Page 1

Instruction Manual

Model 177 Microvolt DMM

and

Model 1788 Battery Pack

01978, Keithley Instruments. Inc.

Cleveland, Ohio, U.S.A.

Document Number 29683

Page 2

Specifications

TEMPERATTURE COEFFlClENT VT-WC and m-55T.I:

*W305% + 0.1 di~itI/~C e~cepf *10.005% + 0.6 digifll°C on the

EXTENDED FREOUENCV ACCURACY ,45Hz--2OkW: i 10.7% + 15

diaitSl

TEtiPERATURE COEFFICIENT 10°-18pC Et ZW-55°C:

--2OkHz,: * ~0.05% + 2 digifs,PC

RESPONSE: True mot mean squsre

CREST FACTOR: 3

INPUT IMPEDANCE: IMO * 1% shunted by less than 75pF.

MnlyMUM *uOWABLE INPUT “OLT*GE: 1000” rms. ,400”

lO’+b maximum

CMRR Ilk0 unbalancel: SOdS at DC. 5OHz and SOHz

RESISTANCE

MAXIMVM ALLOWABLE INPUT: 350” peak

OPEN-CIRCUIT VOLTAGE: 5 volts

45Hz

peak

MAXIMUM INPUT: 2A. 250” DC or rms lfuse protected,

TEMPERATURE COEFFICIENT W-WC and 28D-550C,:

DC: f 10.2 digits)/°C except f 10.01% + 0.6 digitsl/“C on 2OpA range.

GENERAL

DISPLAY: Five 0.5” LED digits, appropriate decimal point and polarity ins

dicatio”

CONVERSION PERIOD: 400mS

OVERRANGE INDICATION: Display blinks all zems above 19999 counts

MAXlM”M COMMON MODE VOLTAGE: MOO” peak

ANALOG OUTPUT: Output Voltage: IV = 10,000 county

ENVIRONMENT: Operating: O’C to SYc; 0% to 80% relative humidih/ up

CONNECTORS: In,,ut: Binding ,mst~

POWER: IOS- 125 or 210-250 volts (switch selected), gOpllOV available.

506-6OHz. 8 warts. Optional 6 hour battery pack, Model 1788

DIMENSIONS WEIGHT: 85mm high x 235mm wide x 275mm deep

13%” x 9%” x 10%“). Net weight: l.,kg (4 lb,

ACCESSORlES *“VAILA.BLE:

Model ,010:

Model ,017:

Model ,301:

Model 1SOOA:

Model ,641:

Model 1651:

Model 1681:

Model 1mzA:

Model ,683:

Model ,684:

Model ,665:

Model ,m,:

Model ,779:

Model 1788:

Model 1792:

Made, ,793:

Output Resistance: 50000

to ‘WC.

storage: --25oc to ~+65T

O”QJ”C smana jacks

Single Rack Mounfing Kif

Dual Rack Mounting Kit

Tempereture Probe

High Voltage Probe 14OkVl

Kelvin Test Leads

50-Ampere Current Shunt

Clip-On Test Lead Set

RF Probe

Universal Test Lead Kit

Hard Shell Carving Case

Clamp~on AC Probe

Genersl Purpose Test Lead Set

Spare Paris Kit

Rechargeable Battery Pack

Isolated BCD OUtput

lsalsted IEEE-488 Output

Specifications subject to change without notice.

Page 3

TABLE OF CONTENTS

Paragraoh

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

1.10

1.10.1

1.102

1.10.3

1.10.4

1.10.5

2.1

2.2

2.3

2.4

2.5

2.6

2.7

2.8

2.9

2.10

2.11

2.12

2.13

2.14

2.15

2.16

Title

SECTION I-GENERAL INFORMATION

Introduction .............................

Model 177 Features. ......................

Warranty Information .....................

ManualAddenda .........................

Safety Symbols and Terms. ................

Safety Precautions .......................

Specifications ...........................

Unpacking and Inspection

Scope of Model 177 Instruction Manual ......

Optional Accessories. .....................

Power Options. ........................

Cables and Connectors. .................

Probes and Shunts .....................

Carrying Case and Rack Mount ...........

Output Options ........................

.................

SECTION 2-OPERATION

Introduction.. .....................................................................

Safety Precautions for High Energy Circuits

Preparation for Use .................................................................

Operationon LinePower ............................................................

Operation on Battery Pack Power

Battery Charging ...................................................................

Operatinglnstructions ...............................................................

Zero Adjustment ...................................................................

DCVoltage Measurement ............................................................

ACVoltageMeasurement ............................................................

Resistance(O) Measurement .........................................................

DCCurrentMeasutement ............................................................

ACCurrentMeasurement ............................................................

TRMS Measurements (AC + DC) ....................................................

Analog Output

TiltBailAdjustment .................................................................

.....................................................................

.....................................................

............................................

......

......

......

......

......

......

......

......

......

......

......

......

......

......

......

Pan.3

l-l

l-l

1-l

1-l

1-l

1-l

., 1-l

1-2

., .,

l-2

1-2

1-2

1-2

1-2

l-2

1-2

2-l

2-1

2-l

2-l

2-1

2-l

2-3

2-3

2-3

2-5

2-6

2-7

2-7

2-8

2-8

2-8

3.1

3.2

3.3

3.4

3.4.1

3.4.2

3.4.3

3.4.4

3.4.5

3.4.6

3.4.7

4.1

4.2

4.2.1

SECTION 3-PERFORMANCE VERIFICATION

Introduction.. .....................................................................

RecommendedTestEquipment

Environmental Condltlons.

Performance Verification Procedure

Initial Conditions

DC Voltage Accuracy Check (2V to 12OOV Ranges)

DC Voltage Accuracy Check (20mV and 200mV Ranges)

ACVoltage Accuracy Check

Resistance (n Accuracy Check)

DCCurrentAccuracyCheck

Analysis ........................................................................

.................................................................

.......................................................

...........................................................

...................................................

....................................

.......................................................

....................................................

.......................................................

SECTION 4-THEORY OF OPERATION

Introduction .......................................................................

OverallOperation ...................................................................

SignalConditioning ...............................................................

..............................

...........

........... 3-l

........... 3-1

........... 3-1

........... 3-2

........... 3-2

........... 3-2

........... 3-3

3-l

3-l

3-l

3-3

4-l

4-l

4-1

Page 4

4.2.2

4.2.3

4.3

4.3.1

4.3.2

4.3.3

4.4

4.4.1

4.4.2

AIDConverter

RangeSwitching

ACConverter

Scaling ....................................................................................

ACConversion

ACCurrentMeasurements

DCSignalConditioning

InputAttenuation

Chopper ...................................................................................

..............................................................................

............................................................................

.................................................................................

..............................................................................

....................................................................

.........................................................................

...........................................................................

4-2

4-2

4-2

4-2

4-2

4-2

4-2

4-3

4-3

4.5

4.5.1

4.5.2

4.5.3

4.6

4.7

4.8

4.8.1

4.8.2

4.8.3

4.9

4.10

4.11

4.11.1

4.11.2

5.1

5.2

5.3

5.4

5.4.1

5.4.2

5.4.3

5.5

5.6

5.6.1

5.6.2

5.6.3

5.6.4

5.6.5

5.6.6

5.6.7

5.7

5.8

5.9

OhmsConversion

Floating

Chopper ...................................................................................

Adjustments and Input Overload Protection.

AnalogOutput

Clock .......................................................................................

AIDConverter

Auto-Zero ..................................................................................

Signal-Interface

Reference-Integrate

Display ......................................................................................

Current Source

ACPowerSupply

Model17888atteryPack..

BatteryChargingCircuit

Battery Operation and Shutdown Circuit

SECTION 5-MAINTENANCE

Introduction ..................................................................................

RecommendedTestEquipment

EnvironmentalCondttlons .........................................................................

CalibrationProcedure

Calibration Shield Installation

Warm-Up ..................................................................................

Calibration Instructions

Troubleshooting

Troubleshootingprocedure .....................................................................

Calibration Shield/Batten/ Pack Removal

LinePower

Battery Power

DisplayandA/DConverter ...................................................................

ACConverter

Chopper Amplifier and Ohms Source

CurrentShunts .............................................................................

