Page 1

MODEL 602

INSTRUCTION MANUAL

Instruction Manual

Solid-State Electrometer

Model 602

Publication Date: June 1963

Document Number: 29111 Rev. C

Contains Operating and Servicing Information for the

Model 602 Solid-State Electrometer

01975, Keithley Instruments, Inc.

Cleveland, Ohio, U.S.A.

Document Number 29111

Page 2

WARRANTY

Keithley Instruments. Inc. warrants this product to be free from defects in material and workmanship for a period of 1 year from date of

shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables, rechargeable batteries,

diskettes, and documentation.

During the warranty period, we will, at our option, either repair or replace any product that proves to be defective.

To exercise this warranty, write or call your local Keithley representative, or contact Keithley headquarters in Cleveland, Ohio. You will

be given prompt assistance and return instructions. Send the product, transportation prepaid, to the indicated service facility. Repairs

will be made and the product returned, transportation prepaid. Repaired or replaced products we warranted for the balance of the original warranty period, or at least 90 days.

LIMITATION OF WARRANTY

This warranty does not apply to defects resulting from pmduct modification without Keithley’s express written consent, or misuse of

any product or part. This warranty also does not apply to fuses, software, non-rechargeable batteries, damage from battery leakage, or

problems arising from normal wear or failure to follow instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. THE REMEDIES PROVIDED HEREIN ARE

BUYER’S SOLE AND EXCLUSIVE REMEDIES.

NEITHER KEITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OF ITS INSTRUMENTS AND

SOFTWARE EVEN IF KEITHLEY INSTRUMENTS, INC., HAS BEEN ADVISED IN ADVANCE OF THE POSSIBILITY OF

SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT ARE NOT LIMITED TO: COSTS OF REMOVAL

AND INSTALLATION, LOSSES SUSTAINED AS THE RESULT OF INJURY TO ANY PERSON, OR DAMAGE TO PROPERTY.

Keithley Instruments, Inc. - 28775 Aurora Road * Cleveland, OH 44139 * 216-248-0400 *Fax: 216-248-6168 * http://www.keithley.com

Page 3

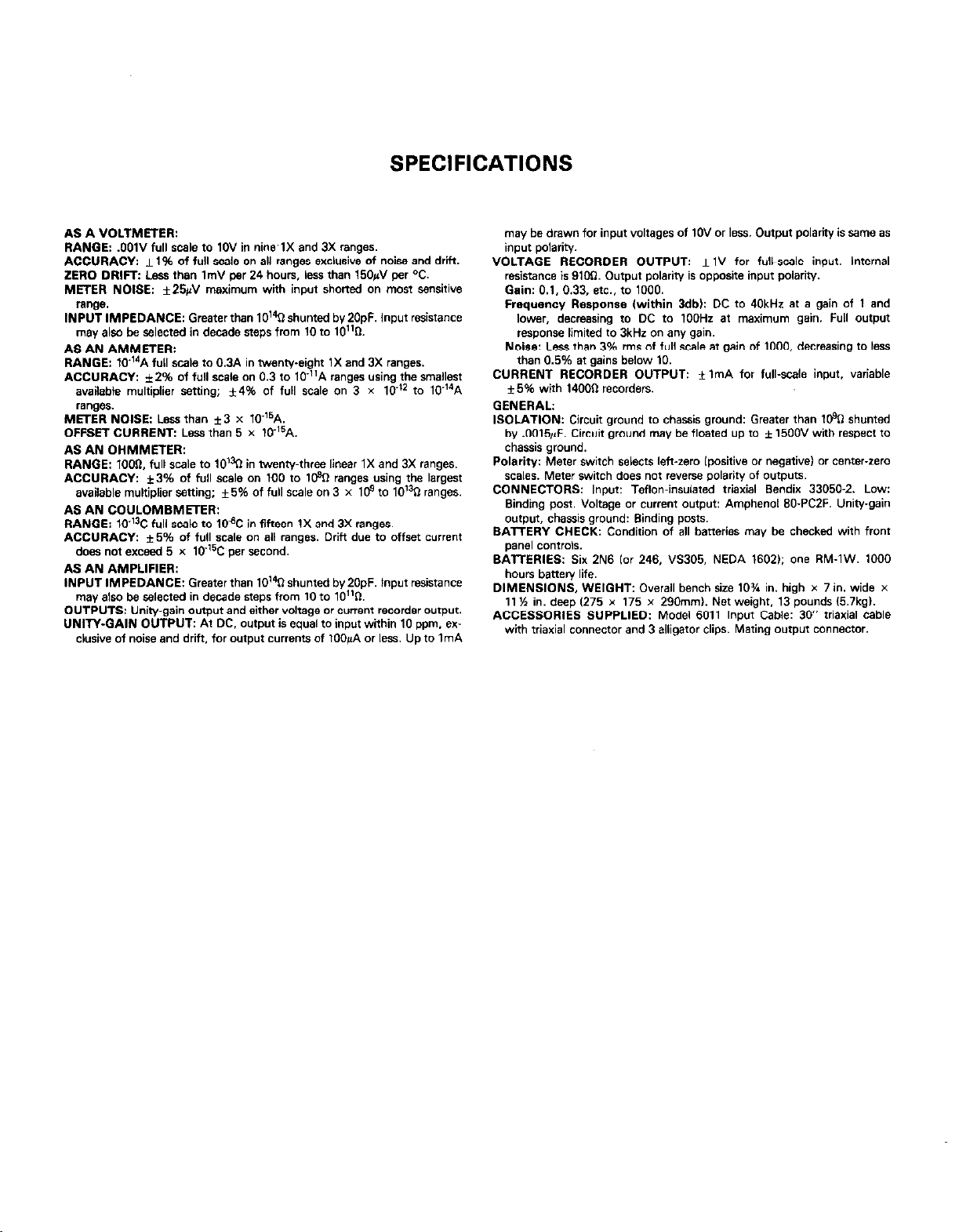

SPECIFICATIONS

AS A VOLTMETER:

RANGE: .OOlV full scale to 1OV in nine’lX and 3X ranges.

ACCURACY: f 1% of full scale on all ranges exclusive of noise and drii.

ZERO DRIFT: Less than Im” per 24 hours, Ikss than 150@ per OC.

METER NOISE: *25&J maxim”m with input shoned on most sensitive

IN?~?iMPEDANCE: Greater than lo’% shunted by2OpF. Input resistance

AS iN AMMETER:

RANGE: lCr14A full scale to 0.3A in twenty-eight 1X and 3X ranges.

ACCURACY: 12% of full scale on 0.3 to 10”A ranges using the mallest

available multiplier setting; *t4% of full scale on 3 x lo-l2 fo 10-14A

ranoes.

METER NOISE: Less than f3 x 10-16A.

OFFSET CVRRENT: Lens than 5 x 10-15A.

AS AN OHMMETER:

RANQE: 7000, full scale to 10% in twent+hree linear IX and 3X ranges.

ACCURACY: *3% of full scale on 100 to l@Q ranges using the largest

available multiplier stting; f5% of full scale on 3 x 109 to 1O’jn ranges.

AS AN COULOMBMETER:

RANGE: lo-‘? full scale to 10dC in fifteen IX and 3X ranges.

ACCURACY: f5% of full scale on all ranges. Dritt due fo offset current

does no, exceed 5 x 10.=C per second.

AS AN AMPLIFIER:

tNPUT IMPEDANCE: Greater than 10’40 shunted by2OpF. input resistance

may a,so be ~&cted in decade steps from 10 fo lO”O.

OUTPUTS: Unitygain output and either voltage or cment recorder o”tp”t.

UNITY-QAIN OUTPUT: At DC, o”tp”t is equal to input within 10 ppm. ex-

clusive of noise and drib?. for o”tp”t currents of lOO@ or less. Up 10 ImA

may be drawn for input voltages of 10” or less. Output polarity is same as

input p&dry.

VOLTAGE RECORDER OUTPUT: *lV for full-scale input. Internal

resistance is g1M1. Output polarity is opposite input polarity.

Gain: 0.1. 0.33, a.. to 1000.

Frequmw Response lwithin 3db): DC to 40kHr 81 a gain of 1 and

lo&, &e&g to DC to 1OOHz at maximum gain. Full o”tp”t

response limited to 3kHz on any gain.

Noise: Less than 3% ms of full scale at gain of 1000. decreasing 10 less

than 0.5% ar gains below 10.

CURRENT RECORDER OUTPUT: i ImA for full-scale input. variable

f6% wtih 14OOll recorders.

GENERAL

ISOLATION: Circuit ground to chassis ground: Greater than l@Q shunted

by .0016~F. Circuit ground may be floated up to f 15OOV with wpecf to

chassis ground.

Polarity: Meter *witch seIects lefvzero Ipositive or negative) or center-zero

scales. Meter witch does nof reverse polarity of o”fp”tS.

CONNECTORS: Input: Teflon-insulated tdaxial Bendix 33050-Z. Low:

Binding post. Voltage or currem o”tp”t: Amphenol 60.PCZF. Unity-gain

o”tp”1, chassis ground: Binding posts.

BATTERY CHECK: Condition of all baneries may be checked with front

paw co”trok.

BATTERIES: Six 2N6 lor 246. VS306. NEDA 16021: one RM-1W. 1000

DIMENSIONS. WEIGHT: Overall bench size 10% in. high x 7 in. wide x

11 ‘h in. deep 1276 x 175 x 2gOmm). Net weight. 13 pounds l57kgl.

ACCESSORIES SUPPLIED: Model 6011 Input Cable: 30” triaxial cable

with friaxial connector and 3 alligator clips. Mating o”tp”f connector.

