Page 1

Model 6517A

Electrometer/High

Resistance Meter

Getting Started Manual

Contains Operating Information

Page 2

W ARRANTY

Keithley Instruments, Inc. warrants this product to be free from defects in material and workmanship for a

period of 1 year from date of shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables,

rechargeable batteries, diskettes, and documentation.

During the warranty period, we will, at our option, either repair or replace any product that proves to be defective.

To exercise this warranty, write or call your local Keithley representative, or contact Keithley headquarters in

Cleveland, Ohio. You will be given prompt assistance and return instructions. Send the product, transportation

prepaid, to the indicated service facility . Repairs will be made and the product returned, transportation prepaid.

Repaired or replaced products are warranted for the balance of the original warranty period, or at least 90 days.

LIMIT A TION OF W ARRANTY

This warranty does not apply to defects resulting from product modification without Keithley’s express written

consent, or misuse of any product or part. This warranty also does not apply to fuses, software, non-rechargeable batteries, damage from battery leakage, or problems arising from normal wear or failure to follow instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE.

THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AND EXCLUSIVE REMEDIES.

NEITHER KEITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR

ANY DIRECT , INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF

THE USE OF ITS INSTRUMENTS AND SOFTWARE EVEN IF KEITHLEY INSTRUMENTS, INC., HAS

BEEN ADVISED IN ADVANCE OF THE POSSIBILITY OF SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT ARE NOT LIMITED TO: COSTS OF REMOVAL AND INSTALLATION,

LOSSES SUSTAINED AS THE RESULT OF INJURY T O ANY PERSON, OR DAMAGE TO PROPERTY.

Keithley Instruments, Inc. • 28775 Aurora Road • Cleveland, OH 44139 • 440-248-0400 • Fax: 440-248-6168 • http://www.k eithley.com

BELGIUM: Keithley Instruments B.V. Bergensesteenweg 709 • B-1600 Sint-Pieters-Leeuw • 02/363 00 40 • Fax: 02/363 00 64

CHINA: Keithley Instruments China Y uan Chen Xin Building, Room 705 • 12 Yumin Road, Dewai, Madian • Beijing 100029 • 8610-62022886 • Fax: 8610-62022892

FRANCE: Keithley Instruments Sarl B.P. 60 • 3, allée des Garays • 91122 Palaiseau Cédex • 01 64 53 20 20 • Fax: 01 60 11 77 26

GERMANY: Keithley Instruments GmbH Landsberger Strasse 65 • D-82110 Germering • 089/84 93 07-40 • Fax: 089/84 93 07-34

GREAT BRITAIN: Keithley Instruments Ltd The Minster • 58 Portman Road • Reading, Berkshire RG30 1EA • 0118-9 57 56 66 • Fax: 0118-9 59 64 69

INDIA: Keithley Instruments GmbH Flat 2B, WILOCRISSA • 14, Rest House Crescent • Bangalore 560 001 • 91-80-509-1320/21 • Fax: 91-80-509-1322

ITALY: Keithley Instruments s.r.l. Viale S. Gimignano, 38 • 20146 Milano • 02/48 30 30 08 • Fax: 02/48 30 22 74

NETHERLANDS: Keithley Instruments B.V. Postbus 559 • 4200 AN Gorinchem • 0183-635333 • Fax: 0183-630821

SWITZERLAND: Keithley Instruments SA Kriesbachstrasse 4 • 8600 Dübendorf • 01-821 94 44 • Fax: 01-820 30 81

TAIWAN: Keithley Instruments Taiwan 1 Fl. 85 Po Ai Street • Hsinchu, Taiwan, R.O.C. • 886-3572-9077• Fax: 886-3572-9031

10/99

Page 3

Model 6517A Electrometer/

High Resistance Meter

Getting Started Manual

All references to the Model 6517 also apply to the Model 6517A.

©1995, Keithley Instruments, Inc.

All rights reserved.

Cleveland, Ohio, U.S.A.

First Printing, July 2000

Document Number: 6517A-903-01 Rev. A

Page 4

Manual Print History

The print history shown below lists the printing dates of all Revisions and Addenda created

for this manual. The Revision Le vel letter increases alphabetically as the manual under goes subsequent updates. Addenda, which are released between Revisions, contain important change information that the user should incorporate immediately into the manual. Addenda are numbered

sequentially . When a new Re vision is created, all Addenda associated with the previous Re vision

of the manual are incorporated into the new Revision of the manual. Each ne w Revision includes

a revised copy of this print history page.

Revision A (Document Number 6517A-903-01)...............................................................July 2000

All Keithley product names are trademarks or registered trademarks of Keithley Instruments, Inc.

Other brand names are trademarks or registered trademarks of their respective holders.

Page 5

Safety Precautions

The following safety precautions should be observed before using this product and any associated instrumentation. Although some instruments and accessories would normally be used with non-hazardous

voltages, there are situations where hazardous conditions may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar

with the safety precautions required to avoid possible injury. Read the operating information carefully

before using the product.

The types of product users are:

Responsible body is the individual or group responsible for the use and maintenance of equipment, for

ensuring that the equipment is operated within its specifications and operating limits, and for ensuring

that operators are adequately trained.

Operators use the product for its intended function. They must be trained in electrical safety procedures

and proper use of the instrument. They must be protected from electric shock and contact with hazardous

live circuits.

Maintenance personnel perform routine procedures on the product to keep it operating, for example,

setting the line voltage or replacing consumable materials. Maintenance procedures are described in the

manual. The procedures explicitly state if the operator may perform them. Otherwise, they should be

performed only by service personnel.

Service personnel are trained to work on live circuits, and perform safe installations and repairs of prod-

ucts. Only properly trained service personnel may perform installation and service procedures.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable con-

nector jacks or test fixtures. The American National Standards Institute (ANSI) states that a shock hazard exists when voltage levels greater than 30V RMS, 42.4V peak, or 60VDC are present.

safety practice is to expect that hazardous voltage is present in any unknown cir cuit before measuring.

Users of this product must be protected from electric shock at all times. The responsible body must ensure that users are prevented access and/or insulated from every connection point. In some cases, connections must be exposed to potential human contact. Product users in these circumstances must be

trained to protect themselves from the risk of electric shock. If the circuit is capable of operating at or

above 1000 volts,

As described in the International Electrotechnical Commission (IEC) Standard IEC 664, digital multimeter measuring circuits (e.g., Keithley Models 175A, 199, 2000, 2001, 2002, and 2010) are Installation

Category II. All other instruments’ signal terminals are Installation Category I and must not be connected to mains.

Do not connect switching cards directly to unlimited power circuits. They are intended to be used with

impedance limited sources. NEVER connect switching cards directly to AC mains. When connecting

sources to switching cards, install protective devices to limit fault current and voltage to the card.

Before operating an instrument, make sure the line cord is connected to a properly grounded power receptacle. Inspect the connecting cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the circuit under test. ALWAYS remove power from the entire test system and discharge any

capacitors before: connecting or disconnecting cables or jumpers, installing or removing switching

cards, or making internal changes, such as installing or removing jumpers.

no conductive part of the circuit may be exposed.

A good

Page 6

Do not touch any object that could provide a current path to the common side of the circuit under test or power

line (earth) ground. Alw ays make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the voltage being measured.

The instrument and accessories must be used in accordance with its specifications and operating instructions

or the safety of the equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications

and operating information, and as shown on the instrument or test fixture panels, or switching card.

When fuses are used in a product, replace with same type and rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as safety earth

ground connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation

requires the use of a lid interlock.

If a screw is present, connect it to safety earth ground using the wire recommended in the user documentation.

!

The symbol on an instrument indicates that the user should refer to the operating instructions located in

the manual.

The symbol on an instrument sho ws that it can source or measure 1000 volts or more, including the combined effect of normal and common mode voltages. Use standard safety precautions to av oid personal contact

with these voltages.

The

WARNING heading in a manual explains dangers that might result in personal injury or death. Always

read the associated information very carefully before performing the indicated procedure.

The

CAUTION heading in a manual explains hazards that could damage the instrument. Such damage may

invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain protection from electric shock and fire, replacement components in mains circuits, including the

power transformer, test leads, and input jacks, must be purchased from Keithley Instruments. Standard fuses,

with applicable national safety approvals, may be used if the rating and type are the same. Other components

that are not safety related may be purchased from other suppliers as long as they are equivalent to the original

component. (Note that selected parts should be purchased only through Keithley Instruments to maintain accuracy and functionality of the product.) If you are unsure about the applicability of a replacement component,

call a Keithley Instruments office for information.

To clean an instrument, use a damp cloth or mild, water based cleaner. Clean the exterior of the instrument

only. Do not apply cleaner directly to the instrument or allow liquids to enter or spill on the instrument. Products that consist of a circuit board with no case or chassis (e.g., data acquisition board for installation into a

computer) should never require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected, the board should be returned to the factory for proper cleaning/servicing.

Rev. 10/99

Page 7

T able of Contents

1

Front Panel Operation

Product overview.................................................................................1-2

Display.................................................................................................1-8

Power-up..............................................................................................1-8

Bench defaults .....................................................................................1-9

Changing functions..............................................................................1-9

Voltage measurements .......................................................................1-10

Current measurements.......................................................................1-12

Resistance measurements ..................................................................1-13

Resistivity measurements ..................................................................1-16

Charge measurements........................................................................1-18

External temperature and relative humidity measurements...............1-20

2

Measurement Options

Multiple displays .................................................................................2-2

Menus ..................................................................................................2-6

Voltage source....................................................................................2-10

Relative..............................................................................................2-13

Zero check .........................................................................................2-14

Zero correct........................................................................................2-14

Triggering..........................................................................................2-15

Speed..................................................................................................2-18

Resolution..........................................................................................2-19

Filter...................................................................................................2-20

Buffer (Data Store)............................................................................2-23

Math...................................................................................................2-24

Test sequences ...................................................................................2-27

Internal scanning................................................................................2-30

External scanning...............................................................................2-32

3

Remote Operation

Overview..............................................................................................3-2

Software support..................................................................................3-3

IEEE-488 bus standards.......................................................................3-4

RS-232 standard...................................................................................3-4

IEEE-488 bus connections...................................................................3-4

RS-232 connections.............................................................................3-5

IEEE-488 interface, address and language selection...........................3-6

RS-232 interface selection and configuration......................................3-7

Common commands............................................................................3-8

SCPI commands...................................................................................3-9

Page 8

SCPI command syntax ......................................................................3-10

SCPI signal oriented commands .......................................................3-13

SCPI subsystem commands ..............................................................3-14

Program examples.............................................................................3-22

Specifications

4

Condensed specifications ....................................................................4-2

Accessories available...........................................................................4-8

Page 9

1

Front Panel

Operation

Page 10

1-2 Front Panel Operation

Product overview

If you have any questions after re viewing this information, please contact your local K eithle y

representative, or call one of our Applications Engineers at

only). Worldwide phone numbers are listed in the front of this manual.

