Page 1

INSTRUCTION MANUAL

MODEL 630

POTENTIOMETRIC ELECTROMETER

Page 2

WARRANTY

We warrant each of our products to be free

from defects in material and workmanship. Our

obligation under this warranty is to repair or

replace any instrument or part thereof which,

within a year after shipment, proves defective

upon examination. We will pay domestic

surface freight costs.

To exercise this warranty, call your local

field representative or the Cleveland factory,

DDD 216-248-0400. You will be given assist-

ance and shipping instructions.

REPAIRS AND RECALIBRATION

Keithley Instruments maintains a complete repair service and standards laboratory in Cleveland, and has an authorized field repair facility

in Los Angeles and in all countries outside the

United States having Keithley field representatives.

To insure prompt repair or recalibration service, please contact your local field representative or the plant directly before returning the

instrument.

Estimates for repairs, normal recalibrations,

and calibrations traceable to the National Bu-

reau of Standards are available upon request.

Page 3

MODEL 630 POTENTIOMETRIC ELECTROMETER

CONTENTS

TABLE OF CONTENTS

section

Page

1.

2.

3.

,4.

GENERAL DESCRIPTION . . . . . .

1-L.

Description . . . . . .

1-2.

Operating Modes . . . .

1-3.

Applications. . . . . .

l-4.

Specifications. . . . .

1-5.

Accessories . . . . . .

1-6.

Equipment Shipped . . .

OPERATION . . . . . . . . . . .

2-l.

2-2.

2-3.

2-4.

2-5.

2-6.

2-7.

2-8.

2-9.

Front Panel Controls

and Terminals . . . .

Rear Controls and

Terminals . . . . . . .

Preliminary Procedures. .

Operating Procedures. . ,

Recorder Output . . . . ,

Effective Input Resis-

tance . . . . . . . . .

Null Sensitivity and

Source Resistance . . .

AC Effects on Measurement

Current Measurements. . .

CIRCUIT DESCRIPTION . . . . . .

3-1.

General . . . . . . . .

3-2.

Reference Voltage Supply.

3-3.

Kelvin-Varley Divider . .

3-4.

Null Detector . .

3-5.

Oscillator. . . . .

3-6.

Guarding . . . . .

SERVICING . . , . . .

4-l.

General . . . . . .

4-2.

Servicing Schedule.

4-3.

Parts Replacement .

4-4.

Troubleshooting . .

4-5.

Adjusting Grid Bias

Cathode Follower.

. . . . .

14

. . . . .

15

. . . . .

16

. . . . .

17

. . . . .

17

. . . . .

17

. . . . .

17

. . . . .

17

of

. . . . .

19

4-b.

Zener Diode Replacement . . . 20

4-7.

Meter Adjustment . . . . . . 20

4-a.

Adjusting Quadrature Control. 20

.

.

1

.

.

1

.

.

1

.

.

2

.

.

2

.

.

3

.

.

3

.

.

5

. . 5

6.

ACCESSORIES . . . . . . . . . , . 35

. . 5

. . 6

. . 6

. . 9

6-1.

Model 6301 Guarded Probe. . 35

6-2.

Rack Mounting . . . . . . . 35

6-3.

Placing in Rack . . . . , . 36

6-4.

Model 6013 pH Electrode

Adapter . , . . . . . . . 37

. . 9

. . 11

. . 11

. . 11

. . 13

. . 13

. . 13

. . 14

7.

REPLACEABLE PARTS , . . . . . , . 39

7-l. Replaceable Parts List. . . 39

7-2.

How to Order Parts. . . . . 39

Model 630 Replaceable

Parts List. . . . . . . . 40

Model 6302 Replaceable

Parts List. . . . . . . 48

Model 630 Schematic Diagram

1826lE . . . . . . . . . 51

Green Repair and

Calibration Form . . . . . 53

Section Page

5.

CALIBRATION . . . . . . . ., . . 21

5-l.

General . . . . . . . . . . 21

5-2.

Calibration Schedule. . . . 22

5-3.

Kelvin-Varley Divider . . .

Verification. . , . . . . 22

5-4.

Input Divider Calibration . 23

5-S. Range Calibration , . . . . 23

5-6.

Reference Voltage Supply

Stability Test , . . . . 26

5-7.

Oscillator Adjustment . . .

27

*Change Notice . . . . . . . . . . . Last

Page

*Yellow Change Notice sheet is included

only for instrument modifications affect-

ing the Instruction Manual.

0 168il

Page 4

MODEL 630 POTENTIOMETRIC ELECTROMETER

GENERAL DESCRIPTION

SECTION 1.

GENERAL DESCRIPTION

l-l.

DESCRIPTION

a.

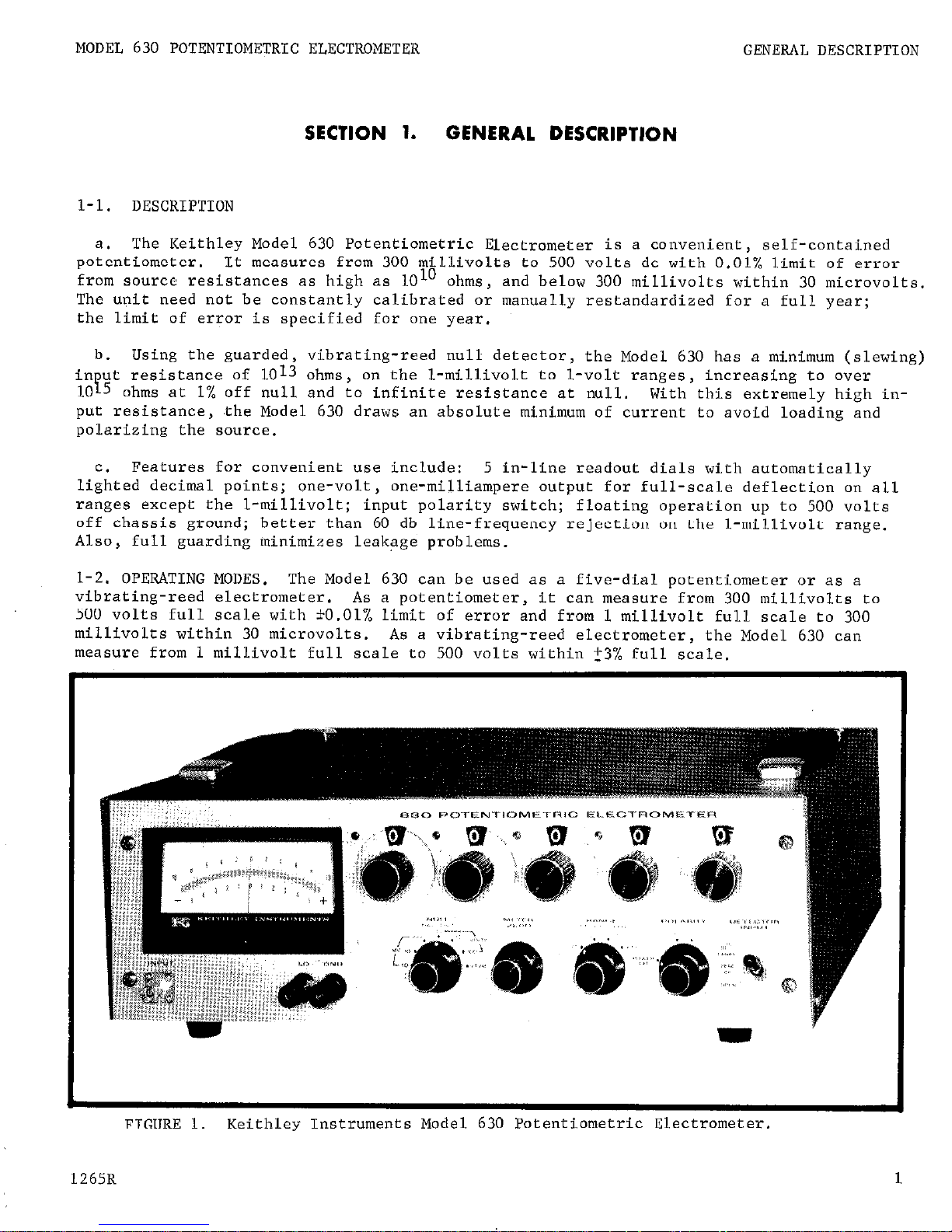

The Keithley Model 630 Potentiometric Electrometer is a convenient, self-contained

potentiometer, It measures from 300 millivolts to 500 volts dc with 0.01% limit of error

from source resistances as high as lOlo ohms,

and below 300 millivolts within 30 microvolts.

The upit need not be constantly calibrated or manually restandardized for a full year;

the limit of error is specified for one year.

in ut resistance of 1013 ohms,

F"'

Using the guarded, vibrating-reed null detector,

the Model 630 has a minimum (slewing)

on the l-millivolt to l-volt ranges, increasing to over

10 5 ohms at 1% off null and to infinite resistance at null.

With this extremely high input resistance , .the Model 630 draws an absolute minimum of current to avoid loading and

polarizing the source.

c.

Features for convenient use include:

5 in-line readout dials with automatically

lighted decimal points; one-volt,

one-milliampere output for full-scale deflection on all

ranges except the l-millivolt; input polarity switch;

floating operation up to 500 volts

off chassis ground; better than 60 db line-frequency rejection on the l-millivolt range.

Also, full guarding minimizes leakage problems.

l-2. OPERATING MODES. The Model 630 can be used as a five-dial potentiometer or as a

vibrating-reed electrometer.

As a potentiometer,

it can measure from 300 millivolts to

500 volts full scale with *O.Ol% limit of error and from 1 millivolt full scale to 300

millivolts within 30 microvolts.

As a vibrating-reed electrometer, the Model 630 can

measure from 1 millivolt full scale to 500 volts within 23% full scale.

FIGURE 1.

Keithley Instruments Model 630 Potentiometric Electrometer.

1265R

1

Page 5

GENERAL DESCRIPTION

MODEL 630 PO'TENTIOMETRIC ELECTROMETER

l-3.

APPLICATIONS.

a.

Due to its very high input resistance,

the Model 630 is very useful in making accurate dc measurements from high resistance sources frequently encountered in electrochemical

and physical-chemical research.

It is especially useful for measuring potentials from

piezo-electric crystals, electro-chemical cells, grids and plates of tubes, biological

cells and pH electrodes.

The Model 630 is also ideally suited for making Hall-effect and

fuel-cell studies,

silicon resistivity and capacitor charge measurements, and for mrasur-

ing gate potentials of field effect transistors.

b.

The null-detector output permits use with potentiometric recorders and digital volt-

meters equipped with automatic print-out.

The Model 630 is

useful

in quality control, pro-

duct development,

inspection and production.

l-4. SPECIFICATIONS.

AS A POTENTIOMETRIC ELECTROMETER:

LIMIT OF ERROR:

?O.Ol% of reading or 30 microvolts, whichever is greater, after 30-min-

ute warm-up.

Accuracy is exclusive of null-detector drift.

LONG-TERM STABILITY:

Will operate within stated limit of error for one year.

TEMPERATURE COEFFICIENT:

Does not exceed 0.001% per OC.

REPEATABILITY:

Within 0.0025% or 30 microvolts, whichever is greater.

MAXIMUM NULL SENSITIVITY:

1 millivolt full scale with 30-microvolt resolution.

INPUT RESISTANCE:

Infinite at null, from 0 to 500 volts.

10 15

ohms at.l% off null frop

0 to 500 volts with DETECTOR INPUT Switch in OPEN position.

FLOATING OPERATION:

500 volts maximum off chassis ground.

INPUT ISOLATION:

Circuit ground to chassis ground: 108 ohms shunted by 0.05 microfarad.

AS A VIBRATING REED ELECTROMETER:

VOLTAGE RANGES:

O-5 volt full scale to 500 volts in four decade ranges.

NULL RANGES:

1 millivolt full scale to 100 volts in six decade ranges.

INPUT RESISTANCE:

1013 ohms or 1010 ohms selectable by switch, L-millivolt to l-volt

ranges; 1010 ohms, 5 to 500-volt ranges.

ELECTROMETER ACCURACY:

f3% of full scale on all ranges, exclusive or noise and drift.

ZERO DRIFT:

Less than 2 millivolts per 24 hours after Z-hour warm-up.

Long term drift is

non-cumulative.

RISE TIME (10% to 90%): Less than 2.5 seconds on any range with 1010 ohm source resistance.

LINE-FREQUENCY REJECTION:

Greater than 60 db on the l-millivolt range, decreasing to 35

db on the 500-volt range.

2

1067R

Page 6

MODEL 630 POTENTIOMETRIC ELECTROMETER

GENERAL DESCRIPTION

GENERAL CHARACTERISTICS:

LINE STABILITY:

Better than 5 ppm for 10% change in line voltage.

RECORDER OUTPUT:

output:

1 volt, 1 milliampere for full-scale meter deflection on all ranges except on

l-millivolt range, where it is 10% less.

Noise:

30 microvolts peak-to-peak referred to input up to 1 cps.

Note: Recorder used must have fully isolated input, lOlo ohms minimum to ground.

POLARITY: Positive or negative, selectable by switch.

CONNECTORS: Input:

Special Triaxial. output: Banana jacks.

POWER:

105-125 or 210-250 volts (switch selected); 50, 60 or 400 cps; 50 watts.

DIMENSIONS, WEIGHT:

5-l/2 inches high x 17-l/2 inches wide x 13-l/2 inches deep; net

weight, 24 pounds.

ACCESSORIES SUPPLIED:

Model 6302 Input Cable consisting of a mating plug and 3-foot

triaxial cable.

l-5.

ACCESSORIES.

a.

Model 6301 Guarded Probe with 3-foot connecting cable allows measurements to be made

more conveniently.

Using the Probe does

not

affect any Model 630 specification.

b.