Page 4

Page 5

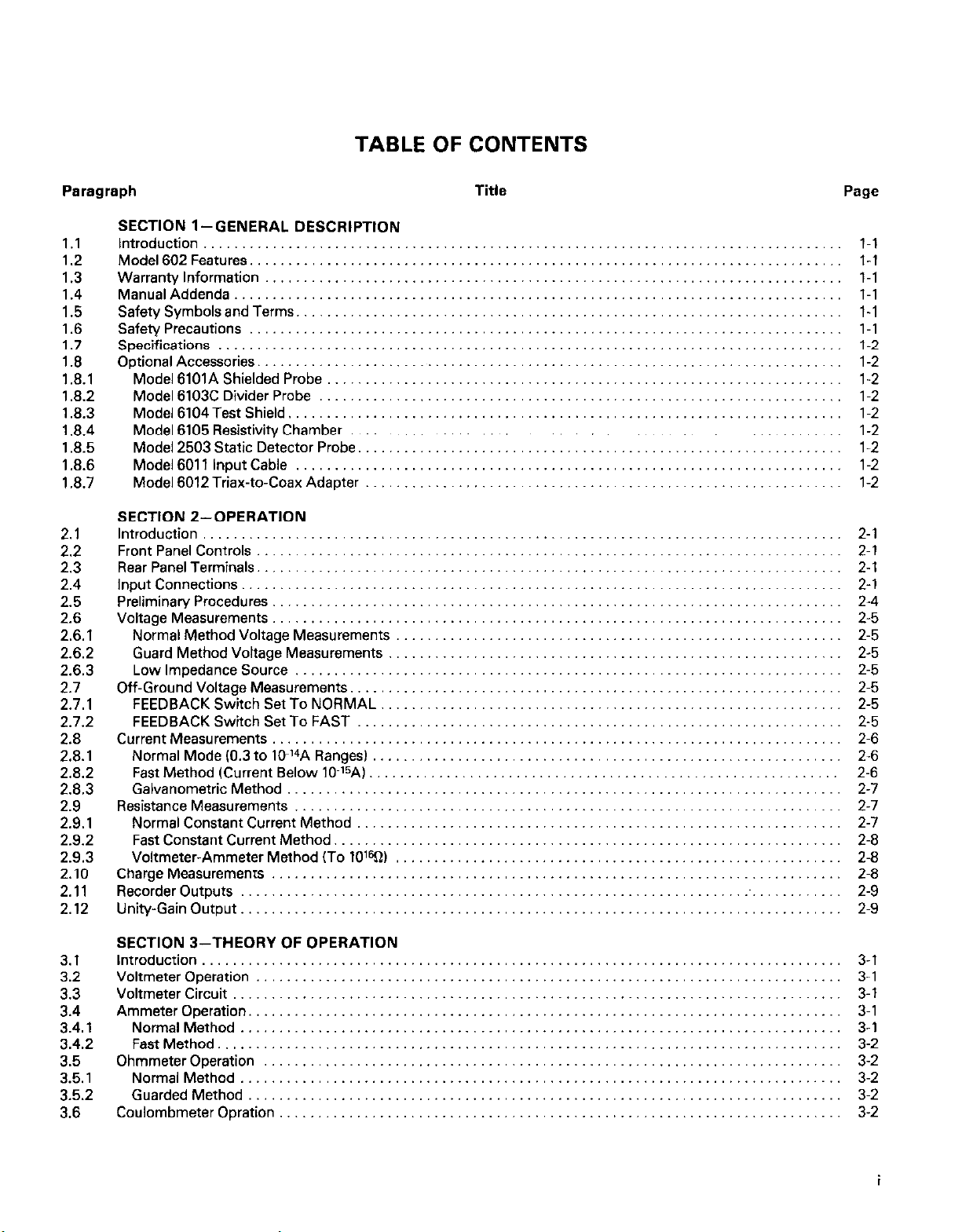

TABLE OF CONTENTS

Paragraph

SECTION l-GENERAL DESCRIPTION

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.8.1

1.82

1.8.3

1.8.4

1.8.5

1.8.6

1.8.7

2.1

2.2

2.3

2.4

2.5

2.6

2.6.1

2.6.2

2.6.3

2.7

2.7.1

2.7.2

2.8

2.8.1

2.6.2

2.8.3

2.9

2.9.1

2.9.2

2.9.3

2.10

2.11

2.12

Introduction ...........................

Model 602 Features. ....................

Warranty Information ...................

ManualAddenda

Safety Symbols and Terms. ..............

Safety Precautions

Specifications .........................

Optional Accessories. ...................

SECTION Z-OPERATION

Introduction ..........................

Front Panel Controls ...................

Rear Panel Terminals. ..................

Input Connections .....................

Preliminary Procedures. ................

Voltage Measurements. ................

Off-Ground Voltage Measurements .......

Current Measurements .................

Resistance Measurements ..............

Charge Measurements .................

Recorder Outputs .....................

Unity-Gain Output .....................

.......................

.....................

Model 6101A Shielded Probe ...........

Model 6103C Divider Probe

Model 6104Test Shield. ...............

Model 6105 Resistivity Chamber ........

Model 2503 Static Detector Probe.

Model 6011 Input Cable ...............

Model 6012 Triax-to-Coax Adapter ......

Normal Method Voltage Measurements

Guard Method Voltage Measurements

Low Impedance Source ..............

FEEDBACK Switch Set To NORMAL ...

FEEDBACK Switch Set To FAST ......

Normal Mode IO.3 to lO~‘4A Ranges) ....

Fast Method (Current Below lo-=A) ....

Galvanometric Method ...............

Normal Constant Current Method ......

Fast Constant Current Method. ........

Voltmeter-Ammeter Method (To 10%)

............

......

................

................

................

................

................

................

................

................

................

................

................

................

................

.............

.............

.............

.............

.............

.............

.............

.............

.............

.............

.............

.............

.............

.............

.............

.............

.............

.............

.............

Title Page

.........

...... ..

.........

.........

.........

.........

.........

.........

.........

.........

1-l

l-l

l-l

l-l

l-1

l-l

1-2

1-2

1-2

1-2

1-2

1-2

1-2

1-2

1-2

2-1

2-l

2-l

2-l

2-4

2-5

2-5

2-5

2-5

2-5

2-5

2-5

2-6

2-6

2-6

2-7

2-7

2-7

2-8

2-8

2-8

2-9

2-9

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

.............

.............

.............

.............

.............

.............

.............

.............

.............

.............

.............

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

3.1

3.2

3.3

3.4

3.4.1

3.4.2

3.5

3.5.1

3.5.2

3.6

SECTION 3-THEORY OF OPERATION

Introduction ..........................

Voltmeter Operation ...................

Voltmeter Circuit ......................

Ammeter Operation. ...................

Normal Method .....................

Fast Method. .......................

Ohmmeter Operation ..................

Normal Method .....................

Guarded Method ....................

Coulombmeter Opration ................

......

......

......

......

......

......

......

......

......

......

......

,,....

......

......

......

......

......

.,....

.............

.............

.............

.............

.............

.............

.............

.............

.............

......

......

3-l

3-1

3-l

3-1

3-l

3-2

3-2

3-2

3-2

3-2

Page 6

4.1

4.2

4.2.1

4.2.2

4.3

4.4

4.5

4.6

4.7

4.8

4.9

4.10

4.10.1

4.10.2

4.10.3

4.10.4

4.11

4.12

4.13

4.14

4.14.1

4.14.2

4.15

4.16

SECTION 4--SERVICING INFORMATION

Introduction ...................................................................................

Calibration

RecommendedEquipment

....................................................................................

.....................................................................

CalibrationSchedule ..........................................................................

Preliminary Procedures

Mechanical Meter Set and Meter Zero Calibration

Tracking Check and 1MA Output Calibration

..........................................................................

....................................................

........................................................

NoiseCheck ...................................................................................

OffsetCurrentCheck

DrinCheck

....................................................................................

High-Megohm ResistorVerification.

AccuracyCheck

...........................................................................

...............................................................

...............................................................................

VoltageAccuracyCheck .......................................................................

CurrentAccuracyCheck .......................................................................

ResistanceAccuracyCheck

....................................................................

ChargeAccuracyCheck .......................................................................

Unity-GainCheck

..............................................................................

FrequencyResponseCheck ......................................................................

CommonModeRejectionCheck ..................................................................

Troubleshooting ...............................................................................

Servicing Schedule ...........................................................................

Par&Replacement

Procedures To Guide Troubleshooting

Servicing High Impedance Circuitry

...........................................................................

.............................................................

................................................................

41

4-l

4-l

4-l

4-l

4-2

4-2

4-2

z

4-3

4-3

43

2

4-4

zl

4.4

45

z

4.2

4-6

5.1

5.2

5.3

5.4

5.5

5.6

5.7

SECTION S-REPLACEABLE PARTS

Introduction

...................................................................................

PartsList .....................................................................................

OrderingInformation ............................................................................

FactoryService ................................................................................

Special Handling of Static Sensitive Devices

ComponentLocationDrawing

....................................................................

........................................................

SchematicDiagram.........................,.,.............,,..,............................... o-1

5-l

5-l

51

5-l

51

51

r*

ii

Page 7

LIST OF FIGURES

Figure

Model 602 Front Panel Controls

2-1

Model 602 Rear Panel Terminals

2-2

Triaxiallnput ..........................................................

2-3

Error Due to Ammeter Resistance.

