Kenmore 1660 User Manual

Kenmore

INSTRUCTIONS

ZIG-ZAG SEWING MACHINE

MODEL 1357/1525/1660/1947

60278

■ A-fe

^USIÑG'THECONTROLS'■■■■■■ .-■■■■■ ■ '

',-V%3

.■í3»'

fkS-

J^-<VA\iviÄ4<^<Äi

m

§0ÍÍ

гЧ<Г<^

í«¿-:

>A^í^sí':r

‘S-SC.Ñé

" ' ' ' '

V,. |'>.''Г- ',1-5.-^' <r,

j'

ШкШ:

йÄ^.йЙЦ*^¡й^• {vSí^

....■•■ •- -'íSi

- ’ -,-,-------^---- l-.-v"'

4f,#JÍ ♦•* *.Мг«1 * * * m* • ♦ ♦ jí '« H * * t

-------------

iw Suttonnòl^OontìròI «.««»■.•«•»4t*«

jy|^jlb«K.r«.*«»«.« «^>»«« к» * »«-♦««««« •'*>»«

«4í'«»f « ![¥«• wM*

4\wC 1ÍW^4'¿*i 4 #;■ V • к * i • « * #* * ■: ¿ M» ♦^»•^**»•••*■*•••••11* él£jm ■ ' '

fiiTl

íTkA««* *.«;«;* ì*ù к Ш IklkliV iik V« * V« * « « м 30 * Зо •

. „ --•«¿•*4 « к «**♦/£'«*»• к к к к к* « « < «'*<*»<(jM к кЧ« k*«vO ' .

j|í:f 1 Ò '

“"'7 " ''г ' ’''

* ■^í' ' 4 yí' '" '

Fi¥‘

,-v - - .4 ■>'/,*', - . , r . ■'

''■ .л':^

Л1.Щ

^^j3?''^Sfc”-K ' 'v'' 'i., • " ‘ C^F^^НННННmGÍ ,Р*в6^ £3ÓÌQ6 "ÉlfltÍ ^ifÜUtuö •••ж V e • »• *i 1 • • e • n • ♦• e « » «»•■ * • к «^4','

kkkkk ':] ■%'.?■,ЛЛ Лi-'^IÍt^‘Ürí<Í0Mmí Cover Máteii

А' QfbH^^MnCiäii^idii »»k'ííkíiilí *»У»«*Гккк *•♦< 4 кав^«««>*кЖк**к«*к ;u4S,4?i

............. oSnfWFáélCóVérHát^....^

Parte List .i.

.....

.........í.......................................

.............

.....

......',

.........

.................47

..45';

48/ 49

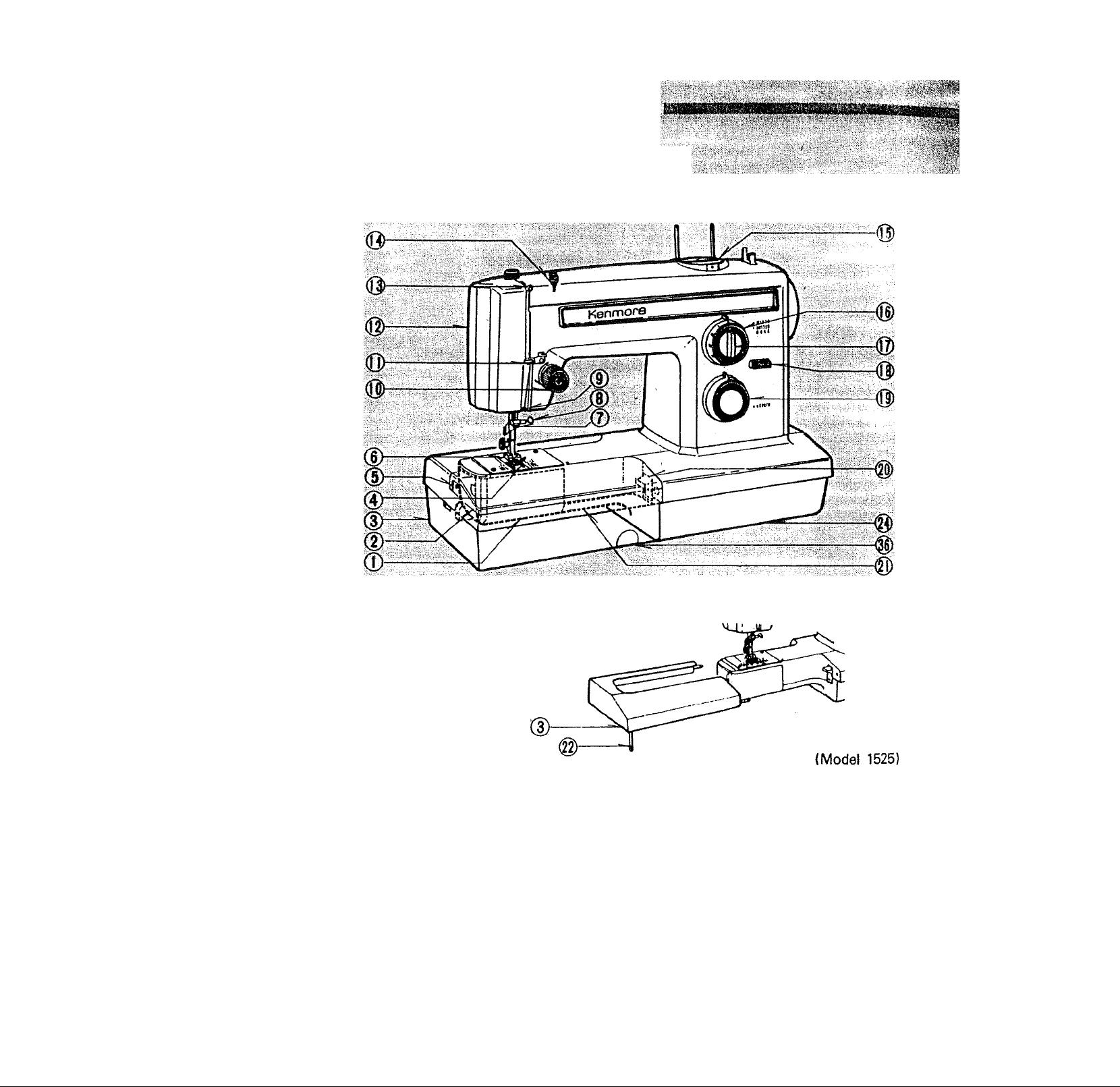

1. KNOWING YOMB MACHIA

»

' -i:' r

FRONT VIEW

1.

Shuttle cover

2.

Base front cover

3.

Base

4.

Zigzag stitch needle plate

5.

Front cover release button

6.

Presser foot

7.

Thread guide

8.

Needle clamp screw

9.

Thread guide

10.

Top thread tension control 20. Feed dog control

11.

Face cover thread guide 21. Free arm

12. Face cover plate

13. Take-up lever

14.

Upper thread guide

Special stitch dial

15.

16.

Stitch width control

17.

Special stitch modifier and

buttonhole control

Reverse stitch lever

18.

19.