Model 4000 Rack Mounting Kit, containing two brackets and a top cover, converts the

Model 630 to fit standard 19-inch racks. Rack mounted,

the Model 630 is 5-l/4 inch&s

high x 19 inches wide x 13-l/2 inches deep. Section 6 has assembly instructions.

C. Model 6013 pH Electrode Adapter,which has a Z-foot cable and triaxial connector,

accepts Leeds & Northrop and Beckman pH electrode connectors.

The Adapter allows accurate

and convenient,pH potential measurements with the Model 630.

l-6.

EQUIPMENT SHIPPED. The Model 630 Potentiometric Electrometer is factory-calibrated

and is shipped with all components in place. All units are shipped for bench use. Model

4000 Kit may be ordered for rack mounting;

refer to Section 6 for assembly instructions.

The shipping carton also contains the Instruction Manual and the Model 6302 Mating

Connec-

tor with 3-foot triaxial cable.

016GR

3

Page 7

OPERATION

?4ODEL 630 POTENTIOMETRIC ELECTROMETER

-

Reference Voleage Dials

s303

5304

s305

S-306 It381

DETECTOR INPUT

Swirch (5102)

Receptacle

5103 5104

Switch

CO"tL-01

Switch

SwFtch

.JlOl

(S101) (R122)

(5104)

(5301)

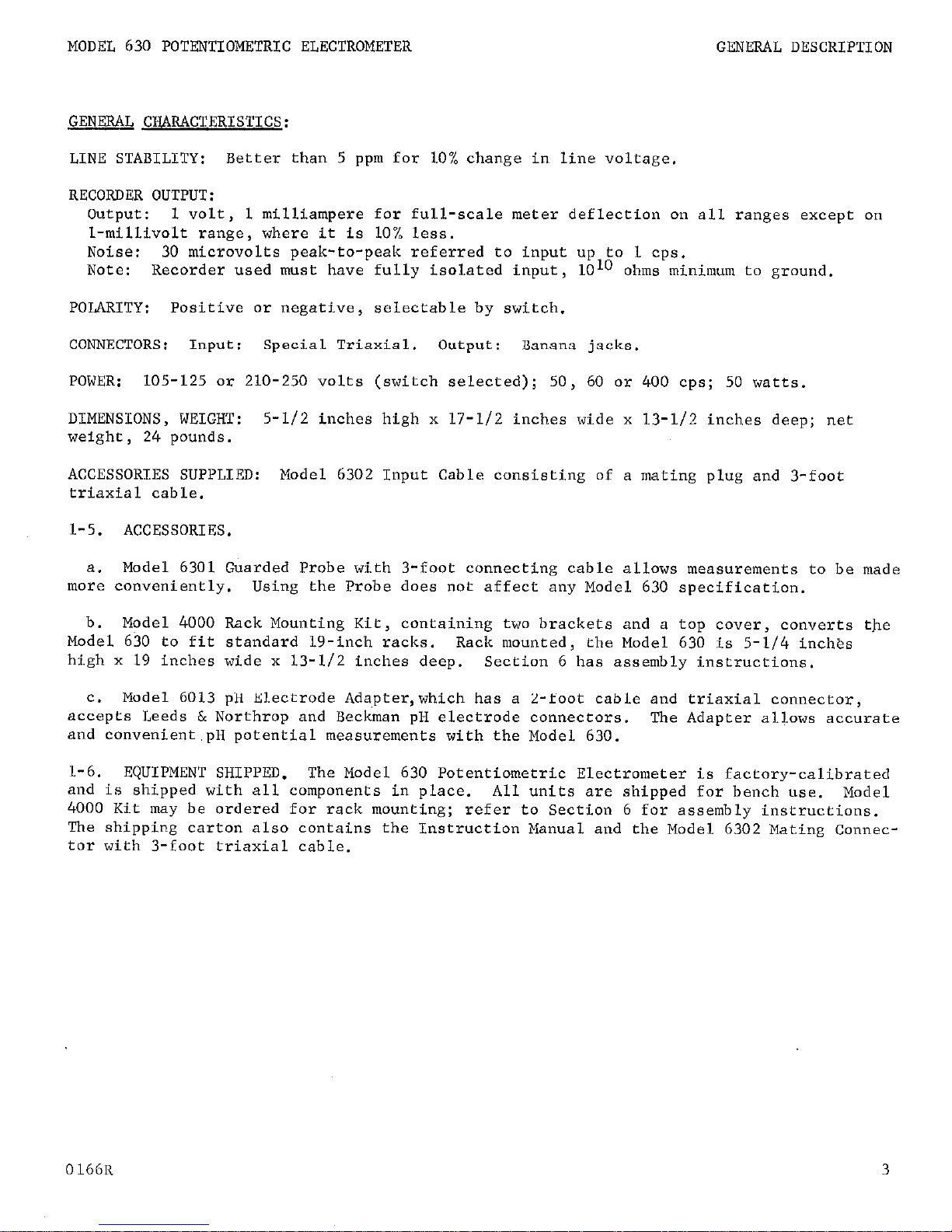

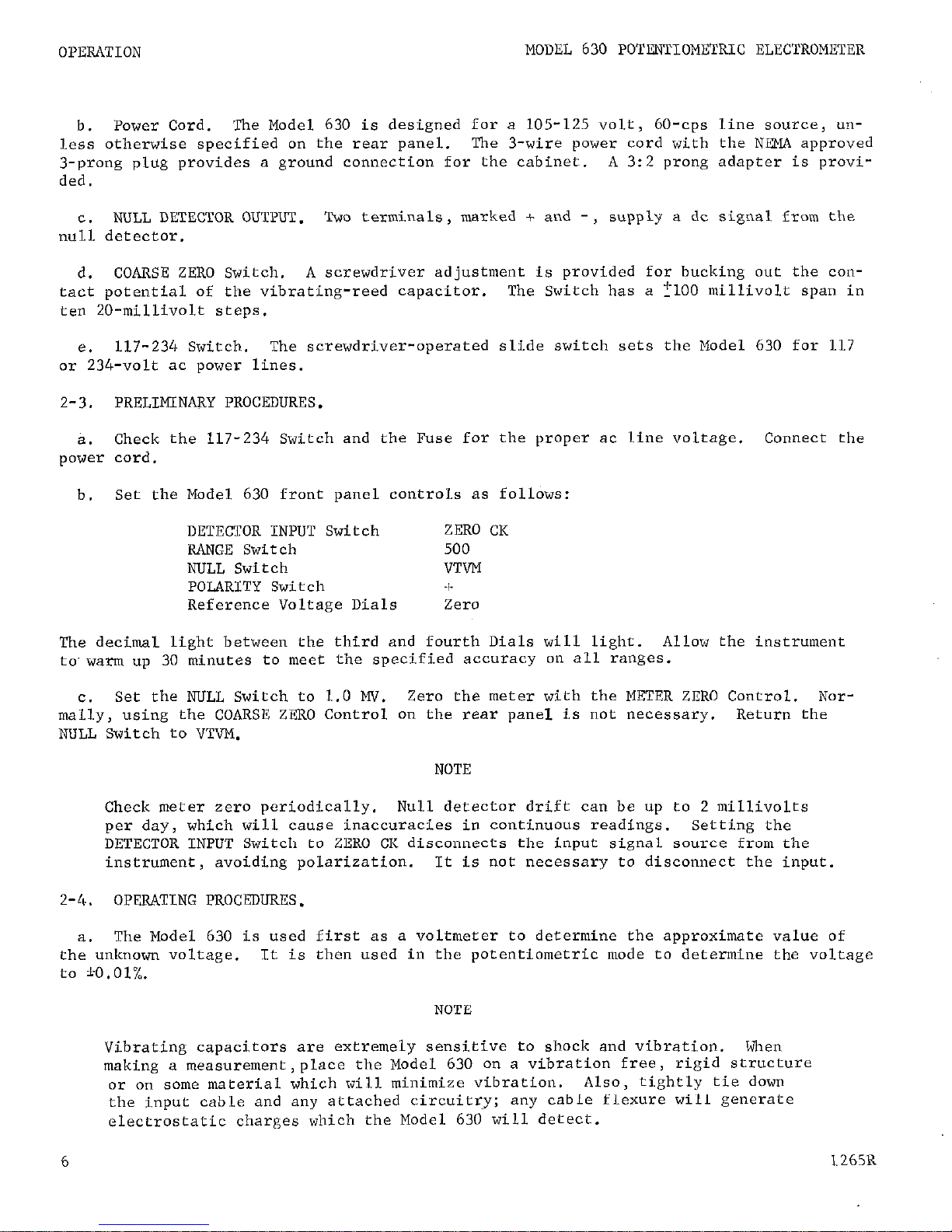

FIGUKlc L.

I'W~~L OJU rronr: .raneL wncrols and Terminals.

The designations refer to the.

Replaceable Parts List and schematic diagram.

1265

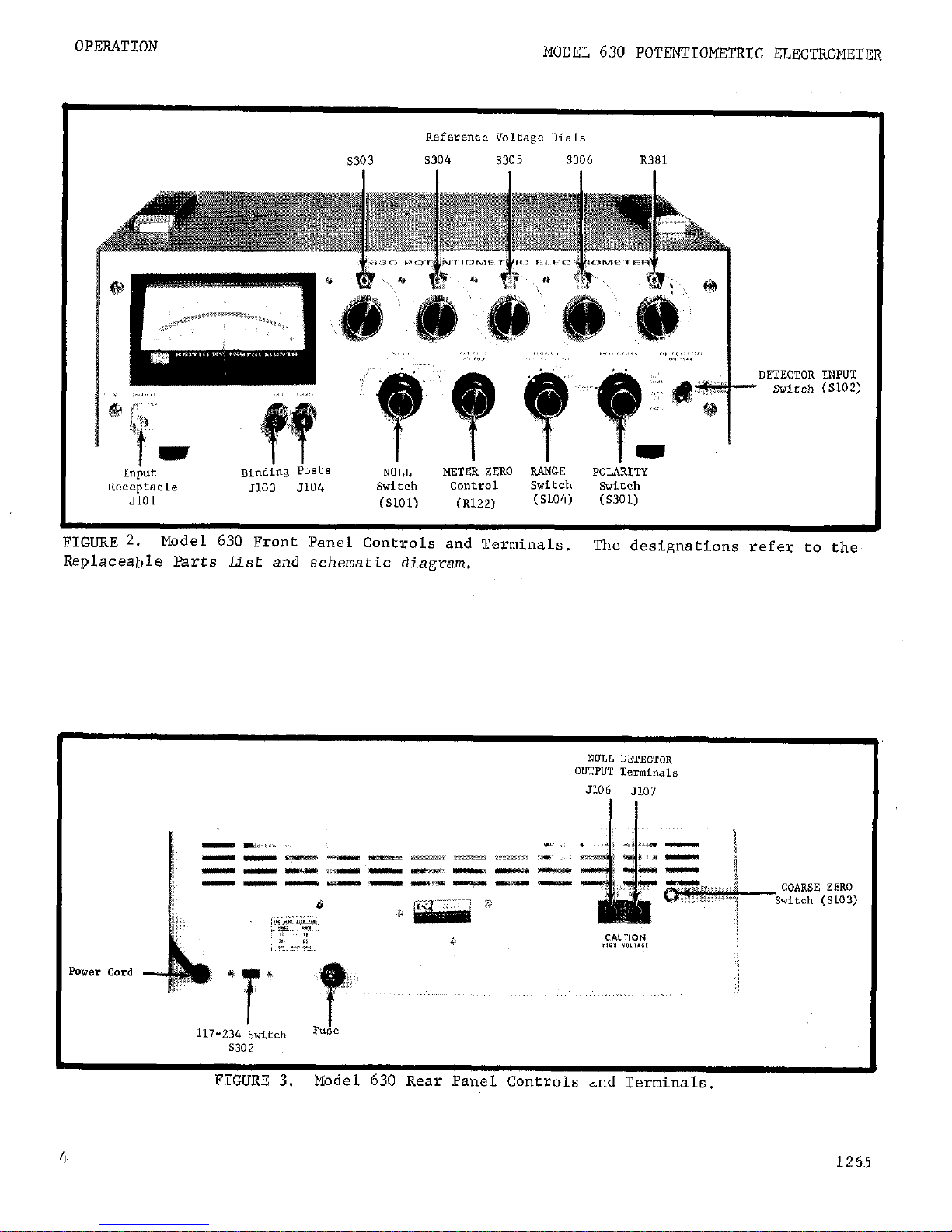

FIGURE 3. Model 630 Rear Panel

Controls

and Tarminzlr.

4

Page 8

MODEL 630 POTENTIOMETRIC ELECTROMETER

OPERATION

SECTION 2.

2-1. FRONT PANEL CONTROLS AND TERMINALS.

a.

polarity.

POLARITY Switch.

The Switch reverses the polarity of the internal rc,Ccrcncc voltage supply so

The POLARITY Switch turns the instrument on and sclccts

OPERATION

(See Figure 2).

the

input

both positive and negative voltages may be measured; it does not reverse the meter polar-

ity.

DETECTOR INPUT Switch.

b.

A 3-position toggle switch allows selection of

the

Model

630 input resistance and also allows checking the meter zero.

1) Setting the Switch to 10 10 OIIMS sets the input resistance at 1010 ohms for all

ranges.

Setting the Switch to OPh'N sets the input resistance at 1013 ohms for the l-milli-

2)

volt through l-volt ranges.

The input resistance remains

at

1010 ohms for the ranges

above 1 volt.

3) Setting the Switch to ZERO CK internally disconnects the input from the vibrating

capacitor and shunts the capacitor to the amplifier low. This allows meter zeroing on

any range without removing the input signal.

'c . NULL Switch.

ranges from 1.0 millivolt full scale to 100 volts.

