Page 1

Installation Instructions

Instrucciones de instalación

Instructions pour l'installation

English / Español / Français

Table of Contents / Índice / Table des matières......2

Models/Modelos/Modèles: 110.2810*

Kenmore®

Top-Loading High Efficiency

Low-Water Washer

Lavadora de alto rendimiento y carga

superior, con nivel bajo de agua

Laveuse haute efficacité à faible

consommation d’eau avec chargement

par le dessus

* = color number, número de color, le numéro de la couleur

P/N W10550315B

Sears Brands Management Corporation

Hoffman Estates, IL 60179 U.S.A.

www.kenmore.com

www.sears.com

Sears Canada Inc.

Toronto, Ontario, Canada M5B 2C3

www.sears.ca

Page 2

Table of Contents

Índice

Table des matières

WASHER SAFETY ������������������������������������2

INSTALLATION REQUIREMENTS �������������3

Tools and Parts ��������������������������������������� 3

Location Requirements ���������������������������4

Drain System ������������������������������������������ 5

Electrical Requirements �������������������������� 6

INSTALLATION INSTRUCTIONS ��������������7

Remove Shipping Materials ��������������������7

Connect Drain Hose �������������������������������� 7

Connect Inlet Hoses �������������������������������� 8

Level Washer �����������������������������������������10

COMPLETE INSTALLATION

CHECKLIST ��������������������������������������������� 11

INSTALLATION NOTES

Date of purchase: _____________________

Date of installation: ___________________

Installer: ___________________________

Model number: _______________________

Serial number: _______________________

SEGURIDAD DE LA LAVADORA �������������12

REQUISITOS DE INSTALACIÓN �������������13

Herramientas y piezas

Requisitos de ubicación

Sistema de desagüe

Requisitos eléctricos

����������������������������13

��������������������������14

�������������������������������15

������������������������������� 15

INSTRUCCIONES DE INSTALACIÓN ����� 16

Quite la base y el anillo de embalaje

Conexión de la manguera de desagüe

Conexión de las mangueras de entrada

Nivelación de la lavadora

����������������������19

�����16

����17

�� 18

COMPLETE LA INSTALACIÓN ��������������� 21

NOTAS SOBRE LA INSTALACIÓN

Fecha de compra: ____________________

Fecha de instalación: __________________

Instalador: __________________________

Número de modelo: ___________________

Número de serie: _____________________

SÉCURITÉ DE LA LAVEUSE �������������������� 22

EXIGENCES D’INSTALLATION ��������������23

Outillage et pièces

Exigences d’emplacement

Système de vidange

Spécications électriques

�������������������������������� 23

��������������������� 24

����������������������������� 24

���������������������� 25

INSTRUCTIONS D’INSTALLATION ��������26

Retrait de la base d’expedition et

de l’emballage en anneau

Raccordement du tuyau d’evacuation

Raccordement des tuyaux de vidange

Mise à niveau de la laveuse

��������������������� 26

���� 26

��� 27

������������������ 29

LISTE DE VÉRIFICATION

POUR INSTALLATION TERMINÉE ����������31

NOTES CONCERNANT L’INSTALLATION

Date d’achat : _______________________

Date d’installation : ____________________

Installateur : _________________________

Numéro du modèle : ___________________

Numéro de série : _____________________

WASHER SAFETY

2

Page 3

INSTALLATION REQUIREMENTS

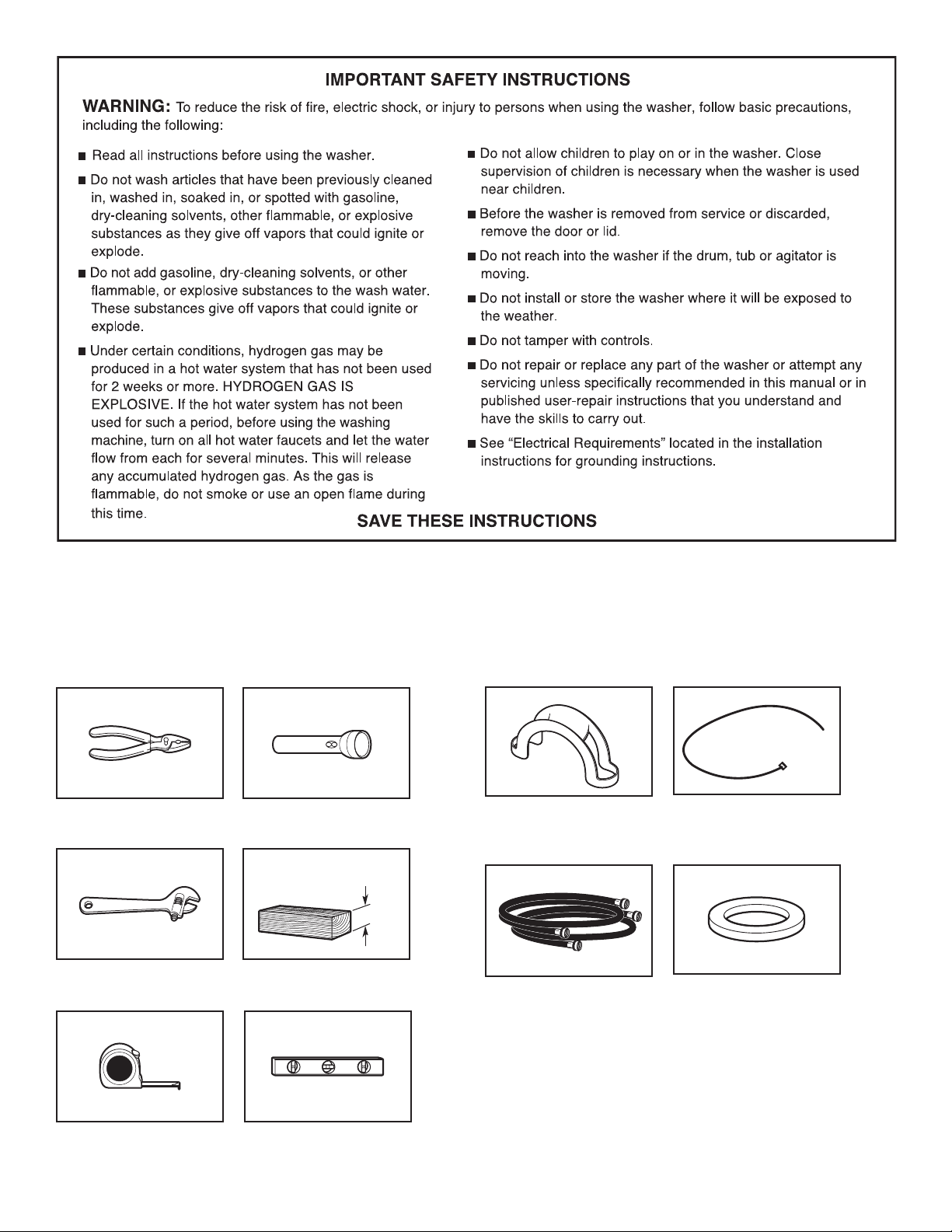

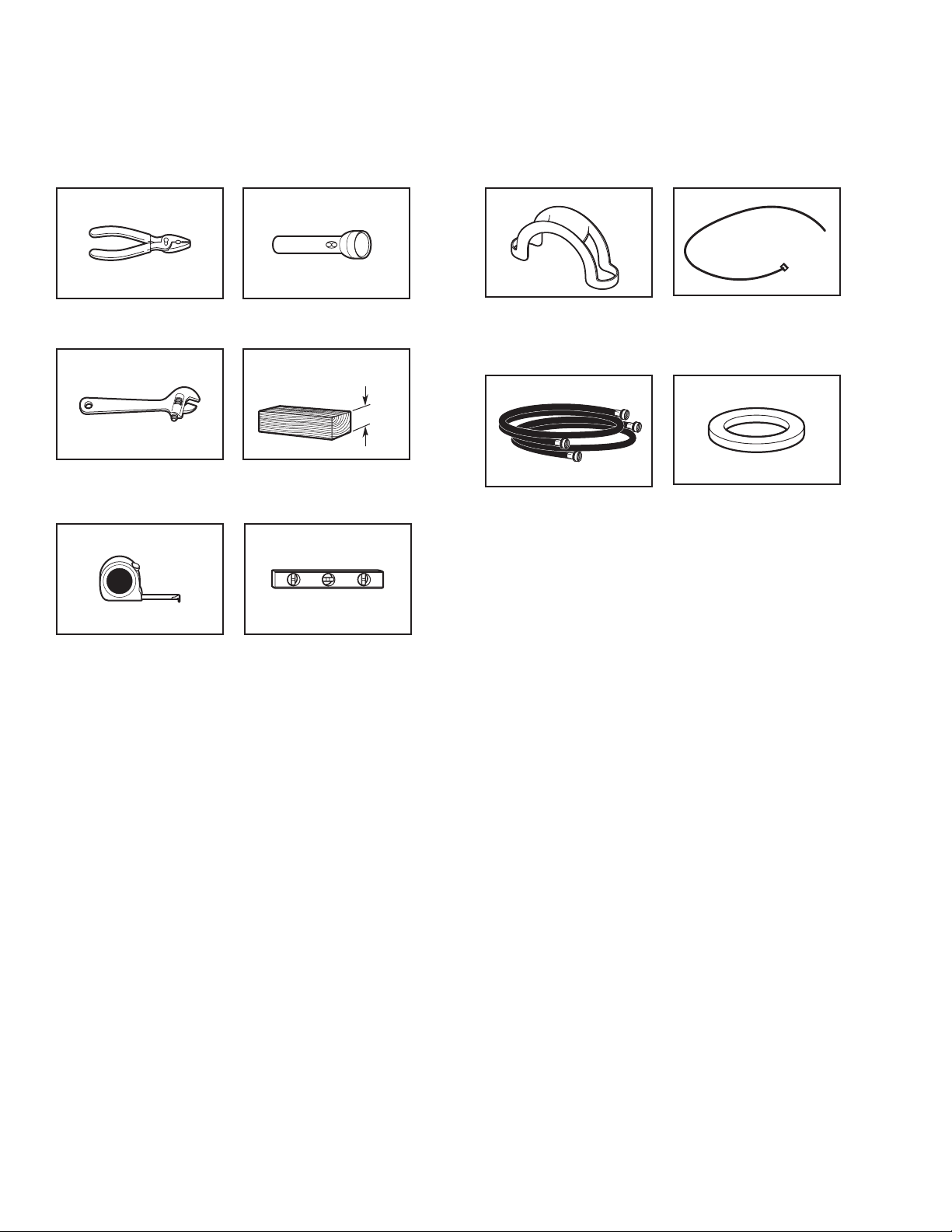

TOOLS AND PARTS

Gather the required tools and parts before starting installation.

Tools needed:

Parts supplied (located in the washer basket):

Pliers that open to 19/16"

(39.5 mm)

Adjustable or open end

wrench 9/16" (14 mm)

Tape measure or ruler Level

Flashlight (optional)

Wood block

4" min

(102 mm)

Drain hose form

Cable Tie

Parts needed (Not supplied with washer):

Water inlet hoses (2)

Flat inlet hose washers (4)

3

Page 4

To order, please refer to the phone number or website on the

back page of your “Use and Care Guide.”

■ 8212656RP 10 ft. (3.0 m) Inlet hose, Black EPDM (2 pack)

■ 8212641RP 5 ft. (1.5 m) Inlet hose, Black EPDM (2 pack)

■ 8212646RP 4 ft. (1.2 m) Inlet hose, Black EPDM (2 pack)

■ 8212545RP 5 ft. (1.5 m) Inlet hose, Red and Blue EPDM

(2 pack)

■ 8212487RP 5 ft. (1.5 m) Nylon braided inlet hose (2 pack)

■ 8212638RP 6 ft. (1.8 m) Nylon braided inlet hose, space

saving 90° elbow, hypro-blue steel couplings

(2 pack)

■ 8212637RP 6 ft. (1.8 m) Inlet hose, Black EPDM, space

saving 90° elbow, hypro-blue steel couplings

(2 pack)

Alternate parts (Not supplied with washer):

Your installation may require additional parts. To order, please

refer to the phone number or website on the back page of your

“Use and Care Guide.”

