Page 1

ANEMOMASTER

MODEL 6113

Operation Manual

取扱説明書本文にでてくる警告事項は、ご使用いただく前に

注意深く読み、よく理解してください。

いつでもご使用いただけるように大切に保管してください。

Please use this instrument properly by reading

this user’s manual and following the warning instructions.

Keep this manual in a place where it can be accessed quickly.

KANOMAX JAPAN INC.

2-1 Shimizu Suita Osaka Zip:565-0805

Phone: +81(6)6877-0183

Fax : +81(6)6879-2080

01001

03. 01

Page 2

Thank you for purchasing Kanomax product.

Please use this instrument properly by reading

the operation manual and following the

warning instructions.

Page 3

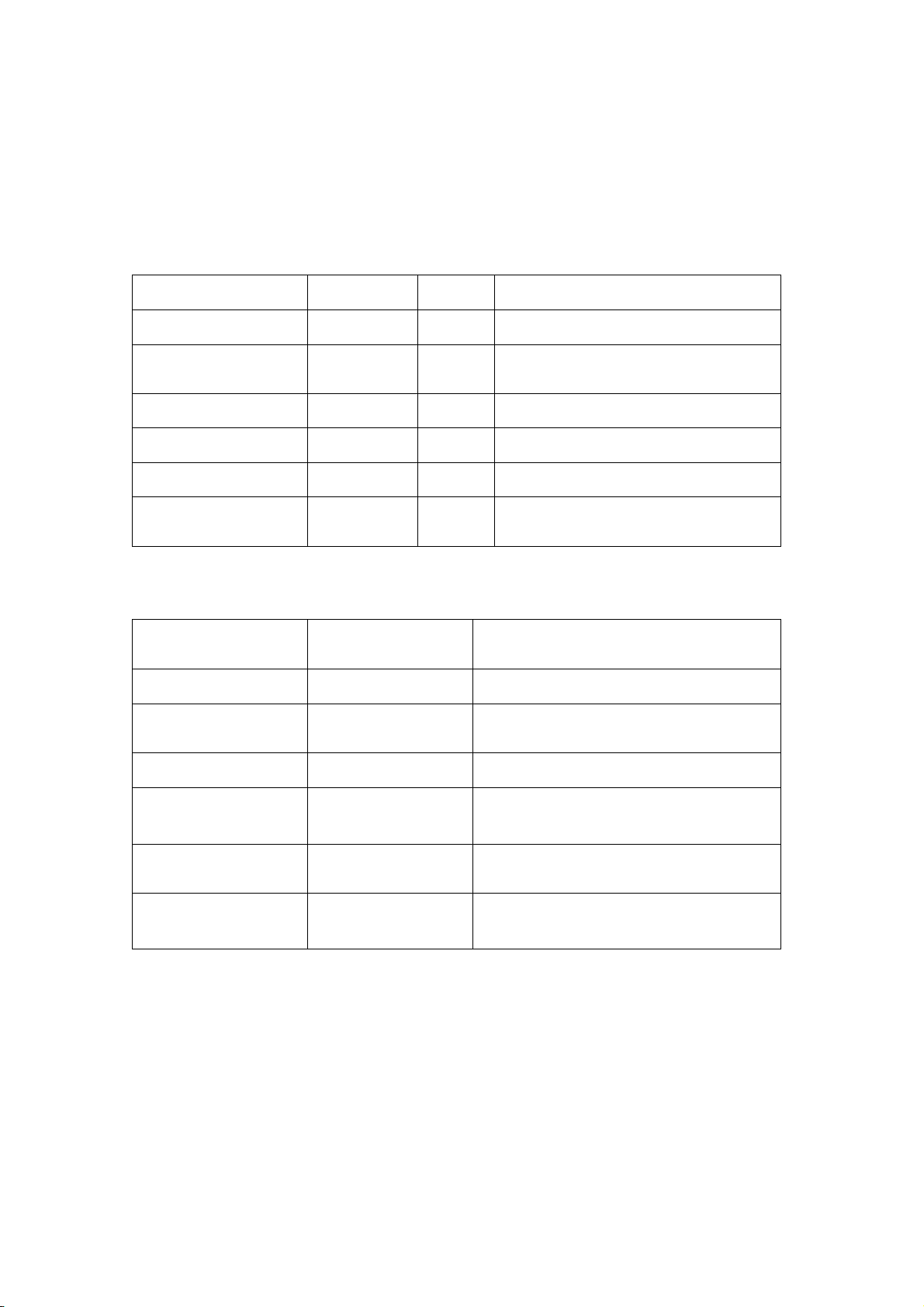

List of Components

■ Standard

Items MODEL Qty Functions

Main Body 6113 1 -

Probe 6113-01 1

Air velocity, air temperature

sensor

Extension Rod 6112-03 1 To measure high places

Shoulder Strap 1 -

Operation Manual - 1 -

AA Manganese

Batteries

- 6 -

■ Options

Items MODEL Functions

Spare Probe 6113-01 For spare

Pressure Sensor 6113-07

Analog Output 6113-08 Analog output terminal

For measurements of differential

pressure

AC Adaptor 6113-02 Power supply

RS232C Cable 6000-02

Portable Anemometer

Data Logging Software

S600-00 Data collection (application) software

For the connection of Main Body and

PC

Page 4

Safety Precautions

Safety Precautions

PLEASE READ CAREFULLY BEFORE PROCEEDING

These precautions explain how to use the device correctly and safely, thereby preventing injury

to yourself or to others. This section has been sub-divided into a WARNING section and a

CAUTION section, according to the likelihood and nature of any potential injuries or damage

inflicted. They relate to your personal safety, and also help you minimize the risk of damaging

the device. Please read these sections carefully before proceeding.

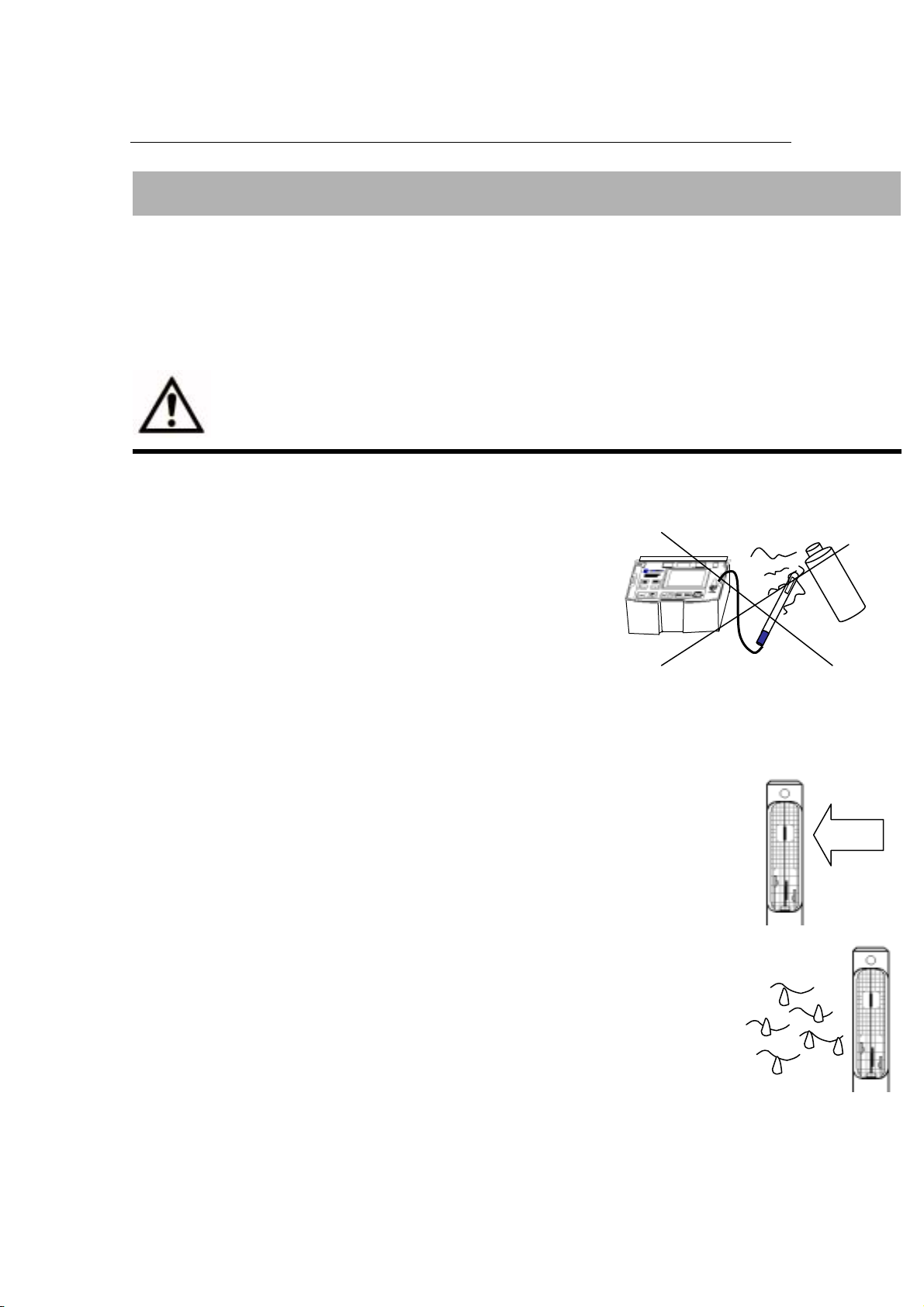

WARNING

Always follow the basic precautions listed below to avoid the possibility of serious injury or

even death from electrical shock, short-circuiting, damages, fire or other hazards. These

precautions include, but are not limited to, the following:

¾ Do not install the probe in an area where flammable gas is present.

Otherwise, there is an increased risk of fire or even explosion.

¾ Do not open the device or attempt to disassemble or modify it.

Otherwise, there is an increased risk of electrical shock or fire. The device contains no

user-serviceable parts. If it appears to be malfunctioning, have it inspected by qualified

service personnel.

¾ Do not insert fingers or foreign objects into the device.

Otherwise, there is an increased risk of personal injury (such as burning yourself),

electrical shock, and damage to the device or fire. Please take particular care if

small children are present.

¾ Do not expose the device to rain, use it near water or in damp or wet conditions or

place containers on it that contain liquids which might spill into any openings.

Otherwise, there is an increased risk of electrical shock, fire or personal injury.

¾ Follow the Operation Manual carefully.

Otherwise, there is an increased risk of personal injury, electrical shock, fire or damage to

the unit. Follow the correct procedure when setting up the device.

i

Page 5

¾ If unusual smells, sounds or smoke emanate from the device or if liquids enter the device,

switch the device off immediately and take out the batteries and/or unplug it from the

power outlet.

Otherwise, there is an increased risk of electrical shock, fire or damage to the device.

Return the device immediately to nearest Kanomax Office or to the Service Center in

Osaka, Japan.

