®

SAFE & EASY

FILTER

OWNERS MANUAL

037402

This Owner’s Guide provides specific operating instructions for your model.

Use the Safe & Easy Filter only as instructed in this Service Guide.

Versión en español

Si desea obtener una copia en español de este Manual de el Usuario,

sirvase escribir a la dirección que se incluye a continuación.

1-800-KEATING

www.keatingofchicago.com

READ AND SAVE THIS MANUAL FOR FUTURE REFERENCE

Record the Model No. and Serial No. (located on the back of the motor housing) of this

Safe & Easy Filter in the space provided below.

Serial No. ____________________________________________________________

Model No. ____________________________________________________________

Keep these numbers for future reference

IMPORTANT: Keep a copy of your bill of sale. The date on the bill establishes the warranty period

should service be required. If service is performed, it is in your interest to obtain and keep all

receipts. Keating commercial fryers are intended for other than household use.

CONTENTS

SECTION A - Preparing the Filter Drawer

Removing the Filter ..................................................1

Installing Components ..............................................1

Connecting the Tub ..................................................1

Connecting the Filter Assembley ..........................1-2

SECTION B - Preparing the Oil for Filtration

Oil Temperature ........................................................2

Removing the Screen................................................3

SECTION C - Filtration

Draining Oil ..............................................................2

Returning the Oil ....................................................2-3

Rinsing the Fryer....................................................2-3

SECTION D - Clean Up

Instructions ................................................................3

Drain Valve Handle Placement ................................3

SECTION E - Discarding the Oil

Preparing the Filter....................................................3

:

Connecting the Discard Hose ................................3-4

Instructions ................................................................4

Filter Side View ........................................................4

SECTION F - Quick Hits

Do’s & Don’ts ............................................................4

SECTION G

Parts List ..................................................................5

SECTION H - Self Help Guide

Problem/Solutions ..................................................6-7

Preventative Maintenance ........................................7

SECTION I

Wiring Diagram ........................................................8

SECTION J

Warranty Information ................................................9

This Owner

’s Guide provides specific operating instructions for your model. Use the Safe & Easy

Filter only as instructed in this Service Guide.