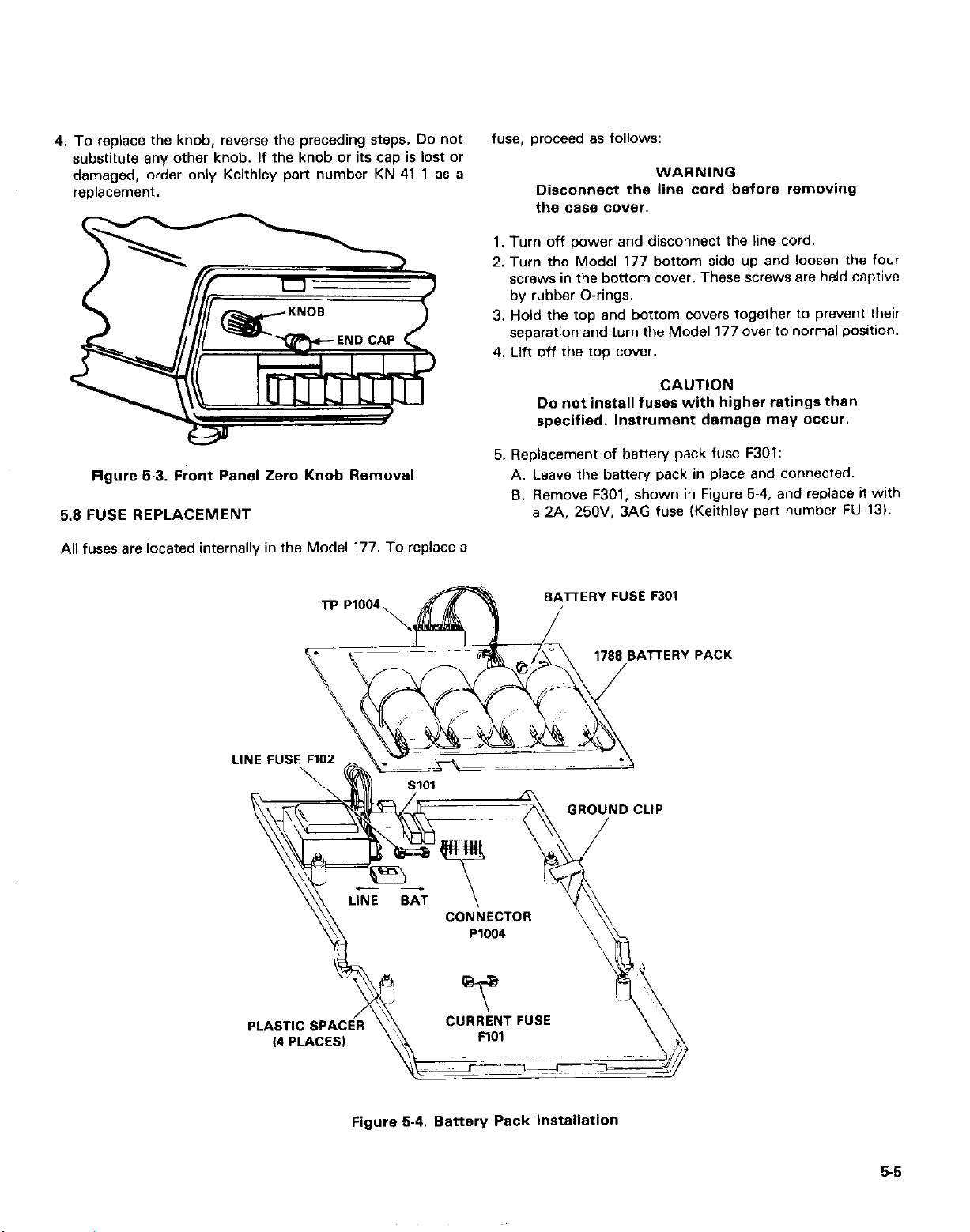

Front Panel ZERO Knob Removal and Replacement

FuseReplacement

Model 1788 Battery Pack Installation.

.............................................................................

......................................................................

.....................................................

................................................................................

................................................................................

.............................................................................

.........................................................................

.............................................................................

.....................................................................

......................................................................

........................................................

..................................................................

..........................................................................

..................................................................

.......................................................................

...............................................................................

.......................................................

.................................................................................

..............................................................................

...............................................................................

...........................................................

................................................

.............................................................................

.............................................................

4-4

4-4

4-4

4-4

4-4

4-4

4-4

4-5

4-5

4-5

4-6

4-6

4-6

4-6

4-6

5-l

5-1

5-1

5-1

5-1

5-l

5-l

5-2

5-2

5-2

5-4

5-4

5-4

5-4

5-4

5-4

5-4

5-5

5-6

6.1

6.2

6.3

6.4

6.5

6.6

6.7

ii

SECTION 6--REPLACEABLE PARTS

Introduction ..................................................................................

PartsList .....................................................................................

Orderinglnformation

FactoryService..

ComponentLocationDrawings

SchematicDiagrams

MaintenanceKit

............................................................................

..............................................................................

...................................................................

.................................................................

...............................................................................

...........

6-l

6-l

6-l

6-l

6-1

6-l

6-l

Page 5

LIST OF FIGURES

Figure

1-l

2-1

2-2

2-3

3-1

4-l

4-2

4-3

5-l

5-2

5-3

5-4

6-l

6-2

6-3

6-4

6-5

6-6

Table

2-1

2-2

3-1

3-2

3-3

3-4

3-5

4-l

4-2

4-3

4-4

5-l

5-2

5-3

5-4

5-5

5-6

5-7

5-8

5-9

5-10

5-11

6-l

6-2

6-3

6-4

Title Page

Model177FrontPanel ..........................................................................

Model 177 Rear View of Standard Line Voltage Instrument

Model 177 Rear View of Optional Line Voltage Instrument

Operating Controls .............................................................................

Test Circuitfor20mVDC Accuracy Check

Model 177 Simplified Signal Flow Block Diagram

Simplified Signal Conditioning

AfDConverterFunction .........................................................................

Test Point Locations

Integrator and Comparator Waveforms.

Front Panel Zero Knob Removal

BatteryPacklnstallation .........................................................................

Model177CoversandPanels .....................................................................

Model 177 PC-476, Component Location Drawing, Dwg. No. 294740,

Display Board PC-475, Component Location Drawing, Dwg. No. 29652C

Model 1788 Battery Pack PC-451, Component Location Drawing, Dwg. No. 29007C

Model 1788 Battery Pack, Schematic Diagram, Dwg. No. 29659C

Model 1774% Digit Multimeter, Schematic Diagram, Dwg. No. 29658E

............................................................................

.................................................................... 4-3

..................................................................

..........................................................

.................................................... 4-l

............................................................

............................................ 2.2

............................................. 2-2

................................. 6-l 1

............................. 6-15

.....................................

................................

LIST OF TABLES

Title

Model 177 DMM Condensed Operating Instructions

Resistance Ranges .............................................................................

Recommended Test Equipment for Performance Verification

DC Voltage Performance Check (2V to 1200V Ranges).

ACVoltage Accuracy Check

Resistance Accuracy Check ......................................................................

DCCurrentAccuracyCheck

Range Switch Correlation ........................................................................

AC Converter Attenuation Amplification

DC Signal Conditioning Attenuation and Gain

OhmsConversion ..............................................................................

Recommended Test Equipment for Calibration

Calibration Procedure

Line Power Checks

BatteryPowerChecks

Display

A/DConverrer

ACConverter ..................................................................................

DC Attenuator and Chopper Amplifier

OhmsSourceandResistors

CurrantShunts

Adjustment of Battery Charge Voltage

Model177SparePartsKit

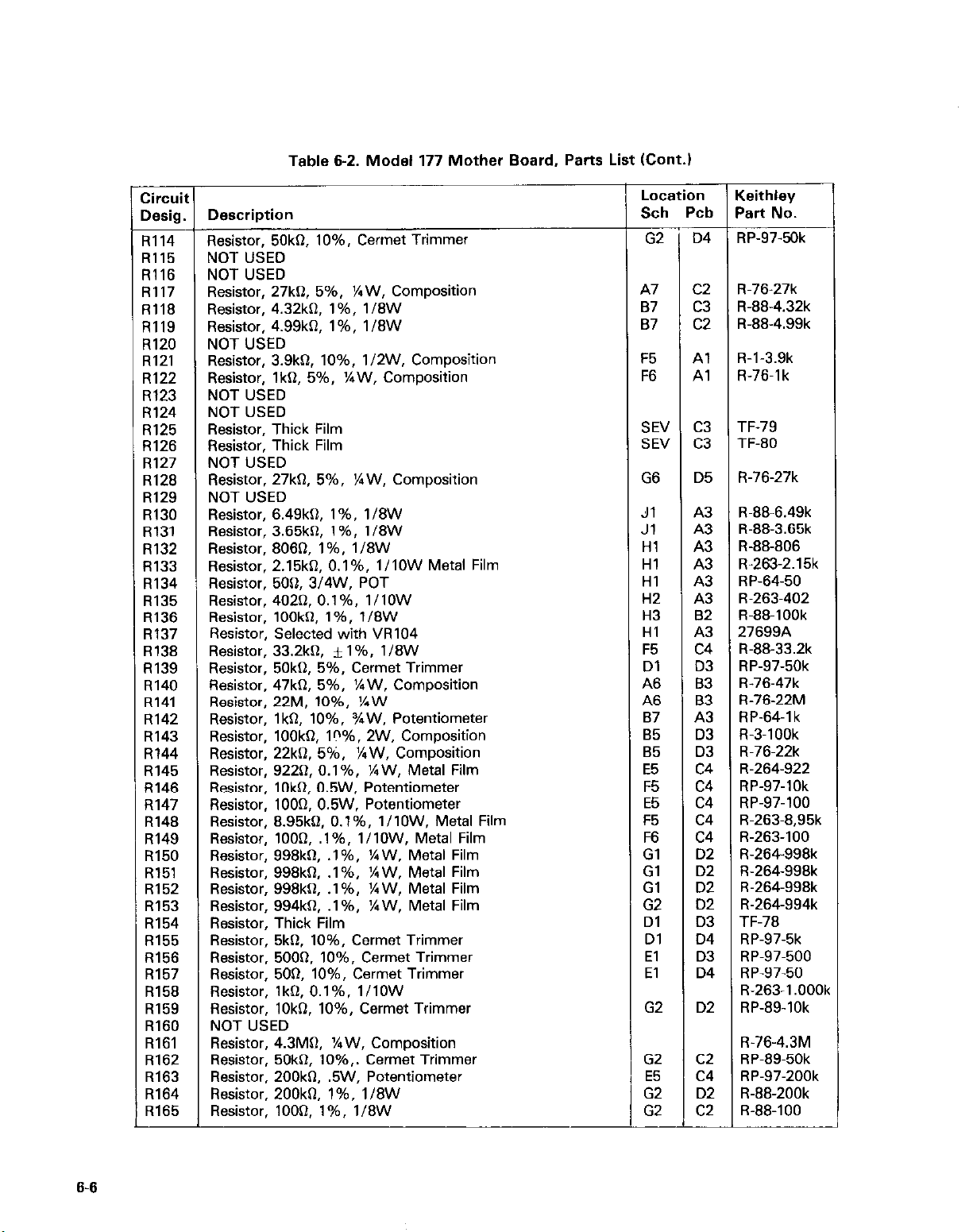

Mother Board,

Modal 1788 Battery Pack, Parts List

Display Board,

....................................................................................... 5-8

............................................................................. 5-6

.................................................................................

