Page 1

ProTig

410 Hyundai

Operating manual • English

EN

Page 2

Page 3

OPERATING MANUAL

English

ProTig 410 Hyundai / © Kemppi Oy / 1135

Page 4

ProTig 410 Hyundai / © Kemppi Oy / 1135

EN

CONTENTS

1. PREFACE ................................................................................................................................ 3

1.1 General ....................................................................................................................................... 3

1.2 Product introduction ............................................................................................................ 3

1.2.1 Operation control and connectors ................................................................................. 4

1.2.2 Accessories and cables .................................................................................................... 6

2. INSTALLATION ................................................................................................................. 8

2.1 Assembly of TIG/MMA equipment ................................................................................... 8

2.1.1 Installation of power source ........................................................................................... 8

2.1.2 Assembly of transport wagon and mounting of Pro power source to wagon ............ 8

2.1.3 Mounting of Protig 410 unit onto the power source (gure page 5) ........................... 8

2.1.4 Mounting of Protig 410 control panel ............................................................................ 8

2.1.5 Connecting cables ........................................................................................................... 8

2.1.6 Connecting torch and extension cable ......................................................................... 8

2.1.7 Use as terminal unit ......................................................................................................... 9

2.1.8 Assembly and controls of MIG / TIG / MMA equipment ................................................ 9

2.1.9 Remote control units ....................................................................................................... 9

2.2 Installation of TIG/MMA equipment ................................................................................ 9

2.2.1 Choice of electrode and ow amount of shielding gas ................................................ 9

2.3 Shield gas ................................................................................................................................10

2.3.1 Installing gas bottle .......................................................................................................10

2.4 Main switch I/O .....................................................................................................................11

2.5 Operation of cooling unit (Procool 10, 30) .................................................................11

3. OPERATIONS OF PANELS .....................................................................................11

3.1 Control panel TL 6271265 .................................................................................................11

3.2 Control panel TX 6271266 .................................................................................................16

4. ACCURACY OF PANEL DISPLAY ......................................................................21

5. REMOTE CONTROL UNIT ......................................................................................21

6. MAINTENANCE ..............................................................................................................22

6.1 Welding torch ........................................................................................................................22

6.2 Cables ........................................................................................................................................22

7. OPERATION DISTURBANCES ............................................................................23

7.2.1 Disposal of the machine ................................................................................................24

8. ORDERING NUMBERS .............................................................................................24

9. TECHNICAL DATA ........................................................................................................25

2

Page 5

1. PREFACE

1.1 GENERAL

Congratulations on choosing the ProTig equipment. Used correctly, Kemppi products can

signicantly increase the productivity of your welding, and provide years of economical

service.

This operating manual contains important information on the use, maintenance and safety of

your Kemppi product. The technical specications of the equipment can be found at the end

of the manual.

Please read the manual carefully before using the equipment for the rst time. For your

own safety and that of your working environment, pay particular attention to the safety

instructions in the manual.

For more information on Kemppi products, contact Kemppi Oy, consult an authorised Kemppi

dealer, or visit the Kemppi web site at www.kemppi.com.

The specications presented in this manual are subject to change without prior notice.

Important notes

Items in the manual that require particular attention in order to minimise damage and

personal harm are indicated with the ’NOTE!’ notation. Read these sections carefully and follow

their instructions.

Disclaimer

While every eort has been made to ensure that the information contained in this guide

is accurate and complete, no liability can be accepted for any errors or omissions. Kemppi

reserves the right to change the specication of the product described at any time without

prior notice. Do not copy, record, reproduce or transmit the contents of this guide without

prior permission from Kemppi.

ProTig 410 Hyundai / © Kemppi Oy / 1135

EN

1.2 PRODUCT INTRODUCTION

Protig 410 is a TIG ignition unit for demanding professional use. The unit is controlled by

means of a microprocessor and ignition spark is generated by means of thyristors.

These operation instructions are for Protig 410 ignition unit, assembly and installation of TIG

equipment as well as panel functions. In addition instructions describe assembly of Mig/TIG/

MMA equipment, cables and main operations of installation.

3

Page 6

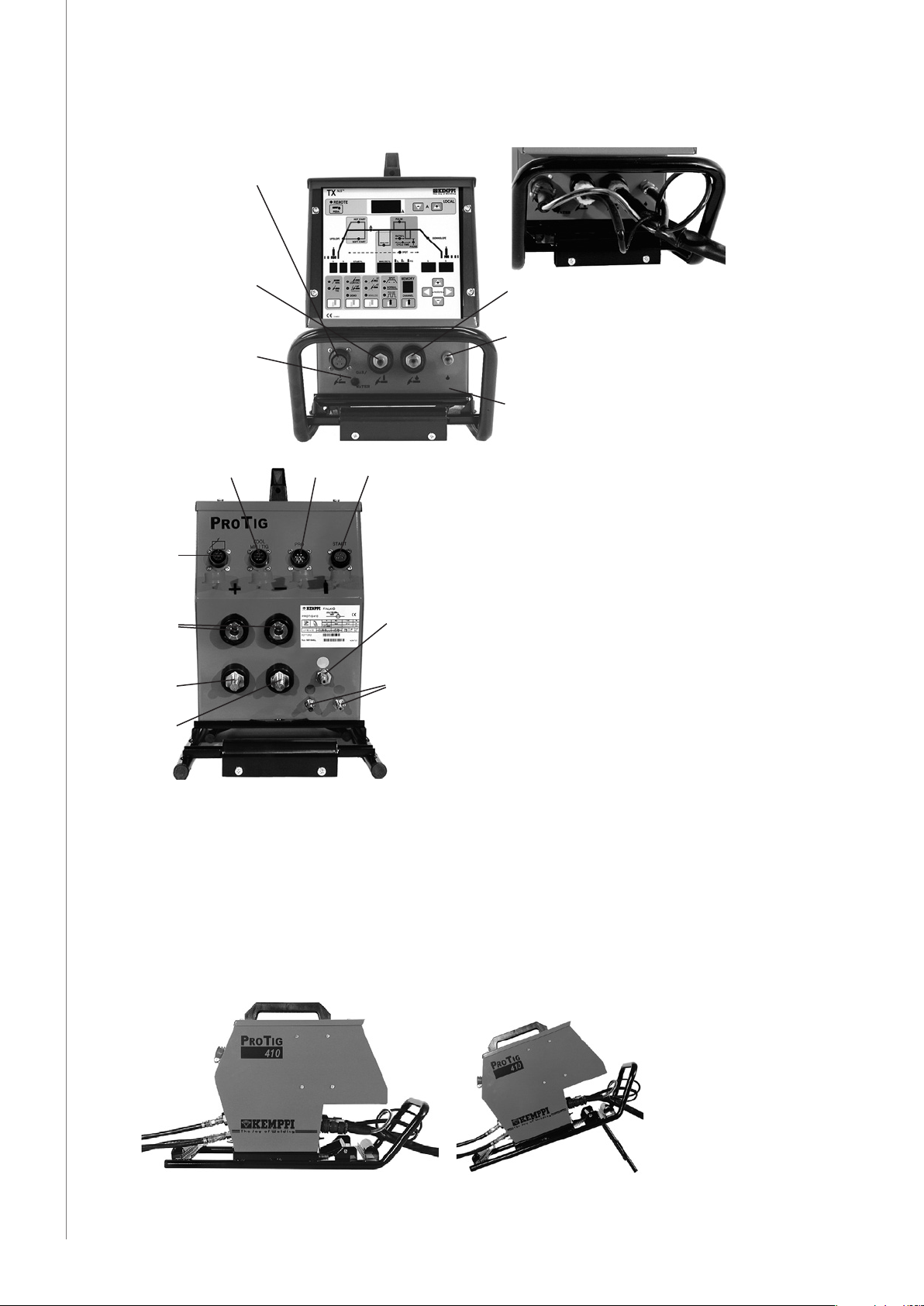

1.2.1 Operation control and connectors

Start connection

of torch

Air-cooled torch

Switch for air-/

liquid-cooled torch

Liquid-cooled torch

Cooling liquid connection,

welding torch

ProTig 410 Hyundai / © Kemppi Oy / 1135

EN

X16

X17

X13

X12

X11

X11 Welding current connections: Supply X12 Welding current connections: Supply +

