Page 1

EN500

VULCAN 500 LTD

Motorcycle

Service Manual

Page 2

Page 3

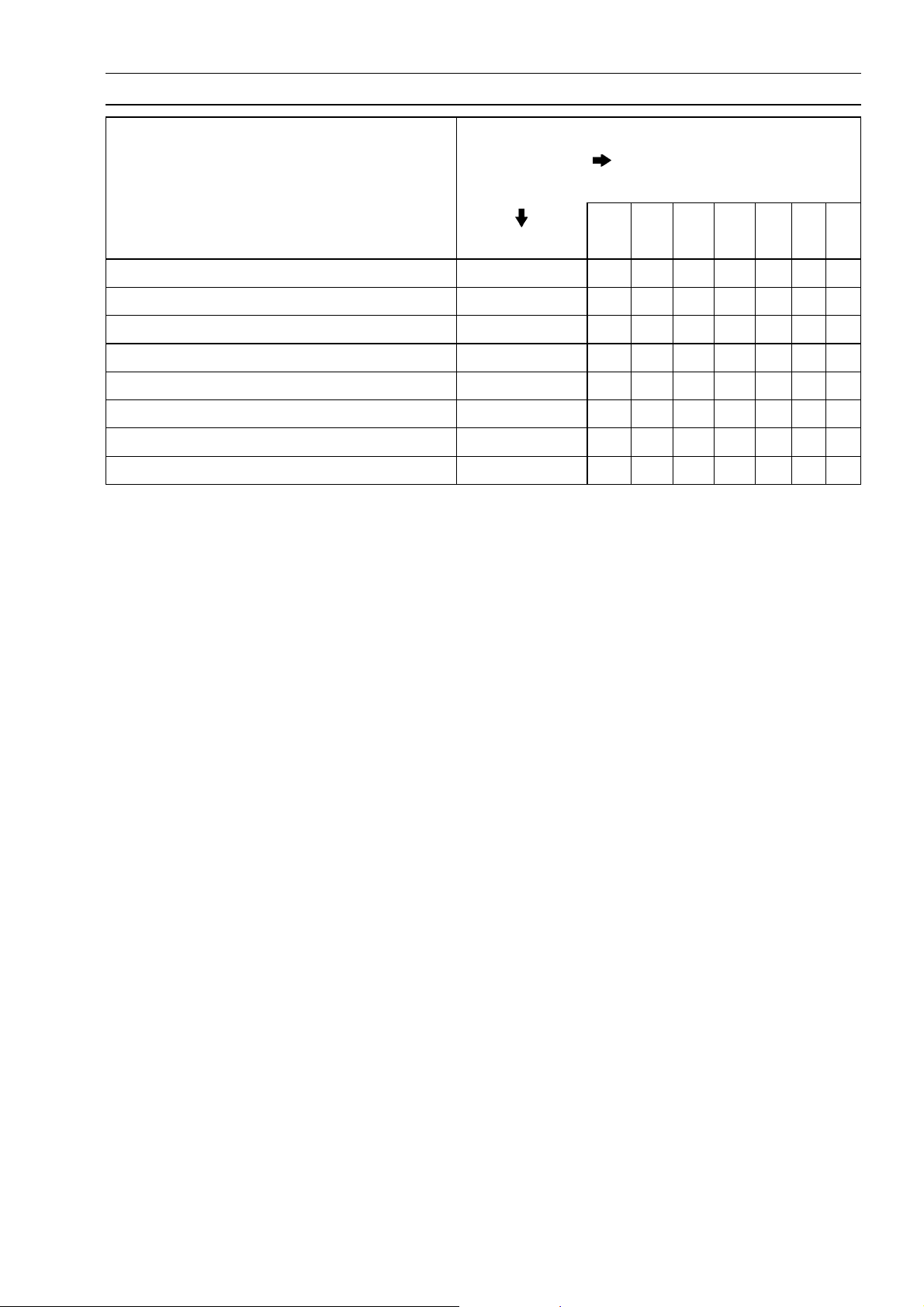

Quick Reference Guide

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

j

General Information 1

Fuel System 2

Cooling System 3

Engine Top End 4

Clutch 5

Engine Lubrication System 6

Engine Removal/Installation 7

Crankshaft/Transmission 8

This quick reference guide will assist

you in locating a desired topic or procedure.

•Bend the pages back to match the

black tab of the desired chapter number with the black tab on the edge at

each table of contents page.

•Refer to the sectional table of contents

for the exact pages to locate the specific topic required.

Wheels/Tires 9

Final Drive 10

Brakes 11

Suspension 12

Steering 13

Frame 14

Electrical System 15

Appendix 16

Page 4

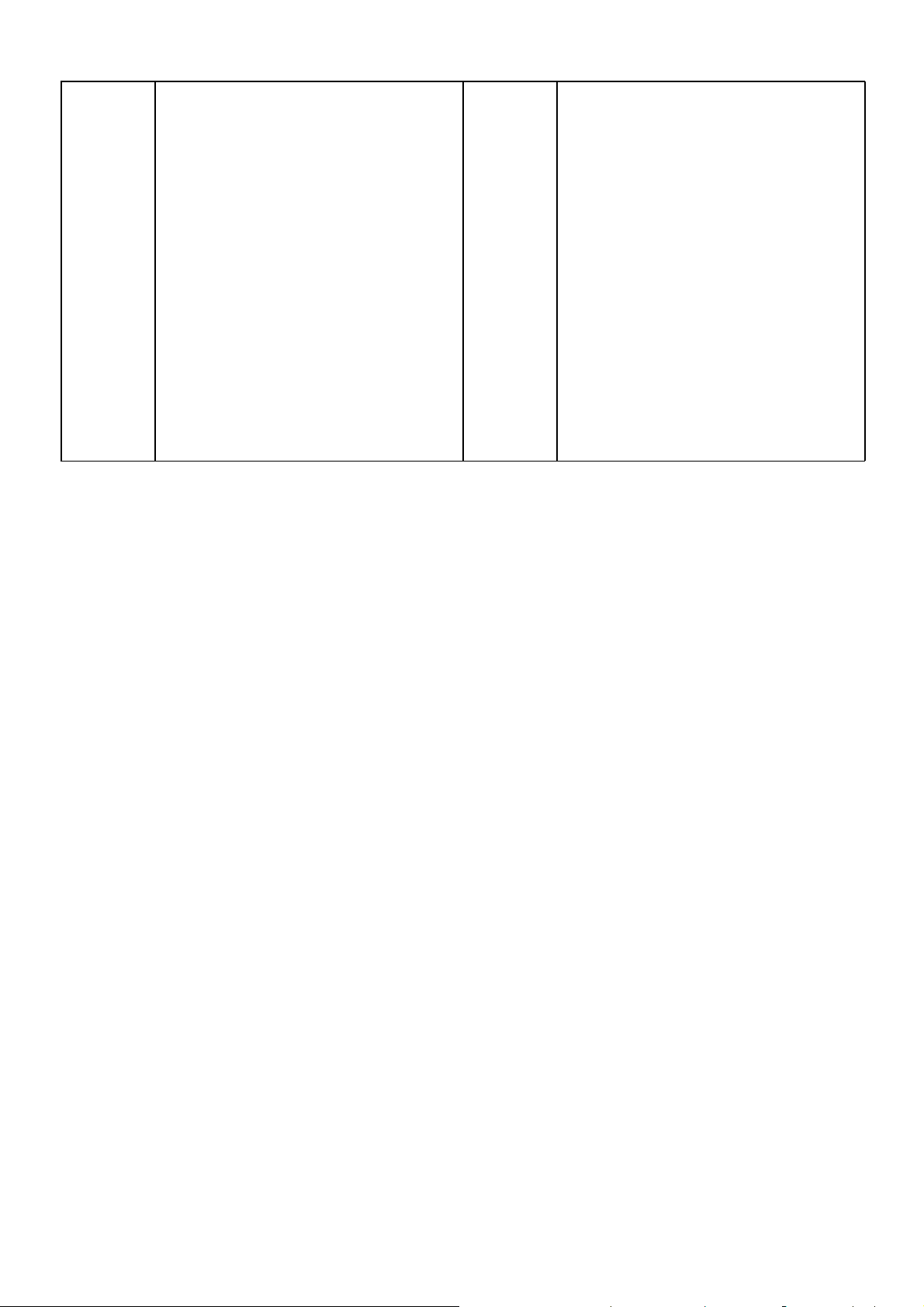

LIST OF ABBREVIATIONS

A ampere(s) lb pound(s)

ABDC after bottom dead center m meter(s)

AC alternating current min minute(s)

ATDC after top dead center N newton(s)

BBDC before bottom dead center Pa pascal(s)

BDC bottom dead center PS horsepower

BTDC before top dead center psi pound(s) per square inch

°C degree(s) Celsius r revolution

DC direct current rpm revolution(s) per minute

F farad(s) TDC top dead center

°F degree(s) Fahrenheit TIR total indicator reading

ft foot, feet V volt(s)

g gram(s) W watt(s)

h hour(s) Ω ohm(s)

L liter(s)

Read OWNER’S MANUAL before operating.

Page 5

EMISSION CONTROL INFORMATION

To protect the environment in which we all live, Kawasaki has incorporated crankcase emission (1) and exhaust emission (2) control systems in compliance with applicable regulations of

the United States Environmental Protection Agency and California Air Resources Board. Additionally, Kawasaki has incorporated an evaporative emission control system (3) in compliance

with applicable regulations of the California Air Resources Board on vehicles sold in California

only.

1. Crankcase Emission Control System

This system eliminates the release of crankcase vapors into the atmosphere. Instead, the vapors

are routed through an oil separator to the intake side of the engine. While the engine is operating,

the vapors are drawn into combustion chamber, where they are burned along with the fuel and air

supplied by the carburetion system.

2. Exhaust Emission Control System

This system reduces the amount of pollutants discharged into the atmosphere by the exhaust

of this motorcycle. The fuel and ignition systems of t his motorcycle have been carefully des

and constructed to ensure an efficient engine with low exhaust pollutant levels.

3. Evaporative Emission Control System

Vapors caused by fuel evaporation in the fuel system are not vented into the atmosphere. In

stead, fuel vapors are routed into the r unning engine to be burned, or stored in a canister when

the engine is stopped. Liquid fuel is caught by a vapor separator and returned to the fuel tank.

The Clean Air Act, which is the Federal law covering motor vehicle p

commonly referred to as the Act’s “tampering provisions.”

“Sec. 203(a) The following acts and the causing thereof are prohibited...

(3)(A) for any person to remove or r ender inoperative any device or e

on or in a motor vehicle or motor vehicle engine in compliance with regulations under this

title prior to its sale and delivery to the ultimate purchaser, or for any manufacturer or dealer

knowingly to remove or render inoperative any such device or el

sale and delivery to the ultimate purchaser.

(3)(B) for any person engaged in the business of repairing, servicing, selling, leasing, or trading

motor vehicles or motor vehicle engines, or who operates a fle

ingly to remove or render inoperative any device or element of design installed on or in a

motor vehicle or motor vehicle engine in compliance with regulations under this title following its sale and delivery to the ultimate purch

aser...”

ollution, contains what is

lement of design installed

ement of design after such

et of motor vehicles know-

igned

-

NOTE

The phrase “remove or render inoperative any device or element of design” has been generally

○

interpreted as follows:

1. Tampering does not include the temporary removal or rendering inoperative of devices or elements of design in order to perform maintenance.

2. Tampering could include:

a.Maladjustment of vehicle components such that the emission standards are ex-

ceeded.

b.Use of replacement parts or accessories which adversely affect the performance

or dura bility of the motorcycle.

c.Addition of components or accessories that result in the vehicle exceeding the stan-

dards.

d.Permanently removing, disconnecting, or rendering inoperative any component or

element of design of the emission control systems.

WE RECOMMEND THAT ALL DEALERS OBSERVE THESE PROVISIONS OF FEDERAL LAW,

THE VIOLATION OF WHICH IS PUN ISHA BLE BY CIVIL PENALTIES NOT EXCEEDING

$10,000 PER VIOLATION.

Page 6

TAMPERING WITH NOISE CONTROL SYSTEM PROHIBITED

Federal law prohibits the following acts or the causing thereof: (1) The removal or rendering

inoperative by any person other than for purposes of maintenance, repair, or replacement, of any

device or element of design incorporated into any new vehicle for the purpose of noise control

prior to i ts sale or delivery to the ultimate purchaser or while it is in use, or (2) the use of the

vehicle after such device or element of design has been removed or rendered inoperative by

any person.

Among those acts presumed to constitute tampering are the acts listed below:

Replacement of the original exhaust system or muffler with a component not in compliance

•

with Federal regulations.

Removal of the muffler(s) or any internal portion of the muffler(s).

•

Removal of the air box or air box cover.

•

Modifications to the muffler(s) or air intake system by cutting, drilling, or other means if such

•

modifications result in increased noise levels.

Page 7

Foreword

This manual is designed primarily for use by

trained mechanics in a properly equipped shop.

However, it contains enough detail and basic information to make it useful to the owner who desires to perform his own basic maintenance and

repair work. A basic knowledge of mechanics,

the proper use of tools, and workshop procedures must be understood in order to carry out

maintenance and repair satisfactorily. Whenever the owner has insufficient experience or

doubts his ability to do the work, all adjustments, maintenance, and repair should be carried out only by qualified mechanics.

In order to perform the work efficiently and

to avoid costly mistakes, read the text, thoroughly familiarize yourself with the procedures

before starting work, and then do the work ca

fully in a clean area. Whenever special tools or

equipment are specified, do not use makeshift

tools or equipment. Precision measurem

can only be made if the proper instruments are

used, and the use of substitute tools may adversely affect safe operation.

For the duration of the warranty period,

we recommend that all repairs and scheduled

maintenance be performed in

this service manual. Any owner maintenance or

repair procedure not performed in accordance

with this manual may void

To get the longest life out of your vehicle:

Follow the Periodic Maintenance Chart in the

•

Service Manual.

Be alert for problems and non-scheduled

•

maintenance.

Use proper tools and

•

torcycle parts. Special tools, gauges, and

testers that are necessary when servicing

Kawasaki moto

Service Manual. Genuine parts provided as

spare parts are listed in the Parts Catalog.

Follow the p

•

fully. Don’t take shortcuts.

Remember to keep complete records of main-

•

tenance a

parts installed.

rcycles are introduced by the

rocedures in this manual care-

nd repair with dates and any new

genuine Kawasaki Mo-

accordance with

the warranty.

re-

ents

How to Use This Manual

In this manual, the product is divided into its

major systems and these systems make up the

manual’s chapters.

The Quick Reference Guide shows you all

of the product’s system and assists in locating

their chapters. Each chapter in turn has its own

comprehensive Table of Contents.

For example, if you want ignition coil information, use the Quick Reference Guide to locate

the Electrical System chapter. Then, use the

Table of Contents on the first page of the chapter to find the ignition coil section.

Whenever you see these WARNING and

CAUTION symbols, heed their instructions!

Always follow safe operating and maintenance

practices.

WARNING

This warning symbol identifies special

instructions or procedures which, if not

correctly followed, could result in per-

sonal injury, or loss of life.

CAUTION

This caution symbol identifies special

instructions or procedures which, if not

strictly observed, could result in dam-

age to or destruction of equipment.

This manual contains four more symbols (in

addition to WARNING and CAUTION) whi

help you distinguish different types of information.

NOTE

This note symbol indicates points of par-

○

ticular interest for more efficient and con-

venient operation.

Indicates a procedural step or work to be

•

done.

Indicates a procedural sub-step or how to do

○

the work of the procedural step it follows. It

also precedes the te

Indicates a conditional step or w hat action to

take based on the results of the test or inspec-

tion in the proced

lows.