1-800-348-3735 (U.S. and Canada

The Model 6517A is a 6

surement capabilities:

• DC voltage measurements from 1µV to 210V

• DC current measurements from 10aA to 21mA

• Charge measurements from 10fC to 2.1µC

• Resistance measurements from 10

• Surface resistivity measurements

• Volume resistivity measurements

• External temperature measurements from -25°C to 150°C using the supplied Model

6517-TP thermocouple

• Relative humidity measurements (0 to 100%) using the optional Model 6517-RH probe

½ -digit electrometer/high resistance system with the following mea-

Ω to 210T Ω

Page 11

Front Panel Operation 1-3

Some additional capabilities of the Model 6517A include:

• Built-in V-Source — The 100V range provides up to 100V at 10mA, while the 1000V

range provides up to 1000V at 1mA

• Data storage

• Single button zeroing (REL)

• Built-in math functions

• Filtering; averaging and median

• Built-in test sequences

• Remote operation using the IEEE-488 (GPIB) bus or the RS-232 interface

• Model 617 emulation using the DDC (device-dependent command) programming language mode

• Scan (measure) channels of an external scanner (e.g., Model 706, 7001 or 7002)

• Scan (measure) channels of an internal scanner card (e.g., Model 6521 or 6522) installed

in the option slot

The Model 6517A front and rear panel overvie ws (Figures 1 and 2) include important abbre-

viated information that should be reviewed before operating the instrument.

Page 12

1-4 Front Panel Operation

Figure 1

Model 6517A front

panel overview

1 ANNUNCIATORS

ERR Questionable reading

REM In remote

TALK Addressed to talk

LSTN Addressed to listen

SRQ Service Request

REL Relative reading displayed

FILT Digital filter enabled

MATH Math calculation enabled

AUTO Autoranging enabled

ARM Trigger armed; not in idle

*(asterisk) Reading being stored

Secondary Display Line

Primary Display Line

19

EDIT ERR REM TALK LSTN SRQ REAR REL FILT MATH 4W AUTO ARM TRIG SMPL

1234567891012345678910

PREV

DISPLAY

NEXT

POWER

6517 ELECTROMETER/HIGH RESISTANCE METER

VI RQ

RELZ-CHK

FILTER MATH

INFO LOCAL

STORE RECALL

OPTION VOLTAGE SOURCE

CARD OPER

TRIG SEQ

EXIT ENTERCONFIG MENU

RANGE

AUTO

RANGE

VOLTAGE

SOURCE

OPERATE

CAL

52 6 7 3 8 4

2 FUNCTION KEYS Select measurement function; volts (V), amps (I), resistivity (R) or

coulombs (Q)

3 RANGE KEYS

▲ Moves to higher range; increments digit

▼ Moves to lower range; decrements digit

AUTO Enables/disables autorange

Page 13

Front Panel Operation 1-5

4 HANDLE (not shown) Pull out and rotate to desired position.

5 DISPLAY KEYS PREV/NEXT Scroll through multiple displays of a function

6 OPERATION KEYS

Z-CHK Enables/disables zero check. Enable zero check before changing functions.

REL Enables/disables relative reading

FILTER Displays digital filter status for present function and toggles filter on/off

MATH Displays math calculation and toggles math on/off if configured

TRIG Triggers unit

SEQ Performs selected test sequence

and Moves cursor among data entry digits, menu selections, and information displays

INFO Shows context-sensitive information about the present display

LOCAL Cancels remote operation

STORE Enables data storage

RECALL Displays reading data (reading, number, time). Use PREV/NEXT DISPLAY for

maximum, minimum average, standard deviation.

CONFIG Configures functions and operations

MENU Saves/restores instrument conditions; sets up communications; performs calibra-

tion and self-tests; defines limits, digital output, and other miscellaneous opera-

tions (see Table 2)

EXIT Cancels selection, moves back within menu structure

ENTER Holds reading, enters selection, moves down within menu structure

7 VOLTAGE SOURCE KEYS

OPER Toggles V-source between operate and standby

▲ and ▼ Adjusts V-source value

8 VOLTAGE SOURCE OPERATE Indicator on when in operate, off when in standby

9 OPTION CARD KEY Use to program and operate an installed option. Also used to scan

external scanner channels.

Page 14

WARNING:NO INTERNAL OPERATOR SERVICABLE PARTS,SERVICE BY QUALIFIED PERSONNEL ONLY.

WARNING:NO INTERNAL OPERATOR SERVICABLE PARTS,SERVICE BY QUALIFIED PERSONNEL ONLY.

CAUTION:FOR CONTINUED PROTECTION AGAINST FIRE HAZARD,REPLACE FUSE WITH SAME TYPE AND RATING.

CAUTION:FOR CONTINUED PROTECTION AGAINST FIRE HAZARD,REPLACE FUSE WITH SAME TYPE AND RATING.

1-6 Front Panel Operation

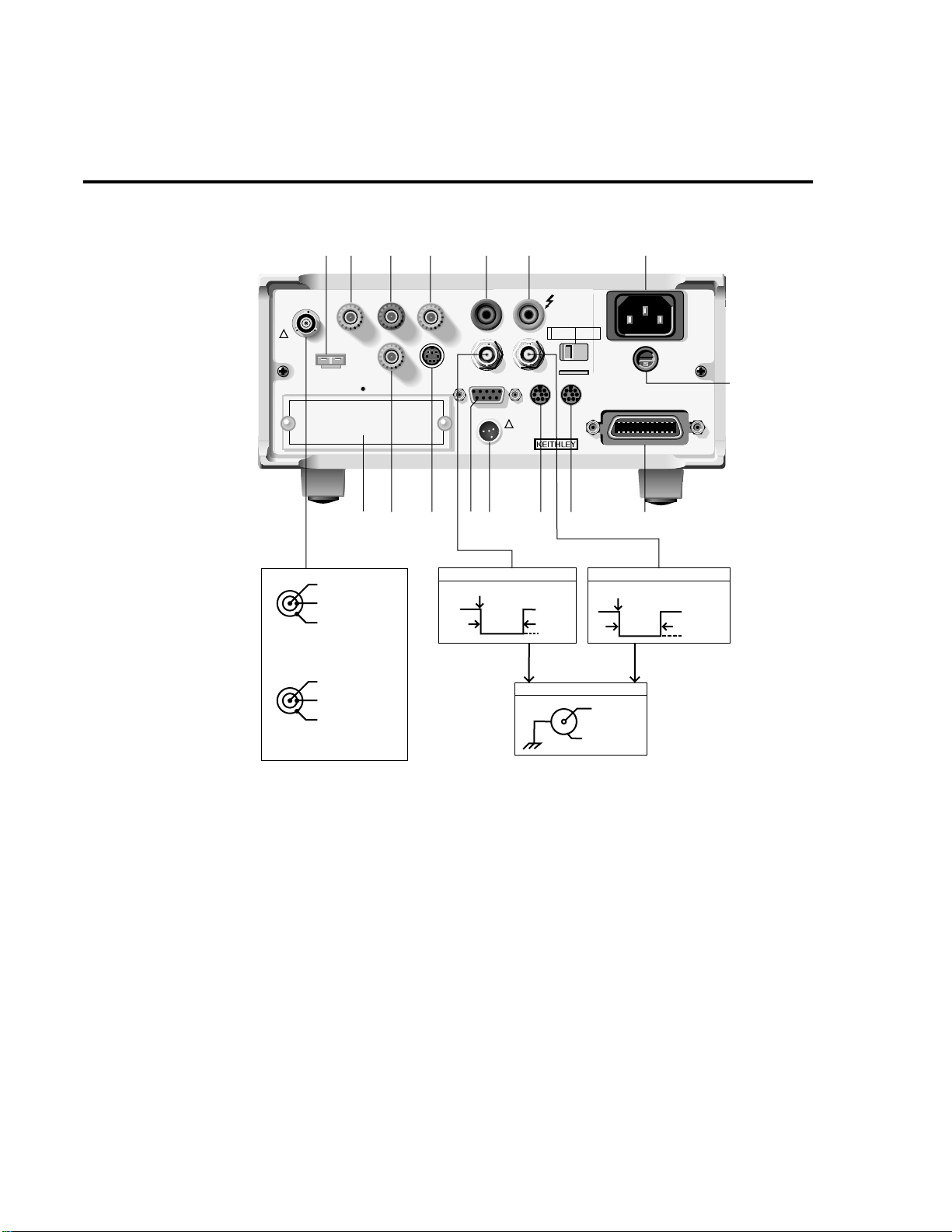

Figure 2

Model 6517A rear

panel overview

23 5 4 9 8 10

1010V

PEAK

HI

SELECTED

LINE VOLTAGE

90-110V

105-125V

OUT

DIGITAL

TRIG LINK

I/O

!

INTERLOCK

TTL HI

TTL LO

BNC CONNECTIONS

INPUT

250V PEAK

1

PREAMP OUT

TEMP

TYPE K

250 PEAK

OPTION SLOT

17

!

Input High

Input Low

Chassis Ground

Unguarded (Guard off)

Input High

Guard

Chassis Ground

Guarded (Guard on)

LO

COMMON 2V ANALOG

OUTPUT

HUMIDITY

750V

PEAK

EXT TRIGINMTR COMP

RS232

V SOURCE

6 7 15 16 14 13 12

EXTERNAL TRIGGER INPUT

Trigger Reading

>10µsec

180-220V

210-250V

115V

LINE RATING

50VA MAX

50-60HZ

AC ONLY

(CHANGE IEEE ADDRESS

WITH FRONT PANEL MENU)

IEEE-488

LINE FUSE

SLOWBLOW

1/2A 90-125V

1/4A 180-250V

METER COMPLETE OUTPUT

Reading

Complete

>10µsec

TTL HI

TTL LO

HI

LO (Chassis)

MADE

U.S.A.

IN

11

Page 15

Front Panel Operation 1-7

1 INPUT CONNECTOR (see Figure 2)

Unguarded Configuration Disable GUARD for amps, ohms, coulombs and unguarded

volts measurements.

Guarded Configuration Enable GUARD for guarded volts measurements.

2 TEMP TYPE K Connect the Model 6517-TP type K thermocouple for temperature mea-

surements.

3 PREAMP OUT Follows the signal amplitude applied to the INPUT terminal. With

GUARD on, PREAMP OUT is internally connected to the inner shell of the INPUT triax

connector to configure the input for guarded volts measurements. Referenced to COMMON. See the Model 6517A User’s Manual for more information.

4 2V OUTPUT Binding post provides a scaled 0 to 2V output that is referenced to COM-

MON. Typically connected to a measuring device such as a chart recorder. See the Model

6517A User’s Manual for more information.

5 COMMON Binding post that is internally connected to INPUT low through a 0.6Ω resis-

tor.