X13 Earth connection

X14 Connection of welding torch

X15 Connection for control cable: Pro power source

X16 Connection for control cable: Procool

X17 Connection for control cable: Remote control unit

X18 Start connection: Remote control unit

X15

X18

Shield gas

Cooling liquid

X14

4

Page 7

Remote control unit

ProTig 410 Hyundai / © Kemppi Oy / 1135

EN

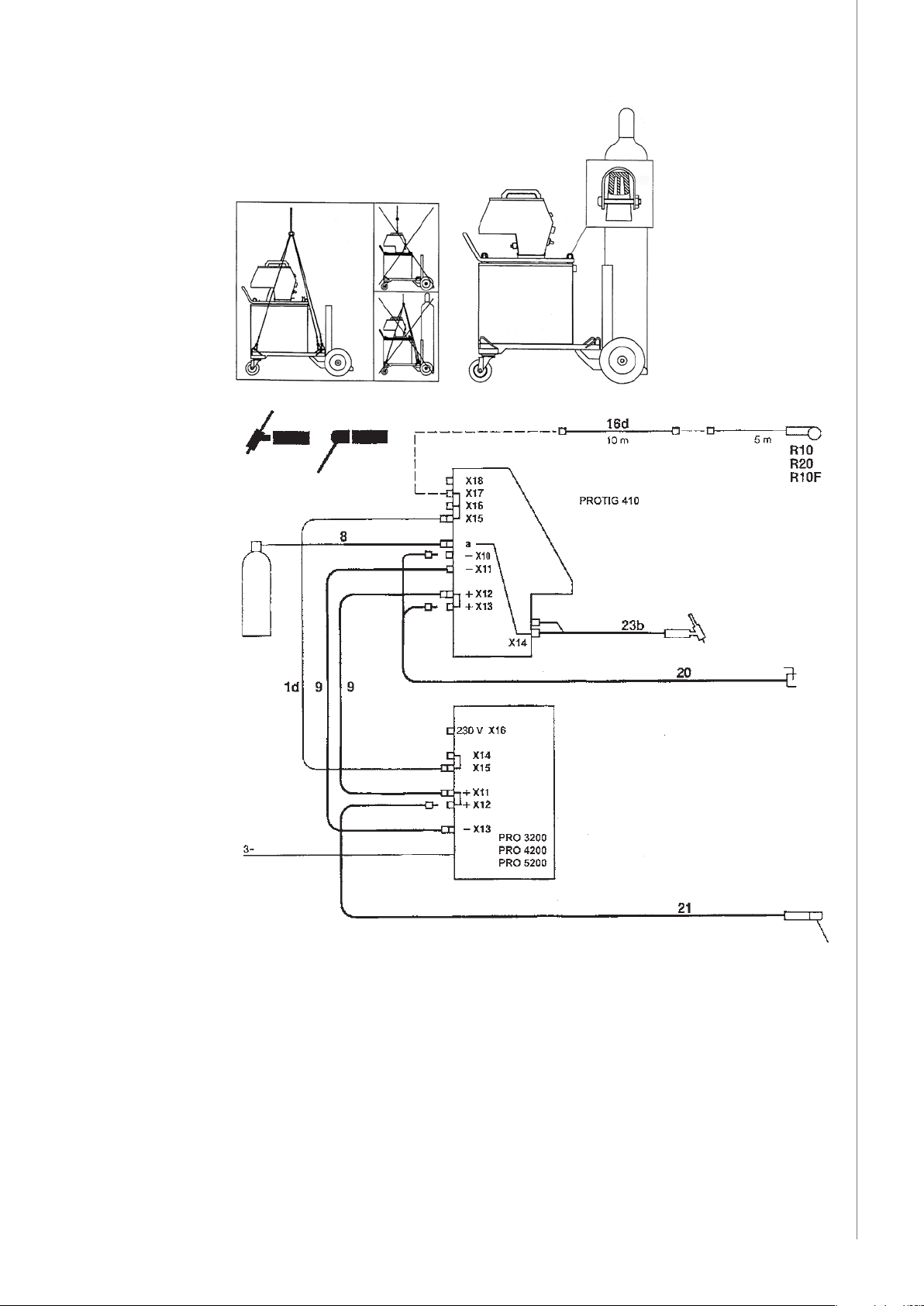

Pro Power source

1d Control cable

8 Shielding gas hose Snap connector - 0

9 Welding current cable

16d Extension cable for remote control

20 Earth cable

21 MMA welding cable

23b TIG torch, air-cooled

5

Page 8

1.2.2 Accessories and cables

ProTig 410 Hyundai / © Kemppi Oy / 1135

Remote control unit

EN

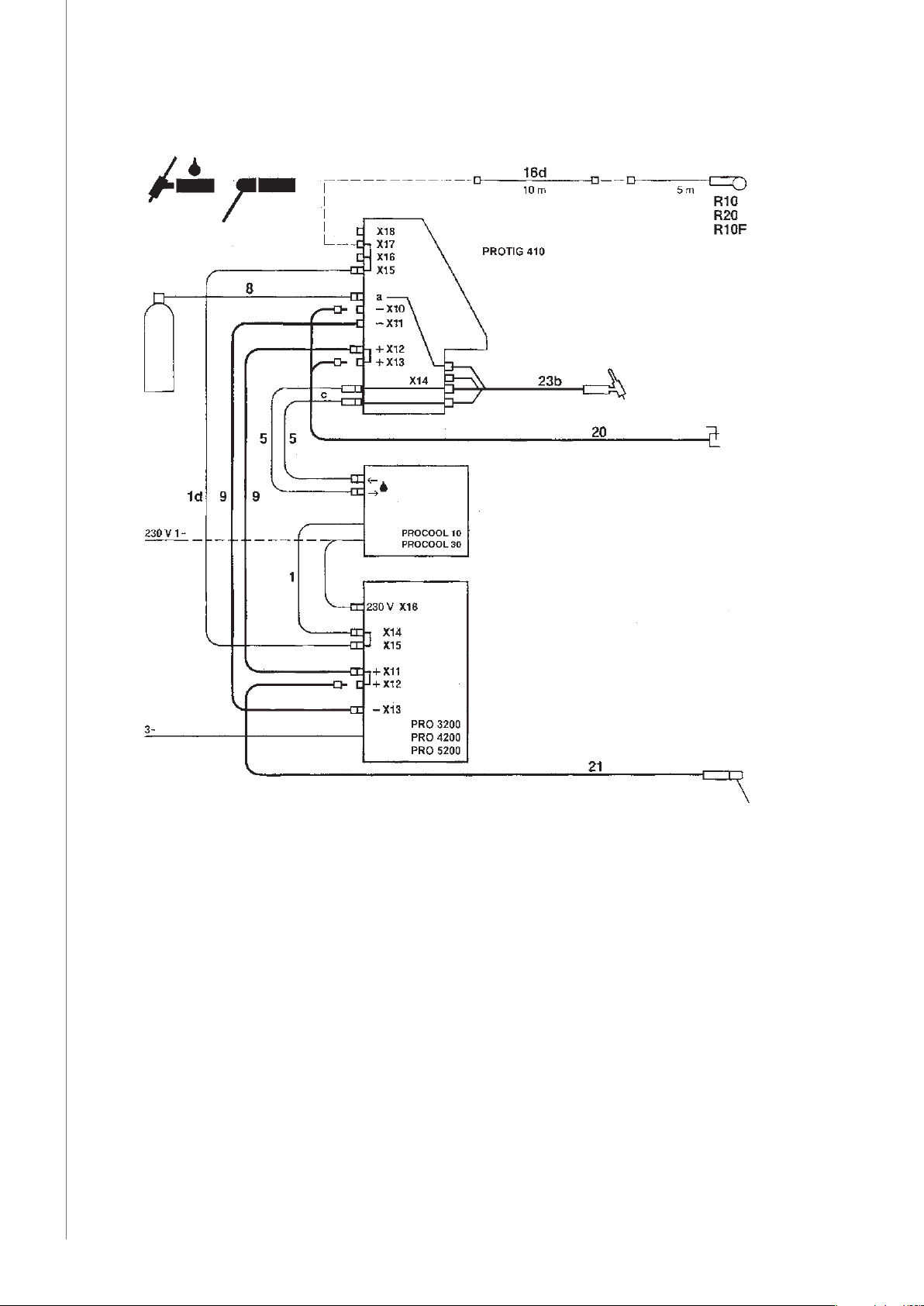

Pro: Power source

Procool 10, Procool 30: Cooling liquid circulation unit

1d Control cable

5 Cooling liquid hose, R3/8 - Snap connector

8 Shielding gas hose, Snap connector - 0

9 Welding current cable

16d Extension cable for remote control

20 Earth cable

21 MMA welding cable

23b TIG torch, liquid-cooled

23c TIG extension cable, air-cooled

23d TIG extension cable, liquid-cooled

6

Page 9

Remote control unit

ProTig 410 Hyundai / © Kemppi Oy / 1135

EN

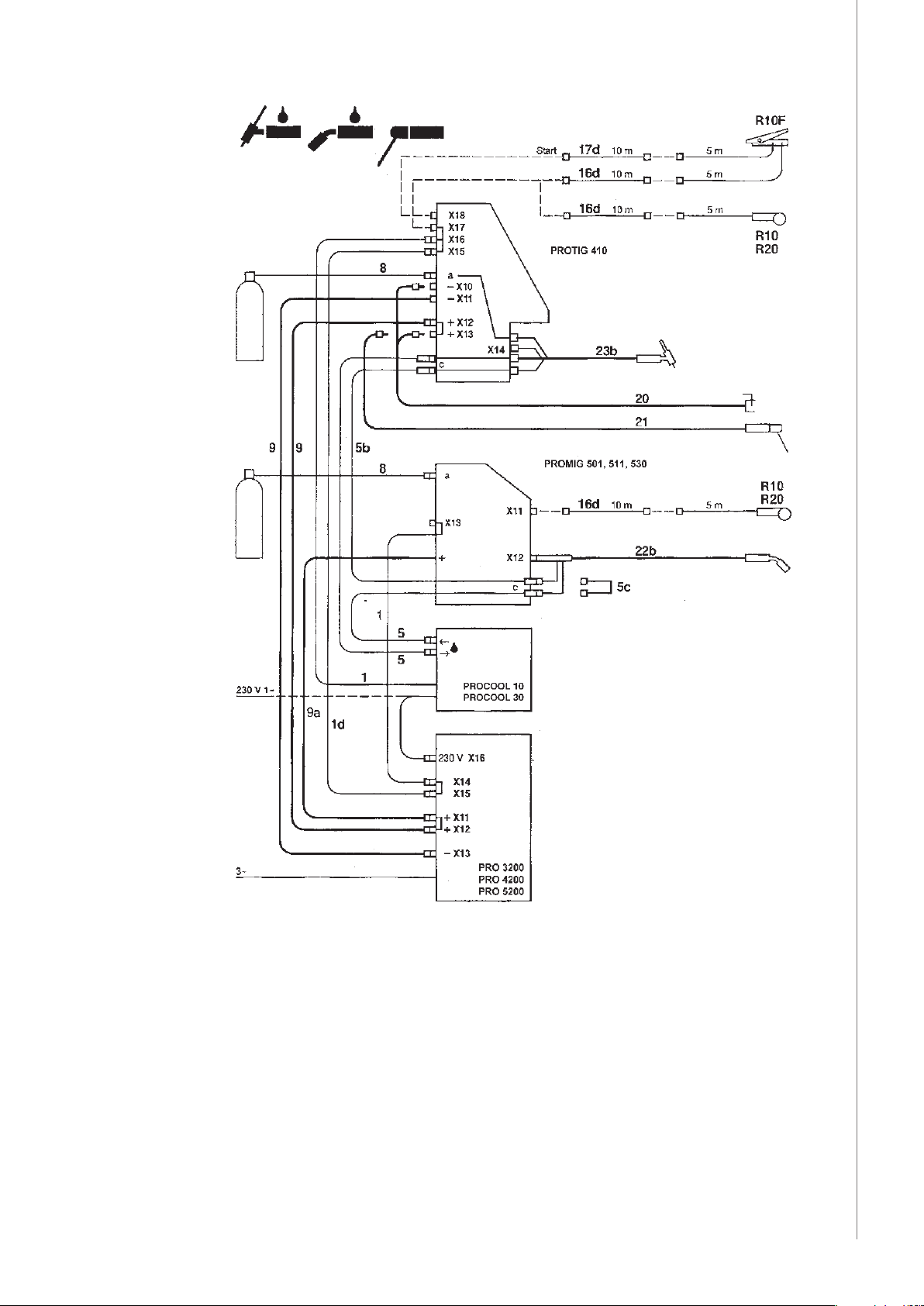

Pro 3200, 4200, 5200: Power source

Procool 10, 30: Cooling liquid circulation unit

Promig 501, 511, 530: MIG-MAG wire feeder

1d Control cable

5 Cooling liquid hose, R3/8-Snap connector

5b Cooling liquid hose, Snap conn. - Snap conn.

5c Cooling liquid hose, Bridge element

8 Shielding gas hose, Snap connector - 0

9a Welding current cable

16d Extension cable for remote control

17d Start extension cable

7

Page 10

20 Earth cable

21 MMA welding cable

22b Mig gun liquid-cooled

23b TIG torch, liquid-cooled

23d TIG extension cable, liquid-cooled