2-4

Measuring Current by the Galvanometric Method,

2-5

Measuring Resistance by the External Voltage Method

2-6

2-7 Divider Curcuits ccross Model 602 Output for Driving 50 and 10OmV Recorders

Measuring Potential of Hich Resistance Source with 0.025% Accuracy.

2-8

Block Diagram of Model 602 in Voltmeter Mode

3-1

Block Diagram of Model 602as a Picoammeter

3-2

Block Diagram of Model 602for Normal Method Measuring Resistance

3-3

4-l Model 602 Case to LO Isolation Check

Model 602 Unity-Gain Test Set-Up.

4-2

Model 602 Chassis, Side View.

5-1

RANGE Switch, S102, Component Location Drawing

5-2

MULTIPLIER Switch, S106, Component Location Drawing

5-3

Model 602, PC186, Component Location Drawing

5-4

Model 602, PC127, Component Location Drawing

5-5

Model 602, Schematic Diagram, Dwg. No. 21174E

5-6

.......................................... ................

..........................................

........................................

..............................

.....................................

....................................... ................

...........................................

Title

...........................

.......................

.........

............................. ................

.........

........................

...................

...........................

...........................

..........................

LIST OF TABLES

...

................

................

................

................

................

................

................

................

................

................

................

................

................

................

................

................

Page

.........

......... 2-3

......... 2-4

......... 2-6

......... 2-7

......... 2-8

......... 2-9

......... 2-9

.........

......... 3-2

......... 3-2

......... 4-2

......... 4-4

.........

......... 53

......... 53

.........

......... 5-9

2-2

3-l

5-2

57

5-7

Table

2-l Color Coding of Alligator Clips for Model 6011 Input Cable ...

2-2 Multiplier Switch Positions for Checking

4-1 Recommended Test Equipment .........................

4-2 Model 602 Internal Controls.

4-3 Coulomb Ranges Accuracy Check

4-4 Model 602 Troubleshooting.

5-l Model 602 Static Sensitive Devices

5-2 Model 602 Replaceable Parts List

............................

............................

..................

.......................

......................

........................

Title

......

......

......

......

......

......

......

......

......

......

......

......

......

..,...

Page

2-l

2-4

4-l

4-2

4-4

4-5

5-l

54

iii/iv

Page 8

Page 9

SECTION 1

GENERAL DESCRIPTION

1.1 INTRODUCTION 1.3 WARRANTY INFORMATION

The Keithley Model 602 Electrometer is a completely solid-

state, battery operated instrument, which measures a wide

range of DC voltage, current, resistance and charge. The

Model 602’s input resistance of greater than 10’4R is the

result of extensive instrument development with high input

impedance transistors. The Model 602 has all the capabilities

of conventional VTVMs, but can also make more measure-

ments without loading circuits.

The Model 602 has nine voltage ranges from O.OOlV full scale

to lOV, 28 current ranges from 10’4A full scale to 0.3A. 23

linear resistance ranges from 1000 full scale to 1OtQ. and 15

charge ranges from lo-‘SC full scale to lo-aC.

The Model 602 offers complete line isolation and excellent

off-ground measuring capability. Up to 1500V may be applied instrument which occur after the printins o! this manual will

between the input low terminal and the case, and stage be found on an addendum sheet included .-:ith this manual.

operation is assured with the case grounded. A triaxial con- Be sure to review these changes before ar:en:$ing to operate

nectar allows complete guarding of the high impedance input or service the instrument.

terminal.

The Model 602 employs matched insulated-gate field-effect

transistors followed by transistor differential amplifier stages

and a compliritentary-output stage. A large amount of

negative feedback is used for stability and accuracy.

1.2 MODEL 602 FEATURES

1. The Model 602 has excellent zero stability which permits

accurate measurements with minimal adjustment. Short

term zero drift is less than 50& per hour. Zero offset due

to temperature change is less than 15O/rV per OC after 30

minute warm-up period. This offset, however, can easily

be compensated for with the front panel zero controls.

2. Fast warm-up is an inherent characteristic of the Model

602. It can be operated 30 minutes after warm-up on the

most sensitive range and almost immediately on less sensi-

tive ranaes.

3. Low offset current 5 X lo-IsA, minimizes zero offset with

high source resistance and permits maximum resolution

when measuring current and charge.

4. The 1000 hour life of the batteries enables usage in long

term experiments without interruptions for recharging.

Battery life is maintained even when the 1OmA recorder

output is used. For further convenience, battery condition

is readily checked on the panel meter.

5. Excellent overload protection without degradation of performance is obtained by use of a unique input circuit. The

Model 602 Electrometer will withstand damage and has

good recovery.

Warranty information may be found inside the front cover of

this manual. Should it become necessary to exercise the

warranty, contact your nearest Keithley representative or the

factory to determine the correct course of action. Keithley

Instruments maintains service facilities in the United States,

West Germany, Great Britain, France, the Netherlands,

Switzerland, and Austria. Information concerning the appli-

cation, operation, or service of your instrument may be

directed to the applications engineer at any of these locations. Check the inside front cover of this manual for addresses.

1.4 MANUAL ADDENDA

Information concerning improvements or changes to the

1.5 SAFETY SYMBOLS AND TERMS

The following safety symbols and terms are used in this

manual or found on the Model 602.

The symbol

should refer to the operating instructions in this ;nanual.

The symbol

tential of 1OOOV or more may be present on the terminaltsl.

Standard safety precautions should be observed when such

dangerous voltages are encountered.

The WARNING heading in this manual explains dangers that

could result in personal injury or death.

The CAUTION heading in this manual explains hazards that

could damage the instrument.

1.6 SAFETY PRECAUTIONS

1. This instrument is intended for use by qualified personnel

who recognize the shock hazards and are familiar with the

safety precautions required to avoid possible injury. Read

over the manual carefully before operating this instrument.

2. Excercise extreme caution when a shock hazard is present

at the instrument’s input. The American National

Standards Institute (ANSI) states that a shock hazard ex-

ists when voltage levels greater than 30V rms or 42.4V

peak are present. A good safety practice is to expect that

hazardous voltage is present in any unknown circuit before

measuring.

on the instrument indicates that the user

A

#

on the instrument indicates that a po-

l-l

Page 10

3. Inspect the test leads for possible wear, cracks or breaks

before each use. If any defects are found, replace with test

leads that have the same measure of safety as those supplied with the instrument.

4. For optimum safety do not touch the test leads or the

instrument while power is applied to the circuit under test.

Turn the power off and discharge all capacitors, before

connecting or disconnecting the instrument.

5. Do not touch any object which could provide a current

path to the common side of the circuit under test or power

line (earth) ground. Always make measurements with dry

hands while standing on a dry, insulated surface, capable

of withstanding the voltage being measured.

6. Exercise extreme safety when testing high energy power

circuits (AC line or mains, etc). Refer to the operating

section.

7. Do not exceed the instrument’s maximum allowable input

as defined in the specifications and operation section.

1.7 SPECIFICATIONS

Detailed Model 602 specifications may be found immediately

preceding this section.

Three-Terminal Connections-The GUARD output on the

Model 602 Electrometer can be used for resistance

measurements where the effects of cable capacitance may be

significant. Connect the unknown between INPUT and EXT

terminals. Connect the EXT terminal to the GUARD output

on the electrometer. Use the electrometer in fast mode for

ohms measurement.

I.E.4 Model 6105 Resistivity Chamber

The Model 6105 is a guarded test fixture for measurement of

surface and volume resistivities. The chamber is designed in

accordance with ASTM Standard Method of Test for Electrical Resistance of Insulated Materials, D257-66. The Model

6105 can be used in conjunction with an electrometer and

voltage supply.

Resistivity can be determined by measuring the current

through a sample with a known voltage impressed. The

measurement can be made most conveniently when a set of

electrodes are used which can be calibrated in terms of

surface or volume resistivity. The Model 6105 has been

designed for use with a Keithley electrometer and an optional

high voltage supply such as the Model 247.

1.8 OPTIONAL ACCESSORIES

The following optional accessories can be used with the

Model 602 to provide additional convenience and versatility.

1.8.1 Model 8lOlA Shielded Probe

The Model 6010A is a shielded cable with a needle point

probe and 30 inches of low noise cable terminated by a UHF

connector.

I.E.2 Model 8103C Divider Probe

The Model 6013C is a shielded cable with a needle point

probe and 30 inches of low noise cable terminated by a UHF

connector. The probe includes a 1OOO:l voltage divider with a

4.5 X 1OW input resistance. Accuracy is f5% at 30kV.

1.8.3 Model 8104 Test Shield

The Model 6104 is a shielded test box for two-terminal or

three-terminal connections. The INPUT terminal is Teflon@

insulated.

Two-Terminal Connections-Resistance measurements

can be made conveniently using the INPUT and GROUND

terminals on the test box. Connect the electrometer to the

BNC output. Use the electrometer in normal mode for ohms

measurement.

1.8.5 Model 2503 Static Detector Probe

Model 2503 is designed to detect voltage due to charge on

relatively small surface areas. Solid coaxial 13mm (% inch)

diameter tube used with 89mm (3% inch) head, 89mm (3%

inch) coupler, 25mm (one inch) adapter and two 90° angle

adapters which may be placed at various junctions along the

tube. It gives a 10,OOO:l & 10% divsion ratio when used with

Model 610C and held 6mm (‘/ inch) away from a charged

plane of at least 13mm (% inch) diameter. Output is a UHF

male plug.

I.E.8 Model 8011 Input Cable

The Model 6011 is a low-noise triaxial cable, 30 inches long,

terminated by three color-coded alligator clips. This cable

mates directly with the triaxial input. The cable is fabricated

using a Keithley connector (P/N CS-141) and low-noise cable

(P/N SC-22).

