www.keatingofchicago.com 1-800-KEATING

SERVICE INSTRUCTIONS

FLAME MASTER® LO-TEMP GRIDDLE CONTROL

LIGHTING INSTRUCTIONS

1. Be sure temperature dial is in “OFF” position.

2. Turn “ON” main gas supply to appliance.

3. With SELECT-A- GAS PILOT ADJUSTOR in

“open” position, (turn ADJUSTOR full clockwise

for natural gas or full counter clockwise for LP

gas) “LIGHT” standby pilot. (See Figure 2).

4. To light GRIDDLE BURNER–turn temperature

dial counterclockwise to desired temperature

setting.

GRIDDLE BURNER WILL IGNITE ABOUT 45

SECONDS AFTER DIAL IS TURNED TO

DESIRE TEMPERATURE SETTING.

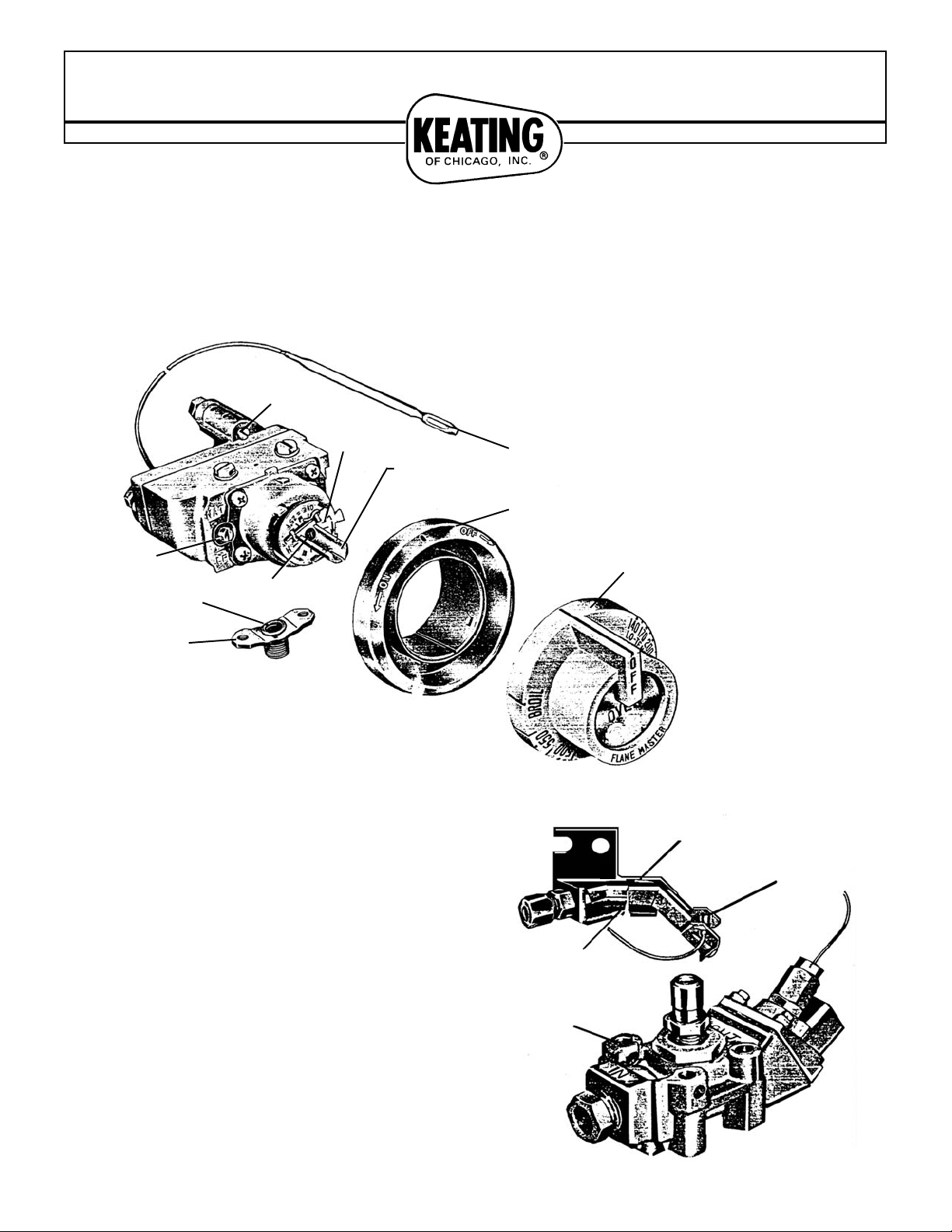

Model UA Flame Master® consists of a gas griddle control and automatic shut-off valve with No. 70

pilot burner, Temperature range–”BROIL” down to 140°F.