..............................................................................

Parts List

Parts List

.....................................................................

.....................................................................

...........................................................

........................................................................... 5-2

...........................................................................

............................................................

..................................................................... 5-11

............................................................

....................................................................... 6-3

.........................................................................

..............................................................

......................................................................... 6-9

.................................................. 2-4

..........................................

..............................................

.......................................................

......................................................

1-O

2-5

3-2

4~5

5-3

5-4

5-5

5-5

6-2

...................... 6-16

6-17

6-19

Page

2-6

3-l

3-2

3-2

3-3

3-3

4-2

4-3

4-3

4-4

5-l

5-7

5-8

5-9

5-10

5-11

5-12

6-4

6-8

iii

Page 6

,’

1-o

Figure l-l. Model 177 Front Panel

Page 7

SECTION 1

GENERAL INFORMATION

1.1 INTRODUCTION

The Keithley Model 177 Microvolt DMM is a versatile, highly

sensitive digital multimeter which is used for measurement of

DC and AC voltages, DC and AC currents, as well as

resistance. For a complete summary of ranges for each of

these five functions, refer to the specifications at the front of

this manual. Ranges and functions are easily selected with

front panel pushbuttons, while connections for all functions

are easily made with a single set of front panel input ter-

minals.

1.2 MODEL 177 FEATURES

1. 4% Digit LED Display-An easy to read 4% digit display

shows 20,000 counts of information with automatic polari-

ty indication.

2. l~V/lmQ Resolution-The Model 177 is capable of

reading DC voltages es low as 1wV and resistances down

to 1mR.

3. Front Panel Zero-The front panel zaro control may be

used to compensate for thermal offsets or lead resistance

when making measurements.

4. Analog Output-An analog output of lV/lO,OOO counts is

available on the rear panel.

1.3 WARRANTY INFORMATION

Warranty information may be found inside the front cover of

this manual. Should it become necessary to usa the warranty, contact your nearest Keithley representative or the factory

to determine the correct course of action. Keithley Instru-

ments maintains service facilities in the United States, West

Germany, Great Britain, France, the Netherlands,

Switzerland and Austria. Information concerning the appli-

cation, operation or service of your instrument may be

directed to the applications engineer at any of these locations. Check inside the front cover of this manual for ad-

dresses.

1.4 MANUAL ADDENDA

Information concerning improvements or changes to the

instrument that occur after the printing of this manual will be

covered in an addendum sheet packed with the instrument.

Be sure to review these changes before attempting to operate

or service the instrument.

1.5 SAFETY SYMBOLS AND TERMS

The following safety symbols and terms are used in this

manual or may be found on the Model 177.

The symbol

should refer to the operating instructions.

The symbol

of 1OOOV or more may be found present on the terminals.

Standard safety practice should be observed when such

dangerous voltages are encountered.

The WARNING heading used in this manual explains

dangers that could result in personal injury or death if nor

handled properly. Be sure to read the WARNING informa-

tion carefully before performing the associated procedure.

The CAUTION heading is used in this manual explains

hazards that could damage the instrument.

1.6 SAFETY PRECAUTIONS

The following safety precautions should be observed before

operating any digital multimeter.

1. This instrument is intended for use by qualified personnel

who recognize shock hazards and are familiar with the

safetY precautions required to avoid possible injury. Read

over the manual carefully before operating this instrument.

2. Exercise extreme caution when a shock hazard is present

at the instrument’s input. The American National

Standards Institute (ANSI) states that a shock hazard exists when voltage levels greater than 30V rms or 42.4V

peak are present. A good safety practice is to expect that

hazardous voltage is present in any unknown circuit before

measuring.

3. Inspect the test leads for possible wear, cracks or breaks

before each use. If any defects are found, replace with test

leads that have the same measure of safety as those supplied with the instrument.

4. For optimum safety do not touch the test leads of the

instrument while power is applied to the circuit under tast.

Turn the power off and discharge all capacitors, before

connecting or disconnecting the instrument.

5. Do not touch any object which could provide a current

path to the common side of the circuit under test or power

line (earth) ground. Always make

hands while standing on a dry, insulated surface, which is

capable of withstanding the voltage being measured.

6. Exercise extreme precaution when tasting high energy

power circuits (AC line or mains, etc.). Refer to the operation section of the manual.

7. Do not exceed the instrument’s maximum allowable input

as defined in the specifications and operation section.

1.7 SPECIFICATIONS

Detailed Modal 177 specifications are located at the front of

this manual.

on the instrument indicates that the user

A

on the instrument denotes that a potential

#M

meawrements

with dry

l-l

Page 8

1.8 UNPACKING AND INSPECTION

1.10.3 Probes and Shunts

The Model 177 was carefully inspected, both mechanically

and electrically, before shipment. Upon receiving the instru-

ment, carefully unpack it from the shipping carton and check

for any obvious signs of physical damage that might have occurred during shipment. Report any damage to the shipping

agent at once. Retain the original packing materials in case

reshipment becomes necessary. The following items are included with every Model 177 shipment.

1. Model 177 Micro\+t DMM

2. Model 177 Instruction Manual

3. Additional accessories as ordered.

1.9 SCOPE OF THE MODEL 177 INSTRUCTION

MANUAL

This manual contains information necessary to operate and

service both the Model 177 and the optional Model 1788 Sattery Pack and is divided into the following sections.

1. Section 2 contains operating information.

2. Information necessary to verify that instrument per-

formance is within specified accuracy is located in Section

3.

3.

Theory of operation is covered in Section 4.

4. Servicing information, including Model 1788 installation

instructions, may be found in Section 5.

5. Replaceable parts information, component layouts and

schematic diagrams are located in Section 6.

1.10 OPTIONAL ACCESSORIES

1.10.1 Power Options

Modal 1600A High Voltage Probe-The Model 1600A

High Voltage Probe extends the measurable DC voltage

range up to 40kV. It has a 1OOO:l division ratio, so that a

reading of 1V on the DMM corresponds to IkV IlOOOV). The

Model 1600A has a basic accuracy of lt25% and an input

resistance of IOOOMQ.

Model 1651 SO-Ampere Shunt-The Model 1651

50.Ampere Shunt permits current measurements of up to

50A AC or DC. The shunt has a resistance of O.OOlQ * 1%.

so that a 50A current will correspond to a reading of 50mV

I0.0500v).

Modal 1692A RF Probe-The Model 1682A RF Probe per-

mits measurement of AC voltages at frequencies of 20kHz to

250MHz. AC to DC transfer accuracy is Id6 at lV, and the

input voltage range is 0.25V to 15V rms.

Model 1685 Clamp-On AC Current Probe-The Model

1685 Clamp-On Current Probe permits measurement of AC

current by clamping around a single conductor, eliminating

the need to interrupt the current path. The Model 1685 has a

current conversion ratio of O.lV/A with three ranges (2A.

20A, 200A). Accuracy is +4% at 60Hz If6% at 50Hz).

1.10.4 Carrying Case and Rack Mounts

Modal 1684 Carrying Case-The Model 1684 Carrying

Case is a hard vinyl case with a fitted foam insert to help pro-

tect the Model 177 from damage. There is also room in the

case for the instruction manual and small accessories.

Models 1010 and 1017 Rack Mounting Kits-The rack

mounting kits permit mounting one 11010) or two (1017)

Model 177 DMMs in a 19 inch rack for convenient viewing.

The Model 177 can be powered by line voltage (105-125V at

50.60Hz or 210.250V at 50-GOHz--standard ranges) or the

optional Model 1788 Rechargeable Battery Pack. (Optional

line voltage rangas are described in Section 2.1 The Model

1788 is available factory-installed or is field-installable. Instal-

lation and operating instructions are given in Section 2.

1.10.2 Cables and Connectors

Model 1881 Clip-On Test Lead

1.2m (48 in.1 leads with banana plugs at one end and springaction clip-on probes at the other end.

Modal 1683 Universal Test Lead Kit-This

two Im (40 in.) test leads and 14 screw-in adapter tips. The

tips consist of two alligator tips with boots, four banana

plugs, phone tips, two spade lugs and four heavy duty tip

plugs which permit connection of theModel 177 to virtually

any source within its measurement range.

Set-This set contains two

kit contains

1-2

1.10.5 Output Options

Model 1792 Isolated SCD Output-The Model 1792 con-

verts displayed reading to an electrically isolated, latched and

buffered parallel BCD format. Output data includes sign,

overrange and busy. It is compatible with Model 177 serial

number 14,500 and above, and can be either factory or field

installed. Installation of the 1792 precludes installation of

Models 1788 or 1793.

