Page 1

Instruction Manual

Model 640

Electrometer

Keithley Instruments, Inc.

Cleveland, Ohio, U.S.A.

Page 2

MODEL 640 ELECIROMETER

1. GENERAL OESCRIPTION------------------------------------------------- 1

2. OPERATION----------------------------------------------------------- 5

CONTENTS

3. CIRC”IT DESCRIPTION-------------------------------------------------

4.

5. SER”ICING----------------------------------------------------------- 20

6.

7.

*CCESSORIES--------------------------------------------------------- 1,

CALIBRATION--------------------------------------------------------- 30

REPLACE&&E PARTS---------------------------------------------------

SCHEMATICS---------------------------------------------------------- 51

14

35

0472B

Page 3

SPECIFICATIONS

MODEL 640 ELECTRO”ETER

AS A MICROVOLTMETER:

RANGE :

ACCURACY: il% of full scale on 30-volt to 300-microZERO DRIFT:

METER NOISE: Less than 0.4 microvolt rm‘m8 (2 microvolts

INPUl’ IMPEDANCE : Greeter than 1016 ohms shunted by

RISE TINS (IO%-90%, with up to 100 megohms source re-

AS AN AMmiTER:

RANGE :

ACCLmcY: 23% of full scale on 3 x 10-5 to 10-11 am-

METER

DAMPING :

30 microvolts full scale to 30 volts in thir-

teen lx and 3x ranges.

volt ranges, decreasing to 25% on 30-microvalt range.

each succeeding 24-hour period after l-hour warm-up.

Less than 35 wVv/‘C.

p-p) with 1 megohm or less input resistance on most

sensitive range.

less than 2 picofarads.

be selected in four steps from 106 to 1012 ohms.

sistance and no external capecitance): Less than 10

milliseconds on 1-mv and higher ranges, increasing

to 6 seconds on the 30-p’! range.

twenty-two lx and 3x ranges using built-in high-

megoh,,, resistors and range switch.

pere ranges using the smallest recommended multiplier setting; 24% of full scale on 3 x 10-12 to

10-15 ampere ranges. Instrurwnt can be calibrated

to 22% accuracy below IO-9 ampere with external

voltage supply and built-in calibrating circuits.

NOISE:

:;;“li-:&,::,‘:. (5 x lo-16

critically damped.

hour as observed on the 30-millivolt range.

ing with 20 picofarads shunting the high-megohm ra-

seas than 35 6” in the first hour and in

Input reaistsnce may also

10-15 ampere fuL1 scale to 3 x 10-5 ampere in

mess ,rhan 2 x 10-l’ ampere rms (lo-16

-15 ampere range when overdamped

ampere p-p) when

Less than 24 alpha pulses per

Variable from critical damping to overdamp-

sister.

CURRENT STABILITY:

after stabilization.

lative.

MAX. EXTERNAL CAPACITANCE (Feedback c”rrent ranges):

500 pf.

RISE TIME: Seconds, from 10% to 90%.

Recommended Resistor Damped;

Full-Scale Value, no external

Ranges

10-15 to 3x10-11

10-12 to 3x10-9 1010 0.2

10-11 to 3x10-7 108 0.05

10-9 to 3x10-5

AS A CO”LOMS”ETER/C”RRENT INTEGRATOR:

RANGE (recoannended): 2 x lo-14 coulombs full scale to

6 x lo-lo coulombs in ten 2x and 6x ranges.

Setter than 5 x 10-L’ ampere/day

Long-term drift is non-cumu-

ohms

1012

106

Critically Overdamped;

cepeeitenC* capecitance

1.5

0.01

up to

maximum

44

0.5

0.05

0.01

ACCURACY :

+0.25%.

METER NOISE: Less than 3 x Lo-16 coulomb rms (1.5 x

lo-L5 coulomb p-p) on lowest recommended range.

Less than 24 alpha pulses per hour a8 observed on

30-mFllivolt range.

AS AN AMPLIFIER:

RECORDER 0"TPLPl':

scale input.

DOlaritY.

Gain: 6.033 to 3.3 x 104.

Frequency Response (Within 3db): dc to 0.07 cps at

e 9 ain of 3.3 x 104, rising to 35 cps at a gain of

10 or below.

NOiS*:

ified function.

output p-p on the 30-v to lo-mv ranges, increasing

to 10% on the 1-w and lower ranges.

UNITY GAIN ODTPW:

within .Ol% or 10 p’f, excLuaiva of zero drift, for

output C”rre*ts of LOO * or less.

ZERO cHEcx:

low through L kilohm in volt8 position, to feedback

in current or integrate position.

ISOLATION:

than LOgG shunted by 0.05 j.,f. Circuit ground may

be floated up to +LOOV with respect to main case.

Head case is circuit nround. On battery o,,eration,

instrument nay be cc.m;Letely isolated f;om’power

Line and ground.

POIARITY: Meter switch selects Left-zero (wsieive

OK

does not reverse polarity of output.

CONNECTORS : Input: Special type, metes with many

commercially available ion chambers and other accessories (adapter to “SF included). Low: Binding

pst. Recorder output: Amphenol SO-PCZP. “nityGain Output and Case Ground: Binding posts.

PCUER:

Line operation: 105-125 or 210-250 volts (switch

selected), 50 or 60 cps, 20 watts.

Battery Operation: Rechargeable nickel-cadmium 6volt battery pack, S hours full charge to complete

discharge.

ation recomuanded for no more than 6 consecutive

hours before recharge.

DIMENSIONS, WRIGHT:

Power Chassis: 7” high x S-314” wide x LO” deep;

net weight, 14 lbs.

Amplifier Head: 6” high x 5” wide x 6” deep; net

weight, 6 Lbs.

ACCESSORIES SUPPLIED: Connecting Cable: 5’ long, con-

nects head to main chassis. UHF Adapter: adapts

input to UtlF connw.tor. Shield Cap. Mating output

COll”*CtO=.

tery pack and charging circuit.

Integrating capacitance ia 20 picofarads

+l vole at up to 1 ma for full-

output polarity is opposite input

Below 1 cps: same 88 meter noise for spec-

Circuit ground to chassis ground: Greater

W3.StiVa)

Above 1 cps: less than 2% of full

At dc, output ia equal to input

Remote “zero” solenoid shorts input to

or center-zero sce3les. Mete; switch

For maximum battery life, battery oper-

InternaLly mounted nickel-cadmium bat-

LL’LR

Page 4

GENERAL DESCRIPTION

SECTION 1.

l-l.

GENERAL.

Electrometer is an ultra-stable, solid-state microvolt

electrometer.

a. As a Microvoltmeter.

meter, the Model 640 has an input resistance greeter

than 1016 ohms with thirteen ranges from 30 micravolts

full scale to 30 volts.

b. As a Picoammeter.

high-megohm SHUNT RESISTORS, the instrument has twenty

two ranges from lo-l5 ampere full scale to 3 x 10m5

ampere.

C. As a Coulombmeter.

guarded capacitor in rhe feedback loop the instrument

is useful as a coulombmeter or current integrating

amplifier.

ment has ten ranges Pram 2 x lo-14 coulomb full scale

to 6 x l’~?-~~ coulomb.

d. As an Amplifier.

of the instrument as e very stable, variable gain

amplifier.

The Model 640 Vibrating Capacitor

When used as a microvolt-

When used with the built-in,

By switching en accurate

In the CURRENT INTEGRATE mode the instru-

The analog OUTPUT permits we

GENERAL DESCRIPTION

1-2.

FEATURES.

a. Excellent Stability. A stability specified at

better than 5 x lo-11 ampere/day is useful for mass

spectrometer, resistivity, end ion chamber meesure-

menes.

b. Remote Inwt Head.

amplifier permits convenient set up of en experiment.

C. High Input Impedance. Guarding plus the use of

sapphire insulation provides an input resistance

greater then

farads.

d.

Battery or Line Operation. A choice af beteery

or line operation permits complete isolation (in

battery mode) from power line when required.

e.

Built-In Shunt’Resistors. Four high-megahm

shunt resistors ten be switch selected (Input Head)

for shunt or feedback current measurements.

1016

A compact Remote Input pre-

ohms shunted by less than 2 pico-

1170

Page 5

GENERAL DESCRIPTION

MODEL 640 ELECTROMETER

TABLE l-l.

Front Panel Controls.

CO”trOl

POWER Switch (5301)

FINCTION Switch (S402)

RANGE Switch (S403)

METER Switch (S404)

Controls the power to the instrument.

Selects the mode of operation.

Selects the meter sensitivity.

Selects meter polarity, center scale, and meter off.

Functional Description

Paragraph

2-3, a

2-3, b

2-3, c

2-3, d

ZERO Controls

KEDIUM (S407)

FINE (R431)

ZERO CHECK Switch (S401)

Adjusts meter zero.

Adjusts meter zero (fine control).

Permits a meter zero check.

2-3, e

2-3, e

2-3, f

!

TABLE 1-2.

Input Head Controls and Terminals.

Control

SHUNT RESISTOR Switch (5102)

Selects P shunt or feedback resistc.r frw 106 to

Functional Description Paragraph

1Ol2 ohms.

ZERO CHECK Switch (SlOl) Permits a meter zero check.

FEEDBACK Terminal (5103) Useful for unity gain or guarded wsauremsnts.

Input Receptacle (5105) Provides connection to Input High

DAMPING Control (RlOS) Adjusts damping for CURRENT INTEGRATE function.

I

2-2, a

2-2, b

2-2, d

2-2, c

2-2, e

2

1170

Page 6

MODEL 640 ELECTROELETER

FUNCTION

Switch

(5402)

GENERAL DESCRIPTION

POWER

Switch

(S301)

ZERO

Switch

(S407)

METER

Switch

(S404)

FIGURE 2. Front Panel Controls.

FEEDBACK

(5103)

RANGE

Switch

(S403)

ZERO

CHECK

(S401)

SHUNT RESISTOR

1170

FIGURE 3.

Input

(JlO5)

ZERO

CHECK

(SlOl)

Input Head Controls.