Stitch length control

22. Support leg

' ' i f’iv 'V' >, , ■" . ,■:

' ' *

..............Iifiiiflir nnin;i.i'i 1^

iiagisrfai^^ v :;:aaw

>lli-

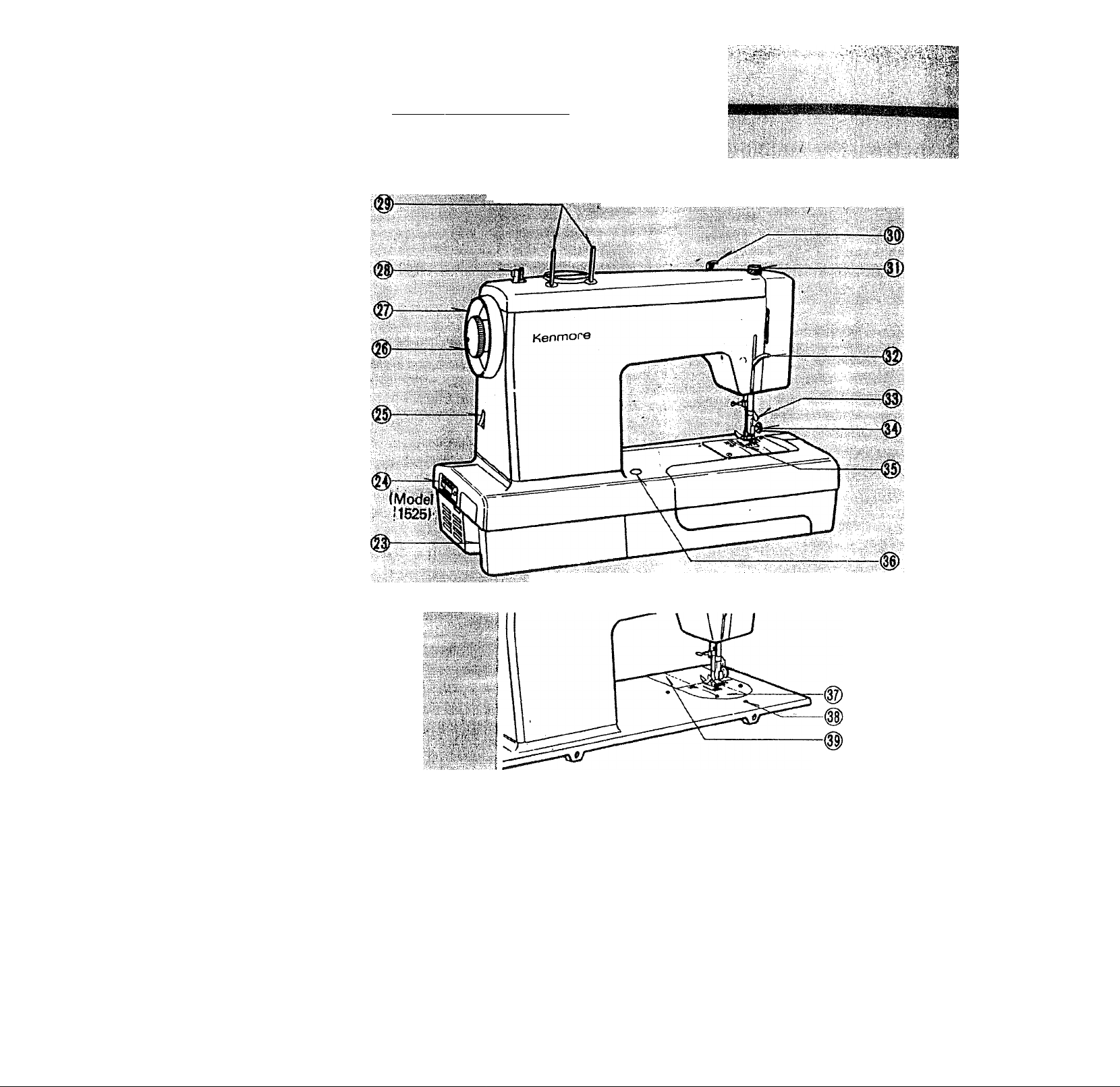

;iiACKVIEW

..........

■■'■■■""

iiiiail®

23. Electric cord receptacle

24. Nomenclature plate

25. Light and power switch

26. Clutch knob

27. Hand wheel

28. Bobbin winder

29. Spool pins

30. Bobbin winder tension disc

31. Pressure regulator

(Model 1660)

{Flat-bed type)

32. Presser foot lever

33. Thread cutter

34. Presser foot thumb screw

35. Feed dogs

36. Base release button

37. Needle plate

38. Guide pin hole

39. Hand hole cover plate

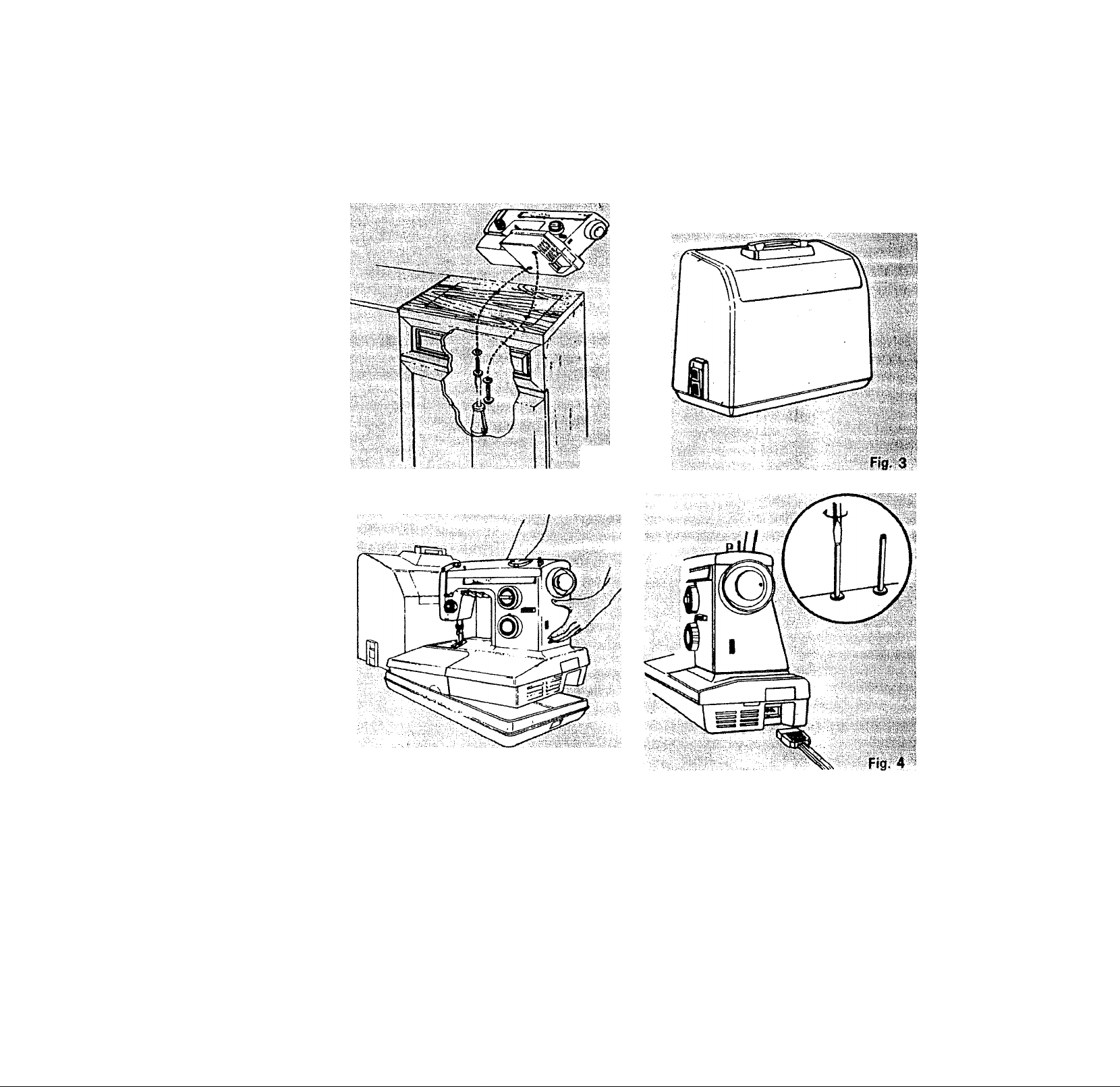

INSTALLING MACHINE (Free-arm type)

