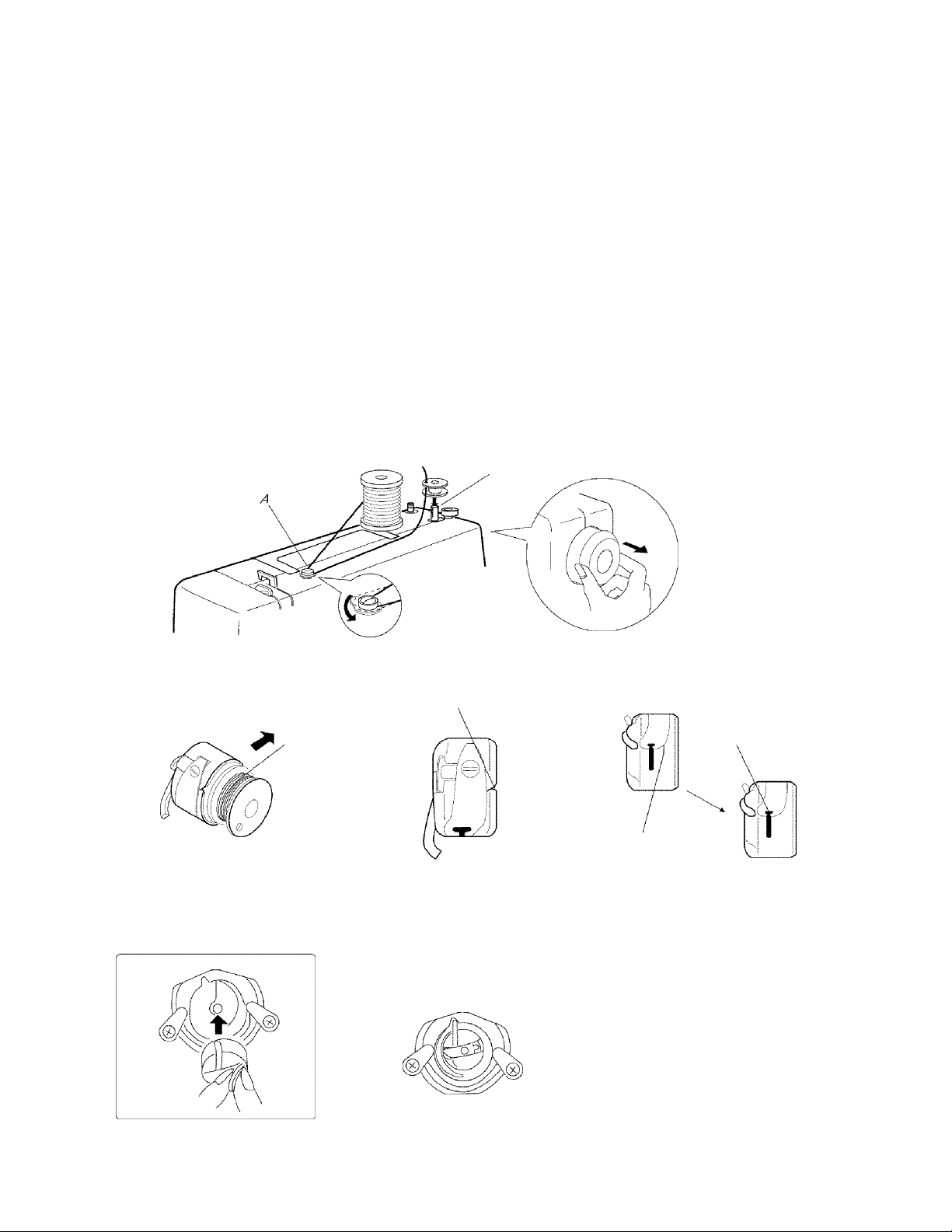

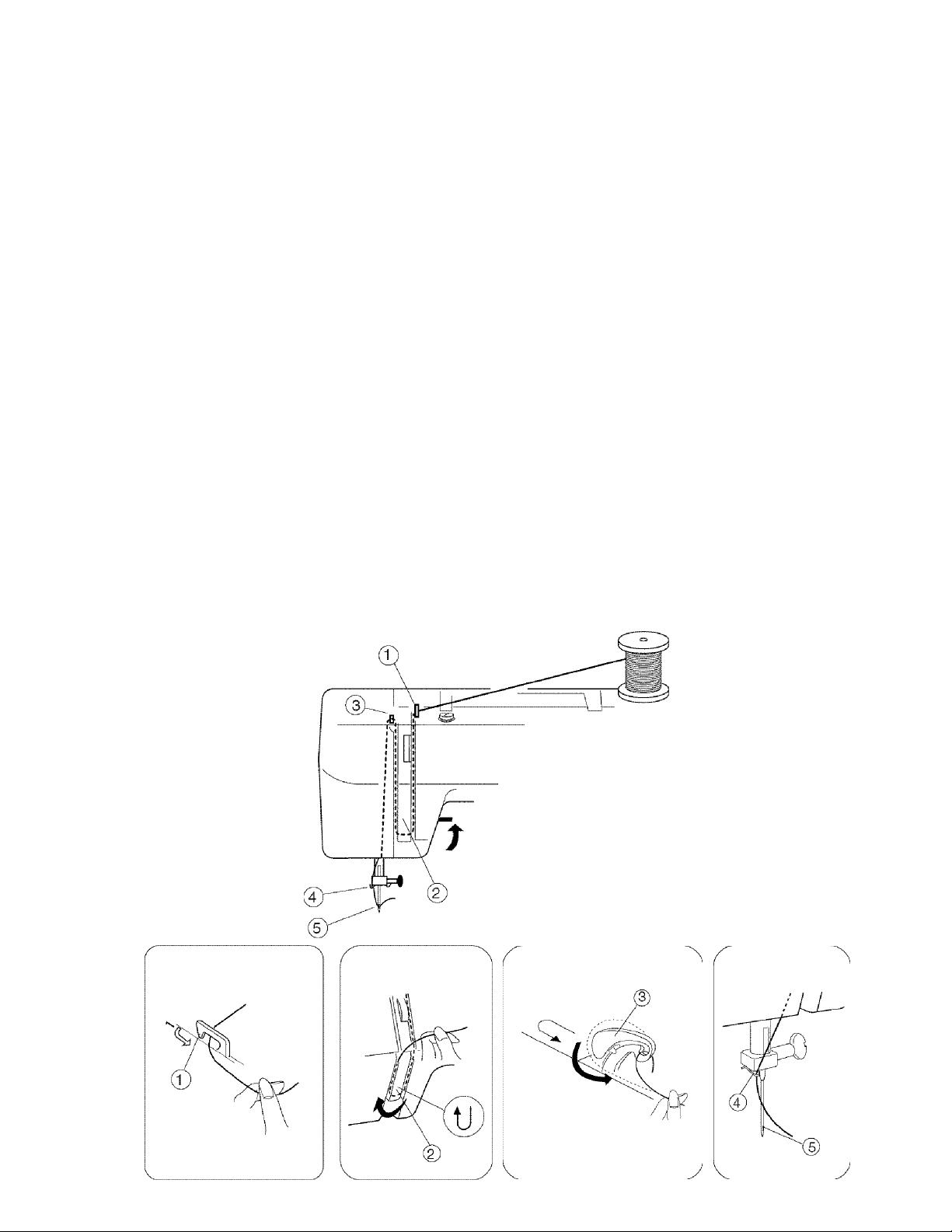

WIND THE BOBBIN

1.

PULL THE HANDWHEEL OUT.

2.

DRAW THREAD FROM THE SPOOL. GUIDE THE THREAD AROUND THE THREAD

GUIDE. THREAD THROUGH THE BOBBIN WINDER TENSION DISK "A" AND THE

HOLE IN THE BOBBIN FROM THE INSIDE TO THE OUTSIDE.

3.

PLACE BOBBIN ONTO BOBBIN WINDING SPINDLE "B" WITH END OF THREAD

COMING FROM THE TOP OF THE BOBBIN.

PUSH BOBBIN WINDING SPINDLE TO THE RIGHT UNTIL IT CLICKS.

HOLDING THE END OF THREAD, START MACHINE. WHEN BOBBIN IS SLIGHTLY

FILLED, SNIP OFF THE END OF THREAD.