3

Page 7

GENERAL DESCRIPTION

CO”tr01 Functional Description Paragraph

MODEL 640 ELECTROMETER

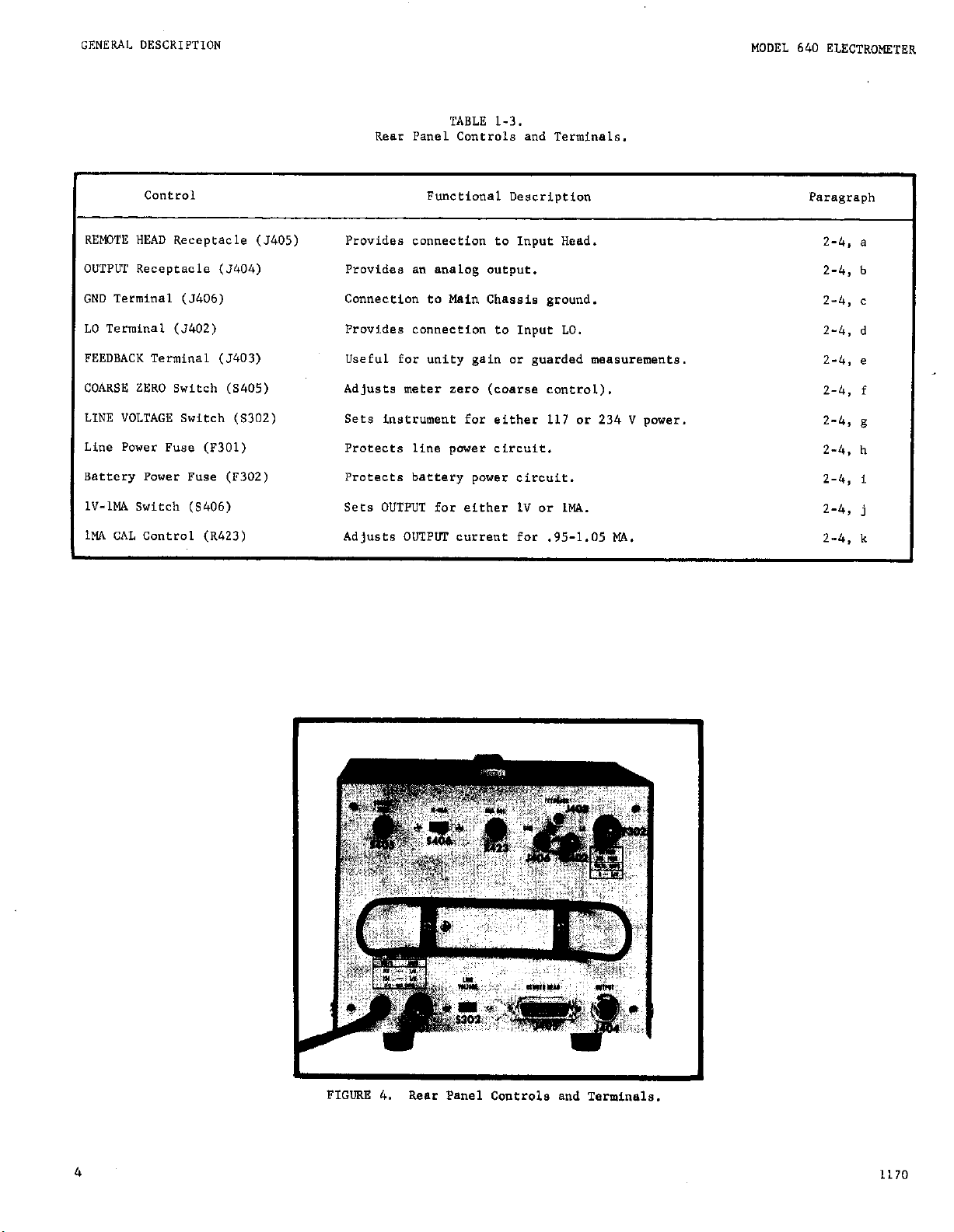

TABLE l-3.

Rear Panel Controls and Terminals.

REMOTE HEAD Receptacle (5405)

OUTPUT Receptacle (5404)

GND Terminal (5406)

LO Terminal (3402)

FEEDBACK Terminal (5403)

COARSE ZERO Switch (S405)

LINE VOLTAGE Switch (S302)

Line Power Fuse (f301)

Battery Power Fuse (F302)

lV-1MA Switch (S406)

IHA CAL Control (R423)

Provides connection to Input Head.

Provides an analog output.

Connection to Main Chassis ground.

Provides connection to Input LO.

Useful for unity gain or guarded measurementa.

Adjusts meter zero (coarse control).

Sets instrument far either 117 or 234 V power.

Protects line power circuit.

Protects battery power circuit.

Sets OUTPUT for either 1V or 1W..

Adjusts OIJTPLW current for .95-1.05 MA.

2-4, a

2-4, b

2-4, c

2-4, d

2-4, e

2-4, f

2-4,

2-4, h

2-4, i

2-4, j

2-4, k

g

FIGURE 4. Rear Panel Controls and Terminals.

4

1170

Page 8

MODEL 640 ELECTROMETER

GENERAL DESCRIPTION

SECTION 2.

2-1.

INPUT CONSIDERATIONS.

Input Head Connections.

a.

Remote Cable. A shielded coaxial cable (5

1.

feet long) is supplied to permit remote location of

the Input Head from the Main Chassis. A” accessory

Model 6401 Cable (25 feet long) also can be used

without degradation of specifications.

2. Mounting.

tom mounted as described in paragraph 2-12.

Input Assembly.

3.

of B” insulated input High terminal (center post)

and a machined housing which is input Low. High in-

put resistance (over 10~6

2 picofarads) is maintained by “se of sapphire in-

sulation.

a.) Custom Connections. The input housing has

been designed to easily adapt for use with ion

chambers and other applications where high input

impedance and low capacitance is required. Dimensions of the input housing are given in Figure 5.

b.) UHF Adapter. The adapter supplied with the

Model 640 is useful when quick connections must

be made using standard UHF cables, However, this

adapter is limited to measurements above lo-l3

ampere or source resistances below lOI4 ohms.

c.) GRg74 (General Radio) Adapter. This accessory adapter is available for use with G&374

Series coaxial accessories. The limitations of

this adapter are similar to those for the UHF

adapter.

b. ~nsulatio”. Use high

riels such as sapphire, teflon, polyethylene or poly-

styrene for insulation of the input circuit.

The Input Head Chassis can be cus-

This assembly (5105) consists

ohms shunted by less than

resistance,

low-loss mate-

OPERATION

NOTE

The input terminal and sapphire insulator

should be protected from contamination so

that the insulation will not be degraded.

Clean, dry connections and cables are very

important to maintain the value of all insulation materials.

tion can be compromised by dust, dirt,

solder, flux, films of oil or water vapor.

A good cleaning agent is methyl alcohol,

which dissolves most common dire without

chemically attacking the insulation.

c. Noise Consideration. The limit of resolution

in voltage and current meaeurements is determined

largely by the noise generated in the source. Stray

low-level noise is present in some form in “early sll

electrical circuits.

guish between stray and signal voltages since it measures the “et voltage.

consider the presence of low-level electrical phenomena such as thermocouples (thermoelectric effect),

flexing of coaxial cables (trioelectric effect),

apparent residual charges on capacitors (die-lectric

absorption), and battery action of two terminals

(gslvanic action).

1. Thermal EMFS.

(thermal emfs) are generated by thermal gradients

between two junctions of dissimilar metals. These

can often be large compared to the signal to be

measured.

To

minimize thg drift caused by thermal

emfs, “se pure copper leads wherever possible in

the source circuit.

m*ine*ining c0**t**t ju*cei0* temperatures especially

by using a large heat sink,“ear the connections.

The Keithley accessory Model 1483 Low Thermal Connection Kit contains all necessary materials for

making very low thermal copper crimp connections for

minimizing thermal effects.

Even the best insula-

The instrument does “ot dtsttn-

When using the microvolt ranges

Thermoelectric potentials

Drift ca” rlso be mL”immLzed by

1170

FIGURE 5.

Dime”sio”s of Input Housing.

2. AC Electric Fields.

The presence of electric

fields generated by power lines or other source8

can have a” effect on instrument operation. AC

voltages which are very large with respect to the

full-scale range sensitivity could drive the ac

amplifier into saturation, thus producing a” erroneous dc output. Proper shielding as described in

paragraph 2-1, d can minimize noise pick-up when

the Fastrument Fa in the presence of large ac fields

or when very sensitive me.ssuremBnta are being made.

3. Magnetic Fields. The presence of strong magnetic fields can be a potential source of BC noise.

Magnetic flux lines which cut a conductor can produce large ac noise especially at power line frequencies. The voltage induced due to magnetic flux

is proportional to the area enclosed by the circuit

as well as the rate of change of magnetic flux. Par

5

Page 9

OPERATION

MODEL

640 ELECTROMETER

example, the motion of a 3-inch diameter loop in the

earth’s magnetic field will induce a signal of several tenths of a microvolt. One way to minimize

magnetic pickup is to arranSe all wiring so that the

loop area enclosed is as small as possible (such as

twisting input leads). A second way to minimize

magnetic pickup is to use shielding aa described in

paragraph 2-1,

d.

d. Shielding.

Electric Fields. Shielding is usually nec-

1.

essary “he” the instrument is in the presence of

very large ac fields or “hen very sensitive measure-

ments are being

ment

circuit and

made.

The shields of the measure-

leads should be connected together

to Sround at only one point. This provides a “tree”

configuration, which minimizes ground loops.

2. Magnetic Fields. Magnetic shielding is useful

where very large magnetic fields are present. Shield-

ing, which is available in the form of plates, foil

or cables, can be used to shield the measuring circuit, the lead wires, or the instrument itself.

e. Moisture.

The Model 640 Inp;t Head is shipped

with a dessicant bag sealed inside. This bag soaks

up the moisture inside the Input Head to insure opti-

mum operation. The dessicant bag, however, will event-

ually become saturated. At this point the Model 640

offset will increase beyond the specified amount.

When this happens take off the bottom cover of the In-

put Head to remove the desaicant bag. Reactivate it

according to the instructions on the bag.

d. FEEDBACK Terminal (51031. This terminal is

used for unity gain or guarded measurements. _

e. DAMPING Control (RlOSl. (Not Shown). This

control permits adjustment of the damping for

INTEGRATE operation.

When the control is set fully

CURRENT

clockwise to “MAX” damping,the rise time is approximately 44 seconds with a 1012 shunt resistor. When

the control ts set fully counter-clockwise to

“MIN”

damping,the rise time corresponds to the critically

damped or CURRENT FAST condition 88 given in the

specifications.

2-3. FRONT PANEL CONTROLS. The front panel controls

are shown in Figures 1 and 2.

The operation of each

control is described 88 follows:

8.

POWER Switch (5301). This switch has four

positions designated AC, OFF, BATTERY, and BATT TEST.

1. AC Position.

This position permits normal

aperacion of the instrument when the power cord is

connected to line power. (The battery charging

circuit operates in this position.)

2. OFF Position.

This position disables both

AC

and BATTERY power to the electrometer circuits except for the battery charging circuit which operates

in this position.

3. BATTERY Position.

normal operation of the

battery

pack

is satisfactorily charged.

This position permits

insteument

when the internal

2-2.

INPLT HEAD CONTROLS AND TESMINALS. The Input

Head is shown in Figures 1 and 3. The operation of

each control or terminal is described aa follows:

a. SHUNT RESISTOR Switch (SlOZ1. This switch selecte 5 positions corresponding to the shunt resistor

(acro88

ment.

and “OPEN”.

input of feedback) require% by the me~8ure.

The switch positions are 10 , lOa, lOlo, 10lz

The “OPEN” position has no resistor

connected.

by 1000 ohms.

c, Input ReceDeecle (JlOSl. This receptacle provides input connection to the Model 640 Input High

and Input Low.

