Page 1

Model

6105

Resistivity Adapter

Instruction Manual

Contains Operating and Servicing Information

Publication Date: October 1972

Document Number: 31415

Page 2

WARRANTY

Keithley Instruments, Inc. warrants this product to be free from defects in material and workmanship for a period of 1 year from date of

shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables, rcchargcablc baitcries,

diskettes, and documentation.

During the warranty period, we will, at our option, cithcr repair or replace any product that proves to be defective.

To exercise this warranty, write or call your local Keithley representative, or contact Keithley headquarters in Cleveland, Ohio. You will

bc given prompt assistance and rctum instructions. Send the product, transpot%~tion prepaid, to the indicated service facility. Repairs

will be made and the product returned, transportation prepaid. Repaired or replaced products are warranted for the balance of the origi“al warranty period, or at Icast 90 days.

LIMITATION OF WARRANTY

This warranty dots not apply to defects resulting from product modification without Keithley’s express written consent, or misuse of

any product or part. This warranty also does not apply to fuses, software, non-rechargeable batteries, damage from battery leakage, or

problems arising from normal weas or failure to follow instructions,

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. THE REMEDIES PROVTDED HEREIN ARE

BUYER’S SOLE AND EXCLUSIVE REMEDIES.

NEITHER KEITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OF ITS INSTRUMENTS AND

SOFTWARE EVEN IF KEITHLEY INSTRUMENTS, INC., HAS BEEN ADVISED IN ADVANCE OF THE POSSIBILITY OF

SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT ARE NOT LIMITED TO: COSTS OF REMOVAL

AND INSTALLATION, LOSSES SUSTAINED AS THE RESULT OF INJURY TO ANY PERSON, OR DAMAGE TO PROPERTY

Page 3

l-l. GENERAL.

