Kenmore 3851284180 Owner’s Manual

OWNER'S MANUAL

SEA/RS

SEWING MACHINE

MODI

SEARS, ROEBUCK AND CO,

Dear Customer:

You have just invested in a very fine zigzag sewing machine. Before using your new Kenmore machine,

please pause for a moment and carefully read th_s booklet which contains instructions on how to operate

and care for your machine.

Specific mstructions are given on threading, tension adiustments, cleaning, oiling, etc. This wiff hetp you

obtain the best sewing results and avoid unnecessary servtce expense for conditions beyond our control.

AdvEce on the operation and care of your machine _salways available at your nearest Sears Retail Store.

Please remember, if you have questions about your machine or need parts and service, always mention

the model number and serial number when you inquire.

Kenmore Sewing Machine

Record in space provided below the model number and serial

number of this appliance. The model number and seria! number

are located on the nomenclature plate, as identified on Page 3 of

this booklet.

Model No. 385. Serial No.

Retain these numbers for future reference.

THIS MODEL IS A CENTER NEEDLE, LOW BAR SEWING MACHINE.

TABLE OF CONTENTS

SECTION 1.

SECTION 2.

SECTION 3.

KNOW YOUR MACHINE

A Portable Caseor Cabinet is Available .............. 2

Locate and Identify the Parts .................. 2_3

Identify the Accessories ........................ 3

PREPARE YOUR MACHINE FOR SEWING

Set Up the Machine ...................... 4_6

• Plug in the Machme and Switch on the Power ....... 4

• Foot Control Use ........................ 4

Setting Spool Pins ......................... 5

• Adjust the Presser Foot Lever .................. 5

o Free Arm Sewing: the Removable

Extension Table ........................ 5_6

Know What the Presser Feet Will Do ............ 7"--8

Choose Your Needle and Thread .............. 9_10

• Check Your Needle ...................... 9

Fabric, Needle, Thread and Stitch Length Chart ..... 10

• To Change Your Needle ..................... 10

Prepare the Bobbin ....................... 11_13

, To Remove the Bobbin Case from the Machine ..... 11

• Wind the Bobbin ..................... 11_12

• Insert the Bobbin into the Bobbin Case .......... 13

Prepare Your Top Thread ................... 14_15

, Thread Your Needle ................... 14_15

Pick Up Your Bobbin Thread ................. 15

Adjust the Top Thread Tension ........... 16_17

Stitch Selector ............................. 1B

Stitch Length Control ..................... 18

Adjusting Stretch Stitch Balance .............. 18

Reverse Stitch Control ...................... 18

Starting To Sew ....................... t9

LEARN THE STITCHES

Practical Stitch Chart ................... 20_22

Straight Stitches ................... 23_24

• Straight Stitch .......................... 23

• Use the Seam Guides ....................... 23

• Turn a Square Corner ..................... 23

• Use the Darning Plate ...................... 24

• Topstitching .......................... 24

, Left Needle Position ....................... 24

Darning ............................ 25

Straight Stretch .......................... 25

Zigzag Stitches .......................... 26_30

• Basic Zigzag ............................ 26

, Satin Stitch ......................... 27

a Applique .............................. 28

• Bar Tacking ............................. 28

° Sew a Button ........................... 29

o Overcasting Stitch ....................... 30

• Rick-R ack Stretch ........................ 30

• Three-Step Zigzag ........................ 31

• Overcasting Stretch Stitching ................. 32

• Serging or Pine Leaf Stretch Stitching ............ 32

Blind Hemming ............................ 33

Lace Work ............................ 34

Buttonholes ......................... 35_36

Sew in a Zipper ......................... 37_38

Shell Stitching ........................... 39

Smocking ............................ 39

Elastic Stretch Stitch ...................... 40

Box Stitching .......................... 40

SECTION 4. PERFORMANCE PROBLEMS CHART

What to Do When ....................... 41_42

SECTION 5. CARE FOR YOUR MACHINE

Replacing the Light Bulb ................. 43

Cleaning the Machine ............... 43_46

• Clean the Feed Dogs ...................... 43

a Clean the Shuttle Race ..................... 44

• Oil behind the Face Cover Plate ............... 45

• Oil under the Top Cover ................... 45

Oil the Underside ......................... 46

PARTS LIST ................................... 47

INDEX ....................................... 48

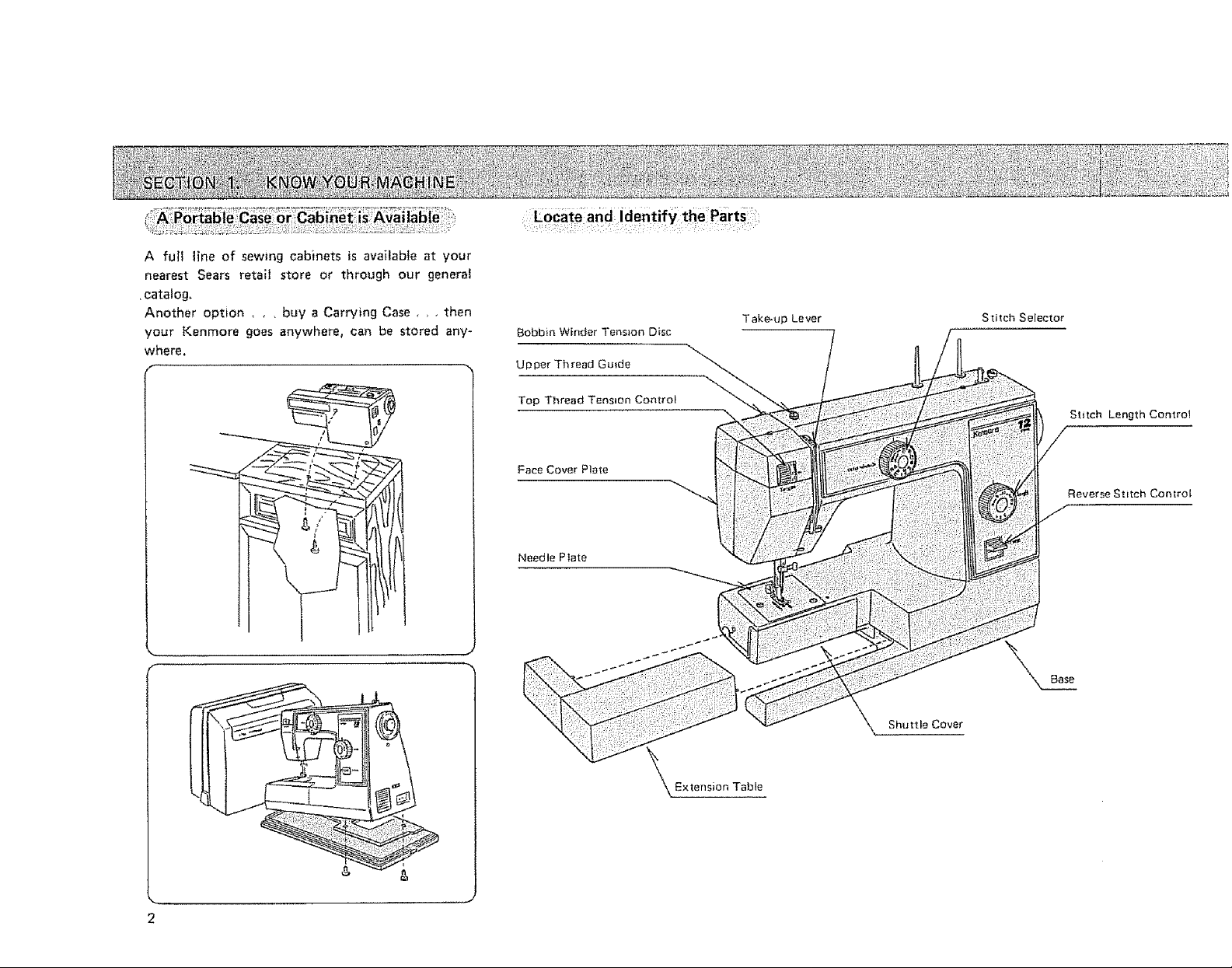

A full line of sewing cabinets is available at your

nearest Sears retail store or through our general

•catalog,

Another option , , , buy a Carrying Case , , , then

your Kenmore goes anywhere, can be stored any-

where.