The Model 6011 may be used for measurements which require a triaxial connection, especially when the input LO is

floated above CASE ground.

I.E.7 Model 6012 Triax-to-Coax Adapter

The Model 6012 is an adapter for mating the triaxial input and

UHF (coax) type connectors. Permits using Models 220,602,

614, 616 and 619 with all Keithley electromete accessories

having UHF type connectors.

l-2

Page 11

2.1 INTRODUCTION

SECTION 2

OPERATION

connected to case ground, only if the shorting link on the rear

panel is connected.

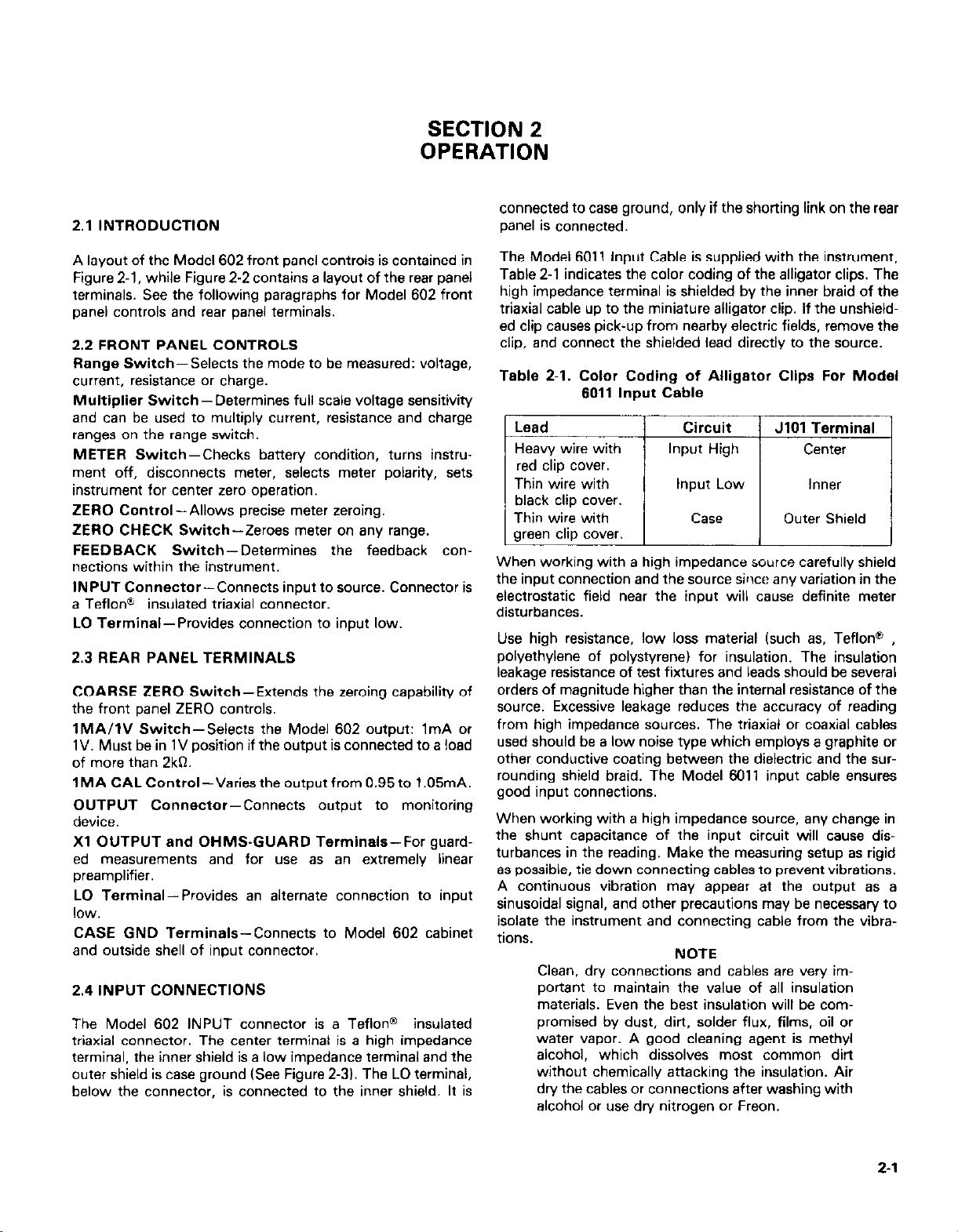

A layout of the Model 602 front panel controls is contained in

Figure 2-1, while Figure 2-2 contains a layout of the rear panel

terminals. See the following paragraphs for Model 602 front

panel controls and rear panel terminals.

2.2 FRONT PANEL CONTROLS

Range Switch-Selects the mode to be measured: voltage,

current, resistance or charge.

Multiplier Switch-Determines full scale voltage sensitivity

and can be used to multiply current, resistance and charge

ranges on the range switch.

METER Switch-Checks battery condition, turns instrument off, disconnects meter, selects meter polarity, sets

instrument for center zero operation.

ZERO Control-Allows precise meter zeroing.

ZERO CHECK Switch-Zeroes meter on any range.

FEEDBACK Switch-Determines the feedback connections within the instrument.

INPUT Connector-Connects input to source. Connector is

a Teflon” insulated triaxial connector.

LO Terminal-Provides connection to input low.

2.3 REAR PANEL TERMINALS

COARSE ZERO Switch-Extends the zeroing capability of

the front panel ZERO controls.

lMA/IV Switch-Selects the Model 602 output: 1mA or

1V. Must be in 1V position if the output is connected to a load

of more than 2kQ.

IMA CAL Control-Varies the output from 0.95 to 1.05mA.

OUTPUT Connector-Connects output to monitoring

device.

Xl OUTPUT and OHMS-GUARD Terminals-For guard-

ed measurements and for use as an extremely linear

preamplifier.

LO Terminal-Provides an alternate connection to input

low.

CASE GND Terminals-Connects to Model 602 cabinet

and outside shell of input connector.

2.4 INPUT CONNECTIONS

The Model 602 INPUT connector is a TeflonO insulated

triaxial connector. The center terminal is a high impedance

terminal, the inner shield is a low impedance terminal and the

outer shield is case ground (See Figure 2-3). The LO terminal,

below the connector, is connected to the inner shield. It is

The Model 6011 Input Cable is supplied with the instrument,

Table 2-1 indicates the color coding of the alligator clips. The

high impedance terminal is shielded by the inner braid of the

triaxial cable up to the miniature alligator clip. If the unshielded clip causes pick-up from nearby electric fields, remove the

clip, and connect the shielded lead directly to the source.

Table 2-l. Color Coding of Alligator Clips For Modal

8011 Input Cable

Lead

Heavy wire with

red clip cover.

Thin wire with

black clip cover.

Thin wire with

green clip cover.

When working with a high impedance source carefully shield

the input connection and the source since any variation in the

electrostatic field near the input will cause definite meter

disturbances.

Use high resistance, low loss material (such as, Teflon@ ,

polyethylene of polystyrene) for insulation. The insulation

leakage resistance of test fixtures and leads should be several

orders of magnitude higher than the internal resistance of the

source. Excessive leakage reduces the accuracy of reading

from high impedance sources. The triaxial or coaxial cables

used should be a low noise type which employs a graphite or

other conductive coating between the dielectric and the sur-

rounding shield braid. The Model 6011 input cable ensures

good input connections.

When working with a high impedance source, any change in

the shunt capacitance of the input circuit will cause disturbances in the reading. Make the measuring setup as rigid

as possible, tie down connecting cables to prevent vibrations.

A continuous vibration may appear at the output as a

sinusoidal signal, and other precautions may be necessary to

isolate the instrument and connecting cable from the vibra-

tions.

Clean, dry connections and cables are very important to maintain the value of all insulation

materials. Even the best insulation will be com-

promised by dust, dirt, solder flux, films, oil or

water vapor. A good cleaning agent is methyl

alcohol, which dissolves most common dirt

without chemically attacking the insulation. Air

dry the cables or connections after washing with

alcohol or use dn/ nitrogen or Freon.

Circuit

Input High Center

Input Low

Case Outer Shield

NOTE

JIOI Terminal

Inner

2-1

Page 12

2-2

Figure 2-l. Model 602 Front Panel Controls

Page 13

Figure 2.2. Model 602 Rear Panel Terminals

2-3

Page 14

batteries checked by position. If the reading for any battery

other than 8203 is below two-thirds, replace all batteries except for 8203. If the reading for B203 is less than two-thirds

full scale, replace it. Note, that, new batteries may cause the

Model 602 to drift more than normal for at least 72 hours due

to change in battery terminal voltage.

Set the controls as follows:

ZERO CHECK Button LOCK

Range Switch VOLTS

Multiplier Switch

FEEDBACK Switch

METER Switch

1

NORMAL

POWER OFF

Figure 2-3. Triaxial Input

For low impedance measurements (below 1080 or above

lO*RA) unshielded leads may be used. When the Model 602

is used on the most sensitive current ranae with the FEED-

BACK switch at FAST, some insulators kuch as Teflon” )

may produce random signals which show up as erratic meter

deflections. Insulation used in the Model 602 is carefully

selected to minimize these spurious signals.

If a well shielded chamber and a well made high impedance

transfer switch is available, it is advantageous to connect the

Model 602 to the circuit only when a reading is being made.

In some cases, the offset current can charge the external test

circuitry. One example of this occurs when measuring a

capacitor’s leakage resistance by observing the decay of ;he

terminal voltage. If the leakage current is less than the offset

current (less than 5 X 10.‘5A there may be no decay of the

terminal voltage when the Model 602 is left connected across

the capacitor’s terminals.

