Page 1

Model 595 Quasistatic CV Meter

Instruction Manual

A GREATER MEASURE OF CONFIDENCE

Page 2

WARRANTY

Keithley Instruments, Inc. warrants this product to be free from defects in material and workmanship for a period of 1 year

from date of shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables, rechargeable

batteries, diskettes, and documentation.

During the warranty period, we will, at our option, either repair or replace any product that proves to be defective.

To exercise this warranty, write or call your local Keithley representative, or contact Keithley headquarters in Cleveland, Ohio.

You will be given prompt assistance and return instructions. Send the product, transportation prepaid, to the indicated service

facility. Repairs will be made and the product returned, transportation prepaid. Repaired or replaced products are warranted for

the balance of the original warranty period, or at least 90 days.

LIMITATION OF WARRANTY

This warranty does not apply to defects resulting from product modification without Keithley’s express written consent, or

misuse of any product or part. This warranty also does not apply to fuses, software, non-rechargeable batteries, damage from

battery leakage, or problems arising from normal wear or failure to follow instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. THE REMEDIES PROVIDED HEREIN ARE BUYER’S SOLE AND EXCLUSIVE REMEDIES.

NEITHER KEITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR ANY DIRECT,

INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OF ITS

INSTRUMENTS AND SOFTWARE EVEN IF KEITHLEY INSTRUMENTS, INC., HAS BEEN ADVISED IN ADVANCE

OF THE POSSIBILITY OF SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT ARE NOT LIMITED TO: COSTS OF REMOVAL AND INSTALLATION, LOSSES SUSTAINED AS THE RESULT OF INJURY TO ANY

PERSON, OR DAMAGE TO PROPERTY.

Keithley Instruments, Inc. 28775 Aurora Road • Cleveland, Ohio 44139 • 440-248-0400 • Fax: 440-248-6168

1-888-KEITHLEY (534-8453) • www.keithley.com

Sales Offices: BELGIUM: Bergensesteenweg 709 • B-1600 Sint-Pieters-Leeuw • 02-363 00 40 • Fax: 02/363 00 64

CHINA: Yuan Chen Xin Building, Room 705 • 12 Yumin Road, Dewai, Madian • Beijing 100029 • 8610-8225-1886 • Fax: 8610-8225-1892

FINLAND: Tietäjäntie 2 • 02130 Espoo • Phone: 09-54 75 08 10 • Fax: 09-25 10 51 00

FRANCE: 3, allée des Garays • 91127 Palaiseau Cédex • 01-64 53 20 20 • Fax: 01-60 11 77 26

GERMANY: Landsberger Strasse 65 • 82110 Germering • 089/84 93 07-40 • Fax: 089/84 93 07-34

GREAT BRITAIN: Unit 2 Commerce Park, Brunel Road • Theale • Berkshire RG7 4AB • 0118 929 7500 • Fax: 0118 929 7519

INDIA: 1/5 Eagles Street • Langford Town • Bangalore 560 025 • 080 212 8027 • Fax: 080 212 8005

ITALY: Viale San Gimignano, 38 • 20146 Milano • 02-48 39 16 01 • Fax: 02-48 30 22 74

JAPAN: New Pier Takeshiba North Tower 13F • 11-1, Kaigan 1-chome • Minato-ku, Tokyo 105-0022 • 81-3-5733-7555 • Fax: 81-3-5733-7556

KOREA: 2FL., URI Building • 2-14 Yangjae-Dong • Seocho-Gu, Seoul 137-888 • 82-2-574-7778 • Fax: 82-2-574-7838

NETHERLANDS: Postbus 559 • 4200 AN Gorinchem • 0183-635333 • Fax: 0183-630821

SWEDEN: c/o Regus Business Centre • Frosundaviks Allé 15, 4tr • 169 70 Solna • 08-509 04 600 • Fax: 08-655 26 10

TAIWAN: 13F-3, No. 6, Lane 99, Pu-Ding Road • Hsinchu, Taiwan, R.O.C. • 886-3-572-9077 • Fax: 886-3-572-9031

2/03

Page 3

Model 595 Quasistatic CV Meter

Instruction Manual

©1986, Keithley Instruments, Inc.

All rights reserved.

Cleveland, Ohio, U.S.A.

November 1986, Second Printing

Document Number: 595-901-01 Rev. B

Page 4

Safety Precautions

The following safety precautions should be observed before using

this product and any associated instrumentation. Although some instruments and accessories would normally be used with non-hazardous voltages, there are situations where hazardous conditions

may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions required to avoid possible injury. Read and follow all installation,

operation, and maintenance information carefully before using the

product. Refer to the manual for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use

and maintenance of equipment, for ensuring that the equipment is

operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be

trained in electrical safety procedures and proper use of the instrument. They must be protected from electric shock and contact with

hazardous live circuits.

Maintenance personnel perform routine procedures on the product

to keep it operating properly, for example, setting the line voltage

or replacing consumable materials. Maintenance procedures are described in the manual. The procedures explicitly state if the operator

may perform them. Otherwise, they should be performed only by

service personnel.

Service personnel are trained to work on live circuits, and perform

safe installations and repairs of products. Only properly trained service personnel may perform installation and service procedures.

Keithley products are designed for use with electrical signals that

are rated Installation Category I and Installation Category II, as described in the International Electrotechnical Commission (IEC)

Standard IEC 60664. Most measurement, control, and data I/O signals are Installation Category I and must not be directly connected

to mains voltage or to voltage sources with high transient over-voltages. Installation Category II connections require protection for

high transient over-voltages often associated with local AC mains

connections. Assume all measurement, control, and data I/O connections are for connection to Category I sources unless otherwise

marked or described in the Manual.

Exercise extreme caution when a shock hazard is present. Lethal

voltage may be present on cable connector jacks or test fixtures. The

American National Standards Institute (ANSI) states that a shock

hazard exists when voltage levels greater than 30V RMS, 42.4V

peak, or 60VDC are present. A good safety practice is to expect

that hazardous voltage is present in any unknown circuit before

measuring.

Operators of this product must be protected from electric shock at

all times. The responsible body must ensure that operators are prevented access and/or insulated from every connection point. In

some cases, connections must be exposed to potential human contact. Product operators in these circumstances must be trained to

protect themselves from the risk of electric shock. If the circuit is

capable of operating at or above 1000 volts, no conductive part of

the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits.

They are intended to be used with impedance limited sources.

NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective devices to limit fault current and voltage to the card.

Before operating an instrument, make sure the line cord is connected to a properly grounded power receptacle. Inspect the connecting

cables, test leads, and jumpers for possible wear, cracks, or breaks

before each use.

When installing equipment where access to the main power cord is

restricted, such as rack mounting, a separate main input power disconnect device must be provided, in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any

other instruments while power is applied to the circuit under test.

ALWAYS remove power from the entire test system and discharge

any capacitors before: connecting or disconnecting cables or jumpers, installing or removing switching cards, or making internal

changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth) ground. Always

make measurements with dry hands while standing on a dry, insulated

surface capable of withstanding the voltage being measured.

The instrument and accessories must be used in accordance with its

specifications and operating instructions or the safety of the equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and operating information, and as shown on the instrument or test fixture panels, or

switching card.

When fuses are used in a product, replace with same type and rating

for continued protection against fire hazard.

Chassis connections must only be used as shield connections for

measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use of a

lid interlock.

5/02

Page 5

If or is present, connect it to safety earth ground using the

wire recommended in the user documentation.

!

The symbol on an instrument indicates that the user should refer to the operating instructions located in the manual.

The symbol on an instrument shows that it can source or measure 1000 volts or more, including the combined effect of normal

and common mode voltages. Use standard safety precautions to

avoid personal contact with these voltages.

The WARNING heading in a manual explains dangers that might

result in personal injury or death. Always read the associated information very carefully before performing the indicated procedure.

The CAUTION heading in a manual explains hazards that could

damage the instrument. Such damage may invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and

all test cables.

To maintain protection from electric shock and fire, replacement

components in mains circuits, including the power transformer, test

leads, and input jacks, must be purchased from Keithley Instruments. Standard fuses, with applicable national safety approvals,

may be used if the rating and type are the same. Other components

that are not safety related may be purchased from other suppliers as

long as they are equivalent to the original component. (Note that selected parts should be purchased only through Keithley Instruments

to maintain accuracy and functionality of the product.) If you are

unsure about the applicability of a replacement component, call a

Keithley Instruments office for information.

To clean an instrument, use a damp cloth or mild, water based

cleaner. Clean the exterior of the instrument only. Do not apply

cleaner directly to the instrument or allow liquids to enter or spill

on the instrument. Products that consist of a circuit board with no

case or chassis (e.g., data acquisition board for installation into a

computer) should never require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected, the board should be returned to the factory for proper

cleaning/servicing.

Page 6

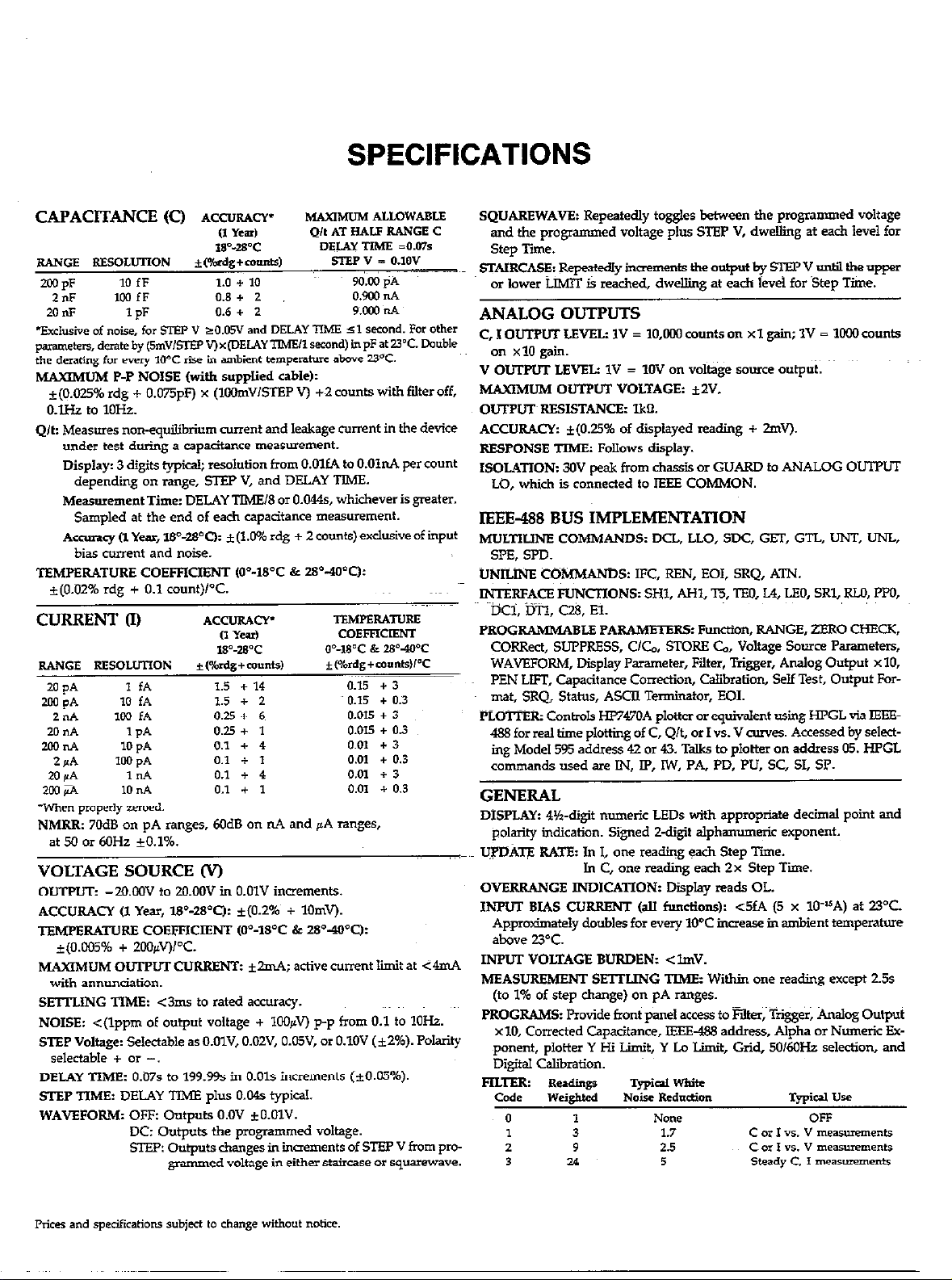

SPECIFICATIONS

CAPACITANCE (C) ACCURACY*

0 Yen,

IBws’c

RANGE REScmmON

mPF

2°F

20°F

+Exdusive of noise, for STEP v am5v and DELAY TIME 51 remnd. For other

parm~w, derateby(~m”,-V)x(DELAY1IMUlrecand) inpFat7.K. Double

the derating for every 10°C rise in ambient temperature above 23’C.

