Page 1

1923740E

0425

Page 2

2 – Promig 540R, Promig 120R/0425

© KEMPPI OY

Promig 540R, Promig 120R/0423 – 3

© KEMPPI OY

CONTENTS

1. PREFACE........................................................................................................................ 3

1.1. Introduction .......................................................................................................................3

1.2. Product introduction ..........................................................................................................3

1.3. Operation safety................................................................................................................ 4

2. INSTALLATION ...............................................................................................................5

2.1. Operation control and connectors ..................................................................................... 5

2.1.1. Promig 540R control unit................................................................................................. 5

2.1.2. Promig 120R wire feeder ................................................................................................ 6

2.2. Units, accessories, cables................................................................................................. 7

2.3. Parts of wire feed mechanism........................................................................................... 8

2.4. Assembly of MIG system ..................................................................................................9

3. INSTALLATION OF MIG SYSTEM ...............................................................................10

3.1. Accessories corresponding to wire diameter ..................................................................10

3.2. Mounting of MIG gun....................................................................................................... 11

3.3. Automatic wire feed to gun.............................................................................................. 11

3.4. Adjustment of pressure ................................................................................................... 11

3.5. Burn back time ................................................................................................................12

3.6. Ground cable................................................................................................................... 12

3.7. Shield gas .......................................................................................................................12

3.7.1. Installing gas bottle ....................................................................................................... 12

3.8. Main switch I / O.............................................................................................................. 13

3.9. Operation of cooling unit (PROCOOL 10, PROCOOL 30).............................................. 13

4. MXE CONTROL PANEL................................................................................................14

5. OTHER USER FUNCTIONS .........................................................................................15

6. JUMPERS...................................................................................................................... 15

7. ERROR CODES OF PANELS....................................................................................... 17

8. SERVICE AND OPERATION DISTURBANES ............................................................. 17

9. ORDERING NUMBERS ................................................................................................18

10. TECHNICAL DATA........................................................................................................ 19

Page 3

Promig 540R, Promig 120R/0423 – 3

© KEMPPI OY

1. PREFACE

1.1. INTRODUCTION

Congratulations on having purchased this product. Properly installed Kemppi products should

prove to be productive machines requiring maintenance at only regular intervals. This manual is

arranged to give you a good understanding of the equipment and its safe operation. It also

contains maintenance information and technical specications. Read this manual from front

to back before installing, operating or maintaining the equipment for the rst time. For further

information on Kemppi products please contact us or your nearest Kemppi distributor.

Specications and designs presented in this manual are subject to change without prior notice.

In this document, for danger to life or injury the following symbol is used:

Read the warning texts carefully and follow the instructions. Please also study the Operation

safety instructions and respect them when installing, operating and servicing the machine.

1.2 PRODUCT INTRODUCTION

Promig 540R is a welding system designed for robotic and automated welding. It consists of

Promig 540R with inbuilt robot interface and a robot arm mounted feed unit Promig 120R.

These two units are connected with an intermediate cable assembly.

Manual control is possible using interchangeable control panel:

MXE: Synergic MIG/MAG and Pulsed MIG in the most demanding welding environment.

MMA welding is also possible.

Welding operation is controlled by microprocessor. The wire feed motor includes an amplied

tachometer feedback system to ensure accurate wire feed speed. The interface stage handles

eldbus signal covering all automated requirements.

Page 4

4 – Promig 540R, Promig 120R/0425

© KEMPPI OY

Promig 540R, Promig 120R/0423 – 5

© KEMPPI OY

1.3. OPERATION SAFETY

Please study these Operation safety instructions and respect them when installing, operating and

servicing the machine.

Welding arc and spatters

Welding arc hurts unprotected eyes. Be careful also with reecting arc ash. Welding arc and

spatter burn unprotected skin. Use safety gloves and protective clothing.

Danger for re or explosion

Pay attention to re safety regulations. Remove ammable or explosive materials from

welding place. Always reserve sufcient re-ghting equipment on welding place. Be prepared

for hazards in special welding jobs, e.g. for the danger of re or explosion when welding

container type work pieces. Note! Fire can break out from sparks even several hours after the

welding work has been nished!

Mains voltage

Never take welding machine inside a work piece (eg. container or truck). Do not place welding

machine on a wet surface. Always check cables before operating the machine. Change defect

cables without delay. Defect cables may cause an injury or set out a re. Connection cable must

not be compressed, it must not touch sharp edges or hot work pieces.