SAFE & EASY®FILTER

OPERATING INSTRUCTIONS

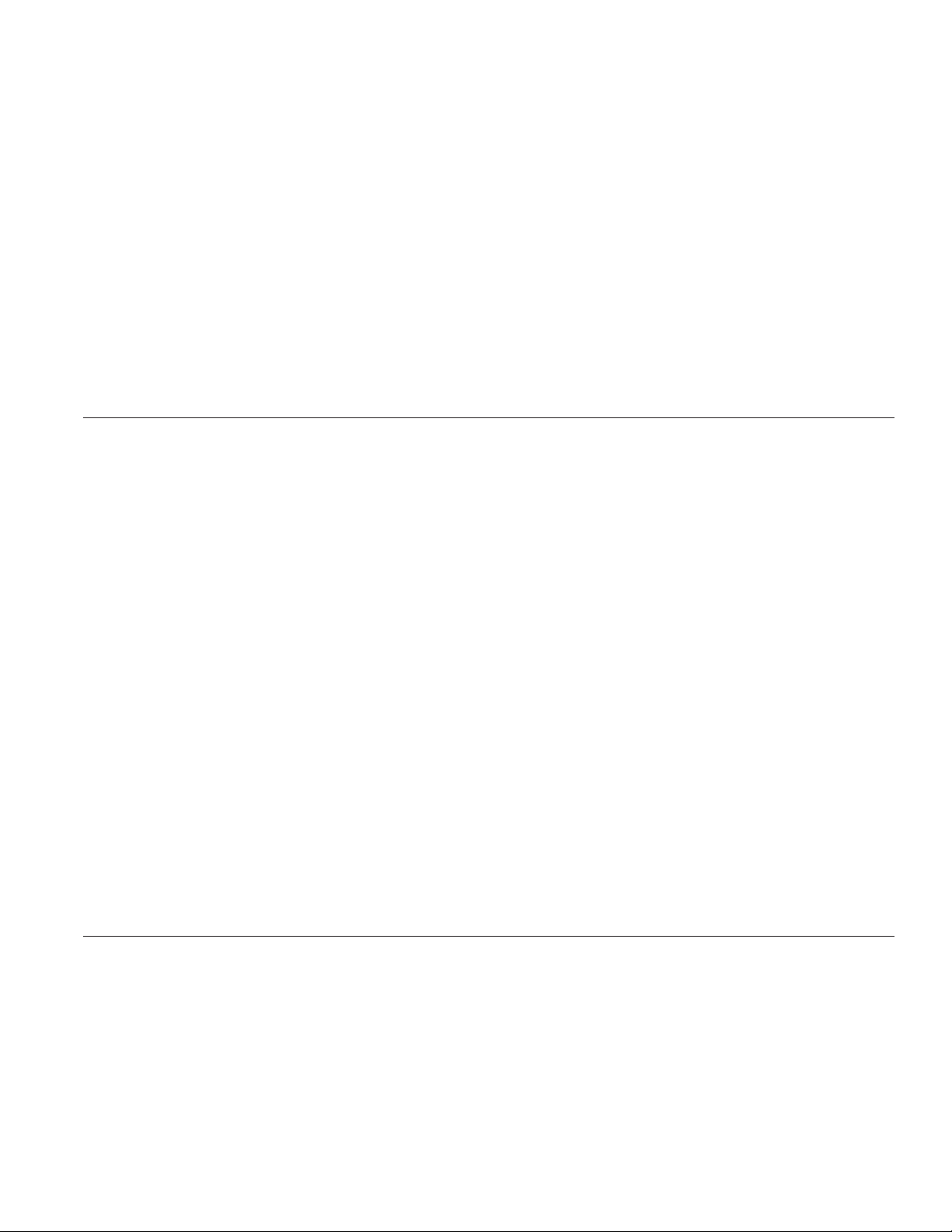

A. PREPARING THE FILTER-DRAWER

CAUTION

WATER IN ANY FORM & HOT OIL DON'T MIX!

NOTE: Operator should be outfitted with proper

protective attire: safety goggles, oil and heat

resistant gloves, apron and footwear

Filter assembly inside of cabinet:

1. Pull the handle marked “Pull to Release Filter”

(top of filter panel).

2. Remove the entire assembly from the cabinet by rolling it

forward.

3. Pull the handle marked “Pull to Release Tub”

(bottom of panel)

4. Slide the tub back, lift up and remove from cart.

Ensure all component

5.

(NOTE: Filter tub and components are dishwasher safe).

Install components into tub as follows:

6.

a. Sump screen

b. Filter p

aper

c. Hold down ring (Note 1)

d. Acidox (1 package per 40lbs oil) (Note 2)

e. Crumb basket

NOTE 1: Hold down ring makes a gasket-like seal on filter

paper. Filter paper must be placed edge to edge from front to

back, overlapping on sides. Filter Paper must be smooth and

flat under hold down ring to get a proper seal. Lock the two

tension arms into place by pushing down and rot

NOTE 2: One p

ackage of

pounds of oil.

Place entire tub assembly onto the cart (NOTE: Ensure

7.

the lip on the tub goes

Reconnect the tub to the motor by pulling together the

8.

handles on the front of the tub and the handles on the

side of the motor housing.

NOTE: Push on the front of the tub to verify connection. If tub

moves, repeat step

s 7-8.

s are clean

See Figure 1

ating 90°.

Acidox is needed for every 40

under

the cart frame in the rear).

See Figure 2

CRUMB

BASKET

HOLD

DOWN RING

FILTER

PAPER

SUMP

SCREEN

FILTER

TUB

Motor Housing

Pull handles

to connect

tub to

pump

SPRINKLE ACIDOX EVENLY ON PAPER

FIGURE 1.

FIGURE 2.

KEEP THIS MANUAL FOR TRAINING NEW PERSONNEL

– 1–

9. Sprinkle Keating Acidox Powder evenly over the paper.

1

0. Replace crumb basket and push drawer fully into cabinet.

Ensure the connection on top of the housing mates with the

connection inside the cabinet.

Pull the front of the filter system lightly to verify proper

connection

NOTE: Cabinet door should be closed during filtration.

NOTE: For best results, new filter paper and Acidox Powder

must be used for each fryer.