fjg-1

Fig. 2

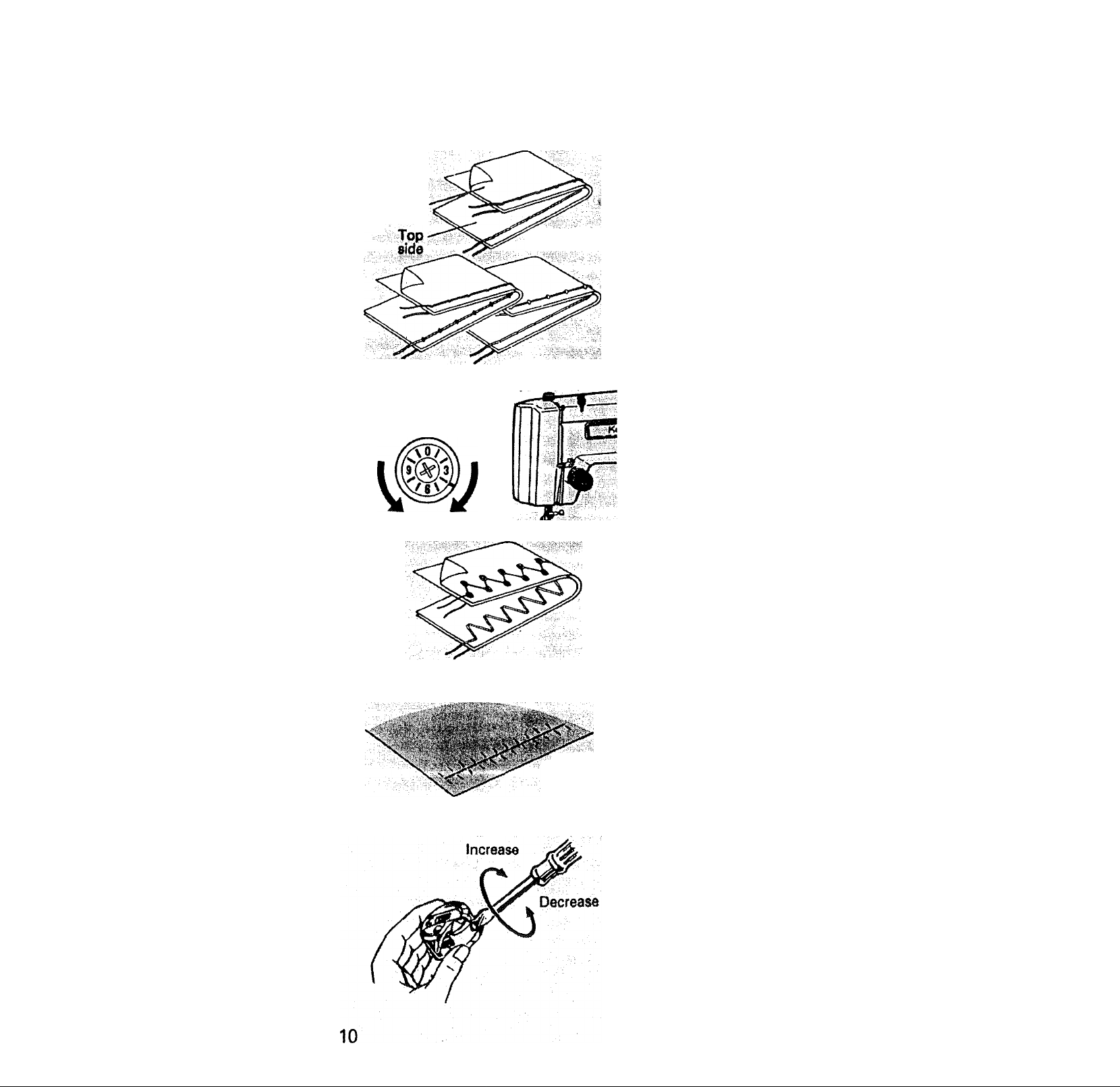

1. To install the machine in cabinet, position

machine head on cabinet platform so that

holes on bottom of machine match those

on board. Insert washers and screws and

tighten into place. (Fig. 1)

2. A separate base and cover is available to

carry the machine when needed. The

base must be removed when machine is

used.

To install machine in carrying case, set

machine into base, with word FRONT in

base facing you. (Fig. 2)

Place cover on machine with word

"SEARS" on handle facing you. The case

slopes in the same direction of the ma

chine. (Fig. 3)

3. Push the speed control plug onto threeprong connector. Plug machine cord into

any 110-120 volt wall outlet. Turn on

power by pushing light and power switch.

(Fig. 4)