The NULL Switch sets the null detector sensitivity for six decade

When the Switch is in the VTVM position, the Model 630 operates as a vibrating-reed electrometer for the four ranges of the

RANGE Switch.

RANGE Switch.

d.

0.5, 5, 50 and 500 volts full scale.

Varley divider and the position of the decimal point light

The RANGE Switch adjusts the sensitivity of the VTVM in four steps:

It also determines the voltage acrws the Kelvin-

- which also serves as a pilot

light - between the five Reference Voltage Dials.

Reference Voltage Dials. Five in-line dials at the top of the front panel set the

e.

reference voltage when the Model 630 is used as a potentiometer.

have decade steps as indicated on the dial.

METER ZERO Control. The METER ZERO Control adjusts the meter needle to zero. The

f.

The last dial is continuously adjustable.

The first four switches

Control allows precise meter zeroing on all ranges when the DETECTOR INPUT Switch is set

to ZERO CK.

Input Terminals. The Model 630 uses a special triaxial receptacle for its INPUT

g.

Receptacle.

Model 6302 Input Cable.

The Control has a. range of approximately 120 millivolts.

The Receptacle is similar to a bnc connector, but requires using the furnished

Using a standard bnc conmctor could damage the INPUT Receptacle.

A set of binding posts marked LO and GND is provided for grounding the LO input terminal

to the chassis when desired.

The LO terminal and the shell of the triaxial INPUT Recep-

tacle are internally connected.

2-2.

REAR CONTROLS AND TERMlNALS.

a.

Fuse.

For LOS-125 volt operation, the Model 630 uses a l-ampere 3 AG fuse.

210-250 volt operation, the Model 630 uses a 0.5-ampere 3 AG fuse.

0166R

(See Figure 3)

For

5

Page 9

OPERATION

MODEL 630 POTmTIOMETRIC ELECTROMETER

b.

Power Cord.

The Model 630 is designed for a 105-125 volt, 60-cps line source, un-

less otherwise specified on the rear panel.

The 3-wire power cord with the NEMA approved

3-prong plug provides a ground connection for the cabinet. A 3:2 prong adapter is provided.

C.

NULL DETECTOR OUTPUT.

Two terminals, marked + and -,

supply a dc signal from the

null detector.

d.

COARSE ZERO Switch.

A screwdriver adjustment is provided for bucking out the con-

tact potential of the vibrating-reed capacitor.

The Switch has a i-100 millivolt span in

ten ZO-millivolt steps.

e.

117-234 Switch.

The screwdriver-operated slide switch sets the Model 630 for 117

or 234volt ac power lines.

2-3.

PRELIMINARY PROCEDURES.

a.

Check the 117-234 Switch and the Fuse for the proper ac line voltage. Connect the

power cord.

b.

Set the Model 630 front panel controls as follows:

DETECTOR INPUT Switch

ZERO CK

RANGE Switch

500

NULL Switch VTVM

POLARITY Switch

-I.

Reference Voltage Dials

ZWXJ

The decimal light between the third and fourth Dials will light. Allow the instrument

to'warm up 30 minutes to meet the specified accuracy on all ranges.

c.

Set the NULL Switch to 1.0 MV.

Zero the meter with the METER ZERO Control.

Normally, using the COARSE ZERO Control on the rear panel is not necessary. Return the

NULL Switch to VTVM.

Check meter zero periodically.

Null detector drift can be up to 2 millivolts

per day,

which will cause inaccuracies in continuous readings.

Setting the

DETECTOR INPUT Switch to ZERO CK disconnects the input signal source from the

instrument, avoiding polarization.

It is not necessary to disconnect the input.

2-4. OPERATING PROCEDURES,

a.

The Model 630 is used first as a voltmeter to determine the approximate value of

the unknown voltage.

It is then used in the potentiometric mode to determine the voltage

to 10.01%.

6

Vibrating capacitors are extremely sensitive to shock and vibration. when

making a measurement,place the Model 630 on a vibration free, rigid structure

or on some material which will minimize vibration.

Also,

tightly tie down

the input cable and any attached circuitry; any cable flexure will generate

electrostatic charges which the Model 630 will detect.

L265R

Page 10

MODEL 630 POTENTIOMETRIC ELECTROMETER

OPERATION

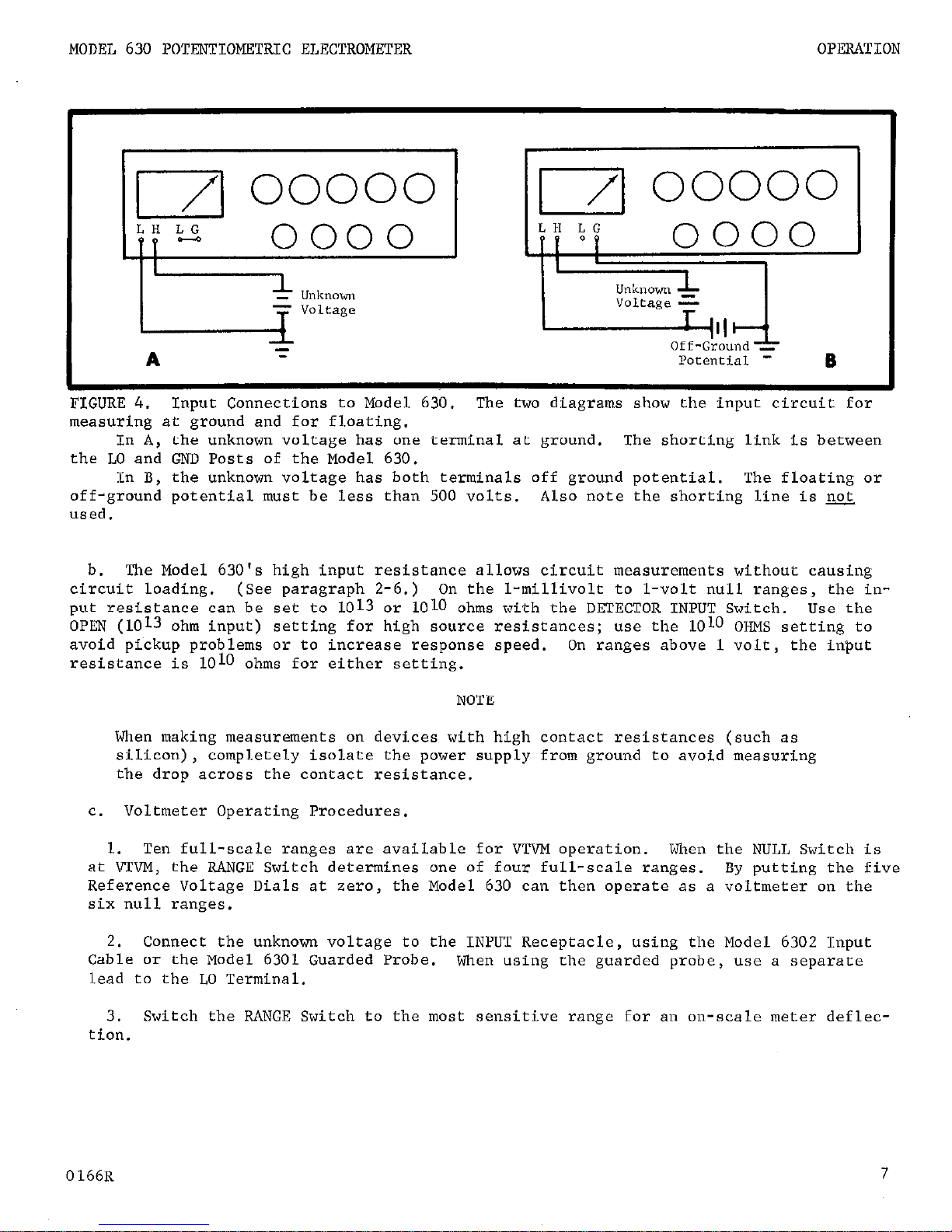

FIGURE 4.

Input Connections to Model 630. The two diagrams show the input circuit for

measuring at ground and for floating.

In A, the unknown voltage has one terminal at ground. The shorting Link is between

the LO and GND Posts of the Model 630.

In B, the unknown voltage has both terminals off ground potential. The floating or

off-ground potential must be less than 500 volts. Also note the shorting line is pe&

used.

b.

The Model 630's high input resistance allows circuit measurements without causing

circuit loading. (See paragraph 2-6.) On the l-millivolt to L-volt null ranges, the input resistance can be set to 1013 er 1010 ohms with the DETECTOR INPUT Switch. Use the

OPEN (1013 ohm input) setting for high source resistances; use the LOLO OHMS setting to

avoid pickup problems or to increase response speed.

resistance is 1010 ohms for either setting.

On ranges above 1 volt, the input

NOTE

When making measurements on devices with high contact resistances (such as

silicon), completely isolate the power supply from ground to avoid measuring

the drop acress the contact resistance.

c. Voltmeter Operating Procedures.

1.

Ten full-scale ranges are available for VTVM operation. When the NULL Switch is

at VTVM, the RANGE Switch determines one of four full-scale ranges.

By putting the five

Reference Voltage Dials at zero,

the Model 630 can then operate as a voltmeter on the

six null ranges.

2.

Connect the unknown voltage to the INPUT Receptacle, using the Model 6302 Input

Cable or the Model 6301 Guarded Probe.

When using the guarded probe, use a separate

lead to the LO Terminal.

3.

Switch the RANGE Switch to the most sensitive range for an on-scale meter deflec-

tion.

7

Page 11

OPERATION

MODEL 630 POTENTIOMETRIC ELECTROMETER

d.

Potentiometric Operating Procedures.

NOTE

Avoid large overload voltages on the null detector. No damage occurs even

with 500~volt overloads, but some open circuit offset will be caused in the

null detector.

The offset will disappear after about 5 minutes.

1.

Leave the RANGE Switch at the last setting used in the voltmeter operation. If

the voltmeter reading is negative, reverse the POLARITY Switch position.

2.

Set the first two Reference Voltage Dials to the first two digits of the unknown

voltage found in the voltmeter operation.

NOTE

When switching between the 50-volt and SOO-volt ranges and when changing the

POLARITY Switch, the meter will sometimes temporarily read off-scale.

This is

due to transients introduced when the circuit is interrupted and it does not

indicate a faulty instrument.

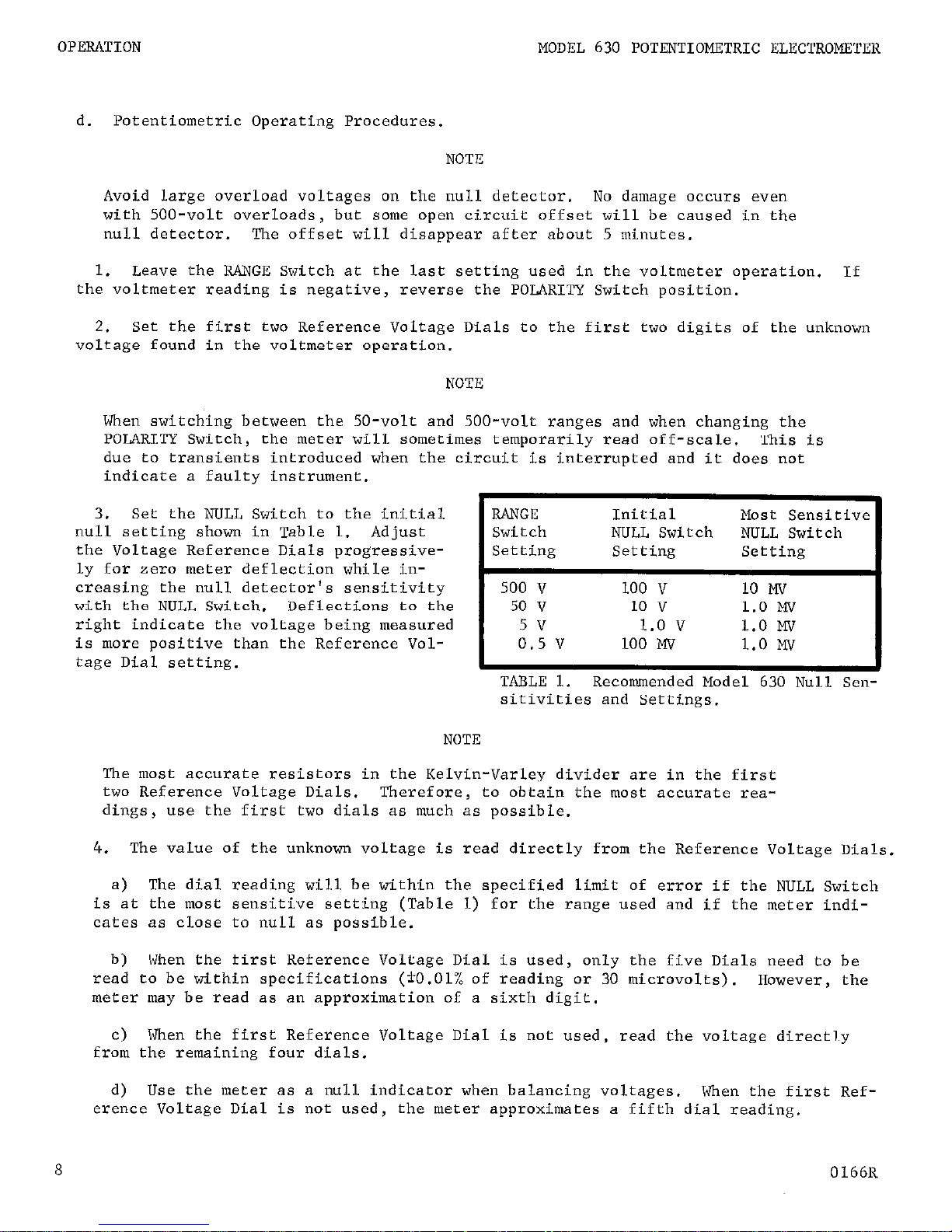

3.