4. BAIT TESTY Position.

This position permits a

check of the battery voltage as indicated by the

meter.

b. FVNCTION Swtich (S4021. This switch has three

positiona designated VOLTAGE,

C”RRENT

INTEGRATE.

CURRENT

FAST, and

1. VOLTAGE Position. This position co,,,,ects the

electrometer .8 8 very sensitive, high impedance

voltmeter with the

SHLMT RESISTORS

connected in

shunt across the input.

2. CDRRENT

FAST.

This position cannects the

electrometer as a feedback pieoammeter which neutralizes the effect of input capacitance and incream response speed.

The SHUNT RESISTORS are

connected in the feedback loop of the amplifier.

3.

CDRRENT INTEGRATE.

This Dosition connects

the 20 picofarad warded caPa&or in the feedback

loop of the ampli ier.

c. RANGE Switch (54031. This switch has thirteen

positions corresponding to full scale voltage sensitivity from 30 microv01ea to 30 volts.

d. METER Swftch (S4041. This switch has 4 poaitions designatad OFF, +, -, and CENTER ZERO.

6

1170

Page 10

SOQEL 640 ELECTROMETER

OPERATION

1. OFF Position.

This position disables the

meter movement to protect against averlaads. This

position has no effect on the OUTPUT voltage when

using a recorder or other instrument.

“i” and ‘I-” Positions. These p0sitiDne select

2.

the polarity af the meter only. The

OUTPUT

voltage

is not affected by these pasitions.

CENTER ZERO. This position sets the meter

3.

circuit so that zero is indicated at center scale

(mid-scale). The deflection of the meter corresponds to one-half RANGE setting, The OUTPUT “oltage is nat affected by this position.

e. ZERO Switch. This switch is a dual-concentric

control.

1. MEDIUM Control (S407). This control is the

cuter knob with eleven pasitions which adjust the

meter-zero.

FINE Confrol (R431). This control is the

2.

inner knob which permits fine meter-zero adjustment.

f. ZERO CHECK (S401). This switch is e normally--

open contact-type switch permitting meter,-zero check.

The ZERO CHECK switch shunts the input HI to input LO

(in voltage function) by 1000 ohms.

ZERO Controls do not provide sufficient range of

CO”tl-01.

g. LINE VOLTAGE Switch (S302). This switch sete

the instrument for either 117 or 234 volt rms linepower. The line-power fuse (F301) should be checked

far proper line voltage rating.

h. Line Power Fuse (F301). This fuse pr~tecee the

power supply circuits when 117-234V line power is

used.

Fuse Racing

117 ”

234 V

1.

Battery Power Fuse (F302). This fuse protects

l/4 smp, 3AG

l/B nmp, 3AG

the power supply circuite when battery power is used.

Fuse rating: 314 amp, 3AG.

j. lv-IMA Switch (5406). This switch sete the

OUTPUT for either 1 volt 0’ 1 mA.

k.

1MA GAL Control (R423). This control permits

adjustment of the

OUTPUT

(with lV-1MA Switch set co

1MA) over the range 0.95 to 1.05 mA.

2-5.

OPERATING CONSIDERATIONS.

REAR PANEL CONTROLS AND TERMINALS. The rear

2-4.

panel controls and terminals sre shown in Figure 4.

The operation of each control or terminal is described

as follows.

a. REMOTE HEAD Receptacle (5405). This receptacle

is a 24-pin cOnnector (Amphenol 57-40240) which mates

with the interconnecting cable between the Main Chas-

is and Input Head (Remote Head). Two “echenical re-

taining clips see provided on the receptacle to Secure

the mating plug (P405).

b.

OUTPUT

Receptacle (5404). This connector pro-

vides en analog output far recording or monitaring

pUrpOSeS. The output is 11 volt at up to 1 “A for

full scale input.

the input palarity.

The output polarity is ~posite

The front panel METER switch has

n0 effect on the polarity of the analog output.

c. GND Terminal (54061. This terminal is connected

to Main Chassis ground and the outside shell of con-

neceor 5405.

With no cOnnection between GND and LO

(shorting link removed), the INPUT LO to Main Chassis

ground isolation is greaterthan 109 : shunted by .05

microfarad,

d. LO Terminal (5402). This terminal is connected

to INPUT LO on INPUT HEAD.

e. FEEDBACK Terminal (5403).

This

terminal is

used for unity gain or guarded measurements. The

terminal (5403) on the Main Chassis is connected to

5103 an the INPuT HEAD by way of the remote cable.

f. COARSE ZERO Switch (5405). This switch hes ten

positions far adjusting the meter-zero circuit. This

switch should only be used when the FINE and MEDIUM

a. Mode of Opereeion.

1. AC Line-Power.

The Model 640 can be operated

using ac line-power at 117V or 234V, 50 .x 60 Hz.

To operete,set LINE VOLTAGE Switch (5302) to 117

or 234, check for proper rated fuse (F301), and

connect the line cord.

Set the POWER Switch (S301)

to “AC” operation.

2. Battery Power.

The Model 640 can be operated

using battery paver supplied by e rechargeable 6-

volt nickel-cadmium battery peck.

a.) To check the battery charge, set the POWER

Switch to “&ATT TEST” position. The meter should

indicate +6V or greeter if charge is sstisfactary.

b.) To recharge the battery pack, connect the

p,yF;z cord to ec power. Set the POWER Switch to

. (The bettery will automatically recharge

when the POWER Switch is in either “AC” or “OFF”

positians).

Battei-y charging-time is approximately 16 hours for full charge after 8 hours of

continuous we.

3. AC Co Battery Switching. The Model 640 ten

be modified so that it will sutomsticallv switch

fro” “AC” operatia t0 “BATTERY” ~peraeibn if the

line power fails.

An explanation of this modifica-

tion is given in paragraph 3-4 in the Circuit Des-

cription section.

b. Warm-UC. If the

instrument

is to be used for

very sensitive measurements,allaw the instrument to

stabilize far an haur or more. The POWER Switch can

be see et either ‘AC” or “BATTERY”.

1170 7

Page 11

OPERATION

MODEL 640 ELECTROMETER

C. Meter zero.

The meter zero circuit utilizes

three conerols PINE, MEDIUM, and COARSE.

1.

After

warm-up, set the METER Switch to CENTER

ZERO.

2. Adjust the MEDIUM ZERO Control for center-

zero meter position.

(The rear panel COARSE ZERO

Switch can be used tf meter reads off scale).

3. Increase sensitivity using the RANGE Switch

and adjust the

FINE

ZERO Control for center-zero

meter indication.

2-h.

VOLTAGE FUNCTION.

a. General.

When the FUNCTION Switch is set to the

VOLTAGE poaition,the Model 640 operates as a high in-

put-impedance electrometer.

The

b. Input Impedance.16

input resistance (HI to

LO) is greater than 10 ohms shunted by less than 2

picofarads. This specification is valid 2 for the

SHUNT RESISTOR Switch sat to “OPEN” with no depreda-

tion of the input HI to input M insulation. ?‘he input resistance can be lowered by se~~ti”gl~lWNUN~RE-

SISTOR

values in four steps from 10 to 10 ,

c. Microvoltmeter Measurements.

1. Theory. The electrometer, when used as a

microvoltmeter, can be illustrated 88 shown in

Figure 6.

In this configuration the instrument is

useful for making sensitive measurements from 30

microvolts full scale to 30 volts. The sensitivity

is adjusted by the RANGE Switch (5403) represented

by RA.

wltage eA is defined by the following expression,

The input voltage is represented by ei.

The

eA = ei (j&)

where K is the amplifier loop gain.

Therefore iA = *A 2 ei where KA is selected by

the RANGE Switch (S403).

XK

2. Voltage “easurement.

a.) High Impedance. Although the electrometer

has a very high input impedance, the useability

of the Model 640 as a micravoltmeter is limited

by the thermal (Johnson) noise generated in the

m impedance.

Refer to paragraph 2-10 for a

complete discussion of thermal notae.

b.) Low Impedance.

The Model 640 can be used

on the more sensitive ranges by setting the SHUNT

RESISTOR Switch to 1012 ohms or lower. The laad-

ing effects should be considered when measuring

high source-impedance.

3. Current Measurement. The Model 640 can be

used for current measurements since the microvolt-

meter measures the volta e ac

resistor selected for 10 , 10 , 1010, or 1012 ohms.

088 a known shunt

k; li

Current can be calculated by the ratio of voltage

reading to shunt resistance. “se this technique

where low noise is important,alehough faster re-

sponse is provided by setting the FUNCTION Switch

to CURRENT FAST as described in paragraph 2-7.

4. Unity Gain Meesurements. The Model 640 can

be used for measuring a potential from B very high

impedance source with .025% accuracy. Connect a

digital voltmeter (or differential) to FEEDBACK and

LO terminals as shown in Figure 7.

SOURCE

VOL’UGE

FEEDBACK -

(INPUT

HEAD)

FIGURE 6. Voltage Function With Shunt Resistor KS

< FEEDBACK

(MAIN CHASSIS)

Page 12

MODEL 640 ELECTROMETER

-

INPUT

OPERATION

LO

FIGURE 7.