Model 1793 IEEE-488 Output-The Model 1793 converts

displayed readings to IEEE-488 bus compatible outputs to

permit automatic gathering of measurement data. Output in-

cludes 4% digit ASCII data, sign an overrange. It operates in

either talk-only or addressable modes. The Model 1793 is

compatible with Model 177s serial number 16,500 and above,

and can be either factory or field installed. Installation of the

1793 precludes installation of the Model 1788 or 1792.

Page 9

SECTION 2

OPERATION

2.1 INTRODUCTION

This section provides information needed for preparation for

use and operation of the Model 177 and Model 1788.

2.2 SAFETY PRECAUTIONS FOR HIGH ENERGY

CIRCUITS

To optimize safety when measuring voltage in high energy

distribution circuits, read and observe the directions in the

following warning.

WARNING

Dangerous arcs of an explosive nature in a

high energy circuit can cause severe

personal injury or death. If the mater is connected to a high energy circuit when sat to

a current range, low resistance range or any

other low impedance range, the circuit is

virtually shorted. Dangerous arcing can

result even when the mater is set to a

voltage range if the minimum safety spacing is reduced.

When making measurements in high energy circuits use test

leads that meet the following requirements:

1. Test leads should be fully insulated.

2. Only use test leads that can be connected to the circuit

(e.g. alligator or spade lugs) for a hands-off measurement.

3. Use test leads that do not reduce the arc protection by

decreasing the voltage spacing between conductors or

terminals.

Use the following sequence when testing power circuits:

1, De-energize the circuit using the regular installed connect-

disconnect device such as the circuit breaker, main switch,

etc.

2. Attach the test leads to the circuit under test. Use appropriate safety rated leads for this application.

3. Set the DMM to the proper function and range.

4. Energize the circuit using the installed connect-disconnect

device and make measurements without disconnecting the

DMM.

5. De-energize the circuit using the installed connectdisconnect device.

6. Disconnect the test leads from the circuit under test.

2.3 PREPARATION FOR USE

The Model 177 is shipped ready-to-use on line power. The

instrument may also be powered from rechargeable batteries

(when the optional Model 1788 Rechargeable Battery Set is

installed.)

2.4 OPERATION ON LINE POWER

The Model 177 DMM has a three-wire line cord which mates

with third-wire grounded receptacles. Connect the insfru-

ment to AC line power as follows:

CAUTION

Connect only to the line voltage selected.

Application of incorrect voltage can

damage the instrument.

Sat the LINE VOLTAGE switch on the back of the instru-

1

ment to correspond to the line voltage available. Standard

ranges are 105V to 125V and 210V to 250V AC as shown

in Figure 2-l. Optional ranges of 9OV to 11OV and 18OV to

220V AC are also available as shown in Figure 2-2. As indicated on their respective rear panels, the standard line

voltage range instruments use an internal line fuse (F102)

of 1/8A rating and the optional line voltage range instruments use a 3/16A fuse. See Section 5.

WARNING

Ground the instrument through a property

earth-grounded receptacle before operation. Failure to ground the instrument can

result in savera injury or death in the avant

of short circuit or malfunction.

2. Plug the power cord into a properly grounded outlat.

Operate the Model 177 DMM as described in paragraph

2.7.

2.5 OPERATION ON BATTERY PACK POWER

The Model 177 DMM may also be operated from

rechargeable sealed lead-acid batteries contained in the

optional Model 1788 Battery Pack. The battery pack will

operate the Model 177 DMM for up to six hours. Circuits

within the battery pack will automatically shut down the instrument when the battery charge is insufficient to maintain

accurate readings. To install the Modal 1788, refer to Section

5.

2.6 BATTERY CHARGING

The Modal 1788 Battery Pack contains an integral battery

charger. To charge the battery pack, install the battew pack

in the Model 177 DMM as described above and proceed as

follows:

1. Connect the instrument to line power as described in

paragraph 2.4.

2-1

Page 10

These adjustments are used only for calibration.

They are not intended for adjustment during operation.

/

(JlOOS)

Figure 2-1. Rear View Of Standard Line Voltage Instrument

These adjustments are used only for calibration.

They we not intended for adjustment during operation.

LINE VOLTAGE

SELECT SWITC

IP1007)

2-2

/+J

H

,JlOO,:

Figure 2-2. Rear View Of Optional Line Voltage Instrument

LINE VOLTAGL &x

SELECT SWITCH

(SlOll

-v

IP10071

Page 11

2. With the power switch off, the battery charge circuitry is

automatically energized to charge the battery et the maximum rate. When the battev pack is first installed, or if it

has completely discharged, allow it to charge for at least 14

hours in this condition.

NOTE

For maximum battery life, do not allow the battery pack to remain completely discharged. Constant charging will not harm either the battery

pack or the instrument. The Model 177 may be

operated up to six hours from fully charged batteries. However, since 10 charge/discharge

cycles may be required to reach full batten/

capacity, less than six hours DMM operation can

be expected when the battery pack is first installed.

3. When the Model 177 DMM is in use on line power, the battery charger maintains a trickle charge on the battery pack.

2.7 OPERATING INSTRUCTIONS

The basic operating instructions for the Model 177 DMM are

outlined in the following steps, and condensed operating instructions are provided on the bottom cover of the instrument and contained in Table 2-l. These instructions should

only be used after becoming completely familiar with the

operation of the Model 177 through day-to-day use. Until this

familiarity has been achieved, best performance and safest

operation will be obtained by using the individual instructions

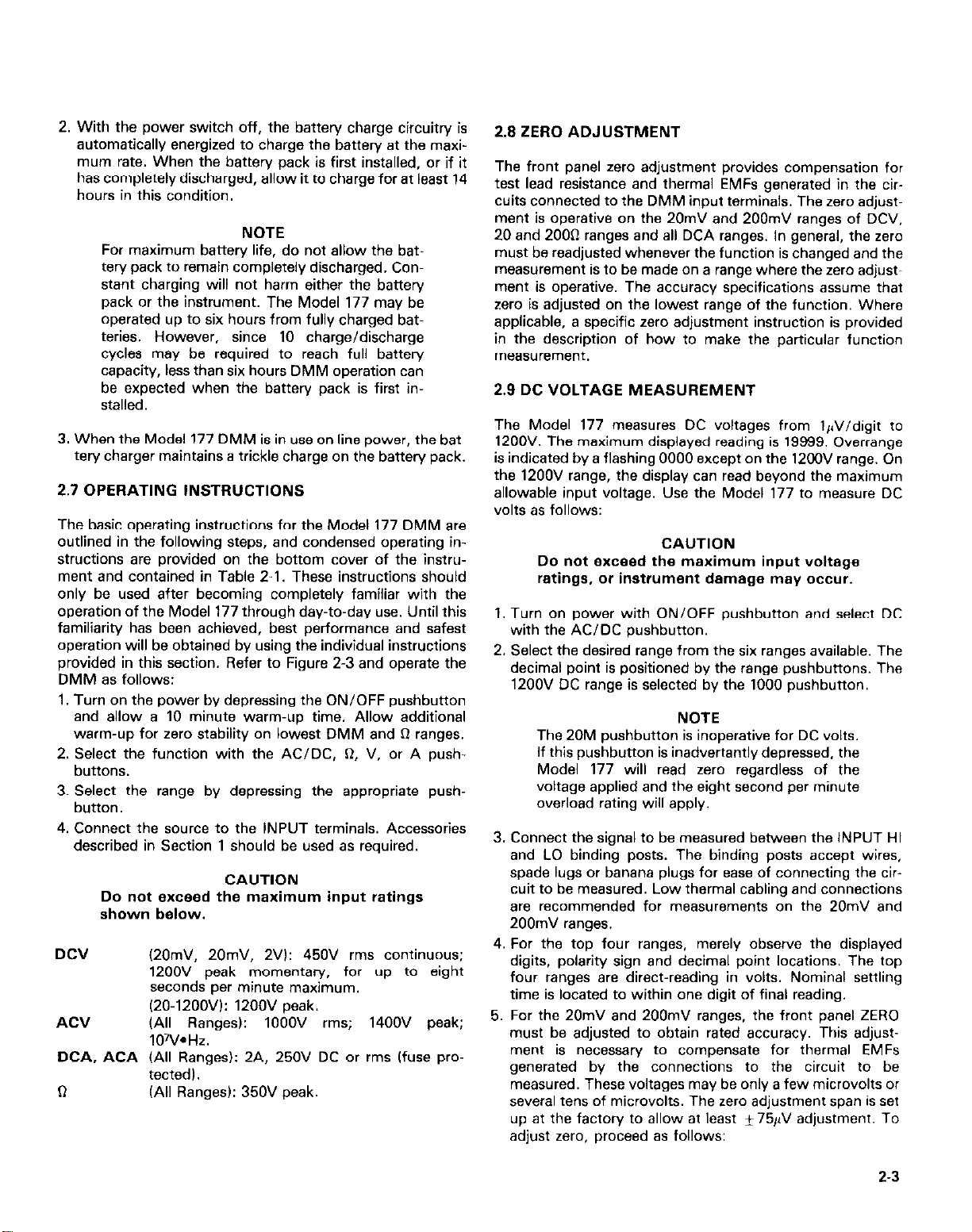

provided in this section. Refer to Figure 2-3 and operate the

DMM es follows:

1. Turn on the power by depressing the ON/OFF pushbutton

and allow a 10 minute warm-up time. Allow additional

warm-up for zero stability on lowest DMM and Q ranges.