In most chapters an exploded view illustration

of the system com

Contents. In these illustrations you will find the

instructions indicating which parts require specified tighten

agent during assembly.

ing torque, oil, grease or a locking

xt of a NOTE.

ural step or sub-step it fol-

ponents follows the Table of

ch will

Page 8

Page 9

GENERAL INFORMATION 1-1

General I nformation

Table of Con tents

Before Servicing ..................................................................................................................... 1-2

Model Identification................................................................................................................. 1-5

General Specifications (EN500-C1 ∼ C6F Models) ................................................................ 1-6

General Specifications (EN500C7F Model ∼)......................................................................... 1-9

Periodic Maintenance Chart ................................................................................................... 1-12

Torque and Locking Agent...................................................................................................... 1-16

Unit Conversion Table ............................................................................................................ 1-21

1

Page 10

1-2 GENERAL INFORMATION

Before Servicing

Before starting to perform an inspection service or carry out a disassembly and reassembly operation on a motorcycle, read the precautions given below. To facilitate actual operations, notes, illustrations, photographs, cautions, and detailed descriptions have been included in each chapter wherever

necessary. This section explains the items that require particular attention during the removal and

reinstallation or disassembly and reassembly of general parts.

Especially note the following

(1) Dirt

Before removal and disassembly, clean the motorcycle. Any dirt entering the engine will shorten

the life of the motorcycle. For the same reason, before installing a new part, clean off any dust or

metal filings.

(2) Battery Ground

Disconnect the ground (–) cable from the battery before performing any disassembly operations

on the motorcycle. This prevents the engine from accidentally turning over while work is being

carried out, sparks from being generated while disconnecting the cables from electrical parts, as

well as damage to the electrical parts themselves. For reinstallation, first connect the positive

cable to the positive (+) terminal of the battery

(3) Installation, Assembly

Generally, installation or assembly is the reverse of removal or disassembly. However, if installation or assembly sequence is given in this Service Manual, follow it. Note parts locations and

cable, wire, and hose routing during removal or disassembly so they can be installed or assembled in the same way. It is preferable to mark and record the locations and routing whenever

possible.

(4) Tightening Sequence

When installing bolts, nuts, or screws for which a tightening sequence is given in this Service

Manual, make sure to follow the sequence. When installing a part with several bolts, nuts, or

screws, start them all in their holes and tighten them to a snug fit, thus ensuring that the part has

been installed in its proper location. Then, tighten them to the specified torque in the tightening

sequence and method indicated. If tightening sequence instructions are not given, tighten them

evenly in a cross pattern. Conversely, to remove a part, first loosen all the bolts, nuts, or screws

that are retaining the part a 1/4-turn before removing them.

(5) Torque

When torque values are given in this Service Manual, use them. Either too little or too much

torque may lead to serious damage. Use a good quality, reliable torque wrench.

(6) Force

Common sense should dictate how much force is necessary in assembly and disassembly. If

a part seems especially difficult to remove or install, stop and examine what may be causing the

problem. Whenever tapping is necessary, tap lightly using a wooden or plastic-faced mallet. Use

an impact driver for screws (particularly for the removing screws held by non-permanent locking

agent) in order to avoid damaging the screw heads.

(7) Edges

Watch for sharp edges, as they could cause injury through careless handling, especially during

major engine disassembly and assembly. Use a clean piece of thick cloth w hen lifting the engine

or turning it over.

(8) High-Flash Point Solvent

A high-flash point solvent is recommended to reduce fire danger. A commercial solvent commonly available in North America is standard solvent (generic name). Always follow manufacturer

and container directions regarding the use of any solvent.

(9) Gasket, O-ring

Replace a gasket or an O-ring with a new part when disassembling. Remove any foreign matter

from the mating surface of the gasket or O-ring to ensure a perfectly smooth surface to prevent

oil or compression leaks.

Page 11

GENERAL INFORMATION 1-3

Before Servicing

(10)Liquid Gasket, Locking Agent

Clean and prepare surfaces where liquid gasket or non-permanent locking agent will be used.

Apply them sparingly. Excessive amount may block engine oil passages and cause serious damage.

(11)Press

When using a press or driver to install a part such as a wheel bearing, apply a small amount of

oil to the area where the two parts come in contact to ensure a smooth fit.

(12)Ball Bearing and Needle Bearing

Do not remove a ball bearing or a needle bearing unless it is absolutely necessary. Replace any

ball or needle bearings that were removed with new ones. Install bearings with the m anufacturer

and size marks facing out, applying pressure evenly with a suitable driver. Apply force only to the

end of the race that contacts the press fit portion, and press it evenly over the base component.

(13)Oil Seal and Grease Seal

Replace any oil or grease seals that were removed with new ones, as removal generally damages seals. Oil or grease seals should be pressed into place using a suitable driver, applying a

force uniformly to the end of seal until the face of the seal is even with the end of the hole, unless

instructed otherwise. When pressing in an oil or grease seal which has manufacturer’s m arks,

press it in with the marks facing out.

(14)Circlip, Retaining Ring, and Cotter Pin

When installing circlips and retaining rings, take care to compress or expand them only enough

to install them and no more. Install the circlip with its chamfered side facing load side as well.

Replace any circlips, retaining rings, and cotter pins that were removed with new ones, as removal weakens and deforms them. If old ones are reused, they could become detached while

the motorcycle is driven, leading to a major problem.

(15)Lubrication

Engine wear is generally at its maximum while the engine is warming up and before all the sliding

surfaces have an adequate lubricative film. During assembly, make sure to apply oil to any sliding

surface or bearing that has been cleaned. Old grease or dirty oil could have lost its lubricative

quality and may contain foreign particles that act as abrasives; therefore, make sure to wipe it off

and apply fresh grease or oil. Some oils and greases in particular should be used only in certain

applications and may be harmful if used in an application for which they are not intended.

(16)Direction of Engine Rotation

To rotate the crankshaft manually, make sure to do so in the direction of positive rotation. Positive rotation is counterclockwise as viewed from the left side of the engine. To carry out proper

adjustment, it is furthermore necessary to rotate the engine in the direction of positive rotation as

well.

(17)Replacement Parts

When there is a replacement instruction, replace these parts with new ones every time they are

removed.

Replacement parts will be damaged or lose their original function once they are removed. Therefore, always replace these parts with new ones every time they are removed. Although the previously mentioned gasket, O-ring, ball bearing, needle bearing, grease seal, oil seal, circlip, and

cotter pin have not been so designated in their respective text, they are replacement parts.

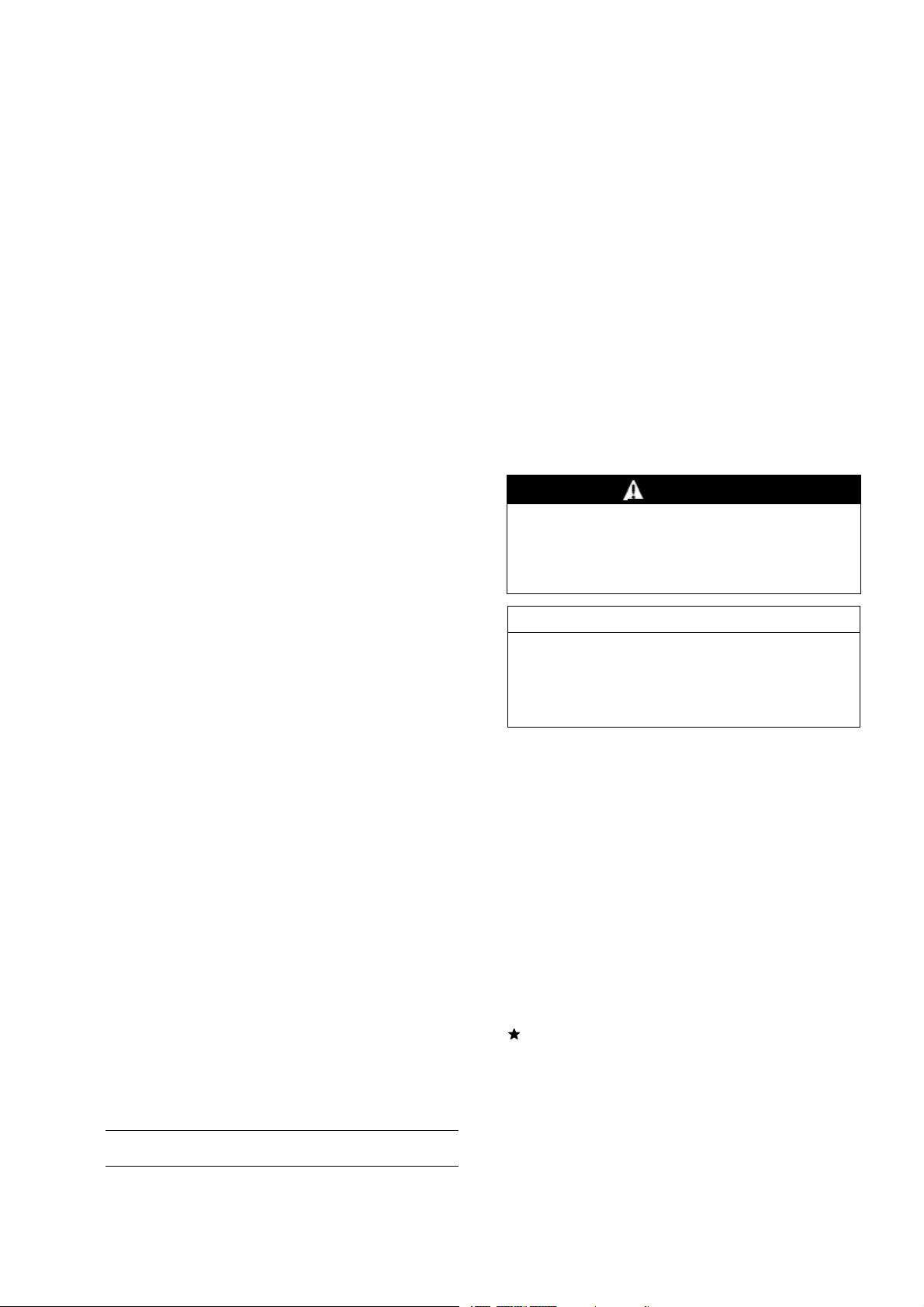

(18)Electrical Leads

All the electrical leads are either one-color or two-color. A two-color lead is identified first by

the primary color and then the stripe color. For example, a yellow lead with thin red stripes is

referred to as a “yellow/red” lead; it would be a “red/yellow” lead if the colors were reversed.

Unless instructed otherwise, electrical leads must be connected to leads of the s ame color.

Page 12

1-4 GENERAL INFORMATION

Before Servicing

Two-Color Electrical

(19)Inspection

When parts have been disassembled, visually inspect these parts for the following conditions

or other damage. If there is any doubt as to the condition of them, replace them with new ones.

Abrasion Crack Hardening Warp

Bent Dent Scratch Wear

Color change Deterioration Seizure

(20)Specifications

Specification terms are defined as follows:

“Standards” show dimensions or performances which brand-new parts or systems have.

“Service Limits” indicate the usable limits. If the measurement shows excessive wear or deteri-

orated performance, replace the dam aged parts.

Page 13

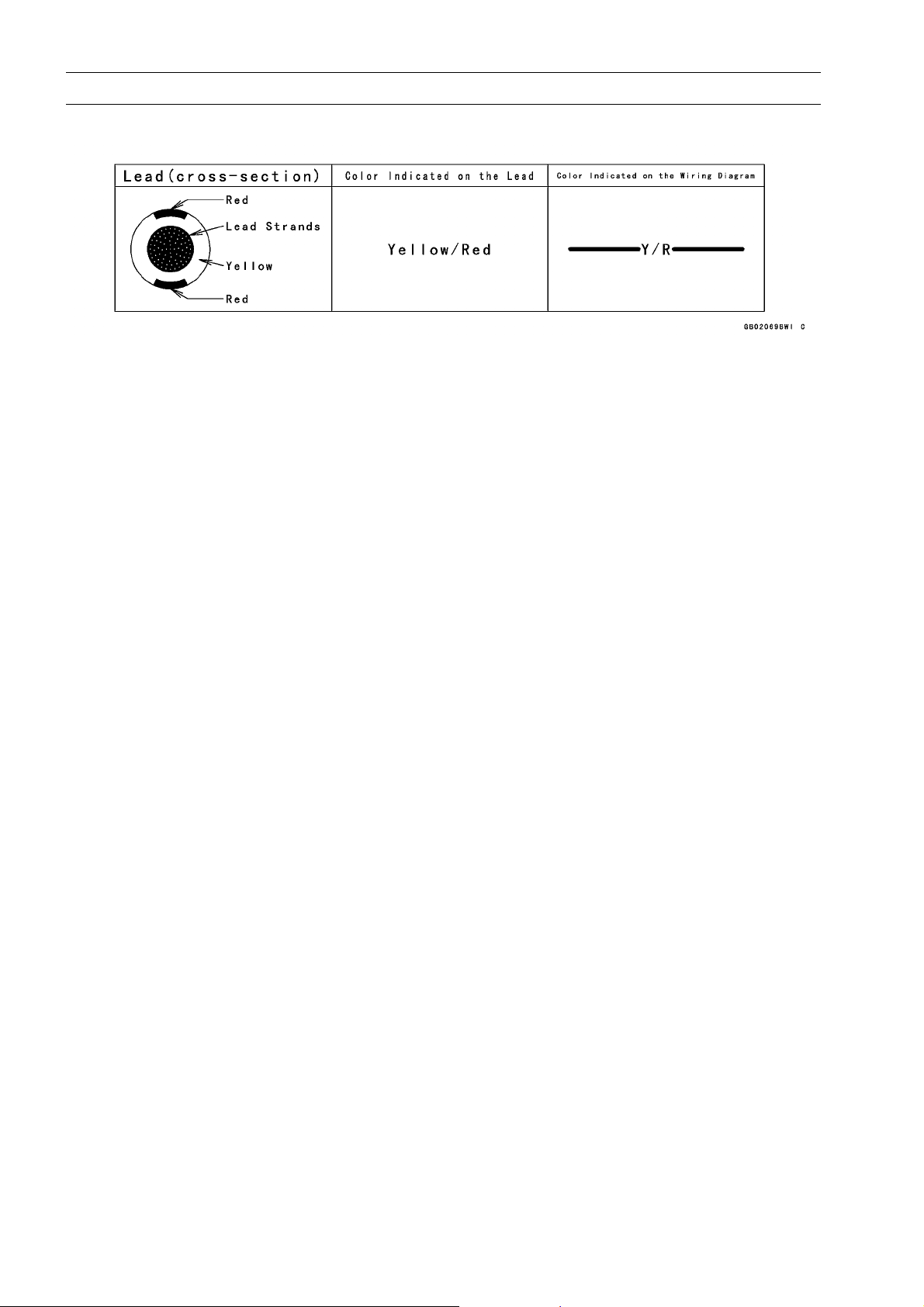

Model Identification

GENERAL INFORMATION 1-5

Page 14

1-6 GENERAL INFORMATION

General Specifications (EN500-C1 ∼ C6F Models)

Items EN500-C1 ∼ C5 EN500-C6 ∼ C6F

Dimensions

Overall Length 2 320 mm (91.3 in.) ←

Overall Width 830 mm (32.7 in.) ←

Overall Height 1 125 mm (44.3 in.) ←

Wheelbase 1 595 mm (62.8 in.) ←

Road Clearance 120 mm (4.92 in.) ←

Seat Height 715 mm (31.5 in.) ←

Dry Weight 199 kg (438 lb) (CAL) 199.5 kg (440 lb) ←

Curb Weight:

Front 95 kg (209 lb) ←

Rear 119 kg (262 lb) (CAL) 119.5 (263 lb) ←

Fuel Tank C apacity 15.0 L (3.9 US gal) ←

Performance

Minimum Turning Radius 2.8 m (9.2 ft) ←

Engine

Type

Cooling System

Bore And Stroke 74.0 × 58.0 mm (2.9 × 2.3 in.)