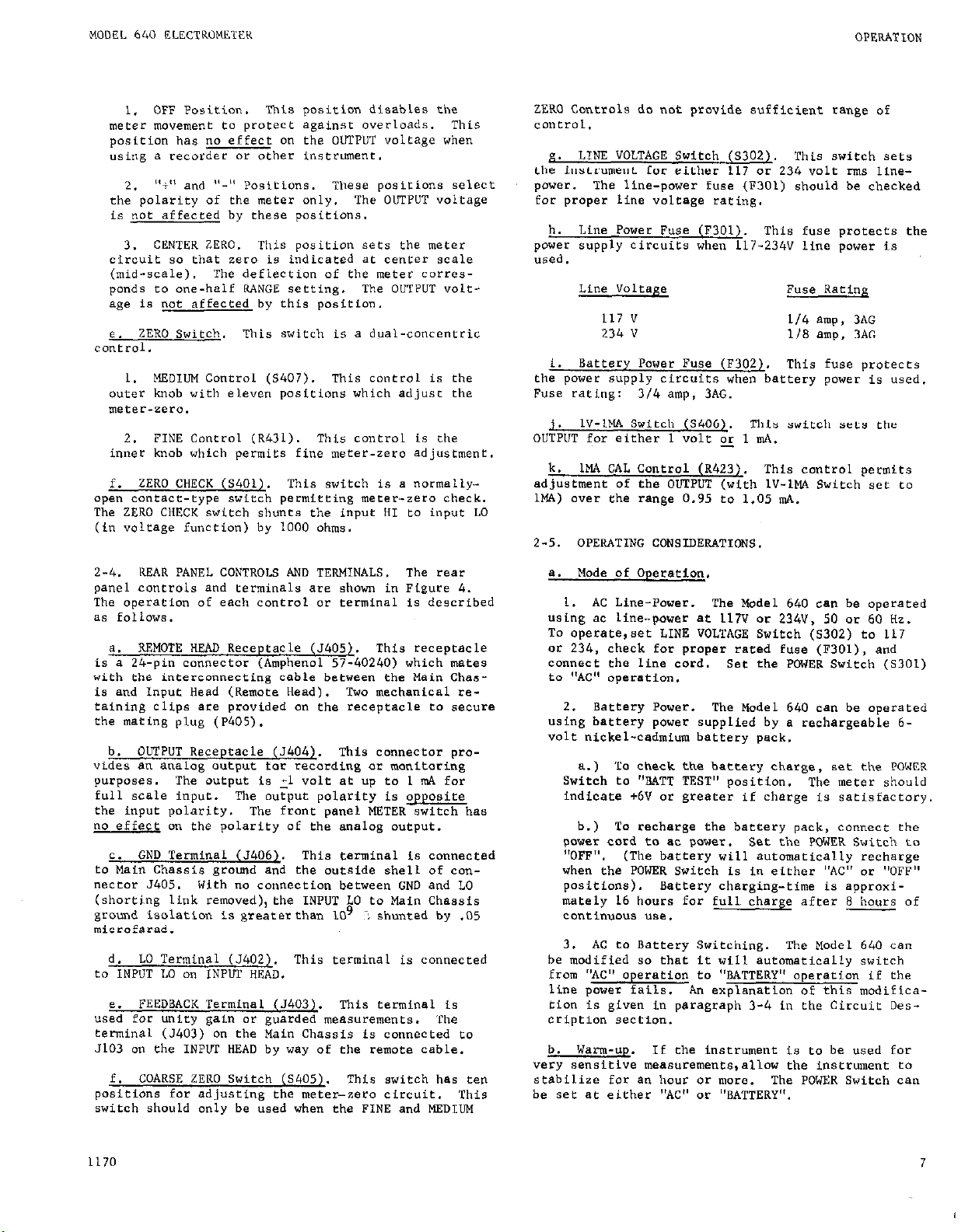

CURRENT FAST FUNCTION.

2-7.

a. General.

CURRENT FAST

“se Of FEEDBACK Connection.

When the FUNCTION Switch is set to the

position,the Model 640 operates es e feedback ammeter with feedback resistors selected by the

SHUNT RESISTOR Switch in four steps from 106 to 1012

ohms.

b. Feedback Aonoeter Measurements.

1. Theory.

The Model 640,when used 8s e feedback

amm?ter,cen be illustrated 88 shown in Figure 8. In

this configuration the instrument is useful for mek-

ing sensitive meesurements from lo-l5 ampere full

scale. Response speed is greatly improved compared

to the VOLTAGE FUNCTION configuration since the

effect of input capacitance is largely neutralized.

The input voltage drop end effective ameter input

resistance is given for each RANGE setting es in

Table 2- 1.

TABLE 2-1.

Inwt Resiacance in CURRENT FAST Function.

RANGE

Current Input

Resistance

1ov 1x10-11

1V

;;:;I$

1OOmV

1OmV

lmv

:g: ::

108

108

108

108

108 O.lvV

Input

Voltage

lmv

1OO~V

1ovv

4Jv

c

0472B

INPUT HI >-+

INPUT LO >

FEEDBACK >

I

I

5

RF

RM

( OUTPUT

t

a0

I

< LO

FIGURE 8.

Current Feet Function.

Page 13

OPERATION

MODEL 640 ELECTROMETER

2. Current

e.) Rise Time.

particular meeeuremene depends on the shunt resistor end residual capacitance ecroes the feedbeck loop.

is given in the specifications for each resistor

value.

stcondition where no external capacitance is

cannected between the FEEDBACK terminal end u

ix

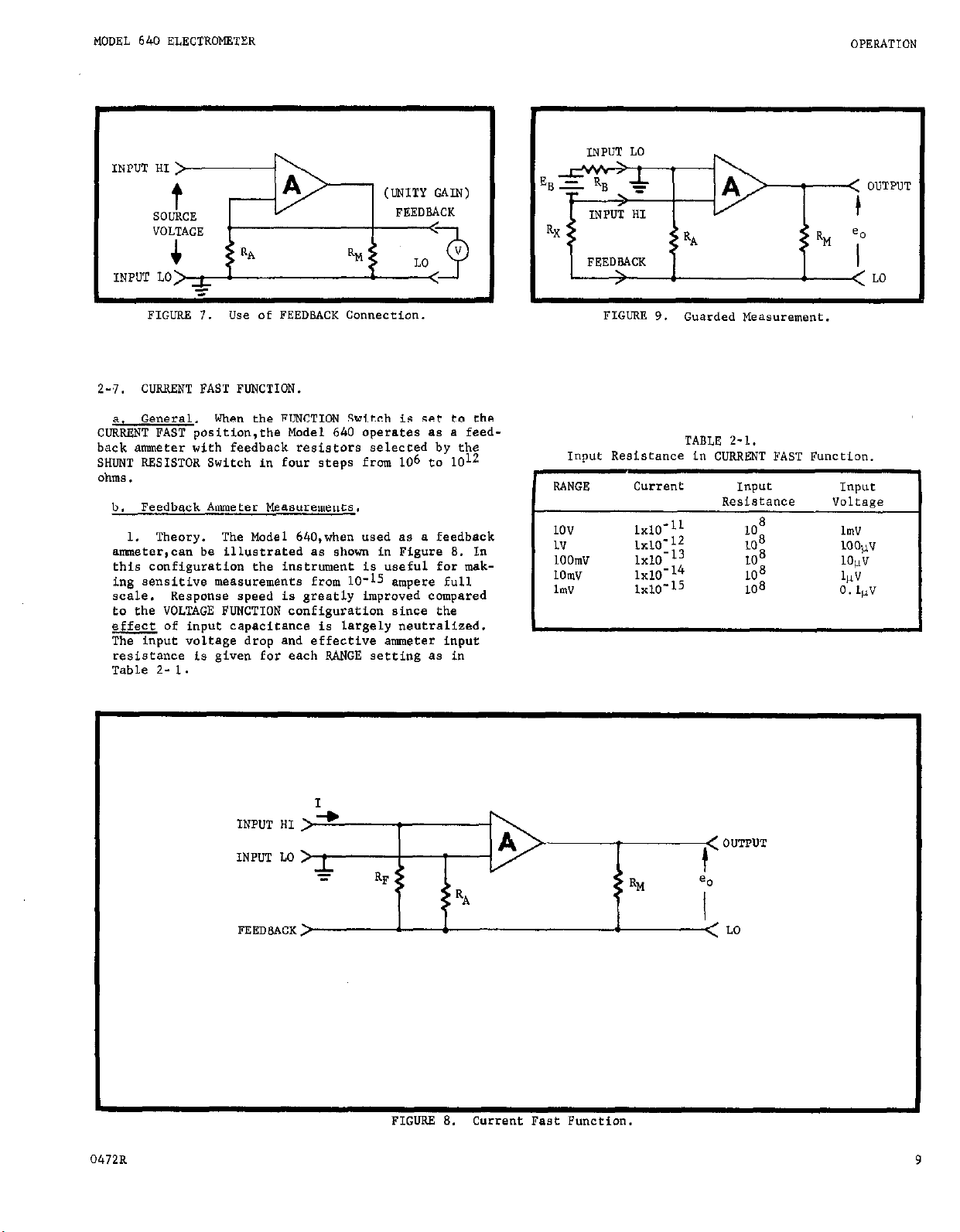

b.) Guarded Measurements. The Model 640 ten

be used for guarded resistance measurements using

the FEEDBACK Terminal and Input HI connections 89

shown in Figure 9. Since EB and RB develop e

known current IB,then the electrometer will indicate the voltege develaped ecrose Rx (un!aowo

resistance).

Rx

CURRRNT INTEGRATE FUNCTION.

2-8.

a. General.

CURRENT INTEGRATE position the Model 640 operates es

e feedback ammeter with damping.

b. Feedback Ammeter Measurements.

1. Theory.

trated es shown in Figure 10. In this configuration

the DAMPING Control is set te WAX” position so thet

a 20 pf cepecitence is connected in the feedback

loop (SHWT RESISTOR Switch set t0 “OPEN”). The

current measured is determined by the following

equation,

Measurement.

The actual rise time for a

The specified rise time (10 to 90%)

These rise times era for a criticallv

, Additional external capacitance ten be

= Eo =

T

When the FUNCTION Switch is eat ta the

The Model 640 operation ten be illus-

%K RB

2-9.

use as en smueter accurate to 20.25%.

10 ) shunt resistors can be accomplished using a

current integrating technique.

voleege eource can be connected in series with the

shunt resistor forming e current source where I =

V/R.

the meter reading EM is e function af cepacitance C

end the integral of the current.

arAEM =

Solving for R,

Where R -

Since the eccuracy of C is +.25% the overall eccurecy

af the calibration will depend on the accurecies of

the voltage swrce V, the meter accuracy EM, end the

time accuracy T.

acy, maesure the enalog OUTPUT using a 0.01% digitel

voltmeter.) Refer to Figure 11 for circuit connec-

tions.

SHUNT RESISTOR CALIBRATION.

8. General. The Model 640 ten be calibrated for

& Theory. Calibration of

With FUNCTION Switch set t0 CURRENT INTEGRATE

c J

$ AT =(!-) AT

shunt resistance, ohms.

V

= eource voltage.

C = integrsting capacitor (20 pf).

E-E0 - chenge in wltage indication.

T-T0 = time ineervel for voltage change.

(To obtain the best possible eccur-

c. Calibretion Procedure.

1. Set the FUNCTION Switch to CURRENT?NTZGRATE.

rhe

high value (lo”,

An

accurately known

where I =

AE

At

2. Variable Damping.

(R108) is adjusted.counter-clockwise,the Model 640

can be used fot current meesuremente with veriable

damping.

10

cm-rent in amperes.

C = feedback capacitance (2 x 10-11).

=

change in the meter resdtng during time

interval

=

time interval of me*aurement.

At.

When the DAMPING Control

2. Set the DAMPING to ‘WAX”.

3. Apply the voltage source between P106 end

input LO. (Remove the Input Heed bottom cover for

access).

4. Zero meter.

5. Select lOlo or 1012 SHUNT RESISTOR.

6. Measure time interval from zero to full scale

an the meter.

7. Calculste the value of R using equation.

Record time interval T-To.

04728

Page 14

MODEL 640 ELECTROMETER OPERATION

INPUT HI

< OUTPUT OUTPUT

INPUT LO

<

1

e. =

l/C

I

LLO LO

--c

FEEDBACK,

>

!

RI.!

1

I

p+k

E -

-

FEEDSACK~

P106

INPUT HI

FIGURE 10.

Equivalent Current Integrator.

-< OUTPUT

RA,

% *o

t

= l/C J E/R dt

‘< Lo

04728

FIGURE 11. Current Integrate - Shunt Resistor Calibration.

11

Page 15

OPERATION

MODEL 640 ELECTROMETER

Z-10.

ANALOG OUTPUTS.

a. OlPPPUT

en analog output for recording or monitoring purposes.

eo161”~“,~i?&,,

full scale input. The-polarity of the output is

opposite the input signal.