Page 6

Safety Precautions

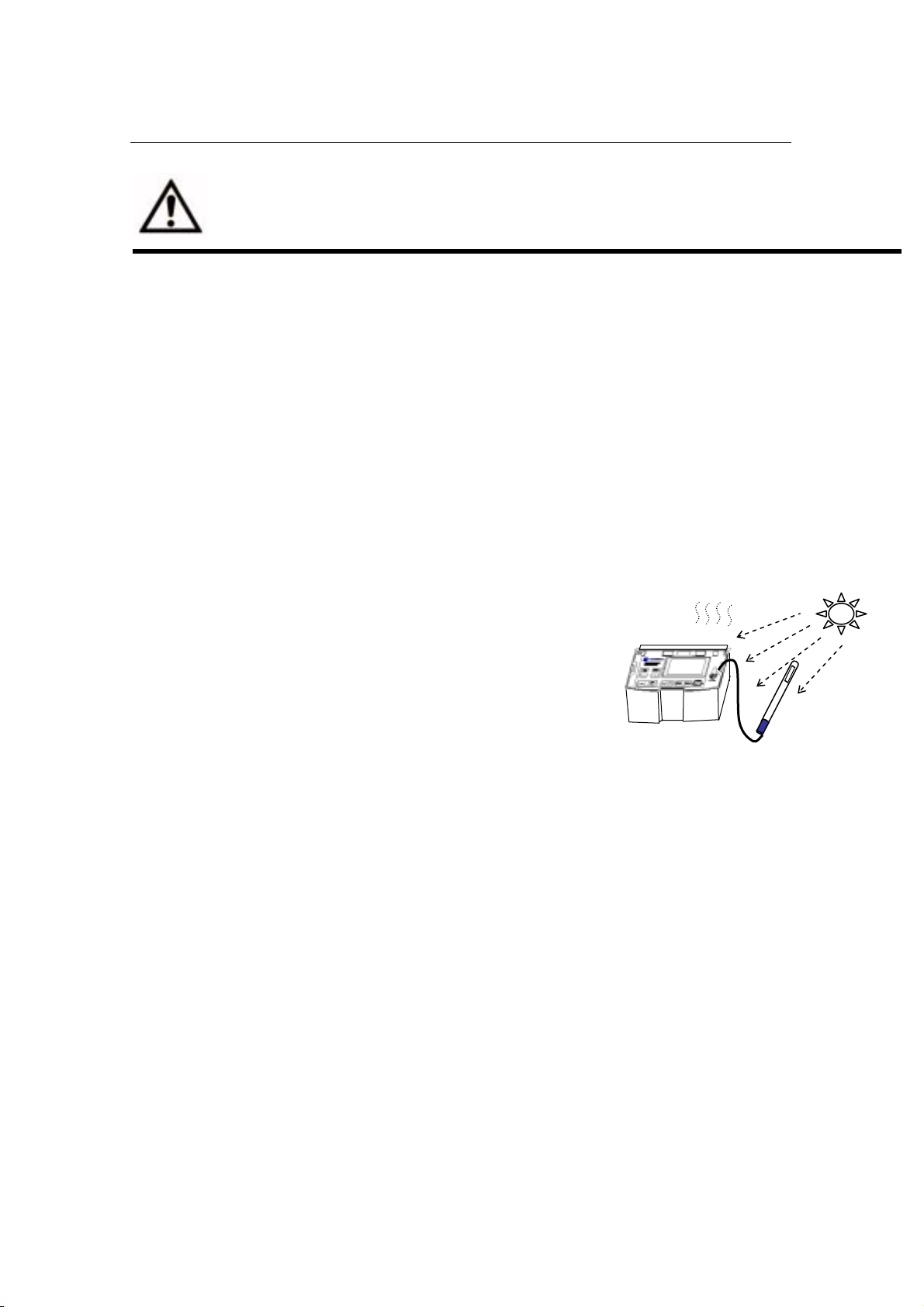

CAUTION

Always follow the basic precautions listed below to avoid the possibility of physical injury to

yourself or others, or damage to the instrument or other property. These precautions include,

but are not limited to, the following:

¾ Always unplug the anemometer from the electrical outlet if it will not be used to for a

prolonged period time of if there is a risk of lightning.

Otherwise, there is an increased risk of electrical shock, short-circuiting or fire.

¾ Always take out the batteries before storing.

Otherwise, there is an increased risk of leakage.

¾ Do not leave exhausted batteries in the unit.

Otherwise, there is an increased risk of leakage.

¾ Do not expose the device to excessive heat or vibrations or

extreme cold or heat (such as in direct sun light or near heater).

Otherwise, the main body may become disfigured or the internal

components may be damaged and no longer function properly.

¾ When cleaning the device, never use benzene, paint thinners, detergents or

chemical-impregnated wiping cloths. Also, do not place vinyl, plastic or rubber objects on

the device.

Otherwise, the device may be damaged or its main body may become discolored or

disfigured. Use a soft, dry cloth to wipe the device.

¾ Do not impact the device by resting your weight on or placing heavy objects on the device;

do not use excessive force on the buttons, switches or connectors.

Otherwise, there is an increased risk of damage to the device or personal injury.

¾ Have the device serviced regularly.

Otherwise, there is an increased risk of not maintaining the accuracy. For information

about servicing charges, contact your nearest Kanomax Office or Kanomax Service Center.

The device should be serviced about once a year.

¾ The sensor is very sensitive to electrostatic. Please handle with care.

ii

Page 7

Table of Contents

1.ANEMOMASTER Anatomy.................................................................................. 1

1.1 Main Body......................................................................................................................... 1

1.2 Operation Panel............................................................................................................. 3

1.3 Probe / Probe Cable................................................................................................... 4

1.4 Telescopic Articulating Extension Rod (Option).............................................. 5

2.Getting Started........................................................................................................ 6

2.1 Installing Batteries........................................................................................................ 6

2.2 Confirming the Probe Number ................................................................................ 7

2.3 Connecting Probe......................................................................................................... 7

2.4 Powering ANEMOMASTER ON / OFF............................................................. 8

2.5 How to Make Measurements.................................................................................... 9

2. 5. 1 Measuring Air Velocity..........................................................................................................9

2. 5. 2 Measuring Air Temperature ................................................................................................9

2. 5. 3 Measuring Pressure ...............................................................................................................9

3.Normal Measurement *** Measurement Mode *** ................................11

3.1 Selecting the Measuring Parameters .................................................................11

3.2 Display Hold..................................................................................................................12

3.3 Changing the Display Range on the Bar Graph ..............................................12

3.4 To Change Time Constant .....................................................................................13

4.Storing and Deleting Stored Measurement Data .....................................14

4.1 To Store Measurement Data.................................................................................14

4.2 To Delete Data.............................................................................................................15

4.2.1 Complete Deletion: Deleting All Stored Measurement Data........................ 15

4.2.2 Simple Deletion: Deleting a Single Measurement Data Last Stored......... 15

4.2.3 Selective Deletion: Deleting a Single Specific Stored Data......................... 16

5.Measuring Mean, Maximum & Minimum *** Calculation Mode ***..........17

6.Data Output ............................................................................................................19

6.1 Printing Out ..................................................................................................................19

6.1.1 Set up the Printer Paper (Roll Paper)..................................................................... 19

6.1.2 Spot Value Print Out .....................................................................................................21

6.1.3 Calculation Results Print Out..................................................................................... 21

6.1.4 Stored Data Print Out ................................................................................................... 22

6.1.5 Function Set Information Print Out (Also for Test Print) ............................... 22

6.2 Digital Output...............................................................................................................23

6.2.1 Preparation......................................................................................................................... 23

6.3 To Access From Your PC.......................................................................................24

6.3.1 Transmission of On-Time Data (Every-second Basis) ............................... 24

6.3.2 Transmission of Data Stored in Memory................................................................ 25

6.4 Setting the Output for Single Parameter Measurement Data .................25

6.4.1 How to Print-out using the Setting for Single Parameter Data Output.... 25

Page 8

6.4.2 Digital Output using the Settings for Single Parameter Output................... 25

6.5 Analog Output (Optional) .................................................................................................... 26

7.Other Settings .......................................................................................................27

7.1 Date .................................................................................................................................27

7.2 Units and Baud Rate.................................................................................................28

7.2.1 Set-up.................................................................................................................................. 28

7.2.2 Dip Switch Set-up Chart.............................................................................................. 29

8.Cleaning the Probe...............................................................................................30

9.Specification ...........................................................................................................31

10.Principle of Measurement ..............................................................................32

11.About Compensation........................................................................................34

11.1 Influence of Measuring Temperature...............................................................34

11.2 Influence of Pressure at Measuring Point .....................................................34

11.3 Measuring Gas Components................................................................................34

12.Probe Directivity (Air Velocity) ...................................................................35

12.1 Horizontal...................................................................................................................35

12.2 Vertical ........................................................................................................................35

13.Trouble Shooting ...............................................................................................36

13.1 Batteries .....................................................................................................................36

13.2 Initial Operations.....................................................................................................36

13.3 During Operations ...................................................................................................36

13.4 Printer Output..........................................................................................................37

13.5 Digital Output ...........................................................................................................37

13.6 Analog Output ..........................................................................................................37

14.Warranty and After Service...........................................................................38

Page 9

p

(

pp

)