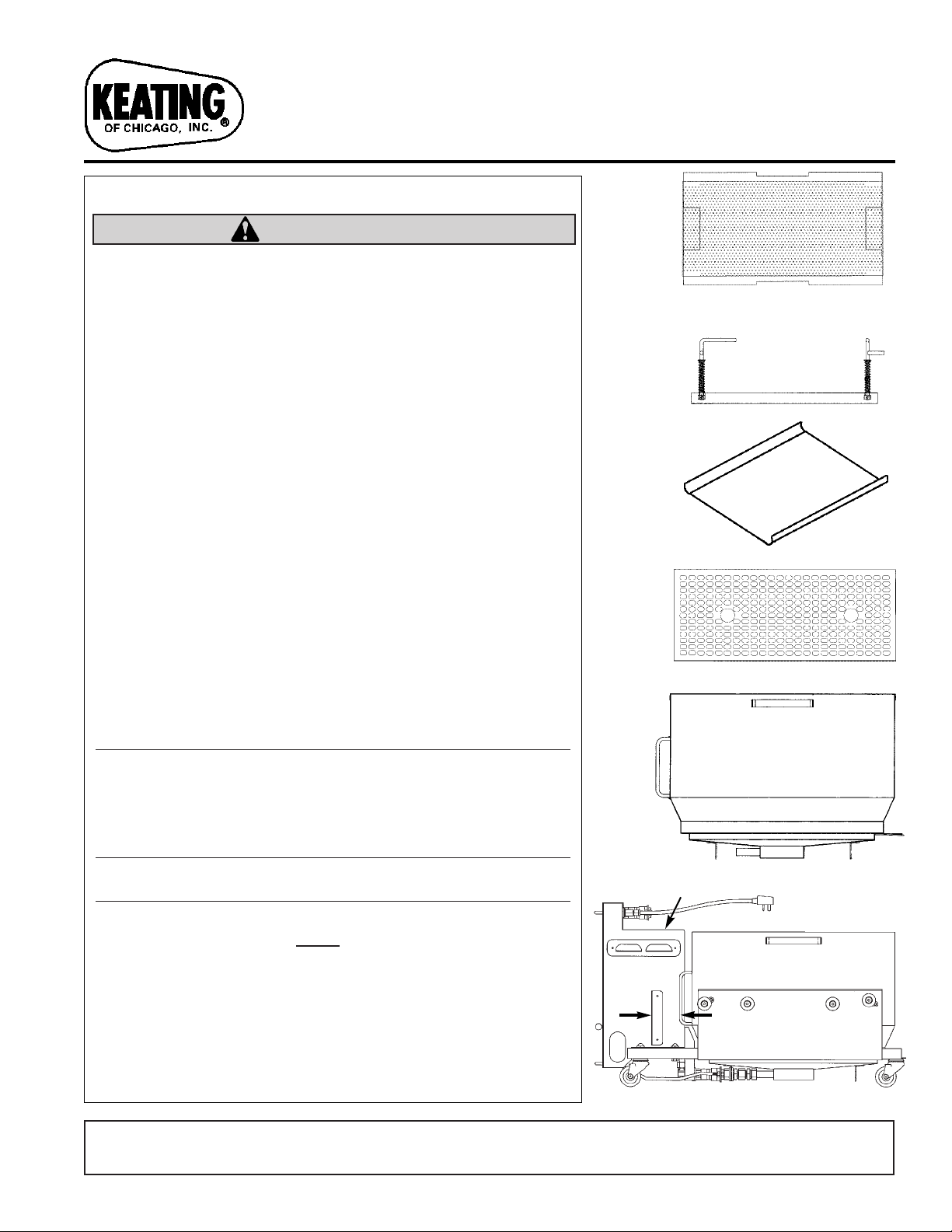

B. PREPARING OIL FOR FILTRATION

NOTE: Oil in fryer must be between 250° - 350°F.

1. Turn fryer completely off.

2. Remove screen from over tubes/element with tongs or a

Drain Clean Out Rod. Refer to Figure 3.

CAUTION

Screen over tubes will be very hot and should be moved to

a safe place.

3. Use spoon provided to stir oil. Bubbling will occur until all

water is removed. Failure to do so will clog the filter paper.

Refer to Figure 4.

NOTE: W

water is not removed, the filter paper absorbs the water

preventing the oil from passing through it.

C. FILTRATION

1. On filter assembly, have handle with the black knob set to

2.

NOTE: A Drain Clean Out Rod may be needed to loosen any

solid residue. Use it only when valve is fully open.

3. Wipe crumbs from splashdeck while fryer is empty. Plug

NOTE: On units with more than one fryer or a separate cabinet

for the filter system, you must open the return valve handle

(small black knob next to drain handle) by pulling it forward. This

will allow the oil to pump into the correct fryer.

4. On the filter panel, turn the pump switch to the “ON” position.

NOTE: If oil does not return to fryer, check the following:

5. Let the pump run with drain valve open to remove crumbs

ater settles in the cooler oil in the Cold Zone. If the

oil to fryer. Refer to Figure 5.

Open the drain valve slowly by lifting and then pulling the

drain valve handle and drain fryer (handle with largest black

knob).

the filter unit into the outlet.

The green light will illuminate. Refer to Figure 5.