If you have: You will need:

Laundry tub or Sump pump system (if not already

standpipe taller available)

than 96" (2.4 m)

1" (25 mm) 2" (50 mm) diameter to 1" (25 mm)

diameter standpipe diameter Standpipe Adapter Kit,

Part Number 3363920 and

Connector Kit, Part Number 285835

Overhead sewer Standard 20 gal. (76 L) 39" (990 mm)

tall drain tub or utility sink, sump

pump, and connectors (available from

local plumbing suppliers)

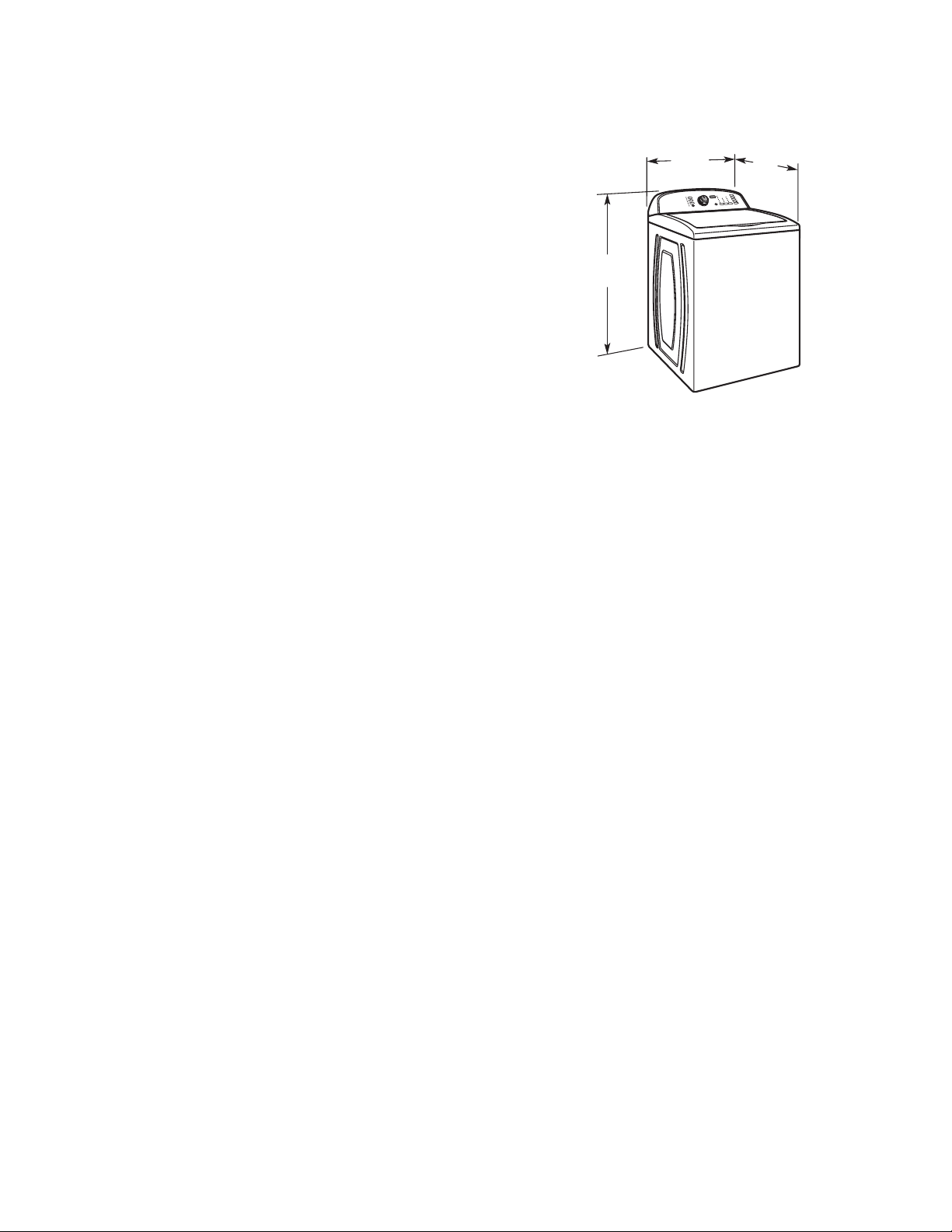

LOCATION REQUIREMENTS

Select proper location for your washer to improve performance

and minimize noise and possible “washer walk.” Install your

washer in a basement, laundry room, closet, or recessed area.

27.5"

(699 mm)

44"

(1118 mm)

You will need:

■ A water heater set to deliver 120°F (49°C) water to the washer.

■ A grounded electrical outlet located within 4 ft. (1.2 m) of

where the power cord is attached to the back of the washer.

See “Electrical Requirements.”

■ Hot and cold water faucets located within 3 ft. (900 mm)

of the hot and cold water ll valves, and water pressure of

20–100 psi (138–690 kPa) for best performance.

■ Level oor with maximum slope of 1" (25 mm) under entire

washer. Installing the washer on carpet is not recommended.

■ A sturdy oor to support the washer weight (washer, water,

and load) of 315 lbs (143 kg).

IMPORTANT: Do not operate, install, or store washer where it

will be exposed to water, weather, or at temperatures below

32° F (0° C). Some water can remain in washer and can cause

damage in low temperatures. See your “Use and Care Guide”

for information on winterizing.

Proper installation is your responsibility.

27"

(686 mm)

Floor drain Siphon Break Kit,

Part Number 285834

Extension Drain Hose,

Part Number 285863

Connector Kit, Part Number 285835

Drain hose too short Extension Drain Hose,

Part Number 285863

Connector Kit, Part Number 285835

Lint clogged drain Drain protector, Part Number 376031

4

Page 5

Spacing for recessed area or closet installation

4.5"

(114 mm)

3"

(25 mm)

All dimensions show recommended spacing allowed, with tested

spacing of 0" (0 mm) clearance on sides.

■ Additional spacing should be considered for ease of

installation and servicing.

■ Additional clearances might be required for wall, door, and

oor moldings.

■ Additional spacing should be considered on all sides of the

washer to reduce noise transfer.

■ For closet installation, with a door, minimum ventilation

openings in the top and bottom of the door are required.

Louvered doors with equivalent ventilation openings are

acceptable.

■ Companion appliance spacing should also be considered.

*

(76 mm)

2

14" max.

(356 mm)

*

*

17"

(432 mm)

48 in.

(310 cm2)

*

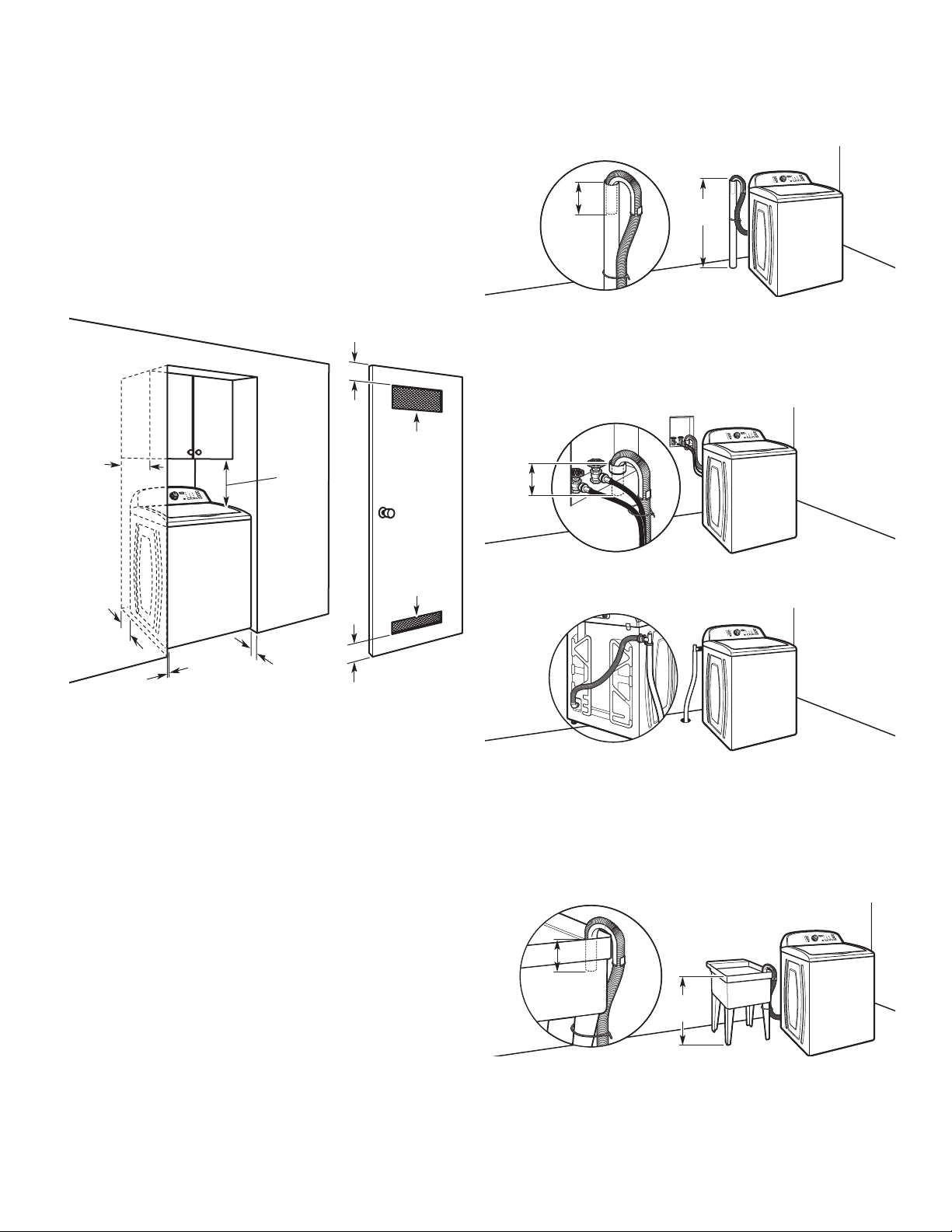

DRAIN SYSTEM

Drain system can be installed using a oor drain, wall standpipe,

oor standpipe, or laundry tub. Select method you need.

Floor standpipe drain system

39"

4.5"

(114 mm)

Minimum diameter for a standpipe drain: 2" (51 mm). Minimum

carry-away capacity: 17 gal. (64 L) per minute. Top of standpipe

must be at least 39" (990 mm) high; install no higher than

96" (2.44 m) from bottom of washer. If you must install higher

than 96" (2.44 m), you will need a sump pump system.

Wall standpipe drain system

4.5"

(114 mm)

(990 mm)

5"

*

(126 mm)

1"

* Required spacing

1"

(25 mm)

*

3"

(76 mm)

2

24 in.

(155 cm2)

*

See requirements for oor standpipe drain system.

Floor drain system

Floor drain system requires a Siphon Break Kit (Part Number

285834), 2 Connector Kits (Part Number 285835), and an

Extension Drain Hose (Part Number 285863) that may be

purchased separately. To order, please see toll-free phone

numbers in your “Use and Care Guide.” Minimum siphon break:

28" (710 mm) from bottom of washer. (Additional hoses may be

needed.)

Laundry tub drain system

30"

39"

(762 mm)

(990 mm)

Minimum capacity: 20 gal. (76 L). Top of laundry tub must

be at least 39" (990 mm) above oor; install no higher than

96" (2.44 m) from bottom of washer.

IMPORTANT: To avoid siphoning, no more than 4.5" (114 mm) of

drain hose should be inside standpipe or below the top of wash

tub. Secure drain hose with cable tie.

5

Page 6

ELECTRICAL REQUIREMENTS

■ A 120 volt, 60 Hz., AC only, 15- or 20-amp, fused electrical

supply is required. A time-delay fuse or circuit breaker on a

separate circuit serving only this washer is recommended.

■ This washer is equipped with a power supply cord having a

3-prong grounding plug.

■ To minimize possible shock hazard, the cord must be plugged

into a mating, 3-prong, grounding-type outlet, grounded in

accordance with local codes and ordinances. If a mating outlet

is not available, it is the personal responsibility and obligation

of the customer to have the properly grounded outlet installed

by a qualied electrician.

■ If codes permit and a separate ground wire is used, it is

recommended that a qualied electrician determine that the

ground path is adequate.

■ Do not ground to a gas pipe.

■ Check with a qualied electrician if you are not sure the

washer is properly grounded.

■ Do not have a fuse in the neutral or ground circuit.

