KB Electronics KBAC-217F, KBAC-48, KBAC-217SF, KBAC-416, KBAC-27D Installation And Operation Manual

...Page 1

INSTALLATION AND OPERATION MANUAL

–

KBAC SERIES

Adjustable Frequency Drive for 3-Phase AC Motors

NEMA 4X / IP65

Variable Speed / Soft-Start AC Motor Drive

With Electronic Motor Overload Protection

Washdown and Watertight for Indoor and Outdoor Use

Rated for 208 – 230 and 400/460 Volt 50 Hz and 60 Hz

3-Phase and PSC

Operates from 115, 208/230, and 400/460 Volt 50/60 Hz AC Line Input3

2

AC Induction Motors from Subfractional thru 10 HP

1

NOTE: The drive is factory set for

60 Hz motors. For 50 Hz motors,

see Section 10.4 on page 19.

KBAC-24D, 27D, 29, 29 (1P), 45, 48, 217, 217S, 217F, 217SF, 416, 416S, 416F, 416SF

The information contained in this manual is intended to be accurate.

However, the manufacturer retains the right to make changes in design which may not be included herein.

Notes: 1. UL approved as an electronic overload protector for motors. 2. Special software is available for PSC

motors – contact Technical Support. 3. Third Generation (3G) drives are jumper selectable (J12) for standard and sensitive

GFCIs. 4. Installation of a CE approved RFI (EMI) filter is required. 5. Third Generation (3G) drives KBAC-24D, 27D, 29,

29 (1P), 45, 48 are marked "(3G)" on the product label.

Copyright © 2017 KB Electronics, Inc.

(See Back Cover)

See Safety Warnings on page 5.

This Manual Covers 2G and 3G Models

All KBAC-217, 416 Series drives are Third Generation (3G).

3,5

LISTED

IND. CONT.

EQ.

70ZA

4

RoHS

Scan this QR Code

to View, Download,

or Print

the Online Manual

Page 2

TABLE OF CONTENTS

Section Page

1 Quick-Start Instructions .................................................................................................................................................................................... 4

1.1 Mounting Instructions .............................................................................................................................................................................. 4

1.2 AC Line Input Fusing .............................................................................................................................................................................. 4

1.3 AC Line Input Connection ....................................................................................................................................................................... 4

1.4 Motor Connection .................................................................................................................................................................................... 4

1.5 Ground Connection ................................................................................................................................................................................. 4

1.6 60 Hz and 50 Hz Motor Operation .......................................................................................................................................................... 4

1.7 Start/Stop Switch .................................................................................................................................................................................... 4

1.8 Jumper Settings ...................................................................................................................................................................................... 4

1.9 Trimpot Adjustments ............................................................................................................................................................................... 4

1.10 Diagnostic LEDs ..................................................................................................................................................................................... 4

2 Safety Warnings ............................................................................................................................................................................................... 5

3 Important Application Information ..................................................................................................................................................................... 5

3.1 Motor with External Fan Cooling ............................................................................................................................................................. 5

3.2 Electronic Motor Overload Protection ..................................................................................................................................................... 5

4 Introduction ....................................................................................................................................................................................................... 6

4.1 Standard Features .................................................................................................................................................................................. 6

4.2 Performance Features ............................................................................................................................................................................ 6

4.3 Protection Features................................................................................................................................................................................. 6

5 Mounting ......................................................................................................................................................................................................... 12

6 AC Line Input Fusing ...................................................................................................................................................................................... 15

7 Electrical Connections .................................................................................................................................................................................... 15

7.1 AC Line Input Connection ..................................................................................................................................................................... 15

7.2 Motor Connection .................................................................................................................................................................................. 16

7.3 Ground Connection ............................................................................................................................................................................... 16

7.4 Remote Main Speed Potentiometer Connection .................................................................................................................................. 16

7.5 Remote Start/Stop Switch Connections ................................................................................................................................................ 17

7.6 Automatic Restart ................................................................................................................................................................................. 17

7.7 Voltage Following Connections............................................................................................................................................................. 17

7.8 Enable Circuit Connection .................................................................................................................................................................... 17

7.9 Run/Fault Relay Connection ................................................................................................................................................................. 18

8 Recommended High Voltage Dielectric Withstand Testing (Hi-Pot Testing) .................................................................................................. 18

9 Reconditioning the Bus Capacitors ................................................................................................................................................................ 18

10 Setting Selectable Jumpers ............................................................................................................................................................................ 19

10.1 AC Line Input Voltage Selection (KBAC-24D, 27D Only) (J1) .............................................................................................................. 19

10.2 Motor Horsepower Selection (J2) ......................................................................................................................................................... 19

10.3 Automatic Ride-Through or Manual Start Selection (J3) ...................................................................................................................... 19

10.4 Motor Frequency Selection (J4 and J5) ................................................................................................................................................ 19

10.4.1 Setting the Drive for 50 Hz or 60 Hz Motor Operation (J4 and J5) .......................................................................................... 19

10.4.2 Setting the Drive for Two Times the Rated Motor RPM (J4 and J5) ........................................................................................ 19

10.5 Boost Mode Selection (J6) .................................................................................................................................................................... 20

10.6 Braking Mode Selection (J7) ................................................................................................................................................................. 20

10.7 Run/Fault Output Relay Operation Selection (J8) ................................................................................................................................ 20

10.8 Stop Contact Type Selection (J9) ......................................................................................................................................................... 20

10.9 Torque Mode Selection (J10) ............................................................................................................................................................... 20

10.10 Jumper J11 (Factory Use Only) ............................................................................................................................................................ 20

10.11 Switching Frequency and GFCI Selection (Third Generation (3G) Drives Only) (J12) ......................................................................... 20

11 Drive Operation .............................................................................................................................................................................................. 20

11.1 Start-Up Procedure ............................................................................................................................................................................... 20

11.2 Restarting the Drive After a Fault Has Cleared .................................................................................................................................... 21

12 Trimpot Adjustments ..........................................................................................................

12.1 Minimum Speed Trimpot (MIN) ............................................................................................................................................................. 21

12.2 Maximum Speed Trimpot (MAX)........................................................................................................................................................... 21

12.3 Acceleration Trimpot (ACCEL).............................................................................................................................................................. 21

12.4 Deceleration Trimpot (DECEL) ............................................................................................................................................................. 21

12.5 DC Injection Brake Trimpot (DECEL) ................................................................................................................................................... 21

12.6 Slip Compensation Trimpot (COMP) .................................................................................................................................................... 22

12.7 Motor Overload (I

12.8 Boost Trimpot (BOOST) ........................................................................................................................................................................ 22

12.9 Jog Trimpot (JOG) ................................................................................................................................................................................ 22

13 Diagnostic LEDs ............................................................................................................................................................................................. 23

13.1 Power On LED (PWR) .......................................................................................................................................................................... 23

13.3 Status LED (ST) .................................................................................................................................................................................... 23

14 Optional Accessories ...................................................................................................................................................................................... 23

Limited Warranty .................................................................................................................................................................................. Back Cover

2

t) with RMS Current Limit Trimpot (CL) ................................................................................................................... 22

............................................................................. 21

Table Page

1 Drive Model No., Part No., and Case Reference Size ...................................................................................................................................... 3

2 Electrical Ratings .............................................................................................................................................................................................. 7

3 General Performance Specifications ................................................................................................................................................................ 7

4 Terminal Block Wire Size and Tightening Torque Specifications ................................................................................................................... 15

5 Drive Operating Condition and Run/Fault Relay Contact Status .................................................................................................................... 18

6 Drive Operating Condition and Status LED Indicator ..................................................................................................................................... 23

7 Optional Accessories ...................................................................................................................................................................................... 23

2

KBAC SERIES INSTALLATION AND OPERATION MANUAL

Page 3

TABLE OF CONTENTS (CONTINUED)

Figure Page

1 General Connection Diagram ........................................................................................................................................................................... 4

2 Maximum Allowed Motor Torque vs. Speed ..................................................................................................................................................... 5

3 Open Ventilated Motor with External Fan Cooling ............................................................................................................................................ 5

4 KBAC-24D Drive Layout ................................................................................................................................................................................... 8

5 KBAC-27D Drive Layout ................................................................................................................................................................................... 9

6 KBAC-29, 29 (1P), 45, 48 Drive Layout .......................................................................................................................................................... 10

7 KBAC-217, 217S, 217F, 217SF, 416, 416S, 416F, 416SF Drive Layout ....................................................................................................... 11

8 KBAC-24D Mechanical Specifications ............................................................................................................................................................ 12

9 KBAC-27D, 29, 29 (1P), 45, 48 Mechanical Specifications ............................................................................................................................ 13

10 KBAC-217, 217S, 217F, 217SF, 416, 416S, 416F, 416SF Mechanical Specifications .................................................................................. 14

11 KBAC-24D, 27D, 29 (1P) AC Line Input, Motor, and Ground Connections.................................................................................................... 15

12 KBAC-29, 45, 48 AC Line Input, Motor, and Ground Connections................................................................................................................. 16

13 KBAC-217, 217S, 217F, 217SF, 416, 416S, 416F, 416SF AC Line Input, Motor, and Ground Connections ................................................ 16

14 Remote Main Speed Potentiometer Connection ............................................................................................................................................ 16

15 Remote Start/Stop Switch Connection with Normally Open Stop Contact ..................................................................................................... 17

16 Remote Start/Stop Switch Connection with Normally Closed Stop Contact ................................................................................................... 17

17 Start/Stop Function Eliminated ....................................................................................................................................................................... 17

18 Voltage Following Connections ...................................................................................................................................................................... 17

19 Enable Circuit Connection .............................................................................................................................................................................. 17

20 Run/Fault Relay Output Contacts Connection ................................................................................................................................................ 18

21 Typical Hi-Pot Test Setup ............................................................................................................................................................................... 18

