Page 1

www.keithley.com

Model 6485 Picoammeter Model 6487 Picoammeter/Voltage Source

User’s Manual

6487-900-01 Rev. C / March 2011

A GREATER MEASURE OF CONFIDENCE

Page 2

Model 6485 Picoammeter

Model 6487 Picoammeter/Voltage Source

User’s Manual

© 2002-2011, Keithley Instruments, Inc.

Cleveland, Ohio, U.S.A.

All rights reserved.

Any unauthorized reproduction, photocopy, or use the information herein, in whole

or in part, without the prior written approval of Keithley Instruments, Inc. is strictly

prohibited.

All Keithley Instruments product names are trademarks or registered trademarks of

Keithley Instruments, Inc. Other brand names are trademarks or registered

trademarks of their respective holders.

The Lua 5.0 software and associated documentation files are copyright © 1994-

2008, Tecgraf, PUC-Rio. Terms of license for the Lua software and associ ated

documentation can be accessed at the Lua licensing site

(http://www.lua.org/license.html).

Keithley's standard terms and conditions of sale in effect at the time of acceptance

of buyer's order by Keithley shall apply to all purchase of goods and performance of

services from Keithley, to the exclusion of any additional or different terms and

conditions, including any terms or conditions which buyer may purport to apply

under any buyer's request for quotation, purchase order or similar d ocument, or

which buyer may offer in response to these terms. A copy of Keithley's current

terms can be accessed at http://www.keithley.com/company/termsandconditions

(these "Terms"). To obtain a printed copy of these Terms, please contact your local

sales office or send an email to orders@keithley.com. Buyer's assent to these

Terms, and only these Terms, shall be conclusively presumed from buyer's

acceptance of delivery of the products and/or services provided by Keithley.

Document number: 6487-900-01 Rev. C / March 2011

Page 3

Safety Precautions

The following safety precautions should be observed before using this product and any associated instrumentation.

Although some instruments and accessories would normally be used with non-hazardous voltages, there are

situations where hazardous conditions may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety

precautions required to avoid possible injury. Read and follow all installation, operation, and maintenance

information carefully before using the product. Refer to the user documentation for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product warranty may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use and maintenance of equipment, for ensuring

that the equipment is operated within its specifications and operating limits, and for ensuring that operators are

adequately trained.

Operators use the product for its intended function. They must be trained in electrical safety procedures and proper

use of the instrument. They must be protected from electric shock and contact with hazardous live circuits.

Maintenance personnel perform routine procedures on the product to keep it operating properly, for example,

setting the line voltage or replacing consumable materials. Maintenance procedures are described in the user

documentation. The procedures explicitly state if the operator may perform them. Otherwise, they should be

performed only by service personnel.

Service personnel are trained to work on live circuits, perform safe installations, and repair products. Only properly

trained service personnel may perform installation and service procedures.

Keithley Instruments products are designed for use with electrical signals that are rated Measurement Category I

and Measurement Category II, as described in the International Electrotechnical Commission (IEC) Standard IEC

60664. Most measurement, control, and data I/O signals are Measurement Category I and must not be directly

connected to mains voltage or to voltage sources with high transient over-voltages. Measurement Category II

connections require protection for high transient over-voltages often associated with local AC mains connections.

Assume all measurement, control, and data I/O connections are for connection to Category I sources unless

otherwise marked or described in the user documentation.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable connector jacks

or test fixtures. The American National Standards Institute (ANSI) states that a shock hazard exists when voltage

levels greater than 30V RMS, 42.4V peak, or 60VDC are present. A good safety practice is to expect that hazardous

voltage is present in any unknown circuit before measuring.

Operators of this product must be protected from electric shock at all times. The responsible body must ensure that

operators are prevented access and/or insulated from every connection point. In some cases, connections must be

exposed to potential human contact. Product operators in these circumstances must be trained to protect

themselves from the risk of electric shock. If the circuit is capable of operating at or above 1000 volts, no conductive

part of the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits. They are intended to be used with impedancelimited sources. NEVER connect switching cards directly to AC mains. When connecting sources to switching cards,

install protective devices to limit fault current and voltage to the card.

Before operating an instrument, make sure the line cord is connected to a properly grounded power receptacle.

Inspect the connecting cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

When installing equipment where access to the main power cord is restricted, such as rack mounting, a separate

main input power disconnect device must be provided in close proximity to the equipment and within easy reach of

the operator.

04/09

Page 4

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the

!

circuit under test. ALWAYS remove power from the entire test system and discharge any capacitors before:

connecting or disconnecting cables or jumpers, installing or removing switching cards, or making internal changes,

such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line

(earth) ground. Always make measurements with dry hands while standing on a dry, insulated surface capable of

withstanding the voltage being measured.

The instrument and accessories must be used in accordance with specifications and operating instructions, or the

safety of the equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and

operating information, and as shown on the instrument or test fixture panels, or switching card.

When fuses are used in a product, replace with the same type and rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as safety earth ground

connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation

requires the use of a lid interlock.

If a screw is present, connect it to safety earth ground using the wire recommended in the user documentation.

The symbol on an instrument means caution, risk of danger. The user should refer to the operating instructions

located in the user documenta ti on in all case s wh ere th e symb ol is ma rked on the instrument.

The symbol on an instrument means caution, risk of danger. User standard safety precautions to avoid

personal contact with these voltages.

The symbol on an instrument shows that the surface may be hot. Avoid personal contact to prevent burns.

The symbol indicates a connection terminal to the equipment frame.

If this symbol is on a product, it indicates that mercury is present in the display lamp. Please note that the lamp

must be properly disposed of according to federal, state, and local laws.

The WARNING heading in the user documentation explains dangers that might result in personal injury or death.

Always read the associated information very carefully before performing the indicated procedure.

The CAUTION heading in the user documentation explains hazards that could damage the instrument. Such

damage may invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain pr otection from ele ctric sh ock and f ire, replacement components in mains circuits - including the power

transformer, test leads, and input jacks - must be purchased from Keithley Instruments. Standard fuses with

applicable national safety approvals may be used if the rating and type are the same. Other components that are

not safety-related may be purchased from other suppliers as long as they are equivalent to the original component

(note that selected parts should be purchased only through Keithley Instruments to maintain accuracy and

functionality of the product). If you are unsure about the applicability of a replacement component, call a Keithley

Instruments office for information.

T o clean an instrument, use a damp cloth or mild, water-based cleaner . Clean the exterior of the instrument only . Do

not apply cleaner directly to the instrument or allow liquids to enter or spill on the instrument. Products that consist

of a circuit board with no case or chassis (e.g., data acquisition board for installation into a computer) should never

require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected,

the board should be returned to the factory for proper cleaning/servicing.

Page 5

Table of Contents

1 Getting Started

Introduction ................................................................................ 1-2

Overview of this manual ............................................................ 1-2

General information ................................................................... 1-2

Warranty information ......................................................... 1-2

Contact information ............................................................ 1-3

Safety symbols and terms ................................................... 1-3

Unpacking and Inspection .................................................. 1-3

Options and accessories ...................................................... 1-4

User’s manual ..................................................................... 1-6

Additional references .......................................................... 1-6

Features ...................................................................................... 1-6

Front and rear panel familiarization ........................................... 1-7

Front panel summary .......................................................... 1-7

Rear panel summary ......................................................... 1-10

Voltage source .................................................................. 1-12

Analog output ................................................................... 1-12

Digital I/O ......................................................................... 1-12

Display .............................................................................. 1-12

Status and error messages ................................................. 1-12

Power-up .................................................................................. 1-13

Line power connection ...................................................... 1-13

Line frequency .................................................................. 1-13

Power-up sequence ........................................................... 1-14

Default settings ........................................................................ 1-15

Saving user setups ............................................................. 1-15

Restoring setups ................................................................ 1-15

Restoring factory default setup ......................................... 1-15

Menu ........................................................................................ 1-18

SCPI programming .................................................................. 1-18

Optional command words ................................................. 1-19

Query commands .............................................................. 1-19

2 Connections

Connection fundamentals ........................................................... 2-2

Input connector ................................................................... 2-2

Voltage source output connectors ....................................... 2-2

Maximum input levels ........................................................ 2-2

Connecting cables and test leads ........................................ 2-3

Basic connections to DUT ......................................................... 2-4

Current measurement connections ...................................... 2-4

Page 6

Ohms measurement connections ......................................... 2-4

Noise and safety shields ...................................................... 2-5

Using a test fixture ...................................................................... 2-6

General purpose test fixture ................................................ 2-6

Model 8009 resistivity test fixture ...................................... 2-6

Interlock ...................................................................................... 2-8

Interlock connections .......................................................... 2-8

Interlock operation .............................................................. 2-8

Analog output ............................................................................. 2-9

Measurement considerations .................................................... 2-10

3 Measurements and Sourcing Voltage

Measurement overview .............................................................. 3-2

Current measurements ......................................................... 3-2

Voltage source ..................................................................... 3-2

Performance considerations ........................................................ 3-3

Warm-up period .................................................................. 3-3

Voltage offset correction ..................................................... 3-3

Autozero .............................................................................. 3-3

Zero check and zero correct ................................................ 3-3

Current measurements ................................................................ 3-5

Procedure ............................................................................. 3-5

SCPI programming — current measurements .................... 3-7

Programming example — current measurements ............... 3-7

Ohms measurements ................................................................... 3-8

Overview ............................................................................. 3-8

Procedure ............................................................................. 3-8

SCPI programming — ohms measurements ..................... 3-10

Programming example — ohms measurements ................ 3-11

Voltage source operation .......................................................... 3-11

Configuring the voltage source ......................................... 3-11

Sourcing voltage ................................................................ 3-12

Compliance indication ....................................................... 3-12

Open interlock indication .................................................. 3-13

SCPI commands — voltage source ................................... 3-13

Programming example — voltage ..................................... 3-13

4 Range, Units, Digits, Rate, and Filters

Range, units, and digits .............................................................. 4-2

Range ................................................................................... 4-2

Units .................................................................................... 4-3

Digits ................................................................................... 4-3

SCPI programming — range and digits .............................. 4-3

Rate ............................................................................................. 4-4

Page 7

Damping ..................................................................................... 4-4

Filters ......................................................................................... 4-4

Median filter ....................................................................... 4-5

Digital filter ......................................................................... 4-5

Filter control ....................................................................... 4-6

5 Relative, mX+b, m/X+b (reciprocal), and log

Relative ...................................................................................... 5-2

Front panel relative ............................................................. 5-2

SCPI programming — relative .......................................... 5-2

mX+b, m/X+b (reciprocal), and Logarithmic ............................ 5-3

mX+b and m/X+b ............................................................... 5-3

Logarithmic ......................................................................... 5-3

Configuring math functions ................................................ 5-4

SCPI programming — mX+b, m/X+b, and log .................. 5-4

6 Buffer and Sweeps

Buffer operations ........................................................................ 6-2

Store .................................................................................... 6-2

Recall .................................................................................. 6-2

Buffer timestamp ................................................................ 6-2

Clear .................................................................................... 6-3

Buffer statistics ................................................................... 6-3

SCPI programming — buffer ............................................. 6-4

Programming example ........................................................ 6-4

Voltage sweeps .......................................................................... 6-5

Front panel sweeps .............................................................. 6-5

SCPI programming — sweeps ............................................ 6-5

Programming example ........................................................ 6-6

7 Remote Operation and Commands

Selecting and configuring an interface ....................................... 7-2

Interfaces ............................................................................. 7-2

Connections ........................................................................ 7-2

Front panel GPIB operation ................................................ 7-3

Remote commands ..................................................................... 7-4

General bus commands ....................................................... 7-4

Common commands ........................................................... 7-4

Signal oriented commands. ................................................. 7-5

SCPI command subsystems ................................................ 7-6

Programming syntax ........................................................... 7-6

A Specifications

Page 8

B General Measurement Considerations

Measurement considerations ..................................................... B-2

Ground loops ...................................................................... B-2

Triboelectric effects ............................................................ B-3

Piezoelectric and stored charge effects .............................. B-3

Electrochemical effects ...................................................... B-4

Humidity ............................................................................. B-4

Light ................................................................................... B-4

Electrostatic interference .................................................... B-4

Magnetic fields ................................................................... B-5

Electromagnetic Interference (EMI) .................................. B-5

C Example Programs

Programming examples ............................................................. C-2

1000 readings/second into internal buffer .......................... C-2

900 readings/second to IEEE-488 bus ............................... C-3

3000 readings into internal buffer ...................................... C-4

Page 9

Model 6485 and 6487 User’s Manual Getting Started 1-1

1

Getting Started

• Introduction — Description of the Models 6485 and 6487 Picoammeters.

•

Overview of this manual — Provides content of this manual.

•

General information — Covers general information that includes warranty infor-

mation, contact information, safety symbols and terms, unpacking and inspection,

and available options and accessories.

•

Features — Summarizes the features of Models 6485 and 6487.

•

Model 6485 front and rear panel familiarization — Summarizes the controls and

connectors of the Model 6485 as well as providing information on the front panel

display.

•

Model 6487 front and rear panel familiarization — Summarizes the controls and

connectors of the Model 6487 and provides information on the front panel display.

•

Power-up — Covers line power connection, line frequency, and the power-up

sequence.

•

Default settings — Covers the five instrument setup configurations available to the

user; three user-defined, GPIB defaults, or factory defaults.

• Menu— Provides menu structures for both the Models 6485 and 6487.

•

SCPI programming — Explains how SCPI commands are presented in this manual.

Page 10

1-2 Getting Started Model 6485 and 6487 User’s Manual

Introduction

The Models 6485 and 6487 are high-resolution bus-programmable (RS-232 and IEEE-488)

picoammeters. The Models 6485 and 6487 have the following current measurement ranges:

eight ranges (from 20mA down to the 2nA range). The Model 6487 also includes a ±500V

DC voltage source and an ohms function that includes an alternating voltage mode to

improve accuracy and repeatability of very high resistance measurements.

Overview of this manual

This manual describes how to connect, program, and maintain the Models 6485 and 6487

Picoammeters. The sections of the manual are organized as follows:

– Section 1: Getting Started

– Section 2: Connections

– Section 3: Measurements and Sourcing Voltage (Model 6487 only)

– Section 4: Range, Units, Digits, Rate, and Filters

– Section 5: Relative, mX+b, m/X+b (reciprocal), and log

– Section 6: Buffer and Sweeps

– Section 7: Remote Operation and Commands

Appendices to this manual contain specification and also provide additional information

on specific topics. The appendices are organized as follows:

– Appendix A: Specifications

– Appendix B: General Measurement Considerations

– Appendix C: Example Programs

General information

Warranty information

Should your Model 6485 or 6487 require warranty service, contact the Keithley representative or authorized repair facility in your area for further information.

Contact information

Worldwide phone numbers are listed at the front of this manual. If you have any questions, please contact your local Keithley representative or call one of our Application

Engineers at 1-800-348-3735 (U.S. and Canada only).

Page 11

Model 6485 and 6487 User’s Manual Getting Started 1-3

!

Safety symbols and terms

The following symbols and terms may be found on the instrument or used in this manual:

If or is present, connect it to safety earth ground using the wire recommended in

the user documentation.

The symbol on an instrument indicates that the user should refer to the operating

instructions located in the manual.

The symbol on an instrument shows that it can source or measure 1000 volts or more,

including the combined effect of normal and common mode voltages. Use standard safety

precautions to avoid personal contact with these voltages.

The WARNING heading used in this manual explains dangers that might result in personal

injury or death. Always read the associated information very carefully before performing the

indicated procedure.

The CAUTION heading used in this manual explains hazards that could damage the

instrument. Such damage may invalidate the warranty.

Unpacking and inspection

Inspection for damage

The Model 6485/6487 was carefully inspected electrically and mechanically before ship-

ment. After unpacking all items from the shipping carton, check for any obvious signs of

physical damage that may have occurred during transit. (There may be a protective film

over the display lens, which can be removed.) Report any damage to the shipping agent

immediately. Save the original packing carton for possible future shipment. Before

removing the Model 6485/6487 from the bag, observe the handling precautions discussed

below.

Handling precautions

• Always grasp the Model 6485/6487 by the covers.

• After removing the unit from its anti-static bag, inspect it for any obvious signs of

physical damage. Report any such damage to the shipping agent immediately.

• When the instrument is not installed and connected, keep the unit in its anti-static

bag and store it in the original packing carton.

Page 12

1-4 Getting Started Model 6485 and 6487 User’s Manual

Package content

Model 6485

The following items are included with every Model 6485 order:

• Model 6485 Picoammeter with line cord.

• Low Noise Cable with Male BNC on both ends (Model 4801).

• Protective BNC Shield/Cap (CAP-18).

• Banana lead to screw terminal adapter (Model CA-186-1B).

• Accessories as ordered.

• Certificate of calibration.

• Model 6485/6487 User Manual (P/N 6487-900-00).

• Manual Addenda (pertains to any improvements or changes concerning the instrument or manual).

• Product Information CD-ROM that contains PDFs of the User’s and Instruction

Manuals.

Model 6487

The following items are included with every Model 6487 order:

• Model 6487 Picoammeter with line cord.

• Triax Protective Shield/Cap (CAP-31).

• 7078-TRX-3 Triax cable.

• Model 8607 1kV Source Banana cable set.

• CS-459 4-pin Female Interlock connector.

• Accessories as ordered.

• Certificate of calibration

• Model 6485/6487 User Manual (P/N 6487-900-00).

• Product Information CD-ROM that contains PDFs of the User’s and

Reference Manuals.

Options and accessories

Model 6485 input cables, connectors, and adapters

Model 4801 Input Cable — This 4 ft (1.2m) low-noise coax cable is terminated with male

BNC connectors on each end. (One Model 4801 is included with every order.)

Model 4802-10 — This 10 ft (3m) low-noise coax cable is terminated at one end with a

male BNC connector (the other end is unterminated).

Page 13

Model 6485 and 6487 User’s Manual Getting Started 1-5

Model 4803 Low Noise Cable Kit — This cable kit includes:

– 15m (50 ft) of low noise coax cable

– 10 male BNC connectors

– 5 female BNC chassis-mount connectors

Model 7078-TRX-BNC adapter — 3-slot male triax to female BNC.

Model 8607 — Banana cable set (1m).

CA-186-1B — Banana lead to screw terminal adapter (one model CA-186-1B is included

with every order).

CAP-18 — Protective shield/cap for BNC connectors (one model CAP-18 is included

with every order).

CS-565 barrel adapter — This barrel adapter allows you to connect two BNC cables

together. Both ends of the adapter are terminated with 2-lug female BNC connectors.

Model 6487 input cables, connectors, and adapters

237-TRX-BAR Barrel Adapter — This barrel adapter allows you to connect

two triax cables together. Both ends of the adapter are terminated with 3-lug female triax

connectors.

Model 237-ALG-2 Triax Cable — This 2m (6.6 ft) low-noise triax cable is terminated

with a three slot male triax connector on one end and 3 alligator clips on the other.

Model 237-TRX-T Adapter — This is a 3-slot male to dual 3-lug female triax tee adapter

for use with 7078-TRX triax cables. Suitable for use with the Model 6487 V-Source in

high voltage applications.

Model 237-TRX-TBC Connector — This is a 3-lug female triax bulkhead connector with

cap for assembly of custom panels and interface connections. Suitable for use with the

Model 6487 V-Source in high voltage applications.

Models 7078-TRX-3, 7078-TRX-10, and 7078-TRX-20 Triax Cables — These are low

noise triax cables terminated at both ends with 3-slot male triax connectors. The -3 model

is 3 ft. (0.9m) in length, the -10 model is 10 ft. (3m) in length, and the -20 model is 20 ft.

(6m) in length.

Model 7078-TRX-TBC Connector — This is a 3-lug female triax bulkhead connector

with cap for assembly of custom panels and interface connections. Suitable for use with

the Model 6487 V-Source in high voltage applications.

Model 8009 Resistivity Test Fixture — This is a guarded test fixture for measuring volume and surface resistivities. It can accommodate sheet samples with a diameter between

64 and 102mm (2 to 4 in.) and a thickness of up to 3.175mm ( in.).

Model 8606 High Performance Probe Tip Kit — Consists of two spade lugs, two alligator

clips, and two spring hook test probes. (The spade lugs and alligator clips are rated at 30V

RMS, 42.4V peak; the test probes are rated at 1000V.) These components are designed to

Page 14

1-6 Getting Started Model 6485 and 6487 User’s Manual

be used with high performance test leads terminated with banana plugs, such as the Model

8607 High Performance Banana Cables.

Model 8607 High Performance Banana Cables — Consists of two high voltage (1000V)

banana cables. The cables are terminated with banana plugs that have retractable sheaths.

CAP-31 Protective Shield /Cap — For use with 3-lug triax connectors.

Model 6487 interlock cables and connector

Model 6517-ILC-3 Interlock Cable — Designed to connect the interlock of the Model 6487

to the Model 8009 test fixture.

Model 8002-ILC-3 Interlock Cable — Designed to connect the lid interlock circuit of a

test fixture to the interlock circuit of the Model 6487.

CS-459 4-pin Female Interlock Connector — Allows custom wiring of external circuits to

the Model 6487 interlock.