NOTE

Keep the shield cap on the INPUT connector

when the Model 602 is not in use.

The Model 6012 Triaxial-to-Coaxial Adapter permits use of

cables and accessories with the Model 602 by adapting the

triaxial INPUT connector to the UHF coaxial type.

CAUTION

The Model 6012 connects low to case

ground. The Modal 602 cannot be used offground when using the Model 6012. The instrument’s cabinet will be at the same

potential as the input low.

2.5 PRELIMINARY PROCEDURES

Check battery condition by holding the METER switch in the

BATTERY CHECK position. Rotate the multiplier switch

through the ,001 to 0.1 positions and observe the meter

readings. The meter should read at least two-thirds of full

scale in each multiplier switch position. Table 2-2 shows the

Table 2-2. Multiplier Switch Positions for Checking

Conditions of Batteries

Multiplier Position

,001

1

1 tc

1. Turn the METER switch

I CENTER ZERO. Within ten

seconds, the mater needle should con?,.? ‘to the center position. If not, adjust the mater zero with the MEDIUM and

FINE ZERO controls. Normally, there is no need to use the

COARSEZERO

‘.

NOTE

Using the center zero scales decreases accuracy

0.5% because the scale span is reduced.

2. After a few moments increase the voltage sensitivity by

advancing the multiplier switch. Continue zeroing with the

FINE ZERO control.

3. After long periods of storage or after an overload, the

Model 602 may drift excessively. The input transistors are

insensitive to mechanical shock; however, a severe input

overload may cause a zero offset. This is corrected with

the ZERO controls. Drifting can occur for several hours.

NOTE

If the Model 602 has been stored for some time,

the offset current will exceed the specification

when first used, then decrease to below the

specified amount after one or two hours of use.

This is an inherent characteristic of the input

transistors; the instrument is not faulty.

4. Although the offset current of the Model 602 is below that

found in conventional voltmeters, it can be observed on

the meter. The current charges the input capacitance, and

the Model 602 appears to drift when the input is open. Use

the ZERO CHECK button to discharge the charge build-up.

Depressing the ZERO CHECK button removes all signal

from the amplifier and reduces the input impedance

between HI and LO terminals of the INPUT connector to

10MR.

2-l

Page 15

5. Follow the procedures in paragraphs 2.6 to 2.10 for

measuring voltage, current, resistance and charge.

NOTE

When using multiplier switch settings of 10, 3

and 1 in the voltage, current, resistance and

charge measuring modes, make sure the OUT-

PUT switch is set to 1V if the output is connected to a load of more than 2kR. Otherwise,

the meter will not read full scale signals correct-

ly. When the output is loaded, this effect is not

present.

2.6 VOLTAGE MEASUREMENTS

Set the controls as follows:

ZERO CHECK Button LOCK

Range Switch VOLTS

Multiplier Switch

10

FEEDBACK Switch FAST

METER Switch CENTER ZERO

Connect the unknown voltage to the high (center) terminal of

the INPUT connector and to the OHMS GUARD terminal on

the rear panel. Use the LO terminal as a guard between circuit

high and low. Unlock the ZERO CHECK button. Set the

METER switch to + or -, as necessary. Recheck zero setting

after increasing sensitivity. To make off-ground voltage

measurements, see paragraph 2.7.

The Model 602 can be used to measure voltages. In the normal method (FEEDBACK switch at NORMAL) the unknown

voltage is connected to the INPUT connector. Input impedance with the range switch in the VOLTS position is

10%. 2OpF.

To reduce the effects of input cable capacity, use the fast

method to measure the voltage. Set the FEEDBACK switch

at FAST and drive the inner shield of the cable with the Xl

OUTPUT which is connected to the LO terminal in the FAST

position, A guarded circuit is possible this way. To reduce

stray pick-up when making routine measurements fix.

measuring from low impedance sources1 the range resistors

or capacitors may be used to shunt the input. Accessory

probes extend the Model 602’s range to 1OkV.

NOTE

Locking the ZERO CHECK switch places 1OMB

between input high and low, which may temporarily cause instability in e.ome types of high

impedance sources.

2.6.1 Normal Method Voltage Measurements

Set the controls as follows:

ZERO CHECK Button LOCK

Range Switch VOLTS

Multiplier Switch 10

FEEDBACK Switch NORMAL

METER Switch CENTER ZERO

Connect the unknown voltage to the high (center) terminal of

the INPUT connector and to the OHMS GUARD terminal on

the rear panel. Use the LO terminal as a guard between circuit

high and low. Unlock the ZERO CHECK button. Set the

mater switch to + or -, as necessary. Increase sensitivity with

the multiplier switch. Recheck zero setting after increasing

sensitivity. To make off-ground voltage measurements, see

paragraph 2.7.

2.6.3 Low Impedance Sources

To decrease input resistance, set the FEEDBACK switch to

NORMAL and the range switch to one of the AMPERES

ranges. The input resistance is now the reciprocal of the current range. For instance, to obtain an input resistance of

lo%, set the range switch to the 10.rA range Set the full

scale voltage range with the multiplier switch. Operating procedures are the same as paragraph 2.6.1. With reduced input

resistance, the Model 602 will not be deflected off scale by

stray fields when the input is left open.

2.7 OFF-GROUND VOLTAGE MEASUREMENTS

The Model 602 can measure an unknown voltage whose low

impedance terminal is up to 1500V off-ground. Safe opera-

tion of the Model 602 is ensured by grounding the case (see

paragraph 2.6).

CAUTION

Operating the Model 602 more than 16OOV

off-ground may permanently damage the

instrument. Isolation between circuit low

and ground may break down somewhere in

the instrument. Since these breakdowns

are very difficult to locate, it might not be

possible to float the instrument safely

again.

2.7.1 FEEDBACK Switch Set To NORMAL

Disconnect the shorting link between LO and CASE

GROUND terminals on the rear panel. Make sure the Model

602 case is securely connected to an earth ground, and that

the low of the unknown voltage is less than 1500V off-

ground. Connect the unknown voltage directly to the INPUT

connector. Operate the Model 602 as described for normal

method voltage measurements.

2.6.2 Guard Method Voltage Measurement

This method reduces the effects of input cable capacity with

very high impedance source.s and allows guarded voltage

measurements.

2.7.2 FEEDBACK Switch Set To FAST

Disconnect the shorting link between the LO and CASE

GROUND terminals on the rear panel. Make sure the Model

602 case is securely connected to an earth ground, and that

2-5

Page 16

the low of the unknown voltage is less than 1500V offground. Connect the high of the unknown voltage to the

center terminal of the INPUT connector. Connect the low to

the OHMS GUARD terminal. Use the LO terminal or inner

shield of the INPUT connector as a guard. Operate the Model

602 as described for fast method voltage measurements.

WARNING

If the output is used for recording when the

Model 602 is off-ground in the normal or

fast mode, make sure the shell of a mating

plug to the OUTPUT connector is not connected to either pin in the connector. Also.

the recorder output will be off-ground.

WARNING

Use only an insulated blade screwdriver to

adjust the COARSE ZERO switch and 1 MA

CAL control when floating the Model 602.

An ordinary screwdriver could short the circuit low to case ground, creating a shock

hazard and damaging the external circuitry.

2.8 CURRENT MEASUREMENTS

The Model 602 can measure current three ways.

1. In the normal method luseable on any range) the current is

determined by measuring the voltage drop across a resistor

shunting the amplifier input. This method is useful when

low noise is more important than fast response speed or if

some damping is needed.

2. In the fast method (for use only below the lC-‘5A range)

the shunt resistor is between the amplifier output and input

in the feedback loop. This circuit largely neutralizes the effect of input capacity and greatly increases the response

speed. Also, the input voltage drop is reduced to a maximum of 1mV on any range.

3. For galvanometric current measurements, the Model 602

acts as a null indicator between a known current and the

unknown current source.

Rise time varies primarily with the current range, the input

capacity and the method used. Wifh the FEEDBACK switch

in the FAST position, the rise time on the most sensitive

range is less than 2sec and on the l@‘A range, less than

3msec. Given a choice, it is better to place the Model 602

nearer to the current source than fo the data reading instrument. Transmining the input signal through long cables

slightly decreases the response speed and greatly increases

noise due to cable capacitance.

To measure from a source with both terminals off-ground in

either method, remove the link between the LO and CASE

GROUND terminals on the rear panel. Connect the unknown

current fo the INPUT connector. The source must be less

than & 15OOV off-ground (see paragraph 2.7 and Figure 2-4).

I

Is = Es/R*

ERROR = 1%. 1.

?&ERROR = E,,/E, Y Km

IF E,N< <Es. THEN IM = Is.

NOTE: CURRENT SDURCES MAY SE CONSIDERED A

VOLTAGE ,E, IN SERIES WITH A RESISTANCE ii?). THE

CURRENT WlTH THE AMMETER SHORT CIRCUITED IS

I=E/R. WITH THE SHORT REMOVED, THE EFFECTIVE

INPUT RESISTANCE OF THE AMMETER

WITH THE SOURCE RESfSTANCE (RI.

Lz-

11

IR,,l IS IN SERIES

I

Figure 2-4. Error Due to Ammeter Resistance

2.8.1 Normal Mode (0.3 to 10’4A Ranges1

Set the controls as follows:

ZERO CHECK Button LOCK

Range Switch lo-’ AMPERE

Multiplier Switch

1

FEEDBACK Switch NORMAL

METER Switch CENTER ZERO

Connect the unknown current to the high terminal (center

terminal) of the INPUT connector and use the low terminal

(inner shield) for the return path. Unlock the ZERO CHECK

button. Set the METER switch to + or -, as necessary. Increase the sensitivity with the range switch and the multiplier

switch. Do not set the multiplier switch higher than 3 for

range switch settings 103 and above. Check zero with the

ZERO CHECK button.