Welding power circuit

Isolate yourself by using proper protective clothing, do not wear wet clothing. Never work on a

wet surface or use defect cables. Do not put MIG gun or welding cables on welding machine or

on other electric equipment. Do not press MIG gun’s switch, if the gun is not directed towards a

work piece.

Welding fumes

Take care that there is sufcient ventilation during welding. Take special safety precautions

when welding metals which contain lead, cadmium, zinc, mercury or beryllium.

Page 5

Promig 540R, Promig 120R/0423 – 5

© KEMPPI OY

2. INSTALLATION

2.1 OPERATION CONTROL AND CONNECTORS

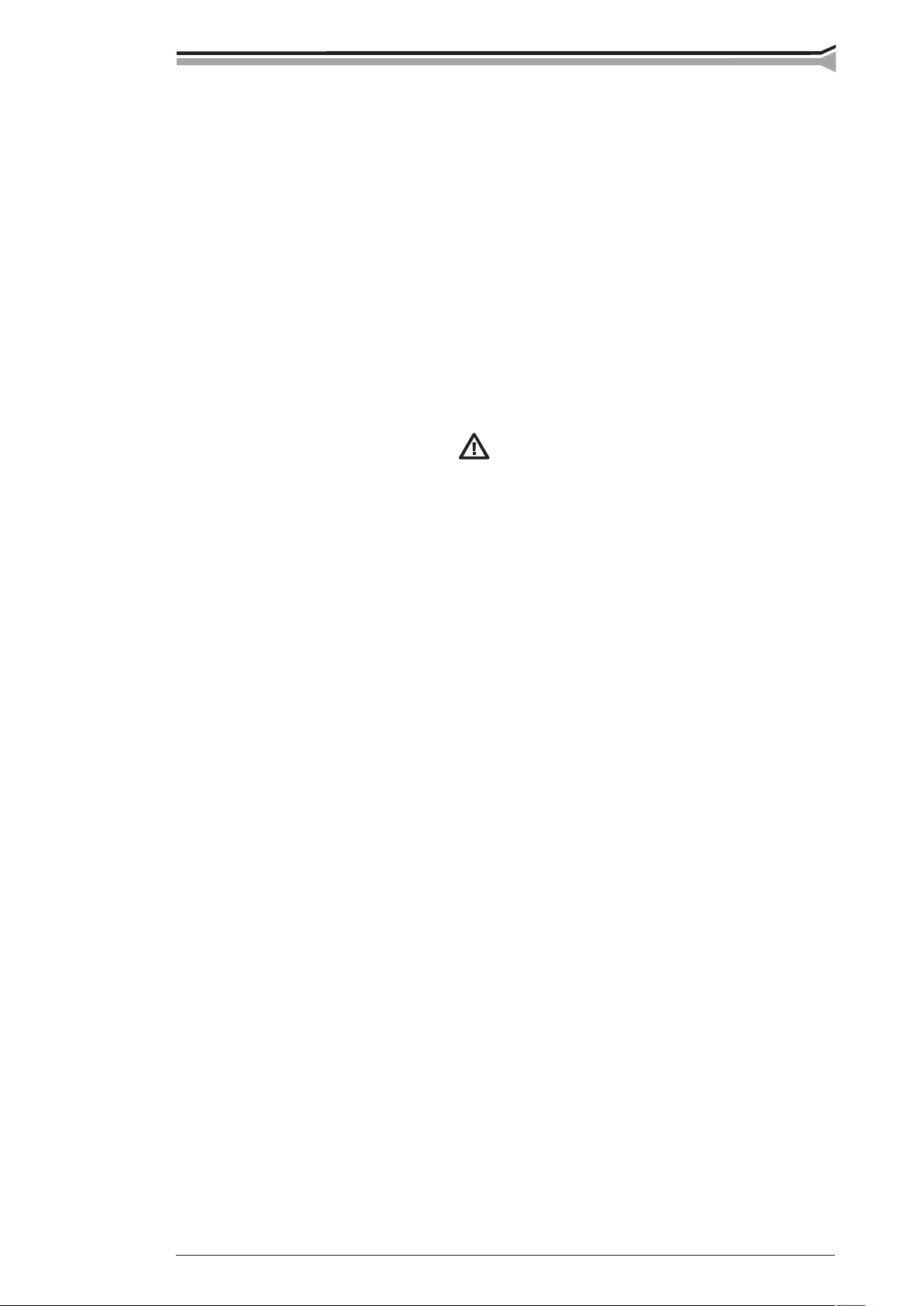

2.1.1. Promig 540R control unit

MXE control panel

Wire inch

Gas purge

Motor overcurrent indicator

Place for user connector

Holes for gas snap connectors

Welding current output connector (+)