GPIB, RS-232, and trigger link cables and adapters

Models 7007-1 and 7007-2 shielded GPIB cables — Connects the Model 6485/6487 to the

GPIB bus using shielded cables and connectors to reduce electromagnetic interference

(EMI). Model 7007-1 is lm long; Model 7007-2 is 2m long.

Model 7009-5 shielded RS-232 cable — Connects the Model 6485/6487 to the RS-232

interface using shielded cable and connectors to reduce electromagnetic interference

(EMI). Model 7009-5 is 5 ft. long.

Models 8501-1 and 8501-2 trigger link cables — Connects the Model 6485/6487 to other

instruments with Trigger Link connectors (e.g., Model 7001 Switch System). Model 85011 is lm long; Model 8501-2 is 2m long.

Model 8502 trigger link adapter — Lets you connect any of the six trigger link lines of the

Model 6485/6487 to instruments that use the standard BNC trigger connectors.

Model 8503 DIN to BNC trigger cable — Lets you connect trigger link lines one

(Voltmeter Complete) and two (External Trigger) of the Model 6485/6487 to instruments

that use BNC trigger connectors. Model 8503 is lm long.

Page 15

Model 6485 and 6487 User’s Manual Getting Started 1-7

Rack mount kits

Model 4288-1 single fixed rack mount kit — Mounts a single Model 6485/6487 in a standard 19-inch rack.

Model 4288-2 side-by-side rack mount kit — Mounts two instruments (Models 182, 428,

486, 487, 2000, 2001, 2002, 2010, 2400, 2410, 2420, 2430, 6430, 6485, 6487, 6517A,

7001) side-by-side in a standard 19-inch rack.

Model 4288-4 side-by-side rack mount kit — Mounts Model 6485/6487 and a 5.25-inch

instrument (Models 195A, 196, 220, 224, 230, 263, 595, 614, 617, 705, 740, 775A, 6512)

side-by-side in a standard 19-inch rack.

Carrying case

Model 1050 padded carrying case — A carrying case for Model 6485/6487. Includes handles and shoulder strap.

Additional references

While reading this document, you may find it helpful to consult the following documentation for reference:

Model 6485 Instruction Manual — Supplied in electronic format on the Product Information CD-ROM included with your shipment, this document provides in-depth information

on Model 6485 operation, as well as performance verification, calibration, and routine maintenance procedures. Check www.keithley.com for details.

Model 6487 Reference Manual — Electronic format manual on the Product Information

CD-ROM included with your shipment, this document provides in-depth information on

Model 6487 operation, as well as performance verification, calibration, and routine maintenance procedures. Check www.keithley.com for details.

Low Level Measurements handbook — Keithley’s guide for effective low current, low

voltage, and high impedance measurements. Check www.keithley.com for details.

Page 16

1-8 Getting Started Model 6485 and 6487 User’s Manual

Features

The Model 6485/6487 is a high-performance picoammeter capable of measuring current

(the Model 6487 also measures resistance). Section 2 contains details on its measurement

capabilities (“Connection fundamentals,” page 2-2). Features of Model 6485/6487

Picoammeter include:

• Setup storage — Five instrument setups (three user, GPIB defaults, and factory

defaults) can be saved and recalled.

• mX+b, m/X+b (reciprocal—for resistance calculations), and log10 — These calculations provide mathematical manipulation of readings (Section 5).

• Relative — Null offsets or establish baseline values (Section 5).

• Buffer — Store data in the internal buffer (Section 6).

• Limits — Set up to two stages of high and low reading limits to test devices (see

Section 8 of the Model 6485 Instruction Manual or Model 6487 Reference Manual).

• Digital I/O port (Model 6487 only) — Four output lines and one input line to control external circuitry as an interface between limit tests and component handler.

(See Section 8 of the Model 6487 Reference Manual.)

• Remote interface — Model 6485/6487 can be controlled using the IEEE-488 interface (GPIB) or the RS-232 interface (Section 7).

• Voltage source (Model 6487 only) — Internal ±500V voltage source is also used

for ohms function (Section 3).

• GPIB programming language — When using the GPIB, the instrument can be programmed using the SCPI or DDC programming language.

Model 6485 front and rear panel familiarization

Model 6485 front panel summary

The front panel of Model 6485 is shown in Figure 1-1.

Page 17

Model 6485 and 6487 User’s Manual Getting Started 1-9

6485

PICOAMMETER

RANGE

AUTO

CONFIG/

LOCAL

MENU

POWER

RANGE

SHIFT

CH1REM

TALK

LSTN

SRQ

STAT

REL

FIL

T

4W

BUFFER

MATH

REAR

SCAN

TIMER

STEP CH2 CH3 CH4 CH5 CH6 CH7 CH8 CH9 CH10

HOLD TRIG FAST MED SLOW AUTO ERR

EXIT ENTER

HALT

RATEDIGITS

STORE RECALL

MEDN

5

1

24

6

AVG MX+B M/X+B LOG REL ZCHK ZCOR

COMM DISP

TRIG

LIMIT AZERO

SAVE SETUP

3

Figure 1-1

Model 6485 front panel

klqb To modify a key’s properties, press the CONFIG / LOCAL key (see Special keys

and power switch) and then the key. Not all keys have configurable properties.

1 Special keys and power switch

CONFIG/ When in Local operation, use to configure properties of the next button pressed.

LOCAL When in Remote operation (REM annunciator lit), cancels GPIB remote mode.

MENU Provides access to menu.

POWER Power switch. In position turns 6485 on (I), out position turns it off (O).

2 Function keys

AVG Use to control and modify properties of the digital filter.

MX+B Use to perform and configure properties of the mX+b math function.

M/X+B Use to perform and configure properties of the m/X+b math function.

MEDN Use to control and modify properties of the median filter.

LOG Use to convert output / display to log10 (on / off).

REL Use to control and configure properties of the rel(ative) function.

ZCHK Use to perform a Zero Check function.

ZCOR Use to control Zero Correct function (on / off).

3 Operation keys

COMM Use to control and modify communication properties (GPIB or RS-232).

DISP Use to turn display on/off.

TRIG Trigger measurement(s). Takes 6485 out of idle state. Use also to configure trigger

properties.

Page 18

1-10 Getting Started Model 6485 and 6487 User’s Manual

HALT Stops measurement process. Puts 6485 in idle state.

DIGITS Use to set display resolution.

RATE Use to select measurement rate.

and Use to control cursor position for making selections or editing values.

SAVE Use to save present setup to a memory location.

SETUP Use to restore setup to either GPIB or factory defaults, or to a user memory location.

Also use to modify properties of power on defaults to either GPIB or factory defaults,

or to a user memory location.

STORE Use to start buffer and modify the number of readings to store.

RECALL Use to display stored readings (including maximum, minimum, peak-to-peak, aver-

LIMIT Use to perform and create limit tests.

AZERO Use to control auto zero function (on / off).

EXIT Use to cancel selection and move back to measurement display.

ENTER Use to accept selection and move to next choice or back to measurement display.

age, and standard deviation). The and range keys scroll through the buffer and the

or 䊳 key toggles between reading number, reading, and timestamp.

4 Range keys

Use to select the next higher measurement range. Also use to modify the upper auto-

range limit.

Use to select the next lower measurement range. Also use to modify the lower auto-

AUTO Enables/disables autorange.

range limit.

5 Display annunciators

* (asterisk) Readings being stored in buffer.

(more) Indicates additional selections are available.

AUTO Autorange enabled.

BUFFER Recalling readings stored in buffer.

ERR Questionable reading or invalid cal step.

FAST Fast (0.1 PLC) reading rate selected.

FILT MEDIAN and/or AVERAGE filter enabled.

LSTN Instrument addressed to listen over GPIB.

MATH mX+b, m/X+b, or log10 calculation enabled.

MED Medium (1 PLC) reading rate selected.

REL Relative enabled for present measurement function.

REM Instrument in GPIB remote mode.

SLOW Slow reading rate selected; 6 PLC for 60Hz or 5 PLC for 50Hz.

SRQ Service request over GPIB.

STAT Displaying buffer statistics.

TALK Instrument addressed to talk over GPIB bus.

TIMER Timer controlled triggering in use.

TRIG External triggering (GPIB or trigger link) selected.

6 Handle

Pull out and rotate to desired position.

Page 19

Model 6485 and 6487 User’s Manual Getting Started 1-11

120

FUSE LINE

630mA

LINE RATING

50, 60Hz

30 VA

T

(SB)

100 VAC

120 VAC

315mAT

(SB)

220 VAC

240 VAC

!

INPUT

(CHANGE IEEE ADDRESS

WITH FRONT PANEL MENU)

IEEE-488

CAT I

TRIGGER LINK

RS-232

MADE IN

U.S .A .

220V PK

ANALOG OUT

1384

567

2

120

FUSE LINE

400mA

LINE RATING

50, 60Hz

30 VA

T

(SB)

100 VAC

120 VAC

200mAT

(SB)

220 VAC

240 VAC

!

INPUT

(CHANGE IEEE ADDRESS

WITH FRONT PANEL MENU)

IEEE-488

CAT I

TRIGGER LINK RS-232

MADE IN

U.S.A.

220V PK

ANALOG OUT

1384

567

2

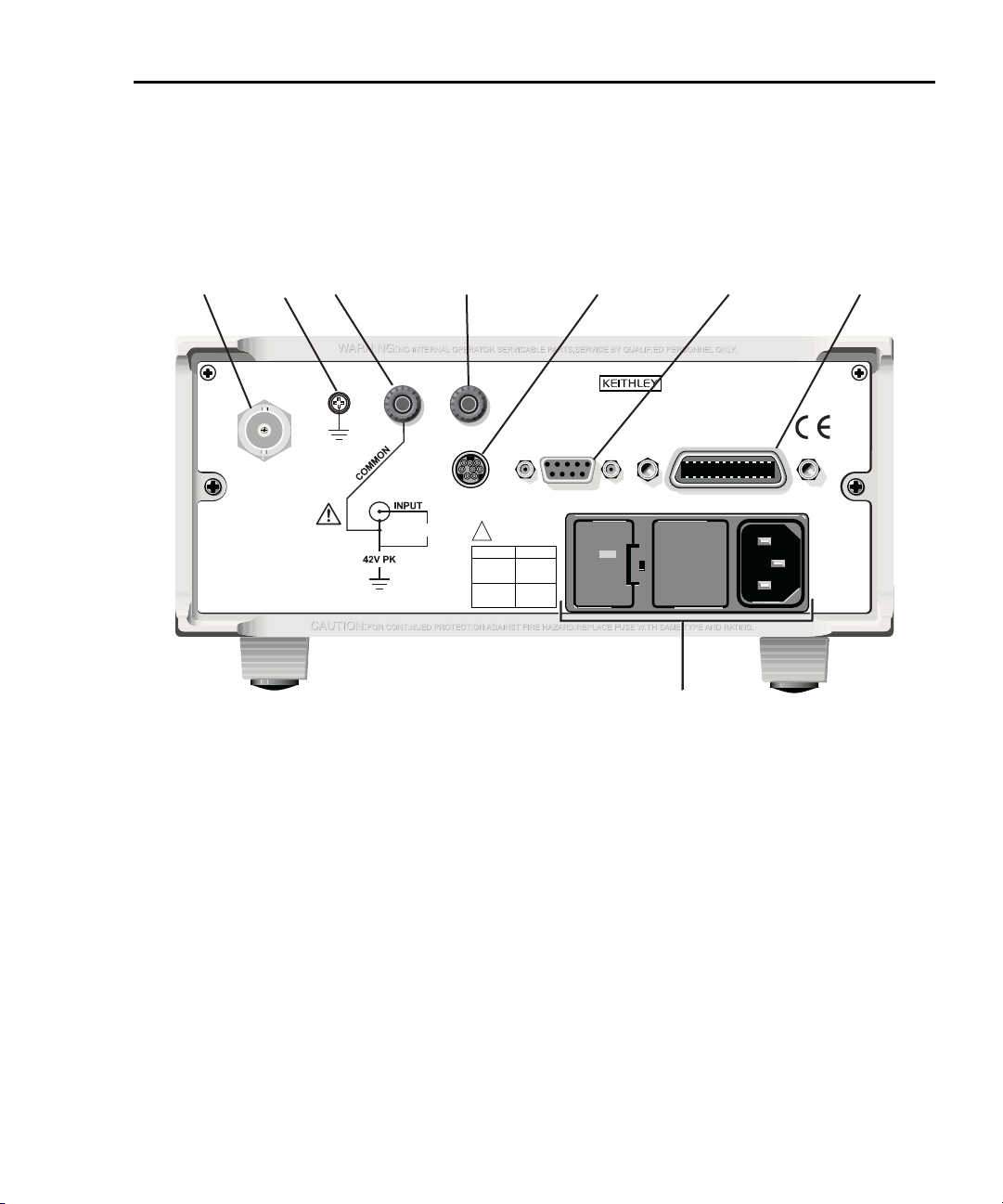

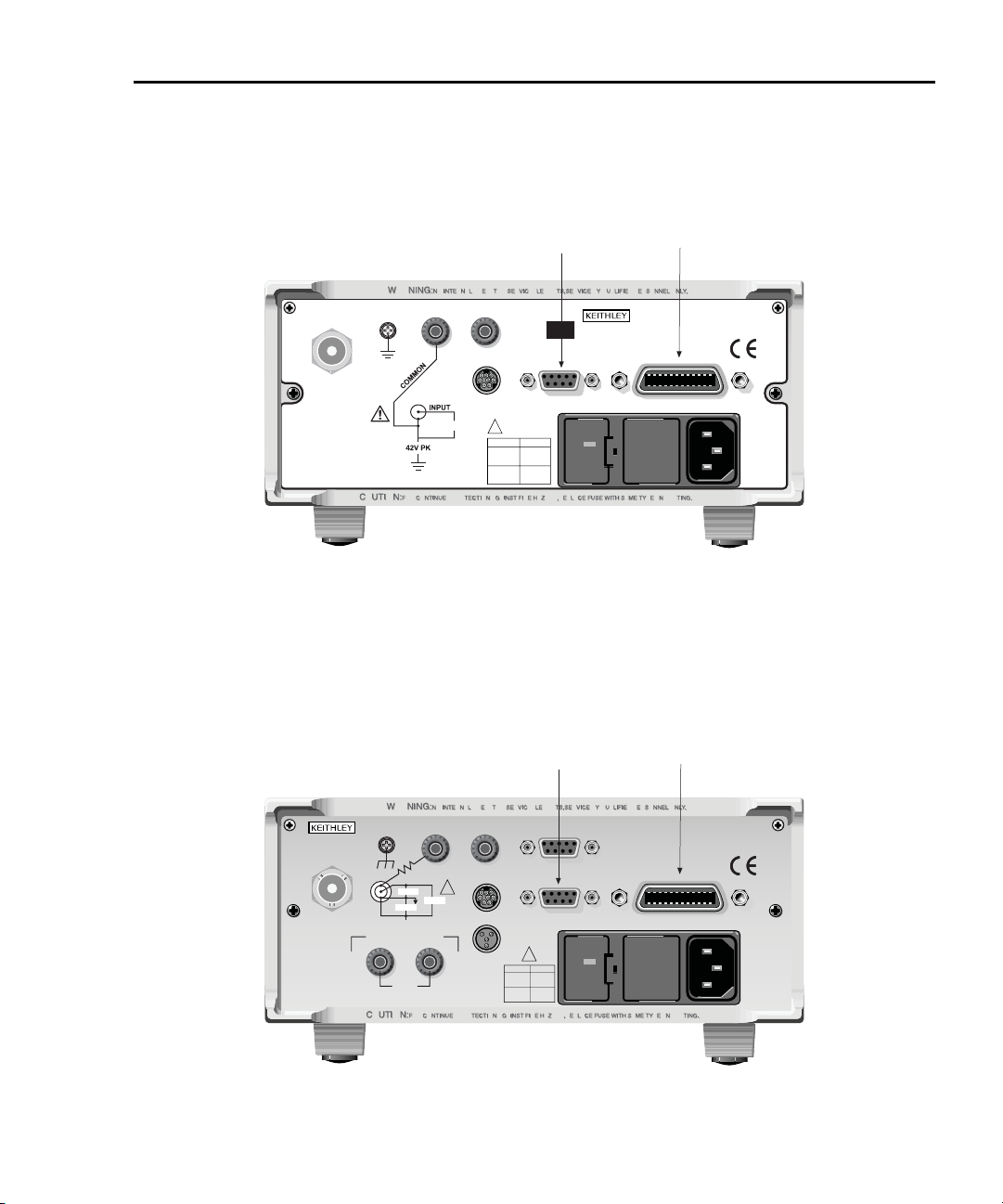

Model 6485 rear panel summary

The rear panel of the Model 6485 is shown in Figure 1-2.

Figure 1-2

Model 6485 rear panel

1INPUT

2CHASSIS

3COMMON

4 ANALOG OUT

This standard female BNC connector is used to connect the signal to be measured to the input of the

Model 6485. Mates to a BNC cable.

This screw terminal is used to connect COMMON to CHASSIS ground via the ground link connector.

This standard banana connector can be used as input LO or as the common for the ANALOG OUT.

Also can be used as a ground link.

This standard banana connector provides a scaled, inverting output (inverting 2V full scale on all

ranges).

Page 20

1-12 Getting Started Model 6485 and 6487 User’s Manual

5 TRIGGER LINK

Eight-pin micro-DIN connector for sending and receiving trigger pulses among connected instruments.

Use a trigger link cable or adapter, such as Models 8501-1, 8501-2, 8502, and 8503.

6RS-232

Female DB-9 connector for RS-232 operation. Use a straight-through (not null modem) DB-9 shielded

cable.

7 IEEE-488

Connector for IEEE-488 (GPIB) operation. Use a shielded cable, such as Models 7007-1 and 7007-2.

8Power module

Contains the AC line receptacle and power line fuse. The instrument can be configured for line voltages of 115V and 230VAC (nominal) at line frequencies of 50 or 60Hz automatically and over the bus.

Changing line voltages requires changing fuses.

Analog output

The Model 6485 has an analog output on the rear panel. The ANALOG OUT provides a

scaled, inverting ±2V output. A full-scale reading corresponds to ±2V output. See “Ana-

log output,” page 2-14 in for full details on analog output operation.

Display

Readings can be displayed in engineering units or scientific notation. Annunciators indicate various states of operation. See “Model 6485 front panel summary,” page 1-8 for a

complete listing of display annunciators.

klqb Changing the display resolution is not allowed if displaying readings in

scientific notation.

The Display and Keys Test allows you to test display digit segments and annunciators, and

check the functionality of front panel keys. These tests are accessed through the MENU.

Status and error messages

Status and error messages are displayed momentarily. During operation and programming, you will encounter a number of front panel messages. Typical messages are either

of status or error variety, as listed in Appendix B of the Model 6485 Instruction Manual.

Page 21

Model 6485 and 6487 User’s Manual Getting Started 1-13

6487 PICOAMMETER /VOLTAGE SOURCE

RANGE

AUTO

CONFIG/

LOCAL

MENU

POWER

RANGE

EXIT ENTER

LIMIT

RATEDIGITS

STORE RECALL

I | Ω

MATH FILT ZCHK REL OPER

COMM

DISP

TRIG

AZERO DAMP

SAVE SETUP

7

1

2345

V-SOURCE

6

VOLTAGE

SOURCE

OPERATE

Model 6487 front and rear panel familiarization

Model 6487 front panel summary

The front panel of the Model 6487 is shown in Figure 1-3.

Figure 1-3

Model 6487 front panel

klqb To modify a key’s properties, press the CONFIG / LOCAL key (see Special keys

and power switch) and then the key. Not all keys have configurable properties.

1 Special keys and power switch

CONFIG / When in Local operation, use to configure properties of the next button pressed.

LOCAL When in Remote operation (REM annunciator lit), cancels GPIB remote mode.

MENU Provides access to menu.

POWER Power switch. In position turns 6487 on (I), out position turns it off (O).

2 Function keys

I Use to toggle between regular current measurements and ohms.

MATH Turns on the selected Math function (selected using the CONFIG >> MATH key

sequence).

FILT Turns on filtering (selected using the CONFIG >> FILT key sequence).

ZCHK Use to perform a Zero Check function.

REL Use to control and configure properties of the rel(ative) function.

Page 22

1-14 Getting Started Model 6485 and 6487 User’s Manual

OPER Toggles the Vsource state (the Vsource state is displayed by an indicator). (Configured

V-SOURCE Increments voltage source value

V-SOURCE Decrements voltage source value

using the CONFIG >> OPER key sequence.)

3 Operation keys

COMM Use to control and modify communication properties (GPIB or RS-232).

DISP Use to turn display on/off.

TRIG Trigger measurement(s). Takes 6487 out of idle state. Use also to configure trigger

LIMIT Use to perform and create limit tests.

DIGITS Use to set display resolution.

RATE Use to select measurement rate.

and 䊳 Use to control cursor position for making selections or editing values.

SAVE Use to save present setup to a memory location.

SETUP Use to restore setup to either GPIB or factory defaults, or to a user memory location.

STORE Use to start buffer and modify the number of readings to store.

RECALL Use to display stored readings (including maximum, minimum, peak-to-peak, aver-

AZERO Use to control auto zero function (on / off).

DAMP Use to control damping function (on / off).

EXIT Use to cancel selection and move back to measurement display.