5.

WIND THREAD UNTIL BOBBIN STOPS. REMOVE BOBBIN.

6.

PUSH THE HANDWHEEL TO THE LEFT.

B

PLACE BOBBIN IN BOBBIN CASE

MAKING SURE THREAD FEEDS

CLOCKWISE AND IS COMING

FROM BOBBIN AS SHOWN.

4 HOLDING LATCH OPEN, POSITION

CASE INTO SHUTTLE AND

RELEASE LATCH.

2 PULL THREAD THROUGH

SLIT OF CASE AS SHOWN.

CASE SHOULD LOCK INTO PLACE

WHEN LATCH IS RELEASED.

PULL THREAD UNDER TENSION

SPRING AND THROUGH THE

OPENING AS SHOWN ABOVE.

SEWING machíne DIV. 20 MODEL 384. 15358

PREPARE YOUR TOP THREAD

FOR THREADING THE MACHINE, FOLLOW THE NUMBERS IN ORDER AS SHOWN

ON THE ILLUSTRATION.

DOTTED LINES SHOW THE PLACES WHERE THE THREAD LOOPS AND THEN

IS PULLED TIGHT.

RAISE THE PRESSER FOOT LEVER.

PLACE A SPOOL ON THE SPOOL PIN, WITH THREAD COMING OFF AS SHOWN.

1. DRAW THREAD THROUGH THE THREAD GUIDE.

2. HOLDING THREAD TAUT WITH RIGHT HAND, DRAW THREAD DOWN INTO THE

TENSION AREA AND THEN AROUND THE CHECK SPRING HOLDER.

3. FIRMLY DRAW THREAD UP AND THROUGH THE TAKE-UP LEVER FROM RIGHT

TO LEFT.

4. DRAW THREAD DOWN AGAIN AND SLIP IT INTO THE NEEDLE BAR THREAD

GUIDE.

5. TREAD NEEDLE FROM FRONT TO BACK.

NOTE; YOU MAY WANT TO CUT THE END OF THREAD WITH SHARP SCISSORS

FOR EASIER NEEDLE THREADING.

SEWING machíne DIV. 20 MODEL 384. 15358

WHAT TO DO WHEN

CONDITION CAUSE HOW TO FIX REFERENCE

1. SKIPPING

STITCHES

1. NEEDLE IS NOT INSERTED

PROPERLY.

2. NEEDLE IS BENT OR WORN. CHANGE THE NEEDLE.

3. INCORRECTLY THREADED RETHREAD.

4. NEEDLE OR THREAD ARE

INAPPROPRIATE FOR

FABRIC BEING SEWN.

5. SEWING ON STRETCH

FABRIC

6. INAPPROPRIATE NEEDLE

BAR HEIGHT

7. INAPPROPRIATE NEEDLE

TO HOOK TIMING

8. INAPPROPRIATE NEEDLE

TO HOOK CLEARANCE

INSERT THE NEEDLE PROPERLY.

USE THE RECOMMENDED

SEWING NEEDLE AND THREAD.

USE A #11 BLUE TIP NEEDLE.

SEE MECHANICAL

ADJUSTMENT

“NEEDLE BAR HEIGHT.”

SEE MECHANICAL

ADJUSTMENT“NEEDLE

TIMING TO SHUTTLE.”

SEE MECHANICAL

ADJUSTMENT“CLEARANCE

BETWEEN NEEDLE AND

HOOK.”

P.19

P.20

P.16,17

2. FABRIC NOT

MOVING

1. INCORRECT

FEED DOG HEIGHT

2. THREAD ON BOTTOM SIDE

OF FABRIC IS JAMMED UP.

3. FEED DOG TEETH ARE

WORN.

SEE MECHANICAL

ADJUSTMENT “FEED DOG

HEIGHT.”

MAKE SURE TO BRING

BOTH NEEDLE AND BOBBIN

THREADS UNDER THE FOOT

WHEN STARTING SEWING.

CHANGE THE FEED DOG.

P.18

SEWING machíne DIV. 20 MODEL 384. 15358

CONDITION CAUSE HOW TO FIX REFERENCE

3. BREAKING

UPPER

THREAD

4. BREAKING

BOBBIN

THREAD

1. INITIAL SEWING SPEED IS

TOO FAST.