The full scale current range is mulriplier switch setting times

range switch setting. Use the smallest multiplier switch setting possible to minimize input voltage drop and thus obtain

the best accuracy. The input resistor varies with the range

switch setting, from 100, to l@‘A to 101% for 1011A. The full

scale input voltage drop is equal to the multiplier switch setting.

2.8.2 Fast Method (Current Below 10’6A)

Set the controls as follows:

ZERO CHECK Button LOCK

Range Switch 106 AMPERES

Multiplier Switch 1

FEEDBACK Switch FAST

METER Switch

CENTER ZERO

Connect the unknown source to the INPUT connector and

lock the ZERO CHECK button. Set the METER switch to t

or -, as necessary. Increase the sensitivity with the range

switch and the multiplier switch. Check zero only with the

ZERO CHECK button. Do not short the input, because this

will remove the feedback from the circuit.

2-6

Page 17

The full scale current range is the multiplier switch setting

times the range switch sening. When selecting the multiplier

switch setting, remember smaller settings permit lower

source resistances, and larger senings improve instrument

zero stability.

With the fast method, the input drop is reduced and the

response speed is increased at least 100 times. However, the

following safety precautions should be observed.

1. The internal impedance of the unknown current source

should not be less than 0.1 of the value of the feedback

resistor being used. Otherwise, adequate feedback voltage

cannot be developed at the input and zero instability

results. The feedback resistor value is the reciprocal of the

AMPERES range of the range switch.

2. The low side (pin No. 2) of the OUTPUT connector is no

longer connected to the low side of the INPUT connector.

Therefore, do not use a grounded recorder. As an alternative use the unity-gain output. (See paragraph 2.12).

3. Use, with caution, the fast method to measure capacitor

leakage. A very stable voltage supply must be used. Connecting a capacitor to the input changes the circuit to a

differentiator, resulting in extreme sensitivity to very small

voltage transients and an increase in meter noise.

2.8.3 Galvanometric Method

Operate the Model 802 as a picoammeter in the fast method.

Use an accurate reference current source such as the

Keithley Model 261 to buck out the unknown current source.

Connect as shown in Figure 2-5.

Set the METER switch to CENTER ZERO and use the higher

current ranges. Adjust the buck out current to indicate null on

the Model 602. Increase the Model 602 sensitivity as needed.

When the Model 602 is as close to null as possible, the

unknown current is equal to the algebraic sum of the Model

261 sening and the Model 602 current reading.

NULL

DETECTOR

2.9 RESISTANCE MEASUREMENTS

The Model 802 can measure resistance by two methods.

In the constant current method, the Model 602 measures

the voltage drop across the unknown sample as a known,

constant current flows through it. The voltage drop is proportional to the resistance of the sample. In this method

the Model 602 can be used in one of two different modes:

normal or fast. The normal mode is recommended for use

from 100 to 101’0. Above 101%, the fast method is preferred. It results in faster response speed and also nullifies

leakage across the Model 602 input, since the potential

across the input terminal is small.

In the preceding method, the voltage across the sample

cannot be arbitrarily set. In some cases, as in measuring

capacitor leakage, this results in excessively long testing

time. In the voltmeter ammeter method, the Model 602 is

used as a picoammeter. The unknown resistance sample is

connected to an external known voltage source and the

current through the sample is measured. Either the normal

or fast method may be used. The resistance is calculated

from the reading.

NOTE

Discharge any capacitor completely before

removina it from the circuit. Depressing the

ZERO CHECK bunon shorts the input through a

1OMQ resistor, providing a discharge path.

2.9.1 Normal Constant Currant Method

Set the controls as follows:

ZERO CHECK Button LOCK

Range Switch 10’2 OHMS

Multiplier Switch

FEEDBACK Switch NORMAL

METER Switch

Connect the high impedance side of the resistance sample to

the high terminal (center terminal) of the INPUT connector

and the low impedance side to the low terminal (inner shield)

of the INPUT connector. Unlock the ZERO CHECK button.

Check zero only with the ZERO CHECK button.

+

I--- - -----w

CURRENT

NOTE: “SE AN ACCURATE REFERENCE CURRENT SOURCE

TO SUCK OUT THE UNKNOWN CURRENT SOURCE. THE

MODEL 602. ON ITS CVRRENT RANGES, SERVES AS A

NULL DETECTOR. USE A UHF-TEE FITTING AND MODEL

6012 ADAPTER AT THE MODEL 602 INPUT. CONNECT THE

MODEL 60.2 TO THE TWO SOURCES WITH COAXIAL CABLE.

SELECT CABLE CAREFULLY FOR VERY LOW CURRENTS.

Figure 2-5. Measuring Current by the Galvanometric

Method

CURRENT

SOURCE

NOTE

Do not open circuit Model 602 on the OHMS

ranges; the input will increase up to 1OV due to

its constant current characteristic. Keep the

input shorted or the ZERO CHECK button locked.

The full scale ohms range is the multiplier switch times the

range switch sening. Use the smallest range switch setting

possible to obtain the best accuracy.

Before making a final reading, manipulate the multiplier and

range switches so the sample is tested at a number of teat

potentials. The applied test voltage is the percentage of full

scale that the meter reads times the multiplier switch setting.

2-7

Page 18

When the test current is applied, the high terminal of the

INPUT connector is positive. The test current is the reciprocal

of the OHMS range setting.

NOTE

Shield the input if the resistance sample exceeds

10%.

2.9:2 Fast Constant Currant Method

Follow the instructions of paragraph 2.5. Set the controls as

follows:

ZERO CHECK Button LOCK

Range Switch 10” OHMS

Multiplier Switch 1

FEEDBACK Switch FAST

METER Switch

+

Connect the high impedance side of the resistance sample to

the center terminal of the INPUT connector and the low im-

pedance side to the OHMS GUARD terminal. Unlock the

ZERO CHECK button. Read the resistance.

NOTE

Shield the input if the resistance sample exceeds

10%

NOTE: A POTENTIAL FROM A KNOWN SOURCE, V. IS APPLIED TO THE KNOWN RESISTANCE SAMPLE, R,. THE

MODEL SO2 MEASURES THE CURRENT THROUGH, A,,

FROM WHICH THE RESISTANCE IS CALCULATED. SWITCH

S CONNECTS THE LOW END OF R, TO INPUT LOW WHEN

NO POTENTIAL IS APPLIED.

Figure 2-6. Measuring Resistance By The External

Voltage Method

To remove the sample, set the ZERO CHECK button to LOCK

and set switch S back to the position shown in Figure 2-6.

The low terminal of the INPUT connector is now a driven

guard. It may be used to minimize the effects of capacity between high and low and errors due to leakage resistance between high and low.

The Model 6011 Input Cable, supplied with the Model 602,

provides a convenient means of making guarded resistance

measurements. Connect the shorting link between the CASE

GROUND and OHMS GUARD terminals on the rear panel.

This allows the CASE GROUND or green test lead terminal to

be connected to the low impedance side of the unknown

resistance. The inner shield or the black test clip is the OHMS

GUARD terminal.

2.9.3 Voltmeter-Ammeter Method ITo 10%)

Turn the ZERO CHECK switch to LOCK. Connect sample

between high terminal of the INPUT connector and power

supply (See Figure 2-6). Put a switch in the high voltage line

to connect the low impedance end of sample to input low

when it is disconnected from the potential.

If the power supply must be floating, remove the link between the CASE GROUND and LO terminals and connect the

CASE GROUND terminal to an earth ground.

Set the FEEDBACK switch to NORMAL. Usually this method

is best, since instabilities can arise for resistance samples less

than 0.1 the value of the feedback resistor.

To make a measurement, start with switch S as shown in

Figure 2-6 and make sure the ZERO CHECK button is set to

LOCK. Set switch S to apply a potential across the sample for

a known period of time. Then unlock the ZERO CHECK

button and take the reading. Set the range switch to l&trA

and increase sensitivity until a reading is obtained.

If the potential applied is at least 100 times the full scale input

drop (multiplier switch setting), the resistance is equal to the

applied potential divided by the current reading. The high

voltage sensitivity of the Model 602, therefore, permits external voltages of O.lV or more to be used.

If the potential applied is less than 100 times the input drop,

the resistance is equal to the difference between the applied

potential and the input drop all divided by the current reading.

If the current is read by the fast method, the input drop is so

slight that it need not be included in the calculation. If the

capacity shunted across the sample is large, such as en-

countered in capacitor leakage measurements, the faster

method increases response speed and this connection is

recommended. Note, however, that power supply transients

will be magnified.

2.10 CHARGE MEASUREMENTS

Follow the instructions of paragraph 2.5. Set the controls as

follows:

ZERO CHECK Button LOCK

Ranae Switch 10’ COULOMBS

Multiplier Switch .Ol

FEEDBACK Switch FAST

METER Switch CENTER ZERO

Unlock the ZERO CHECK button and then connect the

unknown source to the INPUT connector. If the Model 60.2

reads off scale, increase the multiplier switch setting. If the

sensitivity is not enough, decrease the multiplier switch

sening until the reading is on scale. Changing the multiplier

switch setting does not affect the transfer of charge from the

unknown source to the instrument. If increasing sensitivity

with the multiplier switch does not bring the reading on scale,

2-8

Page 19

increase sensitivity with the range switch and repeat the

preceding steps.