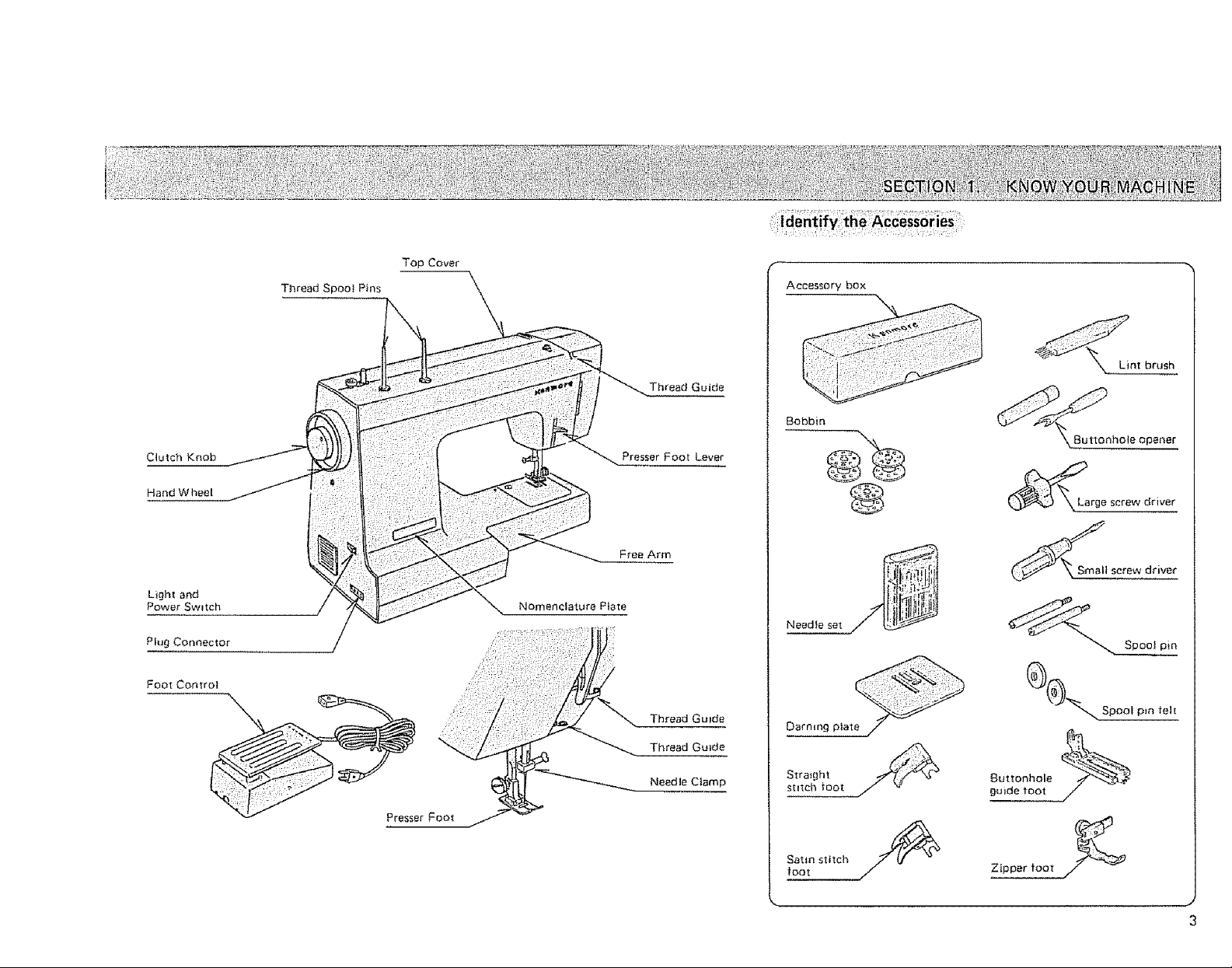

: Locate and identify theParts

_obbin Winder Tension Disc

Upper Thread Gu_de

Top Thread Tension Control

Face Cover Plate

Needle Ple te

Take-up Lever

Stitch Selector

Stitch Length Control

Reverse Stitch Control

\

Extension Table

X,, Shuttle Cover

ClutchKnob

ThreadSpoolPins

Top Cover

Accessory box

" _'_.,,,,,Lint brush

Thread Guide

Bobbin

Buttonhole opener

Presser Foot Lever

Hand W heel

L_ght end

Power Switch

Plug Connector

FOOt Control

Nomenclature Plate

Free Arm

Thread Gupde

Thread Guide

Needle Clamp

Straight

stitch foot

footSatmstitch /_

(_Large screw driver

Af# 9

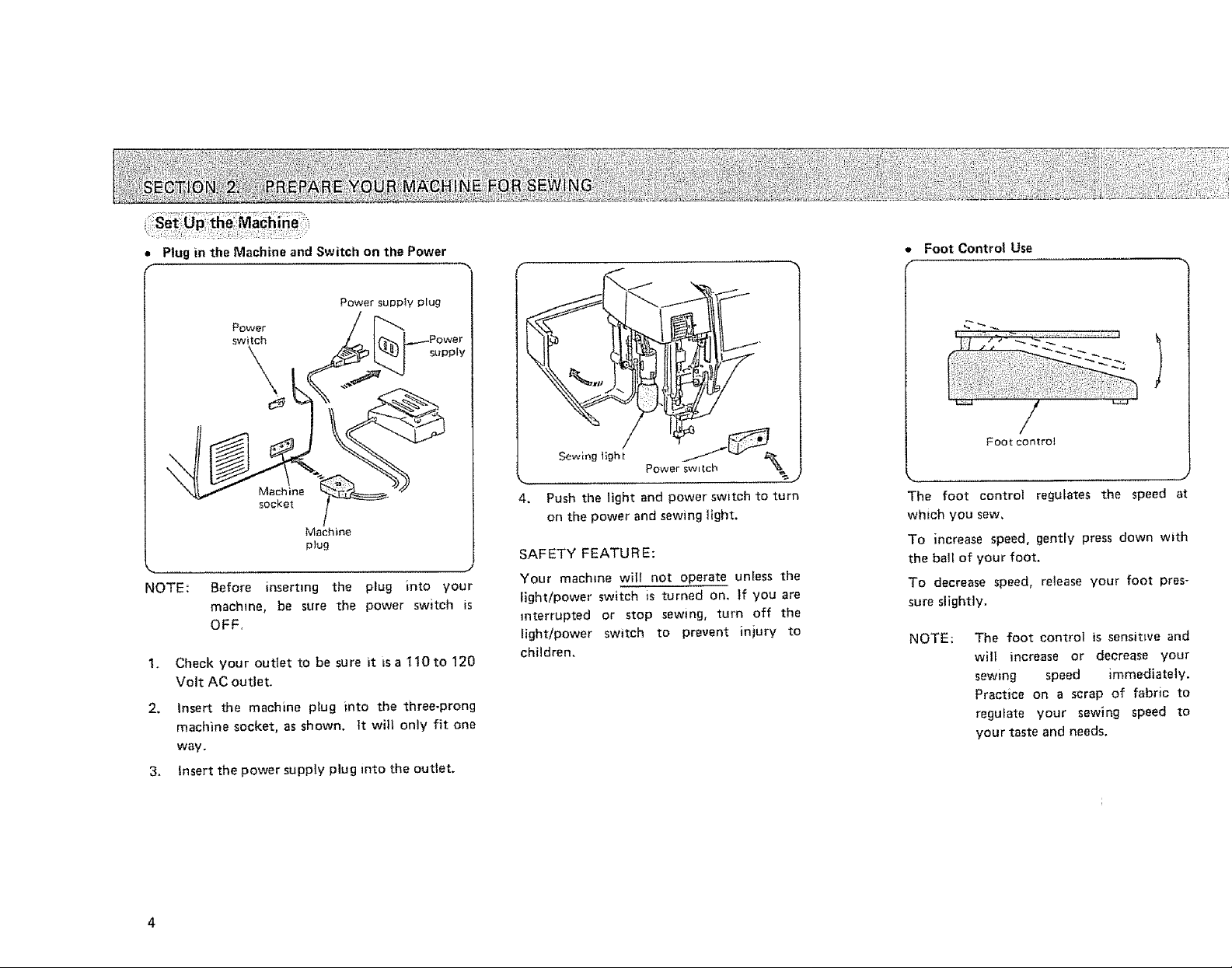

• Plug in the Machine and Switch on the Power

Power supply Plug

Power

switch

\

Machine

socket

Machine

plug

NOTE:

1.

2.

3.

Before inserting the plug into your

machine, be sure the power switch is

OFF,

Check your outlet to be sure )t isa 110to 120

Volt AC outlet.

Insert the machine plug into the three-prong

machine socket, as shown, It will only fit one

way,

Insert the power supply plug into the outlet.

supply

Sewing {igh _/_p{ !__

4_

Push the light and power switch to turn