Control cable connector (to 120R or

voltage controlled wire feeder SWF)

Control cable connector (to 2nd 120R)

Robot controller eldbus

Control cable connector (Probus)

Voltage monitoring connector (–)

Fixed welding cable to Pro power source

Fixed control cable to Pro power source

Lock switch of panel

Signal throughput connector

Analog signal to robot

Page 6

6 – Promig 540R, Promig 120R/0425

© KEMPPI OY

Promig 540R, Promig 120R/0423 – 7

© KEMPPI OY

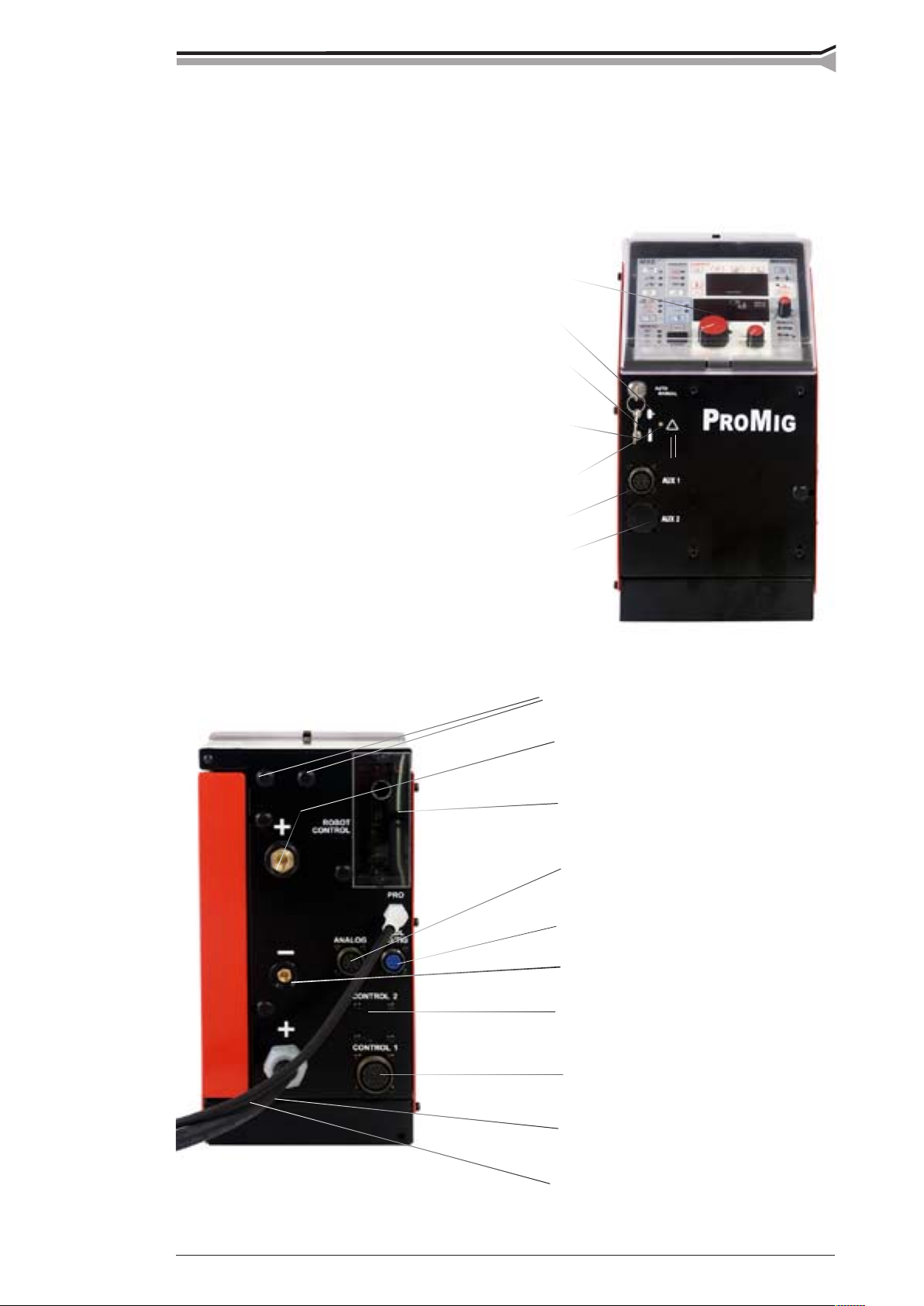

2.1.2. Promig 120R wire feeder

Gas purge

Wire inch

Euro connector for robot gun

Snap connector for air blast

Connector for motorised gun

Snap connectors for

cooling liquid

Control cable connector

Snap connector for gas

Wire liner inlet

Welding current cable connector

Page 7

Promig 540R, Promig 120R/0423 – 7

© KEMPPI OY

A

B

C

D

E

F

G

H

I

J

K

L

2.2. UNITS, ACCESSORIES, CABLES

A Air hose

B Intermediate cable

assembly

C Air blast

D Shielding gas hose

E Cooling liquid hoses

F Control cable

G Control cable

H Welding current cable

I Voltage monitor cable

J Branch connector

K Earth cable

L Robot control

Page 8

8 – Promig 540R, Promig 120R/0425

© KEMPPI OY

Promig 540R, Promig 120R/0423 – 9

© KEMPPI OY

2.3 PARTS OF WIRE FEED MECHANISM

Page 9

Promig 540R, Promig 120R/0423 – 9

© KEMPPI OY

2.4. ASSEMBLY OF MIG SYSTEM

Assemble the units according to the mounting instructions delivered with the unit.

1. Installation of power source

Read paragraph “INSTALLATION” in operation instructions for PRO power sources and

install accordingly.

2. Mounting of PRO power source to transport wagon

P 20 see air-cooled MIG system

P 30W see liquid-cooled MIG system

P 40 see air-cooled MIG system

3. Put PROMIG onto the power source and lock it with bolts to handles of powersource.

4. Installation of the eldbus card

MXE 6263504, installation instruction 4279220

Open side plate and install eldbus card by mounting above the interface card with two M3 nut.

See mounting instructions.