Set the NULL Switch to the initial

null setting shown in Table 1. Adjust

the Voltage Reference Dials progressive-

ly for zero meter deflection while in-

creasing the null detector's sensitivity

with the NULL Switch. Deflections to the

right indicate the voltage being measured

is more positive than the Reference Vol-

I

RANGE

Initial

Most Sensitive

Switch

NULL Switch NULL Switch

Setting Setting Setting

tage Dial setting.

I

TABLE 1. Recommended Model 630 Null Sensitivities and Settings.

I

500 50 0.5 5v v v v 100 100 10 1.0 Mv v v v

1.0 1.0 10 1.0 Mv Mv Mv Mv

NOTE

The most accurate resistors in the Kelvin-Varley divider are in the first

two Reference Voltage Dials. Therefore,

to obtain the most accurate rea-

dings, use the first two dials as much as possible.

4.

The value of the unknown voltage is read directly from the Reference Voltage Dials.

a)

The dial reading will be within the specified limit of error if the NULL Switch

is at the most sensitive setting (Table 1) for the range used and if the meter indicates as close to null as possible.

b) When the first Reference Voltage Dial is used,

only the five Dials need to be

read to be within specifications (*O.Ol% of reading or 30 microvolts).

However, the

meter may be read as an approximation of a sixth digit,

c) When the first Reference Voltage Dial is not used, read the voltage directly

from the remaining four dials.

d) Use the meter as a null indicator when balancing voltages. When the first Ref-

erence Voltage Dial is not used,

the meter approximates a fifth dial reading.

8

0166R

Page 12

MODEL 630 POTENTIOMETRIC ELECTROMETER OPERATION

2-5. RECOFDER OUTPUT.

a.

Recommended recorder for use with the Model 630 is the Keithley Model 370. Any re-

corder used must be able to float 500 volts off ground and its input must be fully isolated

(1010 ohm minimum leakage resistance to ground).

The Model 370 meets these requirements.

b.

before attaching the recorder, set all Reference Voltage Dials to zero. Disconnect

the unknown voltage and short the Model 630 high input to the low. Set the NULL Switch

to 10 MV.

Connect the recorder to the OUTPUT Terminals on the Model 630 rear panel. The

370 Recorder mates directly with the Model 630 using the 3701 Cable.

c.

Set the Reference Voltage Dials to 10 millivolts to apply an accurate lo-millivolt

potential to the null detector on the lo-millivolt null range.

This will provide a full-

scale recorder output of 1 volt at 1 milliampere.

On the l-millivolt null range, the re-

corder may load the Model 630 output. On this range,

output resistance is 100 ohms.

d.

To obtain accurate results and/or

to

prevent ,damage to the instruments, the recorder

must be able to float off-ground with the Model 630. Leakage and pickup between the two

instruments should also be minimized.

The Model 370 meets these requirements.

NOTE

On the l-millivolt range there is a 10% loading error if the recorder draws

1 ma of current. Thus the output for full scale deflection will be .90 volt,

1 ma.

1. Make sure neither recorder terminal is grounded. Use a 3-wire grounded power line

for the recorder.

If a 2-wire line is used,

connect the recorder chassis and the Model

630 chassis with a separate lead.

2. Minimize all sources of leakage between the output terminals, the recorder and

ground. Use polystyrene or Teflon-insulated cable where possible. If the connecting

wires are shielded, connect the shield to the LO Post.

3. Avoid long leads between the Model 630 and the recorder.

Do not short either Model 630 output terminal to the case; this may damage the

Kelvin-Varley divider.

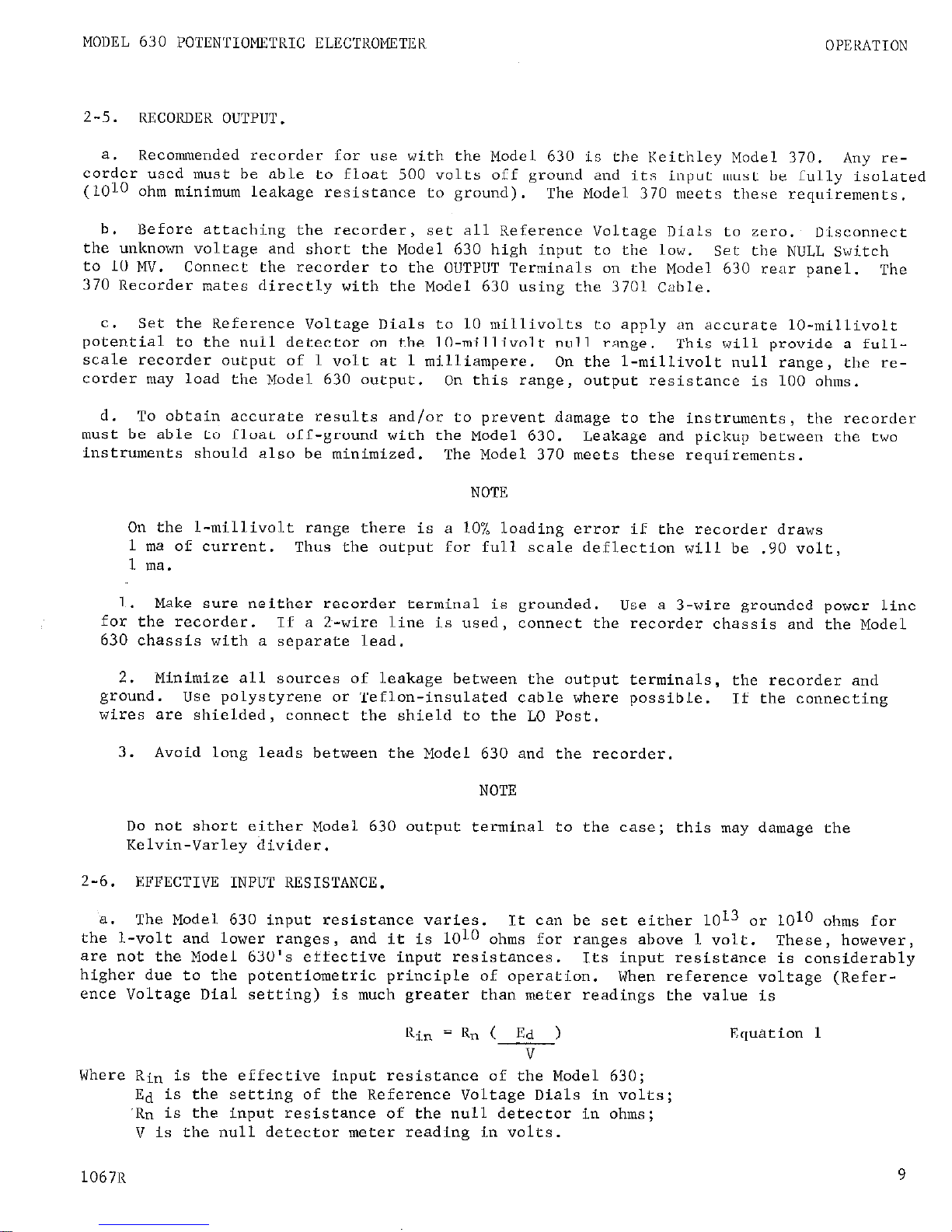

2-6.

EFFECTIVE INPUT RESISTANCE.

a.

The Model 630 input resistance varies. It can be set either 1013 or 1010 ohms for

the l-volt and lower ranges, and it is 1010 ohms for ranges above 1 volt.

These, however,

are not the Model 630's effective input resistances.

Its input resistance is considerably

higher due to the potentiometric principle of operation.

When reference voltage (Refer-

ence Voltage Dial setting) is much greater than meter readings the value is

Ri* =

Rn( Ed )

Equation 1

v

Where Rin is the effective input resistance of the Model 630;

Ed is the setting of the Reference Voltage Dials in volts;

'Rn is the input resistance of the null detector in ohms;

V is the null detector meter reading in volts.

1067R

9

Page 13

OPERATION

MODEL 630 POTENTIOMETRIC ELECTROMETER

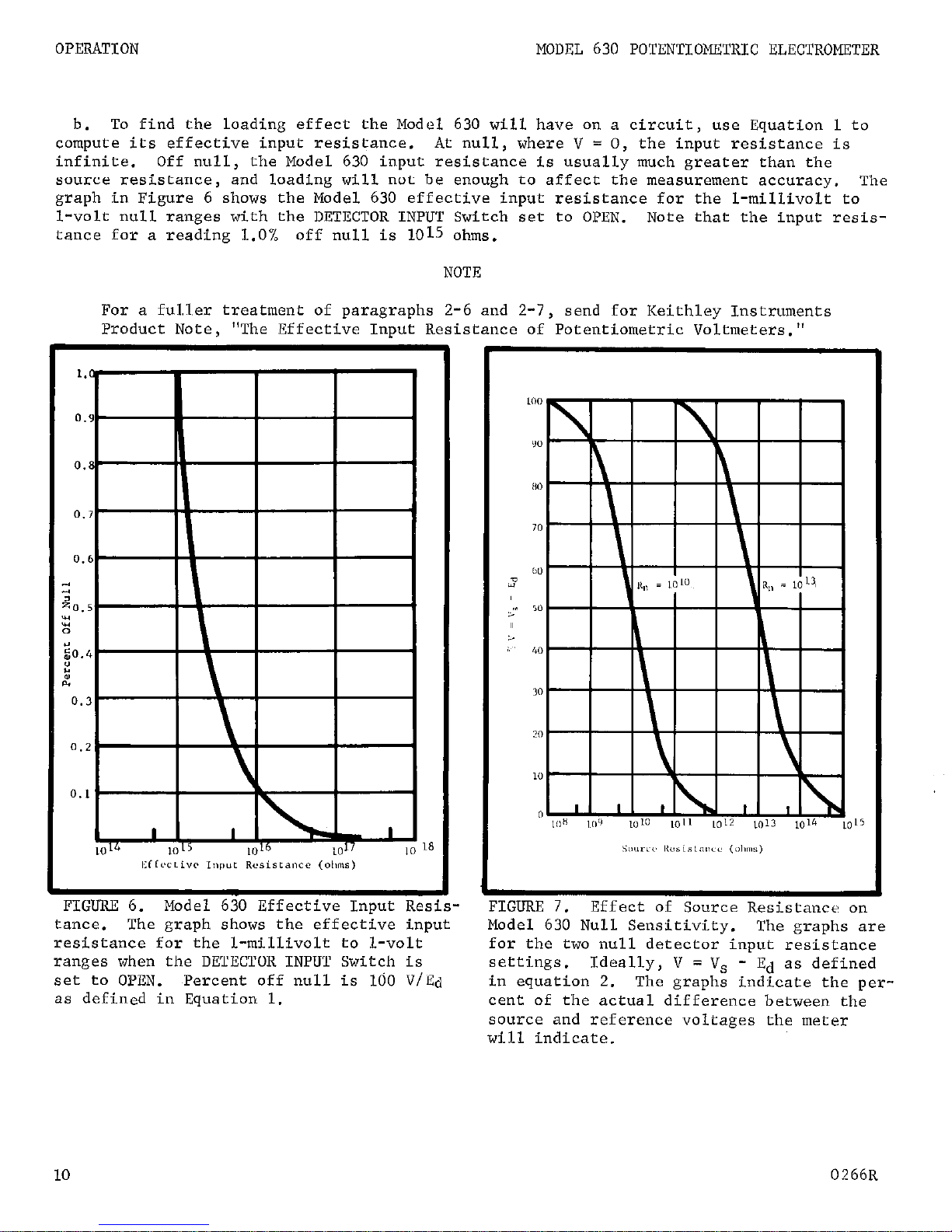

b.

To find the loading effect the Model 630 will have on a circuit, use Equation 1 to

compute its effective input resistance. At null, where V = 0, the input resistance is

infinite. Off null, the Model 630 input resistance is usually much greater than the

source resistance, and loading will not be enough to affect the measurement accuracy.

The

graph in Figure 6 shows the Model 630 effective input resistance for the l-millivolt to

l-volt null ranges with the DETECTOR INPUT Switch set to OPEN.

Note that the input resis-

tance for a reading 1.0% off null is 1015 ohms.

NOTE

For a ful.ler treatment of paragraphs 2-6 and 2-7,

send for Keithley Instruments

Product Note,

"The Effective Input Resistance of Potentiometric Voltmeters."

0.6

zo.5

0

:,o.,

”

0.3

0.2

0.L

18

FIGURE 6.