pp

t

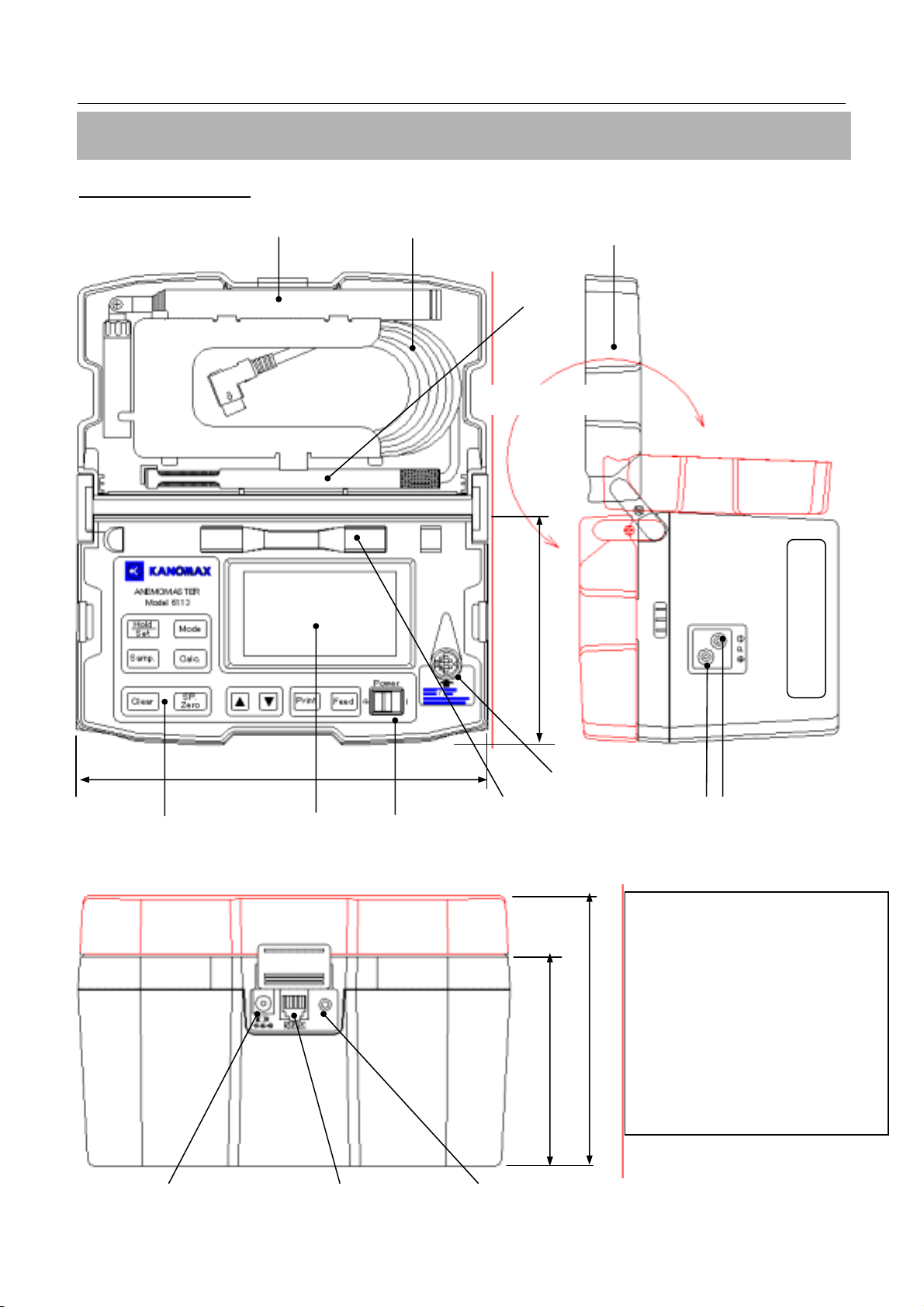

1. ANEMOMASTER Anatomy

1

1.ANEMOMASTER Anatomy

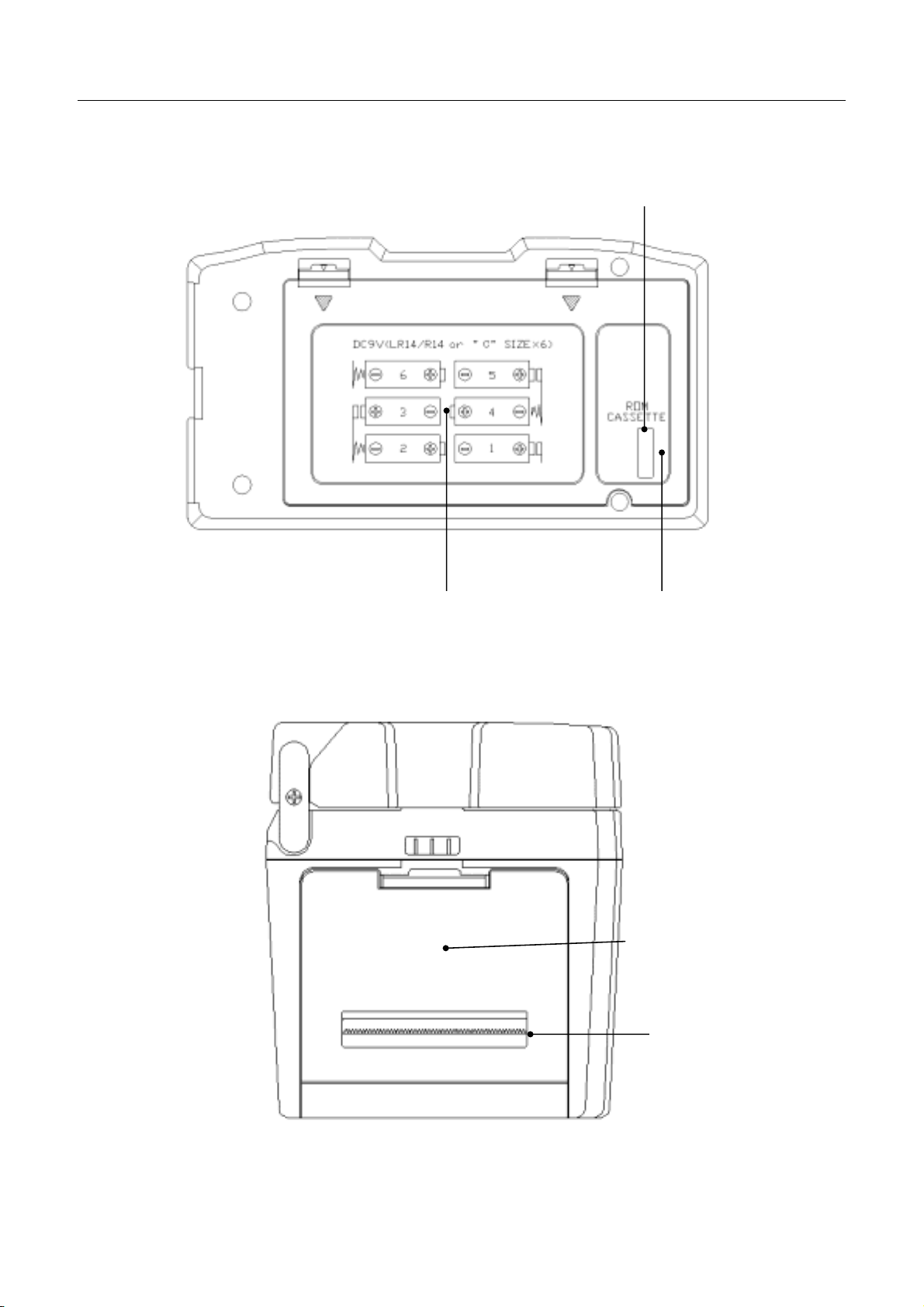

1.1 Main Body

Unit:mm

Operation Panel

DC Input Terminal

Extension Rod (Articulating)

Approx. 210

LCD Display

RS232C Terminal

Cable

Power Switch

I :ON

O:OFF

Analog Output Terminal

Lid (Probe storage area)

Probe

<Rotate>

Approx. 120

Probe Connection Terminal

Probe Rest

(To be used only when measuring)

rox. 107

A

tion)

(O

*) Caution

Whenever you close the Lid, be

sure to disconnect the Probe from

and store on the Probe Rest. If

you close the Lid while the Probe

is still set on the Probe Rest, you

rox. 133

may risk damage such as breaking

the probe cable.

A

Pressure Sensor Port

(Option)

he Probe Connection Terminal,

Page 10

1. ANEMOMASTER Anatomy

<Diagram of the Bottom>

<Diagram of the Left Side>

2

ROM Cassette

Probe Number Display Window

0001

Batteries Compartment ROM Cassette Storage Area

Built-in Printer

Printer Paper Cutter

Page 11

1. ANEMOMASTER Anatomy

3

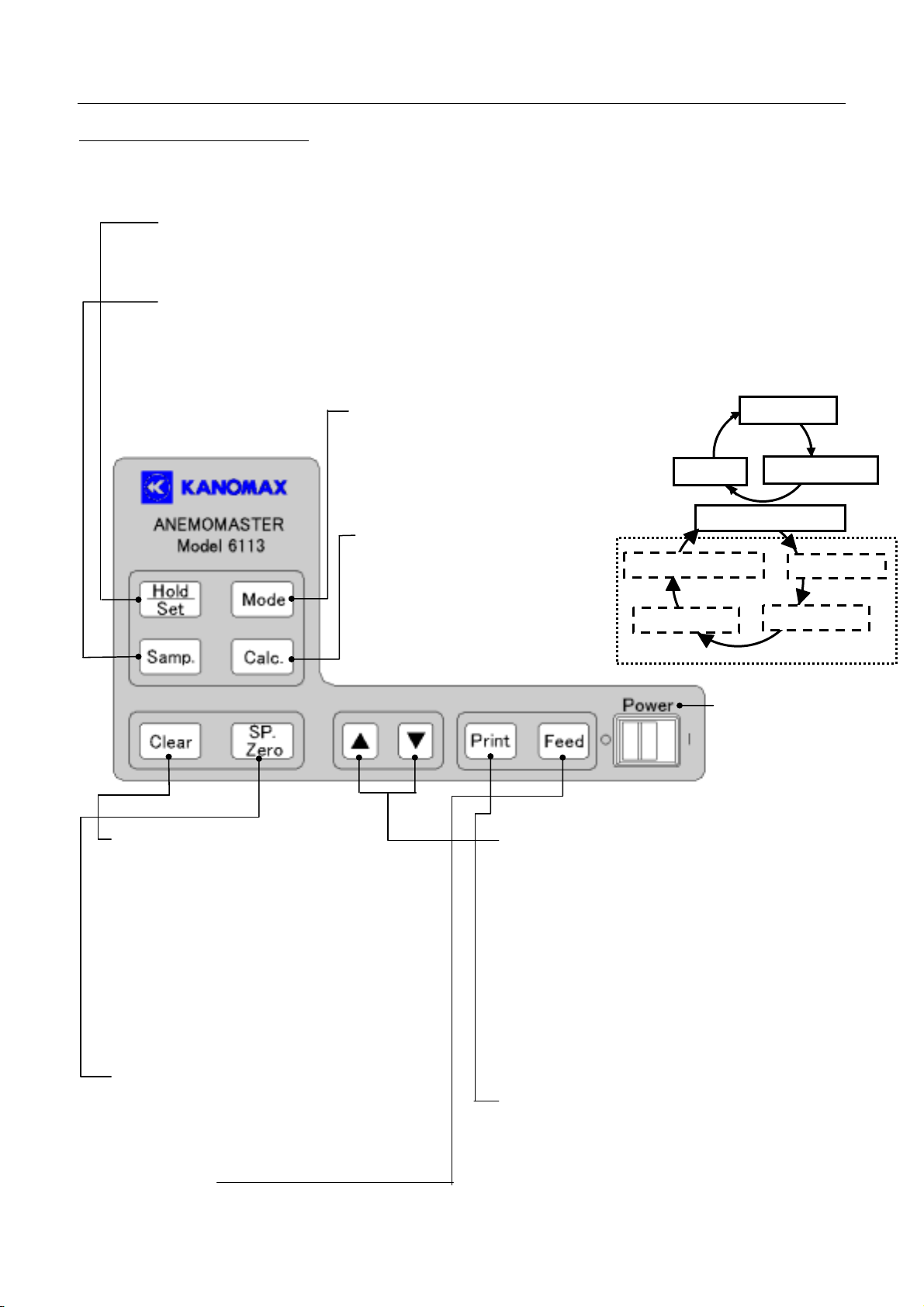

1.2 Operation Panel

The key tone is set “ON” at the time of inspection. You may turn it off by going through the manual. Please

refer to page xxxx

Hold/Set Key

Press this key to hold/reset the displayed value on the measurement mode. You can also use this key to

select and choose the item on the date/time setting mode and function setting mode,

Samp. Key

The displayed value will be stored when you press briefly. (All measurement parameters will be stored.) The maximum number of memory is

100. If you press for an extended length of time, the average value for the duration of that time will be stored. Sampling is done every

second up to a maximum of 60 seconds. (Measurement values beyond 60 seconds will not be acknowledged.)

Mode Key

Air Velocity

Press this key to change

displayed parameter on the

measurement mode and the

calculation mode.

(Option)

Pressure

Air Temperature

Measurement Mode

Calc.Key

Use this key to switch to the

Stored Data Display

calculation mode and go

through the stored data.

Minimum Value

Maximum Value

Calculation Mode

Power Switch

Power Source

ON/OFF

I :ON

O:OFF

Clear Key

・ When you continue to press more than a

second, it deletes the last piece of data stored

on the memory.

・When you are in the function setting mode:

Use this key to finish setting.

・ During printing : Printing will be forced to

stop. (Cannot stop printing for data that has

already been transmitted to the printer.)

▲Key

When you press this key during the measurement

mode, you can select the time constant among 1, 5,

or 10 seconds.

▼Key

When you press this key during the measurement

mode, you can select the range of the bar graph

among 1, 5, 10, 25, or 50m/s.

※In other modes, keys ▲ or ▼ can be used to

select a Parameter or to move numbers up or down.

SP.Zero Key (Option)

When you continue to press for more than 2

seconds when the pressure is displayed during

the measurement mode, it will adjust to zero.

Feed Key

Each time you press this key, the printer

paper will be forwarded by 1 line.

Print Key

When you press this during the measurement mode, the

displayed value will be printed. (All measurement

parameters will be printed.) As for the calculation mode,

the calculation results (average, max, min) of the data

stored in the memory will be printed.