SECTION 1. GENERAL INFORMATION

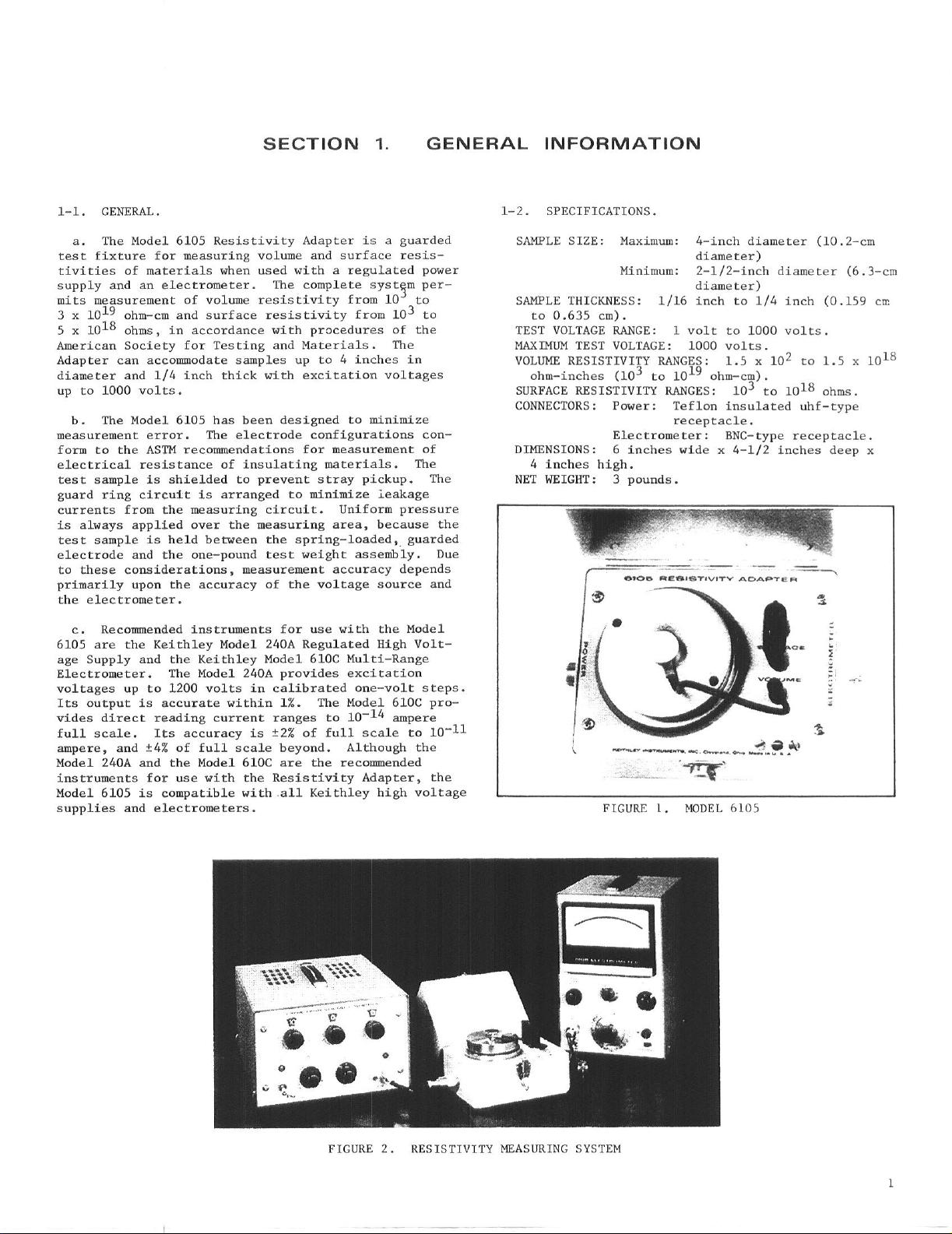

a. The Model 6105 Resistivity Adapter is a guarded

te*t fixture for measuring volume and surface resistivities af materials when used with a regulated power

supply and an eleccromecer. The complete sysc?m permits measurement of volume resistivicy from 10 c0

3 x 1019 ohm-cm and surface resiscivicy from lo3 co

5 x 1018 ohms, in accordance with procedures of cbe

American Society far Testing and Materials. The

Adapter can accommadace samples up co 4 inches in

diameter and 114 inch chick with excitation voltages

up to 1000 volt*.

b. The Model 6105 has been designed c0 minimize

measurement error.

form co the ASTM recommendations for measurement of

electrical resisrance of insulating materials. The

test sample is shielded co prevent stray pickup. The

guard ring circuit is arranged c" minimize ieakage

currents from the measuring circuit. Uniform pressure

is always applied over the measuring area, because the

cesc sample is held beween the spring-loaded, guarded

electrode and the ""e-pound cesc weight assembly. Due

co these cansideracions, measurement accuracy depends

primarily upon the accuracy of the voltage source and

the electrometer.

C. Recwmended inscrumencs for "se with the Model

6105 are the Keichley Model 240A Regulated High Voltage Supply and the Keichley Model 610C Multi-Range

Electrometer.

volcages up c" 1200 volts in calibrated one-volt steps.

Ifs oufput is accurate within 1%. The Model 61OC pro-

vides direct reading current ranges c" lo-l4 ampere

full scale.

ampere, and f4% of full scale beyond. Although the

Model 240A and the Model 610C are the reccmmended

instruments for "se with the Resistivity Adapter, the

Model 6105 is compatible vich.all Keithley high voltage

supplies and electrometers.

Its accuracy is fZ% of full scale f" 10-11

The electrode configurations con-

The Model 240A provides excicacion

SAMPLE SIZE: Maximum:

Minimum:

SAMPLE THICKNESS: l/l6 inch co 114 inch (0.159 cn

to 0.635 cm).

TEST VOLTAGE i&GE: 1 volt c" 1000 vales.

MAXIMUM TEST VOLTAGE:

""LUME

SURFACE RESISTI"ITI RANGES: lo3 cr, 10IS ohms.

CmNECTORS: Power: Teflon insulated uhf-type

"IMENSlONS: 6 inches wide x 4-l/2 inches deep x

NET WEIGHT: 3 pounds.

RESISTI"ITY RANGES: 1.5 x 102 to 1.5 x 1018

ohm-inches (lo3 co 101' ohm-cm).

Electrometer: BNC-type recepcac1e.

4 inches high.

FIGURE 1. MODEL 6105

4-inch diameter (10.2-a

diameter)

Z-l/Z-inch diameter (6.3-cm

diameter)

1000 "OlCS.

receptacle.

Page 4

SECTION 2.

2-l. PREPAEATION FOR USE. The Model 6105 is shipped

with two thumb-screw fasteners holding the test weight

to the guard ring. Remove ehese fasteners and store

for later use.

they should not be used during measurements. In

mounting the sample for measurement, make sure there

are no conductive paths between the electrodes other

than those through the sample. The sample should be

supported from the electrodes so that the elecrrodes

do not touch anything excep,t the sample. Do nof handle

the sample with bare fingers; acetate rayon gloves are

recomended.

faces with an alcohol and ether mixture or'other suitable solvent.

a. Volume Resisrivity Measurements. Place the

short circuit plug o"er the upper wo jacks, leaving

"VOLITME" clearly visible. Inserf the banana plug from

the fest weight assembly into the bottom jack. Close

the Model 6105 cover. An interlock switch disconnecrs

the potential to the sample if the co"er is opened.

Apply the power supply voltage. Read the current on

the electrometer. The value of the volume resisrivity

p, is found through one of the following calculations:

where p is the volume resistivity of the sample;

V is the applied voltage from rhe parer supply

in volts;

ti is the average thickness of the sample in

inches;

tc is the average thickness of the sample in

centimeters; trometer .

I is the current reading from the elecrrmerer.