2. INSTALLATION

2.1 ASSEMBLY OF TIG/MMA EQUIPMENT

Assemble the equipment in below-mentioned order and follow mounting and operation

instructions which are delivered with packages.

2.1.1 Installation of power source

NOTE! Connection of mains cable and mounting operations as well as change of plug should only

ProTig 410 Hyundai / © Kemppi Oy / 1135

2.1.2 Assembly of transport wagon and mounting of Pro power source to wagon

be carried out by a competent electrician.

Read paragraph: ”Installation” in operation instructions (1913130) for Pro power sources and

carry out the installation according to that.

P20 6185261 air-cooled TIG equipment

P30W 6185262 liquid-cooled TIG equipment

P40, P40L 6185264, 6185264L air-cooled TIG equipment

Lifting of wagon together with bottle is forbidden due to safety reasons!

EN

2.1.3 Mounting of Protig 410 unit onto the power source (gure page 5)

NOTE! Lock the Protig unit carefully as shown in g. onto pro power source. Loose unit might cause

a danger situation.

2.1.4 Mounting of Protig 410 control panel

TL 6271265

TX 6271266

2.1.5 Connecting cables

Follow enclosed gures:

Air-cooled equipment on page 5

Liquid-cooled equipment on page 6

When connecting cables take into consideration the fact that the most generally used polarity

in TIG welding is the torch - and ground cable +. In MMA welding the polarity is generally

on the contrary (Electrode holder+). Follow instructions as shown on page 5 and 6 when

changing welding method.

2.1.6 Connecting torch and extension cable

Connection to the Protig 410 unit is shown on page 5 (air-cooled torch) and on page 6 (liquidcooled torch).

Tighten connector of torch carefully in order to avoid heating, contact disturbances and

mechanical damage of connector as well as gas leakage to inside of connector.

