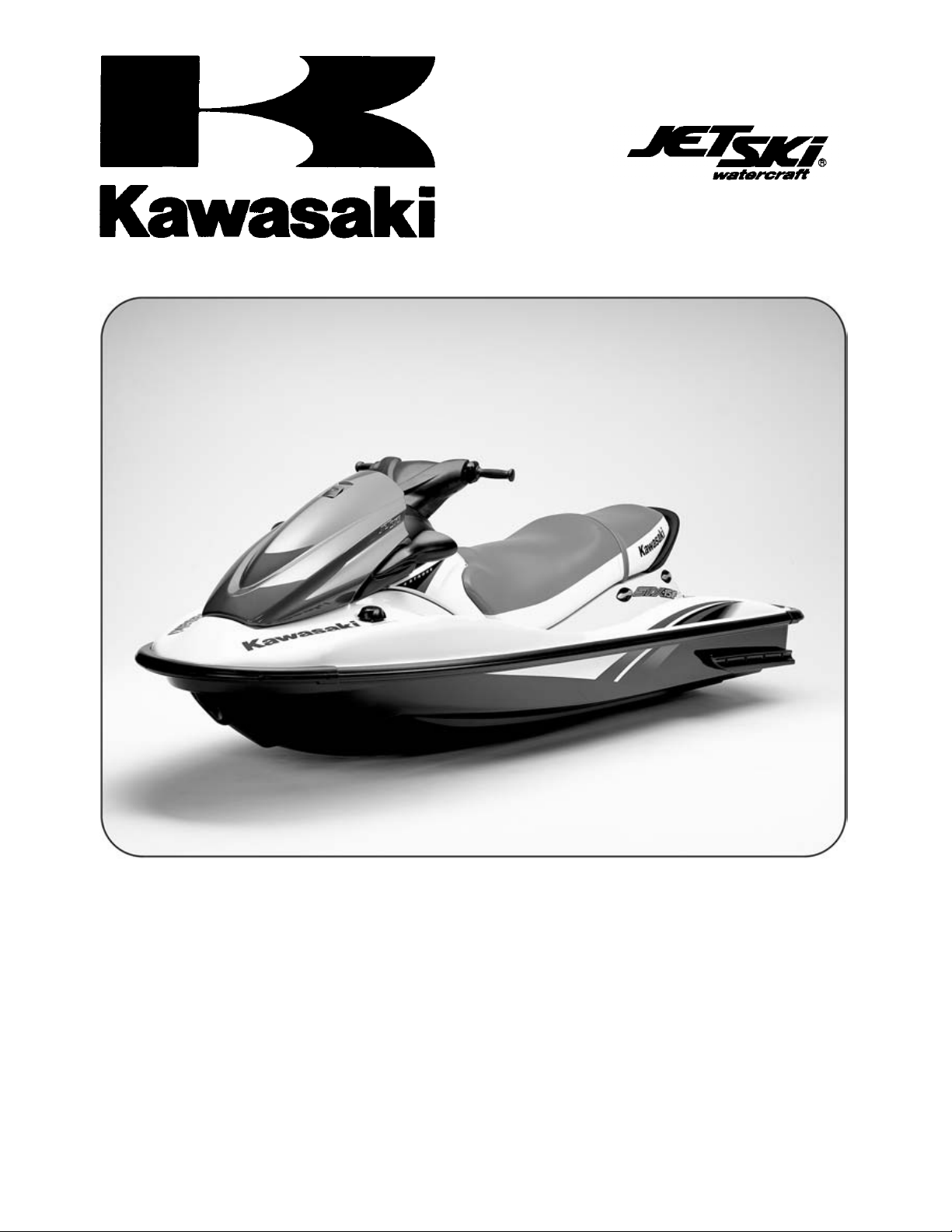

Kawasaki JET SKI STX-15F Service Manual

STX-15F

JET SKI

Service Manual

®

Watercraft

is a trademark of Kawasaki Heavy Industries, Ltd. registered in U.S.A., Japan,

Austria, Benelux, Sweden, Denmark, Switzerland, France, Canada, Finland, Norway, Greece, Italy,

U.K., Portugal, Thailand, and Taiwan.

KAWASAKI JET SKI®is a trademark of Kawasaki Heavy Industries, Ltd. registered in Australia.

Quick Reference Guide

General Information 1 j

Periodic Maintenance 2 j

Fuel System (DFI) 3 j

Engine Lubrication System 4 j

Exhaust System 5 j

Engine Top End 6 j

Engine Removal/Installation 7 j

Engine Bottom End 8 j

Cooling and Bilge Systems 9 j

This quick reference guide will assist

you in locating a desired topic or procedure.

•Bend the pages back to match the

black tab of the desired chapter number with the black tab on the edge at

each table of contents page.

•Refer to the sectional table of contents

for the exact pages to locate the specific topic required.

Drive System 10 j

Pump and Impeller 11 j

Steering 12 j

Hull/Engine Hood 13 j

Electrical System 14 j

Storage 15 j

Appendix 16 j

STX-15F

®

JET SKI

Service M

All rights reserved. No parts of this publication may be reproduced, stored in a retrieval system, or

transmitted in any form or by any means, electronic mechanical photocopying, recording or otherwise,

without the prior written permission of Quality Assurance Department/Consumer Products and Machinery

Company/Kawasaki Heavy Industries, Ltd., Japan.

No liability can be accepted for any inaccuracies or omissions in this publication, although every possible

care has been taken to make it as complete and accurate as possible.

The right is reserved to make changes at any time without prior notice and without incurring an obligation

to make such changes to products manufactured previously. See your JET SKI

latest information on product improvements incorporated after this publication.

All information contained in this publication is based on the latest product information available at the time

of publication. Illustrations and photographs in this publication are intended for reference use only and may

not depict actual model component parts.

Watercraft

anual

®

watercraft dealer for the

© 2003 Kawasaki Heavy Industries, Ltd. Second Edition (1):Oct. 15, 2004 (K)

LIST OF ABBREVIATIONS

A ampere(s) lb pound(s)

ABDC after bottom dead center

AC

ATDC after top dead center

BBDC before bottom dead center Pa pascal(s)

BDC bottom dead center PS horsepower

BTDC before top dead center psi pound(s) per square inch

°C degree(s) Celsius r revolution

DC direct current rpm revolution(s) perminute

F farad(s) TDC top dead center

°F degree(s) Fahrenheit TIR total indicator reading

ft foot, feet Vvolt(s)

ggram(s) W watt(s)

h

L

alternating current

hour(s)

liter(s)

m

min

N

Ω ohm(s)

meter(s)

minute(s)

newton(s)

Read OW

NER’S MANUAL before operating.

MAINTENANCE AND ADJUSTMENTS

Maintenance, replacement, or repair of the emission control devices and systems may

be performed by any marine Sl engine repair establishment or individual.

EMISSION CONTROL INFORMATION

Fuel Information

THIS ENGINE IS CERTIFIED TO OPERATE ON UNLEADED REGULAR GRADE GASOLINE

ONLY.

A minimum of 87 octane of the antiknock index is recommended. The antiknock index is posted

on service station pumps.

Emission Control Information

To protect the environment in which we all live, Kawasaki has incorporated an exhaust emission control system in compliance with applicable regulations of the United States Environmental

Protection Agency.

Exhaust Emission Control System

This system reduces the amount of pollutants discharged into the atmosphere by the exhaust

of this engine. The fuel, ignition and exhaust systems of this engine have been carefully designed and constructed to ensure an efficient engine with low exhaust pollutant levels.

Maintenance

Proper maintenance and repair are necessary to ensure that watercraft will continue to have

low emission levels. This Service Manual contains those maintenance and repair recommendations for this engine. Those items identified by the Periodic Maintenance Chart are necessary

to ensure compliance with the applicable standards.

Tampering with Emission Control System Prohibited

Federal law prohibits the following acts or the causing thereof: (1) the removal or rendering

inoperative by any person other than for purposes of maintenance, repair, or replacement, of

any device or element of design incorporated into any new engine for the purposes of emission

control prior to its sale or delivery to the ultimate purchaser or while it is in use, or (2) the use

of the engine after such device or element of design has been removed or rendered inoperative

by any person.

Among those acts presumed to c onstitute tampering are the acts listed below:

Do not tamper with the original emission related parts.

* Digital Transistor Ignition System

* Fuel Pump

* Spark Plugs

* Throttle Body and Internal Parts

* Fuel Injectors

*ECU

Foreword

This manual is designed primarily for use by

trained mechanics in a properly equipped shop.

However, it contains enough detail and basic information to make it useful to the owner who desires to perform his own basic maintenance and

repair work. A basic knowledge of mechanics,

the proper use of tools, and workshop procedures must be understood in order to carry out

maintenance and repair satisfactorily. Whenever the owner has insufficient experience or

doubts his ability to do the work, all adjustments, maintenance, and repair should be carried out only by qualified mechanics.

In order to perform the work efficiently and

to avoid costly mistakes, read the text, thoroughly familiarize yourself with the procedures

before starting work, and then do the work carefully in a clean area. Whenever special tools or

equipment are specified, do not use makeshift

tools or equipment. Precision measurements

can only be made if the proper instruments are

used, and the use of substitute tools may adversely affect safe operation.

For the duration of the warranty period,

we recommend that all repairs and scheduled

maintenance be performed in accordance with

this service manual. Any owner maintenance or

repair procedure not performed in accordance

with this manual may void the warranty.

To get the longest life out of your JET SKI

watercraft:

Follow the Periodic Maintenance Chart in the

•

Service Manual.

Be alert for problems and non-scheduled

•

maintenance.

Use proper tools and genuine Kawasaki JET

•

®

SKI

watercraft parts. Special tools, gauges,

and testers that are necessary when servicing

Kawasaki JET SKI

by the Special Tool Manual. Genuine parts

provided as spare parts are listed in the Parts

Catalog.

®

watercraft are introduced

Follow the procedures in this manual care-

•

fully. Don’t take shortcuts.

Remember to keep complete records of main-

•

tenance and repair with dates and any new

parts installed.

How to Use This Manual

In this manual, the product is divided into

its major systems and these systems make up

the manual’s chapters. The Quick Reference

Guide shows you all of the product’s system

and assists in locating their chapters. Each

chapter in turn has its own comprehensive Table of Contents.

For example, if you want ignition coil information, use the Quick Reference Guide to locate

the Electrical System chapter. Then, use the

Table of Contents on the first page of the chapter to find the Ignition Coil section.

Whenever you see these WARNING and

CAUTION symbols, heed their instructions!

Always follow safe operating and maintenance

practices.

WARNING

This warning symbol identifies special

instructions or procedures which, if not

correctly followed, could result in per-

®

sonal injury, or loss of life.

CAUTION

This caution symbol identifies special

instructions or procedures which, if not

strictly observed, could result in dam-

age to or destruction of equipment.

This manual contains four more symbols (in

addition to WARNING and CAUTION) which will

help you distinguish different types of information.

NOTE

This note symbol indicates points of par-

○

ticular interest for more efficient and convenient operation.

Indicates a procedural step or work to be

•

done.

Indicates a procedural sub-step or how to do

○

the work of the procedural step it follows. It

also precedes the text of a NOTE.

Indicates a conditional step or what action to

take based on the results of the test or inspection in the procedural step or sub-step it fol-

lows.

In most chapters an exploded view illustration

of the system components follows the Table of

Contents. In these illustrations you will find the

instructions indicating which parts require specified tightening torque, oil, grease or a locking

agent during assembly.

This model, JT1500A, is mounted with a four

-stroke engine.

When the JET SKI

and swamped, the four-stroke engine needs

special care and systematic procedure for recovery compared with the two-stroke engine.

Therefore in this manual, such procedures,

which are not shown in SMs for two-stroke

engines, are explained thoroughly to cope with

the cases.

Refer to the section, After submerging in

Chapter 9, Cooling and Bilge Systems for the

summary and detailed procedures.

