Page 1

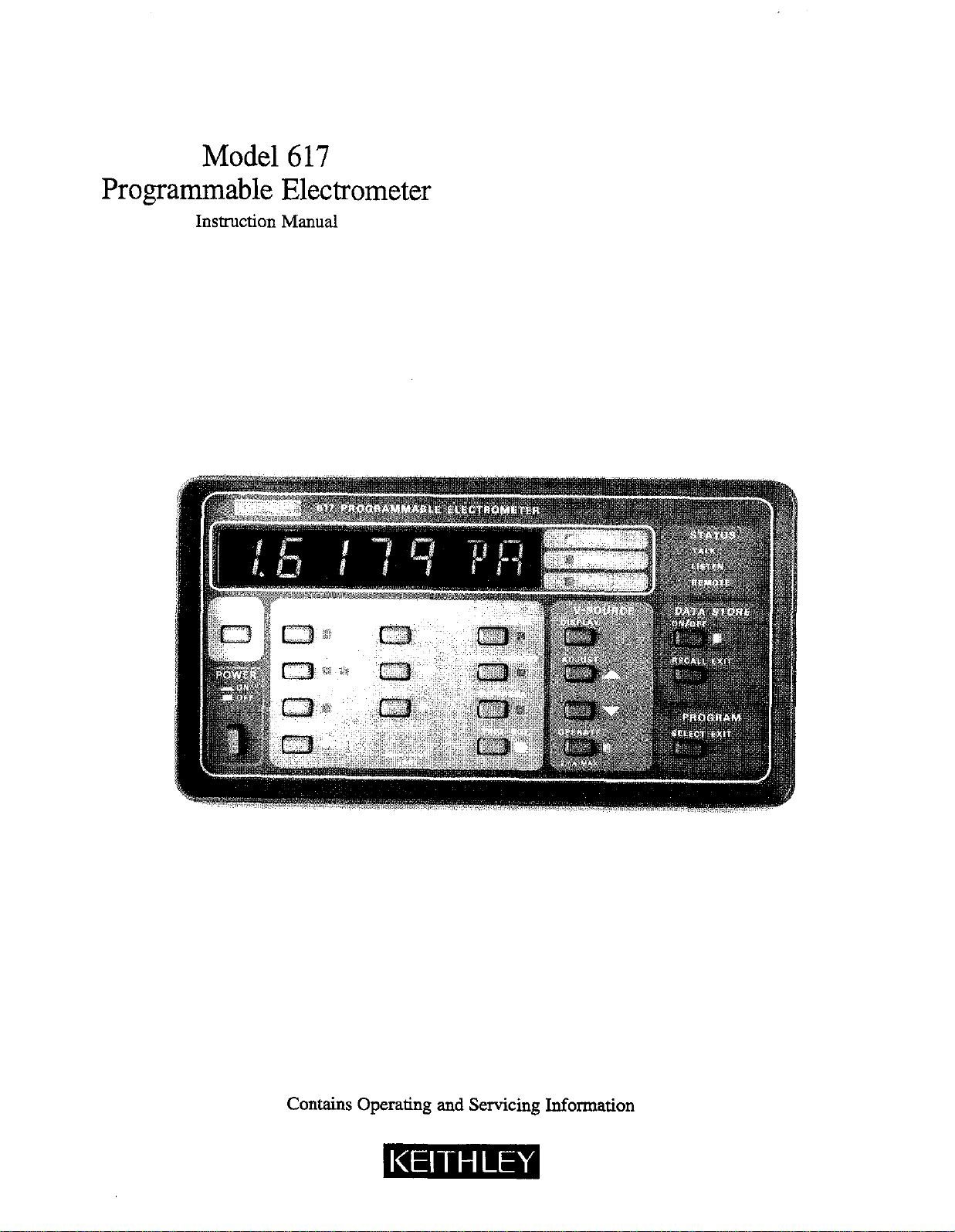

Model 617

Programmable Electrometer

Instruction Manual

Contains Operating and Servicing Information

Page 2

WARRANTY

Keithley Instruments, Inc. warrants this product to be free from defects in material and workmanship for a period of 1 year from date of

shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables, rechargeable batteries,

diskettes, and documentation.

During the warranty period, we will, at our option, either repair or replace any product that proves to be defective

To exercise this warranty, write or call your local Keithley representative, or contact Keithley headquarters in Cleveland, Ohio. You will

be given prompt assistance and return instructions. Send the product, transportation prepaid, to the indicated service facility. Repairs

will be made and the product returned, transportation prepaid. Repaired or replaced products are warranted for the balance of the original warranty period, or at least 90 days.

LIMITATION OF WARRANTY

This warranty does not apply to defects resulting from product modification without Keithley’s express written consent, or misuse of

any product or part. This warranty also does not apply to fuses, software, non-rechargeable batteries, damage from battery leakage, or

problems arising from normal wear or failure to follow instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. THE REMEDIES PROVIDED HEREIN ARE

BUYER’S SOLE AND EXCLUSIVE REMEDIES.

NEITHIZR KEITHLEY INSTRUMBNTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OF ITS INSTRUMENTS AND

SOmWARE EVEN IF KEITHLEY INSTRUMENTS, INC., HAS BEEN ADVISED IN ADVANCE OF THE POSSIBILITY OF

SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT ARE NOT LIMITED TO: COSTS OF REMOVAL

AND INSTALLATION, LOSSES SUSTAINED AS THE RESULT OF INJURY TO ANY PERSON, OR DAMAGE TO PROPERTY.

Keithley Instruments, Inc. - 28775 Aurora Road - Cleveland, OH 44139 - 216-248-0400 - Fax: 216-24X-6168 - http://www.keithley.com

Page 3

Model 617 Programmable Electrometer

Instruction Manual

0 1984, Keithley Instruments, Inc.

Test Instrumentation Group

All rights reserved.

Cleveland, Ohio, U.S.A.

Document Number: 617-901-01 Rev. C

Page 4

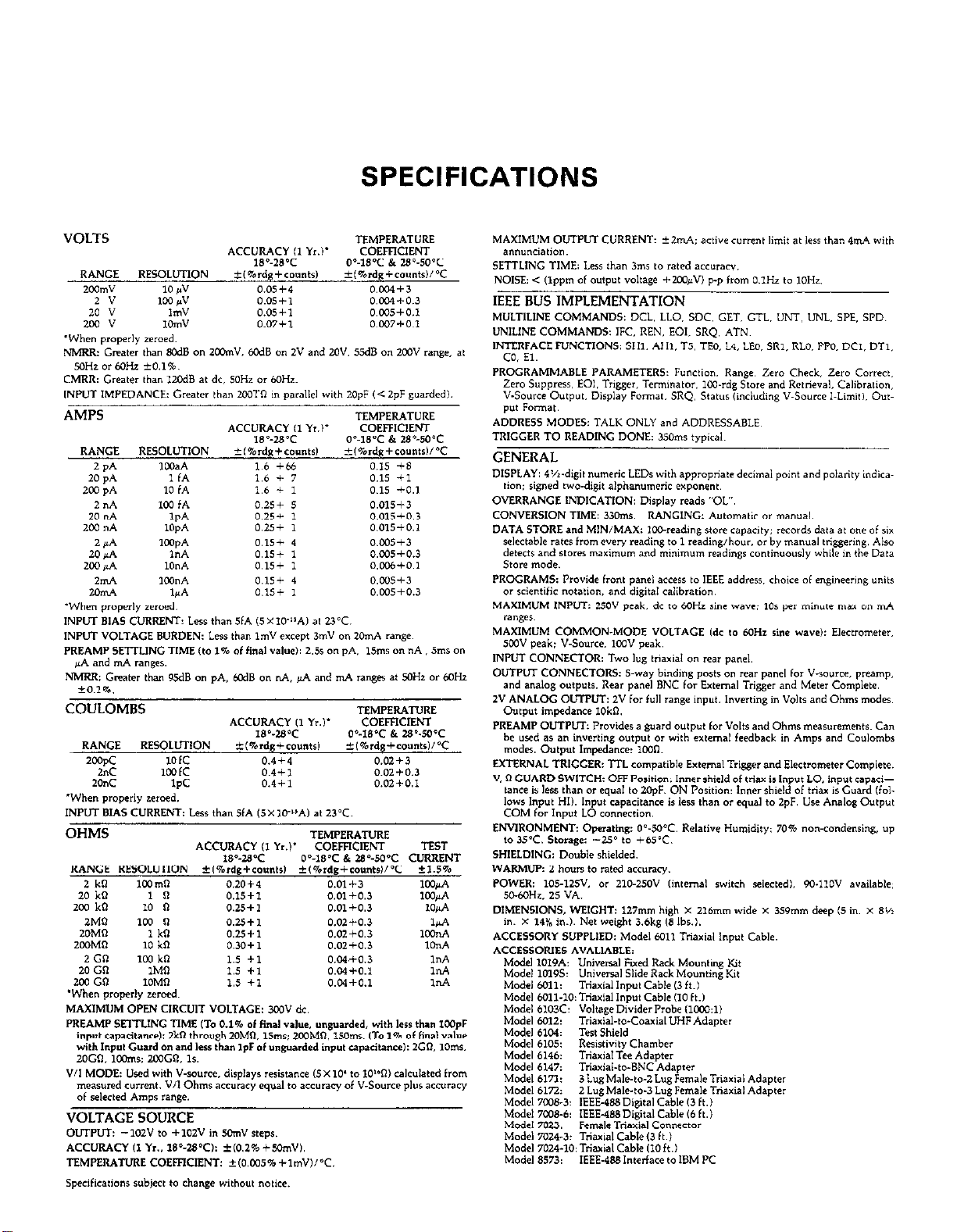

SPECIFICATIONS

Page 5

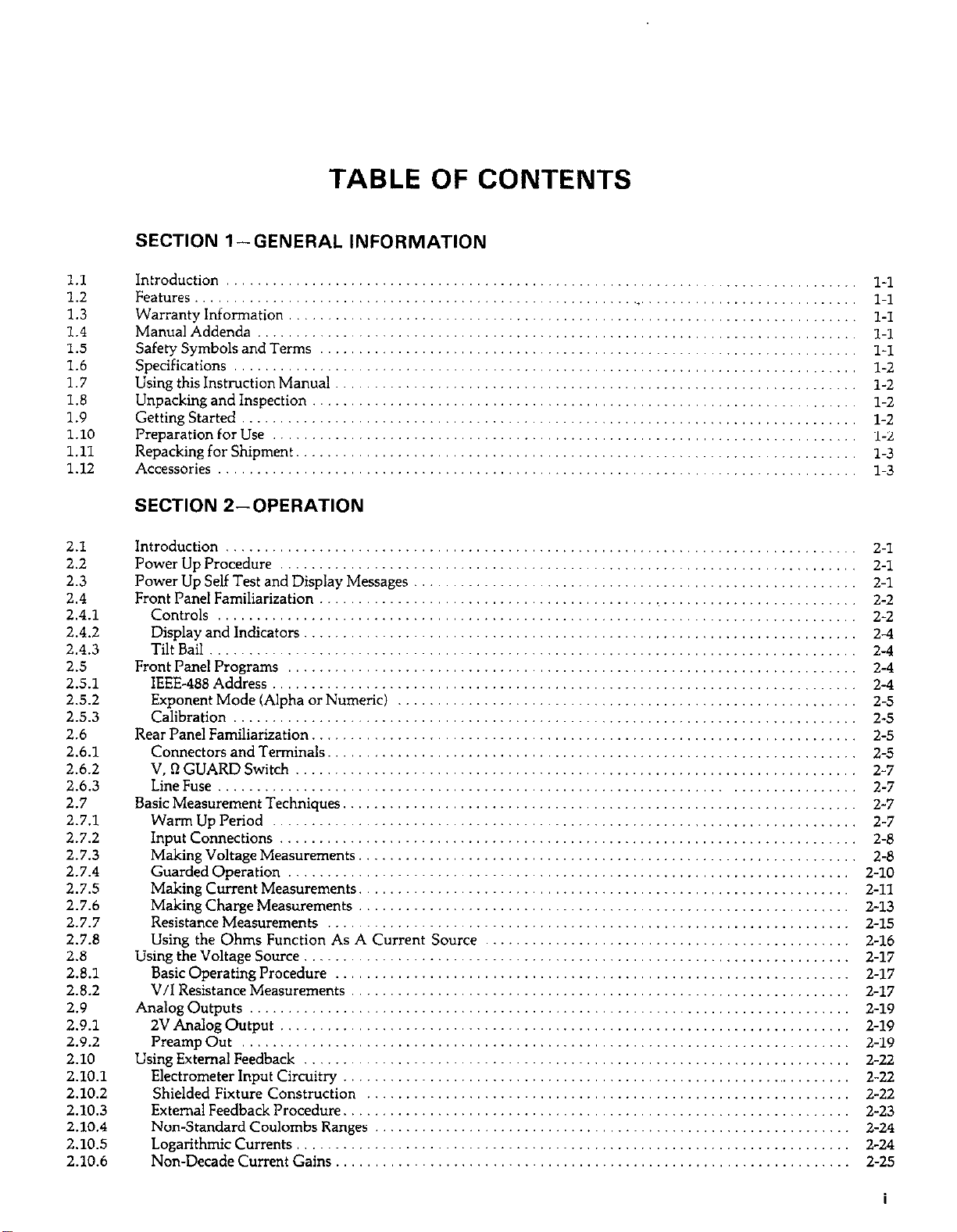

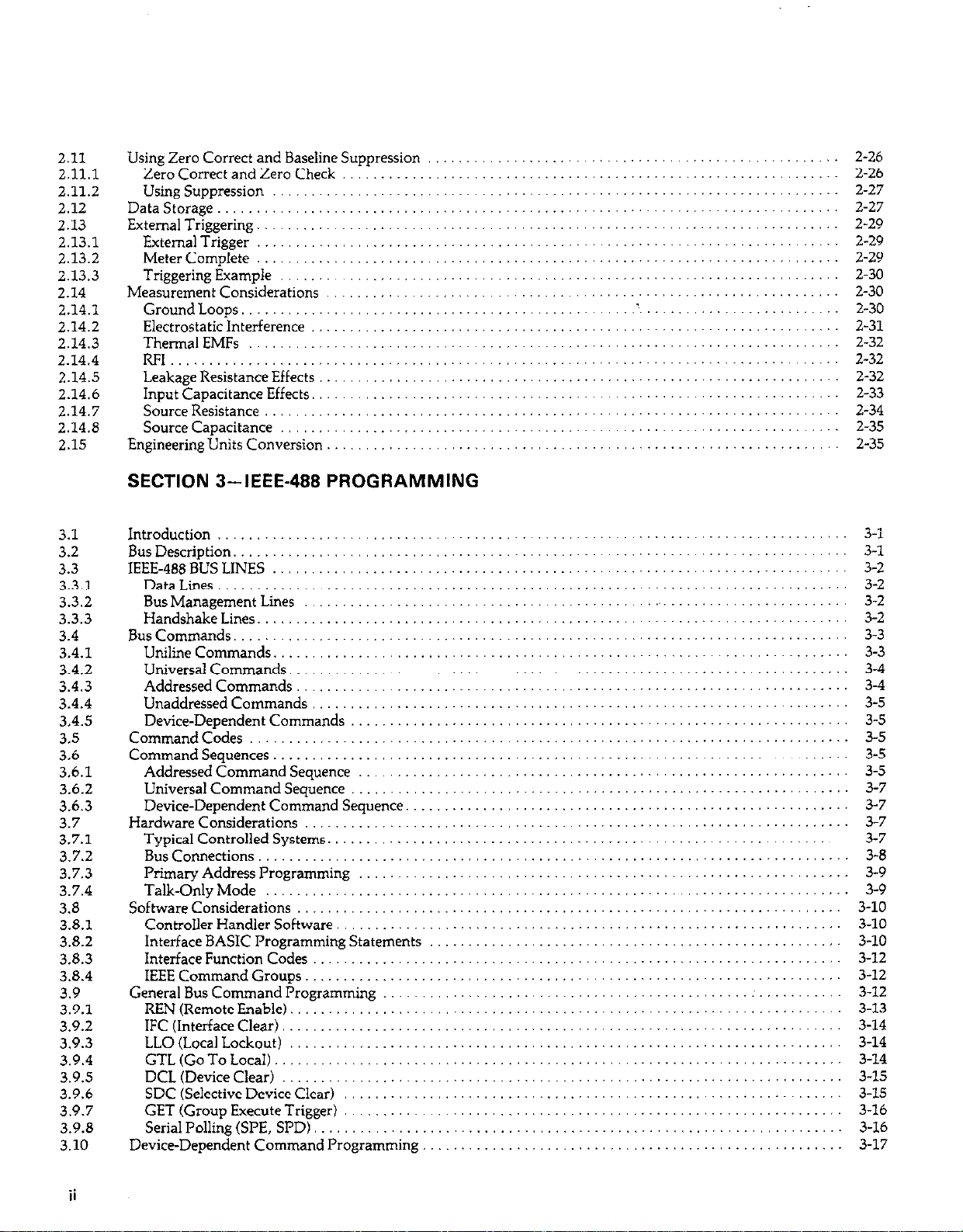

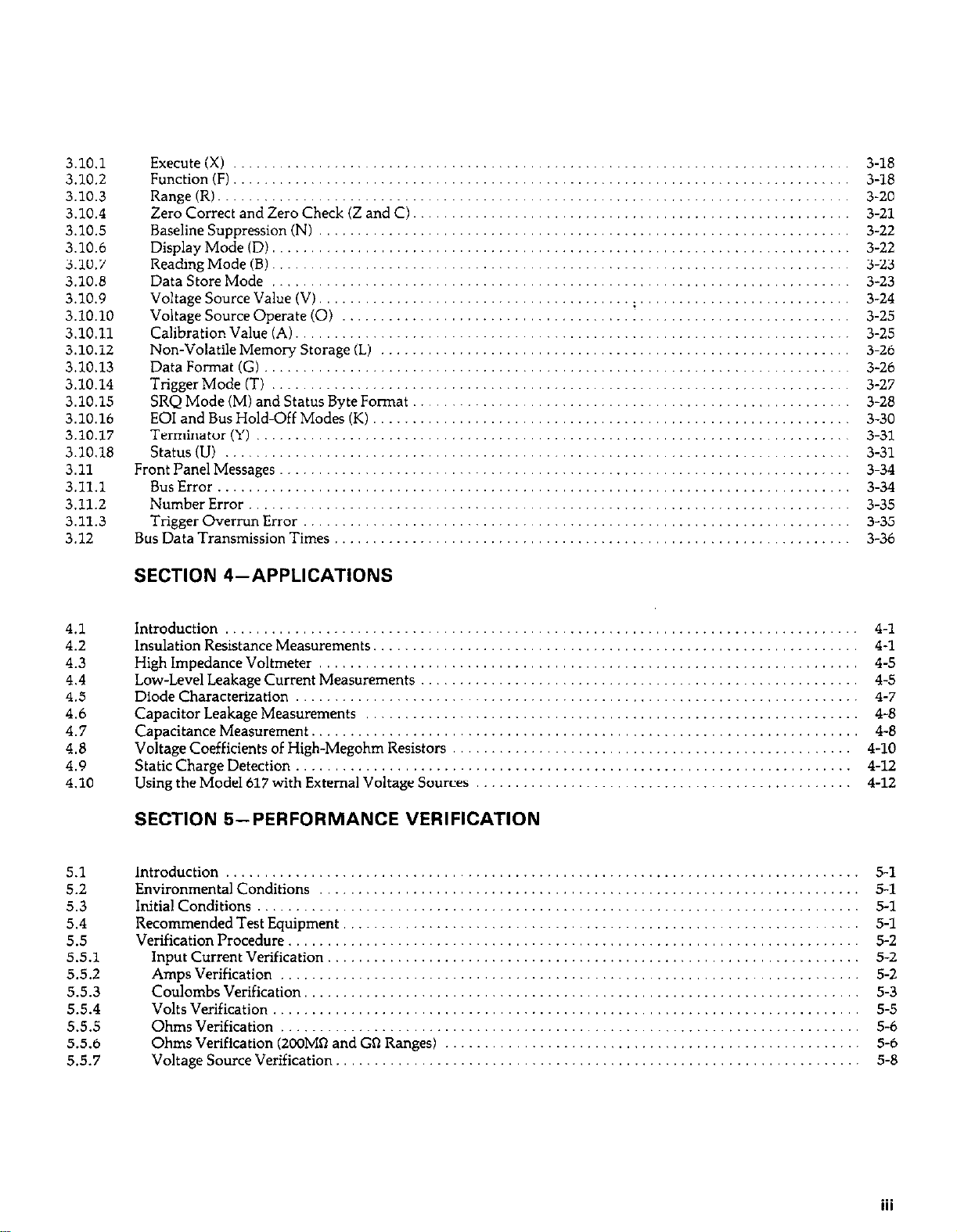

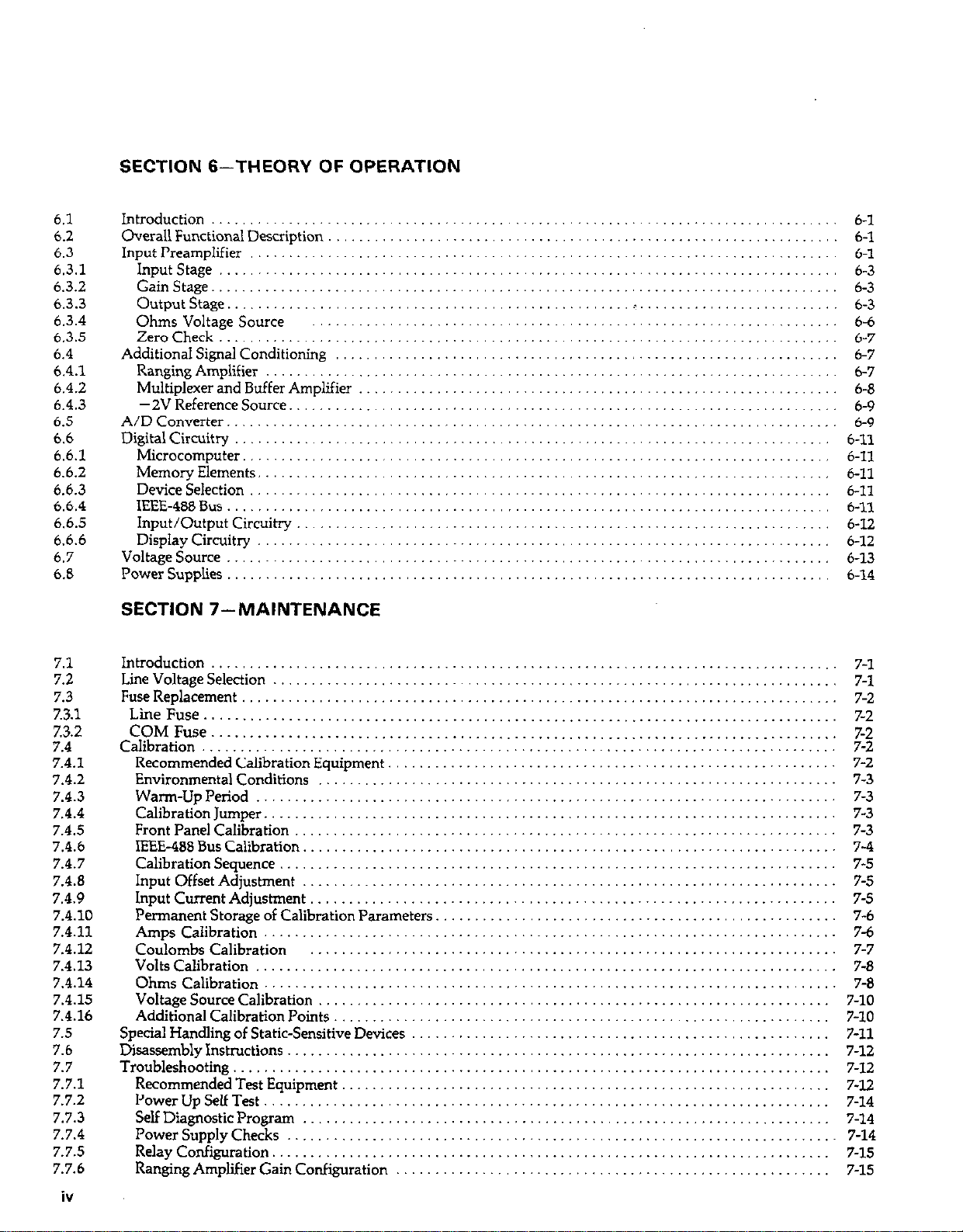

TABLE OF CONTENTS

SECTION l-GENERAL INFORMATION

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

1.10

1.11

1.12

2.1

2.2

2.3

2.4

2.4.1

2.4.2

2.4.3

2.5

2.5.1

2.5.2

2.5.3

2.6

2.6.1

2.6.2

2.6.3

2.7

2.7.1

2.7.2

2.7.3

2.7.4

2.7.5

2.7.6

2.7.7

2.7.8

2.8

2.8.1

2.8.2

2.9

2.9.1

2.9.2

2.10

2.10.1

2.10.2

2.10.3

2.10.4

2.10.5

2.10.6

Introduction

Features ...................

Warranty Information

ManualAddenda..

Safety Symbols and Terms

Specifications

Using this Instruction Manual

Unpacking and Inspection

Getting Started

Preparation for Use

Repacking for Shipment.

Accessories

...................

..

...........

.............

.......

..................

.....

........

.................

.............

.........

....................

SECTION 2-OPERATION

Introduction

Power Up Procedure

Power Up Self Test and Display Messages

Front Panel Familiarization

Controls

Display and Indicators

TiltBan

Front Panel Programs

IEEE-488 Address

Exponent Mode (Alpha or Numeric)

Calibration

Rear Panel Familiarization.

Connectors and Terminals.

V,RGUARDSwitch

LineFuse..

Basic Measurement Techniques.

Warm Up Period

Input Connections

Making Voltage Measurements.

Guarded Operation

Making Current Measurements.

Making Charge Measurements

Resistance Measurements

Using the Ohms Function As A Current Source

Using the Voltage Source

Basic Operating Procedure

V/I Resistance Measurements

Analog Outputs

2v Analog Output

PreampOut

Using External Feedback

Electrometer Input Circuitry

Shielded Fixture Construction

External Feedback Procedure.

Non-Standard Coulombs Ranges

Logarithmic Currents

Non-Decade Current Gains

...................................

............................

...........

.......................

....................................

.........................

.....................................

...........................

.............................

.............

..................................

.......................

.....................

..........................

..................................

...................

.............................

............................

.................

...........................

.................

..................

......................

.........................

.....................

...................

................................

............................

.................................

.........................

....................

.................

...................

................

..........................

.....................

.......

.......

.......

.......

.......

.......

.......

....... 2-2

.......

.......

.......

.......

.......

.......

.......

.......

.......

....... 2-7

.......

.......

.......

......

......

.. ...

....

......

......

...... 2-17

......

......

......

......

......

......

......

......

......

......

......

2-l

2-l

2-l

2-2

2-4

2-4

2-4

2-4

2-5

2-5

2-5

2-5

2-7

2-7

2-7

2-8

2-E

Z-10

2-11

2-13

2-15

2-16

2-17

2-17

2-19

2-19

2-19

2-22

2-22

2-22

2-23

2-24

2-24

2-2.5

I

Page 6

2.11

2.11.1

2.11.2

2.12

2.13

2.13.1

2.13.2

2.13.3

2.14

2.14.1

2.14.2

2.14.3

2.14.4

2.14.5

2.14.6

2.14.7

2.14.8

2.15

Using Zero Correct and Baseline Suppression

Zero Correct and Zero Check

Using Suppression ......................

DataStorage .............................

External Triggering. .......................

External Trigger ........................

Meter Complete ........................

Triggering Example .....................

Measurement Considerations ...............

GroundLoops

Electrostatic Interference .................

Thermal EMFs .........................

RF1 ...................................

Leakage Resistance Effects ................

Input Capacitance Effects. ................

Source Resistance .......................

Source Capacitance .....................

Engineering Units Conversion ...............

..........................

.............

SECTION 3-IEEE-488 PROGRAMMING

.......

.......

......

......

......

......

......

......

......

......

......

......

......

.....

