Page 1

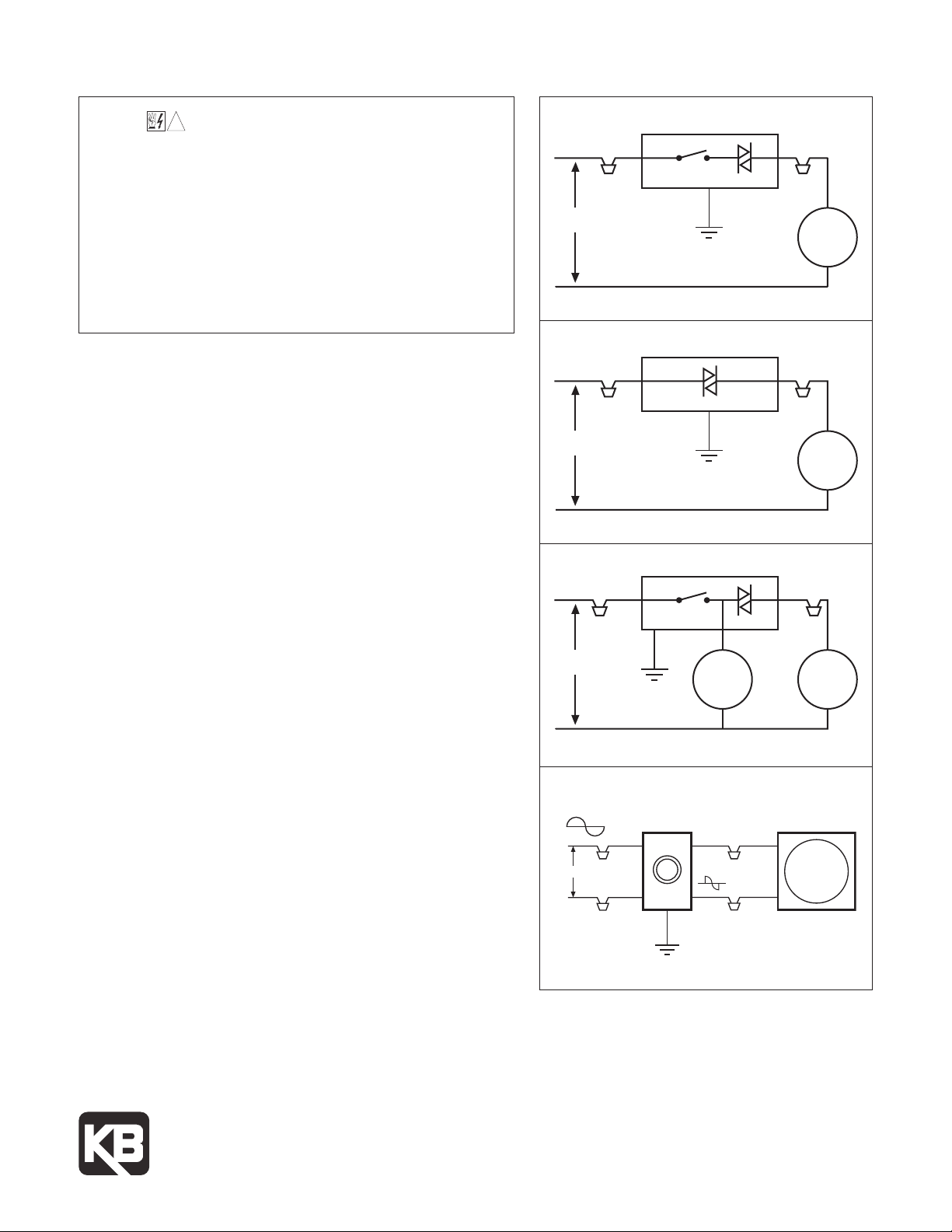

Connection Diagram for 2-Wire* Controls (Switch Models)

Triac

S

witch

A

C Line

L

1

L

2

Ground (Earth)**

Green

Motor

Connection Diagram 2-Wire* Controls for No Switch Model (NS)

A

C Line

L1

L2

Green

Triac

Motor

Ground (Earth)**

Connection Diagram for 3-Wire* Controls (Switch Models)

Triac

Switch

Black

Blue***

AC Line

Auxiliary

Load

L1

L2

Ground (Earth)**

*** Wire may be white in some applications

Green

Red

Motor

Black

Full Voltage

Motor

Red

Red

L2

L1

Black

Variable

Voltage

240 Volt

Connection Diagram for 4-Wire* Controls

Ground (Earth)**

Green

INSTRUCTIONS FOR INSTALLING WALL-MOUNT SPEED CONTROL

!

Safety Warning! Please Read Carefully

nit should be installed by a qualified electrician in accordance with the National

U

lectrical Code and other local codes which may apply. This control must be

E

rounded when installed. Failure to follow these instructions may result in elec-

g

trical shock or a fire hazard. To reduce the risk of fire or electric shock, this con-

trol is to be used only with fans marked as suitable for use with solid state

speed controls. This control is suitable for mounting in a metal or polymeric field

enclosure. These controls must not be used at ratings exceeding those clearly

marked on the device.

We are not responsible for any expense, inconvenience or subsequent damage

aused by items of our manufacture or sale.

c

1 Application

) Motor Type – Shaded Pole, P.S.C., and Universal.

a

) Required Load – Fans, Blowers and Speed Dependent Loads.

b

2 Wiring

arning! Power must be turned off before wiring. Connect control in series with

W

otor and line voltage; never connect control across line.

m

Ground (Earth)** – Be sure to ground control using the green wire.

**Some models do not require grounding, therefore, a ground wire is not provided.

3 Mounting

a) Use 2” deep standard electrical box.

b) Secure control with outer bracket tabs.

4 Minimum Speed Adjustment

Important: If this option is not supplied, disregard Step 4 and continue to Step 5.

This control was designed to operate on motors used in diverse applications.

A minimum speed adjustment is provided to allow independent control of the

minimum speed setting. Minimum speed adjustment ensures motor runs with

sufficient torque to prevent stalling.

a) Motor must be in actual operating condition to achieve proper speed adjust-

ment. Motor will not slow down unless proper load is applied.

b) Turn main control knob to lowest speed position.

c) Locate and adjust minimum speed setting on front plate with screw driver

(rotate clockwise to decrease minimum speed; counter-clockwise to increase

minimum speed).

Special Note: For 2.5 and 3.0 Amp models, adjustment of minimum speed is

reversed. Rotate clockwise to increase minimum speed; counter-clockwise to

decrease minimum speed.

On some models minimum speed adjustment hole is located on side of control.

d) Motor will now operate from this preset minimum speed to full speed.

5 Final Mounting

a) Install front dial plate (remove protective plastic on face of dial plate).

b) Turn main control until switch snaps off. (Switch models only).

c) Push on knob so that pointer is in “off” position.

KB Electronics, Inc.

12095 NW 39th Street, Coral Springs, FL 33065 • (954) 346-4900 • Fax (954) 346-3377

Outside Florida Call TOLL FREE (800) 221-6570 • email – info@kbelectronics.com

www.kbelectronics.com

* Ground wire is not counted when designating 2,3 or 4 wire controls.

** Be sure to ground control using the green wire. Some models

do not require grounding, therefore, a ground wire is not provided.

*** Wire may be white in some applications.

(A40001) – Rev. F – 6/1/2011

Loading...

Loading...