®

watercraft is submerged

GENERAL INFORMATION 1-1

General Information

Table of Contents

Smart Learning Operation mode (SLO) (JT1500-A2 model ∼)............................................... 1-2

Before Servicing ..................................................................................................................... 1-3

Model Identification................................................................................................................. 1-10

General Specifications............................................................................................................ 1-11

Unit Conversion Table ............................................................................................................ 1-13

1

1-2 GENERAL INFORMATION

Smart Learning Operation mode (SLO) (JT1500-A2 model ∼)

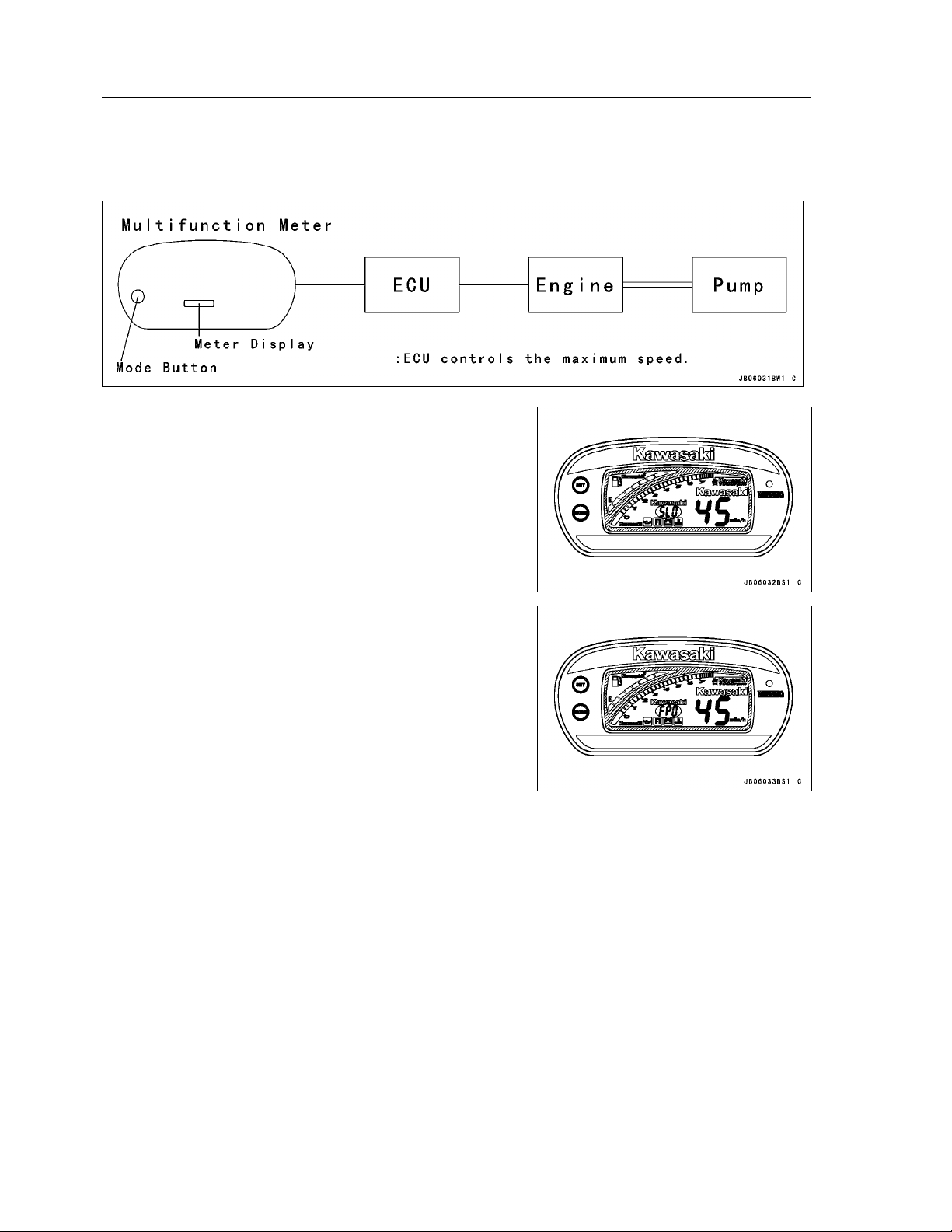

This watercraft is equipped with the Smart Learning Operation mode (SLO) and normal operation

mode (Full Power Operation, FPO). The SLO mode reduces the maximum watercraft speed by approximately 30 percent for a use by unskilled operators. To change the SLO mode to FPO mode, and

back again, push the “MODE” button for 7 seconds or more.

SLO mode is displayed on the meter as SLO.

NOTE

When shifted to the SLO mode, the initial display, as

○

shown when the ignition switch is turned on, is shown

together with a buzzer sound.

Then, “SLO” is shown blinking at every three seconds.

○

Under the SLO mode, all the meter displays and other

○

functions work in the same manner as the normal operation (Full Power Operation, FPO) mode.

Normal operation mode (Full Power Operation mode, FPO)

is shown by FPO display.

NOTE

When shifted to the normal operation mode (Full Power

○

Operation mode, FPO), the same initial display is first

shown and followed by “FPO” for two seconds. However, “FPO” is shown only once when shifted and is not

displayed thereafter.

When the ignition switch is turned off and on again, the

○

same mode when turned off is displayed again.

GENERAL INFORMATION 1-3

Before Servicing

Before starting to perform an inspection service or carry out a disassembly and reassembly operation on watercraft, read the precautions given below. To facilitate actual operations, notes, illustrations, photographs, cautions, and detailed descriptions have been included in each chapter wherever

necessary. This section explains the items that require particular attention during the removal and

reinstallation or disassembly and reassembly of general parts.

Especially note the following:

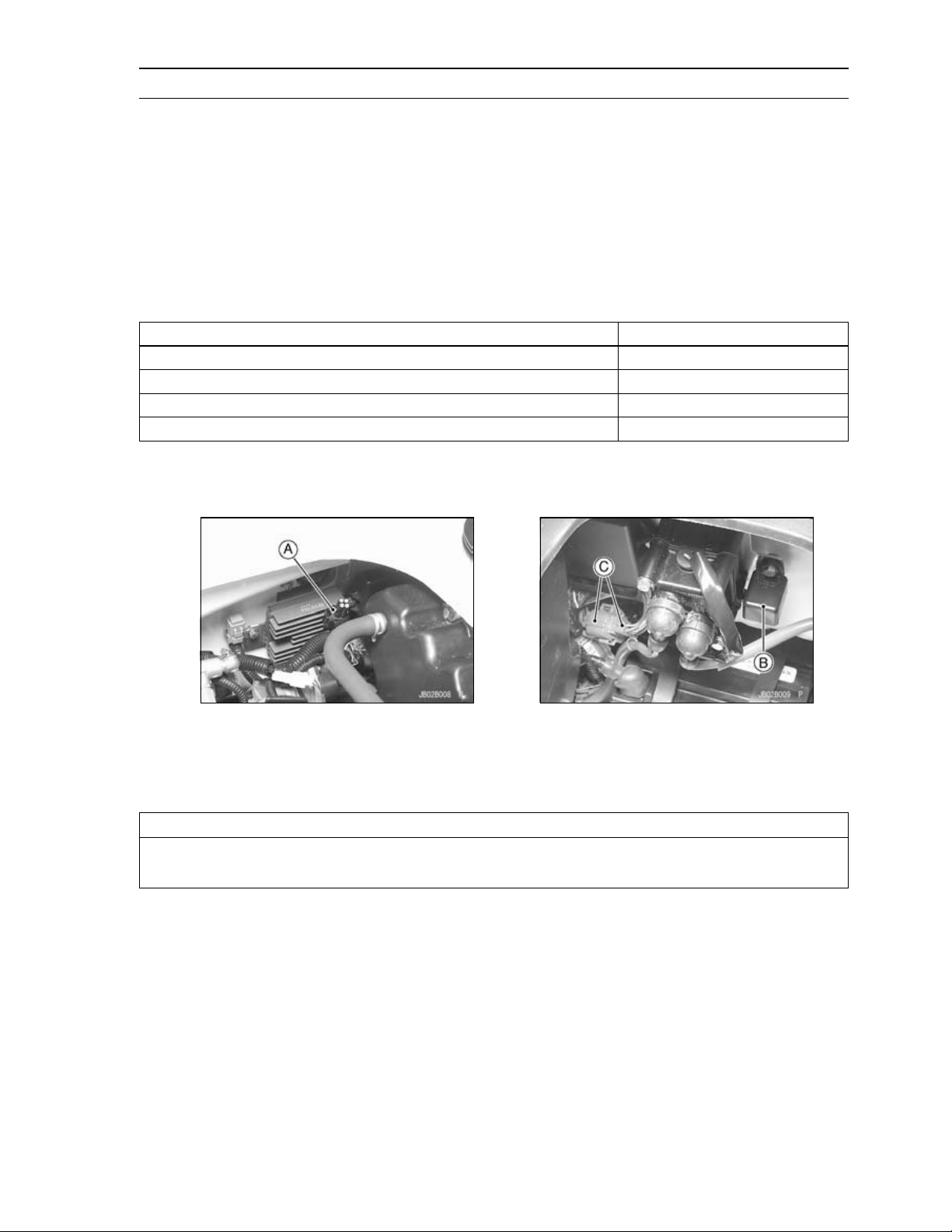

Kawasaki Diagnostic System (KDS) Software

KDS software version 2.2 that runs on Windows personal computer (PC) will be available as a diagnostic tool for watercraft with Kawasaki DFI system.

You need the following items to use the KDS.

Item P/No.

KDS Software Version 2.2 (CD-ROM) 57001-1503

Signal Converter 57001-1504

Communication Cable and Cable Adapter

Relay Cable

The connectors for the communication cable and relay cable are located in the front of the battery.

Connect the communication cable to the KDS connector (4-pin) [A] and the relay cable between

the relay assembly [B] connectors (8-pin) [C].

57001-1470

57001-1535

Adjustments

Adjustments shall be made in accordance with the Periodic Maintenance Chart or whenever troubleshooting or presence of symptoms indicate that adjustments may be required. Whenever running

of the engine is required during maintenance it is best to have the watercraft in water.

CAUTION

Do not run the engine without cooling water supply for more than 15 seconds, especially

in high revolutionary speed or severe engine and exhaust system damage will occur.

Auxiliary Cooling

An auxiliary cooling supply may be used if the watercraft cannot be operated in water during adjustments. If possible, always operate the watercraft in water rather than use an auxiliary cooling supply.