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

3.1

3.2

3.3

3.3.1

3.3.2

3.3.3

3.4

3.4.1

3.4.2

3.4.3

3.4.4

3.4.5

3.5

3.4

3.6.1

3.6.2

3.6.3

3.7

3.7.1

3.7.2

3.7.3

3.7.4

3.8

3.8.1

3.8.2

3.8.3

3.8.4

3.9

3.9.1

3.9.2

3.9.3

3.9.4

3.9.5

3.9.6

3.9.7

3.9.8

3.10

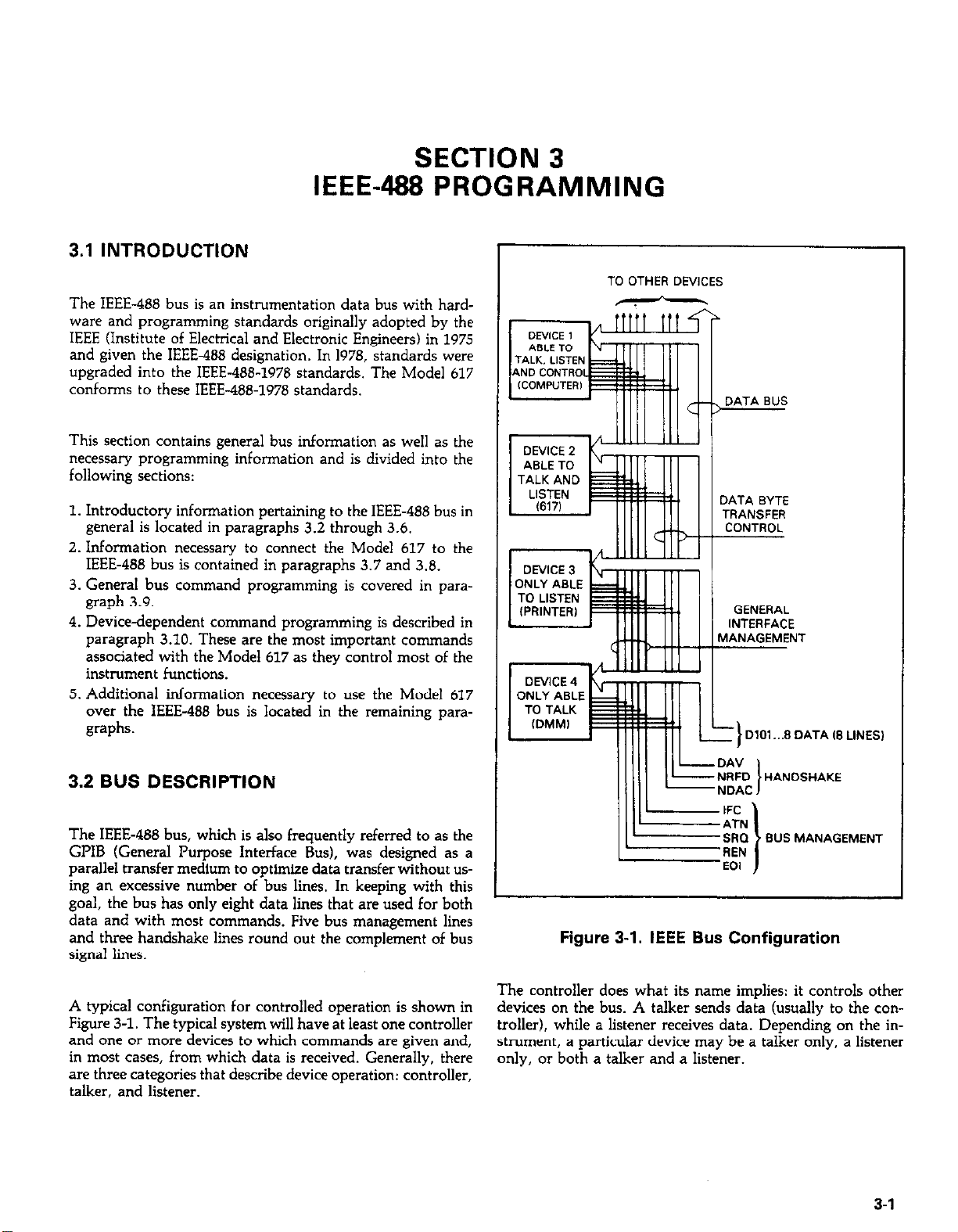

Introduction

BusDescription

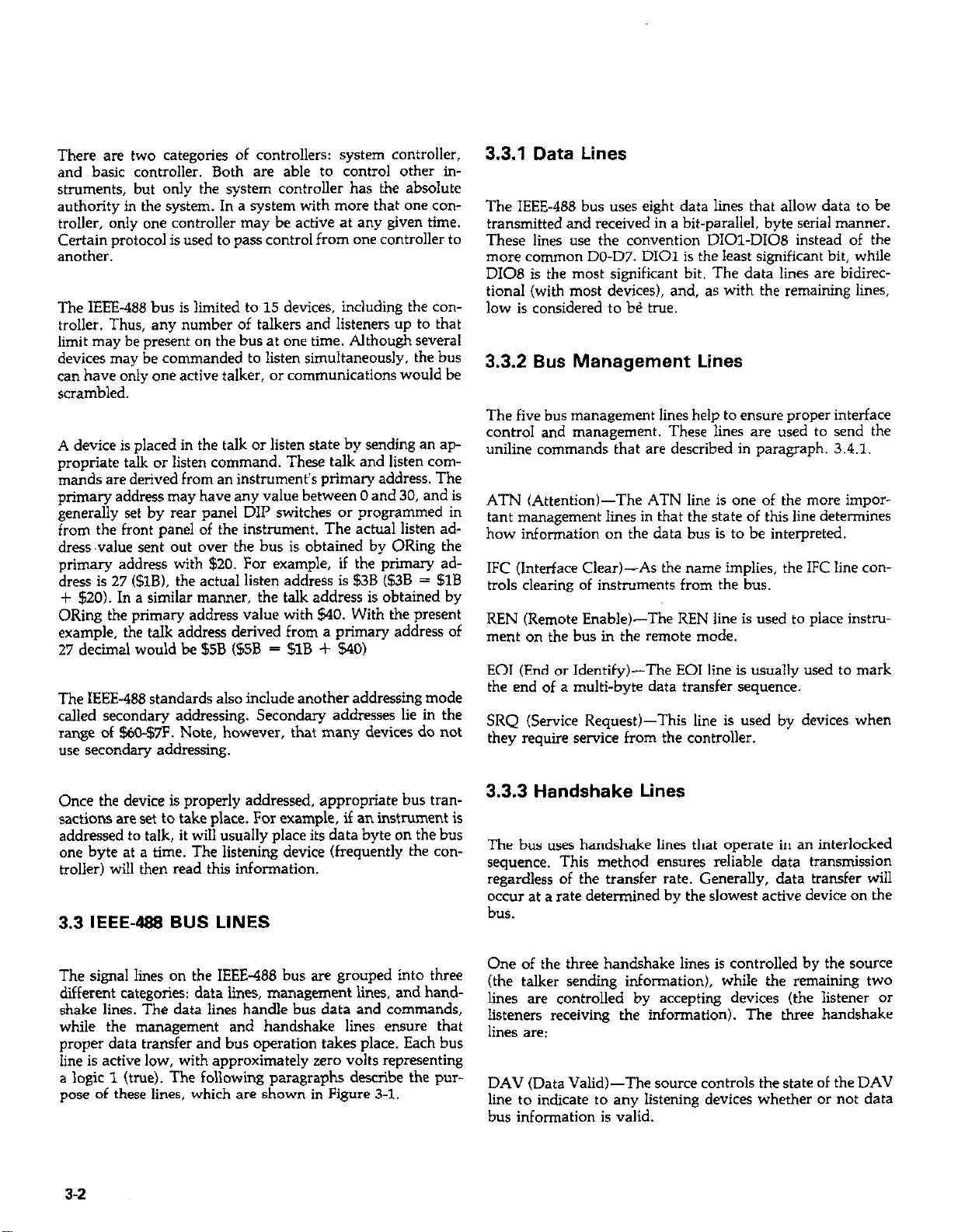

IEEE-488BUSLINES ..........................................................................

DataLines..

BusManagementLines ...........................................

HandshakeLines

BusCommands ...............................................................................

UniIineCommands

UniversalCommands ........................................................................

AddressedCommands .......................................................................

Unaddressedcommands .....................................................................

Device-DependentCommands

CommandCodes.. ...........................................................................

CommandSequences ..........................................................................

AddressedCommandSequence

UniversalCommandSequence

Device-DependentCommandSequence

Hardwareconsiderations.. ....................................................................

Typical Controlled Systems. ..................................................................

BusConnections ............................................................................

PrimaryAddressProgramming ...............................................................

Talk-OnlyMode

Softwareconsiderations

Controller Handler Software,

Interface BASIC Programming Statements

Interface Function Codes

IEEECommandGroups

General Bus Command Programming

REN(RemoteEnable) .......................................................................

IFC(InterfaceClear)

LLO(LocalLockout) .......................................................

GTL(GoToLocaI)

DCL(DeviceClear) ........................................................................

SDC (Selective Device Clear)

GET(GroupExecuteTrigger). ...............................................................

Serial Polling (WE, SPD)

Device-Dependent Command Programming

.................................................................................

...............................................................................

...............................................................................

............................................................................

..........................................................................

................................................................

...............................................................

................................................................

.........................................................

.

.....................

......................................................................

................................................................

.....

.....................................................................

........................................................................

.........................................................................

......................................

............................................

............................................... :

................................................................

.....................

................................................... 3-10

............................. ..........

........................ 3-2

..r

.

..............

............................. 3-16

.._ .............. 3-9

...............

...........

.............

.._

.............

3-l

3-l

3-2

3-2

3-2

3-3

3-3

3-4

3-4

3-5

3-5

3-5

3-5

3-5

3-7

3-7

3-7

3-7

3-8

3-9

3-10

3-10

3-12

3-12

3-12

3-13

3-14

3-14

3-14

3-15

3-15

3-16

3-17

ii

Page 7

3.10.1

3.10.2

3.10.3

3.10.4

3.10.5

3.10.6

3.10.7

3.10.8

3.10.9

3.10.10

3.10.11

3.10.12

3.10.13

3.10.14

3.10.15

3.10.16

3.10.17

3.10.18

3.11

3.11.1

3.11.2

3.11.3

3.12

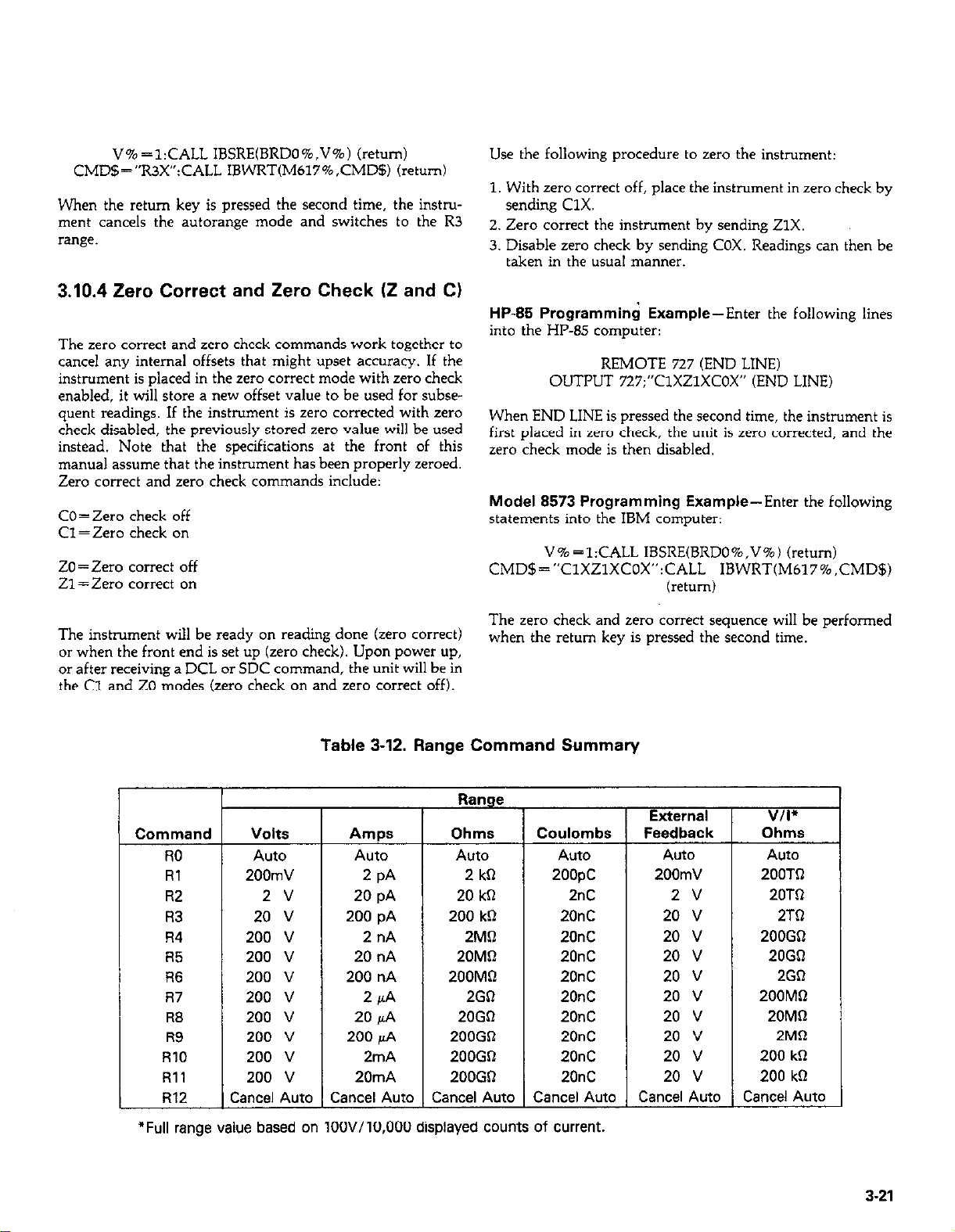

Execute(X) ...... .................

Function (F) ........................

Range(R)

Zero Correct and Zero Check (Z and C)

Baseline Suppression (N) .............

Display Mode CD).

Reading Mode (B) ............ ......

Data Store Mode ...................

Voltage Source Value (V) .............

Voltage Source Operate (0) ..........

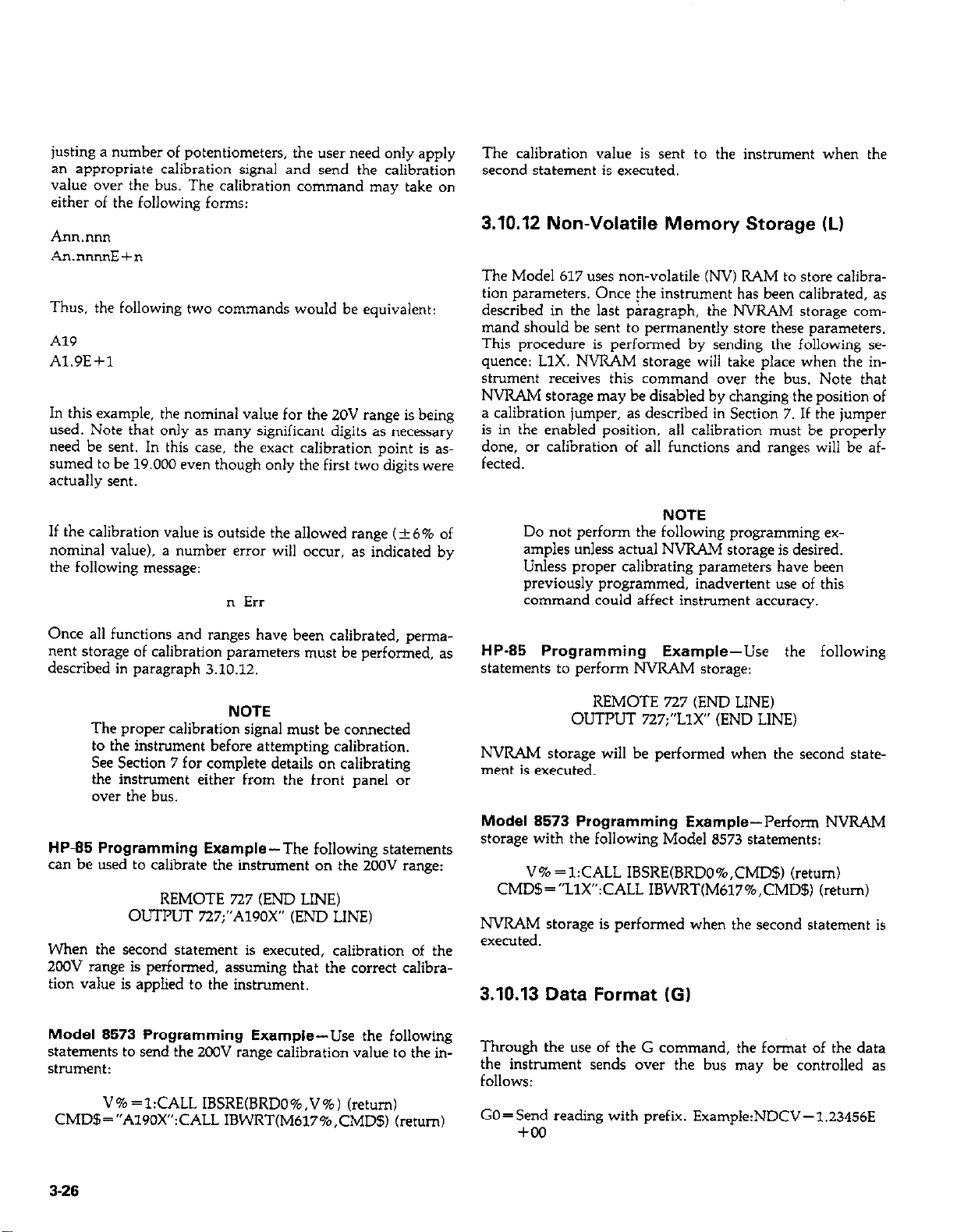

Calibration Value (A). ...............

Non-Volatile Memory Storage (L) .....

Data Format (G) ....................

Trigger Mode (T) ...................

SRQ Mode (M) and Status Byte Format

EOI and Bus Hold-Off Modes (K) ......

Terminator(Y) .....................

Status(u) .........................

Front Panel Messages ..................

BusError.. ........................

NumberError ......................

Trigger Overrun Error ...............

Bus Data Transmission Times ...........

..........................

..................

SECTION 4-APPLICATIONS

3-18

3-18

3-20

3-21

3-22

3-22

3-23

3-23

3-24

3-25

3-25

3-26

3-26

3-27

3-28

3-30

3-31

3-31

3-34

3-34

3-35

3-35

3-36

4.1

4.2

4.3

4.4

4.5

4.6

4.7

4.8

4.9

4.10

5.1

5.2

5.3

5.4

5.5

5.5.1

5.5.2

5.5.3

5.5.4

5.5.5

5.5.6

5.5.7

Introduction .................................................................

Insulation Resistance Measurements.

HighImpedanceVoItmeter

Low-Level Leakage Current Measurements

DiodeCharacterization

CapacitorLeakageMeasurements

CapacitanceMeasurement

Voltage Coefficients of High-Megohm Resistors

Static Charge Detection ........................................................

Using the Model 617 with External Voltage Sources

.....................................................

........................................................

......................................................

.............................................

........................................

...............................................

....................................

.................................

SECTION 5-PERFORMANCE VERIFICATION

Introduction ..............................

Environmental Conditions ..................

Initial Conditions ..........................

Recommended Test Equipment ...............

Verification Procedure ......................

Input Current Verification .................

Amps Verification .......................

Coulombs Verification. ...................

Volts Verification ........................

Ohms Verification .......................

Ohms Verification (200M0 and Gfl Ranges)

Voltage Source Verification. ...............

...........

...........

...........

...........

...........

...........

...........

...........

...........

...........

..........

..........

..........

..........

..........

..........

..........

..........

..............

..............

..............

..............

.............

..............

..............

..............

.............

.............

.............

.............

.............

.............

.............

.............

.............

4-l

4-l

4-5

4-5

4-7

4-8

4-E

4-10

4-12

4-12

5-l

5-l

5-l

5-l

5-2

5-2

5-2

5-3

5-5

5-6

5-6

5-8

iii

Page 8

SECTION 6-THEORY OF OPERATION

6.1

6.2

6.3

6.3.1

6.3.2

6.3.3

6.3.4

6.3.5

6.4

6.4.1

6.4.2

6.4.3

6.5

6.6

6.6.1

6.6.2

6.6.3

6.6.4

6.6.5

6.6.6

6.7

6.6

7.1

7.2

7.3

7.3.1

7.3.2

7.4

7.4.1

7.4.2

7.4.3

7.4.4

7.4.5

7.4.6

7.4.7

7.4.8

7.4.9

7.4.10

7.4.11

7.4.12

7.4.13

7.4.14

7.4.15

7.4.16

7.5

7.6

7.7

7.7.1

7.7.2

7.7.3

7.7.4

7.7.5

7.7.6

Introduction

Overall Functional Description

Input Preamplifier

Input stage ......................

Gain Stage. ......................

Output stage. ....................

Ohms Voltage Source

Zero Check ......................

Additional Signal Conditioning

Ranging Amplifier ................

Multiplexer and Buffer Amplifier ....

- 2V Reference Source. ............

A/D Converter.

Digital Circuitry

Microcomputer. ..................

Memory Elements. ................

Device Selection ..................

IEEE-486 Bus .....................

Input/Output Circuitry ............

Display Circuitry .................

Voltage source

Power Supplies

.......................

........

..................

....................

....................

.....................

.....................

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

SECTION 7-MAINTENANCE

Introduction..

LineVoltageSelection

FuseReplacement

Lim Fuse .................................................................................

COMFuse ................................................................................

Calibration

Recommended Calibration Equipment. ........................................................

EnvironmentalConditions ..................................................................

WarmUpPeriod ..........................................................................

CalibrationJumper

Front Panel Calibration .....................................................................

IEEE-488 Bus Calibration. ...................................................................

Calibration Sequence .......................................................................

InputOffsetAdjustment ....................................................................

InputCurrentAdjustment ...................................................................

Pemxnent Storage of Calibration Parameters

AmpsCalibration.. .......................................................................

Coulombs Calibration ...................................................................

VoltsCalibration.. ........................................................................

OhmsCalibration .........................................................................

Voltage Source Calibration ..................................................................

Additional Calibration Points ................................................................

Special Handling of Static-Sensitive Devices

Disassembly Instructions

Troubleshooting

RecommendedTestEquipment ...............................................................

PowerUpSelfTest .........................................................................

SelfDiagnosticProgram ....................................................................

PowerSupplyChecks ......................................................................

RelayConfiguration ........................................................................

Ranging Amplifier Gain Configuration ........................................................

..............................................................................

........................................................................

............................................................................

.................................................................................

.........................................................................

...................................................

......................................................

......................................................................

.............................................................................

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

6-l

6-1

6-l

6-3

6-3

6-3

6-6

6-7

6-7

6-7

6-8

6-9

6-9

6-11

6-11

6-11

6-u

6-11

6-12

6-12

6-13

6-14

7-l

7-1

7-2

7-Z

7-2

7-2

7-2

7-3

7-3

7-3

7-3

7-4

7-5

7-5

7-s

7-6

7-4

7-7

7-8

7-a

7-10

7-10

7-U

7-12

7-12

7-12

7-14

7-14

7-14

7-15

7-15

iv

Page 9

7.7.7

7.7.8

7.7.9

7.7.10

7.7.11

7.8

7.9

A/DConverterandDisplay .................................

Input and Ranging Amplifiers

DigitalCircuitry.. .................................................

Display Board

VoltageSource ..............................................................

InputStageBalancingProcedure

Handling and Cleaning Precautions

...........................................

.............................................

................................................................

..........................................

SECTION 8--REPLACEABLE PARTS

........

..... ..

............

..... .. .........

.,

......................

.....

...

... 7-16

.....

... 7.17

.....

...

7.17

7-17

7-17

7-17

7-18

8.1

8.2

a.3

a.4

a.5

8.6

Introduction ......................................

Electrical Parts Lists

Mechanical Parts

Ordering Information

Factory Service..

Component Layout Drawings and Schematic Diagrams

................................

..................................

..............................

.................................

......

......

......

......

8-l

8-l

8-l

8-l

8-l

8-l

Page 10

LIST OF ILLUSTRATIONS

2-l

2-2

2-3

2-4

2-5

2-6

2-7

2-a

2-9

2-10

2-11

Z-12

2-13

2-14

2-15

2-16

2-17

2-18

2-19

2-20

2-21

2-22

2-23

2-24

2-25

2-26

2-27

2-28

2-29

Model617FrontPanel..........................................

Model617RearPanel

Input Connector Configuration

Connections For Voltage Measurements

Meter Loading Considerations

Unguarded Circuit

GuardedCircuit

Guarded Input Connections

CurrentMeasurements

Voltage Burden Considerations.

Coulombs Connections

Resistance Measurement Connections

Voltage Source Connections

V/l Resistance Measurement Connections

Typical 2V Analog Output Connections

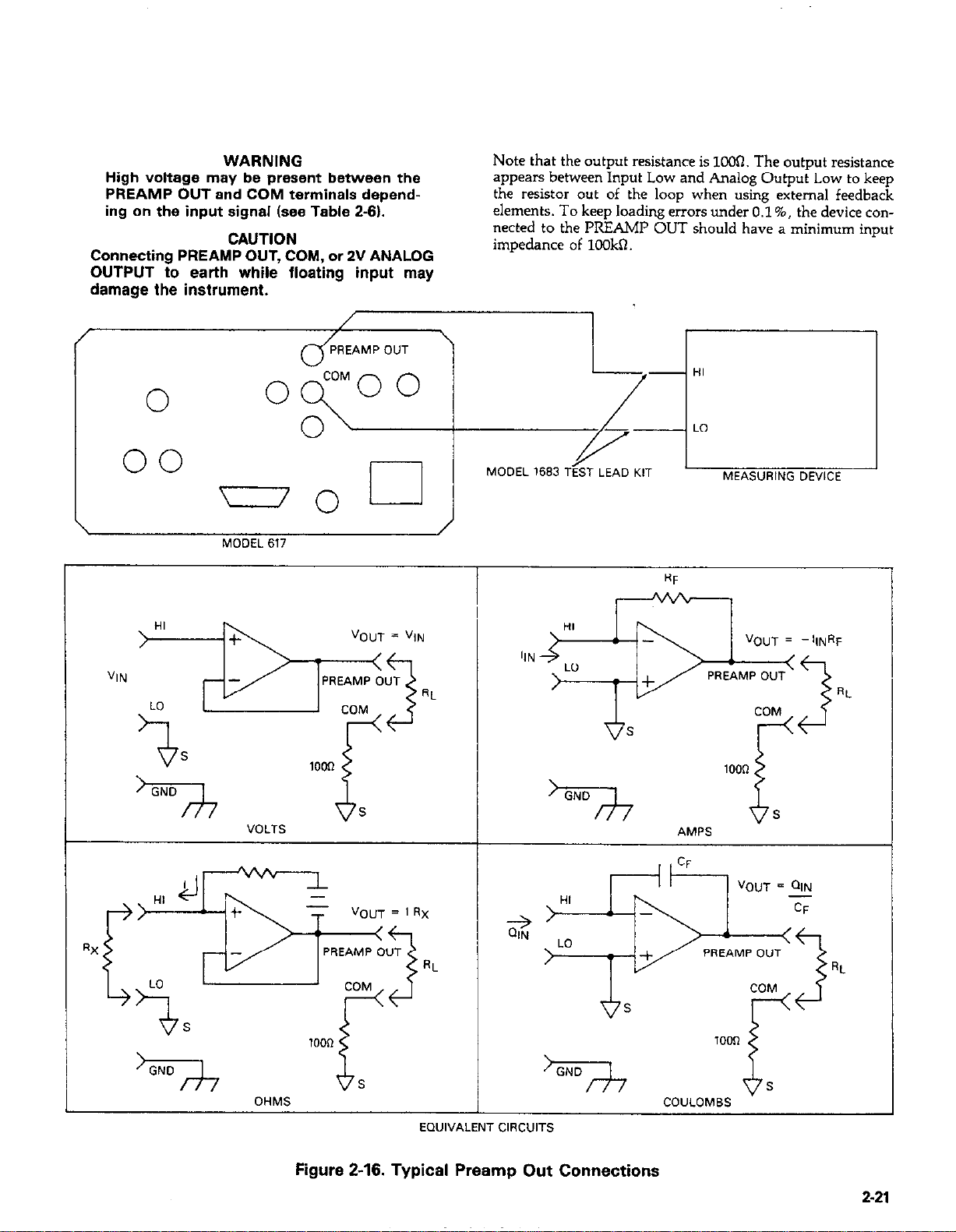

Typical Preamp Out Connections.

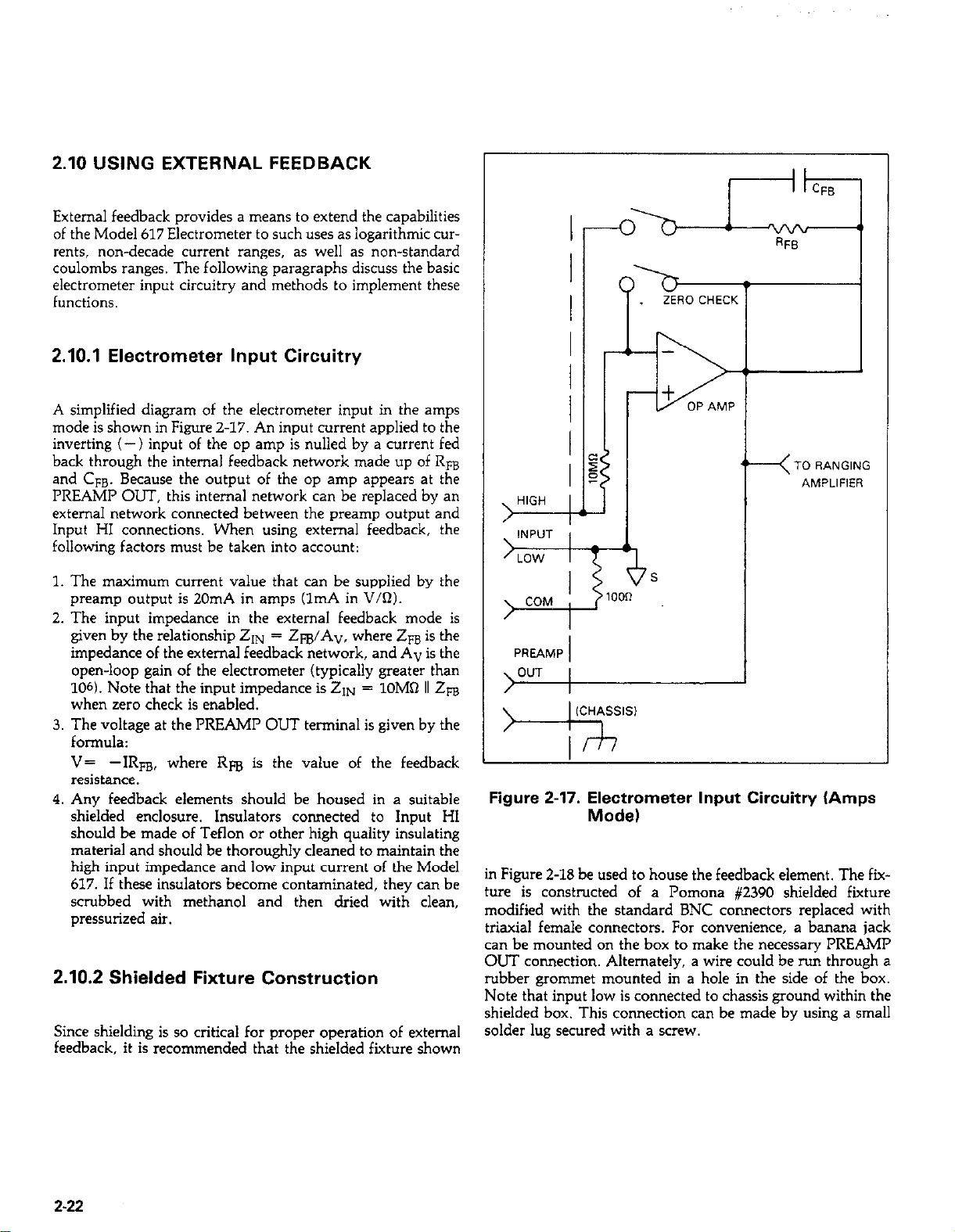

Electrometer Input Circuitry (AmpsMode)

Shielded Fixture Construction

“Transdiode” Logarithmic Current Configuration

Non-Decade Current Gains

Equivalent Input Impedance with Zero Check Enabled.

