kawasaki RS10N User Manual

HIGH-SPEED, HIGH-PERFORMANCE

INDUSTRIAL ROBOTS

The new R-Series Robots are setting the benchmark for all small to medium

duty industrial robots. The compact design, along with industry leading speed,

reach and work range make the R-Series Robots ideal for a wide range of

applications throughout a multitude of diverse industries.

Applications

RS10N

Payload 10 kg

Horizontal Reach 1,450 mm

Vertical Reach 2,582 mm

Repeatability ±0.04 mm

Maximum Speed 11,800 mm/s

• Assembly

• Dispensing

• Inspection

• Machine Tending

• Material Handling

• Material Removal

• Welding

ULTRA HIGH-SPEED OPERATION

The new lightweight arm along with high-output

high-revolution motors provide industry leading

acceleration and high-speed operation. The

acceleration rate automatically adjusts to suit the

payload and robot posture to deliver optimum

performance and the shortest cycle times.

WIDE WORK RANGE

In addition to extending the robot’s maximum

reach, the rotation range of each axis has also been

increased. The extended motion range translates to a

larger usable work area with minimal dead-space and

greater flexibility.

ENVIRONMENTAL PROTECTION

The R-Series incorporates a double-seal construction

on all axes and the electrical connections are water-

resistant offering an IP67 classification for wrist and

IP65 for the remaining axes. If a wash-down arm is

required, the entire robot can be provided as IP67.

HIGH TORQUE

High-output motors, combined with a rigid arm

construction, allow for superior wrist torque

and load capacity.

INTEGRATED FEATURES

Built-in pneumatic lines and internal wiring are

standard. Mounting pads and taps are provided to

allow easy installation of additional cabling, tubing or

equipment.

SPACE SAVING

The slim arm design requires very little floor space.

Multiple robots can be installed in “high-density”

applications without impeding performance.

EASY MAINTENANCE

The Kawasaki design requires very little maintenance

while boasting industry leading mean time between

failures (MTBF).