1-4 GENERAL INFORMATION

Before Servicing

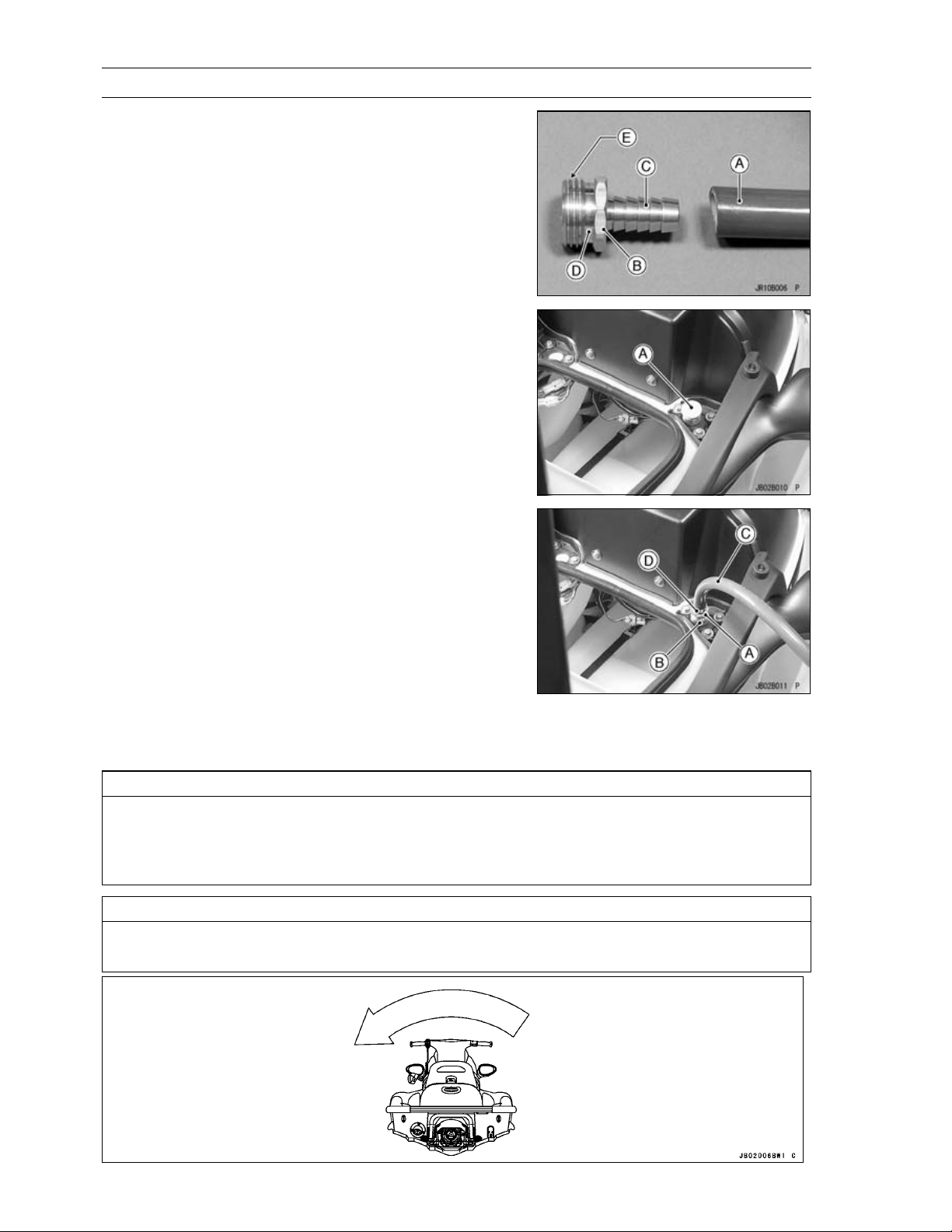

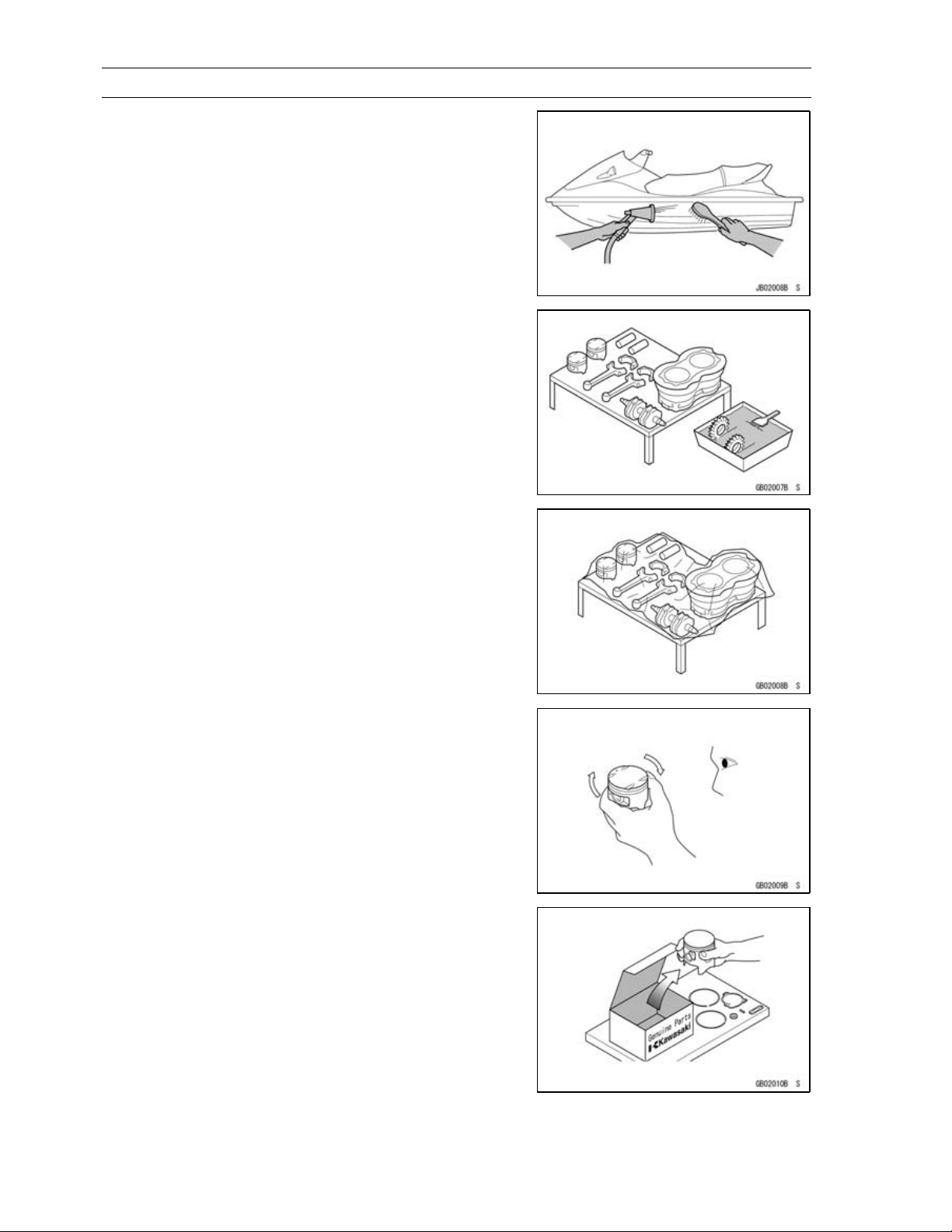

Obtain a standard garden hose [A] and a garden hose

•

adapter [B] as shown.

C: Garden Hose Fitting of Adapter

D: Flushing Fitting of Adapter

E: Thread: Rp 3/4

Optional part (P/No. 92005-3746) is available as a garden

○

hose adapter.

Open the front storage compartment cover.

•

Remove the flushing cap [A] on the brim of the storage

•

compartment.

Screw a garden hose adapter [A] onto the flushing fitting

•

[B].

Attach a garden hose [C] to a garden hose adapter and

•

secure the hose clamp [D].

Attach the garden hose to a faucet. Do not turn on the water until the engine is running and turn it

•

off immediately when the engine stops. The engine requires 2.4 L/min (2.5 qts/min) at 1 800 rpm

and 7.0 L/min (7.4 qts/min) at 6 000 rpm.

CAUTION

Insufficient cooling supply will cause the engine and/or exhaust system to overheat and

severe damage will occur. Excessive cooling supply may kill the engine and flood the cylinders, causing hydraulic lock. Hydraulic lock will cause severe damage to the engine. If the

engine dies while using an auxiliary cooling supply, the water must be shut off immediately.

CAUTION

Always turn the boat on its left side. Rolling to the right side can cause water in the exhaust

system to run into the engine, with possible engine damage.

GENERAL INFORMATION 1-5

Before Servicing

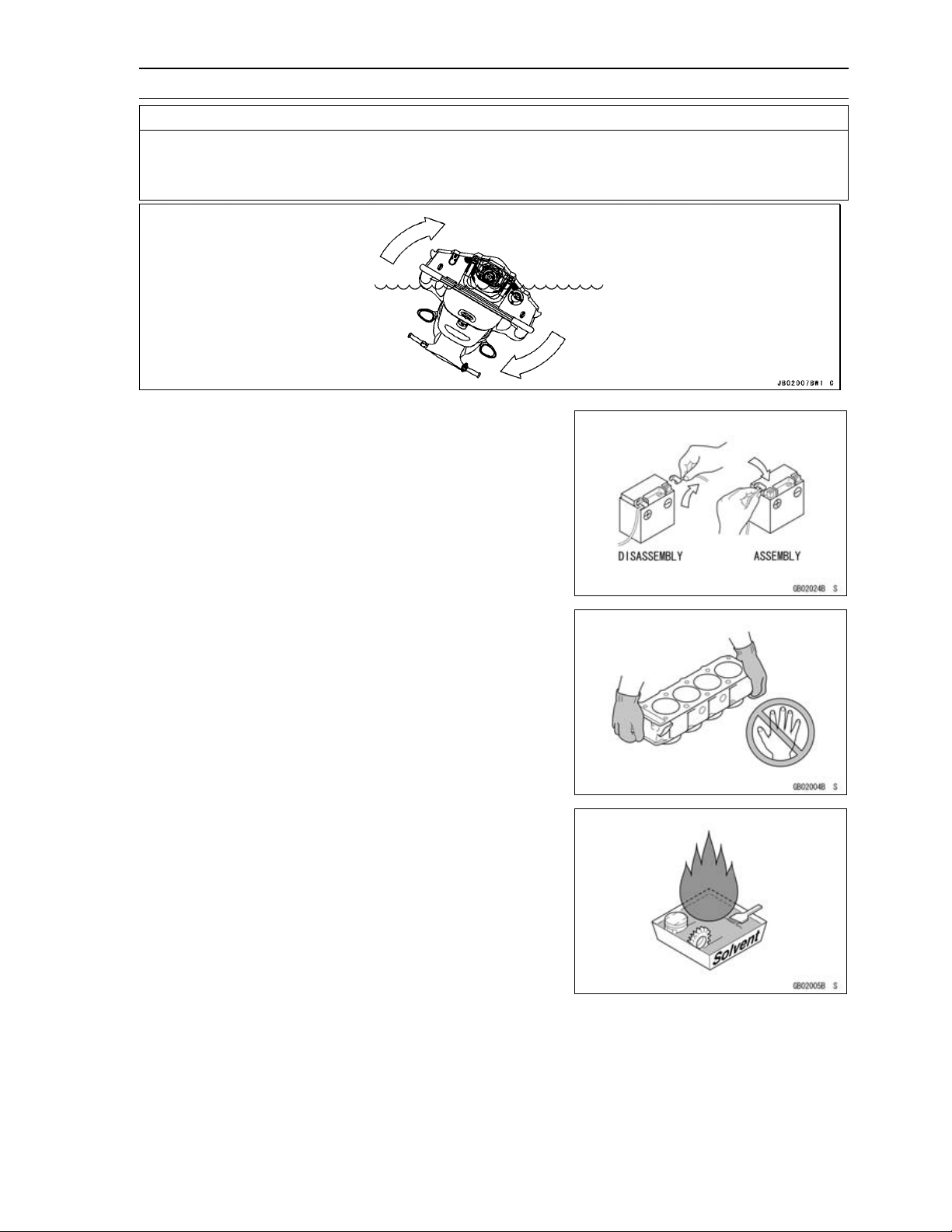

CAUTION

Turn the capsized boat clockwise so that the port side always faces downward. Turning

counterclockwise can cause water in the exhaust system to run into the engine, with pos-

sible engine damage.

Battery Ground

Before completing any service on the watercraft, disconnect the battery wires from the battery to prevent the engine

from accidentally turning over. Disconnect the ground wire

(–) first and then the positive (+). When completed with the

service, first connect the positive (+) wire to the positive (+)

terminal of the battery then the negative (–) wire to the negative terminal.

Edges of Parts

Lift large or heavy parts wearing gloves to prevent injury

from possible sharp edges on the parts.

Solvent

Use a high flush point solvent when cleaning parts. High

flush point solvent should be used according to directions

of the solvent manufacturer.

1-6 GENERAL INFORMATION

Before Servicing

Cleaning Watercraft before Disassembly

Clean the watercraft thoroughly before disassembly. Dirt

or other foreign materials entering into sealed areas during

watercraft disassembly can cause excessive wear and decrease performance of the watercraft.