6

Page 7

INSTALLATION

INSTRUCTIONS

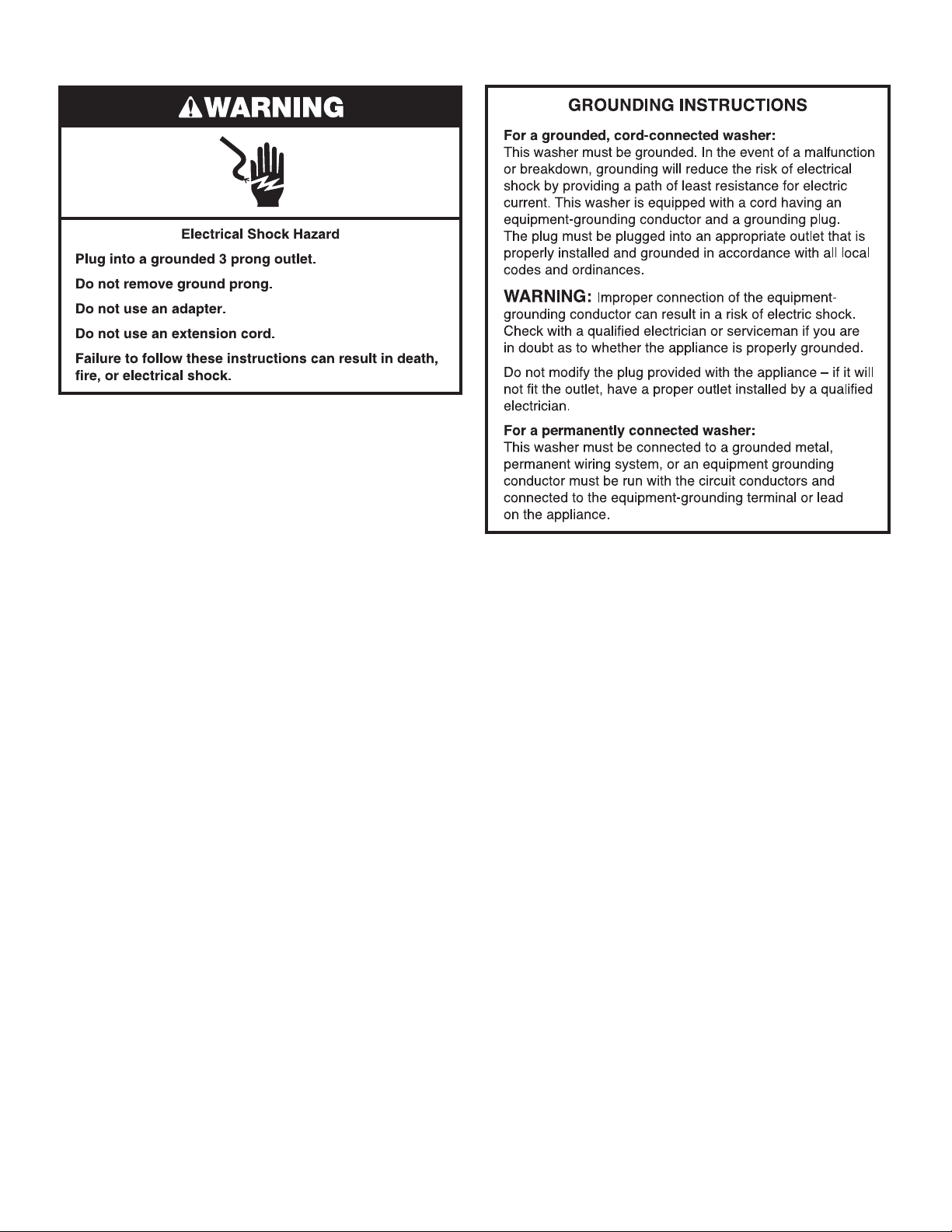

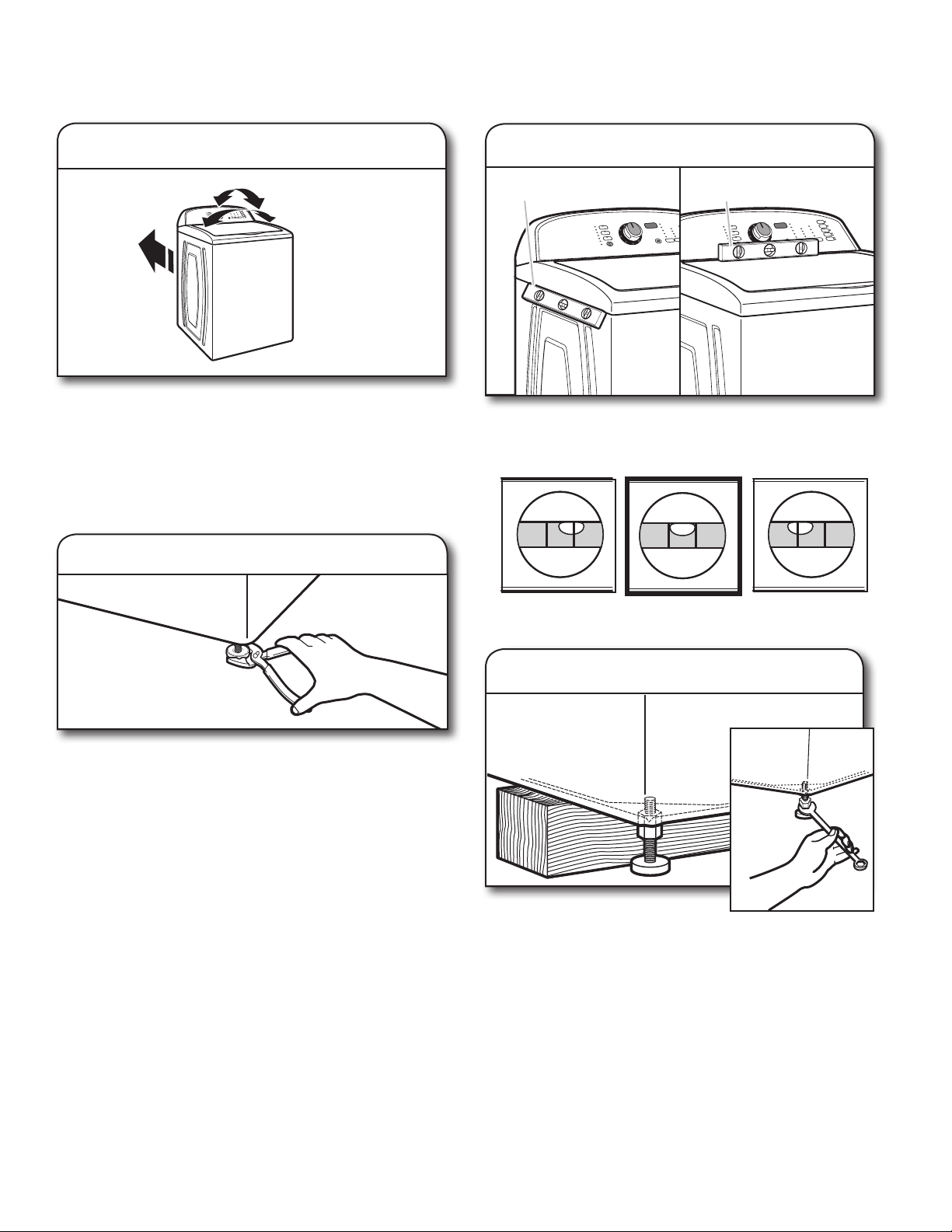

Before you start: remove shipping materials.

It is necessary to remove all shipping materials for proper

operation and to avoid excessive noise from washer.

NOTE: To avoid oor damage during installation, set the washer

onto cardboard before moving across the oor.

IMPORTANT:

■ Be sure the foam shipping base has been removed from the

bottom of the washer as directed in the “Remove Shipping

Base and Packing Ring” section.

■ If foam shipping base has not been removed, be sure lid is

secured with tape before laying washer on its back.

■ Removing the foam shipping base is necessary for proper

operation.

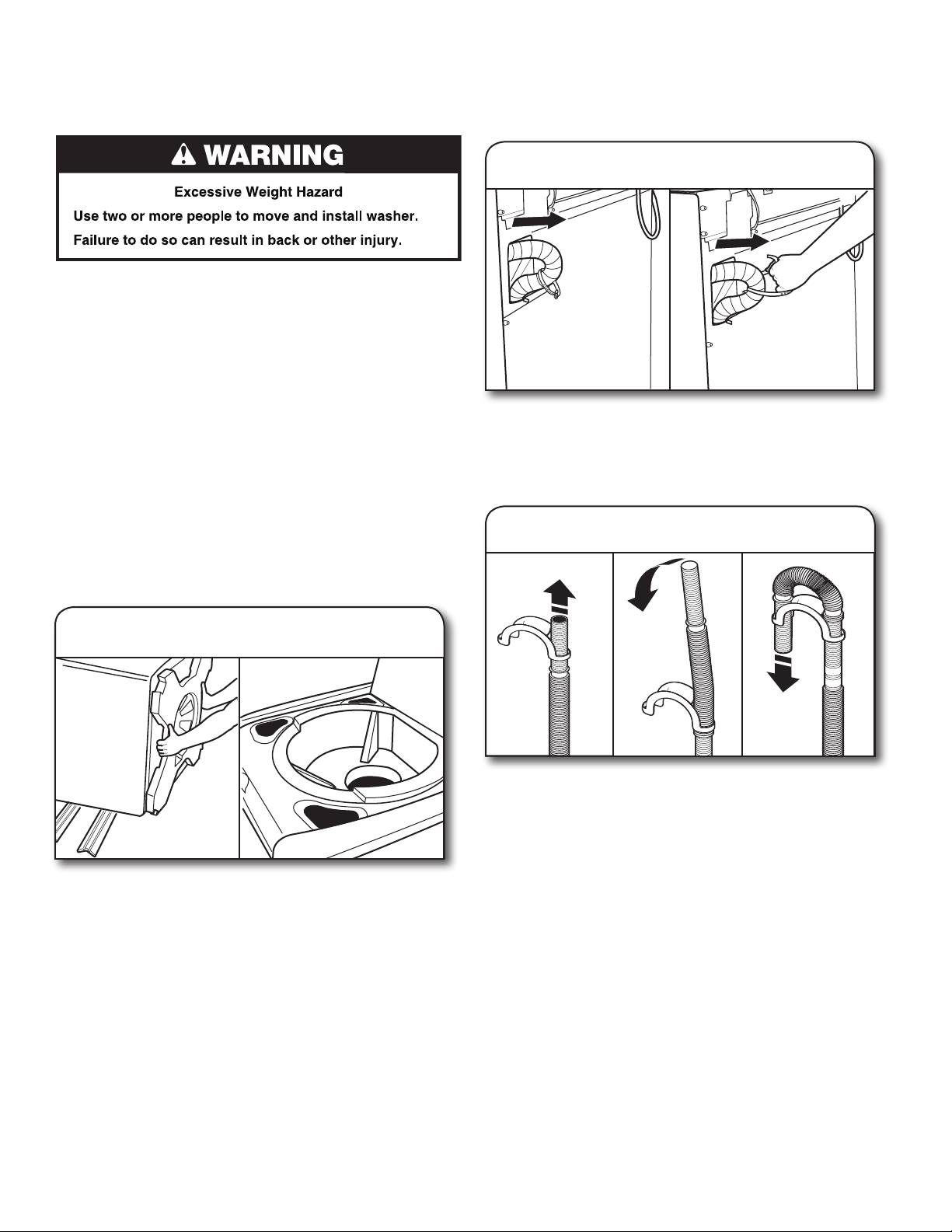

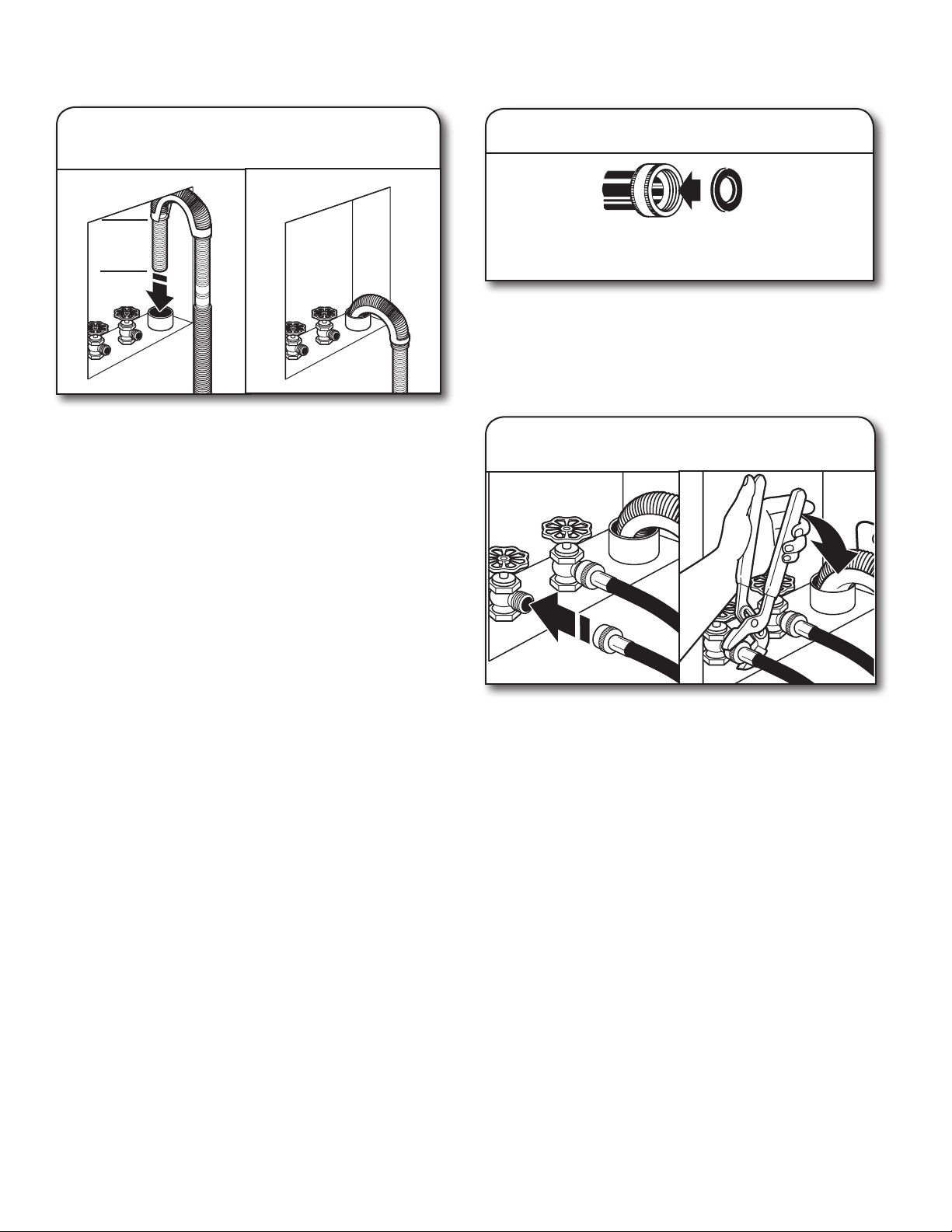

CONNECT DRAIN HOSE

IMPORTANT: Proper connection of the drain hose helps to avoid

water leakage and damage to your oors. The drain hose is

connected to your washer and is stored inside the washer cabinet.