1. Filter tub setup (See Fig. 1)

2. Tub to motor connection (See Fig. 2)

3. Water may have clogged the p

aper (See Fig. 4)

4. Return valve for units with more than one fryer or

separate filter cabinet is not opened.

and residue from the bottom of fryer and the drain lines.

FIGURE 3.

REMOVE SCREEN OVER

TUBES/ELEMENTS

SPOON

FIGURE 4.

STIR WITH SPOON PROVIDED TO

REMOVE WATER

ON/OFF

Switch

Knob must

be in this

position

when hose

is not used

FIGURE 5.

FRONT VIEW OF FILTER

– 2–

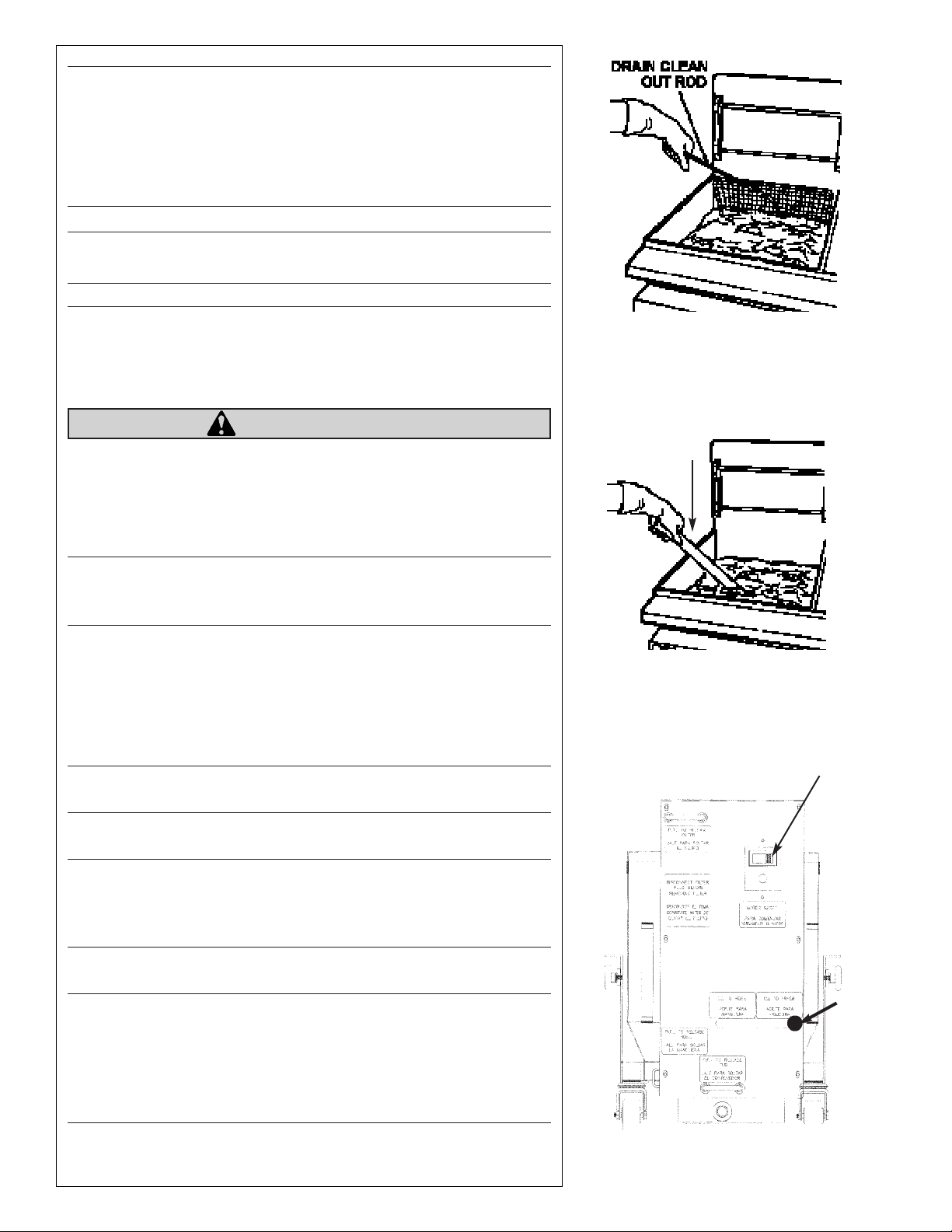

F

ailure to do so may cause the drain lines to clog up.

NOTE: If the pump shuts down, turn it off and let the motor cool.

P

ush the motor reset button located on the filter panel. Check

filtering procedure or clean tub and paper if needed.