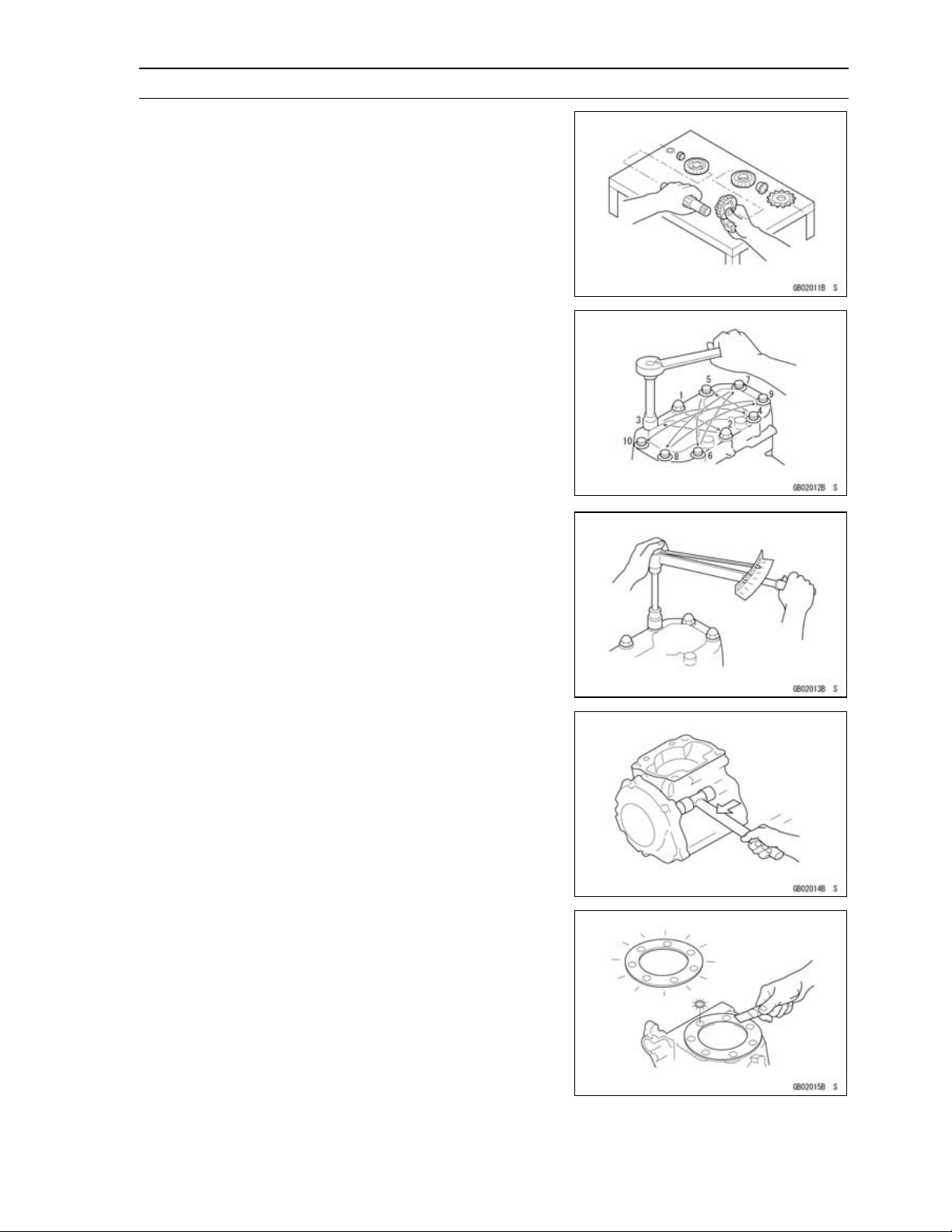

Arrangement and Cleaning of Removed Parts

Disassembled parts are easy to confuse. Arrange the

parts according to the order the parts were disassembled

and clean the parts in order prior to assembly.

Storage of Removed Parts

After all the parts including subassembly parts have been

cleaned, store the parts in a clean area. Put a clean cloth

or plastic sheet over the parts to protect from any foreign

materials that may collect before re-assembly.

Inspection

Reuse of worn or damaged parts may lead to serious accident. Visually inspect removed parts for corrosion, discoloration, or other damage. Refer to the appropriate sections

of this manual for service limits on individual parts. Replace

the parts if any damage has been found or if the part is beyond its service limit.

Replacement Parts

Replacement Parts must be KAWASAKI genuine or

recommended by KAWASAKI. Gaskets, O-rings, Oil seals,

Grease seals, circlips or cotter pins must be replaced with

new ones whenever disassembled.

Before Servicing

Assembly Order

In most cases assembly order is the reverse of disassembly, however, if assembly order is provided in this Service

Manual, follow the procedures given.

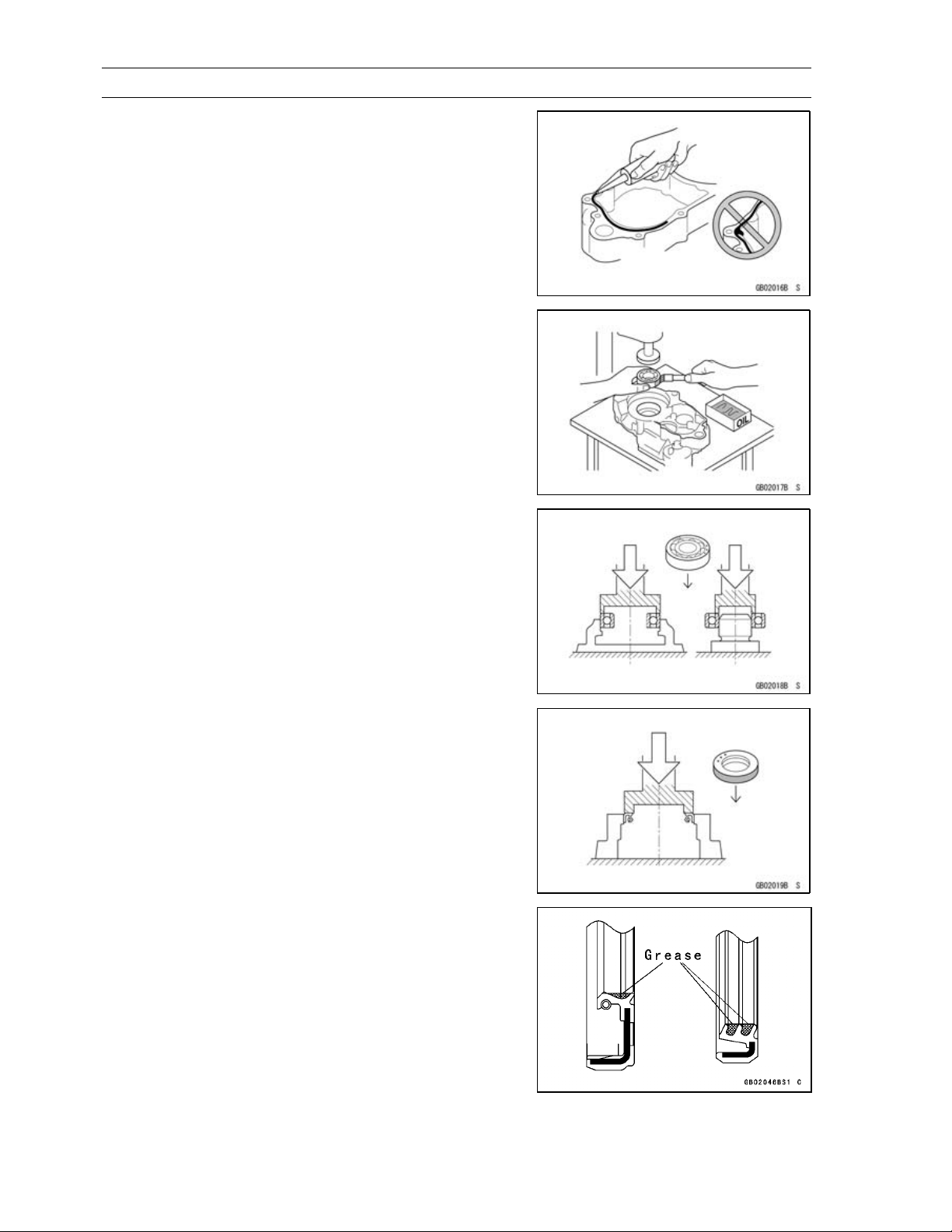

Tightening Sequence

Generally, when installing a part with several bolts, nuts,

or screws, start them all in their holes and tighten them to

a snug fit. Then tighten them according to the specified sequence to prevent case warpage or deformation which can

lead to malfunction. Conversely when loosening the bolts,

nuts, or screws, first loosen all of them by about a quarter turn and then remove them. If the specified tightening

sequence is not indicated, tighten the fasteners alternating

diagonally.

GENERAL INFORMATION 1-7

Tightening Torque

Incorrect torque applied to a bolt, nut, or screw may

lead to serious damage. Tighten fasteners to the specified

torque using a good quality torque wrench.

Force

Use common sense during disassembly and assembly,

excessive force can cause expensive or hard to repair damage. When necessary, remove screws that have a non

-permanent locking agent applied using an impact driver.

Use a plastic-faced mallet whenever tapping is necessary.

Gasket, O-ring

Hardening, shrinkage, or damage of both gaskets

and O-rings after disassembly can reduce sealing performance. Remove old gaskets and clean the sealing

surfaces thoroughly so that no gasket material or other

material remains. Install new gaskets and replace used

O-rings when re-assembling

1-8 GENERAL INFORMATION

Before Servicing

Liquid Gasket, Locking Agent

For applications that require Liquid Gasket or a Locking

agent, clean the surfaces so that no oil residue remains before applying liquid gasket or locking agent. Do not apply

them excessively. Excessive application can clog oil passages and cause serious damage.

Press

For items such as bearings or oil seals that must be

pressed into place, apply small amount of oil to the contact area. Be sure to maintain proper alignment and use

smooth movements when installing.

Ball Bearing

Do not remove pressed ball or needle unless removal is

absolutely necessary. Replace with new ones whenever

removed. Press bearings with the manufacturer and size

marks facing out. Press the bearing into place by putting

pressure on the correct bearing race as shown.

Pressing the incorrect race can cause pressure between

the inner and outer race and result in bearing damage.

Oil Seal, Grease Seal

Do not remove pressed oil or grease seals unless removal

is necessary. Replace with new ones whenever removed.

Press new oil seals with manufacture and size marks facing

out. Make sure the seal is aligned properly when installing.

Apply specified grease to the lip of seal before installing

the seal.

Before Servicing

Circlips, Cotter Pins

Replace circlips or cotter pins that were removed with new

ones. Take care not to open the clip excessively when installing to prevent deformation.

Lubrication

It is important to lubricate rotating or sliding parts during

assembly to minimize wear during initial operation. Lubrication points are called out throughout this manual, apply

the specific oil or grease as specified.

GENERAL INFORMATION 1-9

Direction of Engine Rotation

When rotating the crankshaft, by hand, the free play

amount of rotating direction will affect the adjustment. Rotate the crankshaft to positive direction (counter-clockwise

viewed from stern sinde).

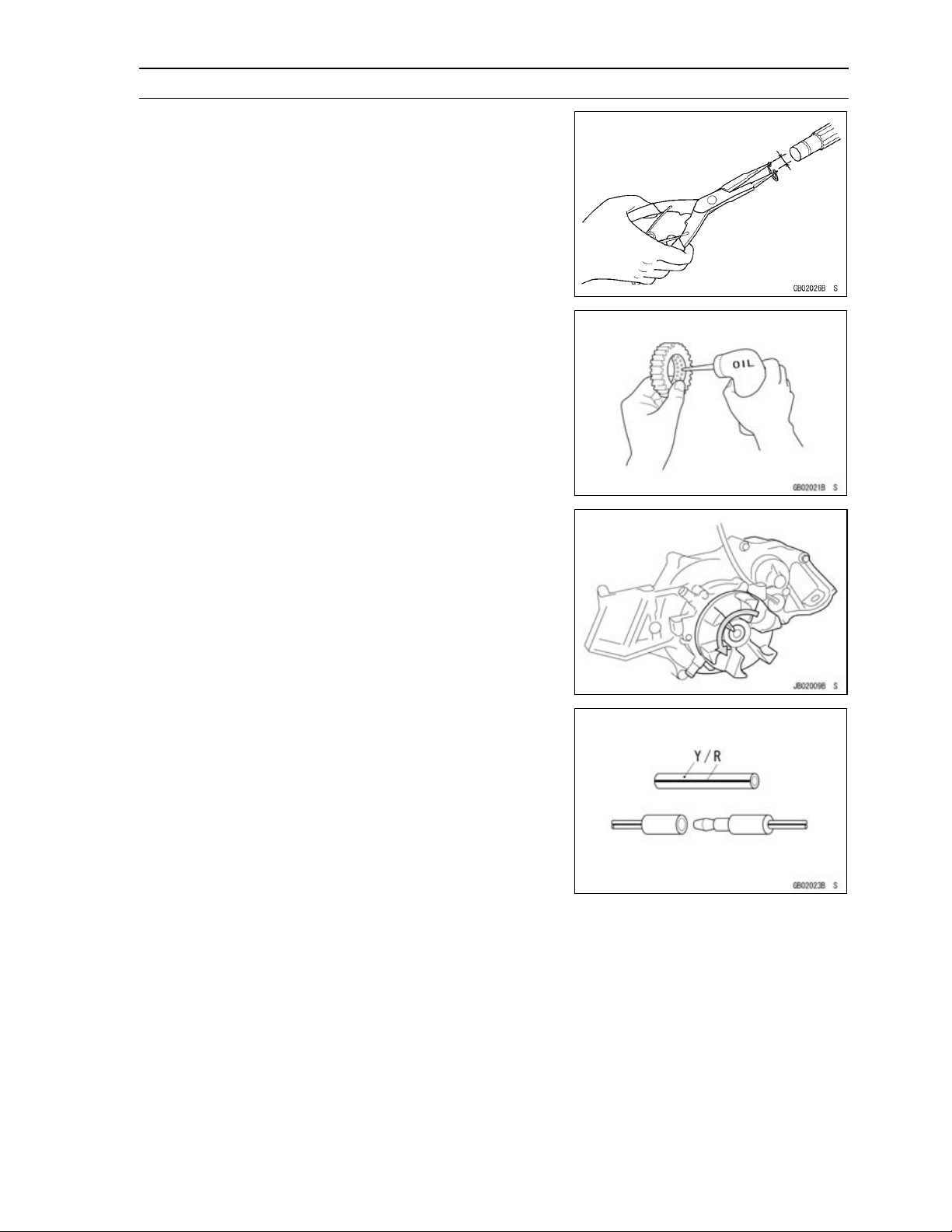

Electrical Wires

A two-color wire is identified first by the primary color and

then the s tripe color. Unless instructed otherwise, electrical

wires must be connected to those of the same color.