NOTE! Check by connection of water and gas hoses that there is no dirt, metal powder or other

waste. Waste might cause blockage of water circulation, throughburning of torch, or stopping or

breaking of pump (Procool 10, Procool 30).

Connect water hoses of torch and interconnecting cable as shown in gure on page 6. (These

are xed to tube frame). Fix water hoses (torch - interconnecting cable - Procool) in such a way

that those having red code always are connected to corresponding red counter connectors

and the blue ones respectively to blue counter connectors.

8

Page 11

NOTE! If connections cross, cooling liquid is circulating to wrong direction in torch and torch

handle and neck body might be considerably heatened.

2.1.7 Use as terminal unit

Between power source and the Protig 410 unit are available 10 m interconnecting cables

which are inside of mutual power.

On page 5 are shown following mecanical operations which are involvel in use of unit.

2.1.8 Assembly and controls of MIG / TIG / MMA equipment

Connecting cables are shown on page 7 (liquid-cooled).

Circulation systems of liquid-cooled torches are series connected. Read carefully warnings in

paragraph 6.

Do not forget to change polarity according to paragraph 5 when you go over from MMA

welding to TIG welding.

Equipment will automatically select Mig welding method and controls when you press

operation switch of Mig gun and respectively TIG welding method when you press switch of

TIG torch.

Remote controls for Mig or TIG welding operate from remote control units which are

connected to respective Promig 501/511/530 and Protig 410 units.

You can select MMA welding from panel of one or the other unit, when remote control for

MMA welding is operating from remote control unit which is connected to device in question.

NOTE! At welding and at no-load of MMA welding also other welding tools are exposed to voltage

depending on polarity. Be careful that welding tools won`t produse any short-circuits.

ProTig 410 Hyundai / © Kemppi Oy / 1135

2.1.9 Remote control units

Connect remote control unit as shown in gures on page 5 or 6. Operation of remote control

unit is explained on page 21.

2.2 INSTALLATION OF TIG/MMA EQUIPMENT

Fasten earthing press of ground cable carefully, preferably direct to welding piece. Contact

surface of press always should be as large as possible.

Clean the fastening surface from paint and rust!

Use in your TIG/MMA equipment 50 mm2 cables. Thinner cross-sectional areas might cause

overheating of connectors and insulations.

Make sure that the torch being in your use is designed for max. welding current needed by

you! Never use a damaged torch!

2.2.1 Choice of electrode and ow amount of shielding gas

Use argon as TIG shielding gas. Electrode size and shielding gas ow rate are dened by

welding current size. The table below is given only as a guide.

Welding

current

A ø mm number ø mm l/min

5 – 80 1,0 4 / 5 6,5 / 8,0 5 – 6

70 – 150 1,6 4 / 5 / 6 6,5 / 8,0 /9,5 6 – 7

140 – 250 2,4 6 / 7 9,5 / 11,0 7 – 8

225 – 330 3,2 7 / 8 11,0 / 12,5 8 – 10

330 – 4,0 10 16,0 10 – 12

Electrode Gas nozzle

EN

Gas flow rate

9

Page 12

2.3 SHIELD GAS

NOTE! Handle gas bottle with care. There is a risk for injury if gas bottle or bottle valve is damaged!

For welding stainless steels, mixed gases are normally used. Check that the gas bottle valve

is suitable for the gas. The ow rate is set according to the welding power used in the job. A

suitable ow rate is normally 8 - 10 l/min. If the gas ow is not suitable, the welded joint will

be sporous. Contact your local Kemppi-dealer for choosing gas and equipment.

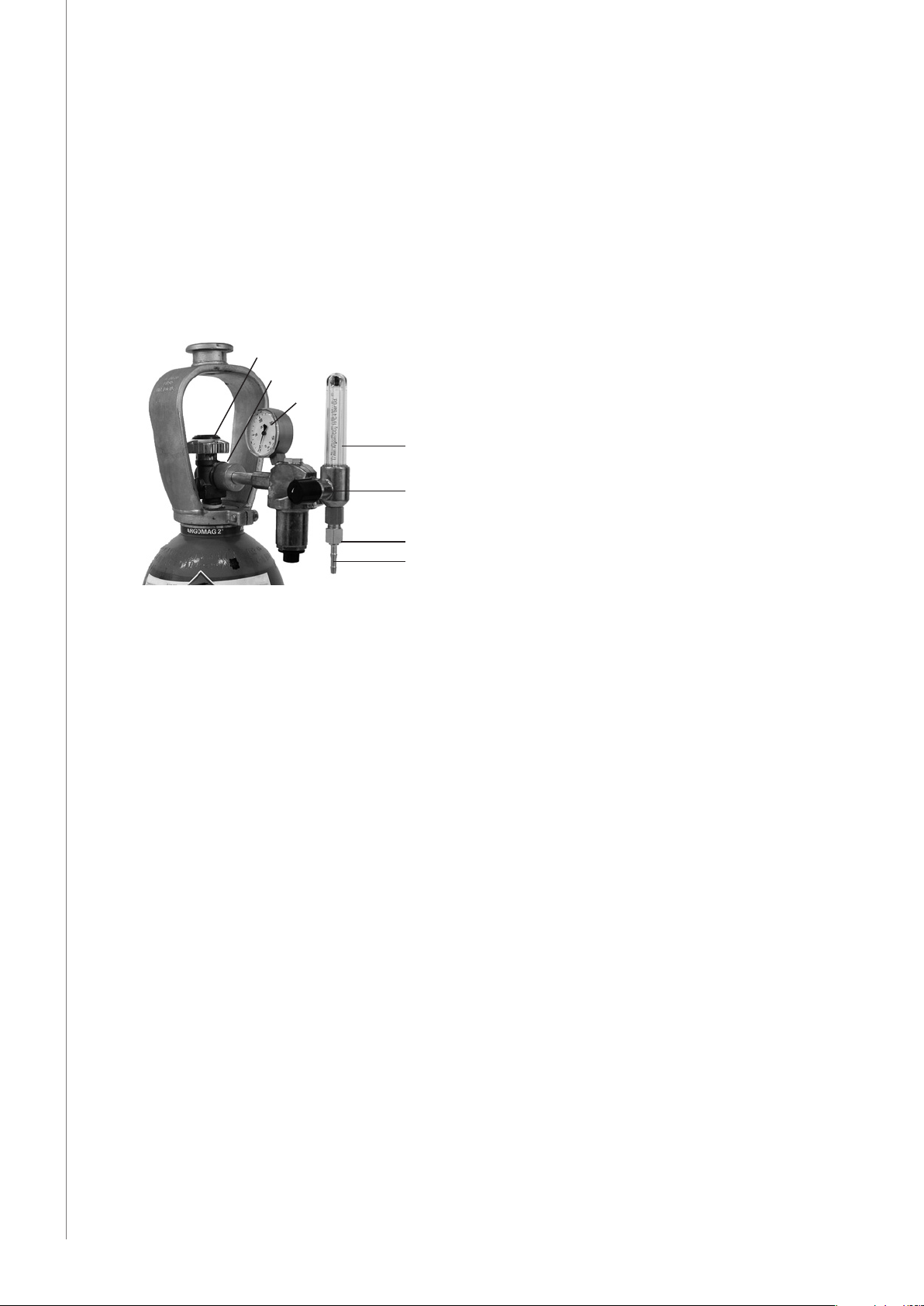

2.3.1 Installing gas bottle

NOTE! Always fasten gas bottle properly in vertical position in a special holder on the wall or on a

carriage. Remember to close gas bottle valve after having nished welding.

ProTig 410 Hyundai / © Kemppi Oy / 1135

A

C

F

G

B

E

D

EN

Parts of gas ow regulator

A. Gas bottle valve

B. Press regulation screw

C. Connecting nut

D. Hose spindle

E. Jacket nut

F. Gas bottle pressure meter

G. Gas hose pressure meter

The following installing instructions are valid for most of the gas ow regulator types:

1. Step aside and open the bottle valve (A) for a while to blow out possible impurities from

the bottle valve.