Gain: 0.033 eo 3.3 x 104

Frequency Response (Within 3 db): dc to 0.07 cps

at a

of 10

Noise: Below lcps: seme es meter noise for spec-

ified function. Above 1 cp8:

output p-p an the 30-v to lo-mv ranges, increasing

co 10% an the 1-w and lower ranges.

dtit~ the o”tp”t is approximately 1X4 for a full

scale input.

b. onio Gain output.

set to VOLTAGE the FEEDBACK terminal can be used for

measuring a potential from a very high impedance

SO”X.2.

in .01X or 10 M”, exclusive of zero drift, for output

current of 100 pA or less.

Terminal

P

ain of 3.3 x 10 , rising to 35 cps at e gain

3

or below.

1MA Output. With the IV-1”A Switch set to

At dc, the output is equal to the input with-

(54041. This terminal provides

With the l”-WA SWitch (S406) set

is + 1 volt corresponding to a

less than 2% of full

When the FUNCTION Switch is

The peak-to-Peak noise is approximately five times the

rms value (from experimental measurements), therefore

the equation can be expressed as follows.

EPP =

If the ambient temPerat”re is 300°K (room ambient)

then the peak-peak noise can be expressed as follows.

EPP =

C. Typical Example. The Peak-peak thermal noise

generated in an ideal so”rce resistance can be illus-

trated as follows.

Given: Amplifier BandwidthAF = 0.08 *

EPP (typically)

KPP =

*AF =

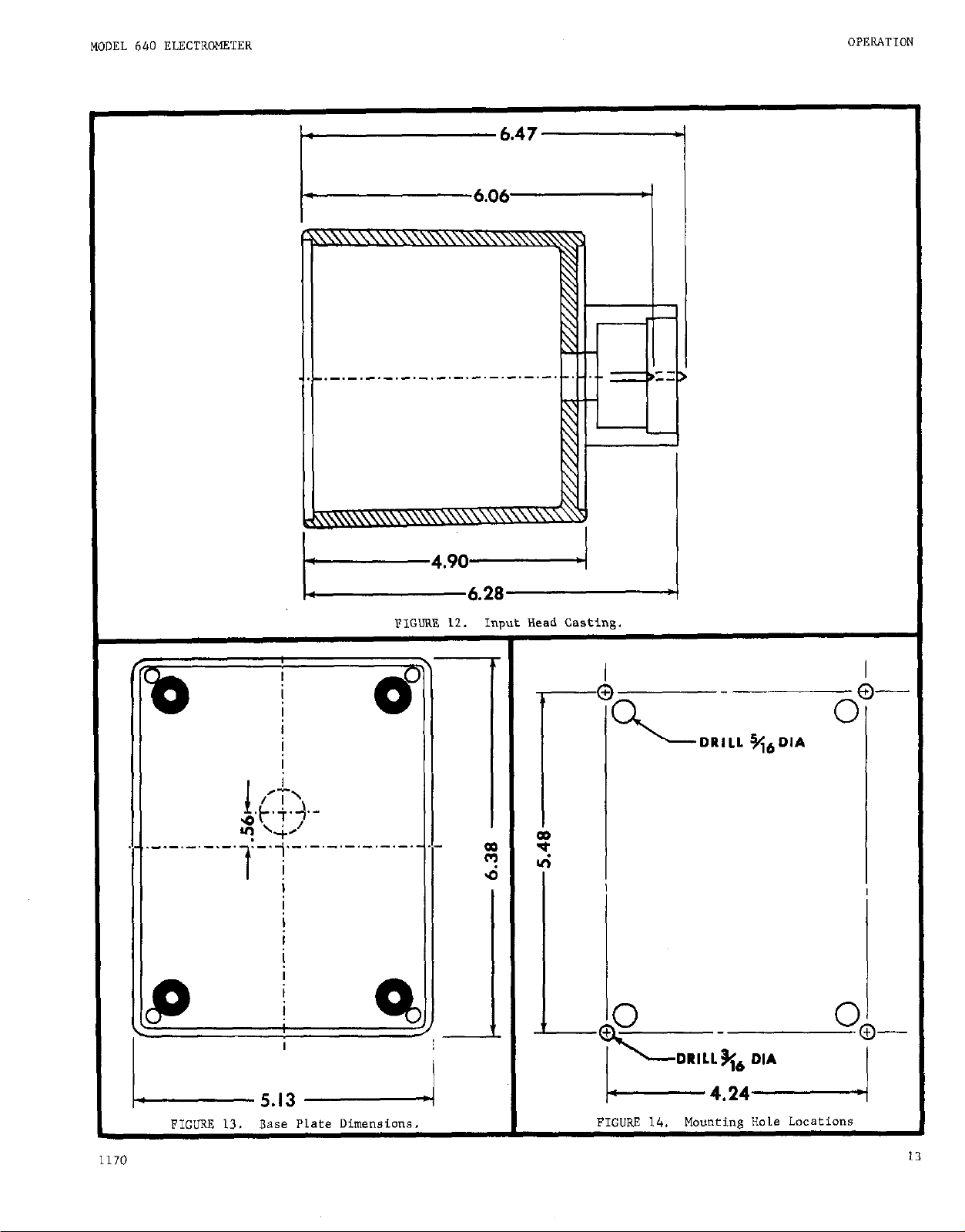

2-12.

8. casting Dimensions.

the Input Head Casting are shown in Figures 12 and

13.

5 x %ms

6.45 x 1O-Lo s

R - 1012 ohms.

RANGE see to 1 MY.

180 vV Peak-Peak

= 6.45 x lo-lo

1

kiK=

MOUNTING DIMENSIONS.

2% lo’& 2 x lo-‘f 2 .OB

The overall dimensions of

2-11. THERMAL NOISE.

e. General. A common limitation of microvoltmeter

measurements from high so”rce impedances is the eherm-

al noise (Johnson noise) generated in the source.

b. Theory. Thermal noise in an w resistance

can be theoretically determined from

noise equation as follows.

%m =

JZXZ

the

Johnson

where

Q-m =

T =

R =

F = amplifier bandwidth, Hz.

K =

rm8 voltage noise generated in the

resistence.

temperature, OK.

ideal resistance, ohms.

soltzmenn CO*Ste”t (1.38 x 10-1ojaulea/4()

b.

Input

loaded with the dimensions from the base 8s shawn in

Figure 12.

c, “auntinn the Base Plate. The Base Plate can be

mounted on a machined surface for custom installation

of the Input Head.

Input Head casting using four type 6-32 x l/4 BCTBWS.

The rubber feet are’attached to the base plate “sing

type 6-32 x l/2 Phillips Heed screws and mating #6

kep nuts.

this hardware).

Casting to e surface Plate.clearance holes must be

drilled in the surface plate as shawn in Figure 14.

The Casting can be fastened to the surface using type

6-32 screwe.

the four 8crews replaced.

ed should provide sufficient clearance for the 6-32

Phillips screw heeds.)

contact. The input COntaCt is spring

The Base Plate is fastened Co the

(The deesicant beg is also attached “sing

In order to mount the Input Head

The rubber feet should be removed and

(Note that the holes drill-

12

04728

Page 16

MODEL 640 ELECTR‘WSTER

1

.I ._.-._.-.-.

:-.i,-‘-‘-‘-‘-‘-.-’

1 i

i

I

i

I

I

FIGURE 12.

6.28

>ut Head Castins.

I”1

4

L5.13 I

FIGURE 13.

1170

Base Plate Dimensions, FIGURE 14.

Mounting Hole Locations

Page 17

CIRCUIT DESCRIPTION

MODEL 640 ELECTROMETER

SECTION 3.

3-l. GENERAL.

Head (Remote Preamplifier) end e Main Chassis (Amplifier end Power Supply).

8. High Impedance Microvoltmeter. When the FLNCTION Switch is set to VOLTAGE,the Model 640 operates

as e very sensitive, stable voltmeter with very high

input Lmpedance .

b. Vibrating Capacitor Electrometer. When the

FUNCTION

Model 640 operates es a stable current enh charge

measuring instrument.

3-2.

amplifier utilizes e vibrating-capacitor input preamplifier end variable-sensitivity emplifier. The

overall amplifier operates es a very sensitive dc

amplifier using e vibrating cepecitor es en input

signal modulator.

amplified end demodulated in the preamplifier circuit.

The dc signal is filtered end amplified further

by the main dc amplifier.

ly to provide gain accuracy end stability, A block

diagram of the overall amplifier is shown in Figure 15.

3-3. INPm HEAD.

Heed contains the input modulator, high-gain ec emplifier, oscillator end demodulator. The Shunt Resistors are connected across the overall amplifierfeedbeck using Switch S102.

Switch is set to either CURRENT position,the

ELECTROMETER AMPLIFIER. The basic electrometer

The Model 640 is composed of an Input

The input signal is modulated,

Feedback is used extensive-

(Remote Preamplifier). The Input

CIRCUIT DESCRIPTION

a. Vibrating Capacitor.

used consisting of two stationary pletes and e vibrating membrane which is excited et e carrier frequency

of approximately 400 kHz. The glass membrane has de-

posited metal surfaces and is sealed in en evacuated

glass “bottle”.

high input-impedance end low drift. When driven et

the carrier frequency (under proper canditions),the

membrane resonates et approximately 6000 Hertz. Since

the carrier (drive) frequency is much higher then the

resonenC

ics does not appreciably effect the amplifier circuit.

b.

to receuescle 5105

is isolated from Main Chassis ground. A 10 megohm

resistor (RIOS) prevents e rapid discharge of the

vibrating capacitor beck ineo the source circuit. The

modulated signal is applied to the first stage ac

amplifier through e guerded, three-terminal air capacitor. (Cl05 which is 20 pF 5 0.25%).

c.

a normally-open control which energizes solenoid RlOl.

When KlOl is energized,a cancect connects input High

to FEEDBACK through a 1000 ohm resistor. The input

source end vibrating cspecitor remain connected in

the circuit during zero check. A loading error will

result in the meter zero reading if the source resistence (RS) is less then 100 K in accordance with the

following equation.

% Error = 100

frequency, the terrier frequency end harmon-

Input circuit. The input High signal is spplied

Zero Check Circuit. The ZERO CHECK control is

RS’1’

This unique capacitor provides very

on

where KS is expressed in kilohms.

A

special capacitor is

the Inwe Heed. The inout LO

r-

-INPUT HEAD -MAIN CHASSIS -INPUT HEAD -MAIN CHASSIS

FEEDBACK FEEDBACK

INPUT INPUT

FIGURE 15. Block Diagram of Model 640

14

1170

Page 18

MODEL 640 El.ECTROMETER

CIRCUIT DESCKIPTION

d. AC Amplifier,

The ac amplifier provides very

high gain through the use of a two-stage amplifier

and a phase splitter amplifier. A" FET (QlOl) provides a high input impedance. A" emitter-follower

stage (transistor Ql02) provfdes impedance matching

between QlOl and transistor Q106. Transistors Q103

9104, Q105 and QlOS are switches providing gain ad-

jwtment to prevent oscillation on the higher ranges.