1-10 GENERAL INFORMATION

Model Identification

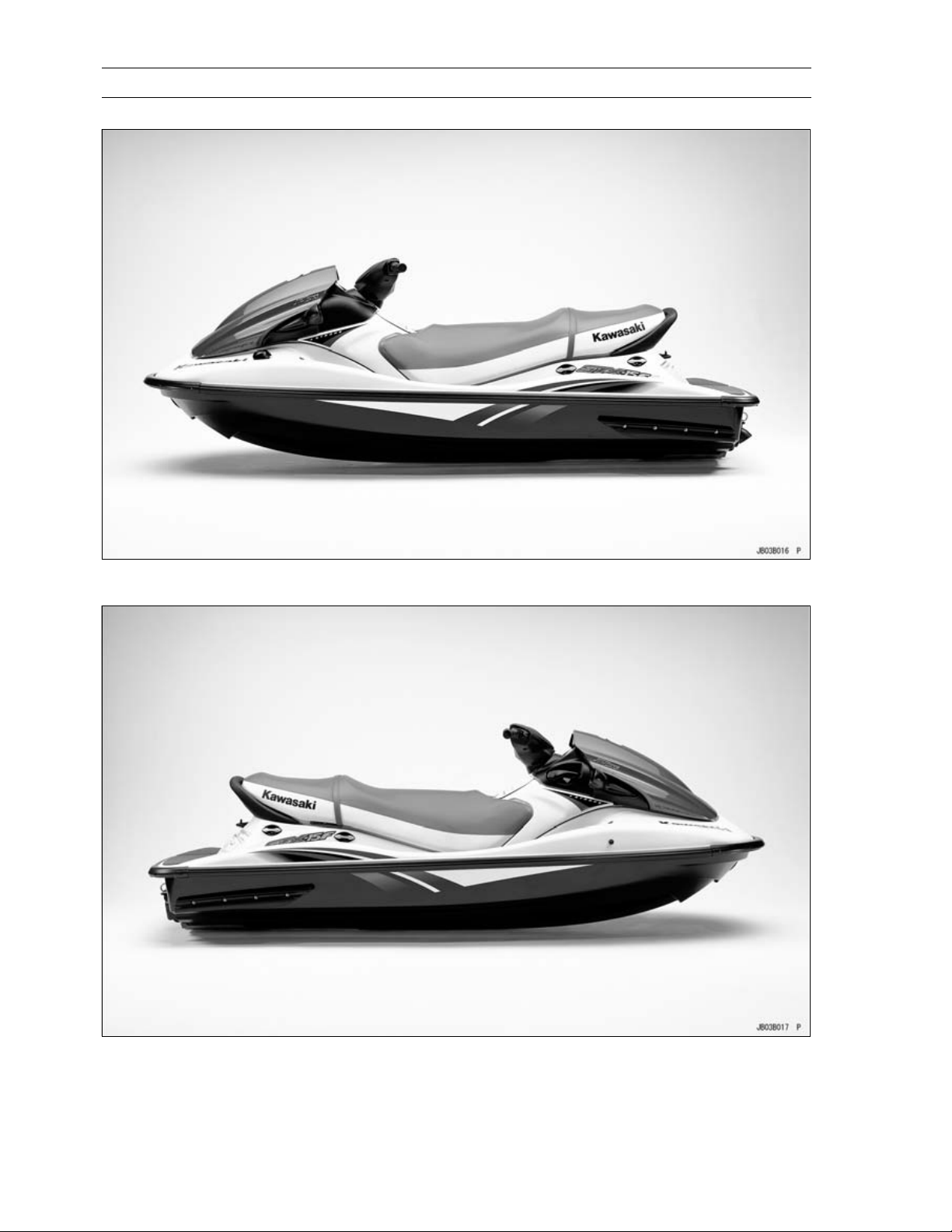

JT1500-A1 Left Side View

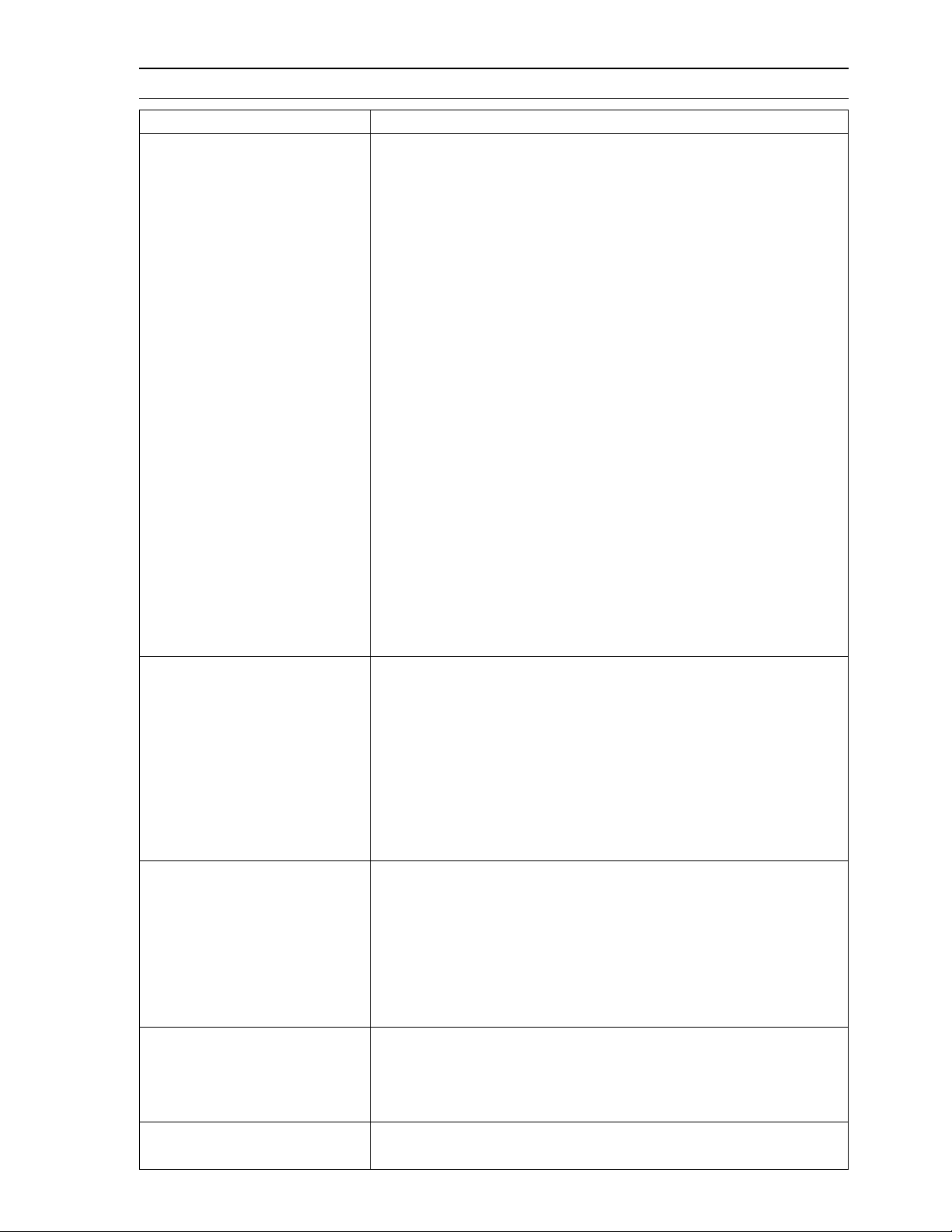

JT1500-A1 Right Side View

GENERAL INFORMATION 1-11

General Specifications

Items JT1500-A1 ∼ A2

Engine

Type

Displacement

Bore and Stroke 83 × 69.2 mm (3.27 × 2.72 in.)

Compression Ratio 10.6 : 1

Maximum Horsepower 118kW(160PS)@7500r/min(rpm)

Maximum Torque 152 N·m (15.5 kgf·m, 112.1 ft·lb) @7 250 r/min (rpm)

Ignition System Digital transistor

Lubrication System Forced lubrication (semi-dry sump)

Carburetion System FI (fuel injection) MIKUNI AC 60 × 1

Starting System Electric starter

Cylinder Numbering Method Front (bow) to rear (stern), 1-2-3-4

Firing Order 1-2-4-3

Valve Timing:

Inlet:

Open 22.5° BTDC

Close 67.5° ABDC

Duration 270°

Exhaust:

Open 74.5° BBDC

Close 9.5° ATDC

Duration

Tuning Specifications

Spark plug:

Type NGK CR9EK

Gap 0.7 ∼ 0.8 mm (0.028 ∼ 0.031 in.)

Ignition Timing 3° ATDC @1 300 r/min ∼ 32° BTDC @3 000 r/min (rpm)

Idle Speed 1 300 ±100 r/min (rpm) -in water

Compression Pressure 1190∼ 1799kPa(12.1∼ 18.3 kgf/cm², 173 ∼ 261 psi) @430

Drive System

Coupling Direct drive from engine

Jet Pump:

Type Axial flow single stage

Thrust 4 250 N (434 kgf, 955 lb)

Steering Steerable nozzle

Braking Water drag

Performance

†Minimum Turning Radius

†Fuel Consumption 43 L/h (11.4 US gal/h) @full throttle

†Cruising Range 134 km (87 mile) @full throttle 1 hour and 26 minutes (3 person)

Dimensions

Overall Length 3 120 mm (122.8 in.)

4-stroke, DOHC, 4-cylinder, water cooled

1498mL(91.4cuin.)

264°

1 300 ±100 r/min (rpm) -out of water

r/min (rpm)

4.0 m (13.1 ft)

1-12 GENERAL INFORMATION

General Specifications

Items JT1500-A1 ∼ A2

Overall Width 1180mm(46.5in.)

Overall Height 1050mm(41.3in.)

Dry Weight

Fuel Tank Capacity 62 L (16.4 US gal)

Engine Oil

Type API SE, SF or SG

Viscosity SAE 10W-40

Capacity 5.0 L (5.3 US qt)

Electrical Equipment

Battery 12 V 18 Ah

Maximum Generator Output 16 A @14 V

†: This information shown here represents resul ts under controlled conditions, and the information

may not be correct under other conditions.

Specifications subject to change without notice, and may not apply to every country.