Model 630 Effective Input Res

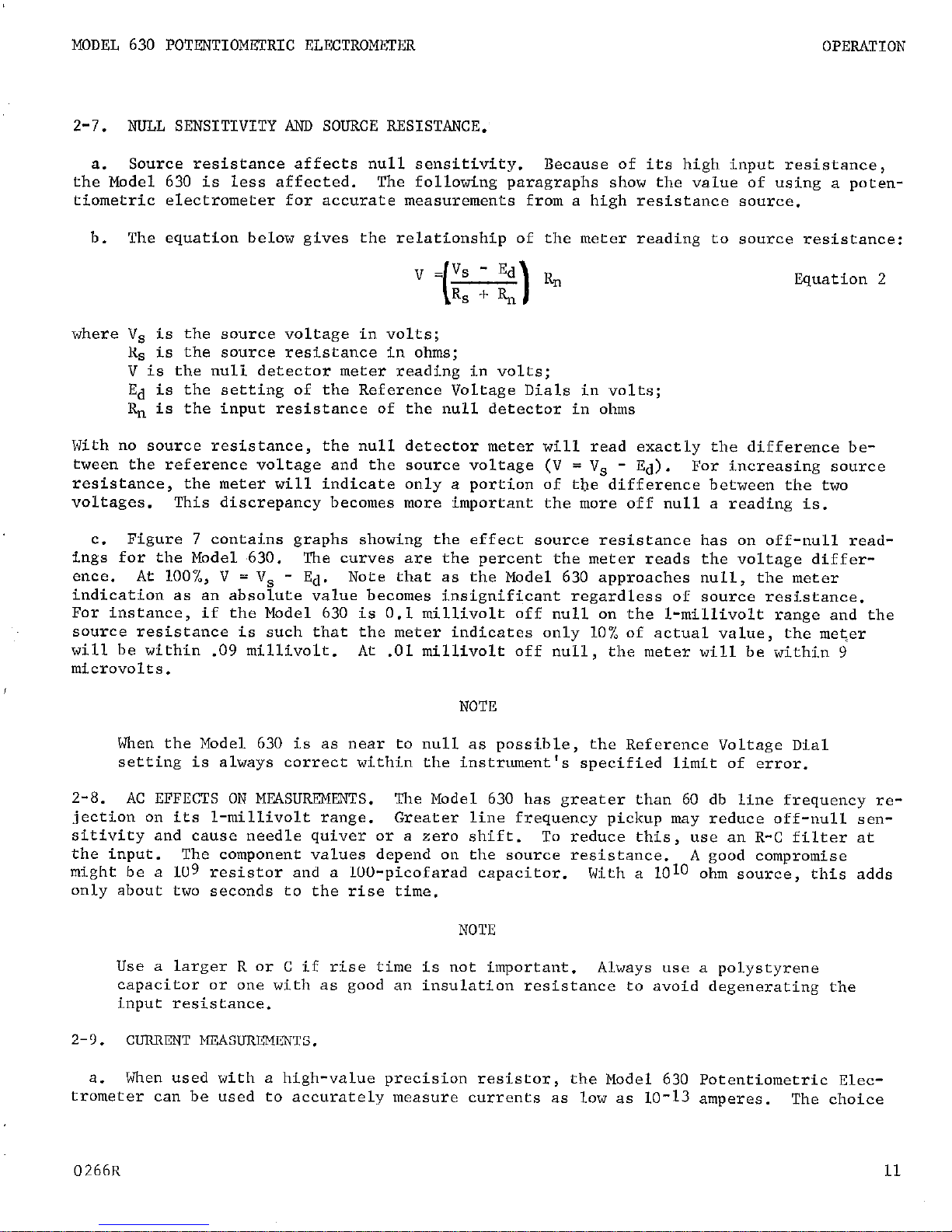

~llrluw /. F,rrecr or xxlL^ce KeSlStnnCc on

tance.

The graph shows the effective input

Model 630 Null Sensitivity.

The graphs are

resistance for the l-millivolt to l-volt

for the two null detector input resistance

ranges when the DETECTOR INPUT Switch is

settings.

Ideally, V = Vs - Ed as defined

set to OPEN. Percent off null is 160 V/Ed

in equation 2.

The graphs indicate the per-

as defined in Equation 1.

cent of the actual difference between the

source and reference voltages the meter

will indicate.

10

0266R

Page 14

MODEL 630 POTENTIOMETRIC ELECTROMETER

OPERATION

2-7.

NULL SENSITIVITY AND SOURCE RESISTANCE.

a.

Source resistance affects null sensitivity. Because of its high input resistance,

the Model 630 is less affected.

The following paragraphs show the value of using a poten-

tiometric electrometer for accurate measurements from a high resistance source.

b.

The equation below gives the relationship of the meter reading to source resistance:

Equation 2

where V, is the source voltage in volts;

R, is the source resistance in ohms;

V is the nuli detector meter reading in volts;

Ed is the setting of the Reference Voltage Dials in volts;

R,, is the input resistance of the null detector in ohms

With no source resistance, the null detector meter will read exactly the difference be-

tween the reference voltage and the source voltage (V = V, - Ed).

For increasing source

resistance, the meter will indicate only a portion of the difference between the two

voltages.

This discrepancy becomes more important the more off null a reading is.

c.

Figure 7 contains graphs showing the effect source resistance has on off-null readings for the Model ,630. The curves are the percent the meter reads the voltage difference. At loo%, V = V, - Ed.

Note that as the Model 630 approaches null, the meter

indication as an absolute value becomes insignif+cant regardless of source resistance.

For instance, if the Model 630 is 0.1 millivolt off null on the l-millivolt range and the

source resistance is such that the meter indicates only 10% of actual value, the metier

will be within -09 millivolt. At .Ol millivolt off null, the meter will be within 9

microvolts.

NOTE

When the Model 630 is as near to null as possible, the Reference Voltage Dial

setting is always correct within the instrument's specified limit of error.

2-8. AC EFFECTS ON MEASUREMENTS. The Model 630 has greater than 60 db line frequency rejection on its l-millivolt range.

Greater line frequency pickup may reduce off-null sen-

sitivity and cause needle quiver or a zero shift.

To reduce this, use an R-C filter at

the input. The component values depend on the source resistance.

might be a 109 resistor and a lOO-picofarad capacitor.

1010

A good compromise

With a

ohm source, this adds

only about two seconds to the rise time.

NOTE

Use a larger R or C if rise time is not important.

Always use a polystyrene

capacitor or one with as good an insulation resistance to avoid degenerating the

input resistance.

2-9. CURRENT MEASUREMENTS.

a. When used with a high-value precision resistor,

the Model 630 Potentiometric Elec-

trometer can be used to accurately measure currents as low as lo-13 amperes.

The choice

0266R

11

Page 15

OPERATION MODEL 630 POTENTIOMETRIC ELECTROMETER

of the shunt resistor depends upon the

current to be measured and the setting of

the Model 630 (Refer to Table 2).

b.

Current measuring procedure:

Shunt the Model 630 input with a

seikcted resistor R. (See Table 2 for

resistor values).

2.

Set the Reference Voltage Dial Setting to zero and the DETECTOR INPUT

Switch to OPEN.

3.

Switch the Model 630 sensitivity

to the lowest.setting to obtain an onscale reading.

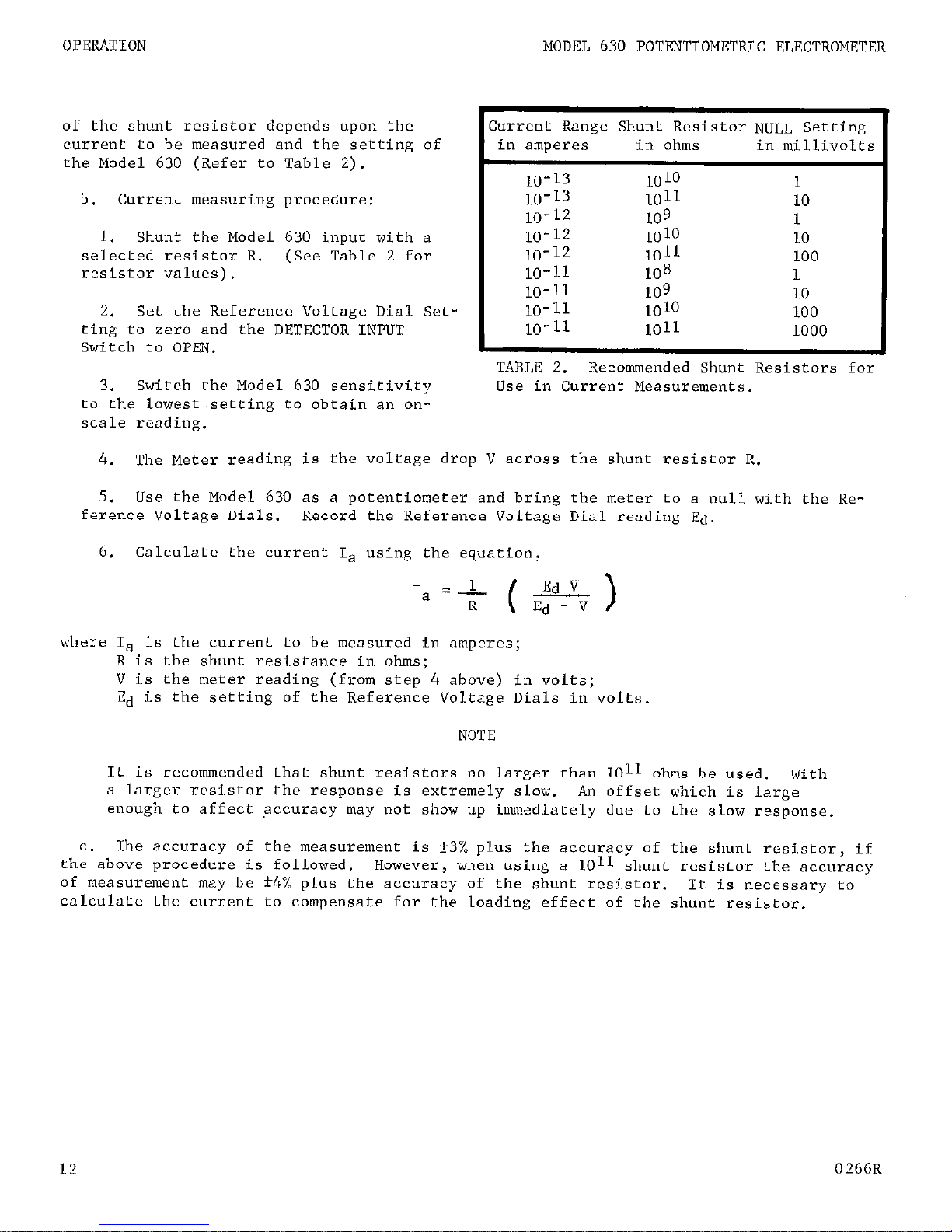

Current Range Shunt Resistor NULL Setting

in amperes in ohms

in millivolts

10-13

10 10

1

10-13

1011

10

10-12

109

1

10-12

1010

10

10-12

1011

100

10-11

108

1

I

10-11 10-11 10-11

109 1010 1011

10

100

1000

I

TABLE 2.

Recommended Shunt Resistors for

Use in Current Measurements.

4. The Meter reading is the voltage drop V across the shunt resistor R.

5.

Use the Model 630 as a potentiometer and bring the meter to a null with the Re-

ference Voltage Dials. Record the Reference Voltage Dial reading Ed.

6.

Calculate the current I, using the equation,

1

I, =-

Ed v

R

(-

Ed - V

where I,

is the current to be measured in amperes;

R is the shunt resistance in ohms;

V is the meter reading (from step 4 above) in volts:

Ed is the setting of the Reference Voltage Dials in volts.

NOTE

It is recommended that shunt resistors no larger than 1011 ohms be used

a larger resistor the response is extremely slow.

An offset which 1s largFth

.

enough

to

affect accuracy may not show up immediately due to the slow response.

c.

The accuracy of the measurement is i3% plus the accuracy of the shunt resistor, if

the above procedure is followed.

However, when using a 1011 shunt resistor the accuracy

of measurement may be *4% plus the accuracy of the shunt resistor.

It is necessary to

calculate the current to compensate for the loading effect of the shunt resistor.

12

0266R

Page 16

MODEL 630 POTENTIOMETRIC ELECTROMETER

CIRCUIT DESCRIPTION

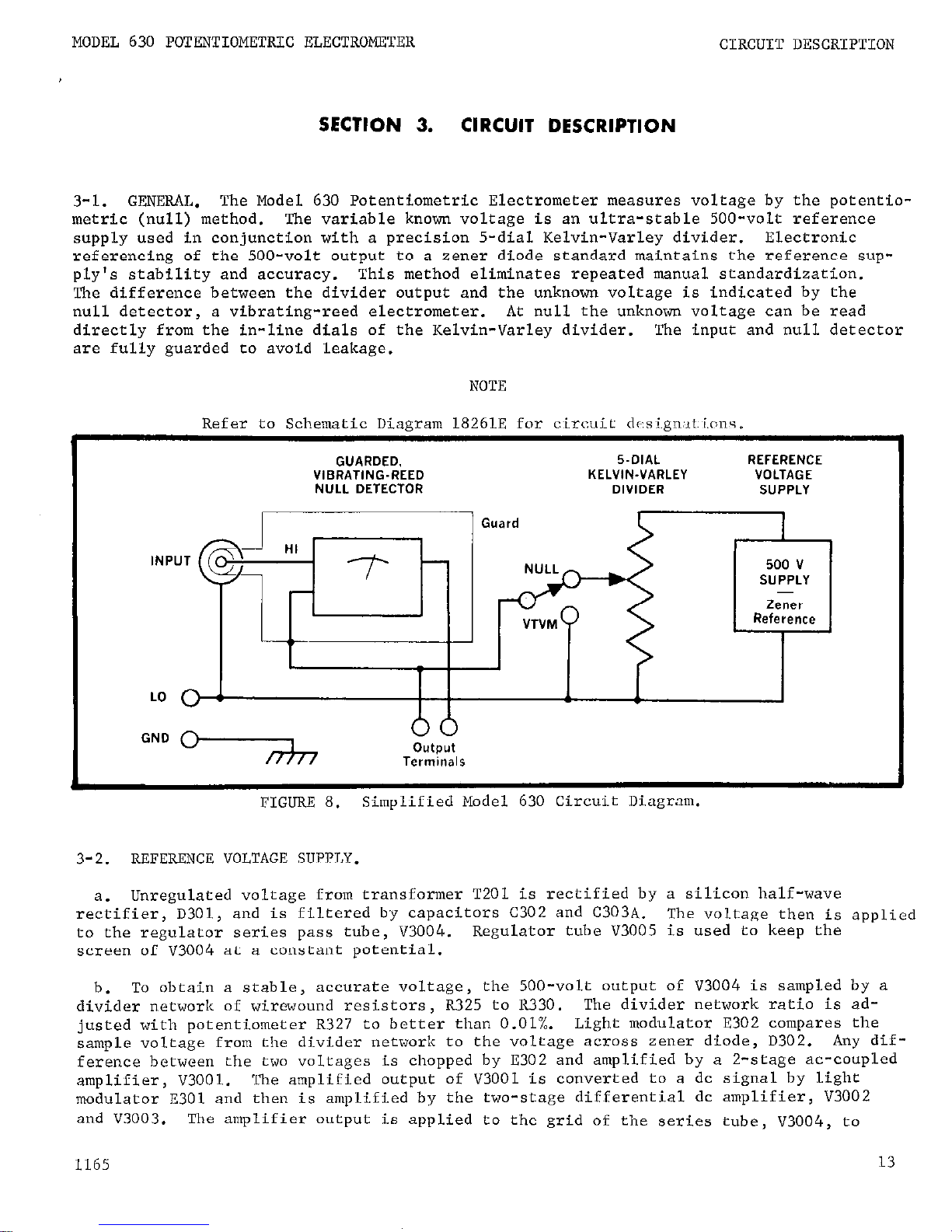

3-1. GENERAL.