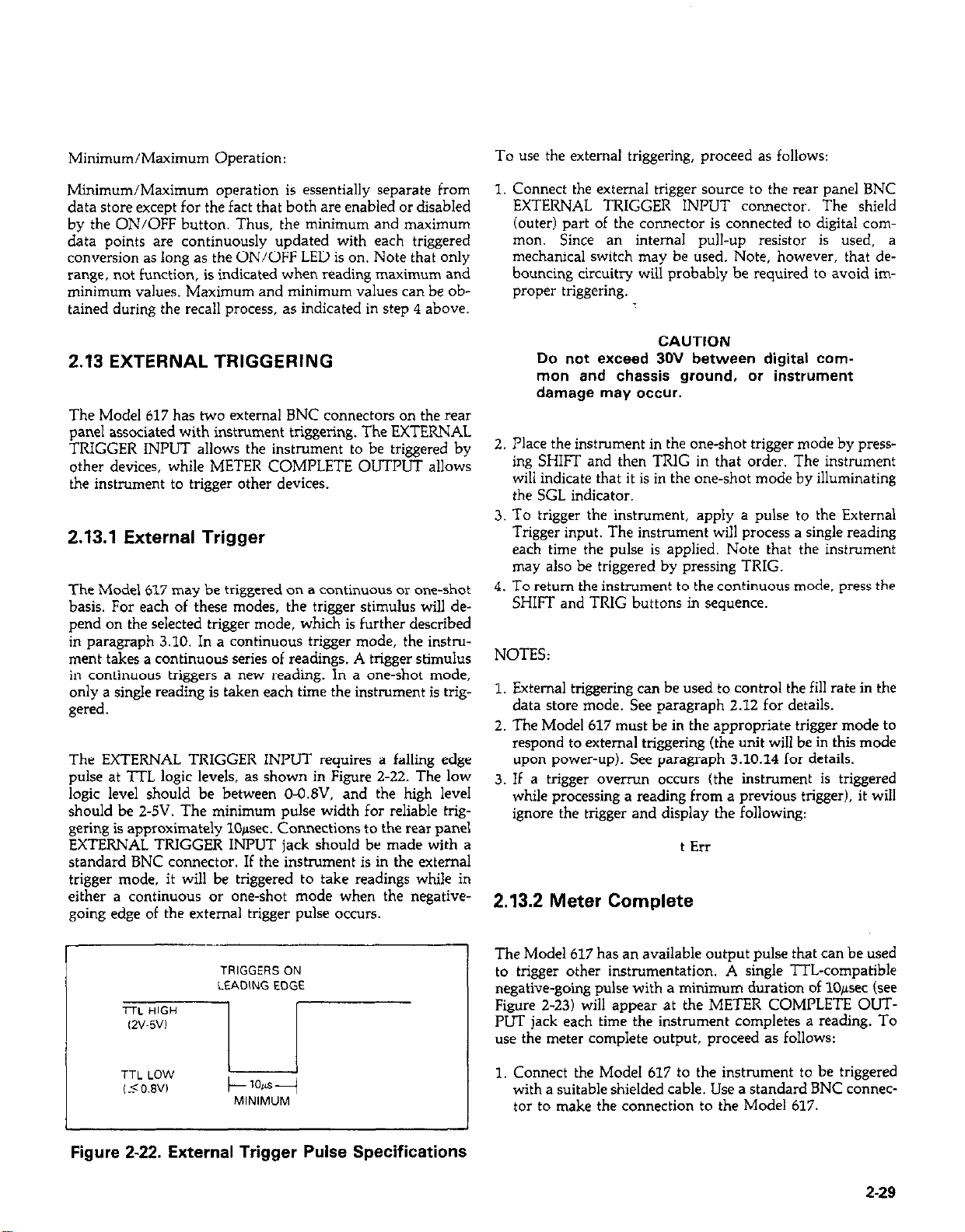

External Trigger Pulse Specifications

Meter Complete Pulse Specifications

Exlemal Triggering Example

Multiple Ground Points Create Ground Loop

Eliminating Ground Loops

Leakage Resistance Effects

Input Capacitance Effects.

Simplified Model of Source Resistance and Source Capacitance Effects

..........................................

..................................

...........................

.................................

...........................................

...............................................

.....................................

..........................................

..................................

.........................................

.............................

.....................................

..........................

...........................

................................

............... .........

....................................

...................

......................................

...............

..............................

..............................

.....................................

......................

......................................

.......................................

.......................................

^.

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

..........

2-2

2-7

2-8

2-9

2-10

2-13

2-13

2-14

2-16

2-17

2-18

2-31

2-33

2-34

2-34

3-l IEEE Bus Configuration

3-2

3-3

3-4

3-5

3-6

3-7 617 Rear Panel IEEE Connector.

3-B Contact Assignments

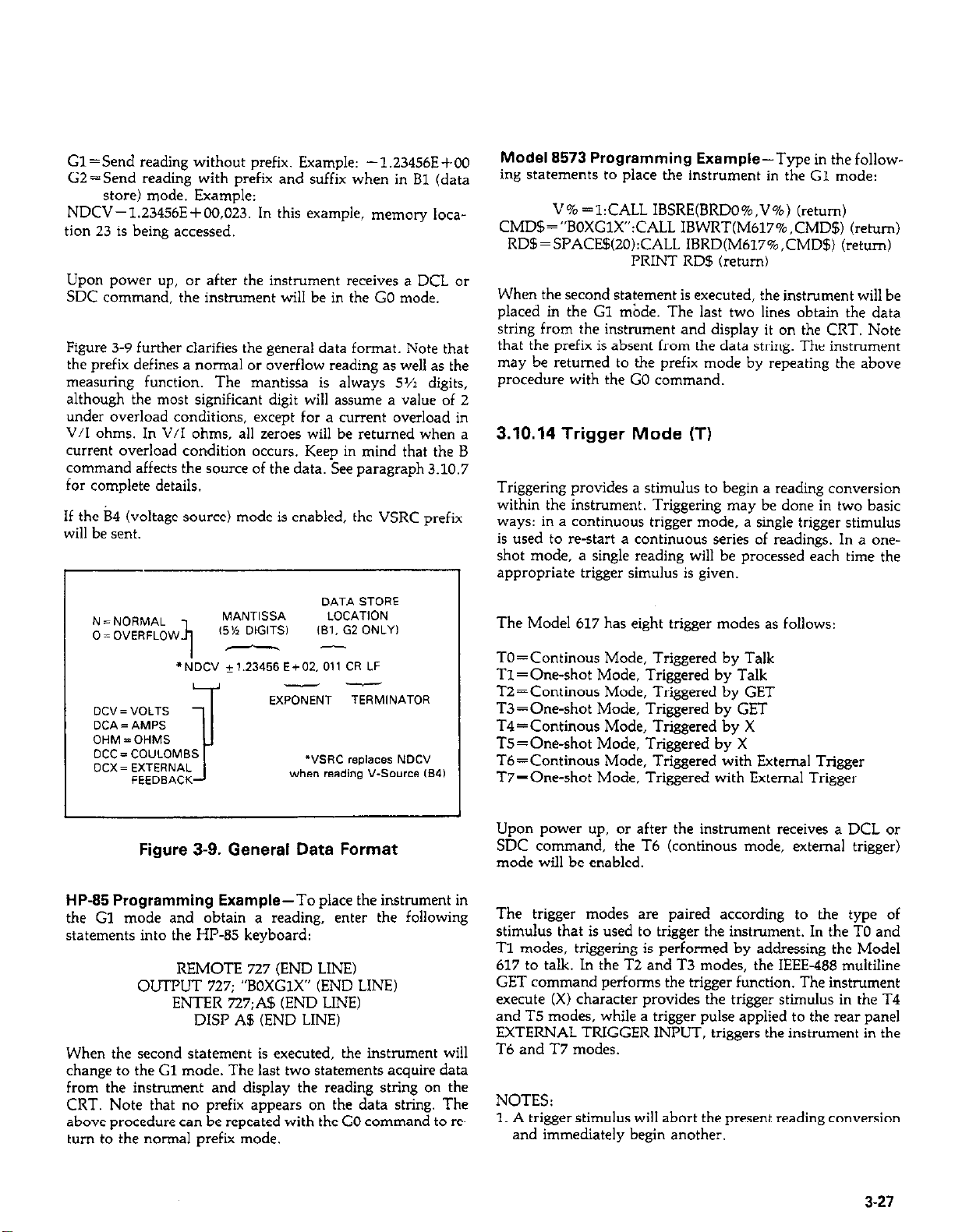

3-9 General Data Format

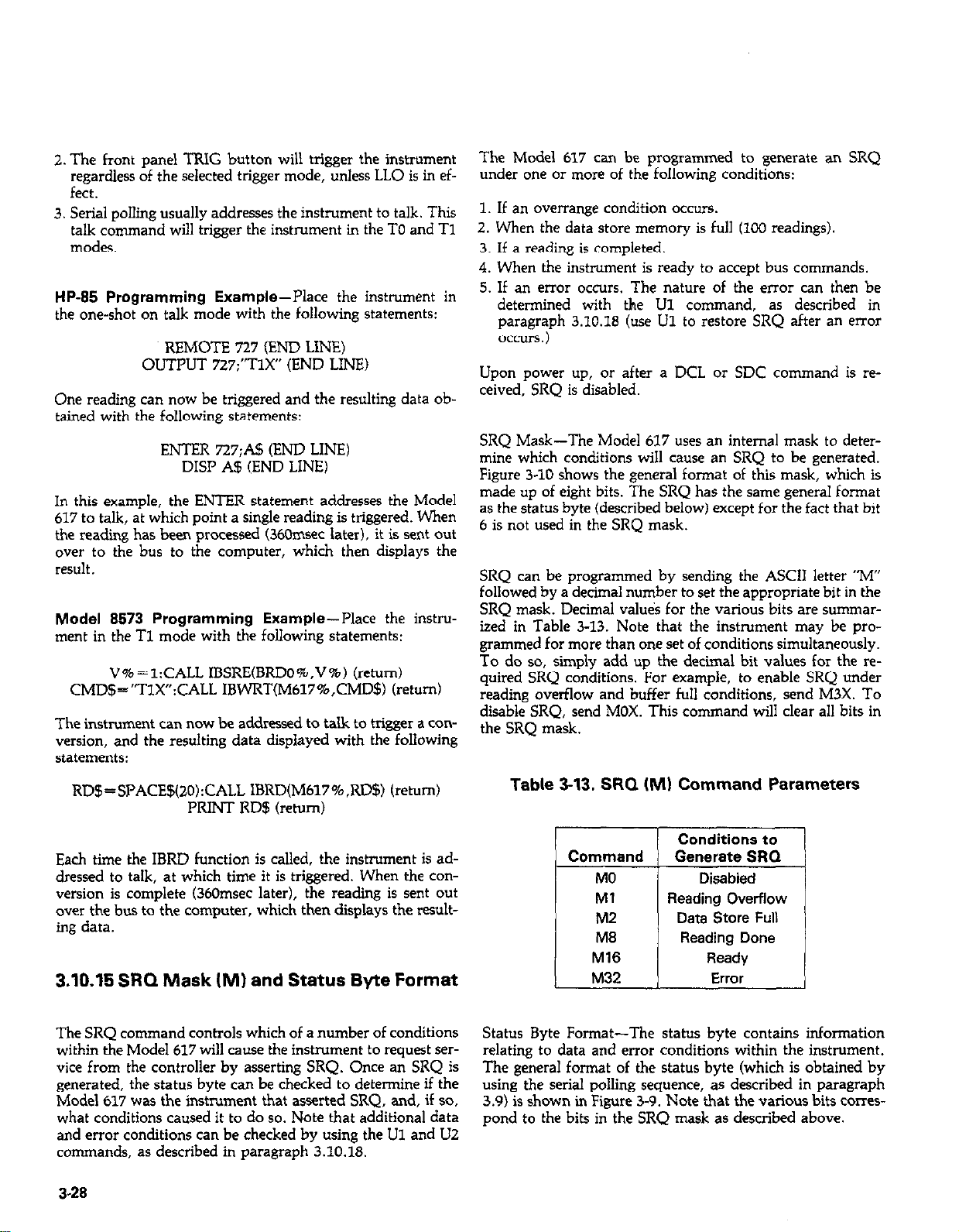

3-10 SRQ Mask and Status Byte Format.

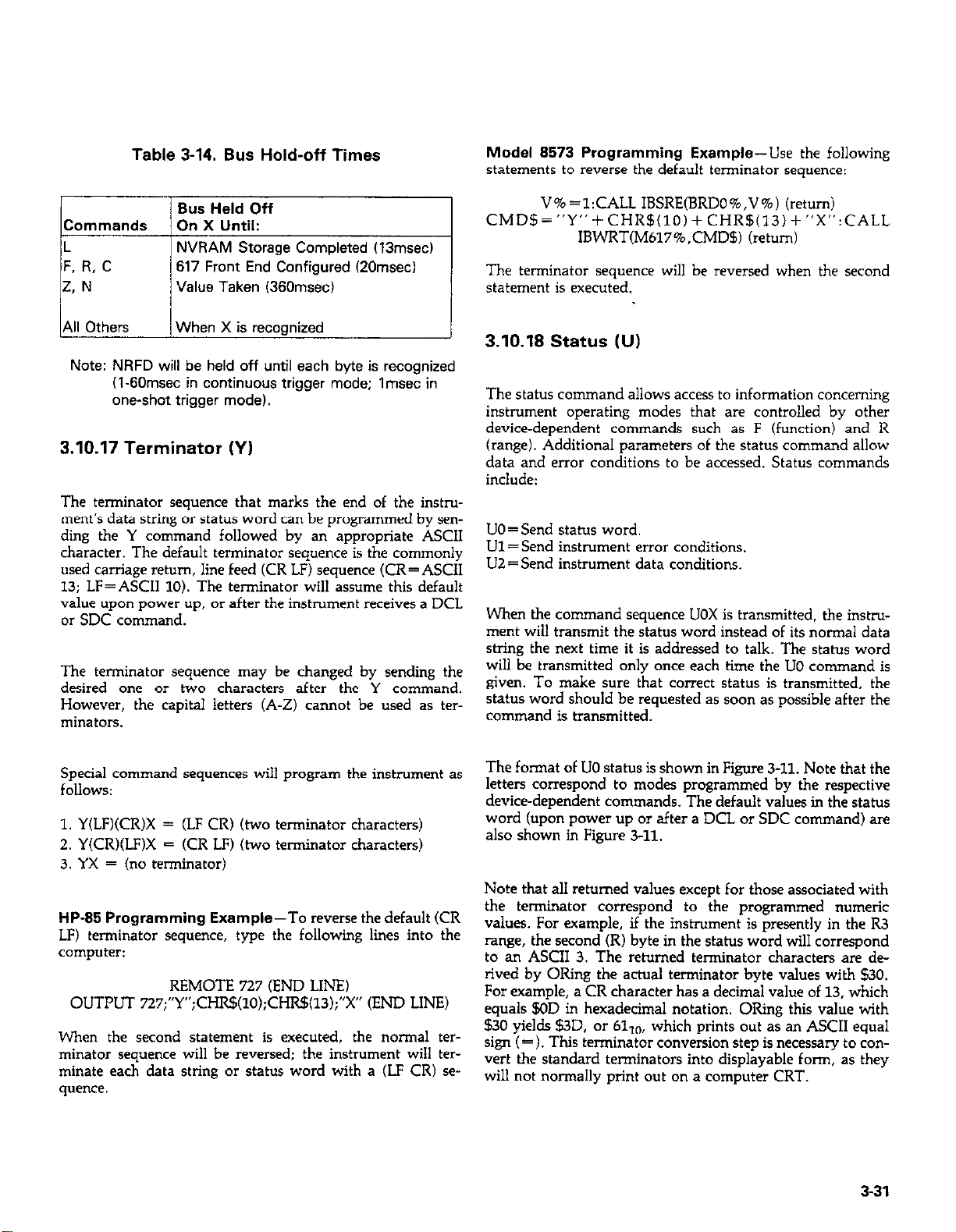

3-11 UO Status Word and Default Values.

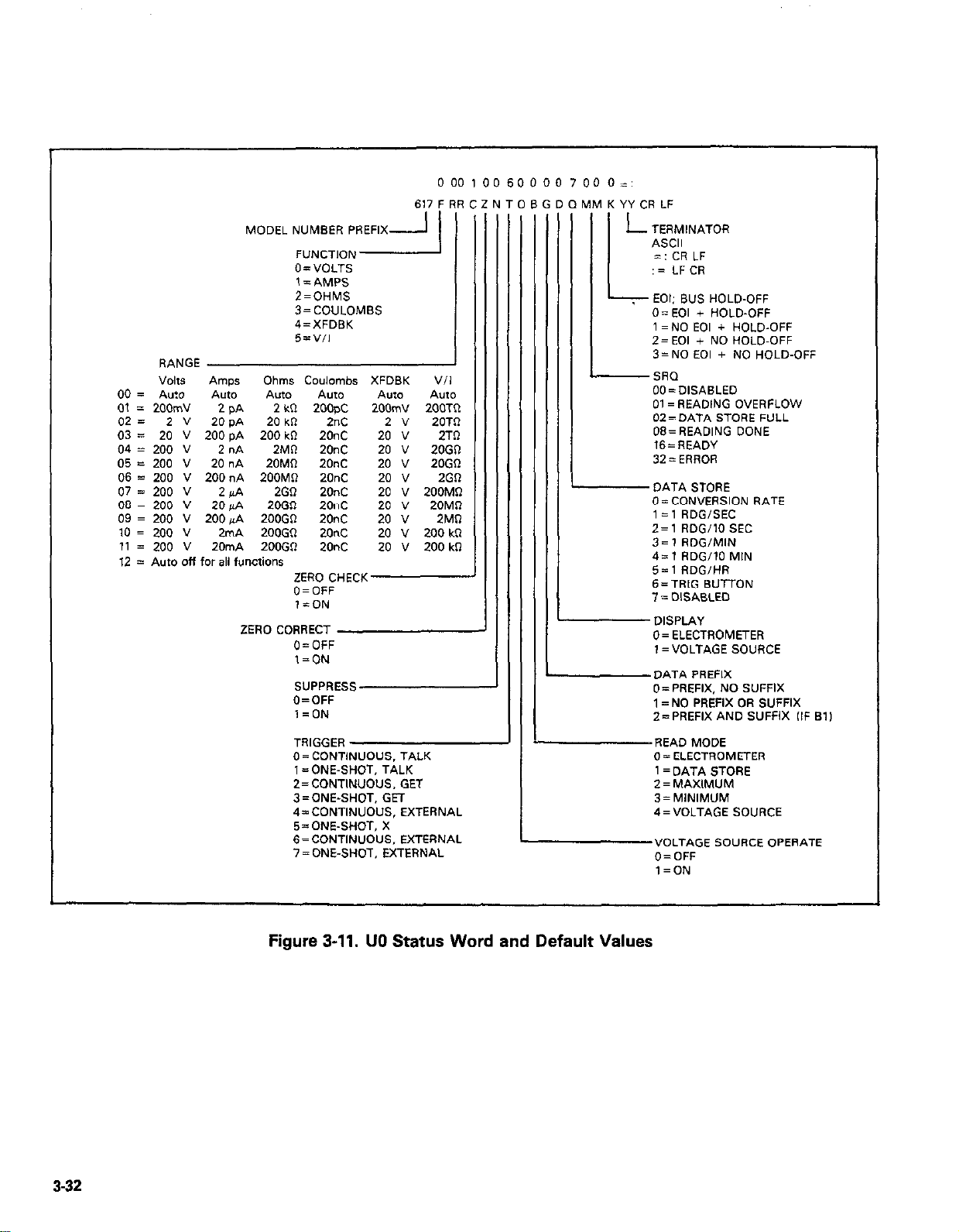

3-12

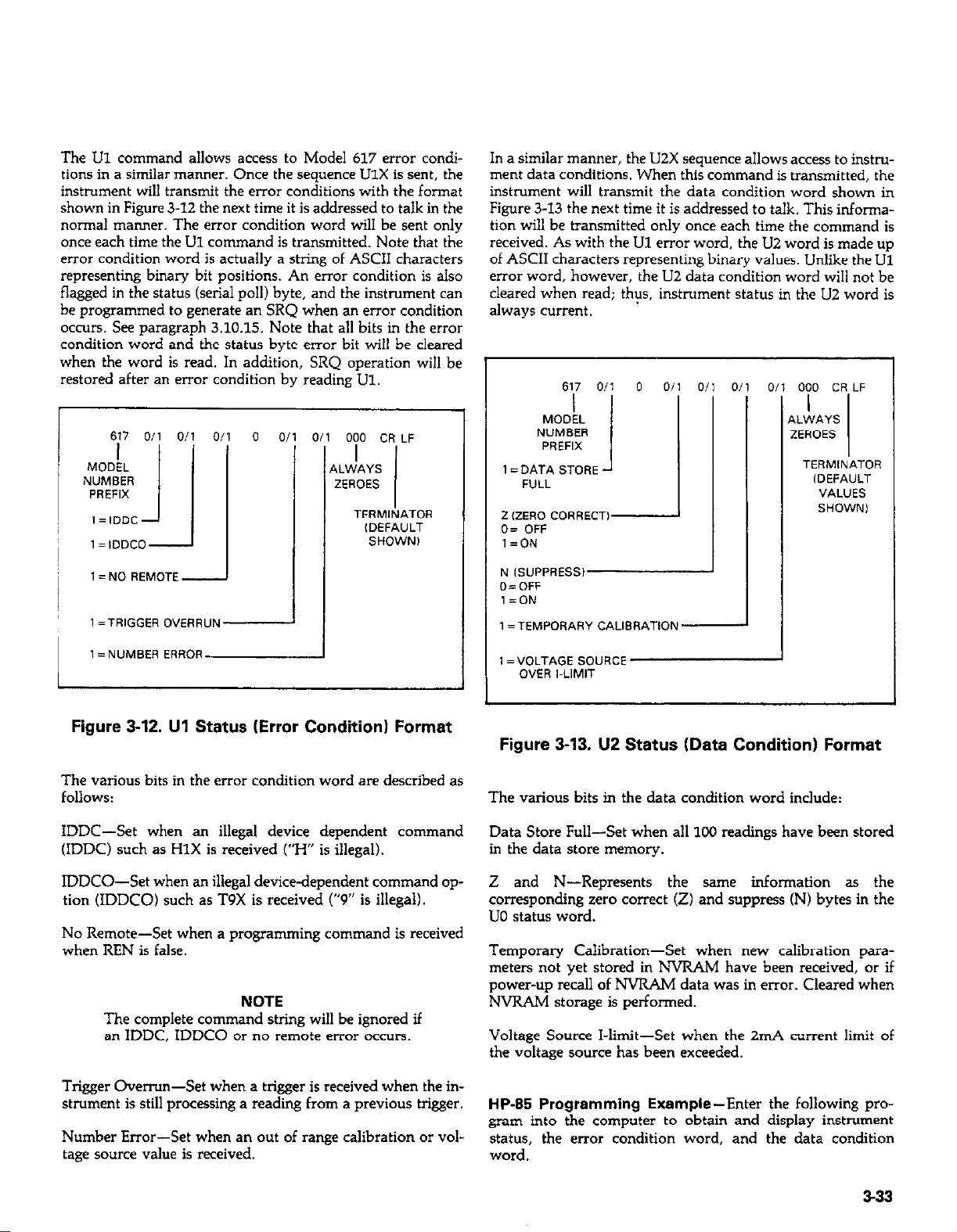

3-13 U2 Status (Data Condition) Format

vi

IEEE Handshake Sequence.

Commands Groups

System Types

IEEE-488 Connector

IEEE-488 Connections

Ul Status (Error Condition) Format

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

.......

Page 11

4-l

4-2

4-3

4-4

4-5

4-6

4-7

4-8

4-9

4-10

4-11

4-12

Insulation Resistance Measurement (Ungaurded)

..........

Insulation Resistance Measurement (Guarded) ............

Insuiation Resistance Measurement Using V/I Ohms Mode.

Measuring High Impedance Gate-Source Voltage ..........

Leakage Current Measurement .........................

Diode Characterization ...............................

DiodeCurves.. .....................................

Capacitor Leakage Tests

..............................

Capacitor Measurement. ..............................

Configuration for Voltage Coefficient Studies ...........

Farady Cup Construction .............................

Using the Model 617 with an External High Voltage Source

......

......

......

......

......

......

5-l

5-2

5-3

5-4

5-5

5-6

5-7

5-8

5-9

6-l

6-2

6-3

b-4

b-5

6-b

6-7

6-8

6-9

6-10

6-11

6-12

b-13

b-14

b-15

6-16

Test Fixture Construction

.....................................

Connections for Amps Verification (200nA-2mA Ranges) ...........

Connections for Amps Verification (2pA-20nA Ranges) ............

Connections for Coulombs Verification ..........................

Connections for Volts Verification

..............................

Connections for Ohms Verification (2kQ-20MQ Ranges) ............

Connections for Ohms Verification (200MR. 2G0 and 20Gfl Ranges).

Input Impedance Verification ..................................

Connections for Voltage Source Verification ......................

Overall Block Diagram ............................

Basic Configuration Electrometer Preamplifier

.........

Electrometer Preamplifier Configuration ..............

Simplified Schematic of Input Stage

..................

GainStage .......................................

Output Stage Configuration (Volts and Ohms) .........

Output Stage Configuration (Amps and Coulombs)

.....

Ohms Voltage Source Simplified Schematic ...........

Zero Check Configuration (Volts and Ohms) ..........

Zero Check Configuration (Amps and Coulombs) ......

Simplified Schematic of Ranging Amplifier ............

Multiplexer and Buffer

.............................

Multiplexer Phases ...............................

-2V Reference Source.

............................

A/D Converter. ..................................

Simplified Schematic of Voltage Source Output Stage ...

..........

..........

..........

.., ..,

...................

...................

6-2

6-3

b-4

b-5

6-5

6-5

6-b

b-6

b-7

6-7

b-8

6-8

6-9

6-9

b-10

6-13

7-l

7-2

7-3

7-4

7-5

7-6

7-7

7-8

7-9

7-10

7-11

Test Fixture Construction .......................................

Calibration Jumper Location .....................................

Input Offset Adjustment Locations.

...............................

Connections for Amps Calibration (20pA Range) ....................

Connections for Amps Calibration (20nA. 20/rA and 20mA Ranges)

Connections for Coulombs Calibration ............................

Connections for Volts Calibration ................................

Connections for Ohms Calibration (20GQ and 2OOMO Ranges) .........

Connections for Ohms Calibration (2Ok%ZOMQ)

Connections for Voltage Source Calibration

....................

.....................

Model617ExplodedView .......................................

......

......

......

......

......

......

......

......

......

7-l

7-3

7-5

7-6

7-7

7-a

7-8

7-9

7-10

7-10

7-13

vii

Page 12

8-l Electrometer Board, Component Location Drawing.

g-2

8-3

Mother Board, Component Location Drawing

Display Board, Component Location Drawing

8-4 Electrometer Board, Schematic Diagram

8-5

Mother Board, Schematic Diagram.

8-6 Display Board, Schematic Diagram

................

................

.......

.......

............

..

8-11

g-13

8-17

8-19

8-21

8-27

. .

VW

Page 13

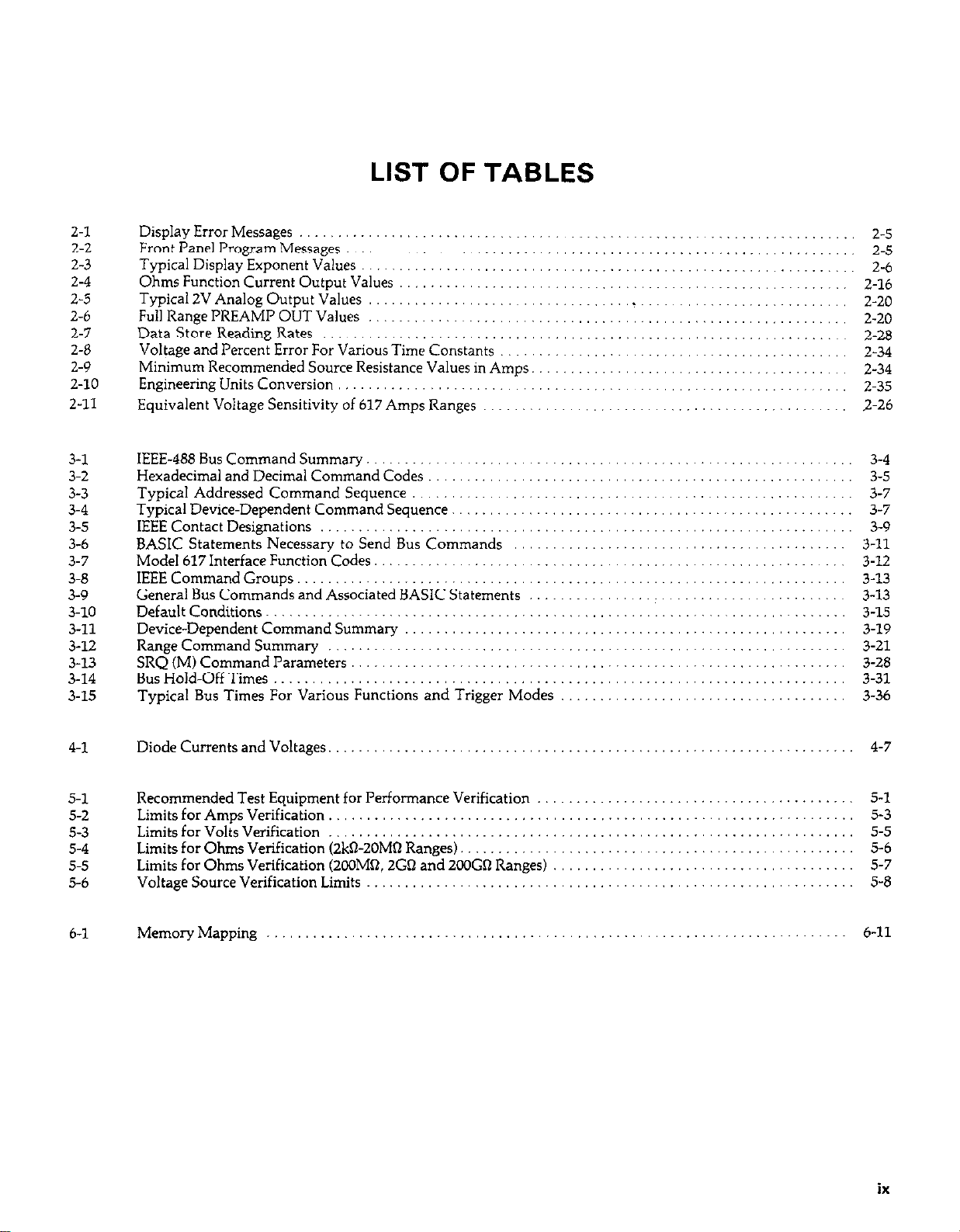

LIST OF TABLES

2-l

2-2

2-3

2-4

2-5

2-6

2-7

2-8

2-9

2-10

2-11

3-l

3-2

3-3

3-4

3-5

3-6

3-7

3-a

3-9

3-10

3-11

3-12

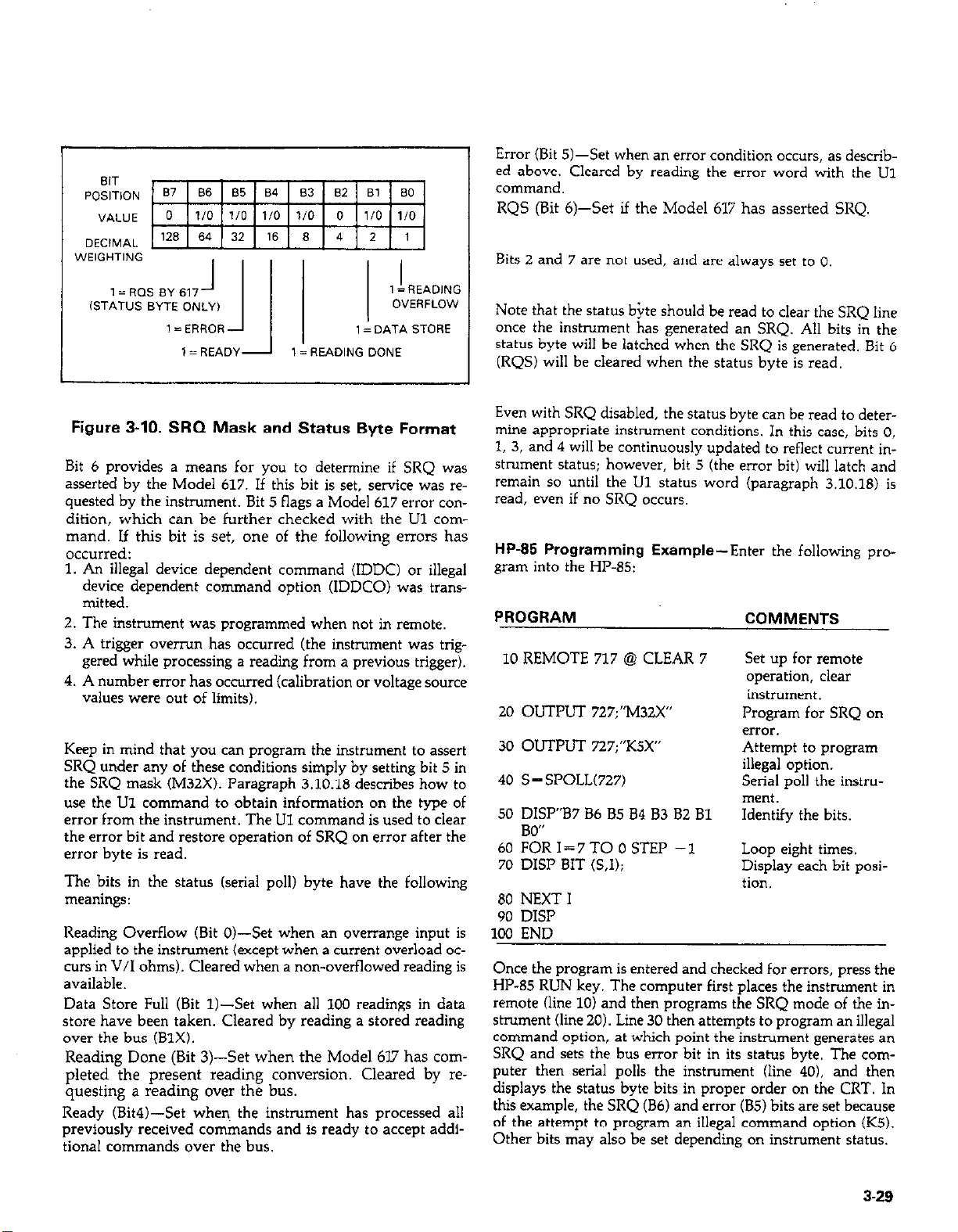

3-13

3-14

3-15

Display Error Messages .................................