6 CHASSIS GROUND Binding post that connects the chassis to ground through the power

line cord. COMMON can be connected to chassis ground by installing the ground link. For

floating measurements, make sure the ground link connection between COMMON and

Chassis Ground is open.

7 HUMIDITY Connect the optional Model 6517-RH probe for relative humidity measure-

ments.

8 V-SOURCE HI and LO Banana jacks for the voltage source.

9 LINE VOLTAGE SWITCH Two-position slide switch configures instrument for avail-

able line power voltage. A 90 to 125V line voltage requires the 115V setting, while a 180 to

250V line voltage requires the 230V setting.

10 POWER LINE INPUT Connect to power line (50 or 60Hz) grounded outlet using 3-wire

power cord.

11 LINE FUSE For the 115V line voltage setting, use a ½ A, 250V, slow blow, 5×20mm

fuse. For the 230V setting, use a ¼ A, 250V, slow blow, 5×20mm fuse.

12 IEEE-488 CONNECTOR Connects the instrument to the IEEE-488 (GPIB) bus. Use

shielded IEEE-488 cables.

13 TRIG LINK An 8-pin micro DIN connector for sending and receiving trigger pulses to

and from other instruments.

14 DIGITAL I/O An 8-pin micro DIN connector for the four TTL-compatible digital output

lines.

15 RS-232 DB-9 connector for the RS-232 interface. Use a standard RS-232 cable.

16 INTERLOCK Connects the safety interlock to the Model 8009 Resistivity Test Fixture

or the Model 8002A High Resistance Test Fixture using the appropriate cable.

17 OPTION SLOT An option card, such as the Model 6521 or 6522 scanner card, installs in

this slot.

Page 16

1-8 Front Panel Operation

Display

As shown in the Model 6517A front panel ov erview (Figure 1), the front panel has three lines

of display information: the primary display line, the secondary display line, and annunciators.

• Primary Display Line: The top line displays readings along with units. It can also display

measurement type, “hold”, math operating type, channel number, menu headings and

messages. Error and status messages are listed in Section 2 of the User’s Manual.

• Secondary Display Line: The bottom line displays the range, V-Source value, menu

items, messages and multiple displays (see Measurement Options section of this manual). Longer text strings are indicated by arrows on either end of the display line. Use the

cursor keys ( and ) to display the additional information.

Power-up

WARNING

W arm-up

Before turning on the Model 6517A, make sure it is connected to a grounded

power receptacle using the supplied power cord or the equivalent. Failure

to properly ground the unit creates a shock hazard that could result in injury or death.

Use the front panel POWER switch to turn power on and off.

During power-up, the Model 6517A performs self-tests on its memory elements. If a failure

occurs, the instrument momentarily displays an error message and turns on the ERR annunciator. If the instrument passes the self-tests, the fi rmware re vision lev el, and bus interf ace information are displayed.

For complete information on the power-up sequence, see Section 2 in the User’s Manual.

The instrument is ready for use as soon as the power-up sequence is completed. However, to

achieve rated accuracy, allow the instrument to warm up for one hour. If the instrument has been

subjected to extreme temperatures, allow additional time to allow internal temperatures to stabilize.

Page 17

Bench defaults

The Model 6517A can save ten user setups in non-v olatile memory. You can select one of the

user setups as the power-on default or ha v e the instrument power up to either of the two factory

defaults (optimized for “BENCH” or “GPIB” operation).

Since the basic measurement procedures in this manual assume the BENCH defaults, reset

the instrument from the SAVESETUP item of the MAIN MENU by performing the following

steps:

1. Press the MENU key to display the main menu:

MAIN MENU

SAVESETUP COMMUNICATION CAL

2. If the SAVESETUP option is not blinking, press the key until it is blinking and then

press ENTER to view the setup menu:

SETUP MENU

SAVE RESTORE POWERON RESET

3. Select the RESET option and press ENTER to view the reset menu:

RESET ORIGINAL DFLTS

BENCH GPIB

4. Select the BENCH option and press ENTER. The following message is displayed:

RESETTING INSTRUMENT

Enter to confirm; EXIT to abort

5. Press ENTER to confirm. The display will go to the volts function with auto-range disabled and zero check enabled.

TEST LIMITS STATUS-MSG GENERAL

Front Panel Operation 1-9

Other BENCH default settings for each function include:

• Triggers — Continuous measurements.

• Measurement speed (integration time) — Normal, 1 power line cycle.

• Digital filter — Enabled, averaging, 10 readings.

• Median filter — Enabled, rank 1.

• Display resolution — 5

Note: See “Menus” in the Measurement Options section of this manual for details on navi-

gating the Main Menu.

Changing functions

T o avoid erratic operation, always enable zero check (“ZeroCheck” displayed) before selecting one of the other measurement functions (V, I, R or Q). The Z-CHK key controls zero check.

See “Zero Check” in Section 2 for more information on the zero check feature.

½ digits.

Page 18

1-10 Front Panel Operation

V oltage measurements

Assuming “BENCH” reset conditions, the basic procedure is as follows:

1. With zero check enabled (“ZeroCheck” displayed), select the v olts function by pressing

V. The Z-CHK key is used to enable/disable zero check.

2. Enable or disable guard as needed. See “Guarding” at the end of this procedure.

NOTE With guard enabled (ON), the “Grd” message is displayed. However, if zero correct

is already enabled (“ZCor” displayed), then “Grd” will not be displayed.

3. To achieve optimum accuracy for low voltage measurements, zero correct the Model

6517A. To do this, use the RANGE

and press REL. With zero correct enabled, the REL indicator is on.

▼ key to select the lowest measurement range (2V)

NOTE With zero correct enabled, the “ZCor” message is displayed. However, if guard is al-

WARNING

CAUTION

ready enabled (“Grd” displayed), then “ZCor” will not be displayed.

4. Select a measurement range or use autoranging.

A. To automatically select the most sensitive range, enable autorange. The AUTO key

enables and disables autorange. When enabled, the AUTO annunciator is on.

B. For manual ranging, use the RANGE

consistent with the expected voltage.

5. Connect the test cable(s) to the voltage to be measured. Figure 3A sho ws connections for

unguarded measurements, and Figure 3B shows connections for guarded measurements.

Hazardous voltage may be present on the inner shield of the triax cable

when GUARD is on. A safety shield connected to safety earth ground (as

shown in Figure 3B) should be used for voltage measurements at or above

30V.

Do not apply more than 250V peak (DC to 60Hz) to the input or instrument

damage may occur.

6. Press Z-CHK to disable zero check and take a reading from the display.

▲ and ▼ keys to select a measurement range

Page 19

CAUTION:FOR CONTINUED PROTECTION AGAINST FIRE HAZARD

CAUTION:FOR CONTINUED PROTECTION AGAINST FIRE HAZARD

WARNING:NO INTERNAL OPERATOR SERVICABLE PARTS

WARNING:NO INTERNAL OPERATOR SERVICABLE PARTS

CAUTION:FOR CONTINUED PROTECTION AG

CAUTION:FOR CONTINUED PROTECTION AG

WARNING:NO INTERNAL OPERATOR

WARNING:NO INTERNAL OPERATOR

Front Panel Operation 1-11

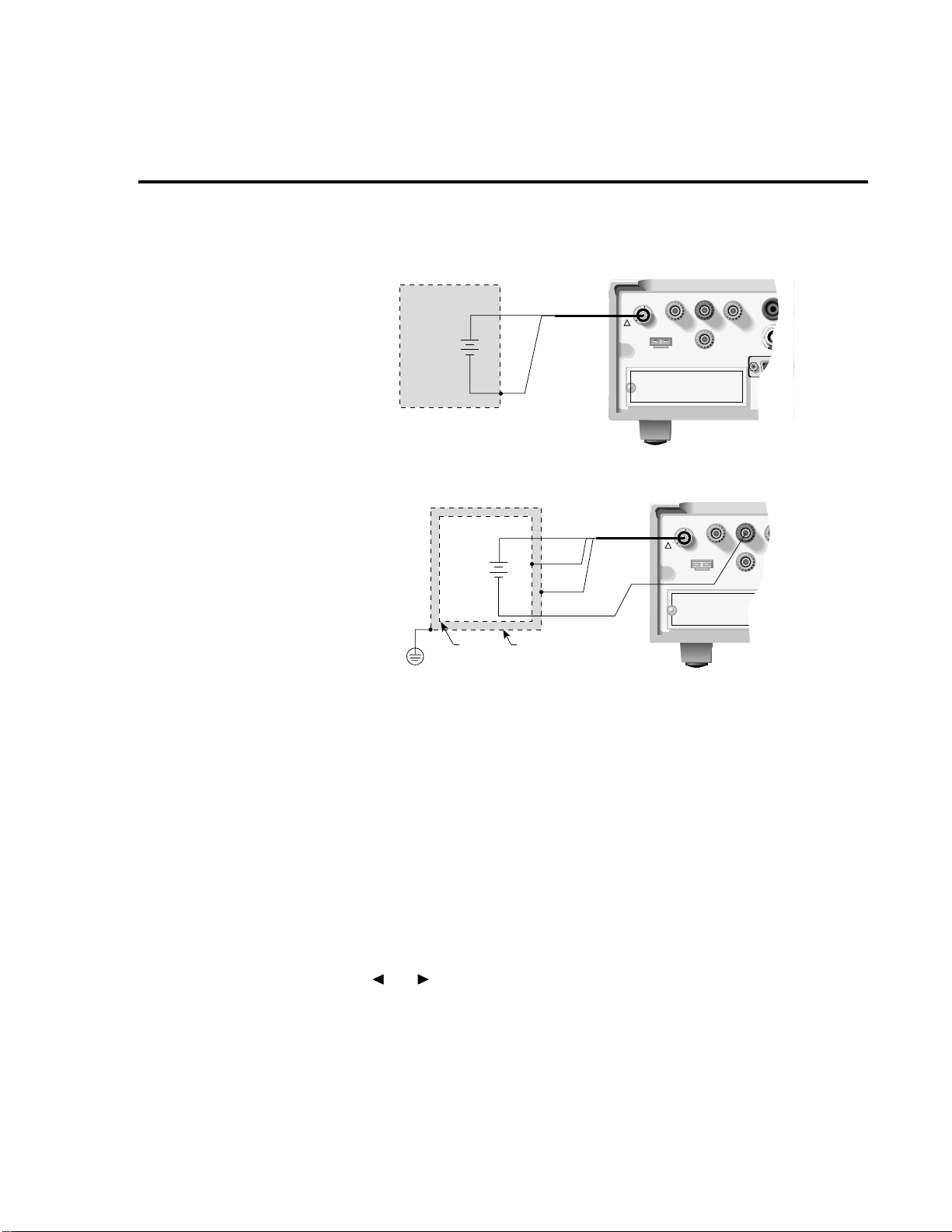

Figure 3

Voltage measurements

A. Unguarded (GUARD off)

B. Guarded (GUARD on)

Measured

Voltage

Shield (Optional)

Safety

Earth

Ground

Measured

Voltage

Guard

6517

237-ALG-2

Red (HI)

Black

Green

LO

Safety Shield

Cable

!