Transistors Q107, Q109 and QllO form a second stage

ac amplifier. A phase splitter circuit is formed by

transistors Qlll and Q112. A tuned circuit composed

of integ. ckt. QAlOl, inductor LlOl and trimmer cap-

acitor Cl24 provide attenuation of carrier frequency

(6000 Hz) second harmonic noise. The ac signal is

synchronously demodulated by transistors 4506 and

Q507 (locatad in the oscillator circuit).

e. Oscillator Circuit. The high frequency drive

(400 kHz) signal is generated by a tuned circuit consisting of transformer T501, capacitors c502, c503

and C504 and transistor Q501. Capacitor C502 adjusts

the 400 kHz carrier frequency. Pote"tiometer R506

adjusts the gain of the drive circuit. The drive o"tput is developed across transformer T502 and capacitor

C509 to excite vibrating capacitor plates (pins 1 and

The actual signal is a modulated "envelope" as

4).

shown in Figure 28 in Section 6. FET Q503 and inte-

grated circuit QA501 form a wave-shaping circuit far

phase and syrranetry control.

Integrated circuit QA502

is part of a phase control circuit for the demodulator

autput. Potentiometer R517 adjusts the phase of the

demodulator drive. Integrated circuit QA503 is part

of a swmletry control circuit.

Potentiometee S.521

adjusts the hemodulator a" and off times (syrmnetry).

Transistor 9505 controls the switching of demodulat-

ing transistors Q506 and Q507.

3-4. MAIN CHASSIS.

The Main Chassis contains a dc

amplifier circuit, meter circuit, sensitivity switching circuit, power supply circuit, and battery charg-

ing circuit 88 shown on Schematic 213833.

a. DC Amplifier.

A differential input stage is

formed by FET's Q401 and Q402 and transistors Q403

and Q404.

balance.

Potentiometer R404 provides dc amplifier

Capacitors C401, C402, and C403 provide

filtering of the demodulator ripple. FET Q405 and

transistors Q406 and Q409 (Darlingto" amplifier) pro-

vide additional gain for driving the meter circuit

and analog O"TPUT.

Transistor Q4OS provides current

limiting when the output is overloaded. Transistor

4407 provides a constant current for biasing purposes.

b. Meter Circuit.

The meter circuit consists of a

meter switch 5404, a 1-W meter movement (M401), and

various meter circuit adjustments. The Meter switch

has a" OFF position (which shorts o"t the meter movement), "t" and 11-11

polarity positions (which connect

the meter for either positive 01: negative deflection),

and a ZERO CENTER position (which biases the meter

such that center scale represents zero).

POtf?"tiOmeter R421 is an internal adjustment of the ZERO

CENTER meter bias current. Pote"tiameter R455 is an

internal adjustment of the meter calibration.

c. Zero Controls.

Switch,5405 is B COARSE ZERO

adjustment which can select up to 11 positions a" a

divider string (resistors R432 thtough R442). Switch

S407 is a~MSDILIM ZERO adjustment which can select up

to 11 positions a" a divider strinn (resistors R443

through R452).

Potentiometer R431-is a FINE ZERO

adjustment.

1170

Page 19

CIRCUIT DESCRIPTION

d. Sensitivity Switching. SANGE Switch 5403 has

13 positions which connect resistors R457 through

R469.

The range resistors determine the voltmeter

gain or sensitivity from 30 microvolts to 30 volts

full scale.

Power Supply, (As shown on Schematic 213823).

a.

The power for the Model 640 is provided by either a

rechargeable 6-volt battery pack or a recitifier cir-

cuit

operated by 50-60 Hz line power.

S301 selects four positions: “AC” (line power),

Power Switch

“OFF”,

“BATT” (battery power) and “SATT TEST” (battery voltage check).

The power supply utilizes a -6 volt unregulated voltage from the battery pack or a rectifier

circuit composed of transformer T303 secondary (yellow

end green taps) and diodes X317-D318. A 5-volt regu-

later is composed ofcapacitor C321, transistors Q317-

Q319 (Darlington series regulator), and reference

diode D319. Transistors 9321 and Q322 compoee an output sensing amplifier to regulate the series transistor

stage.

Potentiometer R338 is a.” internal adjustment

of the regulated output (approximately -5 volts). The

regulated voltage is applied to an Inverter circuit

consisting of transistors Q301-Q302 end saturable core

transformer T301.

MODEL 640 ELECTROMETER

Line Power to Battery Switching. The Model

5.

640 can be modified so that a failure of line power

(with POWER Switch set to

“AC”)

will ca”se an automatic switching to battery operation to occur. A

diode

(0.75A. 5OV,

Keithley Part No. RF-17) can be

connected at the POWER Switch 88 shown in Figure

When line power is present the diode is turned off

and the battery is not used.

f. Battery Charuinp. Circuit. The charging circuit

functions whenever the POWER switch is eet to “AC”

or “OFF”.

Charging c”rrent is provided

by a

rectifier circuit conslating of diodes 0315-0316 and resi*tor 107.9. Fuse F302 is rated for 314 ampere and

used to protect the battery end circuitry during

charging or discharging.

+ 4OV Supply. Power is tapped from B second-

1.

ary winding on Craneformer T302 (brown/yellow,

brown/white, brown). Diodes D301-0304 and capact-

tars C302-C303 provide + 40 volts for the dc ampli-

fier output stage.

- 2ov supply.

2.

This voltage is not used in

the Model 640.

+ 12” supply. Power is tapped from B eecand-

3.

ary winding

on

transformer T302 (red/yellow, yellow/

white, yellow). Diodes 0307-0310, resistor R304,

and capacitor C307 form a rectifier circuit. A

voltage doubling circuit cdnsisting of capacitors

C305-C306, and diodes D30S-D309 forms a bootstrap

voltage).

Transistors Q303-Q304 form a Darlington

series regulator circuit. Feedback is obtained by

sampling the + and - 12 volt outputs at the junction

of resistors R316 and R317. Transistors Q30S and

Q309 form a differential amplifier which senses a

change in either the + or - outputs. Another dif-

ferential pair (transistors Q306-Q307) drives the

base of transistor 9304 to complete the feedback

100p.

Transistor Q305 provides overload-current

protection by sensing the current through resistor

R305.

-12v Supply. Power is tapped from a aecond-

4.

ary winding on transformer T302 (red, blue/ white,

blue). Diodes D311-0312, resistor R318, and capacitor form a rectifier circuit. Transistors Q310Q311 form e Darlington series regulator circuit.

Feedback is obtained by sampling the -12 volt out-

put et the wiper erm of potentiometer R327. This

potentiometer adjusts the output voltage. Transistors Q114-Q115 form a differential amplifier with

the base of Q314 referenced to diode D314. Transistor 9313 drives the base of Q310 to series regulate the output. Transistor Q312 provides overload

current protection by sensing the current through

resistar R345.

FROM BATTERY

I

FIGURE 17. Line to Battery Switching.

3-5.

VOLTAGE FUNCTION.

set to “VOLTAGE”, the Model 640 operates as a sensitive voltmeter with input “OPEN” or shunted by any

one of four resistors,RlOl through R104.

3-6.

CURRENT FAST FUNCTION.

eet to “CDRRENT FAST”, the Model 640 operates as e

feedback ammeter with a Shunt Resistor connected

acrose the amplifier (from High to Feedback). An

external resistance can be connected ,in place of the

four Shunt Resistors “he,, switch 5102 ie *et to “OPEN”.

This

method minimizes the slowing effect of capacit-

ance across the input.

3-7. CURRENT INTEGRATE

Switch set to “CURRENT INTF.GRATE”,the Model 640

operates ee a feedbaok anmeter or coulomb-meter.

With (1 Shunt Resistor connected,(RlOl through R104)

a 20 pF capacitor (ClO5) shunte the amplifier to

therefore slow the response and filteenoisy signals.

With switch S102 set to “OPEN”,capacitor Cl05 acts

as an integrating capacitor for charge or current

integration measurements. A simplified diagrams of

the current integration amplifier is shown in Figure

11 . When the

INTFJXATE”, switch S4O2 connects -5 volts to

FUNCTION Switch is set to “CURRENT

K102 which in turn closes e contact.

connecte the Damping Control (RlOS) such that Capac-

itor Cl05 is connected in the feedback loop. The

Damping Control adjusts the effective capacitance

connected in the feedback loop and thus controls the

amount of damping. When the Damping Control is ad-

justed fully clockwise the maximum damping (20 pF

+ .25%)

is provided.

With the FUNCTION Switch

With the FUNCTION Switch

FUNCTION.

With the FUNCTION

solenoid

The contact

16

1170

Page 20

MOOEL 640 ELECTROMETER

ACCESSORIES

SECTION 4. ACCESSORIES

4-1. GENERAL.

The follo"ing Keithlsy accessories

can be used with the Model 640 to provide additional

convenience and versatility.

Model 6401 Remote Cable

Description:

The Model 6401 is a shielded coaxial cable with a

Keithley B-195 (male) connector on each end. The

cable is 25 feet long.

Model

Description:

The Model

6402 is

special adapter which replaces the

UHF adapter supplied with the instrument.

Application:

The Model 6402 adapts the Input Receptacle for GR074

series Of coaxial accessories. (General Radio Co.).

This adapter is limited to measurements above

10

-13

amperes or source resistances belo” 1014 ohms. The

adapter can be connected to the Input Head as shown

in the illustration.

4-2. OPERATING INSTRUCTIONS. A separate Ins~ructio"

Manual is supplied with each accessory giving com-

p1ete operating information.

Application:

The Model

6401 permits remote location

Head up to 25 feet from the Main Chassis with no degradation to the specifications.

6402

Adqter

of the Input

Model 399 Isolating Amplifier

Description:

The Model 399 is a unity-gain amplifier which permits

operation with the instrument output floated at up to

1500 volts off ground while the Model 399 output is

grounded or floated up to 100 volts off ground.

1170

Application:

The M,,del 399 can be used for ‘FIFO” operation (float-

ing input, floating output) or when it is necessary

ea break ground loops within a system. The 1 volt at

up to 1 mA output enables use of the Model 399 as a

preamp far driving most analog recorders.

Page 21

ACCESSORIES

Specifications:

MODEL 640 ELECTROMETER

Model 399 Isolating Amplifier (Cant’d.)

GAIN: XI, adjustable 23%.

GAIN ACCIJRACY :

GAIN LINEARITY:

,o,za (as set ae factory).

Within 3 millivolts for signal levels

below I volt.

FREQUENCY RESPONSE (minimum): Fast: dc to 100 Hz

(-3 dB); Slow: dc to 0.3 He (-3 dB).

NOISE: Less than 5 millivolts p-p, .Ol Hz to lk”z;*

less than 0.5 millivolt p-p, .Ol Hz to 0.35 HZ.*

ZERO STABILITY: Setter than 3 millivolts/24 hours at

reasansblv constant ambient temperature.

106

INPOT RESIS+ANCE:

INPUT OFFSET CURRENT:

FULL-SCALE INPUT:

ohms.

mess than

lo-6

ampere.