2. Select the function with the AC/DC, R, V, or A pushbuttons.

3. Select the range by depressing the appropriate pushbutton.

4. Connect the source to the INPUT terminals. Accessories

described in Section 1 should be used as required.

CAUTION

Do not exceed the maximum input ratings

shown below.

DCV

ACV

DCA. ACA

R

QOmV, ZOmV, ZVI: 450V rms continuous;

1200V peak momentan/, for up to eight

seconds per minute maximum.

(20.12OOV): 12OOV peak.

;I ;;;ges): 1OOOV rms; 1400V peak;

.

(All Ranges): ZA, 250V DC or rms (fuse protected).

(All Ranges): 350V peak.

2.9 ZERO ADJUSTMENT

The front panel zero adjustment provides compensation for

test lead resistance and thermal EMFs generated in the circuits connected to the DMM input terminals. The zero adjusrment is operative on the 20mV and 200mV ranges of DCV.

20 and 200R ranges and all DCA ranges. In general, the zero

must be readjusted whenever the function is changed and the

measurement is to be made on a range where the zero adjusts

ment is operative. The accuracy specifications assume that

zero is adjusted on the lowest range of the function. Where

applicable, a specific zero adjustment instruction is provided

in the description of how to make the particular function

measurement.

2.9 DC VOLTAGE MEASUREMENT

The Model 177 measures DC voltages from l,lV/digit to

12OOV. The maximum displayed reading is 19999. Overrange

is indicated by a flashing 0000 except on the 12COV range. On

the 1200V range, the display can read beyond the maximum

allowable input voltage. Use the Model 177 to measure DC

volts as follows:

CAUTION

Do not exceed the maximum input voltage

ratings, or instrument damage may occur.

1. Turn on power with ON/OFF pushbunon and select DC

with the AC/DC pushbutton.

2. Select the desired range from the six ranges available. The

decimal point is positioned by the range pushbuttons. The

1200V DC range is selected by the 1000 pushbutton.

NOTE

The 20M pushbutton is inoperative for DC volts.

If this pushbutton is inadvertantly depressed. the

Model 177 will read zero regardless of the

voltage applied and the eight second per minute

overload rating will apply.

3. Connect the signal to be measured between the INPUT HI

and LO binding posts. The binding posts accept wires,

spade lugs or banana plugs for ease of connecting the circuit to be measured. Low thermal cabling and connections

are recommended for measurements on the 20mV and

200mV ranges.

4. For the top four ranges. merely observe the displayed

digits, polarity sign and decimal point locations. The top

four ranges are direct-reading in volts. Nominal settling

time is located to within one digit of final reading.

5. For the 20mV and 200mV ranges, the front panel ZERO

must be adjusted to obtain rated accuracy. This adjustment is necessary to compensate for thermal EMFs

generated by the connections to the circuit to be

measured. These voltages may be only a few microvolts or

several tens of microvolts. The zero adjustment span is set

up at the factory to allow at least f75,tV adjustment. To

adjust zero, proceed as follows:

2-3

Page 12

Taba 2-1. Model 177 DMM Condensed Operating Instructions

Summary of Function, Ranges and Other lr

0.03% Rdg + 1 D

0.5% Rdg +15D

lOOHz-10kHz

0.7% Rdg + 15D

0.2V Burden

lrmation

Max. Input

(Note 1)

1200v

Momentary

1OOOV RMS

10WHz

2A. 250V

DC or rms

(Note 4)

1

Front

Panel

Zero

Yk?S

No

No

YC?S

2A. 250V

0.8% Rdg +15D

DC or rms

(Note 4)

350v

Peak

No

No

ANALOG OUTPUT: f2V full scale. 5k0 outout resistance

Note 1: See manual fir detailed infbrmation.’

Note 2: Overrange is indicated by flashing 0000.

Note 3: True root mean square, crest factor = 3.

Note 4: Current fuse (installed internally) is 2A. 3AG normal blow. See Figure 5-4 for

location.

2-4

Page 13

Polarity (Negative in indicated, positive is

implied when minus I-1 display is off.1

1. SET POWER ON 2. SELECT FUNCTION ‘3. SELECT RANGE 4. CONNECT SOURCE

Figure 2-3. Operating Controls

NOTE

Due to the long thermal time constant of the

20mV range zero, a one hour warm-up time may

be necessary to adjust zero to the final l@ setting. Typically, only a one to three microvolt

zero shift can be expected during this warm-up

period, if the ambient temperature is within the

specified lfl” to 28% and the instrument has not

been subjected to temperature outside of this

range. Thus, since the expected zero shift is

both small and slow, normally zero can be adjusted and several measurements taken without

having to achieve the final zero setting.

A.

Make connections to the Model 177 as described

above. For the best performance, connections should

be made to the binding posts rather than using banana

plugs.

Set the Model 177 to the 20mV range.

Z:

Disconnect the leads at the circuit to be measured and

short them.

Allow the thermal EMFs generated et the connections

D.

to stabilize.

E.

Adjust the front panel ZERO knob for a display indication of O.OOOmV (a flashing fO.OOlmV is permissible.)

NOTE

The ZERO control operates only on the 20mV

and 200mV ranges. It has no effect on the other

DC voltage ran&.

F.

Make the measurements by applying the signal and

reading the mV on the display. Nominal settling time

for the 20mV range is three seconds to within one digit

of final reading.

NOTE

An overload input to the Model 177 may cause

temporary zero shift due to thermal gradients.

The zero setting for the 20mV range will also be valid

G.

for the 200mV range. Nominal setting time for the

200mV range is one second to within one digit of final

reading.

6. The optional Model 1600A High Voltage Probe can be

used with the Model 177 to measure DC voltage up to

40kV. at reduced accuracy.

2.10 AC VOLTAGE MEASUREMENT

The Model 177 measures AC voltages from 1OrV to 1OOOV.

The instrument measures the true root mean square (TRMSI

of a signal within the frequency range of 45Hz to 20kHz. The

maximum reading is 19999. Overrange is indicated by a

flashing 0000 except on the 1OOOV range. On the 1OOOV

range, the display can read beyond the maximum allowable

input voltage. The maximum crest factor for rated accuracy is

3. AC accuracy is specified for 2000 counts and above.

Nominal settling time for all AC voltage ranges is 2.5 second

to within 10 digits of final reading. Use the Model 177 DMM

to measure AC volts as follows:

1. Turn on power and set the AC/DC pushbutton to the in or

AC position. Depress the V pushbutton.

NOTE

The 20~ and 20M ranges are inoperative for AC

volts. If the 20~ pushbutton is inadvenantly

2-5

Page 14

depressed, the display will read overrange,

signalling the user to go to the next higher

range. If 20M is depressed, the display will read

zero regardless of the voltage applied. The

method of calibrating the converter may yield an

offset up to 125 digits with the Model 177 input

shorted. This does not affect instrument accuracy.

2. Select the desired range from the five ranges available.

CAUTION

MAXIMUM ALLOWABLE INPUTVOLTAGE

(All

ranges):

IOOOV rme, 1400V peak.

107V*Hz maximum. Do not exceed the maximum rating. Instrument damage may occur.

3. Connect signal to be measured between INPUT HI and LO

terminals. Observe the displayed digits and decimal point

location. The 200mV range is direct-reading in mV and the

remaining four ACV ranges are direct-reading in volts.

4. The crest factor (CFI is the ratio of the peak voltage to the

rms voltage as follows:

CFrVPEAK

CAUTION

MAXIMUM ALLOWABLE INPUTVOLTAGE

(All ranaesl: 350V oeak. Do not exceed

maximum rating. l&trument damage may

occur.

2. Connect the circuit to be measured to the INPUT binding

posts and select the desired range from the seven

available.

Table 2-2. Resistance Ranges

Nominal

Range Maximum

Setting

200*

2ooll*

2kD 1.9999

20kD

200kD

2000kR 1999.9

20MD 19.999

*Front

Panel

Zero

Reading

19.999

199.99

19.999

199.99

Full Scale

Voltage**

20mV

200mV

2v

2v

2v

2v

2v

All Ranges

Applied

Current

1mA

1mA

1mA

1OOfiA

1 Oj.cA

ld

O.lfiA

VRMS

NOTE

There will be some additional measurement error

for signals with a crest factor greater than 3

fCF>3l.

Typical crest factors are as follows:

Sine Wave

Square Wave

rriangular Wave

Positive pulse train

(duty cycle CF = 3 is 0.11)

5. The optional Model 1682A RF Probe can be used with the

Model 177 to measure 0.25V to 15V rrn.s AC signals with a

frequency of 2OkHz to 250MHz (and above at reduced accuracy).

6. Refer to paragraph 2.14 for TRMS measurements of a

signal with both AC and DC components.

CF = 1.4

CF = 1

CF = 1.7

CF = \/l/duty cycle

2.11 RESISTANCE KZ, MEASUREMENT

The Model 177 DMM measures resistance from lmD/digit to

20MD. See Table 2-2 for ranges. Nominal settling times to

within one digit of final reading are: three seconds on the 200

range; two seconds on the 2000kD and 20MD ranges; one second on the other four g ranges. Use the Model 177 to

measure resistance as follows:

1. Turn on power and depress the R pushbutton.

?iii%gzm

I

x;

il binding post treol IS negatrve.