ENTER Use to accept selection and move to next choice or back to measurement display.

properties.

Also use to modify properties of power on defaults to either GPIB or factory defaults,

or to a user memory location.

age, and standard deviation). The and RANGE keys scroll through the buffer, and

the or 䊳 key toggles between reading number, reading, voltage, and timestamp.

4 Range keys

Use to select the next higher measurement range. Also use to modify the upper autorange limit.

Use to select the next lower measurement range. Also use to modify the lower autorange limit.

AUTO Enables/disables autorange.

5 Handle

Pull out and rotate to desired position.

6 VOLTAGE SOURCE OPERATE indicator

This indicator will turn on when the voltage source is in operate (voltage source output turned on). It

will also turn on for about 0.7 sec at power-on to indicate that it is functional.

t^okfkd Hazardous voltage may be present on the rear panel V-SOURCE

OUTPUT terminals when the operate indicator is on.

Page 23

Model 6485 and 6487 User’s Manual Getting Started 1-15

7 Display annunciators

* (asterisk) Readings being stored in buffer.

(more) Indicates additional selections are available.

AUTO Autorange enabled.

BUFFER Recalling readings stored in buffer.

ERR Questionable reading or invalid cal step.

FAST Fast (0.1 PLC) reading rate selected.

FILT MEDIAN and/or AVERAGE filter enabled (also DAMPING enabled).

LSTN Instrument addressed to listen over GPIB.

MATH mX+b, m/X+b, or log10 calculation enabled.

MED Medium (1 PLC) reading rate selected.

REL Relative enabled for present measurement function.

REM Instrument in GPIB remote mode.

SLOW Slow reading rate selected; 6 PLC for 60Hz or 5 PLC for 50Hz.

SRQ Service request over GPIB.

STAT Displaying buffer statistics.

TALK Instrument addressed to talk over GPIB bus.

TIMER Timer controlled triggering in use.

TRIG External triggering (GPIB or trigger link) selected.

MON Zero correct enabled.

SCAN Voltage sweep armed and ready to run.

OCOMP Voltage source in compliance.

Page 24

1-16 Getting Started Model 6485 and 6487 User’s Manual

120

LINE RATING

50, 60Hz

50 VA MAX

INPUT

(CHANGE IEEE ADDRESS

WITH FRONT PANEL MENU)

IEEE-488

CAT I

TRIGGER LINK

RS-232

MADE IN

U.S.A.

ANALOG OUT

DIGITAL I/O

INTERLOCK

505V

MAX

V-SOURCE OUTPUT

505V PK TO CHASSIS

LO HI

!

!

FUSELINE

400mAT

(SB)

100 VAC

120 VAC

200mAT

(SB)

220 VAC

240 VAC

505V PK

505V PK

505V PK

1

2345678

9 10 11 12

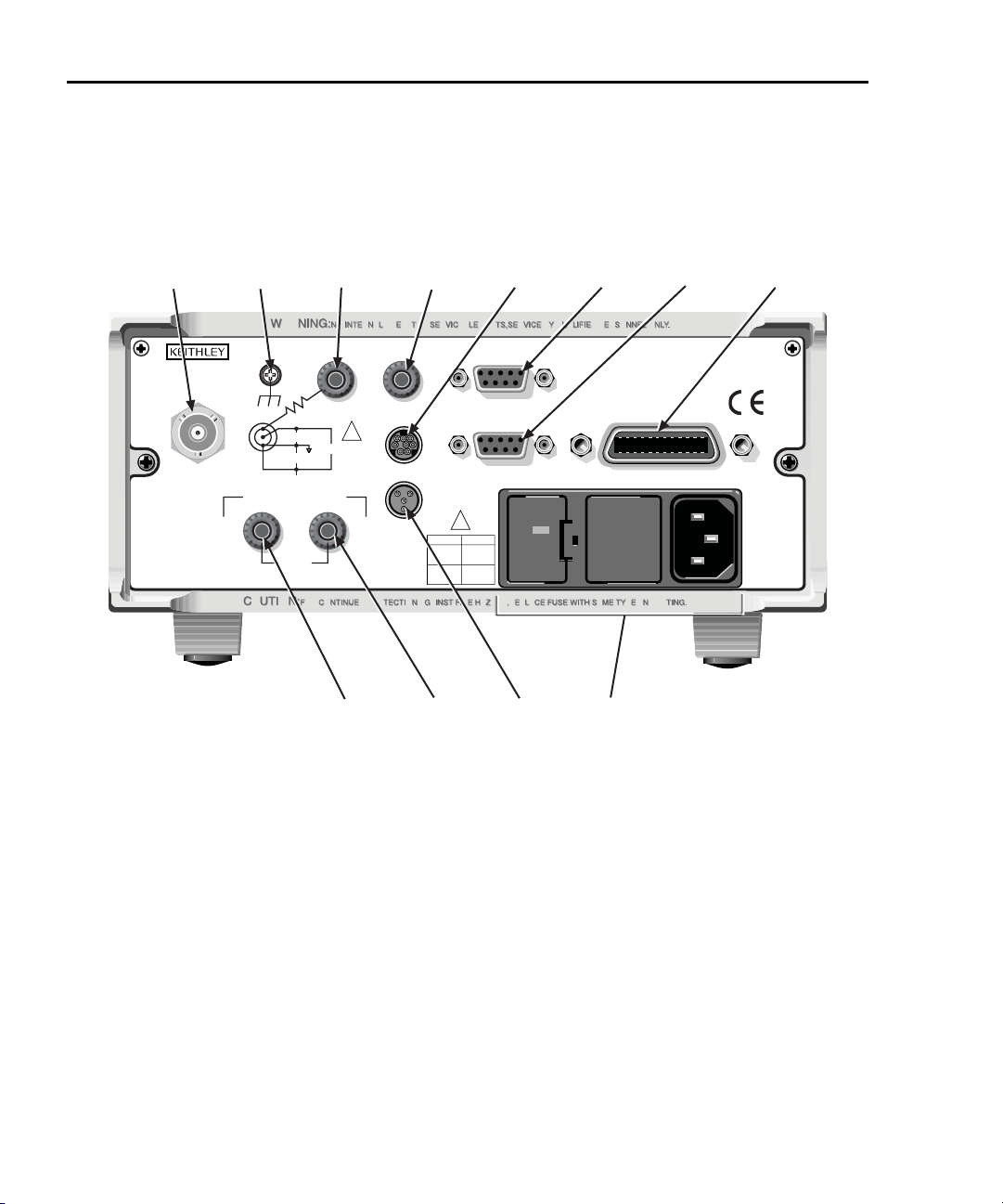

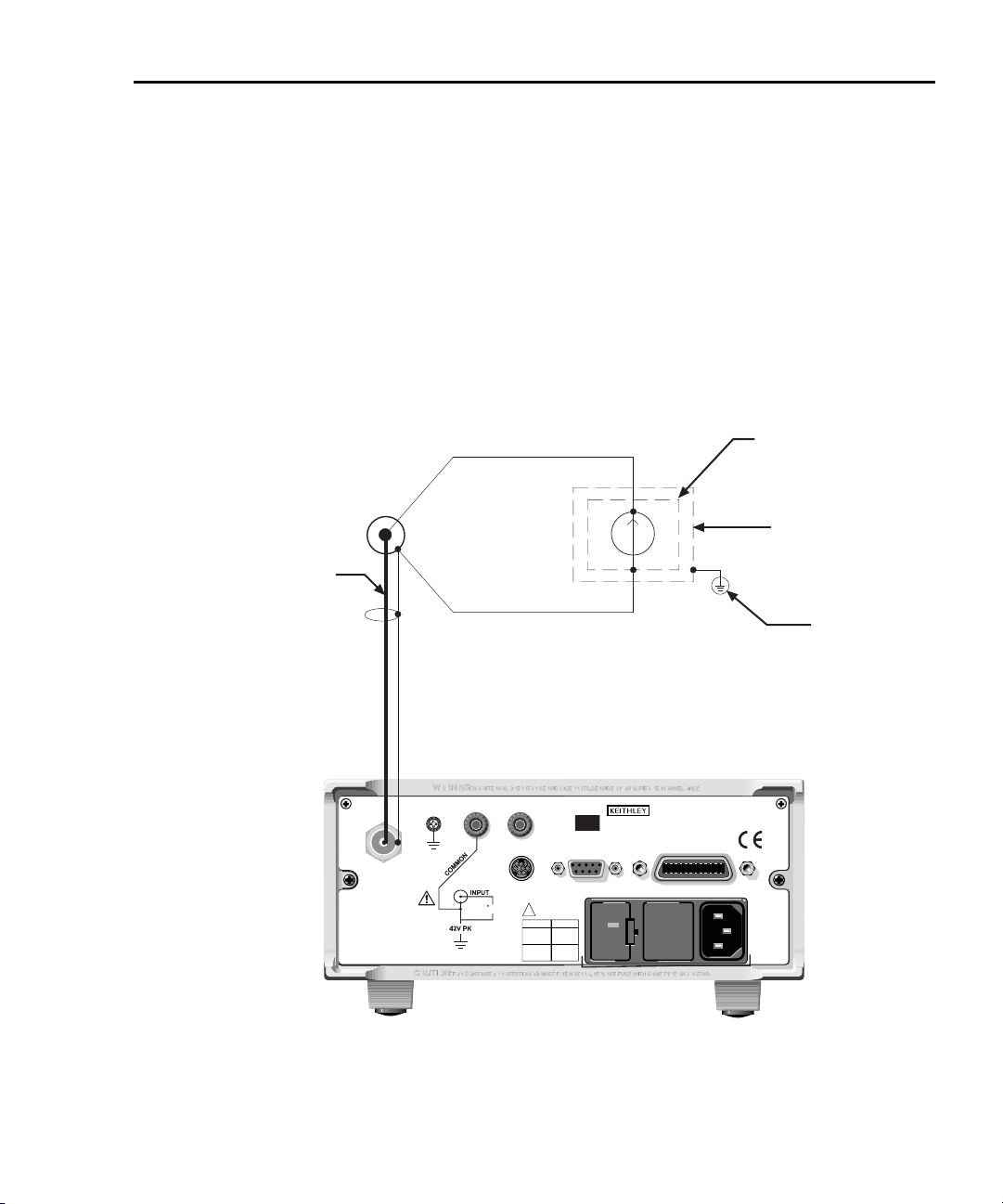

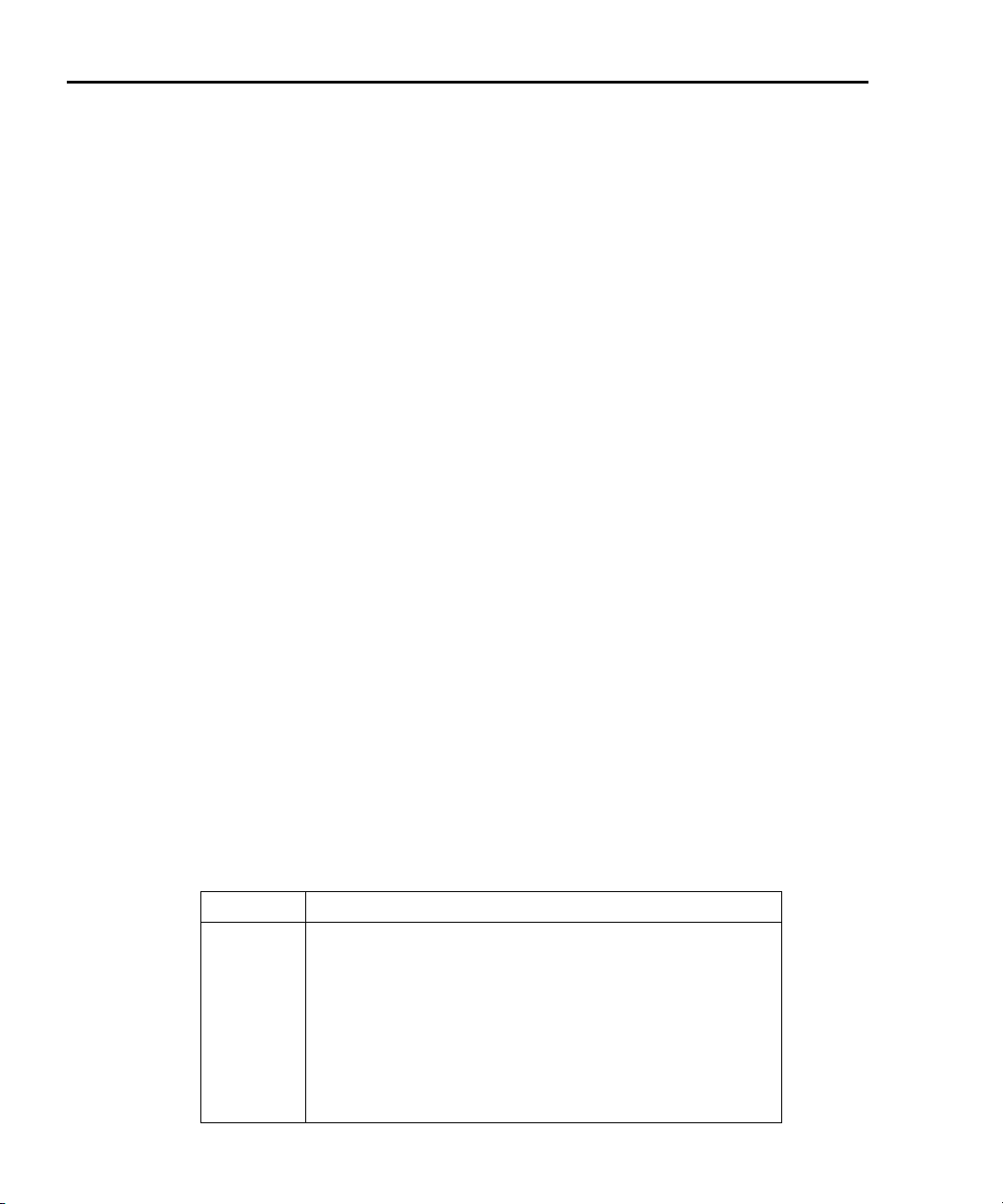

Model 6487 rear panel summary

The rear panel of the Model 6487 is shown in Figure 1-4.

Figure 1-4

Model 6487 rear panel

1INPUT

This standard three-lug female triax connector is used to connect the signal to be measured to the input

of the Model 6487. Mates to a three-slot male triax connector cable.

2CHASSIS

3COMMON

4 ANALOG OUT

This screw terminal is used to connect COMMON to CHASSIS ground via the ground link connector.

This standard banana connector can be used as input LO or as the common for the ANALOG OUT.

Also can be used as a ground link. Note that there is a 1k(ohm) resistance to input LO from the

ANALOG OUT common.

This standard banana connector provides a scaled, inverting output (inverting 2V full scale on all

ranges).

Page 25

Model 6485 and 6487 User’s Manual Getting Started 1-17

5 TRIGGER LINK

Eight-pin micro-DIN connector for sending and receiving trigger pulses among connected instruments. Use a trigger link cable or adapter, such as Models 8501-1, 8501-2, 8502, and 8503.

6 DIGITAL I/O

Male DB-9 connector for digital output lines and component handler signals.

7RS-232

Female DB-9 connector for RS-232 operation. Use a straight-through (not null modem) DB-9 shielded

cable.

8 IEEE-488

Connector for IEEE-488 (GPIB) operation. Use a shielded cable, such as Models 7007-1 and 7007-2.

9 V-SOURCE OUTPUT LO

This standard banana connector provides LO connection to the 6487’s voltage source.

t^okfkd Hazardous voltage may be present on the rear panel V-SOURCE

OUTPUT terminals when the front panel operate indicator is on.

`^rqflk Do not connect external sources to the 6487 voltage source. External

sources may damage the 6487 voltage source.

10 V-SOURCE OUTPUT HI

This standard banana connector provides HI connection to the 6487’s voltage source.

`^rqflk Do not connect external sources to the 6487 voltage source. External

11 INTERLOCK

This interlock connector provides connection of the 6487’s voltage source with an interlock connector

on a test fixture.

12 Power Module

Contains the AC line receptacle and power line fuse. The instrument can be configured for line voltages of 115V and 230VAC (nominal) at line frequencies of 50 or 60Hz automatically and over the bus.

Changing line voltages requires changing fuses.

Voltage source

The Model 6487 voltage source can source up to ±505V DC and is used for the ohms

function. See “Basic connections to DUT,” page 2-5 in for full details on voltage source

operation.

sources may damage the 6487 voltage source.

Page 26

1-18 Getting Started Model 6485 and 6487 User’s Manual

Analog output

The Model 6487 has an analog output on the rear panel. The ANALOG OUT provides a

scaled, inverting ±2V output. A full-scale reading corresponds to ±2V output. See “Ana-

log output,” page 2-14 in for full details on analog output operation.

Digital I/O

The Model 6487's Digital I/O port is a male DB-9 connector located on the rear panel. The

four active-low, digital output lines and one input line are used to control external circuitry. For

detailed connection and usage information, refer to Section 8 of the Model 6487 Reference

Manual.

Display

Readings can be displayed in engineering units or scientific notation. Annunciators indicate various states of operation. See “Model 6487 front panel summary,” page 1-13 for a

complete listing of display annunciators. The normal display also includes the voltage

source value on the right.

klqb Changing the display resolution is not allowed if displaying readings in scientific

notation.

The DISP key can be used to turn the display on or off. The Display and Keys Test allows

you to test display digit segments and annunciators, and check the functionality of front

panel keys. These tests are accessed through the MENU.

Status and error messages

Status and error messages are displayed momentarily. During operation and programming, you will encounter a number of front panel messages. Typical messages are either

of status or error variety, as listed in Appendix B of the Model 6487 Reference Manual.

Page 27

Model 6485 and 6487 User’s Manual Getting Started 1-19

Power-up

Line power connection

Follow the procedure below to connect the Model 6485/6487 to line power and turn on the

instrument.

1. Check to see that the line voltage indicated in the window of the fuse holder assembly (Figure 1-2 or Figure 1-4) is correct for the operating voltage in your area. If

not, refer to the procedure in Section 17 of the Model 6485 Instruction Manual or

Model 6487 Reference Manual for setting line voltage and fuse replacement.

`^rqflk Operating the instrument on an incorrect line voltage may cause damage to

the instrument, possibly voiding the warranty.

2. Before plugging in the power cord, make sure that the front panel power switch is

in the off (O) position.

3. Connect the female end of the supplied power cord to the AC receptacle on the rear

panel. Connect the other end of the power cord to a grounded AC outlet.

t^okfkd The power cord supplied with the Model 6485/6487 contains a separate

4. Turn on the instrument by pressing the front panel power switch to the on (I) position.

Line frequency

The Model 6485/6487 operates at line frequencies of 50 or 60Hz. When auto detect is

enabled (factory default), line frequencies are automatically sensed and set accordingly,

therefore there are no switches to set. Use the :SYST:LFR? command (query) to read the

line frequency. The factory default setting is auto detect enabled.

If the power line is noisy, auto detect may not be able to lock in on a frequency. If this

occurs, set the frequency manually. This may be accomplished using the front panel or

over the bus. From the front panel, use the MENU/LFREQ selection to change the frequency. Via remote, send the SYST:LFR <freq> command.

ground terminal for use with grounded outlets. When proper connections

are made, instrument chassis is connected to power line ground through the

ground wire in the power cord. Failure to use a grounded outlet may result

in personal injury or death due to electric shock.

Page 28

1-20 Getting Started Model 6485 and 6487 User’s Manual

Power-up sequence

The following power-up sequence occurs when the Model 6485/6487 is turned on:

1. The Model 6485/6487 performs self-tests on its EPROM and RAM with all digits

and annunciators turned on. (For the Model 6487 at power-up, the VOLTAGE

SOURCE OPERATE LED will come on for 0.7 seconds to indicate that it is functional.) If a failure is detected, the instrument momentarily displays an error message and the ERR annunciator turns on. Error messages are listed in Appendix B of

the Model 6485 Instruction Manual or Model 6487 Reference Manual.

klqb If a problem develops while the instrument is under warranty, return it to

Keithley Instruments Inc., for repair.

2. If the instrument passes the self-tests, the firmware revision levels are displayed.

For example:

6485 A01 or 6487 A01

3. After the firmware revision levels are displayed, the detected line frequency is

displayed.

For example:

FREQ: 60Hz

4. After the detected line frequency is displayed, information on the selected remote

interface is displayed:

a. GPIB — If the GPIB is the selected interface, the instrument will display the

selected language (SCPI or DDC) and primary address.

Model 6485 Examples:

SCPI ADDR: 14

DDC ADDR: 14

Model 6487 Examples:

SCPI ADDR: 22

DDC ADDR: 22

b. RS-232 — If RS-232 is the selected interface, the instrument will display the baud

rate setting. For example:

RS-232: 9600b

5. If the FACTory setup is selected as the power-on setup, the unit is placed in the

default reading mode after the communication information is displayed. If a setup

other than FACTory is selected, the configured setup will be displayed. For example, if the USR1 setup (User Setup #1) is selected:

USING USR1

Page 29

Model 6485 and 6487 User’s Manual Getting Started 1-21

Default settings

The Model 6485/6487 can be restored to one of five setup configurations: factory default

(FACT), three user-saved (USR0, USR1, and USR2), and bus default (GPIB). As shipped

from the factory, Model 6485/6487 powers up to the factory default settings. Factory

default settings provide a general purpose setup for front panel operation, while the bus

default (GPIB) settings do the same for remote operation. Factory and GPIB default settings are listed in Table 1-1 and Table 1-2.