11 volt with 100% overrange.

MAXIMUM INPUT OVERLOAD: 100 volts.

INPO’I ISOLATION: Greater than 101’ ohms at 50% rela-

tive humdiity and 2PC shunted by less than 100

picofarads.

MAXIMUM COMMON MODE VOLTAGE: 1500 volts peak, dc or

ac.

CMRR: Greater than 120 dS at dc, greater than 100 dB

up to 1 kHz.

OOTPUT :

+l volt at up to 1 milliampere, 100% over-

range.

OUTPUT ISOl.4TION:

Greater than lo* ohms shunted by

less than 0.001 microfarad.

POWER :

105-125 ar 210-250 volts (switch selected),

SO-60 Hz, 5 watts.

DIMENSIONS, WEIGHT:

4-112” high x 4-112” wide x 7”

deep (11 cm x 11 cm x 18 cm); “et weight, 3 pounds

(1.3 kg).

ACCESSORIES PURNISHED:

Model 3991 Input Cable

(to

safely mate Model 399

to most Keithley instruments).

xModulation suikes a few hundredths of B volt D-D

at a IO-kliz. ;ep-rate may be observed with widebind

SyStmS*

Model 370 Recorder

rlescription:

The Model 370

is compatible

is a compact, paper chart recorder which

with most Keithley instruments having a

1 volt; 1 milliampere output.

Application:

The

Model 370 can be used for analog recording applications with inputs floated at up to 500 volts off

ground.

The Model 3701 Input Cable supplied permits

convenient connections to the instrument.

18

1170

Page 22

MODEL 640 ELECTROMETER

ACCESSORIES

Model 4006 Reck Mounting Kit

Description:

The Model 4006 is a rack mounting kit with overall

dimensions, 7 inches high x 19 inches wide. Two top

covers are provided for use with either 10 inch or

13 inch deep instruments.

Application:

The Model 4006 converts the lnetrur,,ent from bench

mounting to rack mounting.

It is suitable for mount-

ing one instrument in one-half of a standard 19-inch

rack.

Pares List:

Item

NO.

OescripCion

1 Top Cover, 10”

2 Panel Adapter Plate

3 Angle Support

4 screw, 1110 x 3/S”

5 connecting Plate

6 screw, ii10 x l/2”

7 Angle

8 Top Cover, 13”

Qcy. Per

Assembly

1

1

1

4

1

4

1

1

Keithley

Pare NO.

200168

19158A

19157A

--19154A

___

191478

200158

Model 4007 Rack Mounting Kit

Description:

The Model 4007 is a rack mounting kit with overall

dimensions, 7 inches high x 19 inches wide. Two top

covers are provided for use with either 10 inch or

13 inch deep instruments.

Application:

The Model 4007 con”erts the instrument from bench

mounting to rack mounting.

It is suitable for mount-

ing two instruments in a standard 19-inch rack.

1170

Parts List:

Item

NO.

Oe.SCriptiO” Assembly Part NO.

1 Top cwer, 10”

screw, n10 x l/2”

4

5 COnneceing Plats

6 screw, ii10 x l/Z”

7 Angle

8 Top Cover, 13”

9 Zee Bracket

10 Plate

Qty. Per

2 200168

s

1 19154A

4 --2 141478

2 200158

1 19167A

1 19700‘4

Keithley

_--

19

Page 23

SERVICING

MODEL 640 ELECTROMETER

SECTION 5.

GENERAL. This section contains procedures for

5-l.

checkout and servicing the instrument.

step-by-step procedures for complete servicing.

SERVICING SCHEDULE. This instrument requires

5-2.

no periodic msintenance

beyond the normal care re-

quired for high-quality electronic equipment.

PARTS KEPLACmT. Refer to the Replaceable

5-3.

parts diet, Section 7, for information regarding corn-

ponent specifications end part numbers.

ponents as indicated using replacement parts which

meet the listed specifications.

Code

etter Instrument Type

Follow the

Replace com-

TABLE 5-l.

Test Equipment.

Specificetion

SEWICiNG

5-4. TROWLESHOOTING.

Test Equipment.

a..

mended test equipment for servicing end calibrating

this instrument.

b. Troubleshootina Guide. Refer to Table 5-2 for

e brief outline of troubleshooting hints. The Table

identifies the Symptoms or Trouble, the Probable

Cause, and the suggested Solution.

If the instrument problem cannot be readily

located or repaired, contact a Keithley representative or the Sales Service Department,

Cleveland, Ohio.

Manufacturer

and Model No.

Refer to Table 5-l for recom-

NOTE

“Se

A

High Voltage Supply

B Nanovolt Source

c

D

E

F

Picoampere Source 10-4 to lo-14A

Megohnrmeter

Differential Voltmeter 1OOmV - 5OOV, .Ol%

Digital Voltmeter

G Function Generator

H

I

J

Oscilloscope

Probes; 1O:l & 1:l

Capacitance Bridge

K “eriable Transformer

& Power Line Meter

L Recorder

o-lOOOV, .01-V steps,

10-10 to 1v

, .25 to .75% accuracy.

.05% accuracy.

, .25 to .l% accuracy.

lo7 to lo13 ohms 220% accuracy.

1wv to lOOOV, 0.1%

1mA sensitivity: .05 8 Rise Time

lo-90%

Keithley, Model 241

Keithley, Model 260

Keithley, Model 261

Keiehley, Model 500

Accuracy checks.

Accuracy checks.

Accuracy checks.

ISOlatio” Resist

ante Check.

Keithley, Model 662

Keithley, Model 163

Wavecek, Type 110

Accuracy checks.

Trouble-shooting

Frequency Respon

Check.

Tektronix 503/5blA

Trouble-shooting

Calibration.

Tektronix

Use with Oscillo

scope.

Generel Radio 1blbA

Variac/RCA

Capacitor checks

Power Supply

Calibration.

Keiehley, Model 370 Drift end Noise

Checks.

20

1170

Page 24

MODEL 640 ELECTROMETER

symptom or Trouble

Probable Cause

TABLE 5-2.

Troubleshaming Guide

SOlUti.3”

SERVICING

Sub-

Assembly Figure

kcessive Voltage Drift

ixcessive Noise at

~UTPIJT or Meter

!xcessive current >ffset or drift

eter Pegs Off-Scale

(all ranges)

DC Amplifier

Vibrating Capacitor

Input PET (QlOl)

Vibrating Capacitor

Defective Insulaeio”

Excessive Humidity

Vibrating capacitor

Power Supplies

AC Amplifier

Oacillatar Circuit

Power Supplies

Replace V.C. (C121).

Check diodes 0405-6 and potentiometer R431.

Replace V.C. (C121).

Replace PET (QlOl).

Replace V.C. (C121).

Check sapphire insulation.

Allow instrument to warm-up. Re-

activate the dessicanc in the

INPUT HEAD.

Calibrate drive circuit as in

para. 6-3.

Check voltages in the INPUT HEAD.

Check for proper gain.

Check drive voltages. Calibrate

as in para. 6-3.

Check voltages on the Main Chassis.

INPUT HEhO

PC-149

PC-150

INPUT

HEAD

PC-151

INPUT HEAD

INPUT HEAD

INPUT HEAD

INPUT HEAD

PC-151

PC-247

23

‘5

24

24

27

(one range only)

1170

DC AmpLifier

Vibrating c*pacieor

RANGE Resistor

Check meter circuit.

Replace V.C. (C121).

Check RANGE switch. Replace RANGE

resistors.

PC-150

INPUT HEAD

S403

25

21

Page 25

SERVICING

MODEL 640 ELECTROMETER

FIGURE 18.

Test Points, PC-148.

22

FIGURE 19.

Test Points,

PC-149.

Page 26

MODEL 640 ELECTROMETER

SERVICING

FIGURE 20.

Chassis, Top view.

23

Page 27

SERVICING

MODEL 640 ELECTROMETER

24

FIGURE 21.

Chassis, mp view.

1170

Page 28

MODEL 640 ELECTROMETER

SERVICING

1170

FIGURE 23.

component layout, PC-149.

25

Page 29

SERVICING

MODEL 640

ELECTROMETER

FIGURE 24.

component Layour, PC-151

FIGURE

component Layout,

25.

PC-150,

1170

Page 30

MODEL 640 ELETROMRTER

SERVICING

1170

FIGURE 26.

Component Layout, ~~-153.

Page 31

SERVICING

MODEL 640 ELECTROElETER

FIGURE 27.

Component Layout, PC-247.

1170

Page 32

MODEL 640 ELECTROMETER

SERVICING

CHECKOUT PROCEDURE.

j-5.

Refer to Table 5-3 for

seep-by-step procedures for instrument checkout.

Use care when troubleshooting an instru-

NOTE

"tent connected to line power and/or with

Power switch an.

Before a step-by-step checkout is started,

inspect the circuits visually to detect

problems such as broken wire, loose parts,

dirty or oily switch contacts, etc.

checks are made, remove all power to

Fnstrument and discharge power supply

capacitors through a law value resistor

(loon).

TABLE 5-3.

Checkout Procedure.

LTS.

.5

Connect the shorting link between GND and LO on

a.

Description

Sub-

Aseembly

Main Chassis

rear panel of Model 640.

Place Dust Cover (20911A) over Input receptacle INPUT HEAD

b.

(To prevent contamination and stray noise pickup)

Check retaining screws on all PC boards in the

c.

INPUT

HEAD

INPUT HEAD. (The LO to case connection is made

through these screws).

d. Check the unregulated voltage an PC-148. Volt- PC-148 18

age should be nominal-11 volts dc with 3 volts

p-p ripple.

"se Oscilloscope (H).

WARNING

whenever resistsme

Tese

FQ"lX POi"?

4

Rear

Panel

-1lV "Iwe*.

CirC"it

Descriptic

Para. 3-4e

Check the regulated voltage on PC-148. Voltage

e.

PC-148 18 -5”

should be nominal -5 volts.

f. Check inverter voltage on X-148. Voltage should PC-148 18 I""erter

be 5V p-p square wave at 1100 Hz.

Check the +4OV unregulated voltages an PC-149.

8.

Check the unregulated voltage at collector of

h.

Q303.

Voltage should be nominal 15 volts dc.

i. Check regulated c12V cm PC-149.

Check regulated -12V on K-149.

j.

PC-149 19

PC-149

PC-149

PC-149

19

19

19 -12v

i4OV pera. 3-4c

+15v ""reg. eara. 3-k

c12v Fara. 3-4e

k. If all power supply voltages are nominal proceed -

to oscillator check.

1.

Check Vibrating Capacitor drive signal an PC-

247.

In.

Check demodulator drive signal on PC-247.

n. Check the dc amplifier circuit on PC-150.

Check meter circuit on PC-149, PC-150.

P.

PC-247

PC-247

PC-150

PC-149,

PC-150

27

27

25

23 eara. 3-4b

25

Pare. 3-4e

ears. 3-k

Pars. 3-48

ears. 3-3e

ears. 3-s

eara. 3-48

1170

29

Page 33

CALIBRATION

MODEL 640 ELECTROMETER

SECTlON 6. CALIBRATION

6-1.