Displacement 498 cm³ (30.4 cu in.) ←

Compression Ratio 10.2 ←

Maximum Horsepower 34 kW (46 PS) @8 000 r/min (rpm),

Maximum Torque 45 N·m (4.6 kgf·m, 33 ft·lb)

Carburetion System Carburetors, Keihin CVK32 × 2 ←

Starting System Electric starter ←

Ignition System Battery and coil (transistorized) ←

Timing Advance Electronically advanced ←

Ignition Timing

Spark Plugs NGK DR9EA or ND X27ESR-U

Cylinder Numbering M ethod Left to right, 1-2 ←

Firing Order 1-2 ←

Valve Timing:

Inlet:

Open 27° BTDC ←

Close 47° ABDC ←

Duration 254° ←

Exhaust:

Open 52° BBDC ←

Close 22° ATDC ←

4-stroke, DOHC, 2-cylinder

Liquid-cooled ←

(CH, DE) 25 kw (34 PS) @7 000 r/min (rpm),

(FR) 33 kw (45 PS) @8 000 r/min (rpm)

(US) –

@6 000 r/min (rpm),

(CH, DE) 39 N·m (4.0 kgf·m, 29 ft·lb)

@4 200 r/min (rpm), (US) –

From 10° BTDC @1 300 r/min (rpm) to

35° B TDC @8 000 r/min (rpm)

or NGK DR8EA or ND X24ESR-U

←

←

←

←

←

←

Page 15

GENERAL INFORMATION 1-7

General Specifications (EN500-C1 ∼ C6F Models)

Items EN500-C1 ∼ C5 EN500-C6 ∼ C6F

Duration 254° ←

Lubrication System Forced lubrication (wet sump) ←

Engine Oil:

Grade SE, SF or SG class API SE, SF or SG

API SH or SJ with

JASO MA

Viscosity SAE10W-40, 10W-50, 20W-40, or 20W-50 SAE10W-40

Capacity 3.4 L (3.59 US qt) ←

Drive Train

Primary Reduction System:

Type Chain ←

Reduction Ratio 2.652 (61/23) ←

Clutch Type Wet multi disc ←

Transmission

Type

Gear Ratios:

1st 2.571 (36/14) ←

2nd 1.722 (31/18) ←

3rd 1.333 (28/21) ←

4th 1.125 (27/24) ←

5th 0.961 (25/26) ←

6th 0.851 (23/27) ←

Final drive system

Type Chain drive ←

Reduction Ratio 2.625 (42/16) ←

Overall Drive Ratio 5.930 @ Top gear ←

Frame

Type Tubular, double cradle ←

Caster (Rake Angle) 33° ←

Trail 151 mm (5.9 in.) ←

Rim Size:

Front 19 MC × MT 2.15 ←

Rear 15 MC × MT 3.00 ←

Front Tire:

Type Tube ←

Size 100/90-19 57S ← (C6 ∼ C7)

Rear Tire:

Type Tube ←

Size 140/90-15 M /C 70S ←

Front Suspension:

Type Telescopic fork ←

Wheel Travel 150 mm (5.9 in.) ←

6-speed constant mesh, return shift

100/90-19 M/C

57S (C8 ∼)

←

Page 16

1-8 GENERAL INFORMATION

General Specifications (EN500-C1 ∼ C6F Models)

Items EN500-C1 ∼ C5 EN500-C6 ∼ C6F

Rear Suspension:

Type Swing arm ←

Wheel Travel 100 mm (3.9 in.) ←

Brake Type:

Front Single disc ←

Rear Drum ←

Electrical Equipment

Battery 12 V 12 Ah ←

Headlight:

Type Semi-sealed beam ←

Bulb 12 V 60/55 W (quartz-halogen) ←

Tail/brake Light 12 V 8/27 W

(AT, CH, EUR, DE, FR, GR, IT, KR, NL, NO,

ES, SE, GB)

12 V 5/21 W

Alternator:

Type Three-phase AC ←

Rated Output 17 A @6 000 r/min (rpm), 14 V ←

12 V 5/21 W

Specifications subject to change without notice, and may not apply to every country.

AT: Austria Model

CA: Canada Model

CAL: California Model

CH: Switzerland Model

DE: Germany Model

ES: Spain Model

EUR: E u rope Model

FR: France Model

GB: United Kingdom Model

GR: Greece Model

IT: Italy Model

KR: Korea Model

NL: Netherlands Model

NO: Norway Model

SE: Sweden Model

US: United States Model

Page 17

GENERAL INFORMATION 1-9

General Specifications (EN500C7F Model ∼)

Items EN500C7F ∼

Dimensions

Overall Length 2 320 mm (91.3 in.)

Overall Width 830 mm (32.7 in.)

Overall Height 1 125 mm (44.3 in.)

Wheelbase 1 595 m m (62.8 in.)

Road Clearance 120 mm (4.92 in.)

Seat Height 715 mm (31.5 in.)

Dry Weight 199 kg (438 lb) (CAL) 199.5 kg (440 lb)

Curb Weight:

Front 95 kg (209 lb)

Rear 119 kg (262 lb) (CAL) 119.5 (263 lb)

Fuel Tank Capacity 15.0 L (3.9 US gal)

Performance

Minimum Turning Radius 2.8 m (9.2 ft)

Engine

Type 4-stroke, DOHC, 2-cylinder

Cooling System Liquid-cooled

Bore And Stroke 74.0 × 58.0 mm (2.9 × 2.3 in.)

Displacement 498 cm³ (30.4 cu in.)

Compression Ratio

Maximum Horsepower

Maximum Torque 45 N·m (4.6 kgf·m, 33 ft·lb)

Carburetion System Carburetors, Keihin CVK 32 × 2

Starting System Electric starter

Ignition System Battery and coil (transistorized)

Timing Advance Electronically advanced

Ignition Timing

Spark Plugs NGK DR9EA or ND X27ESR-U

Cylinder Numbering Method Left to right, 1-2

Firing Order 1-2

V alve Timing:

Inlet:

Open 27° BTDC

Close 47° ABDC

Duration

Exhaust:

Open 52° BBDC

Close 22° ATDC

Duration 254°

10.2

34 kW (46 PS) @8 000 r/min (rpm),

(US) –

@6 000 r/min (rpm),

From 10° BTDC @1 300 r/min (rpm) to

35° BTDC @8 000 r/min (rpm)

or NGK DR8EA or ND X24ESR-U

254°

Page 18

1-10 GENERAL INFORMATION

General Specifications (EN500C7F Model ∼)

Items EN500C7F ∼

Lubrication System Forced lubrication (wet sump)

Engine Oil:

Grade API SE, SF or SG class

API SH, SJ or SL with JASO MA

Viscosity

Capacity 3.4L(3.59USqt)

Drive Train

Primary Reduction System:

Type Chain

Reduction Ratio 2.652 (61/23)

Clutch Type Wet multi disc

Transmission

Type 6-speed constant mesh, return shift

Gear Ratios:

1st 2.571 (36/14)

2nd

3rd

4th

5th 0.961 (25/26)

6th 0.851 (23/27)

Final drive system

Type Chain drive

Reduction Ratio 2.625 (42/16)

Overall Drive Ratio 5.930 @ Top gear

Frame

Type Tubular, double cradle

Caster (Rake Angle) 33°

Trail 151 mm (5.9 in.)

Rim Size:

Front 19 MC × MT 2.15

Rear 15 MC × MT 3.00

Front Tire:

Type Tube

Size 100/90-19 M/C 57S

Rear Tire:

Type Tube

Size 140/90-15 M/C 70S

Front Suspension:

Type Telescopic fork

Wheel Travel 150 mm (5.9 in.)

Rear Suspension:

Type Swing arm

Wheel Travel 100 mm (3.9 in.)

SAE10W-40

1.722 (31/18)

1.333 (28/21)

1.125 (27/24)

Page 19

GENERAL INFORMATION 1-11

General Specifications (EN500C7F Model ∼)

Items EN500C7F ∼

Brake Type:

Front

Rear Drum

Electrical Equipment

Battery 12 V 12 Ah

Headlight:

Type Semi-sealed beam

Bulb 12 V 60/55 W (quartz-halogen)

Tail/brake Light 12 V 5/21 W

Alternator:

Type Three-phase AC

Rated Output 17 A @6 000 r/min (rpm), 14 V

Specifications subject to change without notice, and may not apply to every country.