The instrument will power up to whichever default setup was saved as the power-on setup.

klqb At the factory, the factory default setup is saved into the USR0, USR1, and USR2

setups.

Saving user setups

To save a user setup, configure Model 6485/6487 for the desired measurement application, then press SAVE and select the desired setup (0 = USR0, 1 = USR1, 2 = USR2).

Press ENTER to complete the process. Use the *SAV command to save setups by remote.

To save the power-on setup, press CONFIG and then SETUP, and select FACT, USR0,

USR1, USR2, or GPIB, and press ENTER. Use the SYST:POS command to save the

power-on setup via remote.

Restoring setups

Press SETUP to display the restore menu, then select the setup (FACT, USR0, USR1,

USR2, or GPIB) and press ENTER. Use the *RCL command to recall setups by remote.

Restoring factory default setup

From the front panel, press SETUP, select FACT, and then press ENTER. Use *RST to

restore GPIB defaults or SYST:PRES to restore front panel defaults via remote.

Page 30

1-22 Getting Started Model 6485 and 6487 User’s Manual

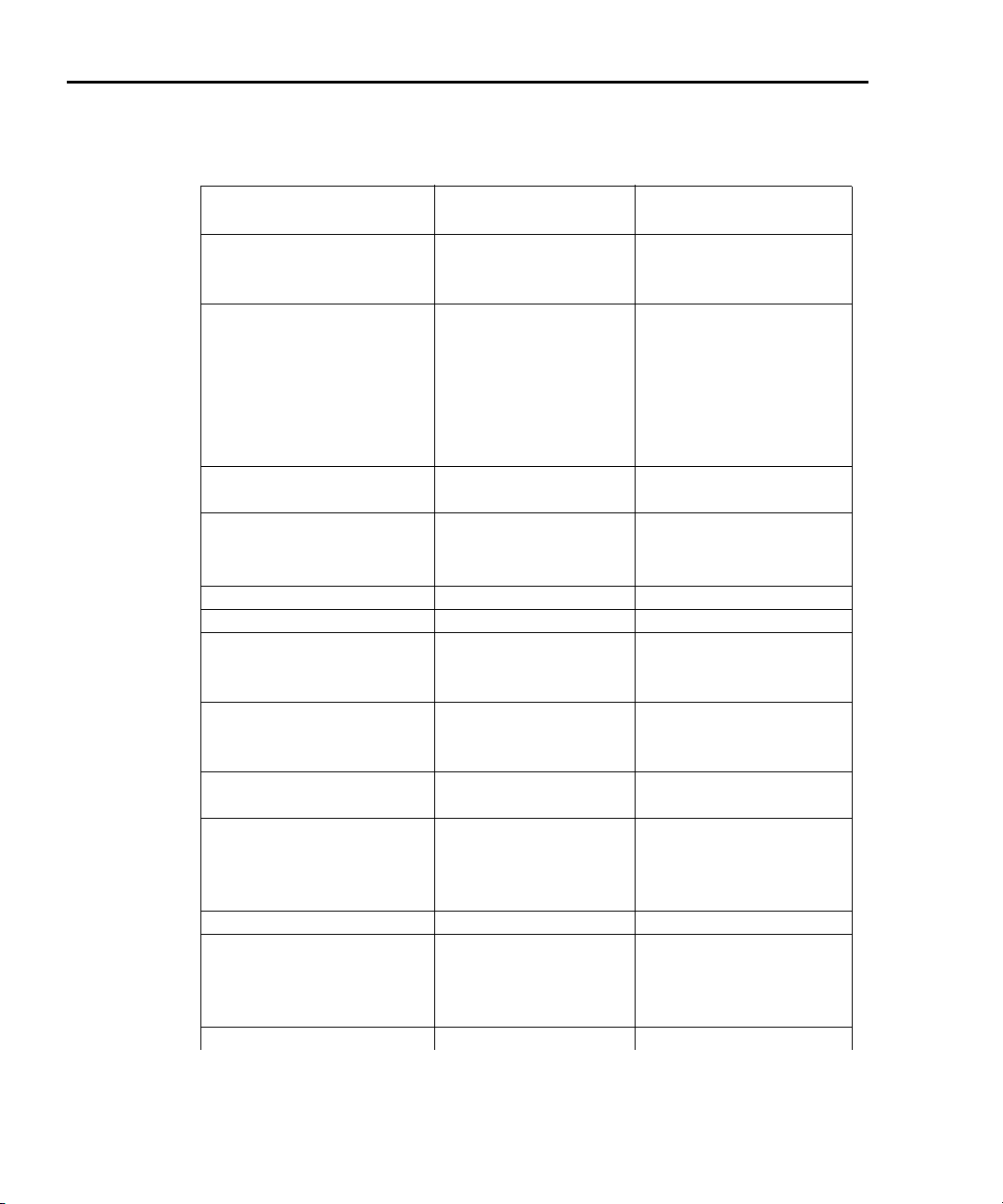

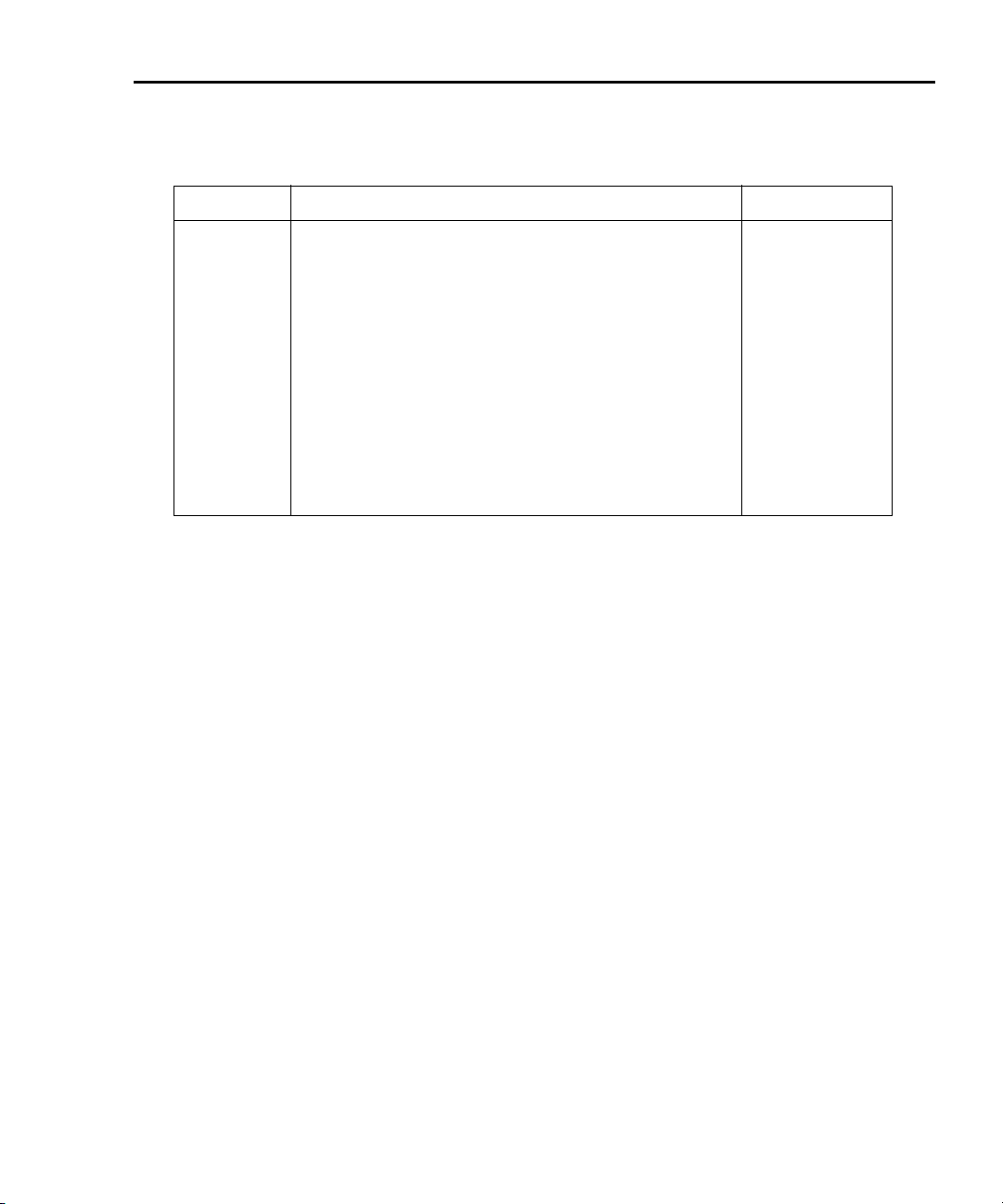

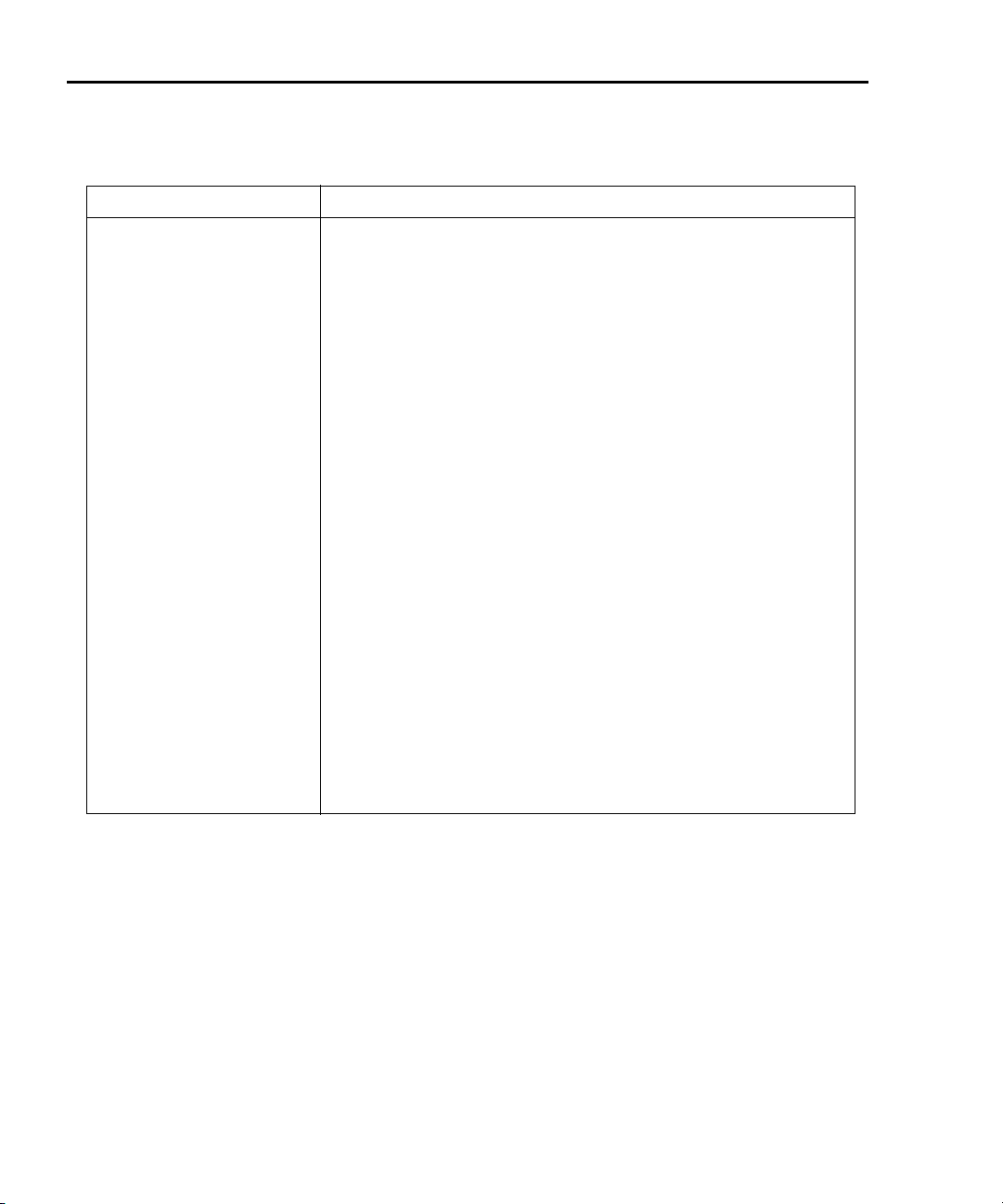

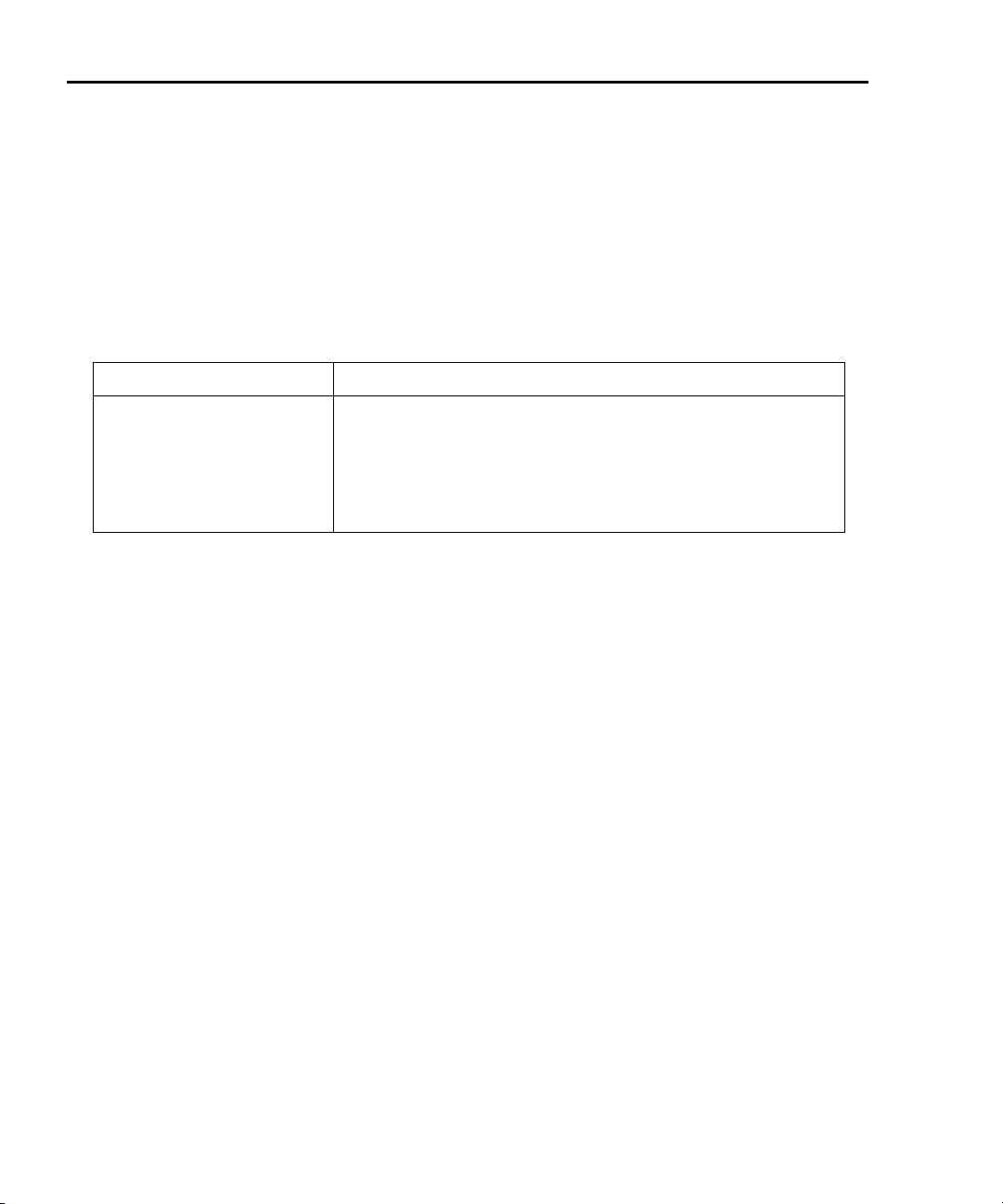

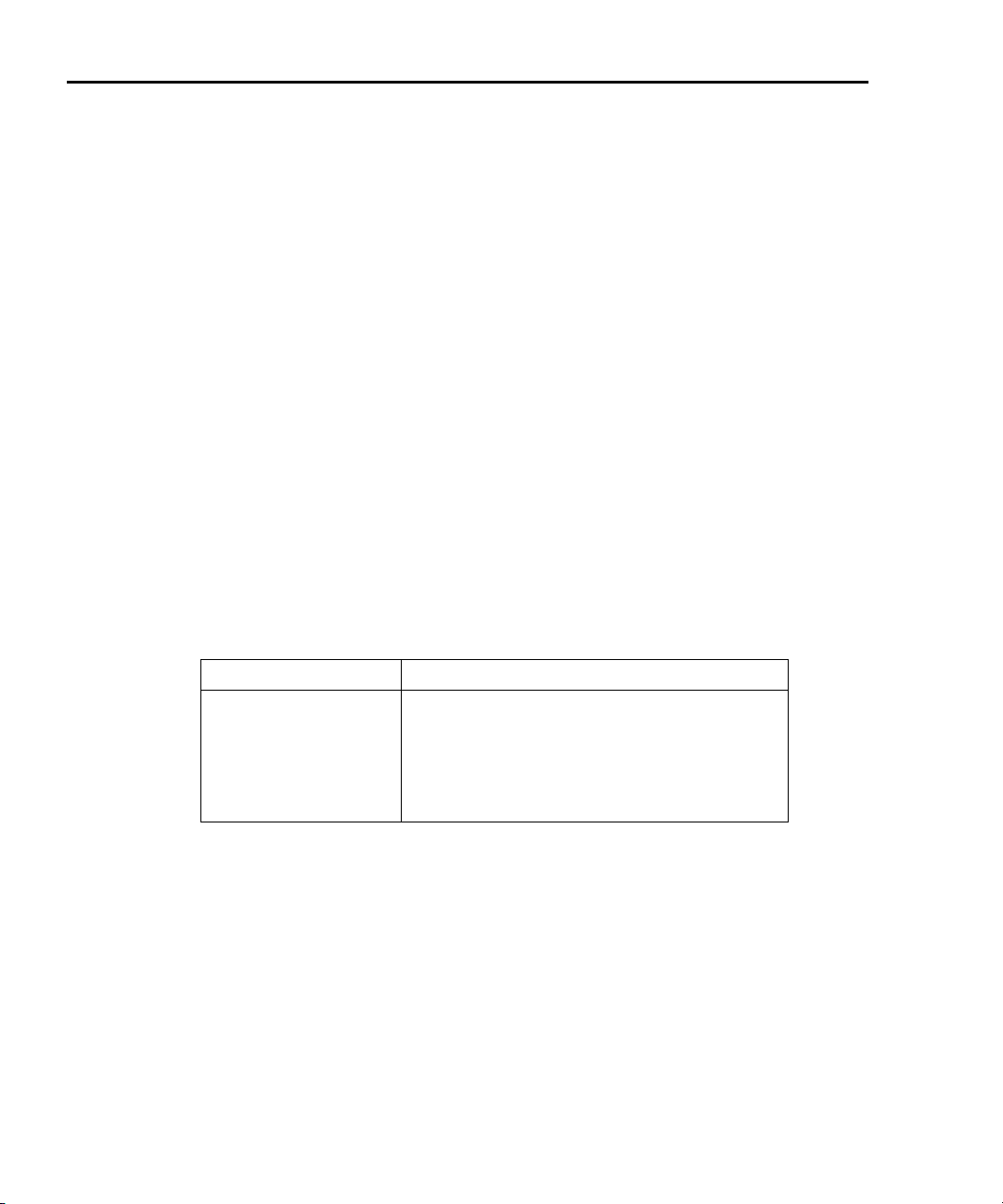

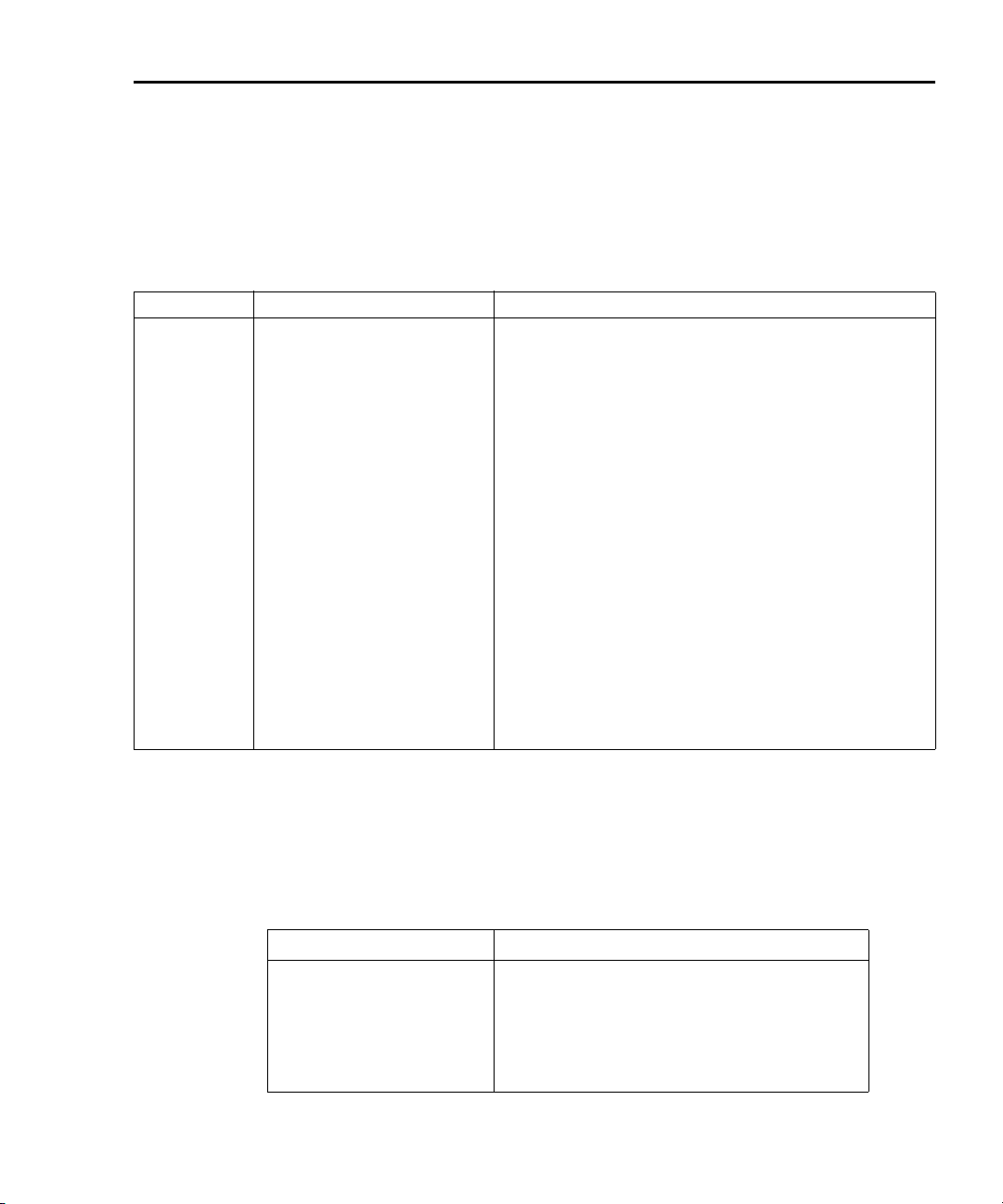

Ta bl e 1 -1

Model 6485 default settings

Setting

Factory

(:SYStem:PRESet)