SECTION 3.

The Model 630 Potentiometric Electrometer measures voltage by the potentio-

CIRCUIT DESCRIPTION

metric (null) method. The variable known voltage is an ultra-stable 500-volt reference

supply used in conjunction with a precision 5-dial Kelvin-Varley divider.

Electronic

referencing of the 500-volt output to a zener diode standard maintains the reference sup-

ply's stability and accuracy. This method eliminates repeated manual standardization.

The difference between the divider output and the unknown voltage is indicated by the

null detector,

directly from the in-line dials of the Kelvin-Varley divider.

a vibrating-reed electrometer.

At null the unknown voltage can be read

The input and null detector

are fully guarded to avoid leakage.

NOTE

_.__ -_ __ l_..l...-__ - 1_1o ^-...

GUARDED,

VIBRATING-REED

NULL DETECTOR

INPUT

__-__- __.^ _~ _^..... -.

KELVIN-VARLEY

Guard

..,..,.. ..^. .

5.DIAL

DIVIDER

REFERENCE

VOLTAGE

SUPPLY

500 v

SUPPLY

Zener

Reference

FIGURE 8.

3-2.

REFERENCE VOLTAGE SUPPLY.

Unregulated voltage from transformer T201 is rectified by a silicon half-wave

reziifier, D301, and is filtered by capacitors C302 and C303A.

to the regulator series pass tube, V3004.

screen of V3004 at a constant potential.

To obtain a stable, accurate voltage,

b.

divider network of wirewound resistors, R325 to R330.

justed with potentiometer R327 to better than 0.01%.

sample voltage from the divider network to the voltage across zener diode, D302. Any dif-

ference between the

amplifier, V3001.

two

voltages is chopped by E302 and amplified by a 2-stage ac-coupled

'L"ne amplified output of V3001 is converted to a dc signal by light

modulator ~301 and then is amplified by the two-stage differential dc amplifier, V3002

and V3003.

The amplifier output is applied to the grid of the series tube, ~3004, to

1165

Simplified Model 630 Circuit Diagram.

The voltage then is applied

Regulator tube V3005 is used to keep the

the 500-volt output of V3004 is sampled by a

The divider network ratio is ad-

Light modulator E302 compares the

13

Page 17

CIRCUIT DESCRIPTION MODEL 630 POTENTIOMETRIC ELECTROMETER

nullify input variations.

Capacitor C305 is used in the ac feedback circuit.

c.

The temperature-compensated zener diode, D302, is used as the basic reference since

typical variations are limited to less than 20 ppm per year and 5 ppm per oC.

Thus, a

highly stable reference which eliminates manual standardization is provided with respect

to both time and temperature.

The zener diode will also withstand shock and vibration.

d.

The regulated 500-volt output of V3004 is either applied directly to the KelvinVarley divider or it is divided to 50, 5 or 0.5 volts by very stable wirewound resistor

networks. The RANGE Switch, S104, determines which network is used.

The 50-volt range

divider consists of resistors R333, R334, and R335; the 5-volt, or R333, R337 and R338;

and the 0.5-volt of R333, R339 and R340. Using potentiometers R334, R337 and R339

accurately sets the voltage division on each range.

3-3. KELVIN-VARLEY DIVIDER.

a.

The Kelvin-Varley divider precisely divides the reference voltage for nulling an

unknown voltage. It is, in effect, a constant input impedance decade potentiometer, consisting of resistors R341 through R381.

The resistors within each decade are matched;

the decades are matched for each instrument.

b.

Each decade of the Kelvin-Varley divider, except the first, R341 through R346,

parallels two resistors of the preceeding string.

Between the two contacts of the first

Reference Voltage Switch, S303, the total resistance is 40 kilohms (80 kilohms in parallel with the 80 kilohms total resistance of the four remaining strings).

With the RANGE

Switch set at 500, 100 volts dc will appear across the contacts of Reference Voltage

Switch S304, 10 volts across S305,

1 volt across 5306, and 0.1 volt across R381.

3-4.

NULL DETECTOR.

a.

The Model 630 uses a null detector which has a vibrating capacitor at the input.

The input signal is attenuated,

if necessary, and filtered. This signal is modulated by

a specially constructed capacitor,

VClOl, having one stationary plate and one moveable

plate. The signal is then amplified and applied to the meter.

b. Input resistance is greater than 1013

ohms when the DETECTOR INPUT Switch is

set

to

OPEN for the l-millivolt through l-volt ranges.

For null ranges greater than 1 volt, the

input signal is attentuated by resistors RlOl through R104.

input resistance is a constant lolo ohms.

Therefore,

above 1 volt, the

To maintain high resistance, switching with

the DETECTOR INPUT Switch (SlO2) is done using reed relays, KlOl to K103.

c. The null detector has full-scale sensitivity from 1 millivolt

to

1 volt.

Above 1

volt, resistors RlOl through R104 divide the input by a 5OO:l ratio.

The full-scale

sensitivity is determined by which of six feedback resistors, R147 through R152, is in

the circuit.

An R-C filter - R107 and capacitor Cl01 - decreases the ac input compo-

nents.

A twin-T filter, tuned for 94 cps, is connected between the plate and grid of

tube V1002.

The filter, consisting of R130, R132, R133, CllO, Cl11 and C112, provides

negative feedback for frequencies other than 94 cps.

The vibrating capacitor, VClOl, is

driven at 94 cps to further minimize ac pick-up effects.

d.

The vibrating capacitor VClOl converts the difference between the input signal and

the Kelvin-Varley divider output into an ac voltage, which is amplified by tubes VlOOl,

V1002, and half of V1003. The amplified voltage is demodulated by a bridge, diodes ~106

through D109,

and filtered by resistor R144 and capacitor Cl21.

The dc voltage is fed

14

0166R

Page 18

MODEL 630 POTENTIOMETRIC ELECTROMETER

CIRCUIT DESCRIPTION

through a cathode follower, half of tube V1003, and drives the meter.

1.

VClOl has a moveable plate driven by an electromagnet which varies the distance

between the two plates. Since the capacitance varies in inverse proportion to the distance between the plates,

a time varying capacitance is produced.

2.

If a charge is placed on the capacitor its value is

Q = CE

Equation 3

where Q is the charge;

C is the capacitance;

E is the wltage across the capacitor.

In terms of the voltage, the equation becomes E = Q/C. If Q is constant and C varies

periodically,,E must also vary. Therefore, an ac voltage which is proportional to the

magnitude of the input voltage will be produced.

e.

Resistors R147 through Rl52 form the feedback network, which divides the output

voltage for all voltmeter and null ranges except the 500-volt and l-volt ranges.

Total

output is fed back for these two ranges. The feedback voltage is returned to the low

end of the vibrating capacitor to provide stability.

f.

The Model 630 uses a "driven guard" at its input:

the feedback voltage is also

applied to the second conductor of the input cable. The potential between the input high

and low is the difference between the applied and feedback voltages.

Therefore, the cable

capacitance charges only to the difference between the two voltages. This reduces the

effect of cable capacitance,

providing faster response speed.

g.

The zero-control network consists of a 1.35-volt mercury battery, BlOl, and resis-

tors R109 through R123.

The rear panel COARSE ZERO Switch,

S103, has a span of Cl00 milli.

volts in 20-millivolt steps.

The front panel METER ZERO potentiometer, R112, has a 220

millivolt span.

h. The recorder output is developed across the top end of meter MlOl. It is one volt

for a full-scale meter deflection for all ranges above 1 millivolt. However, using a recorder with a l-milliampere movement reduces the output to 0.9 volt on the l-millivolt

range since the output impedance is 100 ohms on this range.

3-5. OSCILLATOR.

a.

The oscillator drives the vibrating capacitor and bridge demodulator and supplies

the filament voltage for ,tubes VlOOl and V1002.

b.

The output of transistor Q203,

connected as a regulator, is divided and compared

to zener diode D207. Any voltage difference is amplified by transistors Q235 and Q206,

operating as a differential voltage amplifier.

The signal is further amplified by trans-

istors 4204, Q202, and 4201 and applied to the regulator, Q2U3.

c.

A dc-to-ac converter forms the voltage to drive the vibrating capacitor, VClOl, and

the bridge demodulator, diodes D106 through D109.

Transistors Q207 and Q208 form a switch-

ing network to supply an interrupted dc voltage to transformer T202.

An extra winding

from the transformer supplies feedback to the network to sustain switching action.

Re-

sistor R213 determines the feedback magnitude.

0166R

15

Page 19

CIRCUIT DESCRIPTION

MODEL 630 POTENTIOMETRIC ELECTROMETER

3-6. GUARDING. Guarding is accomplished by floating the null detector and the input

circuitry at a voltage equal to the input voltage from a low impedance source.

This full

guarding eliminates leakage between the input terminal and ground. Such leakage in an

unguarded circuit is difficult to avoid, under laboratory conditions, and can result in

sizeable errors.

of 108

For example, in an unguarded circuit with a 1-megohm source, leakage

ohms will introduce 1% error. A guarded circuit eliminates this element of error.

16

OL66R

Page 20

MODEL 630 POTENTIOMETRIC ELECTROMETER

SERVICING

SECTION 4.

SERVICING

4-1. GENERAL. Section 4 contains the maintenance and troubleshooting procedures for the

Model 630. Follow these procedures as closely as possible to maintain the accuracy and

stability of the instrument.

4-2. SERVICING SCHEDULE.

The Model 630 needs no periodic maintenance beyond the normal

care required of high-quality electronic equipment. No part should need replacement under ordinary use except a pilot lamp, fuse or, occasionally, a vacuum tube.

4-3. PARTS REPLACEMmT.

a.

The Replaceable Parts List in Section 7 describes the electrical components in the

Model 630. Replace components only as necessary, and use only reliable replacements

which meet the specifications.

b.

Replace resistors within any one of the first three Kelvin-Varley divider decades

only as an assembly.

Refer to the Replaceable Parts List for the part number for resis-

tors R341 to R368.

Resistors R325, R326 and R328, resistors R333, R335, R338 and R340

and resistors R329 and R330 are also parts of assemblies.

Reorder using the Keithley

part number (see Section 7) and replace all resistors in the assembly.

Because of its im-

portance in maintaining power supply stability,

order zener diode D302 only from Keithley

Instruments, Inc.,

or its representative.

Refer to paragraph 4-6 for instructions

to

replace the zener.

If replacing the vibrating capacitor, VClOl, order only from Keithley

Instruments, Inc.,

or its representative.

4-4.

TROUBLESHOOTING.

63::

The following procedures are for repairing troubles which might occur in the Model

Use these procedures to troubleshoot and use only specified replacement parts.

Table 3 lists equipment recommended for troubleshooting.

If the trouble cannot be readily

located or repaired, I contact Keithley Instruments, Inc. or its representative.

Instrument Use

Keithley Model 153 dc Microvolt-Ammeter,

3% accuracy, minimum 200 megohm input

Circuit checking

resistance,

1 volt to 500 volts.

Keithley Model 610B Electrometer

Check grid bias at cathode follower

Keithley Model 50211 Ohmmeter

Check resistance

Hewlett-Packard 200CD Oscillator

Check frequency

Tektronix Type 503 Oscilloscope

Check wave forms

Grid-modulated tube tester

Test vacuum tubes

d

TABLi? 3. Equipment Recommended for Model 630 Troubleshooting. Use these instruments

or their equivalents.

0166R

17

Page 21

SERVICING

MODEL 630 POTENTIOMETRIC ELECTROMETER

I

Difficulty

Probable cause Solution

eter rattle, drift, or er-

is observed on all null

Excessive drift on most

sensitive range

Line voltage variations

cause measurements to be

out of specifications

Reference voltage supply

drifts after 30-minute

warm-up, requiring frequent

adjusting of the range controls, R327, R334, R337 and

R339

Measurements out of tolerance on all ranges

Measurements are out of

specifications on one

range other than 500-

volt range

TABLE 4.

Tube VlOOl, V1002 or V1003

Check tubes;

replace if faul

is faulty

tY

-6v power supply is drifting or oscillator circuit

is faulty

Check power supply stability

PC104, and oscillator fre-

quency (paragraph 5-7). If

I

faulty component cannot be

located, return instrument

to

factorv.

Faulty VClOl

I

Replace VClOl

Battery BlOl is faulty

I

Replace BlOl

Tube V3005 is defective

Check tube; replace if faulty

V3001, V3002, V3003 or

I

Check tubes; replace if faul,

V3004 is defective

w

One of the divider resistors, R325 to R330, is

changing value rapidly during warm-up

Return the instrument for

factory check-out

Zener diode, D302, is un-

I

Return the instrument for

stable

factory check-out

Light modulator, F,302,

is defective

Out of calibration

Check light modulator by replacing.