1� Remove drain hose from washer cabinet

Gently pull hose out of back of washer cabinet from top until

end emerges.

IMPORTANT: Do not force excess drain hose back into rear of

washer.

REMOVE SHIPPING BASE

AND PACKING RING

1� Remove shipping base and packing ring

Place cardboard supports from shipping carton on oor behind

washer for support. Secure the lid with tape. Using two or more

people, tip the washer onto its back and place on cardboard

supports. Remove foam shipping base. Then, set washer back

upright, and remove the tape from the lid so that you can open

the lid and remove the foam packing ring from the washer tub.

NOTE: Keep foam packing ring in case you need to move

the washer in the future.

2� Connect drain hose form

For a laundry tub or standpipe drain, connect the drain hose

form. For a oor drain, do not install drain hose form. You may

need alternate parts with separate directions. See “Tools and

Parts” to determine what you may need.

Feed hose into one end of form. Bend hose and feed through

other side, anchoring form on smooth sections of hose. The

hose must extend 4.5" (114 mm) beyond the form.

7

Page 8

CONNECT INLET HOSES

3� Place drain hose in standpipe

4.5"

(114 mm)

Place hose into standpipe (shown in picture) or over side of

laundry tub.

IMPORTANT: To keep drain water from going back into the

washer:

Do not force excess drain hose into standpipe. Hose should be

secure but loose enough to provide a gap for air.

Do not lay excess hose on the bottom of the laundry tub.

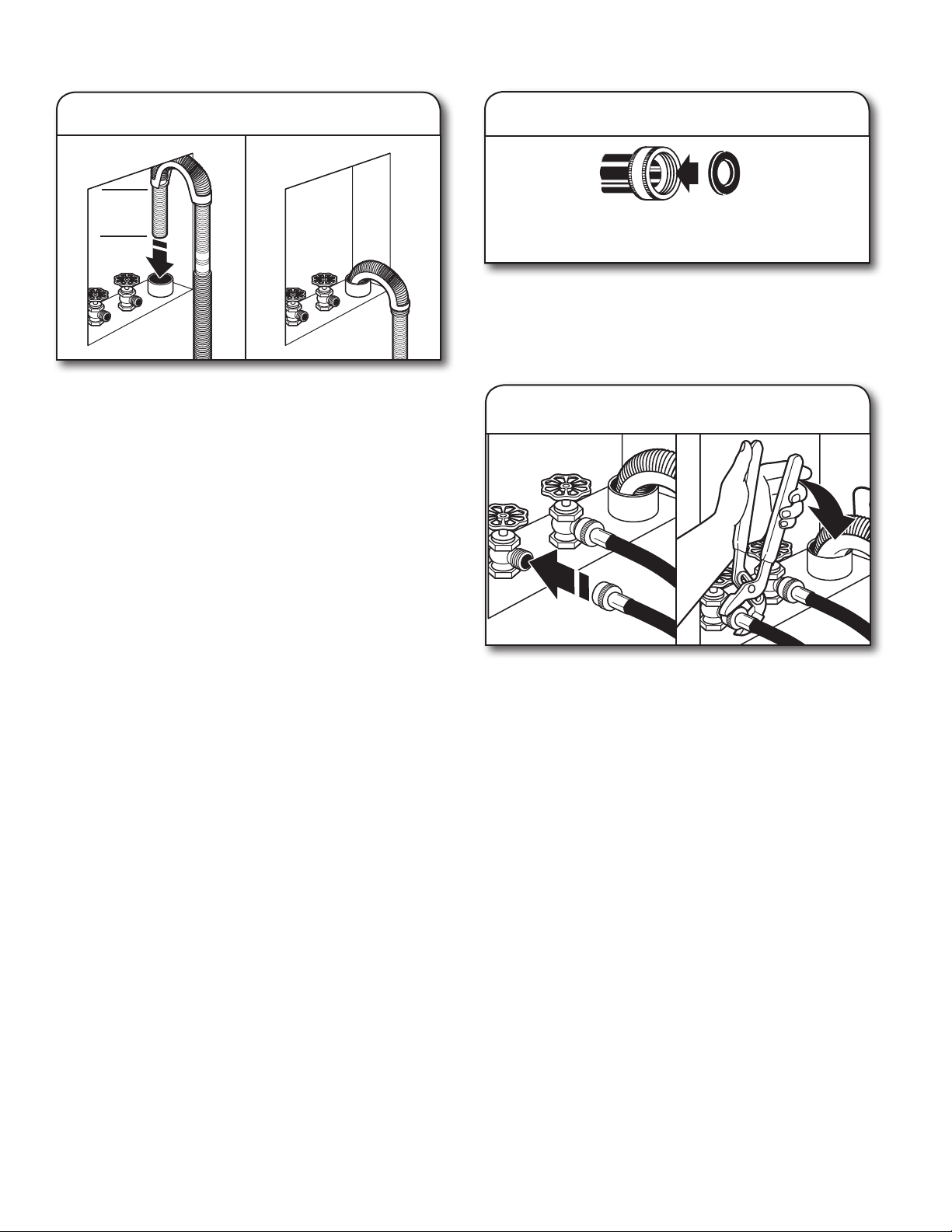

1� Insert new at washers

A B

A. Coupling

B. Washer

IMPORTANT: To avoid leaks, check that your water inlet hoses

have at washers at both ends. Washer must be connected

to water faucets with new inlet hoses with at washers (not

provided). Do not use old hoses. Do not use hoses without

washers.

2� Connect inlet hoses to water faucets

Make sure the washer basket is empty. Attach the hose labeled

hot to hot water faucet. Screw on coupling by hand until it is

seated on washer. Use pliers to tighten couplings an additional

two-thirds turn. Repeat this step with the hose labeled cold for

the cold water faucet. Both hoses must be connected for washer

to work properly.

IMPORTANT: Do not overtighten or use tape or sealants on

valve when attaching to faucets or washer. Damage can result.

HELPFUL TIP: Make note of which hose is connected to hot

water to help in attaching hoses to washer correctly.

8

Page 9

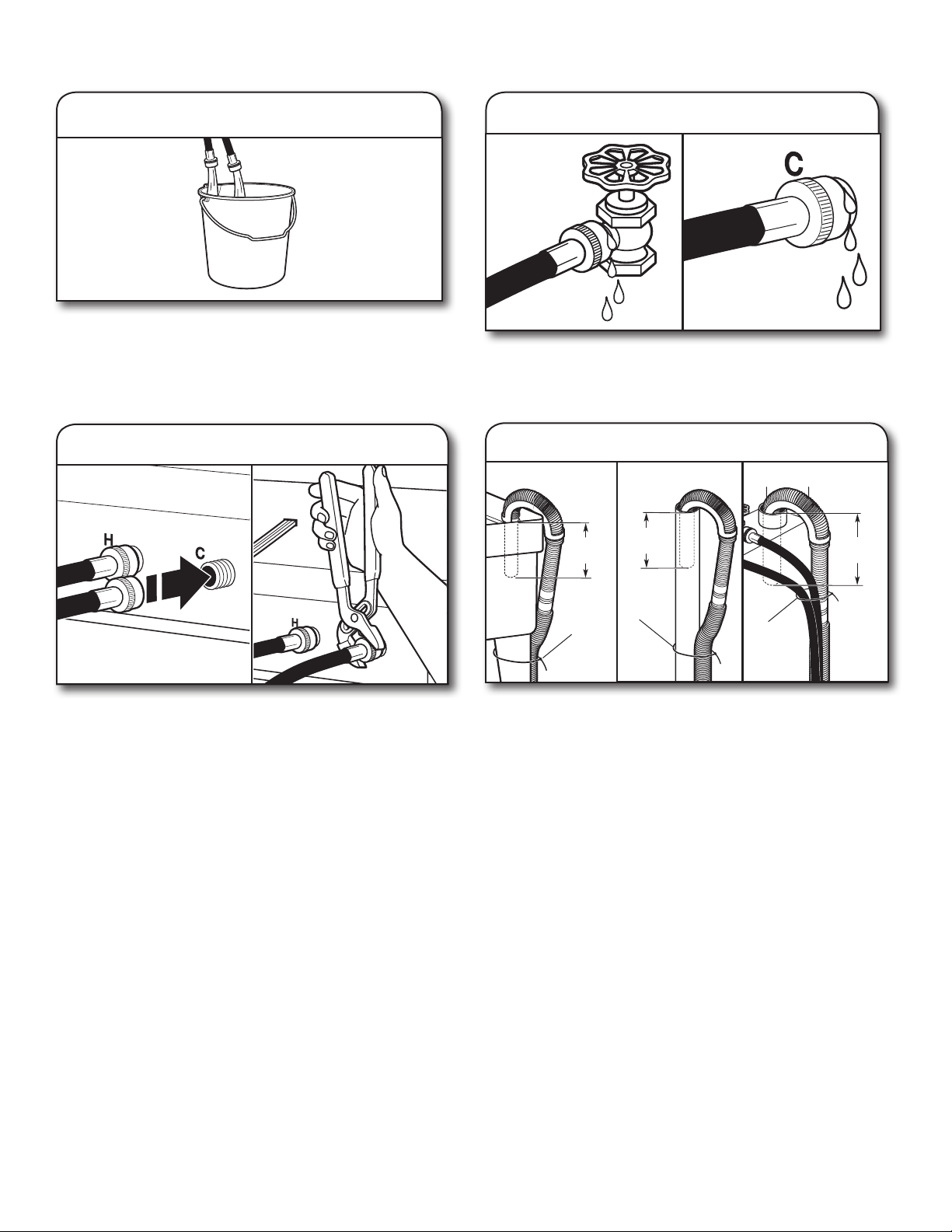

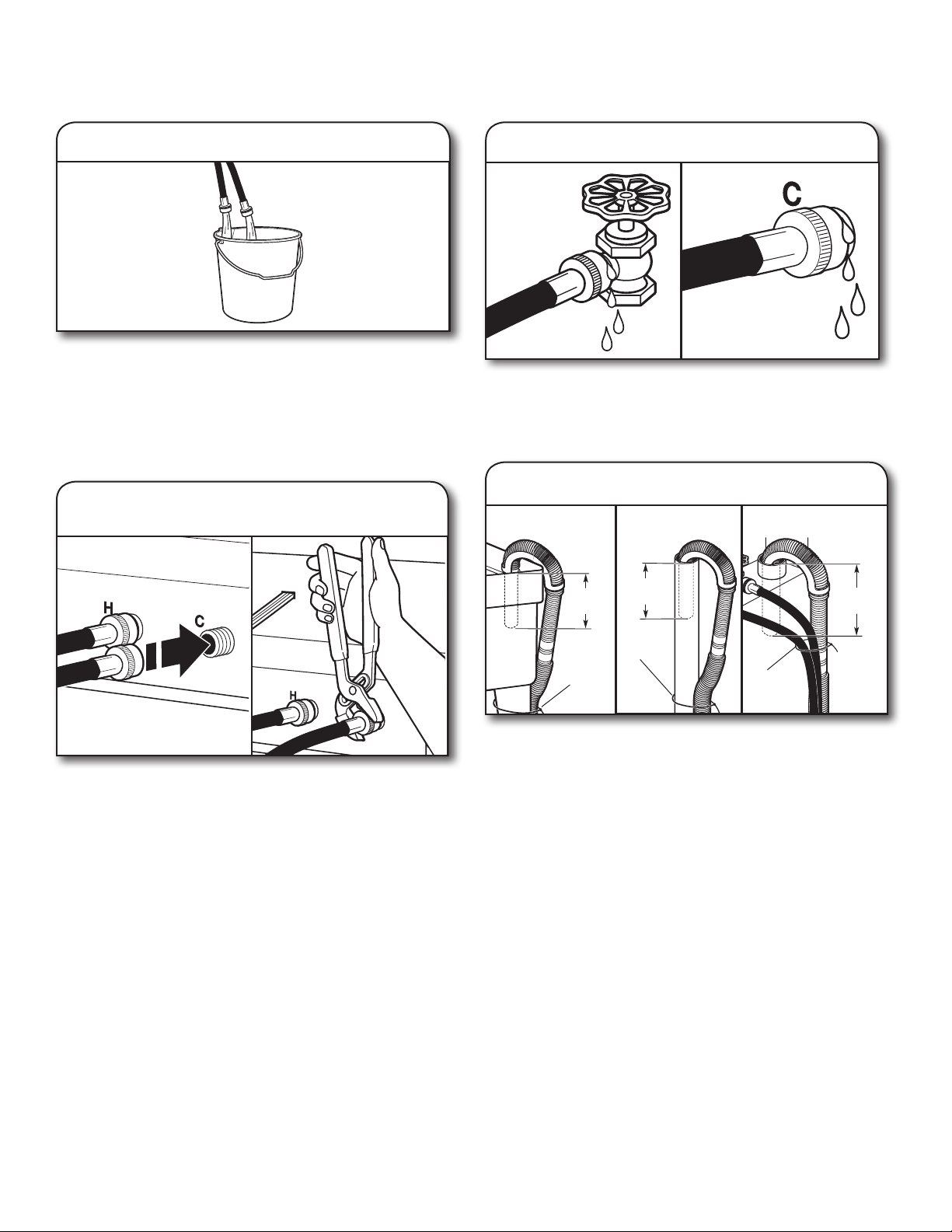

3� Clear water lines

Run water for a few seconds through hoses into a laundry tub,

drainpipe, or bucket to avoid clogs. Water should run until clear.