5. Connecting cables

Connect cables according to paragraph ”UNITS, ACCESSORIES, CABLES”.

6. Max. wire feed speed

By delivery, the max. wire feed speed is 18 m/min, which is enough for most welding

applications. If you need a higher speed, you can increase the wire feed speed to 25 m/min

by replacing the gear wheel on motor shaft. The high ratio wheel (*D40*) is delivered with

the feed unit.

Changing the maximum wire feed speed:

– Open side plate and remove JUMPER 3 on control card A001. This alters the tacho

feedback ratio to 0 - 25 m/min

Fieldbus card

M3 nut

Interface card

Page 10

10 – Promig 540R, Promig 120R/0425

© KEMPPI OY

Promig 540R, Promig 120R/0423 – 11

© KEMPPI OY

20

21 23 2 4 2 1

22 25 22

25

– Open tightening lever (20). Remove lower feed rolls (21). Release screw (23) and its washer.

Remove gear wheel D28 (24) from motor shaft.

– Loosen screws (25) (3 pcs) by one twist. Mount D40 gear wheel onto motor shaft. Screw the

screw (23) with its washer back.

– Put feed rolls (21) back on their shafts.

– Lift motor so that tooth gap between gear wheel and both lower feed rolls is approx. 0,2 mm.

– Tighten screws (25). Check gear teeth gaps, if necessary put the motor into a better position.

Screw on mounting screws of feed rolls (22).

Too small a clearance between drive wheel and feed rolls will overload the

motor. Too large a clearance causes rapid wearing of feed rolls’ drive wheel.

3. INSTALLATION OF MIG SYSTEM

3.1. ACCESSORIES CORRESPONDING TO WIRE DIAMETER

PROMIG wire feed rolls are available with plain groove, knurled groove and with U groove.

Feed rolls with plain groove:

Universal feed roll for welding of all kinds of wires.

Feed rolls with knurled groove:

Special feed roll for cored wires and steel wires.

Feed rolls with U groove:

Special feed roll for aluminium wires.

PROMIG wire feed rolls have two grooves. Correct wire groove is selected by moving selecting

washer from over to underneath the feed rolls. Move also drive wheel with the black plastic

washer.