Refer to paragraph 5-5 for

recalibration

One of the divider resis- Return the instrument for

tars, R325 to R330, is

factory check-out

Resistor in the range divider network is faulty

Paragraph 3-2 d points out

the resistors used for each

range.

Try to bring the

ranges within specifications

by calibrating with the po-

tentiometers in the network.

See paragraph 5-5. If this

does not work, check individual resistors.

(Sheet 1).

Model 630 Troubleshooting

18

Page 22

MODEL 630 POTENTIOMETRIC ELECTROMETER

SERVICING

Difficultv

Measurements are Out of

specifications

on all ran-

ges other than 500-volt

Excessive ac interference

Non-symmetrical response

on polarity switching and

low sensitivity on most

sensitive ranges

Instrument does not respond

to a signal and offset on

all ranges

Greatly increased sensitivity on 10 and 100 null

ranges and 5, 50 and 500V

VTVM ranges

500V supply operates but

null detector is completely

inoperable

Keasurements are Out of

specifications on any range

tihen the Reference Voltage

Dials are at anv settine

other than 4 9 9 9 10 -

Probable cause

Resistor R333 is faulty

R131 out of adjustment

Oscillator frequency has

drifted

Relay K102B is defective

Relay KlOlB is defective

Fuse F201 is blown

One of the Kelvin-Varley

divider resistors is

faulty

Solution

Replace the faulty resistor

Adjust oer oaragraoh 4-8

Check frequency.

Reset to

approximately 94 cps.

(Refel

to paragraph 5-7).

Check operation of relay. 11

faulty replace with Keithley

relay or return t0 factory

Check operation of relay. If

faulty replace with new relay

from Keithlev

or return to

Check for possible short in

-6v supply (~~104).

See paragraph 5-3

TABLE 4.

(Sheet ).

Model 630 Troubleshootir :.

b.

Paragraph 6-2 describes how to remove the Model 630 :over.

Before proceeding with

the troubleshooting, check the vacuum tubes.

Normally,

replacing tubes will clear up the

difficulty.

All tubes can be readily tested on a grid-modulated tube tester.

If replac-

ing a tube does not correct the trouble, continue the procedures.

Replacing tubes does

not necessitate recalibration of the instrument.

c. Table 4 contains the mwze ccnnm~n troubles which might occur.

If the repairs indica-

ted in the Table do not clear up the trouble,

the difficulty will have to be found through

a point-by-point check of the circuits. Refer to the circuit description in Section 3

to find the more crucial components and to determine their function in the circuit. The

complete circuit schematic, 18261E, is found in Section 7,

4-5. ADJUSTING GRID BIAS OF CATHODE FOLLOWER.

The grid bias of the cathode follower,

V1003 (Figure 15), should be -3 volts. Use the Keithley Model 610B to check this value

i5"/,.

If necessary, adjust the DC BAL potentiometer, R157 (Figure 16), to this value.

0166R

19

Page 23

SERVICING MODEL 630 POTENTIOMETRIC ELECT&OMETER

4-6.

ZEhXR DIODE REPLACEMENT.

Zener diode, D302, is a reference for the voltage divider,

resistors R325 to R330.

The values of resistors R329 and R330 (Figure 20) are determined

by the reference voltage across diode D302. When the zener is replaced, the value of

these two resistors may have to be changed.

4-7. METER ADJUSTMENT.

a.

Potentiometer R155 (Figure 16) is the internal meter sensitivity adjustment. It

sets the current through the mater to indicate a full-scale deflection for a full-scale

applied voltage.

b.

Warm up the Model 630 for 30 minutes.

Set the NULL Switch to the l-volt range and

set the Reference Voltage Dials to 1.0000. Adjust potentiometer R155 until the meter

reads full scale.

4-8. ADJUSTING QUADRATURE CONTROL.

a.

Large quadrature components in the

null detector can cause poor ac rejection,

sluggish response, and, in some cases, un-

symmetrical readings on the most sensitive

ranges. Use the QUAD ADJ potentiometer,

Rl31 (Figure 16),

to buck out these compon-

ents when necessary.

While a large component is troublesome, the quadrature need

not be completely eliminated.

b.

To adjust the potentiometer, set the

Reference Voltage Dials to zero and the

DETECTOR INPUT. Switch to ZERO CK. Attach

an oscilloscope to the junction of Cl16 and

R134 (from pin 6 of V1002, Figure 15). Adjust potentiometer, R131, for the correct

wave form (Figure 9).

FIGURE 9. Wave Form with Rl31 Adjusted.

A Type 503 Oscilloscope was used; horizon-

tal sweep was 5 mseclcm; vertical, 2 v/cm.

20

0166R

Page 24

MODEL 630 POTh'NTIOMETRIC ELECTROMETER

CALIBRATION

SECTION 5. CALIBRATION

5-1. GENERAL.

a.

The following procedures are recommended for calibrating the Model 630.

Use the

equipment recommended in Table 5.

If proper facilities - especially important for cal-

ibrating an fO.Ol% instrument

- are not available or if difficulty is encountered, con-

tact Keithley Instruments, Inc.,

or its representative to arrange for factory calibration.

b.

The following procedures are covered:

Kelvin-Varley divider verification, divider

calibrate adjustment,

voltage range calibration, reference voltage supply stability test

and oscillator adjustment.

c.

If the Model 630 is not within specifications after the calibration, follow the

troubleshooting procedures or contact Keithley Instruments, Inc., or its representative.

Instrument

Electra Scientific Industries Model SV194B

Use

Range voltage calibration

Voltage Calibrator, i-0.005% accuracy with

corrections on certificate

Electra Scientific Industries Model RV722

Decade Voltage Divider; terminal linearity

21 ppm; certificate corrected to kO.2 ppm

Electra Scientific Industries Model LC875B

Lead Compensator

Hewlett-Packard Model 200CD Oscillator

Keithley Instruments Model 15OB Microvolt

hmeter

Keithley Instruments Model 241 Regulated

High Voltage Supply

Keithley Instruments Model 662 Guarded dc

Differential Voltmeter

Keithley Instruments Model 370 Recorder

Tektronix Type 503 Oscilloscope

Weston Instruments Model 3 Type 7 Saturated

Standard cell

Weston Instruments Model 66 Oil Bath

Voltage divider for range calibration

Range voltage calibration

Monitor oscillator frequency

Null detector for range calibration

Voltage supply for range calibration

Check voltages in Kelvin-Varley divider

Recorder for reference voltage supply

stability

Check wave forms

Range calibration and reference voltage

supply stability

Range calibration end reference voltage

TABLE 5.

Equipment Recommended for Model 630 Calibration.

Use these instruments or their

equivalents.

1067R

21

Page 25

CALIBRATION

MODEL 630 POTENTIOMETRIC ELECTROMETER

Control

Divider Calibrate

Quad Adjustment

Meter Calibrate

DC Balance

Oscillator

Circuit

Fig.

Refer to

Desig.

Ref. Paragraph

R104 15 5-4

R131 16 4-8

R155 16 4-7

R157 16 4-5

R210 18 5-7

500-volt Calibrate R327 20 5-5

50-volt Calibrate R334 20 5-5

5-volt Calibrate R337 20 5-5

0.5-volt Calibrate R339 20 5-5

TABLE 6.

Model 630 Internal Controls. The Table lists all internal controls, the fig-

ure picturing the location and the paragraph describing the adjustment.

5-2. CALIBRATION SCHEDULE.

a. Recalibrate the Model 630 yearly. This normally means performing the voltage range

calibration (paragraph 5-5). The other verifications need not be done.

b.

Verify the Kelvin-Varley divider (paragraph 5-3) only if trouble is suspected in it,

or if components in the divider have been replaced. Also make the voltage range calibra-

tion after verifying the divider accuracy.

c.

Check the reference voltage supply stability (paragraph 5-6) only if trouble is

suspected in the supply or if some of its components have been replaced.

5-3. KELVIN-VARLEY DIVIDER VERIFICATION.

a.

There is no in-field calibration for the Kelvin-Varley divider; its accuracy can

only be verified.

The divider accuracy depends upon matching resistors and switches. At

manufacture,

each resistor within the first two Reference Voltage switches, S303 and

S304, is matched to *0.00125%. The resistors in the switches are checked as a set to an

accuracy of better than 0.0025%.

Individual resistors cannot be replaced without remat-

ching the string at Keithley Instruments.

b. Kelvin-Varley Divider Accuracy Verification Procedures.

1.

Use the Model 662 Differential Voltmeter or equipment with better limit of

error to match the Model 630 under test.

Connect the Low end of potentiometer R38L of

the Model 630 to the HI terminal of the Model 662.

Connect both LO terminals.

NOTE

Be careful of high voltages when working within the Model 630. Up to 900 volts

dc is present at various points.

2.

Set the dials to random settings on both instruments. Settings should match to

iO.Ol%. This procedure, however, only indicates the Kelvin-Varley divider accuracy.

The errors of the two instruments may be additive, causing a false verification. The

most accurate way is to use standard procedures for checking a Kelvin-Varley divider

or to return the Model 630 to Keithley Instruments, Inc., for checking.

22

1265R

Page 26

MODEL 630 POTENTIOMETRIC ELECTROMETER

3.

If any resistor fails to test out,

the entire divider string will have to he rc-

matched at the factory.

5-4.

INPUT DIVIDER CALIBRATION.

Above 1 volt the input is divided by a constant 5OO:L

ratio. R103 is pre-selected to approximate this ratio and R104 is adjusted to trim to

this ratio more closely.

A misadjustment will show up if the Model 630 maintains spccificrl

'accuracy

on the l-volt and Lower ranges but appears in error for the higher ranges.

'To

check the divider ratio,

use the Model 241 to apply a 500-volt signal to the Hodel 630 in-

put.

The Model 630 meter should have a full scale deflection on its 500-volt range.

If

it does not,

trim R104 (Figure 15) until the meter indicates full scale.

5-5.

RANGE CALIBRATION.

a. The reference voltage supply has a 500-volt output which can be attenuated to 50, 5

or 0.5 volts.

This voltage is then divided by the Kelvin-Varley divider to provide the

accurate buckout voltage. Each of the four voltage ranges is set by internally adjusting

potentiometers R327, R334, R337 and R339 (Figure 20).

b.

The ranges are calibrated by applying an accurate voltage to the Model 630 for each

setting of the RANGE Switch.

The Model 630 is set to furnish the equivalent buckout vol-

tage, and the internal range potentiometer is adjusted until the voltmeter indicates a

null.

I

SUPPlY

I

I

d b

Mode, -~ --

i ‘C 8/,B

d I u-+-z Detector ]

o Compensator

9.9 lm

--+

_ Model

EXte"dGT

- sv 194B

(5 and 0.5"

Calibrator

OlllY)

p+Cd

I

I

Model R'J722

FIGURE 10.

Block Diagram to Establish System Accuracy for Model 630 Range Calibration.

Fully guard the entire system to prevent leakage errors.

Use a l-kilohm copper resistor

to shunt the null detector.

See Table 5 for recoanended equipment.

1067R

23

Page 27

CALIBRATION

MODEL 630 POTENTIOMETRIC ELECTROMETER

NOTE

The accuracy of the Model 630 calibration will be no greater than the

accuracy of the voltage source used for calibrating.

Unless the user is

familiar with techniques for obtaining accuracy greater than 0.002%

(20

PPm) >

it is better to return the Model 630 to the factory for range

calibration.

c.

The most critical part in range calibration is establishing a reference source

whose accuracy exceeds 0.002%..

Use the Model SV194B Voltage Calibrator for the 500, 50,

5 and 0.5-volt outputs. Establish the accuracy of these outputs by determining the corrections for the calibrator's CALIBRATION and OUTPUT dials at these outputs.

The system's

accuracy can be determined to approximately 10 ppm. Added

to

the accuracy of the standard

cell, total accuracy should be approximately 12 ppm. Note that this depends upon proper-

ly executed procedures.

d.

Procedures to Establish System Accuracy.

1.

Set up the system shown in Figure 10.

Use the 9.9-megohm extender for only the

0.5 and 5-volt output.

2.

Establish the corrections for the CALIBRATION dial setting for Model SV194B out-

puts of 500, 50, 5 and 0.5 volts.

Set the Model 241 Voltage Supply to 500 volts.

set

the Model RV722 Divider to a voltage equal to that of the standard cell.

Adjust the

Model SVl94B ratio dial until the null detector indicates a null.

The difference between the settings of the Model RV722 Divider and the ratio dial is the Model SVl94B

correction factor at 500 volts.

With this correction, the 500 volts may be set to

within approximately 12 ppm.

3.

Connect the null detector to the 50, 5 and 0.5-volt taps of the Model SVl94B Cal-

ibrator in that order.

Set the Model RV722 Divider to corresponding voltages.

Use the

9.9-megohm extender for the 5 and 0.5-volt outputs. (See Figure 10). The difference

read on the null detector is the correction factor for each of the three voltages.

These voltages may also be set to within 12 ppm.

4.

Use the four correction factors for calibrating the Model 630 range setting.

f. Procedures for Range Calibration.

1.

Set up the system shown in Figure 11.

The standard cell should be certified to

10 ppm.

Use the dial correction factors found for each output.

If the system accuracy

was properly determined,

the input voltage to the Model 630 should be correct to 20 ppm.

2.

500-volt Range Calibration: Set the Model 630 controls as follows:

DETECTOR INPUT Switch 1010 OHMS

RANGE Switch

500

Reference Voltage Dials 4 9 9.9 9 10

NULL Switch VTVM

POLARITY Switch

+

Adjust the Voltage Calibrator to apply 500 volts to the Model 630.