Check the temperature of the water to make sure that the hot

water hose is connected to the hot water faucet and the cold

water hose is connected to the cold water faucet.

5� Check for leaks

Turn on water faucets to check for leaks from faucet and at

washer connection. A small amount of water may enter washer.

You will drain this in a later step.

4� Connect inlet hoses to washer

Attach hot water hose to hot water inlet valve. Screw coupling

by hand until it is snug. Use pliers to tighten couplings an

additional two-thirds turn. Repeat with cold water inlet valve.

Both hoses must be connected for washer to work properly.

IMPORTANT: Do not overtighten or use tape or sealants on

valve when attaching to faucets or washer. Damage can result.

NOTE: To reduce risk of hose failure, replace the hoses every

5 years. Record hose installation or replacement dates for

future reference.

Periodically inspect and replace hoses if bulges, kinks, cuts,

wear, or leaks are found.

6� Secure drain hose

Laundry Tub Standpipe Wall

4.5"

(114 mm)

A

Secure drain hose to laundry tub leg, drain standpipe, or inlet

hoses for wall standpipe with cable tie (A). This will help reduce

the chance of drain water splashing on the oor.

4.5"

(114 mm)

A

A

4.5"

(114 mm)

9

Page 10

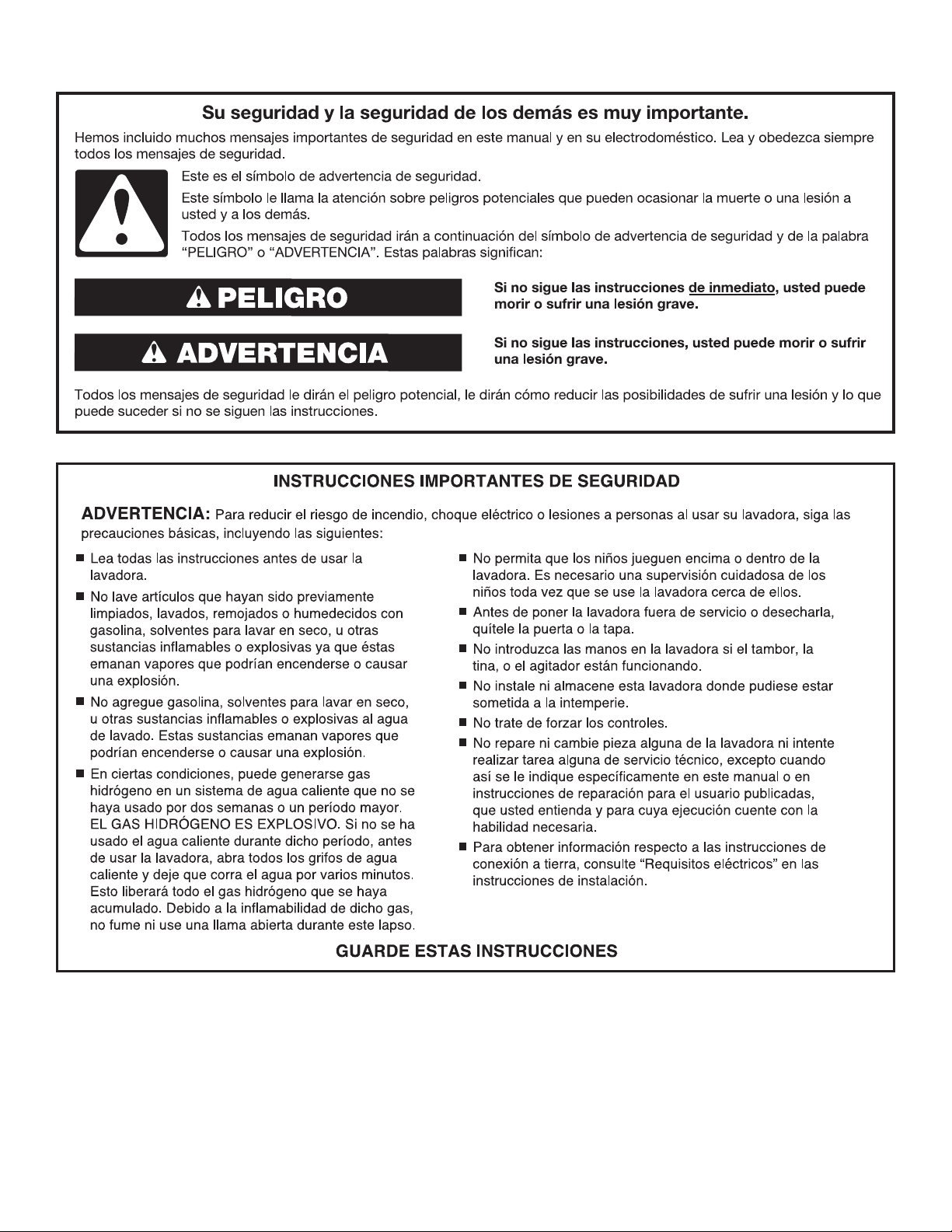

LEVEL WASHER

IMPORTANT: Leveling your washer properly reduces excess noise

and vibration.

1� Move washer to nal location

Move the washer to its nal location. Rock the washer back

and forth to check whether all four feet are stable and in rm

contact with the oor. If the washer rocks, your model may

be one that comes with 3 feet preset at the factory. It will be

necessary to adjust the right front foot to level the washer. If

all 4 feet were preset at the factory, minor adjustments may be

needed to level the washer on your oor.

2� Adjust front leveling foot

3� Check levelness of washer

Place level here

Place level here Place level here

Check the levelness of the washer. First, place a level on the lid

near the console. Then place the level on the side of the washer

in the crease between the top of the washer and the cabinet.

Place level here

For washers with an adjustable right front foot, lower the right

front foot until it contacts the oor. Using pliers, rotate the foot

up to an additional 1 1/2 turns.

10

Not Level Not Level LEVEL

4� Adjust levelness of washer

If the washer is not level, move

the washer out slightly, tip back

and prop up the front of the washer with a wood block. Adjust

the right front foot by loosening the locknut with a 9/16" or

14 mm open-end wrench, then twisting the foot up or down as

needed. After the washer is level, make sure all 4 feet are in

rm contact with the oor by gently rocking it back and forth

and side to side. Adjust the feet if necessary, then using the

wrench again, turn the locknuts counterclockwise on the foot to

tighten to the washer cabinet.

HELPFUL TIP: You may have to adjust the back feet to level the

washer. If you are installing the washer in a tight or hard-toreach area, you may have to move the washer out to reach the

feet comfortably. You may wish to lock the back feet before

moving the washer back into place.

IMPORTANT: If the locknuts are not tight against the washer

cabinet, the washer may vibrate.

Page 11

5� Plug into a grounded 3 prong outlet

COMPLETE INSTALLATION

CHECKLIST

■ Check electrical requirements. Be sure you have correct

electrical supply and recommended grounding method.

See “Electrical Requirements.”

■ Check that all parts are now installed. If there is an extra part,

go back through steps to see what was skipped.

■ Check that you have all of your tools.

■ Keep the foam packing ring from the washer tub for future

relocation of the washer. Dispose of/recycle all packaging

materials.

■ Check that both water faucets are on.

■ Check for leaks around faucets and inlet hoses.

■ Remove lm from console and any tape remaining

on washer.

■ Check that washer is plugged into a grounded 3-prong outlet.

■ Read “Washer Use” in your “Use and Care Guide.”

■ To test and clean your washer, measure 1/2 of normal

recommended amount of High Eciency (HE) powdered

or liquid detergent for a medium-size load and pour it into

detergent dispenser. Close lid. Press POWER. Select a normal

cycle and press START. Allow it to complete

one whole cycle.

11

Page 12

SEGURIDAD DE LA LAVADORA

12

Page 13

REQUISITOS DE INSTALACIÓN

Herramientas y Piezas

Reúna las herramientas y piezas necesarias antes de comenzar la

instalación.

Herramientas necesarias:

Piezas suministradas (localizado en la canasta de la lavadora):

Pinzas que se abran a

Linterna (opcional)

1 9⁄16" (39,5 mm)

4" min

(102 mm)

Llave de tuercas ajustable

Bloque de madera

o de extremo abierto

de 9/16" (14 mm)

Regla o cinta para medir Nivel

Para hacer un pedido, consulte los números gratuitos en la

contraportada del “Manual de uso y cuidado”.

■ 8212656RP Manguera de entrada de 10 pies (3,0 m) de

caucho de etileno propileno negro (EPDM)

(paquete de 2)

■ 8212641RP Manguera de entrada de 5 pies (1,5 m) de

caucho de etileno propileno negro (EPDM)

(paquete de 2)

■ 8212646RP Manguera de entrada de 4 pies (1,2 m) de

caucho de etileno propileno negro (EPDM)

(paquete de 2)

■ 8212545RP Manguera de entrada de 5 pies (1,5 m) de

caucho de etileno propileno rojo y azul (EPDM)

(paquete de 2)

■ 8212487RP Manguera de entrada de 5 pies (1,5 m) de

nylon trenzado (paquete de 2)

■ 8212638RP Manguera de entrada de nylon trenzado de

6 pies (1,8 m), codo de 90° para ahorrar

espacio, acoplamientos de acero “hypro-blue”

(paquete de 2)

■ 8212637RP Manguera de entrada de 6 pies (1,8 m) de

caucho de etileno propileno negro (EPDM), codo

de 90° para ahorrar espacio, acoplamientos de

acero “hypro-blue” (paquete de 2)

Molde de la manguera

Atadura de cables

de desagüe

Piezas necesarias (No se proveen con la lavadora):

Mangueras de entrada

de agua (2)

Arandelas planas para

la manguera de entrada (4)

Piezas alternativas (No se proveen con la lavadora):

Su instalación puede requerir piezas suplementarias. Para hacer

un pedido, consulte los números gratuitos en la contraportada del

“Manual de uso y cuidado”.

Si tiene: Usted necesitará:

Tina de lavandería Sistema de bomba de sumidero

o tubo vertical de (si no está disponible aún)

más de 96" (2,4 m)

de altura

Tubo vertical de Juego de adaptador de tubo vertical

1" (25 mm) de diámetro de 2" (51 mm) de diámetro a 1"

(25 mm) de diámetro,

pieza número 3363920

Juego de conectores,

pieza número 285835

Una alcantarilla Tina de desagüe estándar de 20

suspendida galones (76 L) 39" (990 mm) de altura

o lavadero utilitario, bomba de

sumidero y conectores (disponible

con proveedores locales)

Desagüe por el piso Interruptor de efecto de sifón,

pieza número 285834

Juego de extensión de desagüe,

pieza número 285863

Juego de conectores,

pieza número 285835

Una manguera de Juego de extensión de desagüe,

desagüe corta pieza número 285863

Juego de conectores,

pieza número 285835

Desagüe obstruido Protector del desagüe,

por pelusa pieza número 376031

13

Page 14

REQUISITOS DE UBICACIÓN

3"

(25 mm)

Seleccione una ubicación apropiada para su lavadora, para

realzar el rendimiento y reducir al mínimo el ruido y la posible

“caminata” de la lavadora. Instale su lavadora en un sótano,

cuarto para lavar, clóset o un lugar empotrado.

27, 5 "

27,5"

(699 mm)

44"

(1118 mm)

Usted necesitará:

■ Un calentador de agua jado en 120°F (49°C).

■ Un contacto con conexión a tierra ubicado a no más de 4 pies

(1,2 m) del cable eléctrico en la parte posterior de la lavadora.

Vea “Requisitos eléctricos”.

■ Grifos de agua caliente y de agua fría ubicados a una

distancia de no más de 3 pies (0,9 m) de las válvulas de

llenado del agua caliente y fría en la lavadora y una presión

de agua de 20–100 lb/pulg² (138–690 kPa) para un mejor

rendimiento.

■ Un piso nivelado con un declive máximo de 1" (25 mm) debajo

de la lavadora completa. No se recomienda la instalación

sobre una alfombra.

■ El piso debe sostener el peso total de la lavadora (con el agua

y la carga) de 315 lb (143 kg).