2. Turn the press regulation screw (B) of the regulator until no spring pressure can be felt.

3. Close needle valve, if there is one in the regulator.

4. Install the regulator on bottle valve and tighten connecting nut (C) with a wrench.

5. Install hose spindle (D) and jacket nut (E) into gas hose and tighten with hose clamp.

6. Connect the hose with the regulator and the other end with the wire feed unit.Tighten

the jacket nut.

7. Open bottle valve slowly. Gas bottle pressure meter (F) shows the bottle pressure.

NOTE! Do not use the whole contents of the bottle. The bottle should be lled when the bottle

pressure is 2 bar.

8. Open needle valve if there is one in the regulator.

9. Turn regulation screw (B) until hose pressure meter (G) shows the required ow

(or pressure). When regulating ow amount, the power source should be in switched on

and the gun switch pressed simultaniously.

Close bottle valve after having nished welding. If the machine will be out of use for a long

time, unscrew the pressure regulation screw.

10

Page 13

2.4 MAIN SWITCH I/O

When you turn the main switch of the Pro power source into I-position, pilot lamp close to it

is lighted and the equipment is ready for welding. The equipment is returned to that welding

method with which the welding was last carried out before the main switch was turned to

zero position.

NOTE! Always start and switch o the machine with the main switch, never use the mains plug as a

switch.

2.5 OPERATION OF COOLING UNIT PROCOOL 10, 30

Operation of cooling unit is controlled in such a way that pump is started when welding is

started. After welding stop pump is rotating for approx. 5 min cooling the liquid to ambient

temperature. Purpose of this operation is to make maintenance intervals of pump longer.

Read in operation instructions for the Procool 10 / Procool 30 unit the trouble situations of the

liquid circulation system and protection against torch etc. damage.

3. OPERATIONS OF PANELS

3.1 CONTROL PANEL TL 6271265

H26 P23 P24 P25

P21

P22

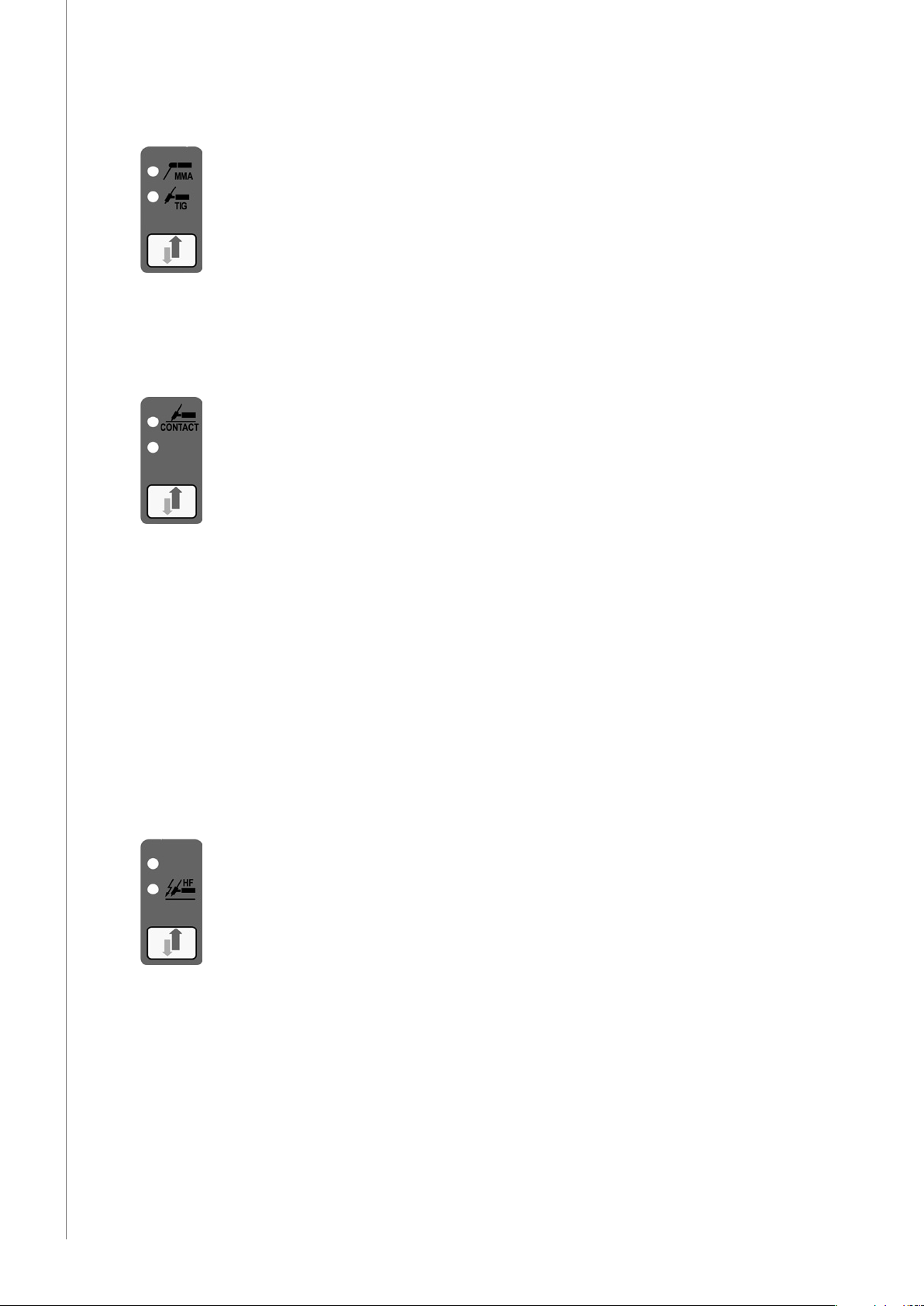

S21 Selection of MMA/TIG welding

S22 Selection of TIG ignition method

S23 Selection of operating mode of torch switch

S27 Selection of adjustable parameter

S28 +/- adjustment of selected parameter

P21 Display for pre-gas time

P22 Display for current up-slope time

P23 Display of welding current

P24 Display of down-slope time of current

P25 Display of post gas time

Led-lamp is illuminated to show those selections and operations which are used.

H21

S21

H22

S23S22 S27

ProTig 410 Hyundai / © Kemppi Oy / 1135

H24

EN

H25

S28

11

Page 14

ProTig 410 Hyundai / © Kemppi Oy / 1135

EN

3.1.1 Selection of MMA/TIG welding

Don`t forget to change polarity of voltage when you go over from one method to another: TIG

welding generally in torch-, MMA welding generally in eletrode holder +, see connection on

page 4 or 5.

3.1.2 Selection of TIG ignition method

Contact ignition:

Spark generation is prevented and arc will be ignited as follows:

1. Touch work piece with an electrode.

2. Start power source with the torch switch.

3. Lift electrode o from work piece in which case arc will be ignited. If arc is not ignited

within 1 s, the ignition must be repeated.

Scratch ignition is not recommended.

Control of ignition spark

Spark power may cause interference with eletronics equipment, which are not properly

protected. If there is interference, use contact ignition.

In order to reduce spark voltage in dicult interference situations, take contact with

authorized Kemppi service work shop.

Spark ignition:

Arc is ignited with high frequency with high voltage spark without touching work piece.

Use of torch switch starts spark generation. Spark strikes from electrode to work piece and arc

is ignited. Welding current is immediately set at set value. Spark distance, shielding gas ow

and current through earthing press have a profound eect on ignition.

If arc is not igniteed within 1s, the ignition must be repeated.

NOTE! Be careful that the torch tip is not touching near skin, clothes or components which are

sensitive for damage, like panels, connectors or switches.