Turn the Model 630

NULL Switch to 10 MV and adjust the 500 V CAL potentiometer, R327 (Figure ZO), for

null on the Potentiometric Electrometer.

24

0166R

Page 28

MODEL 630 POTENTIOMETRIC FLECTROMETER

CALIBRATION

FIGURE 11. Block Diagram for Model 630 Range Calibration. Fully guard the entire system

to

prevent leakage errors. See Table 5 for recommended equipment.

3.

50-volt Range Calibration: Set the Model 630 controls as follows:

DETECTOR INPUT Switch 1010 OHMS

RANGE Switch 50

Reference Voltage Dials 4'9.9 9 9 10

NULL Switch 10 Mv

POLARITY Switch +

Adjust the Voltage Calibrator to apply 50 volts dc to the Model 630. Adjust the 50 V

CAL potentiometer, R334 (Figure ZO),

for an off-null reading on the Model 630 equal to

the correction factor at 50 volts.

4.

5-volt Range Calibration:

set the Model 630 controls as follows:

DETECTOR INPUT Switch

1010 OHMS

RANGE Switch

'5

Reference Voltage

Dials 4.9 9

9 9 10

NULL Switch 1Mv

POLARITY Switch +

Adjust the Voltage Calibrator to apply 5 volts dc to the Model 630. Adjust the 5 V CAL

potentiometer, R337 (Figure 2o), for an off-null reading on the Model 630 equal to the

correction factor at 5 volts.

5.

0.5~volt Range Calibration:

Set the Model 630 controls as follows:

DETECTOR INPUT Switch 1010 OHMS

RANGE Switch

0.5

Reference Voltage

Dials .4 9

9 9 9 10

NULL Switch

0.1 MV

POLARITY Switch

+

1067~

25

Page 29

CALIBRATION

MODEL 630 PO'TENTIOMETRLC ELECTROMETER

Oil Bath;

I

I

t

- I

-

- I

- I

,-------

FIGURE 12. Circuit Diagram for Model 630 Reference Voltage Supply Stability Test.

voltage across the 530-ohm resistor is slightly higher than the standard cell.

Model 150B

H

Null

Recorder

The

Use the

lo-kilohm potentiometer to shunt the divider voltage down. All resistors are wirewound.

See Table 5 for recommended equipment.

Adjust the Voltage Calibrator to apply 0.5 volt dc to the Model 630. Adjust the 0.5 v

CAL potentiometer, R339 (Figure ZO), for an off-null reading on the Model 630 equal to

the correction factor at 0.5 volt.

5-6.

REFERENCE VOLTAGE SUPPLY STABILITY TEST.

The reference voltage supply,

a.

consisting of the power transformer and the main supply (printed circuit PC92), is factory calibrated for an output of 500 volts dc greater

than 0.002%. The 500-volt output is adjustable to meet specifications. If the stability

of the supply is not within specifications,

then troubleshoot for a faulty component.

Routine calibration of the Model 630 does not require a stability test of the ref-

b.

erence voltage supply. However, a stability test is recommended if one of the components

in the supply is replaced.

For the 24-hour test, the 500-volt output of the reference voltage supply is divided

c.

and compared to a 1.02-volt saturated standard cell using a sensitive null detector.

Var-

iations between the reference voltage supply and the standard cell are detected by the

Model 150A and are recorded on a recorder.

Refer to Figure 12 for the block diagram of

the test circuit.

In using the test circuit,

d.

Saturated standard cells,

1.

ture coefficient and require a controlled environment during use.

ton Oil Bath, which is maintained at ~350 M.OloC, is used for the test.

the following points are important.

though extremely stable with time, have a high tempera-

Therefore, the Wes-

Unsaturated

standard cells have a lower temperature coefficient, but they do not have the long term

stability required for this test.

The resistor divider network is constructed from wire of the same spool for an

2.

extremely close temperature coefficient match (4 ppm, typically).

26

Additional stability

1067R

Page 30

MODEL 630 POTENTIOMETRIC ELECTROMETER

CALIBRATION

results when the resistors are immersed in an oil bath to hold the ambient temperature

variations

to

+O.Ol%.

e.

Procedures for the Reference Voltage Supply Stability Test.

1.

After the saturated standard cell and the resistor divider network are placed in

the oil bath, allow sufficient time for the cell to stabilize at ~35°C. (Consult Keith-

ley Instruments, Inc., or its representative for details.) Connect the standard cell

to the circuit after turning on the 500-volt supply. Set the Model 630 controls as

follows:

DETECTOR INPUT Switch

1010 OHMS

RANGE Switch 500

Reference Voltage Dials 4 9 9.9 9 10

NULL Switch 10 Mv

POLARITY Switch

OFF

Connect the resistor divider network across the Model 630's reference voltage supply,

the positive side of the divider input to the wiper arm of the last Reference Voltage

Switch, S306, and the negative side of the divider to the LO terminal on the Model 630

front panel.

2.

Connect the Model 150B and the recorder as shown in Figure 12. Set the Model 1500

to the 3-volt range.

Advance the Model 630 POLARITY Switch to -I- to put 500 volts across

the divider. If the Model 150B reads two volts, the standard cell and the divider voltages are improperly connected in series. If the circuit is correct, the Model l50B

will read zero. Increase the Model 15OB's sensitivity to the O.l-millivolt range. If

it reads more than 20 microvolts, adjust the 500 V CAL potentiometer, R327 (Figure 20),

shunting the divider.

NOTE

Any adjustment of potentiometer R327 requires all other ranges to be calibrated,

3.

After l-hour warm-up,

the drift of the entire system should not exceed i-25 micro-

volts in 24 hours.

5-7. OSCILLATOR ADJUSTMENT.

a.

The oscillator circuit drives the light modulator, vibrating capacitor and bridge.

demodulator. Before adjusting the oscillator, make sure the reference voltage supply

is operating correctly.

b.

Connect the Type 503 Oscilloscope Vertical Input to the plate and low side of tube

V1003 (Figure 15) and the Horizontal Input to the Model 200CD Oscillator. Adjust the

oscillator frequency to approximately 94 cps with potentiometer R210 (Figure 18). The

Model 630 oscillator is then adjusted for minimum meter noise - normally within a cycle

of 94 cps.

Disconnect the Oscilloscope before adjusting potentiometer R210. The

Oscilloscope will cause a small loading error.

1067R

27

Page 31

CALIBRATION

MODEL 630 POTENTIOMETRIC ELECTROMETER

R30 1

0302

Q203

Cl22

(hid,

PC-103

Null Detector Input

(Refer to Figures 15 and 16)

(Refsr to Figure 17)

FIGURE 13. Top view of Model 630 Chassis.

Front panel faces to the right.

28

0166

Page 32

MODEL 630 POTENTIOMETRIC ELECTROMETER

CALIBRATION

'IGURE 14. Bottom view of Model 630 Chassis.

Front panel faces to the right.

Figure

13 shows the top view.

0166

29

Page 33

CALIBRATION

MODEL 630 POTENTIOMETRIC ELECTROMETER

Cl01

I

A

OS101

Cl06

Cl07 Cl13

Cl15

Clll.-elj

Cl10 ----+

Cl19 -".q

Cl09

c12oa-+

c117nn"y

Dlb9

I

D108

VCiOl Djoy166

;

-cl08

+D104

~V1002

*cl16

Fl [GURE 15.

Capacitor,

Tube and Diode Locations on Printed Circuit PC-103.

Re-

fer to Figure 16 for Resistor Locations. Hidden from view, in locations A and B

are, potentiometer Rl04, resistors R124 and R154, and capacitors Cl03 and C105.

30

0166

Page 34

MODEL 630 POTENTIOMETRIC ELECTROMETER

CALIBRATION

R107-

Rl33 -mm..&

i,j

R130,

R158

R109

R15.1 R108

29

R141

thru

R118

KeS1StOr

Diode and Tube Locati

on lx-L”J.

Keter

to Figure 13 tar Capacitor,

0166

31

Page 35

CALIBRATION

MODEL 630 POTENTIOMETRIC ELECTROMETER

I,

tector Input.

Locations

on Null De

'IGURE 18.

Component bzations on -6.3 vo

ower Supply, PClO4.

32

0166

Page 36

MODEL 630 POTENTIOMETRIC ELECTROMETER

CALIBRATION

GURE 19.

Capacitor, Diode, Modulator and Tube Locations on Printed Circuit Board PC-92.

,fer to Figure 20 for Resistor

Locations.

D301

v3003

c 5

I

I

P

008

C306

,~_,,,., I‘....

VW0 1

Page 37

CALIBRATION MODEL 630 POTENTIOMETRIC ELECTROMETER

R30 2

R312 R314

R303 R305 R315

I

I I I I I

R307

“:“kc

R33111

R30

9

R310

4

R308

R332

.iii‘::*&

R328

-

?osition

R324

,m

R313

R339

R3.33

R327

R317

R316

-

R318

R319

R325

Position

R326

Position

-R330

positiac

c

R334

FIGURE 20.

Resistor Locations on Printed Circuit Board PC-92.

Refer to Figure 19 for

Capacitor, Diode, Modulator and Tube Locations.

34

0166

Page 38

MODEL 630 POTENTIOMETRIC ELECTROMETER

ACCESSORIES

SECTION 6. ACCESSORIES

6-1. MODEL 6301 GUARDED PROBE. (Figure 21)

a.

The Model 6301 is a guarded probe and shielded lead to make measurements with the

Model 630 nvxe convenient.

It does not alter any Model 630 specification.

The lead is

furnished with 3 feet of low-noise cable,

terminated by a special triaxial type plug.

The

plug connects directly into the Model 630 Input Receptacle.

b. Using the Model 6301 Probe allows point by point measurements.

Its operation witli

the Model 630 is explained in paragraph 2-4.

6-2. RACK MOUNTING.

(See Figure 22)

The Model 630 is shipped for bench use with four feet and a tilt-bail

The Model

4&% Rack Mounting Kit converts the instrument to rack mounting to the stan&nd EIA (RET@)

19-inch width.

b.

To convert the Model 630, remove the four SC~BWS at the bottom of each side of the

instrument case. Lift off the top cwer assembly with the handles; save the four screws.

To remcwe the feet aid tilt bail from the bottom cover assembly, turn the two screws near

the back. The two pawl-type fasteners will release the cwer and allow it to drop off.

Remove the feet and the tilt bail and replace the cwer (2).

c. Attach the pair of rack angles (3) to the cabinet with the four screws (4) previou

S-

y removed.

Insert the top cwer assembly (1) in place and fasten to the chassis with t

he

m

FIGURE 21.

Keithley Instruments Model 6301 Guarded Probe with the Model 630.

Besides the

probe tip,

the Model 6301 can have banana plug, alligator clip, and bnc-type connections.

Unscrew tip to make the connection.

1265

35

Page 39

ACCESSORIES

MODEL 630 POTENTIOMETRIC ELECTROMETER

two pawl-type fasteners at the rear. Store the top cover with handles, feet and tilt-bail

for future use.

6-3.

PLACING IN RACK.

The Model 630, once converted for rack mounting, easily fits into

the rack.

It is recommended, however,

that a blower be used in the rack enclosure in

which the Model 630 is mounted. The instrument specifications state a 0.002% per "C tem-

perature coefficient. A temperature rise of 5 W (9 OF) will cause a 0.01% error.

Item

(See Fig. 22)

Description

Keithley

Part No. Quantity

1 Cover Assembly

14623B 1

2

Cover Assembly, Bottom (Supplied with

Model 630)

14590B 1

3

Angle, Rack

14624B

2

4 SCYCeW)

Slot Head, lo-32 UNC-2 x l/4

(Supplied with Model 630)

----

4

5

Front Panel (Supplied with Model 630)

__--

1

I

TABLE 7.

Parts List for Model 4000 Rack Mounting Kit.

P

4

SCREW

~@COVER ASSEMBLY

OVER ASSEMBLY

FIGURE 22. Exploded

View

for Rack Mounting with Model 4000 Kit.

Refer to

'Table 7 for parts.

1265

Page 40

MODEL 630 POTENTIOMETRIC ELECTROMETER

ACCESSORIES

FIGURE 23. Model 6013 pH Electrode Adapter Connected to pH Electrodes,

The Model 6013,

shown here with the Keithley Model 601 Electrometer,

is used similarly with the Model630.

6-5.

MODEL 370 RECORDER.

a. The Model 370 Recorder is uniquely compatible with the Model 630 as well as other

Keithley electrometers,

picoammeters and microvoltmeters.

The Recorder is a high quality

economical instrument that epitomizes the performance of the Model 630 and many other

Keithley instruments, even in the most critical applications.

The Model 370 can be used

with the Model 630 to

record

over the Model 630's entire range.

b. The Model 630 has the output necessary to drive the Recorder directly (1 volt, 1

milliampere), thus eliminating the need for a preamplifier.

The Model 370 floats f500

volts off ground, enabling the Model 630 to be used to its specified off-ground voltage.

The Recorder is specially shielded to avoid pickup of extraneous signals. The response

1067R

37

Page 41

ACCESSORIES MODEL 630 POTENTIOMXTRIC ELECTROMETER

time of the Model 370 Recorder is 0.5 second; linearity is *l% of full scale. Ten chart

speeds - from 3/4 inch per hour to 12 inches per minute - are selectable with front panel

controls. The 6-inch chart has a rectilinear presentation. The Model 370 Recorder has a

self-priming inking system. Chart paper and ink refills are easy to install.

C. The Model 370 is ‘very easy to use with the Model 630.

Just connect the Model 630’s

OUTPUT Receptacle to the Model 370 with the furnished 3701 Input Cable and adjust an

easily accessible control for full-scale recorder deflection.

38

1067R

Page 42

MODEL 630 POTENTIOMETER ELECTROMETER REPLACEABLE PARTS