MkylMuM P-P NOISE (with supplied cable):

k(O.O25% rdg + 0.075pF) x (ltiV/STEP V) +2 counts With filter off,

o.lHz to 1oHz.

Q,t: Measures non-equilibrium current and leakage current in the device

under test during a capacitance measurement.

Display: 3 digits typical; resolution from O.MfA to O.OlnA per count

Measurement Time: DELAY TIME/S or 0.044s, whichever is greater.

Accuracy E1 Year, W-WC% * (1.0% rdg + 2 counts) exclusive of input

TEMPERATURE COEFPICIBNT lO”lB”C & 2S”-400Ch

+(O.OZ% rdg + 0.1 count)l°C.

10 fF 1.0 + 10

1w fF 0.8 + 2

1 PF

depending on range, STEP V, and DELAY TIME

Sampled at the end of each capacitance measurement.

bias current and noise.

CURRENT Q

+t?ag+munrr)

0.6 + 2

ACcuRAcK*

” Year)

W-WC

RANGE IlESOLuTfON *wdg+cou*)

20

PA

ZWPA 10 fA 1.5 + 2 0.15 + 0.3

2”A ml fA 0.25 + 6 0.015 + 3

20

Il.4

ml”*

2PA *w

20

PA

*wja 10 “A 0.1 + I 0.01 + 0.3

NMRR: 70dB on pA ranges, 6OdB on nA and pA ranges,

at 50 or 6OHz +O.l%.

1 fA 1.5 + 14 0.15 + 3

IPA 0.25 + 1 0.015 + 03

10oQ

PA

1 “A 0.1 + 4 0.01 + 3

0.1 + 4 0.01 + 3

0.1 + 1 0.01 + 0.3

MAylMuM ALI.cwABLE

Q/t AT HALF RANGE c

DEf.m! TIME =o.m

STEP ” 5 0.10”

5lxQpA

0.900 “A

9~..wo “A

TEMPERATURE

COEFFICIENT

o=wc k 28’MV

*mdg+m”“ts)PC

VOLTAGE SOURCE 0

OUTPET: -2O.OOV to ZO.OOV in O.OlV increments.

ACCURACY (1 Year, lB%WO: i(O.296 + 1OmV.

TEMPERATURE COEPFICIENT to=--WC & 28~4oTb

*(O.COj% + ZOOpVVT.

MAXIMUM OITI-IWT CURRENI: &ZmA; active current Iiit at <4mA

with annunciation.

SE’ITLING TIME: c3ms to rated accuracy.

NOISE: <(lppm of output voltage + lO@V) p-p from 0.1 to 1OHz.

STEP Voltage: Selectable as O.OlV, O.OZV, O.O5V, or O.lOV (iZ%). Polarity

selectable + or -_

DELAY TIME: 0.07s to 199.59s in 0.01s increments (*O.ffi%).

SITP TIME: DELAY TIME plus 0.04s typical.

WAVEFORM: OFF: Outputs O.OV kO.OlV.

DC: Outputs the programmed voltage.

STER Outputs changes in inaements of STEP V from pr*

grammed voltage in either staircase or squarewave.

SQUAREWAVE: Repeatedly toggles between the programmed voltage

and the programmed voltage plus STEP V, dwelling at each level for

step Time.

STAIRCASE: Repeatedly inuements the output by SlEP V until the upper

or lower LIMIT ii reached, dwelling at each iwei for ‘Step Time.

ANALOG OUTPUTS

c, I OUTPUT LEVEL: 1v = 10,wo counts on x 1 gain; 1v = 1Oco counts

on x10 gain.

” OUTPUT LEVEL: 1V = 1OV on voltage sowce output.

MAXMUM OUTPUT VOLTAGE: f7.V.

OUTPUT RESISTANCE: lkn.

ACCURACI: r(O.25% of displayed reading + 2mV).

RESPONSE TIME: Follows display.

ISOLATION: 30V peak from chassfs cm GUARD to ANALOG OurpuT

LO, which is connected to IEEE COMMON.

IEEE-488 BUS IMPLEMENTATION

MULTILINE COMMANDS: DCL, LLO, SDC, GFI; GTL, UNT, UNL,

SPE, sm.

UNILINE COMMANDS: IFC, REN, EOI, SRQ, ATN.

INTERFACE FUNCTIONS: SHI, AHl, T5, ‘CEO, I.4, LEO, SRl, RJR, PPU,

Xi, ‘ml, c28, El.

PROGRAMMABLE PA RAMETERS: Function, RANGE, ZERO CHECK,

CORRect, SLi’PPRESS, C/Co, STORE Co, Voltage Source Parameters,

WAVEFORM, Display Parameter, Filter, Trigger, Analog Output x 10,

PEN LIFT, Capacitance Correction, Calibration, Self Test, Output For-

mat, SRQ. Status, ASCII Terminator, EOI.

PLOTTER: Controls HF747OA plotter or equivalent using HPGL via IEEE-

488 for real time plotting of C, Q/t, OT I vs. V curves. Accessed by select-

ing Mode, 595 address 42 or 43. Talks to plotter on address 05. HPGL

commands used are IN, Ip, IW, PA, PD. PU, SC, SI, SP.

GENERAL

DISPLAY: 4%-d@ numeric LEDs with appropriate decimal point and

aolaritv indication. Sikned Zdkit al~hanuneric exponent.

IJiD‘iTp RATE: In I, one reading wh step Tiie.

OVERRANGE INDICATION: Display reads OL.

INPUT BIAS CURRENT @I functions): c5fA (5 x 10.‘IA) at 23°C.

/,~pmi$~Iy doubles for every 1O’C increase in ambient temperahue

1NP”T VOLTAGE BURDEN: <lmV.

MEASUREMENT SETiUN

(to 1% of step change) on pA ranges.

PROGRAMS: Rovide front panel access to mter; Trim+; tiog Output

x10, Corrected Capacitance, BXEa88 address, Alpha or Numeric Exponent, plotter Y Hi Li+t, Y Lo Limit, Grid, 50/6OHz selection, and

Digital Calibration.

FILTER: ReAngP Typid White

Code we&ted Noise Rechei.m Typid “se

0

0 1 NO”e OFF

1 3 1.7 c or I YS. ” meas-ents

2 9 2.5 c or I YS. ” meanueme”ts

3 24 5 Steady c, I measluemenh

- -.

In c, one reading each 2x step Time.

G TIMEz Within one reading except 2.5s

Page 7

MAXIMUM INPUTz 3oV peak, dc to @IF& sine wave.

nl- COMMON MODE VOLTAGE: 3OV nwimum, dc to 6OHz

sine wave.

NPLT CONNECTOR Isolated BNC on rear panel.

3UTFWT CONNECTORS: Mated BNCs on rear panel for VOLTAGE

SOURCE OUTPUT, EXTERNAL TRIGGER, and METER COMPLETE.

5way binding posts on rear panel for ANALOG OUTPUTs, PEN LIFT,

GUARD, and Chassis.

~rmRHAL TRIGGER: 777, comptiile EXTERNAL TRIGGER and

METER COMPLETE.

-nNIRONMENTz Operating: 0’ to 40°C, relative humidity 70% non-

condensing up to 35OC. Storage: -25O to +WC

XRMUP: 2 hours to rated accuracy (see manual for recommended

pmcedure).

;~~

POWER: 105125V or 21~25OV (internal switch selected), 5OI-k to M)&,

15VA max. 9&llOV and 18X22OV version available upon request.

DIMENSIONS, WEIGHT: l27mm high x 216mm wide x 359mm deep

(5 in. x 8% in. x 14% in.). Net weight 3.2kg (6 Ibs., 14 oz.).

ACCESSORY SUPPLIED: Two Model 4801 Low Noise BNC Input Cables.

ACCESSORIES AVAILABLE:

Model iO19A: Universal Fixed Rack Mounting Kit

Model 10195: Univenal Slide Rack Mounting Kit

Model 4801: Low Noise Input Cable, 1.2m (4 ft.), BNC to BNC

Model 4803: Low Noise Cable Kit

Model 5955: Calibration Standards

Mcdel61134: Test Shield

Model 7007-k Shielded IEEE-488 Digital Cable, lm (3.3 ft.)

Model 7037-Z Shielded IEEE-488 Diittal Cable, 2m (6.6 ft.)

Page 8

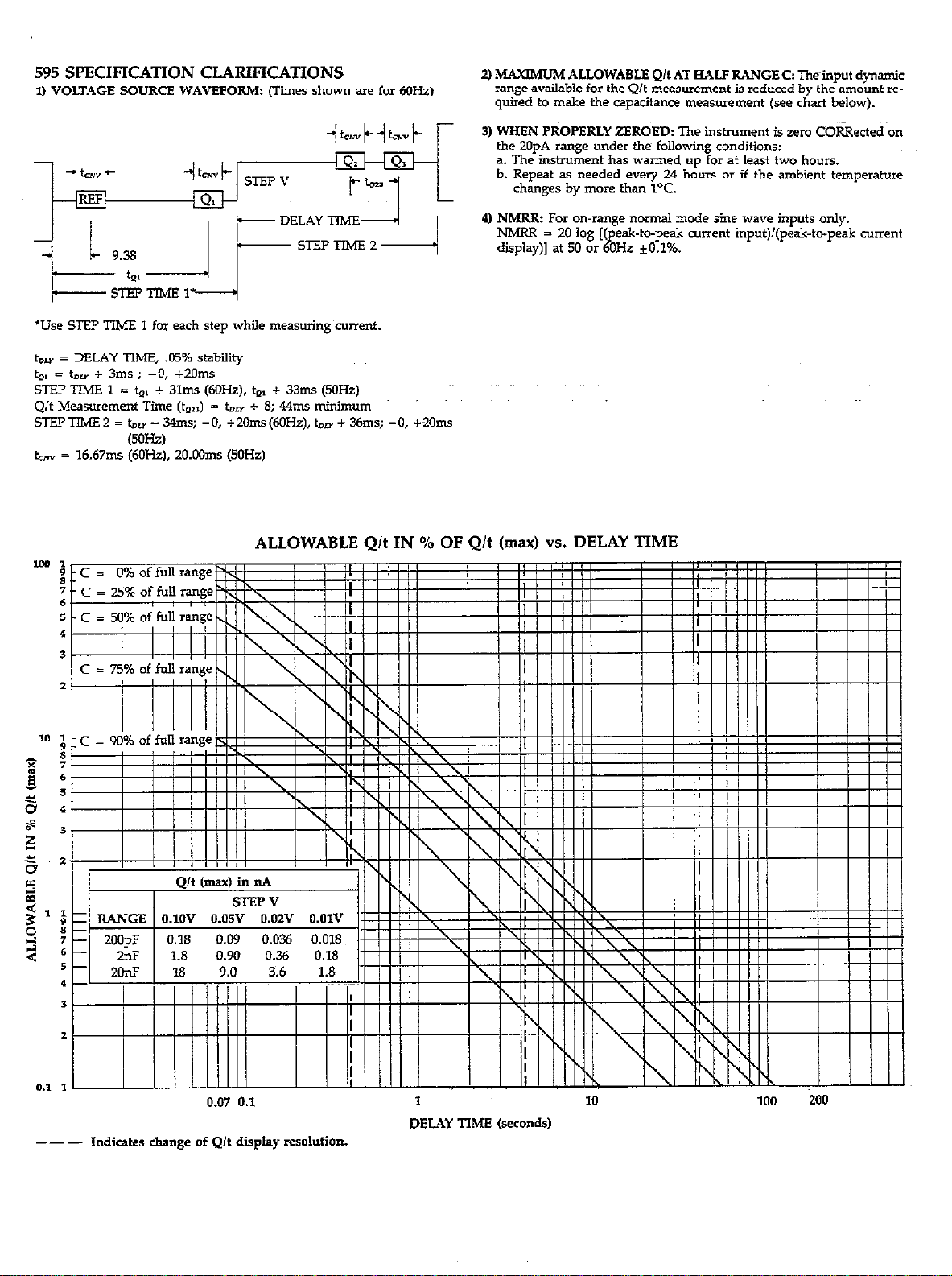

595 SPECIFICATION CLARIFICATIONS

U VOLTAGE SOURCE WAVEFORM: (Tiies shown are for 6OHz)