CA: Canada Model

CAL: California Model

US: United States Model

Single disc

Page 20

1-12 GENERAL INFORMATION

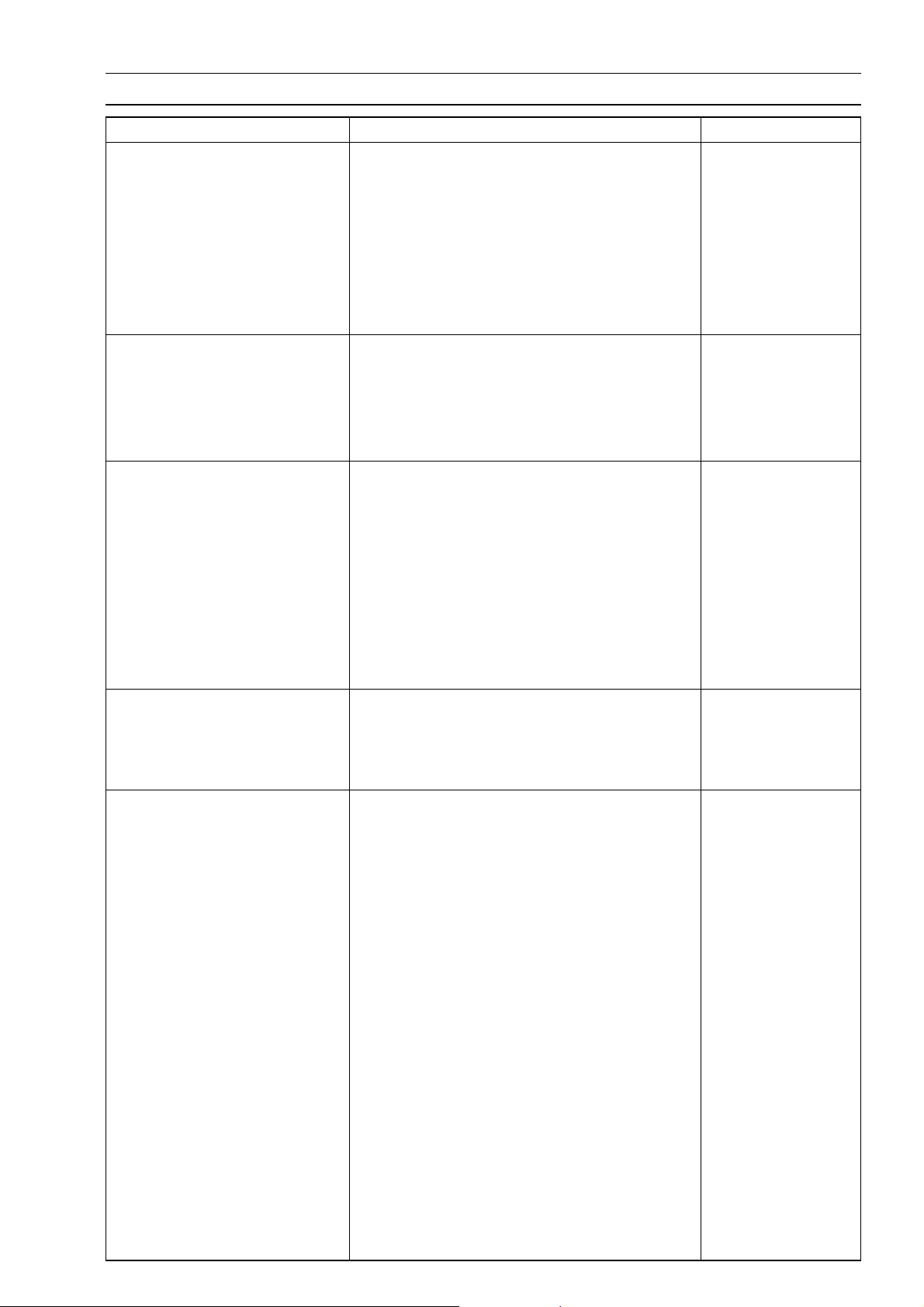

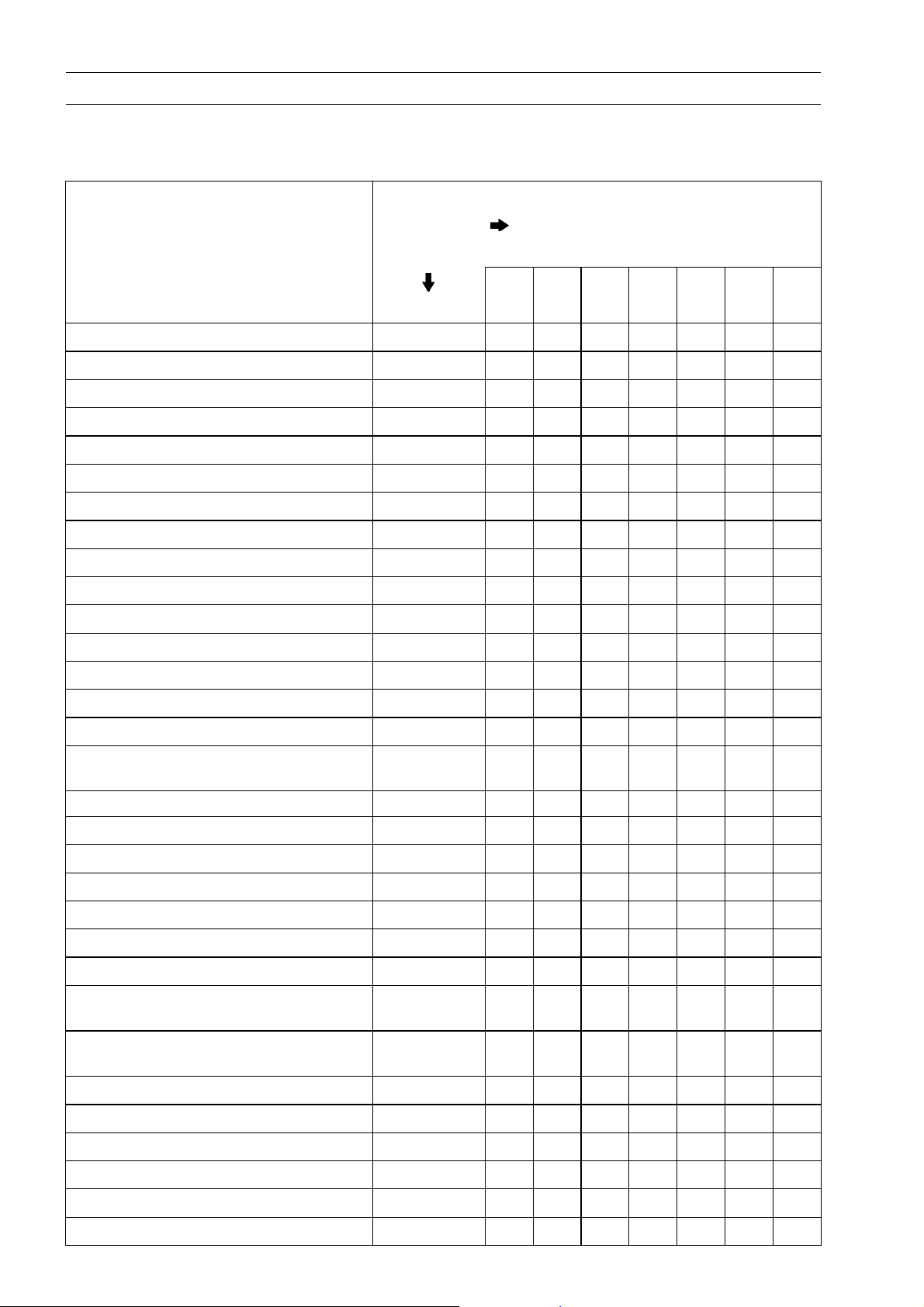

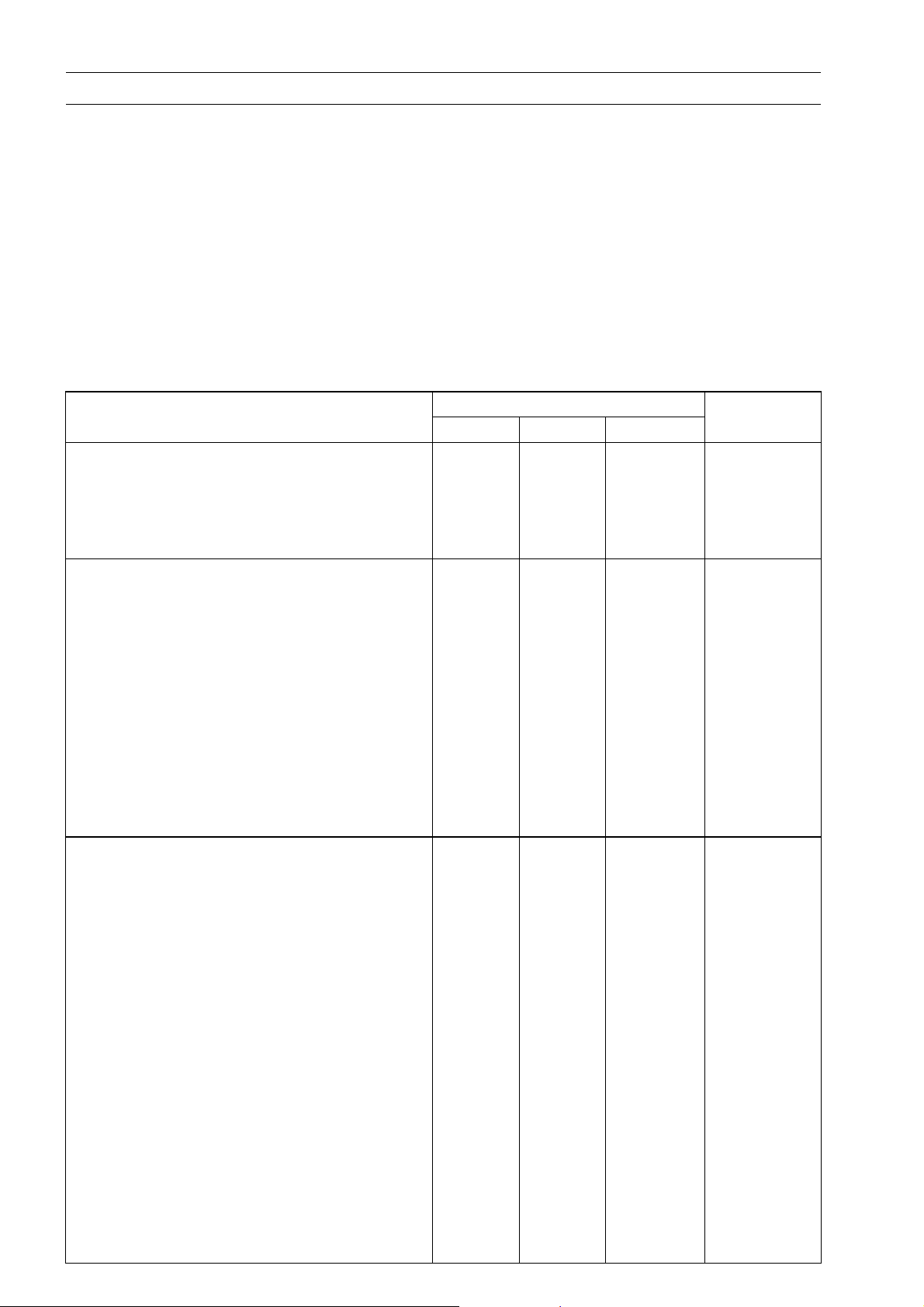

Periodic Maintenance Chart

The scheduled maintenance m ust be done in accordance with this chart to keep the motorcycle in

good running condition. The initial maintenance is vitally important and must not be neglected.

( Other than United States and Canada Models)

FREQUENCY Whichever

comes

first

OPERATION

Carburetor synchronization - inspect †

Idle speed - adjust †

Throttle grip play - inspect †

Spark plug - clean and gap †

Valve clearance - inspect †

Air suction valve - inspect †

Air cleaner element - clean † #

Fuel hose, connections - inspect †

Battery electrolyte level - inspect † 6 month

Brake play - inspect †

Brake light switch - inspect †

Brake lining or pad wear - inspect †#

Brake fluid level - inspect † month

Brake fluid - change † 2 years

Brake hose, connections - inspect †

Brake master cylinder cup and dust

seal - replace

Caliper fluid seal and dust seal - replace 4 years

Every

4 years

*ODOMETER

READING

× 1 000 km

(× 1 000 mile)

1 6 12 18 24 30 36

(0.6) (4.0) (7.5) (12) (15) (20) (24)

• • •

• • • •

• • • •

• • • • • •

•

• • • • • •

• • •

• • • • • •

• • • • • •

• • • • • • •

• • • • • • •

• • • • • •

• • • • • • •

•

• • • • • •

Brake cable - replace 2 years

Clutch - adjust

Steering - inspect †

Drive chain wear - inspect †#

Drive chain - lubricate # 600 km

Drive chain slack - i nspect †# 1000 km

Spoke tightness and rim runout inspect †

Nut, bolts, and fasteners tightness inspect †

Tire wear - inspect †

Engine oil - change # 6 month

Oil filter - replace

General lubrication - perform #

Front fork oil - change 2 years

Front fork oil leak - inspect †

•

• • • • • • •

• • • • • • •

• • • • • •

• • • • • •

• • • • • • •

• • • • • • •

• • • •

• • • • • •

• • • • • • •

• • • •

• • •

•

• • •

Page 21

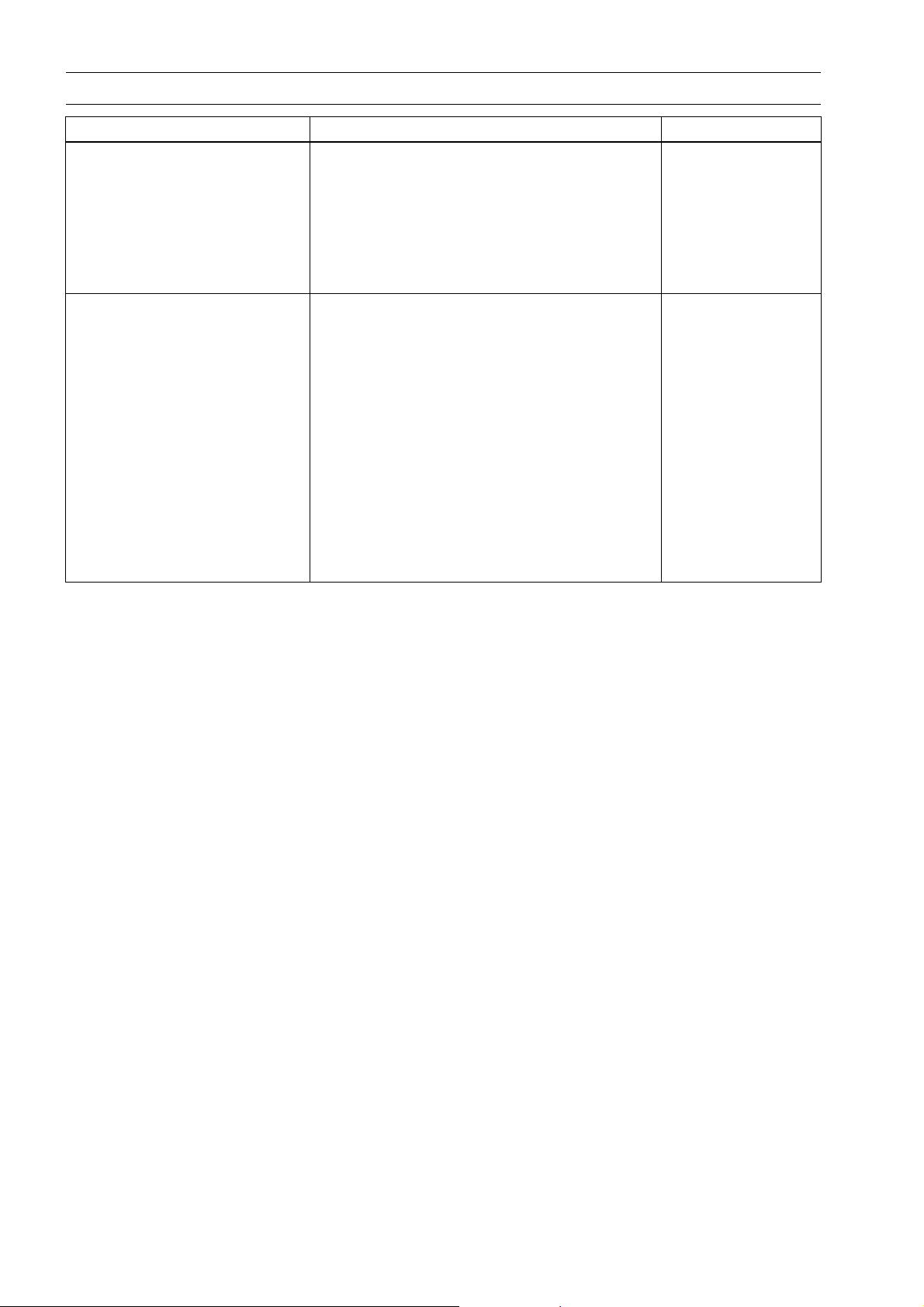

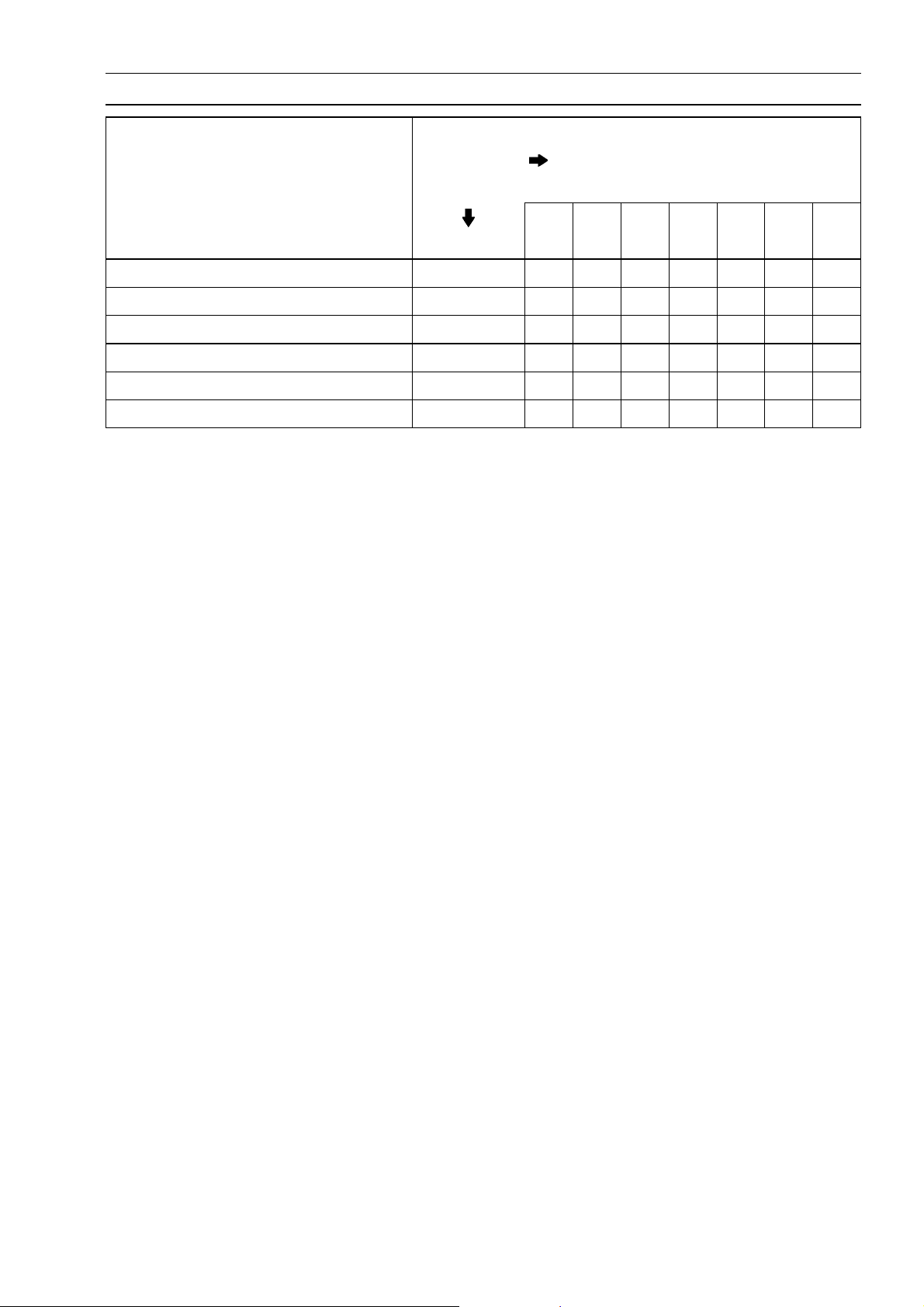

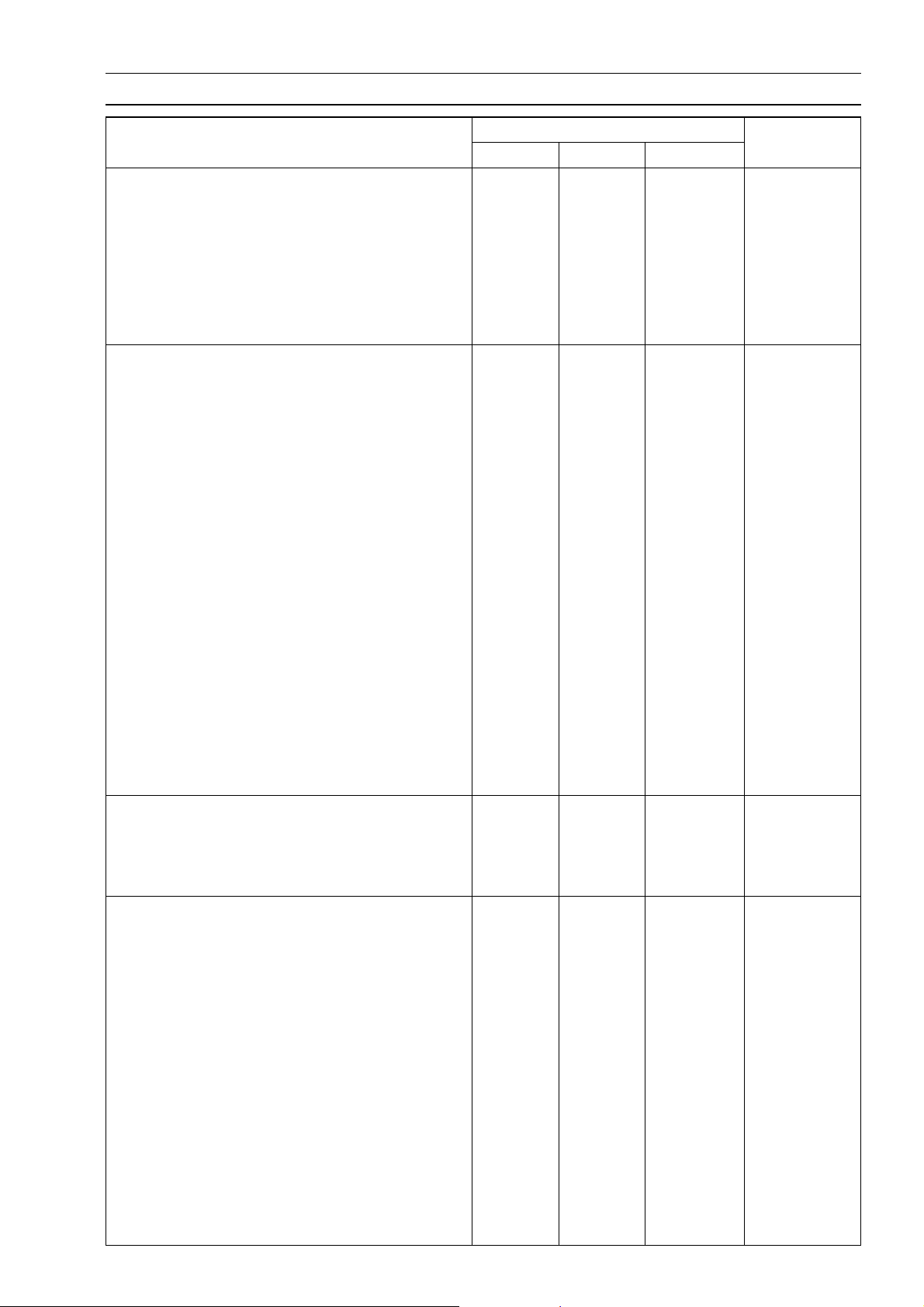

Periodic Maintenance Chart

GENERAL INFORMATION 1-13

FREQUENCY Whichever

comes

first

1 6 12 18 24 30 36

OPERATION Every (0.6) (4.0) (7.5) (12) (15) (20) (24)

Swingarm pivot - lubricate

Radiator hoses, connections - inspect †

Coolant - change 2 years

Coolant filter - clean year

Steering stem bearing - lubricate 2 years

Rear shock absorber oil leak - inspect †

#: Service more frequently when operating in severe conditions dusty, wet, muddy, high speed, or

frequent starting/stopping.