22 AC Line Input Voltage Selection (KBAC-24D, 27D Only) (J1) ........................................................................................................................ 19

23 Motor Horsepower Selection (J2) ................................................................................................................................................................... 19

24 Automatic Ride-Through or Manual Start Selection (J3) ................................................................................................................................ 19

25 Available Torque vs. Output Frequency ......................................................................................................................................................... 19

26 Motor Frequency Selection (J4 and J5) .......................................................................................................................................................... 19

27 Boost Mode Selection (J6) ............................................................................................................................................................................. 20

28 Braking Mode Selection (J7) .......................................................................................................................................................................... 20

29 Run/Fault Output Relay Operation Selection (J8) .......................................................................................................................................... 20

30 Stop Contact Type Selection (J9) ................................................................................................................................................................... 20

31 Torque Mode Selection (J10) ......................................................................................................................................................................... 20

32 Switching Frequency and GFCI Selection (Third Generation (3G) Drives Only) (J12) .................................................................................. 20

33 Minimum Speed Trimpot (MIN) Range ........................................................................................................................................................... 21

34 Maximum Speed Trimpot (MAX) Range ......................................................................................................................................................... 21

35 Acceleration Trimpot (ACCEL) Range ............................................................................................................................................................ 21

36 Deceleration Trimpot (DECEL) Range ........................................................................................................................................................... 21

37 DC Injection Brake Trimpot (DECEL) Range ................................................................................................................................................. 21

38 Slip Compensation Trimpot (COMP) Range .................................................................................................................................................. 22

39 Current Limit Trimpot (CL) Range .................................................................................................................................................................. 22

2

t Trip Time vs. Motor Current ....................................................................................................................................................................... 22

40 I

41 Boost Trimpot (BOOST) Range ...................................................................................................................................................................... 22

42 Jog Trimpot (JOG) Range .............................................................................................................................................................................. 22

43 Run-Stop-Jog Switch Connection ................................................................................................................................................................... 22

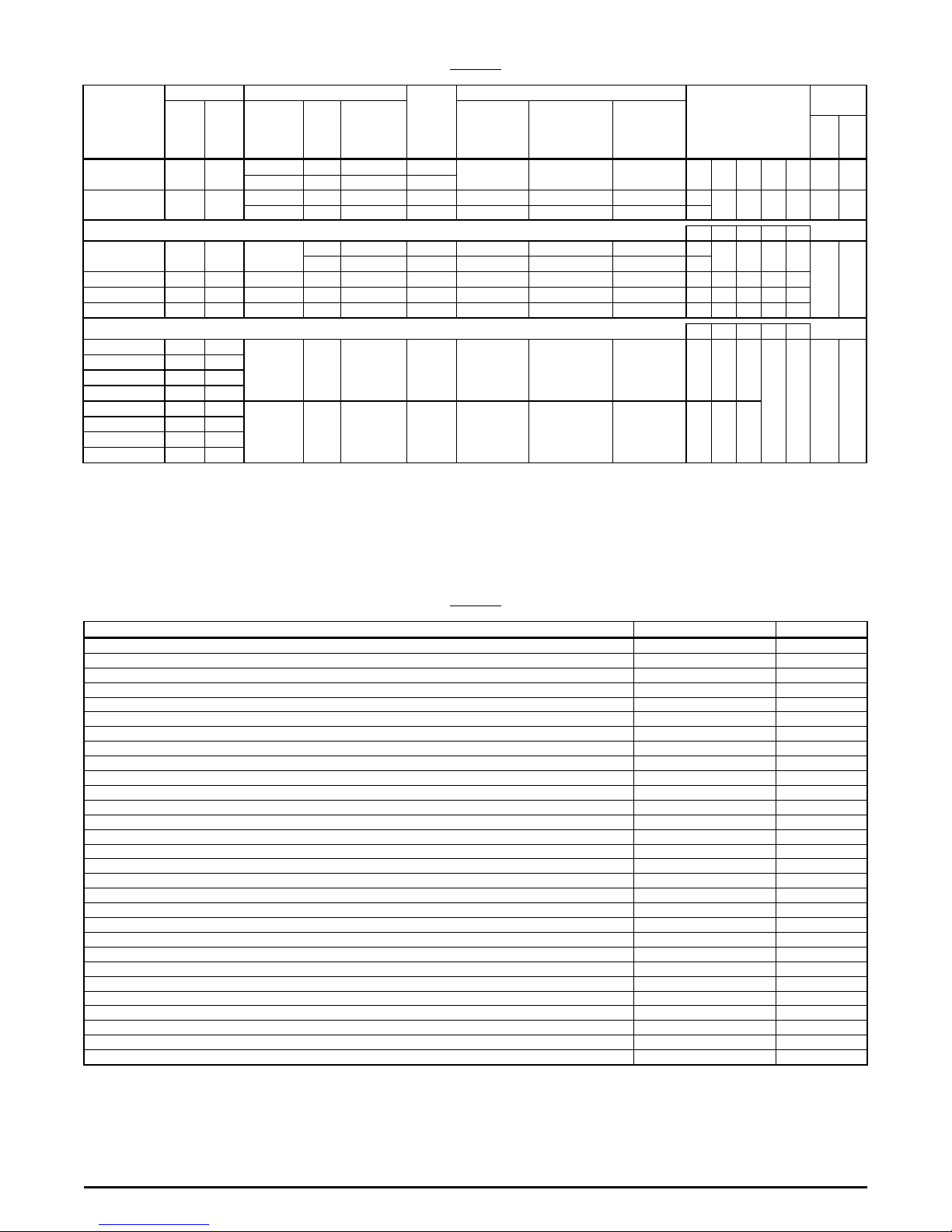

TABLE 1

DRIVE MODEL NO., PART NO., AND CASE REFERENCE SIZE

Model No.

Gray Case

(2G and 3G

Part No.

2

)

(2G and 3G

White Case

1

2

Case

Reference

) Gray Case White Case1

Size Model No.

3

Part No.

Case

Reference

Size

KBAC-24D 9987 9988 A KBAC-217 8868 8879 C

KBAC-27D 9520 9521 B KBAC-217S 8863 8855 C

KBAC-29 9528 9529 B KBAC-217F 8861 8853 C

KBAC-29 (1P) 10001 10002 B KBAC-217SF 8869 8880 C

KBAC-45 9530 9531 B KBAC-416 8870 8881 C

KBAC-48 9540 9541 B KBAC-416S 8864 8856 C

KBAC-416F 8874 8883 C

KBAC-416SF 8871 8882 C

Notes: 1. White FDA approved finish. 2. Third Generation (3G) drives KBAC-24D, 27D, 29, 29 (1P), 45, 48 are marked "(3G)" on the product

label. Third Generation (3G) drives are jumper selectable (J12) for standard and sensitive GFCIs. 3. All KBAC-217, 416 Series drives are

Third Generation (3G).

UL NOTICE

230 Volt Drives: Suitable for use on a circuit capable of delivering not more than 5 kA RMS symmetrical Amperes. 230 Volts maximum.

Use copper conductors rated 75 °C. Suitable for operation in a maximum surrounding air temperature of 40 °C.

460 Volt Drives: Suitable for use on a circuit capable of delivering not more than 5 kA RMS symmetrical Amperes. 460 Volts maximum.

Use copper conductors rated 75 °C. Suitable for operation in a maximum surrounding air temperature of 40 °C.

KBAC SERIES INSTALLATION AND OPERATION MANUAL

3

Page 4

1 – QUICK-START INSTRUCTIONS

Also see Section 4 – Important Application Information on page 5.

Important: You must read these simplified instructions before proceeding. These instructions are to be used as a reference only and are not

intended to replace the details provided herein. You must read the Safety Warnings on page 5 before proceeding.

Reconditioning the Bus Capacitors: If this drive has been in storage for over one year, it is necessary to recondition the power supply bus

capacitors. To recondition the bus capacitors, apply the AC Line, with the drive in the Stop Mode, for a minimum of one hour. Not following

this procedure will cause the bus capacitors to fail.

WARNING! High Voltage! Disconnect the main power before making connections to the control. Do not depend on the POWER or

STATUS LEDs, located on the front cover, to no longer be illuminated as a guaranteed power off condition.

1.1 – MOUNTING INSTRUCTIONS

See Section 5 on page 12.