12

Page 15

3.1.3 Selection of torch switch operation

2-function:

1. After having pressed torch switch down, shielding gas starts to ow. Welding starts after

ca. 0,3 s pregas time, welding current goes immediately up to current level according to

settings.

2. When you release torch switch up, welding current begins to go down smoothly, and

current is cut o after time dened by down-slope time. When welding current is zero,

there begins post gas time.

3. Tack weld automatics with 2-function: if welding time was less than 3s, there won`t come

any down-slope time.

Begin trial operation of unit with this mode of switch in order to avoid confusion. Go through

all operations and controls of panel.

ProTig 410 Hyundai / © Kemppi Oy / 1135

4-function:

1. Press torch switch down, shielding gas begins to ow.

2. Release the switch up, welding is started as above. Welding is continued, when the

switch is released.

3. Press the switch again down, welding is continued.

4. Release the switch up, welding is stopped as above.

Stopping unintentional start

With spark ignition:

If arc is not ignited, e.g. torch has not been directed towards work piece, ignition spark will go

out within 1 s from pressing down the torch switch. If eletrode is fastened on the work piece

when the torch is pressed down, welding current will be switched o immediately and there

comes no ignition spark.

With contact ignition:

If electrode is fastened on the work piece, when torch is switched down, and electrode is not

lifted o from the work piece, welding current is switched o within 1 s.

EN

13

Page 16

3.1.4 Adjustment of control unit

With + and - keys, parameters (time or current) are adjusted to higher or lower values.

Adjustable operation is selected with arrow keys: welding current, current down-slope time or

post gas time.

Adjustment speed is growing during adjustment.

ProTig 410 Hyundai / © Kemppi Oy / 1135

3.1.5 Parallel control unit for welding current

Controlling is directed only on welding current, in which case changing current is rapid in

operation mode. Control unit is operating in parallel with key S39 on right lower corner

of panel if welding current is adjusted from them. Parallel control unit cannot be used for

adjusting times or per cents.

EN

3.1.6 Pre-gas time display and current up-slope time display

Control ranges are 0 – 9 s.

3.1.7 Display of current down-slope time

Control range is 0 – 30 s.

3.1.8 Display of post gas time

Control range is 0 – 99 s.

3.1.9 Display of welding current

On no-load the meter shows set value of welding current and at welding true value.

14

Page 17

3.1.10 Local and remote control of welding current

Local control is carried out from +/- keys. Remote control unit R10 can be put into operation

by pressing the selection key for remote control.

3.1.11 Controls for TIG welding

5

ProTig 410 Hyundai / © Kemppi Oy / 1135

1 2 3 4

Starting situation: Torch is switched, but start switch is not pressed.

1. Select TIG welding.

2. Select spark ignition.

3. Select 2-function position.

4. Press one or the other of arrow keys until light H23 will be lighted.

5. Press the + or the - key and adjust the needed current value to display P23. You can test

suitability of current by welding and adjust current again if necessary.

6. Press arrow key once to right, until lamp H24 will be lighted. Adjust the down-slope time

as suitable. Seconds are displayed in P24.

7. Press again arrow key and H25 will be lighted. Adjust post gas time as suitable. Seconds

are displayed in P25.

8. Keep pressing the arrow key, and adjust the pre-gas time and current up-slope time

correspondingly (H21 ja H 22).

Breaking of down-slope time at 2-function of torch is done by pressing down the switch,

when current starts to go up to set value with the same speed with which it had gone down.

At 4-function down-slope of current is stopped when torch switch is pressed down and downslope operation will be continued by releasing the switch. Intermittent up- and down-slope

operations are produced by pressing the switch for a short time.

EN

15

Page 18

3.1.12 Controls for MMA welding

ProTig 410 Hyundai / © Kemppi Oy / 1135

1

1. Select the MMA welding.

2. Adjust with the +/- keys current needed.

Set value can be seen in display P23 on no-load. At welding the display shows welding

current. When the light H26 for remote control is lighted, you can control welding current

from remote control unit R10.

Don`t forget to change polarity of welding current by changing connection of cables as

shown in gures on page 5 or 6.

2

EN

3.2 CONTROL PANEL TX 6271266

H26 P23 S29

P25

S28

S21 S22 S24 S51 P51 S27S23

Read following paragraphs in operation instructions for panel TL:

Selection of MMA/TIG welding (S21)

Selection of TIG ignition method (S22)

Selection of operation mode of torch switch (S23)

Operation of control unit (S27), (S28)

Display for post gas time (P25)

Local and remote control of welding current (H26)

Welding current display (P23)

Controls for MMA welding

16

Page 19

In panel TX there are also following operation and controls:

Demo: learning and control state

Controls for continuous welding

Controls for pulsed TIG welding

Controls for fusion spot welding

Minilog-function and control of start current

Breaking the down-slope operations

Program storing of selectotig

3.2.1 Control ranges for time and per cent

Pre-gas time 0 – 9 s

Current up-slope time 0 – 9.9 s, 100 ms steps

Start current 30 – 150 %

Minilog basic current 10 – 90 %

Pulse ratio 10 – 80 %

Length of cycle 0,002 – 4 s (max. 500 Hz)

Pause current of pulse 10 – 100%

Spot welding time 0 – 9 s

Current down-slope time 0 – 25.5 s, 100 ms steps

Post gas time 0 – 99 s

Minilog pressing: short: less than 0,7 s

long: more than 0,7 s

Per cent values of table are calculated from control value.

ProTig 410 Hyundai / © Kemppi Oy / 1135

3.2.2 Demo: Learning and control state

In demo state coming of ignition spark and gas are stopped. All other controls operate as

during welding. Basic controls for current, times and per cent can be carried out safely in this

state and after that you can go over to welding using either spark or contact ignition.

Use arrow keys when you go over to control dierent functions. You can go to available

controls by selected welding mode. It is indicated by pilot lamp, in which stage of operation

ow chart you are now and which parameters can be controlled by you.

EN

17

Page 20

3.2.3 Controls for continuous welding

H22 H23 H24

H21

P21

H25

P25P24P22

ProTig 410 Hyundai / © Kemppi Oy / 1135

EN

1. Select Demo, 2-function switch operation and continuous welding S24.

2. Adjust welding current with parallel control S29, or go over to adjustment for welding

current with arrow keys S27 and adjust current with +/- keys S28. Reading will be visible

in display P23.

3. Go with arrow keys S27 to pre-gas point H21. Adjust pre-gas time P21 with +/- keys S28.

4. Go to up-slope point of current H24. Adjust up-slope time P22 with keys +/-.

5. Go to down-slope point of current H24. Adjust down-slope time P24 with +/- keys.

6. Go to post gas point H25. Adjust post gas time P25 with +/- keys.

By pressing the torch switch you can go through the whole operation cycle and after that go

to welding by selecting the ignition mode. You can use as operation models of torch switch

also the 4-function and Minilog operations.

Note the up- and down-slope times changing with current control and adjust when necessary.

If arc is not ignited within 4 sec from start, the unit will automatically go to stop without

timing.

Values of up- and down-slope times change automatically, when set values of welding current

are changing. Due to automatics you don`t need to change times in many welding cases,

when you change current.

3.2.4 Controls for pulsed TIG welding

H32 H31 H33 H34

18

P31H35

1. Select TIG welding, Demo, 2-function switch operation and pulsed welding S24.

2. Adjust welding parameters as above in point: ”Controls for continuous welding”.

Automatics of unit set pulse parameters automatically according to start values in

storage. Automatics of unit calculate a new average value for current, when pulse values

are changed. Automatics make the operations in that way easier that you need not

always adjust again other parameters of pulse, when pulse or mean current value is

changed.

3. Adjust pulse values in turns by going with arrow keys S27 to required adjustment point:

pulse current H31, pulse ratio H32, cycle time H33 and pause current H34. Control values

can be seen in display P31.