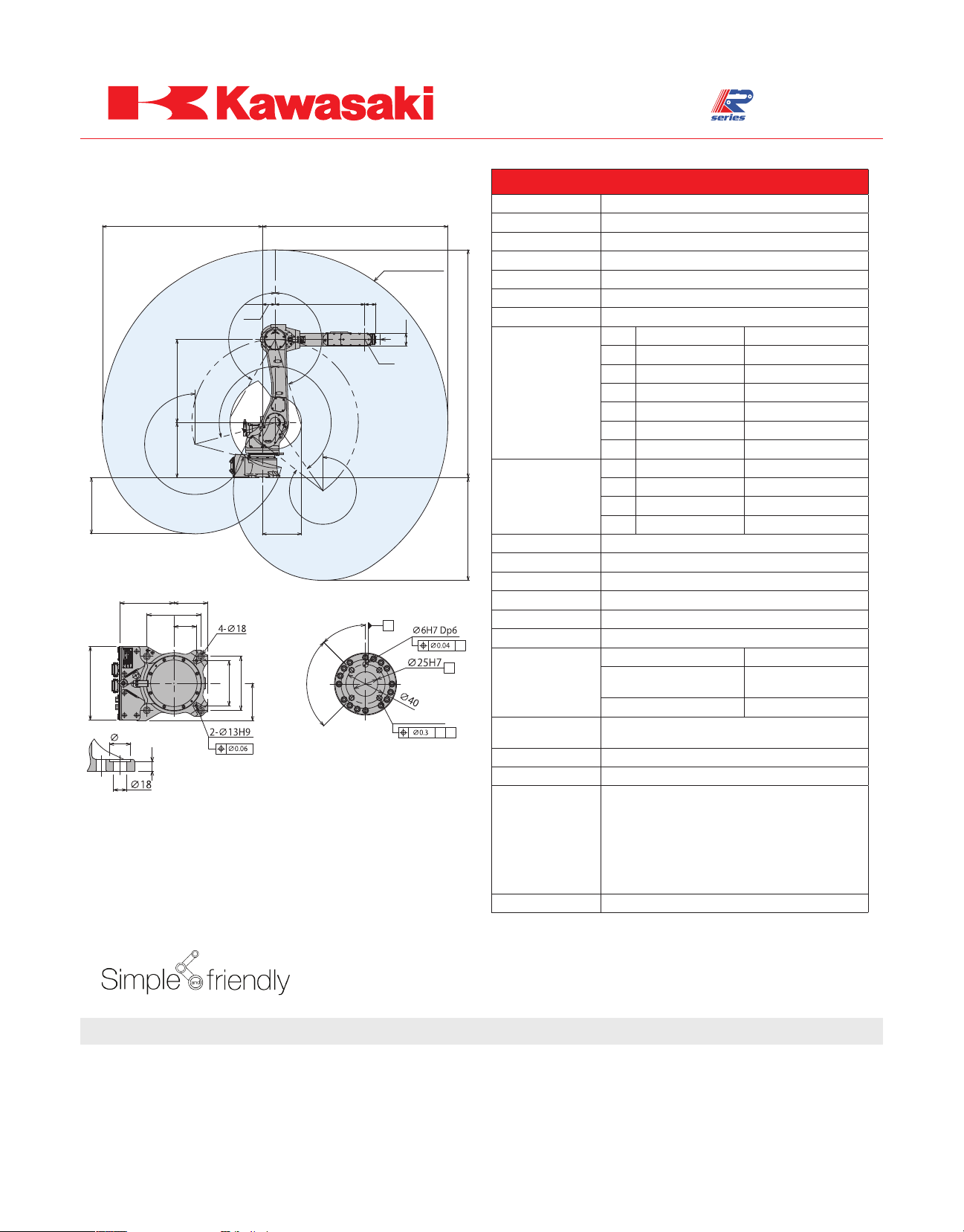

RS10N

MOTION RANGE & DIMENSIONS

90°

700

JT3:163°

JT2:

145°

308°

45°

1,450

VIEW A

1,250

JT2:

105°

184

100

305.6

220

153±0.1

JT3:150°

650

430

255°

438.2

138±0.1

220

220

92

300

30

13

INSTALLATION DIMENSIONS

Note: Detailed drawings are available upon request.

Working range

based on point P

88

A

P

Y

4-M6 Dp8

100

Dp6

X

YX

(mm)

Type

Degrees of Freedom

Payload

Horizontal Reach

Vertical Reach

Repeatability

Maximum Speed

Work

1,780

Envelope

(degrees)

&

Maximum Speed

(degrees/s)

Wrist Load

Capacity

802.4

Motor(s)

Brakes

Hard Stops

Mass

Body Color

Installation

X

Environmental

Conditions

Protection

Classification

Built-in Harness

Built-in Utilities

Options

Controller

RS10N SPECIFICATIONS

Articulated

6 axes

10 kg

1,450 mm

2,582 mm

±0.04 mm

11,800 mm/s

Axis Motion Range Maximum Speed

JT1 ±180° 250°/s

JT2 +145° ~ - 105° 250°/s

JT3 +150° ~ -163° 215°/s

JT4 ±270° 365°/s

JT5 ±145° 380°/s

JT6 ±360° 700°/s

Axis Maximum Torque Moment of Inertia

JT4 22 N·m 0.7 kg·m

JT5 22 N·m 0.7 kg·m

JT6 10 N·m 0.2 kg·m

Brushless AC Servomotor

All axes

Adjustable mechanical stopper JT1/JT2/JT3

150 kg (excluding Options)

Kawasaki Standard

Floor, wall, ceiling

Temperature 0 ~ 45º C

Humidity

35 ~ 85 % (no dew, nor

frost allowed)

Vibration Less than 0.5 G

Wrist: IP67 Base: IP65 * Equivalent

Sensor harness 12 inputs 24VDC, GND

Pneumatic piping (ø8 x 2 lines)

IP67 entire arm

Linear track options

Riser (300/600 mm)

Base plate

Double/single solenoid valves (4 units max.)

Air cleaning equipment (filter, regulator, mist separator)

Limit switch JT1

E30/E77 (see E Controller data sheet for specifications)

2

2

2

Assembly • Cutting • Dispensing • Grinding • Handling

Kawasaki Robotics (USA), Inc.

United States

28140 Lakeview Drive

Wixom, Michigan 48393

Phone (248) 446-4100

Email sales@kri-us.com

Canada

Phone (905) 304-7784

Mexico

Phone (52) 33-3110-1895

•

Inspection • Packaging • Painting • Palletizing • Polishing • Tending • Welding

www.kawasakirobotics.com

RS10N - REV04/11

© Kawasaki Robotics (USA), Inc. All rights reserved.

Technical specifications subject to change without notice.

Loading...

Loading...