GPIB

(*RST)

Trig Layer (CONF-TRIG):

TRIG:

Arm-In Source Event

TRIG-IN

IMM

*

*

Arm Layer (CONF-ARM):

Arm-In Source Event

Arm Count

Input Trigger Link Line

Source Bypass

Output Trigger Link Line

Output Trigger

Buffer (STORE):

Count

Digital Filter (AVG):

Count

Type

IMM

INF

1

NEVER

2

Off

Disabled

No effect

Off

10

Moving

*

1

*

*

*

*

*

*

*

*

*

Display Resolution (DIGITS) 5 -digits *

Format byte order Swapped Normal

GPIB:

Address

Language

No effect (On at factory)

No effect (14 at factory)

No effect (SCPI at factory)

*

*

*

Limit Tests:

Limit 1 and Limit 2:

HI and LO Values

Median Filter:

Rank

MX+B:

“M” Value

“B” Value

Units

Disabled

1, -1

Off

1

Disabled

1.0

0.0

X

*

*

*

*

*

*

*

*

Log OFF *

M/X+B (reciprocal)

“M” Value

“B” Value

Units

Disabled

1.0

0.0

X

*

*

*

*

Range AUTO *

*The factory (:SYStem:PRESet) and bus (*RST) GPIB defaults are the same. Bus settings that are different

from factory reset are as shown.

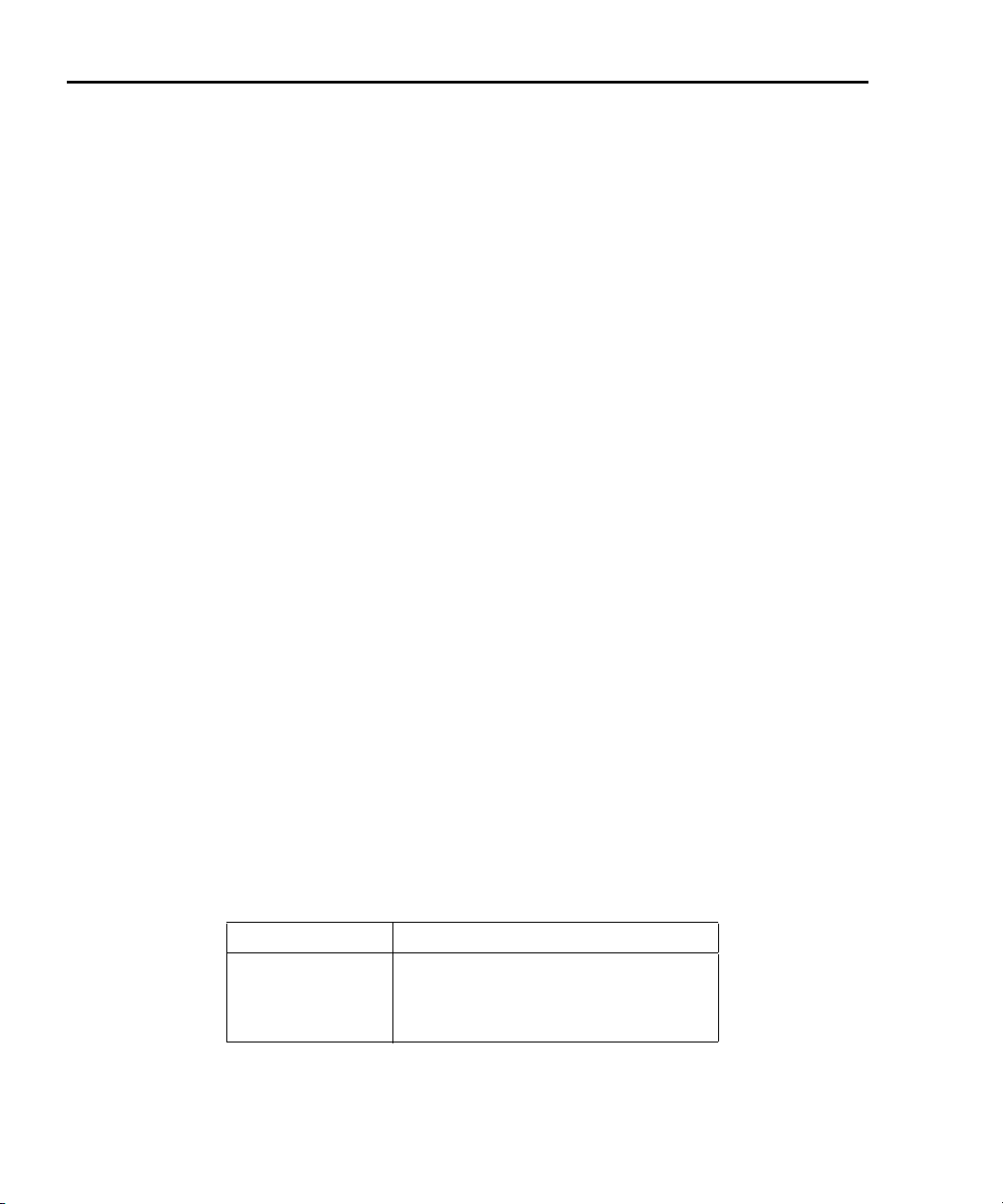

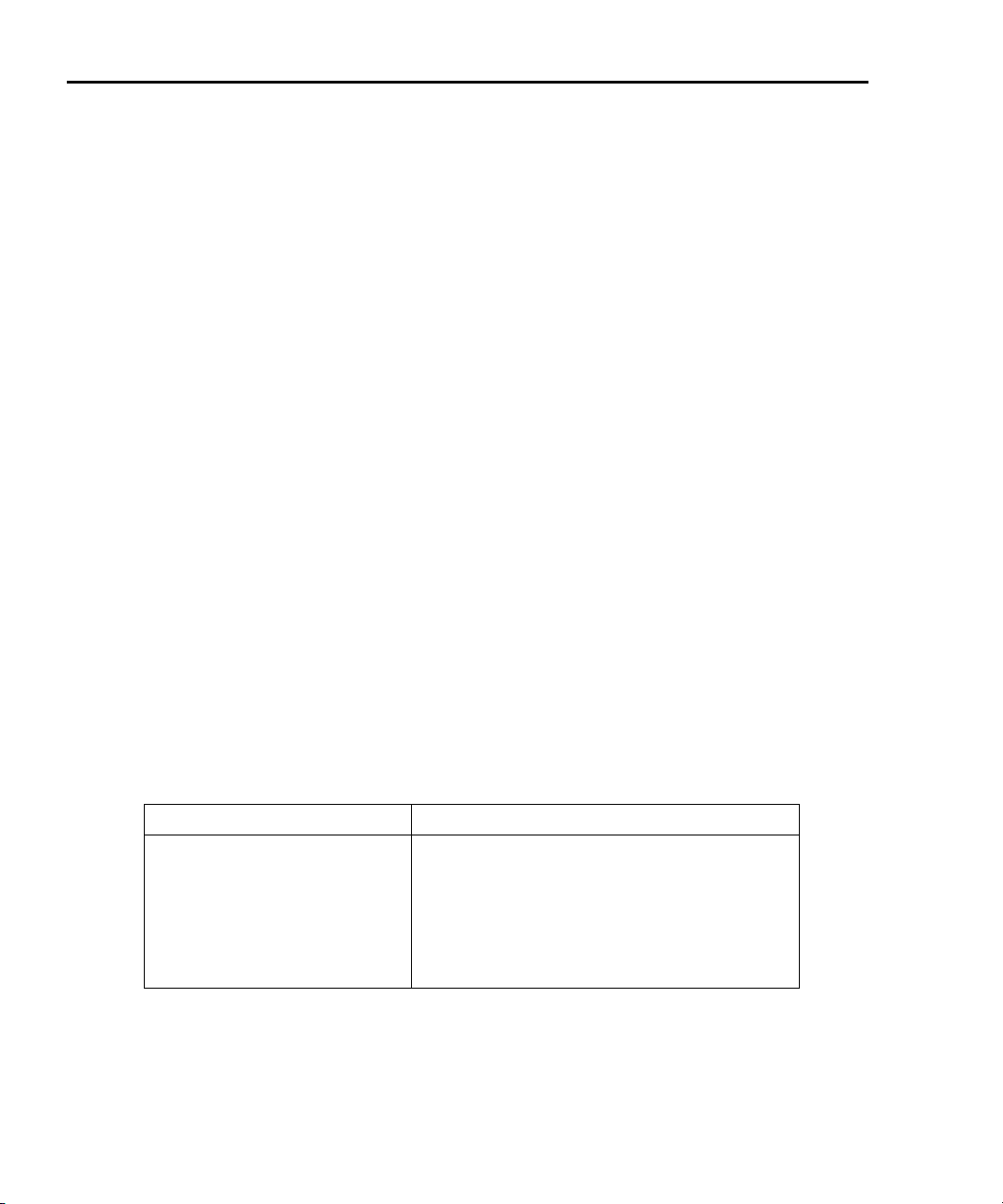

Page 31

Model 6485 and 6487 User’s Manual Getting Started 1-23

Tab le 1 -1 (c on t. )

Model 6485 default settings

Setting

Rate:

NPLC

Rel:

Rel Value (VAL)

RS-232:

All Settings

Factory

(:SYStem:PRESet)

Slow

6.0 (60Hz) or 5.0 (50Hz)

Off

0.0

No effect (Off at factory)

No effect

GPIB

(*RST)

*

*

*

*

*

*

Trigger Layer (CONF-TRIG):

Trig-In Source Event

Trigger Count

Trigger Delay

Input Trigger Link Line

Source Bypass

Output Trigger Link Line

IMM

1

0

1

NEVER

2

*

*

*

*

*

*

Units No effect *

Zero Check Enabled *

Zero Correct Disabled *

*The factory (:SYStem:PRESet) and bus (*RST) GPIB defaults are the same. Bus settings that are different

from factory reset are as shown.