Feed rolls and wire guide tubes of wire feed unit have colour codes to make identication easier.

Page 11

Promig 540R, Promig 120R/0423 – 11

© KEMPPI OY

3.2. MOUNTING OF MIG GUN

To ensure trouble-free welding, check in welding gun operating instructions that wire liner and

contact tip are correct for wire feed diameter and wire type. Too tight a wire liner might cause

disturbances in wire feed, and motor overload (this is also a symptom of liner blockage).

Ensure that the welding gun connector is tight.

When you are using liquid-cooled gun, mount water hoses according to the diagram.

Error signal lamp of PROMIG 540R indicates overloading of wire feed motor. Operation of

signal lamp is as follows (also see error codes):

Wire feed motor is slightly overloaded e.g. due to a blocked gun. At a predetermined load the

error signal lamp starts to blink.

If the load is too great the system will shut down (wire feed) and the display panel will indicate

Err 9.

Error code 9, followed by blinking signal lamp is cleared by next start if error condition is no

longer present or motor is not overheated any more.

3.3. AUTOMATIC WIRE FEED TO GUN

Automatic wire feed in PROMIG wire feed units makes changing of wire reel more rapid. When

changing the reel, feed rolls need not be released as the wire will pass directly through.

Groove selecting washer

– Make sure that groove of feed roll matches the diameter of welding wire used. Feed roll

groove is selected by moving the groove selecting washer from top to bottom or vice versa.

– Straighten the wire at a length of about 20 cm and see that its end has no sharp edges (le

off if necessary). A sharp edge may damage the wire guide tube and contact tip of welding

gun.

Automatic feed may sometimes fail with thin wires (Fe, Fc, Ss: 0,6...0,8 mm, Al: 0,8...1,0 mm).

Then you might have to open feed rolls and feed wire manually through feed rolls.

– Feed wire through wire cone until it touches the feed rolls. Do not release pressure of feed

rolls!

– Press wire inch switch and feed wire until wire goes through both sets of rolls.

– Keep inch switch pressed until wire has come through contact tip.

3.4. ADJUSTMENT OF PRESSURE

Adjust feed roll pressure with the control screw (20) so that some resistance may be applied to

the wire without slipping at the feed rolls.

Excessive pressure causes attening of ller wire and damage to the coating. It

also causes undue wear of feed rolls as well as friction.

Page 12

12 – Promig 540R, Promig 120R/0425

© KEMPPI OY

Promig 540R, Promig 120R/0423 – 13

© KEMPPI OY

A

C

G

B

E

D

F

3.5. BURN BACK TIME

The system includes an electronic burn back control which is pre-set.

3.6. GROUND CABLE

Use at least 70 mm2 cables. Thinner cross-sectional areas cause overheating of connectors and

poor Pulsed MIG performance.

Never use a damaged welding gun!

3.7. SHIELD GAS

Handle gas bottle with care. There is a risk for injury if gas bottle or bottle valve

is damaged!

For welding stainless steels, mixed gases are normally used. Check that the gas bottle valve

is suitable for the gas. The ow rate is set according to the welding power used in the job. A

suitable ow rate is normally 8 - 15 l/min. If the gas ow is not suitable, the welded joint will be

sporous. Contact your local Kemppi dealer for choosing gas and equipment.

3.7.1. Installing gas bottle

Always fasten gas bottle properly in vertical position in a special holder on the

wall or on a carriage. Remember to close gas bottle valve after having nished

welding.

Parts of gas ow regulator

A Gas bottle valve

B Press regulation screw

C Connecting nut

D Hose spindle

E Jacket nut

F Gas bottle pressure meter

G Gas hose pressure meter

Following installing instructions are valid for most gas ow regulator types:

1. Step aside and open bottle valve (A) for a while to blow out possible impurities.

2. Turn press regulation screw (B) of regulator until no spring pressure can be felt.

3. Close needle valve if there is one in the regulator.

4. Install regulator on bottle valve and tighten connecting nut (C) with a wrench.

5. Install hose spindle (D) and jacket nut (E) into gas hose and tighten with hose clamp.

6. Connect hose with regulator and the other end with wire feed unit.

Tighten jacket nut.

7. Open bottle valve slowly. Gas bottle pressure meter (F) shows bottle pressure.

Note! Do not use the whole contents of the bottle. Bottle should be lled when bottle

pressure is 2 bar.