2. THREAD PATH IS

INCORRECT.

3. NEEDLE IS BENT OR DULL. REPLACE WITH A NEW NEEDLE.

4. UPPER THREAD TENSION IS

TOO STRONG.

5. NEEDLE SIZE IS

INAPPROPRIATE FOR

FABRIC.

6. NEEDLE EYE IS WORN. CHANGE THE NEEDLE.

7. NEEDLE HOLE IN NEEDLE

PLATE IS WORN OR BURRED.

1. INCORRECTLY THREADED

BOBBIN CASE.

2. TOO MUCH THREAD IS

WOUND ON THE BOBBIN.

3. LINT IS STUCK INSIDE THE

HOOK RACE.

START WITH MEDIUM SPEED.

USE THE PROPER THREAD

PATH.

ADJUST UPPER THREAD

TENSION CORRECTLY.

USE APPROPRIATE NEEDLE

AND THREAD FOR FABRIC

IN USE.

REPAIR THE HOLE OR

REPLACE THE NEEDLE PLATE.

THREAD BOBBIN CASE

CORRECTLY.

ADJUST THE POSITION OF

STOPPER.

CLEAN THE HOOK RACE.

P.11

5. NEEDLE

BREAKS

4. THREAD QUALITY IS

TOO LOW.

5. THREAD IS JAMMING

AROUND THE BOBBIN.

6. BOBBIN THREAD TENSION IS

TOO STRONG.

1. NEEDLE IS HITTING THE

NEEDLE PLATE.

2. NEEDLE IS BENT OR WORN. CHANGE THE NEEDLE.

3. NEEDLE IS HITTING THE

HOOK RACE.

4. THE FABRIC MOVES WHILE

THE NEEDLE IS PIERCING

IT, OR THE NEEDLE ZIGZAGS

WHILE IN FABRIC.

5. FABRIC IS BEING PULLED TOO

STRONGLY WHILE SEWING.

CHANGE TO A HIGH QUALITY

SEWING THREAD.

CLEAR OUT THE JAMMING

THREAD.

ADJUST BOBBIN THREAD

TENSION CORRECTLY.

SEE MECHANICAL

ADJUSTMENT “NEEDLE DROP.”

SEE MECHANICAL

ADJUSTMENT “CLEARANCE

BETWEEN NEEDLE AND HOOK”.

SEE MECHANICAL

ADJUSTMENT “NEEDLE SWING”.

GUIDE THE FABRIC GENTLY

WHILE SEWING.

P.12

P.15

P.16, 17

P.14

SEWING machíne DIV. 20 MODEL 384. 15358

CONDITION CAUSE HOW TO FIX REFERENCE

6. NOISY

OPERATION

7. DEFORMATION

PATTERN

1. BACKLASH BETWEEN

SHUTTLE HOOK GEAR AND

LOWER SHAFT GEAR IS TOO

GREAT.

2. LOWER SHAFT GEAR IS

LOOSE.

3. INAPPROPRIATE BELT

TENSION.

4. UPPER SHAFT GEAR IS LOOSE.

5. NOT ENOUGH OIL. OIL ALL MOVING PARTS.

1. INAPPROPRIATE ZIGZAG

SYNCHRONIZATION.

2. INAPPROPRIATE

DISENGAGEMENT OF CAM

FOLLOWER.

SEE MECHANICAL

ADJUSTMENT "CLEARANCE

BETWEEN NEEDLE AND HOOK

(N0.2)”.

ELIMINATE THE LOOSENESS.

SEE MECHANICAL

ADJUSTMENT “MOTOR BELT

TENSION”.

ELIMINATE THE LOOSENESS.

SEE MECHANICAL

ADJUSTMENT“NEEDLE

SWING”.

SEE MECHANICAL

ADJUSTM

“DISENGAGEMENT OF CAM

FOLLOWER”.

P.17

P.26

P.14

P.24

3. UPPER THREAD TENSION

IS TOO STRONG.

ADJUST UPPER THREAD

TENSION CORRECTLY.