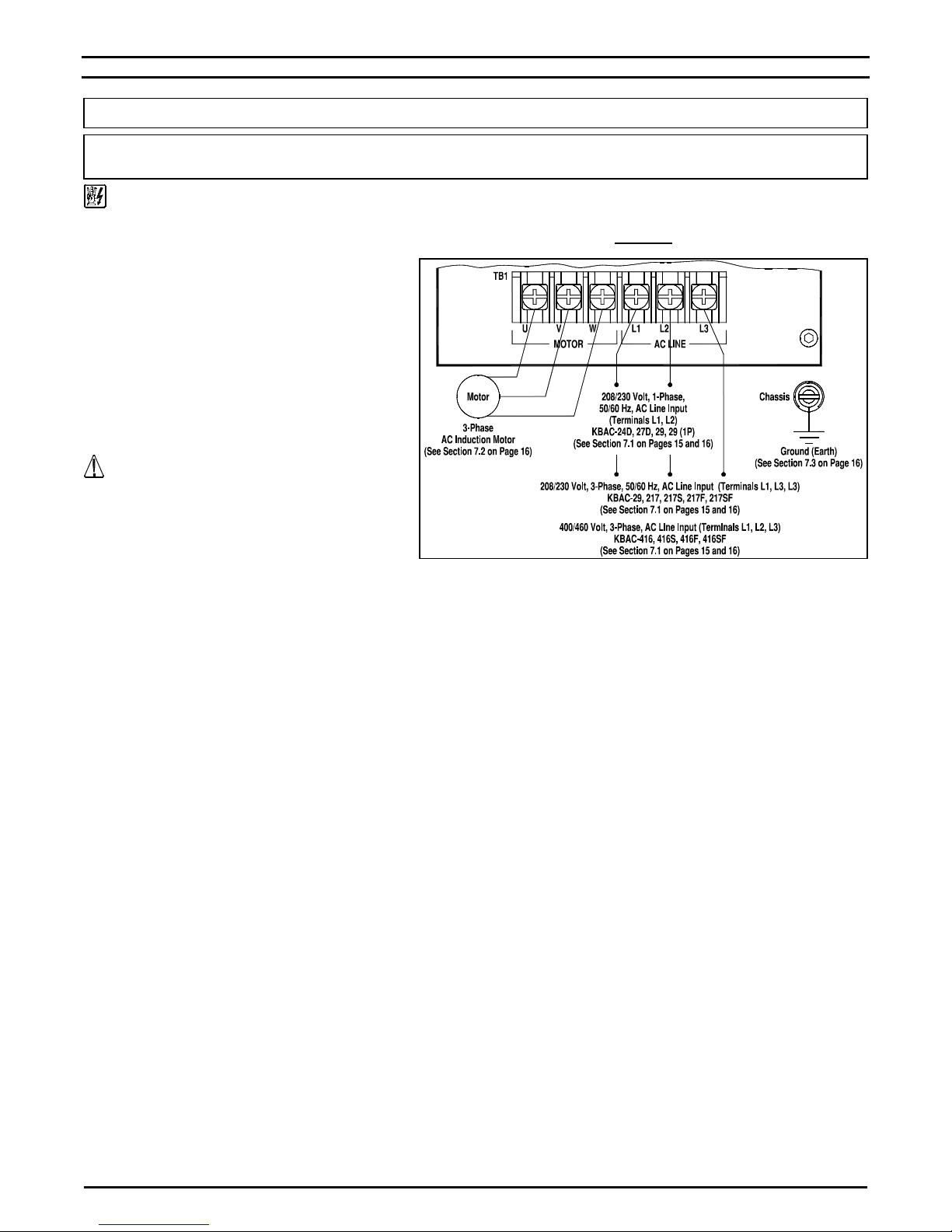

GENERAL CONNECTION DIAGRAM

FIGURE 1

1.2 – AC LINE INPUT FUSING

It is recommended that a fuse(s) or circuit breaker be

installed in the AC Line. Fuse each conductor that is not at

ground potential. For the recommended fuse size, see

Table 2 on page 7. Also see Section 6 on page 15.

1.3 – AC LINE INPUT CONNECTION

Connect the AC Line input to Terminal Block TB1, as

shown in Figure 1. Also see Section 7.1 on pages 15 and

16.

GFCI Operation: Third Generation (3G) drives are jumper

selectable (J12) for standard and sensitive GFCIs.

CAUTION! The rated AC Line voltage of the drive

must match the actual AC Line input voltage.

On KBAC-24D, 27D the setting of Jumper J1 must match

the actual AC Line input voltage.

KBAC-24D, 27D, 29 (1P): Designed to accept 1-phase

(Terminals L1, L2) AC Line input only. Rated for 208/230

Volt AC Line input with Jumper J1 set to the "230V" position (factory setting). Rated for 115 Volt AC Line input with Jumper J1 set to the

"115V" position. KBAC-27D is rated for 1½ HP maximum with 115 Volt AC Line input and 2 HP maximum with 208/230 Volt AC Line input.

KBAC-29: Designed to accept 1-phase (Terminals L1, L2) or 3-phase (Terminals L1, L2, L3) AC Line input. Rated for 208/230 Volt AC Line

input only. Rated for 2 HP maximum with 1-phase AC Line input and 3 HP maximum with 3-phase AC Line input.

KBAC-217, 217S, 217F, 217SF: Designed to accept 3-phase (Terminals L1, L2, L3) AC Line input only. Rated for 208/230 Volt AC Line input

only.

KBAC-45, 48, 416, 416S, 416F, 416SF: Designed to accept 3-phase (Terminals L1, L2, L3) AC Line input only. Rated for 400/460 Volt AC

Line input only.

1.4 – MOTOR CONNECTION

Connect the motor to Terminal Block TB1 Terminals U, V, W, as shown in Figure 1 above. See Section 7.2 on page 16. Motor cable length

should not exceed 100 ft. (30 m) – special reactors may be required – contact Technical Support.

1.5 – GROUND CONNECTION

Connect the ground wire (earth) to the ground screw, as shown in Figure 1 above. See Section 7.3 on page 16. Be sure the motor is also

properly grounded.

1.6 – 60 Hz AND 50 Hz MOTOR OPERATION

The drive is factory set for 60 Hz motor operation (Jumper J4 set to the "1X" position and Jumper J5 set to the "60Hz" position). For 50 Hz

motor operation, be sure Jumper J4 is set to the "1X" position and set Jumper J5 to the "50Hz" position. See Section 10.4 on page 19.

1.7 – START/STOP SWITCH

A prewired Start/Stop Switch is supplied to electronically "start" and "stop" the drive, as described in Section 7.5 on page 17. This switch must

be used to "start" the drive each time the AC Line is applied to the drive or to "restart" the drive. Also see Section 10.8 on page 20.

1.8 – JUMPER SETTINGS

All jumpers have been factory set for most applications. However, some jumpers may need to be set in order to tailor the drive for a specific

application. See Section 10 on pages 19 and 20.

IMPORTANT: To ensure that the motor is properly protected with the I2t Overload Protection feature, it is required that Jumper J2 is set to the

corresponding position for the motor horsepower being used, as shown in Figure 23 on page 19.

1.9 – TRIMPOT ADJUSTMENTS

All trimpots have been factory set for most applications. Some applications require adjustment of the trimpots to tailor the drive for a specific

requirement. See Section 12 on page 21 and 22.

1.10 – DIAGNOSTIC LEDs

After power has been applied, observe the LEDs to verify proper drive operation, as described in Section 13 on page 23.

4

KBAC SERIES INSTALLATION AND OPERATION MANUAL

Page 5

2 – SAFETY WARNINGS

r

Definition of Safety Warning Symbols

Electrical Hazard Warning Symbol: Failure to observe this warning could result in electrical shock or electrocution.

Operational Hazard Warning Symbol: Failure to observe this warning could result in serious injury or death.

SAFETY WARNING! – PLEASE READ CAREFULLY!

This product must be installed and serviced by a qualified technician, electrician, or electrical maintenance person familiar with its operation

and the hazards involved. Proper installation, which includes electrical connections, fusing or other current protection, and grounding, can

reduce the chance of electrical shocks, and/or fires, in this product or products used with this product, such as electric motors, switches,

coils, solenoids, and/or relays. Do not use this drive in an explosion-proof application. Eye protection must be worn and insulated adjustment

tools must be used when working with drive under power. This product is constructed of materials (plastics, metals, carbon, silicon, etc.)

which may be a potential hazard. Proper shielding, grounding, and filtering of this product can reduce the emission of radio frequency

interference (RFI) which may adversely affect sensitive electronic equipment. It is the responsibility of the equipment manufacturer and

individual installer to supply this Safety Warning to the ultimate end user of this product. (SW 8/2012)

The control contains electronic Start/Stop circuits, which can be used to start and stop the control. However, these circuits are never to be

used as safety disconnects since they are not fail-safe. Disconnect the input power for this purpose. Be sure to read and follow all

instructions carefully. Fire and/or electrocution can result due to improper use of this product.

This product complies with all CE directives pertinent at the time of manufacture. Contact Technical support for Declaration of

Conformity. Installation of a CE approved RFI filter is required. See RFI Filters & Chokes Selection Guide D-321 (Part No. A42027) for

selection of filters that meet the Industrial or Residential Standard. Additional shielded cable and/or AC Line cables may be required along

with a signal isolato

.

3 – IMPORTANT APPLICATION INFORMATION

3.1 – MOTOR WITH EXTERNAL FAN COOLING

Most totally enclosed fan-cooled (TEFC) and open ventilated 3-phase AC induction motors will overheat if used beyond a limited speed range

at full torque. Therefore, it is necessary to reduce motor load as speed is decreased.

Note: Some fan-cooled motors can be used over a wider speed range. Consult the motor manufacturer for details.

CAUTION! 1. Some motors have low speed characteristics which cause overheating and winding failure under light load or no-load

conditions. If the motor is operated in this manner for an extended period of time, it is recommended that the unloaded motor current be

checked from 2 – 15 Hz (60 – 450 RPM) to ensure motor current does not exceed the nameplate rating. Do not use the motor if the motor

current exceeds the nameplate rating. 2. It is recommended that the drive be used with Inverter Duty or TENV motors. Inverter duty and most

totally enclosed non-ventilated (TENV) motors can provide full rated torque over an extended speed range without overheating. See Figure 2.

3. If external fan cooling is provided, open ventilated motors can also achieve an extended speed range at full rated torque. A box fan or

blower with a minimum of 100 CFM per HP is recommended. Mount the fan or blower so the motor is surrounded by the airflow. See Figure 3.

MAXIMUM ALLOWED MOTOR TORQUE VS. SPEED

FIGURE 2

OPEN VENTILATED MOTOR WITH EXTERNAL FAN COOLING

FIGURE 3

Inverter Duty

and TENV

Motors

TEFC and Open Ventilated

3.2 – Electronic Motor Overload Protection

The drive contains Modified I

2

t Overload Protection (UL approved as an overload protector for motors). Part of this function consists of a

Current Limit (CL) circuit, which limits the drive current to a preset level of 160% of the rated drive current. The CL Trimpot is used to

recalibrate the drive current from 60% thru 200%. The Power Start™ circuit provides an overshoot function that allows most motors to develop

more than 200% of starting torque and breakdown torque.