The full scale charge range is the range switch setting times

the multiplier switch sening. Input offset contributes a charge

of 5 X lo-‘SC per second maximum.

Use the ZERO CHECK button to discharge the integrating

capacitor. Discharge for at least 20sec on the 1OrC range

before making another measurement. On the 10-8C range,

discharge for at least two seconds.

2.11 RECORDER OUTPUTS

Recorders, oscilloscopes and similar instruments can be used

with the Model 602. The Model 602 has two outputs, k 1V

and * lmA, to amplify signals within % % for recorders,

oscilloscopes and similar instruments. These can be used on

all ranges of the Model 602.

WARNING

The Model 602 may be used with the FEED-

BACK switch in FAST position with other

instruments. However, make sure there is

no common ground connection between

low terminals of the Model 602 and the

other instrument.

1V Output-Connect osciiloscopes and pen recorder

amplifiers to the OUTPUT connector. Pin 1 is the output ter-

minal and pin 2 is grounded when the FEEDBACK switch is

sat to NORMAL. Set the OUTPUT switch to 1V. The Model

602 output is now + 1V for full scale meter deflection on any

range, Internal resistance is 910R. The frequency response

(+3db) is DC to 1OOHz at a gain of 1000, rising to 4OHz at

gains of 1 .O and below. Noise is less than 3% rms of full scale

at a gain of 1000, decreasing to less than 0.5% at gains of 10.

The METER switch does not reverse the output polarity. Out-

put polarity is opposite input signal polarity.

For servo rebalance recorders, use a divider of not greater

than a total of 2kO across the Model 602 OUTPUT connector

ISee Figure 2-71. Set the OUTPUT switch to 1 MA. Use the 1

MA CAL control to trim the output for full scale recorder

deflection. Operation is the same as for current outputs.

J103

OUTPUT 1

NOTE: USE 5% RESISTORS IN THE DIVIDERS. THE VALVE

OF RESISTOR R IS 10 FOR EVERY Im” OF OUTPUT.

Figure 2-7. Divider Circuits Across Model 602 Output

for Driving 50 and 1OOmV Recorders

When the FEEDBACK switch is in the NORMAL position, the

negative side of the output terminal is connected to the LO

terminal. Therefore, no difficulty will be experienced using

oscilloscopes and recorders with the Model 602 set for

normal operation. In FAST position, however, neither output

terminal is common to the LO terminal. If this is used, make

sure there is no common connection between the recorder or

oscilloscope and the Model 602 LO terminal, or use the unity

gain output (See Figure 2-B).

WARNING

Neither terminal of the OUTPUT conneotor

will be at case ground potential if the Modal

602 is used off-ground. Make sure the shall

of any mating plug is not connected to

either terminal in the connector. Use a

recorder with an isolated input when making off-ground measurements.

1mA Output-Connect 1mA instruments to the OUTPUT

connector pin 1 is the negative terminal (for positive inputs).

Set the OUTPUT switch to 1 MA. The output is approximately 1 milliampere for full scale meter deflection on any range.

For exact output, adjust the meter on the .003V range with

the FINE ZERO control for full scale deflection., Then adjust

the 1 MA CAL control until the recorder reads full scale.

Check the recorder and meter zero and repeat adjustment if

necessary. The METER switch does not reverse the output

polarity. Use only insulated screwdriver to adjust the 1 MA

CAL control.

I

NOTE:

THE MODEL SO2 IS USED BETWEEN A HlGH

RESlSTANCE SOURCE, Vx, AND A 0.01% VOLTMETER TO

OSTAlN HlGH ACCURACY WITHOUT CAUSING CIRCUIT

LOADING. THE DMM CONNECTS

UNIN-GAIN TERMINALS.

I

TO

THE

MODEL 602

Figure 2-8. Measuring Potential of High Resistance

Source with 0.025% Accuracy

2.12 UNITY-GAIN OUTPUT

The unity-gain amplifier can be used as an impedance

matching device to minimize circuit loading errors or for convenient connections to a recorder when the FEEDBACK

switch is in FAST position.

The unity-gain output is equal to the input within 1Oppm

when the load resistance is 1OOkO or greater. By placing the

Model 602 between a lOrOn source, for example, and a

2-9

Page 20

0.01% voltmeter with 1MQ input resistance, overall accuracy

better than 0.025% can be achieved.

1. Connect the voltmeter to the Xl OUTPUT and GUARD

terminals as shown in Figure 2-8. The GUARD terminal is

connected to LO terminal with the FEEDBACK switch in

NORMAL. Maximum output amplitude is f 1OV.

2. Adjust the Model 602 zero controls to obtain a zero

voltage reading on the external voltmeter. Make sure the

latter’s sensitivity is high enough for a precise zero ad-

justment. This adjustment is necessary because a slight

zero shift may cxxur when the Model 602 is changed from

the O.lV range or lower to a range above O.lV. The shift,

caused by a gain-reducing network switched in by the

amplifier on the 1V and higher ranges, is too slight to be

read on the meter, but it can cause an error in accurate

measurments using the unity-gain output.

3. To avoid the shift use the Model 602 with the multiplier

switch set to 10.

When the FEEDBACK switch is in FAST position, the unitygain terminals permit more convenient connections to

oscilloscopes with a load resistance of greater than 1OOkQ

without special precautions. In this mode, the Xl OUTPUT

terminal is common to the input low and the OHMS GUARD

terminal delivers an output equal to the input signal.

2-10

Page 21

SECTION 3

THEORY OF OPERATION

3.1 INTRODUCTION

The Keithley Model 602 is an extremely stable and linear DC

voltmeter with a full scale sensitivity of 1mV and an input impedance of 1014R shunted by 2OpF. By using the front panel

controls, shunt resistors and capacitors are selected to make

measurements over a total of 75 voltage, current resistance,

and coulomb ranges. Current and resistance are measured

using precision resistance standards, from 100 wirewound

resistors to 101’0 glass sealed, deposited carbon resistors.

Coulombs are measured using close tolerance polystyrene

film capacitor standards. Batteries furnish the necessary

amplifier power.

3.2 VOLTMETER OPERATION

The Model 602 uses matched insulated gate, field-effect tran-

sistors followed by a transistor differential amplifier with a

high voltage complementary output stage. Figure 3-l shows

the block diagram for the voltmeter mode of operation.

Voltmeter operation of the Model 602 is as follows.

1. The amplifier is always in a unity-gain, input voltage to

output current converter configuration. The internal circuitry is arranged such that a full scale input voltage (e,l

results in exactly a 1mA output current, through the

divider string composed of R,, R167 and the meter.

Voltage gain of the circuit is determned by the ratio of

R167 to R,. Output is taken across R167.

2. The voltage drop across the amplifier is:

ei

a

e =K+1

where K is the amplifier loop gain, greater than 10s on all

ranges.

The complementary output stage, Q114 and Q115, drives the

amplifier ground at the same potential as the input signal.

Thus the impedance is maintained for any value input voltage

and the need for input dividers is eliminated. The amplifier

ground is not chassis ground, but is connected directly to

J105, the unity-gain output.

NOTE

Refer to schematic diagram 21174E for circuit

designations.

3.3 VOLTMETER CIRCUIT

1. The amplifier input stage is a pair of insulated gate, fieldeffect transistors, 0101 and Q102, in a differential configuration. The gate of Q102 is returned to amplifier

common, the unity-gain output.

NOTE:

CIRCUIT DESIGNATIONS AEFER TO SCHEMATlC

DIAGRAM. S106 IS THE MULTIPLIER SWITCH, R, IS THE

RESISTOR FOR A GIVEN SElTING. R, IS THE RESlSTOR

SELECTED BY THE RANGE SWITCH, S102. SIOS IS THE

FEEDBACK SWITCH.

Figure 3-1. Block Diagram of Model 602 in Voltmeter

Mode.

2. Depressing the ZERO CHECK button, S103, places the

gate of the active insulated gate devices at zero potential.

3. The input stage is followed by a transistor differential

amplifier, composed of 0103X11 10. Q108 and Q109 makeup the output gain stage, which is utilized in a gain

multiplier configuration. This stage provides the remainder

of the high gain required by the amplifier. Also, this stage

prevents fold-over and lock-up with positive input

overloads. Diode DlOl, between base and emitter of

QllO. prevents fold-over and lock-up under negative input

overloads.

4. Frequency compensation is provided by capacitors Cl 14,

C115, resistors R145, R148 and capacitor C116. The com-

pensation networks provide a controlled frequency

characteristic to ensure stability under all conditions of

capacitive loading on input and output while on any range.

5. The recorder output is derived from the current flow from

Q114 and (1115 through the divider, R,, R167 and the

meter. With the lV-1MA switch, S108 on 1V f 1V for full

scale deflection is obtained at output connector, J103, by

f l.lmA flowing through the divider. With S108 at 1MA.

R187 and R188 are connected across J103, allowing

* 1mA f 556, to pass through an external load.

3.4 AMMETER OPERATION

3.4.1 Normal Method

In the normal method of current measurements (FEEDBACK

switch in NORMAL position), one of the range switch

resistors, R102 through R112, shunts the input (See Figure

3-2). The Model 602 then measures the voltage drop across

the resistor. The meter is calibrated to read the current in

amperes for the appropriate range.

3-l

Page 22

L

r

-

M

-

lY

NOTE: CIRCUIT DESIGNATIONS REFER TO SCHEMATIC

DIAGRAM. S106 IS THE MULTIPLIER SWITCH; R, IS THE

RESISTOR FOR A GIVEN SETTING. R, IS THE UNKNOWN

RESISTANCE BEING MEASURED; E IS THE VOLTAGE

SOURCE; R, IS THE RANGE RESISTOR SELECTED WlTH

THE RANGE SWITCH.