P.11

SEWING machíne DIV. 20 MODEL 384. 15358

SERVICE ACCESS

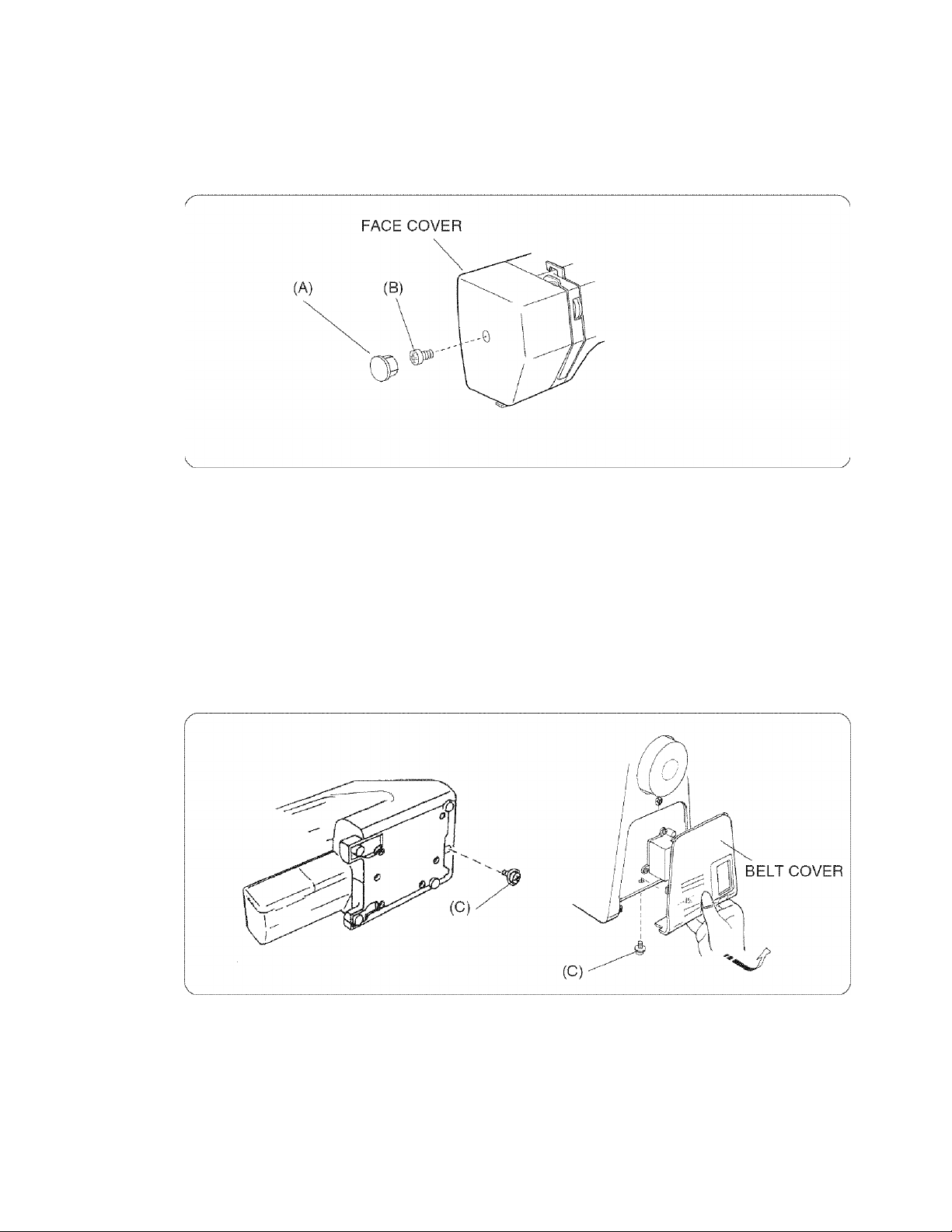

FACE COVER

TO REMOVE:

1. REMOVE THE FACE COVER BY REMOVING THE CAP (A) AND SETSCREW (B)

TO ATTACH:

2. FOLLOW THE ABOVE PROCEDURE IN REVERSE.

BELT COVER

TO REMOVE:

1. LOOSEN SETSCREW (C).

2. TAKE THE BELT COVER OUT.

TO ATTACH:

3. FOLLOW THE ABOVE PROCEDURE IN REVERSE.

SEWING machíne DIV. 20 MODEL 384. 15358

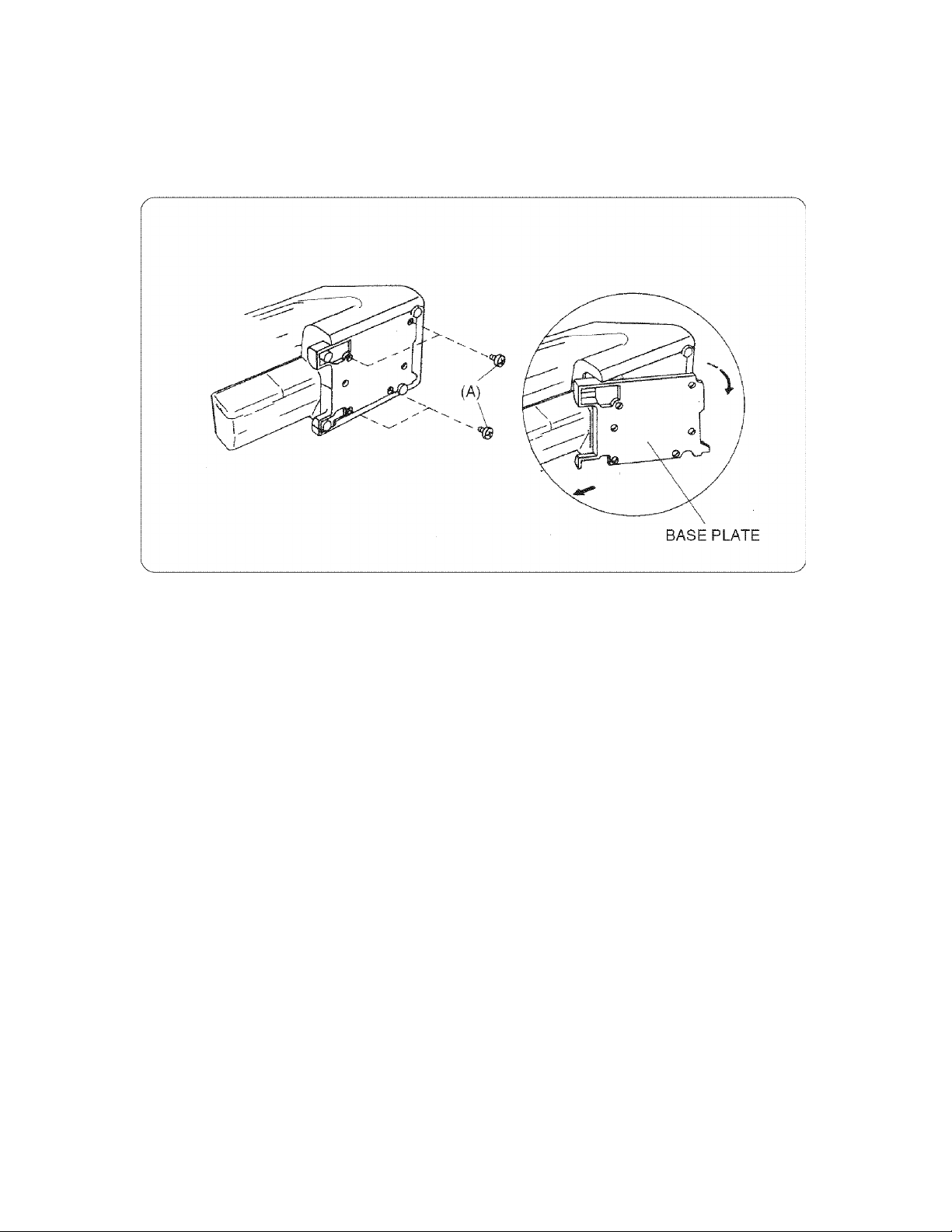

SERVICE ACCESS

BASE PLATE

TO REMOVE:

1. LOOSEN THE SETSCREWS (A).

2. REMOVE THE BASE PLATE.

TO ATTACH:

3. MOUNT THE BASE PLATE AND SECURE !T WITH FOUR SETSCREWS.

Loading...

Loading...