†: Replace, add, adjust, clean, or torque if necessary.

*: For higher odometer readings, repeat at the frequency interval established here.

•

• • •

• • •

• • •

*ODOMETER

READING

× 1 000 km

(× 1 000 mile)

•

•

Page 22

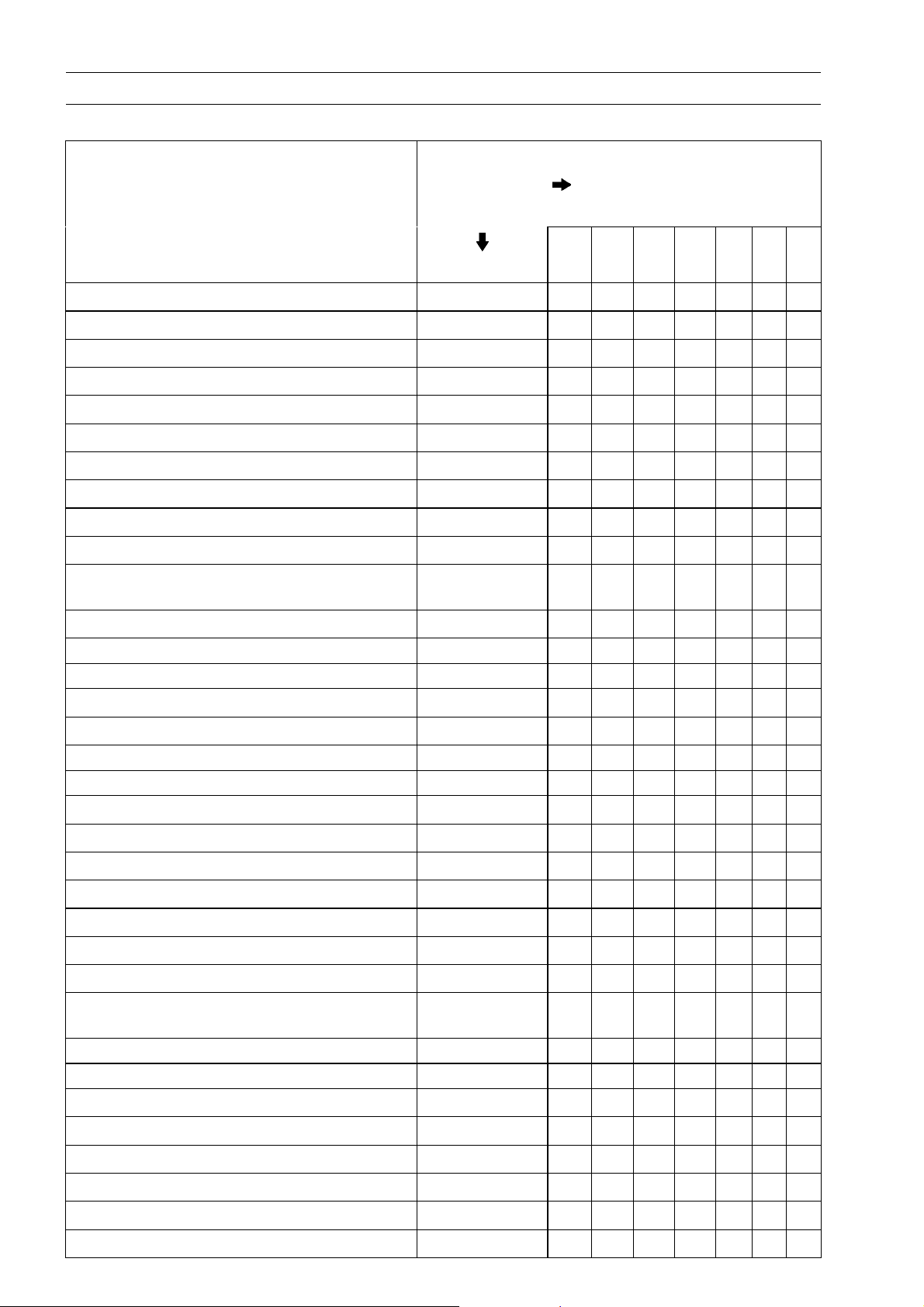

1-14 GENERAL INFORMATION

Periodic Maintenance Chart

(United States and Canada Models)

FREQUENCY

OPERATION Every (0.5) (3.1) (6.2) (9.3) (12) (16) (20)

Carburetor synchronization - inspect †

Idle speed - adjust †

Throttle grip play - inspect †

Spark plug - clean and gap †

Valve clearance - inspect †

Air suction valve - inspect †

Air cleaner element - clean

Air c leaner element - replace 5 cleaning

Fuel system - inspect

Fuel hose, connections - inspect †

Evaporative emission control system (CAL) inspect

Whichever

comes

first

0.8 5 10 15 20 25 30

• • • • • • •

• • • • • • •

• • • •

• • • • • •

• • • •

• • • • • •

• • • •

• • •

• • • • • •

• • • • • • •

*ODOMETER

READING

× 1 000 km

(× 1 000 mile)

•

Radiator Hoses, connections - inspect † year

Drive chain - lubricate # 600 km

Drive chain slack - inspect †# 1 000 km

Spoke tightness and rim runout - inspect †

Rim runout - inspect †

Fuel hose-replace 4 years

Brake hose-replace 4 years

Battery electrolyte level - inspect † m onth

Brake play - inspect †

Brake light switch - inspect †

Brake lining or pad wear - inspect †

Brake fluid level - inspect † month

Brake fluid - change † 2 years

Brake hose, connections - inspect †

Brake master cylinder cup and dust seal replace

Caliper fluid seal and dust seal - replace 2 years

Brake cable - replace 2 years

2 years

• • • •

• • • • • • •

• • • • • • •

• • • • • • •

• • • • • • •

• • • • • • •

• • • • • •

• • • • • • •

•

• • • • • •

Brake camshaft - lubricate 2 years

Clutch - adjust

Steering - inspect †

Drive chain wear - inspect †#

Nut, bolts, and fasteners tightness - inspect †

Tire wear - inspect †

•

• • • • • • •

• • • • • • •

• • • • • •

• • • •

• • • • • •

Page 23

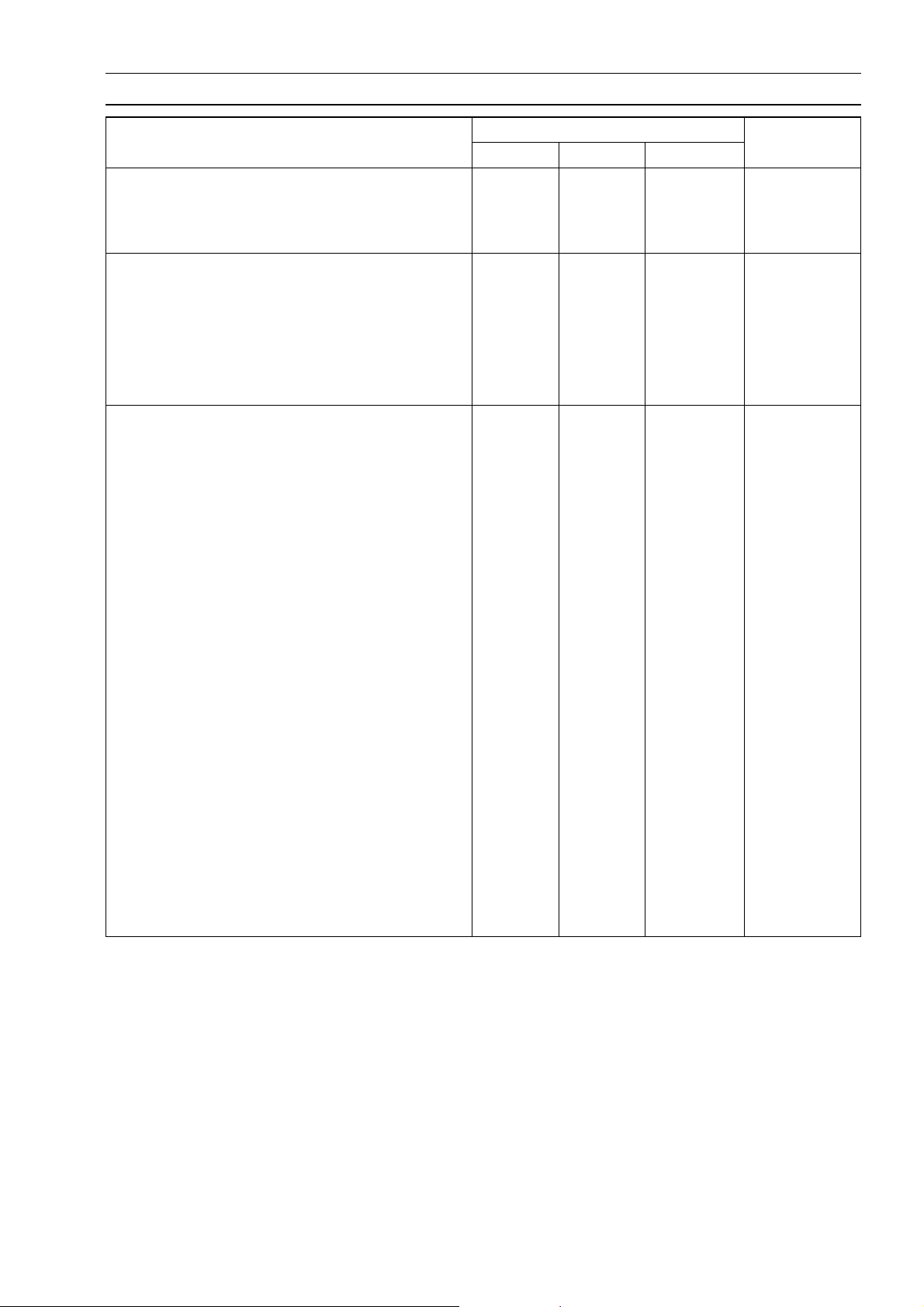

Periodic Maintenance Chart

GENERAL INFORMATION 1-15

FREQUENCY

OPERATION Every (0.5) (3.1) (6.2) (9.3) (12) (16) (20)

Engine oil - change year

Oil filter - replace

General lubrication - perform #

Front fork oil - change

Swingarm pivot - lubricate

Coolant - change 2years

Coolant filter - clean year

Steering stem bearing - lubricate 2years

#: Service more frequently when operating in severe conditions dusty, wet, muddy, high speed, or

frequent starting/stopping.

†: Replace, add, adjust, clean, or torque if necessary.

*: For higher odometer readings, repeat at the frequency interval established here.

CAL: California Model

Whichever

comes

first

0.8 5 10 15 20 25 30

• • • •

• • • •

• • • • • •

• • •

• • •

*ODOMETER

READING

× 1 000 km

(× 1 000 mile)

•

•

•

Page 24

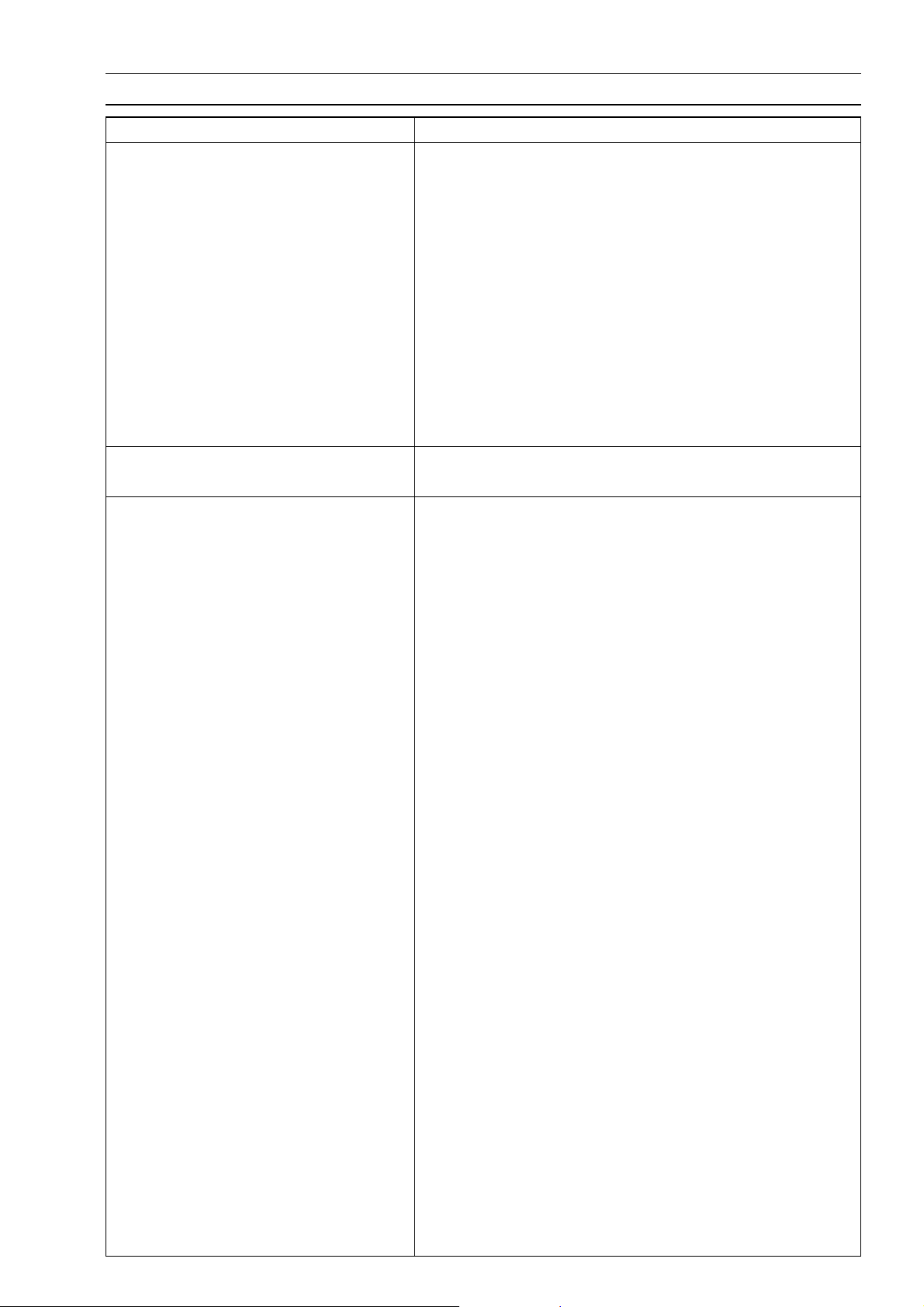

1-16 GENERAL INFORMATION

Torque and Locking Agent

Tighten all bolts and nuts to the proper torque using an accurate torque wrench. An insufficiently

tightened bolt or nut may become damaged or fall off, possibly resulting in damage to the motorcycle

and injury to the rider. A bolt or nut which is overtightened may become damaged, strip an internal

thread, or break and then fall out. The following table lists the tightening torque for the major bolts

and nuts, and the parts requiring use of a non-permanent locking agent or liquid gasket.

When checking the tightening torque of the bolts and nuts, first loosen the bolt or nut by half a turn

and then tighten it to the specified torque.

Letters used in the “Remarks” column mean:

L: Apply a non-permanent locking agent to the threads.