237-ALG-2

Cable

INPUT

250V PEAK

6517

!

250V PEAK

INPUT

COMMON

COMMON

Red (HI)

+

Vs

-

Black (LO)

+

Vs

-

Guarding

measurements that use long input cables. In a high impedance circuit, guarding greatly reduces

leakage currents. When using long input cables, guarding cancels the effects of cable capacitance that can significantly slow down the measurement response time.

tential to the inner shell of the INPUT triax connector. With this configuration, the COMMON

banana jack is used for input low . Figure 3 sho ws both the guarded and unguarded configuration

of the INPUT connector.

Guarding should be used for high impedance ( ≥ 10

9

Ω ) voltage measurements and for voltage

When GUARD is enabled, the INPUT triax connector is reconfigured to apply the guard po-

Perform the following steps to enable or disable guard:

1. Press CONFIG and then V to display the volts configuration menu.

2. Use the and keys to place the cursor (blinking menu item) on GUARD and press

ENTER.

3. Place the cursor on the desired selection (OFF to disable or ON to enable) and press ENTER.

4. Use the EXIT key to back out of the menu.

Page 20

CAUTION:

FOR CONTIN

CAUTION:

FOR CONTIN

WARNING:

NO IN

WARNING:

NO IN

1-12 Front Panel Operation

Current measurements

Assuming “BENCH” reset conditions, the basic procedure is as follows:

1. With zero check enabled (“ZeroCheck” displayed), select the amps function by pressing

I. The Z-CHK key is used to enable/disable zero check.

2. To achieve optimum accuracy for low current measurements, zero correct the Model

6517A. To do this, use the RANGE

(20pA) and press REL. W ith zero correct enabled, the REL indicator is on, and the message “ZCor” is displayed.

3. Select a measurement range or use autoranging:

A. To automatically select the most sensitive range, enable autorange. The AUTO key

enables and disables autorange. When enabled, the AUTO annunciator is on.

B. For manual ranging, use the RANGE

consistent with the expected current.

4. Connect the instrument to the current to be measured as shown in Figure 4.

▼ key to select the lowest measurement range

▲ and ▼ keys to select a measurement range

CAUTION

5. Press Z-CHK to disable zero check and take a reading from the display.

NOTE To disable zero correct, enable zero check and then press REL.

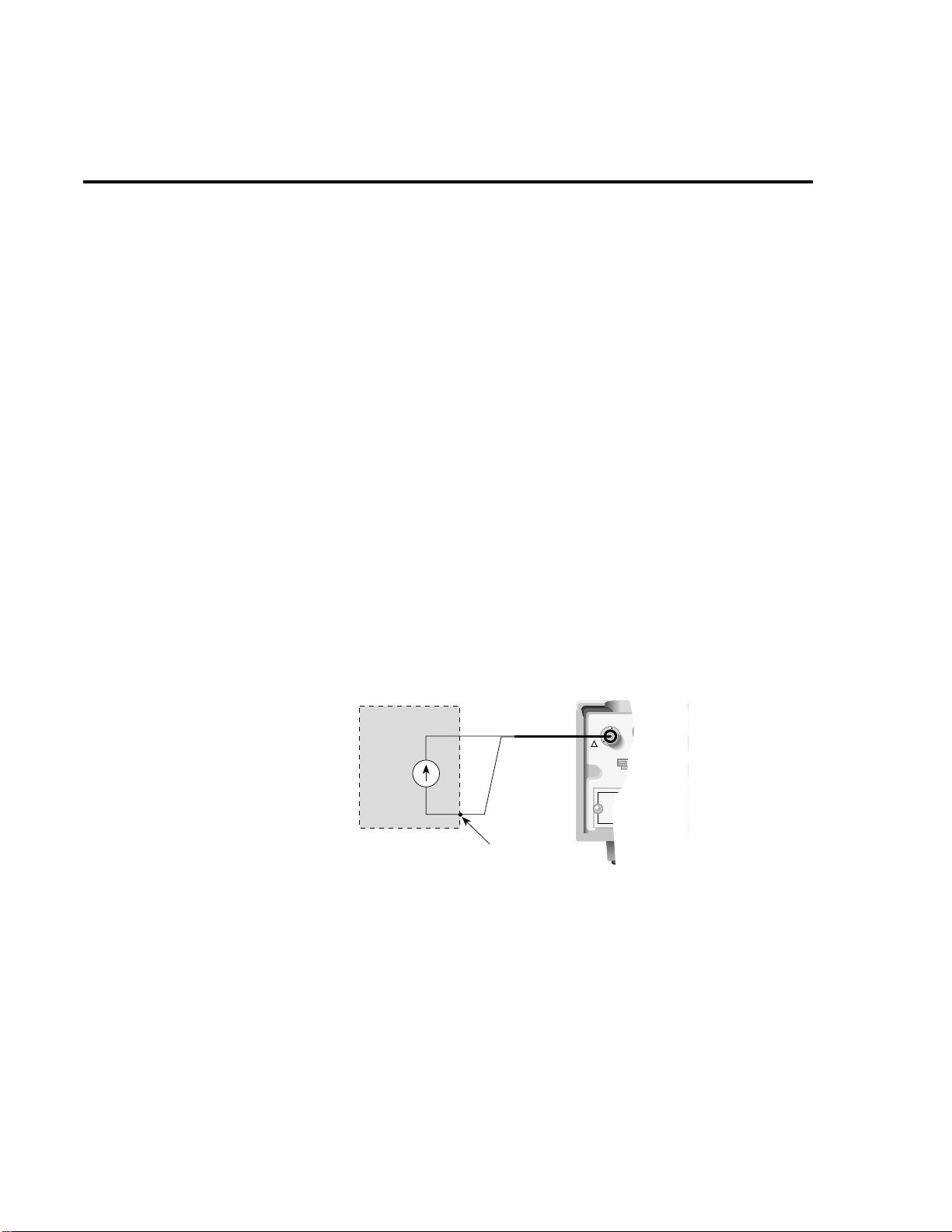

Figure 4

Current measurements

Do not apply more than 250V peak (DC to 60Hz; 10 seconds per minute

maximum on mA ranges), or instrument damage may occur.

6517

237-ALG-2

Black (LO)

Cable

!

INPUT

250V PEAK

COMMON

Measured

Current

Shield (Recommended

below 1µA)

CAUTION: Maximum Input = 250V peak (DC to

60Hz) ; 10s per minute maximum on

mA ranges.

I

Red (HI)

s

Input low connected

to shield

Page 21

Resistance measurements

NOTE Accurate high resistance measurements require the use of a low-leakage test fixture,

such as the Model 8002A.

The following procedure requires “BENCH” reset conditions. See “Bench defaults” to reset

the instrument.

1. With zero check enabled (“ZeroCheck” displayed), select the ohms function by pressing

R.

2. Select Auto V-Source ohms. In this mode, the V-Source is automatically set to a voltage

(nominally 40V or 400V) that optimizes measurement accuracy . See “ Auto V-Source” to

select Auto V -Source ohms.

Front Panel Operation 1-13

NOTE “BENCH” reset conditions selects Manual V-Source ohms. In this mode, you must

manually set the V -Source le vel for the measurement. See “Voltage Source” in Section

2 for details on using the V-Source.

WARNING Selecting Auto V-Source ohms may set the V-Source to 400V.

3. Select a measurement range or use autoranging:

A. To automatically select the most sensitive range, enable autorange. The AUTO key

enables and disables autorange. When enabled, the AUTO annunciator is on.

B. For manual ranging, use the RANGE ▲ and ▼ keys to select a measurement range

consistent with the expected resistance.

4. Connect the Model 6517A to the test fixture. Generic connections are shown in Figure

5A. Note that this connection scheme requires that ammeter LO be internally connected

to V-Source LO. See “Configuring V-Source” in Section 2 to control this internal LO-toLO connection. If using the Model 8002A test fixture, refer to Figure 5B.

NOTE For optimum accuracy, leakage currents in the test fixture can be cancelled by per-

forming REL on the current component of the measurement. To cancel leakage current, perform the procedure in “Amps Rel”.

5. Disable zero check by pressing Z-CHK and press OPER to source voltage to the test fixture DUT.

6. Take a reading from the display.

7. Place the V-Source in standby when finished by again pressing OPER.

WARNING Place the V -Source in standby before making or breaking connections to the

test fixture or DUT.

Page 22

CAUTION:FOR CONTINUED PROTECTION AGAINST FIRE HAZARD,REPLACE FUSE

CAUTION:FOR CONTINUED PROTECTION AGAINST FIRE HAZARD,REPLACE FUSE

WARNING:NO INTERNAL OPERATOR SERVICABLE PARTS,SERVICE BY QU

WARNING:NO INTERNAL OPERATOR SERVICABLE PARTS,SERVICE BY QU

CAUTION:

FOR CONTINUED PROTECTION AGAINST FIRE HAZARD,REPLACE FUSE WITH SAME TY

CAUTION:

FOR CONTINUED PROTECTION AGAINST FIRE HAZARD,REPLACE FUSE WITH SAME TY

WARNING:

NO INTERNAL OPERATOR SERVICABLE PARTS,SERVICE BY QUALIFIED PERSO

WARNING:

NO INTERNAL OPERATOR SERVICABLE PARTS,SERVICE BY QUALIFIED PERSO

1-14 Front Panel Operation

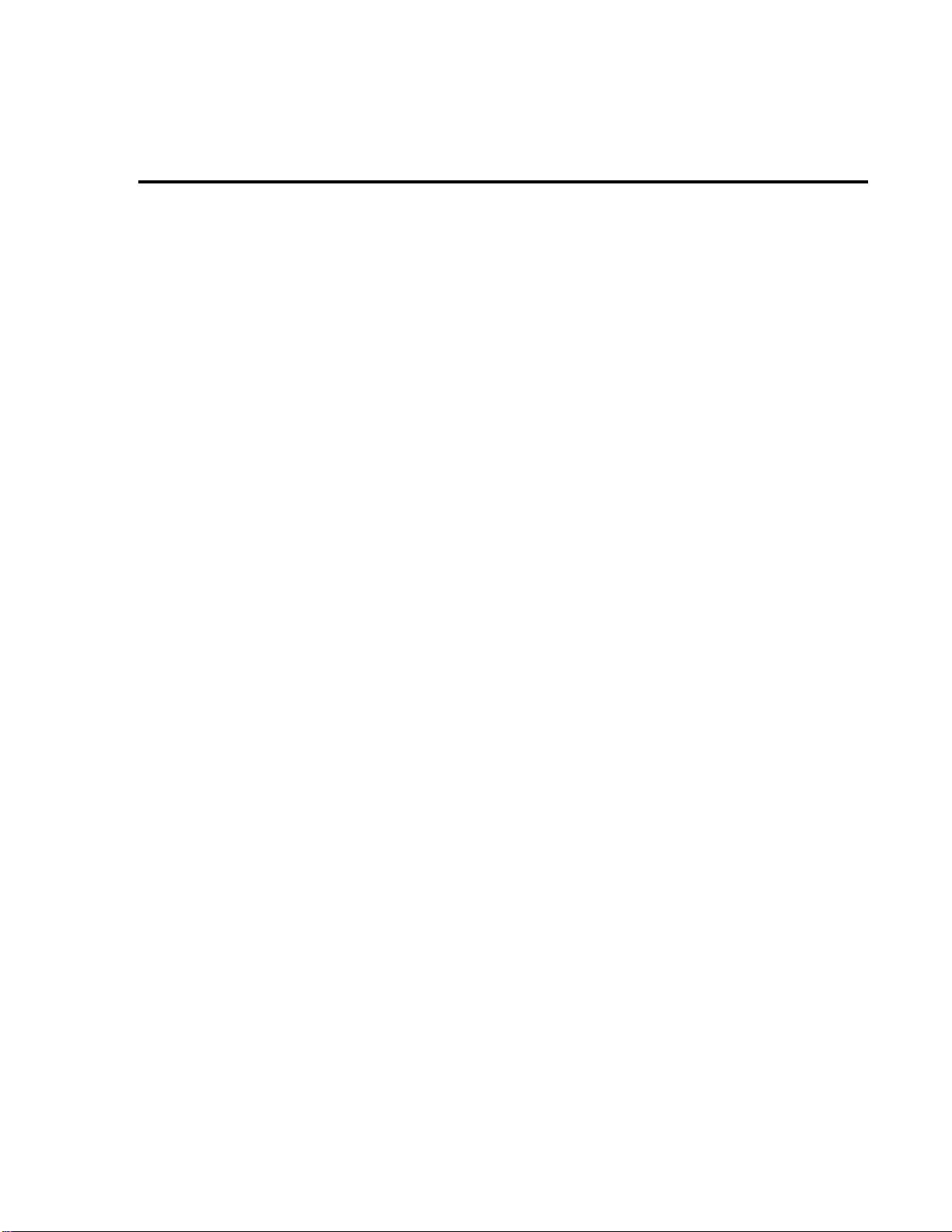

Figure 5

Resistance measurements

A. Generic connections

B. Connections using 8002A

test fixture

Red

Measured

Resistance

R

X

Black

LO connected

to shield

Shield

8002A HIGH RESISTANCE TEST FIXTURE

7078-TRX-3 Triax Cable

Note: Set fixture mode switch

to picoammeter operation.

Warning: Connect of fixture

to safety earth ground using

safety ground wire (supplied

with 8002A test fixture).

6517

237-ALG-2

Cable

!

INPUT

250V PEAK

Note: V-Source low internally

connected to electrometer

low.

8002-ILC-3 Interlock Cable

!

250V PEAK

8607 Banana Plug Cables

LO HI

COMMON

PREAMP OUT

250V PEAK

COMMON

PREAMP OUT

250V PEAK

INPUT

V SOURCE

LO HI

V SOURCE

!

INTERLOCK

IN

TRIGG

LINK

OUT

Model 6517

Auto V -Source

Auto V-Source should be used to achieve optimum accuracy for ohms measurements. With

Auto V-Source selected, the V-Source is automatically set for either 40V or 400V. For the 2MΩ

through 200GΩ ranges, the V-Source is set to 40V. For the 2TΩ through 200TΩ ranges, a 400V

test voltage is used. With Manual V-Source selected, you can manually set the voltage level of

the V -Source.

Perform the following steps to select the V-Source mode for the ohms function:

1. Press CONFIG and then R to display the ohms configuration menu.

2. Use the and keys to place the cursor (blinking menu item) on VSOURCE and

press ENTER.

3. Place the cursor on AUTO (Auto V-Source ohms) or on MANUAL (Manual V-Source

ohms), and press ENTER.

4. Use the EXIT key to back out of the menu.

Page 23

Amps Rel

the following steps:

NOTE This procedure assumes that steps 1 through 4 of the Resistance Measurement proce-

Front Panel Operation 1-15

Amps Rel is used to cancel leakage current in a test fixture for ohms measurements. Perform

dure have been performed.

1. With the V-Source in standby, remove the DUT from the test fixture.

2. Select the amps (I) function and disable zero check. Make sure REL is disabled.

3. Place the V-Source in operate by pressing OPER. The VOLTAGE SOURCE OPERATE

indicator is on when in operate.

4. Select the lowest possible measurement range to display the leakage current in the test

fixture.

5. Enable relative (REL annunciator on) by pressing REL. This zeroes the display, cancelling the leakage current reading.

6. Press OPER to place the V-Source in standby and enable zero check.

7. Perform the following steps to establish the amps Rel value for the ohms function.

A. Press CONFIG and then R to display the ohms configuration menu.

B. Use the and keys, place the cursor (blinking menu item) on AMPSREL and

press ENTER.

C. Place the cursor on YES and press ENTER to use the amps Rel value for the ohms

measurement.

D. Use the EXIT key to back out of the menu.

8. Re-install the DUT in the test fixture.

9. Select the ohms function (R) and proceed to step 5 of the Resistance Measurement procedure.

Page 24

1-16 Front Panel Operation

Resistivity measurements

NOTE The following procedur e to measur e resistivity (surface or volume) r equir es the use of

the Keithley Model 8009 Resistivity Test Fixtur e. Refer to the Model 8009 Instruction

Manual for details on using the test fixture.

The following procedure requires “BENCH” reset conditions. See “Bench defaults” to reset

the instrument.

1. With zero check enabled (“ZeroCheck” displayed), select the ohms function by pressing

R.

2. Select Auto V-Source ohms. In this mode, the V-Source is automatically set to a voltage

(nominally 40V or 400V) that optimizes measurement accuracy. See “Auto V-Source”

located under “Resistance Measurements” to select Auto V-Source ohms.

NOTE “BENCH” reset conditions selects Manual V-Source ohms. In this mode, you must

manually set the V -Source le vel for the measurement. See “Voltage Source” for details

on using the V-Source.

WARNING Selecting Auto V-Source ohms may set the V-Source to 400V.

3. Select a measurement range or use autoranging:

A. To automatically select the most sensitive range, enable autorange. The AUTO key

enables and disables autorange. When enabled, the AUTO annunciator is on.

B. For manual ranging, use the RANGE ▲ and ▼ keys to select a measurement range

consistent with the expected resistance.

4. Connect the Model 6517A to the Model 8009 test fixture as shown in Figure 6, and set

the switch on the test fixture to the desired measurement type (Surface or Volume).

5. Select the resistivity measurement mode as follows:

A. Press the CONFIG and then R to display the ohms configuration menu.

B. Use the and keys to place the cursor (blinking menu item) on MEAS-TYPE

and press ENTER.

C. Place the cursor on RESISTIVITY and press ENTER.

NOTE The Model 6517A senses the switch position (surface or volume) on the Model 8009

through the interloc k cable, and automatically configur es the instrument for that measurement type.

Page 25

CAUTION:FOR CONTINUED PROTECTION AGAINST FIRE HAZARD,REPLACE FUSE WITH SAME TYPE AND RATING.

CAUTION:FOR CONTINUED PROTECTION AGAINST FIRE HAZARD,REPLACE FUSE WITH SAME TYPE AND RATING.

WARNING:NO INTERNAL OPERATOR SERVICABLE PARTS,SERVICE BY QUALIFIED PERSONNEL ONLY.

WARNING:NO INTERNAL OPERATOR SERVICABLE PARTS,SERVICE BY QUALIFIED PERSONNEL ONLY.

Front Panel Operation 1-17

D. Cursor position (SURFACE or V OLUME menu item blinking) indicates the select-

ed measurement type:

• SURFACE — If Surf ace is the selected measurement type, you do not have to

proceed any further into the menu structure. Use the EXIT key to e xit from the

menu.

• VOLUME — If Volume is the selected measurement type, proceed as follows

to specify the thickness of the sample:

a. With the cursor on VOLUME, press ENTER to display the parameters menu

for volume.

b. Place the cursor on THICKNESS and press ENTER. The present thickness pa-

rameter for the sample will be displayed.

c. Use the cursor keys ( and ) and the RANGE ▲ and ▼ keys to specify

the thickness (in millimeters) of the sample, and then press ENTER.

d. Use the EXIT key to back out of the menu structure.

6. Disable zero check by pressing Z-CHK.

7. Press OPER to source voltage to the DUT and, after an appropriate electrification time,

take a reading from the display. Typically, an electrification time of 60 seconds is used.

8. Place the V-Source in standby when finished by again pressing OPER.

WARNING Place the V -Source in standby before making or breaking connections to the

test fixture or DUT.