< c 9.38 I j---s~p------

*Use STEP TIME 1 for each step while measuring current.

t,, = DELAY TIME, .05% stability

b, = t,, + 3ms ; -0, +ZOms

STEP TIME 1 = bx + 31ms (6OHz). ton. + 331x (5OHz)

Q/t Measurement Time (to.,) = torr + 8; 44ms minimum

STEP TIME 2 = t,, + 34nxs; -0, +ZOms @Hz), t,, + 36ms; -0, +20ms

(5OHz)

t, = 16.67ms (6OIiz). ZO.Wms (5OHz)

2) MAXIMUM ALLOWABLE Q/t ATHALFRANGEC: The~input dynamic

range available for the Q/t measurement is reduced by the amount required to make the capacitance measurement (see chart below).

3) WHEN PROPERLY ZEROED: The instrument is zero CORRected on

the 2OpA range under the following conditions:

a. The instrument has warmed up for at least two hours.

b. Repeat as needed every 24 hours or if the ambient temperature

changes by more than 1°C.

41 NMRR: For on-range normal mode sine wave inputs only.

NMRR = 20 log [(peak-to-peak current input)@?&-to-peak current

display)] at 50 or 6OH.z +O.l%.

ALLOWABLE Q/t IN % OF Q/t (maw) vs. DELAY TIME

0.0, 0.1

--- Indicates change of Q/t display resolution.

1

DELAY TIME (seconds)

10

100

200

Page 9

TABLE OF CONTENTS

SECTION l-GENERAL INFORMATION

1.1 J.N”IRODUCTION

1.2

1.3

1.4

FEATURES

MANUAL ADDENDA

SAFETYTERMS

.................................................

.......................................................................

.....................

........................................................ ..,__

UNPACKING AND INSPECTION

E

1.7

1.8

REPACKING FOR SHPMENT

WARRANlY INFORMATION

ACCESSORIES

.................................................................

.... ______

.....................................................

SECTION 2-GETTING STARTED

2.1

2.2

2.2.1

2.2.2~~

2.2.3

2.3

23.1

2.3.2

2.4

2.51

2.5.2

2.5.3

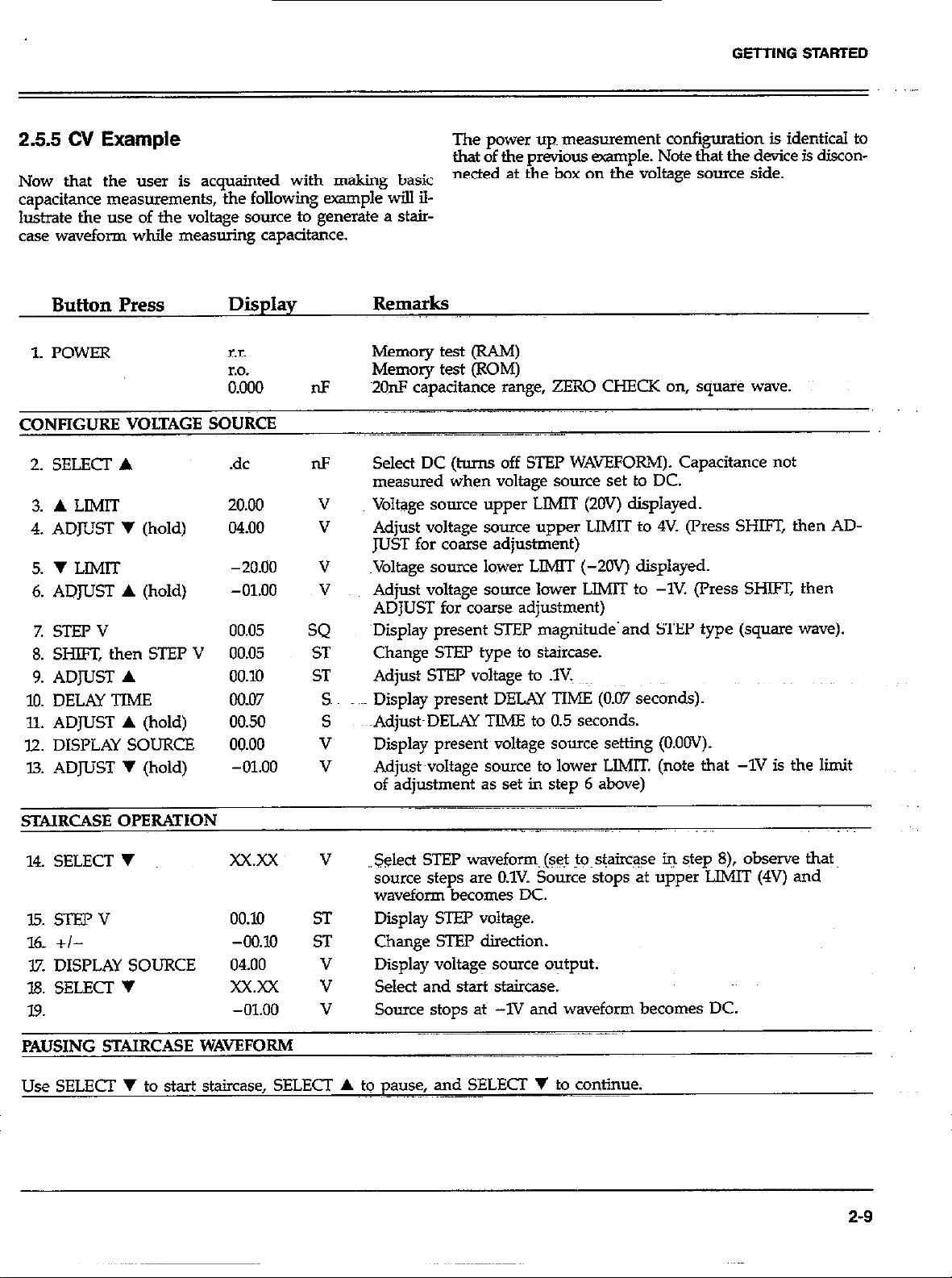

2.5.4

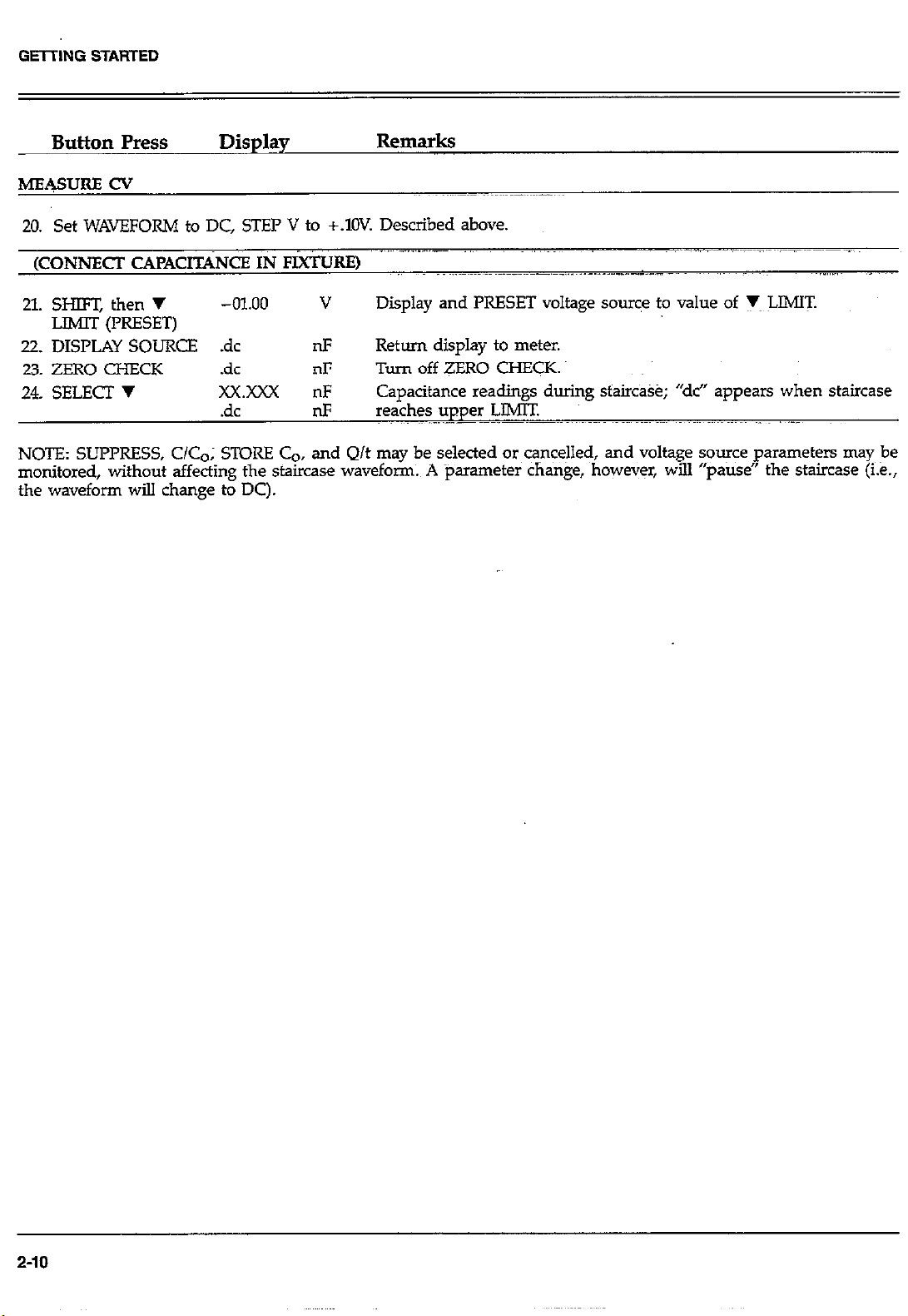

2.55

2.56

2.5.7

INTRODUCTION..

PREPARHION FOR USE

LinePower.. ..................................

LineVoltage Selection ........................................................................

LieFrequency

POWERUPPROCEDURE

PowerCord.........................~....................~....--.........................~

Defaults..

.............

RAM and ROM Test Messages

GENERAL DISPLAY MESSAGES ................................

INSTRUMENT FAMILIARIZATION.

Model595FrontPanel...............................---......-......-..-..........-....~~~~

Model595RearPanel..