Lh: Left-hand threads.

LG: Apply liquid gasket to the threads.

S: Tighten the fasteners following the specified sequence.

SS: Apply silicone sealant to the threads.

Fastener

Fuel System

Fuel Tap Mounting Bolts

Cooling System

Radiator Hose Clamp Screws

Radiator Fan Switch

Thermostat Housing Bolts 11 1.1 95 in·lb

Water Temperature Switch 7.8 0.8 69 in·lb SS

Water Pump Cover Bolts 11 1.1 95 in·lb

Water Pump Shaft 25 2.5 18 Lh

Water Pump Impeller 9.8 1.0 87 in·lb Lh

Water Pipe Screws 4.9 0.5 43 in·lb

Coolant Passage Blank Caps 9.8 1.0 87 in·lb L

Coolant Drain Plug 11 1.1 95 in·lb

Engine Top End

Air Suction Valve Cap Bolts 11 1.1 95 in·lb

Cylinder Head Cover Bolts 9.8 1.0 87 in·lb

Camshaft Cap Bolts 12 1.2 104 in·lb S

Rocker Shafts 39 4.0 29

Valve Adjuster Locknuts 25 2.5 18

Camshaft Sprocket Bolts 15 1.5 11 L

Cylinder Head Bolts (M10) 51 5.2 38 S

Cylinder Head Bolts (M6) 9.8 1.0 87 in·lb S

Cam Chain Tensioner Mounting Bolts 11 1.1 95 in·lb

Cam C hain Tensioner Cap Bolt 4.9 0.5 43 in·lb

Main Oil Pipe Upper Banjo Bolts M8 12 1.2 104 in·lb

Main Oil Pipe Lower Banjo Bolt M10 20 2.0 14.5

Oil Pipe Bolts (in the cylinder head) 11 1.1 95 in·lb

Oil Pipe Mounting Bolt

N·m kgf·m ft·lb

4.9 0.5 43 in·lb with black

2.5 0.25 22 in·lb with white

2.5 0.25 22 in·lb

18 1.8 13

11 1.1 95 in·lb

Torque

Remarks

washer

washer

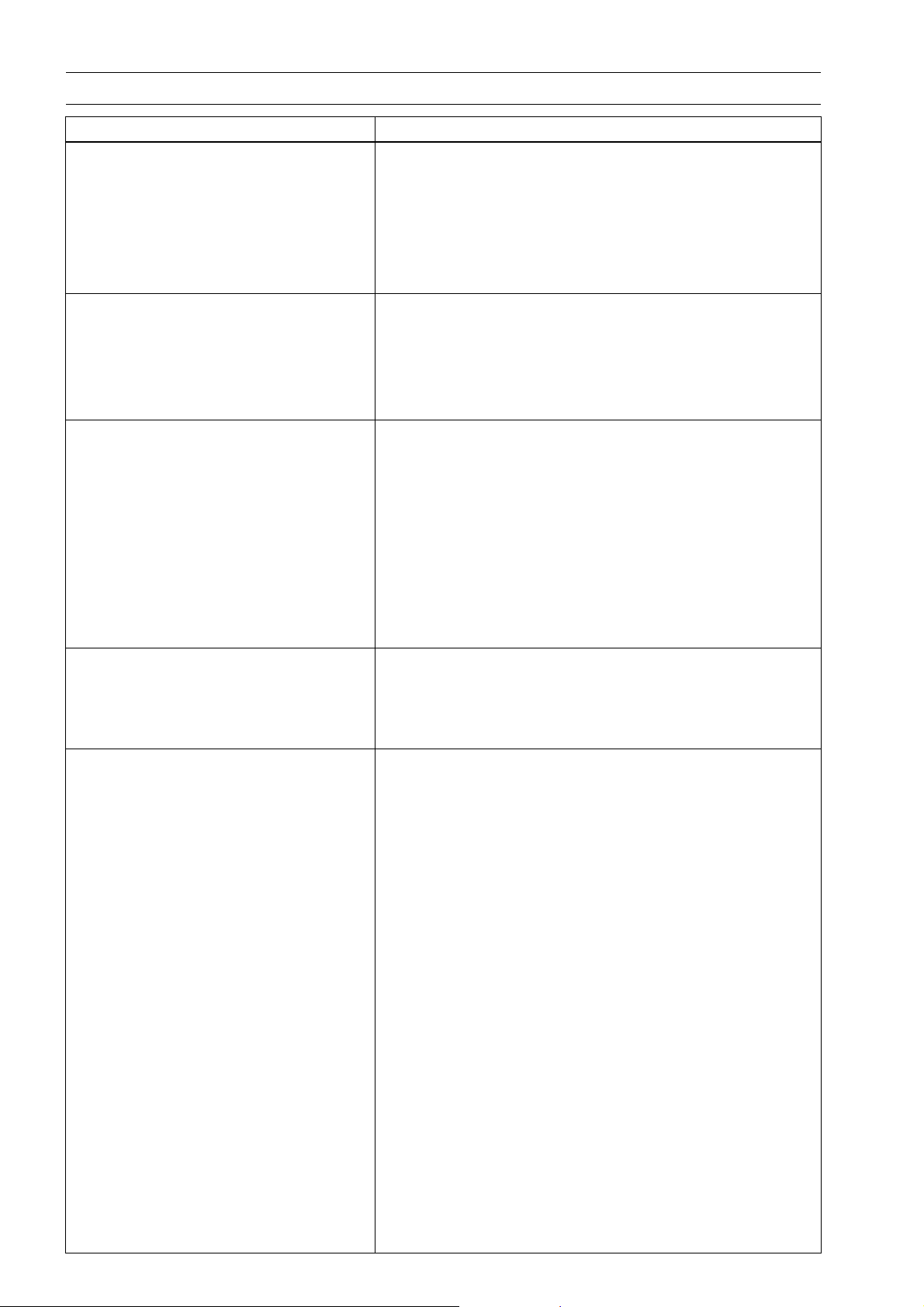

Page 25

Torque and Locking Agent

GENERAL INFORMATION 1-17

Fastener

Clutch

Oil Filler Plug

Clutch Hub Nut

Clutch Spring Bolts 9.3 0.95 82 in·lb

Clutch Cable Holder Bolt 11 1.1 95 in·lb

Clutch Cover Bolts 11 1.1 95 in·lb

Clutch Cover Damper Plate Bolts 9.8 1.0 87 in·lb L

Engine Lubrication System

Oil Passage Plug 18 1.8 13

Oil Filter Mounting Stud 25 2.5 18 L

Oil Filter (Cartridge Type) 17 1.75 12.5

Oil Pipe for Balancer Shaft Banjo B olt 20 2.0 14.5

Oil Pipe for Drive Shaft Upper Banjo Bolt M6 7.8 0.80 69 in·lb

Oil Pipe for Drive Shaft Lower Banjo Bolt M8 12 1.2 104 in·lb

Oil Pipe for Output Shaft Upper Banjo Bolt M6 7.8 0.80 69 in·lb

Oil Pipe for Output Shaft Lower Banjo Bolt M8 12 1.2 104 in·lb

Oil Pipe for O utput Shaft Mounting Bolt 11 1.1 95 in·lb L

Oil Pump Outer Oil Pipe Bolt 11 1.1 95 in·lb L

Oil Pum p Mounting Bolts 11 1.1 95 in·lb L

Relief Valve 15 1.5 11 L

Oil Pressure Switch 15 1.5 11 SS

Engine Oil D rain Plug 29 3.0 22

Oil Pan Mounting Bolts 11 1.1 95 in·lb

Breather Body Bolt 5.9 0.6 52 in·lb

Engine Removal/Installation

Engine Mounting Nuts 44 4.5 33

Engine Mounting Bracket Nuts 25 2.5 18

Engine Mounting Bracket Bolts 25 2.5 18

Crankshaft/Transmission

Crankcase Bolts (M8) 27 2.8 20 S

Crankcase Bolts (M6) 12 1.2 104 in·lb S

Upper Primary Chain Guide Mounting Nut 11 1.1 95 in·lb L

Lower Primary Chain Guide Mounting Bolt 11 1.1 95 in·lb L

Connecting Rod Big End Cap Nuts 36 3.7 27

Return Spring Pin 20 2.0 14.5 L

Gear Positioning Lever Pivot Stud – – – L

Gear Positioning Lever Nut 11 1.1 95 in·lb

Shift Lever Clamp Bolts 11 1.1 95 in·lb

Shift Linkage Rod Lock Nuts 11 1.1 95 in·lb Lh (1)

Shift Pedal Mounting Bolt 8.8 0.9 78 in·lb

Shift Drum Bearing Holder Bolts 11 1.1 95 in·lb L

N·m kgf·m ft·lb

1.5 0.15 13 in·lb

132 13.5 98

Torque

Remarks

(planted side)

(planted side)

Page 26

1-18 GENERAL INFORMATION

Torque and Locking Agent

Fastener

Shift Drum Cam Pin Plate Screw – – – L

Shift R od Stopper Bolt 11 1.1 95 in·lb

External Shift Mechanism Cover Bolts 11 1.1 95 in·lb

Neutral Switch 15 1.5 11

Wheels/Tires

Front Axle Nut 88 9.0 65

Front Axle Clamp Allen Bolt 34 3.5 25

Rear Axle Nut 88 9.0 65

Spoke Nipples

Torque Link Nuts 34 3.5 25

Final Drive

Engine Sprocket Nut 127 13 94

Rear Sprocket Nuts 74 7.5 54

Rear Coupling Studs – – –

Drive Chain Guide Bolts 11 1.1 95 in·lb

Brakes

Brake Hose Banjo Bolts 25 2.5 18

Reservoir Cap Screws 1.5 0.15 13 in·lb

Brake Lever Pivot Bolt 1.0 0.1 9in·lb

Brake Lever Pivot Locknut 5.9 0.6 52 in·lb

Master Cylinder Clamp Bolts 11 1.1 95 in·lb S

Front Brake Light Switch Mounting Screw

Caliper M ounting Bolts

Caliper Bleed Valves

Brake Disc Mounting Bolts 27 2.8 20 L

Brake Pedal Mounting Bolt 25 2.5 18

Torque Link Nuts 34 3.5 25

Brake Cam Lever Bolt

Suspension

Front Fork Top Plug 23 2.3 16.5

Front Fork Upper Clamp Allen Bolts 20 2.0 14.5

Front Fork Lower Clamp Allen Bolts 29 3.0 22

Front Fork Bottom Allen Bolt 29 3.0 22 L

Rear Shock Absorber Upper Mounting Bolt 25 2.5 18

Rear Shock Absorber Lower Mounting Bolt 34 3.5 25

Swingarm Pivot Nut 88 9.0 65

Steering

Handlebar Mounting Nuts 34 3.5 25

Steering Stem Head Bolt 44 4.5 33

N·m kgf·m ft·lb

5.2 0.53 46 in·lb

59 6.0 43 (Self Locknut)

1.2 0.12 10 in·lb

34 3.5 25

7.8 0.8 69 in·lb

19 1.9 14

Torque

(planted side)

Remarks

L

Page 27

Torque and Locking Agent

GENERAL INFORMATION 1-19

Fastener

Steering S tem Nut

Frame

Side Stand Mounting Bolt 44 4.5 33

Footpeg Holder Bolts (M10) 34 3.5 25

Footpeg Holder Bolts (M12) 54 5.5 39

Muffler Bracket Bolts (M8) 25 2.5 18

Muffler Bracket Bolts (M10) 34 3.5 25

Electrical System

Front Brake Light Switch Mounting Screw 1.2 0.12 10 in·lb

Crankshaft Sensor Mounting Allen Bolts 8.3 0.85 74 in·lb L

Timing Inspection Plug 2.5 0.25 22 in·lb

Alternator Rotor Bolt Plug 1.5 0.15 13 in·lb

Alternator Cover Bolts 11 1.1 95 in·lb

Alternator Cover Allen Bolt 13 1.3 113 in·lb

Alternator Lead Clamp Screws 2.9 0.30 26 in·lb

Spark Plug 14 1.4 10

Alternator Stator Allen Bolts 12 1.2 104 in·lb

Alternator Rotor Bolt 69 7.0 51

Starter Motor Mounting Bolts

Starter Chain Guide Screws

Starter Motor Through Bolts

Starter Motor Terminal Nut 6.9 0.7 65 in·lb

Starter Motor Cable Clamp Nut 4.9 0.5 43 in·lb

Starter Clutch Allen Bolts 34 3.5 25 L

Side Stand Switch Mounting Screw 3.9 0.4 35 in·lb L

Oil Pressure Switch 15 1.5 11

Neutral Switch 15 1.5 11

Tail Light Mounting Nuts 5.9 0.6 52 in·lb

N·m kgf·m ft·lb

Hand

-Tighten

(about

4.9)

11 1.1 95 in·lb

4.9 0.5 43 in·lb L

6.9 0.7 65 in·lb

Torque

Hand

-Tighten

(about

0.5)

Hand

-Tighten

(about 43

in·lb)

Remarks

Page 28

1-20 GENERAL INFORMATION

Torque and Locking Agent

The table relating tightening torque to thread diam eter, lists the basic torque for the bolts and nuts.

Use this table for only the bolts and nuts which do not require a specific torque value. All of the values

are for use with dry solvent-cleaned threads.

General Fasteners

Threads Torque

Diameter (mm) N·m kgf·m ft·lb

5 3.4 ∼ 4.9 0.35 ∼ 0.50 30 ∼ 43 in·lb

6 5.9 ∼ 7.8 0.60 ∼ 0.80 52 ∼ 69 in·lb

8 14 ∼ 19 1.4 ∼ 1.9 10.0 ∼ 13.5

10 25 ∼ 34 2.6 ∼ 3.5 19.0 ∼ 25

12 44 ∼ 61 4.5 ∼ 6.2 33 ∼ 45

14 73 ∼ 98 7.4 ∼ 10.0 54 ∼ 72

16 115 ∼ 155 11.5 ∼ 16.0 83 ∼ 115

18 165 ∼ 225 17.0 ∼ 23.0 125 ∼ 165

20 225 ∼ 325 23 ∼ 33 165 ∼ 240

Page 29

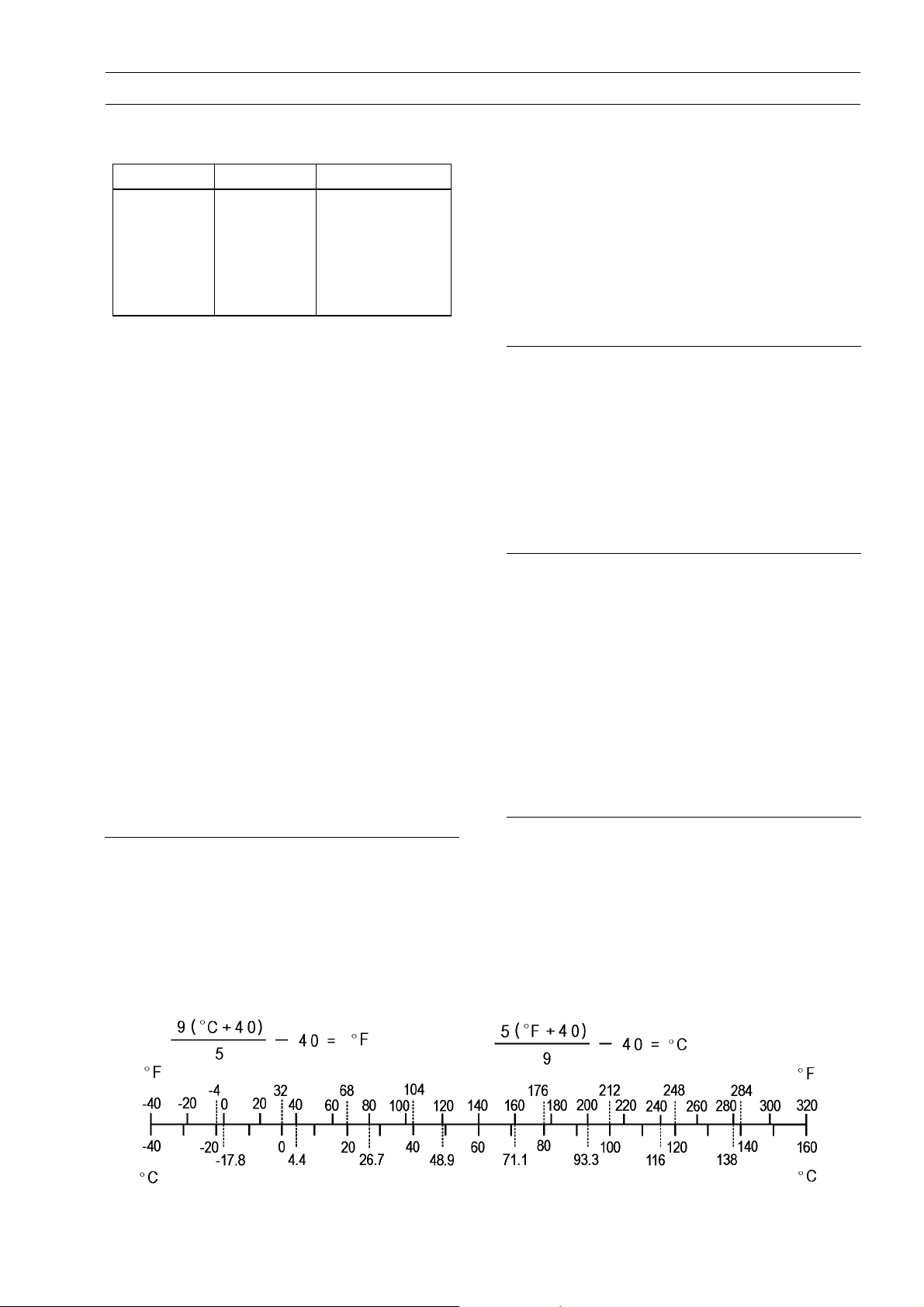

Unit Conversion Table

GENERAL INFORMATION 1-21

Prefixes for Units

Prefix Symbol Power

mega M × 1 000 000

kilo k × 1 000

centi c ×0.01

milli m ×0.001

micro μ × 0.000001

Units of Mass

kg ×2.205=lb

g × 0.03527 = oz

Units of Volume

L × 0.2642 =

L × 0.2200 = gal (imp)