IMPORTANTE: No instale, guarde ni utilice la lavadora en donde

estará expuesta a la intemperie o en temperaturas por debajo de

32°F (0°C). El agua que queda en la lavadora después del uso

puede causar daños en temperaturas bajas. Vea “Cuidado de la

lavadora” en el “Manual de uso y cuidado”, para saber cómo

acondicionarla para el invierno.

La instalación correcta es su responsabilidad.

27"

(686 mm)

Instalación en zona empotrada o en el clóset

Se recomiendan las siguientes dimensiones de espacio para esta

lavadora. Esta lavadora fue puesta a prueba para la instalación

con un espacio de 0" (0 mm) en ambos lados.

■ Debe considerarse espacio adicional para facilitar la

instalación y el servicio técnico.

■ Se podrían necesitar espacios libres adicionales para las

molduras de la pared, de la puerta y del piso.

■ Se debe considerar agregar espacio adicional en todos los

lados de la lavadora para reducir la transferencia de ruidos.

■ Para la instalación en clóset, con una puerta, se requieren

aberturas de ventilación mínimas en la parte superior e inferior

de la puerta. Se aceptan puertas tipo persiana con aberturas

de ventilación equivalentes.

■ También se debe considerar espacio adicional para otro

electrodoméstico que le acompañe.

*

(76 mm)

2

48 in.

(310 cm2)

2

24 in.

(155 cm2)

*

*

5"

*

(126 mm)

*

1"

14" max.

(356 mm)

* Espacio necesario

17"

(432 mm)

1"

(25 mm)

*

*

3"

(76 mm)

14

Page 15

SISTEMA DE DESAGÜE

4,5"

(114 mm)

El sistema de desagüe de la lavadora se puede instalar utilizando

un desagüe de piso, un tubo vertical de pared, un tubo vertical de

piso o una tina de lavadero. Seleccione el método que necesita.

Sistema de desagüe de tubo vertical de piso

39"

4,5"

(114 mm)

Diámetro mínimo para el desagüe de tubo vertical: 2" (51 mm).

Capacidad de desplazamiento mínima: 17 gal. (64 L) por minuto.

La parte superior del tubo vertical debe estar a 39" (991 mm) de

altura como mínimo; instálela a no más de 96" (2,4 m) de la base

de la lavadora. Si la instala a más de 96" (2,4 m), necesitará un

sistema de bomba de sumidero.

Sistema de desagüe de tubo vertical de pared

(990 mm)

Sistema de desagüe de tina de lavadero

30"

39"

(762 mm)

(990 mm)

Capacidad mínima: 20 gal. (76 L). La parte superior de la tina

de lavadero debe estar a 39" (990 mm) del piso como mínimo;

instálela a no más de 96" (2,4 m) de la base de la lavadora.

IMPORTANTE: Para evitar el efecto de sifón, no debe haber

más de 4,5" (114 mm) de manguera de desagüe dentro del tubo

vertical o debajo de la parte superior de la tina de lavado.

Siempre ajuste la manguera de desagüe con una atadura de

cables.

REQUISITOS ELÉCTRICOS

4,5"

(114 mm)

Vea los requisitos para el sistema de desagüe de tubo vertical

de piso.

Sistema de desagüe de piso

Un sistema de desagüe por el piso requiere de un juego de

desviación de sifón (pieza número 285834), 2 juegos de

conectores (pieza número 285835) y extensión de manguera de

desagüe (pieza número 285863), la cual puede comprarse por

separado. Para ordenar, sírvase consultar los números gratuitos

en el “Manual de uso y cuidado”. Desviación de sifón mínima:

28" (710 mm) de la base de la lavadora. (Se pueden necesitar

mangueras adicionales.)

■ Se necesita un suministro eléctrico de 120 voltios, 60 hertzios,

CA solamente, de 15 ó 20 amperios y protegido con fusible.

Se recomienda un fusible retardador o un cortacircuitos, en

un circuito independiente que preste servicio únicamente

a este aparato.

■ Esta lavadora viene equipada con un cable eléctrico dotado

de un enchufe de 3 terminales con conexión a tierra.

■ Para reducir al mínimo el peligro de posibles choques

eléctricos, el cable debe ser enchufado en un contacto

apropiado de pared de 3 terminales, conectado a tierra de

acuerdo con los códigos y normas locales. Si no hay disponible

una salida equivalente, es responsabilidad y obligación

personal del cliente de tener un contacto apropiado con

conexión a tierra instalado por un electricista calicado.

■ Si los códigos lo permiten y se emplea un alambre de

conexión a tierra separado, es recomendable que un

electricista calicado determine si la trayectoria de

conexión a tierra es adecuada.

■ No conecte a tierra usando una tubería de gas.

■ Si no está seguro de que la conexión a tierra de la lavadora

sea la adecuada, verifíquela con un electricista competente.

■ No instale un fusible en el circuito neutral o de tierra.

15

Page 16

INSTRUCCIONES DE INSTALACIÓN

Antes de comenzar: Quite los materiales de transporte.

Es necesario quitar todos materiales de transporte para

obtener un funcionamiento adecuado y para evitar ruido

excesivo de la lavadora.

NOTA: Para evitar daños en el piso, coloque la lavadora sobre

un cartón antes de moverla.

IMPORTANTE:

■ Asegúrese de que se ha quitado la base de embalaje de

espuma de la parte inferior de la lavadora como se indica

en la sección “Quite la base y el anillo de embalaje”.

■ Si no se ha quitado la base de embalaje de espuma, asegúrese

de que la tapa esté ajustada con cinta adhesiva antes de

colocar la lavadora sobre su parte posterior.

■ Para un funcionamiento adecuado es necesario quitar la base

de embalaje de espuma.

QUITE LA BASE Y EL ANILLO

DE EMBALAJE

1� Saque la base de transporte

y el anillo de embalaje

Coloque los soportes de cartón del embalaje sobre el piso detrás

de la lavadora para soporte. Asegure la tapa con cinta adhesiva.

Con la ayuda de 2 o más personas, incline la lavadora sobre su

parte posterior y colóquela sobre los soportes de cartón. Quite

la base de embalaje de espuma. A continuación, coloque la

lavadora nuevamente en posición vertical y quite la cinta adhesiva

de la tapa para poder abrirla; quite el anillo de embalaje de

espuma de la tina de la lavadora.

NOTA: Conserve el anillo de embalaje de espuma en caso de que

necesite mover la lavadora en el futuro.

16

Page 17

CONEXIÓN DE LA MANGUERA

DE DESAGÜE

IMPORTANTE: Para proteger sus pisos de los daños ocasionados

por las fugas de agua, conecte correctamente la manguera de

desagüe. La manguera de desagüe está conectada a su lavadora

y está guardada dentro de la carcasa de la misma.

1� Quite la manguera de desagüe

de la carcasa de la lavadora

Jale cuidadosamente la manguera fuera de la parte

posterior de la carcasa de la lavadora, desde la parte

de arriba, hasta que salga el extremo.

IMPORTANTE: No fuerce el exceso de la manguera

de desagüe nuevamente dentro de la parte posterior

de la lavadora.

2� Conecte el molde de la manguera

de desagüe

3� Coloque la manguera de desagüe

en el tubo vertical

4,5"

(114 mm)

Coloque la manguera dentro del tubo vertical (se muestra

en la ilustración) o sobre el lado de la tina de lavadero.

IMPORTANTE: Para evitar que el agua de desagüe vuelva

a su lavadora:

No fuerce el exceso de la manguera de desagüe dentro

del tubo vertical. La manguera debe estar asegurada pero

a la vez lo sucientemente oja que permita un espacio

para el aire.

No tienda el exceso de la manguera en el fondo de la tina

del lavadero.

Para un desagüe a través de la tina de lavadero o por tubo

vertical, conecte el molde de la manguera de desagüe. Para

un desagüe por el piso, no instale el molde de la manguera

de desagüe. Puede ser que necesite piezas alternativas con

instrucciones por separado. Vea “Herramientas y piezas” para

determinar lo que pueda necesitar.

Haga pasar la manguera dentro de un extremo del molde.

Doble la manguera e insértela a través del otro lado,

asegurándola en las secciones lisas de la misma. La manguera

deberá extenderse 4,5" (114 mm) más allá del molde.

17

Page 18

CONEXIÓN DE LAS MANGUERAS

DE ENTRADA

1� Inserte nuevas arandelas planas

A B

A. Acoplamiento

B. Arandela

IMPORTANTE: Para evitar los escapes, verique que las

mangueras de entrada de agua tengan arandelas planas

en ambos extremos. La lavadora debe estar conectada

a los grifos de agua con mangueras de entrada nuevas y

arandelas planas (no provistas). No use mangueras viejas.

No use las mangueras sin las arandelas.

2� Conecte las mangueras

de entrada a los grifos del agua

3� Despeje las líneas de agua

Deje correr agua por algunos segundos por las mangueras, a una

tina de lavadero, tubo de desagüe o cubeta para evitar que se

obstruya. El agua debe correr hasta que salga limpia. Verique

la temperatura del agua para asegurarse de que la manguera de

agua caliente esté conectada al grifo de agua caliente y que la

manguera de agua fría esté conectada al grifo de agua fría.

4� Conecte las mangueras

de entrada a la lavadora

Asegúrese de que la canasta de la lavadora esté vacía. Conecte

la manguera con la etiqueta “hot” (caliente) al grifo de agua

caliente. Atornille el acoplamiento con la mano hasta que

se asiente en la arandela. Apriete los acoplamientos con los

alicates, girándolos dos tercios de vuelta adicional. Repita este

paso con la manguera marcada con la etiqueta “cold” (fría)

para el grifo de agua fría. Deben conectarse ambas mangueras

para que la lavadora funcione correctamente.

IMPORTANTE: No apriete en exceso ni use cinta o selladores en

la válvula cuando la sujete a los grifos o a la lavadora. Puede

resultar en daños.

CONSEJO ÚTIL: Tome nota de cuál de las mangueras está

conectada al agua caliente, para ayudar a conectar las

mangueras a la lavadora correctamente.

Sujete la manguera de agua caliente a la válvula de entrada

del agua caliente. Atornille el acoplamiento a mano hasta que

quede apretado. Use pinzas para apretar los acoplamientos

dos tercios de vuelta adicional. Repítalo con la válvula de

entrada del agua fría. Deben conectarse ambas mangueras

para que la lavadora funcione correctamente.

IMPORTANTE: No apriete en exceso ni use cinta o selladores

en la válvula cuando la sujete a los grifos o a la lavadora.

Puede resultar en daños.

NOTA: Para reducir el riesgo de que las mangueras fallen,

reemplácelas cada 5 años. Para consulta en el futuro, anote en

las mangueras la fecha de instalación o la fecha de reposición

de las mismas.

■ Inspeccione periódicamente y reemplace las mangueras

si aparecen bultos, torceduras, cortaduras, desgaste o

ltraciones de agua.

18

Page 19

NIVELACIÓN DE LA LAVADORA

IMPORTANTE: El nivelar adecuadamente su lavadora reduce el

ruido y la vibración en exceso.

5� Revise si hay fugas

Abra los grifos del agua para revisar si hay fugas de agua en el

grifo y en la conexión a la lavadora. Una pequeña cantidad de

agua podría entrar en la lavadora. Ésta se desaguará más tarde.

6� Asegure la manguera de desagüe

Tina de lavadero Tubo vertical Pared

4,5"

4,5"

4.5"

(114 mm )

(114 mm)

4.5"

(114 mm )

(114 mm)

4.5"

4,5"

(114 mm)

(114 mm )

1� Mueva la lavadora a su ubicación nal

Mueva la lavadora a su ubicación nal. Balancee la lavadora

hacia atrás y hacia delante para ver si las cuatro patas están

estables y en contacto rme con el piso. Si la lavadora se

balancea, es posible que su modelo sea uno que viene con

3 patas ajustadas previamente de fábrica. Será necesario

ajustar la pata frontal derecha para nivelar la lavadora. Si las

4 patas fueron ajustadas previamente de fábrica, es posible

que se necesite hacer pequeños ajustes para nivelar la lavadora

en el piso de su casa.

2� Ajuste la pata frontal de nivelación

A

A

Asegure la manguera de desagüe a la pata del lavadero,

al tubo vertical o a las mangueras de entrada para el tubo

vertical de pared, utilizando la atadura de cables (A).

Esto contribuirá a reducir la posibilidad de que se salpique

agua del desagüe en el piso.

A

Para las lavadoras con una pata frontal derecha regulable,

baje la pata frontal derecha hasta que haga contacto con

el piso. Con las pinzas, gire la pata hacia arriba 1 ½ giro

adicional.

19

Page 20

3� Revise la nivelación de la lavadora

Coloque el nivel aquí

Place level here

Verique el grado de nivelación de la lavadora. Primero

coloque un nivel sobre la tapa cerca de la consola. Después

coloque el nivel al costado de la lavadora, en la plegadura

que está entre la parte superior de la lavadora y la carcasa.

NIVELADANo está nivelada No está nivelada

Coloque el nivel aquí

Place level here

4� Cómo ajustar la nivelación

de la lavadora

Si la lavadora no está nivelada,

muévala levemente hacia afuera, inclínela hacia atrás y

apuntale el frente de la lavadora con un bloque de madera.