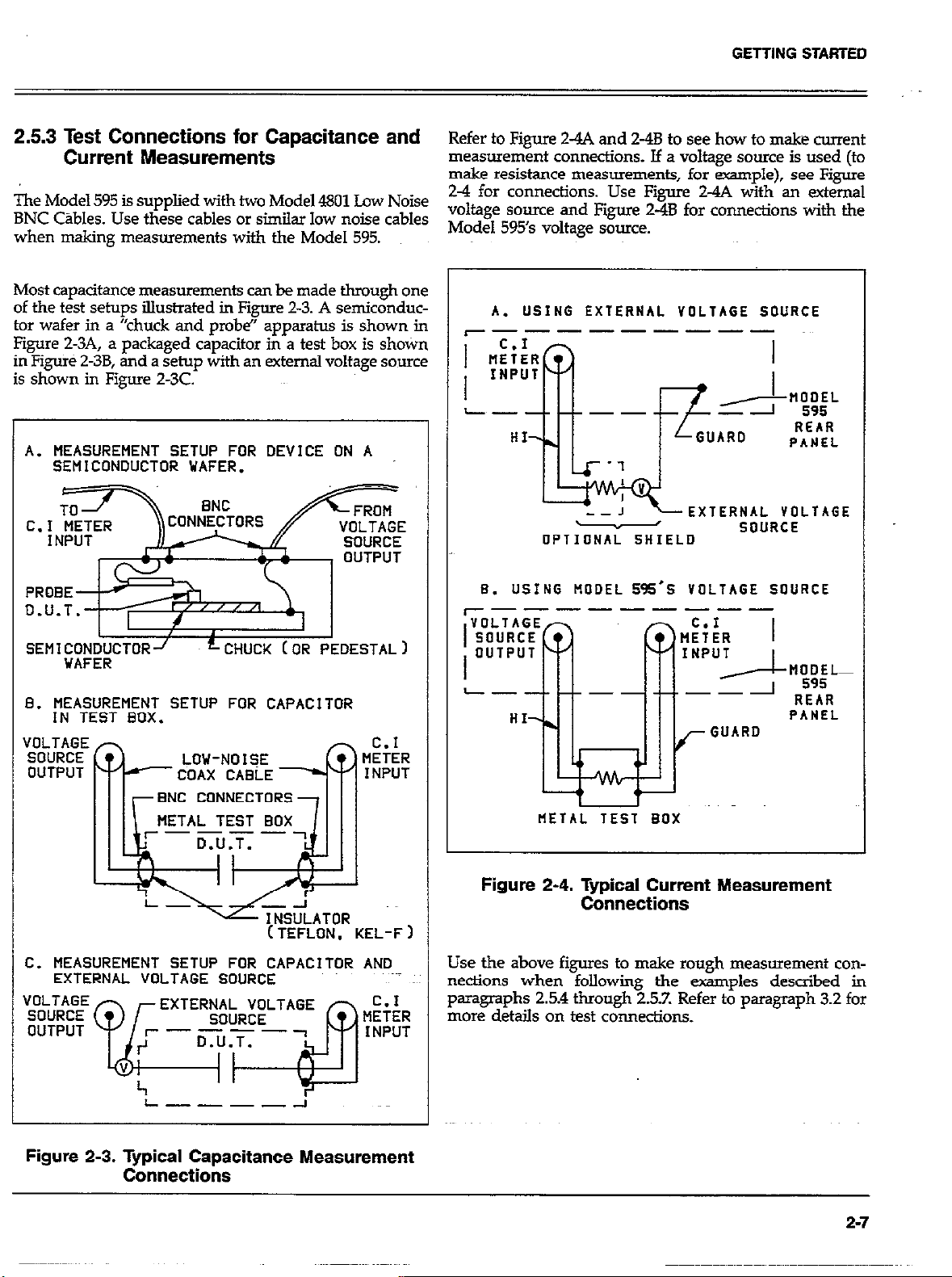

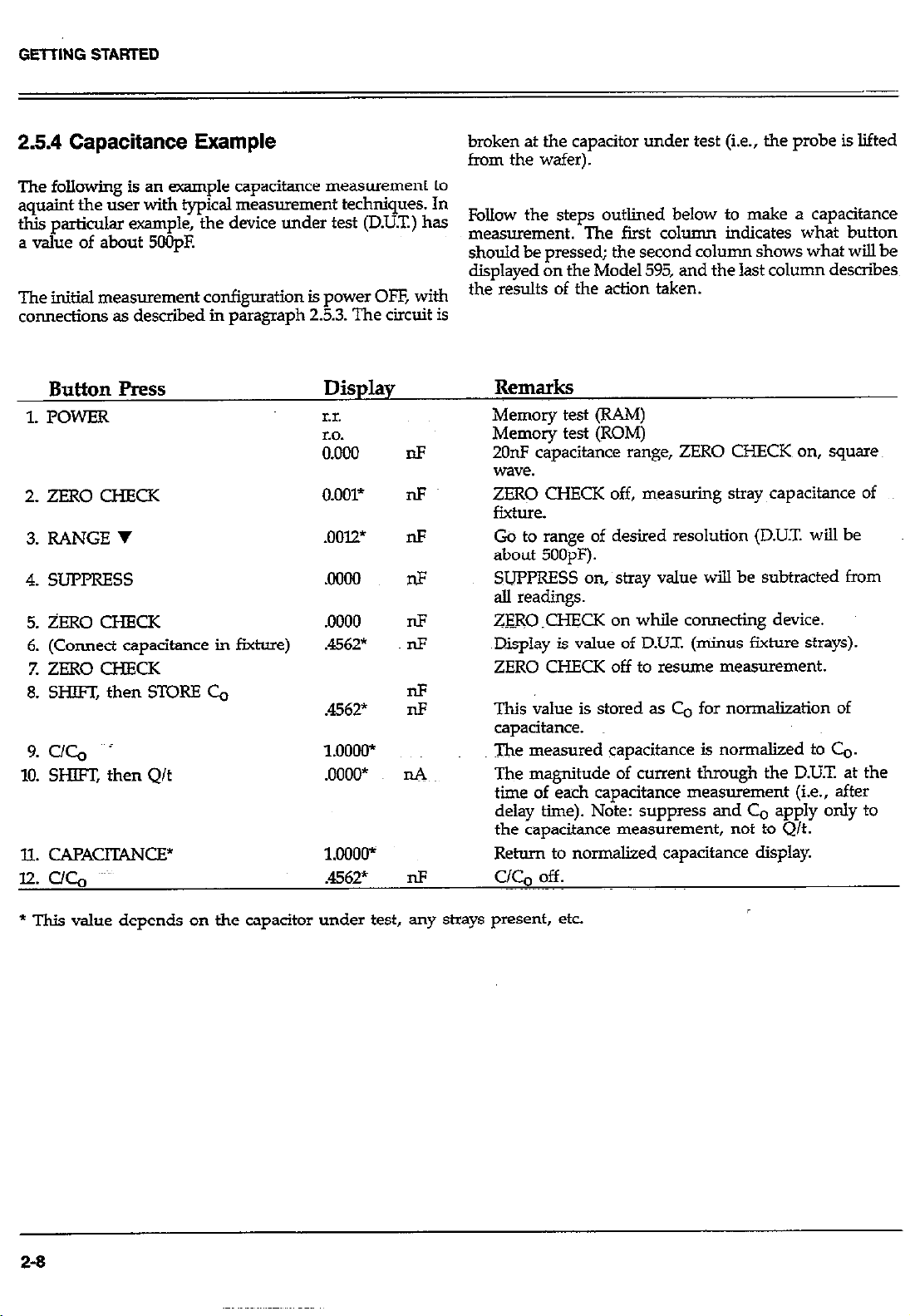

Test Cormxtions for Capacitance and Ctient Measurements

Capacitance Example

CVExample.. ..................................

Measurin‘g Current: AnExample

IV Example ............... ._. ._..__ ._

...................

.......................................................................

.................................

..............

_______

..............

..........................................................................

_.__ __

_

..........................................

..

...............................................................

...............................................

..........

_

.............................................

..~. __r______

.................

.._

_

...............................

.

.....

.

....................................

............................

.......

..__

_._~_

.........................................

........

................................................

_.

. . _____ _..._....._........_~

___._ . .,._

.............................................

................................

................

._____

.._

_._

.............. l-l

......................

__ __ .....

.............

._

...........

.._

_._l .,_.____.

_._~_.______._.

.................................

........

_,

~:

.............................

..............

__

............................. 2-6

....................................

.._ .............................. 2-9

......

.................

. . .

.

. . .

................

.......

...

___

_.

...

.,

..

..~2- 1

...

....

;...~2- 2

_~__. 2-2

..

l-l

l-l

l-1

l-l

l-2 ..

l-2

l-2

2-l

2-l

~2-1~

2-l

2-l

2-l

2-2

2-2

2-4

2-7

2-8

2-n

2-12

SECTION 3-OPERATION

3.1 ;i INTRODUCTION ___._......~..___._........................... ___ . . . .

PART i-Front and Rear Panel Description

3.2

3.2.1

3.2.2

3.3

3.3.1 ..

3.3.2

TEST CONNECI-IONS

Cap&zitance C$yeclions

Connections for Cment Measurements

DETAILED FRONT PANEL CONTROL DESCRlPnONS

CURRENT

CAPACITANCE.. .....................

33.3 ~cl~-mREc,.

y. : SUPPRESS

ZERO CHECKand CORRect.......~..........~.........................I

RANGE A, v.. .........................................

A LIM.IT, v LIMIT and PRESET

3.3.9

DELAY TIME

.....

_,_ __._. I_____~~. . _.

................................

....................................................

............................................................

........................................................................

....................................................

.......................

.......

...............

_

; ;

...............

__.,__ _ .. . . . .._-... 3-l

.........................................

...........................................

..~ ...

____ ___.__. .............................................

_..__

................

......................................................

__ _.

. .

.

. .

.

. . . . . . . . . 3-l

. .

. .

. .

. .

. .

_.-

~. . . . . .

.............

__ _

~;.;.

...................... 3-2

..-

......

.__.

_._

.......

.......................

.._

.............

__ . _

.......

......

3-l

3-2

3-2

3-2~

3-3

3-3

3-3

3-4

3-5

3-5

Page 10

3.3.10

3.3.3.11

3.3.12,

3.4

3.4.1

3.4.2

3.4.3

3.4.4

3.4.5

3.4.6

3.4.7

3.4.8

3.4.9

3.4.4.10

3.5

3.5.1

35.2

3.5.3

DISPLAY SOURCE

ADJUST A , V

+I-, Front Panel Trigger .......................... ._

FRONT PANEL PROGRAMS ................... :_ .. __ ._ ........................................... 3-6

Power Lime Frequency.. ............... ..___

Calibration

Filter. ................................. ..~~-.........................~ ........................

Trigger .............................. ~...;.~..;.;~. ....................... . ............. :.~..:.~ .. 3-10

Andog output xlmo

C~irectedCapacitance ........................................................................

IEEE-488Address..~..................................................................~..~ .... 3-11

Display (Alpha or Numeric) .................................................................. 3-11

Grid ....................................................................................... 3-13

Y HI-YLO ................................................................................ 3-13

REAR PANELS

ExternalTrigger.. ...........................................................................

MeterComplete....................................................................~--.- .... 3-14

Analog Output .............................................................................. 3-M

..........................

FEATURES.. ......................................................................... 3-13

..........................................................

.................................................................................

...........................................

.._.._._

...

..~.~---------................~.~............~~~ ........ 3-8

........................................................................

...................

.._.

.:~.~..;..I~;

...................

.......

3-6

3-6

3-6

3-8

3-8

3-71

%J.I

3-13

PART 2-MAKING CV, IV or Q/t-V Plots

3.6 SETTE’JG UP THE TEST FIXTURE .............................................................

3.7 SETTING UP MEASUREMENT PARAMETERS .................................................. ::

3.8 BEGINNINGTHEMEASUREMENT..

3.9

3.10 ANALOG PLOTTING ..........................................................................

3.11 PRINTING RESULTS .......................................................................... 3-19

3.12 USE OF JXI’ER ON CURVES ........................................... : ...................... 3-20

3.13 MEASUREMENTCONSID~ONS..;..~ ... .._. .......... .._._ ...................... . ......... 3-22

3.X3.1 Ground Loops .............................................................................. 3-22

3.X3.2 Electrostatic Interferences ....................................................................... 3-22

3.13.3 The~~EMFs.............................~...;...........~

3.X3.4

3.13.5

3.X3.6

D.&TALPLOTTING

RFI ........................................................................................ 3-23

Source Capacitance ......................................................................... 3-23

Engineering Units Conversion .................. 1.. ....................... ;. ..... ;~. ;. ............. 3-24

...................................................................