L × 1.057 = qt (US)

L × 0.8799 = qt (imp)

L × 2.113 = pint (US)

L × 1.816 = pint (imp)

mL × 0.03381 = oz (US)

mL × 0.02816 = oz (imp)

mL × 0.06102 = cu in

gal (US)

Units of Length

km × 0.6214 = mile

m × 3.281 =

mm × 0.03937 = in

ft

Units of Torqu e

N·m × 0.1020 = kg·m

N·m × 0.7376 = ft·lb

N·m × 8.851 = in·lb

kgf·m × 9.807 = N·m

kgf·m × 7.233 = ft·lb

kgf·m × 86.80 = in·lb

Units of Pressure

kPa × 0.01020 = kg/cm²

kPa × 0.1450 = psi

kPa × 0.7501 = cmHg

kg/cm² × 98.07 = kPa

kg/cm² × 14.22 = psi

cmHg×1.333=kPa

Units of Speed

km/h × 0.6214 = mph

Units of Force

N × 0.1020 = kg

N × 0.2248 = lb

kg ×9.807=N

kg ×2.205=lb

Units of Temperature

Units of Power

kW ×1.360=PS

kW ×1.341=HP

PS × 0.7355 = kW

PS × 0.9863 = HP

Page 30

Page 31

Fuel System

Table of Contents

FUEL SYSTEM 2-1

2

Exploded View................................... 2-2

Specifications .................................... 2-4

Special Tools ..................................... 2-5

Throttle Grip and Cable ..................... 2-6

Throttle Grip Free Play Inspection 2-6

Throttle Cable Adjustment ........... 2-6

Throttle Cable Inspection ............. 2-7

Throttle Cable Lubrication............ 2-7

Carburetors........................................ 2-8

Idle Speed Inspection .................. 2-8

Idle Speed Adjustment................. 2-8

High Altitude Performance

Adjustment (United States

Model) ....................................... 2-8

Vacuum Synchronization

Inspection .................................. 2-8

Synchronization Adjustment ........ 2-9

Service Fuel Level Inspection ...... 2-9

Service Fuel Level Adjustment .... 2-10

Fuel System Cleanliness

Inspection .................................. 2-11

Carburetor Removal..................... 2-11

Carburetor installation.................. 2-12

Carburetor Disassembly/Assem-

bly.............................................. 2-12

Carburetor Separation/Assembly. 2-14

Carburetor Cleaning..................... 2-14

Carburetor Inspection .................. 2-15

Coolant Filter Cleaning (AT,

DE, FR, IT, NL, CH, GB, KR,

Models) ..................................... 2-16

Air Cleaner......................................... 2-17

Air Cleaner Housing Removal...... 2-17

Air Cleaner Housing Installation... 2-17

Air C leaner Element

Removal/Installation .................. 2-17

Air Cleaner Element Cleaning and

Inspection .................................. 2-18

Oil Draining .................................. 2-18

Fuel Tank ........................................... 2-19

Fuel Tank Removal ...................... 2-19

Fuel Tank Installation ................... 2-20

Fuel Tap Removal........................ 2-20

Fuel Tap Installation ..................... 2-20

Fuel Tank and Tap Cleaning ........ 2-20

Fuel Tap Inspection...................... 2-21

Fuel Tank and Cap Inspection ..... 2-21

Evaporative Emission Control System

(California Model only).................... 2-22

Parts Removal/Installation ........... 2-22

Hose Inspection ........................... 2-22

Separator Inspection.................... 2-22

Separator Operation Test............. 2-23

Canister Inspection ...................... 2-23

Page 32

2-2 FUEL SYSTEM

Exploded View

A: Austria, Germany, France, Italy, Korea, Netherlands, Switzerland and United Kingdom Models

Europe Models (EN500-C6 ∼)

B: California Model

CL: Apply cable lubricant.

G: Apply grease.

Page 33

Exploded View

FUEL SYSTEM 2-3

1. Jet Needle

2. Pilot Screw

3. Plug (United St

land Models)

4. Pilot Jet

5. Needle Jet

6. Needle Jet Holder

7. Main Jet

T1: 2.5 N·m (0.

washer)

25 kgf·m, 22 i n·lb) (with white

ates, Canada and Switzer-

4.9 N·m (0.5 kgf·m, 43 in·lb) (with black

washer)

A: United States,

rea and California Models

Canada and Germany Models (EN500

-C2 ∼)

Europe and France Models (EN500-C6 ∼)

B: California Model

C: EN500-C1 ∼ EN5

Switzerland, Austria, Ko-

00C7F Models

Page 34

2-4 FUEL SYSTEM

Specifications

Item

EN500-C1 ∼ C4 EN500-C5 ∼

Throttle Grip and Cables

Throttle Grip Free Play 2 ∼ 3 mm (0.08 ∼ 0.12 in.) ←

Carburetor specifications

Make/Type Keihin/CVK32 ←

Main Jet #102 ←

Main Air Jet #100 ←

Jet Needle N2WE, C1: (AT, CH, US, CAL)

C2 ∼ C4: (AT, CH, US, CAL, CA, DE)

N2WD, C1: (FR, GB, IT, NL, DE, EUR, GR ,

SE, NO, ES, CA)

C2 ∼ C4: (FR, GB, IT, NL, EUR, GR,

SE, NO, ES, KR, ML)

Pilot Jet #35 ←

Pilot Air Jet #150 ←

Pilot Screw 2 1/8 (turns out) ←

Starter Jet #48 ←

Service Fuel Level 0.5 ±1 mm (0.02 ±0.04 in.) ←

(above the bottom edge of carburetor body) ←

Float Height 17.0 ±2.0 mm (0.67 ±0.08 in.) ←

Idle Speed 1 300 ±50 r/min (rpm)

Air Cleaner Element Oil

Grade SE, SF, or SG class ←

Viscosity SAE30 ←

Standard

N2WE (US, CAL,

CA,DE,FR,EUR)

←

AT: Austria Model

CA: Canada Model

CAL: California Model

CH: Switzerland Model

DE: Germany Model

ES: Spain Model

EUR: E u rope Model

FR: France Model

GB: United Kingdom Model

GR: Greece Model

IT: Italy Model

KR: Korea Model

NL: Netherlands Model

NO: Norway Model

SE: Sweden Model

US: United States Model

ML: Malaysia Model

Page 35

Special Tools

FUEL SYSTEM 2-5

Fuel Level Gauge:

57001-1017

Pilot Screw Adjuster, C:

57001-1292

Vacuum Gauge:

57001-1369

Page 36

2-6 FUEL SYSTEM

Throttle Grip and Cable

ThrottleGripFreePlayInspection

Check the throttle grip free play [A].

•

If the free play is incorrect, adjust the throttle cable.

Throttle Grip Free Play

Standard: 2 ∼ 3mm(0.08∼ 0.12 in.)

Check that the throttle grip moves smoothly from full open

•

to close, and the throttle closes quickly and completely in

all steering positions by the return spring.

If the throttle grip does not return properly, check the throttle cable routing, grip free play, and cable damage. Then

lubricate the throttle cable.

Run the engine at the idle speed, and turn the handlebar

•

all the way to the right and left to ensure that the idle speed

does not change.

If the idle speed increase, check the throttle cable free

play and the cable routing.

Throttle Cable Ad justment

Loosen the locknuts [A], and screw both throttle cable ad-

•

justers [B] in fully at the upper end of the throttle cables

so as to give the throttle grip plenty of play.

Turn out the decelerator cable [C] adjuster until there is

•

no clearance between the cable bracket and the stopper

when the throttle grip is completely closed. Tighten the

locknut.

Turn the accelerator cable [D] adjuster until the proper

•

amount of throttle grip free play is obtained. Tighten the

locknut.

If the throttle cables can not be adjusted by using the cable adjusters at the upper end of the throttle cables, use

the cable adjusters at the lower ends of the throttle cables.

First give the throttle grip plenty of play by turning the

•

adjusters at the grip in fully. Tighten the locknuts.

Turn out both upper nuts [A] and turn in both lower nuts [B]

•

as far as they will go so as to give the throttle grip plenty

of play.

With the throttle grip completely closed, turn out the lower

•

nut and turn in the upper nut of the decelerator cable until

the inner cable just becomes tight.

Turn out the lower nut and turn in the upper nut of the

•

accelerator cable until the correct free play is obtained.

Check that the throttle linkage lever stops against the idle

•

adjusting screw with the throttle grip closed.

Start the engine.

•

Turn the handlebar from side to side while idling the en-

•

gine.

If idle speed varies, the throttle cable may be poorly

routed or it m ay be dam aged.

Correct any problem before operating the motorcycle.

•

WARNING

Operation w ith an incorrectly routed or improperly

adjusted cables could result in an unsafe riding

condition.

Page 37

Throttle Grip and Cable

Throttle Cable Inspection

Remove both ends of the throttle cables.

•

With the cable disconnected at both ends, the cable

•

should move freely [A] within the cable housing.

If cable movement is not free after lubricating, if the cable

is frayed [B], or if the cable housing is kinked [C], replace

the cable.

FUEL SYSTEM 2-7

Throttle Cable Lubrication

Whenever the throttle cables are removed, lubricate the

throttle cables as follows:

Apply a thin coating of grease to the throttle cable lower

•

ends [A].

Lubricate the throttle cable with a penetrating rust inhib-

•

iter.

Page 38

2-8 FUEL SYSTEM

Carburetors

Idle Speed Inspection

Start the engine and warm it up thoroughly.

•

With the engine idling, turn the handlebar to both sides.

•

If handlebar movement changes the idle speed, the throttle cable may be improperly adjusted or incorrectly routed,

or it may be damaged. Be sure to correct any of these

conditions before riding.

WARNING

Operation with improperly adjusted, incorrectly

routed, or damaged cables could result in an unsafe riding condition.

Check idle speed.

•

If the idle speed is out of the specified range, adjust it.

Idle Speed

1300±50r/min(rpm)

Idle Speed Adjustment

tart the engine and warm it up thoroughly.

S

•

Turn the adjusting screw [A] until idle speed is correct.

•

Open and close the throttle a few times to make sure that

○

the idle speed is within the specified range. Readjust if

necessary.

High Altitude Performance Adjustment (United States Model)

To i mprove the EMISSION CONTROL PERFORMANCE

○

of vehicle operated above 4 000 feet, Kawasaki recommends the following E nvironmental Protection Agency

(EPA) approved modification.

Change the main jet and pilot jet for high altitude use.

•

High Altitude Carburetor Specifications

Main Jet: #100

Pilot Jet: #32

Vacuum Synchronization Inspection

Situate t he motorcycle so that it is perpendicular to the

•

ground.

Warm up the engine.

•

Check idle speed and adjust if necessary.

•

Pull the vacuum hoses off, and attach vacuum gauge [A]

•

to the vacuum hose fittings [B] on the carburetors.

Special Tool - Vacuum Gauge: 57001-1369

Page 39

Carburetors

Start the engine and let it idle to m easure the carburetor

•

intake vacuum.

If the intake vacuum difference between the two cylinders

exceeds the limit, adjust the synchronization.

Engine Vacuum Synchronization

Less than 2.7 kPa (2 cmHg) difference between both

cylinders

Synchronization Adjustment

Turn the adjusting screw [A] to synchronize the carbure-

•

tor.

If the carburetor synchronization cannot be obtained by

using the adjusting screw, check for dirt or blockage, and

then check the pilot screw settings.

Special Tool - Pilot Screw Adjuster, C: 57001-1292

NOTE

Do not turn the pilot screws carelessly during carburetor

○

synchronization. You may cause poor running at low

engine speed.

FUEL SYSTEM 2-9

Check idle speed and adjust if necessary.

•

Service Fuel Level Inspection

WARNING

Gasoline is extremely flammable and can be explosive under certain conditions. Turn the ignition

switch OFF. Do not sm oke. Make sure the area is

well-ventilated and free from any source of flame

or sparks; this includes any appliance with a pilot

light

Situate the motorcycle so that it is perpendicular to the

•

ground.

Connect a suitable r ubber hose (5 mm inside diameter

•

and about 300 m m long) to the fitting at the bottom of

each carburetor float bow l.

Connect fuel level gauge [A] to the rubber hose.

•

Special Tool - Fuel Level Gauge: 57001-1017

Hold the gauge vertically against the side of the carburetor

•

body so that the “middle” line [B] is several millimeters

higher than the bottom edge [D] of the carburetor body.

Turn the fuel tap to the PRI position to feed fuel to the

•

carburetor, then turn out the carburetor drain plug [C] a

few turns.

Wait until the fuel level [E] in the gauge settles.

•

Page 40

2-10 FUEL SYSTEM

Carburetors

Keeping the gauge vertical, slowly lower the gauge until

•

the “middle” line is even with the bottom edge of the carburetor body.

NOTE

Do not lower the “middle” line below the bottom edge of

○

the carburetor body. If the gauge is lowered and then

raised again, the fuel level measured shows somewhat

higher than the actual fuel level. If the gauge is lowered

too far, dump the fuel out of it into a suitable container

and start the procedure over again.

Read the fuel level in the gauge and compare it to the

•

specification.

Screw in the carburetor drain plug.

•

Service Fuel Level

0.5 ±1 mm (0.02 ±0.04 in.) above the bottom edge of

carburetor body

Turn the fuel tap to the ON position and remove the fuel

•

level gauge.

Inspect the fuel level in another carburetor in the same

•

manner.

If the fuel level is incorrect, adjust it (see Service Fuel

Level Adjustment).

Service Fuel Level Adjustment

WARNING

Gasoline is extremely flammable and can be explosive un der certain conditions. Turn the ignition

switch OFF. Do not smoke. Make sure the area is

well-ventilated and free from any source of flame

or sparks; this includes any appliance with a pilot

light.

Remove the carburetor, and drain the fuel into a suitable

•

container.

Remove the float bowl by taking out the screws with lock-

•

washers.

Slide out the pivot pin [A] and remove the float [B].