Regule la pata frontal derecha aojando la contratuerca

con una llave de boca de 9/16" o 14 mm; después gire

la pata hacia arriba o hacia abajo, según sea necesario.

Después de que la lavadora se haya nivelado, asegúrese de

que las cuatro patas estén estables y en contacto rme con

el piso, balanceando suavemente la lavadora de adelante

hacia atrás, de lado a lado y diagonalmente. Regule las

patas si es necesario; luego gire las contratuercas hacia

la izquierda sobre la pata usando nuevamente la llave de

tuercas, para apretarlas a la carcasa de la lavadora.

Tal vez tenga que regular las patas posteriores para nivelar

la lavadora. Si usted va a instalar la lavadora en un área

apretada o difícil de acceder, tal vez necesite mover la

lavadora hacia fuera para poder alcanzar las patas con

comodidad. Tal vez desee trabar las patas posteriores antes

de mover la lavadora nuevamente en su lugar.

Si las contratuercas no están apretadas contra la carcasa de

la lavadora, la misma podría vibrar.

20

Page 21

5� Conecte a un contacto de pared de

conexión a tierra de 3 terminales

COMPLETE LA INSTALACIÓN

■ Revise los requisitos eléctricos. Asegúrese de contar con la

fuente de electricidad correcta y el método recomendado de

conexión a tierra. Vea “Requisitos eléctricos”.

■ Verique que todas las piezas estén ahora instaladas. Si hay

alguna pieza extra, vuelva a revisar todos los pasos para ver

qué se omitió.

■ Verique que tenga todas las herramientas.

■ Guarde el anillo de embalaje de espuma que vino en la tina

de la lavadora para poder cambiar de lugar la lavadora en

el futuro. Deshágase de todos los materiales de embalaje o

recíclelos.

■ Verique que los ambos grifos de agua estén abiertos.

■ Verique si hay fugas alrededor de los grifos y de las

mangueras de entrada.

■ Quite la película de la consola y la cinta que quede en la

lavadora.

■ Revise que la lavadora esté conectada en un contacto

de 3 terminales con conexión a tierra.

■ Lea “Uso de la lavadora” en las Manual de uso y cuidado

de la lavadora.

■ Para probar y limpiar su lavadora, mida de la cantidad

de detergente de alto rendimiento (HE) en polvo o líquido

recomendada por el fabricante para una carga mediana

y viértalo en el depósito de detergente. Cierre la tapa.

Oprima POWER (Encendido). Seleccione un ciclo normal

y oprima START (Puesta en marcha). Deje que la lavadora

funcione durante el ciclo completo.

21

Page 22

SÉCURITÉ DE LA LAVEUSE

22

Page 23

EXIGENCES D’INSTALLATION

OUTILLAGE ET PIÈCES

Rassembler les outils et composants nécessaires avant

d’entreprendre l’installation.

Outillage nécessaire :

Pince – ouverture jusqu’à

1 9⁄16" (39,5 mm)

Clé plate ou clé à molette

de 9/16" (14 mm)

Lampe de poche

(facultative)

4" min

(102 mm)

Cale en bois

Pour commander, consulter les numéros d’appel sans frais gurant

sur la couverture arrière des “Instructions d’utilisation” de la

laveuse.

■ 8212656RP Tuyau d’arrivée d’eau de 10 pi (3 m), EPDM

noirs (lot de 2)

■ 8212641RP Tuyau d’arrivée d’eau de 5 pi (1,5 m), EPDM

noirs (lot de 2)

■ 8212646RP Tuyau d’arrivée d’eau de 4 pi (1,2 m), EPDM

noirs (lot de 2)

■ 8212545RP Tuyau d’arrivée d’eau de 5 pi (1,5 m), EPDM

rouge et bleu (lot de 2)

■ 8212487RP Tuyau d’arrivée en nylon tressé de 5 pi (1,5 m)

(lot de 2)

■ 8212638RP Tuyau d’arrivée en nylon tressé de 6 pi (1,8 m),

coude compact de 90°, raccords hypro-blue

en acier (lot de 2)

■ 8212637RP Tuyau d’arrivée de 6 pi (1,8 m), EPDM noir,

coude compact de 90°, raccords hypro-blue

en acier (lot de 2)

Autres pièces : (Non fournies avec la laveuse)

Il se peut que l’installation nécessite des pièces supplémentaires.

Pour commander, consulter le numéro de téléphone sans frais ou le

site Web sur la page arrière du “Guide d’utilisation et d’entretien”.

Mètre-ruban ou règle Niveau

Pièces fournies (dans le panier de la laveuse) :

Bride de retenue pour

tuyau de vidange

Attache-câble

Pièces nécessaires (Non fournies avec la laveuse) :

Tuyaux d’admission

d’eau (2)

Rondelles plates pour

tuyau d’arrivée d’eau (4)

Si vous avez : Il vous faudra :

Évier de buanderie Système de pompe de puisard

ou tuyau de rejet (si non déjà disponible)

à l’égout plus

haut que 96" (2,4 m)

Tuyau de rejet Ensemble pour adaptateur de

à l’égout de 1" (25 mm) 2" (50 mm) à 1" (25 mm) de diamètre

de diamètre pour tuyau de rejet à l’égout; pour

tuyau de rejet à l’égout, pièce

numéro 3363920 et ensemble

de connexion, pièce numéro 285835

Égout surélevé Tuyau rigide d’évacuation standard

de 20 gal. (76 L) de 39" (990 mm)

de haut ou évier de décharge, pompe

de puisard et connecteurs (disponibles

chez les vendeurs de matériel

de plomberie locaux)

Égout au plancher Ensemble de brise-siphon, pièce

numéro 285834; Tuyau de vidange

supplémentaire, pièce numéro

285863; Ensemble de raccord,

pièce numéro 285835

Un tuyau de vidange Tuyau de vidange supplémentaire,

trop court pièce numéro 285863

Ensemble de connection,

pièce numéro 285835

Système d’évacuation Protecteur de canalisation,

obstrué par de la pièce numéro 376031

charpie

23

Page 24

EXIGENCES D’EMPLACEMENT

4,5"

(114 mm)

3"

(25 mm)

Le choix d’un emplacement approprié pour la laveuse en améliore

le rendement et réduit au minimum le bruit et le “déplacement”

possible de la laveuse. La laveuse peut être installée dans un

sous-sol, une salle de buanderie, un placard ou un encastrement.

*

(76 mm)

27,5"

(699 mm)

44"

(1118 mm)

27"

(686 mm)

Il vous faudra :

■ Un chaue-eau réglé pour fournir de l’eau à 120°F (49°C)

à la laveuse.

■ Une prise électrique reliée à la terre située à 4 pi (1,2 m)

maximum de l’emplacement de la prise du cordon électrique

se trouvant à l’arrière de la laveuse. Voir “Spécifications

électriques”.

■ Des robinets d’eau chaude et d’eau froide situés

à 3 pi (900 mm) maximum des valves de remplissage

d’eau chaude et d’eau froide, et une pression d’eau de

20–100 lb-po2 (138–690 kPa) pour une performance

optimale.

■ Un plancher de niveau avec une pente maximale de

1" (25 mm) sous l’ensemble de la laveuse. L’installation

de la laveuse sur de la moquette ou un tapis n’est pas

recommandée.

■ Un plancher robuste pour supporter la laveuse avec

un poids total (laveuse, eau et charge) de 315 lb (143 kg).

IMPORTANT : Ne pas installer, remiser ou faire fonctionner

la laveuse à un emplacement où elle sera exposée à de

l’eau, des intempéries ou à des températures inférieures

à 32° F (0° C). Une certaine quantité d’eau peut rester

dans la laveuse et causer des dommages à des températures

basses. Consulter le “Guide d’utilisation et d’entretien” pour

plus d’informations sur l’hivérisation.

C’est à l’utilisateur qu’incombe la responsabilité de réaliser une

installation correcte.

Espacement pour une installation dans un encastrement

ou dans un placard

Toutes les dimensions indiquent le dégagement autorisé, avec

un dégagement testé de 0" (0 mm) de chaque côté.

■ Prévoir davantage d’espace pour faciliter l’installation et

l’entretien.

■ Des espaces supplémentaires peuvent être requis pour les

moulures de porte et de plancher et pour les plinthes.

■ Un espace supplémentaire doit être envisagé de tous les côtés

de la laveuse an de réduire le transfert de bruit.

■ Pour une installation dans un placard avec porte, on doit

prévoir des ouvertures minimums d’entrée d’air en haut et en

bas de la porte. Les portes à claire-voie orant des ouvertures

équivalentes de passage de l’air sont acceptables.

■ Il faut aussi prendre en compte l’espace requis entre

les appareils voisins.

24

2

48 in.

(310 cm2)

2

24 in.

(155 cm2)

*

*

5"

*

(126 mm)

*

1"

14" max.

(356 mm)

*Espacement requis

17"

(432 mm)

1"

(25 mm)

*

*

3"

(76 mm)

SYSTÈME DE VIDANGE

Le système de vidange de la laveuse peut être installé à l’aide

d’un conduit d’évacuation au plancher, un tuyau de rejet à l’égout

au plancher ou mural ou un évier de buanderie. Sélectionner la

méthode à utiliser.

Système de vidange avec tuyau de rejet à l’égout

au plancher

39"

4,5"

(114 mm)

Diamètre minimal pour un tuyau de rejet à l’égout : 2" (51 mm).

Capacité minimale d’acheminement : 17 gal. (64 L) par minute.

Le sommet du tuyau de rejet à l’égout doit avoir une hauteur d’au

moins 39" (990 mm); ne pas l’installer à plus de 96" (2,44 m) du fond

de la laveuse. Si on doit l’installer à plus de 96" (2,44 m) de hauteur,

un système de pompe de puisard est nécessaire.

Système de vidange avec tuyau de rejet à l’égout mural

Voir les exigences pour le système de vidange avec tuyau de rejet à l’égout

au plancher.

(990 mm)

Page 25

Système de vidange au plancher

4,5"

(114 mm)

Le système de vidange au plancher nécessite un ensemble

de brise-siphon (pièce numéro 285834), deux ensembles de

connection (pièce numéro 285835), et un tuyau de vidange

supplémentaire (pièce numéro 285863) qui peuvent être achetés

séparément. Pour commander, consulter les numéros d’appel sans

frais gurant dans les “Instructions d’utilisation” de la laveuse.

Dimension minimale pour le brise-siphon : 28" (710 mm) à partir

du fond de la laveuse. (Des tuyaux supplémentaires peuvent être

requis).

Système de vidange dans un évier de buanderie

30"

39"

(762 mm)

(990 mm)

■ Pour minimiser les risques de choc électrique, on doit

brancher le cordon sur une prise de courant de conguration

correspondante, à 3 alvéoles, reliée à la terre et installée

conformément aux codes et règlements locaux. Si une prise de

courant de conguration correspondante n’est pas disponible,

le client a la responsabilité et l’obligation de faire installer par

un électricien qualié une prise de courant correctement reliée

à la terre.

■ Si les codes le permettent et si l’on utilise un conducteur distinct

de liaison à la terre, il est recommandé qu’un électricien

qualié vérie la qualité de la liaison à la terre.

■ Ne pas utiliser une tuyauterie de gaz pour le raccordement à

la terre.

■ En cas de doute quant à la qualité de la liaison à la terre

de la laveuse, consulter un électricien qualié.

■ Ne pas installer un fusible dans le conducteur neutre ou le

circuit de liaison à la terre.

Capacité minimale : 20 gal. (76 L). Le sommet de l’évier de

buanderie doit se trouver à au moins 39" (990 mm) du plancher;

ne pas l’installer à plus de 96" (2,44 m) du fond de la laveuse.

IMPORTANT : Pour éviter un eet de siphon, ne pas introduire plus

de 4,5" (114 mm) de tuyau de vidange à l’intérieur du tuyau de

rejet à l’égout ou sous la partie supérieure d’évier de buanderie.

Immobiliser le tuyau de vidange avec un attache-câble.

SPÉCIFICATIONS ÉLECTRIQUES

■ Une alimentation de 120 volts, 60 Hz, CA seulement, de

15 ou 20 ampères, protégée par un fusible est requise. On

recommande d’utiliser un fusible ou un disjoncteur temporisé

ainsi qu’un circuit distinct pour cette laveuse.

■ Cette laveuse comporte un cordon d’alimentation électrique

à trois broches pour liaison à la terre.

25

Page 26

INSTRUCTIONS

D’INSTALLATION

Avant de commencer : Retirer le matériel d’expédition.

Il est nécessaire de retirer tout le matériel d’expédition pour un

fonctionnement correct et pour éviter que la laveuse ne fasse trop

de bruit.

REMARQUE : Pour éviter d’endommager le plancher durant

l’installation, installer la laveuse sur un carton avant de la

déplacer sur le sol.

IMPORTANT :

■ Vérier que la base d’expédition en mousse a été retirée

de la partie inférieure de la laveuse tel qu’indiqué dans

“Retrait de la base d’expédition et de l’emballage en anneau”.