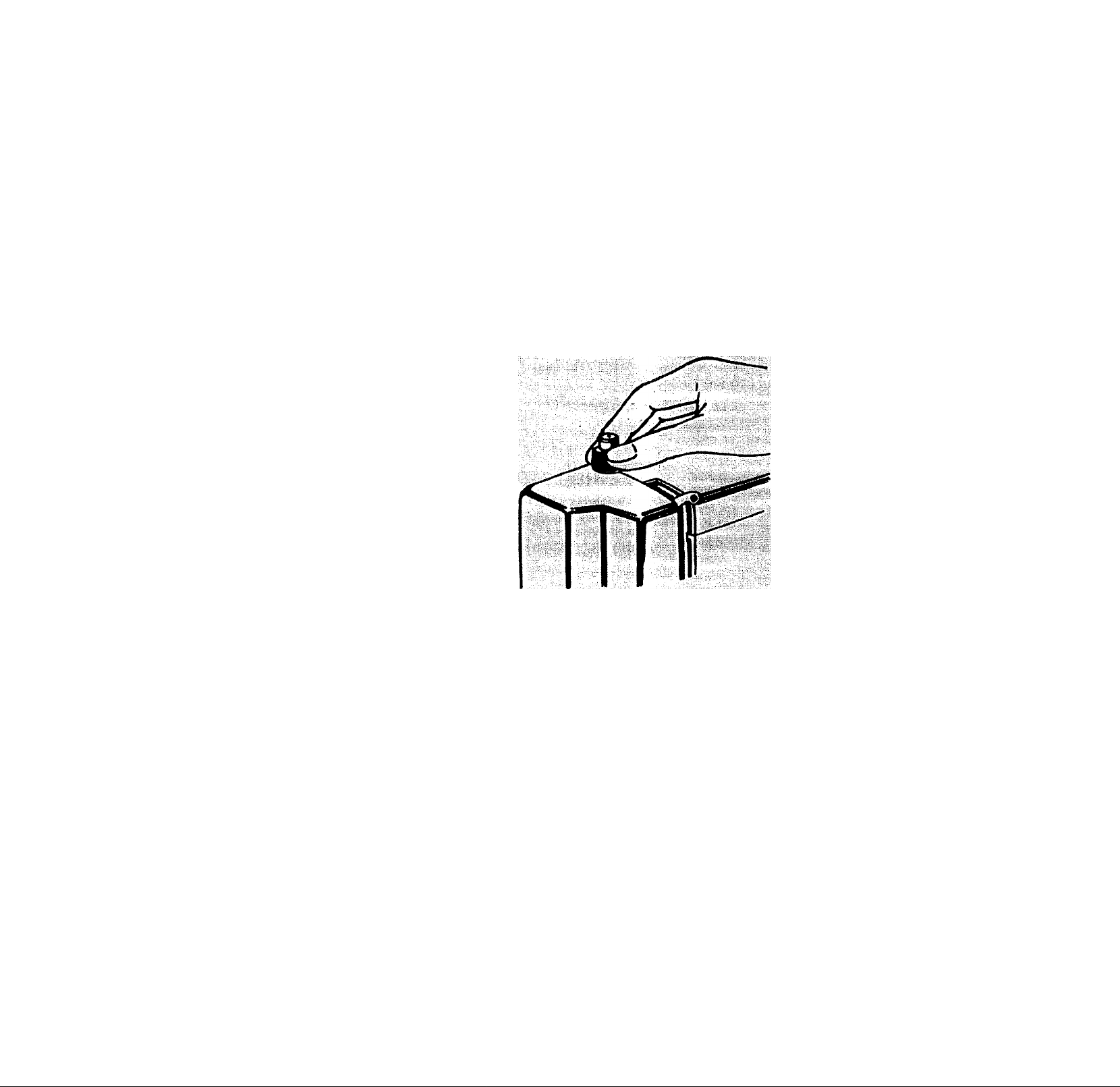

4. Spool pins are packed in accessory box.

Screw thread spool pins in place securely

with a screw driver. Position nylon discs

as shown in illustration.

INSTALLING MACHINE (Flat bed type)

0

mm

(D

0

I#*

(D

0

1.

Loosen the two hinge screws under

holes in the rear edge of the machine

bed.

2.

Raise hinge pins in the cabinet or

case. Slip machine head onto pins.

3, Tighten hinge screws securely.

4. Push the speed control plug onto

three-prong connector under the

bed plate. Lower machine head to

front cabinet flap.

5. Plug machine cord into any 110-120

volt wall outlet. Turn on power by

pushing light and power switch.

6. Spool pins are packed in accessory

box. Screw thread spool pins in

place securely with a screw driver.

Position nylon discs as shown in

illustration.

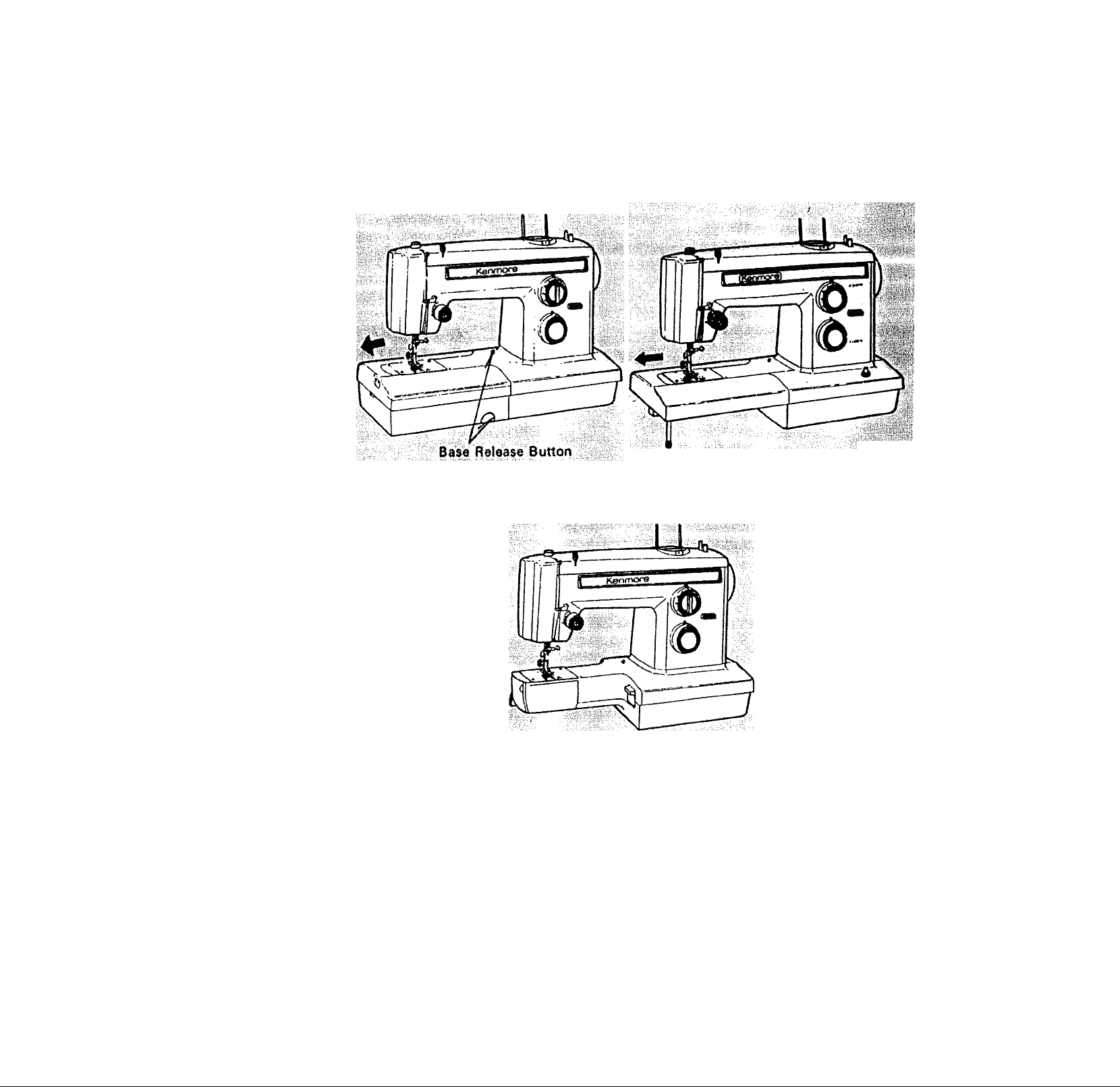

CONVERTING TO FREE-ARM SEWING

Fig. 1

Remove the base from the machine

by pushing the release button (if

applicable) and pulling the base to

the left, (Fig. 1, 2)

Fig. 2

2, To replace the base, simply slide it

along the free arm to its original

position. (Fig. 1)

Note: Base cannot be removed or

replaced unless shuttle cover is

closed.