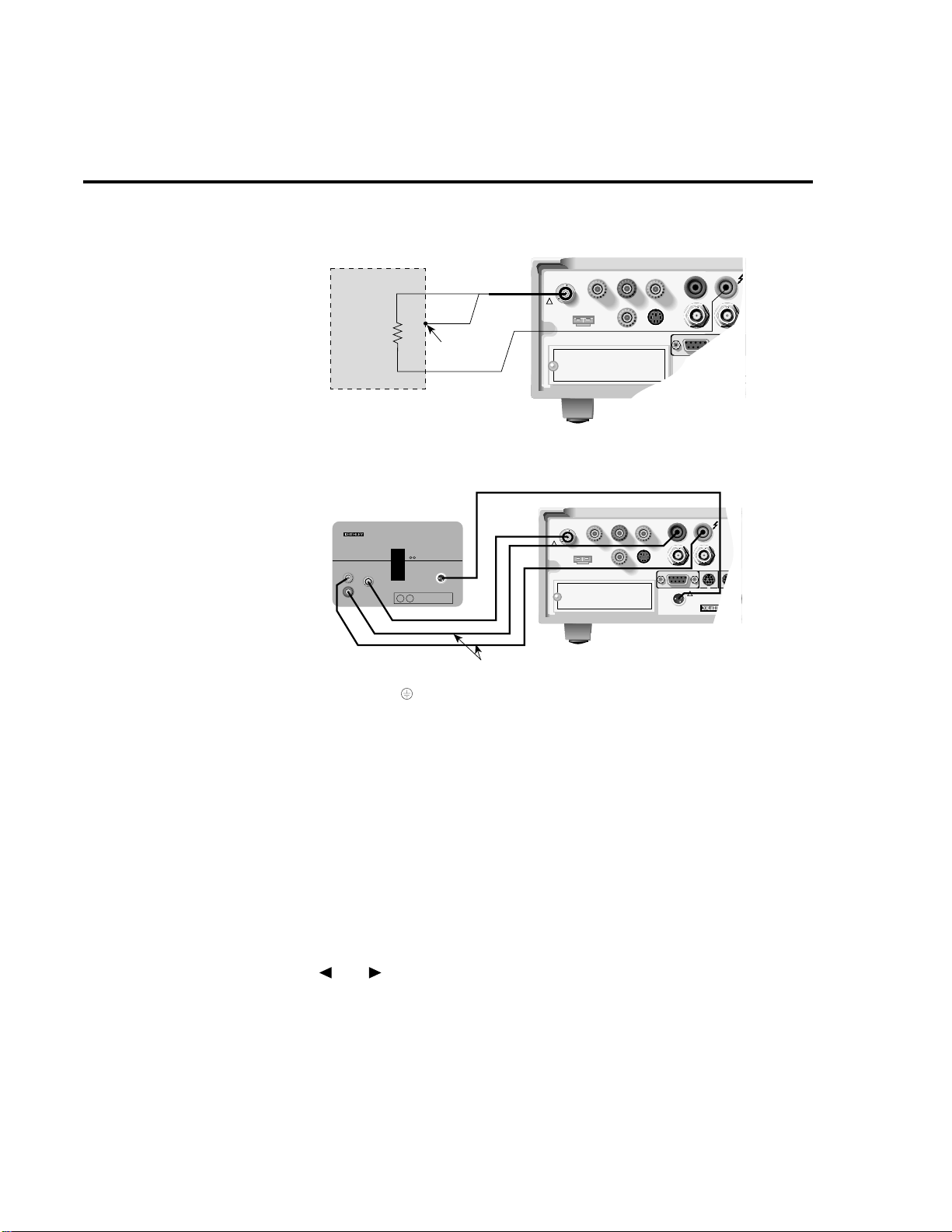

Figure 6

Resistivity measurements

MAX INPUT

LID

INTERLOCK

1100V

METER SOURCE

TRIAX

250 MAX

HI-LO

8607 Banana Plug Cable

8607 Banana Plug Cable

7078-TRX-3 Triax Cable

PREAMP OUT

!

250V PEAK

INPUT

250V PEAK

!

Warning: Connect of fixture

to safety earth ground using

safety ground wire.

6517-ILC-3 Interlock Cable

LO HI

COMMON

V SOURCE

INTERLOCK

!

OUT

LINE RATING

90-134VAC

180-250VAC

50, 60, 400HZ

55VA MAX

(CHANGE IEEE ADDRESS

WITH FRONT PANEL MENU)

IEEE-488

LINE FUSE

SLOWBLOW

1/2A, 250V

Page 26

CAUTION:FOR CONTINUED PROTECTION AGAINST FIRE HAZARD,R

CAUTION:FOR CONTINUED PROTECTION AGAINST FIRE HAZARD,R

WARNING:NO INTERNAL OPERATOR SERVICABLE PARTS,S

WARNING:NO INTERNAL OPERATOR SERVICABLE PARTS,S

1-18 Front Panel Operation

Charge measurements

Assuming “BENCH” reset conditions, the basic procedure is as follows:

1. With zero check enabled (“ZeroCheck” displayed), select the coulombs function by

pressing Q.

2. Select a measurement range or use autoranging:

A. To automatically select the most sensitive range, enable autorange. The AUTO key

enables and disables autorange. When enabled, the AUTO annunciator is on.

B. For manual ranging, use the RANGE ▲ and ▼ keys to select a measurement range

consistent with the expected charge reading.

3. Connect the test cable (see Figure 7) to the input of the Model 6517A and, with the input

open, disable zero check. If needed, press REL to zero the display.

4. Connect the instrument to the charge to be measured as shown in Figure 7.

CAUTION Do not apply more than 250V peak (DC to 60Hz) or instrument damage

may occur.

5. Take a reading from the display.

NOTE The reading can be r eset to zero by enabling zero check. If you wish to have the r ead-

ing reset to zero when a specified charge level is reached, enable Auto Discharge as

explained in the following paragraph.

Figure 7

Charge measurements

Measured

Charge

Shield (Optional)

Red (HI)

Q

s

237-ALG-2

Cable

Black (LO)

Input low connected

to shield

6517

!

INPUT

250V PEAK

COMMON

Page 27

Auto discharge

When enabled, Auto Dischar ge is used to automatically reset the charge reading to zero when

the specified charge level is reached. After the inte grator resets, the charge measurement process

simply restarts at zero. Perform the following steps to enable or disable Auto Discharge.

1. Press the CONFIG and then Q to display the coulombs configuration menu.

2. Use the and keys to place the cursor (blinking menu item) on AUTO-DISCHARGE and press ENTER.

3. Perform step A to enable Auto Discharge or perform step B to disable it:

A. Enable Auto Dischar ge — Place the cursor on ON nad press ENTER to display the

B. Disable Auto Discharge — Place the cursor on OFF and press ENTER.

4. Use the EXIT key to exit from the menu.

Front Panel Operation 1-19

present discharge level. Use the and keys, and the RANGE ▲ and ▼ keys

to set a different discharge level and press ENTER.

Page 28

CAUTION:

FOR CONTINUED PROTECTION AGAINST FIRE HAZARD,REPLACE FUSE WITH SAME TYPE AND RATING.

CAUTION:

FOR CONTINUED PROTECTION AGAINST FIRE HAZARD,REPLACE FUSE WITH SAME TYPE AND RATING.

WARNING:

NO INTERNAL OPERATOR SERVICABLE PARTS,SERVICE BY QUALIFIED PERSONNEL ONLY.

WARNING:

NO INTERNAL OPERATOR SERVICABLE PARTS,SERVICE BY QUALIFIED PERSONNEL ONLY.

1-20 Front Panel Operation

External temperature and

relative humidity measurements

The Model 6517A can make external temperature measurements from -25°C to 150°C using

the Model 6517-TP type K thermocouple (which is a supplied accessory).

The Model 6517A can make relative humidity measurements (0 to 100%) using the Model

6517-RH humidity probe (which is available as an option).

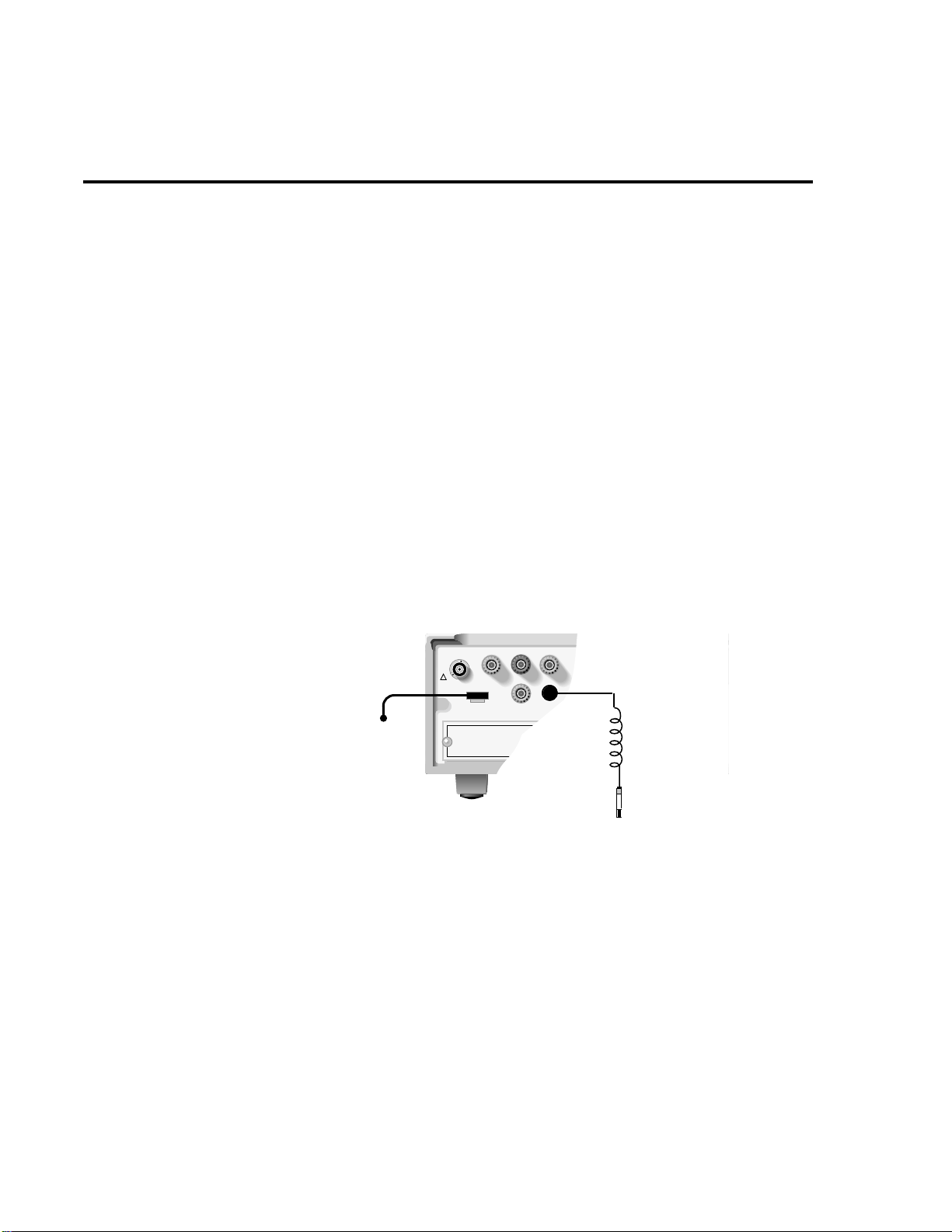

Connections

The Models 6517-TP (thermocouple) and 6517-RH (humidity probe) connect to the rear pan-

el connectors labeled “TEMP TYPE K” and “HUMIDITY” as shown in Figure 8.

NOTE It is recommended that the thermocouple junction of the Model 6517-TP be electri-

cally insulated from ground and voltage potentials. Erroneous reading will result if

the thermocouple comes in contact with ground or a voltage potential.

Figure 8

External temperature and

humidity

Model 6517-TP

Thermocouple

!

6517

INPUT

250V PEAK

PREAMP OUT

250V PEAK

COMMON

LO

V SOURCE

Extension Cable (P/N CA-129-1)

LINE RATING

90-134VAC

180-250VAC

50, 60, 400HZ

55VA MAX

Model 6517-RH

Humidity Probe

Page 29

Measurement control

BENCH reset disables temperature and humidity measurements. These measurements can be

enabled from the front panel as follows:

1. Press MENU to display the main menu.

2. Use the and keys to place the cursor (blinking menu item) on GENERAL and

press ENTER to display the menu items of the general menu.

3. Place the cursor on A/D-CONTROLS and press ENTER to display the A/D controls

menu.

4. Place the cursor on DAT A-STAMP and press ENTER. The present control state for temperature and humidity will be displayed. OFF indicates that the measurement is disabled,

while ON indicates that the measurement is enabled.