These are used only for shipping and

For best results, clean the sample sur-

3.53 v

p = x ohm-inches

I

_ 22.9 v

ohm-centimeters

% 1

b. Surface Resisrivicy Measurements. Place the

short circuit slug over the lower two iacks, leavina

"SURFACE" cle&ly-visible. Insert the-ban&a plug I

from the fesf weight assembly into the top jack. Close

the Model 6105 cover.

age. Read the current on the electrometer. The value

of the surface resistivity is found through the following calculation:

where 0 is the surface resistivity of the sample;

V is the applied voltage from the power supply

in volts;

I is rhe cu+rent reading from the electrometer.

2-2. CONNECTIONS. Connect the power supply to the

uhf-type recepracle. Connect the electrometer to the

bnc-type receptacle. Place rhe sample under the test

weight

should be between l/l6 and 114 inch (0.159 and 0.635

cm). The diameter should be beween 2-l/2 and 4 inches

(6.29 and 10.2 cm).

2-3.

menc Of a sample. The test sample is placedabeween

the two electrodes; the desired test potential is

selected from the voltage supply and the current passing through the test sample is measured by the elec-

the electrometer, the resistiviries can be computed.

as shown in Figure 5.

PROCEDURE.

From

readings from the voltage supply and

Apply the power supply "olt-

The sample thickness

The Model 6105 Demits eas" measue-

I

118

in.

.31 cm. I

FIGURE 3. DIMENSIONING FOR MODEL 6105 ELECTRODES

2

1

Page 5

SURFACE

RESISTIVITY NOMOGRAPH RESISTIVITY NOMOGRAPH

.r

p, : 53.36 y

EXAMPLE:

200 “d’s

,O, = 3.56.10”ohm,

__--

3.0x lO%mps

_---

I ohms

_*--

.ly---

_*-- ”

- 100 100

2-

i i

= 10’0 10’0

1

= 10”

z

0 1

- 10’2

2 -

; 10’3

;i

z _A--

2 10”

!s -

10’5

3 lo-’

e 10-a

___

y lo-”

= 10’6 10’6

2 10” 10”

VOLTAGE

RESISTIVITY RESISTIVITY

VOLUME RESISTIVITY NOMOGRAPH

- 10-12

CURRENT

-

10-12

-

10-l’

.--__

=

10-10 kc

-

10-q 2

5

z

i

5

s

l-i

THICKNESS

I

VOLTA1

GE

lo9

RESISTIVITY

= 10-e

2-3 10-T

CURRENT

Page 6

SECTION 3.

THEORY OF OPERATION

VOLUME RESISTIVITY. The ASTM Standard* states

3-l.

that volume resistivity, o, shall be calculated as

follows:

where K is the volume resistance, in ohms, measured

For the Model 6105, which uses circular electrodes,

A is

where Do is the dimension indicated in Figure 3. For

the Model 6105, Do is equal to Z-118 inches or 5.40 cm.

as specified in the publication;

t is 'the average thickness of the sample:

A is the effective area of the guarded electrode

for the particular elecmode arrangement

employed.

IT2

A=$.

VOLUME

3-2. SURFACE KESISTI"ITY. The ASTM Standard* states

that surface resistivity, s, shall be calculated as

follows:

where R is the surface resistance, in ohms, measured

as specified in tl>e publication;

g is the distance between the electrodes;

P is the effective perimeter of the guarded

electrode for the particular electrode

arrangemenr employed.

For the Model 6105, which uses circular electrodes,

P, is

P = Do r

where Do is the dimensj~on indicated in Figure 3.

FIGUP.% 4. "OLum RESISTIVITY

*American Society for Testing and Materials, Standard

Methods of Test for Electrical Resistance of Insul-

acing Materials, ASTM Designation D257-66

4

FIGURE 5. SOWACE RESISTIVITY

Page 7

SECTION 4.

MAINTENANCE

ReSiSti”ity Adapter 80164 wade1 6105

1 Test Weight, Stainless Steel 80164 16371A

2

3 Test Lead Assembly 80164 157063

4 Banana Pl.“g

5 FE fener , Thumb-screw 80164 SK-4

6

8 . Guard Ring Insulator 80164 15708A

9 Receptacle, bnc

10 Receptacle, uhf, Mil. x0. so-239

II ildifed Short circuit Plug 80164 23443A

. ‘Test Weight Assembly 801~64 15702A

. Handle Assembly 80164 16231A

108-303

Banana Jack (3 rcqd.)

chard Ring

Test Plate Assembly 80164 15709B

Test Plate 80X4 3~6369A

&ate of bnc receptacle)

im of uhf receptacle, Mil. NO. 49190

108-901

31-221

31-002

6804

5127 91737 c-49

74970 Lx-5

7497" W-6

80164 1637OPx

02660 cs-15

02660 cs-44

91737 cs-64

Page 8

Test Instrumentation Group

Keithley Instruments, Inc.

20775

Cleveland, Ohio 44139

Aurora Road

Printed

in the tJ.S.A

Loading...

Loading...