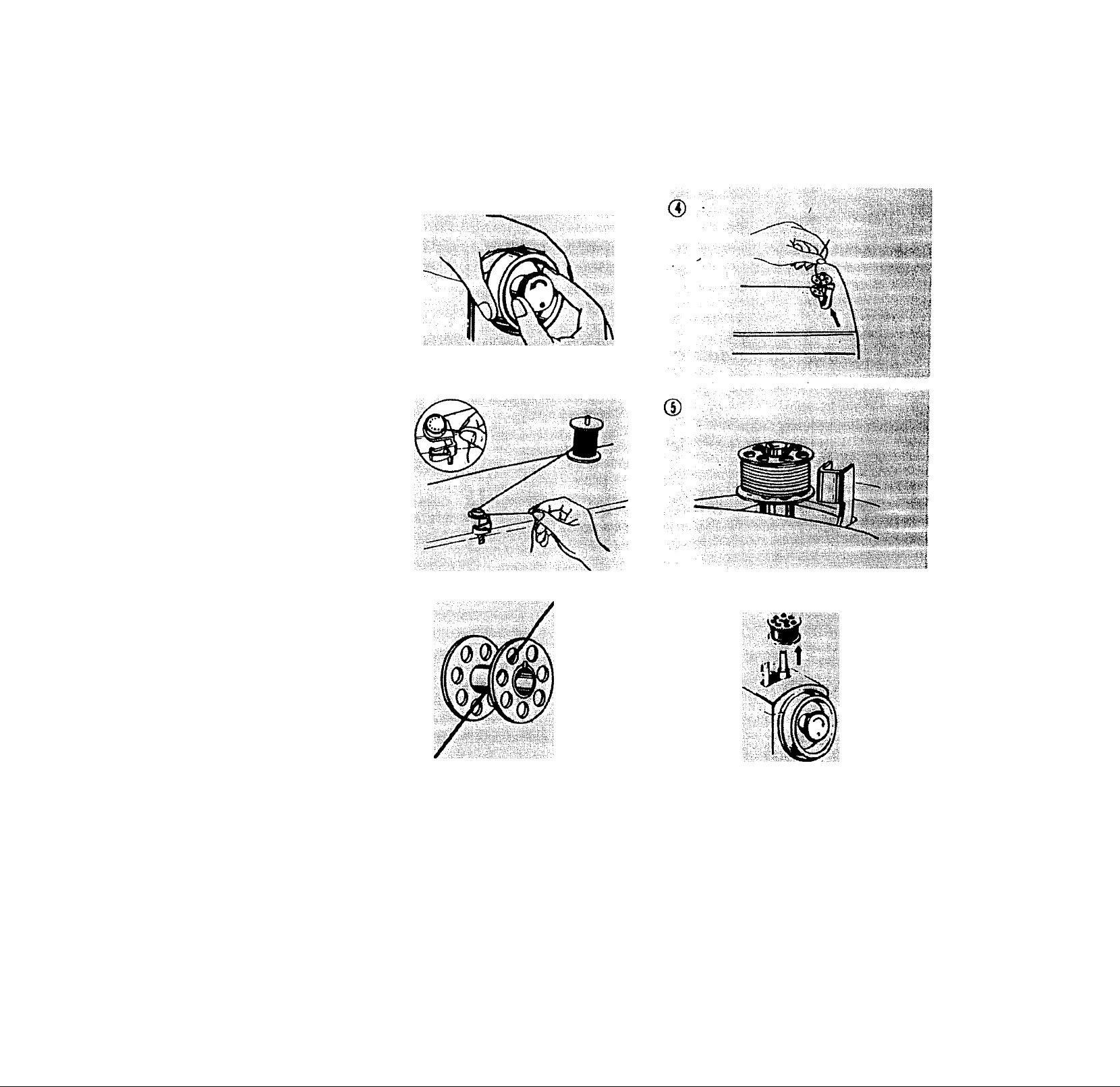

WINDING THE BOBBIN

0

0

0

1. Release clutch by turning clutch

knob toward you.

2. Draw thread from spool through

bobbin winder tension disc as

shown.

3. Pull end of thread through hole in

bobbin as shown.

4. Place bobbin onto bobbin winder

shaft with end of thread coming

from the top of the bobbin. Push

'i,

' '''' y*-a

•f'tt

iii!

bobbin winder latch against bobbin

until it clicks. Holding onto end of

thread, start nhachine. When bobbin

is slightly filled, snip off end of

thread.

5. Start machine. Wind thread until

bobbin winder latch releases.

6. Tighten clutch knob and remove

bobbin.

V "-r i

I

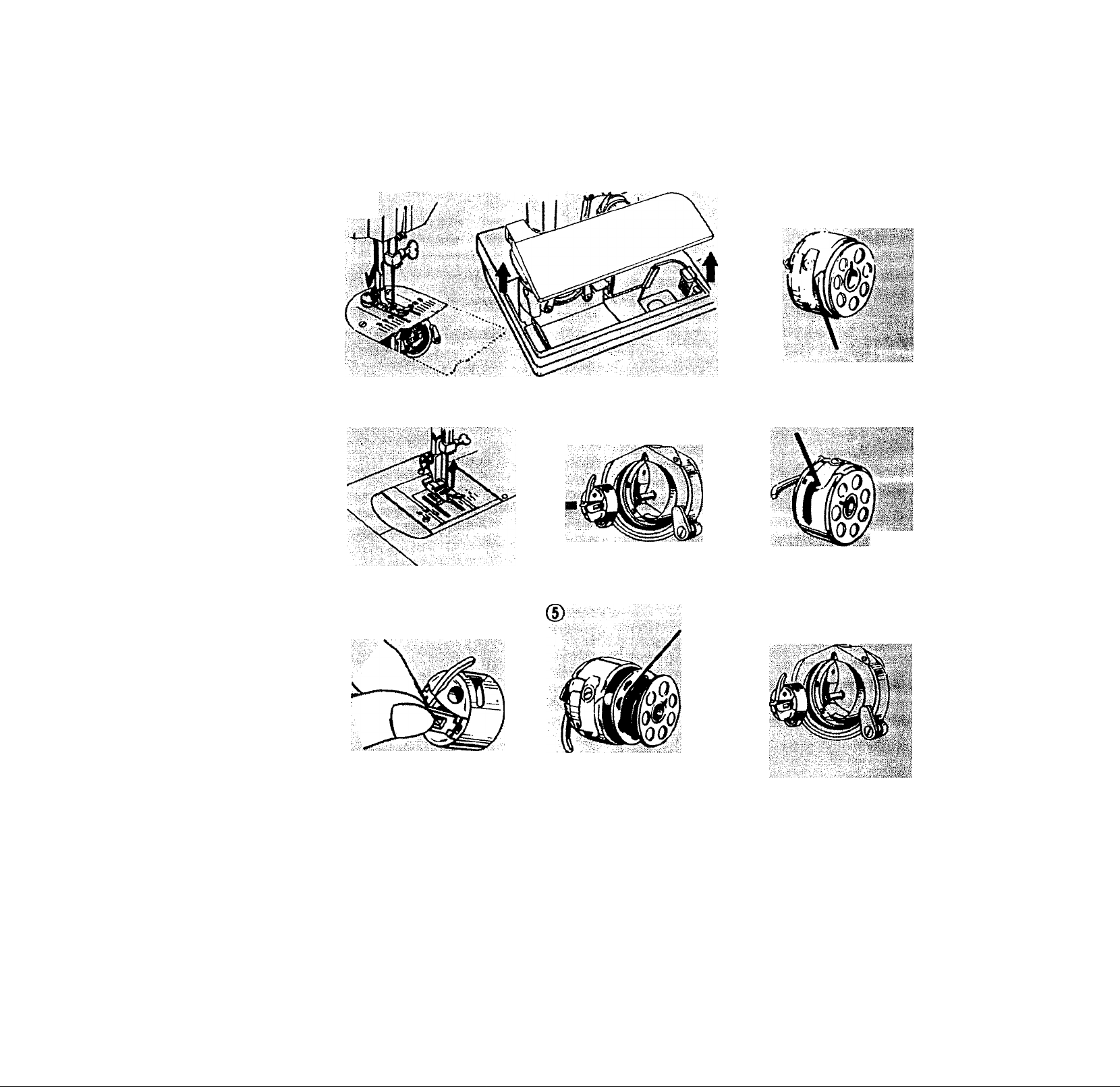

THREADING THE BOBBIN CASE

■ - ■ ..........

0

(D

d)

l|s®l

I*

1. Remove base front cover by push

ing the release button on the left

side. Open the shuttle cover.

2. Raise needle to its highest position

by rotating hand wheel toward

you.

3. To remove bobbin case from shut

tle, pull open latch of bobbin case.

4. Pull bobbin case straight out of

shuttle,

*

5. Insert bobbin into bobbin case mak

ing sure thread is coming from

bobbin as shown.