Page 32

1-24 Getting Started Model 6485 and 6487 User’s Manual

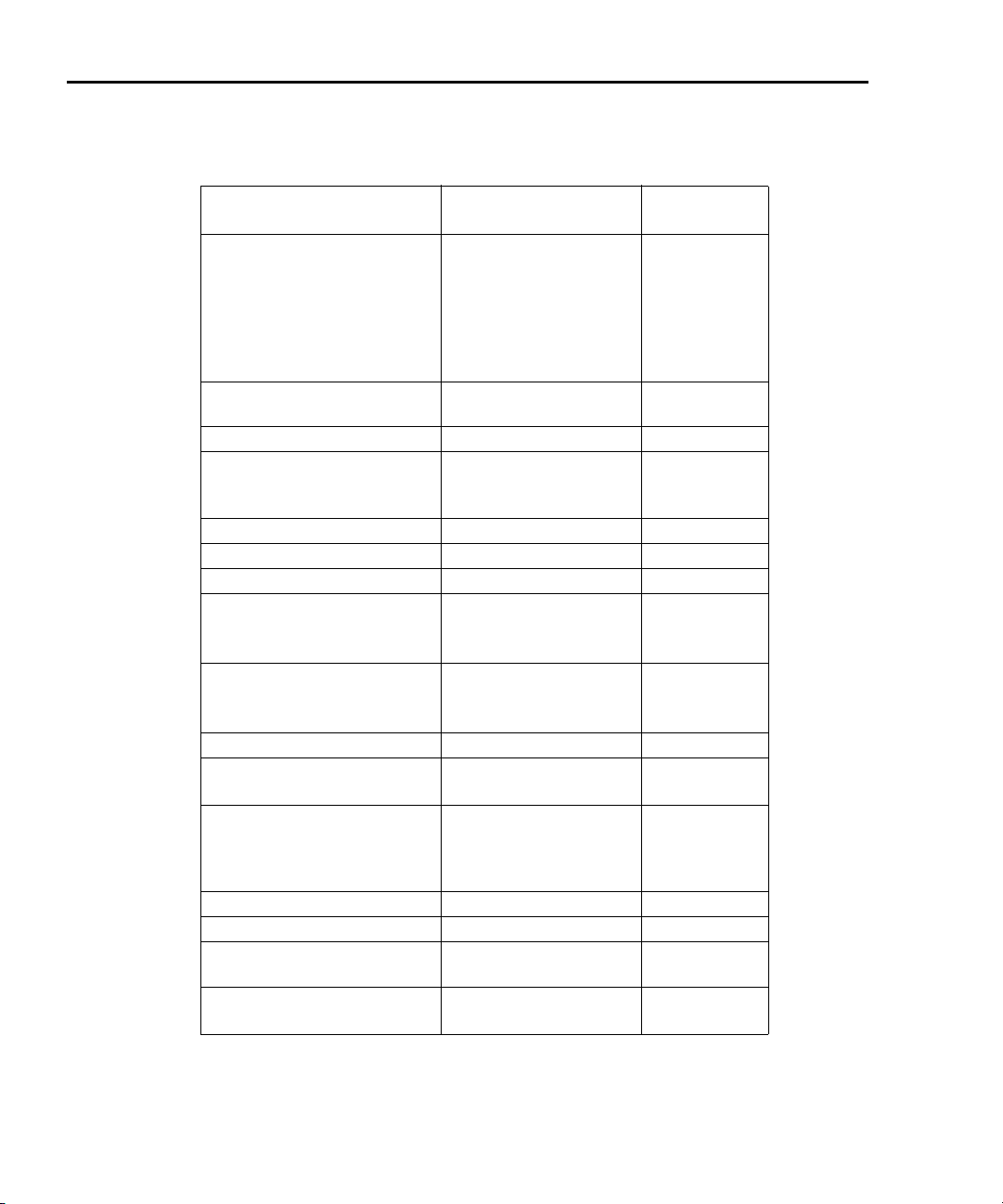

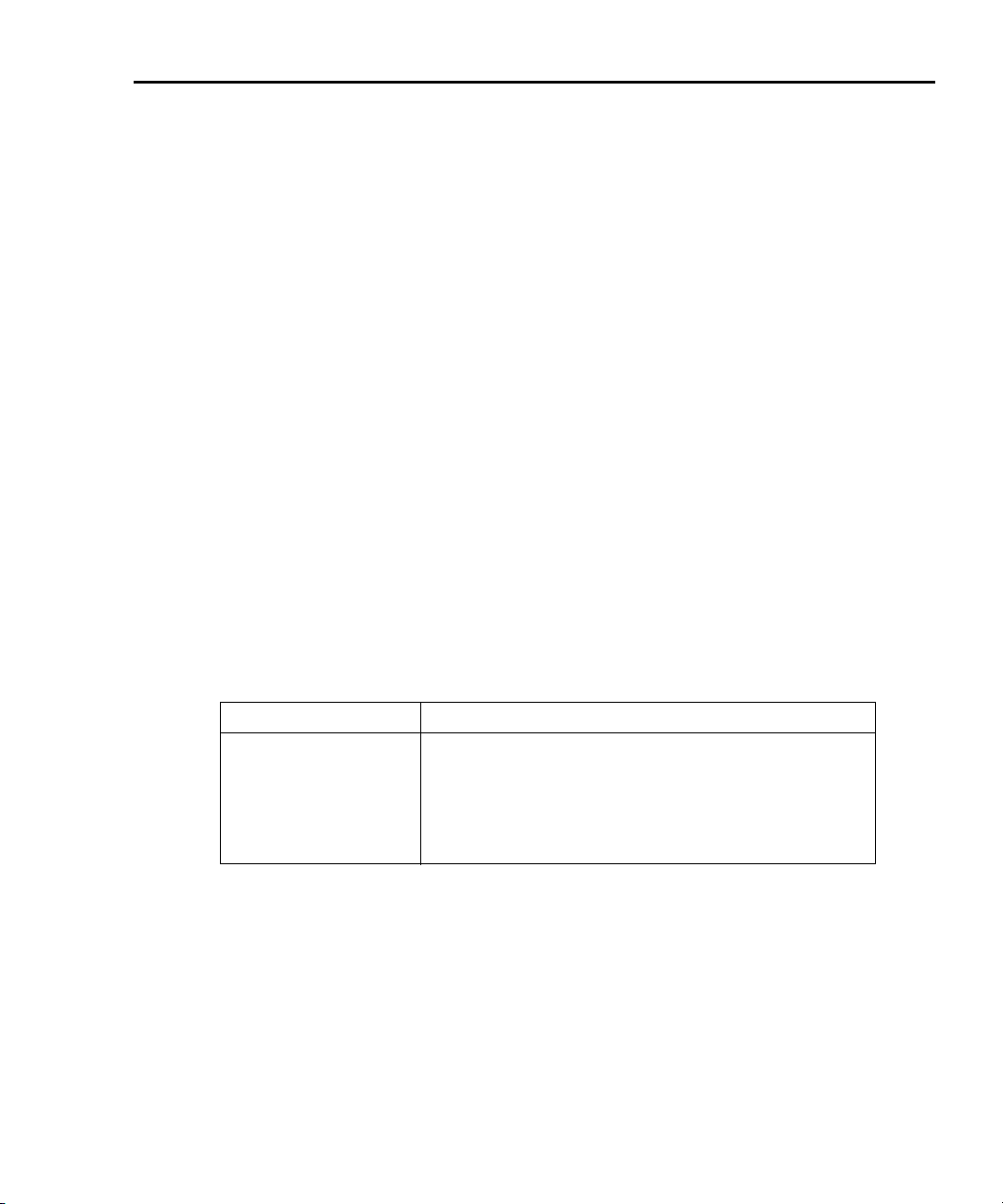

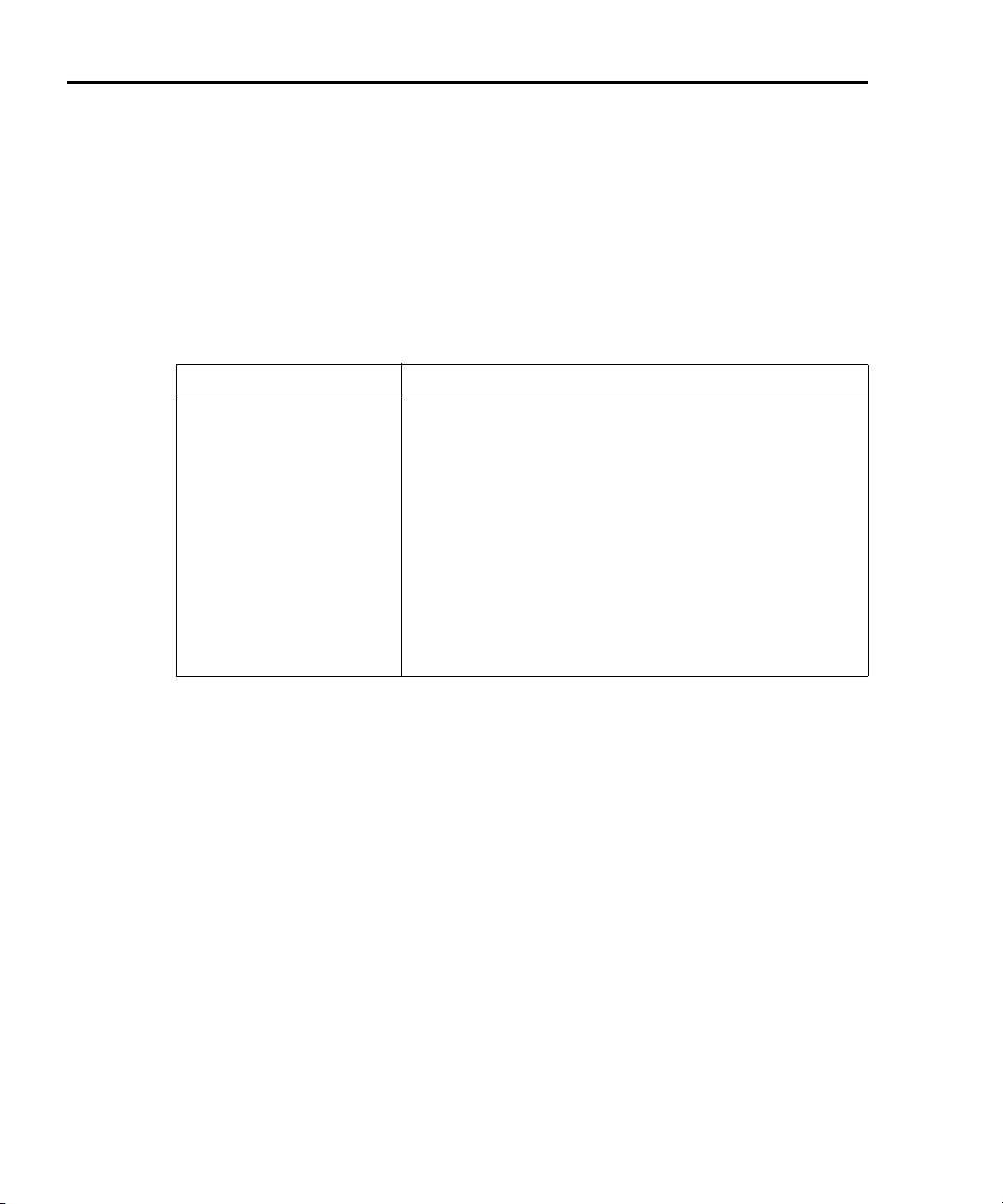

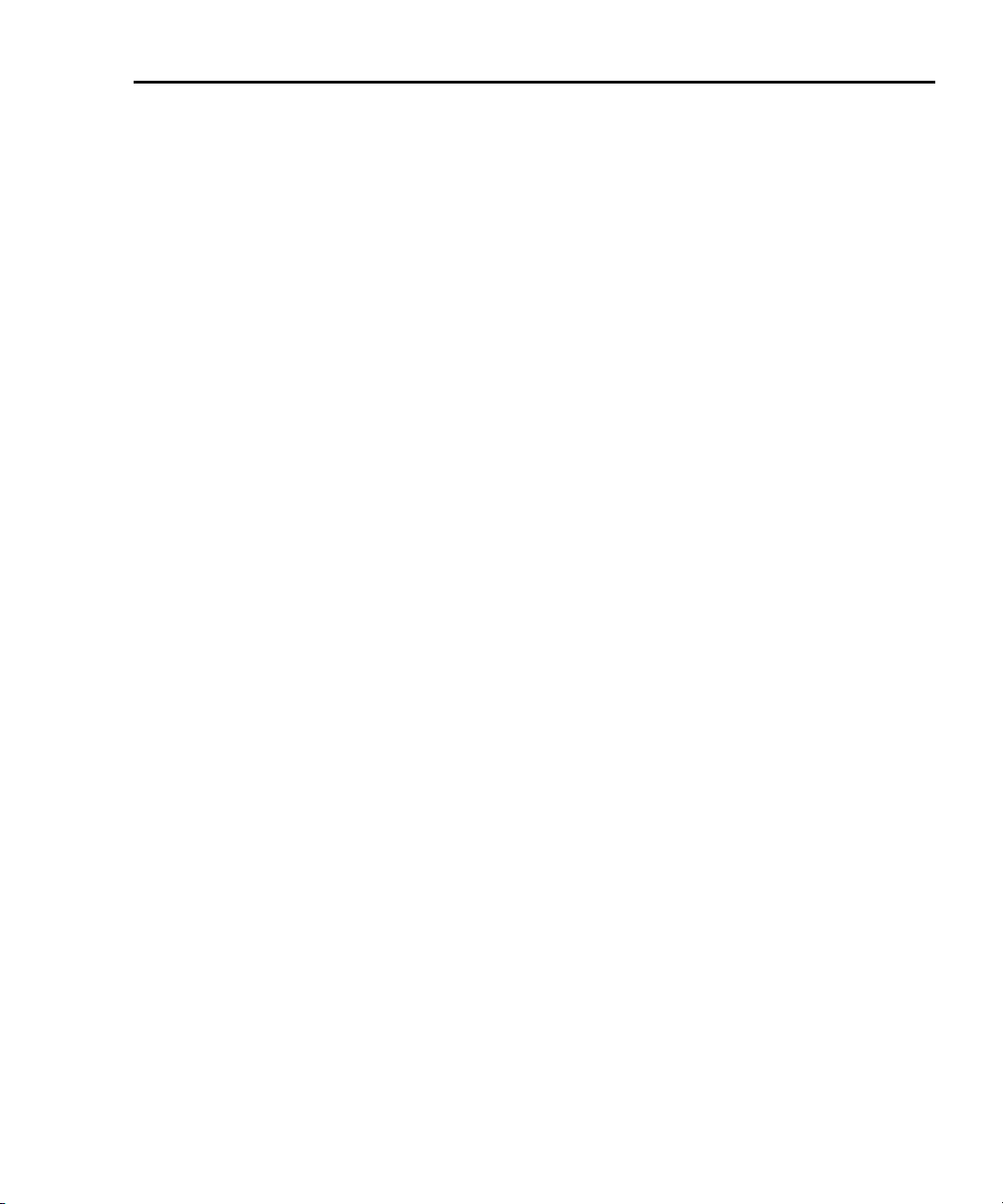

Ta bl e 1 -2

Model 6487 default settings

Setting

Factory

(:SYStem:PRESet)

GPIB

(*RST)

Arm Layer (CONFIG ARM):

Arm-In Source Event

Arm Count

Input Trigger Link Line

Source Bypass

Output Trigger Link Line

Output Trigger

Buffer (STORE):

Count

IMM

INF

1

NEVER

2

Off

Disabled

No effect

*

1

*

*

*

*

*

*

Damping (DAMP) On *

Digital Filter (FILT):

Count

Type

Off

10

Moving

*

*

*

Display Resolution (DIGITS) 5 -digits *

Format byte order Swapped Normal

Function Amps *

GPIB:

Address

Language

No effect (On at factory)

No effect (22 at factory)

No effect (SCPI at factory)

*

*

*

Limit Tests:

Limit 1 and Limit 2:

HI and LO Values

Disabled

1, -1

*

*

Log (MATH) OFF *

Median Filter (FILT):

Rank

M/X+B (MATH)

“M” Value

“B” Value

Units

Off

1

Disabled

1.0

0.0

X

*

*

*

*

*

*

Ohms Mode Normal *

Range AUTO *

Rate:

NPLC

Rel:

Rel Value (VAL)

*The factory (:SYStem:PRESet) and bus (*RST) GPIB defaults are the same.

Bus settings that are different from factory reset are as shown.

Slow

6.0 (60Hz) or 5.0 (50Hz)

Off

0.0

*

*

*

*

Page 33

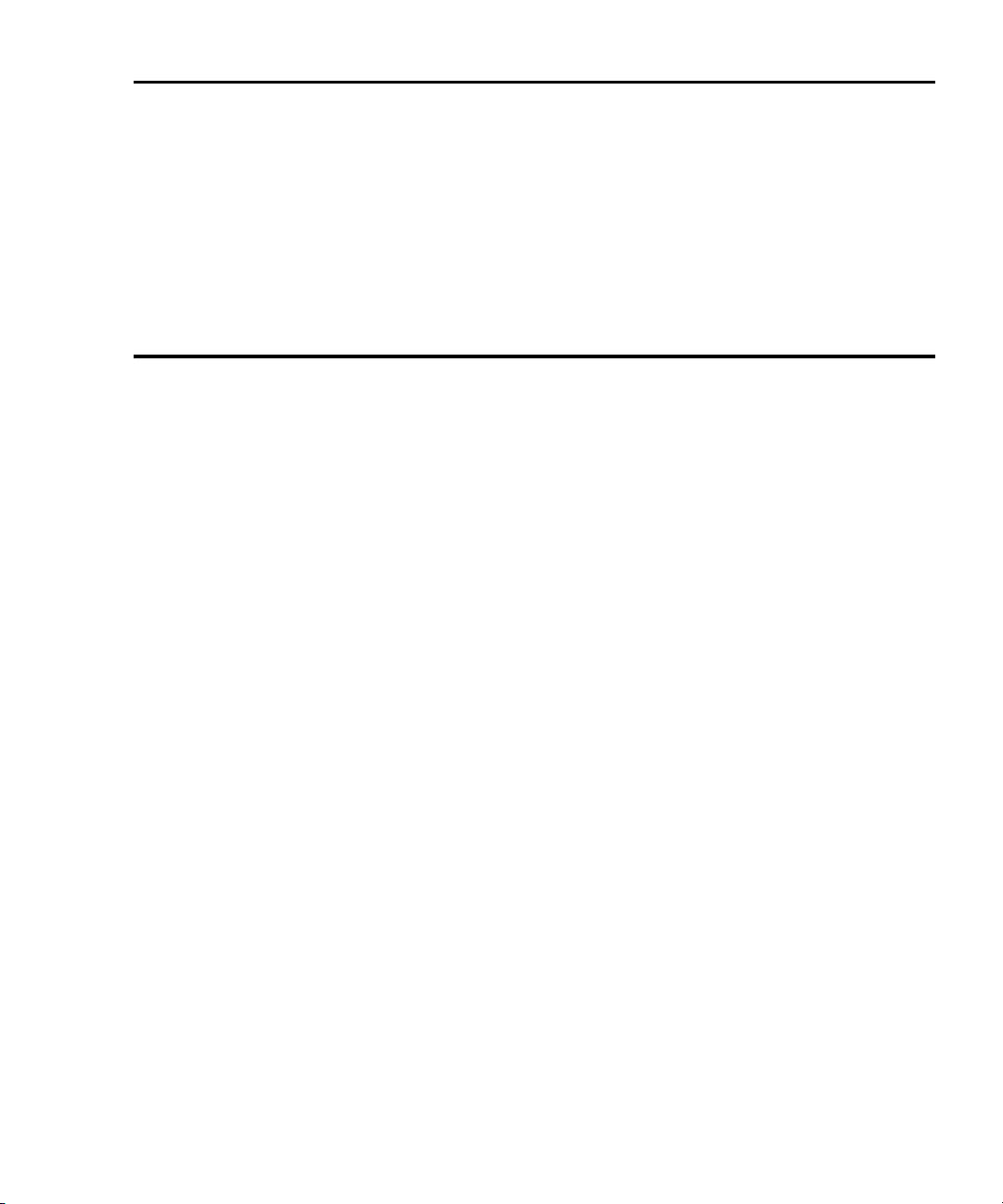

Model 6485 and 6487 User’s Manual Getting Started 1-25

Tab le 1 -2 (c on t. )

Model 6487 default settings

RS-232:

All Settings

Setting

Factory

(:SYStem:PRESet)

No effect (Off at factory)

No effect

GPIB

(*RST)

Trigger Layer (CONFIG TRIG):

Trig-In Source Event

Trigger Count

Trigger Delay

Input Trigger Link Line

Source Bypass

Output Trigger Link Line

IMM

1

0

1

NEVER

2

Units No effect *

Voltage Source:

Operate

Amplitude

Range

Current Limit

10V Range Interlock

Off

0V

10V

25mA

Off

Sweeps:

Start Voltage

Stop Voltage

Step Voltage

Center Voltage

Span Voltage

Delay

0V

10V

1V

5V

10V

1s

Zero Check Enabled *

Zero Correct Disabled *

*The factory (:SYStem:PRESet) and bus (*RST) GPIB defaults are the same.

Bus settings that are different from factory reset are as shown.

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

Page 34

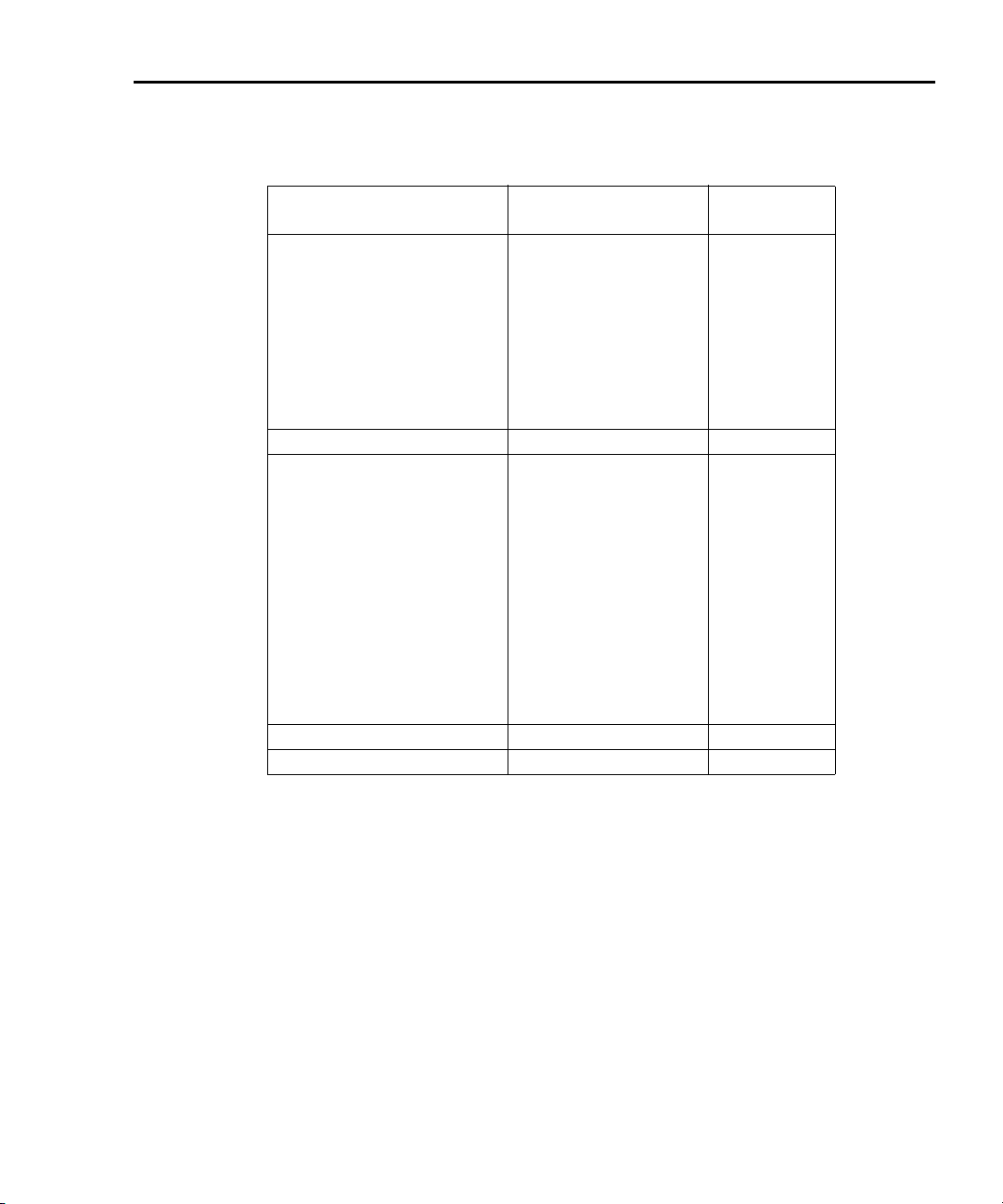

1-26 Getting Started Model 6485 and 6487 User’s Manual

Menu

Many aspects of operation are configured through the menus summarized in Table 1-3 and

Table 1-4. Refer to the section listed in the table for in-depth information. To access the

menu, press the MENU key. Use the

and the

and 䊳 cursor keys to change options. Press ENTER to save any changes made

and then leave the menu. Press EXIT to leave the menu without saving changes.

klqb The MENU key is used to access the menu structure. However, if in remote for

IEEE-488 bus operation (REM annunciator is lit), pressing the menu key has no

effect. Press the LOCAL key to place the unit in local operation, then press the

MENU key to access the menu items.

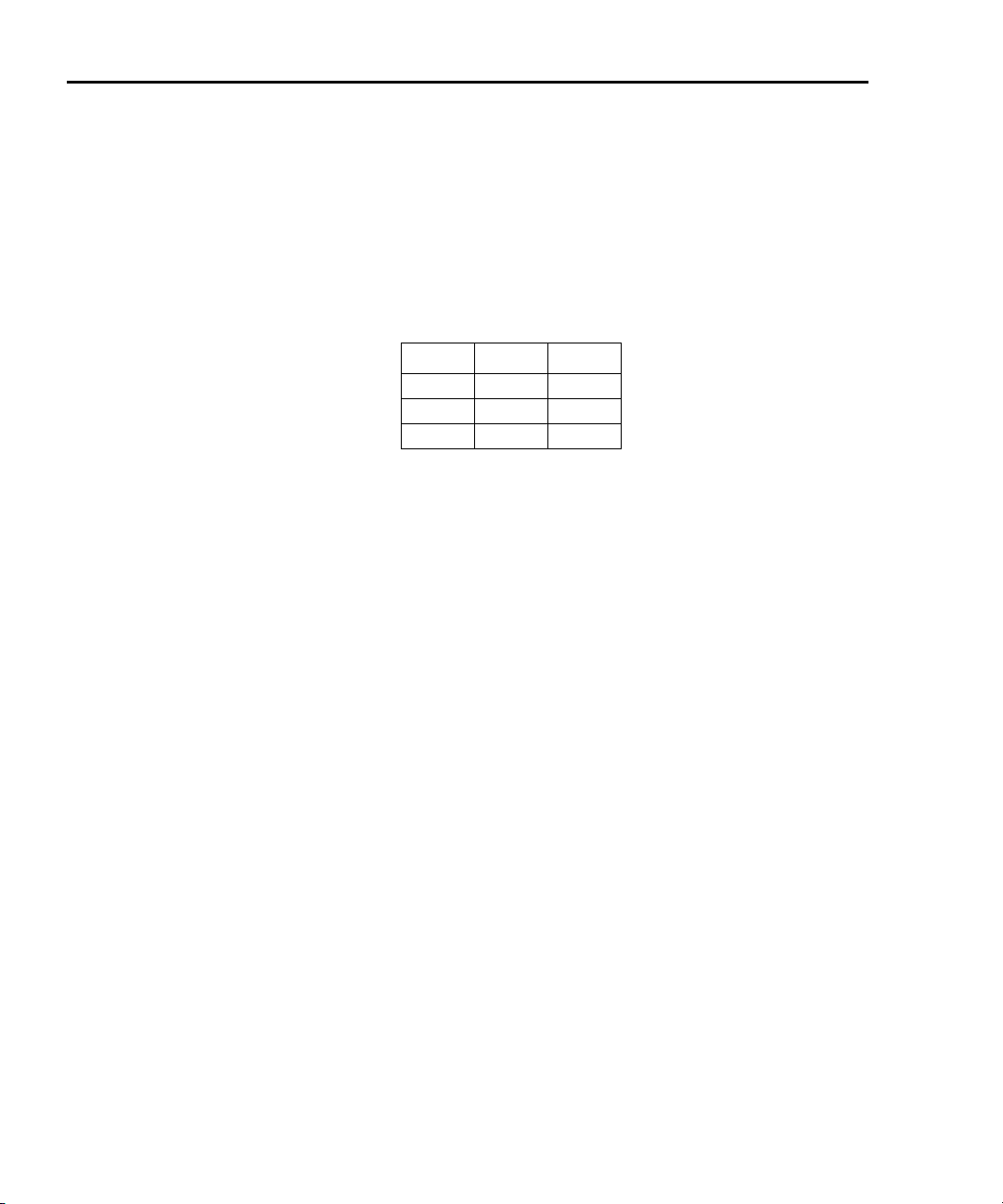

Ta bl e 1 -3

Model 6485 MENU structure

Menu item Description Reference

CAL Provides path to the following calibration submenu items:

VOFFSET, COUNT, RUN, DATES, UNLOCK, LOCK, and

SAVE.

TSTAMP Timestamp format can be ABSolute or DELTa. Section 6

UNITS Readings can be displayed in ENGineering units or

SCIentific notation.