5. To change the control state for temperature and/or humidity, place the cursor on the appropriate menu item and use the RANGE ▲ and ▼ keys to toggle the control state. W ith

the desired states for temperature and humidity displayed (ON or OFF), press ENTER.

6. Use the EXIT key to back out of the menu.

T emperature units

All temperature readings by the Model 6517A can be displayed in °C, °F or K. BENCH reset

selects °C measurement units. Perform the following steps to change units:

Front Panel Operation 1-21

1. Press MENU to display the main menu.

2. Use the and keys to place the cursor (blinking menu item) on GENERAL and

press ENTER to display the menu items of the general menu.

3. Place the cursor on DISPLAY and press ENTER to display the SET READING DISPLAY menu.

4. Place the cursor on TEMP-UNITS and press ENTER. The blinking cursor indicates the

present temperature units selection.

5. T o change temperature units, place the cursor on the desired selection (°C, K or °F) and

press ENTER.

6. Use the EXIT key to back out of the menu.

Display reading options

T emperature and humidity readings are available as multiple (NEXT) displays. Using multiple displays, temperature and humidity readings can accompany each normal A/D measurement,

and they can be included as data storage elements for each reading stored in he buf fer . See “Multiple Displays” in Section 2 of this manual.

External temperature and humidity are selected as data store elements from the data store

configuration menu. See “Buffer (Data Store)” in Section 2.

Page 30

1-22 Front Panel Operation

Page 31

2

Measurement

Options

Page 32

2-2 Measurement Options

This section describes the details of making measurements. Configuration options, triggers,

reading storage, and scanning are just a few of the topics discussed. You will find this information useful whether operating the Model 6517A from the front panel or IEEE-488 bus.

Multiple displays

Each measurement function and some operations provide “multiple displays” by using the

bottom line of the front panel. These multiple displays provide multiple type measurements,

show a reading in a different form, or give additional information about the reading.

Multiple displays are summarized in this section. All the multiple displays are shown in T able 1.

The NEXT and PREV (previous) DISPLAY keys scroll through the multiple displays for the

selected function or operation. The multiple display mode can be cancelled by pressing and

holding in either key.

Page 33

Measurement Options 2-3

Table 1

Multiple displays by function

Function Next display

All

Ohms (R)

Buffer

Time, day and date

Bar graph

Zero-centered bar graph

Maximum and minimum values

Relative and actual values

Calculated and actual values

Limits bar graph

Relative humidity and external temperature

Source (V) and measure (I) values.

Relative humidity and external temperature, V-

Source value, maximum reading, minimum reading, average reading, standard deviation, and

print buffer data.

Page 34

2-4 Measurement Options

FILT 4W ARM

6517 ELECTROMETER/HIGH RESISTANCE METER

FILT 4W ARM

6517 ELECTROMETER/HIGH RESISTANCE METER

FILT 4W ARM

6517 ELECTROMETER/HIGH RESISTANCE METER

FILT 4W ARM

6517 ELECTROMETER/HIGH RESISTANCE METER

Time, Day and Date — This display provides the

time, day of week, and the date. The time, date and format (12-hour or 24-hour) are set from the CLOCK option of the GENERAL MENU (see main Menu).

Bar Graph — The bar graph is a graphical represen-

tation of the reading with zero at the left end. Each full

segment of the bar represents approximately 4% of the

range limit.

Zero-centered Bar Graph — The zero-centered bar

graph is a graphical representation of the reading using

plus/minus limits with zero in the center . Each full segment represents 10% of the limit.

Maximum and Minimum — This display shows

the maximum and minimum readings that have occurred since the display was entered. Maximum and

minimum values are reset by pressing the present function key or by leaving the display.

FILT ARMREL

6517 ELECTROMETER/HIGH RESISTANCE METER

6517 ELECTROMETER/HIGH RESISTANCE METER

Relative and Actual — This display is used with

the rel (relative) feature. While the top line shows the

result of the rel operation, the bottom line shows the actual (raw) reading.

Calculated and Actual — This display is used with

a math calculation. While the top line provides the result of the math calculation, the bottom line provides

the raw reading.

Page 35

Measurement Options 2-5

FILT 4W ARM

6517 ELECTROMETER/HIGH RESISTANCE METER

FILT 4W ARM

6517 ELECTROMETER/HIGH RESISTANCE METER

FILT 4W ARM

6517 ELECTROMETER/HIGH RESISTANCE METER

Limits — This display provides the result of the lim-

it test. The graphical representation of the reading is

shown on a zero-centered bar graph. If the reading is

between the specified high and low limits, the PASS

message is displayed. If the reading is outside of the

limits, the FAIL message is displayed. Limits are set

and enabled from the LIMITS option of the Main

Menu.

Relative humidity and external temperature —

This display is used to display the relative humidity and

external temperature readings. Note that the appropriate option has to be connected and enabled as explained

in Section 1 of this manual.

Measure/source — This display is used to display

the measured current and the V-Source level for ohms

measurements.

FILT 4W ARM

6517 ELECTROMETER/HIGH RESISTANCE METER

FILT 4W ARM

6517 ELECTROMETER/HIGH RESISTANCE METER

Buffer — When in RECALL, there are seven dis-

plays for buffer readings:

Relative humidity (RH) and external temperature

(ET).

V-Source value.

Maximum reading (shown at left).

Minimum reading.

Average reading (shown at left).

Standard deviation.

Print buffer data.

Page 36

2-6 Measurement Options

Menus

There are two basic menu structures used by the Model 6517A: the main menu and the CONFIGure menus. The main menu accesses items for which there are no dedicated ke ys; the CONFIGure menus configure measurement functions and other instrument operations.

T able 2 summarizes main menu selections. Tables 3 and 4 show configuration settings for the

measurement functions and instrument operations.

Table 2

Summary of main menu

Option Description

SAVESETUP

COMMUNICATION

CAL

TEST

LIMITS

STATUS-MSG

GENERAL

Save and restore setups stored in memory, set power-on

defaults, and return unit to default conditions.

Select and configure interface (GPIB or RS-232).

Calibrate the Model 6517A (see Calibration Manual),

perform offset adjustments and check calibration date.

Perform self-tests (see Repair Manual).

Configure unit to perform limit tests.

Enable/disable status message mode.

Control output lines of digital output port, check serial

number of unit and firmware revision le v els, control linesync, limit control and data stamp, configure timestamp,

set reading display and set real-time clock.

Page 37

Table 3

Configuration settings for each measurement function

Reso-

Function Speed Filter

lution

Autorange

limits Damping Guard

External

feedback

Measurement Options 2-7

Amps

Meas

rel

type*V-Source**

Auto

discharge

Volts

Amps

Ohms

Coulombs

•

•

•

•

•

•

•

•

*Resistance or resistivity.

**Auto or manual.

•

•

•

•

•

•

•

•

•

•

••

•• •

•

Table 4

Configuration settings for instrument operations

Option Description

CONFIG REL

CONFIG FILTER

CONFIG MATH

Set rel (relative) value and enable.

Select and configure averaging and median filters.

Select and configure math calculation: polynomial, percent,

percent deviation, ratio or log10.

CONFIG TRIG

CONFIG SEQ

CONFIG STORE

Select and configure basic or advanced trigger model.

Select and configure test sequence.

Configure data store: set count, control, timestamp, elements

and display, and clear buffer.

CONFIG VOLTA GE SOURCE*

Configure V-Source: range, V-limit, resistive I-limit and meter

connect.

CONFIG CARD

CONFIG NEXT

*To access the V-Source menu, press CONFIG and then any one of the VOLTAGE SOURCE keys: OPER, ▲ or ▼ .

Select and configure internal or external scanning.

Change the scale for the zero-center bar graph.

Page 38

2-8 Measurement Options

Navigating menus

Use the following rules to navigate through the menu structures. T able 5 summarizes the front

panel keys used for navigation.

1. From the instrument’s normal state of displaying readings, you can:

• View a configuration menu by pressing CONFIG and then the desired function or operation key (V, TRIG, etc.).

• View the top level of the main menu by pressing the MENU key.

2. The unit is returned to the normal reading display by:

• Pressing EXIT or MENU from the top level of the main menu.

• Pressing EXIT from the top level of a configuration menu.

• Pressing a measurement function key from within a menu.

3. Pressing the ENTER key selects an item and, if further definition is needed, mo ves down

within the menu structure. Pressing the EXIT key backs up within a menu structure.

4. The cursor position is denoted by a blinking menu item or parameter. The cursor is

moved from one item to the next using the cursor k e ys ( and ). To select an item,

highlight it with the cursor, then press ENTER.

5. A displayed arrow ( and ) on the bottom line indicates there is more information

or additional menu items to select from. When “ ” is displayed, use the cursor

key. The cursor keys have an auto-repeat feature.

6. A numeric parameter is keyed in by placing the cursor on the digit to be changed, and

pressing the RANGE

7. A change is only executed when the ENTER key is pressed. Entering an invalid parameter generates an error, and the entry is ignored. Changes are also ignored if an EXIT is

performed.

8. The INFO key can be used anywhere in a menu to display helpful information messages

concerning operation. To cancel an information message and remain in the menu, press

INFO a second time, EXIT, or ENTER. Pressing a function key cancels INFO and a

menu, and returns the instrument to a reading display.

▲ or ▼ keys to increment or decrement the digit.

Page 39

Table 5

Menu summary

Action Description

Measurement Options 2-9

CONFIG-(function)

MENU

or

RANGE

RANGE ▼

ENTER

EXIT

INFO

▲

Press the CONFIG key, then a function key (e.g., V) to

view the top level of a function configuration menu.

Press the MENU key to view the top level of the main

menu. The operations that have no corresponding key are

included in the main menu.

Use the cursor keys to move the highlighted cursor among

menu selections, or the digits of a parameter value, or

change channels on the scanner.

Use the RANGE keys to increment and decrement digits of

a parameter value.

Accepts menu selection or data entry.

Cancels changes menu selection. Also returns you to the

previous menu level.

Displays context-sensitive information about the present

menu level. Toggles information message on/off.

Page 40

2-10 Measurement Options

V oltage source

The built-in, bipolar, 1W v oltage source can output up to ±1000V. W ith the instrument in the

normal measurement mode, the programmed V-Source level is shown on the bottom line of the

display.

Connections

WARNING To prevent electric shock that could cause injury or death, NEVER make

or break connections to the instrument (or test circuit) while the V-Source

is in operate (VOLTAGE SOURCE OPERATE indicator on). The OPER

key toggles the V-Source between standby and operate.

Figure 9

Independent

V-Source connections

If used as an independent source, voltage is av ailable at the V-SOURCE HI and LO terminals

on the rear panel (see Figure 9). If used as an FVMI (force voltage measure current) source, VSource LO can be internally connected to ammeter LO from the METER CONNECT option of

the CONFIGURE V-SOURCE menu (see “Configuring V-Source”). Figure 10 shows the connections for this configuration.