Front Panel Program Messages

Typical Display Exponent Values ................

Ohms Function Current Output Values

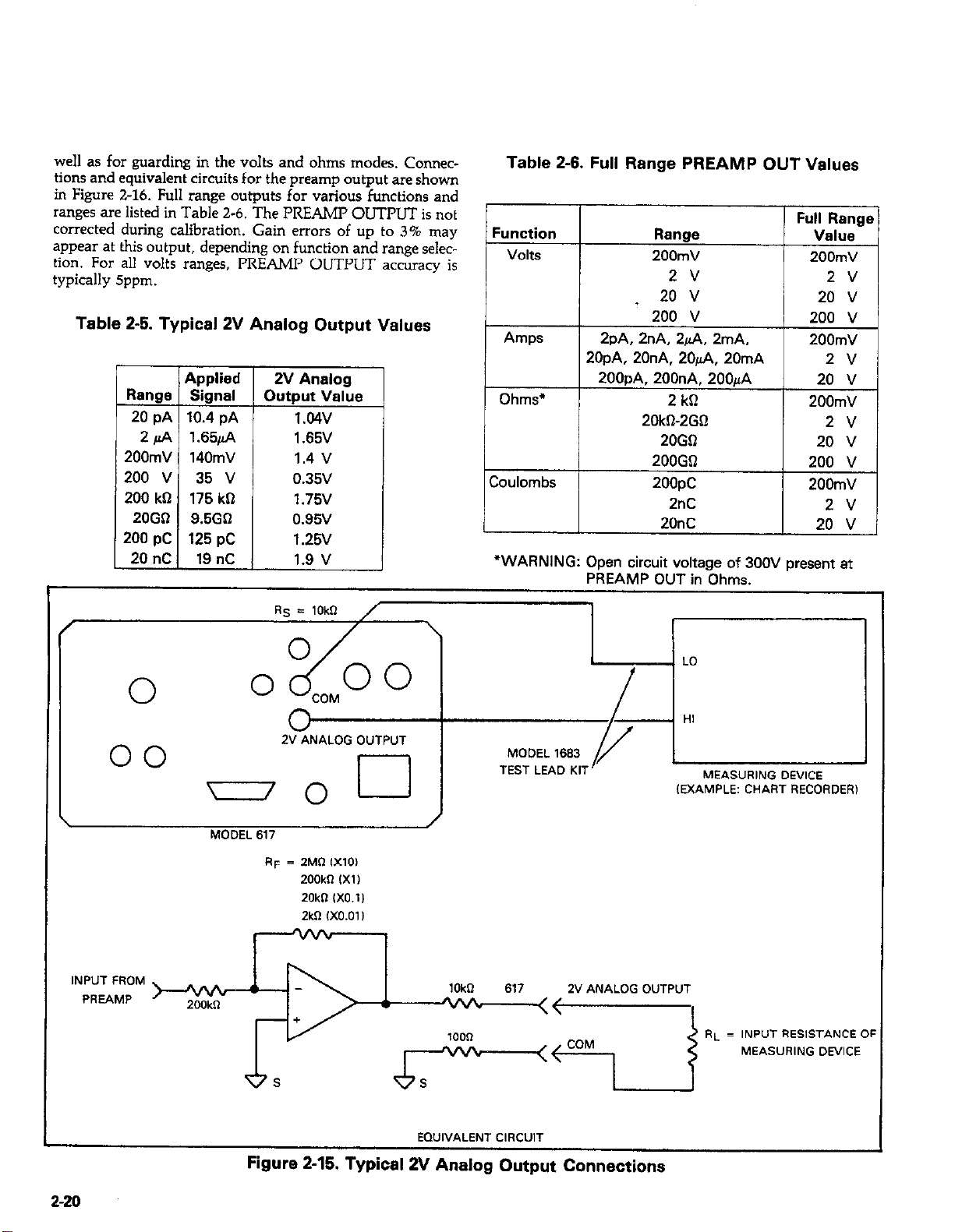

Typical 2V Analog Output Values ........................

Full Range PREAMP OUT V&es ......

Data Store Reading Rates ...........

Voltage and Percent Error For Various Time Constants

Minimum Recommended Source Resistance Values in Amps. ..

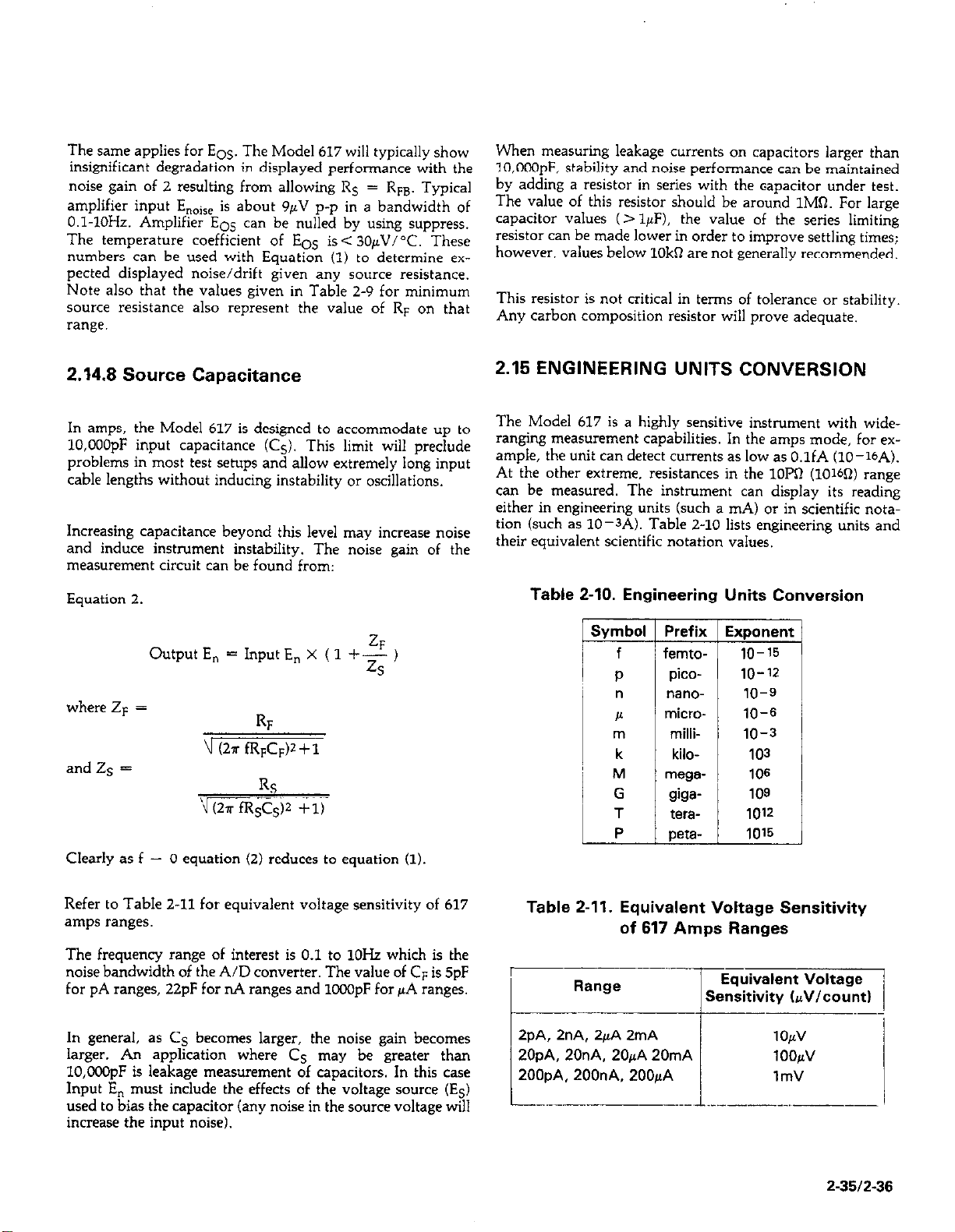

Engineering Units Conversion ..................

Equivalent Voltage Sensitivity of 617 Amps Ranges

IEEE-488 Bus Command Summary. .........................

Hexadecimal and Decimal Command Codes

Typical Addressed Command Sequence

Typical Device-Dependent Command Sequence.

IEEE Contact Designations ................................

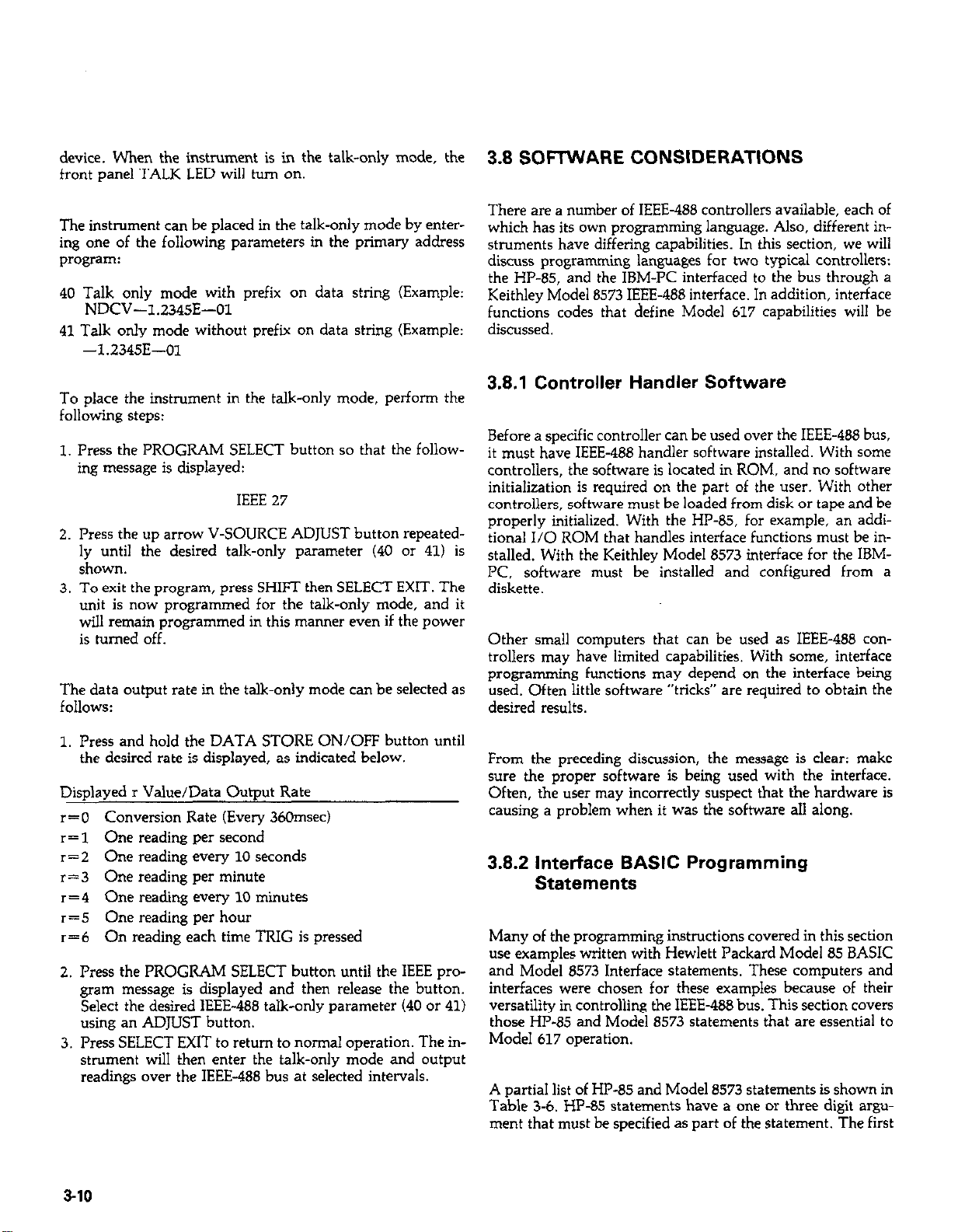

BASIC Statements Necessary to Send Bus Commands

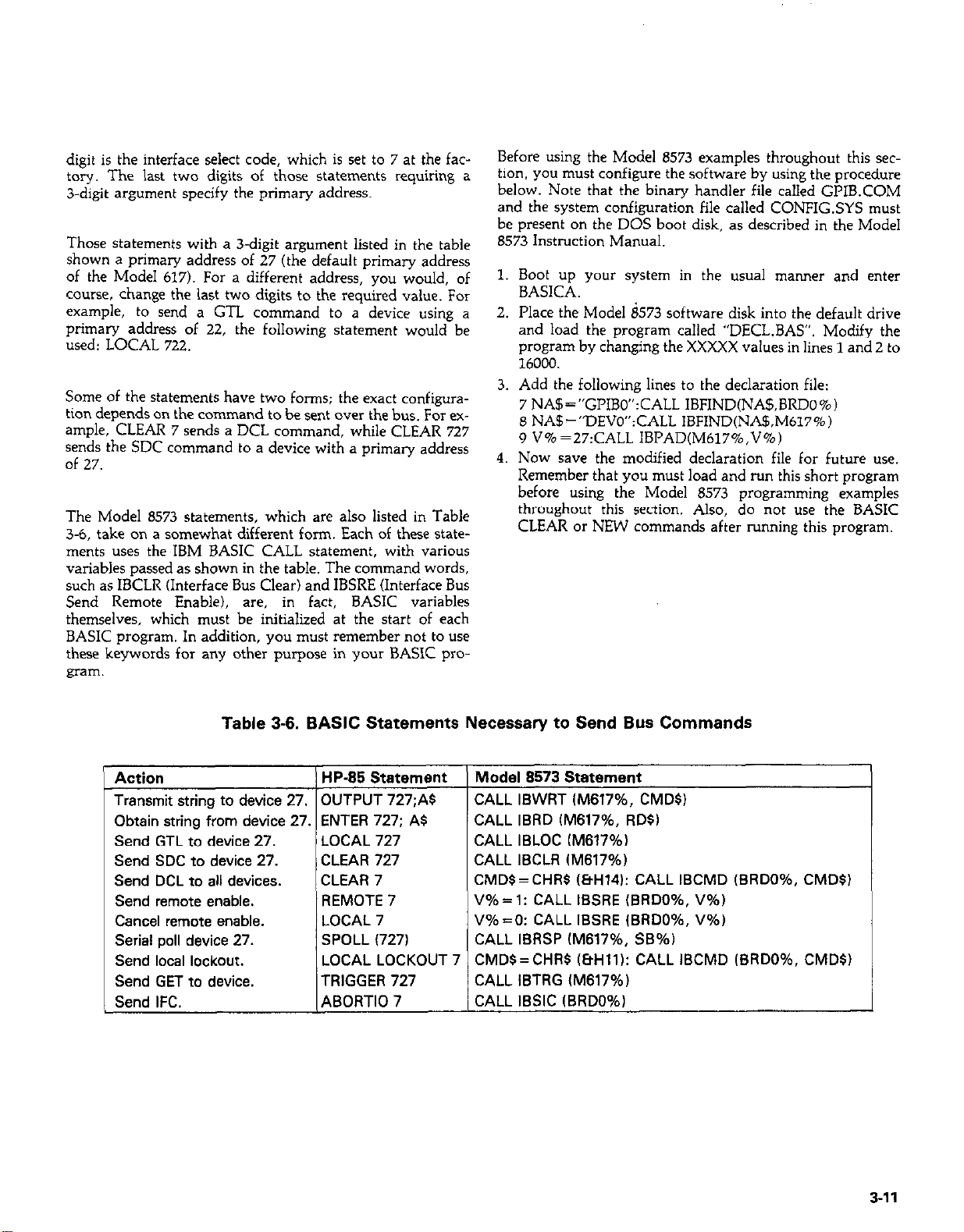

Model 617Interface Function Codes. ........................

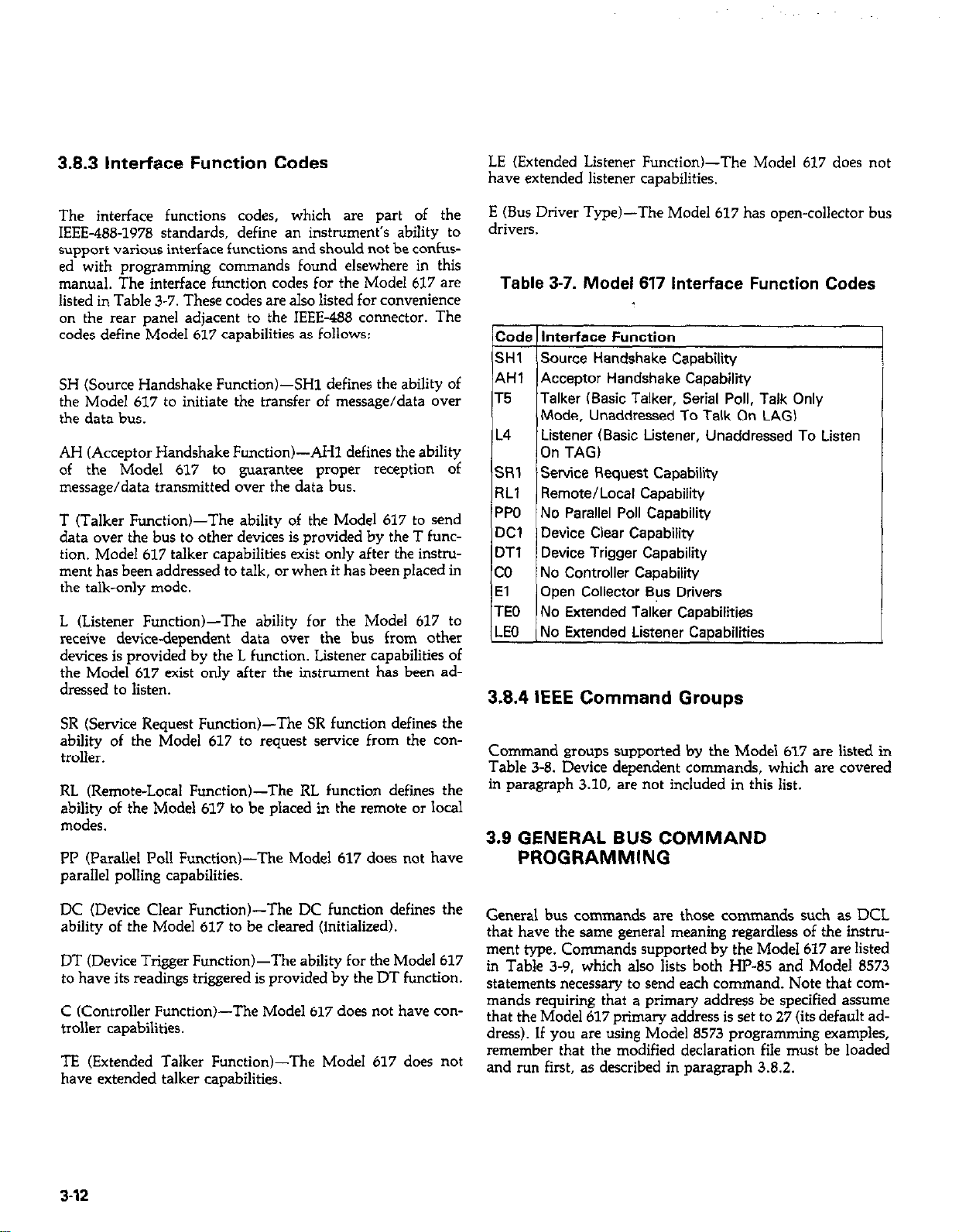

IEEE Command Groups.

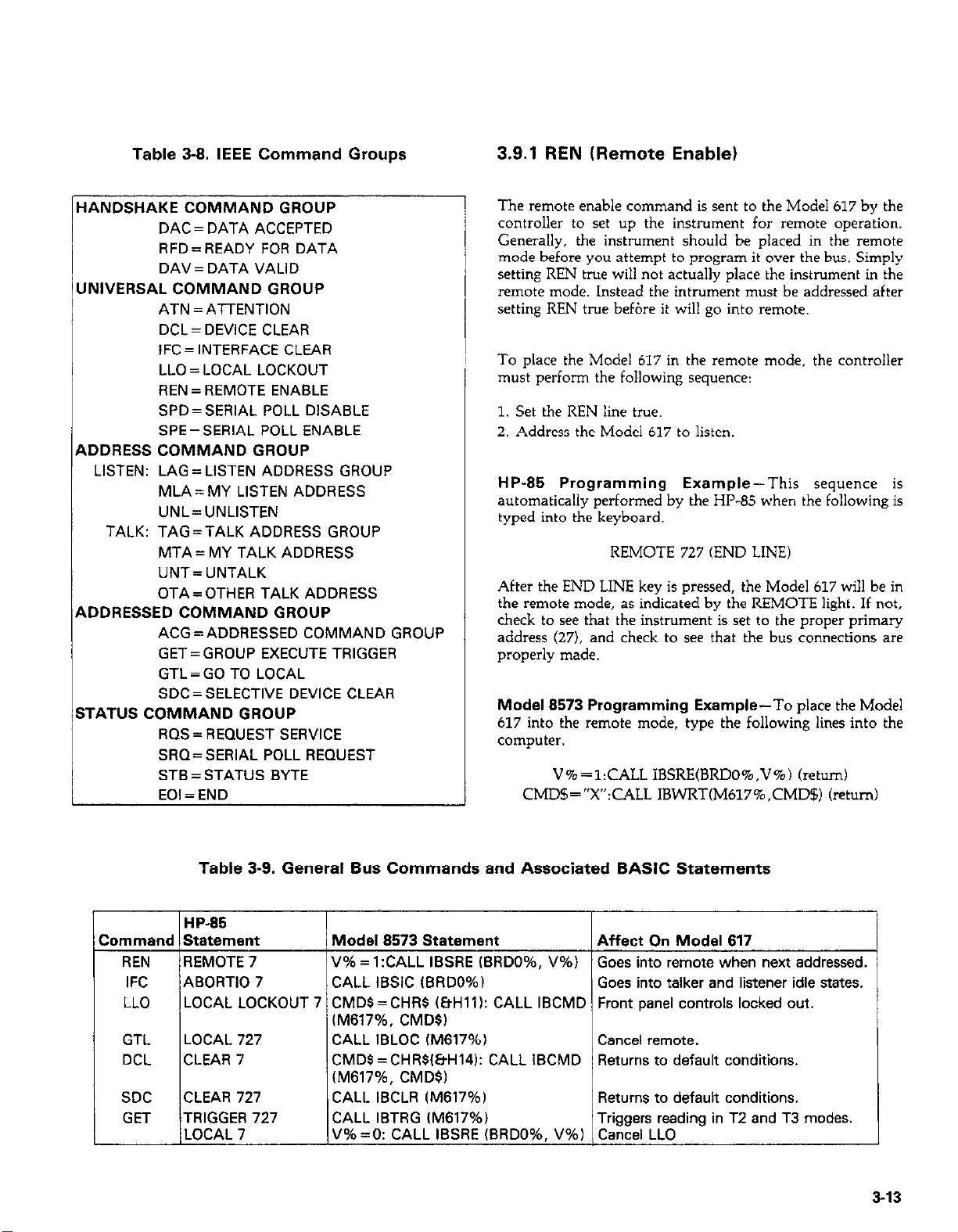

General Bus Commands and Associated BASIC Statements

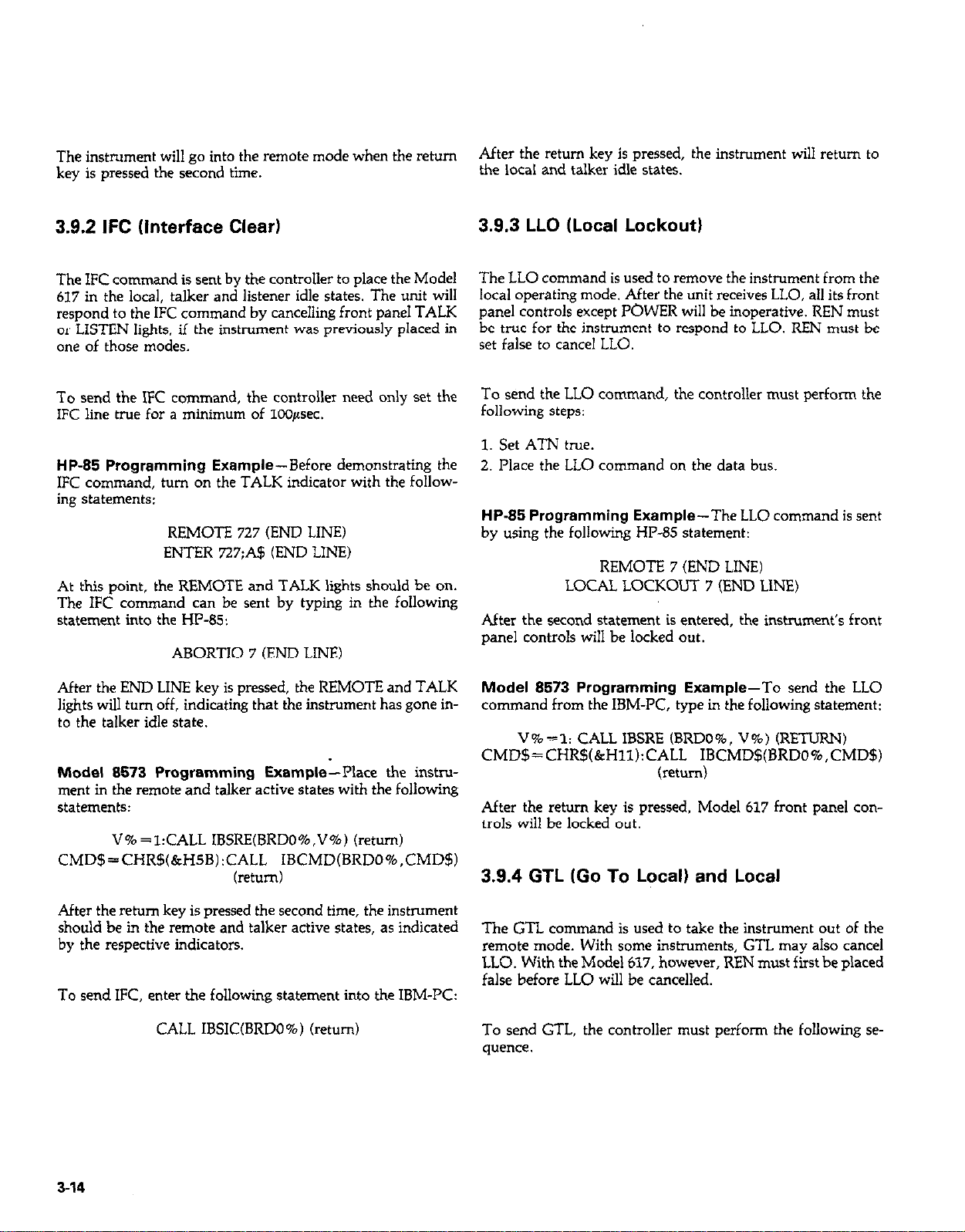

Default Conditions.