...................... . ....................................

..................................

~;

.......

3%

3%

3-19

3-23

SECTION 4-IEEE-488 PROGRAMMING

4.1

4.2

4.3

4.3.1

4.3.2

4.4

4.5

4.6

4.6.1

4.6.2

4.7

4.7.1

4.7.2

4.7.3

4.7.4

4.8

4.8.1

4.8.2

ii

INTRODUCTION .............................................................................. &l

SHORTCUT TO IEEE-488 OPERATION .......................................................... 41

BUS CONNECTIONS ....................... _.,_-,_ ...................................... .~_ ........ 41

Typical Controlled Systems ................................... .; ................................ 41

Cable Connections .. .._ ...................................................................... 42

PRIMARY ADDRESS PROG RAMMING ......................................................... 4-4

INTERRACEFUNCTIONCODES..;.;..;;. ............. .

CONI’ROLLER PROGRAMMIN

Controller Handler Software ..................... :. ............................................ 45

Interface BASIC Pro gramming Statements ........................................................ 4-6

FRONT PANEL ASPECTS OF IEEE-488 OPERATION ............................................. 4-6

BusError........................................................................~ ............ 46

TriggerOvemmE~or ........................................................................ 47

Number and Conflict Errors

WaitingforTriger ........................................................................... 47

GENERAL BUS COMMAND S

REN (Remote Enable) ........................................................................ 48

IFC (Interface clear) .......................................................................... 48

G ................................................................. 45

...................................................................

......................................................................

.............................

..;.

........

4-4

&7

48

Page 11

4.83 LLO (Local Lockout) .........................................................................

4.8.4

4.8.5

4.86 SDC(SelectiveDevice clear) ................................................................. 4-10

4.8.7 GET (Group Execute Trigger) ................................................................. 410

ES ~;

4.9.1

4.9.2

4.9.3

4.9.4

4.9.5

4.9.6

;:;; ~:

4.9.9

4.9.10

4.9.n

4.9.12

4.9.13

4.9.14

49.15

49.16

4.9.37

4.9.18

4.9.19

4.9.20

4.9.21

4.9.22

4.9.23

4.9.24

4.9.25

4.10 PROGRAMMIN GEXAMYLES

4.10.1 Square Wave Capacitance Measurements ....................................................... 4-48

4.10.2 StaircaseMeasurements

4.10.3 Cti@ntMeasurements ........................... .

4.11

4.12 IEEE-PLOT..

4.13

GTL (Go To Local) and Local ..................................................................

DCL(D&ce Clear) ..........................................................................

SPE, SPD (Serial Polling). ..................................................................... 4-10

DEVICE-DEPENDENT CO

Programming Overviav........~ .............................................................. 4ll

Execute (X) ................................................................................. 4-16

Display (D) ................................................................................. 417

FundionO.................................; ............................................... 4-18

Ran@(R). .................................................................................... 419

ZeroCheck,ZeroCorrect(Z). ...... . ............ ;.~. ..... I..................... Y . ..i.. ....... 420

Suppress (N) ................................................................................ 421

F&r(r). ....................... ;..~.~.l~.~....~ .:. .... . ................ . ......................... 422

Egh Limit (H) ............................................................................. 423

Low Limit (L). ................................................................................ 424

Voltage Source (V) ........................................................................... 425

Step Voltage (S) ............................................................................. 4-26

Delay Tie (I) .............................................................................. 427

wavefoml (W) .............................................................................. 428

c/c,J (C) ................................................................................... 429

CapacitanceModifiers ................................................ . ............... :1~.~~430

Pr&s (G)

Analog output (0). .........................................................................

TriggerModeo.............~.....~............................................; ............

SRQ Mask (M) and Serial Poll Byte Format.

EOI and Bus Hold-off Modes (K) ............................................................. 438

Terminator(y).

status (u) .................................................................................. 44

Digital Calibration (A) ....................................................................... 446

Self-Test and Permanent Memory Storage u) .................................................... 4-47

TALK ONLY

BUS DP;TZ1TRANSMISSIONTIMES ............................................................ 450

........................

.............................................................................

..................................................................................

....................................................................................

IvcGANDs :..: ......................................................... 4u

.......................................

.~I~.

....................................................

....................................................

......................................................................

...........................................

..............

;

...........

:.~:.

49

49

49

; 431

433

434

435

4-40

~4-48

4-48

4-49

4-49

4-49

SECTION 5-APPLICATIONS

5.1

5.2

5.2.1

5.2.2 Voltage Coefficients of High Resistances

5.2.3 IVCharacteristicsofDiodes

5.2.4

5.25

5.3 APPLICATIONS OF THE CAPACITANCE FUNCTION

5.3.1

5.3.2 Characterizing the MOS Capacitor in Depletion and Accumulation

5.3.3 Characterizing the MOS Capacitor in Inversion

5.3.4

5.3.5 ~:

5.3.6 Comparison of the Feedback Charge Method with the Traditional Ramp Method

5.3.7

5.4

INTRODUCTION

APPLICATIONS OF THE

HighResistanceMeasurements...................................~ .............................

IV Characteristics of Transistors

~w LevelLeakageCurrentMeasurements ..................................................... 5-6

Ccmsiderationsfor CapadtanceMeasurem~nfS;.~.;;~.~;. ........... 1.~.

Determining Delay Tiie for Equilibrium Measurement

MOS Non-equilibrium and Roper Use of the Corrected Capacitance Program .................... 5-13

Comparison of the Feedback Charge Method with the Static or Q-V Method ...................... 5-19

BIBLIOGRAPHY OF QUASISTATIC CV MEASUREMENTS AND RELATED TOPICS

..............................................................................

CURRENTFUNCTION ...... __._._

..........................................................

...................................................................

...............................................................

...............................................

..................................................

..........................................

................

...............................

. .................... 5-l

............

5-l

5-1

5-l

5-2

5-4

5-S

.:.............. 54

5-8

5-9

510

.................. 5-17

................

5-21

iii

Page 12

SECTION C-PERFORMANCE VERIFICATION

6.1 INTRODUCTION..

6.2 ENVIRONMENTAL CONDITIONS

6.3 INITIALCONDITIONS..

6.4

El

6.5.2

65.3

6.5.4 Capacitance Verification

6.5.5

RECOMMENDEDTESTEQUIPMENT.. ............... .,.:.

VERIFICATION PROCEDURES

InputCurrentVerification....................:.........................................~

Current Verification

Q/t Verification

Voltage Source Verification

............................................................................

..............................................................

......................

......................

......................

...............................................................................

.................................................

....................

SECTION 7-THEORY OF OPERATION

7.1

7.2

z3

%4

%4.1

%4.2

%4.3

7.4.4

7.5

z5.1

Z5.2

z5.3

z5.4

76

7.7

Z8

z9

ZlO

7.10.1

7.102

z10.3

ZlO.4

z10.5

ZlO.6

7.11

7.12

INTRODUCTION

CVMEASUREMENTMETHOD.. ...............................................................

OVERALL FUNCTIONAL DESCRIPTION

VCKTAGESOURCE.. ........... .................

D/A Converter

PrecisionStep Source.................................................~...............~

Output Stage.. ...........................

ResetCircuit.. .........................

PREAMPHFIER..

PreamplifierConfiguration..

InputandGain Stages................................................~

FeedbackElements..

Past Discharge Bridge .................. . ..................

Xl0 AMPLIFIER

MUITIPLFXER and BUFFERAMFLIFIER

-2VREF!.XF!NCESOURCE _ ..........

A/D CONVERTER..

DIGITAL CIRCUITRY

Microcomputer...........................~...-......................................-

Memory Elements

Device Selection.......................................................................~

IEEE488Bus..........................~..~..~.~

Input/output circuitry..

-. . -. .~

I&play cacti

ANALOG OUTPUTS

MAIN POWER SUPPLY

.............................

.......................................................

......................... _~.._

............

.....................

........................

..................

...........................................................................

...................................

..................... ,^.,..., -

............................................................................

...................

.......................................................................

____; ...........................................

.......................................

:.

............................................

.~___.

.....................................

.,_

..........

;. .......

_.

...............................................

..............................

i..;.;

.1..~

~.~.~._~._~_~.~._~.

.~;.Z;; __

........................................................

:.:::.:.‘; .... ~-..:;...;.~...:‘...:.:.:..:_..:.;..;.~;....::;..I~;’

.: .:.~.:~I~.

_.

.................

._ ..__

..-_ ._

...................

.... .1.~. .... .;....... -y..;...;;

....................................................

............................

..........................

...................

.................................................

..

.

.I

...........

..............

..~................-.--.........~

......... ..__

_.

......................................

... . . . . . . . . . . . . . . . . . . _.

;.

.:

.~;~I..

.....................

_._._ ..: .............. .._ .........

.................................

_

...............

.., .. ._ ........ ______,_________

__

........................

.

_,.___ _.___.__~.

.....

;.;.

... .1..~....‘.....1.....

......................

........................

.._

.__-____

_,

.........

.,,

.........

., _._,

.........

..............

..........

1-..~

..:

........

............

........

......

.........

.......

.....

....

64

E

6-1

6-2

6-2

6-3

6-6

66

6-7

7-1

7-1

7-2

7-Z

7-2

7-5

7-5

7-a

7-8

7-8

7-10

Ku

7-12

7-14

7-14

7-26

7-16

7-18

%I8

7-18

%I8

7-19

7-19

7-20

7-20

7-22

SECTION 8-MAINTENANCE

8.1

8.2

8.3

8.4

8.5

85.1

8.5.2

8.53

8.5.4

8.5.5

8.5.6

iv

INTRODUCTION

LINE FREQUENCY SELECTION

LINE VOITAGE SELECTION

FUSE REPLACEMENT

CALIBRATION

Recommended Calibrated Equipment

Environmental Conditions

Warm-Up Period

Ca&ration Jumper

;Frt$yr

.....................................................

.......................

.......................

.........................................................

......................

ration..

.....................................

......................................................................

~..I~.:.~:.

._

..........................................................

...................

...........................................

.....................................................

__.

.....

.~.~_._-~__

...............................................

.,

................................................

............................................

....................

_,

.........................

__

........

.;

.......................

_

_

.....

.....

_ .................

_.

..................

_.

..............

...................

8-l

8-l

81

8-2

8-2

8-2

8-3

8-3

8-3

8-5

8-5

Page 13

._~.

8.5.7 Calibration Sequence ............. ..

8.58

8.5.9 Input Offset Voltage Adjustment

8.5.10

8.5X Input Current Adjustment

8.5.12 Capacitance Offset Compensation

8.5.73

8.5.14 Current Calibration

8.5.15

8.5.16

8.5.17

8.5.18

8.5.19 Additional Calibration Points

8.6

8.7

8.8 TROUBLESHOOTING ........................

8.8.1

8.8.2

8.8.3

8.8.4

8.85-- AIDConverterChecks.. ...............

8.8.6

8.8.7 Relay Configuration........~

8.8.8

8.8.9 Digital Ciitry

8.8.10

8.9

8.10 HANDLING AND CLEANING PRECAU'IIONS

DigitalCalibration....................................................~

............................................................... 8-6

Zen,HopCompensation......................................-....-

.................................................................... 8-8

Voltage SourceCalibration..

............................................................................

1,CAnalogOutputAdjustment ...............................................................

Q/t CaIibration

Capititance Calibration ......................................................................

Storage of Calibration Parameters

... DISASSEMBLY INSTRUCTION

SPECIAL HANDLING OF SIXTIC SENSITIVE DEVICES.

RecommendedTest Equipment ................................................................

Power UpSeIfTest

Self DiagnosticProgram ......................................................................

Power Supply Checks. .......... .._

Voltage Source Checks

Input Conditioning Circuitry Checks

DisplayBoard Checks

INPUT STAGE BALANCING PROCEDURE .......................................................