Standard I

2

t is undesirable because it causes nuisance tripping. It allows a very high motor current to develop and will turn the drive off after a

short period of time. The RMS Current Limit Circuit, which includes I

this nuisance tripping while providing maximum motor protection.

If the motor is overloaded to 120% of full load (75% of the CL setting), the I•t Timer starts. If the motor continues to be overloaded at the 120%

level, the timer will shut down the drive after 30 minutes. If the motor is overloaded to 160% of full load, the drive will trip in 6 seconds.

KBAC SERIES INSTALLATION AND OPERATION MANUAL

Fan Cooled

Motors

2

t plus an I•t timing circuit (as described in the paragraph below), avoids

5

Page 6

4 – INTRODUCTION

Thank you for purchasing the KBAC Adjustable Frequency Drive. KB Electronics, Inc. is committed to providing total customer satisfaction by

producing quality products that are easy to install and operate. The KBAC is manufactured with surface mount components incorporating

advanced circuitry and technology.

The drives are variable speed controls housed in a rugged NEMA 4X / IP65 washdown and watertight die-cast aluminum enclosure. They are

designed to operate 208 – 230 and 400/460 Volt 50 & 60 Hz 3-phase AC induction motors from subfractional thru 10 HP. The sine wave

coded Pulse Width Modulated (PWM) output operates at a carrier frequency of 16 kHz which provides high motor efficiency and low noise.

Adjustable Linear Acceleration and Deceleration are provided, making the drive suitable for

soft-start applications.

Due to its user-friendly design, the KBAC AC drive is easy to install and operate. Tailoring to specific applications is accomplished with

selectable jumpers and trimpots, which eliminate the computer-like programming required on other drives. However, for most applications no

adjustments are necessary.

Main features include adjustable RMS Current Limit and I

2

t Motor Overload Protection (UL approved as an electronic overload protector for

motors). In addition, Adjustable Slip Compensation with Static Auto-Tune and Boost provides high torque and excellent load regulation over a

wide speed range. Power Start™ delivers over 200% motor torque to ensure start-up of high frictional loads. Electronic Inrush Current Limit

(EICL™) eliminates harmful AC Line inrush current. A Run/Fault Relay is provided, which can be used to turn equipment on or off, to signal a

warning if the drive is put into the Stop Mode, or if a fault has occurred. The drive is suitable for machine or variable torque (HVAC)

applications. Also, a jumper is provided for selection of Regenerative or DC Injection Braking.

Standard front panel features include Diagnostic LEDs for "Power On" and "Drive Status", a Start/Stop Switch, and a Main Speed

Potentiometer. Other features include a Barrier Terminal Block to facilitate wiring of the AC Line and motor, adjustable trimpots (MIN, MAX,

ACCEL, DECEL, COMP, CL, JOG, BOOST), customer selectable jumpers (Line Voltage (dual voltage models only)), Motor Horsepower,

Automatic Ride-Through / Manual Start, Motor Frequency, Frequency Multiplier, Fixed/Adjustable Boost, Regenerative / Injection Braking,

"Run" or "Fault" Output Relay Operation, NO/NC Stop Contact, Constant/Variable Torque, Switching Frequency, and GFCI operation

(Third Generation (3G) drives only).

Optional accessories include: Forward-Stop-Reverse Switch, On/Off AC Line Switch, Run-Stop-Jog Switch, Signal Isolator, Auto/Manual

Switch, Class A AC Line Filter, Multi-Speed Board, and Liquidtight Fittings. A connector is provided for easy installation of accessories.

Custom software: all models can be factory programmed for applications which require special timing, PLC functions, and GFCI operation.

4.1 – STANDARD FEATURES

Industrial Duty Die-Cast Aluminum Case with Hinged Cover: Available in dark gray finish or FDA approved white finish.

Simple to Operate: Does not require programming. Uses trimpots and jumpers, which are factory set for most applications.

Motor HP Selection Jumper (J2): Allows the drive to be used on a wide range of motors without recalibration.

Switching Frequency and GFCI Selection Jumper (J12): Allows the drive to be operated at 8 kHz or 12 kHz and on Standard (G1) or

Sensitive (G2) GFCIs. (Third Generation (3G) drives only.)

Diagnostic LEDs: Power on (POWER) and drive status (STATUS).

Run/Fault Relay Output Contacts: Can be used to turn equipment on or off, to signal a warning if the drive is put into the Stop Mode, or a

fault has occurred.

Start/Stop Switch: Provides electronic start and stop functions.

Barrier Terminal Block: Facilitates wiring of motor, AC Line, and Run/Fault Relay Output Contacts.

Jumper Selection of Drive Output Frequency: Increases the motor speed up to two times the rated RPM.

Ride-Through: Provides smooth recovery to the previous set speed during a momentary power loss (of less than 2 seconds).

Holding Torque at Zero Speed: Resists motor shaft rotation when the drive is in Stop Mode.

Adjustable Trimpots: Maximum Speed (MAX), Minimum Speed (MIN), Acceleration (ACCEL), Deceleration (DECEL), DC Injection Brake

(DECEL), Boost (BOOST), Current Limit (CL), Jog (JOG), Slip Compensation (COMP).

Selectable Jumpers: AC Line Input Voltage (J1 – KBAC-24D, 27D only), Motor Horsepower (J2), Automatic Ride-Through or Manual Start

(J3), Frequency Multiplier (J4), Motor Frequency (J5), Fixed or Adjustable Boost (J6), Regeneration or DC Injection Braking (J7), "Run" or

"Fault" Output Relay Operation (J8), Normally Open or Closed Stop Contact (J9), Constant or Variable Torque (J10), Switching Frequency

and GFCI (J12 – Third Generation (3G) drives only).

4.2 – PEERFORMANCE FEATURES

Power Start™: Provides more than 200% starting torque which ensures startup of high frictional loads.

Slip Compensation with Static Auto-Tune and Boost: Provides excellent load regulation over a wide speed range.

Speed Range: 60:1.

4.3 – PROTECTION FEATURES

Motor Overload (I

trips. UL approved as an electronic overload protector for motors.

Electronic Inrush Current Limit (EICL™): Eliminates harmful Inrush AC Line current during startup.

Short Circuit: Shuts down the drive if a short circuit occurs at the motor (phase-to-phase).

Regeneration: Eliminates tripping due to high bus voltage caused by rapid deceleration of high inertial loads.

Undervoltage and Overvoltage: Shuts down the drive if the AC Line input voltage goes above or below the operating range.

MOV Input Transient Suppression: Protects the drive components against damaging voltage spikes on the AC Line.

2

t) with RMS Current Limit: Provides motor overload protection which prevents motor burnout and eliminates nuisance

Microcontroller Self-Monitoring and Auto Reboot.

6

KBAC SERIES INSTALLATION AND OPERATION MANUAL

Page 7

TABLE 2

A

–

–

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

ELECTRICAL RATINGS

Part No.

Model No.

Gray White1

KBAC-24D 9987 9988

KBAC-27D 9520 9521

Volts AC

(50/60 Hz)

c Line Input

Fuse or

Circuit

Maximum

Phase

(Ф)

Current

(Amps AC)

115 1 14.4 20

208/230 1 8.1 15

Breaker

Rating

(Amps)

(Volts AC)

0 – 208/230 3.6 1 (0.75) 1 3/4 1/2 1/4 1/8 5.9 2.7

115 1 22 25 0

Voltage

Range

208/230 5.5 1½ (1.13) ─

Output

Maximum

Continuous

Load Current

(Amps/Phase)

Maximum

Horsepower

(HP (kW))

208/230 1 16.7 20 0 –208/230 6.7 2 (1.5) 2

Horsepower

Selection

(Jumper J2)

3

1 3/4 1/2 10.3 4.7

1½

2

Net

Weight

lbs kg

A B C D E

KBAC-29 9528 9529 208/230

1 16.7 20 0

3 11.7 15 0 –208/230 9.0 3 (2.25) 34

KBAC-29 (1P) 10001 10002 208/230 1 20.5 25 0 –208/230 9.0

KBAC-45 9530 9531 400/460 3 7.2 10 0 –400/460

KBAC-48 9540 9541 400/460 3 11 15 0 –400/460

208/230 6.7 2 (1.5) ─

6

6

5

5.5 3 (2.25) 3 2 1½ 1 3/4

8.3 5 (3.75) 5 3 2 1½ 1

3 (2.25) 3 2 1½ 1 3/4

4

1½ 1 3/4

2

10.3 4.7

A B C ─ ─

KBAC-217 8868 8879

KBAC-217S 8863 8855

KBAC-217F 8861 8853

KBAC-217SF 8869 8880

KBAC-416 8870 8881

KBAC-416S 8864 8856

KBAC-416F 8874 8883

208/230 3 22.1 25 0 – 208/230 17 5 5 3 2

6

400/460 3 20.8 25 0 – 400/460

16 10 10 7.5 3

─ ─ 22 10

KBAC-416SF 8871 8882

Notes: 1. White FDA approved finish. 2. Bold indicates factory setting. KBAC-24D: J2 is labeled "1", "3/4", "1/2", "1/4", "1/8" (factory set to the

"1" position). KBAC-27D: J2 is labeled "2", "1½", "1", "3/4", "1/2" (factory set to the "1½" position). KBAC-29, (29 (1P), 45, 48: J2 is labeled

"A", "B", "C", "D", "E" (factory set according to the table). KBAC-217, 416 Series: J2 is labeled "A", "B", "C" (factory set to the "A" position).

3. KBAC-27D: Rated 1½ HP maximum with 115 Volt AC Line input and 2 HP maximum with 208/230 Volt AC Line input. 4. KBAC-29: Rated

2 HP maximum with 1-phase AC Line input and 3 HP maximum with 3-phase AC Line input. 5. KBAC-29 (1P): Rated 9 Amps at 35 °C / 95 °F

and derated to 8.3 Amps at 40 °C / 104 °F. For ambient temperatures above 40 °C / 104 °F, the drive is derated 2.5% per °C.