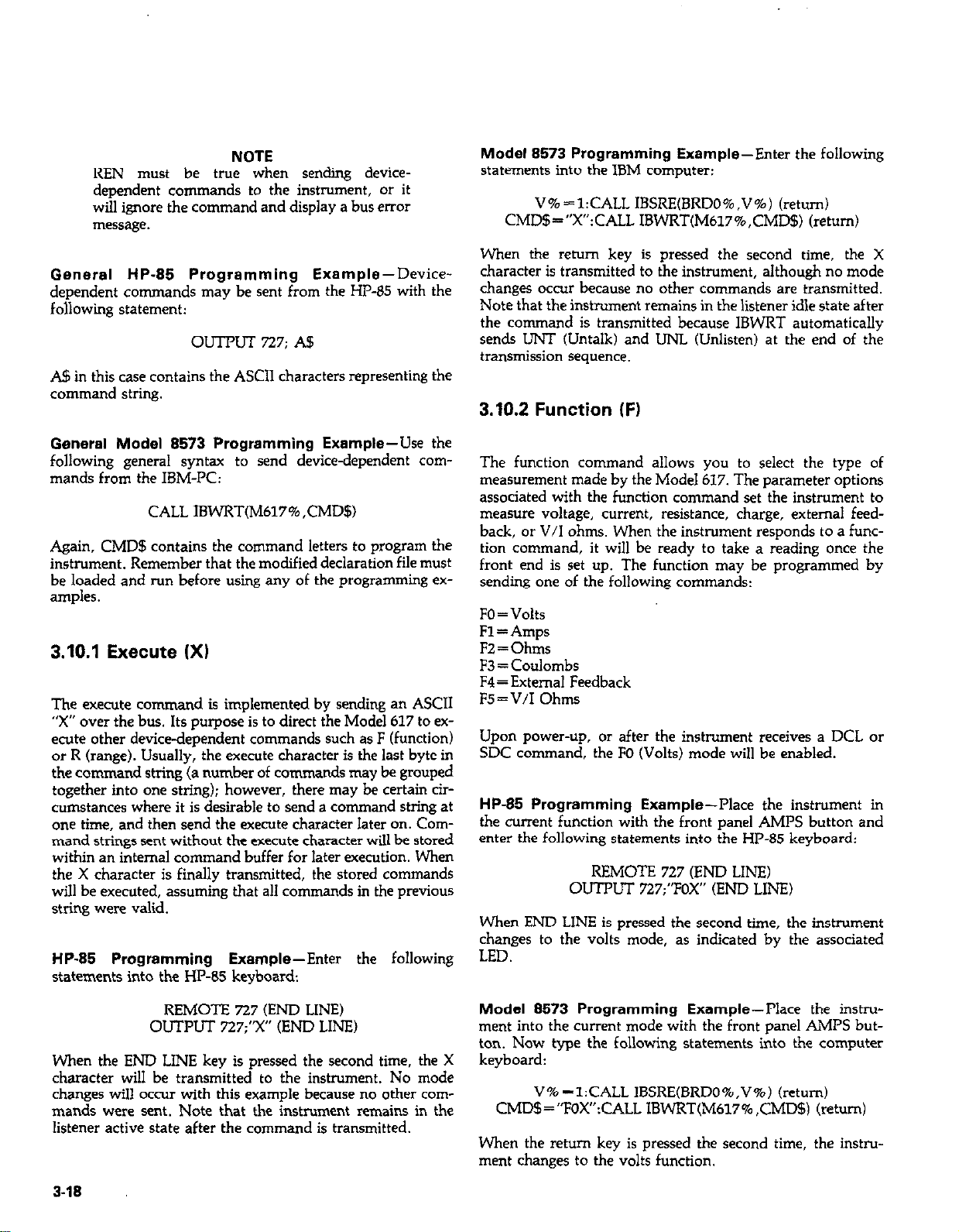

Device-Dependent Command Summary

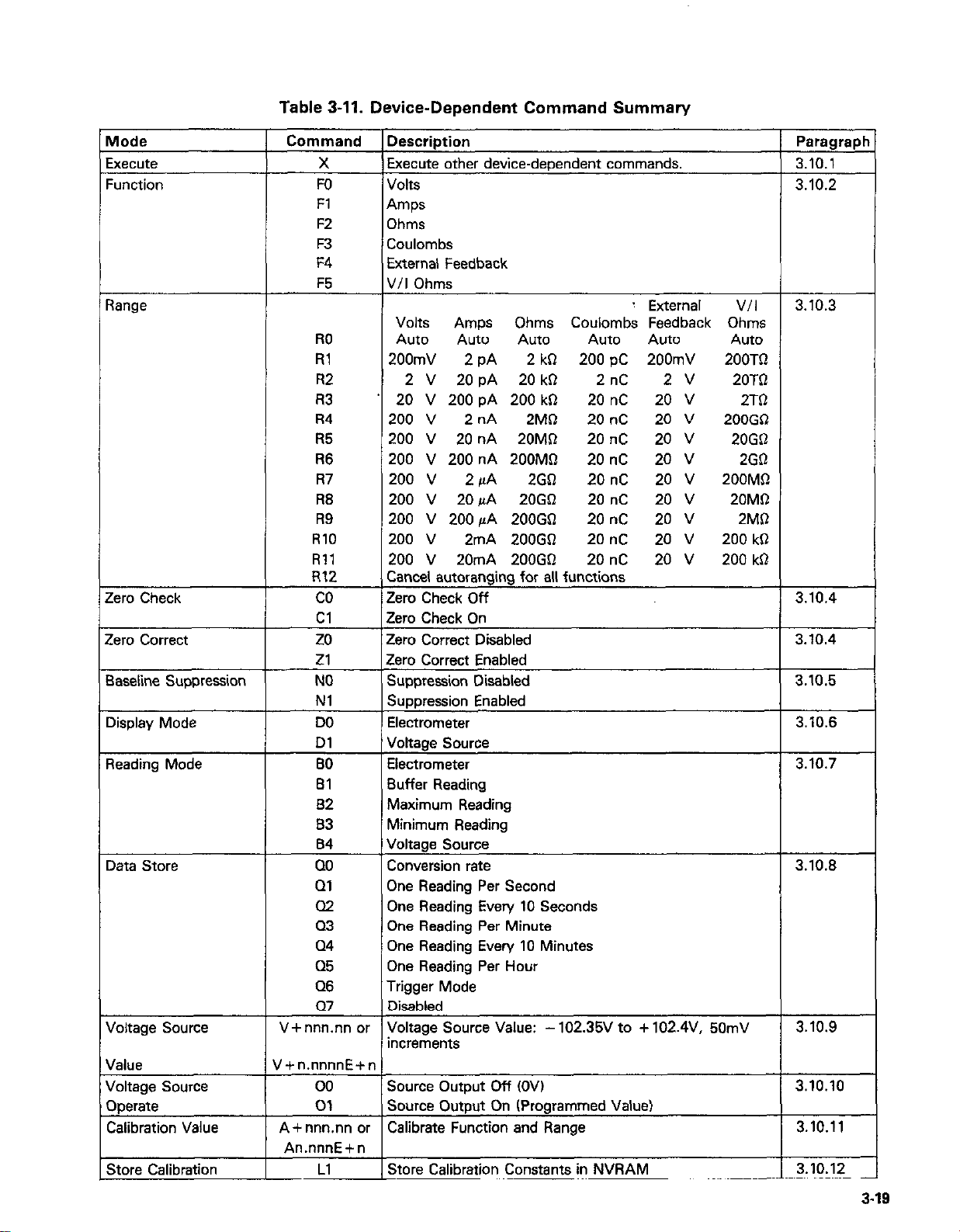

Range Command Summary ...............................

SRQ (M) Command Parameters ............................

Bus Hold-Off Times

Typical Bus Times For Various Functions and Trigger Modes

......................................

......................................

............

.. ........... ....

..................................

.. .... .....

...

......... ... ..

........... ....

.......

.....

.........

..................

............. ......

..............

.......

.....

.....................

......

......

......

......

......

......

......

......

......

......

......

3-4

3-5

3-7

3-7

3-9

3-11

3-12

3-13

3-13

3-15

3-19

3-21

3-28

3-31

3-36

4-l

5-l

5-2

5-3

5-4

5-5

5-6

6-l

Diode Currents and Voltages.

Recommended Test Equipment for Performance Verification

Limits for A mps Verlflcatlon

Limits for Volts Verification

Limits for Ohms Verification (2kn-2OMa Ranges).

Limits for Ohms Verification (2COMn, 2Gn and 2OOGil Ranges)

Voltage Source Verification Limits

MemoryMapping .._......................................................

......

......

......

......

4-7

5-l

5-3

5-5

5-b

5-7

5-8

6-11

ix

Page 14

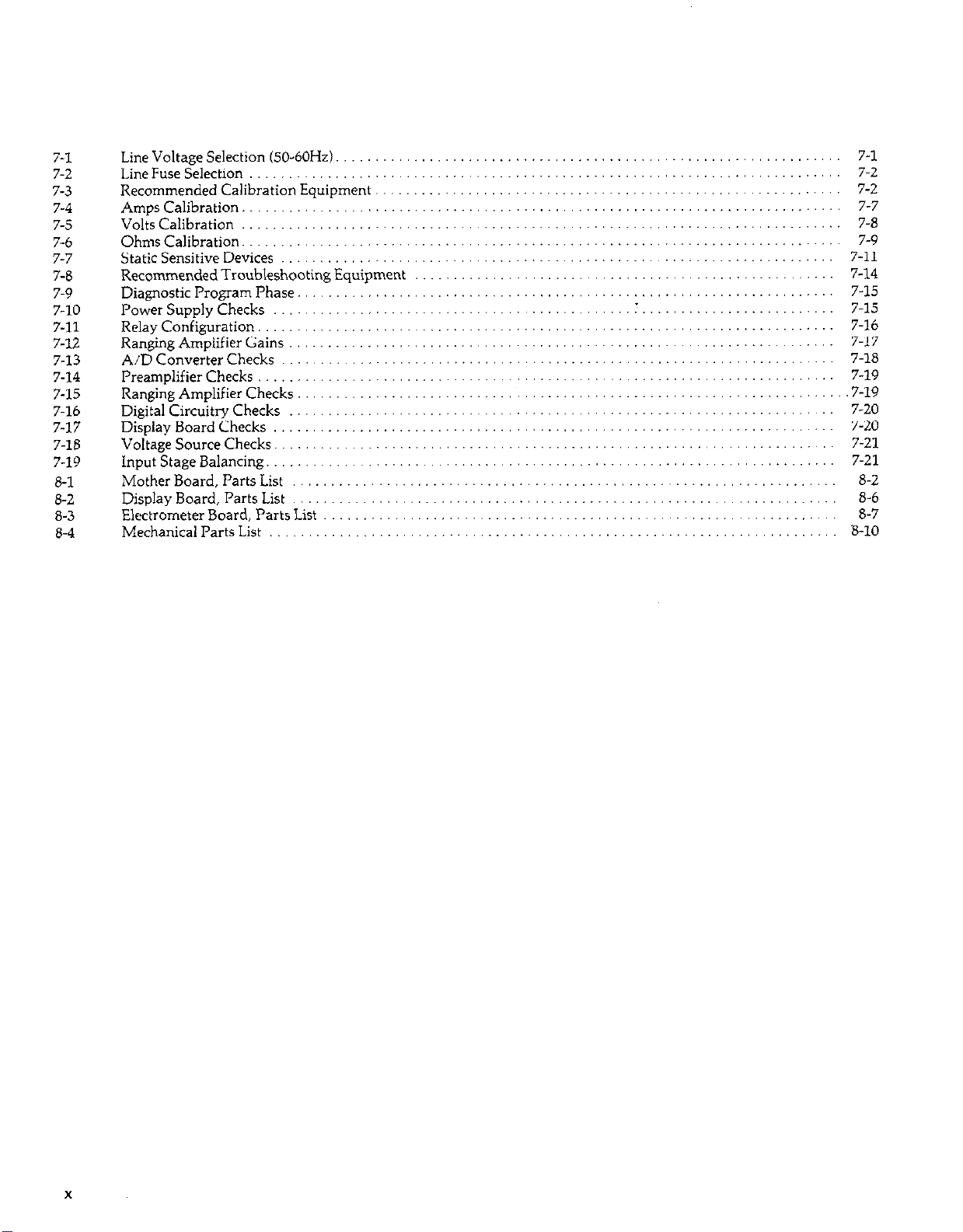

7-1

7-2

7-3

7-4

7-5

7-6

7-7

7-8

7-9

7-10

7-11

7-12

7-13

7-14

7-15

7-16

7-17

7-18

7-19

8-l

a-2

8-3

8-4

Line Voltage Selection (50-60Hz).

LineFuseSelection

Recommended Calibration Equipment

AmpsCalibration .............................................................................

VoltsCalibration..

OhmsCalibration .............................................................................

StaticSensitiveDevices

Recommended Troubleshooting Equipment

DiagnosticProgramPhase

PowerSupplyChecks

Relayconfiguration

Ranging Amplifier Gains

A/DConverterChecks

Preamplifierchecks .......................................................................... 7-19

RangingAmplifierChecks.......................................................................7-1 9

DigitalCircuitryChecks

DisplayBoardChecks

VoltageSourceChecks

InputStageBalancing .........................................................................

MotherBoard,PartsList .......................... .... ...... .......... .. ....

DisplayBoard,PartsList

Electrometer Board, Parts List

Mechanicall’artsList

............................................................................

........ .. ........................ ........ .......

..... . ...........................

..............................................

.......................................................................... 7-16

......... ......... ............. .......... .......

................ .........................

........ ... ........

........................................................................ 7-21

......................... .. ...... ..... ..... ....

....... ............

...........................

........................ ...... .. ...... ......... ......

...............

..................................................................... 7-15

... ......... ..........

........ ......

... .........

........... .....

.................. ........ ......

....................................

................................

... ...

........ ...... .............

... ......

.........................

.

........................

................................

..........

.................

..............

..............

...... ....

.,

........

....

7-l

7-2

7-2

7-7

7-8

7-9

7-11

7-14

7-15

7-17

7-18

7-20

7-20

7-21

8-2

8-6

8-7

S-10

x

Page 15

SAFETY PRECAUTIONS

The following safety precautions should be observed before operating the Model 617

This instrument is intended for use by qualified personnel who recognize shock hazards and are familiar with the

safety precautions required to avoid possible injury. Read over the manual carefully before operating this instrument.

Exercise extreme caution when a shock hazard is present at the instrument’s input. The American National Standards Institute (ANSI) states that a shock hazard exists when voltage levels greater than 30V rms or 42.4V peak

are present. A good safety practice is to expect that a hazardous voltage is present in any unknown circuit before

measuring.

Do not exceed 5oOV peak between input low and earth ground. Do not connect PREAh4P OUT, COM, OI

2V ANALOG OUTPUT to earth ground when floating input.

Inspect the test leads for possible wear, cracks or breaks before each use. If any defects are found, replace with test

leads that have the same measure of safety as those supplied with the instrument.

For optimum safety do not touch the test leads or the instrument while power is applied to the circuit under test.

Turn the power off and discharge all capacitors, before connecting or disconnecting the instrument.

Do not touch any object which could provide a current path to the common side of the circuit under test or power

line (earth) ground. Always make measurements with dry hands while standing on a dry, insulated surface,

capable of withstanding the voltage being measured.

Do not exceed the instrument’s maximum allowable input as defined in the specifications and operation section.

Safe operation and good measurement practice dictates use of an external resistor when necessary to limit input

currents to less than 30mA.

Page 16

SECTION 1

GENERAL INFORMATION

1.1 INTRODUCTION

The Keithley Model 617 Programmable Electrometer is a

highly sensitive instrument designed to measure voltage, current, charge, and resistance. Two forms of resistance

measurements are included in the standard configuration: a

constant current method, and a constant voltage method that

uses a built in voltage source for greater sensitivity. The

measuring range of the Model 617 is between 1OpV and 200V

for voltage measurements, O.lfA and 2OmA in the current

mode, O.ln and 200GO (up to 1OlQ using the built in voltage

source), and lOfC and 20°C in the coulombs mode. The very

high input impedance and extremely low input offset current

allow accurate measurement in situations where many other

instruments would have detrimental effects on the circuit being measured. A 4% digit display and standard IEEE-488 interface give the user easy access to instrument data.

1.2 FEATURES

Some important Model 617 features include:

l 4% Digit Display-An easy to read front panel LED display

includes a 4% digit mantissa plus a two-digit alpha or

numeric exponent.

l Autoranging-Included for all functions and ranges.

l Digital Calibration-The instrument may be digitally

calibrated from the front panel or over the IEEE-488 bus.

l Zero Correct-A front panel zero correct control allows the

user to cancel any offsets.

l Baseline Suppression-One button suppression of a

baseline reading is available from the front panel or over the

IEEE-488 bus.

l One-shot Triggering-A front panel control for triggering

one-shot readings from the front panel is included.

l Isolated IOOV Voltage Source-A built in 1OOV scwrce is

isolated from the electrometer section. The voltage source is

programmable in 50mV steps.

l Selectable Guarding-A selectable driven cable guard is in-

cluded to optimize speed.

l Standard IEEE-488 Interface-The interface allows full bus

programmable operation of the Model 617.

l Analog Outputs-Both preamp and 2V full range analog

outputs are included on the rear panel.

l 100~Point Data Store-An internal buffer that can store

up to 100 readings is accessible from either the front panel

or over the IEEE-488 bus.

l Minimum and maximum data points can be stored and are

accessible from the front panel or over the IEEE-488 bus.

1.3 WARRANG INFORMATION

Warranty information for your Model 617 may be found inside the front cover of this manual. Should you need to use

the warranty, contact your Keithley representative or the factory for information on obtaining warranty service. Keithley

Instruments, Inc. maintains service facilities in the United

States, West Germany, Great Britain, France, the

Netherlands, Switzerland, and Austria. Information concerning the operation, application, or service of your instrument

may be obtained from the applications engineer at any of

these locations.

1.4 MANUAL ADDENDA

Information concerning improvements or changes to the instrument which occur after the printing of this manual will be

found on a” addendum sheet included with this manual.

Please be sure that you read this information before attempting to operate or service your instrument.

1.5 SAFETY SYMBOLS AND TERMS

The following safety symbols and terns are used in this

manual and found on the instrument:

The A

should refer to the operating instructions in this manual for

further details.

The WARNING heading as used in this manual explains

dangers that might result in personal injury or death. Always

read the associated information very carefully before performing the indicated procedure.

The CAUTION heading used in this manual explains hazards

that could damage the instrument. Such damage may in-

validate the warranty.

symbol on the instrument indicates that the user

l-l

Page 17

1.6 SPECIFICATIONS

The following items aw included with every Model 617 shipment:

Detailed Model 617 specifications may be found immedi-

ately preceding the table of contents of the manual. Note

that accuracy specifications assume that the insinxnent has

been properly zero corrected, as discussed in Section 2.

1.7 USING THIS INSTRUCTION MANUAL

This manual contains all the information necessary for you to

operate and service your Model 617 Programmable Elec-

trometer. The manual is divided into the following sections:

l Section 1 contains general information about your instru-

ment including that necessary to unpack the instrument and

get it operating as quickly as possible.

l Section 2 contains detailed operating information on how to

use the front panel controls and programs, make connec-

tions, and basic measuring techniques for each of the

available measuring functions.

l Information necessary to connect the Model 617 to the

IEEE-488 bus and program operating modes and functions

from a controller is contained in Section 3.

l Typical applications for the Model 617 are included ‘in Sec-

tion 4. At least one application for each of the measuring

functions is included in this section.

l Performance verification procedures for the instrument

may be found in Section 5. This information will be helpful

if you wish to verify that the instrument is operating in

compliance with its stated specifications.

l Section 6 contains a complete description of operating

theory for the Model 617. Analog, digital, power supply,

and IEEE-488 interface operation is included.

l Should your instrument ever require servicing, refer to the

information located in Section 7. This section contains in-

formation on fuse replacement, line voltage selection,

calibration. and troubleshooting.

l Replacement parts may be ordered by using the information

contained in Section 8. Parts lists as well as schematic

diagrams and component layouts are located in this section.

1.8 UNPACKING AND INSPECTION

The Model 617 Programmable Electrometer was carefully in-

spected before shipment. Upon receiving the instrument,

carefully unpack all items from the shipping carton and check

for any obvious signs of physical damage that might have oc-

curred during shipment. Report any damage to the shipping

agent at once. Retain the original packing material in case

reshipment becomes necessary.

Model 617 Programmable Electrometer

Model 617 Instruction Manual.

Model 6011 Triaxial Input Cable

Additional accessories as ordered

If an additional instruction manual is required, order the

manual package (Keithley Part Number 617-901-W). The

manual package includes an instruction manual and all perti-

nent addenda.

1.9 GElTING STARTED

The Model 617 Programmable Electrometer is a highly

sophisticated instrument with many capabilities. Although

there are a number of complex aspects about the instrument,

you can use the following procedure to get your instrument

up and running quickly. For more detailed information, you

should consult the appropriate section of the manual.

1.

Carefully unpack your instrument as described in

paragraph 1.8.

2.

Locate the power cord and plug it into the rear panel

power jack. Plug the other end of the line cord into an appropriate power source. See Section 2 for more complete

information.

3.

Connect the supplied triaxial cable to the rear panel input

jack. Make sure the rear panel V, R GUARD switch is in

the off position.

4.

Press in the front panel POWER switch to apply power to

the instrument. The instrument will power up the the

autorange volts mode with zero check enabled. Thus, you

could simply connect the red and black input leads to a

voltage source and take a voltage reading at this point by

disabling zero check. Remember that the Model 617

measures DC voltages up to 2COV.

5.

To change to a different measuring function, simply press

the desired function button. For example, to measure

resistance. simply press the OHMS button.

6.

Complete detailed operation concerning Model 617 front

panel operation may be found in Section 2. If you wish to

control these functions over the IEEE-488 bus, consult

Section 3.

1.10 PREPARATION FOR USE

Once the instrument is unpacked, it must be connected to an

appropriate power source as described below.

l-2

Page 18

Line Power-The Model 617 is designed to operate from

105-125V or 210-250V power sources. A special power transformer may be installed for 90-1lOV and 195-235V ranges.

The factory set range is marked on the rear panel of the in-

strurnent. Note that the line plug is designed to mate with the

supplied 3-wire power cord.

CAUTION

Do not attempt to operate the instrument

on a supply voltage outside the indicated

range, or instrument damage might occur.

Line Voltage Selection-The operating voltage of the instrument is internally selectable. Refer to Section 7 for the procedure to change or verify the line voltage setting,

Line Frequency-The Model 617 may be operated from either

50 or 60Hz power sources.

IEEE-488 Primary Address-If the Model 617 is to be programmed over the IEEE-488 bus, it must be set to the arrect

primary address. The primary address is set to 27 at the factory, but it may be programmed from the front panel as

described in Section 3.

1.11 REPACKING FOR SHIPMENT

Before shipping, the instrument should be carefully packed in

its original packing material.

Model 6011 and 6011-10 Triaxial Cables-The Model 6011 is

made up of 3 feet of triaxial cable that is terminated with a

trim plug on one end and 3 alligator clips on the other end.

The Model 6011-10 is a similar cable 10 feet in length. Note

that the Model 6011 is supplied with the Model 617.

Model 6012 Triax to UHF Adapter-The Model 6012 allows

the Model 617 to be used with accessories having UHF type

co”nectors.

Model 6lOlA Shielded Test Lead-The Model 610lA is a

straight through probe and shielded lead equipped with 0.8m

(3O”) of shielded low noise cable terminated by a Tefloninsulated UHF connector. The Model 6012 must be used to

adapt the Model 6101A to the Model 617 triaxial input.

Model 6103C Voltage Divider Probe-The Model 6103C extends Model 617 voltage measurement range to 30kV. The

Model 6103C has a division ratio of 1OOO:l with a nominal

accuracy of 5%. The probe has an input resistance of 4.5 x

10110 and is equipped with a UHF male plug. The Model 6012

adapter must be used to connect the Model 6103C to the

Model 617.

Model 6104 Test Shield-The Model 6104 facilitates

resistance, voltage, or current measurements with either 2- or

3-terminal guarded connections at voltages up to 1200V. The

Model 6104 provides excellent electrostatic shielding and high

isolation resistance. Clips plug into banana jacks, allowing

custom connections. The Model 6104 has a BNC camector

on one side and binding posts on the other. The Model 6147

adapter (below) is required to connect the Model 6104 to the

Model 617.

If the instrument is to be returned to Keithley Instruments for

repair or calibration, include the following:

Write ATTENTION REPAIR DEPARTMENT on the shipping label.

Include the warranty status of the instrument.

Complete the service form at the back of this manual.

1.12 ACCESSORIES

The following accessories are available to enhance Model 617

capabilities.

Models 1019A and 1019s Rack Mounting Kits-The Model

1019A is a fiied or stationary rack mounting kit with two

front panels provided to enable either single or dual side-byside mounting of the Model 617 or other similar Keithley instrument. The Model 1019s is a similar rack mounting kit

with a sliding mount configuration.

Model 6105 Resistivity Chamber-The Model 6105 is a

guarded test fixture for measuring voltage and surface

resistivities. The unit assures good electrostatic shielding and

high insulation resistance. The complete system requires the

use of an external high-voltage supply such as the Model 247

as well as the Model 617. Volume resistivity up to 105Q/cm

and surface resistivity up to 1018Q can be measured in accordance with ASTM test procedures. Sheet samples 64 to

102mm (2Yz X 4”) in diameter and up to 6.4mm (IA”)

thickness can be accommodated. Excitation voltages up to

1OOOV may be used.

Model 6146 Triax Tee Adapter-The Model 6147 allows the

simultaneous connection of two triaxial cables to the single

triaxial input of the Model 617.

Model 6147 Triax to BNC Adapter-The Model 6147 allows

the Model 617 input to be connected to accessories having

BNC connectors.

Model 6171 and 6172 3 Lug-to-2 Lug Adapters-The Model

6171 is a 3 lug male-to-2 lug female triaxial adapter, while the

Model 6172 is a 2 lug male-to-3 lug female triaxial adapter.

1-3

Page 19

Model 7008 IEEE-488 Cables-The Model 7008 cables are

designed to connect the Model 617 to the IEEE-466 bus and

are available in two similar versions. The Model 7008-3 is

0.9m (3 ft.) in length, while the Model 7008-6 is 1.&n (6 ft.)

long. Each cable is terminated with a standard IEEE-488 connector on each end, and each connector is equipped with two

metric SCTBWS.

Model 7024 Triaxial Cables-The Model 7024 cables are

similar units with male triaxial connectors on each end. The

Model 7024-l is 0.3m (1 ft:) in length, while the Models

7024-3 and 7024-10 are 0.9m (3 ft.) and 3.0m (10 ft.) long

respectively. These cables may be used to connect the Model

617 signal input to other equipment having similar triaxial

connections.

Model 7023 Female Triaxial Connector-The Model 7023 is a

chassis mount connector that mates with the Models 6011 and

7024 triaxial cables.

Model 8573 IEEE-488 Interface for the IBM PC-The Model

8573 allows the Model 617 to be connected to and controlled

from the IBM PC via the IEEE-488 bus.

1-4

Page 20

SECTION 2

OPERATION

2.1 INTRODUCTION

Operation of the Model 617 may be divided into two general

categories: front panel operation and IEEE-488 bus operation.

This section contains information necessary to use the instrument on a front-panel basis. Note that many of these func-

tions can also be programmed over the IEEE-488 bus, as

described in Section 3.

The following paragraphs contain a complete description of

Model 617 front panel operation. First a complete description

of each front and rear panel function is presented. Next the

complete procedure for each of the measuring functions is

presented, followed by a description of the built in voltage

source. Finally, the analog output and guard functions are

described along with a method to apply external feedback.

2.2 POWER UP PROCEDURE

Use the procedure below to connect the Model 617 to line

power and power up the instrument.

1. Connect the female end of the power cord to the AC receptacle on the rear panel of the instrument. Connect the other

end of the cord to a grounded AC outlet.

switch. The switch will be at the inner most position when

the instrument is turned on.

3. The instrument will power up in the volts function, in the

autorange mode aqd with zero check enabled, as indicated

by the associated front panel LEDs. All other LEDs will be

off when the instrument is first turned on.

2.3 POWER UP SELF TEST AND DISPLAY

MESSAGES

The RAM memory is automatically tested as part of the

power up procedure. If a RAM memory error occurs, the “rr”

message will remain on the display. If the instrument was not

able to read the stored calibration constants and configuration, the decimal points in the two exponent digits will flash.

If such errors occur, the instrument may be partially or completely inoperative. Refer to Section 7 for more complete

details.

A power up self test may be run and the software revision

level may be displayed by pressing and holding the TRIG but-

ton when the unit is first turned on. During the test, all front

panel LEDs and the display segments will turn on as in the example below:

WARNING

The Model 617 is equipped with a 3-wire

power cord that contains a separate ground

wire and is designed to be used with

grounded outlets. When proper connec-

tions are made, instrument chassis is con-

nected to power line ground. Failure to use

a grounded outlet may result in personal in-

jury or death because of electric shock.

CAUTION

Be sure that the power line voltage agrees

with the indicated range on the rear panel

of the instrument. Failure to observe this

precaution may result in instrument

damage. If necessary, the line voltage may

be changed as decribed in Section 7.

2. Turn on the power by pressing in the front panel POWER

The instrument will then display the software revision level

when TRIG is released, for example:

E.4

The instrument will then enter the diagnostic mode, which is

used as an aid in troubleshooting problems within the instrument. See Section 7 for details. The power must be turned off

to remove the instrument from the diagnostic mode.

NOTE

If the instrument is still under warranty (less

than one year from the date of shipment), and

problems develop, it should be returned to

Keithley Instruments for repair. See paragraph

1.11 for details on returning the instrument.