6. Let swirling action rinse down fryer.

7. Fully drain fryer.

NOTE: Pump should be run for at least 30 seconds after

crumbs are removed from fryer. This will help prevent blockage

in the drain lines.

8. Close drain valve by pushing in the large black knob and

locking it into place and completely refill fryer. Refer to

Figure 6.

NOTE: The drain valve handle controls fryer’s Main Power

Switch. If drain valve is not fully closed and locked, fryer

will not operate. See Figure 6.

9. Turn pump switch to the “OFF” position. Close return valve

by pushing in the small black knob completely, after turning

OFF the pump switch (for units with more than one fryer or

central filter). See Figure 7.

D. CLEAN UP

FIGURE 6.

WARNING

Filter drawer and pipes will remain hot following filtration.

Allow the unit to cool down before clean up. Failure to do

so may result in serious injury to the operator.

See 1-4 on page 1.

Remove crumb basket.

5.

6. Push down on the 2 tension arms on the hold down ring,

rotate 90°, and remove.

7. Remove the used filter paper and discard.

8. Remove sump screen.

Throughly clean the entire filter tub and all components.

9.

NOTE: Tub and components are diswasher safe.

10. Prepare drawer for next use (see section A “Preparing the

Filter Drawer”).

NOTE: Instructions for cleaning the fryer are in the Operating

Section of the Fryer Service Manual.

E. DISCARDING THE OIL

NOTE:

be used to discard the oil ONLY. DO NOT use the filter

assembly to transport hot oil. DO NOT remove filter tub

containing hot oil!

1. Prepare the filter drawer (see section A).

NOTE: Acidox is

2. Prepare the oil (see section B).

3. Connect the hose to the right side of the filter assembly in

The 6 foot hose provided with the filters should

not needed when discarding the oil.

the front. See Figure 8.

Return valve (small

black knob) must

be pulled to open

when filtering and

pushed closed

when complete.

BATTERY OF 2 FRYERS WITH SAFE & EASY

FILTER. NOTE: ONLY 1 FRYER CAN BE

FIGURE 7.

TERED AT A TIME

FIL

– 3–

4. Push the small black knob on the filter panel to the left

(“Oil to Hose”).

5

. Place the nozzle of the hose in an approved discard

container.

6. Drain the oil.

7. Plug the filter into the receptacle.

8. Turn the motor switch ON (the green light will illuminate).

CAUTION

A KEATING FRYER OR FILTER SHOULD BE DRAINED

ONLY UNDER THE SUPERVISION OF PROPERLY

TRAINED PERSONNEL. WHEN DISCARDING OIL, A

COVERED RECEPTACLE APPROVED FOR USE WITH

HOT OIL SHOULD BE USED. USE OF A NON-APPROVED

RECEPTACLE OR METHOD OF DRAINING THE OIL

COULD JEOPARDIZE THE SAFETY OF THE OPERATOR.

NOTE: Keep the pump turned “ON” until bubbles occur

in the discard receptacle. Allow the pump to run an

additional 15 seconds to clear all pipes.

9. Turn the motor switch “OFF”.

Push the small black knob on the filter p

10.

right (“Oil to Fryer”).

11. Close drain valve of the fryer (large black knob).

Hose can be removed by pulling the handle on the left

12.

of the motor housing.

13. Prepare filter tub for next useage (see section A).

Clean excess oil from wand and quick disconnect on the

14.

hose.

anel to the

CAUTION

To avoid damaging the fryer, do not power wash, spray

or hose it down while cleaning it.

Pump must be primed with oil after boil-out with water.

Failure to lubricate pump may cause severe damage to Filter

System and void the warranty

.

Connect hose here to discard oil

FIGURE 8.

CAUTION

HOT FLU ID. DO NOT FILL

BEYOND MAXIMUM FILL LINE

LOCATED IN TH E FRYER VESSEL.

Do’s

1. Read and follow the filtering procedure.

Always verify

2.

when filtering.

• Quick disconnect under the tub to the

motor housing.

• Quick disconnect on top of the motor

housing to the fryer or central filter quick

disconnect.

3. Stir the oil completely before draining.

4. Place the sump screen under

5. Change the filter paper for each

2

connections are engaged

the filter paper.

fryer filtered.

Quick Hits

s

Don’t

1. Run water through the pump.

Filter oil without wearing the proper attire.

2.

Filter cold oil (must be between 250°- 350°).

3.

4. Use the 6 foot hose to clean the fry tank (hose

should only

5. Powerwash, spray, or hose down the motor

housing area, as electrical components are

present.

– 4–

be used to discard the oil).