........................................................

.......................................................................... 8-18

.............................................................................

..................................................

......................... _,

................................................................. 815

.................................................................. M5

................. ~....; .... .

................................................................. 8-24

..............

........

.............................................................

.....

.._

..........................................................

.._..............~....~..................~............~ ... 8-30

__

_

..... _ ....................................

..

........................ 8-6

.......................... 8-7

..-

.............

__ _.

....................

...................................

.....

__.__.; ....... .._. ................................ &l7

.......................................

:;.~

...................................................

.....

_.__.:

..................................................

...

._

_.

............................

....................................

___.._.._

...

8-6

8-8

8-8

a10

813

&I3

&I.3

8-14

8-17

&I8

818

8-19

8-19

~8-19

8-24

8-24

8-31

8-31

SECTION 9--REPLACEABLE PAFiTS

9.1 ~~. INTRODUCTION. . . . . . . . . . . . . .___. . __. _. _. _. _. . . .__. . . . . . .__. _. . . . . . . . . 9-l

9.2 PARTS LIST . .._...._.... . . . . . ._ .___..__.._._.._._. .,. ..~ ._._._____.___.. . .._. .__.. . . . . . 9-l

9.3 ORDERING INFORMATION . . . . . . . . . . _ _ . . . . . . . _ _ . . . . _ . . . . . . . . . . . . . . . . . 9-1

9.4 ~~ FACTORY SERVICE . __. ..____ .__~__~.~ ____ .___~ ____ _____ ______. __. . __. .___. . . . . . . . . . . . . . . . . . 9-l

9.5 S-C DIAGRAMS AND COMPONENT LOCATION DRAWINGS . . _ . . . . _ _ _ . _ . . . _ . _ _ _ _ . _ _~. . 9-l

APPENDIX A

APPENDIX B

APPENDIX C

APPENDIX D ......................................................................................

APPENDIX E .......................................................................................

APPENDIX F .......................................................................................

APPENDIX G ........................................................................................

APPENDIX H

.......................................................................................

..........................................................................................

A-l

B-l

...................................................................................... C-l

D-l

E-l

Gl

...................................................................................... H-l

F-l

v/vi

Page 14

SECTION 2-GETTING STARTED

LIST OF TABLES

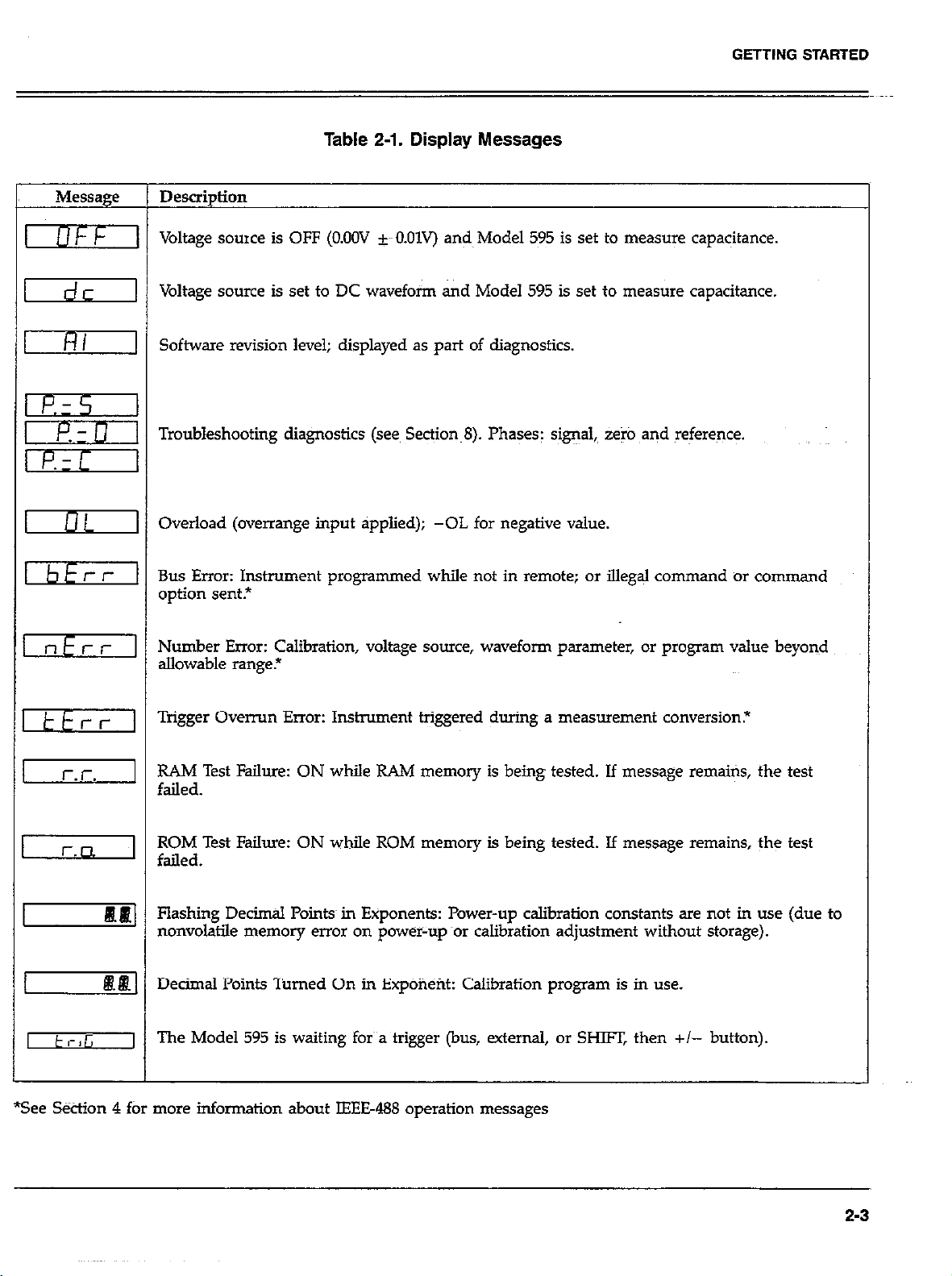

2-I.

Display Messages . . . . . . . . . . . . . . . . . . . . ;~.- .._.. _ ___............_............. . . . .._ . . ..~.....~.~Y ..,.,.. 2-3

SECTION 3-OPERATION

FrontPanelPrograms.................................................~.......................-

z

3-3

Display ExponentValues .......................................................................

Engineering Units Conversion

...........................

SECTION 4-IEEE-488 PROGRAMMING

41

42

43

4-4

45

t73

IEEE488 Contact Designation ...........................................................

Model 595 Interface Function Codes.

BASIC Statements Necessary to Send Bus Commands ...............................................

IEEE-488FrontPanelMessages ...............................................................

General Bus Commands and Associated BASIC Statements

Device-Dependent Command Summary .........................................................

Bus Hold-Off Ties ................ __ __

Trigger to Reading Ready ‘Iiies~ (in Ksec) ..........................................

............................................................

....... _

SECTION B-PERFORMANCE VERIFICATION

Recommended Test Equipment for Performance Verification.

2

6-3

6-I

6-5 ...

Liits for Current Verification

DeterKnin g Capacitance Limits ....................................................................

CapacitanceVerification .........................................................................

Limits for Voltage Source Verification ................................................................

...........................................

1.

...................................

.........................

................................................

........................................

_ ..........

.. 3-7

3-12

:.

3-24

..

_ ........ 44

45

46

..- 46

., .............. 48

4-13

438

.-I

..........

: ............. 6-3

., . 450

6-2

6-6

6-7

6-7

SECTION 7THEORY OF OPERATION

7-1

7-2

RelaySwitchConfiguration..

Memory Mapping ..............................................................................

................................... ~..~.;.:..Y.~ .._.

SECTION S-MAINTENANCE

8-1

8-2

8-3 ..

8-4

8-6

Lie Voltage Selection (50~&X-Iz) ................................................................

Line Fuse Selection .............................................................................

Recommended Calibration Equipment

Current Calibration ..............................................................................

Capacitancecalibration ........................................................................

Recommended Troubleshooting Equipment

DiagnosticProgramPhases.........~ ............................................................

...........................................................

......................................................

...... .I

...........

~..~?ll

7-1

_ 8-l

8-2

8-3

8-u)

8-X

8-18

8-19

vii

Page 15

8-8 PowerSupplyChecks

A/D~~Converter Checks

Voltage Source C,hecks

Relay Confiitihon

Amplifier Cams

833

a14

845

846

al7

Capacitance Circuitry Checks

Cu&ntCktiitryChecb

Digital Circuitry Checks

DisplayCircuitryChecks..

InputStageBalancing................-......~...........--...........-.-........~----...-~~~

...............................

..............................

........................................................................

....................

.............

...........................

........... ..__. _ .~-.

.._...........~~.~.~.........~.~..............~~.~...............~

........................................................

.............

SECTION g--REPLACEABLE PARTS

.-__-___

.

................

.....................

.

.........................................

~___~ .

...................................................

__~.~~.-~_~~__.

........................

..___.__. _..__

- .. -

...........................

_.,..-. _,_._.

..............

................ -

...

.,

.

...............

.~.~...~.~__ . 8-28

......

.......

....

_,_

8-19

8-20

i$

8-25

8-25

8-27

%3:

...

9-1

9-2

9-3

9-4

MotherBoard,Parts List....................................~~.~~..~

Display Board, Parts List..

Preamp Board, Parts List

Miscellaneous Parts, Parts List

.............................................

........................

............................................................

APPENDIX D

D-l

BASIC Staten-tents Necessary to Send Bus Commands . . . . . . _ . . . _ _ . . . . . . _ :. . _ . . D-l

APPENDIX F

Fl

F2

~-3 Typical Addressed Command Sequence.. . . . . . . .

M

F-5

IEEE488 Bus Command Summary . . . . . . . . . . .,~ .,__ ~___.~ __....__.._... .____.. ._. _. __ _..~ ..____ “TV... W

Hexadecimal and Decimal Command Codes.. . . _ _ . . _ _ . _ _ . . . _ . . . _ _ . _~_. . . . . . _ . . . . . _ . . F7

Typical Device-Dependent Command Sequence. . . _ . _ . . . _ . . . . . _ _ _ _ _ . _ _ _ _ _ __ _ _ _ _ _ _ . _ _

IEEE Command Group . . . . _ _ . _. . . . . _ . _ _ . . ___. _~_ ._ . . . _ . . . . _ . . . . . . . . . . _. . _. . . . . F7

APPENDIXG

Device-Dependent Command Summary . . . _ . . _ . . . _ _ _ . _ _ _ _ _ . . . . _ _ _ _ ..- _ _ _ _ _ __ _ _~_ _ _ . .

.............................

..~.

.............

............

..

.‘. I

:

. . . . ~.~ _,.. _.~ _.__ * . . . . _ . . . . . . . . . . . . . . . . . . . . . . . . . .

:

......

......................

_

.........

.

._

....