■ Si la base d’expédition en mousse n’a pas été retirée, vérier

que le couvercle est bien immobilisé avec du ruban adhésif

avant de faire reposer la laveuse sur sa partie arrière.

■ Le retrait de la base d’expédition en mousse est nécessaire

au bon fonctionnement de l’appareil.

RETRAIT DE LA BASE D’EXPÉDITION ET

DE L’EMBALLAGE EN ANNEAU

RACCORDEMENT DU TUYAU

D’ÉVACUATION

IMPORTANT : Un bon raccordement du tuyau d’évacuation

permet d’éviter les fuites d’eau et les dommages au plancher.

Le tuyau de vidange est connecté à la laveuse et est remisé à

l’intérieur de la caisse de la laveuse.

1� Libérer le tuyau de vidange

de la caisse de la laveuse

Libérer le tuyau de vidange de la caisse de la laveuse.

IMPORTANT : Ne pas forcer l’excédent du tuyau de vidange

dans l’arrière de la laveuse.

2� Raccordement de la bride

de retenue pour tuyau de vidange

1� Retrait de la base d’expédition

et de l’emballage en anneau

Placer des supports de carton de la boîte d’emballage en

carton sur le sol derrière la laveuse. Fixer le couvercle avec

du ruban adhésif. À l’aide de deux personnes ou plus, incliner

la laveuse sur sa partie arrière et la placer sur les supports de

carton. Ôter la base d’expédition en mousse. Remettre ensuite

la laveuse debout et retirer le ruban adhésif du couvercle de

façon à pouvoir ouvrir le couvercle et retirer l’emballage en

anneau de la cuve de la laveuse.

REMARQUE : Conserver l’anneau de l’emballage en mousse en

cas de déplacement ultérieur de la laveuse.

Pour un système d’évacuation par l’évier de buanderie ou le

tuyau rigide de rejet à l’égout, xer le support de xation pour

tuyau d’évacuation. Pour un système d’évacuation au plancher,

ne pas installer le support de xation pour tuyau d’évacuation.

Des pièces supplémentaires avec des directives distinctes seront

peut-être nécessaires. Voir “Outils et pièces” pour déterminer

les outils nécessaires.

Introduire le tuyau d’évacuation dans l’une des extrémités du

support. Replier le tuyau et l’introduire dans l’autre côté en

xant le support sur les parties lisses du tuyau. Le tuyau doit

être étiré de 4,5" (114 mm) au-delà du support.

26

Page 27

RACCORDEMENT DES TUYAUX

DE VIDANGE

3� Placer le tuyau de vidange dans

le tuyau de rejet à l’égout

4,5"

(114 m m)

Placer le tuyau dans le tuyau de rejet à l’égout (illustré à

l’image) ou par-dessus le côté de l’évier de buanderie.

IMPORTANT : Pour empêcher l’eau de vidange de reuer

dans la laveuse :

■ Ne pas forcer l’excédent du tuyau de vidange dans le

tuyau rigide de rejet à l’égout. Le tuyau doit être bien

immobilisé, tout en permettant le passage d’air.

■ Ne pas mettre l’excédent du tuyau de vidange dans le

fond de l’évier de buanderie.

1� Insérer les rondelles plates neuves

A B

A. Raccord

B. Rondelle

IMPORTANT : Pour éviter des fuites, vérier que les tuyaux

d’arrivée d’eau ont les rondelles plates aux deux extrémités.

La laveuse doit être raccordée aux robinets d’eau à l’aide des

nouveaux tuyaux d’arrivée d’eau avec les rondelles plates (non

fournis). Ne pas utiliser de tuyaux usagés. Ne pas utiliser de

tuyaux sans rondelles.

2� Connecter les tuyaux d’arrivée d’eau

aux robinets

S’assurer que le panier de la laveuse est vide. Fixer le tuyau

dont l’étiquette porte la mention “hot” (chaud) au robinet

d’eau chaude. Visser le raccord à la main pour qu’il repose

sur la rondelle. Serrer les raccords de deux tiers de tour

supplémentaires à l’aide d’une pince. Répéter cette étape avec

le tuyau portant la mention “cold” (froide) pour le robinet d’eau

froide. Les deux tuyaux doivent être raccordés pour que la

laveuse fonctionne correctement.

IMPORTANT : Ne pas serrer excessivement ni utiliser de ruban

adhésif ou de dispositifs d’étanchéité lors de la xation des

robinets ou de la laveuse. Cela pourrait entraîner des dommages.

CONSEIL UTILE : Repérer quel tuyau est raccordé à l’eau chaude

pour permettre une xation correcte des tuyaux à la laveuse.

27

Page 28

3� Purger les canalisations d’eau

Faire couler de l’eau dans les tuyaux de l’évier de buanderie,

le tuyau rigide de rejet à l’égout ou le seau pendant quelques

secondes pour éviter toute obstruction. On doit laisser couler

l’eau jusqu’à ce qu’elle soit limpide. Vérier la température de

l’eau pour s’assurer que le tuyau d’eau chaude est connecté au

robinet d’eau chaude et que le tuyau d’eau froide est connecté

au robinet d’eau froide.

4� Connecter les tuyaux d’arrivée

d’eau à la laveuse

5� Vérier l’absence de fuites

Ouvrir les deux robinets pour vérier l’absence de fuite au

niveau du robinet et du raccordement des rondelles. Une petite

quantité d’eau peut entrer dans la laveuse. Vous eectuerez une

vidange lors d’une étape ultérieure.

6� Immobiliser le tuyau de vidange

Évier de buanderie Tuyau rigide Mur de rejet à l’égout

4,5"

4,5"

4.5"

(114 mm)

4.5"

(114 mm)

4,5"

4.5"

(114 mm)

Fixer le tuyau d’eau chaude au robinet d’arrivée d’eau chaude.

Visser le raccord à la main jusqu’à ce qu’il soit bien serré. Serrer

les raccords de deux tiers de tour supplémentaires à l’aide

d’une pince. Répéter pour le robinet d’eau froide. Les deux

tuyaux doivent être raccordés pour que la laveuse fonctionne

correctement.

IMPORTANT : Ne pas serrer excessivement ni utiliser de

ruban adhésif ou de dispositifs d’étanchéité lors de la xation

des robinets ou de la laveuse. Cela pourrait entraîner des

dommages.

REMARQUE : Pour réduire le risque de défaillance des

tuyaux, remplacer les tuyaux tous les 5 ans. Inscrire la date

d’installation ou de remplacement des tuyaux pour référence

ultérieure.

■ Inspecter périodiquement les tuyaux et les remplacer en cas

de renement, de déformation, de coupure, d’usure ou si une

fuite se manifeste.

A

A

Fixer le tuyau d’évacuation au pied de l’évier de buanderie, au

tuyau rigide de rejet à l’égout ou aux tuyaux d’arrivée d’eau pour

le tuyau de rejet à l’égout mural avec l’attache-câble (A). Ceci

aidera à réduire le risque d’éclaboussement d’eau sur le plancher.

A

28

Page 29

MISE À NIVEAU DE LA LAVEUSE

IMPORTANT : L’établissement correct de l’aplomb de la laveuse

permet de réduire un niveau sonore et des vibrations excessifs.

1� Déplacer la laveuse à son

emplacement nal

Déplacer la laveuse à son emplacement nal. Pousser la laveuse

d’avant en arrière pour vérier que les quatre pieds sont stables

et en contact ferme avec le plancher. Si la laveuse bascule, ce

modèle de laveuse correspond peut-être à celui qui est livré

avec 3 pieds préréglés à l’usine. On doit alors régler le pied

avant droit pour établir l’aplomb de la laveuse. Si les 4 pieds

sont préréglés à l’usine, de petits réglages seront peut-être

nécessaires pour mettre la laveuse d’aplomb sur le plancher.

2� Ajuster les pieds de nivellement avant

3� Vérier le bon aplomb de la laveuse

Placer le niveau à cet endroit Placer le niveau à cet endroit

Place level here

Vérier le bon aplomb de la laveuse. Placer d’abord un niveau

sur le couvercle près de la console. Puis, placer le niveau sur le

côté de la laveuse dans l’espace situé entre la partie supérieure

de la laveuse et la caisse.

Place level here

Pour las laveuses avec un pied avant droit réglable, abaisser

le pied avant droit jusqu’à ce qu’il soit en contact avec le

plancher. À l’aide d’une pince, faire pivoter le pied vers le haut

d’un tour et demi supplémentaire.

Pas d’aplomb Pas d’aplombD’APLOMB

29

Page 30

4� Régler le bon aplomb de la laveuse

Si la laveuse n’est pas d’aplomb, déplacer

légèrement la laveuse pour la dégager,

l’incliner vers l’arrière et soulever l’avant

de la laveuse avec une cale de bois. Régler le pied avant en

desserrant l’écrou de blocage à l’aide d’une clé plate de 9/16"

ou 14 mm puis faire tourner le pied vers le haut ou vers le bas

selon le besoin.

Une fois la laveuse d’aplomb, s’assurer que les 4 pieds sont en

contact ferme avec le plancher en la faisant doucement pivoter

d’avant en arrière et d’un côté à l’autre. Régler les pieds de

nivellement si nécessaire puis utiliser à nouveau la clé et tourner

les écrous de blocage dans le sens antihoraire sur les pieds pour

serrer les pieds contre la caisse de la laveuse.

CONSEIL UTILE : Il faudra peut-être régler les pieds arrière pour

établir l’aplomb de la laveuse. Si l’on installe la laveuse dans un

endroit exigu ou dicile d’accès, il faudra peut-être dégager la

laveuse de l’emplacement pour pouvoir avoir pleinement accès

aux pieds. Il peut être utile de bloquer les pieds arrière avant de

réinstaller la laveuse dans son emplacement.

IMPORTANT : Si les écrous de blocage ne sont pas bien serrés

contre la caisse de la laveuse, la laveuse peut vibrer.

5� Brancher l’appareil sur une prise

à 3 alvéoles reliée à la terre

30

Page 31

LISTE DE VÉRIFICATION POUR

INSTALLATION TERMINÉE

■ Consulter les spécications électriques. S’assurer de disposer

d’une source d’électricité appropriée, et d’une liaison à la terre

conforme à la méthode recommandée. Voir “Spécications

électriques”.

■ Vérier que toutes les pièces sont maintenant installées. S’il

reste une pièce, passer en revue les diérentes étapes pour

découvrir laquelle aurait été oubliée.

■ Vérier la présence de tous les outils.

■ Conserver l’anneau de l’emballage en mousse de la cuve en

cas de réinstallation ultérieure de la laveuse. Éliminer/recycler

tous les matériaux d’emballage.

■ Vérier que les robinets d’eau sont tous les deux ouverts.

■ Vérier qu’il n’y a pas de fuite autour des robinets et des

tuyaux d’arrivée d’eau.

■ Ôter la pellicule protectrice de la console et tout ruban

adhésif resté sur la laveuse.

■ Vérier que la laveuse est branchée sur une prise de courant

à 3 alvéoles reliée à la terre.

■ Lire la section “Utilisation de la laveuse” dans le “Guide

d’utilisation et d’entretien”.

■ Pour tester et nettoyer votre laveuse, mesurer la moitié de

la quantité normale recommandée de détergent Haute

Ecacité (HE) en poudre ou liquide pour une charge de

taille moyenne et la verser dans le distributeur de détergent.

Fermer le couvercle. Appuyer sur POWER (mise sous tension).

Sélectionner un programme normal et appuyer sur START

(mise en marche). Laisser un programme complet s’eectuer.

31

Page 32

Get it fixed, at your home or ours!

Your Home

For troubleshooting, product manuals and expert advice:

www.managemylife.com

For repair – in your home – of all major brand appliances,

lawn and garden equipment, or heating and cooling systems,

no matter who made it, no matter who sold it!

For the replacement parts, accessories and

owner’s manuals that you need to do-it-yourself.

For Sears professional installation of home appliances

and items like garage door openers and water heaters.

1-800-4-MY-HOME

Call anytime, day or night (U.S.A. and Canada)

www.sears.com www.sears.ca

®

(1-800-469-4663)

Our Home

For repair of carry-in items like vacuums, lawn equipment,

and electronics, call anytime for the location of your nearest

Sears Parts & Repair Service Center

1-800-488-1222 (U.S.A.) 1-800-469-4663 (Canada)

www.sears.com www.sears.ca

To purchase a protection agreement on a product serviced by Sears:

1-800-827-6655

Para pedir servicio de reparación

a domicilio, y para ordenar piezas:

(U.S.A.)

1-888-SU-HOGAR

(1-888-784-6427)

www.sears.com

1-800-361-6665

Au Canada pour service en français:

®

1-800-LE-FOYER

(1-800-533-6937)

www.sears.ca

(Canada)

MC

W10550315B

® Registered Trademark /™ Trademark of KCD IP, LLC in the United States, or Sears Brands, LLC in other countries

® Marca Registrada /™ Marca de Fábrica de KCD IP, LLC en Estados Unidos, o Sears Brands, LLC in otros paises

MC

Marque de commerce / MD Marque déposée de Sears Brands, LLC

8/13

Printed in U.S.A.

Impreso en EE.UU.

Imprimé aux É-U

Loading...

Loading...