Mean Value

Page 12

1. ANEMOMASTER Anatomy

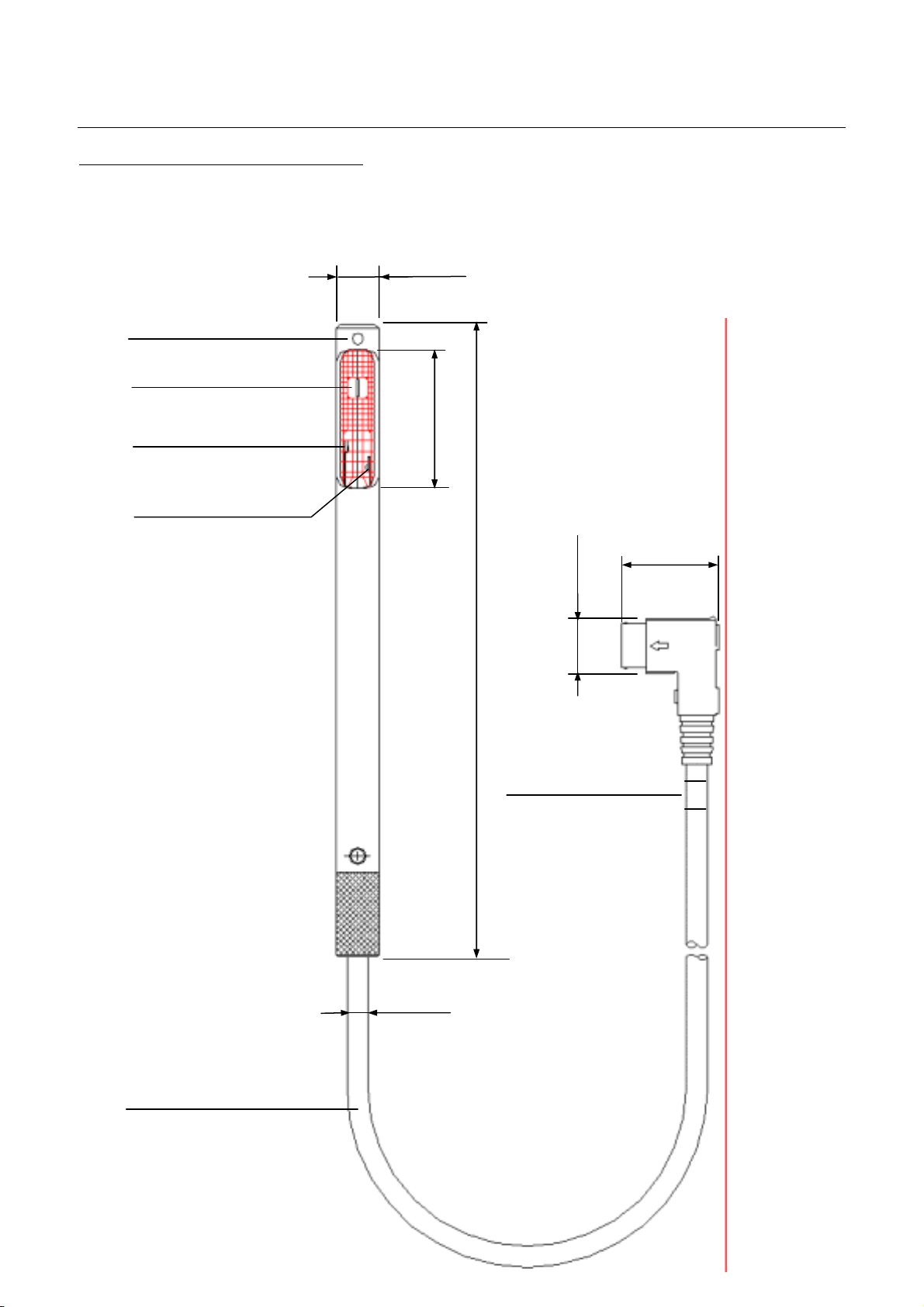

1.3 Probe / Probe Cable

Unit:mm

Wind Direction Mark

Air Velocity Sensor

Temp. Compensation

Sensor

Temperature Sensor

Cable Length: Approx 2000

4

Approx. φ10

Approx. 33

Approx. 23

Approx. φ13

Approx. 150

Probe Number

001

Approx. φ5

本体側

Page 13

1. ANEMOMASTER Anatomy

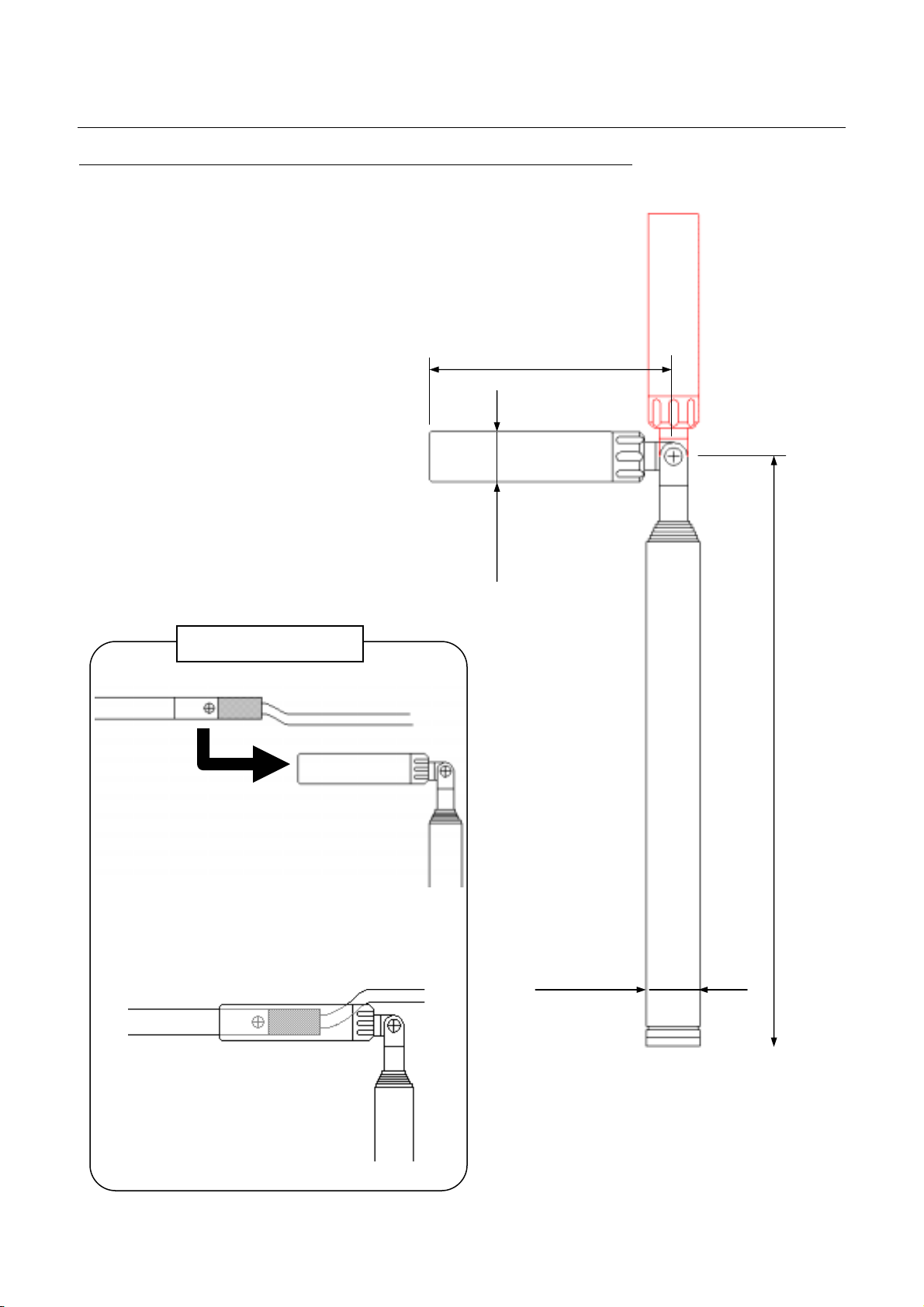

1.4 Telescopic Articulating Extension Rod (Option)

Unit:mm

①

Probe

②

How to Connect

Telescopic Articulating

Extension Rod

Approx. 68

Approx.φ12

Approx. φ15

5

Approx. 167 (Max. extended length 960)

Page 14

t

t

2. Getting Started

2.Getting Started

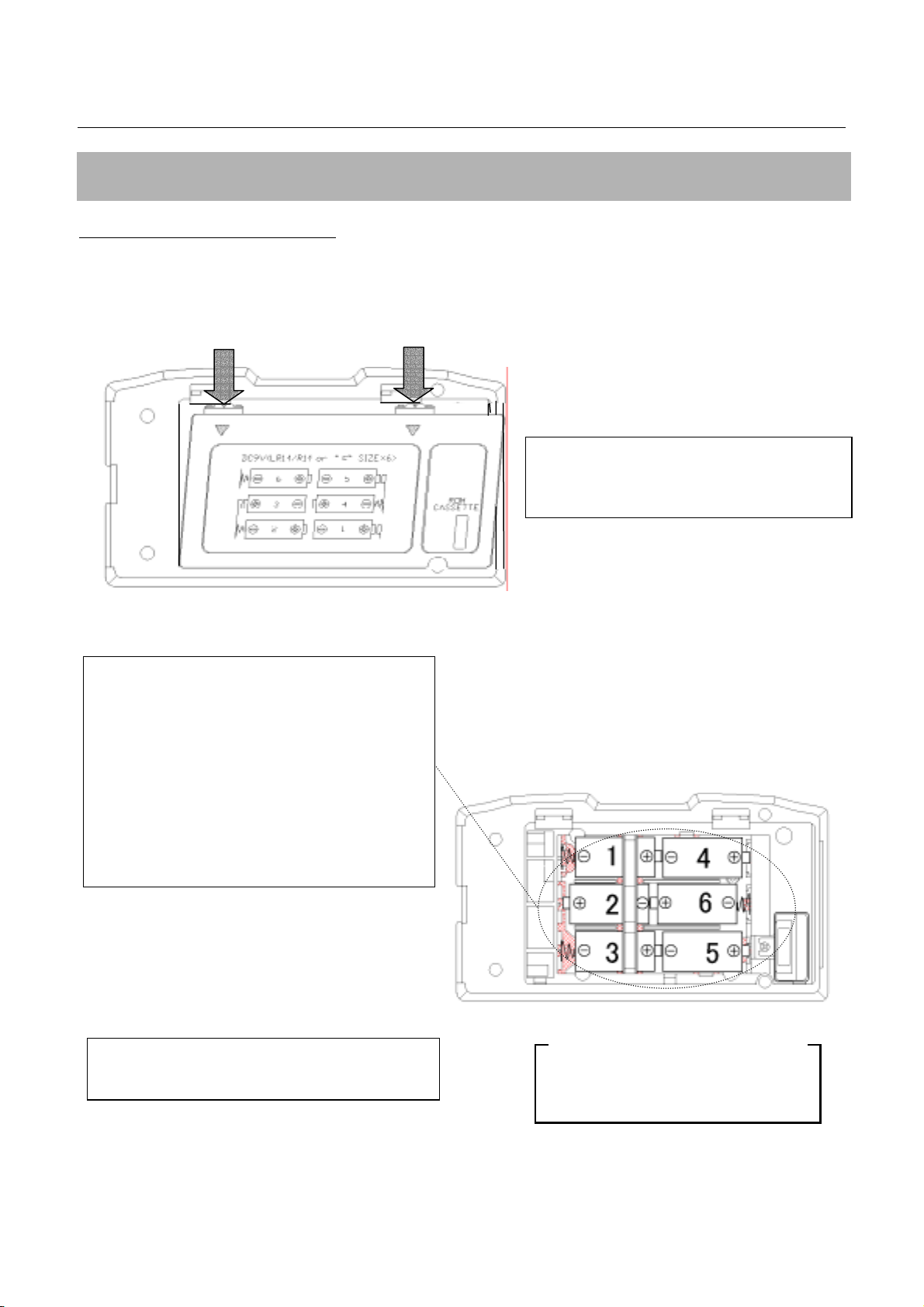

2.1 Installing Batteries

<Diagram of the Bottom of the Main Body>

②Insert batteries in the order as shown.

(※Be sure to observe the polarity.) This

instrument requires six AA batteries. Use only

AA size Manganese (R6), alkaline (LR6) or

Ni-Cd batteries. Do not mix battery types,

otherwise it may lead to leakage or damage to

the Main Body.

※Batteries cannot be recharged by the

optional AC Adapter.

③ Put the cover back on in the opposite

order it was removed.

①Remove the lid by pressing lightly on

he 2 areas (see arrows) and pulling

owards you.

Acceptable Battery Types

Manganese (R6) AA Batteries

Alkaline (LR6) AA Batteries

Ni-Cd AA Batteries

6

Page 15

2. Getting Started

7

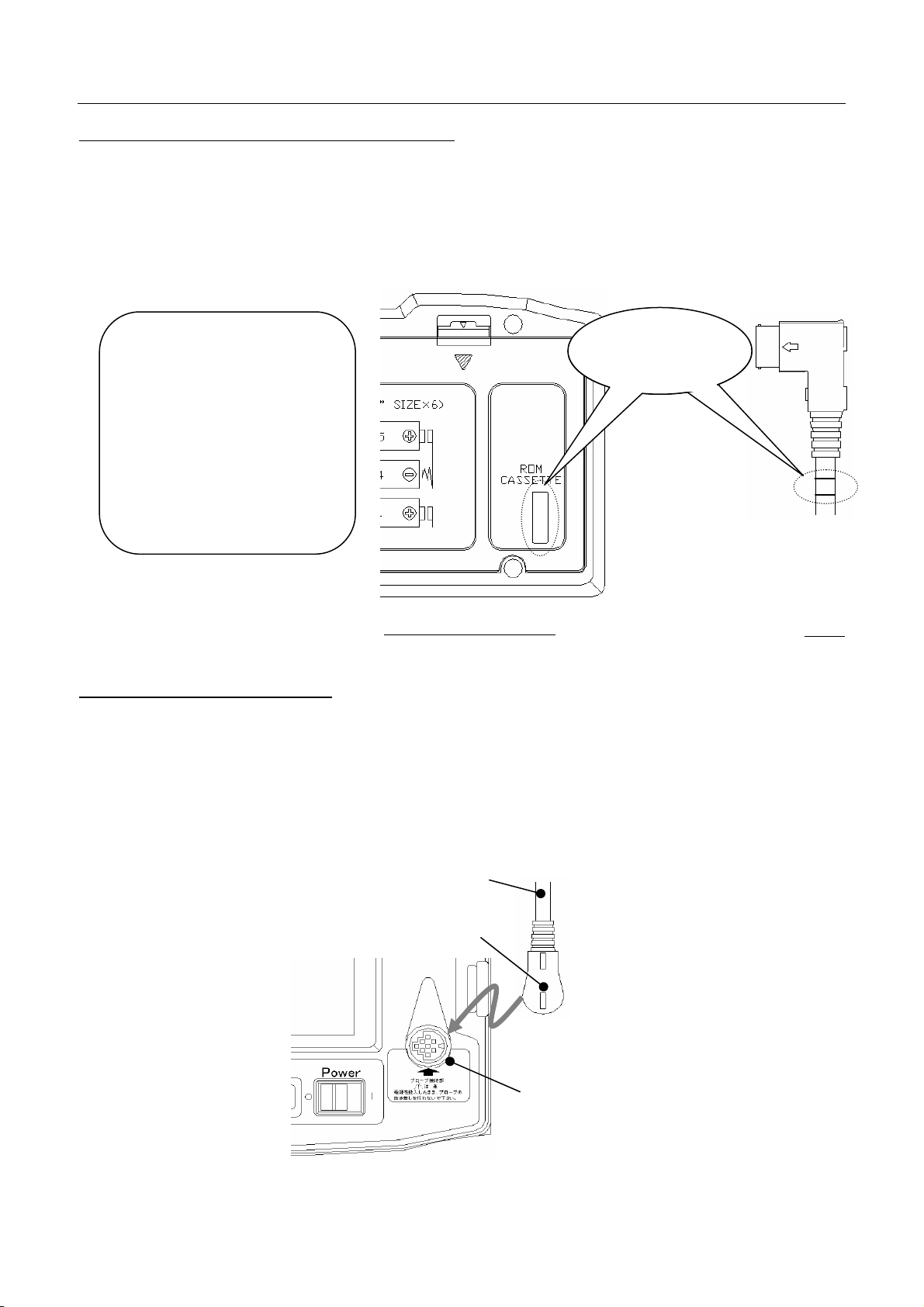

2.2 Confirming the Probe Number

Confirm that the number on the Probe and the number on the Main Body (indicated on the ROM cassette

inserted in the bottom of the Main Body) matches.