on the power and sewing light.

SAFETY FEATURE:

Your machine will not operate unless the

light/power switch is turned on. If you are

interrupted or stop sewing, turn off the

light/power switch to prevent injury to

children,

Foot Control Use

/

Foot control

, J

The foot control regulates the speed at

which you sew,

To increase speed, gently press down with

the ball of your foot,

To decrease speed, release your foot pres-

sure slightly.

NOTE: The foot control is sensitwe and

wilt increase or decrease your

sewing speed immediately.

Practice on a scrap of fabric to

regulate your sewing speed to

your taste and needs.

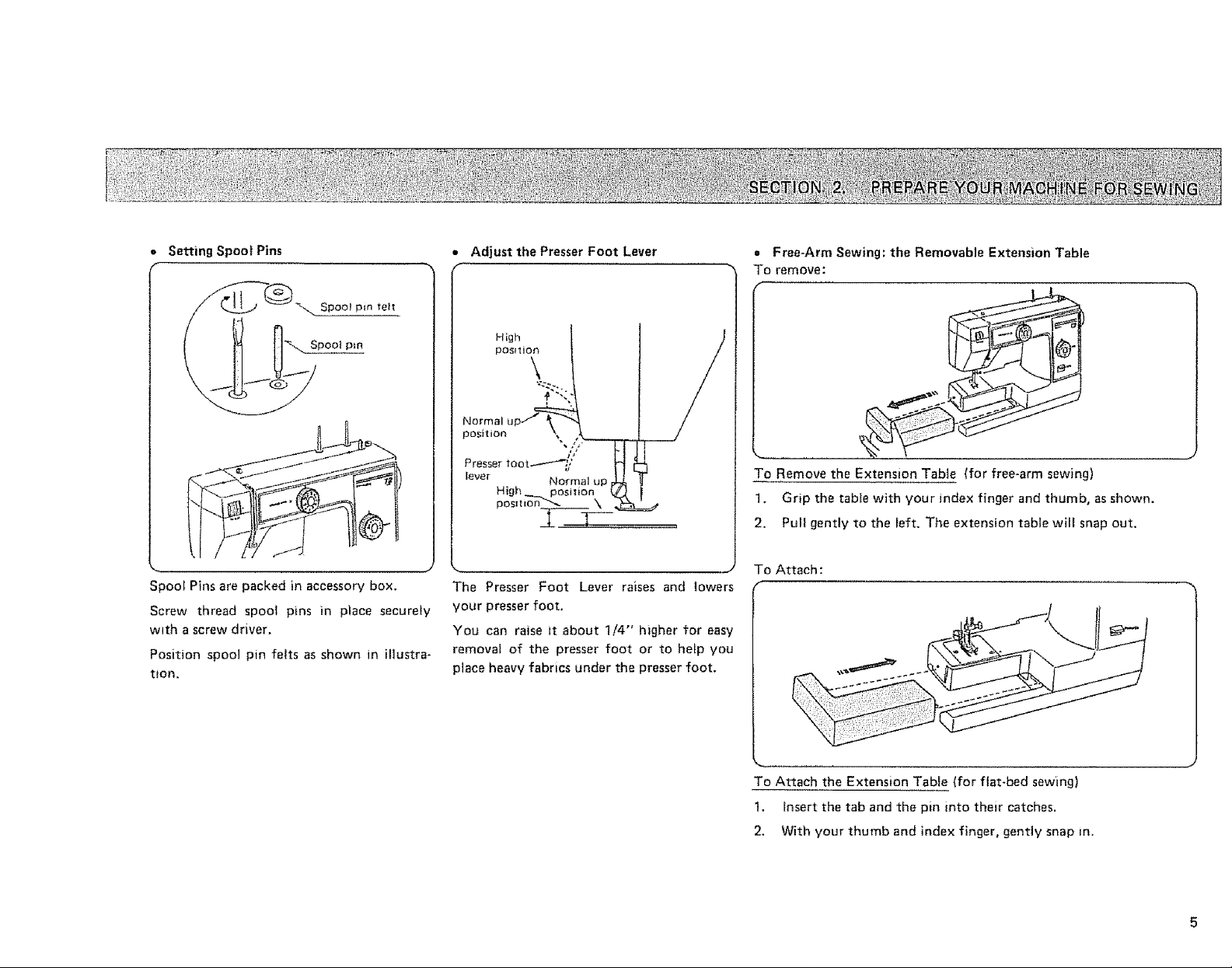

Setting Spool Pins

Spool pin tell

Spool Pins are packed in accessory box.

Screw thread spool pins in pface securely

with a screw driver,

Position spool pin felts as shown in iflustra-

tion.

Adjust the Presser Foot Lever

High

posHion

\

..~

pOSitiOn

Presser toot _--_'_;

lever Normal up

High posilion

The Presser Foot Lever raises and lowers

your presser foot.

You can raise it about 1/4" higher for easy

remova_ of the presser foot or to help you

ptace heavy fabrics under the presser foot.