6. KBAC-45, 48, 416 Series: Rated 0 – 400 Volts AC for 50 Hz motor operation and 0 – 460 Volts AC for 60 Hz motor operation.

TABLE 3

GENERAL PERFORMANCE SPECIFICATIONS

Description Specification Factory Setting

115 Volt AC Line Input Voltage Operating Range (Volts AC) 115 (±15%)

208/230 Volt AC Line Input Voltage Operating Range (Volts AC) 208 (-15%) / 230 (+15%)

400/460 Volt AC Line Input Voltage Operating Range (Volts AC) 380 (-15%) – 460 (+15%)

Maximum Load (% Current Overload for 2 Minutes) 150

Switching Frequency (kHz) (Jumper J12) (3G Drives Only)

1

8, 12 8

Signal Following Input Voltage Range2 (Volts DC) 0 – 5

Output Frequency Resolution (Bits, Hz) 10, 0.06

Maximum Speed Trimpot (MAX) Range (% Frequency Setting) 70 – 110 100

Minimum Speed Trimpot (MIN) Range (% Frequency Setting) 0 – 40 0

Acceleration Trimpot (ACCEL) Range (Seconds) 0.3 – 20 1.5

Deceleration Trimpot (DECEL) Range (Seconds) 0.3 – 20 1.5

DC Injection Brake (DECEL) (Seconds) 0.3 – 6.0 1.7

Boost Trimpot (BOOST) Range (Volts) 0 – 30 5

Current Limit Trimpot (CL) Range (% Full Load) 40 – 200 160

Jog Trimpot (JOG) Range (% Frequency Setting) 0 – 100 35

Slip Compensation Trimpot (COMP) Range at Drive Rating (Volts/Hz) 0 – 3 1.5

Motor Frequency Setting (Hz) (Jumper J5) 50, 60 60

Output Frequency Multiplier (1X, 2X) (Jumper J4)3 1, 2 1

Minimum Operating Frequency at Motor (Hz) 1

Speed Range (Ratio) 60:1

Speed Regulation (30:1 Speed Range, 0 – Full Load) (% Base Speed)

Overload Protector Trip Time for Stalled Motor (Seconds) 6

Undervoltage/Overvoltage Trip Points for 115 Volt AC Line Input (± 5%) (Volts AC)

Undervoltage/Overvoltage Trip Points for 208/230 Volt AC Line Input (± 5%) (Volts AC)

Undervoltage/Overvoltage Trip Points for 400/460 Volt AC Line Input (± 5%) (Volts AC)

4

5

5

5

2.5

76 – 141

151 – 282

302 – 567

Run/Fault Relay Output Contact Rating (Amps at 30 Volts DC, 125 Volts AC, 250 Volts AC) 1, 0.5, 0.25

Operating Temperature Range (°C / °F) 0 – 40 / 32 – 104

Operating Humidity Range (% Relative, Non-Condensing) 0 – 95

Storage Temperature (°C / °F) -2.5 – +85 / -13 – +185

Notes: 1. Third Generation (3G) drives are marked "(3G)" on the product label. 2. Requires an isolated signal. If a non-isolated signal is used,

or if using 0 to ±2.5 thru 0 to ±25 Volts DC, or 4 – 20 mA DC signal input, install the Signal Isolator. 3. Allows the motor to operate up to two

times the rated RPM. Constant horsepower will result when operating the drive in the "X2" mode above the motor rated frequency.

4. Dependent on motor performance. 5. Do not operate the drive outside the specified AC Line input voltage operating range. 6. See Table 2

above.

KBAC SERIES INSTALLATION AND OPERATION MANUAL

7

Page 8

KBAC-24D DRIVE LAYOUT (SEE LEGEND BELOW FOR NUMBERED ITEMS)

FIGURE 4

1

2

3

4

5

6

7

8

10

11

12

13

14

15

J1

16

17

WVU L1 L2

MOTOR

LEGEND:

1. Jog Terminal: Used with optional Run-Stop-Jog Switch Kit. See Section 14 on page 23.

2. Adjustable Trimpots: Maximum Speed (MAX), Minimum Speed (MIN), Acceleration (ACCEL), Deceleration (DECEL), DC Injection Brake

(DECEL), Boost (BOOST), Current Limit (CL), Jog (JOG), Slip Compensation (COMP). See Section 12 on pages 21 and 22.

3. Jumper J3: Automatic Ride-Through or Manual Start selection. See Section 10.3 on page 19.

4. Jumper J4: Frequency Multiplier selection. See Section 10.4 on page 19.

5. Jumper J2: Motor Horsepower selection. See Section 10.2 on page 19.

6. Jumper J5: Motor Frequency selection. See Section 10.4 on page 19.

7. Jumper J12: Switching Frequency and GFCI selection. Third Generation (3G) drives only. See Section 10.11 on page 20.

8. Jumper J6: Adjustable Boost selection. See Section 10.5 on page 20.

9. Jumper J7: Regeneration or DC Injection Braking. See Section 10.6 on page 20.

10. Jumper J8: "Run" or "Fault" Output Relay Operation selection. See Section 10.7 on page 20.

11. Jumper J9: Normally Open or Closed Stop Contact selection. See Section 10.8 on page 20.

12. Jumper J10: Constant or Variable Torque selection. See Section 10.9 on page 20.

13. Jumper J11: Factory use only.

14. Connector CON1: Used to connect optional accessories to the drive.

15. Jumper J1: AC Line Input Voltage selection. See Section 10.1 on page 19.

16. Terminals L1A/L1B and L2A/L2B: Used for optional On/Off AC Line Switch Kit and RFI Filter Kit. See Section 14 on page 23.

17. Terminal Block TB1: AC Line input and Motor connections. See Sections 7.1 and 7.2 on page 15 and 16.

AC LINE

8

KBAC SERIES INSTALLATION AND OPERATION MANUAL

Page 9

KBAC-27D DRIVE LAYOUT (SEE LEGEND BELOW FOR NUMBERED ITEMS)

FIGURE 5

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

LEGEND:

1. Jog Terminal: Used with optional Run-Stop-Jog Switch Kit. See Section 14 on page 23.

2. Adjustable Trimpots: Maximum Speed (MAX), Minimum Speed (MIN), Acceleration (ACCEL), Deceleration (DECEL), DC Injection Brake

(DECEL), Boost (BOOST), Current Limit (CL), Jog (JOG), Slip Compensation (COMP). See Section 12 on pages 21 and 22.

3. Connector CON1: Used to connect optional accessories to the drive.

4. Jumper J2: Motor Horsepower selection. See Section 10.2 on page 19.

5. Jumper J3: Automatic Ride-Through or Manual Start selection. See Section 10.3 on page 19.

6. Jumper J6: Adjustable Boost selection. See Section 10.5 on page 20.

7. Jumper J4: Frequency Multiplier selection. See Section 10.4 on page 19.

8. Jumper J7: Regeneration or DC Injection Braking. See Section 10.6 on page 20.

9. Jumper J5: Motor Frequency selection. See Section 10.4 on page 19.

10. Jumper J8: "Run" or "Fault" Output Relay Operation selection. See Section 10.7 on page 20.

11. Jumper J9: Normally Open or Closed Stop Contact selection. See Section 10.8 on page 20.

12. Jumper J10: Constant or Variable Torque selection. See Section 10.9 on page 20.

13. Terminals B+ and B-: Used to power optional accessories.

14. Jumper J11: Factory use only.

15. Jumper J12: Switching Frequency and GFCI selection. Third Generation (3G) drives only. See Section 10.11 on page 20.

16. Jumper J1: AC Line Input Voltage selection. See Section 10.1 on page 19.

17. Terminals L1A/L1B and L2A/L2B: Used for optional On/Off AC Line Switch Kit and RFI Filter Kit. See Section 14 on page 23.

18. Terminal Block TB1: AC Line input and Motor connections. See Sections 7.1 and 7.2 on page 15 and 16.

KBAC SERIES INSTALLATION AND OPERATION MANUAL

9

Page 10

KBAC-29, 29 (1P), 45, 48 DRIVE LAYOUT (SEE LEGEND BELOW FOR NUMBERED ITEMS)

FIGURE 6

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

LEGEND:

1. Jog Terminal: Used with optional Run-Stop-Jog Switch Kit. See Table 14 on page 23.

2. Adjustable Trimpots: Maximum Speed (MAX), Minimum Speed (MIN), Acceleration (ACCEL), Deceleration (DECEL), DC Injection Brake

(DECEL), Boost (BOOST), Current Limit (CL), Jog (JOG), Slip Compensation (COMP). See Section 12 on pages 21 and 22.

3. Connector CON1: Used to connect optional accessories to the drive.

4. Jumper J2: Motor Horsepower selection. See Section 10.2 on page 19.

5. Jumper J3: Automatic Ride-Through or Manual Start selection. See Section 10.3 on page 19.

6. Jumper J6: Adjustable Boost selection. See Section 10.5 on page 20.

7. Jumper J4: Frequency Multiplier selection. See Section 10.4 on page 19.

8. Jumper J7: Regeneration or DC Injection Braking. See Section 10.6 on page 20.

9. Jumper J5: Motor Frequency selection. See Section 10.4 on page 19.

10. Jumper J8: "Run" or "Fault" Output Relay Operation selection. See Section 10.7 on page 20.

11. Jumper J9: Normally Open or Closed Stop Contact selection. See Section 10.8 on page 20.

12. Jumper J10: Constant or Variable Torque selection. See Section 10.9 on page 20.

13. Terminals B1 and B-: Used to power optional accessories.

14. Jumper J11: Factory use only.

15. Jumper J12: Switching Frequency and GFCI selection. Third Generation (3G) drives only. See Section 10.11 on page 20.

16. Terminals L1A/L1B, L2A/L2B, L3A/L3B (Not Installed on KBAC-29 (1P)): Used for optional On/Off AC Line Switch Kit and RFI Filter Kit.