※ You will need to confirm the Probe Number if you purchase in multiples or if you own a spare Probe.

(The number on the Main Body is also displayed when you turn on the power. See Chapter 2.4, “Powering

ANEMOMASTER On/Off” for details.)

The characteristics data

pertaining to each probe is

stored in the ROM cassette

inserted underneath the Main

Body. Each Probe has

different characteristics so

you must confirm that the

numbers match in order to

measure properly.

Bottom of the Main Body

0001

Do the numbers

match?

001

Probe

2.3 Connecting Probe

Per the illustration below, connect the Probe by paying attention to the direction of the connector (Probe Cable

sticks out from the “up” side) and attach to the Probe Terminal located on the Main Body.

※ Make sure that the power is OFF when connecting or disconnecting the Probe Cable.

※ Do not force the connector into the socket without confirming the correct direction, and do not rotate the

connector after attaching as these will cause damage.

※ When you close the Lid, be sure to remove the Probe Connector otherwise it may damage the cable.

Probe Cable

Connector

Probe

Terminal

Page 16

p

⑤

2. Getting Started

8

2.4 Powering ANEMOMASTER ON / OFF

When you connect the Probe onto the Main Body and turn on the switch, the software version followed by the

Probe Number will be displayed before you see the Normal Mode (Normal Measurement display).

Power Switch

When the ROM Cassette is not properly inserted, you will

get an alarm and an error message as shown above.

(Refer to Chapter 13 “Trouble Shooting” for Error Codes.)

Turn off the instrument and check if the ROM Cassette is

properly inserted.

Display Icons (Normal Mode: Refer to Chapter 3 “Normal

Measurement” for details.)

① InstructedValueorFixedValue,

② BarGraph,③BarGraphRange,④Unit,

BatteryLevelIndicator

◆ Battery Level Indicator

The indicator changes as you see it below.

― LOCK ―

When “E - - 0” is displayed, every function of the instrument will be locked. The

measurement will stop and data will NOT be saved. To unlock, turn off the power and

re

lace batteries.

I ON (Turn the switch on)

O OFF(Turn the switch off)

Battery level is indicated upper right. Battery

consumption depends on the air velocity being measured.

When this indicator starts to flash, it is time to change

m/s

batteries. Caution : Measurement may suddenly stop

depending on the wind velocity if the battery is low.

Connect Probe to the Main Body

Power ON

⑤

①

④

m/s

②

③

Normal Mode

Time to replace batteries

(Flashes)

(Locked)

Software

Version

Display

Probe

Number

Display

Page 17

2. Getting Started

2.5 How to Make Measurements

2. 5. 1 Measuring Air Velocity

Probe has its own directivity characteristics. Make sure that the wind

direction mark is facing the wind (For more details on directivity

characteristics, refer to Chapter 12 “Probe Directivity (Air Velocity)”. If

you are not sure of wind direction, slowly rotate Probe and measure at

the point where you get the highest air velocity reading.

To make the temperature compensation more effective, make sure that

the Air velocity sensor and Temperature compensation sensor of Probe

are evenly exposed to the airflow.

To take a measurement in temperature changing situation, leave Probe

for more than 20 seconds until the display becomes stable.

2. 5. 2 Measuring Air Temperature

The faster the wind, the shorter the response time for temperature measurement. (The response time is

approximately 30 seconds at the airflow of 1m/s). Take the measurement after the reading is stabilized

on the display.

With no airflow present, the instrument’s air temperature reading may become higher than it actually is

due to the heat generated by the air velocity sensor. It is recommended to take a measurement with at

least 0.1m/s of wind present for accurate reading.

Wind Mark

Wind

9

2. 5. 3 Measuring Pressure

Do not apply more than 75kPa of pressure to the pressure sensor (optional). This may cause serious

damage to the sensor.

When you make a measurement, make sure that the temperature is somewhere between 5 to 40℃ or 41

O

to 104

F.

Before you make a pressure measurement, make sure you execute the zero adjustment. When you

make the adjustment, leave the both pressure ports ((+) and (-)) open.

Page 18

2. Getting Started

10

<Zero Adjustment Procedure>

DISPLAY PROCEDURE

Press

pressure measurement.

kPa

Each time you press the MODE key, it will show in order air velocity

->air temperature -> pressure.

kPa

When you press for more than 2 seconds, you will hear a

beep, and the pressure display will show “0.00”.

<Connecting Pressure Tube>

Connect the pressure tube to the (+) or (-) port as you see on the bottom.

Connect/insert the other end of the tube to the measuring hole of the duct. If the pressure that you are going

to measure is positive, connect the tube to (+) Port. If it is negative, connect the tube to (-) Port.

In order to make a precise measurement, the tube

must have no holes and must be connected

securely. Also, the tube must not be bent at any

! CAUTION !

Positive(+)Port

Negative(-)Port

when you are in the Measurement Mode, and select

Pressure Port

Page 19

3. Normal Measurement

3.Normal Measurement *** Measurement Mode ***

When you first turn on the instrument this will be the first mode that

you will be in (Air Velocity Measurement Mode). You cannot save any

data in this mode. The display will be updated every 1 second.

<Air Velocity Measurement Display>

3.1 Selecting the Measuring Parameters

DISPLAY PROCEDURE

①

<NORMAL MODE>

m/s

Press

on the left.)

in the Normal Measurement display. (See example

m/s

11

②

③

℃

kPa

Press

, and display mode moves in order, as shown below.

②Air Temperature→③Pressure(Optional)→①Air

Velocity(=Normal)

<AIR TEMPERATURE MEASUREMENT MODE>

※In the Air Temperature Measurement Mode, there will be no bar

graphs displayed under the measured value.

<PRESSURE MEASUREMENT MODE>

※In the Pressure Measurement Mode, there will be no bar graphs

displayed under the measured value.

※This mode is available only to instrument with optional pressure

sensor.

Page 20

3. Normal Measurement

3.2 Display Hold

DISPLAY PROCEDURE

m/s

m/s

12

While measuring, press

.

(The same procedure applies when you are in Air Temperature

Measurement Mode, and Pressure Measurement Mode.)

“HOLD” indicator appears on the display to indicate that the

reading shown is held.

Press

once again to release.

3.3 Changing the Display Range on the Bar Graph

Bar graphs are displayed only for air velocity measurement.

DISPLAY PROCEDURE

m/s

m/s

m/s

Press key when you are in the Normal Measurement Mode

(Air Velocity Measurement Mode)

※The initial range is 0 - 10m/s and

each scale equals 2m/s.

You will see the value on the right end of the bar graph change. The

range is now between 0 – 25m/s.

1 scale now equals 5m/s.

Each time you press , the value on the right end of the bar

graph will change. The range will change in the following order:

0~10m/s(1 scale:2m/s、1 bar:0.4m/s)<Initial Default Setting>

→0~25m/s(1 scale:5m/s、1 bar:1m/s)

→0~50m/s(1 scale:10m/s、1 bar:2m/s)

→0~1m/s(1 scale:0.2m/s、1 bar:0.04m/s)

→0~5m/s(1 scale:1m/s、1 bar:0.2m/s)

→0~10m/s

※Once you turn off the power, the setting will revert to the default

range(0~10m/s).

1 Bar:0.4m/s

1 scale:2m/s

Page 21

3. Normal Measurement

13

3.4 To Change Time Constant

You can change the Time Constant only when measuring air velocity. The Time Constant for air temperature

and pressure (option) is fixed at 1 second.

DISPLAY PROCEDURE

When you hit

(Air Velocity Measurement Mode)you will see a display (see left)

which briefly flickers the set Time Constant.

※Default setting is 1 second.

m/s

Time Constant

*** What is Time Constant? ***

Time Constant determines the time span of the moving average. When you set the Time Constant to a larger

value, the indicating value will become stable. When you select the smaller (=shorter) Time Constant value, the

reading will become more responsive and sensitive to the change in air velocity.

This function will not be in effect in Calculation Mode and Air Flow Mode.

In the Normal Measurement Mode, you can change the Time

Constant by pressing

You can select Time Constant from 1sec, 5sec and 10sec.

00:01 :Display moving average of 1sec.

00:05 :Display moving average of 5sec.

00:10 :Display moving average of 10sec.

※Once you turn the switch off, the Time Constant will revert to the

default setting of 1 second.

when you are in the Normal Measurement Mode

MODE How to Take In Measured Data EXPLANATION

0 5 10 15 20sec. (Measuring Time)

00:01

(1 sec.)

Average of 1 sec

Take the data 10 times in a

second and indicate its

average as an instantaneous

value at every 1 second.

00:05

(5 sec.)

00:10

(10 sec.)

0 5 10 15 20sec. (Measuring Time)

Average of 5 sec

0 5 10 15 20sec. (Measuring Time)

Average of 10sec

Indicate the average value

of 5 seconds at every 1

second. Data shifts by 1

second.

Indicate the average value

of 10 seconds at every 1

second. Data shifts by 1

second.

Page 22

4. Storing and Deleting Stored Measurement Data

14

4.Storing and Deleting Stored Measurement Data

4.1 To Store Measurement Data

① Storing Spot Data

DISPLAY PROCEDURE

Hit the key when you are in the Normal Measurement

Mode. You can do the same on the displays for the Air Velocity, Air

℃

As per the illustration on the left, you will see “Samp ” , Data

Samp

℃

Temperature, and Pressure measurement modes.

Number, and a bar graph flicker briefly. After this, the data for all

measurement parameters (Air Velocity, Air Temperature, Pressure)

will be stored as one set. (The bar graph that flickers briefly

indicates the approximate accumulated amount of stored data.) The

maximum number of data that can be stored is 100.

Approx. amount of stored data

② Storing the Average Value … For Consecutive Data Not Exceeding 60 Seconds

Data Number

DISPLAY PROCEDURE

Samp

m/s

※Once the measurement data is stored, it will not be lost even if the switch is turned off. In addition, data will

be preserved even during battery change since the built-in back-up battery will kick in.

However, please be warned that if the built-in back-up battery has worn out over time, it is possible that data

may not be stored.

Press for longer than 1 second when you are in the

Normal Measurement Mode. By doing so, the average value for the

data spanning the length you continued to hold will be stored as 1

set of data.

Sampling is done every second (you will hear a beep) and you will

get the average value for consecutive data not exceeding 60

seconds.

Also note that while you hold onto

Number, and bar graph will continue to be displayed.

(For example, if you pressed 10 seconds, the single average value

pertaining to the 10 sampled values will be stored.)

※If you held beyond 60 seconds, you will hear an alarm and the

measurement will end.

, the “Samp”, Data

Page 23

4.Storing and Deleting Stored Measurement Data

4.2 To Delete Data

4.2.1 Complete Deletion: Deleting All Stored Measurement Data

DISPLAY PROCEDURE

When you simultaneously press and for more

than 4 seconds when you are in the Normal Measurement Mode, you

m/s

4.2.2 Simple Deletion: Deleting a Single Measurement Data Last Stored

DISPLAY PROCEDURE

<Measurement Mode Display>

The Total Number of

Measurement Data Stored

m/s

m/s

will see the “n-00” display (as on the left), and all stored data will

be deleted.

Press for more than 1 second when you are in the Normal

Measurement Mode. (This can be done for Air Velocity, Air

Temperature, Pressure measurement modes.)

You will briefly see a display “n-xx” (as on the left) and the latest

(newest) stored data will be deleted.

(The number in “xx” indicates the total number of stored data that

will remain after the deletion. “n-00” indicates there are no stored

measurement data.)

The only data you can delete using this method is the last (newest)

data you stored. For example, it is not possible to delete anything in

th

between, such as the 40

data from a total of 75 data.