3. Observe the displayed digits and decimal point to measure

resistance using the 2k, 20k. 200k. 2000k and 20MR

ranges. The full scale voltage drop for these ranges is 2V

which is sufficient to cause forward conduction of

semiconductor junctions. The HI (Red) terminal is

negative. To measure a resistance in parallel with a

semiconductor junction without turning on the junction,

either reverse bias the junction or select the next higher D

range. The latter method is possible because of the one

decade reduction of applied test current, but will result in a

measurement with 3% digit accuracy. It is suggested that

the 2kg range be used for diode testing. This range has a

nominal 1mA test current and the displayed reading is the

forward voltage drop in volts.

NOTE

The front panel ZERO control operates only on

the 200 end 2OOD ranges. It has no effect on the

other resistance ranges.

4. Before making measurements on the 2051 or 200R ranges,

adjust front panel ZERO on the 20R range to compensate

for test lead resistance. Best performance will be obtained

on the low ohm ranges when test connections are made to

the binding posts, rather than using banana plugs. Adjust

ZERO and make resistance measurements as follows:

2-6

Page 15

A. Select 200 range.

B. Disconnect the test leads at the circuit to be measured

and short them. If measurement is to be made right at

the INPUT terminals (no test leads used) place a short, current as follows:

such as a piece of copper wire, across the binding

posts.

C. Adjust the front panel ZERO knob for a display indica-

tion of 0.000 *O.OOlG (flashing). The nominal ZERO

adjustment span is 200mD.

D. Adjust front panel ZERO knob for a display indication of

O.OOO,rA * ,001 flashing.

2. After adjusting ZERO, use the Model 177 to measure DC

Do not install e larger capacity fuse then

the one originally supplied L?Al. Current

fuse FlOl (shown in Figure 5-4) protects the

instrument against over-current.

NOTE

The specified accuracy for the 2OD and 2OOG

ranges assumes that ZERO was adiusted on the

20irange. Re-adjust zero on the 2dg range each

time that a different set of leads is used or

whenever measurements have been made on

either the two lowest DC voltage ranges or any

DC current range. The zero setting for those

measurements will be different than the zero setting of ohms, Also, re-adjust zero whenever the

instrument is used outside the temperature

range of 18O to 28OC.

D. Reconnect the test leads to the circuit to be measured.

E. Select either 2OD range or 2000 range. Read the

displayed digits and decimal point.

NOTE

An input overload to the Model 177 may cause a

temporary zero shift due to thermal gradients.

A. Select the desired range from the six ranges available.

8. Connect the circuit to be measured to the INPUT terminals.

C. Read the displayed polarity, digits and decimal point.

Select the next higher range if overrange is indicated.

2.13 AC CURRENT MEASUREMENT

The Model 177 measures AC current from 1OnAldigit to 2A.

over five ranges. (The’ 20r~A and 20M ranges are not

operative. See note below.1 The 200r~A range is direct-

reading in microamperes. The remaining AC current ranges

are direct-reading in milliamperes. The maximum reading is

19999. Overrange is indicated by a flashing 0000. Overload is

protected by fuse FlOl, a 2A, 3AG normal-blow fuse. The

instrument measures the true root mean square ITRMSj of

waveforms in the frequency range of 45 to 10kHz. Use the

Model 177 to measure AC current as follows:

1. Turn on power and set the AC/DC pushbunons to in or

AC position. Depress the A pushbunon.

2.12 DC CURRENT MEASUREMENT

The Model 177 measures DC current from lnA/digit to 2A.

over six ranges (the 20M range is not operative and the

instrument will read zero if 20M pushbutton is depressed).

The maximum reading is 19999. Overrange is indicated by a

flashing 0000. Overload is protected by fuse FlOl, a 2A 3AG

normal-blow fuse. Nominal settling time for DC current

ranges is one second to within one digit of final reading except three seconds on 20pA range.,

1. Before making DC current measurements, the front panel

ZERO must be adjusted on the 20@ range. This adjustment is necessary to remove any offset that was introduced by adjusting ZERO for a low DC voltage measurementor a low g measurement. This adjustment will also be

necessary whenever the instrument is used outside of the

temperature range of 18O to 28Y. The specified accuracy

for the DC current ranges assumes that ZERO was ad-

justed on the 2OpA range. Adjust ZERO as follows:

A. Disconnect all circuits from the Model 177 INPUT ter-

minals. The INPUT terminals must have an open circuit~

_-...

8. Turn on power and set the AC/DC pushbunon to the

out or DC position.

C. Depress A and 20~ pushbuttons.

Do not install a larger capacity fuse then

the one supplied. Current fuse FlM (shown

in Figure 5-41 protects the instrument

against over current.

2. Connect the circuit to be measured to the INPUT terminals

and select the desired range from the five ranges available.

The 20/1A and 20M ranges are not operative for

AC current measurements. If the 20uA pushbutton is inadvertently depressed, an overrange

will be indicated, signalling the user to go to the

next higher range. If the 20M pushbutton is depressed, the instrument will read zero.

3. Read the displayed digits and decimal point.

AC accuracy is specified for 2000 counts and

above. The method of calibratina the converter

may yield an offset up to 80 digits with the

Model 177 input shorted. This does not affect instrument accuracy. There will be some additional measurement error for signals with a crest

CAUTIONS

CAUTION

NOTE

NOTE

2-7

Page 16

factor greater than 3 (CF>31.Refer to paragraph

2.10 for information on how to determine the

crest factor of a waveform.

4. Refer to paragraph 2.14 for TRMS measurements of a

signal with both AC and DC current components:

2.14 TRMS MEASUREMENTS (AC + DC)

The Model

and does not measure the DC component. Use the Model

177

to measure TRMS of a signal which has both AC and DC

components as follows:

1. Measure and record the AC and DC components separatelV.

A. Refer to paragraph 2.9 for DC voltage measurement.

6. Refer to paragraph 2.10 for AC voltage measurement.

C. Refer to paragraph 2.12 for DC current measurement.

D. Refer to paragraph 2.13 for AC current measurement.

2. Compute the TRMS value using the following equation:

ETRMS =“EDc~ + EACH OR lTRMS =‘IDC2 + lAC2

177

measures the AC component of a waveform

2.15 ANALOG OUTPUT

The rear panel accessible ANALOG OUTPUT provides a

f2V full scale DC signal IlOk counts = 1V). The ANALOG

OUTPUT is operable for all instrument ranges and functions.

The output polarity of the analog voltage is negative for the

ohms (0) function, positive for AC function and non-inverting

for DC functions. The effective analog output resistance is

5kR (4kn in series with the HI output to protect the Model

against externally applied voltage and 1 k0 between input LO

and analog output LO to prevent a ground loop when con-

nection is made to a grounded load, oscilloscope or

recorder). The analog output voltage is compatible with most

modern analog recorders and may be used to determine

signal changes with respect to time or other variables. With

respect to the signal input and analog output, the Model

acts as an amplifier (for mV signals), an attenuator (for kV

signals) or a converter to DC volts (for AC current or

resistance signals). Output accuracy is the same as the

display except on ohms; up to *0.05% error can be ex-

pected due to the ratio-metric method used. The analog out-

put floats at input LO. For this reason, do not connect a

voltage source across INPUT LO and ANALOG LO. This will

result in a measurement error and may damage the Model

177

if the voltage is greater than 15V. When the instrument is

in an overrange condition, up to + 15V DC may be at the

ANALOG OUTPUT dependent upon the function, range and

level of the input signal.

177

177

2.16 TILT SAIL ADJUSTMENT

The tilt bail of the Model

strument to a convenient viewing height. To adjust the bail,

pull the bail out from each side of the case and rotate it to the

desired position. Release the bail to allow it to lock into position.

177

may be used to elevate the in-

2-6

Page 17

SECTION 3

PERFORMANCE VERIFICATION

3.1 INTRODUCTION

Performance verification may be performed upon receipt of

the instrument to ensure that no damage or misadjustment

has occurred during transit. Verification may also be parformed whenever ther is question of the instrument’s accuracy, and following calibration, if desired.

NOTE

For instruments that are still under warranty (less

than 12 months Since date of shipment), if the

instrument’s performance falls outside specifications at any point, contact your Keithley

representative or the factory immediately.

3.2 RECOMMENDED TEST EQUIPMENT

Recommended test equipment for performance verification is

listed in Table 3-1. Alternate test equipment may be used.

However, if the accuracy of the alternate test equipment is

not at least IO times better than the instrument’s specifications, additional allowance must be made in the readings obtained. Some of the equipment listed in Table 3-I is not 10

times batter than the Model I77 specifications because such

equipment is not readily available. In these instances, the

verification procedures indicate the equipment

manufacturer’s specified uncertainty, and include the uncsrtainty in determining the allowable reading for the Model 177.

3.3 ENVIRONMENTAL CONDITIONS

All measurements should be made at an ambient temperature

within the range of 18” to 28OC (65” to 62OFl. and a relative

humidity of less than 80%.

3.4 PERFORMANCE VERIFICATION PROCEDURE

Use the following procedures to verify the basic accuracy of

the Model

measursments. If the instrument is out of specification at any

177

DMM for voltage, resistance and current

Table 3.1. Recommended Test Equipment For Perfomance Verification

point, perform a complete calibration as described in Section

5, unless the instrument is still under warranty.