Page 21

However, it is impossble to distinguish separate pulses from arc during rapid pulse cycle times

2, 4, 8 and 16 ms, controls are working in the normal way. Welding of thin materials can be

considered as one application because there directing arc to narrow range is very important,

or if slow transportation speed is necessary.

3.2.5 Controls for fusion spot welding

1. Select TIG welding, Demo, 2-function operation and fusion spot welding S24.

2. Adjust welding parameters as above in point: Controls for continuous welding.

3. Go with arrow keys S27 to fusion welding point H35. Adjust spot welding time P31 with

+/- keys S28.

Spot welding is working also in 4-function position, then torch switch needs not be pressed

until at start.

3.2.6 Minilog-operation and control for start current

H42 H41 H43

ProTig 410 Hyundai / © Kemppi Oy / 1135

P42P41

Operation of Minilog is based on two pressings of dierent length, short and long (over

0,7 s), on torch switch.With long pressing you make rst the gas to ow. When the switch is

released,you go through pre-gas time and up-slope current to start current, when lamps H41

and/or H42 are lighted.

If start current has been adjusted onto dierent value from welding current, you go to welding

current with short pressing. If start current is the same as the welding current, you go directly

to welding current without any additional pressing. After that you can alternate with short

pressings between welding current and basic current levels.

1. Select TIG welding, Demo, Minilog operation S23 and continuous or pulsed welding.

2. Adjust the welding parameters as above in point: Controls for continuous welding.

3. You can adjust start current value with +/- keys S28 either to lower or higher value by

means or display P41. Control range for start current is approx. 30...150 % of welding

current value. When upper pilot lamp H41 is lighted, there is in display reading

exceeding 100 %. When lower pilot lamp H42 is lighted, there is in display reading under

100 %.

4. Adjust basic current level H43 with +/- keys. Reading will come to display P42.

5. Stop welding with long pressing, when releasing switch you go to down-slope current

and post gas time. You can start down-slope from any point operation cycle you like.

EN

19

Page 22

3.2.7 Breaking down-slope operations

In 2-function position of torch switch welding current begins to slope down, when torch

switch is released. If you press the torch switch again, current begins to slope up (in its

maximum to the reference value) with the same speed as it was earlier sloping down. With the

operation the slope-down can be controlled without interfering the down-slope time.

In 4-function and Minilog positions the respective operation can be produced by short

pressing of the torch switch. Current down-slope can also be stopped to value of that moment

ProTig 410 Hyundai / © Kemppi Oy / 1135

by keeping the switch pressed down. When the switch is released, current down-slope is

continued until the down-slope time is at end.

3.2.8 Program storing of Selectotig

EN

The unit has as standard 20 channels. For all channels there are stored reference values, which

you can change and store as changed.

Numeric channels are channel numbers from 0 to 9 without dot. Dot channels are channel

numbers from 0...9 with dots.

Ranges from 0 to 4 are directly in use, to range from 5 to 9 and back you can get with long

pressing of CH key S51. Dot channels should be used to store values which you would like to

keep in storage more permanently.

You can store values of dot channel only in Demo state S22. Welding takes always place on

respective numeric channel to which you go automatically from respective dot channel or

with CH key. Dot channel values are copied only to respective numeric channel and destroy

previous values when you start welding from this dot channel.

3.2.9 Programming of numeric channels

On numeric channel there are always the last welded values.The storing is made by welding

automatically always when the post gas time begins after normal stopping. Reference

values don`t get lost even though you cancel the welding program made by you in the

below-mentioned way.

3.2.10 Programming of dot channels

1. Select dot channel (number and dot) or numeric channel with key CH.

2. On dot channel: Carry out necessary controls and selections S22 in Demo-position. You

cannot make storing in position for spark or contact ignition. On numeric channel: If you

want to store the welding values used by you permanently, you can go to Demo state

and store the values as in point 3, in which case the values are stored on corresponding

dot channel.

3. Start the program with torch switch to welding current and press key CH, when capital

letter P comes to CH display P51.

4. Go over to weld stop from torch switch and wait until the post gas time begins. Your

program has been stored to dot channel, when on display P25 for post gas time appear

for two seconds horizontal lines - -.

20

Page 23

The parameters which are shown last in display and welded or stored last are kept in storage,

though electricity would be disconnected from unit. At connection electricity is restored to

the channel, on which you were last. All channels have reference values which don`t disappear

from memory though you would store to channnels anything. You can cancel program of

channel from memory as follows:

1. Select channel number to display CH.

2. Press at the same time both arrow keys. All lights on panel are lighted at the same time

and the program is cancelled and original reference values are restored to channel.

4. ACCURACY OF PANEL DISPLAY

Accuracy of digital meters in TL and TX panels as follows: Accuracy of current set value in ratio

to true value is ±2,5 %, ±2 A.

5. REMOTE CONTROL UNIT

R10

ProTig 410 Hyundai / © Kemppi Oy / 1135

Control of welding current min. – max.

R20

R10F

Control of welding current min. – max.

EN

No operation

Foot pedal control unit for TIG welding

• Start operation

• Control for welding current with movement on pedal

• Limiting of welding current range with min. and max. potentiometers

(reference scale 1 – 10).

21

Page 24

6. MAINTENANCE

The amount of use and the working environment should be taken into consideration when

planning the frequency of maintenance of Protig 410 unit. Careful use and preventive

maintenance will help to ensure trouble-free operation.

6.1 WELDING TORCH

Due to high temperatures and wear the welding end of TIG torch requires most maintenance,

but also condition of other parts should be checked regularly.

Welding end

Check that...

• all insulations of welding end are undamaged and at their place.

• gaz nozzle is undamaged and suitable for work.

• ow of shielding gas is free and even.

• electrode is undamaged. Use electrode size and tip sharpening angle which is suitable

ProTig 410 Hyundai / © Kemppi Oy / 1135

for welding case. Make sharpening grinding lengthwise of electrode.

• fastening parts of electrode are undamaged and electrode is fastened tightly at ist place.

Torch cable

Check that...

• insulations of handle and torch cable are undamaged.

• there are no sharp bends in torch cable.

Replace damaged parts immediately by new ones!

Follow in all maintenance and reparation measures instructions given by torch manufacturer.

EN

6.2 CABLES

Check the condition of welding and connection cables daily. Don`t use any damaged cables!

Make sure that the mains connection cables in use are safe and according to regulations!

The repair and mounting of mains connecting cables must be carried out only by an

authorised electrician.

22

Page 25

7. OPERATION DISTURBANCES

Error codes

E.1 Not in use

E.2 Bit error in the message content

E.3 Bit error in the end of the message

E.4 Power source doesn´t acknowledge the TIG start

E.5 Conict of states

E.6 The power source sent message ”error in message”

E.7 EEPROM can´t be programmed

E.8 A message during TIG welding doesn´t get acknowledged

E.9 Error in ”Power source size” information

E.10 Error in ”Power source voltage” information

E.11 Error in momentary voltage information

E.12 Error in message coming from the remote controller

E.13 Error in current information

E.14 Error in version

E.15 ”TIG welding stopped” message doesn´t get acknowledged

E.16 ”Cooler unit stop” command doesn´t get acknowledged

E.17 ”Cooler unit start” command doesn´t get acknowledged

E.18 MMA states in conict

E.19 Error in voltage information

E.20 Error in MMA set value information

E.21 Waiting for upslope loading (polling)

E.22 Waiting for downslope loading

E.23 Waiting for basic slope loading

E.24 The cooler unit doesn´t answer to start command during welding

E.25 The cooler unit stopped the welding

E.26 Too many bytes in the message

ProTig 410 Hyundai / © Kemppi Oy / 1135

EN

The most usual operation disturbances:

Arc is not ignited:

• Cable is loose or there is a bad connection.

• Electrode of torch is highly oxidized (grey). Sharp again lengthwise. Check that post gas

time is long enough. Check ignition by using pre-gas e.g. by 4-function operation of

torch.