SAFE & EASY®FILTER PARTS LIST

Front View

Motor & Pump Assembly

4

Motor & Pump Assembly

14

15

16

17

055173

OR

5A

6

Front View

052982

Description Part No.

1. Quick Connect Coupler 052573

ompression Fitting Straight

C

Female 011087

2. Caster Swivel 2" 054919

3

/8-16 Acorn Nut 011763

12

3

/8 Split Lockwasher 009085

3. Quick Connect Nipple Male 052572

4. Motor & Pump 052982

4A. Motor & Pump 055173

11

5. Three Way Valve 030792

5A. Valve Handle 053233

6. Knob Black 031532

10

7. Filter Tub Only 14" 053444

18" 053172

20" 053123

9

24" 054173

8. Sump Screen 14" 059279

18" 053195

20" 053128

24" 054331

9. Filter Paper SE 14" 058779

8

18" 058780

20" 058780

24" 058781

5

10. Hold Down Ring 14" 052227

18" 053200

20" 053133

24" 054315

11. Hold Down Ring Handle 052817

7

Spring 006656

Collar 000512

12. Crumb Basket 14" 052662

053197

053130

21

18"

20"

24" 054313

13. Hose Assembly 6' 054031

14. Quick Connect Handle 052647

15. ON/OFF switch (Not Shown) 015119

16. Quick Connect Handle to Hose

(Not Shown)

3

20

Acorn Nut 015159

053438

17. Quick Connect Handle 052613

For Replacement Tubing, please

18.

19

call Keating

19. Roller 000520

18

20.

Fitting

Fitting

5

/8

1

/2 ×3/8 HEX 013743

CC ×

1

/2

FPT

01

1837

21. Power Cord 055240

2

1

Recept

acle

055227

13

– 5–

Self-Help Guide

PROBLEM PROBABLE SOLUTION

CAUSE (Follow Sequentially)

Motor runs but will not

pump oil.

Tub not set up properly.

Tub not connected to the motor

housing properly

Place components in tub per the following:

1. Sump screen on the very bottom

. Filter paper over sump screen (Lie it flat

2

on the bottom, creasing the sides).

3. Hold down ring (ensure paper is not

folded, lock hold down ring into place

ensuring a tight seal).

4. Sprinkle Acidox powder evenly over filter

paper (1bag per 40 lbs. of oil).

5. Crumb basket for large debris.

1. Remove tub from the filter cart

completely by pulling the release handle

located on the bottom of the filter control

panel.

2. Place the tub onto the filter cart by first

inserting the rear lip under the filter cart

frame and then laying down the front of

the tub flat onto the cart.

3. Connect the tub to the motor housing by

pulling together the handles on the tub

and the handles on the motor housing

(NOTE: Verify tight connection by pushing

back on the tub).

Filter not connected inside of

cabinet

alve not switched to “Oil to Fryer”

V

If there’s more than one fryer,

return valve not open.

1. Ensure filter assembly is rolled straight

onto the rails inside of the cabinet.

2. Push filter assembly back as far as

possible

3. Ensure quick disconnect fitting on top of

filter connects automatically with quick

connect fitting inside of cabinet.

4. Pull on filter lightly to ensure a tight

connection

1. Set the black knob in the middle of the

filter control panel to the far right.

2. Try to filter again.

1. Open the door of the fryer you wish to

filter.

2. Pull the return valve handle (small black

knob) out as far as possible.

3. Attempt to filter again. When completed,

push the black knob in as far as possible

to close.

– 6–

Self-Help Guide (Continued)

PROBLEM PROBABLE SOLUTION

CAUSE (Follow Sequentially)

Motor runs but will not

pump oil.

Motor not making any

noise

Oil not pumping through

the hose

Oil has not penetrated the filter

paper

Not plugged in

Motor has overheated

Valve not switched to “Oil to Hose”

1. Let oil sit in the filter pan for

approximately 2 minutes and try again

1. Plug filter into the receptacle inside of

cabinet

2. Turn ON/OFF switch to ‘ON’.

1. Allow motor to cool for approximately 10

minutes.

2. Press the reset button near the ON/OFF

switch on the filter control panel and try

again.

1. Set the black knob in the middle of the

filter control panel to the far left.

PREVENTIVE MAINTENANCE: Familiarize yourself with the proper filtering procedure prior to

attempting to filter

1. To remove water, stir oil until bubbling stops; water will clog filter paper pores.

2. V

erify all connections, especially quick disconnects (under tub and inside fryer or CF cabinet) are

tight; not leaking oil or sucking air.

3. Use only one sheet of filter paper properly sealed under hold down ring.

4. Use a drain clean out rod if p

artial or full blockage in fryer drain is suspected.