2-I

Page 21

J

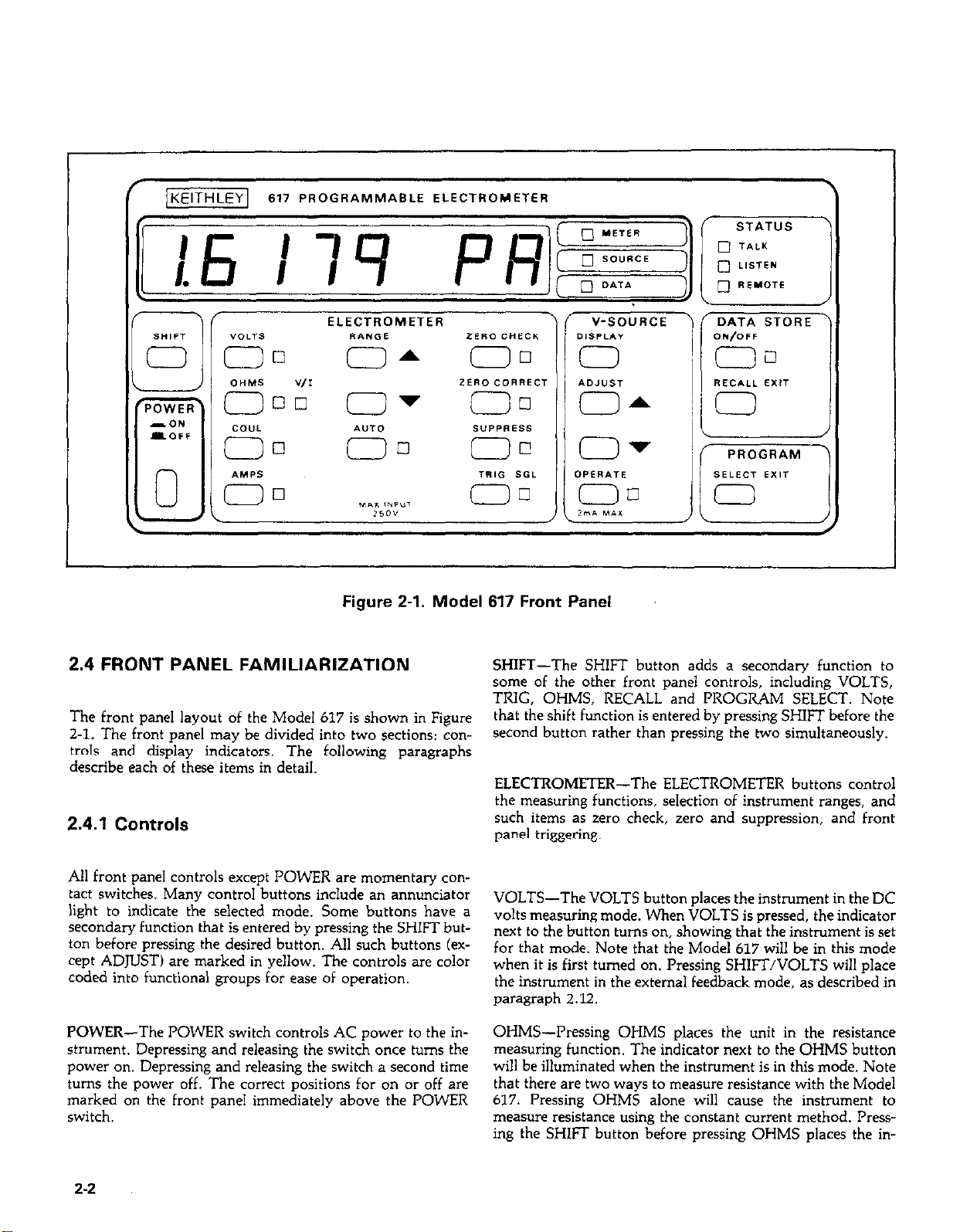

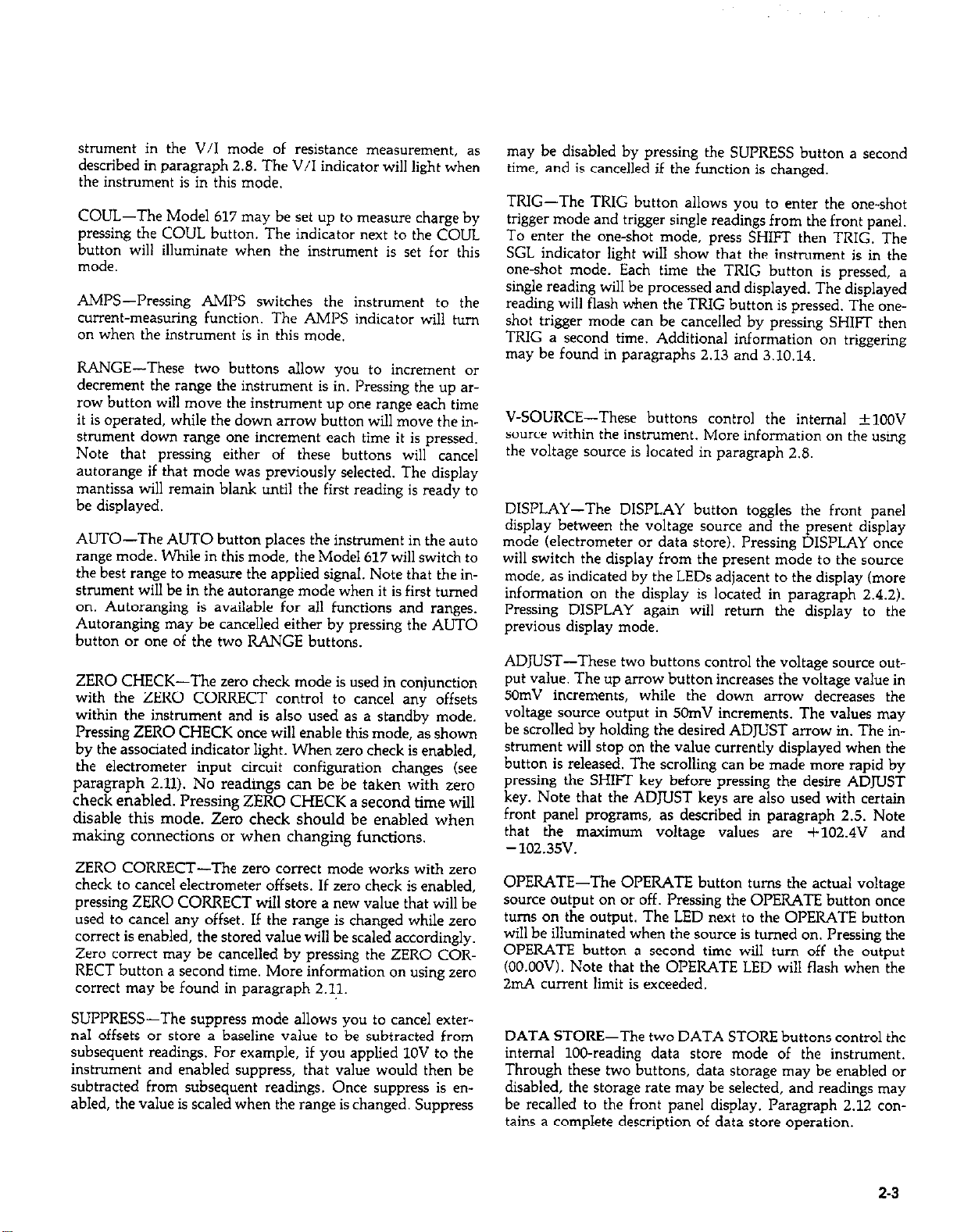

Figure 2-1. Model 617 Front Panel

\

PROGRAM PROGRAM

SELECT EXIT SELECT EXIT

0 0

i, i,

2.4 FRONT PANEL FAMILIARIZATION

The front panel layout of the Model 617 is shown in Figure

2-1. The front panel may be divided into two sections: controls and display indicators. The following paragraphs

describe each of these items in detail.

2.4.1 Controls

All front panel controls except POWER are momentary con-

tact switches. Many control buttons include an annunciator

light to indicate the selected mode. Some buttons have a

secondary function that is entered by pressing the SHIFT button before pressing the desired button. All such buttons (except ADJUST) are marked in yellow. The controls are color

coded into functional groups for ease of operation.

POWER-The POWER switch controls AC power to the in-

strument. Depressing and releasing the switch once turns the

power on. Depressing and releasing the switch a second time

turns the power off. The correct positions for on or off are

marked on the front panel immediately above the POWER

switch.

SHIFT-The SHIFT button adds a secondary function to

some of the other front panel controls, including VOLTS,

TRIG, OHMS, RECALL and PROGRAM SELECT. Note

that the shift function is entered by pressing SHIFT before the

second button rather than pressing the two simultaneously.

ELECTROMETER-The ELECTROMETER buttons control

the measuring functions, selection of instrument ranges, and

such items as zero check, zero and suppression, and front

panel triggering.

VOLTS-The VOLTS button places the instrument in the DC

volts measuring mode. When VOLTS is pressed, the indicator

next to the button turns on, showing that the instrument is set

for that mode. Note that the Model 617 will be in this mode

when it is first turned on. Pressing SHIFT/VOLTS will place

the instrument in the external feedback mode, as described in

paragraph 2.12.

OHMS--Pressing OHMS places the unit in the resistance

measuring function. The indicator next to the OHMS button

will be illuminated when the instrument is in this mode. Note

that there are two ways to measure resistance with the Model

617. Pressing OHMS alone will cause the instrument to

measure resistance using the constant current method. Pressing the SHIFT button before pressing OHMS places the in-

2-2

Page 22

strument in the V/I mode of resistance measurement, as

described in paragraph 2.8. The V/I indicator will light when

the instrument is in this mode.

COUL-The Model 617 may be set up to measure charge by

pressing the COUL button. The indicator next to the COUL

button will illuminate when the instrument is set for this

mode.

AMPS-Pressing AMPS switches the instrument to the

current-measuring function. The AMPS indicator will turn

on when the instrument is in this mode.

RANGE-These two buttons allow you to increment or

decrement the range the instrument is in. Pressing the up ar-

row button will move the instrument up one range each time

it is operated, while the down arrow button will move the instrument down range one increment each time it is pressed.

Note that pressing either of these buttons will cancel

autorange if that mode was previously selected. The display

mantissa will remain blank until the first reading is ready to

be displayed.

AUTO-The AUTO button places the instrument in the auto

range mode. While in this mode, the Model 617 will switch to

the best range to measure the applied signal. Note that the instrument will be in the autorange mode when it is first turned

on. Autoranging is available for all functions and ranges.

Autoranging may be cancelled either by pressing the AUTO

button or one of the two RANGE buttons.

ZERO CHECK-The zero check mode is used in conjunction

with the ZERO CORRECT control to cancel any offsets

within the instrument and is also used as a standby mode.

Pressing ZERO CHECK once will enable this mode, as shown

by the associated indicator light. When zero check is enabled,

the electrometer input circuit configuration changes (see

paragraph 2.11). No readings can be be taken with zero

check enabled. Pressing ZERO CHECK a second time will

disable this mode. Zero check should be enabled when

making connections or when changing functions.

ZERO CORRECT-The zero correct mode works with zero

check to cancel electrometer offsets. If zero check is enabled,

pressing ZERO CORRECT will store a new value that will be

used to cancel any offset. If the range is changed while zero

correct is enabled, the stored value will be scaled accordingly.

Zero correct may be cancelled by pressing the ZERO CORRECT button a second time. More information on using zero

correct may be found in paragraph 2.11.

may be disabled by pressing the SUPRESS button a second

time, and is cancelled if the function is changed.

TRIG-The TRIG button allows you to enter the one-shot

trigger mode and trigger single readings from the front panel.

To enter the one-shot mode, press SHIFT then TRIG. The

SGL indicator light will show that the instrument is in the

one-shot mode. Each time the TRIG button is pressed, a

single reading will be processed and displayed. The displayed

reading will flash when the TRIG button is pressed. The oneshot trigger mode can be cancelled by pressing SHIFT then

TRIG a second time. Additional information on triggering

may be found in paragraphs 2.13 and 3.10.14.

V-SOURCE-These buttons control the internal 2100V

source within the instrument. More information on the using

the voltage source is located in paragraph 2.8.

DISPLAY-The DISPLAY button toggles the front panel

display between the voltage source and the present display

mode (electrometer or data store). Pressing DISPLAY once

will switch the display from the present mode to the source

mode, as indicated by the LEDs adjacent to the display (more

information on the display is located in paragraph 2.4.2).

Pressing DISPLAY again will return the display to the

previous display mode.

ADJUST-These two buttons control the voltage source out-

put value. The up arrow button increases the voltage value in

50mV increments, while the down arrow decreases the

voltage source output in 5OmV increments. The values may

be scrolled by holding the desired ADJUST arrow in. The in-

strument will stop on the value currently displayed when the

button is released. The scrolling can be made more rapid by

pressing the SHIFT key before pressing the desire ADJUST

key. Note that the ADJUST keys are also used with certain

front panel programs, as described in paragraph 2.5. Note

that the maximum voltage values are +102.4V and

-102.35V.

OPERATE-The OPERATE button turns the actual voltage

source output on or off. Pressing the OPERATE button once

turns on the output. The LED next to the OPERATE button

will be illuminated when the source is turned on. Pressing the

OPERATE button a second time will turn off the output

(OO.oOV). Note that the OPERATE LED will flash when the

2mA current limit is exceeded.

SUPPRESS-The suppress mode allows you to cancel external offsets or store a baseline value to be subtracted from

subsequent readings. For example, if you applied 1OV to the

instrument and enabled suppress, that value would then be

subtracted from subsequent readings. Once suppress is enabled, the value is scaled when the range is changed. Suppress

DATA STORE-The two DATA STORE buttons control the

internal loo-reading data store mode of the instrument.

Through these two buttons, data storage may be enabled or

disabled, the storage rate may be selected, and readings may

be recalled to the front panel display. Paragraph 2.12 con-

tains a complete description of data store operation.

2-3

Page 23

ON/OFF--This control enables or disables data store opera-

tion. In addition, reading rates can be selected by holding the

button in when first enabling data store. When data store is

enabled, the indicator light next to the ON/OFF button will

be on. Minimum and maximum values are stored and up-

dated as long as the ON/OFF LED is on.

RECALL/EXIT-This single button serves to recall readings

previously stored by data store. Pressing and holding this

button causes the instrument to scroll through the pointer ad-

dresses as indicated on the display. Once the desired reading

number is displayed, releasing the button causes the actual

reading to be displayed. To exit the recall mode, press SHIFT

EXIT.

PROGRAM-A single PROGRAM button controls such

modes as IEEE address, alpha or numeric display exponent,

and digital calibration. Paragraph 2.5 further describes front

panel programming.

SELECT/EXIT-This button enters the program mode to

allow access to parameters described above. Pressing

SELECT repeatedly causes the instrument to scroll through a

program menu. To cancel the program mode, press SHIFT

and then SELECT/EXIT in that order. Note that the program mode is cancelled by pressing SELECT/EXIT after a

program parameter change is made.

2.4.2 Display and Indicators

The operation of the 4% digit display and various indicators

is described below. The display updates at about three

readings per second.

STATUS Indicators-These three indicators apply to operation of the Model 617 over the IEEE-488 bus. The REMOTE

indicator shows when the instrument is in the IEEE-488

remote state, while the TALK and LISTEN indicators show

when the instrument is in the talk and listen states respect-

ively. See Section 3 for more information on using the Model

617 over the IEEE-486 bus.

2.4.3 Tilt Bail ’

The tilt bail, which is located on the bottom of the instru-

ment, allows the front panel to be elevated to a convenient

viewing height. To extend the bail, rotate it out 90” from the

bottom cover and latch it into place. To retract the bail, pull

out until it unlatches and rotate it against the bottom cover.

2.5 FRONT PANEL PROGRAMS

The Model 617 has three front panel programs that can be

used to set the primary address, set the display exponent

mode (alpha or numeric), or calibrate the instrument from the

front panel. To select a program, press PROGRAM SELECT

button repeatedly while bbserving the display. The instrument will scroll through the available programs with identifying messages. as shown in Table 2-2. When in the program

mode, the DISPLAY and DATA STORE RECALL buttons

are inoperative; the data store mode may be turned off, but

not on. The operation of the various programs is described in

the following paragraphs. To exit a program, press SHIFT

EXIT. If a change was made, pressing SELECT alone will exit

the program.

Display-The Model 617 has a display made up of a 4% digit

signed mantissa as well as a two-digit signed exponent. The

exponent can be represented either in scientific notation, or

with an alphanumeric subsript such as nA. The exponent dis-

play mode can be changed with a front panel program, as

described in paragraph 2.5. Note that, when scientific nota-

tion is used, the decimal point remains fixed as in 1.9999. The

range is indicated by the exponent. In addition, the display

has a number of front panel error messages, as shown in

Table 2-l.

Display Indicators-The METER, SOURCE, and DATA

LEDs indicate what the display is actually showing. When the

METER LED is on, the display represents an electrometer

reading. When the SOURCE LED is illuminated, the voltage

source value is being displayed. A data store reading is

displayed when the DATA LED is turned on. Normally, the

display will be the the meter mode, but the DISPLAY and

RECALL buttons will switch the display to the source and

data modes respectively.

2-4

2.5.1 IEEE-488 Address

Selection of the IEEE-488 address program is indicated by the

following message:

IEEE 27

Along with the message, the presently programmed IEEE-488

address (27 in this example) will be displayed. To select a new

address, use the V-SOURCE ADJUST keys. When the desired

value is shown in the display, press SHIFT then SELECT

EXIT to return to normal operation (or if a change was made,

simply press SELECT). For complete information on using the

Model 617 over the IEEE-488 bus, refer to Section 3.

Page 24

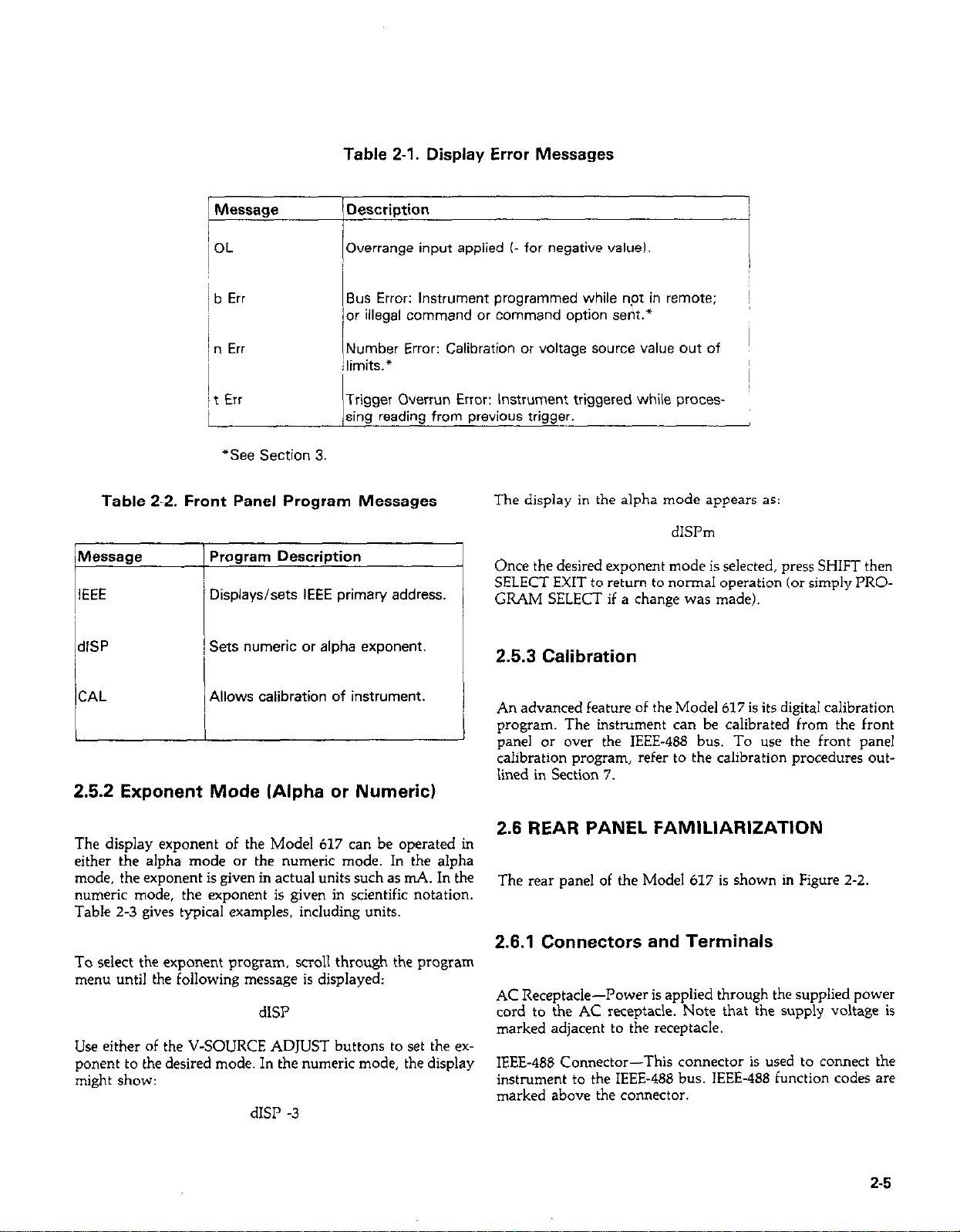

Table 2-1. Display Error Messages

Message

OL

b Err

Description

Overrange input applied (- for negative valueI.

Bus Error: Instrument programmed while npt in remote; ~

or illegal command or command option sent.*

n Err

(Number Error: Calibration or voltage source value out of

; limits.*

‘t Err

Trigger Overrun Error: Instrument triggered while processing reading from previous trigger.

“See Section 3.

Table 2-2. Front Panel Program Messages

Displays/sets IEEE primary address.

IdlSP

Sets numeric or alpha exponent.

I

I

The display in the alpha mode appears as:

dISI’m

Once the desired exponent mode is selected, press SHIFT then

SELECT EXIT to return to normal operation (or simply PRO-

GRAM SELECT if a change was made).

2.5.3 Calibration

CAL

Allows calibration of instrument.

2.5.2 Exponent Mode (Alpha or Numeric)

The display exponent of the Model 617 can be operated in

either the alpha mode or the numeric mode. In the alpha

mode, the exponent is given in actual units such as mA. In the

numeric mode, the exponent is given in scientific notation.

Table 2-3 gives typical examples. including units.

To select the exponent program, scroll through the program

menu until the following message is displayed:

dISI’

Use either of the V-SOURCE ADJUST buttons to set the ex-

ponent to the desired mode. In the numeric mode, the display

might show:

dISP -3

An advanced feature of the Model 617 is its digital calibration

program. The instrument can be calibrated from the front

panel or over the IEEE-488 bus. To use the front panel

calibration program, refer to the calibration procedures outiined in Section 7.

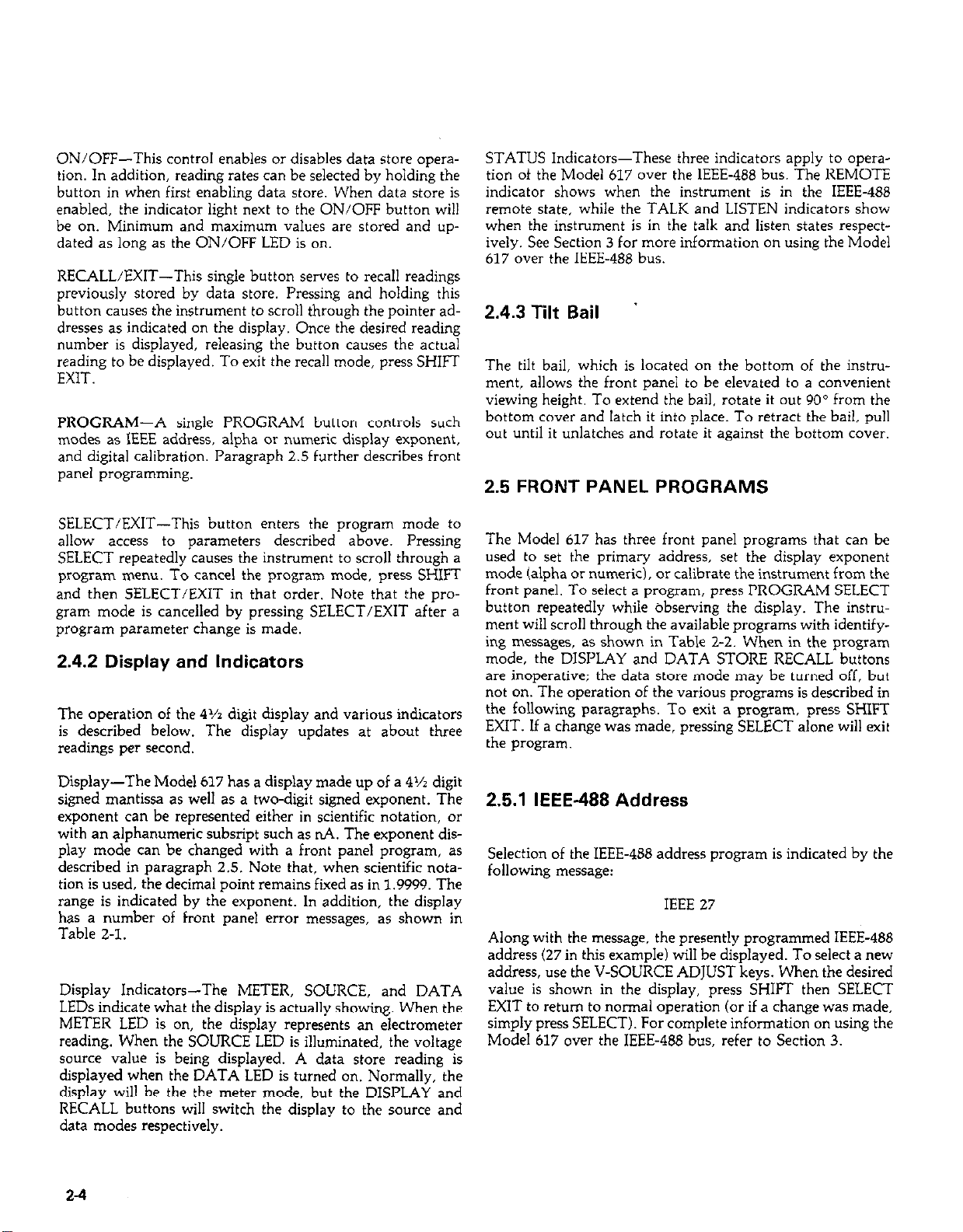

2.6 REAR PANEL FAMILIARIZATION

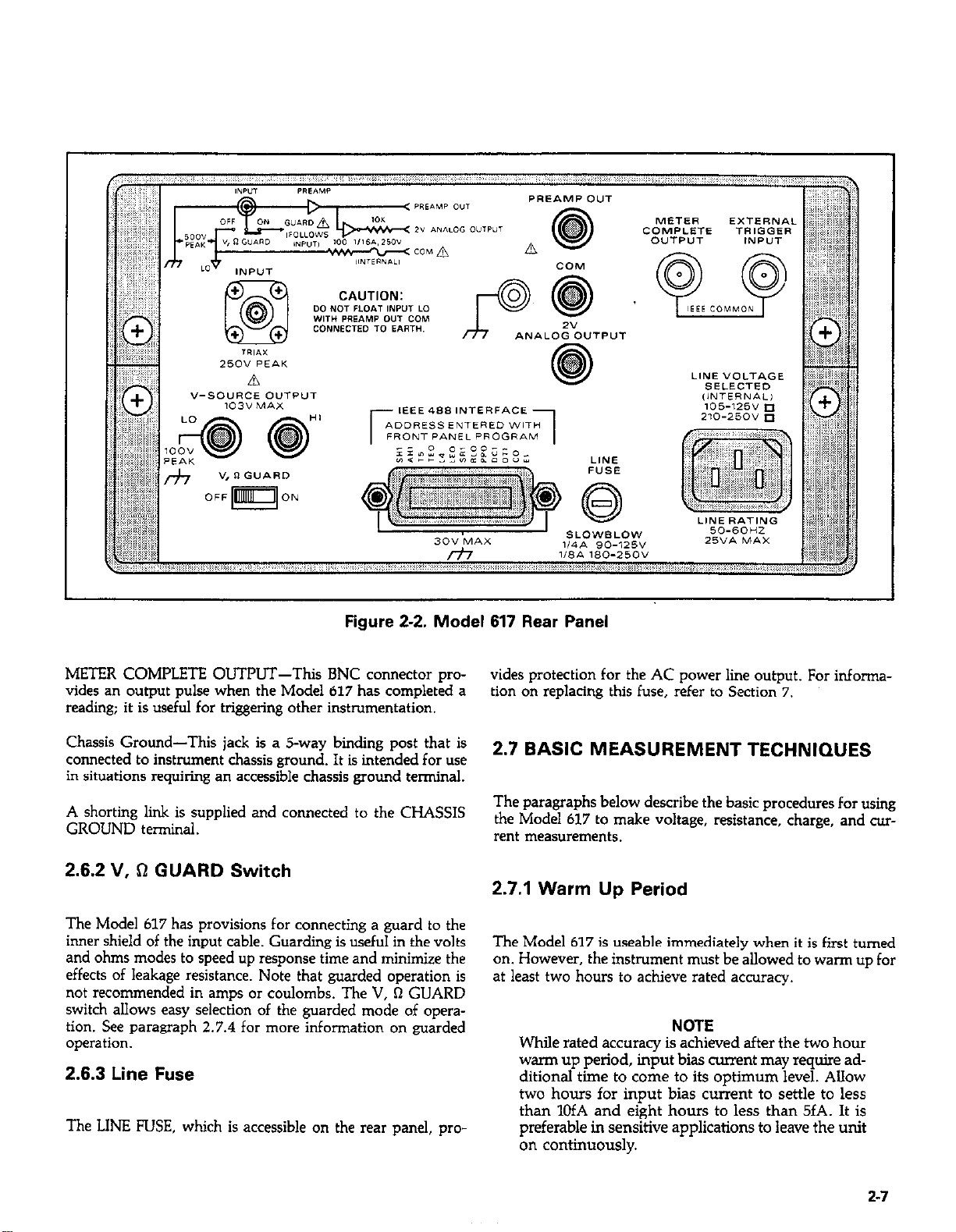

The rear panel of the Model 617 is shown in Figure 2-2.

2.6.1 Connectors and Terminals

AC Receptacle-Power is applied through the suppiied power

cord to the AC receptacle. Note that the supply voltage is

marked adjacent to the receptacle.

IEEE-488 Connector-This connector is used to connect the

instrument to the IEEE-488 bus. IEEE-488 function codes are

marked above the connector.