See Section 14 on page 23.

17. Terminal Block TB1: AC Line input and Motor connections. See Sections 7.1 and 7.2 on page 15 and 16.

10

KBAC SERIES INSTALLATION AND OPERATION MANUAL

Page 11

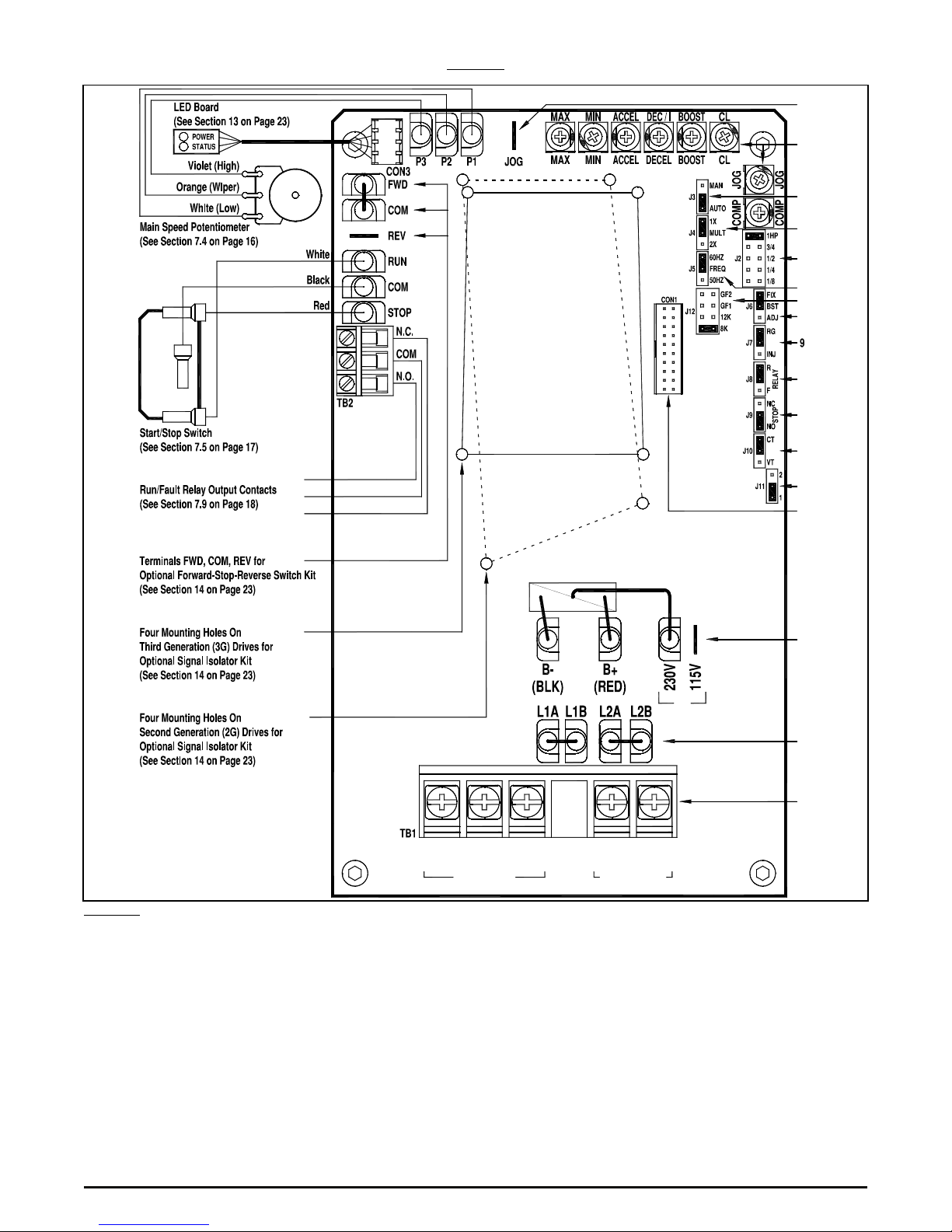

KBAC-217, 217S, 217F, 217SF, 416, 416S, 416F, 416SF DRIVE LAYOUT (SEE LEGEND BELOW FOR NUMBERED ITEMS)

FIGURE 7

UW

V

MOTOR

LEGEND:

1. Connector CON3: For diagnostic LED board. See Section 13 on page 23.

2. Terminals RUN, COM, STOP: For factory installed Start/Stop Switch. See Section 7.5 on page 17.

3. Terminals FWD, STOP, REV: For optional Forward-Stop-Reverse Switch. See Section 14 on page 23.

4. Terminals P1, P2, P3: For factory installed Main Speed Potentiometer. See Section 7.4 on page 16.

5. Terminal Block TB2: Run/Fault Relay Output Contacts. See Section 7.9 on page 18.

6. Jog Terminal: Used with optional Run-Stop-Jog Switch Kit. See Section 14 on page 23.

7. Adjustable Trimpots: Maximum Speed (MAX), Minimum Speed (MIN), Acceleration (ACCEL), Deceleration (DECEL), DC Injection Brake

(DECEL), Boost (BOOST), Current Limit (CL), Jog (JOG), Slip Compensation (COMP). See Section 12 on pages 21 and 22.

8. Selectable Jumpers:

Motor Horsepower (J2), Automatic Ride-Through or Manual Start (J3), Frequency Multiplier (J4), Motor Frequency

(J5), Fixed or Adjustable Boost (J6), Regeneration or DC Injection Braking (J7), "Run" or "Fault" Output Relay Operation (J8), Normally

Open or Closed Stop Contact (J9), Constant or Variable Torque (J10), Switching Frequency and GFCI (J12). See Section 10 on pages 19

and 20.

9. Connector CON1: Used to connect optional accessories to the drive.

10. Four mounting holes for optional Signal Isolator. See Section 14 on page 23.

11. Terminals L1A, L2A, L3A: Used for factory installed On/Off AC Line Switch and factory installed RFI Filter Kit. See Section 14 on page 23.

12. Terminal Block TB1: AC Line input and Motor connections. See Sections 7.1 and 7.2 on page 15 and 16.

13. Ground Screws: Chassis (earth ground).

KBAC SERIES INSTALLATION AND OPERATION MANUAL

L1 L2 L3

AC LINE

11

Page 12

5 – MOUNTING

*

It is recommended that the drive be mounted vertically on a flat surface with adequate ventilation. Leave enough room below the drive to allow

for AC Line, motor connections, and any other wiring that is required. Although the drive is designed for outdoor and washdown use, care

should be taken to avoid extreme hazardous locations where physical damage can occur. When mounting the drive in an enclosure, the

enclosure should be large enough to allow for proper heat dissipation so that the ambient temperature does not exceed 40 °C (104 °F) at full

rating. See Figures 8 – 10 on pages 12 – 14.

WARNING! Do not use this drive in an explosion-proof application. Be sure the control is securely mounted.

KBAC-24D MECHANICAL SPECIFICATIONS (Inches / mm)

FIGURE 8

Tighten these screws, in the sequence shown, to 12 in-lbs (14 kg-cm).

12

KBAC SERIES INSTALLATION AND OPERATION MANUAL

Page 13

KBAC-27D, 29, 29 (1P), 45, 48 MECHANICAL SPECIFICATIONS (Inches / mm)

*

FIGURE 9

Tighten these screws, in the sequence shown, to 12 in-lbs (14 kg-cm).

KBAC SERIES INSTALLATION AND OPERATION MANUAL

13

Page 14

KBAC-217, 217S, 217F, 217SF, 416, 416S, 416F, 416SF MECHANICAL SPECIFICATIONS (Inches / mm)

FIGURE 10

14

KBAC SERIES INSTALLATION AND OPERATION MANUAL

Page 15

6 – AC LINE INPUT FUSING

A

A

The drive does not contain line fuses. Most electrical codes require that each ungrounded conductor contain circuit protection. Do not fuse

neutral or ground connections. It is recommended to install a fuse (Littelfuse 312/314, Buss ABC, or equivalent) or a circuit breaker in series

with each ungrounded conductor. Do not fuse motor leads. For the recommended fuse size, see Table 2 on page 7.

CAUTION! Do not fuse neutral or grounded connections.

7 – ELECTRICAL CONNECTIONS

Wire the drive in accordance with the National Electrical Code requirements and other local codes that may apply to the application.

WARNING! Read Safety Warnings, on page 5, before using the drive. Disconnect main power before making connections to the drive.

To avoid electric shock, be sure to properly ground the drive. It is highly recommended that the Signal Isolator be installed when using signal

following.

WARNING! HIGH VOLTAGE! REMOTE CONNECTIONS OF POTENTIOMETER, SWITCHES, ETC., WILL HAVE WIRING THAT IS AT

LINE POTENTIAL. IT IS REQUIRED THAT THE SIGNAL ISOLATOR BE INSTALLED FOR REMOTE CONNECTIONS.

Be sure to properly fuse each AC Line conductor that is not at ground potential. Do not fuse neutral or grounded conductors. A separate AC

Line switch or contactor must be wired as a disconnect so that each ungrounded conductor is opened. For fuse or circuit breaker selection,

see Table 2 on page 7. Also see Section 6 above.

To maintain the watertight integrity of the drive, be sure to use suitable liquidtight fittings and wiring which are appropriate for the application.

Liquidtight Fittings Kits are available for all models. See Section 14 on page 23.