TEST Run display or key tests. Instruction Manual

SNUM Displays the unit’s serial number.

LFREQ Line frequency can be manually set to 50 or 60 Hz or

AUTOmatically set. The number after AUTO indicates

present detected frequency value.

and RANGE keys to scroll through the menu items

Instruction Manual

Section 16

Section 17

“Line frequency,”

page 1-19

Page 35

Model 6485 and 6487 User’s Manual Getting Started 1-27

Ta bl e 1 -4

Model 6487 MENU structure

Menu item Description Reference

CAL Provides path to the following calibration submenu items:

VOFFSET, COUNT, RUN, VSRC-RUN, DATES,

UNLOCK, LOCK, and SAVE.

TSTAMP Timestamp format can be ABSolute or DELTa. Section 6

UNITS Readings can be displayed in ENGineering units or

SCIentific notation.

TEST Run display or key tests. Reference Manual

SNUM Displays the unit’s serial number.

LFREQ Line frequency can be manually set to 50 or 60 Hz or

AUTOmatically set. The number after AUTO indicates

present detected frequency value.

Reference Manual

Section 16

Section 17

“Line frequency,”

page 1-19

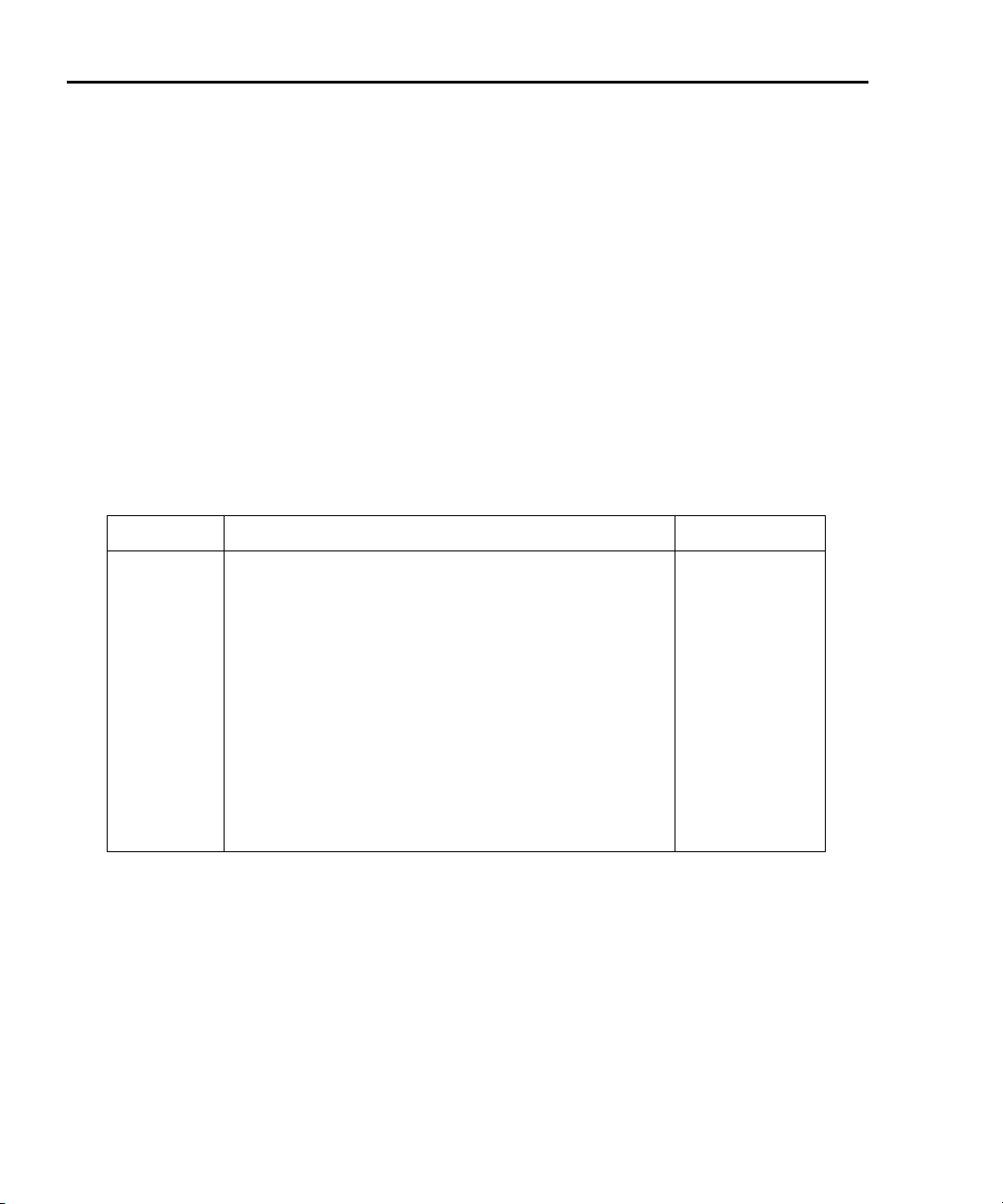

SCPI programming

SCPI programming information is integrated with front panel operation throughout this

manual. SCPI commands are listed in tables and additional information that pertains

exclusively to remote operation is provided after each table. The SCPI tables may reference you to other sections of this manual.

klqb SCPI tables in this manual are abridged. That is, they do NOT include most

optional command words and query commands. See Section 14 of the

Model 6485 Instruction Manual or Model 6487 Reference Manual for a complete listing of SCPI commands.

Optional command words

In order to be in conformance with the IEEE-488.2 standard, the Model 6485/6487

accepts optional command words. Any command word that is enclosed in brackets ([]) is

optional and does not have to be included in the program message. Programming examples in this manual use the short form and do not include optional command words for

simplicity.

Query commands

Most command words have a query form. A query command is identified by the question

mark (?) that follows the command word. A query command requests (queries) the programmed status of that command. When a query command is sent and Model 6485/6487

is addressed to talk, the response message is sent to the computer.

Page 36

1-28 Getting Started Model 6485 and 6487 User’s Manual

Page 37

Model 6485 and 6487 User’s Manual Connections 2-1

2

Connections

• Connection fundamentals — Covers fundamental information about connecting

test circuits to the picoammeter.

• Basic connections to DUT — Details connecting test circuits to the picoammeter

for current measurement and Model 6487 ohms measurements.

• Using a test fixture — Discusses using general test fixtures as well as the Model 8009

test fixture.

• Model 6487 interlock — Provides information on using the Model 6487 interlock,

which must be used to optimize safety.

• Analog output — Covers analog output connections and discusses considerations

when using the analog output.

• Measurement considerations — Summarizes considerations that could affect

overall measurement accuracy.

Page 38

2-2 Connections Model 6485 and 6487 User’s Manual

Shield

(LO or GND)

Input

(Center Conductor)

CAT I

INPUT

Connection fundamentals

The following provides important fundamental information on input connections to the

Models 6485 and 6487. Typical connection drawings are provided in “Basic connections

to DUT,” page 2-5. More detailed connections for specific measurements are in Section 3.

Model 6485 connections

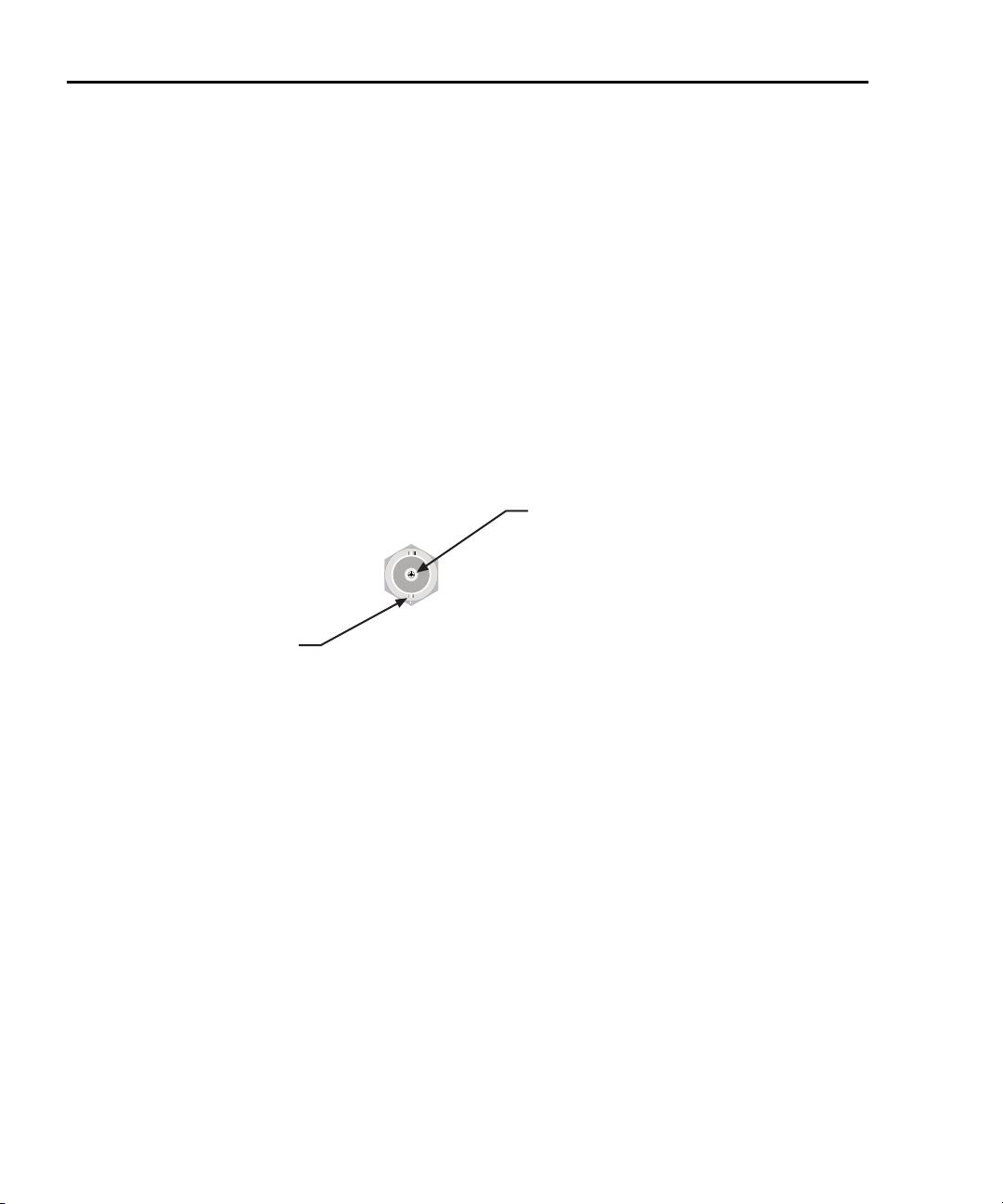

Input connector

The rear panel INPUT connector is a 2-lug female BNC connector (Figure 2-1). Make

connections using a male terminated BNC cable (“Low noise input cables,” page 2-3).

Figure 2-1

Model 6485 BNC Input connector

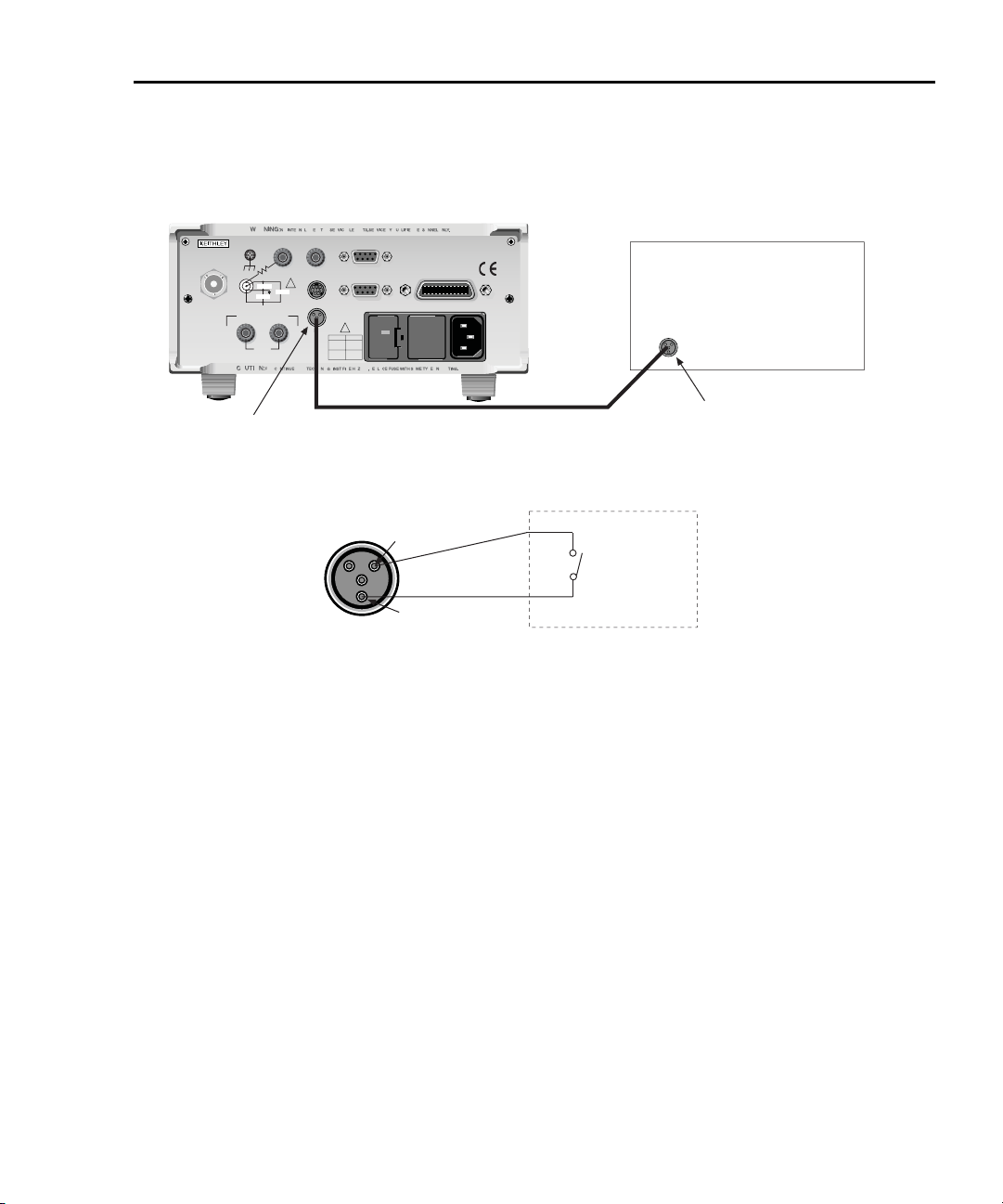

Maximum input levels

The maximum input levels to the Model 6485 are summarized in Figure 2-2.

t^okfkd The maximum safe voltage between picoammeter LO and chassis ground

(common mode voltage) is 42V. The Model 6485 does not internally limit

the LO-to-chassis voltage. Exceeding 42V can create a shock hazard.

`^rqflk The LO-to-chassis breakdown voltage is 500V. Exceeding this voltage

may cause damage to the instrument.

Connecting COMMON or ANALOG OUTPUT to earth while floating the

input may damage the instrument.

klqb Analog outputs will be at same voltages as applied to the BNC shell.

Page 39

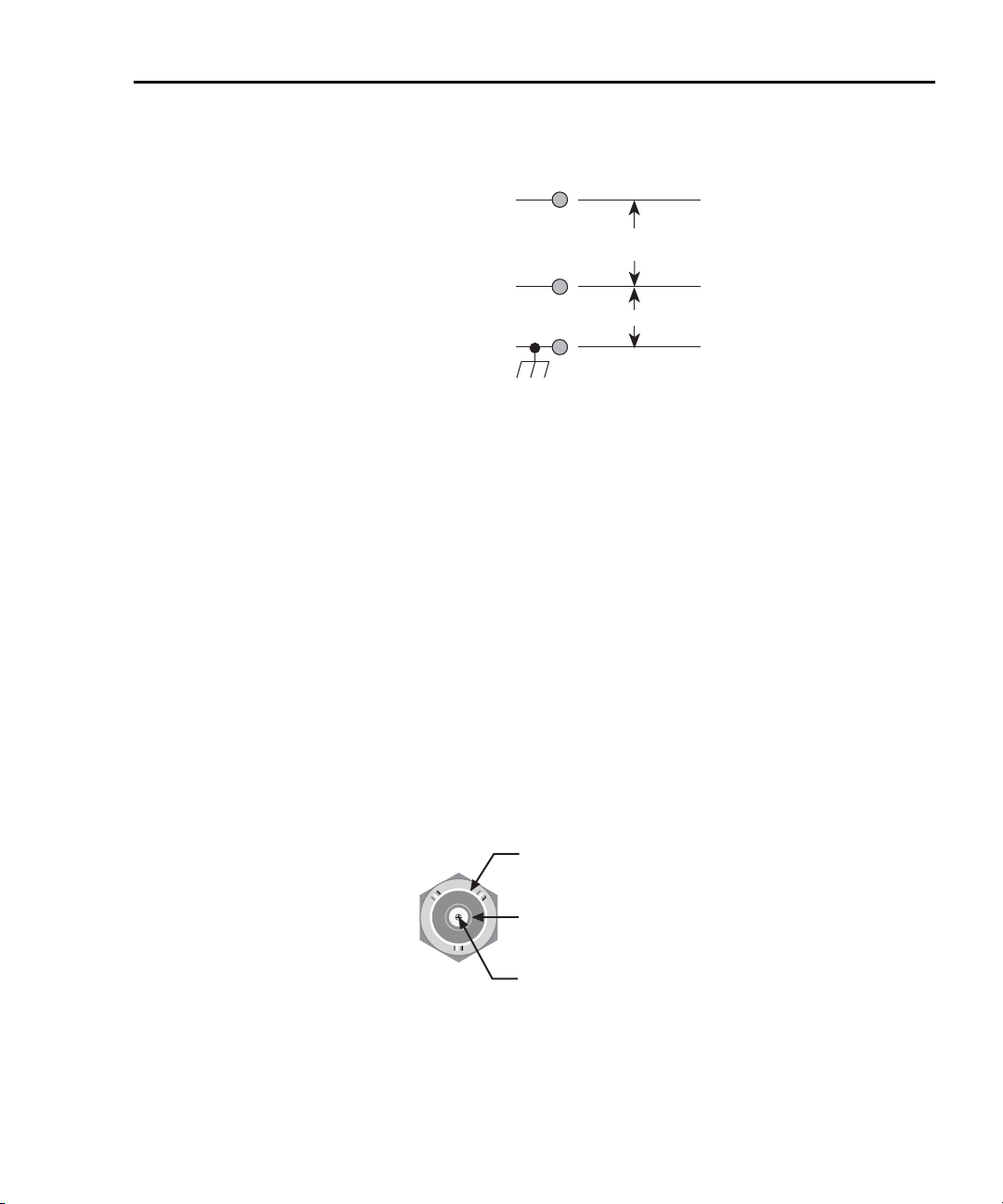

Model 6485 and 6487 User’s Manual Connections 2-3

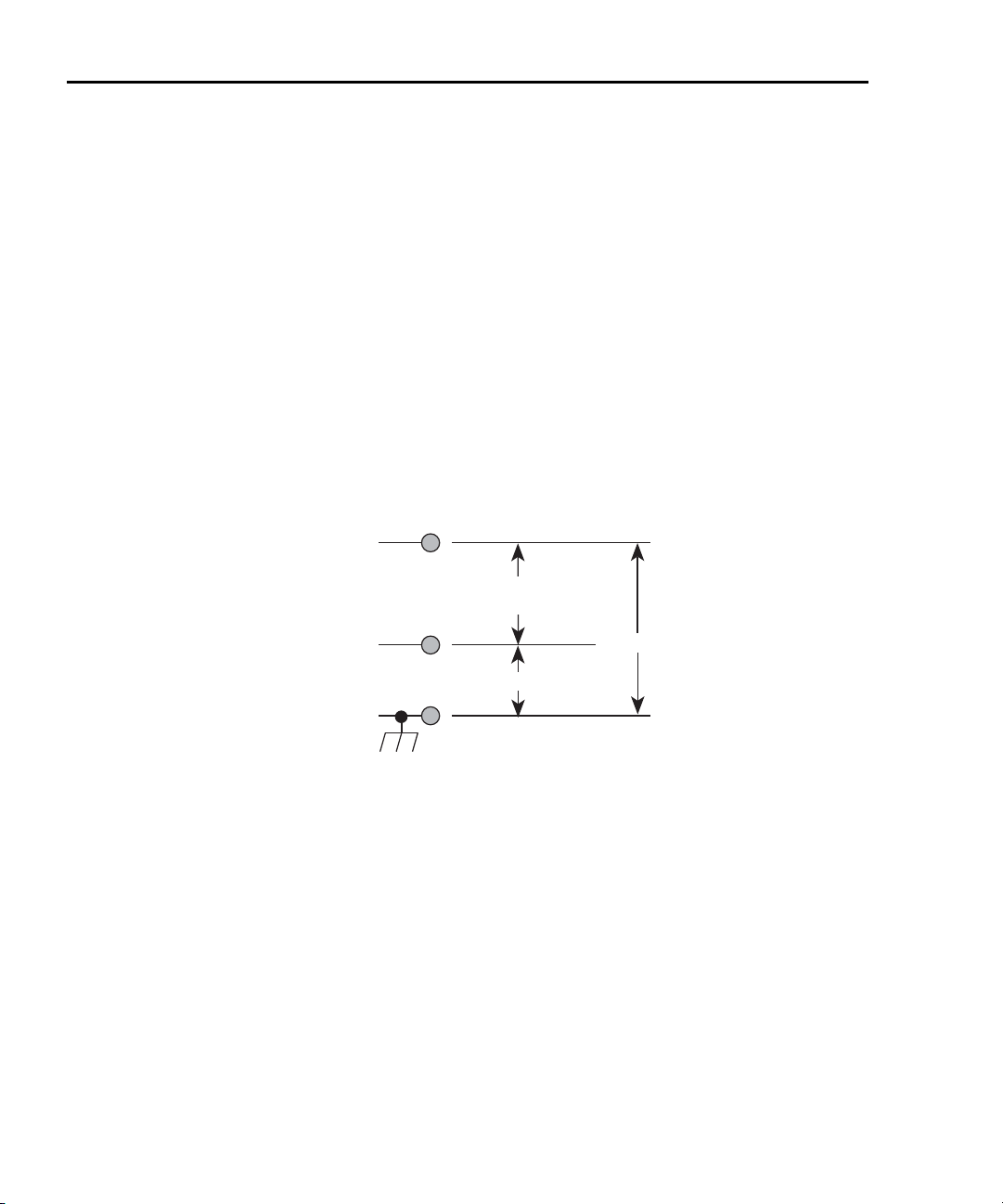

Input HI

Input LO

42V Peak

Chassis Ground

* Maximum Continuous Input Signals

220V Peak, DC to 60Hz sine wave

Max Continuous

Input Signal *

Input Low

CAT I

Chassis Ground

Input High

Figure 2-2

Model 6485 maximum input levels

Low noise input cables

When making precision measurements, you should always use low noise cables. As a general rule, always use the shortest possible cable for measurements. See “Model 6485 input

cables, connectors, and adapters,” page 1-4 for recommended cables.