70

“LIGHT”

(STANDBY PILOT)

TEMPERATURE

RESPONSIVE

BULB

FIGURE 2

No. 70

PILOT BURNER

MSC SHUT-OFF

VALV E

TOP BURNER

PILOT ADJUSTOR

CALIBRATION

PLATE AND MARKS

“D”STEM

(SHOWN AT APPROX.

450 DIAL SETTING)

BEZEL

GRIDDLE TEMPERATURE

FIGURE 1

TEMPERATURE

DIAL

SELECT-A-GAS

PILOT ADJUSTOR

CALIBRATION

SCREW

GASKET

INLET FITTING

MOUNTING FLANGE

Lotempoc

4-96

ADJUSTMENTS:

SELECT-A-GAS PILOT ADJUSTOR

Under NORMAL GAS PRESSURES, the standby and heater pilot flames

do not require adjustment. Simply remove dial assembly and bezel, then

turn the SELECT-A-GAS ADJUSTOR to the proper gas position, making

sure standby pilot is ignited.

Note: Clockwise to full stop for natural gas and counterclockwise to full

stop for LP-gas. “OFF” is midway between NAT and LP positions.

Where ABNORMAL GAS PRESSURES exist, variable pilot adjustments

can be made for STANDBY PILOT on NATURAL gas and for HEATER

PILOT ON LP-gas. It is not necessary to reduce BOTH pilot flames on

either type of gas.

FOR NATURAL gas, turn adjustor approximately halfway between full open

(NAT) and “OFF”. This lowers STANDBY pilot flame which should

not extend higher than mounting holes of pilot bracket (See Figure 3).

FOR LP-gas, turn adjustor approximately halfway between full open (LP)

and “OFF”. This lowers HEATER pilot flame. The size of HEATER pilot

flame should be checked and adjusted, when griddle is “cold”. If

adjustment is necessary, adjust flame to that it surrounds “temperature

responsive bulb” (See Figure 2).

TOP BURNER PILOT ADJUSTMENT

(See Figure 1) Controls equipped with filtered top burner pilots are

adjusted by one adjustment screw as follows:

Turn adjustor clockwise to lower the top burner

pilot flame or counterclockwise to increase the flame.

TO RECALIBRATE GRIDDLE CONTROL

To check griddle temperatures when recalibrating, use a test instrument or

equivalent. Place the thermocouple of test instrument in the middle of the

griddle.

All AUTOMATIC FLAME MASTER griddle controls are carefully calibrated

at the factory (i.e.: The dial is properly set to control griddle

temperatures accurately). It is recommended that only a qualified service

man perform this adjustment because calibration should not be changed

until sufficient experience with cooking results has definitely proved that

the control is not maintaining proper griddle temperatures.

1. Light griddle burner and turn dial to 350 mark.

2. Allow griddle to heat about 15 to 20 minutes.

NOTE: The griddle burner will snap at full burner rate “ON” “OFF” at all dial

settings up to 575 mark. No by-pass flame or by-pass adjustment is

needed.

3. After griddle burner has been on approximately 15 to 20 minutes, wait

and watch for the griddle burner to snap “off” and “on” then check griddle

temperature.

The griddle control should be recalibrated if a temperature variation from

350 degrees (dial setting) is greater than 25 degrees. If recalibration is

required, make the following adjustment.

4. Carefully remove dial assembly and bezel, by pulling straight out,

making sure “D” stem does not rotate in either direction which would

change the dial setting.

5. Insert a screwdriver through center of the “D” stem and engage

calibration adjustment screw. Using the screwdriver bit as a reference

point, turn calibration screw clockwise to obtain a lower temperature or

counterclockwise for a higher temperature. Each calibration mark on front

of calibration plate, represents 25°F. Be careful that “D” stem does not

move during this adjustment.

The griddle temperature should now increase or decrease, as required, to

agree with the 350 degree dial setting.

Example:–Dial Setting 350

Test Instrument reading 300° Fah.

The griddle control is 50° too low. Turn calibration screw counterclockwise two marks.

6. Replace bezel and dial, turning dial clockwise to “OFF”.

7. Recheck calibration by repeating step 1 except set dial at 350

mark. Check griddle temperature again as instructed in steps 2 and 3.

If the griddle temperature is not within 25 degrees of the dial setting

(350 degrees), it means that the sensing element is defective and the

griddle control should be replaced.