338 kg (745 lb)

API SH or SJ with JASO MA

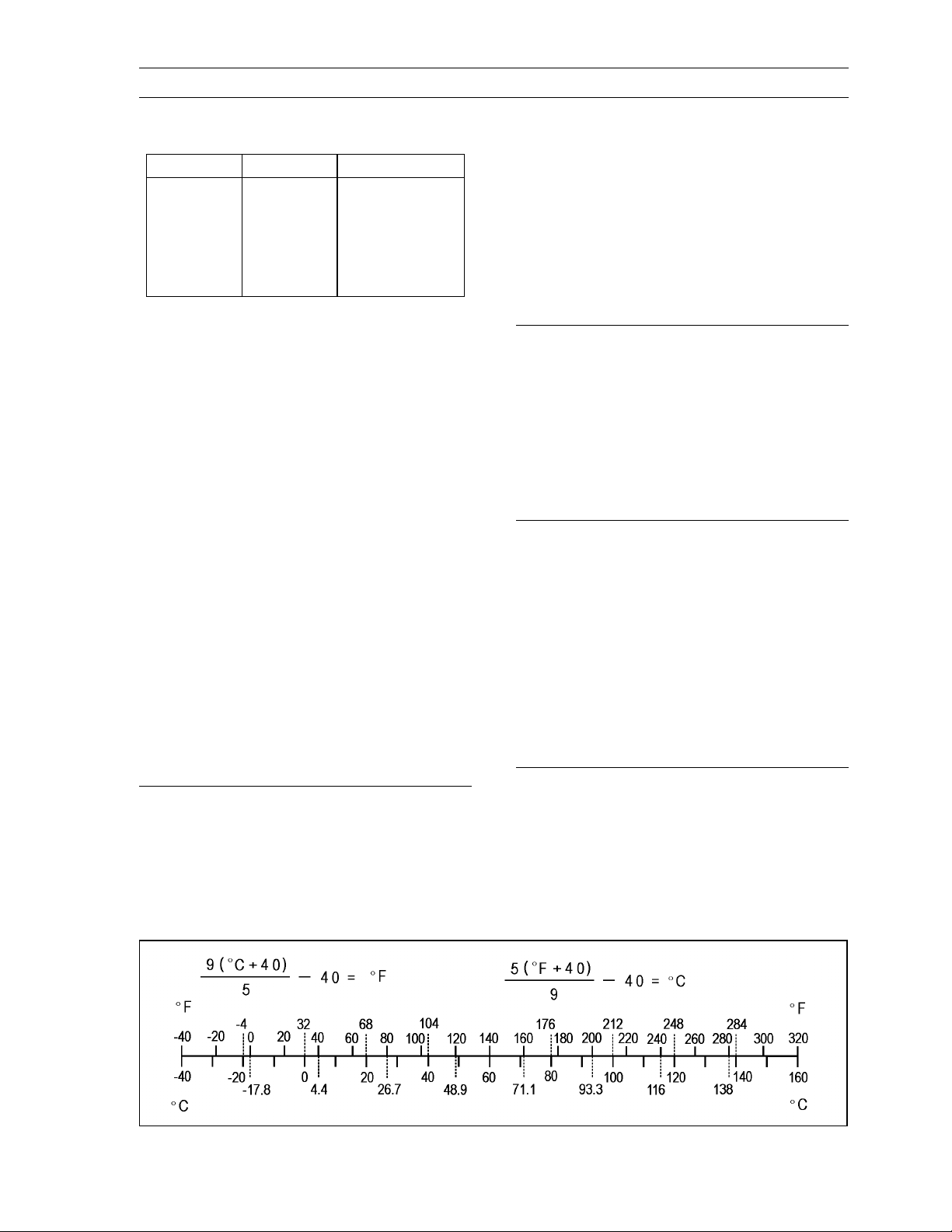

Unit Conversion Table

GENERAL INFORMATION 1-13

Prefixes for Units

Prefix Symbol

mega M × 1 000 000

kilo k ×1000

centi c ×0.01

milli m × 0.001

micro µ × 0.000001

Power

Units of Mass

kg ×2.205=lb

g × 0.03527 = oz

Units of Volume

L × 0.2642 = gal (US)

L × 0.2200 = gal (imp)

L × 1.057 = qt (US)

L × 0.8799 =

L×2.113=

L × 1.816 = pint (imp)

mL × 0.03381 = oz (US)

mL × 0.02816 = oz (imp)

mL × 0.06102 = cu in

qt (imp)

pint (US)

Units of Length

km × 0.6214 = mile

m × 3.281 = ft

mm × 0.03937 = in.

Units of Torque

N·m × 0.1020 = kgf·m

N·m × 0.7376 = ft·lb

N·m × 8.851 = in·lb

kgf·m × 9.807 = N·m

kgf·m × 7.233 = ft·lb

kgf·m × 86.80 = in·lb

Units of Pressure

kPa × 0.01020 = kgf/cm²

kPa × 0.1450 = psi

kPa × 0.7501 = cmHg

kgf/cm² × 98.07 = kPa

kgf/cm² × 14.22 = psi

cmHg×1.333=kPa

Units of Speed

km/h

× 0.6214 = mph

Units of Force

N × 0.1020 = kg

N × 0.2248 = lb

kg ×9.807=N

kg ×2.205=lb

Units of Temperature

Units of Power

kW ×1.360=PS

kW ×1.341=HP

PS

PS × 0.9863 = HP

× 0.7355 = kW

PERIODIC MAINTENANCE 2-1

Periodic Maintenance

Table of Contents

Periodic Maintenance Chart ................................................................................................... 2-2

Torque and Locking Agent...................................................................................................... 2-3

Specifications ......................................................................................................................... 2-8

Special Tools and Sealant ...................................................................................................... 2-9

Periodic Maintenance Procedures.......................................................................................... 2-10

Fuel System......................................................................................................................... 2-10

Throttle Control System Inspection ................................................................................... 2-10

Air Filter Drain Caps Inspection and Cleaning .................................................................. 2-10

Air Filter Inspection and Cleaning..................................................................................... 2-11

Fuel Vent Check Valve Inspection .................................................................................... 2-11

Fuel Pump Screen Cleaning ............................................................................................. 2-12

Throttle Shaft Spring Inspection........................................................................................ 2-12

Engine Lubrication System.................................................................................................. 2-12

Engine Oil Change............................................................................................................ 2-12

Oil Filter Replace .............................................................................................................. 2-14

Engine Top End ................................................................................................................... 2-15

Air Suction Valve Inspection ............................................................................................. 2-15

Valve Clearance Inspection .............................................................................................. 2-15

Engine Mounting Bolts Inspection and Tightness ............................................................. 2-19

Engine Bottom End.............................................................................................................. 2-19

Coupling Damper Inspection............................................................................................. 2-19

Cooling and Bilge Systems .................................................................................................. 2-19

Cooling System Flushing .................................................................................................. 2-19

Bilge System Flushing ...................................................................................................... 2-21

Pump and Impeller............................................................................................................... 2-22

Impeller Inspection............................................................................................................ 2-22

Steering ............................................................................................................................... 2-22

Steering Cable/Shift Cable Inspection .............................................................................. 2-22

Handlebar Pivot Lubrication.............................................................................................. 2-22

Hull/Engine Hood.................................................................................................................2-23

Drain Plug Inspection........................................................................................................ 2-23

Electrical System ................................................................................................................. 2-23

Battery Charging Condition Inspection ............................................................................. 2-23

Battery Terminals Inspection............................................................................................. 2-23

Spark Plug Cleaning and Inspection................................................................................. 2-24

Lubrication ........................................................................................................................... 2-24

All Hoses, Hose Clamps, Nuts, Bolts and Fasteners Check ............................................... 2-27

Nuts, Bolts, and Fasteners Tightness Inspection.............................................................. 2-27

Hose and Hose Connect Inspection ................................................................................. 2-27

Rubber Strap Inspection ................................................................................................... 2-29

2

2-2 PERIODIC MAINTENANCE

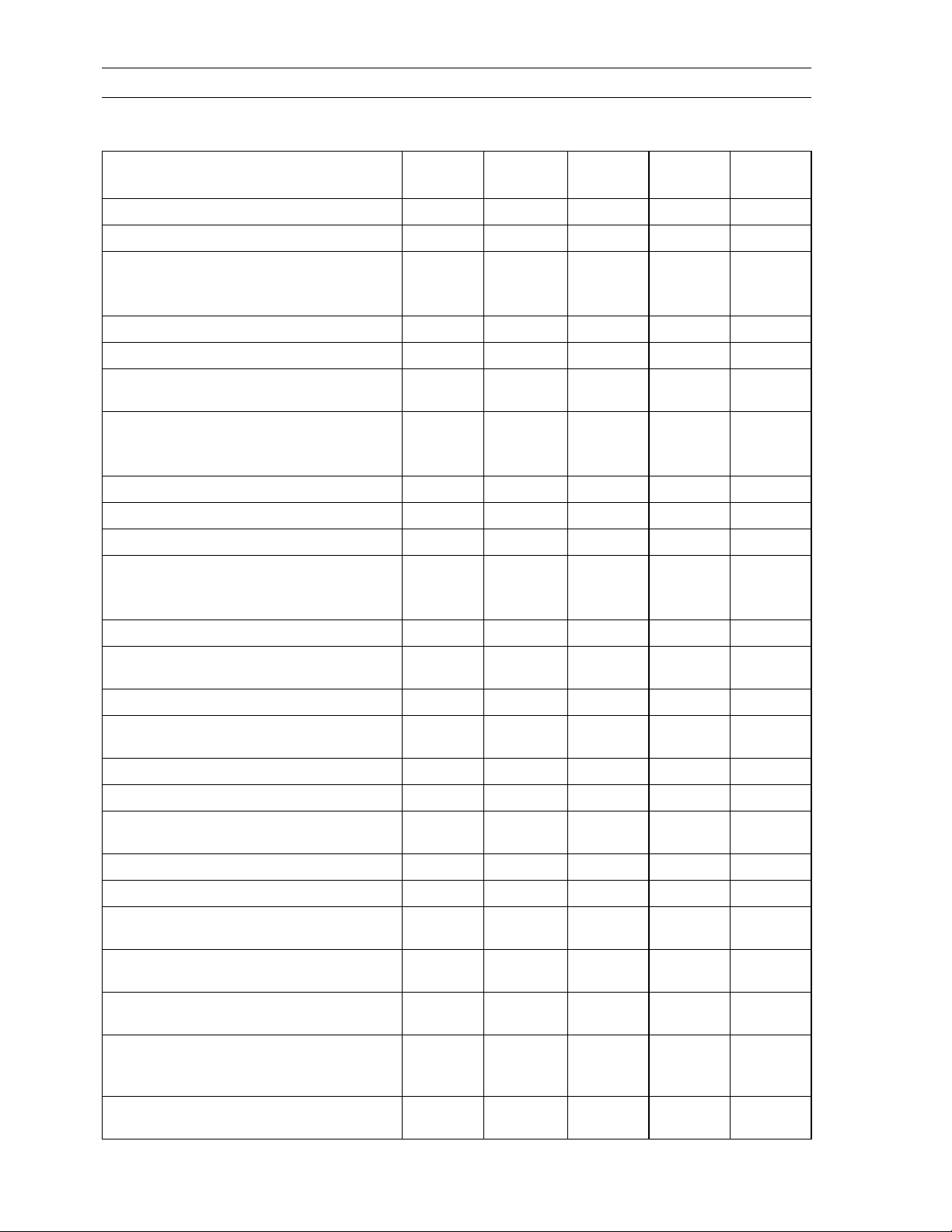

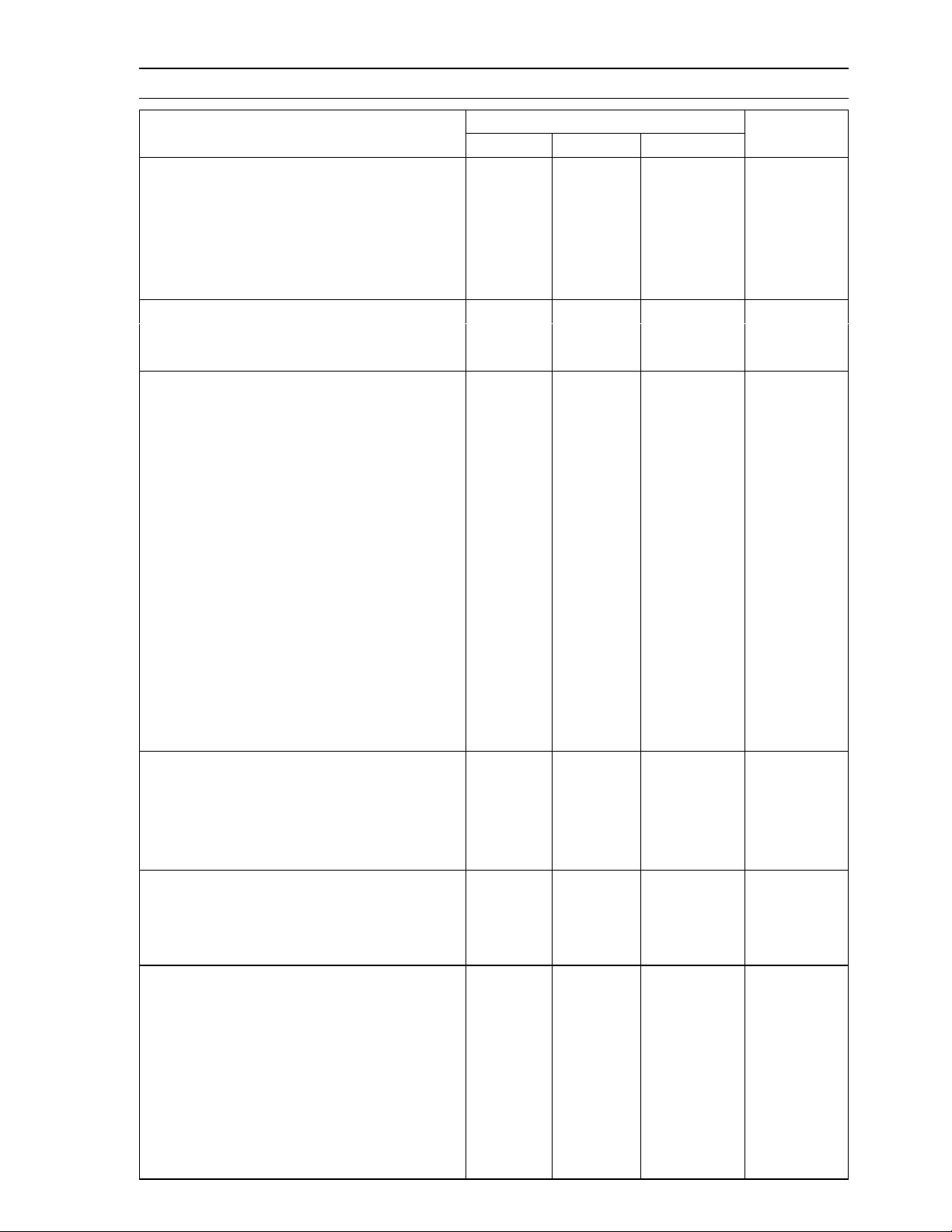

Periodic Maintenance Chart

The scheduled maintenance must be done in accordance with this chart to keep the watercraft in

good running condition. The initial maintenance is vitally important and must not be neglected.