6. Pull thread through slot of case as

shown.

7. Pull thread under tension spring.

8. Holding latch open, position case

into shuttle, and release latch. Case

should lock into place when latch

is released.

8

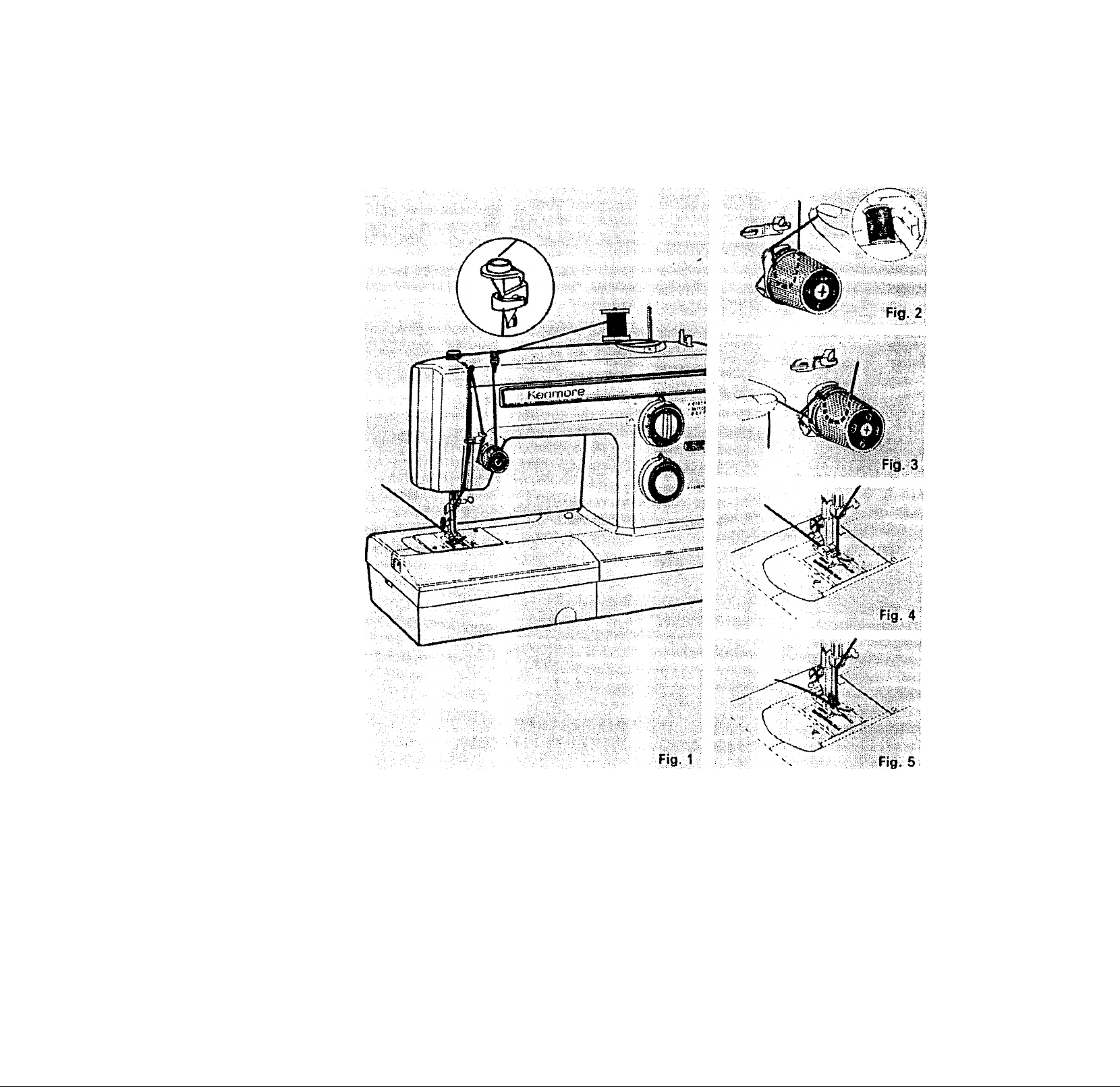

THREADING OF TOP THREAD

Place thread on spool pin as shown

with thread coming from the back of

the spool. Draw thread through the

top thread guide. Holding the spool

stationary with right hand, pull the end

of the thread between the tension discs

as shown. Pull the spring wire loop up

and past the top hook until the thread

can be slipped into the hook (See Fig.

2). When the thread is released, the

spring wire loop will return to position

(See Fig. 3) with thread in proper place.

Release spool of thread and continue to

thread machine exactly as shown.

Needle must always be threaded in

direction as shown in Fig. 4.

Hold needle thread loosely in left hand

and rotate hand wheel toward you one

complete turn. Bring bobbin thread up

by pulling upper thread. (Fig, 5),

STRAIGHT STITCHING

ADJUSTING TOP THREAD TENSION

Under

side

Top stitch

too tight

X .

D«cr«s«« IncrMM

tension tension

ZIGZAG STITCHING

Well balanced

Top Stitch

too loose

STRAIGHT STITCHING

The good looking appearance of your

stitching Is largely determined by the

balanced tension of both top and bobbin

threads. The tension is well balanced

when these two threads 'lock' In the

middle of layers of fabric you are

sewing.

If, when you start to sew, you find that

the stitching is Irregular, you will need to

adjust the tensron control.

Make any adjustments vyith presser foot

'down'.

1. If the threads are locking on the top

surface with the top thread lying flat,

the top stitch is too tight. Tension

can oe decreased by turning the

tension control to lower numbers.

2. If the reverse is happening with the

threads on the underside of the

fabric, (fie tension is too loose. This

can be corrected by turning the

tension control to higher numbers.

Fabric

puckers

ZIGZAG STITCHING

The top thread may appear on the

bottom depending on the thread, fabric,

type of stitch and sewing speed, but the

bobbin thread must never appear on the

top of the fabric.

ADJUSTING BOBBIN

THREAD TENSION

BOBBIN THREAD TENSION REQUIRES

ADJUSTMENT LESS FREQUENTLY

THAN THE TOP THREAD TENSION.

If the tension is well balanced, but the

fabric puckers badly, both top and

bobbin thread tensions may be too tight

and have to be adjusted.

When adjusting the tension on the

bobbin case, make only slight adjust

ments with a srewdriver.