5. If filter was used for fryer boil out, run oil through filter to lubricate motor/pump.

6. Clean filter and all components after each use. Do not permit oil to remain in filter drawer; it will clog

the pump.

7. Verify all lights and controls operate.

8. Adhere to operating instructions in sequence given for proper filtration.

9. Prep

are filter for next use by using new filter paper and Acidox Powder for each fryer.

– 7–

WIRING DIAGRAM

NOTE: Use this diagram with motor/pump

part # 052982 (See parts list)

NOTE: Use this diagram with motor/pump

part # 055173 (See parts list)

If you have any questions regarding filtering

procedures or need assist

1-800-KEATING.

ance, call:

– 8–

est 50th Street, McCook, Illinois 60525-6001

W

8901

oll Free 1-800-KEA

T

KEATING OF CHICAGO, INC.

Tel. 708-246-3000 • Fax 708-246-3100

TING (In U.S. and Canada)

www.keatingofchicago.com

Safe N Easy Filter 0107

9/07

REFILE/warranty 8/07

, Custom Pasta Systems, Top-Side™ Cookers, Computer Timers, Fryer &

®

.COM

TINGOFCHICAGO

KEA

duct or part be shipped to Keating for repair or replacement, as appropriate. Any defective part subject to a

WWW.

WARRANTY

EXCLUSIONS

LIMITED WARRANTY

& PASTA VESSEL WARRANTY

LENGTH OF WARRANTY

FRYER

61-72 months 80%

73-84 months 60%

85-96 months 40%

13-60 months 100%

97-108 months 20%

Time from Installation Date Fryer Vessel Warranty Credit

LIMITATIONS OF LIABILITY

OTHER TERMS AND CONDITIONS

109-120 months 10%

ime, Monday through Friday). When calling, please have the following information available: (1) name, address and

O SECURE WARRANTY SERVICE

T

duct, if different; (3) name, model number and serial number of the product; (4) installation date; and (5) description of defect. Keating will then issue a service

arranty must be authorized by Keating or performed at Keating. Authorization may be obtained by calling 1-800-KEATING within the Continental United States, Alaska, Hawaii,

TING

KEATING

NC., 1-800-KEA

, I

CHICAGO

OF

TING

EA

K

arranty must be shipped freight prepaid to Keating for testing and examination. Keating's decision as to the cause and nature of any defect under this Limited Warranty shall be final.

days from the date of installation. Fryer & Pasta Vessels are warranted as described below.

Pasta Vessels, and Keating replacement parts ("products") installed after June 1, 1994 to be free to defects in material or workmanship, subject to the following terms and conditions.

Keating Of Chicago, Inc. ("Keating”) warrants to the original purchaser. ("Customer"), all new Keating Fryers, Filter Systems, Griddles, Keep Krisp

All products other than Fryer & Pasta Vessels and replacement parts shall be warranted for a period of one year from the date of original equipment installation. Keating replacement parts are warranted for a period of ninety

Fryers purchased after June 1, 1994 carry a prorated vessel warranty on defects in materials or workmanship to the Customer based on the following scale:

The credit for the defective fryer & pasta vessel shall be applied against the cost of the replacement vessel, utilizing Keating's then current price, upon return of the vessel to Keating, (Freight to be paid by Keating within

the first 2 months only), only during the first 60 months as described above, subject to the limitations described below.

hour, labor costs of more than one person, overtime rates, truck charges, difference between ground and other mode of transportation, and holiday charges. Any repair or replacement under this Limited Warranty does not

at the expense of Keating except that the Customer shall pay the following expenses: all freight and labor expense for Keating replacement parts for all other products, mileage exceeding 50 miles or travel more than one

In the event of warranty claim or otherwise, the sole obligation of Keating shall be the repair and/or replacement at the option of Keating of the product or component or part thereof. Such repair or replacement shall be

constitute an extension of the original warranty for any period for the product or for any component or part thereof. Parts to be replaced under this Limited Warranty will be repaired at the option of Keating with new or

THE LIABILITY OF KEATING ON ANY CLAIM OF ANY KIND, INCLUDING CLAIMS BASED ON WARRANTY, EXPRESSED OR IMPLIED, CONTRACT, NEGLIGENCE, STRICT LIABILITY OR ANY

functionally operative parts. Keep Krisps and Computer Timers must be returned to Keating for warranty repair or replacement. Field repairs of those items are not authorized.