Page 13

Promig 540R, Promig 120R/0423 – 13

© KEMPPI OY

8. Open needle valve if there is one in the regulator.

9. Turn regulation screw (B) until hose pressure meter (G) shows the required ow (or

pressure). When regulating ow amount, power source should be switched on and gun

switch pressed simultaniously.

Close bottle valve after having nished welding. If the machine will be out of use for a long

time, unscrew pressure regulation screw.

3.8. MAIN SWITCH I/O

When you turn the main switch of PRO power source into position I, pilot lamp next to it is

lit and the equipment is ready for welding. The equipment reverts to the welding method used

before the main switch was turned to position zero.

Always start and switch off the machine with the main switch, never use the

mains plug as a switch.

3.9. OPERATION OF COOLING UNIT (PROCOOL 10, PROCOOL 30)

Operation of cooling unit is controlled so that pump is turned on when welding is started. After

welding stop pump is rotating for approx. 5 min, thus cooling the liquid to ambient temperature.

Read in operation instructions for cooling unit the trouble situations in liquid circulation system

and protection against damage of gun etc.

Page 14

14 – Promig 540R, Promig 120R/0425

© KEMPPI OY

Promig 540R, Promig 120R/0423 – 15

© KEMPPI OY

4. MXE CONTROL PANEL

Operations of MXE control panel are described in manual delivered with MXE.

Exceptions to the operations of MXE in robot use:

- 4T start switch function is not active

- gun remote control is not active

- there are 63 active memory channels

Other functions related to robot use:

MXE panel can be used in normal local control by setting MEMORY OFF and LOCAL. Key

switch on machine front is turned to position MANUAL. All adjustments are set with the panel.

In this case start and stop of machine can be controlled with robot.

By setting MXE panel to REMOTE mode, wire feed speed/voltage or power/ne control can be

regulated with robot via analog lines.

Memory channels can be programmed as described in the operating manual of MXE panel.

When retrieving memory channels, you can choose with robot whether to use wire feed speed/

voltage or power/ne control values retrieved from memory, or whether these values are

controlled with robot via analog lines (see technical manual).

When controlling memory channels with robot, memory functions are to be set to MEMORY

ON mode. Key switch is turned to position AUTO.

Note! On memory channel 0 (= no memory channel selected) machine always retrieves memory

channel which was used last.

Page 15

Promig 540R, Promig 120R/0423 – 15

© KEMPPI OY

1 2 3 4 5 6 7 8 9 10 11 12

1 2 3 4 5 6 7 8 9 10 11 12

1 2 3 4 5 6 7 8 9 10 11 12

1 2 3 4 5 6 7 8 9 10 11 12

5. OTHER USER FUNCTIONS

Selection between gas-cooled and water-cooled gun is made using the switch inside the control

unit.

Wire inch switch function is in the front of control unit and feeder unit.

– displays main motor current on welding current window and gun motor current on voltage

display window

– inch speed is set by local control setting (panel)

Gas purge switch is in the front of control unit and feeder unit.

– gas purge when pressed

Gas valve is mounted inside the feeder unit but it can also be moved into the control unit where

there is a place for it.

A gas pressure switch can be mounted inside the control unit.

Inside the control unit there is a 20 kg MIG wire spool system.

6. JUMPERS

1. Selection of wire feeder address

102, set 1

105, set 2

2. Robot control input voltage range for analog channels:

0-10 V

0-5 V

3. Selection of max. wire feed speed for feed unit 1

0-18 m, delivery setting

0-25 m

4. Selection of max. wire feed speed for feed unit 2

0-18 m / min

0-25 m / min

Page 16

16 – Promig 540R, Promig 120R/0425

© KEMPPI OY

Promig 540R, Promig 120R/0423 – 17

© KEMPPI OY

1 2 3 4 5 6 7 8 9 10 11 12

1 2 3 4 5 6 7 8 9 10 11 12

1 2 3 4 5 6 7 8 9 10 11 12

1 2 3 4 5 6 7 8 9 10 11 12

5,6 Wire feed and motor pistol selection

for one feeding unit only

for one feeding unit and motor pistol

for two feeding units (dual)

not used

7,8 Motor pistol selection

Hulftegger (3,3 kohm)

Binzel, water cooled (6,8 kohm)

Binzel, gas cooled (10 kohm)