Model 6487 connections

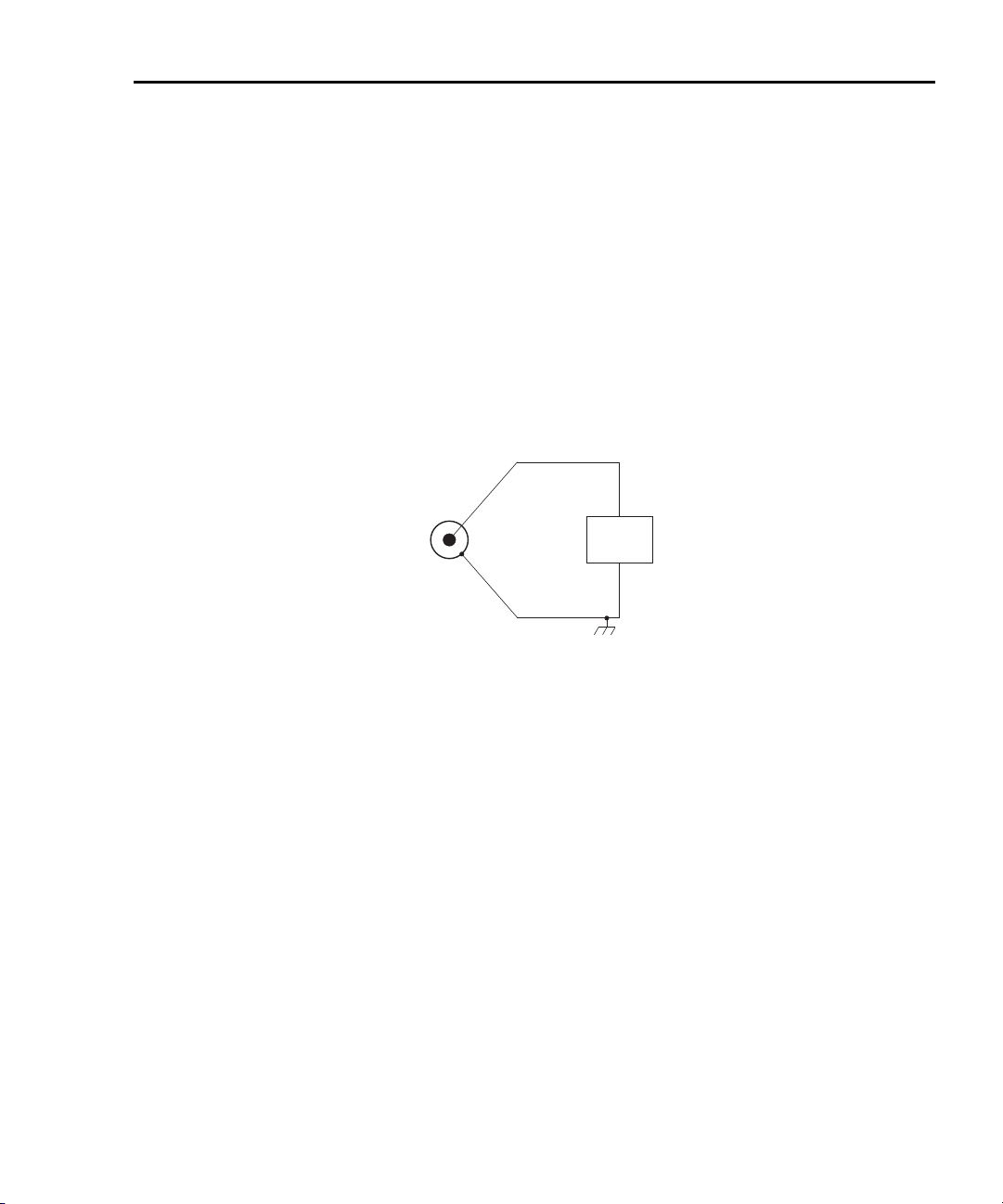

Input connector

The rear panel INPUT connector is a 3-lug female triax connector (Figure 2-3). Make connections using a male terminated triax cable.

Figure 2-3

Model 6487 triax Input connector

Page 40

2-4 Connections Model 6485 and 6487 User’s Manual

Input HI

Input LO

505V Peak

Chassis Ground

Max Continuous

Input = 505V Peak

505V Peak

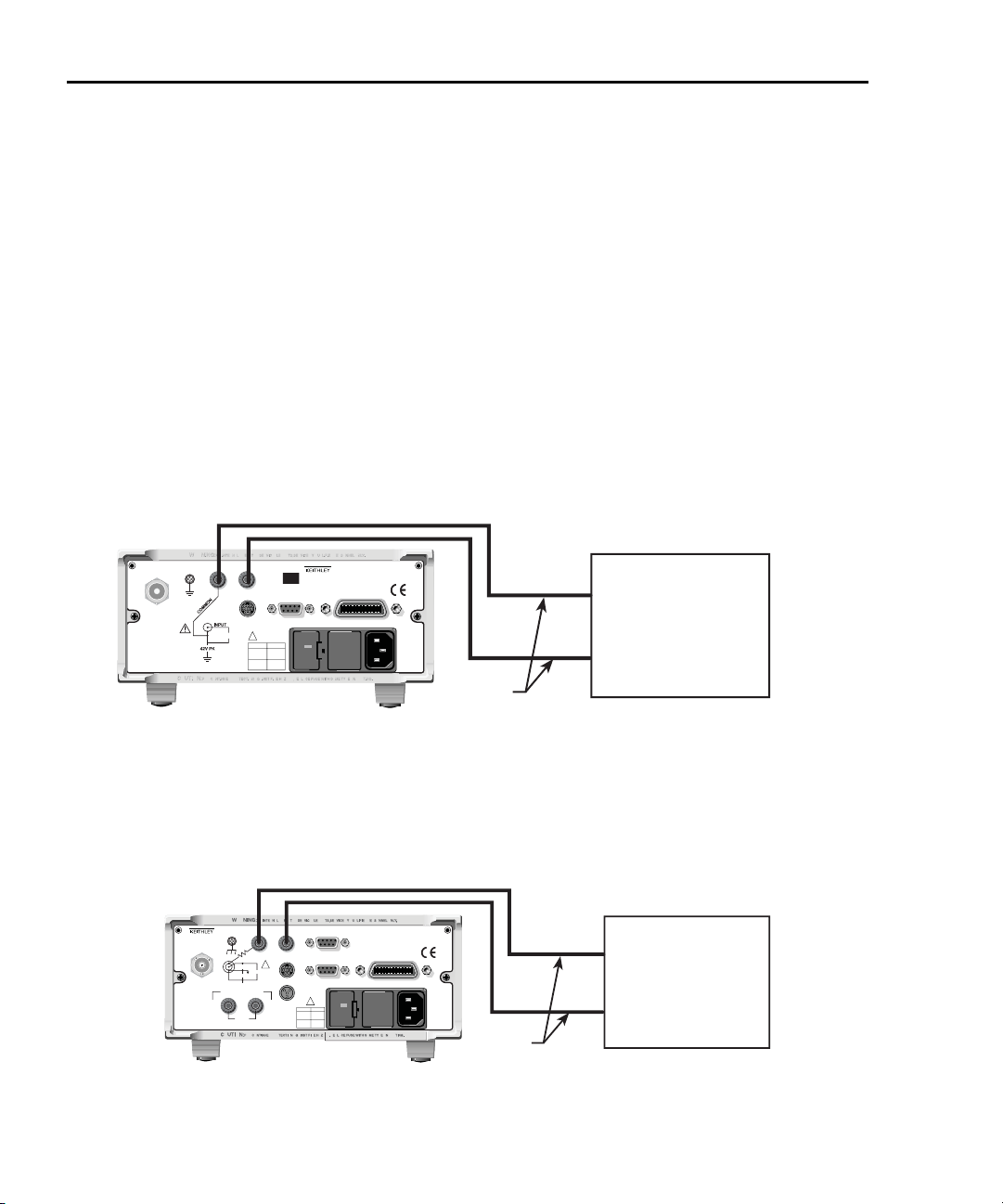

Voltage source output connectors

The rear panel V-SOURCE OUTPUT HI and LO connectors (see Figure 1-4 in Section 1)

are used to connect the voltage source to the DUT. The voltage source is primarily used

for ohms measurements. See “Ohms measurement connections,” page 2-7 for details.

Maximum input levels

The maximum input levels to the Model 6487 are summarized in Figure 2-4.

t^okfkd The maximum safe voltage between the voltage source or ammeter com-

mon and chassis ground (common mode voltage) is 505V peak. Exceeding

this voltage can create a shock hazard.

Figure 2-4

Model 6487 maximum input levels

Connecting cables and test leads

When making precision measurements, you should always use low-noise triax cables for

INPUT connections. As a general rule, always use the shortest possible cable for measurements. When using the voltage source, the test leads must be rated for 505V minimum and

should include safety sheaths. See “Model 6487 input cables, connectors, and adapters,”

page 1-5 in for recommended cables and test leads.

Page 41

Model 6485 and 6487 User’s Manual Connections 2-5

HI

LO

DUT

INPUT*

* Maximum Continuous Input Signals

220V Peak, DC to 60Hz sine wave

Basic connections to DUT

Model 6485 DUT connections

Connections

Basic connections are shown in Figure 2-5, the DUT is the current to be measured. Circuit

high is connected to the center conductor of the input connector and circuit low is connected to the connector’s shell.

Figure 2-5

Basic Model 6485 connections

t^okfkd If it is possible for the DUT or external supply to present more than 42V to

the input HI, it is imperative that the connection between input LO and the

external voltage source be sufficiently low impedance and capable of carrying the short-circuit current of the source, in order that the LO not exceed

42V.

`^rqflk Current limiting resistors are required for DUTs capable of forcing volt-

ages 220V or greater. Damage to the instrument may result if voltages

greater than 220V are forced on the Model 6485 Input HI.

Noise and safety shields

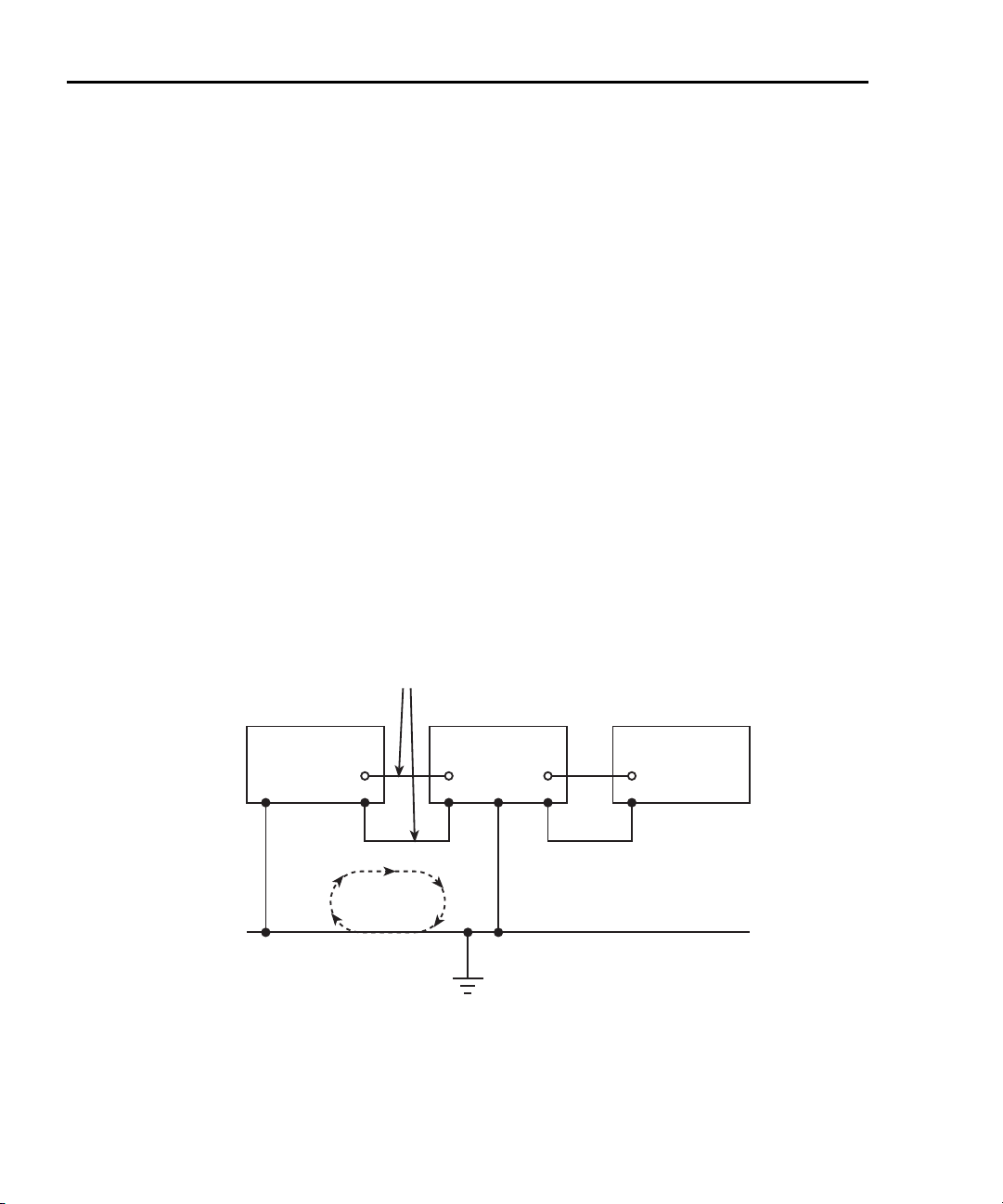

Figure 2-6 shows typical measurement shielding. A noise shield is used to prevent

unwanted signals from being induced on the picoammeter input. Amps measurements

below 1A may benefit from effective shielding. Typically, the noise shield is connected

to picoammeter input LO. Additionally, Figure 2-6 shows LO connected to earth ground

via the ground link.

Page 42

2-6 Connections Model 6485 and 6487 User’s Manual

HI

LO

DUT

Metal Noise Shield

B. Safety Shield

Metal Safety

Shield

Safety

Earth

Ground

HI

LO

DUT

INPUT

(

220V

Peak)

Metal Noise Shield

A. Noise Shield

INPUT

(

220V

Peak)

t^okfkd The maximum safe voltage between picoammeter LO and chassis ground

(common mode voltage) is 42V. The Model 6485 does not internally limit

the LO-to-chassis voltage. Exceeding 42V can create a shock hazard.

If it is possible for the DUT or external supply to present more than 42V to

the input HI, it is imperative that the connection between input LO and the

external voltage source be sufficiently low impedance and capable of carrying the short-circuit current of the source, in order that the LO not exceed

42V.

`^rqflk The LO to chassis breakdown voltage is 500V. Exceeding this voltage may

cause damage to the instrument.

Figure 2-6

Shielding for Model 6485 measurements (unguarded)

Model 6487 DUT connections

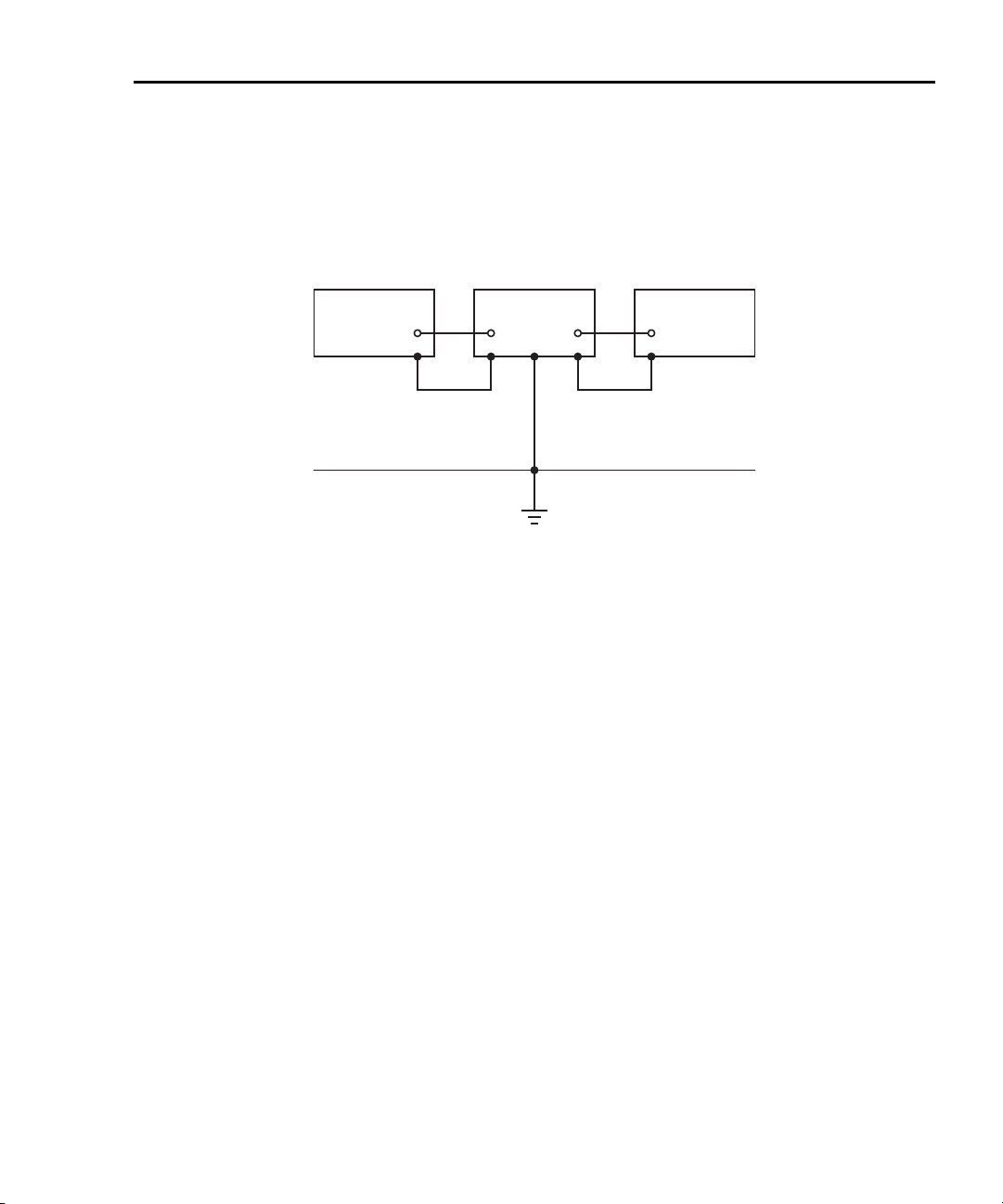

Current measurement connections

Basic connections for current measurements are shown in Figure 2-7; the DUT is the current to be measured. Circuit high is connected to the center conductor of the input connector and circuit low is connected to the connector’s input LO (inner shield).

Page 43

Model 6485 and 6487 User’s Manual Connections 2-7

HI

LO

DUT

INPUT*

6487

* Maximum Continuous Input: 505V Peak

Figure 2-7

Basic Model 6487 current measurement connections

t^okfkd If it is possible for the DUT or external supply to present more than 505V