2-5

Page 25

Table 2-3. Typical Display Exponent Values

I Display

IPA

nC

PA

mV

kR

MQ

GQ

Tfl

ingineering

Units

PA

!lC

PA

mV

kCI

MO

GR

TQ

icientific

Uotation

10-77-A

10-w

lo-GA

lo-3v

103Q

lO@l

low

1012sl

f

N,

anocoulombr

rv

licroamperes

Millivolts

Kilohms

1

Megohms

Gigohms

Teraohms

PQ

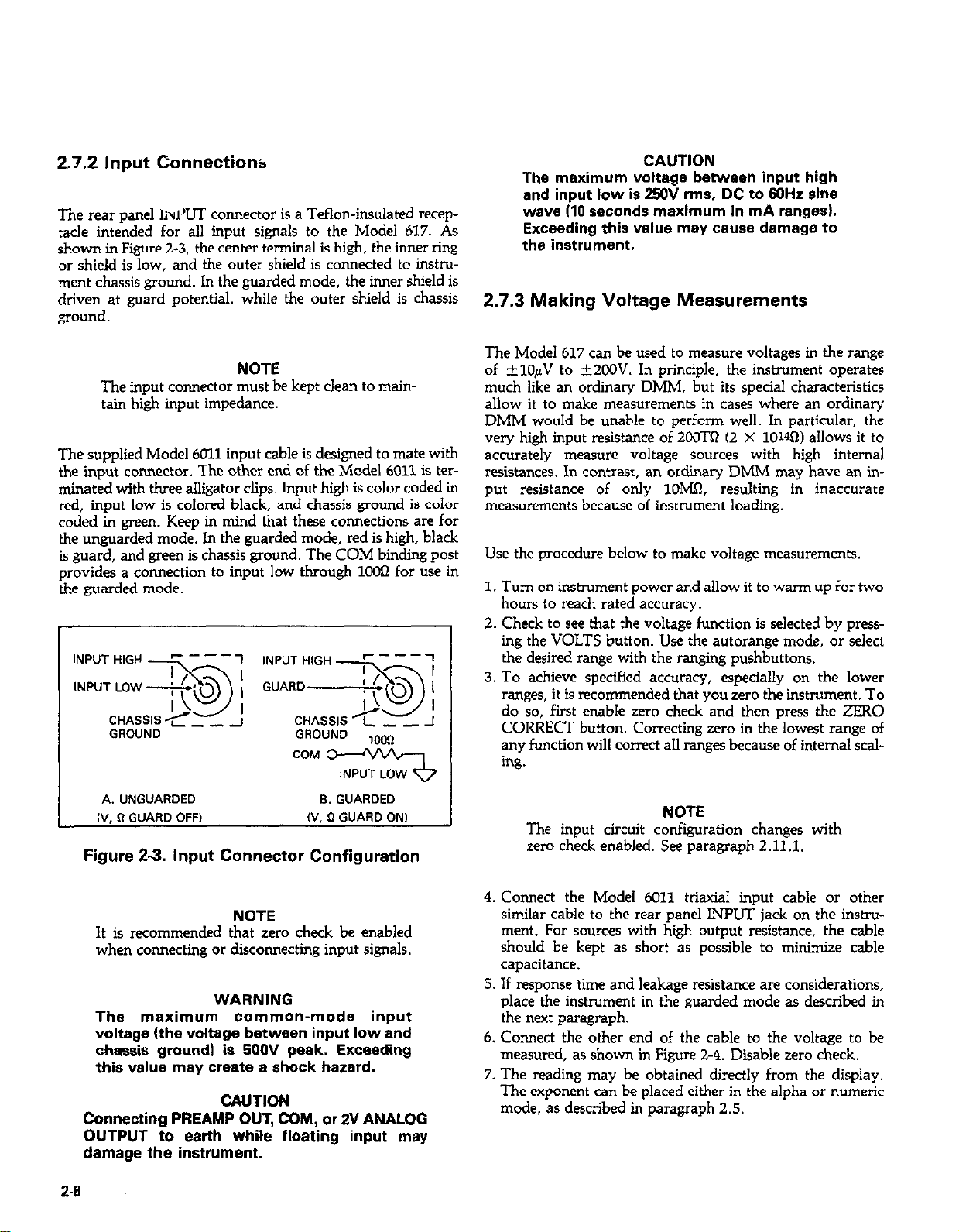

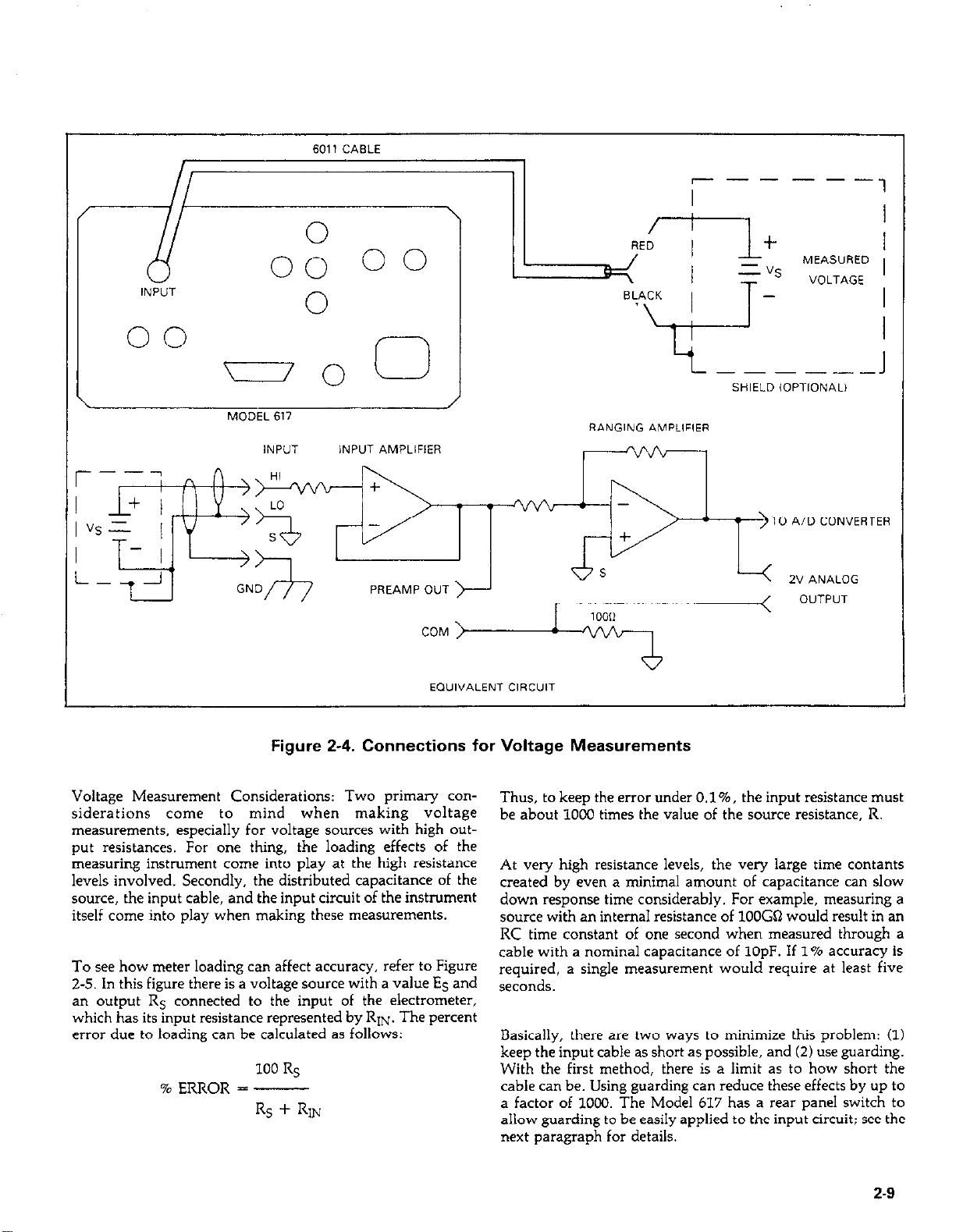

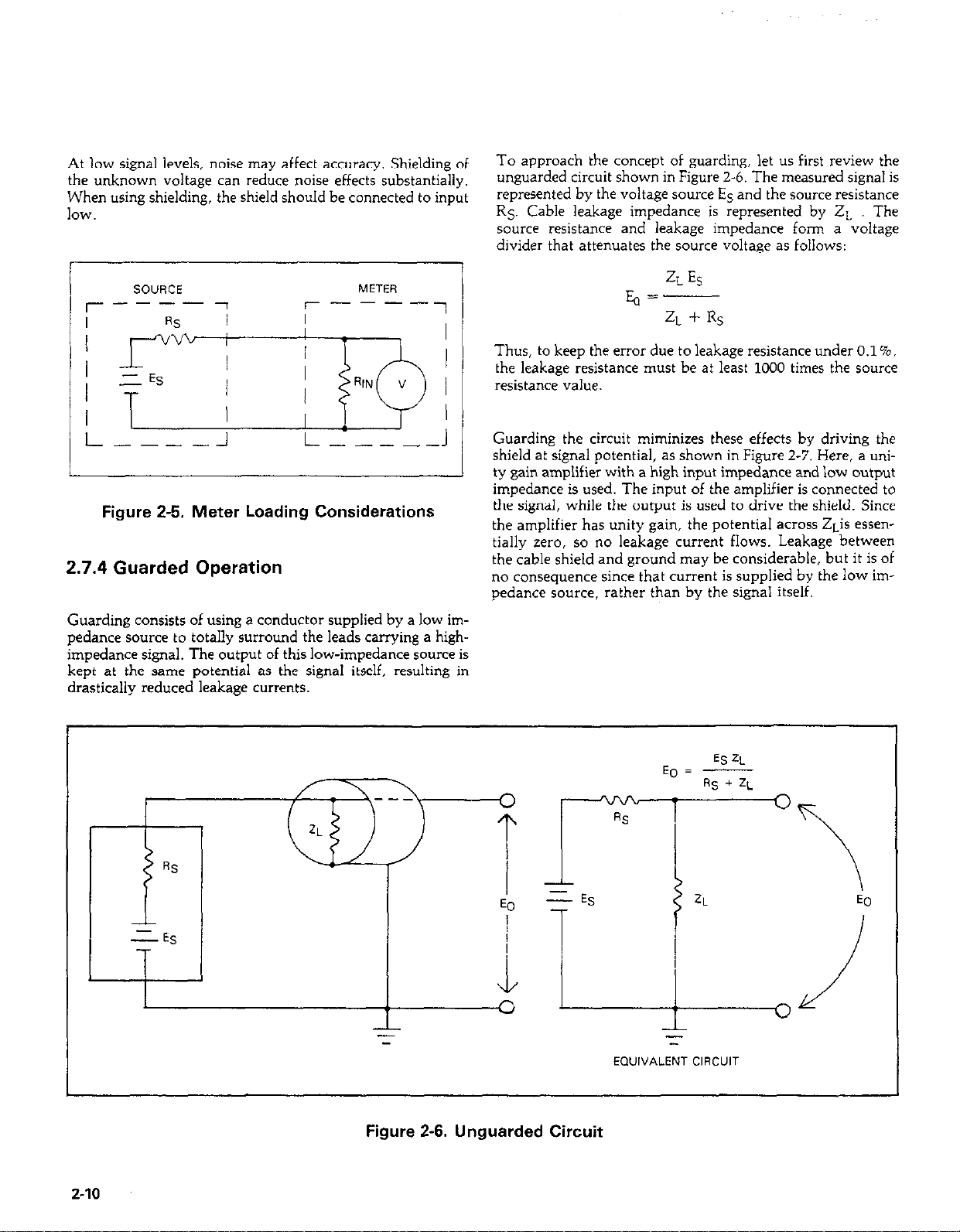

INPUT-The INPUT connector is a 2-lug triax connector to

be used for all electrometer signal inputs. Note that you

should not confuse a triaxial connector with the BNC type

that is used for the EXTERNAL TRIGGER and ELEC-

TROMETER COMPLETE connections. Also, do not attempt

to force a 3-lug triaxial connector onto the INPUT Connector. The Models 6171 and 6172 adapters are available to

make the necessary conversion.

2V ANALOG OUTPUT-The 2V ANALOG OUTPUT prc-

vides a scaled O-2V output from the electrometer (2V output

for full range input). The output uses a standard S-way bind-

ing post and is inverting in the volts and ohms modes.

PR!ZAMP OUT-The PREAMI’ OUT provides a guard cutput for voltage and resistance measurements. This output can

also be used as an inverting output or with external feedback

when measuring current or charge. The PREAMP OUT has a

maximum output value of k3C0V and uses a standard s-way

binding post.

WARNING

Hazardous voltage may be present at the

PREAMP OUT, depending on the input

signal.

PO

101522

COM Terminal-The COM terminal is a 5way binding post

that provides a low connection for both the 2V ANALOG

OIJ’IT’LT and the PREAMP OUT This terminal is also used

for input low connection when in guarded mode; COM

is internally connected to input low through a lC0Q resistor.

Do not connect PREAMP OUT, COM, or 2V ANALOG

OUTPUT to earth when floating input.

V-SOURCE OUTPUT-The HI and LO outputs are the connections for the internal voltage source. This source can be

used as a stand-alone source or in conjunction with the elec-

trometer section to make resistance measurements as high as

1owL

EXTERNAL TRIGGER INPUT-This BNC connector can be

used to apply external trigger pulses to the Model 617 to trigger the instrument to take one or more readings, depending

on the selected trigger mode.

Petaohms

i

2-6

Page 26

Figure 2-2. Model 617 Rear Panel

METER COMPLETE OUTPUT-This BNC connector prcvides an output pulse when the Model 617 has completed a

reading; it is useful for triggeling other instrumentation.