SPECIFICALLY RENOUNCES ANY RIGHTS TO RECOVER, SPECIAL, INCIDENTAL, CONSEQUENTIAL OR OTHER INJURIES TO PERSONS OR DAMAGE TO PROPERTY, LOSS OF PROFITS OR

OTHER THEORIES SHALL BE SOLELY AND EXCLUSIVELY THE REPAIR OR REPLACEMENT OF THE PRODUCT AS STATED HEREIN, AND SUCH LIABILITY SHALL NOT INCLUDE, AND CUSTOMER

ANTICIPATED PROFITS, OR LOSS OF USE OF THE PRODUCT.

WARRANTY OF MERCHANTABILITY OR FITNESS FOR PARTICULAR PURPOSE OR WARRANTY AGAINST LATENT DEFECTS.

THIS LIMITED WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ALL OTHER WARRANTIES WHETHER WRITTEN, ORAL, STATUTORY OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY

statement with regard to warranties.

If any oral statements have been made regarding the Keating products, such statements do not constitute warranties and are not part of the contract sale. This Limited Warranty constitutes the complete, final and exclusive

workmanship. Proper installation and maintenance are the responsibility of the installer and Customer, respectively. Proper installation and maintenance procedures are prescribed by the Keating Service Manual.

The warranties provided by Keating of Chicago, Inc. do not apply in the following instances:

1. Defects arising out of or resulting from improper installation or maintenance, abuse, misuse, modification or alteration by unauthorized service personnel, or any other condition not attributable to a defect in material or

2. In the event that the product was damaged after leaving the factory due to flood, fire, other acts of God or accident, damage during shipment should be reported to the carrier and is not the responsibility of Keating.

calibrations are the responsibility of the installer. Proper installation procedures are prescribed by the Keating Service Manual.

4. On parts which would normally be worn or replaced under normal conditions, including but not limited to electric bulbs, fuses, interior and exterior finishes, gaskets and radiants.

6. In the event of unauthorized repairs or alterations to the Keating product.

5. With regard to adjustments and calibrations such as leveling, tightening of fasteners or plumbing connections, improper gas pressure or improper electrical supply, the checking of and changes in adjustment and

3. In the event the serial number or rating plate has been removed from the product or altered.

This Limited Warranty is valid in the 50 United States, its territories, and Canada, and is void elsewhere.

Keating products are sold for commercial use only. If any Keating product is sold as a component of another product or used as a consumer product, such Keating product is sold As Is without any warranty.

The Customer must provide proof of purchase from Keating.

7. With the use of sodium chloride in pasta vessels or harsh chemicals in fryer or pasta vessels.

If any provision of this Limited Warranty is held to be unenforceable under the law of any jurisdiction, such provision shall be inapplicable in such jurisdiction, and the remainder of the warranty shall remain unaffected.

Further in such event, the maximum exclusion or limitation allowable under applicable law shall be deemed substituted for the unenforceable provision.

This Limited Warranty shall be governed by and construed in accordance with the laws of the State of Illinois.

Puerto Rico and Canada during normal business hours (7:00 a.m. through 6:00 p.m. Central T

telephone number of the Customer; (2) location of pro

All repair services under this Limited W

authorization work order number to one of its approved independent servicing organizations, or request the pro

claim under this Limited W

SERVICE INFORMATION

If you have a service related question call 1-800-KEATING.

Please state the nature of the call; it will ensure speaking with the appropriate person.

Have your serial and model number available when ordering parts.

KEATING OF CHICAGO, INC.

8901 West 50th Street, McCook, Illinois 60525-6001

Phone: (708) 246-3000 FAX: (708) 246-3100

Toll Free 1-800-KEATING (In U.S. and Canada)

www.keatingofchicago.com

*As continuous product improvement occurs, specifications may be changed without notice.

KEATING LIMITED WARRANTY CARD

PLEASE COMPLETE AND MAIL AT ONCE–WARRANTY IS NOT IN EFFECT UNTIL CARD IS RETU RNED

COMPANY: __________________________________________________________________________________________________________________________

ADDRESS: __________________________________________________________________________________________________________________________

CITY: ______________________________________________________________________________ STATE: ________________ ZIP: ____________________

DEALER: ____________________________________________________________________________________________________________________________

DATE OF PURCHASE: ________________________________________________________________ INVOICE NUMB ER: ____________________________

SERIAL NUMBER:________________________________________ q FRYER q FILTER SYSTEM q GRIDDLE

REMARKS: ______________________________________________ q TOP-SIDE COOKER q HOT PLATE q PASTA PLUS

I HAVE READ THE INSTALLATION AND OPERATION INSTRUCTIONS.

SIGN ED: __________________________________________________________________________________ DATE: __________________________________

Loading...

Loading...