• There are impurities in shielding gas (moisture, air).

• Protective hose of torch is broken and ignition spark is ”escaping” from elsewhere than

from eletrode of torch.

• Torch or extension cable is wet.

• There are leakages due to moisture or dirt in connectors or cables of Protig 410 unit.

• At low current too big or blunt electrode.

• If with operation disturbances there comes to current display continuously error code

in form ”E + number”, take contact with Kemppi service work shop and tell them also

above-mentioned error code.

23

Page 26

ProTig 410 Hyundai / © Kemppi Oy / 1135

EN

7.2.1 DISPOSAL OF THE MACHINE

Do not dispose of electrical equipment with normal waste!

In observance of European Directive 2002/96/EC on waste electrical and electronic

equipment, and its implementation in accordance with national law, electrical equipment

that has reached the end of its life must be collected separately and taken to an appropriate

environmentally responsible recycling facility.

The owner of the equipment is obliged to deliver a decommissioned unit to a regional

collection centre, per the instructions of local authorities or a Kemppi representative. By

applying this European Directive you will improve the environment and human health.

8. ORDERING NUMBERS

Protig 410 6271262C1

Kemppi Pro Evolution 3200 6131320

Kemppi Pro Evolution 4200 6131420

Kemppi Pro Evolution 5200 6131520C1

R10 6185409

R20 6185419

R10F 6185406

Remote control cable 10 m 6185481

Start extension cable 10 m 6185482

Return current cable 5m - 50 mm

MMA welding cable 5 m - 50 mm

TTK welding torch:

TTK 130 TTK 130F TTK 160 TTK 160S

4m 627063004 627063104 627066004 627066204

8m 627063008 627063108 627066008 627066208

16m 627063016 627063116 627066016 627066216

TTK 220 TTK 300W TTK 350W TTK 250WS

4m 627072004 627080504 627085504 627075704

8m 627072008 627080508 627085508 627075708

16m 627072016 627080516 627085516 627075716

TTK 220S

4m 627072304

8m 627072308

16m 627072316

Intermediate cable 50-1-G 1 m - 50 mm

Intermediate cable 50-10-GH 10 m - 50 mm

Procool 10 6262012

Procool 30 6262016

P30W 6185262

P 40 6185264

P 40 L 6185264L

Intermediate cable 50-1-W 1 m - 50 mm

Intermediate cable 50-10-WH 10 m - 50 mm

2

2

2

2

2

2

6184511

6184501

6271906

6271913

6271907

6271914

24

Page 27

Promig 501 6232501

Promig 501 L 6232505

Promig 511 6232511

Promig 530 6232530

Promig 501 + Protig

Intermediate cable PROTIG/MIG 501-III-W

Promig 511 + Protig

Intermediate cable PROTIG/MIG 511-III-W

9. TECHNICAL DATA

Protig 410

Working voltage (safety voltage) 50 VDC

Rated power 50 W

Max. load 60 % ED 400 A

Pressure endurance of gas hose 600 kPa max.

Connection of gas hose snap connector

Welding cable connectors DIX 70

Torch connection (adapter) Multi-function

Operation temperature range -20...+40 °C

Storage temperature range -40...+60 °C

Temperature class B (130 °C)

Degree of protection¹) IP 34

Dimensions length 615 mm

Weight 17 kg

1) IP 34 means that the device is protected against water coming from any direction,

directly or splashing.

1m - 50 mm

1m - 50 mm

100 % ED 310 A

width 260 mm

height 400 mm

2

2

3135780

3135790

ProTig 410 Hyundai / © Kemppi Oy / 1135

EN

Control panels

Main operations of Protig 410 panels TL and TX are in enclosed table.

TL 6271265 TX 6271266

Spark ignition yes yes

Contact ignition yes yes

2 function / 4 function torch operation yes yes

Fusion point timer -- yes

Pulsing -- yes

Minilog operation -- yes

Up-slope timer for current yes yes

Down-slope timer for current yes yes

Selectotig memory channels -- yes

Current display (digital) yes yes

25

Page 28

KEMPPI OY

Hennalankatu 39

PL 13

FIN-15801 LAHTI

FINLAND

Tel +358 3 899 11

Telefax +358 3 899 428

export@kemppi.com

www.kemppi.com

Kotimaan myynti:

Tel +358 3 899 11

Telefax +358 3 734 8398

myynti.@kemppi.com

KEMPPI SVERIGE AB

Box 717

S-194 27 UPPLANDS VÄSBY

SVERIGE

Tel +46 8 590 783 00

Telefax +46 8 590 823 94

sales.se@kemppi.com

KEMPPI NORGE A/S

Postboks 2151, Postterminalen

N-3103 TØNSBERG

NORGE

Tel +47 33 346000

Telefax +47 33 346010

sales.no@kemppi.com

KEMPPI DANMARK A/S

Literbuen 11

DK-2740 SKOVLUNDE

DANMARK

Tel +45 4494 1677

Telefax +45 4494 1536

sales.dk@kemppi.com

KEMPPI BENELUX B.V.

Postbus 5603

NL-4801 EA BREDA

NEDERLAND

Tel +31 765717750

Telefax +31 765716345

sales.nl@kemppi.com

KEMPPI (UK) Ltd

Martti Kemppi Building

Fraser Road

Priory Business Park

BEDFORD, MK44 3WH

UNITED KINGDOM

Tel +44 (0)845 6444201

Telefax +44 (0)845 6444202

sales.uk@kemppi.com

KEMPPI FRANCE S.A.S.

65 Avenue de la Couronne des Prés

78681 EPONE CEDEX

FRANCE

Tel +33 1 30 90 04 40

Telefax +33 1 30 90 04 45

sales.fr@kemppi.com

KEMPPI GmbH

Otto-Hahn-Straße 14

D-35510 BUTZBACH

DEUTSCHLAND

Tel +49 6033 88 020

Telefax +49 6033 72 528

sales.de@kemppi.com

KEMPPI SPÓŁKA Z O.O.

Ul. Borzymowska 32

03-565 WARSZAWA

POLAND

Tel +48 22 7816162

Telefax +48 22 7816505

info.pl@kemppi.com

KEMPPI AUSTRALIA PTY LTD.

13 Cullen Place

P.O. Box 5256, Greystanes NSW 2145

SMITHFIELD NSW 2164

AUSTRALIA

Tel. +61 2 9605 9500

Telefax +61 2 9605 5999

info.au@kemppi.com

OOO KEMPPI

Polkovaya str. 1, Building 6

127018 MOSCOW

RUSSIA

Tel +7 495 739 4304

Telefax +7 495 739 4305

info.ru@kemppi.com

ООО КЕМППИ

ул. Полковая 1, строение 6

127018 Москва

Tel +7 495 739 4304

Telefax +7 495 739 4305

info.ru@kemppi.com

KEMPPI, TRADING (BEIJING) COMPANY,

LIMITED

Room 420, 3 Zone, Building B,

No.12 Hongda North Street,

Beijing Economic Development Zone,

100176 Beijing

CHINA

Tel +86-10-6787 6064

+86-10-6787 1282

Telefax +86-10-6787 5259

sales.cn@kemppi.com

肯倍贸易(北京)有限公司

中国北京经济技术开发区宏达北路12号

创新大厦B座三区420室 (100176)

电话: +86-10-6787 6064

+86-10-6787 1282

传真: +86-10-6787 5259

sales.cn@kemppi.com

KEMPPI INDIA PVT LTD

LAKSHMI TOWERS

New No. 2/770,

First Main Road,

KAZURA Gardens,

Neelangarai,

CHENNAI - 600 041

TAMIL NADU

Tel +91-44-4567 1200

Telefax +91-44-4567 1234

sales.india@kemppi.com

www.kemppi.com

1927320

1135

Loading...

Loading...