Chassis Ground-This jack is a s-way biding post that is

connected to instrument chassis ground. It is intended for use

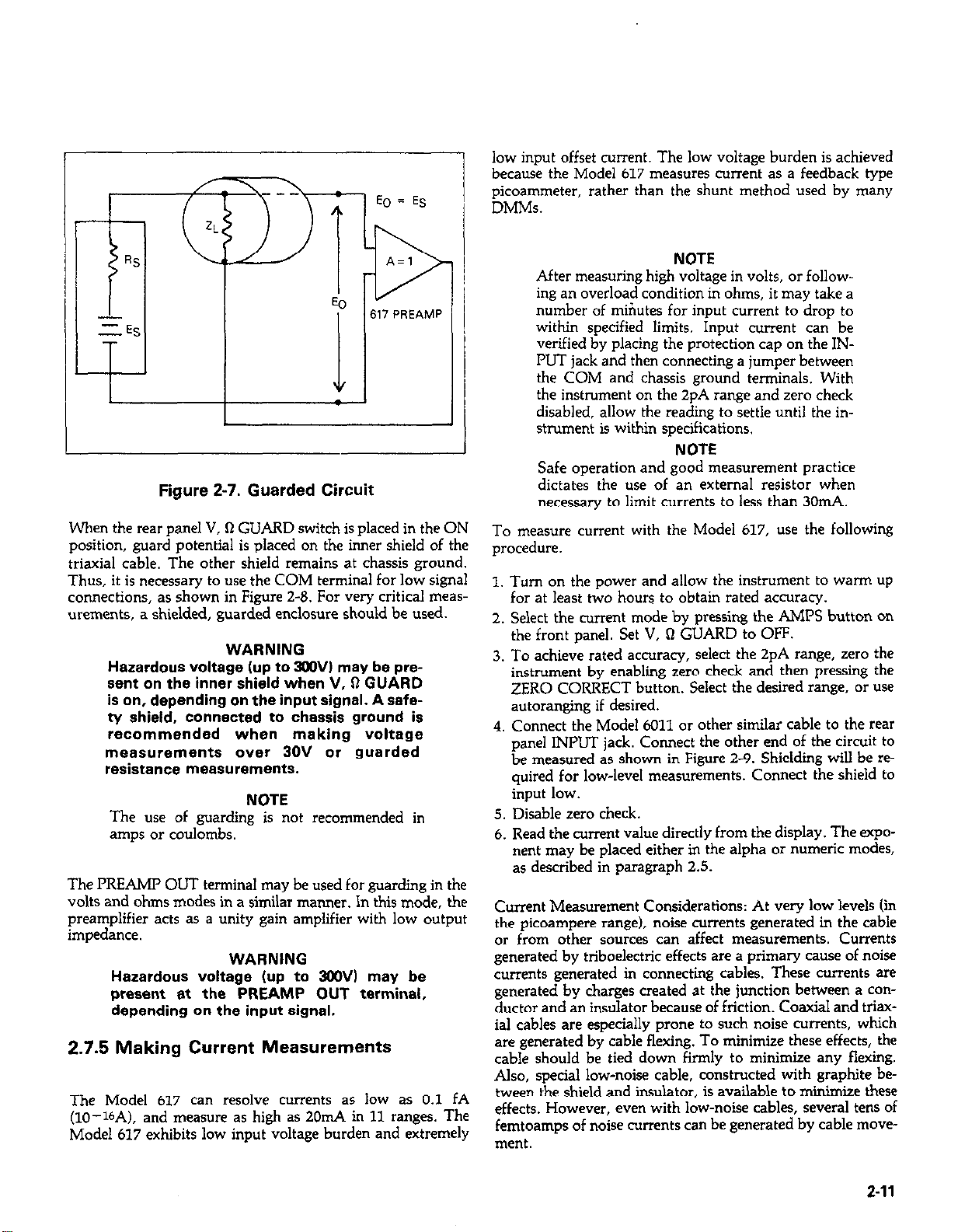

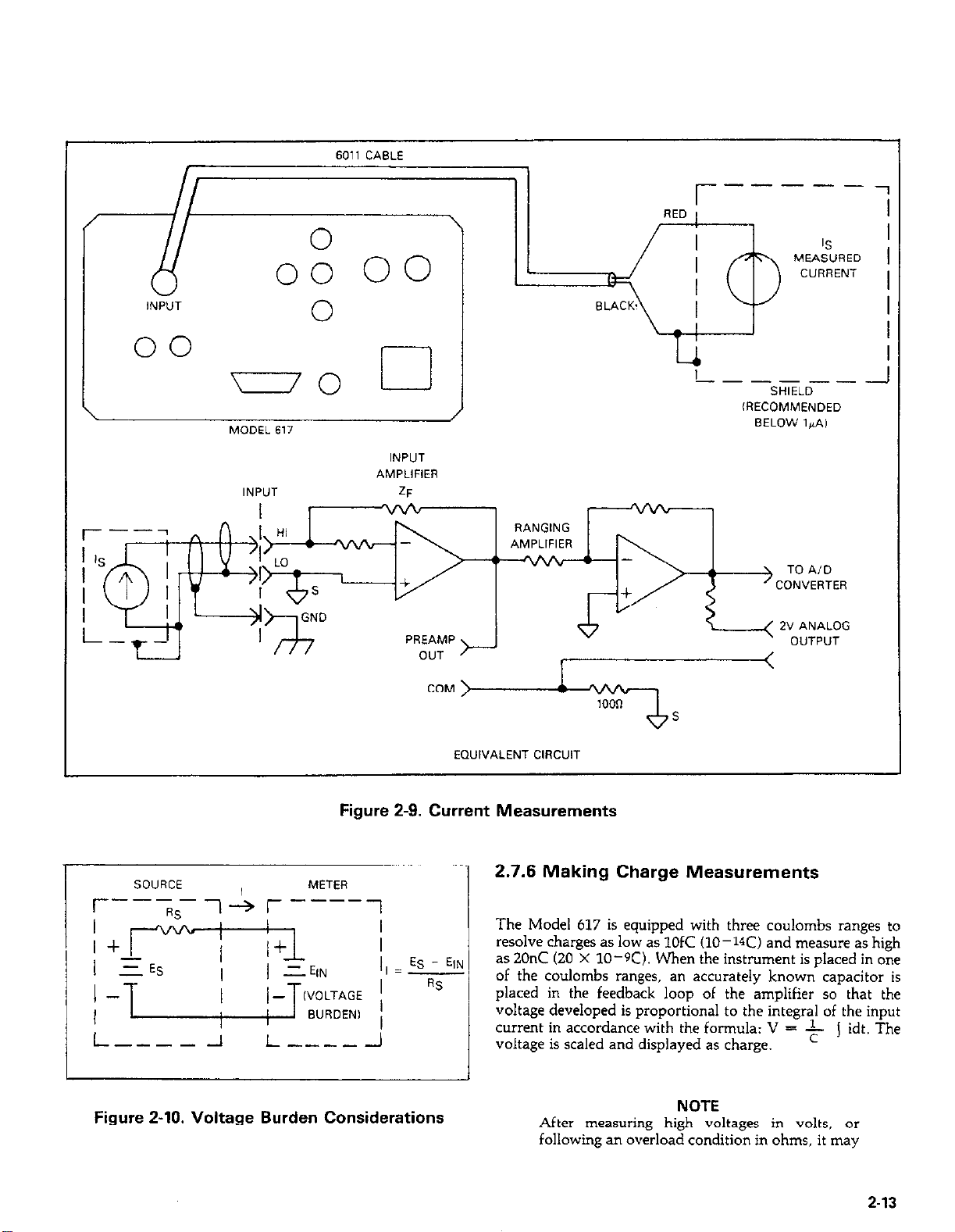

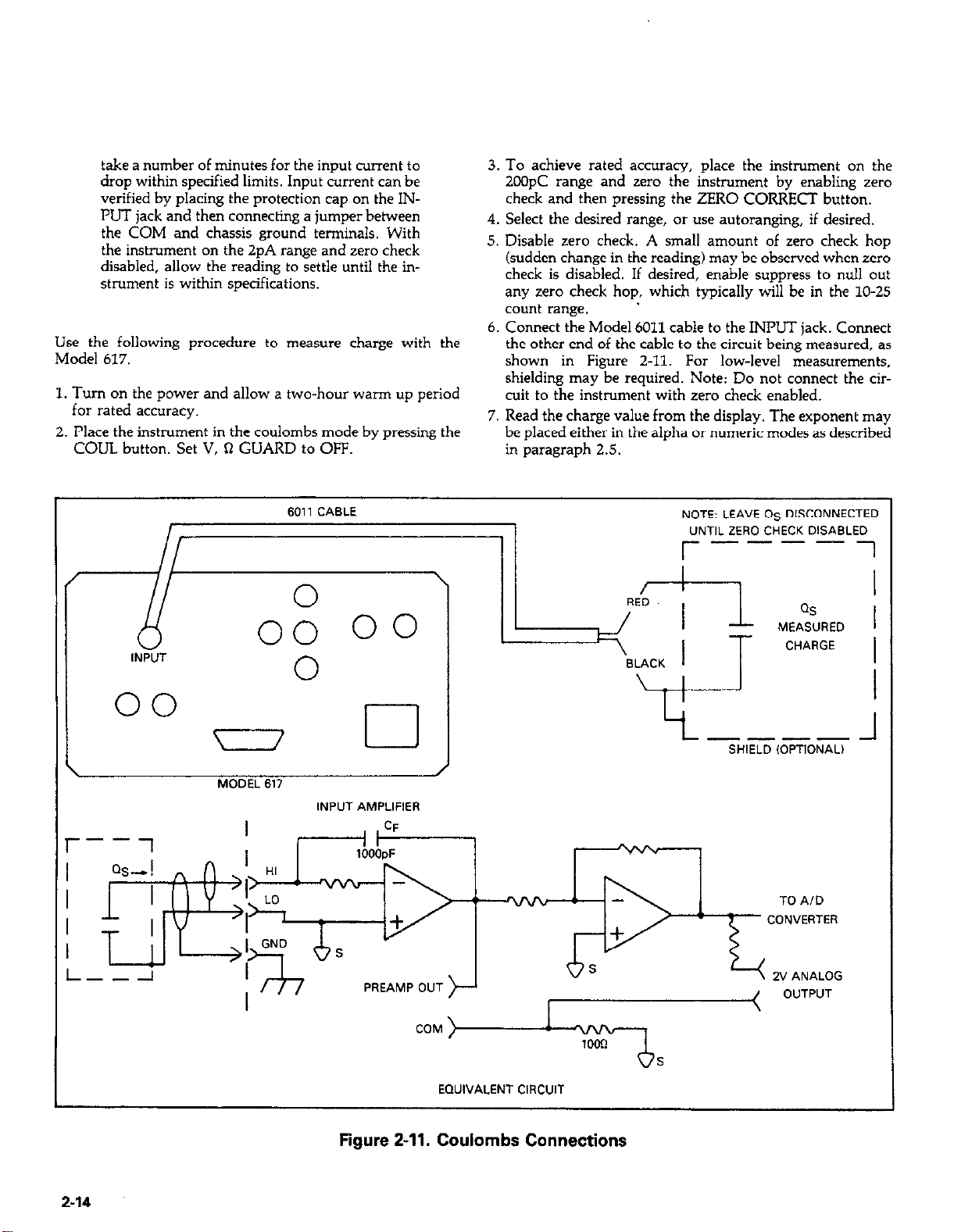

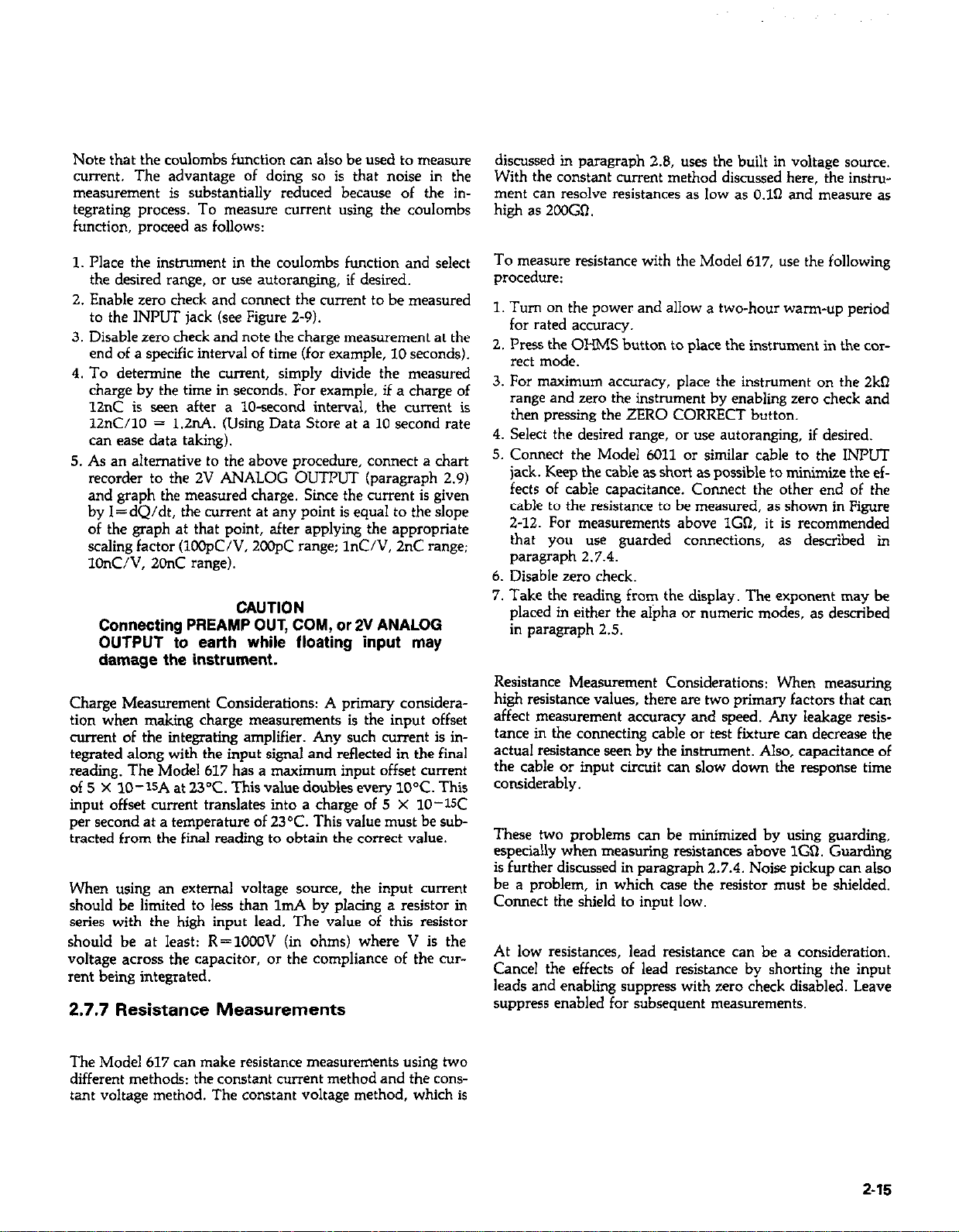

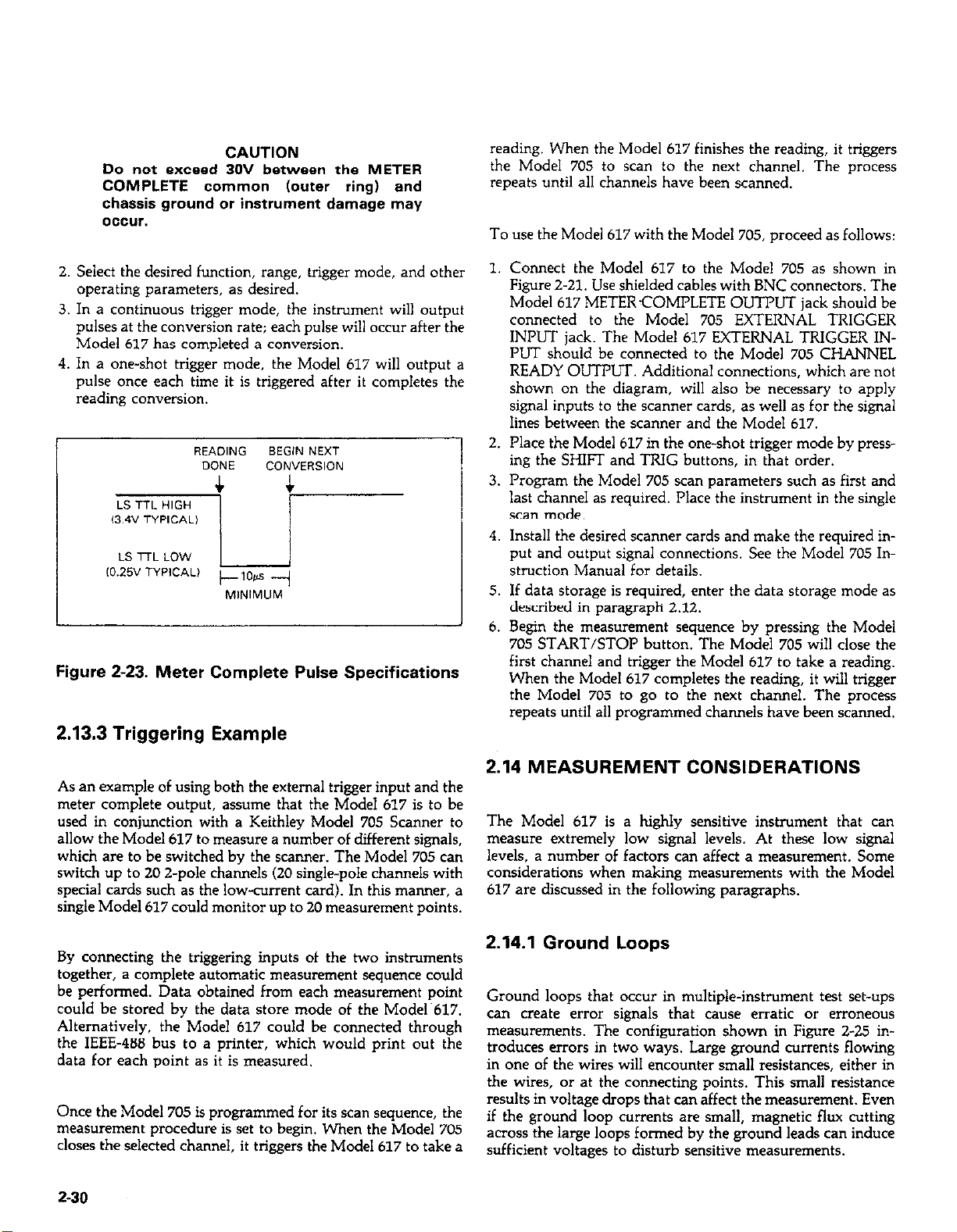

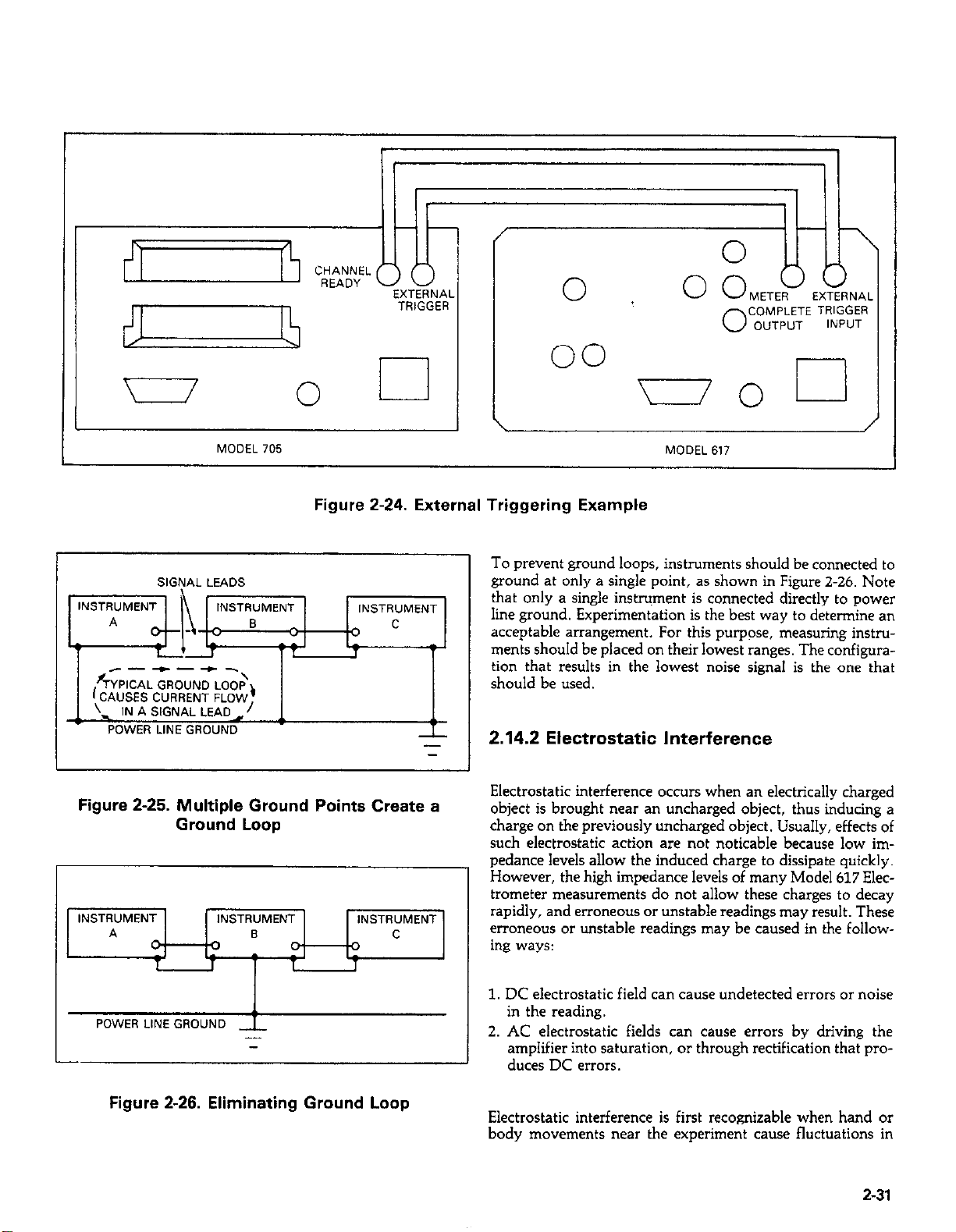

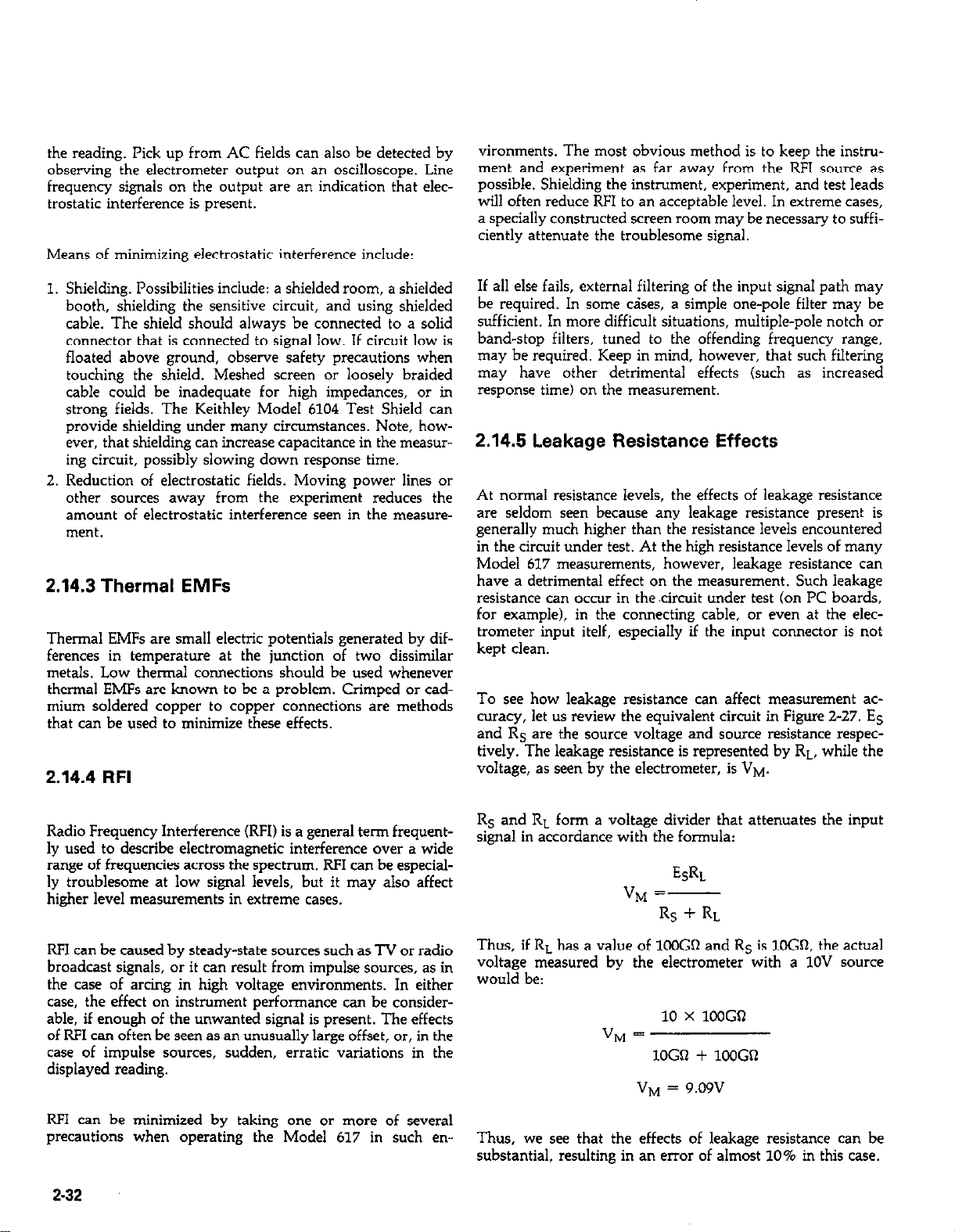

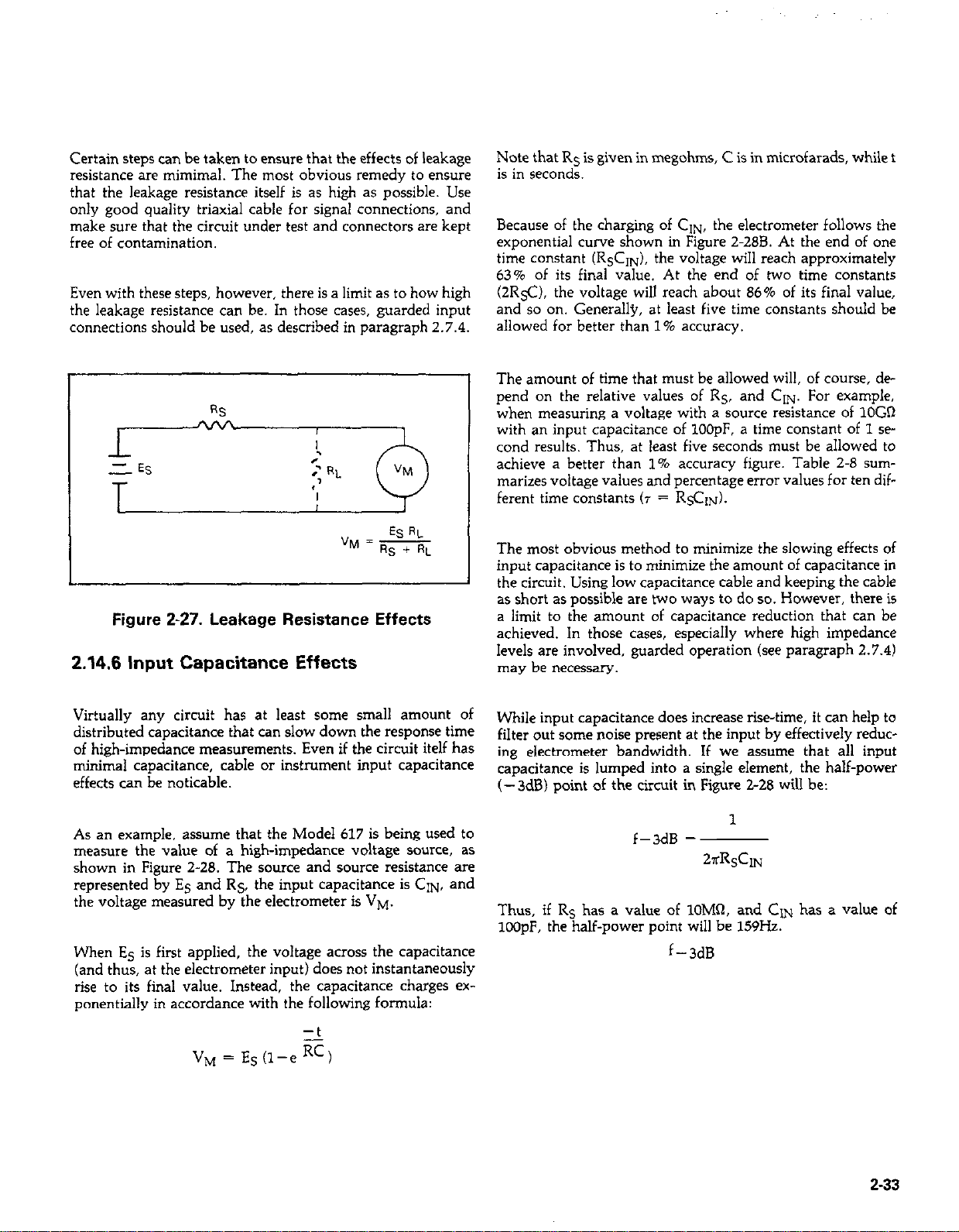

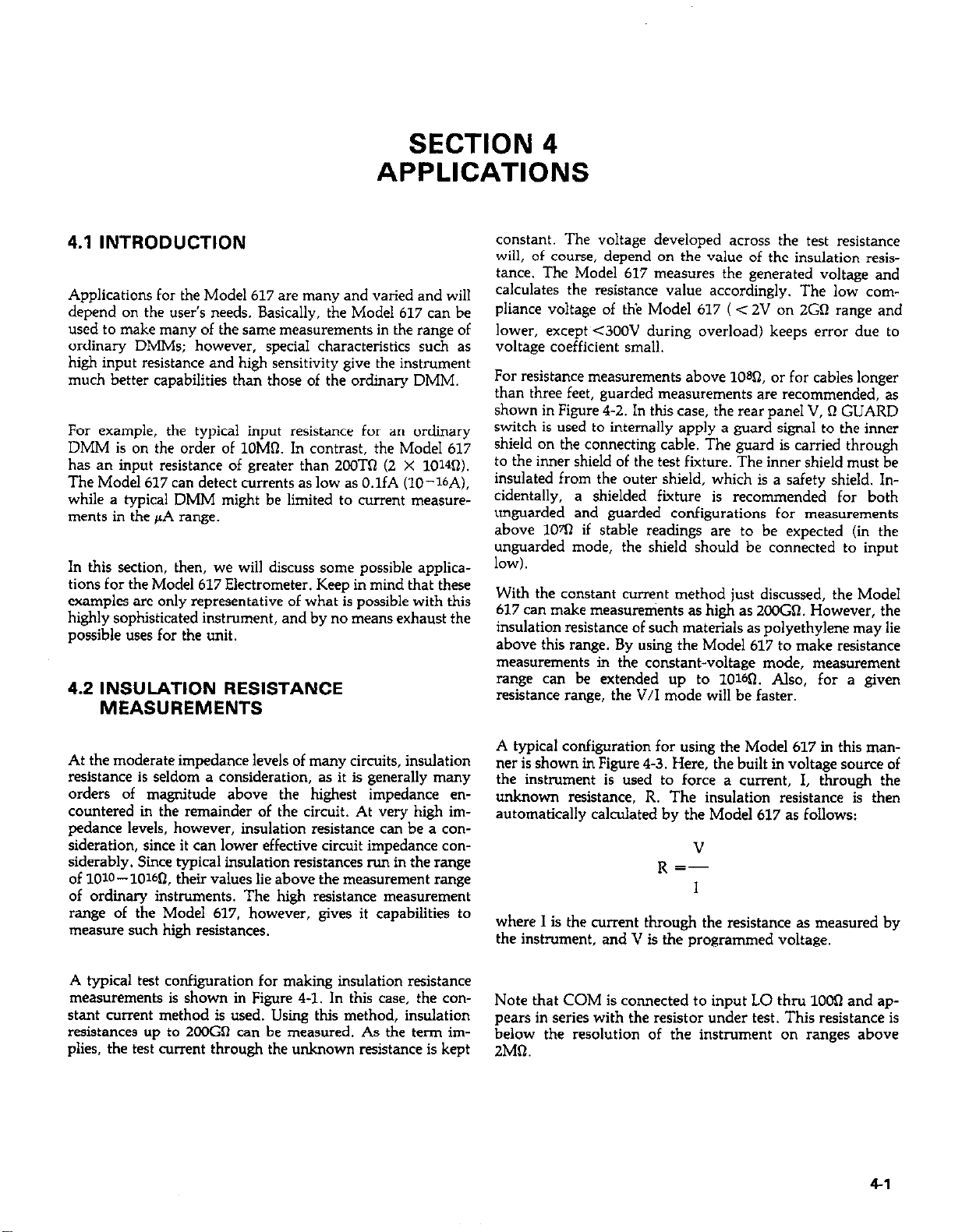

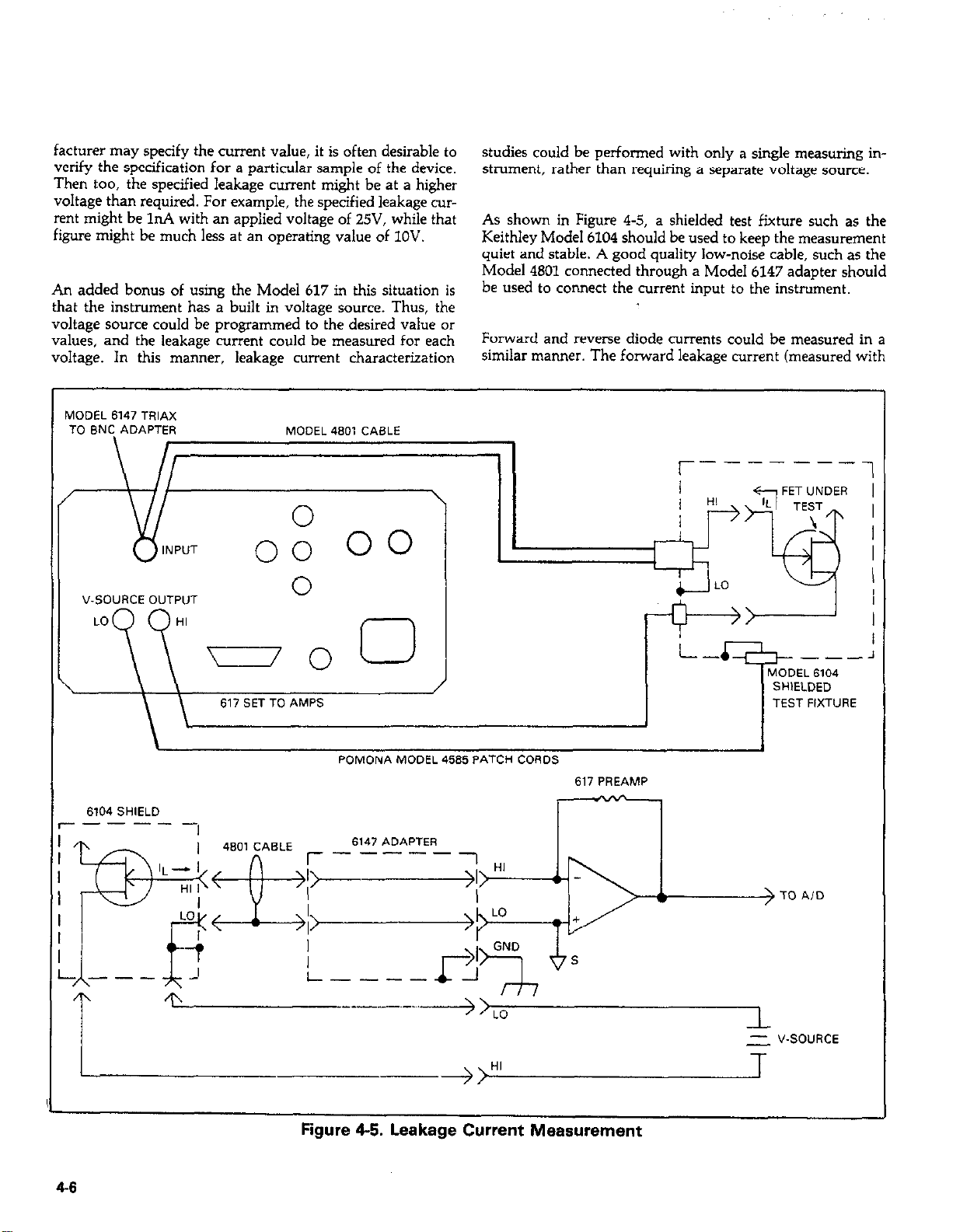

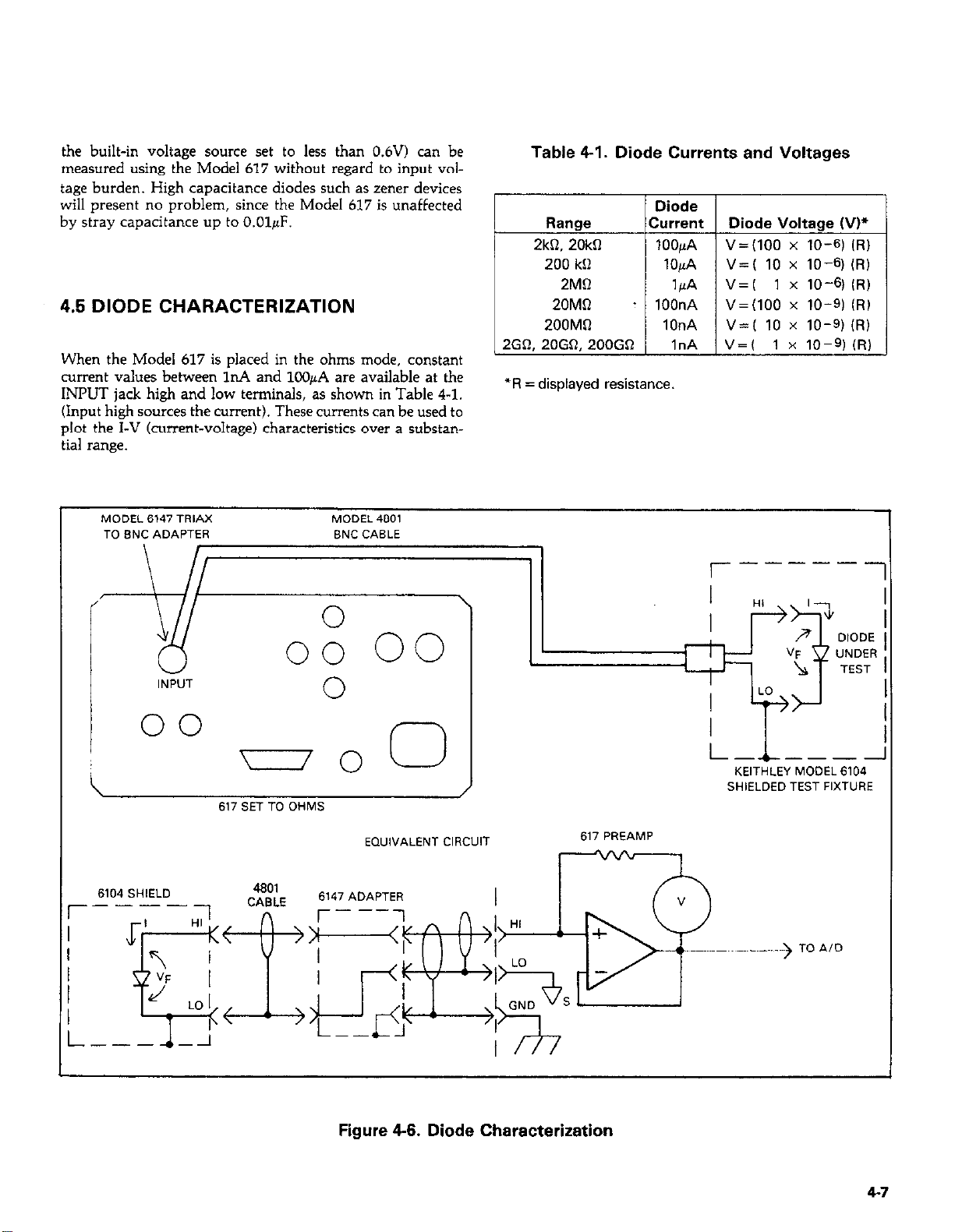

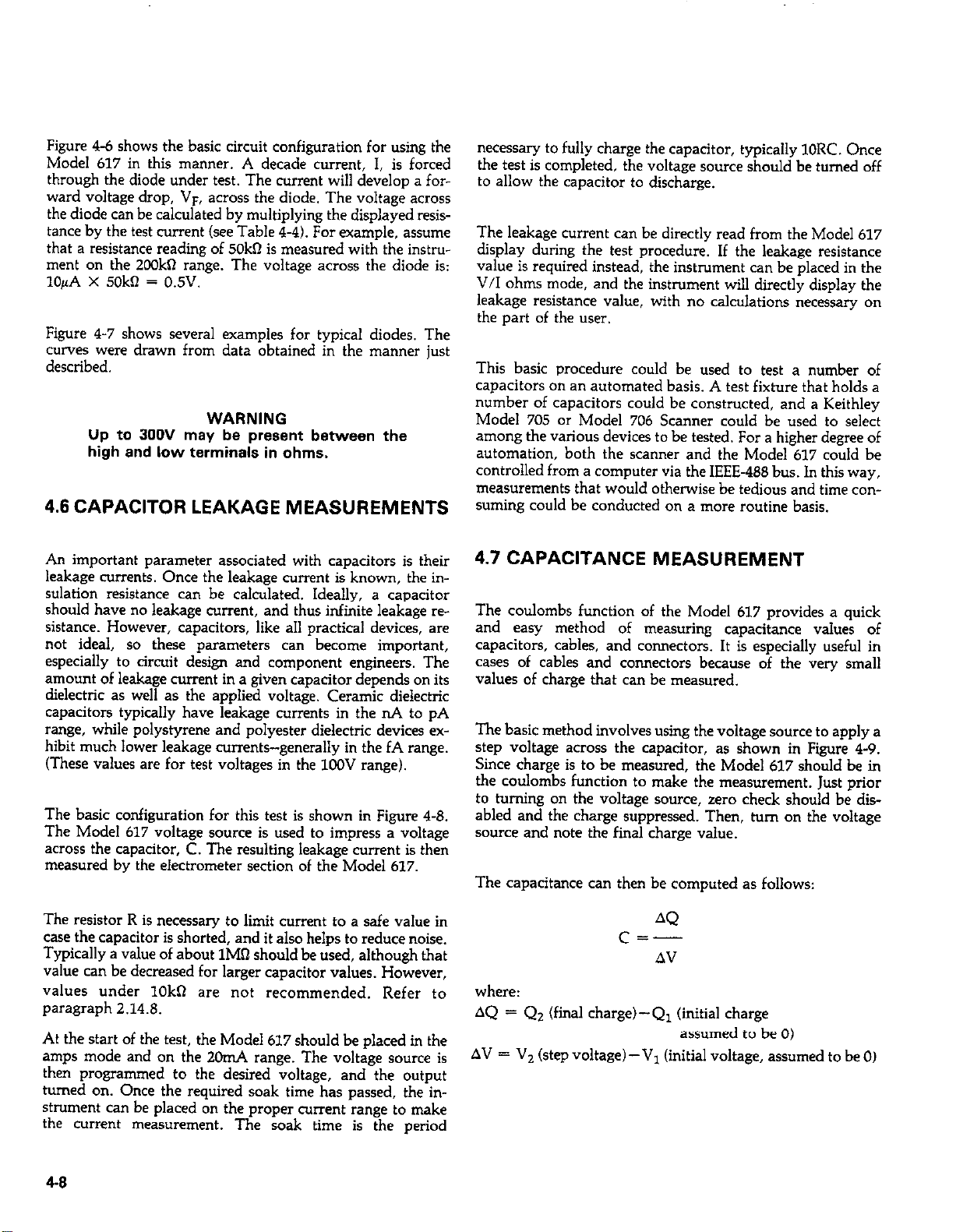

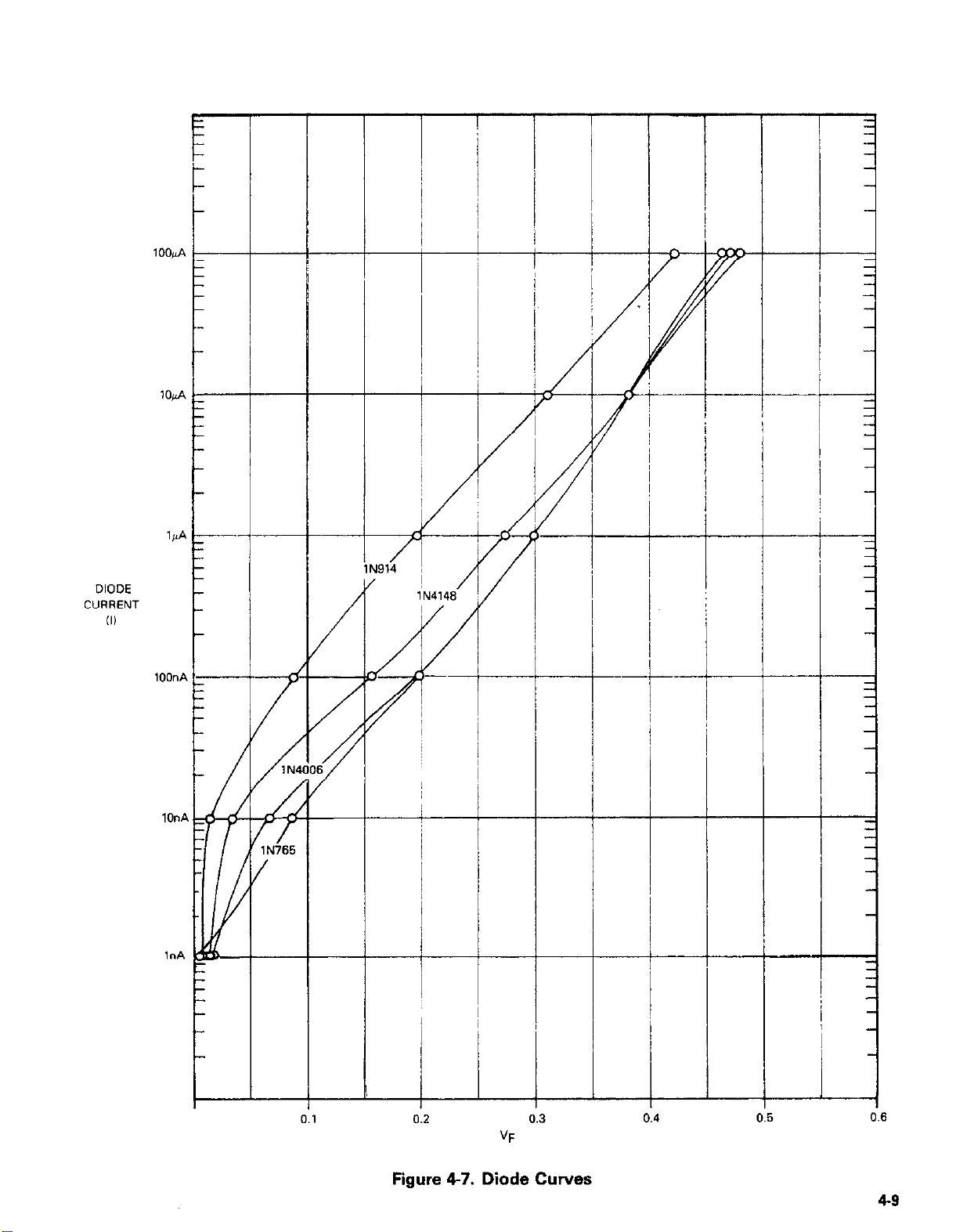

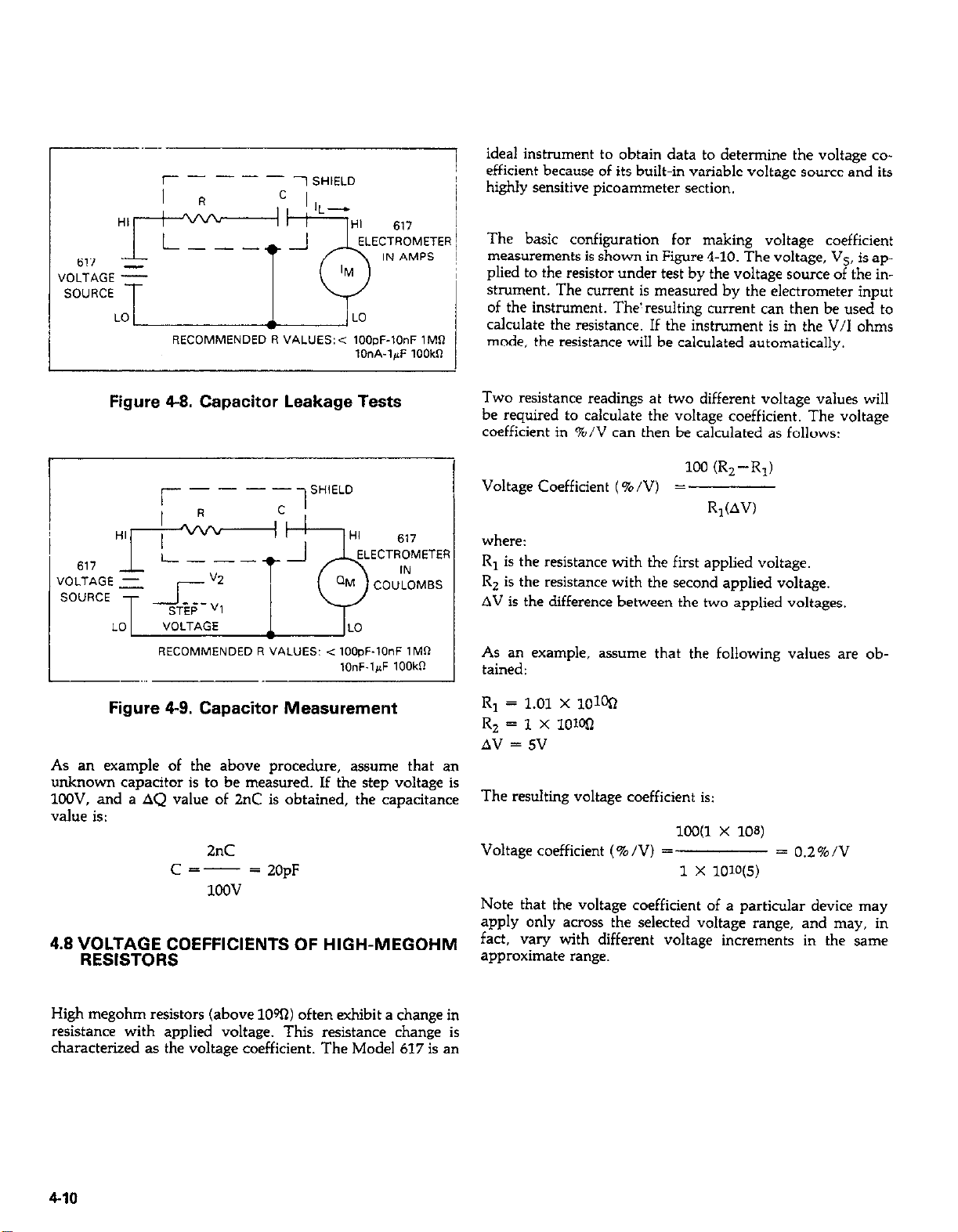

in situations requiring an accessible chassis ground terminal.