Frequency

Description

Inspect throttle control system (e)

Inspect/clean air filter drain caps

Initial 10

Hours

Every 25

Hours

•

•

Every 50

Hours

Every 100

Hours

Refer-

ence

2-10

2-10

Inspect/clean air filter

Inspect fuel vent check valve

Clean fuel pump screen (e)

Inspect throttle shaft spring (replace

throttle body if necessary) (e)

Replace engine oil

Replace engine oil fil

Check air suction valve

Inspect/adjust valve clearance (e)

Inspect/tighten engine mounting bolts

Inspect/replace coupling damper

Flush cooling system (after each use in

salt water)

Flush bilge line and filter

Inspect impeller blades for damage

(remove)

Inspect steering ca

Lubricate handlebar pivot (disassemble)

Inspect hull drain screws (replace if

necessary)

Inspect battery charging condition

Inspect battery terminals

Clean and gap spark plugs (replace if

necessary) (e)

Lubricate throttle cable fitting at throttle

body

Lubricate throttle cable and throttle fitting

at throttle case

Lubricate steering cable/shift c able ball

joints and stee

pivots

Check all hoses, hose clamps, nuts,

bolts, and fasteners

(e): Emission Related Items

ter

ble/shift cable

ring nozzle/reverse bucket

• •

•

(or every

year)

•

•

•

•

(or every

year)

•

•

•

•

(or every

year)

•

•

•

•

•

•

•

•

•

•

•

•

•

2-11

2-11

2-12

2-12

2-12

2-14

2-15

2-15

2-19

2-19

2-19

2-21

2-22

2-22

2-22

2-23

2-23

2-23

2-24

2-24

2-24

2-24

2-27

PERIODIC MAINTENANCE 2-3

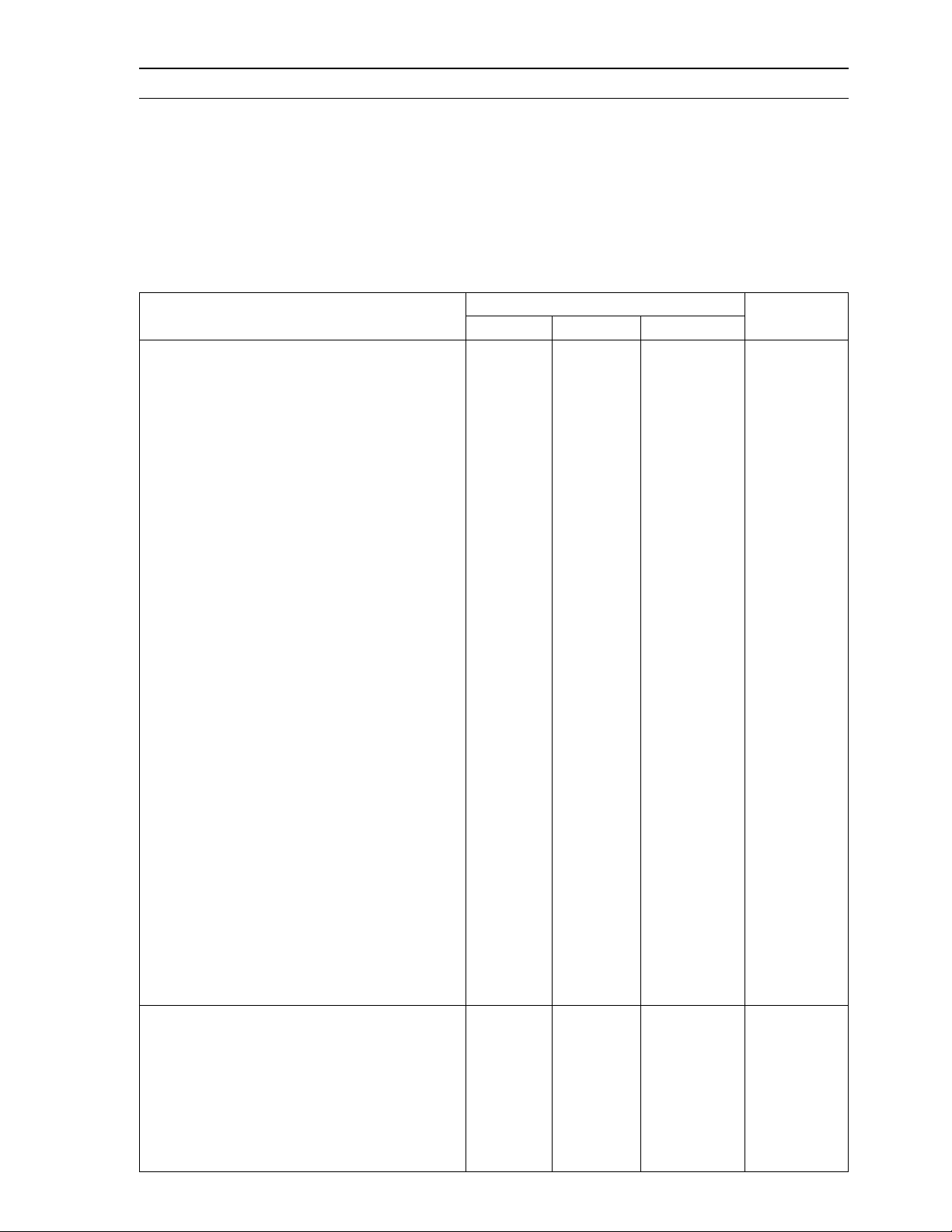

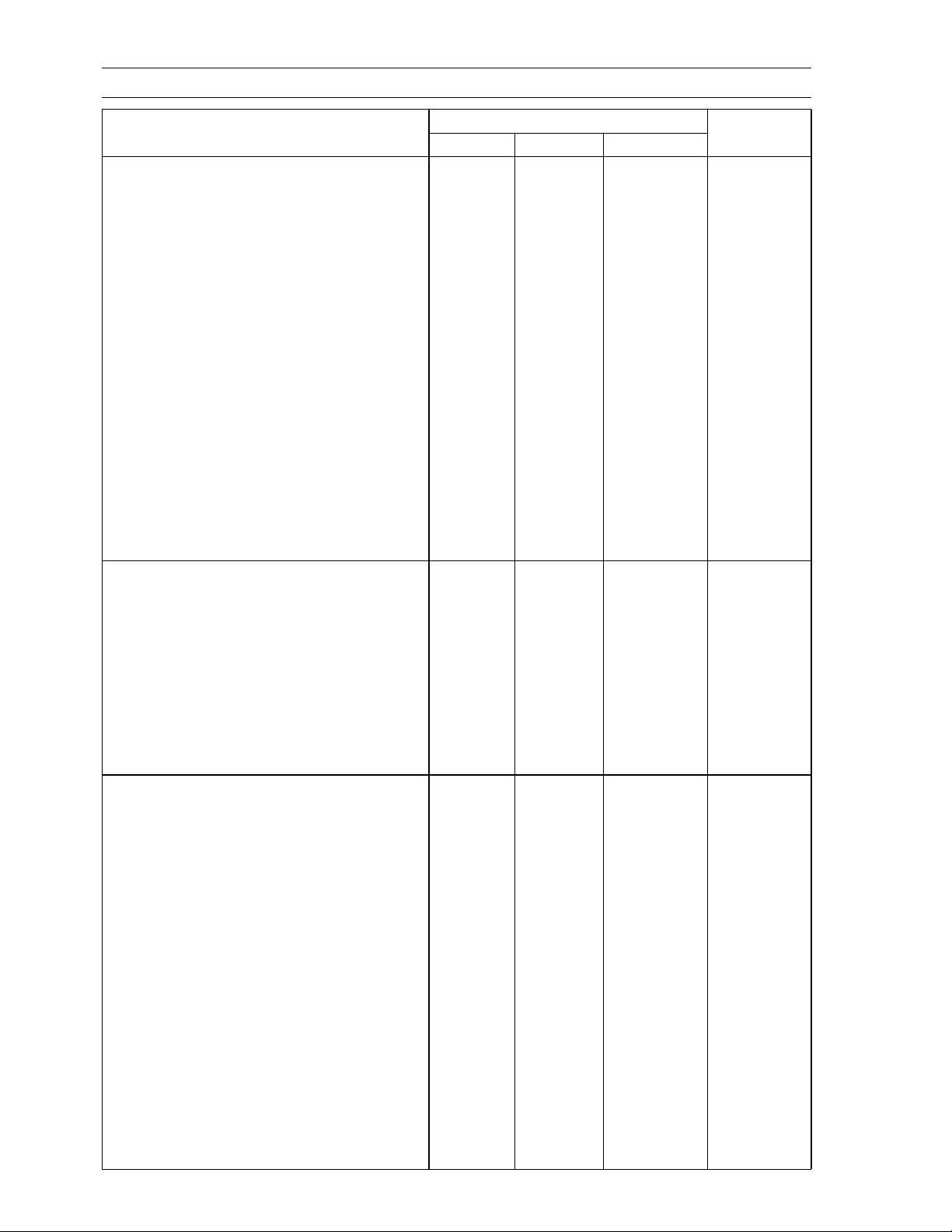

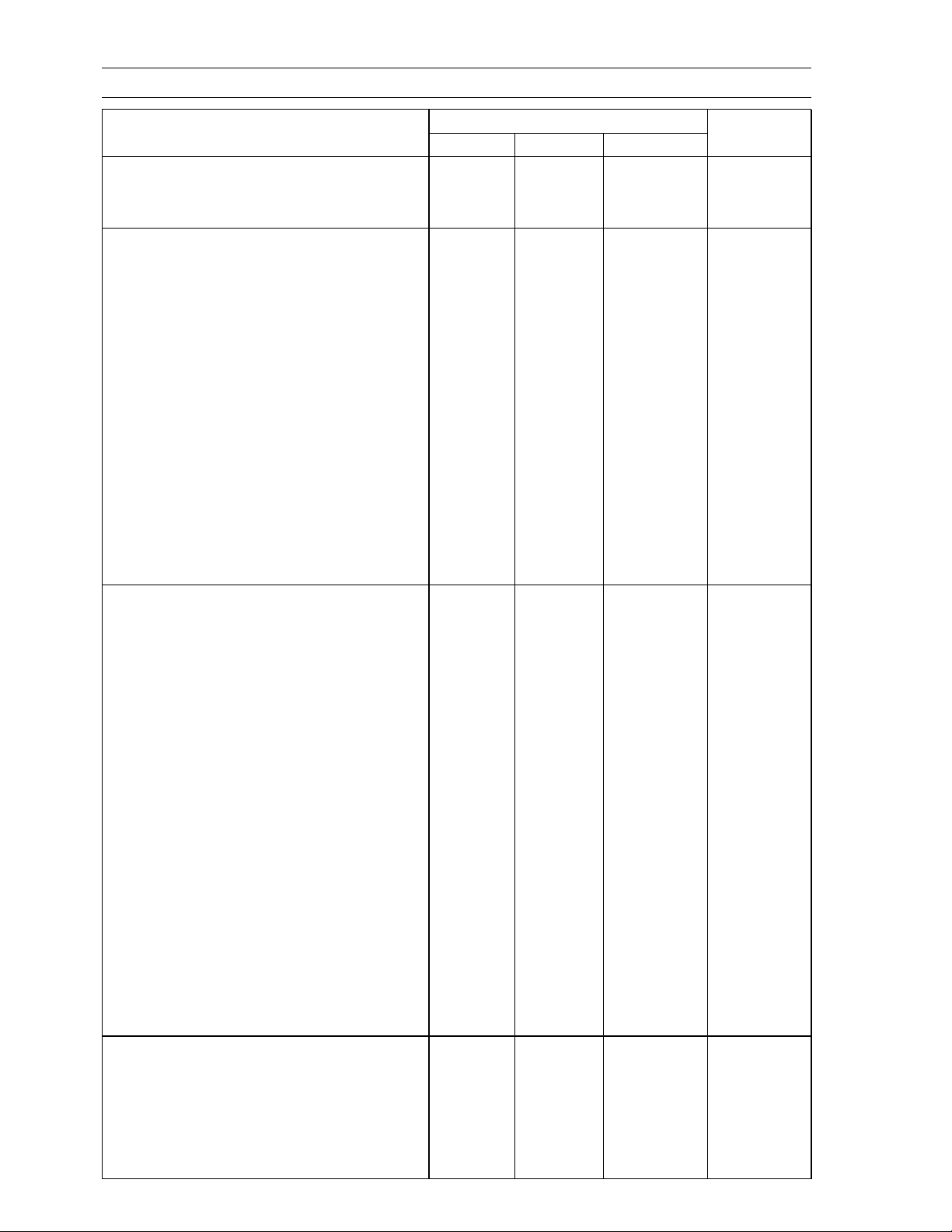

Torque and Locking Agent

The following table list the tightening torque for the major fasteners, and the parts requiring use of

a non-permanent locking agent or silicone sealant.