NOTE

Performance verification should be performed

by qualified personnel using accurate and

reliable test equipment.

3.4.1 Initial Conditions

Before beginning the verification procedure the instrument

must meet the following conditions:

1. If the instrument has been subjected to extremes of

temperature, allow internal temperatures to stabilize for

one hour minimum at the environmental conditions

specififed in paragraph 3.3

2. Turn on the Model I77 and allow it to warm up for one

hour. The instrument may be operated from either line

power or from battery pack power, as long as the battety

pack has been fully charged as described in paragraph 2.6.

WARNING

Some procedures require the usa of high

voltage. Take care to prevent contact with

live circuits which could causa electrical

shock resulting in injury or death.

3.4.2 DC Voltage Accuracy Check (2V to 1200V Ranges)

I. Select DC voltage function with the AC/DC V push-

buttons.

2. Connect the DC calibrator to the instrument.

3. Select the 2V range. and apply positive 2VDC to the

DMM. The reading must be within the limits specified in

Table 3-2.

4. Select each remaining range and apply required voltage

specified in Table 3-2. Verify that the reading is within

specifications.

5. Repeat all checks with negative voltage.

Description

DC Calibrator

AC Calibrator

AC Amplifier

Decade Resistor

current source

1OOn Per Step 4-Terminal

Low Thermal Resistor

*0.002% or 2O@V

O.lV, 1v. IOV, IOOV 10.01%

1ooov @ 0.04%

1900, 1.9kQ. 19kQ. 190kn.

1.9MQ. IOMn, iO.OI%

100rA. lmA, lOmA, IOOmA, 1A

10:1 divider within 50 PPM

Mfr.

Fluke

Fluke

Fluke

ESI

Fluke

ESI

3-l

Page 18

Table 3-2. DC Voltage Performance Check (2V to 1200V

Rangel

3.4.3 DC Voltage Accuracy Check (20mV and 200mV

Rangesl

1. Select

2. Disconnect test leads at the DC calibrator and short

them. Adjust Model 177 front panel ZERO for a display

indication of O.OOOmV *O.OOlmV flashina.

3. Connect the DC calibrator and select 200mV range.

4. Set the DC calibrator to an output of +O.l9OOOOV.

5. Verify that the Model 177 reading is between + 189.89 to

calibrator.

6. Repeat steps 4 and 5 with negative voltage.

7.

8. Connect the DC calibrator, low thermal resistor and

9. Temporarily disconnect the leads from the DC calibrator

and short them. Adjust Model 177 front panel ZERO for a

display indication of 0.000 * O.OOlmV flashing.

10. Set the DC calibrator to an output of +O.l9OOOOV.

11. Verify that the Model 177 readin is between + 18.987

ancl + IY.VIXnV. Note, that, the allowable reading includes *2 digits for DC calibrator uncertainty and * 1

digit for low thermal resistor uncertainty.

12. Repeat steps 10 and 11 with negative voltage.

DCV and 20mV range.

+ 190.11mV. Note that the allowable reading includes a

i2 digit allowance for the uncertainty of the DC

Select 20mV M”Qc?.

Model 177 as shown in Figure 3-1.

~~^^_^ .,~

THERMAL

R6SlSTOR

Figure 3-I. Test Circuit For 20mV DC Accuracy Check

3.4.4 AC Voltage Accuracy Check

1. Select AC voltage function with the AC/DC and V

pushbuttons.

2. Connect the AC calibrator to the DMM. Set the calibrator

frequency to 1 kHz.

3. Set the DMM to the 200mV range and apply 1OOmV AC

to the DMM. The reading must be within the limits

specified in Table 3-3.

4. Select the 2,20 and 200mV ranges and apply the required

voltages as specified in Table 3-3. Verify that the readings

are within spcifications.

5. To check 1OOOV range, connect the AC calibrator

amplifier to the output of the AC calibrator per the

manufacturer’s instructions. Connect the amplifier output

to the Model 177 INPUT terminals. Set the AC calibrator

for amplifier output of lOOO.OOOV at 1kHz. Verify that the

DMM reading is within the specified limits in Table 3-3.

6.

To check accuracy at 45kHz and 20kHz. select the 20V

range. Apply the voltage specified in Table 3-3 at 45Hr.

then repeat at 20kHz. Verify that the DMM readings are

within the specified limits.

Table 3-3. AC Voltage Accuracy Check

Range

200mV

2v

2ov

2oov

1ooov

2ov

Applied

Voltage

@lkHz

lOO.OOmV

1 .oooov

1o.ooov

1oo.oov

1ooo.ov

@45Hz

1o.ooov

Allowable Readings at

180 to 28Y.z

1

99.35 to 100.65mV

0.9935 to 1.0065V

9.935 to 10.065V

99.35 to 100.65V

993.5 to 1006.5V

9.915 to 10.085V

@2OkHz

2ov

1o.ooov

9.915 to 10.085V

3.4.5 Resistance KU Accuracy Check

1. Select resistance function by depressing n pushbuttons.

2.

Select 2000 range.

3. Connect the decade resistor to the DMM.

4. Set the decade resistor to zero and compensate for lead

resistance by adjusting front panel ZERO for a display in-

dication 00.10 f .OlQ flashing.

5. Set the decade resistor to 190% Verify that the reading for

the 200R range is within the limits specified in Table 3.4.

6.

Select the 2k0 ra”Qe.

7.

Set the decade resistor to zero and measure the resistance

of the test leads. Subtract this reading from the displayed

reading in all of the following steps.

8. Set the decade resistor to 1.900kfI. Verify that the reading

is within the limits specified in Table 3-4.

9. Continue by selecting the next range and measure the next

resistance as specified in Table 3-4. Test each item in the

table and verify that each reading is within specifications.

I

3-2

Page 19

Table 3-4. Resistance Accuracy Check

Allowable Reading at

Range Resigtance

2000 1900 189.86 to 190.140

2kQ 1.900kR 1.8989 to 1.9011 kO

20kR

200kR

2000kO 1900.0k0 1898.9 to 1901.lkR *2 digits

20MR

*Manufacturer’s specified unceflainty of the decade resistor in

digits. This uncertainty has been added to the specified accuracy

of the Model 177 to obtain the allowable reading.

3.4.6 DC Current Accuracy Check

1. Select the DC current function with the AC/DC and A

pushbuttons.

2. Select the 20cA range. With an open circuit at the INPUT

terminals of the Model 177, adjust the front panel ZERO

for a display indication of 0.000 1tO.00l~A flashing.

3. Connect the DC current source to the DMM.

4. Select each range and apply the required current as

specified in Table 3-5. Verify that each reading is within

specification.

Table 3-5. DC Current Accuracy Check

Applied Current

lOO.OO~A --

1 .OOOOmA

lO.OOOmA

lOO.OOmA

lOOO.OmA

L

0.9979 to 1.002imA

9.979 to 10.021mA

I

99.79 to 100.21mA

997.9 to 1002.lmA

19.000kfl

190.00kfI

lO.OOOMfl 9.988 to 10.012MR f 1 digit

180 to

18.989 to 19.011kR

189.89 to 190.11kfI

28%

3.4.7 Analysis

If the instrument is out of specified limits at any point in Table

3-2 through 3-5, calibrate the DMM as described in Section 5.

If the unit is still under warranty, refer to the ncate in

paraQraph 3.1.

It is not necessary to specifically check the 20R

or 20uA ranaes. or a”” of the ACA ranaes. The

circuit components that determine th& accuracy have been checked elsewhere in the

verification procedure.

l

* 2 diQits

+ 2 disits

+ 2 digits

+2 digits

NOTE

3-313-4

Page 20

Page 21

SECTION 4

THEORY OF OPERATION

4.1 INTRODUCTION

This section contains circuit descriptions for the Model 177

DMM and the optional Model 1788 Battery Pack. An overall

block diagram of signal flow is provided in Figure 4-l. The

schematic diagrams are contained in Section 6 of this

manual. The Model 177 schematic is drawing number

29658E and schematic drawing number 29659C is for the

Model 1788.

4.2 OVERALL OPERATION

The Model 177 w?s a 2V (20,000 count) full scaleanalog-to-

digital (A/D) converter with a 4% digit multiplexed display.

Signal conditioning permits the AID converter to accomodate full scale DC voltage and current measurements

over seven ranges.

AC AMPLIFIER/

-4x=

R CURRENT OUTPUT

DC INPUT

DC AlTEN”ATOR/R

SOURCE RESISTORS

FUNCTION e RANGE

SWITCHING

il;-

0 SENSE

FEEDBACK

*ZVFS OUT

390Hz CHOPPER DRIVE

FRONT

PANEL

ZERO

OPTIONAL

SAlTERY

PACK

r-----7

I MODEL ’

I 1788

L-----A

I

CHOPPER

BUFFER/

AMPLIFIER

t

0

4.2.1 Signal Conditioning

Signal conditioning icludes: DC attenuation (on the 20, 200

and 1200V ranges), modulation and demodulation of the DC

signal by the chopper buffer/amplifier with Xl00 and X10

gain Ion the 20 and 200mV ranges, respectively), AC atten-

uation (on the 20, 200 and 1OOOV ranges), AC amplification

(on the 200mV and 20V ranges), AC-to-DC conversion,

ohms source and conversion, and current shunts as shown in

Figure 4-l.