,/

= Free*Arm Sewing: the Removable Extension Table

To remove:

To Remove the Extension Table (for free-arm sewing)

1. Grip the table with your index finger and thumb, as shown.

2, Pull gently to the left. The extension table will snap out,

To Attach:

To Attach the Extension Table (for flat-bed sewing)

1. Insert the tab and the pin into their catches.

2. With your thumb and index finger, gently snap m.

_, i_Z_':i_!i_i_!_:: _i_y'_'_,i'_}_i_:_;!,:_!_.:_i_::j_:_ _<_?_'_:AI_'!_;_I!I_!_?_:;',!<_:_,_L _

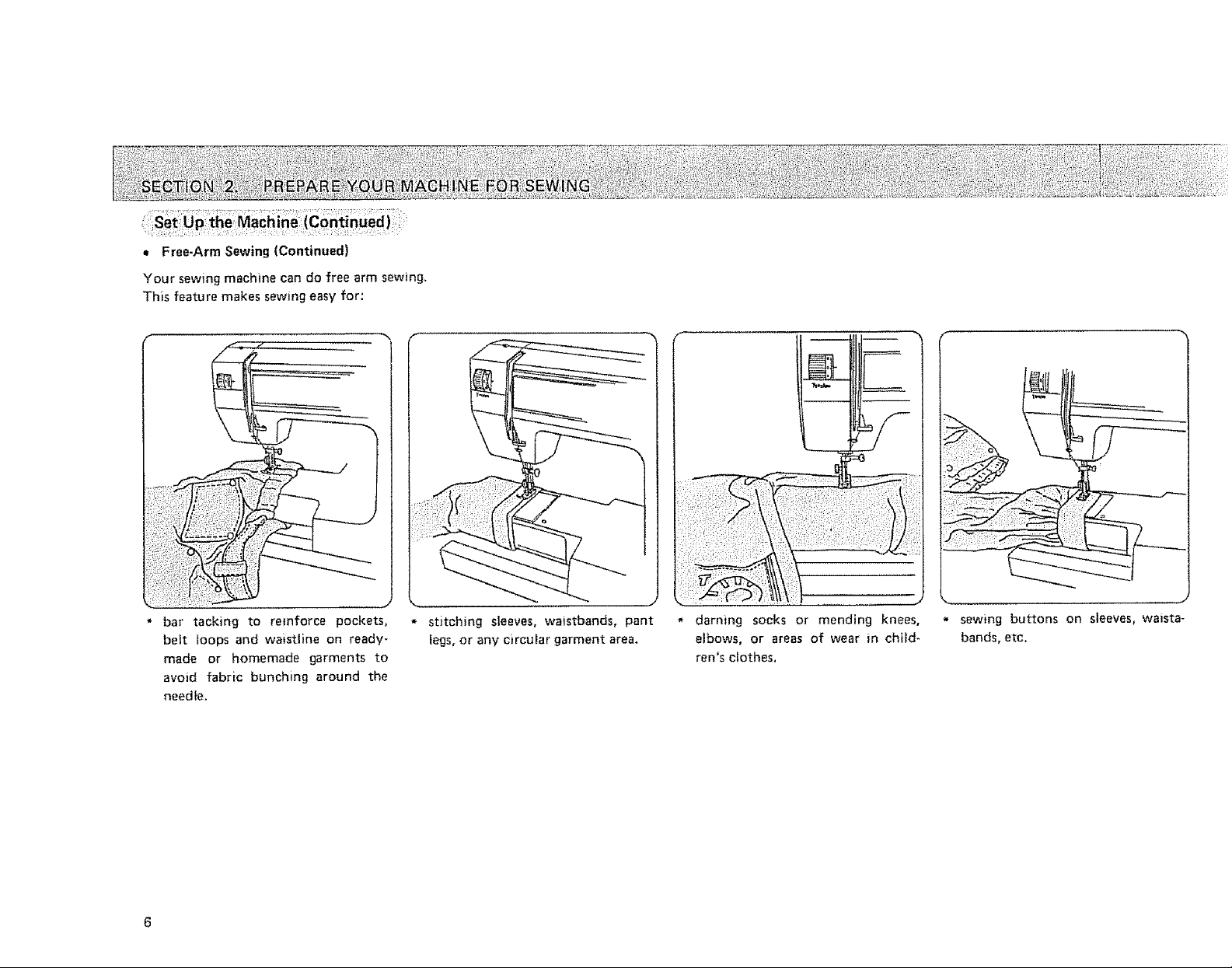

* Free-Arm Sewing (Continued)

Your sewing machine can do free arm sewing.

This feature makes sewing easy for:

$

* bar tacking to reinforce pockets,

belt foops and waistline on ready-

made or homemade garments to

avoid fabric bunching around the

needle,

¸,

* stitching sleeves, waistbands, pant

legs, or any circular garment area.

* darning socks or mending knees,

elbows, or areas of wear in child*

ren's clothes,

* sewing buttons on sleeves, waista-

bands, etc,

ThePresserfeetareanimportantfeatureofthismachine.Youneedtoknowwhateach foot does in order to use them effectively.

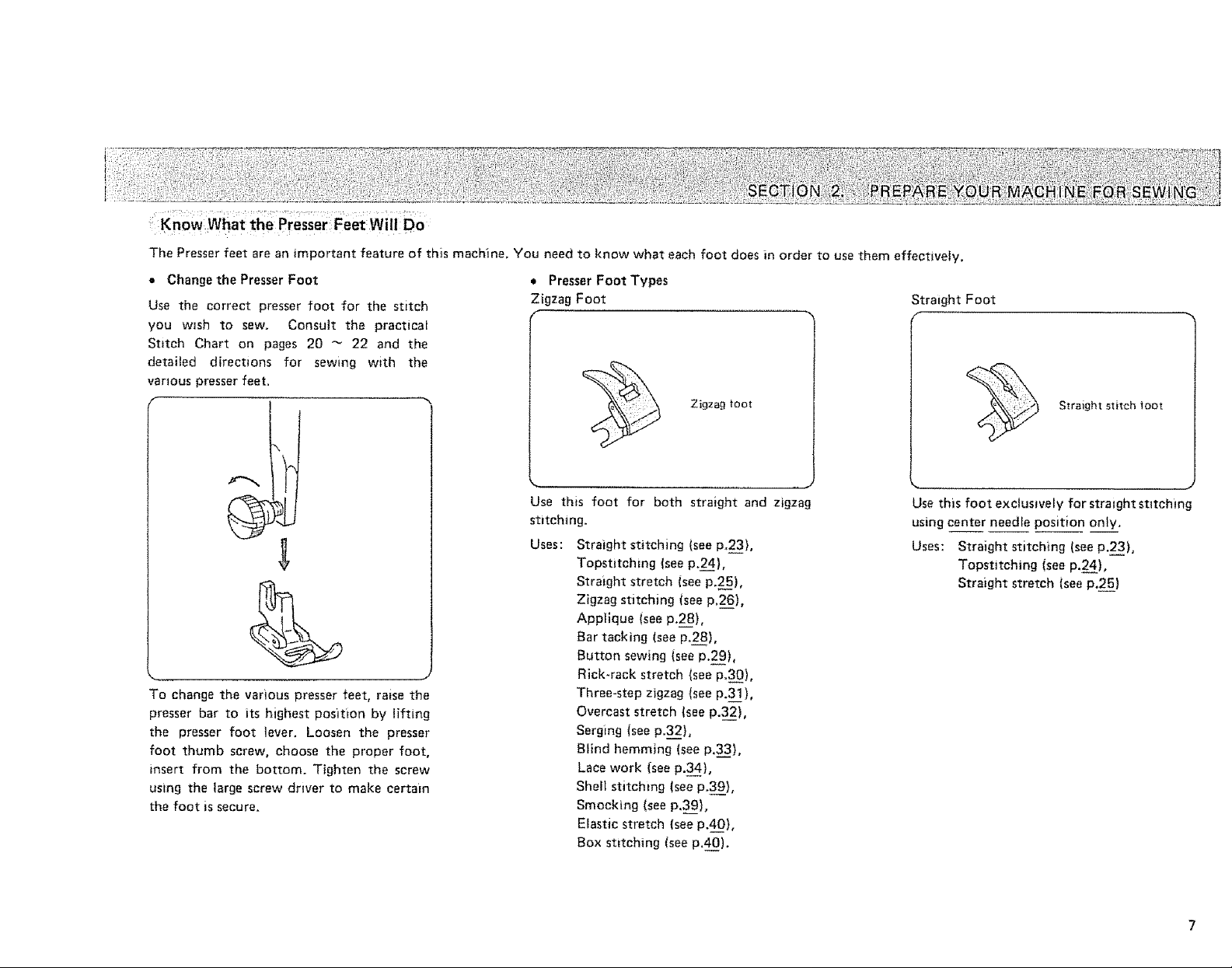

= Change the Presser Foot

Use the correct presser foot for the stitch

you wish to sew. Consult the practical

Stitch Chart on pages 20 _ 22 and the

detailed directions for sewing with the

various presser feet.