Dinse (22 kohm)

9. Not used

10. Not used

11. Dynamic adjustment for 1-knob and normal MIG

Dynamic adjustment from MXE-control panel

(or without control panel A001/R165)

Dynamic adjustment through eldbus

12. Gas valve control

Gas valve is controlled by the eldbus

Gas valve is controlled internally by PROMIG 540R

Page 17

Promig 540R, Promig 120R/0423 – 17

© KEMPPI OY

8. SERVICE AND OPERATION DISTURBANCES

The amount of use and working environment should be taken into consideration when planning

the frequency of maintenance of PROMIG. Careful use and preventive maintenance will help to

ensure trouble-free operation.

Following maintenance operations should be carried out at least every six months:

Check:

– Feed roll grooves. Excessive wear of grooves causes wire feed

problems.

– Wire guide tubes. Badly worn feed rolls and wire guide tubes

should be discarded.

– Wire guide tube in the gun should be set as near the feed rolls

as possible and the wire must follow a straight line from the end

of the tube to the groove of the feed roll.

– Reel brake adjustment.

– Electrical connections:

* Oxidized couplings must be cleaned

* Loose couplings must be tightened

Clean dust and dirt from the equipment.

twice a year

When using compressed air, always protect your eyes with proper eye

protection.

In case of problems contact your KEMPPI dealer.

7. ERROR CODES OF PANELS

Error codes inform the user about welding system malfunctions. They are displayed on MC/ML

panels.

Err 1 Robot identication failed. Robot identication is done using XW114 on A003 X8.

Err 2 Power source has been started for MMA or TIG mode.

Err 3 Same as Err 2 but up (+) / down (–) buttons are active on PX panel (optional).

Err 4 Cooling unit (Procool 10 / 30) is not starting (check gas/water switch).

Err 5 Cooling unit (Procool 10 / 30) has a cooling failure (overheating sensor or pressure

switch has reacted or unit is missing supply voltage).

Err 6 Water unit (Procool 10 / 30) has been started normally, but wire feed unit

(Promig 540R) has lost serial communication link to cooling unit (check interconns).

Err 7 Emergency stop is active. Input relay K2 must be active on A003 to cancel emergency

stop (only Promig 540R - KU).

Err 9 Overload of wire feed motor which may be caused by blocked wire guide of gun or by

gun cable which is too curved.

Err 10 PRO power supply reports error when start message from Promig 540R is sent.

Operation of thermal protection of PRO power source has stopped welding.

Err 14 Supply overvoltage in Promig 540R.

Error code display is cleared by next start if the cause of error code has been eliminated.

Page 18

18 – Promig 540R, Promig 120R/0425

© KEMPPI OY

Promig 540R, Promig 120R/0423 – 19

© KEMPPI OY

9. ORDERING NUMBERS

Wire feed units

Promig 540R wire feed control unit ................................................. 6231540

Promig 120R wire feed unit ............................................................. 6236320

Fieldbus cards

Fieldbus card Interbus s.................................................................... 9774120IBC

Fieldbus card Interbus s optical........................................................ 9774120IBO

Fieldbus card Probus

...................................................................... 9774120PRF

Fieldbus card Devicenet ................................................................... 9774120DEV

Accessories of Promig 540R

MXE function panel ......................................................................... 6263504

Prosync 50 synchronisation set ........................................................ 6263121

Voltage sensor

................................................................................... 4289560

Current sensor................................................................................... 4288790

Wire reel hub...................................................

................................. 4289880

Power sources

Kemppi Pro Evolution 3200............................................................. 6131320

Kemppi Pro Evolution 4200............................................................. 6131420

Kemppi Pro Evolution 5200............................................................. 6131520

Cooling unit

PROCOOL 10................................................................................... 6262012

PROCOOL 30

................................................................................... 6262016

Cabels

Voltage monitor cable ....................................................................... 4288700

Branch connector.............................................................................. 9771637

Intermediate cable assembly..................... 5 m................................. 6260421

...................................................................................... 10 m .......... 6260425

Earth cable ............................................... 50 mm2...... 5 m ............ 6184511

.................................................................. 50 mm2...... 10 m .......... 6184512

Earth cable................................................ 70 mm2...... 5 m ............ 6184711

.................................................................. 70 mm2...... 10 m .......... 6184712