15

Page 24

4.Storing and Deleting Stored Measurement Data

4.2.3 Selective Deletion: Deleting a Single Specific Stored Data

DISPLAY PROCEDURE

<Stored Measurement Data Display>

Data Number

m/s

m/s

Total Number of

Stored Measurement Data

Press 4 times when you are in the Normal Measurement

Mode and change over to the display of Stored Measurement Data

in the Calculation Mode.

(For details on Calculation Mode, refer to Chapter 5 “Measuring

Mean, Maximum, Minimum”.)

Press

to find the Data Number you would like to delete.

Press for more the 4 seconds. (This can be done for Air

Velocity, Air Temperature, Pressure measurement modes.) You will

hear a beep along with a display of the total number of stored

measurement data. After this, the display will return to show the

remaining stored data.

To delete successively, press and select the data to

16

for more than 4 seconds to delete. You can

m/s

delete. Press

delete only one data a time.

The selected page will be deleted and the remaining data will shift

up. (See example below.)

Example:

rd

There are data, 1 through 4. If you delete the 3

rd

now becomes the 3

data (likewise, the assigned Data Number

data, the 4th data

changes to 3), and there will now remain data pertaining to pages 1

through 3.

Data1

Data2

Data3

Data4

Data1

Data2

Data4

Data1

Data2

Data3

The Data Number changes

Page 25

5. Measuring Mean, Maximum & Minimum

17

5.Measuring Mean, Maximum & Minimum *** Calculation Mode ***

Calculation Mode will automatically calculate the maximum, minimum, mean from the stored data.

If there are no stored data, you must first store the measurement data in order to compute.(Refer to Chapter 4

“ To Store and Delete Measurement Data” on how to store.)

The calculation is performed on all stored measurement data. (It is not possible to select certain data and

perform calculations on them.)

DISPLAY PROCEDURE

①

<Normal Measurement Display>

m/s

Press when you are in the Normal measurement Mode

(You can do the same for Air Velocity, Air Temperature, Pressure.)

Each time you press

, there will be displays in the following

order:

② Mean Value Display (Avg) → ③ Max Value Display(Max) → ④

Minimum Value Display(Min)→⑤Stored Measurement Value Data

Display→①Normal Measurement Display

②

Avg

m/s

Total Number of Stored Measurement Data

③

④

Maximum Value Mark

Max

m/s

Minimum Value

<Mean Value Display>

Along with the Mean Value display, you will see the total number of

stored measurement data at the bottom.

Each time you press

, it will show in order the mean values

for: Air Temperature ÆPressureÆ Air Velocity.

<Maximum Value Display>

Along with the Maximum Value display, you will see the total number

of stored measurement data at the bottom.

Each time you press

, it will show in order the maximum

values for: Air Temperature ÆPressureÆ Air Velocity

Min

Along with the Minimum Value display, you will see the total number

of stored measurement data at the bottom.

<Minimum Value Display>

m/s

Each time you press

, it will show in order the minimum

values for: Air Temperature ÆPressureÆ Air Velocity

Page 26

5.Measuring Mean, Maximum & Minimum

DISPLAY PROCEDURE

⑤

m/s

Approximate Location

m/s

18

<Stored Measurement Data Display>

The latest measurement data that was stored will be displayed with

the Data Number and bar graph.(The bar graph indicates the

approximate location of the data stored. )

Each time you press

, it will show in order the stored

measurement values for : Air Temperature ÆPressureÆ Air

Velocity

Data Number

In addition, when you press you can display other data

pertaining to other Data Numbers.

Each time you press

, it will show in order the stored

measurement values for : Air Temperature ÆPressureÆ Air

Velocity

※You can also select and delete data from this display. For details

refer to Chapter 4 “Storing and Deleting Stored Measurement

Data”.

Page 27

6.Data Output

6.Data Output

6.1 Printing Out

6.1.1 Set up the Printer Paper (Roll Paper)

How to Cut the Roll Paper

× × ○

Roll Paper

As shown in the left illustration, cut the right side of the Roll Paper so it is

longer than the left. The Roll Paper Sensor is located at the right side of the

Roller, therefore, Roll Paper installation will be easier if the right side is

longer.

※Use the designated thermal paper. (Seiko Instruments TP-202L).

Roller

① Open the cover by lightly pressing on the

arrows, and pulling the printer cover towards you.

② Turn on the Power Supply Switch and press

.

③ Confirm the sides of the paper - front and back.

(The illustration shows the back (inner) side of the

roll paper facing upwards toward you.) Insert the front

end of the roll paper underneath the Roller.

※Install the Roll Paper with the Head Lever

pulled down.

Here is the Paper

Sensor.

19

Page 28

t

t

t

6.Data Output

Approx. 5cm

Head Lever

④ When you insert the tip of the Roll Paper into

he Roller, the Roller will automatically rotate and

crank up the paper, and the paper will come out

from the top.

※If you have problems properly setting the paper

(slanted, bent, etc), pull the Head Lever up,

remove the paper, and repeat steps ② to ④.

⑥ Install the paper into the Holder as

you tighten the roll. Make sure the paper

comes out of the Paper Outlet located on

Roll Paper

Holder

he Printer Cover. Close the Printer

Cover to complete installation.

※Be sure to eliminate any slack on

Paper

Tip of the Roll Paper

20

⑤ Press until the tip of

he approximately 5 cm of the

paper has come out of the Roller.

※ Be careful that the paper

coming out of the Roller does

not get fed back into the Roller.

the Roll Paper as much as possible.

Otherwise, the loose portion may

accidentally get pulled into the

Roller.

Page 29

6.Data Output

6.1.2 Spot Value Print Out

DISPLAY PROCEDURE

Press while you are in the Normal Measurement Display. It

m/s

℃

Example of Print Out

<Measuring Results>

2002/10/29 09:41:29

VEL(m/s)TEMP(℃)PRS(kPa)

0.0620.80.13

Air Velocity Air Temperature Pressure

will hold the measurement value for all parameters (Air Velocity, Air

Temperature, Pressure) .Those values will be printed out.

21

Date of Measurement

6.1.3 Calculation Results Print Out

DISPLAY PROCEDURE

Avg

m/s

Example of Print Out

<Calculation Results>

Condition

Calculation

Results

DATE:2002/10/29

TIME:09:41:29

DATA:063

MODE:VELTEMPPRS

MAX7.25m/s

AVG5.79m/s

MIN2.66m/s

MAX22.5℃

AVG21.0℃

MIN19.4℃

MAX0.78kPa

AVG0.43kPa

MIN0.27kPa

Display the Calculation Mode ( Press in the Normal

Measurement Mode) and then press

for all measurement parameters (mean, maximum, minimum) will be

printed out.

. The calculated values

Date of Measurement

Time of Measurement

Number of Stored Data

Measurement Parameter

Air Velocity

Air Temperature

Pressure

Page 30

6.Data Output

6.1.4 Stored Data Print Out

DISPLAY PROCEDURE

Avg

m/s

6.1.5 Function Set Information Print Out (Also for Test Print)

Display the Calculation Mode (Press in the Normal

Measurement Mode. By pressing

will get the print out of the calculation values for all measurement

parameters (mean, maximum, minimum) along with the stored

measurement data.

DISPLAY PROCEDURE

Press keys together for more than 2 seconds. This

will print out the information pertaining to the functions that were

℃

set up.

※For details on how to set up functions, refer to Chapter 7 “Other

Settings”.

※This function can be used to do test print.

22

together with you

Example of Data Print Out

<Calculation Results+Measurement Data> <Information on Function Set-up>

Measurement

Calculation

Conditions

Results

Measurement Data

DATE:2002/10/29

TIME:09:41:29

DATA:063

MODE:VELTEMPPRS

MAX7.25m/s

AVG5.79m/s

MIN2.66m/s

MAX22.5℃

AVG21.0℃

MIN19.4℃

MAX0.78kPa

AVG0.43kPa

MIN0.27kPa

NUMm/s℃kPa

01 3.8921.80.33

02 4.4122.00.41

03 5.0122.40.32

Probe Number

Information on

Hardware Setup

(This cannot be changed)

Baud Rate

Buzzer ON/OFF

Air Velocity Unit

Air Temperature Unit

Pressure Unit

Analog Output Range(Air Vel)

Analog Output Range(Air Temp)

Analog Output Range(Pressure)

Test Print

6113ANEMOMASTER

Ver.1.000

DATE:2002/10/29

TIME:15:06:49

********************

PROBENo.1

PROBEType.10

SensorTime150min

‑‑‑‑‑‑‑‑‑‑‑‑‑‑‑‑‑‑‑‑

HARDSWSETTING

BitPRON

BitPRSON

‑‑‑‑‑‑‑‑‑‑‑‑‑‑‑‑‑‑‑‑

SOFTSWSETTING

BAUDRATE4800

BUZZERON

VelUnitm/s

TempUnit℃

PRSUnitkPa

ANALOGVel0‑5.0

ANALOGTemp0–50.0

ANALOGPRS–5.0–5.0

DATEDISPLAYJP

********************

TESTPRINT

0123456789‑+/*()

Information on Function Setup

Page 31

6.Data Output

6.2 Digital Output

6.2.1 Preparation

You can download the data stored in the ANEMOMASTER to your PC, by

connecting ANEMOMASTER and your PC with the RC232C cable (Optional).

<Need To Have>

●Personal Computer

●RS-232C Cable (Optional)

●Software ( Example: Windows has software for hyper terminals.)

<Check the BAUD RATE>

You need to coordinate the Baud rate on both Main Body and your PC.

The factory setting of Main Body is as follows:

Data Bit Length 8 bits

Parity Permission Without

Parity Condition Odd

Stop Bit 1

Delimiter CRLF

Baud Rate ※Depends on the set up value

For setting your PC, refer to the operation manual of your PC

※To change the BAUD RATE, please refer to

Chapter 7 “ Other Settings”

23

RS232C Terminal

<Connecting PC>

① Turn OFF the ANEMOMASTER

② Connect PC to Main Body using an RS-232C cable.

③ Turn ON the ANEMOMASTER

④ Make sure that the ANEMOMASTER is displaying the NORMAL Measurement Mode.

RS232C Cable Wiring Diagram

PC (D-Sub9 pin) ANEMOMASTER (MODEL6113)

Signal Pin No.

NC 1 1 GND Signal Ground

RXD 2 2 TXD Transmitting Output

TXD 3 3 RXD Receiving Input

NC 4 4 CTS Transmission Approval Input

GND 5 5 RTS Transmission Request Output

NC 6 6 NC

RTS 7

CTS 8

NC 9

◆ We also have measurement software available for Windows. (Sold separately.)

Connection

Pin No. Signal Purpose Direction

Page 32

6.Data Output

6.3 To Access From Your PC

To connect to ANEMOMASTER to your PC, please refer to the previous Section 6. 2 “Digital Output”.

―――Icons and its Meaning ------

:Space

:Return or Press Enter

*:A Number

※ All commands must be in capital letters.

6.3.1 Transmission of On-Time Data (Every-second Basis)

DISPLAY PROCEDURE

Example:

Air Velocity Measurement Mode

and typed

D****

AD

0.19; 26.8; 73.4

0.51; 26.8; 73.5

0.61; 27.0; 76.1

0.24; 27.0; 77.5

0.15; 26.9; 76.0

<Set Number of Data Needed>

Press “D**** ” (※Must type in 4 digits)

After entering you will receive “AD” and the data will be displayed.

Each data represents 1second of measurement. If you ask for 20 data,

it takes approximately 20 seconds to display.

The maximum number that can be set is 9999. If you need more,

re-send the command.

<Output Content>

With Pressure (Option):

Air Velocity; Air Temperature; Pressure

Without Pressure:

Air Velocity; Air Temperature;: 0000000

Command Function

D**** Number of Downloading Data

N Receiving Cancelled

S Output of Measuring Condition

(of On-time Data)

U Output of Measuring Units

P Output of Page Number and

Amount of Data

T**** Output of Stored Data

24

<To Cancel>

AN

DISPLAY PROCEDURE

AS

VT‑;01;

AU

m/s;℃;kPa

DISPLAY PROCEDURE

Press “N”. You will receive “AN” and the transmission will be

cancelled.

<To Download Measuring Conditions>

Press “S

After entering“S”, you will receive “AS” and the data will be displayed.

You will see the measurement Parameter, and Time Constant that

appears on the display. (See Section 3. 4 “To Change Time Constant”)

<Output Content>

Measuring Parameter (VT- PRS); Time Constant;

<To Download Measuring Units>

Press “U

After entering “ U ” , you will receive “AU” and the data will be

displayed. You will see the measurement unit that is currently set up.