• Presser Foot Types

Zigzag Foot Straight Foot

Zigzag fooI

I

Straight stitch loot

0

To change the various presser feet, raise the

presser bar to its highest position by lifting

the presser foot lever. Loosen the presser

foot thumb screw, choose the proper foot,

insert from the bottom, Tighten the screw

using the large screw driver to make certain

the foot is secure.

Use this foot for both straight and zigzag

stitching.

Uses: Straight stitching (see p.23),

Topstitching Isee p.24),

Straight stretch (see p.25),

Zigzag stitching (see p.2_66),

Appllque (see p.28),

Bar tacking (see P,2i88),

Button sewing (see p.29),

J

Rick-rack stretch (see p,30),

Three-step zigzag {see p.31),

Overcast stretch {see p.32),

Serging (see p.3__22),

Blind hemming (see p.3_33),

Lace work (see p.34),

Shell stitching (see p.399},

Smocking (see p.39),

Elastic stretch (see p.4__O),

Box stitching (see p.4_O).

Use this foot exclusively for straight stitching

using center needle position only.

Uses: Straight stitching (see p.23),

Topstitching (see p.244),

Straight stretch (see p.255)

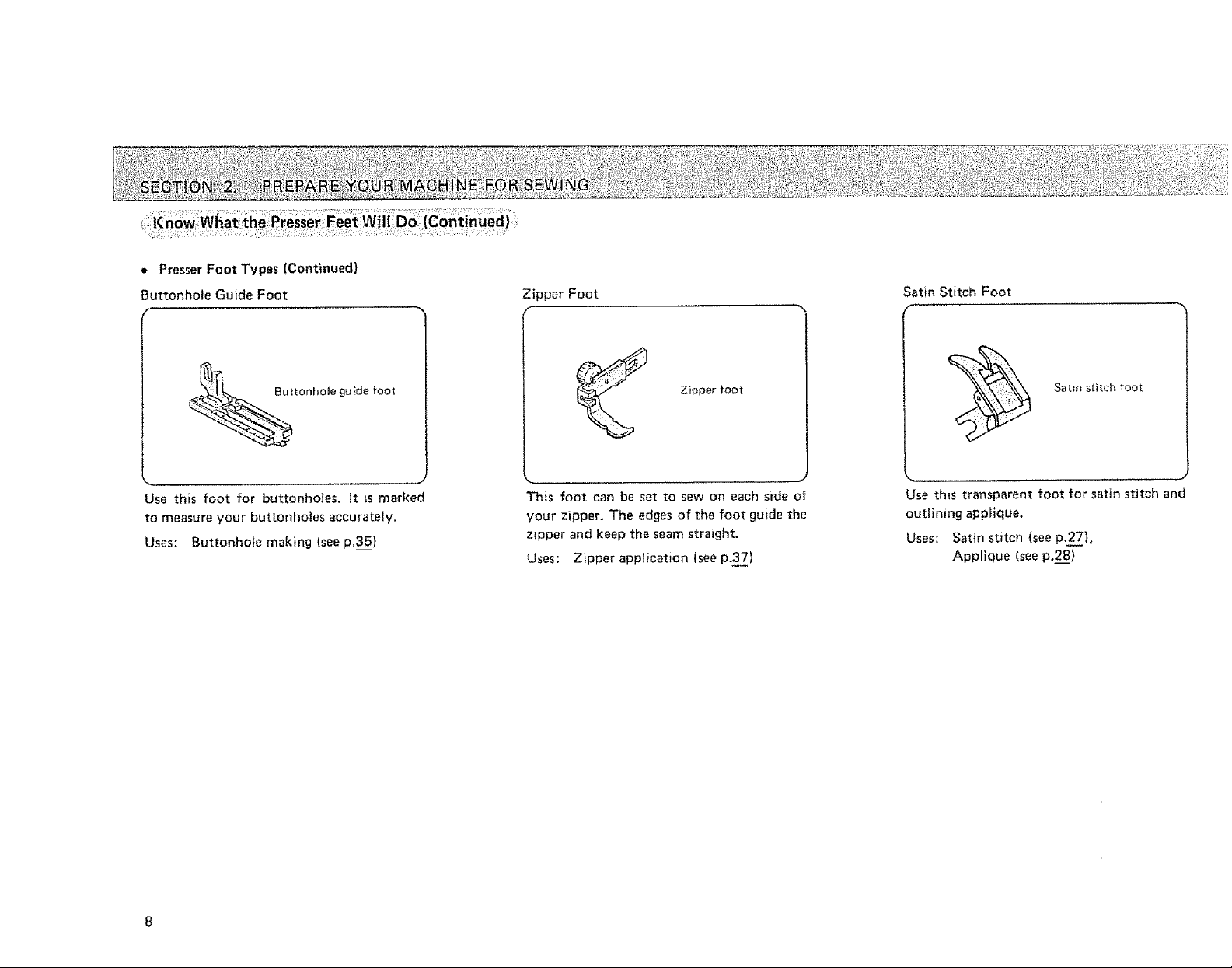

Presser Foot Types (Continued}

Buttonhole Guide Foot

r

Zipper Foot

f

Satin Stitch Foot

Buttonhole guide _'oot

Use this foot for buttonholes. It is marked

to measure your buttonholes accurately,

Uses: Buttonhole making {see p.3__55)

Zipper foot

This foot can be set to sew on each side of

your zipper. The edges of the foot guide the

zipper and keep the seam straight.

Uses: Zipper application (see p.3Z7)

Satin stitch foot

Use this transparent foot for satin stitch and

outlining appiique.

Uses: Satin stitch (see p.2Z7),

Applique (see p.2_88)

Yourchoiceofneedleandthreaddependsonthefabricyouaresewing.

tnyourneedlecase,youwillfindthefollowingcolor-codedneedles:

Blue(11)........... forstretchfabrics

Orange(11)......... for lightweightfabrics

Red(14)........... formediumormedium-heavyweightfabrics

Purple(16)....... for medium-heavyweightanddecorative

topstitchingonthesefabrics

(Thisneedlehasa largerthreadholefor

thickertopstitch_ngthread.)

Green(18) .......... forheavyweightfabricsanddecorativetop-

stitchingon these fabrics

Specialty needles are also available.

Denim Needle ....... for sewing dense fabrics such as denim or

canvas,

Topstitching Needle .... its larger eye wilt hotd heavier thread.

Leather Needle ....... punches tiny holes in leather and suede.

When buying needles other than Kenmore needles, be sure the needle fits the

length and shape of the needle shown above. A longer or shorter needle will

skip stitches or break.

= Check Your Needle

1. Look for barbed or blunt point.

2. A damaged needle can cause permanent snags or runs in knits, fine silks

and silk-like fabrics.

Always buy a good quality thread, tt should resist tangling and be strong,

smooth and consistent in thickness.