MIG guns for robotic and automated welding

MT-51MW.................................................................... 1,5 m / SK . 6255156

MT-51MW

.................................................................... 1,5 m / K30 6255157

MT-51MW

.................................................................... 3,0 m / SK . 6255158

MT-51MW

.................................................................... 3,0 m / K30 6255159

Transport wagons

P 20................................................................................................... 6185261

P 30W

............................................................................................... 6185262

P 40

................................................................................................... 6185264

Page 19

Promig 540R, Promig 120R/0423 – 19

© KEMPPI OY

10. TECHNICAL DATA

Promig 540R, Promig 120R

Operating voltage (safety voltage) 50 V DC

Rated power 100 W

Max. load 80 % ED 520 A

(nominal values) 100 % ED 400A

Operation principle 4-roll feed

Diameter of feed roll 32 mm

Wire feed speed I 0...18 m/min

II 0...25 m/min

Filler wires ø Fe, Ss 0,6...2,4 mm

ø Cored wires 0,8...2,4 mm

ø Al 1,0...2,4 mm

Wire reel max. weight 20 kg

max. size ø 300 mm

Gun connector Euro

Operation temperature range -20...+40 oC

Storage temperature range -40...+60 oC

Degree of protection IP 23

Promig 540R

Dimensions (without handle)

length 620 mm

width 230 mm

height 480 mm

weight 20 kg

Promig 120R

Dimensions length 319 mm

width 152 mm

height 167 mm

weight 8 kg

The products meet conformity requirements for CE marking.

Page 20

KEMPPI OY

PL 13

FIN – 15801 LAHTI

FINLAND

Tel (03) 899 11

Telefax (03) 899 428

www.kemppi.com

KEMPPIKONEET OY

PL 13

FIN – 15801 LAHTI

FINLAND

Tel (03) 899 11

Telefax (03) 7348 398

e-mail: myynti.@kemppi.com

KEMPPI SVERIGE AB

Box 717

S – 194 27 UPPLANDS VÄSBY

SVERIGE

Tel (08) 59 078 300

Telefax (08) 59 082 394

e-mail: sales.se@kemppi.com

KEMPPI NORGE A/S

Postboks 2151, Postterminalen

N – 3103 TØNSBERG

NORGE

Tel 33 34 60 00

Telefax 33 34 60 10

e-mail: sales.no@kemppi.com

KEMPPI DANMARK A/S

Literbuen 11

DK – 2740 SKOVLUNDE

DANMARK

Tel 44 941 677

Telefax 44 941 536

e-mail:sales.dk@kemppi.com

KEMPPI BENELUX B.V.

Postbus 5603

NL – 4801 EA BREDA

NEDERLAND

Tel (076) 5717 750

Telefax (076) 5716 345

e-mail: sales.nl@kemppi.com

KEMPPI (UK) Ltd

Martti Kemppi Building

Fraser Road

Priory Business Park

BEDFORD, MK443WH

ENGLAND

Tel 0845 6444201

Fax 0845 6444202

e-mail: sales.uk@kemppi.com

KEMPPI FRANCE S.A.

S.A. au capital de 5 000 000 F.

65 Avenue de la Couronne des Prés

78681 EPONE CEDEX

FRANCE

Tel (01) 30 90 04 40

Telefax (01) 30 90 04 45

e-mail: sales.fr@kemppi.com

KEMPPI GmbH

Otto – Hahn – Straße 14

D – 35510 BUTZBACH

DEUTSCHLAND

Tel (06033) 88 020

Telefax (06033) 72 528

e-mail:sales.de@kemppi.com

KEMPPI SP. z o.o.

Ul. Piłsudskiego 2

05-091 ZA¸BKI

Poland

Tel +48 22 781 6162

Telefax +48 22 781 6505

e-mail: info.pl@kemppi.com

KEMPPI SWITZERLAND AG

Chemin de la Colice 4

CH-1023 Crissier/ Lausanne

SUISSE

Tel. +41 21 6373020

Telefax +41 21 6373025

e-mail: sales.ch@kemppi.com

KEMPPI WELDING

MACHINES AUSTRALIA PTY LTD

P.O. Box 404 (2/58 Lancaster Street)

Ingleburn NSW 2565, Australia

Tel. +61-2-9605 9500

Telefax +61-2-9605 5999

e-mail: info@kemppi.com.au

Ver. 7

www.kemppi.com

Loading...

Loading...