1. In the DCV mode, signal conditioning to the A/D converter

consists of range and function switching, range resistors

(attenuator) and the chopper buffer/amplifier. For all

ranges, the DC input signal is attenuated/amplified to pro-

vide a *2V full scale output to the AID converter. In the

DCA mode, the voltage developed across the shunt

resistor is applied directly to the input of the chopper

amplifier. A chopper gain of Xl0 is used for all ranges except 20A which uses X100.

DIGITAL

OUTPUT

TRMS AC

CONVERTER

c---7

L---J

DISPLAY

L

A

AC

0

ii

%

I

I

REFERENCE

IWkHz

CLOCK

I

OSClLLATOR

Et

DIVIDER

t

Figure 4-1. Model 177 Simplified Signal Flow Block Diagram

4-1

Page 22

2. In the ACV mode, AC inputs for all ranges pass through

the AC converter which consists of an amplifier/attenuator

and a TRMS converter, as shown in Figure 4-2. The AC in-

put is scaled by the amplifier/attenuator to 2V rms full

scale for all ranges. The TRMS converter provides a

positive DC output signal which is proportional to the true

root mean square AC signal. This DC signal is the input to

the A/D converter. In the ACA mode, the shunt voltage is

applied to the input of the AC converter. The amplifier/attenuator provides a x 10 gain for all AC current ranges.

3. Ohms conversion-Resistance measurements ara made by

supplying a constant current from the ohms converter to

the unknown resistor (Rx). The resulting voltage developed

across the unknown resistor is proportional to its

resistance, and this voltage is applied to the input of the

chopper amplifier used for DC volts. The chopper amplifier

output to the A/D converter is scaled to -2V full scale for

all ohms ranges. Scaling of the ohms signal over the seven

ranges is accomplished by using five constant current

levels and the three gains of the chopper amplifier.

4.2.2 AID Converter

The A/D converter is a large scale integration (LSI)

ratiometric device. Converter output is a multiplexed five digit

number, in binary coded decimal IBCD) form which is equal

to the ratio of the input voltage to the reference voltage. A

separate clock circuit supplies a 1OOkHz timing input to the integrated circuit, which also multiplexes the BCD output. The

full scale AID input for all ranges of the Model 177 is 2VDC.

with the polarity determined by the function as follows: ACV

and ACA. +2V; DCV and DCA. rt2V; Resistance (0). -2V.

4.2.3 Range Switching

It is important to note that the range switches on schematic

29658E are identified by the front panel marking for the

L2 ranges. The corresponding V and A ranges may either be

determined from the instrument front panel or by using Table

4-l.

4.3 AC CONVERTER

When making AC voltage measurements, the AC converter

scales the input signal by appropriate attenuation or

amplification, performs TRMS conversion and provides the

equivalent positive DC level to the A/D for display. Input

resistance for AC volts is 1MD IR107). Shunt capacitance is

less than 75pF. Signal conditioning is as follows:

4.3.1 Scaling

Scaling

schematic drawing number 29658E and summarized in Table

42. Scaling is performed by using a relay and FET switches

to switch feedback resistors in the attenuator IUlOl) and the

amplifier (U102). The actual gains used in attenuator UlOl

are 0.99, 0.0099 and 0.00099. Amplifier U102 gains are

nominally 1.003 and 10.03. The combined gain of UlOl and

U102 is offset low to permit gain adjustment in the TRMS

stage. The only adjustments provided in the attenuator and

amplifier stages are two high frequency compensation

capacitors (Cl02 and C103). AC coupling is used at the input

and output of the attenuator and amplifier stages. Input

overload protection is provided by diodes (CRlOGand CR1071

and resistors R107 (1MQ. 2WI.

4.3.2

AC-to-DC conversion is performed b a monolithic TRMS

module lU103). Output V,

output filtering are done be ore the internal output buffer to

give a low impedance for the analog output. Potentiometer

R113 provides midband (10K count) gain adjustment and

R114 establishes output zero (1K count). Capacitor Cl08 is

used in the averaging circuit, and Cl09 provides filtering as

described above.

4.3.3 AC Current Measurements

For AC current measurements, the appropriate shunt resistor

is placed in front of the AC converter. The 200mV range gain

configuration is used for all current ranges.

4.4 DC SIGNAL

For DC voltage measurements, the input resistance is lOMO,

which is established by all of the range resistors being connected in series to signal ground. On low voltage ranges, the

DC input is applied to the top of the resistive divider (range

resistor) and to the buffer amplifier input without attenuation.

Also, the chopper amplifier has appropriate gain to provide a

f2V full scale output to the A/D. On high voltage ranges,

the DC signals are scaled down to *2V full scale by the

resistive divider and the chopper is used in the unity-gain

Ifollower) mode as a buffer. A summary of input attenuation

and chopper amplifier gain is given in Table 4-3.

is performed in the first two stages, as shown on

AC Conversion

F =&. Averaging and

CONDITIONING

4-2

Table 4-l. Range Switch Correlation

Function

0

V 20mX 200m 2 20 200 1000**

A 20/L*

*DC Only

l

*ACV 1000, DCV 1200

20 200 2k 20k 200k 2000k 20M

2oofl

Ranges

2m 20m 200m 2000m

Page 23

Table 4-2. Converter Attenuation and Amplification

**x100 = a101 On

**x 1000 = KlOl On

AC CONVERTER

Table

4-3. DC Signal Conditioning Attenuation

and

Gain

1

x 10

Xl

Xl

Xl

Xl

Range

20mV

200mV

2v

2ov

2oov

1200v

Input

Attenuation

-

+ 10

t 100

i 1000

Chopper

Gain

x 100

t

4.4.1 Input Attenuation

On the 20, 200 and 1200V ranges, the input signal is atten-

uated by the resistive divider to divide by 10, 100 and 1000,

respectively. Depressing one of the above range pushbuttons, interrupts the unattenuated signal from the volts

switch pin 17 and connects the wiper of the appropriate

range potentiometer to the input of the chopper. Division by

10, 100 and 1000 is accomplished by connecting the wiper of

R155, R156 or R157, respectively.

4.4.2 Chopper

The input signal to the chopper is filtered and applied to a

modulator circuit. The AC signal is then amplified and

demodulated. A final high gain DC amplifier provides a DC

signal to the AID converter and the analog output.

1. Modular Circuit-This circuit converts the input DC signal

to an AC signal with a fundamental frequency component

of approximately 390Hz. This frequency was chosen

because it reduces the amplitude of higher harmonics of

the 50Hz and 60Hz line frequencies, which minimizes

beating. The circuit utilizes a dual MOSFET (Q104A and

010413) connected in a series-shunt configuration to maintain the required high input impedance.

2. AC Amplifier-The AC amplifier uses a JFET-input opera-

tional amplifier (U108). The amplifier feedback network

provides a gain of approximately 133 at the modulating frequency of 390Hz. while maintaining a gain of one for

amplifier (U108) DC offset voltages.

6

OHMS CONVERTER

Figure 4-2. Simplified Signal Conditioning

3. Demodulator Circuit-The demodulator is sychronized

with the input modulator. A JFET (01051 with low onresistance is used to alternately attenuate and pass the

signal present at the output of AC amplifier U108. This

produces a “half-wave rectified” DC signal at the input of

the integrator stage, that is inverted with respect to the

chopper input signal.

4. DC Amplifier-Amplifier lU109) is connected as an integrator with an offset adjustment. U109 provides suffcient gain to bring the total open-loop DC gain to about

one million. U109 drives the feedback divider network and

the A/D converter, and provides the low output im-

pedance necessary to drive the analog output. Feedback

capacitor (Cl381 was selected to provide nominal settling

time, while meeting NMR requirements. When the chop-

per is operating as a unity-gain follower, the DC signal prey

sent at the output of U109 is the chopper feedback. This is

the condition for the 2VDC range and above. On the

200mV and 20mV ranges, where chopper gains of 10 and

100 are required, the resistive divider feeds back a portion

of the output of U109 to provide the required gain.

5. Modulator-Demodulator Drive Circuit-CMOS inverters

lUlllA and UlllF) provide opposite phase 0 to -15V

square waves used to drive MOSFET modulator transistors

Q104A and Q1048. lnverter UlllF also drives the

4-3

Page 24

demodulator JFET Q105. Resistors R118, R119 and R142

and capacitors Cl31 and Cl32 affect the rise and fall times

of drive signals. R142 adjusts the rise and fall time of the

drive signal to Q104A only, so that the total charge, both

positive and negative, transfered to the input can be

minimized. The frequency of the drive signal is determined

by the clock circuit. Circuitry in UllO divides down a

nominal clock frequency of 100kHz to produce 390Hz.

6. Adjustments and Input Protection-The front panel zero

control CR2031 permits adjustment of the chopper feed-

back to compensate for input thermal EMFs. It functions

only on ranges where chopper gain is greater than one. A

span of f75V is considered adequate; however, it is

typical for R203 to provide a greater than 400V change as

it is turned end-to-end. The span is skewed by R128 to

give best resolution in both DCV and n. Potentiometer

R146 provides a calibration adjustment to compensate

200mV range (X10 gain configuration) and R147 adjusts

the Xl00 gain used on the 20mV range. Chopper input

resistor R143 limits the input current during momentan/ in-

put overloads to 12mA. which is then absorbed by the

chopper load resistance (R145 and/or R149) or the power

supplies through CR116 and CR117.

7. DC Current Measurements-As previously described, DC