<Output Content>

Velocity Unit; Temperature Unit; Pressure Unit

”

VT-: Air Velocity, or Air Temperature

PRS: Pressure (Optional)

”

Page 33

6.Data Output

6.3.2 Transmission of Data Stored in Memory

DISPLAY PROCEDURE

AP

P0012

AT

2002/10/30;14:25:46

011; 0.15; 25.5; 0.10

ED

DISPLAY PROCEDURE

DISPLAY PROCEDURE

<To Download Page Number>

Press “P

You will receive “AP”. Number of data stored pages will be

downloaded.

<To Download Stored Data>

Press “T****

Type in the desired page number after “T”.

You will receive “AT ”, and the data which is stored under that

number will be displayed.

※There will be no output of calculation data (Min, Mean, Max).

※The measurement unit currently set up will be applied to the output

data.

<Output Content>

With Pressure (Option):

Data Number, Air Velocity, Air Temperature, Pressure

Without Pressure:

Data Number, Air Velocity, Air Temperature, 00000

<Error Message>

You will get this message if you enter the wrong number of pages. Re-type

the command.

25

”

” (※Must type in 4 digits)

6.4 Setting the Output for Single Parameter Measurement Data

When you turn on this function, you can output only the value that was shown in the operation. See Pag xxxx

“Other Settings” for details.

6.4.1 How to Print-out using the Setting for Single Parameter Data Output

Please refer to Section 6. 1 “Printing Out” on how to print out measurement data.

Example of a Print Out

<Measurement Results (Air Velocity)> <Calculation Results(Pressure)>

6.4.2 Digital Output using the Settings for Single Parameter Output

Please refer to Section 6.2 “Digital Output” on how to digitally print out measurement data.

Display

<Output of Downloaded Data(Air Temperature)> <Output of Stored Data (Air Velocity)>

2002/10/29 09:41:29

MODEVEL

0.06m/s

AD

0000000;

0000000; 26.7;0000000

26.8;0000000

DATE:2002/10/30

TIME:07:52:55

DATA:006

MODE:PRS

MAX0.44kPa

AVG0.33kPa

MIN0.21kPa

AT

2002/10/30;14:25:46

011; 0.15;0000000;0000000

Page 34

6.Data Output

26

6.5 Analog Output (Optional)

Analog Output Terminal

①Data Update Interval ………0.1 seconds

②Load Impedance ……Above 5KΩ

③Output Current ………………DC 0~1V

For the analog output, you must select one setting from the table below.

The measurement value that is displayed on the Normal Measurement

Display will be out put. See “Other Settings” for details.

Output Range Conversion Formula

Velocity

(U)

0 ~ 5 m/s U= 5×V m/s

0 ~ 10 m/s U=10×V m/s

0 ~ 25 m/s U=25×V m/s

0 ~ 50 m/s U=50×V m/s

0 ~ 1000 FPM U=1000×V FPM

0 ~ 2000 FPM U=2000×V FPM

0 ~ 5000 FPM U=5000×V FPM

0 ~ 9999 FPM U=9999×V FPM

Temperature

(T)

-10 ~ 40 ℃ T= 50×V-10 ℃

0 ~ 50 ℃ T= 50×V ℃

0 ~ 100 ℃ T=100×V ℃

14 ~ 104 oF T= 90×V+14 oF

32 ~ 122 oF T= 90×V+32 oF

32 ~ 212

o

F T=180×V+32 oF

-5 ~ +5 kPa P= 10×V-5 kPa Pressure

(P)

-2 ~ +2 kPa P= 4×V-2 kPa

Of the output range, the low end will be set at 0V and the high end will be set at 1V. The voltage is linear.

The Time Constant (0.1 second at normal) will be in effect. To change the setting of Time Constant, refer

Section 3. 4 “To Change Time Constant”.

Mode

TC1

Average of 1sec.

Way To Take In Measured Data (Analog Output)

0 0.5 1.0 1.5 2.0sec (Measuring Time)

Explanation

Take the data 10 times

in a second and indicate

its average as an

instantaneous value at

every 0.1 sec.

TC5

TC10

0 2.5 5.0 7.5 10sec (Measuring Time)

Average of 5sec.

0 5 10 15 20sec (Measuring Time)

Average of 10sec.

Output the average

value of 5sec. at every

0.1sec. Data shifts by

0.1sec.

Output the average

value of 10sec. at every

0.1sec. Data shifts by

0.1sec.

Page 35

t

7.Other settings

7.Other Settings

7.1 Date

DISPLAY PROCEDURE

Set-up Level

m/s

27

When you are in the Normal Measurement Mode, press

together for more than 2 seconds.

The set-up level will be displayed on the bottom left and the last 2

digits of the year will flicker. Press either keys

to the desired number. Then press

※ The Set-up Level numbers correspond to the following:

1 ………… Year 4 ………… Time

2 ………… Month 5 ………… Minute

3 ………… Day

to adjust

.

and

Next, there will be a display to set up the month.

Press either keys

press

Next, there will be a display to set up the day.

Press either keys

press

Next, there will be a display to set up the time.

Press either keys

press

.

.

.

to adjust to the desired number. Then

to adjust to the desired number. Then

o adjust to the desired number. Then

Page 36

7.Other settings

28

Next, there will be a display to set up the time.

Press either keys

press

Mode, and the set up will be complete.

※ If you press

Menu and the setting will NOT be saved.

. This will return you to the Normal Measurement

to adjust to the desired number, and

before you save, you will return to Main

7.2 Units and Baud Rate

You can set up the Baud Rate, measurement units, data output parameters, using the bit set-up (Soft Dip

Switch). Once the set-up is stored, it will not be lost even if the switch is turned off because of the back-up

batteries.

7.2.1 Set-up

DISPLAY PROCEDURE

Turn the switch OFF first. Then turn the switch back ON by holding

onto

. Continue to hold until you see a display

Bit Number shows zero

Indicates the Bit Status

m/s

like the one on the left.

The “b0” (see left) indicates the Bit Number. “01” on the right

indicates the Bit Status. (See the next page Section 7.2 “Dip

Switch Set-up Chart” for definitions on Bit Number and Bit Status.)

Using either keys, select the Bit Status. Press

to save the set-up. Move onto the next bit number. (After 9 is

displayed, it will display 0 (zero) ).

Press when you have finished setting up all Bit Numbers.

This will return you to the Normal Measurement Display.

Page 37

7.Other settings

7.2.2 Dip Switch Set-up Chart

※ = Set up at the time of ship-out

Set-up Parameter Specification Display of Bit Status

4800bps b0:00 b1:00

Baud Rate Setup

[b0、b1]

9600bps b0:01 b1:00

19200bps b0:00 b1:01

38400bps b0:01 b1:01

Buzzer ON/OFF Setup

[b2]

Wind Velocity Unit

YES b2:00 -

NO b2:01 -

m/s b3:00 -

Setup

[b3]

Air Temperature Unit

Setup

[b4]

FPM <1m/s = 196FPM> b3:01 -

℃ b4:00 -

o

F <T( oF) = 1.8×T(℃)+32 > b4:01 -

29

Analog Output

(Option)

[b5]

Range Setup

Wind

Velocity

Wind

Temp.

0~5m/s b5:00 b6:00

0~10m/s b5:01 b6:00

0~25m/s b5:00 b6:01

0~50m/s b5:01 b6:01

0~1000FPM b5:00 b6:00

0~2000FPM b5:01 b6:00

0~5000FPM b5:00 b6:01

0~9999FPM b5:01 b6:01

0~50℃ b5:00 b6:00

0~100℃ b5:01 b6:00

-10~40℃ b5:00 b6:01

32~122oF b5:00 b6:00

32~212oF b5:01 b6:00

14~104oF b5:00 b6:01

Data Output Parameter

Setup

[b7]

Date Display Format

Setup

[b8、b9]

-5~+5kPa b5:00 b6:00

Pressure

-2~+2kPa b5:01 b6:00

All Parameters b7:00 -

Single Parameter b7:01 -

Japanese Format:Yr/Mo/D b8:00 b9:00

American Format:Mo/D/Yr b8:01 b9:00

European Format:D/Mo/Yr b8:00 b9:01

Page 38

8. Cleaning the Probe

30

8.Cleaning the Probe

Dust or particles attached on the velocity sensor would alter the amount of heat diffusion, which leads to less

precise reading. Also, deformation or clogging up of the protective mesh around the sensor of ANEMOMASTER

would also affect the accuracy of the instrument.

Users are encouraged to clean up Probe regularly for maintaining accurate measurement

Clean the sensor by soaking it to water in ultrasonic cleaner for 10 to 20 seconds. Do not soak

it for too long, since there is an increased risk of damaging the coating of the sensor.

You can also clean the sensor with neutral detergent, when it should be washed up with water

fully.

!CAUTION!

!)When cleaning, make sure that the power is OFF.

!)Make sure that the sensor is dry before turning it ON.

Procedure

Page 39

9. Specification

9.Specification

Product Name ANEMOMASTER Air Velocity Meter

Model 6113

Measuring Object Clean air flow

Measuring

Range

(Resolution)

Accuracy

Response

Time

Temperature

Compensation

(Air Velocity)

Air Vel. 0.10~50.0 m/s

Air Temp

Pressure

※

Air Vel. ±(3% of reading + 0.1) m/s

Air Temp

Pressure

※

Air Vel. Approx. 1 second (at 1m/s, 90% response time)

Air Temp

Pressure

※

0.0~100.0 ℃ (0.1℃)

-5.00~+5.00 kPa (0.01kPa)

±1.0 ℃

±(3% of reading + 0.01) kPa

Approx. 30 seconds (at 1m/s, 90% response time)

Approx. 1 second

±(5% of Reading + 0.1)m/s (in the temperature range 5 to 80.0℃)

31

(0.00~9.99m/s:0.01m/s,10.0~50.0m/s:0.1m/s)

Functions

Output

Power

Battery Life

Operating

Environment

Weight Approximately 1000 g (without batteries)

Measurement Hold: Max., Min., Avg,; Time Constant (1, 5, 10 seconds);

Battery Level Indicator (5 Levels),

Unit selection: (Air Velocity: m/s, FPM, Temperature: ℃,

Static Pressure

Measurement data storage:Spot value, Mean value(max 60seconds);

Max upload of 100 data.

Calculation functions:Max, Min, Mean calculation; Unprocessed data display; Calendar

feature; Bar graph display for air velocity value.

Digital Output: RS-232C (Baud Rate 4800, 9600, 19200 and 38400 bps) for output to

※

PC

Printer Output: Calculation results, measurement data

Analog Output

6 × AA Batteries (Manganese,Alkaline, Ni-Cd),

AC Adaptor

Approximately 10 hours continuous (at air velocity 5m/s, 20 ℃ , with alkaline

batteries, and not using printer)

Main Body 5~40 ℃

Probe 0~100 ℃

Storage

Environment

5~40 ℃

o

※

: kPa)

※

: DC 0~1V (select one from Air Velocity, Temperature, Pressure)

※

: AC 100~240V (50/60Hz)

F;

Accessories

Options

Operation Manual, 6×AA Batteries, Probe Cable (2m), Extension Rod, Shoulder

Strap, Printer Roll Paper

Spare Probe, Analog Output, Pressure Sensor, RS-232C Cable, Software (for

Windows), AC Adaptor

※Optional

Page 40

RI

H

=

y

[

]

10.Principle of measurement

32

10.Principle of Measurement

¾ Principle of Hot-Wire Anemometer

The principle of the thermal Probe is based on

a heated element from which heat is extracted by

the colder impact flow. The temperature is kept

constant via a regulating switch. The controlling

current is directly proportional to the velocity.

When thermal velocity Probes are used in turbulent

flows, the

measured result is

influenced by the flows impacting the heated body from all directions.

In turbulent flows, a thermal velocity sensor indicates higher measured

values than a vane Probe. This can be observed during measurements in

ducts. Depending on the design of the duct, turbulent flows can occur

H

Quantit

Heat Diffusion

Quantity [H]

Heat Diffusion

Current

Sensor

Current

Sensor

Ta1 < Ta2

Velocity [U]

Compensation

Velocity [U]

even at low velocities. The amount of heat that is extracted by the colder

impact flow from the sensor can be expressed by:

Where H: Heat diffusion quantity T: Temperature of the sensor Ta: Air

Ta1

temperature U: Air velocity a, b: Constant

Ta

2

Also, heat diffusion quantity can be expressed by the formula:

Where R is resistance and I is current

(R is kept constant regardless of air velocity since the temperature in

constant).

Therefore,

¾ The Temperature Compensation

The air velocity sonsor is heated to and elevated temperature relative to

the surrounding air by means of control electronics. The temperature

))(( TaTUba −+

compensation sensors senses the ambient, or surrounding air temperature

and forces the velocity sensor to stay at a constant overheat above the

ambient. The circuit foeces the voltage to be equal by means of an

operational amplifier. Air flowing past the sensor tends to cool the sensor,

thus driving down its resistance. The amplifier responds by immediately

delivering more power to the circuit to maintain voltage equilibrium.