The drive is designed with a hinged case so that when the front cover is open, all wiring stays intact. To open the cover, the four screws must

be loosened so they are no longer engaged in the case bottom. After mounting and wiring, close the cover making sure that the wires do not

get caught or crimped as the cover is closed. Tighten the four screws so that the gasket is slightly compressed. The recommended tightening

torque is 12 in-lbs (14 kg-cm) – do not overtighten. See Figures 8 – 10 on pages 12 – 14 for the tightening sequence.

Application Note: To avoid erratic operation, do not bundle the AC Line and motor wires with each other or with wires from signal following,

start/stop contacts, or any other signal wires. Also, do not bundle motor wires from multiple drives in the same conduit. Use shielded cables on

all signal wiring over 12" (30 cm). The shield should be earth grounded on the drive side only. Wire the drive in accordance with the National

Electrical Code requirements and other local codes that may apply.

TERMINAL BLOCK WIRE SIZE AND TIGHTENING TORQUE SPECIFICATIONS

Terminal

Block Description Model

TB1

TB2

AC Line Input and

Motor Wiring

Run/Fault Relay

Output Contacts

KBAC-27D, 29, 29 (1P), 45, 48 12 3.3 12 14

KBAC-24D, 27D, 29, 29 (1P), 45, 48 14 2.08 3.5 4

KBAC-217, 217S, 217F, 217SF, 416, 416S, 416F, 416SF 12 3.3 4.4 5

KBAC-24D 12 3.3 7 8

7.1 – AC LINE INPUT CONNECTION

Connect the AC Line input to Terminal Block TB1. See Figures 11 – 13 on pages 15 and 16.

GFCI Operation: Second Generation (2G) models require custom software – contact Technical Support. Third Generation models are jumper

selectable (J12) for Standard (G1) or Sensitive (G2) GFCIs.

CAUTION! The rated AC Line voltage of the drive must match the actual AC Line input voltage. On KBAC-24D, 27D the setting of Jumper

J1 must match the AC Line input voltage.

KBAC-24D, 27D: Designed to accept 1-phase AC Line input only (Terminals

L1, L2). Rated for 208/230 Volt AC Line input with Jumper J1 set to the "230V"

position (factory setting). Rated for 115 Volt AC Line input with Jumper J1 set

to the "115V" position. See Figure 11.

KBAC-29 (1P): Designed to accept 1-phase AC Line input (Terminals L1, L2).

Rated for 208/230 Volt AC Line input only. See Figure 11.

TABLE 4

Maximum

Wire Size (Cu)

Recommended

Tightening Torque

WG mm2 in-lbs kg-cm

FIGURE 11

KBAC-24D, 27D*, 29 (1P)

C LINE INPUT, MOTOR, AND GROUND CONNECTIONS

WVU L1 L2

MOTOR

AC LINE

KBAC SERIES INSTALLATION AND OPERATION MANUAL

15

Page 16

KBAC-29: Designed to accept 1-phase

A

A

(Terminals L1, L2) or 3-phase (Terminals

L1, L2, L3) AC Line input. Rated for

C LINE INPUT, MOTOR, AND GROUND CONNECTIONS

FIGURE 12

KBAC-29*, 45, 48

208/230 Volt AC Line input only. See

Figure 12.

KBAC-45, 48: Designed to accept 3-phase

AC Line input only (Terminals L1, L2, L3).

Rated for 400/460 Volt AC Line input only.

See Figure 12.

KBAC-217, 217S, 217F, 217SF: Designed

to accept 3-phase (Terminals L1, L2, L3)

AC Line input. Rated for 208/230 Volt AC

Line input only. See Figure 13.

KBAC-416, 416S, 416F, 416SF: Designed

to accept 3-phase (Terminals L1, L2, L3)

AC Line input. Rated for 400/460 Volt AC

Line Input only. See Figure 13.

7.2 – MOTOR CONNECTION

Connect the motor to Terminal Block TB1 Terminals U, V, W.

See Figures 11 – 13 on pages 15 and 16.

KBAC-217, 217S, 217F, 217SF, 416, 416S, 416F, 416SF

C LINE INPUT, MOTOR, AND GROUND CONNECTIONS

FIGURE 13

Motor cable length should not exceed 100 feet (30 m) – special

reactors may be required – contact Technical Support. Be sure Jumper

J2 is set to the corresponding motor horsepower rating, as described

in Section 10.2 on page 19.

7.3 – GROUND CONNECTION

Connect the Ground Wire (Earth) to the Green Ground Screw.

UW

V

MOTOR

L1 L2 L3

AC LINE

The Ground Screws are located next to Terminal Block TB1.

See Figures 11 – 13 on pages 15 and 16.

7.4 – REMOTE MAIN SPEED POTENTIOMETER CONNECTION

The drive is supplied with a prewired Main Speed Potentiometer

mounted on the front cover. To operate the drive from a remote

potentiometer (5 kΩ), remove the white, orange, and violet

potentiometer leads from Terminals P1, P2, P3. The wires may be

taped and left inside the drive. The potentiometer assembly may be

removed if a watertight seal is used to cover the hole in the front cover.

Connect the Main Speed Potentiometer to Terminals P1 (low side), P2

(wiper), and P3 (high side). See Figure 14.

WARNING! Do not earth ground any Main Speed Potentiometer terminals.

Application Note: If it is required that the Remote Main Speed Potentiometer be isolated from the AC Line, install the Signal Isolator.

See Section 14 on page 23.

FIGURE 14

REMOTE

MAIN SPEED POTENTIOMETER

CONNECTION

WARNING! HIGH VOLTAGE!

See Warning on page 15.

16

KBAC SERIES INSTALLATION AND OPERATION MANUAL

Page 17

7.5 – REMOTE START/STOP SWITCH CONNECTIONS

V

The drive is supplied with a prewired Start/Stop Switch mounted on the front cover to electronically start and stop the drive. Also see Section

10.8 on page 20.

To operate the drive from a remote Start/Stop Switch (type (ON)-OFF-ON, SPDT), remove the white, black, and red wires from Terminals

RUN, COM, and STOP. The wires may be taped and left inside the drive. The switch assembly may be removed if a liquidtight seal is used to

cover the hole in the front cover. After applying power to the drive, momentarily set the Start/Stop Switch to the "START" position. Jumper J9

must be set to the "NO" position. See Figure 15.

For Start/Stop Switch with normally closed stop contact, set Jumper J9 to the "NC" position. See Figure 16.

FIGURE 15

REMOTE START/STOP SWITCH CONNECTION

WITH NORMALLY OPEN STOP CONTACT

(J9 SET TO THE "NO" POSITION)

FIGURE 16

REMOTE START/STOP SWITCH CONNECTION

WITH NORMALLY CLOSED STOP CONTACT

(J9 SET TO THE "NC" POSITION)

WARNING! HIGH VOLTAGE! See Warning on page 15.

7.6 – AUTOMATIC RESTART

Automatic restart requires the elimination of the Start/Stop Switch. Remove the

white, black, and red wires from Terminals RUN, COM, and STOP. The wires may

be taped and left inside the drive. The switch assembly may be removed if a

liquidtight seal is used to cover the hole in the front cover.

To eliminate the Start/Stop function, hardwire Terminals RUN and COM with the

jumper that is provided. Be sure Jumper J9 is set to the "NO" position. See Figure

17.

START/STOP FUNCTION ELIMINATED

(TERMINALS HARDWIRED) (JUMPER INSTALLED)

(J9 SET TO THE "NO" POSITION)

WARNING! Using a jumper to eliminate the Start/Stop function will cause the

motor to run at the Main Speed Potentiometer setting when the AC Line is applied.

7.7 – VOLTAGE FOLLOWING CONNECTIONS

An isolated* 0 – 5 Volt DC analog signal input can also be used to control

motor speed in lieu of the Main Speed Potentiometer. The drive output will

linearly follow the analog signal input. Wire the signal input positive lead (+) to

Terminal P2 and the negative lead (-) to Terminal P1. With external circuitry,

a 0 – 10 Volt DC analog signal can also be used. See Figure 18.

OLTAGE FOLLOWING CONNECTIONS (ISOLATED)

+

V

WARNING! The signal input must be isolated from the AC Line. Earth

grounding signal wiring will damage the drive and void the warranty. It is

highly recommended that the Signal Isolator be installed when using signal

following.

*If a non-isolated signal is used, install the Signal Isolator. It accepts voltage

(0 to ±2.5 thru 0 to ±25 Volts DC) or current (4 – 20 mA DC) signal inputs.

See Section 14 on page 23.

Note: For signal following operation, the Minimum Speed Trimpot (MIN) must be set fully counterclockwise.

7.8 – ENABLE CIRCUIT CONNECTION

The drive can also be started and stopped with an Enable circuit (close to run,

open to stop). See Figure 19.

The Enable function is established by wiring a switch or contact in series with

the orange Main Speed Potentiometer lead which connects to Terminal P2.

When the Enable Switch is closed, the motor will accelerate to the Main

Speed Potentiometer setting. When the Enable Switch is opened, the motor

will decelerate to stop.

WARNING! HIGH VOLTAGE! See Warning on page 15.

ENABLE CIRCUIT CONNECTION

WARNING! If the Enable Switch is to be mounted remotely, it is highly

recommended that the Signal Isolator be installed.

WARNING! HIGH VOLTAGE! See Warning on page 15.

FIGURE 17

WARNING! HIGH VOLTAGE!

See Warning on page 15.

FIGURE 18

+

V

FIGURE 19

KBAC SERIES INSTALLATION AND OPERATION MANUAL

17

Page 18

7.9 – RUN/FAULT RELAY CONNECTION

The Run/Fault Relay Output Contacts are located at Terminal Block TB2 and can be used to turn

equipment on or off or to signal a warning if the drive is put into the Stop Mode or a fault has occurred.