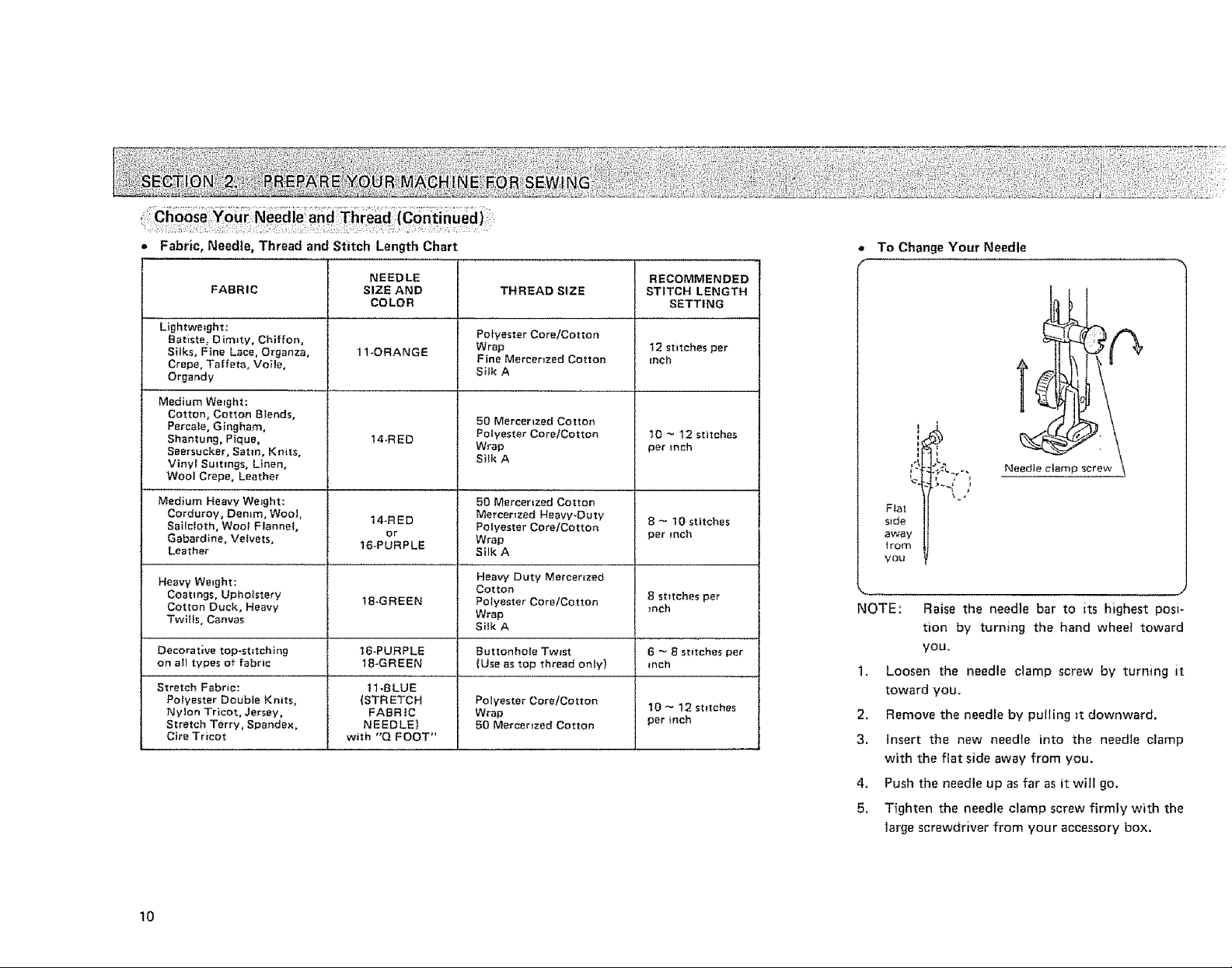

Fabric, Needle, Thread and Stitch Length Chart

= To Change Your Needle

FABRIC SIZE AND

Lightweight:

Batrste= Dimity, Chiffon.

Silks, Fine Lace, Organza,

Crepe, Taffeta. Voile,

Organdy

Medium Weight:

Cotton, Cotton B_ends,

Percale, Gingham,

Shantung, Pique,

Seersucker. Satm. Knits.

Vinyl Suitings. Linen,

Wool Crepe. Leather

Medium Heavy Weight:

Corduroy, Denim, Wool,

Sailcloth. Wool Flannet,

Gabardine, Velvets,

Leather

Heavy Wmght;

Coatings, Upholstery

Cotton Duck, Heavy

Twi!ls. Canvas

Oecorative top-stttchlng

On all types of fabric

Stretch Fabric:

Polyester Double Knits,

Nylon Tricot, Jersey,

Stretch Terry, Spande×,

Cite Tricot

NEEDLE

COLOR

11-ORANGE

14-RED

14-R ED Mercerized Heavy-Duty 8 _ 10 stitches

or Polyester Core/Cotton

16-PURPLE Wrap per inch

18-GREEN PoJyester Core/Cotton inch

IS*PURPLE Buttonhole Twist 6 _ 8 stitches per

18oGREEN (Use as top thread onJy} inch

11-BLUE

(STR ETCH Polyester Core/Cotton 10 _ 12 stitches

FABRIC Wrap

NEEDLE) 50 Mercerized Cotton per inch

with "Q FOOT"

THREADSIZE

Polyester Core/Cotton

Wrap

Fine Mercerized Cotton

Silk A

50 Mercerized Cotton

Polyester Core/Cotton

Wrap

Silk A

50 Mercerized Cotton

Silk A

Heavy Duty Mercerized

Cotton

Wrap

Siik A

R ECOi'_MENDED

STITCH LENGTH

SETTING

12 stitches per

_neh

10 _ 12 stitches

per inch

8 stitches per

Needle clamp screw

NOTE:

-'4 "g:%" ""

Fiat

s_de

away

tfore

Raise the needle bar to its highest posi-

tion by turning the hand wheel toward

you.

1. Loosen the needle clamp screw by turning it

toward you.

2. Remove the needle by pulling it downward.

3. Insert the new needte into the needle clamp

with the flat side away from you.

4. Push the needle up as far as it will go.

5. Tighten the needle clamp screw firmly with the

large screwdriver from your accessory box.

10

:: Prepare the Bobbin:

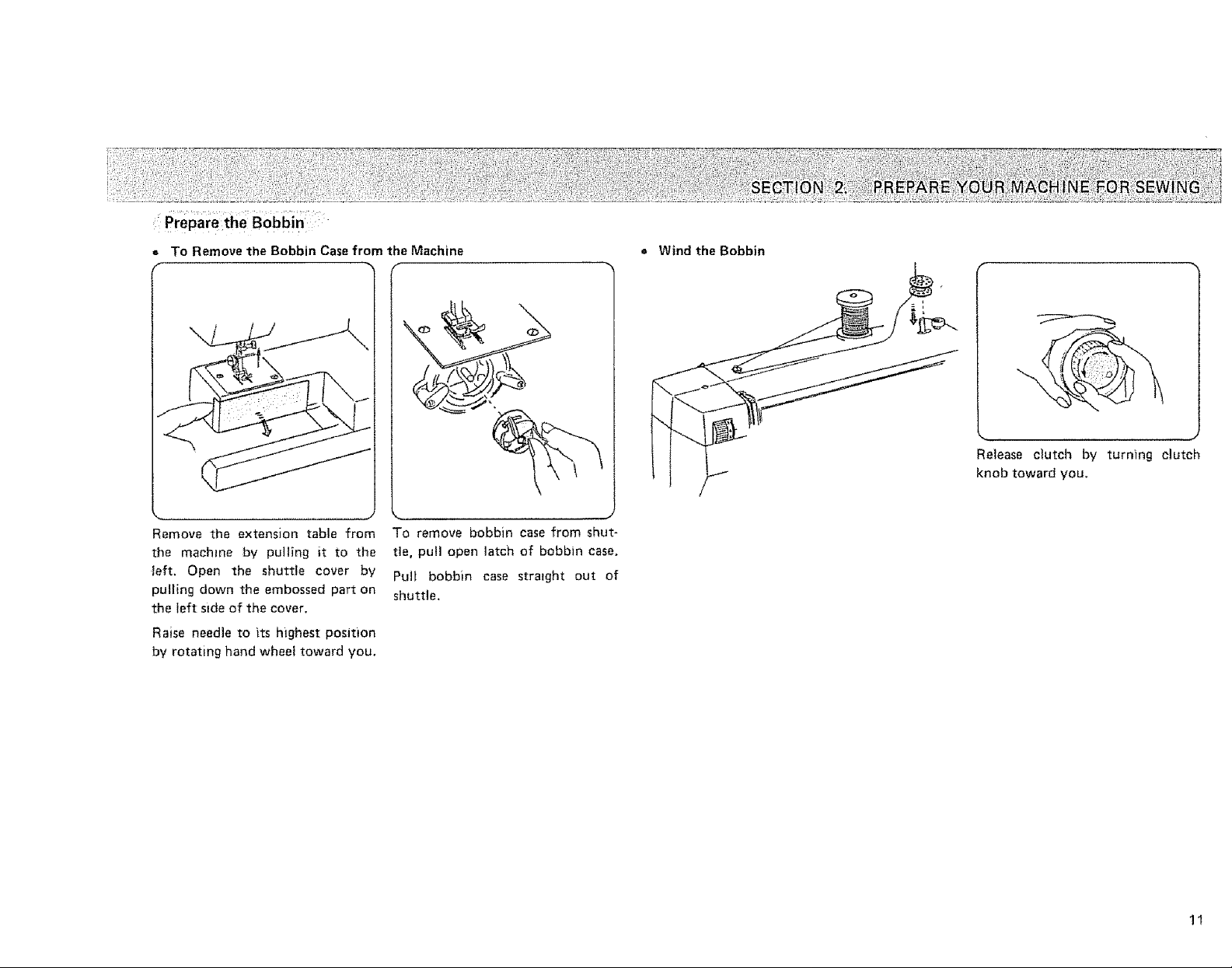

= To Remove the Bobbin Case from the Machine = Wind the Bobbin

Release clutch by turning clutch

knob toward you.

Remove the extension table from

the machine by pulling it to the

left, Open the shuttle cover by

pulling down the embossed part on

the left side of the cover.

Raise needle to its highest position

by rotating hand wheel toward you.

To remove bobbin case from shut-

tie, pull open latch of bobbin case.

Pull bobbin case straight out of

shuttle.

1!

,_i!P_areith_¸gob_niliCo.ti._ed_i_!

__, !_i!i;!i:_!_i:_i;i_:; _ <': _:," __i!_;i!:_i _ :!i!;:_:_:i _ :_:- • i i _'!'i i_I!i: :! :: _ x: ;

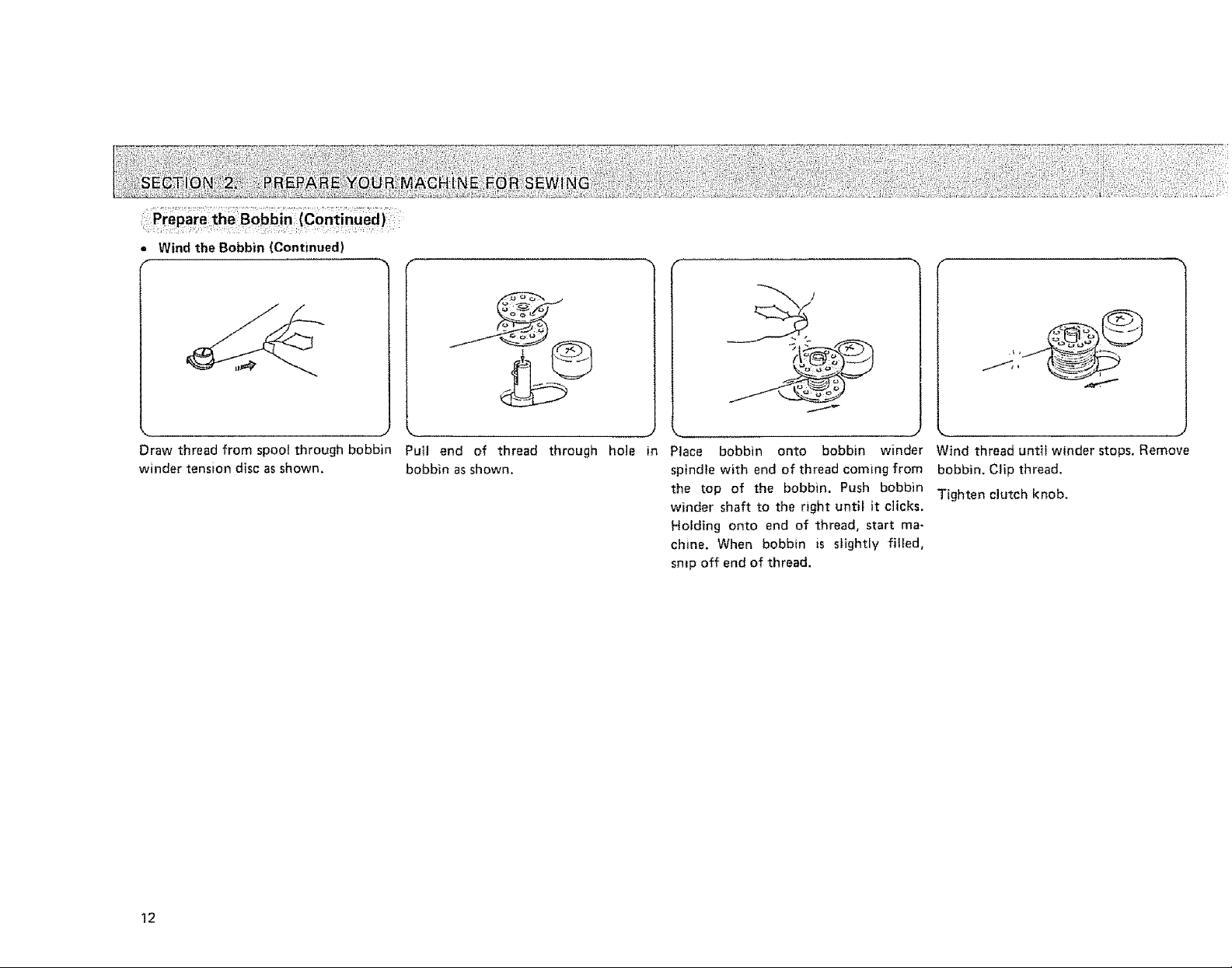

Wind the Bobbin (Continued)

7

Draw thread from spool through bobbin

winder tension disc as shown.

Pull end of thread through

bobbin as shown.

hole in Place bobbin onto bobbin winder

spindle with end of thread coming from

the top of the bobbin. Push bobbin

winder shaft to the right until it dicks.

Holding onto end of thread, start ma-

chine. When bobbin is slightly fiIled,

snip off end of thread,

Wind thread untif winder stops, Remove

bobbin. Clip thread.

Tighten clutch knob.