8. Turn dial clockwise to OFF position.

ALTERNATE CALIBRATION:

To insure “D” stem not moving while making calibration adjustment,

turn dial to “OFF” before proceeding with step 4 and 5. Replace bezel

and dial to “OFF” position then recheck calibration beginning with

Step 1.

www.keatingofchicago.com 1-800-KEATING

SERVICE INSTRUCTIONS

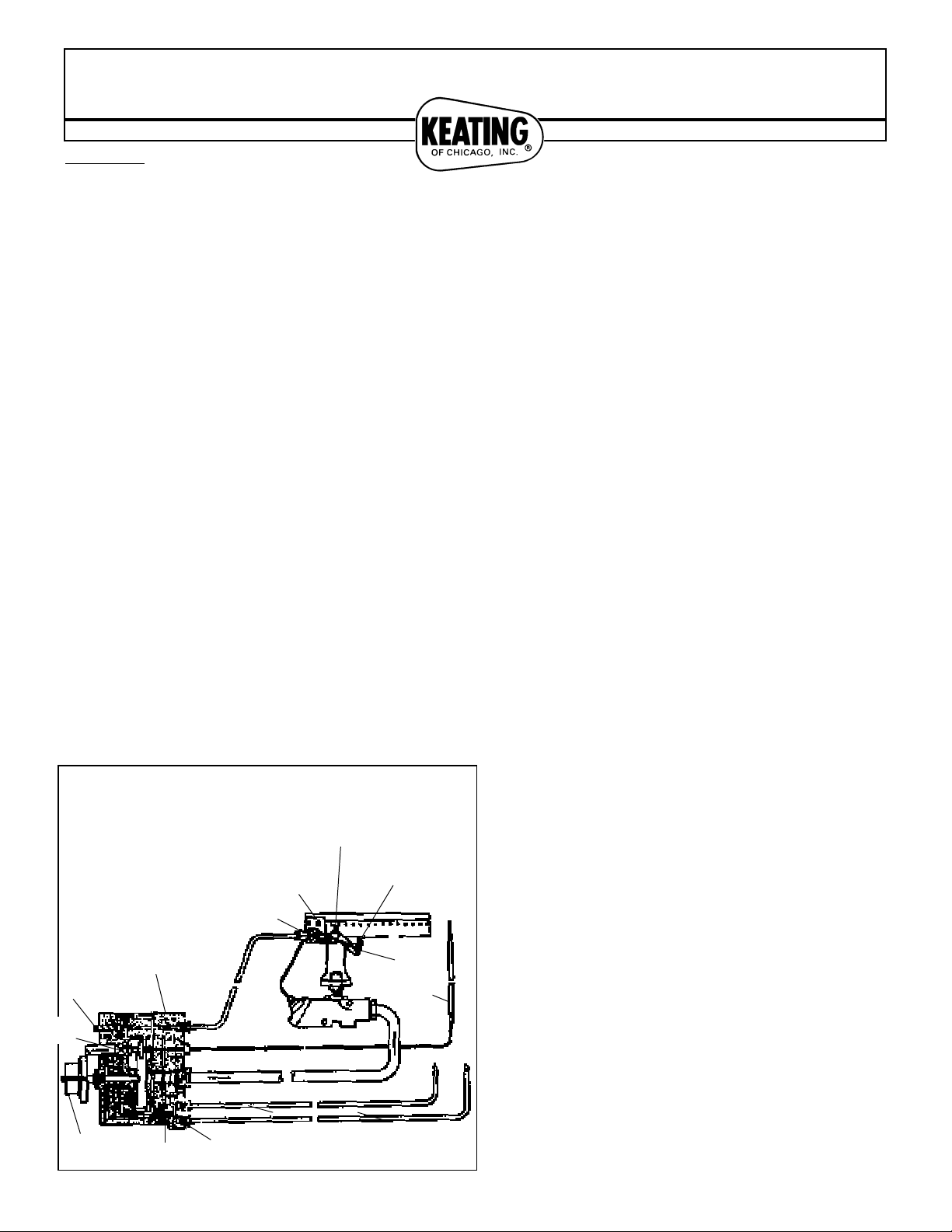

*NOTE:

STANDBY PILOT FLAME

SHOULD NOT EXTEND

HIGHER THAN MOUNTING

HOLE IN PILOT BRACKET.

PILOT BRACKET

NO. 70

SINGLE TUBE

PILOT BURNER

UA TYPE CONTROL

SELECT-A-GAS

PILOT ADJUSTOR

INTEGRAL

GAS COCK

TEMPERATURE

DIAL

FILTER

TOP BURNER

PILOT ADJUSTOR

FIGURE 3

TOP BURNER PILOTS

MISC SHUT-OFF VALVE

GRIDDLE

TEMPERATURE

SENSING

BULB

TEMPERATURE

RESPONSIVE

BULB

GRIDDLE BURN-

HEATER

PILOT FLAME

*STANDBY

PILOT FLAME

continued

Lotempoc

4-96

Loading...

Loading...