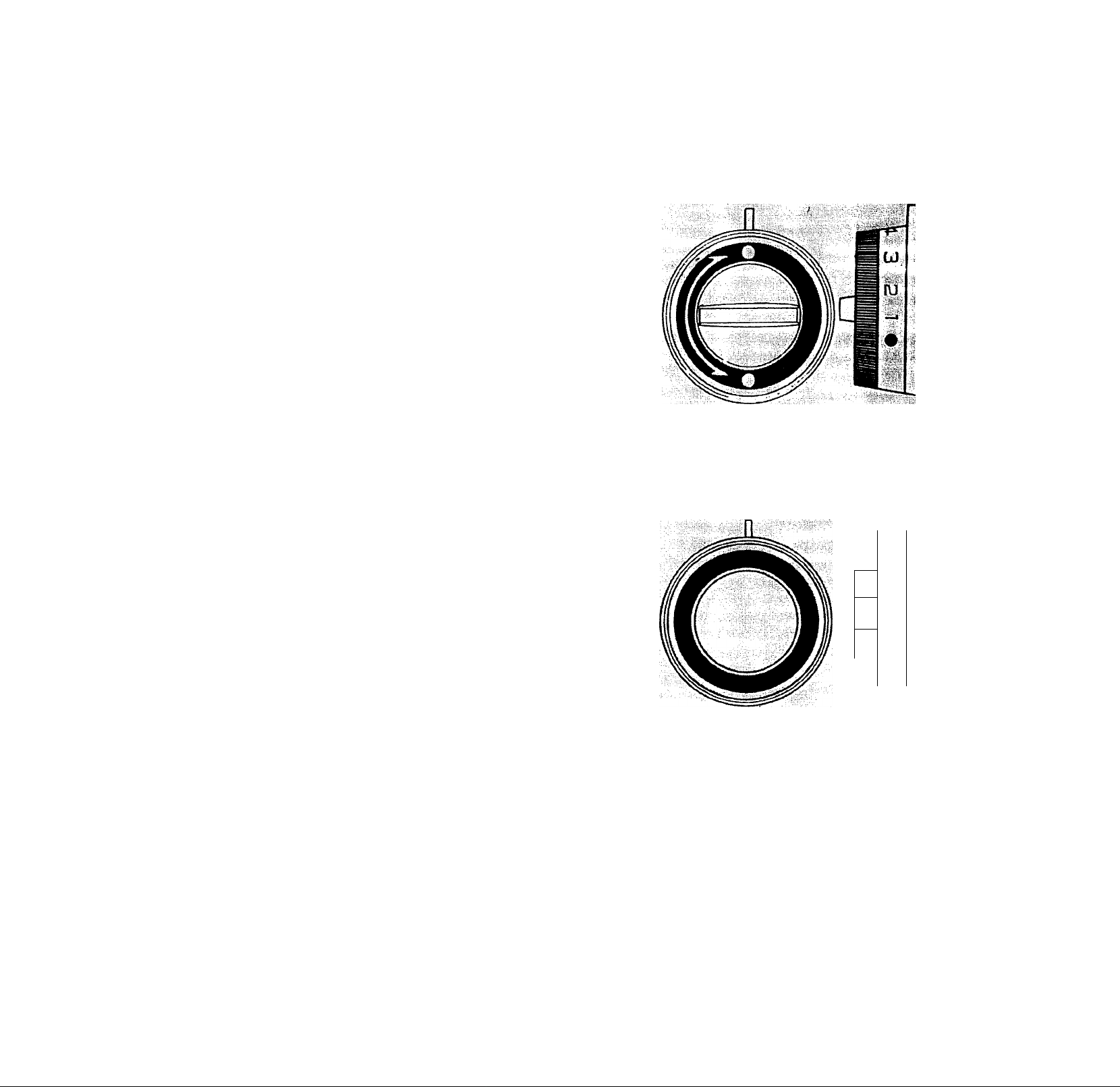

STITCH WIDTH CONTROL

This control regulates the width of the

stitch you select. THE HIGHER THE

NUMBER-THE WIDER THE STITCH.

You may vary your zigzag stitch width

by adjusting this control to the setting

you desire.

This control must be on Red Dot in

order to do straight stitching. Turn only

the outer rim of this control to set the

stitch width. The center of the control

dials the special stitches the machine is

capable of sewing.

STITCH LENGTH CONTROL

The stitch length control regulates the

length of the stitch you select. THE

HIGHER THE NUMBER-THESHORTER

THE STITCH.

The number on stitch length control

indicates the approximate number of

stitches per inch. The stitch setting you

use will be determined by the thickness

of the fabric you are sewing.

ff

p

fU

0

00

A longer stitch setting should be used

for thicker fabric or more layers of fabric.

The middle range of the control is the

10-12 stitch per inch range which is the

most commonly used.

A basting stitch is made by using the

longest possible stitch setting-6 stitches

per inch. The red marking on the

control is the setting used for the

shortest stitches such as in Satin

Stitching.

d)

11

y ■•'#

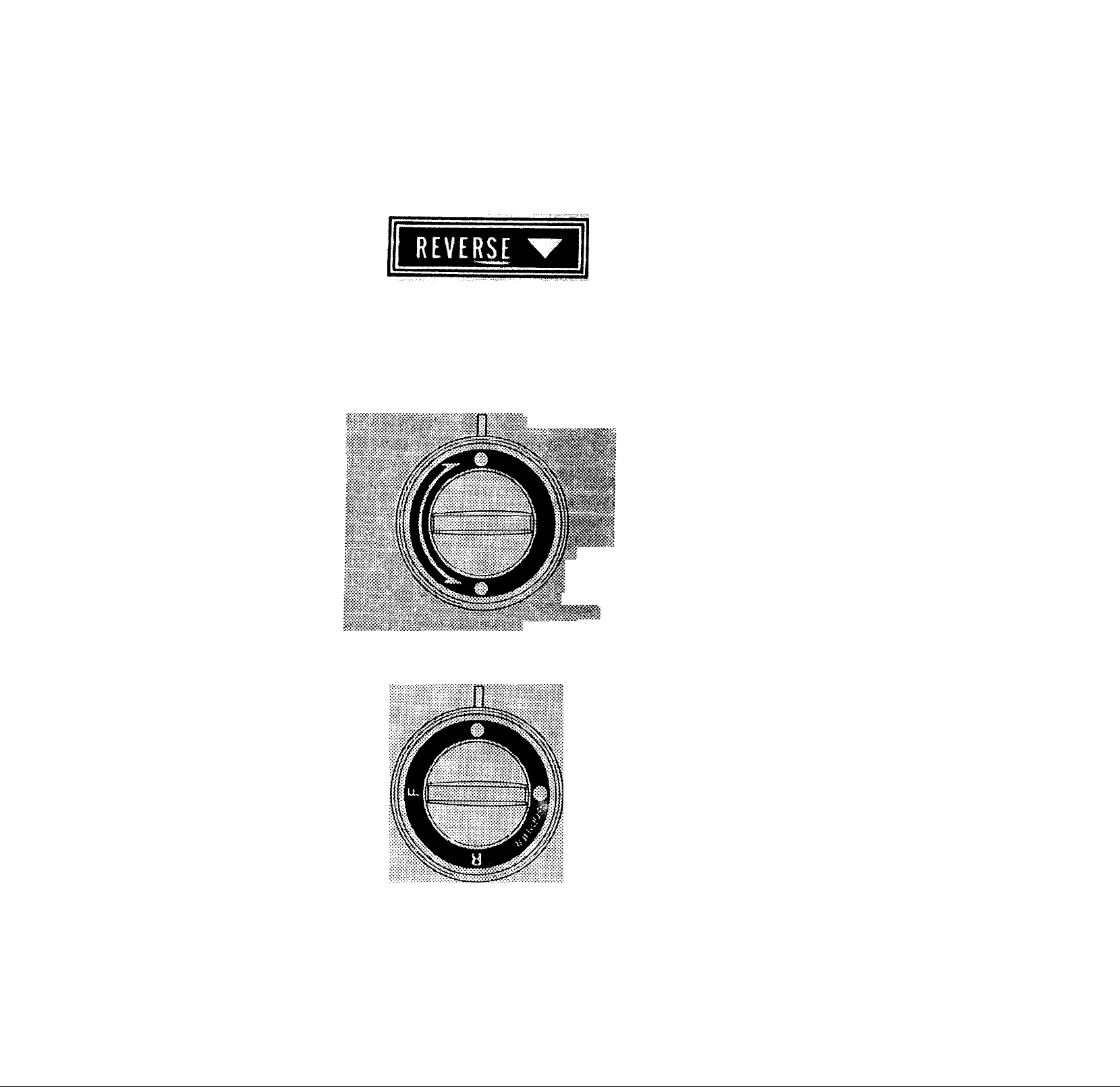

REVERSE STITCH CONTROL

It Is best to begin and end seams with a

few stitches taken In reverse. This is

called back tacking. Back tacking

fastens the ends of the seams firmly and

prevents raveling.