12

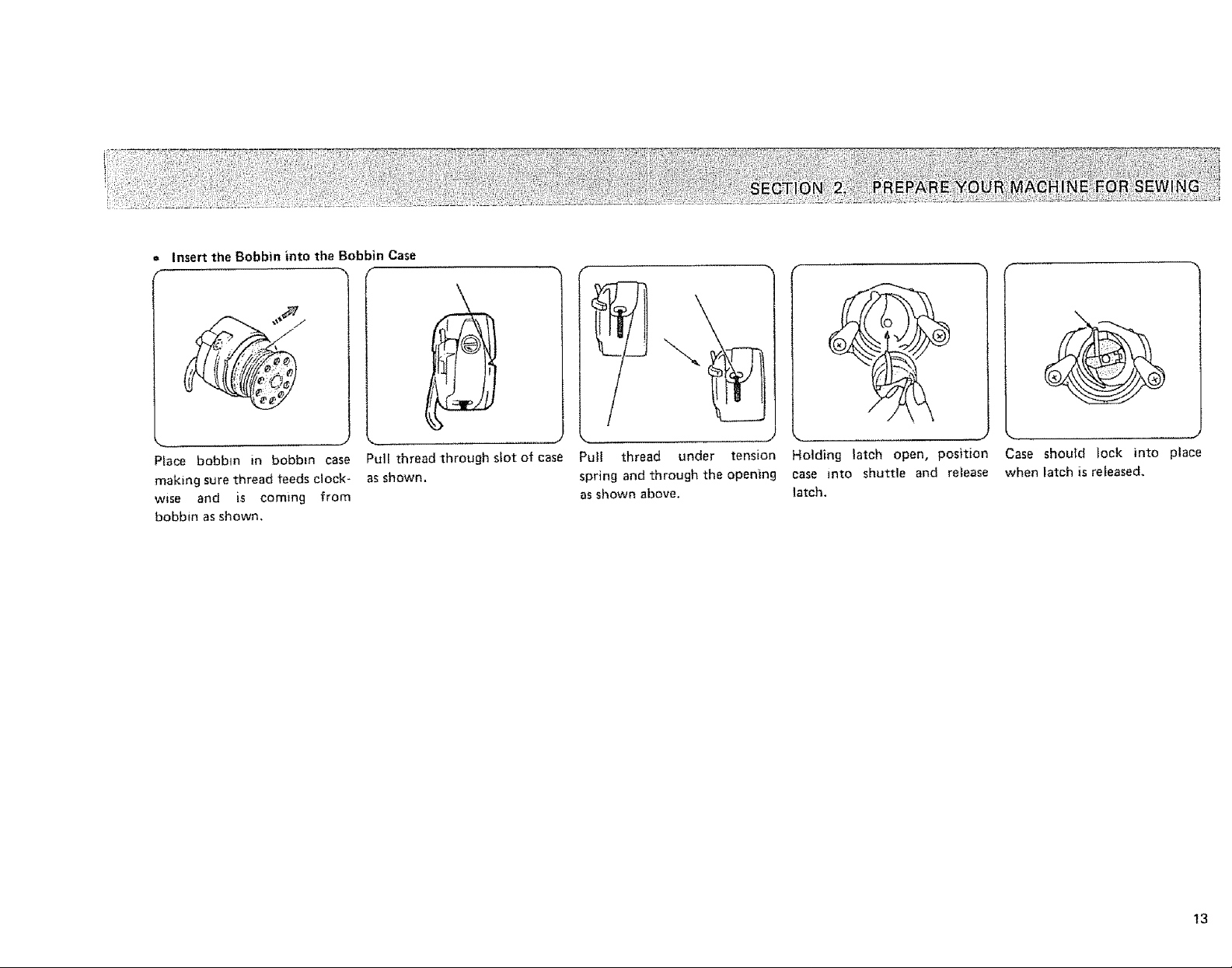

Insert the Bobbin into the Bobbin Case

Place bobbin in bobbin case

making sure thread leeds clock-

wlse and is coming from

bobbin as shown.

Pull thread through slot of case

as shown,

.......... J

Pull

thread under tension

spring and through the opening

as shown above,

Holding latch open, position

case into shuttle and re|ease

latch.

" r

Case should lock into place

when latch is released.

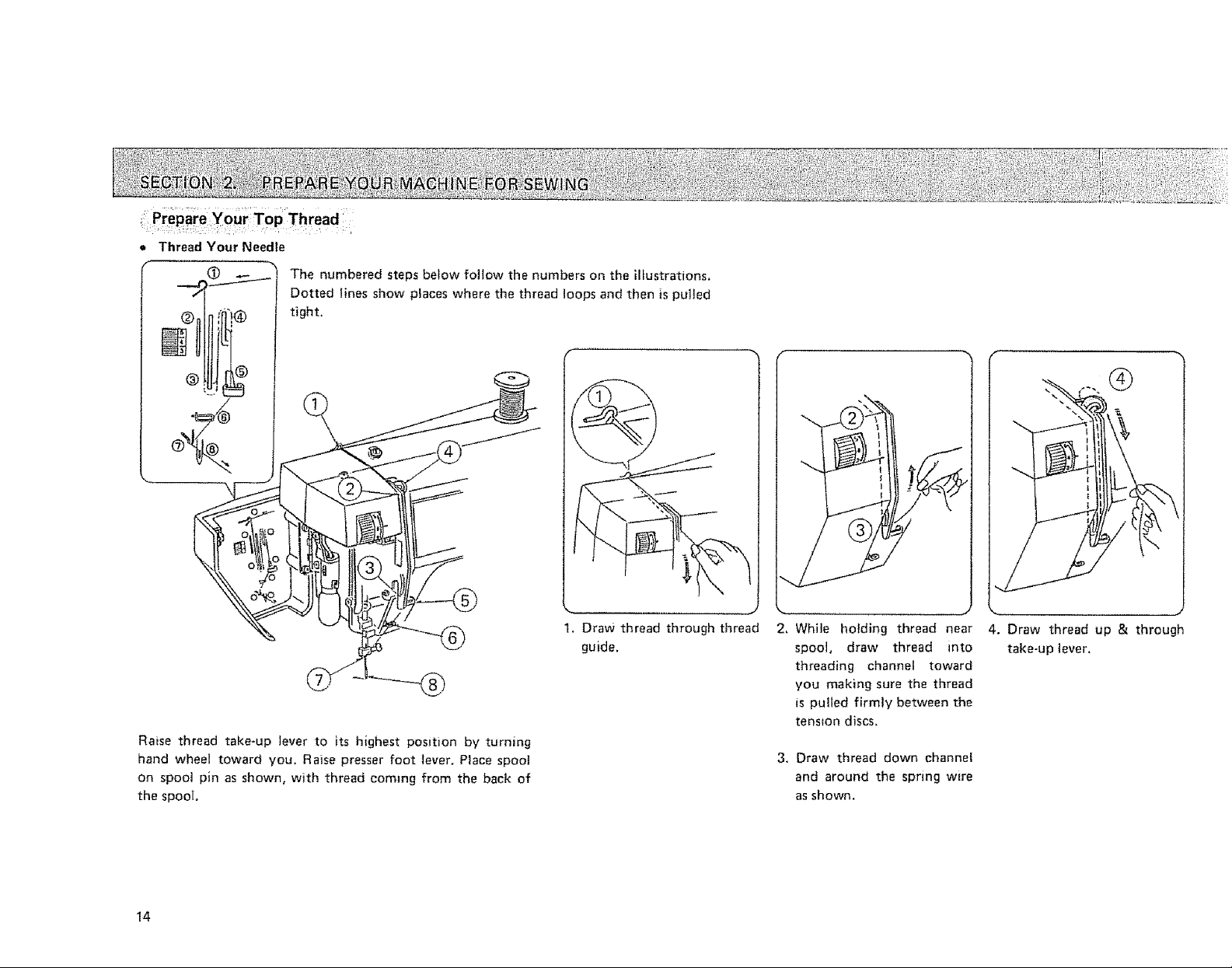

Thread Your Needle

@

The numbered steps below follow the numbers on the illustrations.

Dotted lines show places where the thread loops end then is pulled

tight.

Raise thread take-up ]ever to its highest position by turning

hand wheel toward you. Raise presser foot lever, Place spool

on spool pin as shown, with thread coming from the back of

the spool

14

1, Draw thread through thread

guide.

J

2, While holding thread near

spoo]0 draw thread into

threading channel toward

you making sure the thread

is pulled firmly between the

tenston discs,

3. Draw thread down channel

and around the spring wire

as shown,

__ J

4. Draw thread up & through

take-up lever,

Loading...

Loading...