Figure 3-2. Block Diagram of Model 602 as a Picoam-

meter.

3.4.2 Fast Method

In the fast method of current measurements (FEEDBACK

switch in FAST position), the Model 602 functions as an

ammeter with negative feedback. The differential amplifier

output is divided by the multiplier switch resistors, R156 to

R164. and fed back to the amplifier input through a feedback

resistor selected with the range switch (See Figure 3-2).

Floating ground is connected to the low impedance side of

the input, and the output ground is floating. This method increases the response speed by minimizing the effects of input

capacity; it also rsduces the input drop to less than 1mV.

3.5 OHMMETER OPERATION

3.5.1 Normal Method

In the normal method of resistance measurements

BACK switch in NORMAL position) the Model 602 uses a

constant-current, voltage drop circuit. Refer to Figure 3-3. Rx

is the unknown resistor. A voltage source, E, applies a po-

tential across Rx. The source is obtained from the batteries,

8201 and 8202, through the resistor divider network, R184,

R142 and R143. E varies depending upon the OHMS range

used. The voltage source is connected between floating

ground and the input gate of QlOl through R,, the range

resistor. R

equal to E

voltage drop across Rx does not exceed the multiplier switch

is one of the resistors, R102 through R112. I is

R,, regardless of the value of Rx, as long es the

7

r

(FEED-

setting. This circuit provides a true source regardless of the

input. The Model 602 can then measure the voltage drop

acmss Rx and indicate the resistance value on its calibrated

meter.

35.2 Guarded Method

In the guarded method of resistance measurements (FEED-

BACK switch in FAST position and the sample resistance

connected between the INPUT terminal, J108, and the

GUARD terminal, J107) feedback is applied through the

sample. Refer to Figure 3-2. The circuit is similar to the nor-

mal method, except for the feedback. This reduces slowing

effect of the instrument’s input capacity. Leakage error is also

reduced since the potential acmss the input terminal is small.

In this mode, floating ground is connected to the low impedance side of the input and the output ground is floating.

The GUARD terminal is at output ground potential.

NOTE: CIRCUIT DESIGNATIONS REFER TO SCHEMATIC

DIAGRAM. SlO6 IS THE MULTIPLIER SWITCH; RM IS THE

RESISTOR FOR A GIVEN SETTING. R, IS THE UNKNOWN

RESISTANCE BEING MEASURED; E IS THE VOLTAGE

SOURCE: Rs IS THE RANGE RESISTOR SELECTED WITH

THE RANGE SWITCH.

Figure 3-3. Block Diagram of Modal 602 for Normal

Method Measuring Resistance

3.6 COULOMBMETER OPERATION

The Model 602 circuit for measuring charge is similar to that

used for an ammeter with the fast method. A negative feedback is applied around a shunt capacitor, Cl08 to Clll,

selected with the range switch. The shunt capacitor replaces

R, in Figure 3-2. The stored charge is proportional to the

voltage acmss the capacitor, which is measured by the Model

602 voltmeter circuits,

3-2

Page 23

SECTION 4

SERVICING INFORMATION

4.1 INTRODUCTION

This section contains information necessary to maintain,

calibrate and troubleshoot the Model 602 Electrometer.

WARNING

The procedures described in this section

ere for use only by qualified service personnel. Do not perform these procedures

unless qualified to do so. Many of the steps

covered in this section may expose the individual to potentially lethal voltages that

could result in personal injury or death if

normal safety precautions are not ob-

served.

4.2 CALIBRATION

The calibration information provided is a method of checking

the Model 602 to make sure it operates properly and within

specification. See the specifications that precede Section 1.

4.2.1 Recommended Equipment

Recommeded calibration equipment is listed in Table 4-l.

Alternate test equipment may be used as long as equipment

accuracy is et least as good as the specifications listed in

Table 4-1.

NOTE

Unless otherwise stated, all the following

calibration procedures will be made with the

FEEDBACK switch set to NORMAL and the

IV-1MA switch set to 1V.

4.2.2 Calibration Schedule

1. Check offset current (paragraph 4.7) at regular intervals to

make sure the input transistors are functioning correctly.

2. Verify the value of the high megohm resistors (paragraph

4.9) approximately every six months.

3. Calibrate the meter zero (paragraph 4.4) about once a year

or when components are replaced.

4. Check the Model 602 accuracy (paragraph 4.10) once a

year, after adjustment,

suspected.

4.3 PRELIMINARY PROCEDURES

Battery Check-Check the condition of the batteries as

outlined in paragraph 2.5 and Table 2-2.

Zero Balance-Set the Model 602 to the 1OV range and turn

the instrument on. Set the ZERO CHECK button to lock.

1. If the unit is operative, the meter should be on scale + or -.

Zero the meter with the COARSE, MEDIUM, and FINE

controls. Increase the voltage sensitivity in steps to the

1mV range by advancing the multiplier switch. Zero the

instrument on each range.

2. If the instrument is inoperative (meter pinned, etc.) check

error in setup end obvious problems before

troubleshooting.

Isolation Check-Set up the test circuit in Figure 4-1.

Disconnect the shorting link from CASE to LO. Set the Model

480 to the 1OnA range and zero check. Program the Model

230 to output 1OOV. Take the Model 480 out of zero check.

The Reading on the Model 480 should be less than WA

IlOnA). Usina Ohms law calculate the isolation resistance.

For example:-R = E/I = lOOV/lO-aA= 1O”‘D.

or if improper operation is

Table 4-l. Recommended Test Equipment

Item Description

A

B Voltage Source 1oov Keithley

C Picoammeter

0 RMS Voltmeter

E Chart Recorder

F Null Detector 1OOpV Null Resolution Keithley

G Current Source

H 10-W Resistor 1O”D +2% Keithley

I Signal Generator

J AC Voltmeter

K 1OW Resistor low +2%

L

M 1WD Resistor l@D *2% Keithley

DMM

109R Resistor low *29/o Keithley

Specification

lpV-1ooov Keithley

10.9A sensitivity

-

-

lo-5A to 10.‘A f0.2%

-

Mfg.

Keithley

H-P

H-P 70358

Keithley

H-P

H-P

Keithley R-289-10”’

Model

195

230

480

3400A

165

220

R-289-10”

200CD

400F

R-289-109

R-289-108

4-l

Page 24

MODEL so2

“EAR PANEL,

0 XIOUTPUT

0 OHMS OUARD

-0 CASE

p LO

MODELaO

PlCOAMMETER

LO

Figure 4-l. Model 602 Case To LO Isolation Check

4.4 MECHANICAL METER SET AND METER ZERO

CALIBRATION

Zero the Model 802 whenever adjustments are made. To set

the mechanical zero meter, turn the METER switch to

METER OFF and set the mechanical zero meter adjustment

for zero meter reading (top-scale zero). Refer to Table 4-2 for

Model 602 internal controls. To calibrate meter zero do the

following:

1. Turn the Model 602 on. Zero the meter on the ,001

multiplier switch setting. Set the multiplier switch to 1; apply 1V -+0.06% with the Model 230 to the Model 280

INPUT connector. Monitor the output with the Model 195.

Adjust the FINE ZERO control for l.OOOV at the output.

Adjust the meter cal potentiometer, R177, for full scale

meter reading.

2. Set the center zero by first zeroing the meter on the ,001

multiplier switch sening. The switch to the 1 position. Set

the METER switch to CENTER ZERO and adjust the

CENTER ZERO CAL potentiometer, R179, for exact

center-scale meter zero.

Table 4-2. Model 602 Internal Controls

Circuit Refer to

Control

Meter Calibration

Center Zero Calibration

Desig.

R177

Paragraph

4-2

R179 4-2

4.5 TRACKING CHECK AND 1MA OUTPUT

CALIBRATION

Tracking-Set the METER switch to +, the multiplier

switch to 1 and apply 1V with the Model 230 to the INPUT

connector.

1. If the 1V range has good accuracy, the meter should indicate full scale. If not, use the .l or 10 multiplier switch

settings, whichever has the beet full scale accuracy.

2. Check the meter O-10 scale for no more than ‘A% (‘A division) tracking error going from zero to full scale in l/10 of

full scale voltage steps.

1MA Output-Load output of the Model 602 with a 14OOQ

resistor.

1. Set the lV-1MA switch to 1MA. the multiplier switch to 1

and apply 1V to INPUT connector with the Model 230.

2. Adjusting the 1MA CAL control (R187) should vary the

output voltage from 1.33V to 1.47V. indicating a current

variation from 0.95 to 1.05mA.

3. Depending on the exact value of the 14003 load, the

voltage range may be slightly higher or lower then 1.33 to

1.47V (for example: 1.34 to 1.48V or 1.32 to 1/46V). This

is at least 140mV and the maximum voltage is near 1.47V.

4. Remove the 14003 load end set the lV-1MA switch to 1V

when completed.

4.6 NOISE CHECK

1. Zero check the unit and connect the output to a Model

3400A rms voltmeter.

A. Set the METER switch to CENTER ZERO and zero the

Model 802 on the 1mV range.

B. The meter noise must be less than 5OwV peak-to-peak.

C The output noise must be less than 30+ rms.

2. Switch the Model 802 to the 300mV range. Output noise

must be less than 6mV rms.

3. Typical rms output noise is approximately 20mV on the

1mV range and 1 to 2mV on the 300mV range.

4.7 OFFSET CURRENT CHECK

Check offset current whenever excessive noise or drift is

suspected. To reed the offset current of the Model 602, set

the front panel controls as follows:

ZERO CHECK Button LOCK