When reverse stitching is needed, turn

the control clockwise and hold there

during sewing. The fabric will imme

diately start feeding backwards and

seam will be fastened.

SPECIAL STITCH MODIFI

ER AND BUTTONHOLE

CONTROL

This control gives you the means of

varying the stitches on the Special

Stitch Dial. When the pointer is turned

to the Red Dot, the machine sews

forward only. When the pointer is

turned to the White Dot, the forward

designs are varied by the machine

sewing in a forward and reverse manner.

Carefully read directions given in the

next section of the book in order to

accomplish the various stitches

correctly.

12

This control is also used in making

buttonholes (Model 1525 only). Detailed

instructions are given in the next section

s

f

of the book.

SPECIAL STITCH DIAL

There are certain types of utility stitches you will use often in your honrte

sewing. This control enables you to just dial the stitch you need for the

task at hand. '

All stitches printed in red on the dial must be sewn with the Special Stitch

Modifier set at the Red Dot. -

To make the stitches printed in black on this dial, the Special Stitch Modifier

must be set at the White Dot.

THE RED DOT SETTING

The setting illustrated above is the one used for most of your stitching. At this

setting you may straight stitch, stretch stitch and make a simple zig zag stitch.

As each stitch is dependent upon the settings of your other controls, carefully

read the directions in the next section of the book for the various stitches.

BLIND STITCH AND OVERLOOK STRETCH STITCH <|S

Blind hems are made by using the setting illustratedc with the Stitch Modifier set

on the Red Dot. When the Modifier is set on the White Dot, overcast stretch

stitching is made.

SPECIAL BOX STITCH AND ELASTIC STRETCH

The setting illustrated is used for special edge finishing and special stretch stitch

for sewing elastic such as sportswear, girdles and other garments that require

stretch. See next section of this book for detailed use of the stitches.

13

SPECIAL MENDING STITCH AND SMOCKING STRETCH :i:8i

You will iind that much of your sewing is in the mending category. For this

reason you have been provided with a stitch for the repair of tears. It is

accomplished with the illustrated setting and the Modifier set at the Red Dot

When the Modifier is turned to the White Dot a Smocking Stitch results. For

directions see the next section of this book.

SERGING OR PINE LEAF STRETCH

Serging or pine leaf stretch is used for seam finishing on all types of fabrics. It is

a stitch used in the garment industry. It forms a good looking seam, stitching

and overcasting the edges. This stitch is useful for seaming of swimwear, stretch

ski pants and other types of knit sportswear. Modifier must be set on the White

Dot. ■

If Modifier is set on the red dot, a Shell Stitch can be made on nylon tricot.

BUTTONHOLE SETTING

The three settings illustrated are used in making a bar tacked buttonhole.

Detailed instructions are given in the next section of the book.

14

t -«I ^ ^ ^ «sysi^x-

OTHER ADJUSTMENTS OF MACHINE IN SEWING

In addition to the obvious controls of your machine, there are other small

regulators and controls to aid you in using your sewing machine.

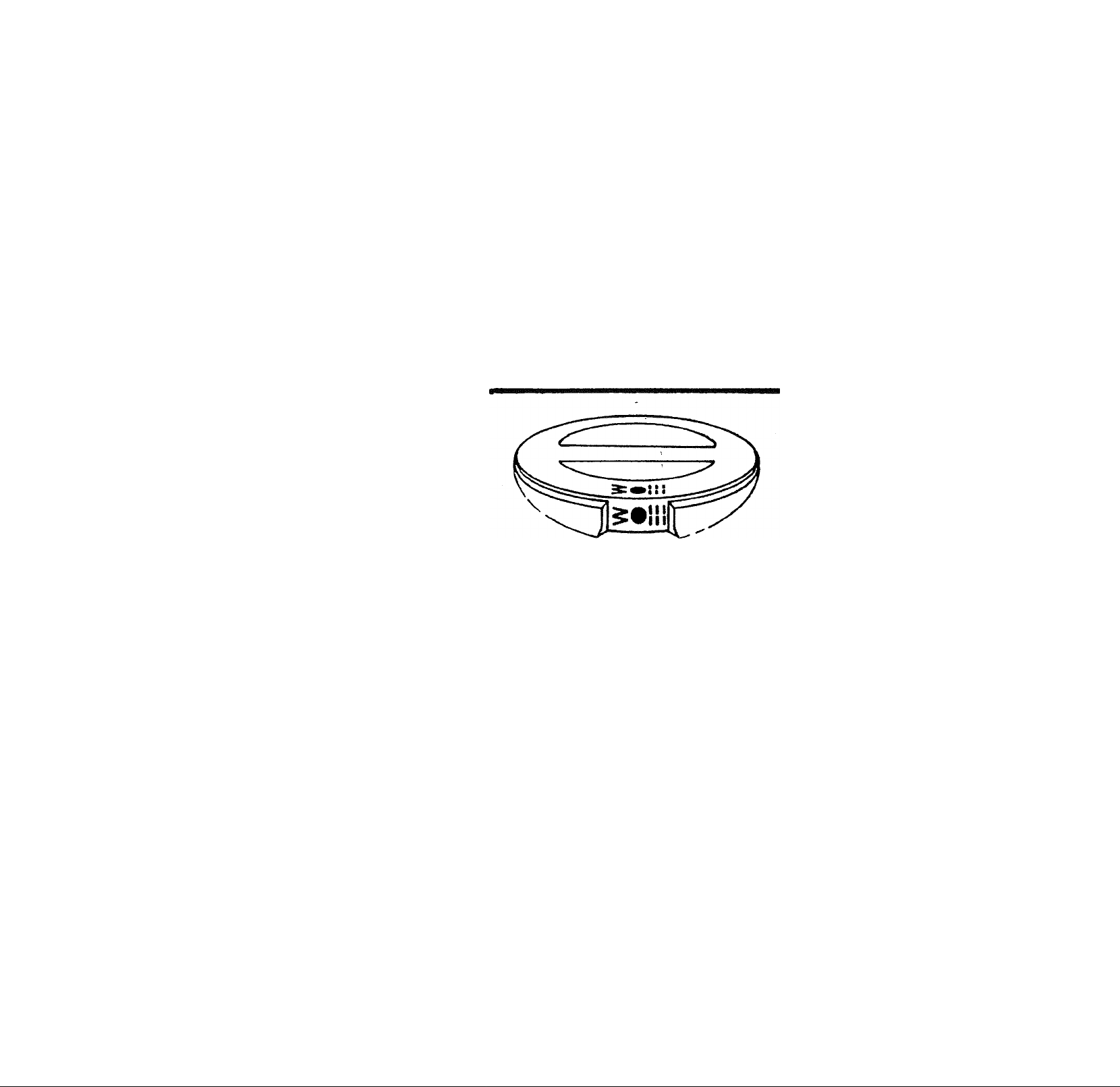

PRESSURE REGULATOR

" 'Is i

Push down the outer ring of the pressure regulator. This will release the

pressure on the presser foot. (See above).

To increase the pressure, push down inner pin until a suitable pressure is

obtained.

Insufficient pressure may cause poor feeding of the fabric, skipped stitches,

or difficulty In guiding the fabric. If feed dogs or presser foot marks appear

on the fabric, reduce the pressure.

When sewing multiple thickness or heavy fabric, reduce the pressure. Increase

pressure when sewing lighter weight fabrics.

15

Loading...

Loading...