LO

V-Source Out

R

L

V-Source

LO HI

HI

R

L

Page 41

Figure 10

FVMI connections

LO

Measurement Options 2-11

HI

Basic operation

Basic operation simply consists of setting the V-Source level, and placing the V-Source in operate to output the voltage. Other V-Source operations are performed from the CONFIGURE VSOURCE menu. See “Configuring V-Source” to select range (100V or 1000V), set voltage limit,

select resistance current limit and control the LO-to-LO connection between the V-Source and

the ammeter.

V-Source

R

V SOURCE

R

OUT

INPUT

250V PEAK

Note: V-SOURCE LO connected to ammeter input LO

via METER-CONNECT option of CONFIGURE

V-SOURCE Menu.

Ammeter

LO

A

HIHI

Setting V-Source level — The V-Source level is set with the instrument in the normal mea-

surement mode. The V OLTA GE SOURCE

▲ and ▼ keys, and the cursor keys ( and ) are

used to adjust the voltage lev el. Pressing any one of these four keys will enable the V-Source edit

mode. The flashing digit on the V-Source display indicates the cursor position. Use the cursor

keys to place the cursor on the desired digit, and use the VOLTAGE SOURCE

▲ and ▼ keys to

adjust the level. Polarity can be changed by placing the cursor on the polarity sign, and pressing

VOLTAGE SOURCE

▲ and ▼ .

Sourcing voltage — The displayed voltage le v el is applied to the output terminals when the

instrument is placed in operate by pressing the OPER key. In operate, the VOLTA GE SOURCE

OPERATE indicator is on. Pressing OPER a second time places the V-Source in standby.

Page 42

2-12 Measurement Options

Configuring V -Source

Perform the following steps to configure the V-Source:

1. Press the CONFIG key and one of the VOLTAGE SOURCE keys (OPER,

display the following configuration menu:

RANGE: Select the 100V range or 1000V range.

V-LIMIT: Control (on/off) and set a voltage limit (absolute value).

RESISTIVE LIMIT: Control (on/off) the resistive (1M

METER CONNECT: Control (on/of f) the internal connection between V -Source LO and

ammeter LO.

2. Use the menu items to configure the V-Source. A menu item is selected by placing the

cursor (using the and keys) on it and pressing ENTER. Options for a menu item

are selected in the same way . Parameter v alues are changed using the cursor keys and the

RANGE keys, and then pressing ENTER. See “Menus” pre viously in this section if you

need more information to navigate through the menu structure.

3. Use the EXIT key to back out of the menu structure.

Ω ) current limit.

▲ or ▼ ) to

Page 43

Relative

Measurement Options 2-13

Rel subtracts a reference value from actual readings. When rel is enabled, the instrument uses

the present reading as a relative value. Subsequent readings will be the difference between the

actual input value and the rel value.

Actual Input – Reference = Displayed Reading

The rel (relative) operation is enabled by pressing the REL k ey (REL annunciator turns on).

Pressing REL a second time disables rel. You can also enter and enable a rel value from the

CONFIG-REL display.

A rel value can be established for each measurement function. The state and value of rel for

each measurement function are saved when changing functions. Once a rel value is established

for a measurement function, the value is the same for all ranges.

Configuring Rel

To check or change a rel value for a measurement function, perform the following steps:

1. Select the desired measurement function.

2. Press the CONFIG key and then the REL key to display the present rel value.

3. Use the cursor keys ( and ) and the RANGE keys to change the rel value and press

ENTER. The instrument will return to the normal display state with rel enabled.

Page 44

2-14 Measurement Options

Zero check

With zero check enabled (“ZeroCheck” displayed), the input signal is routed to low through

a high impedance shunt. For volts, amps and ohms measurements, zero check should be enabled

when connecting or disconnecting input signals. For charge measurements, zero check should

be disabled. If left enabled, the charge will dissipate through the 10M

The Z-CHK key is used to enable and disable zero check.

NOTE To ensure proper operation, always enable zero check before changing functions (V,

I, R or Q).

Ω shunt.

Zero correct

The Z-CHK and REL keys work together to cancel (zero correct) any internal offsets that

might upset accuracy for voltage and current measurements.

Perform the following steps to zero correct the volts or amps function:

1. Select the V or I function.

2. Enable Zero Check.

3. Select the range that will be used for the measurement, or select the lowest range.

4. Press REL to zero correct the instrument. The REL indicator turns on and the “ZCor”

NOTE F or the volts function, the “ZCor” messa ge will not be displayed if guar d was already

5. Press Z-CHK to disable zero check.

6. Readings can now be taken in the normal manner.

NOTES The instrument will remain zer oed even if the instrument is upr anged. If downr anged,

message is displayed.

enabled (“Grd” displayed).

re-zero the instrument.

To disable zero correct, first enable zero check and then press REL.

Page 45

T riggering

Measurement Options 2-15

The following overview is intended to acquaint you with triggering. For a complete explanation, see the Model 6517A User’s Manual. Triggering is configured from the Trigger Configuration menu which is accessed by pressing CONFIG and then TRIG.

There are two trigger modes for the Model 6517A; basic and advanced. These two trigger

modes are summarized by the simplified trigger models shown in Figures 11 and 12. As shown

in the drawings, the basic trigger model uses one layer of operation, while the adv anced trigger

model uses three layers to provide more trigger options.

Figure 11

Basic trigger

model (simplified)

One

Shot

Idle

MODEMODE

Event

Detection

Continuous

Device

Action

Output Trigger

Page 46

2-16 Measurement Options

Figure 12

Advanced trigger

model (simplified)

Arm

Layer

Scan

Layer

Measure

Layer

Idle

Arm

Event

Scan

Event

Measure

Event

Device

Action

Yes

Yes

Yes

No

Another

Arm

?

No

Another

Scan

?

No

Another

Measure-

ment

?

Output

Trigger

Arm

Count

Scan

Count

Measure

Count

Idle

The instrument is in idle whenever it is not within one of the layers of the trigger model. When

the Model 6517A is taken out of idle by pressing TRIG (or sending :INIT or :INIT:CONT ON

over the bus), the ARM indicator turns on and operation proceeds in the trigger model.

Control sources

With advanced triggering and basic one-shot triggering, operation is controlled by control

sources, which hold up operation until the programmed event occurs. Basic one-shot triggering

uses one control source, while advanced triggering uses three control sources. The control sources are described as follows:

• Immediate – Event detection is immediately satisfied, allowing operation to continue.

• External – Event detection is satisfied when an input trigger via the EXT TRIG IN connector is received.

Page 47

Measurement Options 2-17

• Manual – Event detection is satisfied by pressing the TRIG key.

• GPIB – Event detection is satisfied when a bus trigger (GET or *TRG) is received.

• TrigLink – Event detection is satisfied when an input trigger via the TRIGGER LINK

connector is received. Not available for basic triggering.

• TIMER – Event detection is immediately satisfied on the initial pass through the layer.

Each subsequent detection is satisfied when the programmed timer interval elapses. Not

available in the Arm Layer of the advanced trigger model.

• Hold – With this selection, event detection is not satisfied by any of the above control source events and operation is held up. Not available for basic triggering.

If continuous basic triggering is being used, then operation bypasses the control source as

shown in Figure 11 and performs a device action.

Device action

The primary device action is a measurement. However, the device action could include a

function change and a channel scan (if scanner is enabled). A channel is scanned (closed) before

a measurement is made. When scanning internal channels, the previous channel opens and the

next channel closes (break-before-make). Also included in the device action is the internal settling time delay for the relay.

Output trigger

After each measurement (device action), an output trigger pulse occurs and is a vailable at the

rear panel of the Model 6517A. When used with an external scanner (such as a Model 7001 or

7002 Switch System), each output trigger would be used to select the next channel in a scan (see

“External Scanning” later in this section).

Counters (Advanced triggering)

All three layers of the advanced trigger model use programmable counters that allow operation to return to or stay in the respective layer. For example, programming the Measure Layer

counter to infinite keeps operation in the Measure Layer. After each device action, operation

loops back to the Trigger Layer control source. A counter resets when operation loops back to a

higher layer (or idle).

Bench default trigger model setup

The bench default setup selects advanced triggering and takes the Model 6517A out of idle,

sets the control sources of all layers to Immediate, and sets the Measure Layer counter to infinite.

With this trigger model setup, operation simply f alls into the Measure Layer (and stays there) to

make continuous measurements.

Page 48

2-18 Measurement Options

Speed

SPEED sets the integration time of the A/D converter, the period of time the input signal is

measured. The SPEED can be set for each measurement function. The integration time is specified in parameters based on a number of power line cycles (NPLC), where one PLC for 60Hz

is 16.67msec and one PLC for 50Hz and 400Hz is 20msec.

In general, the fastest integration time (0.01 PLC) results in increased reading noise and less

usable resolution, while the slowest integration time (10 PLC) pro vides the best common-mode

and normal-mode rejection. In-between settings are a compromise between speed and noise.

Configuring speed

Each measurement function, can have a unique integration time. Speed is set from the configure function menu structures. The procedure is summarized as follows:

1. Press the CONFIG key and then the desired function key (V, I, etc.).

2. Using the cursor keys ( and ), select SPEED and press ENTER to display the following speed options:

NORMAL: Sets the integration time to 1 PLC.

FAST: Sets the integration time to 0.01 PLC.

MEDIUM: Sets the integration time to 0.1 PLC.

HIACCURACY: Sets the integration time to 10 PLC.

SET-SPEED-EXACTLY: This options prompts you to enter a PLC value (0.01 to 10).

SET-BY-RESOLUTION: Automatically optimizes the integration time for the present

resolution setting (see the User’s Manual).

3. Use the menu items to configure speed. A menu item is selected by placing the cursor

(using and keys) on it and pressing ENTER. P arameter values are changed using

the cursor keys and the RANGE keys, and then pressing ENTER. See MENUS if you

need more information to navigate through the menu structure.

NOTE For more information, see SPEED in Section 2 of the User’s Manual.

Page 49

Resolution

unique resolution setting.

Configure resolution

Measurement Options 2-19

All functions can operate from 3½ to 6½ digits of resolution. Each function can have a

Perform the following steps to set resolution for a measurement function:

1. Press the CONFIG key and then the desired function key (V, I, etc.).

2. Using the

play the following resolution options:

3.5 to 6.5d: Select one of these options to set the display resolution.

AUTO: This option automatically optimizes the resolution for the present integration

time (speed) setting (see the User’s Manual).

3. Set resolution by placing the cursor (using and keys) on the menu option pressing ENTER. See “Menus” if you need more information to navigate through the menu

structure.

cursor keys ( and ), select RESOLUTION and press ENTER to dis-

Page 50

2-20 Measurement Options

Filter

Filtering stabilizes noisy measurements. The Model 6517A uses a digital filter and a median

filter. When a filter is enabled by pressing FILTER (FILT annunciator turns on), the selected filter for that measurement function is in effect. Pressing FILTER a second time disables the filter.

Filter types