9-2

9-15

9-21

9-27

F7

M

G-l

Page 16

SECTION 2-GETTING STARTED

LIST OF FIGURES

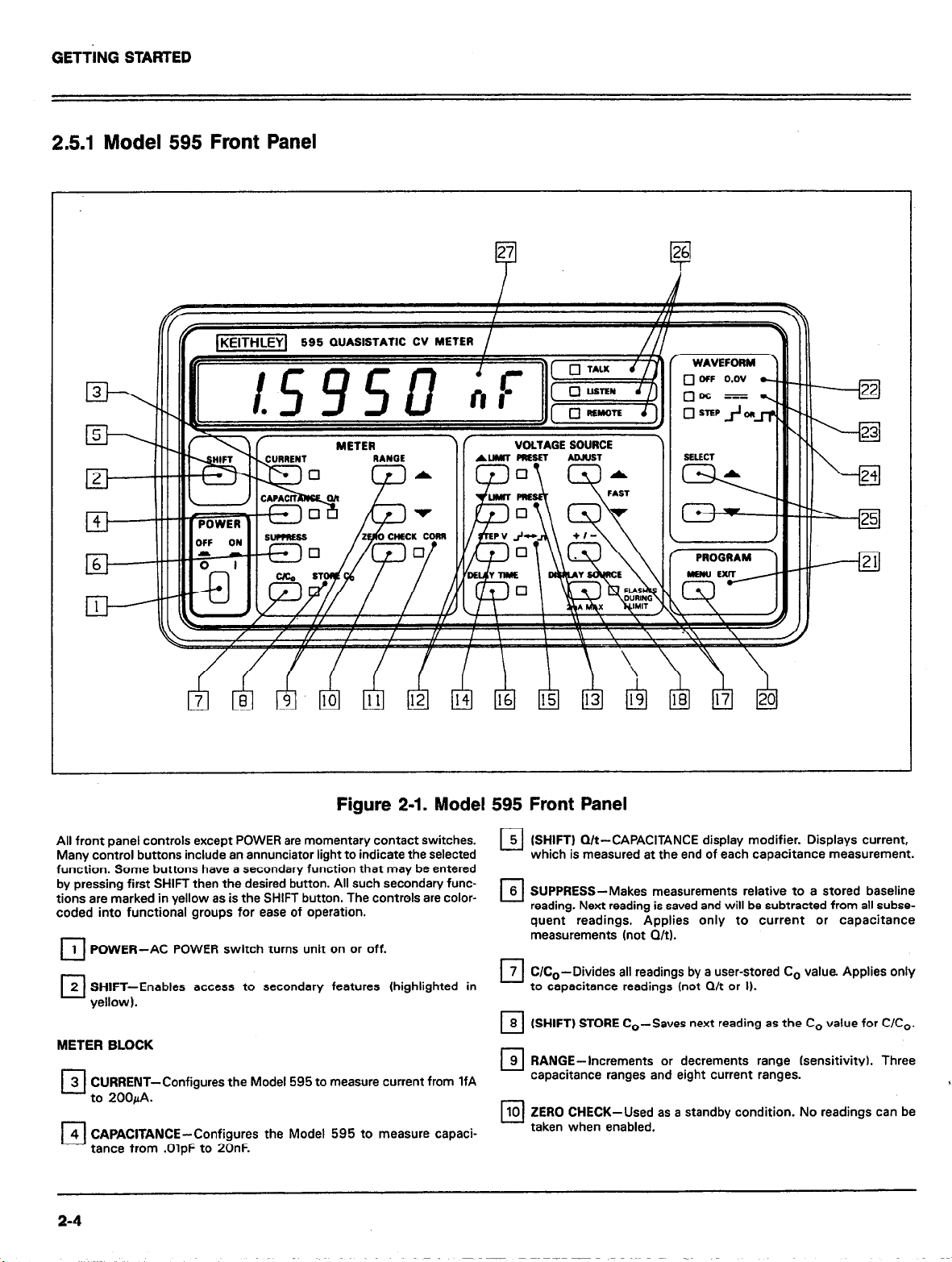

2-l

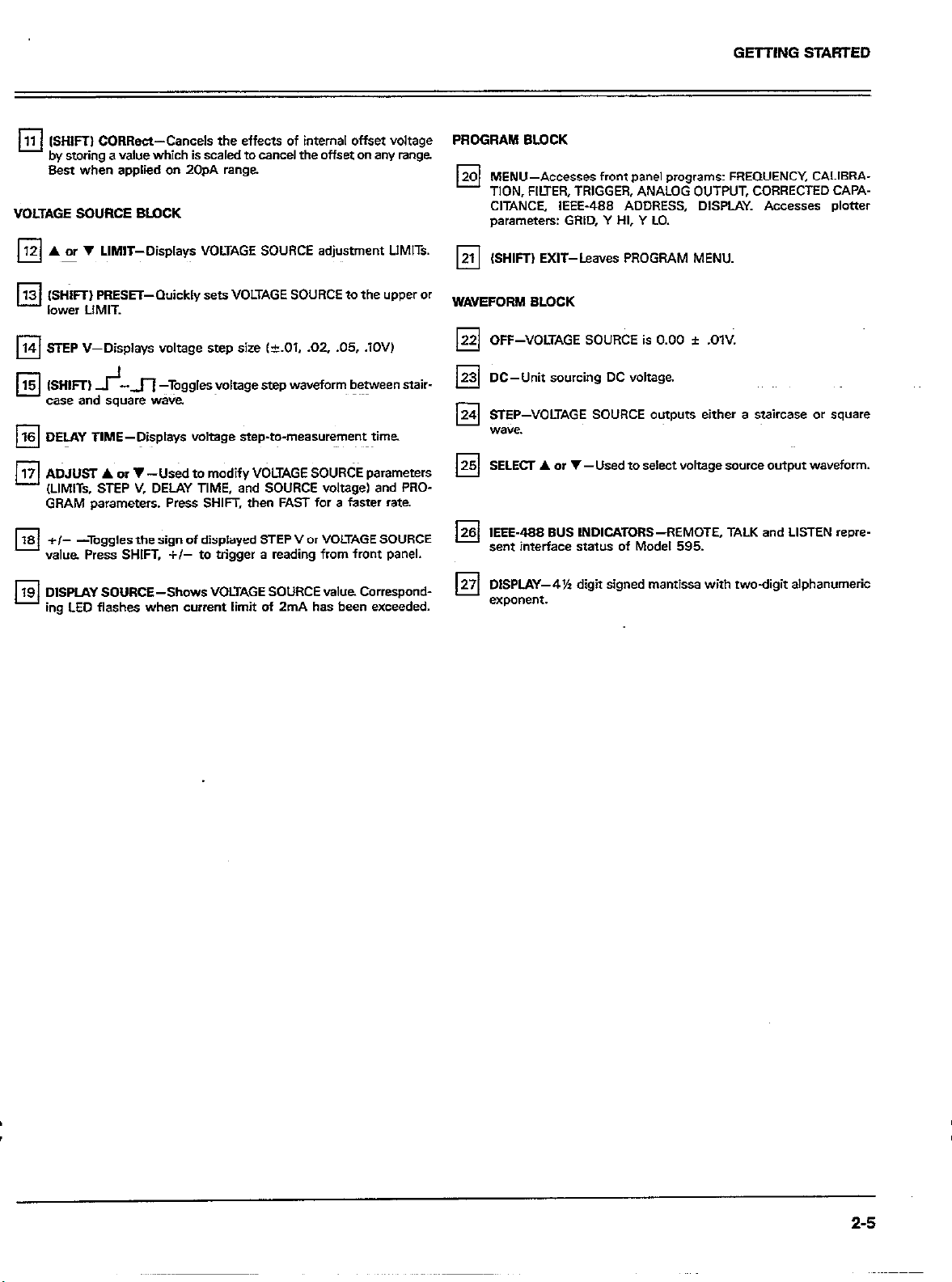

2-2

2-3 Typical Capacitance Measurement Corinetions . . . . .~. . . _ . _ . . _. . . . . . . . _ . . . . . . . . . . . . . . . . . . . . . . 2-7

2-4 Typical Cment Measurement Confections . . . . . . . . . . . . _ __ . . . _. ., -- ., . . ., . - -. . .,., . . . . . . . . . . . .~.

Model 595 Front Panel

Model 595 Rear Panel .

.._. . . . . . . . . . . . . .._..___... . . . . . . . . . . . . . . . . . .._.... . . . ~.-~ .._... _.__ ,...

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..-...................................

z-j

2-7

SECTION 3-OPERATION

..-

_~_

...

..

..

3-l

3-2

3-3

3-5

3-9

3-10

3-14

3-14

3-18

3-22

CapacitanceMeasurementConnections.

ii

3-3

3-4

3-5

34

3-7 &&md Trigger P&e Specifications ............. .., .................................................

3-8

3-9 NCurvesofa6.3VZenerDiode..

tt

3-z

Cbnnections for Current Measurements.

Integrator Charge vs Tme Cur+ Ior a Capacitance Measurement

VoltageOutput Waveform

Exainple:UsingtheFilteronaMOSDevi@Cu.rve. ................................

Coefficients in Filter 2

Meter Complete Pulse Specifications

MOSDeviceCVCurvewithFilters. ........................

~MultipleGroundPointsCreatingaGroundLoop..

EliminatingGrotidLoops.

..................

.........................

........

...........

.................

.

.........................................................

...............................

.

.......

. __

.

......................................

._, __ __

........................................

..-......................-.~..~...~~.-.~

.......................

~...~_.._.~.._

..

..

_,__.

..................................

.._._..,

........................

.............

.

... ............

.........

..~

__ _,_

.._ _____

........

.~~.------

..........

.....

.._._..._. 3-21

.....

..............

.......

.._

..............

_.._

.

........

__.._ _ _,._._ ., .._ ~.~3-22

;.m.

SECTION 4-IEEE-488 PROGRAMMING

....

42

43

43

44

432

437

442

443

4-44

.

.

2

41

42

43 IEE.E-488~connections..

44 Model 595 Rear Panel IEEE-488 Connedor

45

4-6

47

z

4la

4l.l

zg

SystemTypes

~IFXE-488 Connector.............................................................---.~....~.~..~~4 2

ContactAssignments...........................................--.-.....-........~- .............

GeneralDataFormat............................----.......................- ..................

SRQ Mask and Serial Poll ByteFormat.......................- ..................................

UO Machine Status Word (Default Conditions Shown).

~UlErrorStatusWord

U2 Data Status Word

U3DelayTme

U4VoltageSourceLfrmts

U5 Voltage SourceBlas Se~gs

.................

..................................

............................

.......................................................................... 443

.... . ...............

.....................................................

..~..~.-.~-~........~.....-~-.-.-..-.~.............-

..-......-.-- .............

.................................

...........................................

_..,_

.........................

___.~.~

.........................................

_____~_ _,.-_....,

.,

.................................

.............

.........................

.....

.,

__,__

.._....._..,._

.._

.............................................

_~^.

.

........

SECTION 5-APPLICATIONS

5-1

5-2

5-3

5-5

Current Measurement Corrections Using the Model 595 Voltage Source.. . . . . _ _ _ . . . . . . .

NCharacteristicsofaZenerDiode(5.1V)lN751.....___..___._ ___ _.___ ____ . ..__. _ ..___.__.._.... 5-3

Connections for Bipolar Common:Emilter N Characteristics . _ . _. . . . . _ .,_ . _ _ _ _. _ ______ _ _ . . _ . _. 5-4

Typical Bipolar Common-Emitter Characteristics . . . . . . . . . . . . . _ _ . _ . . . . . _ . . _ . . . . . . 5-4

Conmctions for Common-Source FET N Characteristics

5-l

_ _ _ . . . . .~. . . . . . . . _ . _ _ . _ _ _ . . . . _ _ 5-5

ix

Page 17

5-6

5-7

5-8

5-9

5-10

5-11

5-12

Typical Common-Source FET lV Characteristics

Leakage Current Measurement.

................

Ca~acitorLeakageTests .......................................................................

cvs.vGwe..

.........................

Equivalent Circuits of the MOS Capacitor.

..-- .- ~.~..~_

...............................................

Recognizing Equilibrium Using C and Q/t VS. Delay Tie: Inversion: Substrate Voltage = +8V,

Squarewave Test Signal = +O.OZV

............................................

Corrected vs. Uncorrected CV Curves of a SimulatedLeaky Capacitor C(corrected) = C-(Q/t)

(StepTiie)/(VStep). .................. -.~ ..:.

5-13

5-14

5-15

5-16

5-17

Recognizing Equilibrium Using C vs. V and Q/t, ys,~,V

Misuse of Corrected Capacitance Program-on Non-Equilibrium Curves

Comparison of ~Quasistatic CV Methods

FrequencyResponse..

....................

Comparison of Quasistatic~ CV Methods

.......................................................

.......................................................

SECTION 6-PERFORMANCE VERIFICATION

6-l

6-2

6-3

6-4

Test Fixture Construction..

.............................

Setup for Current Verification (2001x.4 to 200SA Ranges)

Setup for Current Verification (2Op.A to 2OnA Ranges)

Setup for Voltage Source Verification

.................................................