Delivered power is converted into electrical signal to display.

Wind

Sensor (Platinum Coil)

2

2

UbaRI +∝

Current

Cooling

-off

Current

Velocity m/s

fomulasKingTaTUbaH ・・・・・・ '))(( −+=

Page 41

10.Principle of measurement

¾ Measurement of Wind-Temperature

in

Temp Sensor

(Platinum Resistor)

¾ Measurement of Humidity (Hygrometer)

The sensor is a pair of condenser and its electro-capacity is

depended upon the amount of water contained in its

hydrophilic macromolecule (humidity sensitive) membrane.

The components of the sensors are glass foundation; lower

electrode; macromolecule membrane and upper electrode.

The upper electrode will capture the change in permittivity

caused by condensation or evaporation of water vapors to

the macromolecule membrane. (Electrostatic Capacity Type)

There is another type of hygrometer that uses a resistor

instead of a condenser. It is usually said that the

Electrostatic Capacity is good for low humidity measurement

and the resistor is good for high humidity measurement.

¾ Theory of detecting static pressure.

To measure static pressure, we use a diffusion-type semiconductor pressure sensor. The diffusion-type

semiconductor pressure sensor is incorporated under the principle that the resonant frequency of a

piezo-crystal decreases linearly with the pressure applied. On a thin diaphragm of silicon, there are four

diffusion resistors (sensor chips) placed in a fixed distant apart. (Pic.1)

When the pressure is applied from above, the diaphragm will deflect downward. When it is deflected, the

sensors near center (R3 and R4) will have compressing stress and the sensors near perimeter (R1 and R2)

will have tensile stress instead. (Pic.2) The diffusion coefficient of diffusion resistor change according to

these two stresses.

Diaphragm

R3

R1

R4

R1~R4:Diffusion Resistant

Pic.1 Pressure Sensor

If we create a bridge among these diffusion resistors (Pic.3), it will be possible to detect voltage that is

proportional to the amount of pressure applied. These sensors can be affected by the temperature, and

therefore, temperature compensation circuit must be added.

The coefficient of resistance of the temperature sensor has a direct proportional

relationship with the temperature. We can measure the wind temperature by

adjusting the sensor’s temperature to the wind-temperature, and measuring its

coefficient of resistance.

Upper

Electrode

Macromolecule

Membrane

Lower Electrode

Glass

Foundation

F

i

R2

x

e

d

V

o

l

t

a

g

e

R1

R4

Output

R3

R2

Pic.2

Pic.3 Detecting Circuit

33

Page 42

11. About Compensation

34

11.About Compensation

This instrument has been calibrated at normal temperature and pressure. Therefore, if you are going to

measure velocity at a different temperature and pressure, the indicating value will be affected.

11.1 Influence of Measuring Temperature

This instrument has been calibrated at normal temperature. Because of theoretical fundamentals of hot-wire

anemometer, it can easily be effected by the ambient temperature. To prevent such influence, temperature

compensation is needed. The temperature compensation sensor senses the ambient, or surrounding air

temperature and forces the velocity sensor to stay at a constant overheat above the ambient. By adopting

temperature compensation sensors, you can measure air velocity accurately within the range of 5~80℃ (41

o

~176

F)

11.2 Influence of Pressure at Measuring Point

This instrument has been calibrated at 1013hPa. Change in pressure does affect the amount of heat diffusion.

Therefore, the pressure compensation, using the following equation, is needed.

Where: Um: Actual Velocity[m/s] Uc: Indicating Value Pm: Pressure at the Measuring Point[hPa]

Um ×=

1013

Pm

Uc

11.3 Measuring Gas Components

This instrument has been calibrated using air. The ANEMOMASTER indicates air velocity based on the heat

capacity, i.e. the heat diffusion quantity to deprive a device of in fluid. If the fluid, which is dealt with for the

measurement, is different from the fluid when the instrument is calibrated, the diffusion quantity changes and

the indicating air velocity, too, will be affected.

In order to compensate, you first need to find the heat diffusion quantity of air to the indicating value in mixture

measurement. By substituting this heat diffusion quantity to the value in the heat diffusion-velocity relation

formula, you can find the actual velocity value of the mixture.

Page 43

12.Probe directivity(air velocity)

12.Probe Directivity (Air Velocity)

12.1 Horizontal

-180°

-90°

Wind Mark

90°

0°

35

At Air Velocity 5m/s

12.2 Vertical

90°

-180°

0°

Wind Mark

-90°

At Air Velocity 5m/s

Page 44

13.Trouble shooting

13.Trouble Shooting

13.1 Batteries

Problem Possible Cause(s) / Solution (s)

ANEMOMASTER will not turn

ON

Nothing appears on the display

even when batteries are

replaced.

Display shows “E - - 0” The batteries are low.

13.2 Initial Operations

Problem Possible Cause(s) / Solution (s)

Display shows ”E - - 9” ROM Cassette is not inserted.

Display shows ”- - - -” Probe/Probe Cable not connected properly.

The measurement unit is not

correct.

The battery is old or defective.

→Turn OFF the power and replace the batteries.

Batteries are installed incorrectly.

→Turn OFF the power and place in the correct polarity.

→Turn OFF the power and replace the batteries.

→If already inserted, turn OFF the power and re-insert.

→Turn the OFF the power and connect Probe.

You may switch to the Air Velocity Measurement unit (m/s,

FPM), Air Temperature Measurement Unit (℃、

o

36

Refer To

(Page No.)

6

6

6

Refer To

(Page No.)

7

7

28

F).

13.3 During Operations

Problem Possible Cause(s) / Solution (s)

“ ‐‐‐‐” is displayed for

measured value.

ANEMOMASTER is not

displaying the right speed.

Higher temperature is

displayed.

The response for Air Velocity

Measurement is slow.

doing Zero Adjustment

Procedure

This means the value exceeds the specified measurement

range.

→Use within the specified range.

Probe/Probe Cable is not connected property.

→Check the connection.

Probe/Probe Cable may be damaged.

→Contact your local Kanomax Office or service center.

Probe is not facing the wind.

→Make sure the Wind Mark is facing the wind.

Theoretically, ANEMOMASTER cannot measure temperature

in no-wind environment.

→Measure the temperature in environment with more than

0.1m/s of wind.

Confirm the Time Constant settings. 13

Pressure Port(+、-)is blocked.

→Unblock both ports for + and -.

The adjustment exceeds the range specified for the Zero

Adjustment.

→Contact your local Kanomax Office or service center.

Refer To

(Page No.)

31

7

9

9

9 Display shows ”E - - 8” when

9

Page 45

13. Trouble shooting

13.4 Printer Output

37

Problem Possible Cause(s) / Solution (s)

Cannot printout.

Printer paper not installed correctly.

→Open the printer cover and reinstall. Also, check for paper

accidentally pulled into the printer.

Out of printer paper.

→Change the remaining amount on the roll when you start

seeing red marks on the edges of the paper.

Batteries are low.

Refer To

(Page No.)

→Turn OFF the power and replace the batteries.

Prints only the value shown on

the display.

Cannot cancel the printout. You cannot cancel the printout.

Display shows ”E - - 1”. The printer paper is not set.

The set-up for data output is in the SINGLE Parameter

output mode.

ÆUse the set-up function to switch to ALL parameters

output mode.

→Check if the printer paper is properly set up in the Roller.

Display shows ”E - - 2”.

Batteries are low.

→Turn OFF the power and replace the batteries.

Printer Head is overheated due to continuous use of the

printer.

→Temporarily stop printing out and recommence.

Display shows ”E - - 3”. The Printer Head Lever is up.

→Pull down the lever.

19

19

6

28

19

6

19

13.5 Digital Output

Problem Possible Cause(s) / Solution (s)

Cannot load the data

13.6 Analog Output

Problem Possible Cause(s) / Solution (s)

Printer Head Lever

Refer To

(Page No.)

Cable not correctly connected or using wrong cable.

23

→You need to use the RS232C cable.

Baud rate setup is incorrect.

→Check the settings between the ANEMOMASTER and the

computer.

Transmission command is wrong. 24

Wrong polarity.

→Correct the polarity.

23

Refer To

(Page No.)

26

Page 46

14.Warranty and after service

Mode problem.

38

11

→Need to use the Normal Measurement Mode.

The Air Velocity output looks

like a “staircase”.

Output value is different

Check the Time Constant setting. 13

Analog output setting is wrong. 26

The output range setting is wrong. 26

The load impedance is lower than the designated value.(Load

impedance needs to be over 5kΩ).

26

14.Warranty and After Service

Kanomax Limited Warranty

The limited warranty set below is given by KANOMAX JAPAN, Inc. (hereafter referred to as “KJI”) with

respect to the KANOMAX brand anemometer, its attachment parts including Probe and other accessories

(hereafter referred to as “PRODUCT”) that you have purchased. PRODUCT you have purchased shall

be the only one that the limited warranty stated herein applies to.

Your PRODUCT, when delivered to you in new condition in its original container, is warranted against

defects in materials or workmanship as follows: for a period of one (1) year from the date of original

purchase, defective parts or a defective PRODUCT returned to KJI, as applicable, and proven to be

defective upon inspection, will be exchanged for a new or comparable rebuilt parts, or a refurbished

PRODUCT as determined by KJI. Warranty for such replacements shall not extend the original warranty

period of the defective PRODUCT.

This limited warranty covers all defects encountered in normal use of the PRODUCT, and does not apply

to the following cases:

Use of parts or supplies other than the PRODUCT sold by KJI, which cause damage to the PRODUCT

(1)

or cause abnormally frequent service calls or service problems.

If any PRODUCT has its serial number or date altered or removed.

(2)

Loss of damage to the PRODUCT due to abuse, mishandling, improper packaging by the owner,

(3)

alteration, accident, electrical current fluctuations, failure to follow operating, maintenance or

environmental instructions prescribed in the PRODUCT's instruction manual provided by KJI, or

service performed by other than KJI.

NO IMPLIED WARRANTY, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE, APPLIES TO THE PRODUCT AFTER THE APPLICABLE PERIOD OF

THE EXPRESS LIMITED WARRANTY STATED ABOVE, AND NO OTHER EXPRESS WARRANTY OR

GUARANTY, EXCEPT AS MENTIONED ABOVE, GIVEN BY ANY PERSON OR ENTITY WITH RESPECT TO

THE PRODUCT SHALL BIND KJI. KJI SHALL NOT BE LIABLE FOR LOSS OF STORAGE CHARGES,

LOSS OR CORRUPTION OF DATA, OR ANY OTHER SPECIAL, INCIDENTAL OR CONSEQUENTIAL

DAMAGES CAUSED BY THE USE OR MISUSE OF, OR INABILITY TO USE, THE PRODUCT,

REGARDLESS OF THE LEGAL THEORY ON WHICH THE CLAIM IS BASED, AND EVEN IF KJI HAS BEEN

ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. IN NO EVENT SHALL RECOVERY OF ANY

Page 47

14.Warranty and after service

39

KIND AGAINST KJI BE GREATER IN AMOUNT THAN THE PURCHASE PRICE OF THE PRODUCT SOLD

BY KJI AND CAUSING THE ALLEGED DAMAGE. WITHOUT LIMITING THE FOREGOING, THE OWNER

ASSUMES ALL RISK AND LIABILITY FOR LOSS, DAMAGE OF, OR INJURY TO THE OWNER AND THE

OWNER'S PROPERTY AND TO OTHERS AND THEIR PROPERTY ARISING OUT OF USE OR MISUSE OF,

OR INABILITY TO USE, THE PRODUCT NOT CAUSED DIRECTLY BY THE NEGLIGENCE OF KJI. THIS

LIMITED WARRANTY SHALL NOT EXTEND TO ANYONE OTHER THAN THE ORIGINAL PURCHASER OF

THE PRODUCT, OR THE PERSON FOR WHOM IT WAS PURCHASED AS A GIFT, AND STATES THE

PURCHASER'S EXCLUSIVE REMEDY.

After Service

Whenever the PRODUCT is malfunctioning, please check with “Troubleshooting” to find possible cause

first.

Repair parts are retained for a minimum period of five (5) years after production cessation of the

PRODUCT. This storage period of repair parts is considered as the period during which KJI can provide

repair service.

For more information, please contact your local distributor, or call us at KJI’s service desk from 9:00 a.m.

to 5:00 p.m. JST on weekdays excluding holidays. When you make a call, please have the following

information of your PRODUCT at hand:

PRODUCT name;

(1)

Model number;

(2)

Serial number;

(3)

Probe number;

(4)

Description of Symptom, and;

(5)

(6) Date of purchase

Loading...

Loading...