Letters used in the “Remarks” column mean:

EO: Apply oil to the threads and seating surface.

L: Apply a non-permanent locking agent to the threads.

MO: Apply molybdenum disulfide grease oil solution.

R: Replacement Part

S: Tighten the fasteners following the specified sequence.

SS: Apply silicone sealant to the threads.

Fastener

Fuel System

Vehicle-down Sensor Mounting Screws 1.5 0.15 13 in·lb

Bracket Mounting Bolts – – – L

Inlet Manifold Mounting Bolts 25 2.5 18 L

Inlet Manifold Mounting Nuts 20 2.0 14

Delivery Pipe Mounting Bolts 7.8 0.80 69 in·lb

Inlet Air Pressure Sensor Bolts 7.8 0.80 69 in·lb

Throttle Cable Holder Bolts 8.8 0.90 78 in·lb L

Inlet Air Temperature Sensor 20 2.0 14

Throttle Body Assy Mounting Bolts 20 2.0 14

Inlet Manifold Drain Plug

Inlet Manifold Plate Bolts 7.8 0.80 69 in·lb

Crankshaft Sensor Screws 4.4 0.45 39 in·lb L

Camshaft Position Sensor Bolt 7.8 0.80 69 in·lb L

Oil Temperature Sensor 15 1.5 11 see text

Water Temperature Sensor 15 1.5 11 see text

Regulator/Rectifier Bolts 7.8 0.80 69 in·lb

ECU Mounting Bolts 8.8 0.90 78 in·lb L

Throttle Sensor Mounting Screws 2.0 0.20 18 in·lb

ISC Actuator Mounting Bolts 4.9 0.50 43 in·lb

Oil Pressure Switch

Fuel Filler Tube Clamp Screws

Fuel Level Sensor Clamp Screw

Fuel Filter Mounting Bolts 8.8 0.90 78 in·lb L

Air Filter Mounting Bolts 9.8 1.0 87 in·lb

Air Filter Bracket Mounting Bolts 7.8 0.80 69 in·lb L

Throttle Cable Locknut

Throttle Case Mounting Screws

Engine Lubrication System

Breather Plate Bolts 7.8 0.80 69 in·lb

Oil Filler Cap 1.0 0.10 8.7 in·lb

Oil Passage Plugs 20 2.0 14 L

Oil Separator Tank Mounting Screws

Breather Case Mounting Bolts

Breather Pipe Bolts 8.8 0.90 78 in·lb

N·m kgf·m ft·lb

20 2.0 14

15 1.5 11

2.9 0.30 26 in·lb

2.9 0.30 26 in·lb

7.8 0.80 69 in·lb

3.9 0.40 35 in·lb

4.9 0.50 43 in·lb L

7.8 0.80 69 in·lb

Torque

Remarks

SS

2-4 PERIODIC MAINTENANCE

Torque and Locking Agent

Fastener

Oil Passage Joints 11 1.1 95 in·lb L

Oil C ooler Assembly Bolts

Oil Pressure Switch

Oil Passage Bolt

Oil Filter 18 1.8 13 EO

Oil C ooler Positioning Bolt 20 2.0 14 S

Oil Pan Bolts 7.8 0.80 69 in·lb S

Dipstick Tube Bolts 7.8 0.80 69 in·lb L, S

Oil Pump Sprocket Bolt 15 1.5 11 L

Oil Pump Cover Bolts 7.8 0.80 69 in·lb

Oil Pressure Relief Valve 15 1.5 11 L

Oil Pipe Bolts 7.8 0.80 69 in·lb

Chain Guide Spring Plate Bolt 7.8 0.80 69 in·lb

Oil Pump Body Plug

Oil Pump Body Bolts

Oil Screen Bolts

Water Pipe Joints 20 2.0 14 L

Exhaust System

Exhaust Manifold Mounting Nuts 25 2.5 18 S

Exhaust Manifold Mounting Bolts

Bypass Nozzle – – – L

Flushing Hose Joint 11 1.1 95 in·lb SS

Water Hose Joint 11 1.1 95 in·lb SS

Water Temperature Sensor 15 1.5 11 see chapter 3

Exhaust Pipe Mounting Plate Bolts 30 3.0 22 L

Exhaust Pipe Mounting Bolts 30 3.0 22

Engine Top End

Air Suction Valve Cover Bolts 9.8 1.0 87 in·lb

Cylinder Head Cover Bolts 9.8 1.0 87 in·lb

Upper Camshaft Chain Guide Bolts 12 1.2 104 in·lb S

Camshaft Cap Bolts 12 1.2 104 in·lb S

Cylinder Head Bolts (M7)

Cylinder Head Bolts (M11)

Cylinder Hea

Water Jacket Plugs 20 2.0 14 L

Cylinder Head Bolts (M6) 12 1.2 104 in·lb S

Engine Hook Bolts 20 2.0 14

Camshaft Position Sensor Bolt 9.8 1.0 87 in·lb L

Exhaust Side Camshaft Chain Guide Bolts

(Upper)

Exhaust Side Camshaft Chain Guide Bolts

(Lower)

Upper Camshaft Chain Guide Bolts 12 1.2 104 in·lb S

dBolts(M11)

N·m kgf·m ft·lb

7.8 0.80 69 in·lb

15 1.5 11

78 8.0 58

20 2.0 14 L

7.8 0.80 69 in·lb

7.8 0.80 69 in·lb

25 2.5 18

20 2.0 14

23 2.3 17

59 6.0 43

25 2.5 18

12 1.2 104 in·lb

Torque

Remarks

SS

S

L, S

S

First, MO, S

Final, MO, S

Torque and Locking Agent

PERIODIC MAINTENANCE 2-5

Fastener

Inlet Side Camshaft Chain Guide Bolts 12 1.2 104 in·lb L

Camshaft Chain Tensioner Mounting Bolts 9.8 1.0 87 in·lb L

Camshaft Chain Tensioner Cap Bolt 20 2.0 14

Camshaft Position Sensor Rotor Bolt 12 1.2 104 in·lb L

Water Hose Joint 11 1.1 95 in·lb SS

Oil Passage Joint 11 1.1 95 in·lb L

Engine Removal/Installation

Engine Mounting Bolts 36 3.7 27 L

Engine Damper Mounting Bolts 16 1.6 12 L

Engine Bottom End

Crankshaft Sensor Cover Bolts 7.8 0.80 69 in·lb

Engine Bracket Mounting Bolts 29 3.0 22 L

Timing Rotor Bolt 29 3.0 22 L

Connecting Rod Nuts

Oil Passage Plugs

Stator Mounting Bolts 12 1.2 104 in·lb L

Grommet Cover Bolts 9.8 1.0 87 in·lb L

Magneto Cover Bolts 20 2.0 14

Output Cover Bolts 7.8 0.80 69 in·lb

Output Shaft 245 25 180 MO

Coupling 98 10 72

Crankcase Bolts (M10) 50 5.0 36 MO, S

Crankcase Bolts (M8) 29 3.0 22 MO, S

Crankcase Bolts (M8) 29 3.0 22 S

Crankcase Bolts (M6)

Cooling and Bilge Systems

Breather Mounting Bolt – – – L

Water Hose Joint (L Shape Type) 11 1.1 95 in·lb SS

Water Hose Joint (Straight Shape Type) 20 2.0 14 SS

Water Hose Joint (Straight Shape Type) 11 1.1 95 in·lb SS, see text

Drive System

Coupling

Drive Shaft Holder Mounting Bolts

Coupling Cover Bolts 8.8 0.90 78 in·lb L

Pump and Impeller

Steering Nozzle Pivot Bolts 19 1.9 14 L

Pump Mounting Bolts 36 3.7 27 L

Pump Outlet Mounting Bolts 19 1.9 14 L

Pump Cap Bolts 9.8 1.0 87 in·lb L

Pump Cap Plug 3.9 0.40 35 in·lb

Impeller 98 10 72

Pump Bracket Mounting Bolts (2) 19 1.9 14 L, SS

Pump Bracket Mounting Bolts (4) 9.8 1.0 87 in·lb L

N·m kgf·m ft·lb

– – –

20 2.0 14 L

12 1.2 104 in·lb

39 4.0 29 L

22 2.2 16 L

Torque

Remarks

MO, see text

S

2-6 PERIODIC MAINTENANCE

Torque and Locking Agent

Fastener

Pump Cover Mounting Bolts 7.9 0.80 69 in·lb L

Grate Mounting Bolts

Filter Cover Mounting Bolts

Steering

Handlebar Clamp Bolts 16 1.6 12 L

Start/stop Switch Case Mounting Screws 3.9 0.40 35 in·lb

Throttle Case Mounting Screws 3.9 0.40 35 in·lb

Steering Shaft Locknut 49 ∼ 59 5.0 ∼ 6.0 36 ∼ 43

Steering Shaft Nut – – – Hand-Tight

Steering Holder Mounting Bolts 20 2.0 14.5 L

Steering Neck Mounting Bolts 16 1.6 12 L

Steering Cable Joint Bolt 9.8 1.0 87 in·lb L

Ball Joint 9.8 1.0 87 in·lb L

Shift Cable End Nut 9.8 1.0 87 in·lb

Reverse Bucket Pivot Bolts 19 1.9 14 L

Shift Cable Nut

Steering Cable Nut 39 4.0 29

Shift Lever Locknut 20 2.0 14.5

Hull/Engine Hood

Crossmember Bolts 7.8 0.80 69 in·lb L

Handrail Bolts 9.8 1.0 87 in·lb L

Lock Assembly Nut 4.9 0.50 43 in·lb

Front Duct Bolts – – – L

Damper Bolts – – – L

Damper Bracket Bolts – – – L

Front Storage Compartment Cover Bolts – – – L

Hinge Bolts – – – L

Front Storage Co

Steering Cover Bolts – – – L

Meter Screen Bolts – – – L

Seat Hook Bolts – – – L

Seat Locknut – – – L

Reboarding Step Bolts – – – L

Mirror Stay Bolts – – – L

Stabilizer Bolts 9.8 1.0 87 in·lb L

Air inlet Duct Bolts – – – L

Exhaust Outlet Bolts – – – L

Electrical System

Vehicle-Down Sensor Mounting Screws 1.5 0.15 13 in·lb

Electrical Parts Bracket Screws 4.9 0.50 43 in·lb L

Starter Relay Case Bolts 7.8 0.80 69 in·lb

Ignition Coil Mounting Bolts 8.8 0.90 78 in·lb L

Water Temperature Sensor 15 1.5 11 see text

mpartment Hook Bolts

N·m kgf·m ft·lb

9.8 1.0 87 in·lb L

9.8 1.0 87 in·lb L

39 4.0 29

– – – L

Torque

Remarks

Loading...

Loading...