SECTION 7-THEORY OF OPERATION

.......................

....................................

._

.................

......

................

.

..................

...........................................

......................

__ .,_.

..

_

._

,_.

..

.._ _

......

YI..;

..__

....

.. 1 .............

YT T

.......

..

:~.

..........

..................

..

_. __

_,_-__.

--.~.

1~;.

.......

-.

......

.....

............................. 5-16

;

..~........~.....-.......~

............................................ 6-l

.:

....

..............

_.

__ __.

......

.......

-._~.lT~-

.......

__ ._

.. _ ...

...

...

....

5-5

5-7

5-8

5-9

5-9

5-12

5-x

5-15

5-18

5-19

5-20

6-4

6-5

6-8

7-l

7-2

7-3

7-4

7-5

7-6

7-7

7-8

7-9

7-10

7-11

7-12

7-13

7-14

7-15

7-16

7-17

7-18

7-19

Feedback Charge Method

TiingVoltageandChargeWaveforms

Model 595 Simplified Diagram

Voltage Source D/A Converter Circuitry

PrecisionStep Source...............................................~.................~ ........

Output Stage Circuitry (Simplified)

Current Limiting for Output Stage

Voltage Source Reset Circuitry

BlockDiagramofInputPr~ampIifier.....................................~

Circuit Configuration for Current and Capacitances

Input Stage and Gain Stage

FeedbackElement ............................................................................

FasfDischargeCircuitry.. ..................

XlO~Amplifier Circuirry.......................................................~...........~.~

Multiplexer and Buffer

Multiplexer Phases.. ..............................................

-2V Reference Source

A/D Converter

Analog Outputs

...................................

..............................................................................

SECTION 8-MAINTENANCE

8-1

8-2

8-3

L-2

8-6

8-7

~Test Fiiture~~Conshuction

Calibration Jumper and Calibration Pots

Equipment for Zero Hop Compensation

Voltage Source Output Calibration Setup

V Analog Output Calibration Setup

Current Calibration Setup (200pA and 20nA Ranges)

Current Calibration Setup (20pA to 200& Ranges)

........................................................................

............ _~.:. .......................

..........................................

.................

:.

...... _ ......... .;

............................................

.................... ._

...............

:

..........

............. _ _,_ ......

...............

:

..................

...........

................................................

.~;

:~

...................................

........................................................................

........................................

.................

..;

...................................................

...................................

...................................

...............

- ..................

........................................

.......................

.............................

...... I

_~I

...........................

..I

.......

__

......................

............ .I

;

..,

................

........

........................

_.

..:.

~.;

........

..........

., . .~l.-. ...........

._

......

................

-.:.::

............

..

:

:.

.

.

. . .

.

.

,..

. . .

. . .

7-l

.....

_

....

7-2

7-3

7-4

:.~.

.,

........

7-5

.......

.._

7-6

7-7~~

........

.,

7-8

7-9

7-9

......

.;.

7-10

7-12

it

......

7-13

..

7-14

.

.,_, 7-15

.__

..

.;. .~I

......

....

7-16,

7-16

7-17

7-21

. ..~:;. ...... 8-2

............ 8-4~

............ 87

............ 8-9~

............. 8-9

........... 8-11

............

~812

x

Page 18

C, I Analog Output Calibration Setup

Model595EqkdedView

8-10 Input Stage Balancing

......... _ __

................ ..___

..........................................................

.............................

.....

.__,.___ _____ _

. .._ . .__.,._...._._

.,__ - .._

.,_ .

..................

_

_

.. . .

.,

..

...... 8-13

......

_,

...

816

8-32

SECTION g--REPLACEABLE PARTS

9-l ~~ Mother Board, Component Location Drawing, Dwg. No. 595-100 _ . _ _. . . _. . . _ _. . . . _ _ _. . _. . . . _. . _ . 9-8

9-2

9-3

9-4

9-5 & Board, Component Location, Dwg. No. 595-160 . . . _ . . _ _ _ _ . _,_ _ __ .,. _ _ . _ _ . . . . . _ . _ . . . . 9-24

9-6

Mother Board, Schematic Diagram, Dwg. No. 59X06 _ . . . . . ___ __ . . _ _ _. . . . . _. _. . . ___ _. __ _ ._ . . . 9-9

Display Board, Component Location, Dwg. No. 595~ll0 _ _. _ _ _ _ _ _. _ _ _. _. . . . _. . . _ . . _ _ _ . .~.___~_ . . __ _ 9-18

Display Board, Schematic Diagram, Dwg. No. 595-116 . . . . . _ _ _ . . . . . . . _ . _ . . . _ . _ . . . . . _ _ _ _ . _~_ _ _ .9-19

Preamp Board, Schematic Diigram, Dwg. No. 595-166. . . . . _ . . .; _ _ . _ . _ __ . . . _ _ _ _ _ _ _ _ _ . _ . . _ . _ . . . 9-25

APPENDIX F

iEBE.BusConfiguration . . . .._..__._.._ _,_ _______._._. ~I __.___._ ______ .._.... _ __...__ _ ___.__.._.._..

IF,EB488HandshakeSequence _......_.__ ~...:~ __..__. _ _._.......___..._ _ .._. _____.__ .__.____._ _.__ F3

~3 Co-andcodes . .._......__....__....~. _.._.. _ .._. _ ._.__......_....--. _ .-.- ~_-_ _--.... _.._ .-..... F6

M

xi/xii

Page 19

SECTION 1

GENERAL INFORMATION

1.1 INTRODUCTION

The Keithley Model 595 Quasistatic CV Meter is a sensitive

instrument designed to measure capacitance and current.

The Model 595 uses a unique feedback charge method to

stimulate and measure charge steps in the device under

test, from which capacitance is determined. (A DC voltage

is ah available to make basic current measurements). This

method of measuring capacitance is superior to the traditional ‘%oltage ramp” method as it allows the user to

distinguish between error currents and the stimulated

signal charge. Correction of capacitance m+surrtients for

the effect of error currents is selectable and can be used

to improve measurement accuracy. The Model 595 has a

built-in &‘OV sowce with four precision ~step~voltage

sources. The measuring range of the Model 595 is O.OlpF

to 2OnF for capacitance measurements and lfA to ZOOfi

for current measurements. A 4% digit display and standard

data.

1.2 FEATURES

Some important Model 595 features include:

l Built-in Voltage Source-&IV @ 2mA voltage source with

lOmV resolution.

l Bias Waveforms-DC, square wave, and staircase voltage

bias waveforms allow the user to make stepped current

or capacitance measurements, as well as DC current

measurements.

l Voltage Steps-In -clOmV, 2OmV, 5OmV, and 1OOmV grada-

tions at 0.07 to 199.99sec intervals in O.Olsec increments.

l Q/t Measurement-Q/t monitors current during

capacitance measurement.

l Compensates for Error Currents-Selectable capacitance

correction for leakage current errors.

l 4% Digit Display-An easy-to-read front panel LED

display includes a 4% digit mantissa with selectable

alphanumeric or scientific range annunciation.

l Zero Correct-A front panel zero correct control allows

the user to cancel offsets internal to the Model 595.

l Reading Modifiers-Baseline suppression and C/C, nor-

malization of readings.

l Standard IEEE-488 Inte*ace--The built-in interface allows

full bus operation of the Model 595.

. CV and IV Outputs--Built-in C, Q/t or I vs. V analog out-

puts (with automatic pen lii) or IEEE488 digital plotter

output.

l Digital Calibration-The instrument may be digitally

calibrated from the front panel or over the IEEE-488 bus.

1.3 MANUAL ADDENDA

Information concerning improvements or changes to the

instrument which occur after the printing of this manual

will be found on an addendum sheet included with this

manual. Please be sure that you read thii information

before attempting to operates or service your instrument.

1.4 SAFETY TERMS

The following safety terms are used in this manual:

The WARNING heading as used in this manual explains

dangers that might result in personal injmy or death.

Always read the associated information very carefully

before perfotig the indicated procedure.

The CAUTION heading used in this manual explains

hazards that could damage the inshument. Such damage

may invalidate the warranty.

1.5 UNPACKING AND INSPECTION

The Model 595~Quasistatic CV Meter was carefully in-

spected before shipment; Upon receiving the instrument,

carefully unpack all items from the shipping carton and

check for any obvious signs of physical damage that might

have occurred during shipment. Report any damage to the

shipping agent at once. Retain the original packing material

in case reshipment becomes necessary.

l-l

Page 20

The following items are included with every Model 595

shipment:

Model 595 Qua&static CV Meter

Model 595 Instruction Manual

Model 4801 Low Noise Coax Cables with BNC Connectors

(two)

Additional accessories as ordered.

If an additional instruction manual is required, order the

manual package (Keithley Part Number 595-901-00). The

memud package includes an instruction manual and all pertinent addenda.

1.6 REPACKING FOR SHIPMENT

Before shipping the instrument should be carefully packed

in its original packing material.

If the instrument is to be returned to Keithley Instruments

for rep’air or calibration, include the following:

Write XI’ENTION REPAIR DEPARTMENT on the shipping label.

Include the warranty status of the instrument.

Complete the service form at the back of this manual.

1.6 ACCESSORIES

The following accessories are available to enhance Model

595 capabilities.

Model 1019A and 1019s Rack Mounting Kits-The Model

lOl9A is a fixed or stationary rack mounting kit with two

front panels provided to enable either single or dual sideby-side mounting of the Model 595 or other similar Keithley

instrument. The Model 10195 is a similar rack mounting

kit with a sliding mount configuration.

Model 4801 Coax Inp~ut Cables-The Model 48M, two of

which are included with every Model 595 shipment, are

low noise coaxial cables, 1.2m (48 in.) in length, with male

BNC connectors.

Model 4803 Low Noise Cable Kit-Kit includes 50 ft. of low

noise coaxial cable, 10 male BNC connectors, and five

female BNC chassis-mount connectors.

Model 6104 Test Shield-Model 6104 facilitates measurements with 2- or3terminal guarded connections. Provides

electrostatic shielding, high isolation resistance, and easy

connection to Model 595. Clips plug into banana jacks,

allowing modified connections. Shield has BNC connector on one side, binding posts on the other. Useful when

making current measurements with external voltage source.

Model 6105 Resistivity Chamber-Guarded test future for

measuring volume and surface resistivitles. Assures good

elechostatic shielding and high insulation resistance.

1.7 WARRANTY INFORMATION

Warranty information for your Model 595 may be found in-

side the front cover of this manual. Should you need to

use the warranty, contact your Keithley representative or

the factory for information on obtaining warranty service.

Keithky Jhslmments, Inc. maintains service facilities in the

United States, West G

Netherlands, Switzerland, and Austria. Information concerning the operation, application, or service of your instrument may be obtained from the applications engineer

at any of these locations.

ermany, Great Britain, France, the

Model 7007 Shielded IEEE488 Cables-The Model 7007

cables are designed to connect the Model 595 to the

IEEE488 bus and are available in two versions. The Model

7007-1 is lrn (3.3 ft.) in length, and Model 700%2 is 2m (6:6

ft.) jn length. Cables have shielded connectors on each end.

Model 7051 BNC-to-BNC Cables-Available in two lengths.

Model 7051-2 is 1.8m (2 ft.) in length, and Model 7051-S is

15m (5 ft.) in length.

l-2

Page 21

SECTION 2

GETTING STARTED

2.1 INTRODUtilON

The Model 595 can be controlled from the front panel or

over the IEEE-488 bus. This section will acquaint the user

with front panel operation. IEEE-488 bus operation is

described in Section 4.

The following paragraphs will briefly describe the front

panel buttons and their operation to help the user get

started with the Model 595. Then rear panel descriptions

and power-up information will be presented. Lastly, basic

capacitance and current measurement examples will be

discussed.

2.2 PREPARATION FOR USE

Once the instrument is unpacked, it must be connected to

an appropriate power source as described below.

2.2.1 Line Power

The Model 595 is designed to operate from lO5XW or