GENERAL.

This section contains procedures for

checking the instrument in order to verify operation

wfrhin specifications.

6-2. TEST EQUIPMENT.

Refer to +able 5-l for recom-

mended teec equipment for servicing and calibrating

this instrument.

CALIBRATION PROCEDURE.

6-3.

Refer to Table 6-1 for

step-by-step procedures for calibrating this instru-

ment.

Calibration Procedures.

eara.

6-3

a.

Specification

or AdjustInent

LO to GND Isolation

Description Measurement

Set Power to “OFF”. Remove shorting LO to GND should Main

link between GND -and Lo an rear be SreaCer than Chassis

pane 1. Measure LO to GND resistance log&

using Megohmeter (D).

Mechanical Zero see meter zero.

b.

Adjust

TABLE 6-1.

NOTE

If proper facilities and equipment are not

available, contact a Keirhley representative

or the Sales Service Department, Cleveland,

Ohio.

Keithley Instruments, Inc. maintains

a compleee repair and calibration facility

with equipment traceable to

the National

Bureau of Standards.

Sub- Test

Assembly Figure PoFnt

4

LO to GND

Hair!

2

Meter

Chassis

Line Voltage Setting Connect Variac and set line voltage

C.

for 115v.

d. -5v Reg. VoltaRe

e.

_ _

Ripple Voltage hleaaure ripple on -5v supply using

Set Power to “AC” Measure -5V Supply Adjust wtentioon PC-148 using Diff. Voltmeter ii,;

Oscilloscope (Ii).

Voltage Checks Check remaining voltages.

f.

SUPPlY.

(Ripple should not exceed

5mv p-p).

+12v Supply. (Ripple should not

exceed 15mV p-p).

-40V Supply, (Ripple should not

exceed 50mV p-p).

+4ov Supply.

(Ripple should not

exceed 5OmV p-p).

!3.

Zero circuit

Check zener voltage an PC-149

using Diff. Voltmeter (E).

Check zener voltage on PC-149 using

Diff. Voltmeter (E).

-12v

115v nominal.

PC-148

meter RI338

-5v +5mv.

for

Ripple to be less PC-148

than

5OOmV

p-p.

Adjust potentio-

meter R327 far

-12v +5mv.

.-

t12v +5oom" PC-149

-40v +2v

+4ov +2v PC-148

D405

voltage

PC-148

PC-149

should be +9V 25%

Noise less

than 0.3mV.

0406

voltage PC-149

should

be -9,

+5%.

Noise less

5han 0.3mV.

22

18,

22

L9,

23

18,

22

18,

22

23

23

30

0472R

Page 34

TABLE 6-1. (cont’d)

Calibration Procedures.

CALIBRATION

Pam.

6-3

h.

Speciftcaeio”

or Adjustment

Battery Charging

circuit

Description

Set Parer to ‘OFP”. With line cord

connected measure the charging

voltage *t K329.

i.

Battery Check Set PWER Switch to “BAT’f TEST”.

Oscillator check

1.

Check waveform on PC-247 using

Oscilloscope (H).

NOTE : Use P 1O:l Probe for the

Oscilloscope in*ut. “se 1:l

Probe

for & T&GER and c~naect

to R521 (wiper).

k. Oscillaeor Recovery

Set Payer to ‘WF” for 10 seconds.

When Power is eet to “‘AC” the

Oecfllator signal should recover.

1.

Oscfllator

Mjustsnt

Adjust variable capacitor C502 to

“start” oecilletor if neceaasry.

Set the Gain Adjust potentimeter

X506 to obtain B stable waveform.

m.

symmtry Adjustint

Set the Sym. Adjust potentiometer

S521 for equal demodulator “ON”

and “ORF” times.

Voltage should be

-22V with less

than 2N p-p

ripple.

Meter should in-

dicate greater

than 6V.

see *igum 28

for desired

Wavefom.

se* Figure 29.

Sub-

Assembly

Main

Chassis

Main

Chessis

PC-247

PC-247

PC-247

FigUCe

27,

28

27

27

8

20

Test

Point

R329

Meter

Oscillator

Waveform

5104

n521

lls21

n.

Phase Adjustment Set Fuse Adjust potenticmeter

ll517 for proper phasins 88 shmm

in Pi& 30. Not*: The amplifier

must be driven into eaturetia, to

obtain e phase petter,,.

lhdty Gain Check

P.

Set FLNCl’IOII to VOLTAGE

FANG?3 to LVOLT

titer

to

Hwga

"+"

to AC

sm RKSISTOR to 106

Connect the Nenovolt Source (II) to

the Model 640 Input using UHF

adapter. Connect the Differenciel

Voltmeter to read the difference

potential between the Input hi@ end

PEKDBACK

terminala of the “ode1 640.

With the Nanwolt Source set to O-O-

0, adjust the Model 640 zero controls

for null on the Diff. Voltmeter

(+lwJ).

and check the Diff.

Apply +L.OOOV to Model 640

The Diff. Voltmeter should indicate

vithin +lOO microvolts.

Voltmeter null.

see Figure 30

for phasir.&

PC-247

INPUT

HKAB

27.

29

R517

- FBEDSACR

TeminaL

on INPUT

HEAD

04728

31

Page 35

CALIBRATION

MODEL 640 ELECTROMETER

TABLE 6-1. (cont’d)

Calibration Procedures.

Meter Cal. for

q.

r.

Full Scale

Meter Cal. far

center Scale

Voltage Range

8.

Accuracy Check

e.

Meter Noise

“*

OUTPUT Noise

Set front panel controls as in 6-3~.

Apply +1 volt using Nanovolt Source Input +1.ooov

(8).

Observe the Model 640 OUTPUT using OUTPUT should

Diff. Voltmeter. be Cl.OOOV +

1omv.

Adjust Meter Cal potentiometer R455

far full scale deflection.

Without readjusting the Zero controls

set the

Meter

for Center Scale. Ad-

just the Center Zero potentiometer

R421 far zero while in ZERO CHECK

mode.

Set front panel controls as in 6-3

p. Check all voltage ranges far

full scale accuracy. “se the Neno-

volt source as input reference.

Accuracy to be +l%

of full scale on

3ov-30o~v ranges.

15% on the 3O,,V

range.

Set front panel controls as in 6-3

Place Dust Cap over the Input.

P.

Observe Meter Noise an the 30 ,,”

Range.

Observe OUTPUT Noise using Oscillo-

scope (H).

Meter Noise to be -

less than 2 pV p-p,

OUTPUT noise to be -

less than 1OOmV

p-p, however occasianal spikes may

exceed 1OOmV.

PC-147

PC-147

-

20

20

R455

R42 1

V.

current Range

w.

current Range

32

Accuracy

(1060 Shunt)

Accuracy

(10&l Shunt)

Set RANGE to 1OV

FUNCTION to CURRENT FAST

METER to “+”

POWER to “AC”

SHUNT RESISTOR eo

106

Check the OUTPUT accuracy with the

Picoampere Source (C) used as Input current reference.

e CURRENT

1ov TT

1v lo-6A

1oonlv 10-7A

1 Om”

lo-BA

1mv lo-PA

Verify OUTPDT accuracy as in 6-a

v.wieh SHUNT RESISTOR set to 10

and RANGE to 1V.

Accuracy

should be -

i3% Of full scale.

Accuracy should be -

+3% of lo-SA full

&ale.

0472R

Page 36

MODEL 640 ELECTROMETER

CALIBRATION

TABLE 6-l. (cont’d)

Calibration Procedures.

Para. Specification

6-3

X.

or Adjustment Description MeamremenC

Current Range

Accuracy

( lOloo Shunt)

Current Range

Y.

Accuracy

( 1012fl Shunt)

Current Rise Time

Z.

as. Frequency Response

Verify 0LrrP”T accuracy with SHUNT

RESISTOR set to 10~~ and RANGE te

1v.

Repeat above using 1hnV RANGE.

(lo-12A).

Verify OoTPUT accuracy with SHUNT

RESISTOR see to 1012 and RANGE to

1v.

See RANGE to 1V

FUNCTION to CURRENT INTEGRATE

METER to OFF

POWER to AC

SHUNT RESISTORS to 1012

Set Damping to MAX: Apply +10-12A

input current using PFcoampere

source. Observe lo-90% rise time

“sing oscilloscope.

Set RANGE t” 1OmV

FUNCTION to VOLTAGE

METER to OFF

POWER to

AC

SHUNT RESISTOR to 106

Accuracy should be

23% of full scale.

Accuracy should be

24% of full scale.

Accuracy should be

24% of full scale.

lo-PO% Rise

Time

to be less then

44 sec.

Sub-

Assembly Figure

-

-

-

Test

Point

bb. Drift Check

Apply 10 Hz sinewave to Input “sing

Function Generator (C). Adjust

signal for 1.6V p-p as observed at

OUTPUT using Oscilloscape (Ii).

Set Function Generator (G) far

1HZ.

Increase the frequency of Function

Generator until OKfP1pp 1s reduced

D l.lV p-p. (3 dB down).

NOTE :

The Model 640 power must be

off far at least 2 hours prior to

this check.

Connect Recorder (L)

co the Model 640 OUTPUT. With o”et

Cover in place allaw a 60 minute

warm-up.

Set RANGE to 100 MICROVOLTS

FUNCTION to VOLTAGE

SHUNT

to 106

NOTE :

Maintain a constant ambient

temperature if passible. Otherwise

monibx temperature change to COW

pensate for 35 PVV/~C drift.

After weno-up period the drift

should not exceed 35 UV per 24

hours.

OUTPUT should remain at 1.6V p-p.

Frequency et 3 dB

down should be 35

Hz or higher.

Drift less then

35 @V per 24

hours.

-

-

0172R

33

Page 37

CALIBRATION

MODEL 640 ELECTROMETER

lYP!CAL WAVEFORM

FIGURE 28. Typical Oscillator Waveform.

34

FIGURE 29.

FIGURE 30.

Proper Symmetry Adjustment

CORRECT

PHASE

INCORRECT

Proper Phase Adjustment.

1170

Page 38

MODEL 640 ELECTROMETER

RBPLACEABLE PARTS

SECTION 7.

7-1. REPULCEABLE PARTS LIST: This section contains

a list of components used in this instrument for

user reference. The Replaceable Parte List describes

the individual pares giving Circuit Designation,

Description, Suggested Manufacturer (Cade Number),

Abbreviations end Symbols

A ampere

CbVar

CerD Ceramic Disc

Cer Trimmer

ComP

DCb

Desig.

PAL

ETB

ETT

Carbon Variable

Ceramic Trimmer

Composition

Deposited Carbon

Designation

Electrolytic, Aluminum

Electrolytic, tubular

Electrolytic, tantalum

F

Fig

GCb

k

11

M

Mfr.

MtF

MY

REPLACEABLE

Manufacturer’s Pert Number, and the Keithley Part

Number.

where applicable. The complete “eme end address of

each Manufacturer is listed in the CODE-TO-NAME