See Figure 20. The Run/Fault Relay Contact status for various drive operating conditions is shown in

RUN/FAULT RELAY OUTPUT

FIGURE 20

CONTACTS CONNECTION

Table 5.

TABLE 5

DRIVE OPERATING CONDITION AND RUN/FAULT RELAY CONTACT STATUS

Run Relay Operation

Drive

Operating

Condition Description

(J8 set to the "R" Position)

(Factory Setting)

Normally

Open

Contact

Normally

Closed

Contact

Run Relay Operation

(J8 set to the "R" Position)

Normally

Open

Contact

Normally

Closed

Contact

Power Off Main Power Disconnected Open Closed Open Closed

Run Mode1 Normal Drive Operation Closed Open Closed Open

Stop Mode1 Selected by Operator Open Closed Closed Open

Fault2 Drive Tripped Open Closed Open Closed

Notes: 1. Run Mode or Stop Mode is selected using the Start/Stop Switch. 2. Overload, I2t, Short

Circuit, Undervoltage and Overvoltage.

WARNING! HIGH VOLTAGE!

See Warning on page 15.

8 – RECOMMENDED HIGH VOLTAGE DIELECTRIC WITHSTAND TESTING (HI-POT TESTING)

Testing agencies such as UL, CSA, VDE, etc., usually require that equipment undergo a hi-pot test. In order to prevent catastrophic damage

to the drive which has been installed in the equipment, the following procedure is recommended. A typical hi-pot test setup is shown in Figure

21. All drives have been factory hi-pot tested in accordance with UL requirements.

WARNING! All equipment AC Line inputs must be disconnected from the AC power.

Connect all equipment AC power input lines together and connect them to the H.V. lead of the hi-pot tester. Connect the RETURN lead of the

hi-pot tester to the frame on which the drive and other auxiliary equipment are mounted.

The hi-pot tester must have an automatic ramp-up to the test voltage and an automatic ramp-down to zero voltage.

Note: If the hi-pot tester does not have automatic ramping, then the hi-pot output must be manually increased to the test voltage and then

manually reduced to zero. This procedure must be followed for each machine to be tested. A suggested hi-pot tester is Slaughter Model 2550.

CAUTION! Instantly applying the hi-pot voltage will cause irreversible damage to the drive, which will void the warranty.

TYPICAL HI-POT TEST SETUP

FIGURE 21

AC Line Input

9 – RECONDITIONIONG THE BUS CAPACITORS

If this drive has been in storage for over one year it is necessary to recondition the power supply bus capacitors. To recondition the bus

capacitors, apply the AC Line, with the drive in the Stop Mode, for a minimum of one hour. Not following this procedure will cause the bus

capacitors to fail.

18

KBAC SERIES INSTALLATION AND OPERATION MANUAL

Page 19

10 – SETTING SELECTABLE JUMPERS

—

—

C

-

A

The drive has customer selectable jumpers which must be set before the drive can be used.

WARNING! HIGH VOLTAGE! Disconnect the AC Line before changing position of jumpers.

10.1 – AC LINE INPUT VOLTAGE SELECTION (KBAC-24D, 27D ONLY) (J1)

CAUTION! The rated AC Line voltage of the drive must match the actual

AC LINE INPUT VOLTAGE SELECTION

AC Line input voltage. On KBAC-24D, 27D the setting of Jumper J1 must

match the actual AC Line input voltage.

208/230 Volt AC line Input

(Factory Setting) 115 Volt AC Line Input

Jumper J1 is factory installed on Terminal "230V" for 208/230 Volt AC Line

input. For 115 Volt AC Line input, the jumper must be removed and installed

on Terminal "115V". To remove the terminal, use pliers to gently rock the

terminal back and forth while pulling it upward. See Figure 22.

*Layout of KBA

10.2 – MOTOR HORSEPOWER SELECTION (J2)

Jumper J2 must be set to the corresponding position for the motor being used. See Figure 23.

FIGURE 23

MOTOR HORSEPOWER SELECTION (J2)

KBAC-24D KBAC-27D KBAC-29* KBAC-29 (1P)* KBAC-45* KBAC-48* KBAC-217 Series* KBAC-416 Series*

1 2** A 3*** 3 3 5 5 10

3/4 1½** B 2*** 2 2 3 3 7.5

1/2 1 C 1½ 1½ 1½ 2 2 5

1/4 3/4 D 1 1 1 1½ —

1/8 1/2 E 3/4 3/4 3/4 1 —

The factory setting is shown in bold. *J2 on KBAC-29, 29 (1P), 45, 48 is labeled "A, B, C, D, E" and on KBAC-217, 416 Series is labeled "A, B,

C". **KBAC-27D: Rated 1½ HP maximum with 115 Volt AC Line input and 2 HP maximum with 208/230 Volt AC Line input. ***KBAC-29:

Rated 2 HP maximum with 1-phase AC Line input and 3 HP maximum with 3-phase AC Line input.

10.3 – AUTOMATIC RIDE-THROUGH OR MANUAL START SELECTION (J3)*

Jumper J3 is factory set to the "A" position for Automatic Ride-Through. If the power is

interrupted for up to 2 seconds, the drive will shut down and then "ride-through" and

automatically return to the set frequency. See Figure 24.

If Jumper J3 is set to the "M" position, the drive will have to be manually restarted for a

Automatic Ride-Through

(Factory Setting) Manual Start

momentary power loss using the Start/Stop Switch. Also see Section 13.2 on page 23

for the Status (ST) LED indication.

*On KBAC-24D, 217, 217S, 217F, 217SF, 416, 416S, 416, 416F, 416SF Jumper J3 is

labeled "AUTO" and "MAN".

10.4 – MOTOR FREQUENCY SELECTION (J4 AND J5)

Both Jumpers J4 and J5 must be set for the appropriate motor nameplate frequency rating. See Figures 25 and 26.

10.4.1 – SETTING THE DRIVE FOR 60 Hz OR 50 Hz MOTOR OPERATION

The drive is factory set to operate 60 Hz motors. Jumper J4 is factory set to the "1X"

VAILABLE TORQUE VS. OUTPUT FREQUENCY

position and Jumper J5 is factory set to the "60Hz" position. For 50 Hz motors, set

Jumper J5 to the "50Hz" position, and be sure Jumper J4 is set to the "1X" position.

See Figure 26.

10.4.2 – SETTING THE DRIVE FOR TWO TIMES THE RATED MOTOR RPM

The drive can also operate the motor up to two times the rated RPM. However,

constant horsepower will result when operating the drive in the “2X” mode above the

motor rated frequency. For 120 Hz output with 60 Hz motor, set Jumper J4 to the

"2X" position and be sure Jumper J5 is set to the "60Hz" position. For 100 Hz output

with 50 Hz motor, set Jumper J4 to the "2X" position and set Jumper J5 to the "50Hz"

position. See Figure 26.

60 Hz

Motor Operation

(Factory Setting)

MOTOR FREQUENCY SELECTION

FIGURE 26

50 Hz

Motor Operation

120 Hz

Motor Operation

100 Hz

Motor Operation

FIGURE 22

(KBAC-24D*, 27D ONLY)

24D varies slightly.

FIGURE 24

AUTOMATIC RIDE-THROUGH

OR MANUAL START SELECTION

FIGURE 25

KBAC SERIES INSTALLATION AND OPERATION MANUAL

19

Page 20

10.5 – BOOST MODE SELECTION (J6)

y

V

Jumper J6 is factory set to the "FIX" position for Fixed Boost. For Adjustable Boost using the

BOOST Trimpot, set Jumper J6 to the "ADJ" position. See Figure 27 Also see Section 12.8

on page 22 for the Boost Trimpot.

BOOST MODE SELECTION

Fixed Boost

(Factory Setting) Adjustable Boost

FIGURE 27

10.6 – BRAKING MODE SELECTION (J7)

Jumper J7 is factory set to the "RG" position for Regenerative Braking when the Start/Stop

Switch is set to the "STOP" position. For DC Injection Braking, set Jumper J7 to the "INJ"

position. See Figure 28. Also see Section 12.5 on page 21 for the DC Injection Brake

Trimpot.

When the Injection Brake Mode is selected, the DECEL Trimpot is used to set the amount of

time the DC current is applied to the motor.

BRAKING MODE SELECTION

Regenerative Braking

(Factory Setting) DC Injection Braking

FIGURE 28

10.7 – RUN/FAULT OUTPUT RELAY OPERATION SELECTION (J8)

Jumper J8 is factory set to the "R" position for "Run" operation of the Run/Fault Relay. For

"Fault" operation of the Run/Fault Relay, set Jumper J8 to the "F" position. See Figure 29.

For Run/Fault Relay output contacts, see Section 7.9 on page 18. The Run/Fault Relay

contact status for various drive operating conditions is shown in Table 5 on page 18.

10.8 – STOP CONTACT TYPE SELECTION (J9)

RUN/FAULT OUTPUT RELAY

"Run" Operation

(Factory Setting) "Fault" Operation

FIGURE 29

OPERATION SELECTION

Jumper J9 is factory set to the "NO" position for a normally open stop contact. For remote

normally closed stop contact, set Jumper J9 to the "NC" position. See Figure 30. For wiring

information, see Section 7.5 on page 17.

10.9 – TORQUE MODE SELECTION (J10)

Jumper J10 is factory set to the "CT" position for Constant Torque Mode, which is desirable

for most machine applications. For Variable Torque Mode, used for HVAC and fan

applications, set Jumper J10 to the "VT" position. See Figure 31.

STOP CONTACT TYPE SELECTION

Normally Open

Stop Contact

(Factory Setting)

FIGURE 30

Normally Closed

Stop Contact

10.10 – JUMPER J11

Factory use only.

10.11 – SWITCHING FREQUENCY AND GFCI SELECTION (J12)

(THIRD GENERATION (3G) DRIVES ONLY)