•

Bend the tang [A] on the float arm very slightly to change

•

the float height. Increasing the float height lowers the fuel

level and decreasing the float height raises the fuel level.

Float Height

17.0±2.0mm(0.67±0.08in.)

Page 41

Carburetors

NOTE

Do not push the needle rod [A] in during the float height

○

measurement [B].

Assemble the carburetor, and recheck the fuel level.

•

If the fuel level cannot be adjusted by this method, the

float or the float valve [C] is damaged.

Fuel Sys tem Cleanliness Inspection

WARNING

Gasoline is extremely flammable and can be explosive under certain conditions. Turn the ignition

switch OFF. Do not sm oke. Make sure the area is

well-ventilated and free from any source of flame

or sparks; this includes any appliance with a pilot

light.

FUEL SYSTEM 2-11

Connect a suitable hose [A] to the fitting at the bottom of

•

each carburetor float bow l.

Run the lower ends of the hoses into a suitable container.

•

Turn the fuel tap to the PRI position.

•

Turn out each drain plug [B] a few turns and drain the float

•

bowls.

Check to see if water or dirt comes out.

•

If any water or dirt appears during the above inspection,

clean the fuel system (see Carburetor Cleaning and Fuel

Tank Cleaning).

Tighten the drain plugs and turn the f uel tap to the ON

•

position.

Carburetor Removal

WARNING

Gasoline is extremely flammable and can be explosive under certain conditions. Turn the ignition

switch OFF. Do not sm oke. Make sure the area is

well-ventilated and tee from any source of flame

or sparks; this includes any appliance with a pilot

light.

Remove:

•

Side Covers (see Right and Left Side Cover Removal in

the Frame chapter)

Seat (see Seat Removal/Installation in the Frame chapter)

Fuel Tank (see Fuel Tank Removal)

Page 42

2-12 FUEL SYSTEM

Carburetors

Loosen the carburetor clamps [A] and slide back the

•

spring bands [B].

Remove the carburetor from the end of the air cleaner

•

duct, and then pull it out of the carburetor holder.

Remove the carburetor to the left side.

•

Slip the throttle cable lower ends out of the cable bracket.

•

After removing the carburetors, stuff pieces of lint-free,

•

clean cloths into the carburetor holders and the intake

ducts to keep dirt out of the engine and air cleaner.

WARNING

If dirt or dust is allowed to pass through into the

carburetors, the throttle may become stuck, possibly causing an accident.

CAUTION

If dirt gets through into the engine, excessive engine wear and possible engine damage will occur.

Carburetor installation

Installation is the reverse of removal.

•

Check fuel leakage from the carburetors.

•

WARNING

Fuel spilled from the carburetors is hazardous.

Adjust the following items if necessary.

•

Idle Speed

Vacuum Synchronization

Throttle Cables

Carburetor Disassembly/Assembly

Read the WARNINGS in the Carburetor Removal.

•

For the United States and Switzerland models, remove

•

the pilot screw plug as follows:

Punch a hole in the plug and pry it out with an awl or other

○

suitable tool.

Turn in the pilot screw and count the number of turns until

•

it seats fully but not tightly, and then remove the screw.

This is to set the screw to its original position when assembling.

After installing the upper chamber cover, check that the

•

vacuum piston slides up and down smoothly without binding in the carburetor bore.

CAUTION

During carburetor disassembly, be careful not to

damage the diaphragm. Never use a sharp edge to

remove the diaphragm.

Page 43

Carburetors

Turn in the pilot screw [A] fully but not tightly, and then

•

back it out the same number of turns counted during disassembly.

For the United States and Switzerland models, install the

•

pilot screw plug as follows:

Install a new plug [B] in the pilot screw hole [C], and apply

○

a small amount of a bonding agent [D] to the circumference of the plug to fix the plug.

CAUTION

Do not apply too much bond on the plug to keep the

pilot screw itself from being fixed.

Turn the carburetor body upside-down, and drop the nee-

•

dle jet [A] into place so that the smaller diameter end [B]

of the jet goes in first.

FUEL SYSTEM 2-13

Carefully screw in the needle jet holder. It will seat against

•

the needle jet, pushing the end of the jet into the carburetor bore.

CAUTION

Do not force the needle jet holder [A] and main jet

[B] or overtighten them. The needle jet or the carburetor body could be damaged requiring replacement.

Slip the jet needle through the hole in the center of the

•

vacuum piston, and put the spring seat [A] on the top of

the needle. Turn the seat so that it does not block the hole

[B] at the bottom of the vacuum piston.

Page 44

2-14 FUEL SYSTEM

Carburetors

Carburetor Separation/Assembly

Read the WARNINGS in the Carburetor Removal.

•

The center lines of the carburetor bores must be parallel

•

both horizontally and vertically. If they are not, l oosen

the mounting screws and align the carburetors on a flat

surface. Retighten the mounting screws.

After assembling the choke mechanism, check to see that

•

the choke plunger lever slides from side to side smoothly

without abnorm al f riction.

CAUTION

Fuel mixture trouble could result if the choke

plunger does not seat properly in its rest position

after the choke lever is returned.

Visually synchronize the throttle (butterfly) valves.

•

Check to see that the throttle valves open and close

○

smoothly without binding when turning the pulley.

Visually check the clearance [A] between the throttle

○

valve and the carburetor bore in each carburetor.

If there is a difference between the throttle valves, turn the

balance adjusting screw [ B] to obtain the same clearance.

Carburetor Cleaning

WARNING

Clean the carburetors in a well-ventilated area, and

take care that there is no spar

near the working area; this includes any appliance

with a pilot light. Because of the danger of highly

flammable liquids, do not

-point solvents to clean the carburetors.

k or flame anywhere

use gasoline or low flash

Page 45

Carburetors

CAUTION

Do not use compressed air on an assembled carburetor, or the floats may be crushed by the pressure,

and the vacuum piston diaphragms m ay be damaged.

Remove as many rubber or plastic parts from the

carburetor as possible before cleaning the carburetor with a cleaning solution. This will prevent damage to or deterioration of the parts.

The carburetor body has plastic parts that cannot be removed. Do not use a strong carburetor

cleaning solution which could attack these parts;

instead, use a mild, high-flash point cleaning solution safe for plastic parts.

Do not use wire or any other hard instrument t o

clean carburetor parts, especially jets, as they may

be damaged.

Disassemble the carburetors.

•

Immerse all the metal parts in a carburetor cleaning solu-

•

tion.

Rinse the parts in water.

•

When the parts are clean, dry them with compressed air.

•

Blow through the air and fuel passages with compressed

•

air.

Assemble the carburetors.

•

FUEL SYSTEM 2-15

Carburetor Inspection

WARNING

Gasoline is extremely flammable and can be explosive under certain conditions. Turn the ignition

switch OFF. Do not sm oke. Make sure the area is

well-ventilated and free from any source of flame

or sparks; this includes any appliance with a pilot

light.

Remove the carburetors.

•

Before disassembling the carburetors, check the fuel level

•

(see Fuel Level Inspection).

If the fuel level is incorrect, inspect the rest of the carburetor before correcting it.

Move the choke plunger lever from side t o side to check

•

that the choke plungers move smoothly without abnormal

friction.

If the choke plungers do not work properly, replace the

carburetors.

Turn the throttle cable bracket to check that the throttle

•

butterfly valves [A] move smoothly and return with spring

tension.

If the throttle valves do not move smoothly, replace the

carburetors.

Page 46

2-16 FUEL SYSTEM

Carburetors

Disassemble the carburetors.

•

Clean the carburetors.

•

Check that the O-rings on the float bowl and drain plug

•

and the diaphragm on the vacuum piston are in good condition.

If any of the O-rings or diaphragms are not in good condition, replace them.

Check the plastic tip [A] of t he float valve needle [B]. It

•

should be smooth, without any grooves, scratches, or

tears.

If the plastic tip is damaged [C], replace the needle.

Push in the rod [D] in the other end of the float valve nee-

•

dle, and then release it [E].

If it does not spring out, replace the needle.

Check the tapered portion [A] of the pilot screw [B] for

•

wear or damage.

If the pilot screw is worn or damaged on the tapered portion, it will prevent the engine from idling smoothly. Replace it.

Check that the vacuum piston [A] moves smoothly in the

•

carburetor body. The surface of the piston must not be

excessively worn.

If the vacuum piston does not move smoothly, or if it is

very loose in the carburetor body, replace the carburetor.

Coolant Filter Cleaning (AT, DE, FR, IT, NL, CH, GB, KR, Models)

Before winter season starts, clean the filter of carburetor

system.

Remove the fuel tank (see Fuel Tank Removal).

•

Drain the coolant (see Coolant Draining in the Cooling

•

System chapter).

Remove the filter [A] from the cooling hoses [B] of carbu-

•

retor system.

Blow off dirt and sediment on the filter with compressed

•

air.

AT: Austria Model NL: Netherlands Model

DE: Germany Model CH: Switzerland Model

FR: France Model GB: United Kingdom Model

IT: Italy Model KR: Korea Model

Page 47

Air Cleaner

Air Cleaner Housing Removal

Remove:

•

Side Covers (see Right and Left Side Cover Removal in

the Frame chapter)

Seat (see Seat Removal in the Frame chapter)

Fuel Tank (see Fuel Tank Removal)

Air Suction Valve Vacuum Hose (AT, KR, CH and US

Models),

(EN500-C2 ∼ CA, DE Models)

Carburetor

Tool Cover

Housing Mounting Screws [A]

Pull the housing forward.

•

Unscrew the surge tank bolts [A] and separate the surge

•

tank [B] from the housing [C].

Remove the housing.

•

FUEL SYSTEM 2-17

Air Cle aner Housing Inst allation

Installation is the reverse of removal.

•

Be sure to fit the following hoses.

•

Engine Breather Hose

Air Cleaner Drain Hose

Air Suction Valve Vacuum Hose (AT, KR, CH and US

Models)

(EN500-C2 ∼ CA, DE Models)

Canister Return Hose

Air Cleaner Element Removal/Installation

Remove the left side cover (see Left Side Cover Removal

•

in the Frame chapter).

Disconnect the alternator connector [A ] and remove the

•

starter relay [B].

Pull out the air cleaner element holder [C] and remove the

•

element.

Push a clean, lint-free towel into the air cleaner housing

•

to keep dirt or other foreign material from entering.

WARNING

If dirt or dust is allowed to pass through into the carburetors, the butterfly valves may become stuck,

possibly causing an accident.

CAUTION

If dirt gets through into the engine, excessive engine wear and possible engine damage will occur.

Page 48

2-18 FUEL SYSTEM

Air Cleaner

Air C leaner Element Cleaning and Inspection

NOTE

In dusty areas, the element should be cleaned more

○

frequently than the recommended interval.

After riding through rain or on muddy roads, the element

○

should be cleaned immediately.

WARNING

Clean the element in a well-ventilated area, and take

care that there are no sparks or fame anywhere near

the working area.; this includes any appliance with

a pilot light.

Because of the danger of highly flammable liquids,

do not use gasoline or a low flash-point solvent to

clean the element.

Remove the air cleaner element (see Air Cleaner Element

•

Removal).

Clean the element [A] in a bath of a high-flash point sol-

•

vent.

Squeeze it dry in a clean towel.

•

After cleaning, saturate the element with SE, SF, or SG,

•

class SAE30 oil, squeeze out the excess, then wrap it in

a clean rag and squeeze it as dry as possible. Be careful

not to tear the element.

Visually check the element for tears or breaks. Also check

•

the sponge gasket [A], the plastic holders [B] and wire

screen [C].

If the element or gasket has any tears or breaks, replace

the element.

If the holders and screen are distorted, replace them.

If the sponge gasket comes loose, stick it back on with an

adhesive sealant.

Oil Draining

A drain hose is connected to the bottom of the air cleaner

housing to drain water or oil accumulated in the housing.

Visually check the catch tank [A] of t he drain hose if the

•

water or oil accumulates in the tank.

If any water or oil accumulates in the tank, drain it by

taking off the drain plug [ B] at the lower end of the drain

hose.

WARNING

Be sure to reinstall the plug in the drain hose after

draining. Oil on tires will make them slippery and

can cause an accident and injury.

Page 49

Fuel Tank

Fuel Tank Removal

WARNING

Gasoline is extremely flammable and can be explosive under certain conditions. Turn the ignition

switch OFF. Do not sm oke. Make sure the area is

well-ventilated and free from any source of flame

or sparks; this includes any appliance with a pilot

light.

CAUTION

For California model, if gasoline, solvent, water or

any other liquid enters the canister, the canister’s

vapor absorbing capacity is greatly reduced. If the

canister does become contaminated, replace it with

a new one.

Remove the seat.

•

Turn the fuel tap [A] to the ON or RES position.

•

Pull the hoses [B] off the tap.

•

For California vehicles, the breather and fuel return hoses

○

must be disconnected from the tank fittings before tank removal. Plug the fuel return fitting. This prevents gasoline

from flowing into the canister.

FUEL SYSTEM 2-19

Unscrew the mounting bolt [A] and remove the meter

•

instruments [B] (see Meter Instruments Removal in the

Electrical System chapter).

Remove the fuel tank mounting bolts [A].

•

Remove the fuel tank.

•

Drain the fuel tank.

•

Put a suitable container under the fuel tank.

○

Turn the fuel tap to the PRI position to drain the fuel into

○

the container.

Page 50

2-20 FUEL SYSTEM

Fuel Tank

Fuel Tank Installation

Read the WARNING in the Fuel Tank Removal section.

•

Check the rubber dampers [A] on the frame top-tube.

•

If the dampers are damaged or deteriorated, replace

them.

Route the hoses and leads correctly ( see Cable, Wire and

•

Hose Routing in the Appendix c hapter).

Be sure the hoses are clamped to the fuel tap and fuel

•

tank to prevent leaks.

Fuel Tap Removal

Remove the fuel tank and drain it.

•

Remove the bolts [A] with nylon flat washers and take out

•

thefueltap[B].

Fuel Tap Installation

Fuel tap installation is the re

•

following.

Be sure the O-ring is in good condition to prevent leaks.

•

Be sure to clamp the fuel hos

•

Be sure the nylon washers are in good condition to pre-

•

vent leaks.

Torque - Fuel Tap Mounting Bolts:

2.5 N·m ( 0.25 kgf·m, 22 in·lb)

(with white washer)

4.9 N·m ( 0.5 kgf·m, 43 in·lb)

(with black washer)

Do not use steel washers in place of the nylon washers,

○

because they will not seal the bolts properly and fuel will

leak.

Fuel Tank and Tap Cleaning

Remove the fuel tank and drain it.

•

our some high-flash point solvent into the fuel tank and

P

•

shake the tank to remove dirt and fuel deposits.

WARNING

Clean the tank in a well-ventilated area, and take

care that there are no sparks or flame anywhere

near the working area; this includes any appliance

with a pilot light. Because of the danger of highly

flammable liquids, do not use gasoline or low flash

-point solvents to clean the tank.

verse of removal. Note the

etothetaptopreventleaks.

Pour the solvent out of the tank.

•

Remove the fuel tap from the tank by taking out the bolts

•

with nylon washers.

Clean the fuel tap filter screens in a high-flash point sol-

•

vent.

Page 51

Fuel Tank

Pour high-flash point solvent through the tap in all lever

•

position.

Dry the tank and tap w ith compressed air.

•

Install the tap i n the tank.

•

Install the fuel tank.

•

Fuel Tap Inspection

Remove the fuel tap.

•

Check the fuel tap filter screens [A] for any breaks or de-

•

terioration.

If the f uel tap screens have any breaks or are deteriorated, they m ay allow dirt to reach the carburetor, causing

poor running. Replace the fuel tap.

If the fuel tap leaks, or allows fuel to flow when it is at

ON or RES without engine running, replace the damaged

gasket [B] or O-ring [C].

Fuel Tank and Cap Inspection

Open the tank cap.

•

Visually inspect the gaskets [A] on the tank cap for any

•

damage.

Replace the gaskets if they are damaged.

Remove the breather and fuel return pipe and check to

•

see if the pipes in the tank do not clogged up. Check the

tank cap breather also.

If they are clogged, remove the tank and drain it, and then

blow the breather free with compressed air (California vehicle only).